Page 1

Alpha 40 ARF

Assembly Manual

Specications

Wingspan: ................................................... 63 in (1600mm)

Length: ..................................................... 52.5 in (1334mm)

Wing Area: ....................................... 710 sq in (45.8 sq dm)

Weight: ............................................ 5–5.5 lb (2.27–2.49 kg)

Radio: ..................................................4-channel minimum

Engine: ................. .40–.46 2-stroke (glow), Power 25 (EP)

Page 2

Table of Contents

Notice

Product Support

Product Support ....................................................................2

Specifications .........................................................................2

Included Parts Listing ............................................................3

Contents of Kit and Parts Layout ...........................................4

Safety Precautions and Warnings ..........................................4

Important InformationRegarding Warranty ............................5

Using the Manual ...................................................................5

EasyCote™ Covering Colors ...................................................5

Before Starting Assembly ......................................................5

Radio Systems Requirements ................................................5

Recommended Setup - Glow .................................................5

Recommended Setup - Power 25 ..........................................5

Field Equipment Required ......................................................5

Optional Field Equipment .......................................................5

Tools and Supplies .................................................................5

Additional Required Adhesives ..............................................6

Servo Installation-Fuselage ....................................................6

Glow Engine Installation ........................................................7

Fuel Tank Installation ...........................................................10

Muffler Installation ...............................................................12

Propeller and Spinner - Glow Engine Installation ................12

Electric Motor Installation ....................................................13

Propeller and Spinner Installation-Electric Motor ................18

Landing Gear Installation .....................................................20

Receiver Installation-Electric Motor Option .........................23

Receiver Installation-Glow Engine Option ............................23

Wing Dowel Installation .......................................................26

Fin and Stabilizer Installation ...............................................27

Throttle Linkage Connection ................................................29

Elevator Linkage Installation ................................................31

Rudder and Steering Linkage Installation ............................34

Aileron Servo Installation .....................................................38

Wing Assembly ....................................................................40

Optional: Gluing the Wing Halves ........................................42

Wing Installation ..................................................................44

Checking the Control Surface Movement.............................45

Checking the Throttle Operation ..........................................46

Balancing Your Alpha ARF ...................................................47

Control Throws ....................................................................48

Maintaining Your Model .......................................................48

Flight Preparations ...............................................................49

Safety Do’s and Don’ts for Pilots .........................................49

Daily Flight Checks ...............................................................49

Glossary of Terms ................................................................49

Safety, Precautions and Warnings .......................................50

Warranty and Repair Policy .................................................50

2010 Official Academy of Model Aeronautics Safety Code ..52

All instructions, warranties and other collateral documents

are subject to change at the sole discretion of Horizon

Hobby, Inc. For up-to-date product literature, visit http://

www.horizonhobby.com and click on the support tab for this

product.

Meaning of Special Language

The following terms are used throughout the product

literature to indicate various levels of potential harm when

operating this product:

NOTICE: Procedures, which if not properly followed, create

a possibility of physical property damage AND a little or no

possibility of injury.

CAUTION: Procedures, which if not properly followed, create

the probability of physical property damage AND a possibility

of serious injury.

WARNING: Procedures, which if not properly followed,

create the probability of property damage, collateral damage,

and serious injury OR create a high probability of superficial

injury.

WARNING: Read the ENTIRE instruction manual to

become familiar with the features of the product

before operating. Failure to operate the product

correctly can result in damage to the product, personal

property and cause serious injury.

This is a sophisticated hobby product and NOT a toy. It must

be operated with caution and common sense and requires

some basic mechanical ability. Failure to operate this Product

in a safe and responsible manner could result in injury or

damage to the product or other property. This product is not

intended for use by children without direct adult supervision.

Do not attempt disassembly, use with incompatible

components or augment product in any way without the

approval of Horizon Hobby, Inc. This manual contains

instructions for safety, operation and maintenance. It is

essential to read and follow all the instructions and warnings

in the manual, prior to assembly, setup or use, in order to

operate correctly and avoid damage or serious injury.

For technical assistance with this product, please contact the

appropriate Horizon Product Support office. See page 51.

Specications

Wingspan: ................................................... 63 in (1600mm)

Length: ..................................................... 52.5 in (1334mm)

Wing Area: ....................................... 710 sq in (45.8 sq dm)

Weight: ............................................ 5–5.5 lb (2.27–2.49 kg)

Radio: ..................................................4-channel minimum

Engine: ................. .40–.46 2-stroke (glow), Power 25 (EP)

2 Hangar 9 Alpha 40 ARF Assembly Manual

Page 3

Included Parts Listing

BAGGED SEPARATELY

Fuselage with hatch (1)

Right wing panel with aileron (1)

Left wing panel with aileron (1)

Vertical fin (1)

Horizontal stabilizer (1)

Aluminum wing tube, 12mm x 318mm (1)

FUSELAGE

9 oz (260cc) fuel tank (assembled) (1)

#4 x 5/8-inch wood screw (1) Tank support tray

3mm x 12mm socket head cap screw (2) Fuselage lower hatch

#4 flat washer (2) Fuselage lower hatch

EZ connector with setscrew (1) Nose gear

#2 flat washer (2) EZ connector spacers

C-Clip (2) Secures EZ connector

3

4

/4 x 1/4-inch dowel rod (2) Wing to fuselage

Rubber band (10) Wing to fuselage

Plywood tank support tray (1) Secures tank in position

Plywood EP battery tray (2) Holds EP battery

Silicone safety clear tubing (2) Clevis keepers

Nylon clevis (1) Throttle

Snap link (1) Throttle

MOTOR MOUNT

8-32 x 3/4-inch socket head cap screw (4) EP motor to EP standoffs

8-32 x 1-inch socket head cap screw (4) Motor mount to firewall/EP

standoffs to firewall

#8 Silver flat washer (4) Motor mount to firewall/EP

standoffs to firewall

4-40 x 1-inch socket head cap screw (4) Engine to motor mount

#4 silver flat washer (4) Engine to motor mount

8-32 blind nut (4) Engine mount

4-40 nylon inserted locknut (4) Engine to motor mount

Black nylon motor mount (2)

45mm EP standoffs (4)

2-inch (50mm) 2-blade spinner, red (1)

WING

Nylon Clevis (2) Ailerons

Snap link (2) Ailerons

Clear wing center tape 1/2 x 14-inch (1) Seal top center wing joint

White covering 3/4 x 14-inch (1) Seal top center wing joint

Red covering 3/4 x 14-inch (1) Seal bottom center wing joint

RUDDER AND ELEVATOR

3mm x 10mm socket head cap screw (2) Stabilizer to fuselage

#4 silver flat washer (2) Stabilizer to fuselage

#4 silver flat washer (2) Rudder to stabilizer

3mm wing nut (2) Stabilizer to vertical fin

Nylon clevis (2) Rudder and elevator

Snap link (2) Rudder and elevator

LANDING GEAR

Main landing gear assembly (2) Includes 2

1

/2-inch (65mm) wheel

and 4mm wheel collars

Nose gear assembly (1) Includes with 2

1

/2-inch (65mm)

wheel and 4mm wheel collars

#4 x 3/8-inch wood screw (4) Landing gear to fuselage

Landing gear straps (2) Landing gear to fuselage

Nose gear control arm with setscrew (1)

PUSHRODS

3

3

/8 x 1/4-inch hardwood support pieces (2) Fuel tank support

2-56 x 6

2-56 x 16

2-56 x 16

1

/8-inch one end threaded pushrod (2) Ailerons

3

/4-inch pushrod with Z-bend (1) Nose gear

1

/4-inch one end threaded pushrod (1) Throttle

2-56 x 28-inch one end threaded pushrod (2) Elevator and rudder

3Hangar 9 Alpha 40 ARF Assembly Manual

Page 4

Safety Precautions and Warnings

Read and follow all instructions and safety precautions

10

2

5

3

1

5

7

9

5

before use. Improper use can result in fire, serious injury

and damage to property.

COMPONENTS

Use only with compatible components. Should any

compatibility questions exist please refer to the product

instructions, the component instructions or contact Horizon

Hobby, Inc.

FLIGHT

Fly only in open areas to ensure safety. It is recommended

flying be done at AMA (Academy of Model Aeronautics)

approved flying sites. Consult local ordinances before

choosing a location to fly.

PROPELLER

2

4

6

9

8

Keep loose items that can get entangled in the propeller

away from the prop, including loose clothing, or other

objects such as pencils and screwdrivers. Especially keep

your hands away from the propeller as injury can occur.

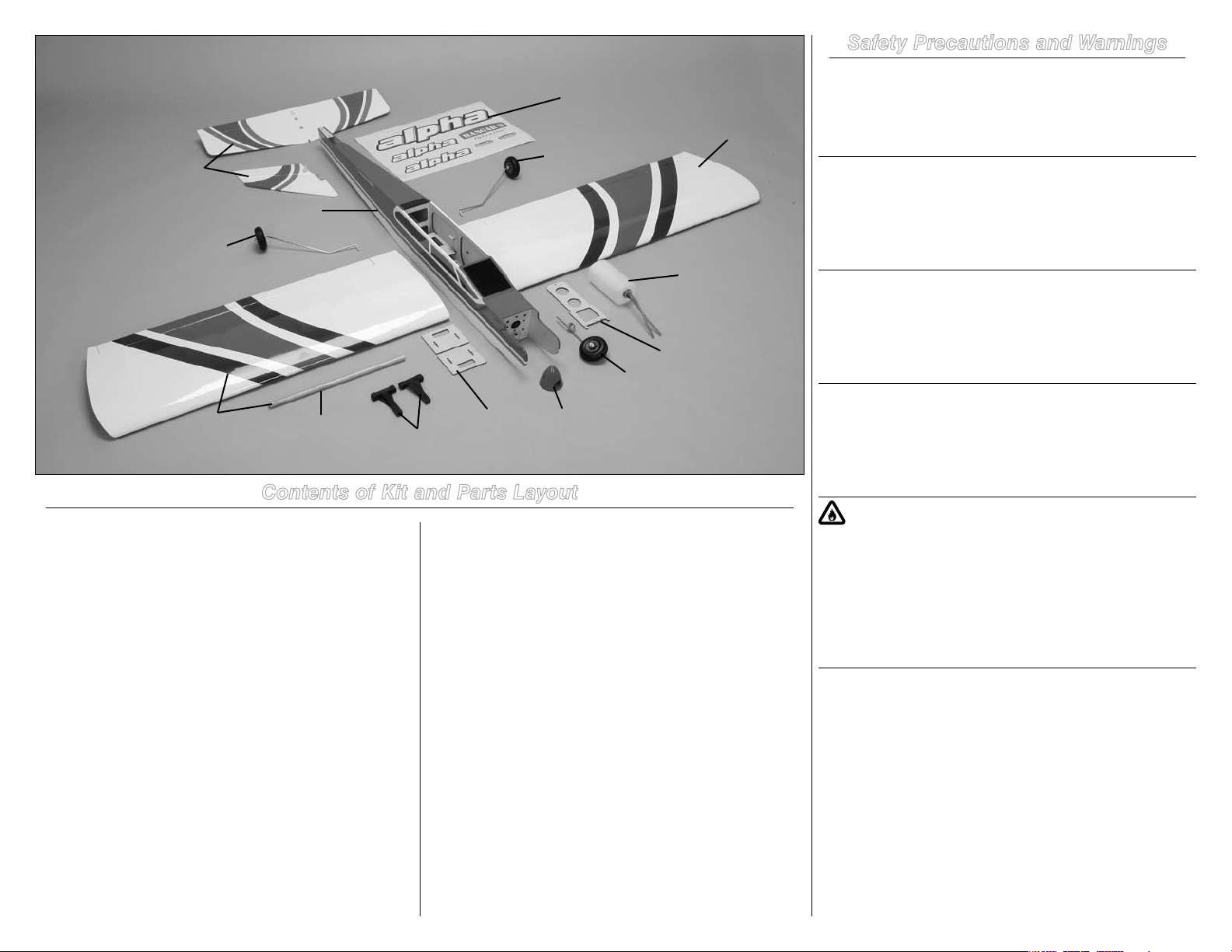

Contents of Kit and Parts Layout

BATTERIES

Notes on Lithium Polymer Batteries

Large Replacement Parts

1. HAN246001 Fuselage with Hatch

2. HAN246002 Wing Set with Wing Tube

3. HAN246003 Tail Set

4. HAN246004 Wing Tube

5. HAN246005 Landing Gear Set with Wheels

Small Replacement Parts (not shown)

HAN246008 EP 45mm Standoffs

HAN246010 Pushrods

HAN246011 Hardware Package

HAN246012 Nylon Parts Package

HAN246014 Tail Set Wing Nuts

When used improperly, Lithium Polymer batteries are

significantly more volatile than alkaline or Ni-Cd/Ni-MH

batteries used in RC applications. Always follow the

manufacturer’s instructions when using and disposing of any

batteries. Mishandling of Li-Po batteries can result in fire and

explosion causing serious injury and damage.

6. HAN246006 Engine Nylon Mount

7. HAN246007 Fuel Tank 9 oz

8. HAN246009 Red 2-inch 2-blade Spinner

9. HAN246013 Small Wood Parts

10. HAN246015 Decals

SMALL PARTS

This kit includes small parts and should not be left

unattended near children as choking and serious injury could

result.

Safe Operating Recommendations

• Inspect your model before every flight to make certain it is

airworthy.

• Be aware of any other radio frequency user who may

present an interference problem.

• Always be courteous and respectful of other users of your

selected flight area.

• Choose an area clear of obstacles and large enough to

safely accommodate your flying activity.

4 Hangar 9 Alpha 40 ARF Assembly Manual

Page 5

• Make certain this area is clear of friends and spectators

prior to launching your aircraft.

• Be aware of other activities in the vicinity of your flight path

that could cause potential conflict.

• Carefully plan your flight path prior to launch.

• Abide by any and all established AMA National Model

Aircraft Safety Code.

Important Information

Regarding Warranty

Please read our Warranty and Liability Limitations section on

page 50 before building this product. If you as the purchaser

or user are not prepared to accept the liability associated

with the use of this Product, you are advised to return this

Product immediately in new and unused condition to the

place of purchase.

Using the Manual

This manual is divided into sections to help make assembly

easier to understand, and to provide breaks between each

major section. In addition, check boxes have been placed

next to each step to keep track of each step completed.

Steps with a single box () are performed once, while

steps with two boxes () indicate the step will require

repeating, such as for a right or left wing panel, two servos,

etc. Remember to take your time and follow the directions.

EasyCote™ Covering Colors

• Midnight Blue HANU70500

• White HANU7000

• True Red HANU70100

Before Starting Assembly

Before beginning the assembly of your model, remove

each part from its bag for inspection. Closely inspect the

fuselage, wing panels, rudder and stabilizer for damage.

If you find any damaged or missing parts, contact the

place of purchase.

If you find any wrinkles in the covering, use a heat gun or

covering iron to remove them. Use caution while working

around areas where the colors overlap to prevent separating

the colors.

HAN100 – Heat Gun

HAN150 – Covering Glove

HAN101 – Sealing Iron

HAN141 – Sealing Iron Sock

Radio Systems Requirements

Spektrum™ Radio System (recommended)

• DX6i 6-channel radio or greater with receiver

(SPM6600)

• DS821 Digital Sport Servo (4) (JRPS821)

• 6-inch Servo Extension (JSP98110)

• Receiver Battery, 2300mAh (JRPB5006)

®

• JR

Switch, Chargeswitch (JRPA004)

Recommended Setup - Glow

• Evolution® Trainer Power System: A (EVOE100)

or

• Evolution .46NX with Muffler (EVOE0461)

• Evolution Propeller 11 x 5 (EVO11050)

• Evolution Propeller, 3-Blade (EVO100P) (optional)

• 3-Blade Spinner, White (EVOE100S) (optional)

• Exhaust Diverter (DUB697) (optional)

Recommended Setup - Power 25

• Power 25 Brushless Outrunner Motor,

870Kv (EFLM4025A)

• 11 x 8e Electric Propeller (APC11080E)

• 60-Amp Lite Switch-Mode BEC Brushless (EFLA1060)

• 3200mAh 4S 14.8V 20C Li-Po,

13AWG EC3 (EFLB32004S)

Field Equipment Required

• Fuel (15% recommended)

• Propeller

• Long Reach Glow Plug Wrench (HAN2510)

• Metered Glow Driver with Ni-Cd & Charger (HAN7101)

• 2-Cycle Sport Plug (EVOGP1)

• Manual Fuel Pump (HAN118)

Optional Field Equipment

• Selfstick Weights, 6 oz (HAN3626)

• PowerPro

• 12V 7Ah Sealed Battery (HAN102)

• Power Panel (HAN106)

• Blue Block After Run Oil (EVOX1001)

• Cleaner and towels

™

12V Starter (HAN161)

Tools and Supplies

Drill Epoxy brush

Felt-tipped pen Hook and loop tape

Hobby knife with #11 blade Low-tack tape

Sandpaper Mixing cup

Mixing stick Paper towel

Phillips screwdriver: #1, #2 Pencil

Pin vise Pliers

Ruler Diagonal cutters

Rubbing alcohol Felt-tipped pen

Threadlock Hook and loop tape

Hook and loop strap

Foam rubber, 1/4-inch (6mm)

Nut driver or box wrench: 1/4-inch

Box wrench to fit propeller nut

Box end or open end wrench: 10mm (2)

Hex wrench or ball driver: 1.5mm, 2.5mm, 3/32-inch,

9/64-inch

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm), 1/8-inch

(3mm), 5/32-inch (4mm), 11/64-inch (4.5mm)

5Hangar 9 Alpha 40 ARF Assembly Manual

Page 6

Additional Required Adhesives

30-Minute Epoxy (HAN8002)

Medium CA (PAAPT02)

Thin CA (PAAPT08)

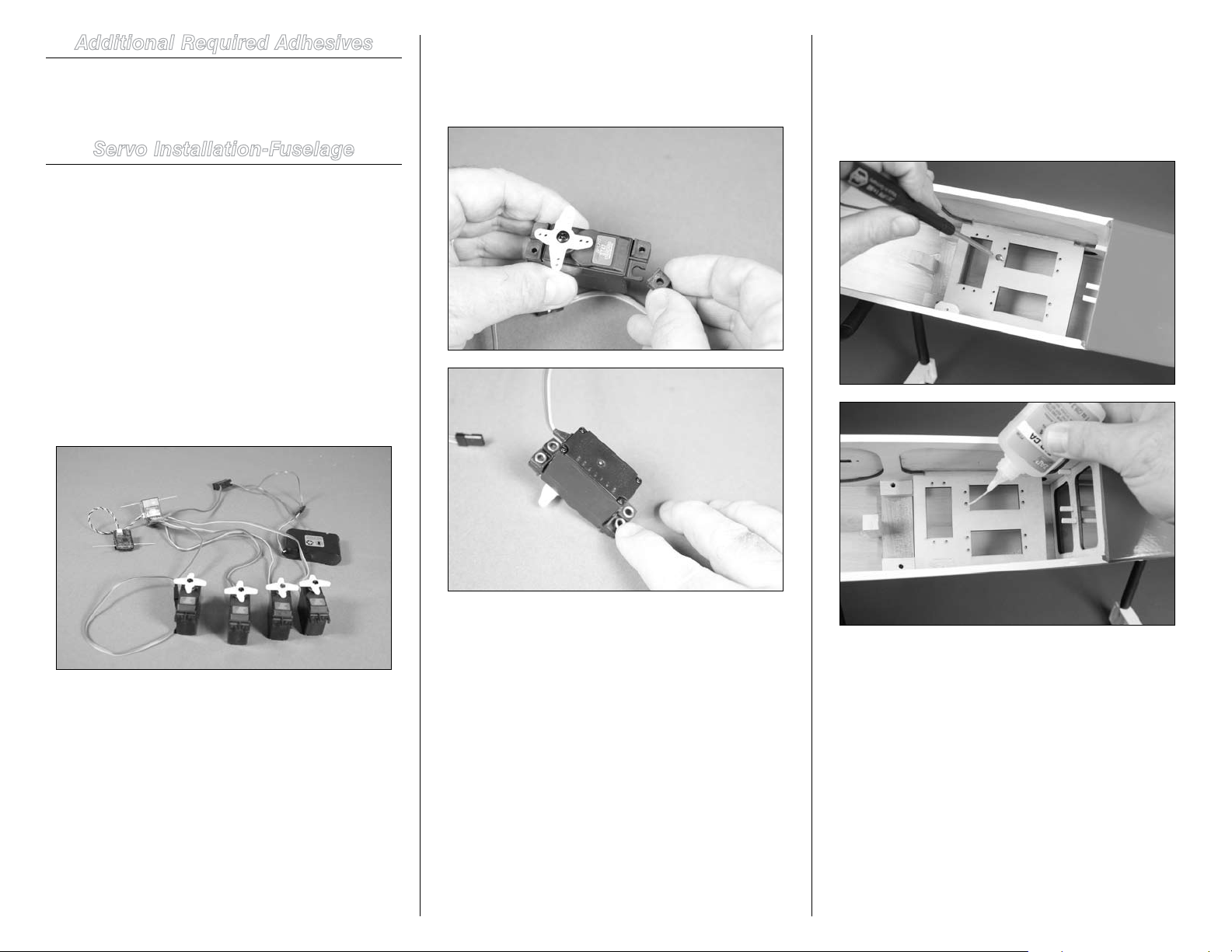

Servo Installation-Fuselage

Required Parts

Fuselage Servo with hardware (4)

Receiver Receiver battery

Switch harness

6-inch (152mm) servo extension

Required Tools and Adhesives

Phillips screwdriver: #1 Thin CA

Step 1

Locate the necessary items for your radio system. Plug the

servos and switch harness in the receiver. Plug a battery into

the switch harness. Check that all the servos work properly.

Step 2

Prepare the servos by installing the rubber grommets and

brass eyelets in the servos. Note that the eyelets are inserted

from the bottom of the servo.

Step 3

Use a #1 Phillips screwdriver to thread a servo mounting

screw into the holes in the servo tray inside the fuselage.

Apply 2–3 drops of thin CA in the holes to harden the

surrounding wood. This makes the screws more secure and

less likely to vibrate loose.

Note: You may need to bind your radio system if you

are using a 2.4GHz system. Follow the instructions

provided with your radio system to do so.

Note: Make sure to turn off both the transmitter and

receiver before unplugging the servos.

Important: You will need to connect a 6-inch (152mm)

extension in the Aileron port of the receiver to connect

to the servo used for the Ailerons. Leave the extension

plugged into the receiver when unplugging the servos.

6 Hangar 9 Alpha 40 ARF Assembly Manual

Page 7

Step 4

Mount the rudder and elevator servos in the fuselage using

the screws provided with the servos. Use a #1 Phillips

screwdriver to tighten the screws. Note the direction of the

servos in the photo.

Step 5

If you are installing a glow engine, you will need to install the

servo used to control the throttle at this time.

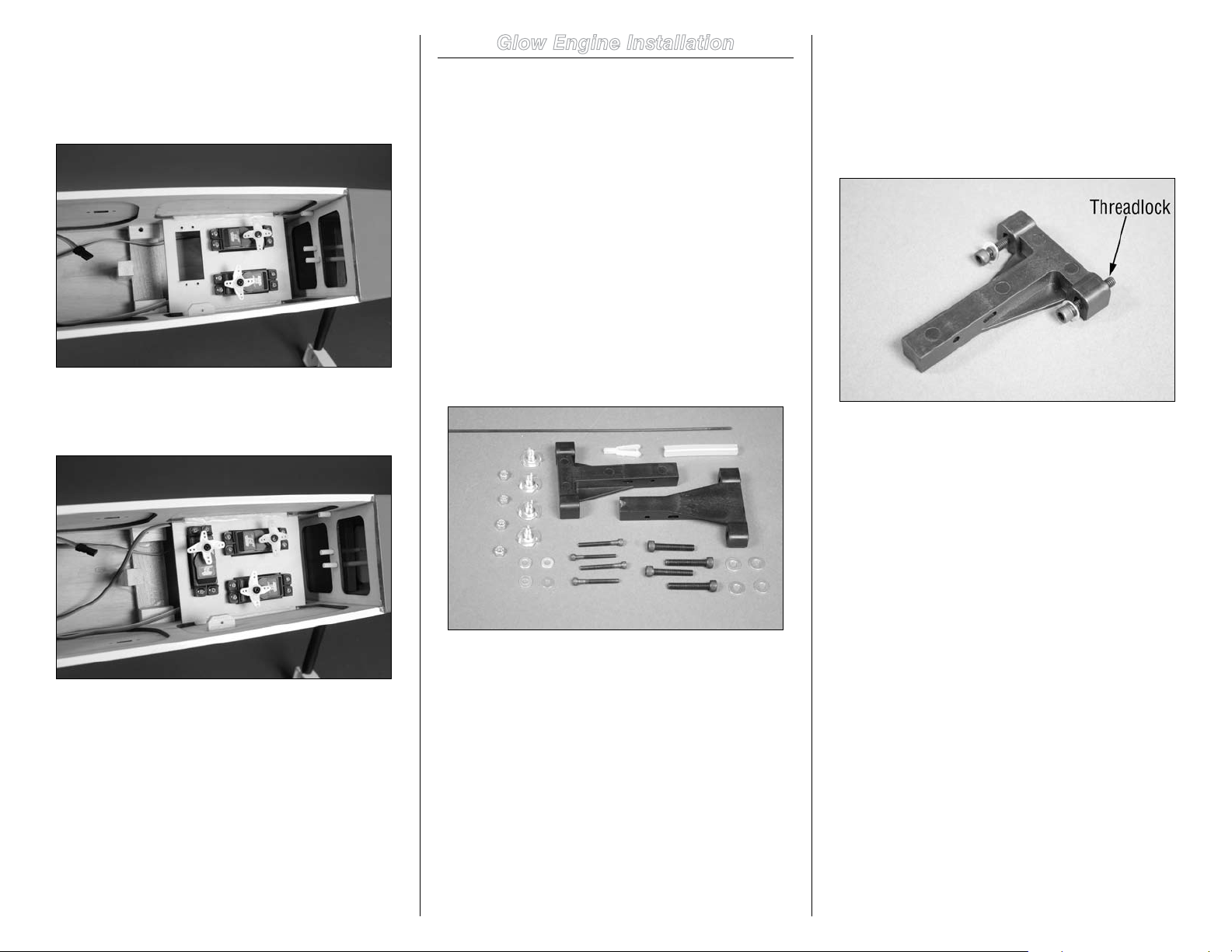

Glow Engine Installation

Required Parts

Fuselage assembly Engine mount rail (2)

#8 washer (4) #4 washer (4)

8-32 blind nut (4) 4-40 locknut (4)

Safety tubing Clevis

2-56 x 16

4-40 x 1-inch socket head screw (4)

8-32 x 1-inch socket head screw (4)

Required Tools and Adhesives

Nut driver: 1/4-inch Threadlock

Hex wrench or ball driver: 3/32-inch, 9/64-inch

1

/4-inch throttle pushrod

Step 1

Locate the necessary hardware to install the engine on

your model.

Step 2

Slide a #8 washer on an 8-32 x 1-inch socket head screw.

Slide the screw into the engine mount rail as shown. You will

be using four screws, four washers and two engine mount

rails in this step to prepare the right and left engine mount

rails. Place a drop of threadlock on the threads of each bolt.

Threadlock will prevent the bolts from vibrating loose in flight.

7Hangar 9 Alpha 40 ARF Assembly Manual

Page 8

Step 3

Position an engine mount rail on the fuselage. Thread an

8-32 blind nut on the screw. Note that the prongs on the

blind nut will go into the backside of the firewall to keep

them from rotating. The nuts are not to be tightened at this

time so the mount can be positioned for your engine. The

bolts wil be tightened once the engine has been secured to

the mounting rails.

Step 4

Place a #4 washer on each of the four 4-40 x 1-inch socket

head bolts. Slide the screws through the holes in the engine

mount flange.

Step 5

Place the engine on the mounting rails. The screws will go

through the holes in the rails. Thread a 4-40 locknut on each

screw. The nuts are only finger-tight at this time.

8 Hangar 9 Alpha 40 ARF Assembly Manual

Page 9

Step 6

Use a 9/64-inch hex wrench or ball driver to tighten the

screws that attach the mount to the firewall. Make sure the

blind nuts are drawn into the back of the firewall. Also make

sure you have placed a small amount of threadlock on each

of the screws so they don’t vibrate loose in flight.

Step 7

Use a 3/32-inch hex wrench or ball driver and a 1/4-inch

nut driver to tighten the hardware securing the engine to the

engine mounting rails.

Step 9

Slide the piece cut in the previous step on a nylon clevis.

Thread the clevis 10-turns onto the threaded end of the 2-56

1

x 16

/4-inch throttle pushrod wire.

Step 10

Slide the pushrod wire into the tube in the firewall that aligns

with the carburetor arm. Connect the clevis to the carburetor

arm and slide the tubing over the forks of the clevis to keep

the clevis from opening accidentally.

Step 8

Use a hobby knife to cut a 1/4-inch (6mm) piece of tubing

from the 2-inch (52mm) safety tubing.

9Hangar 9 Alpha 40 ARF Assembly Manual

Page 10

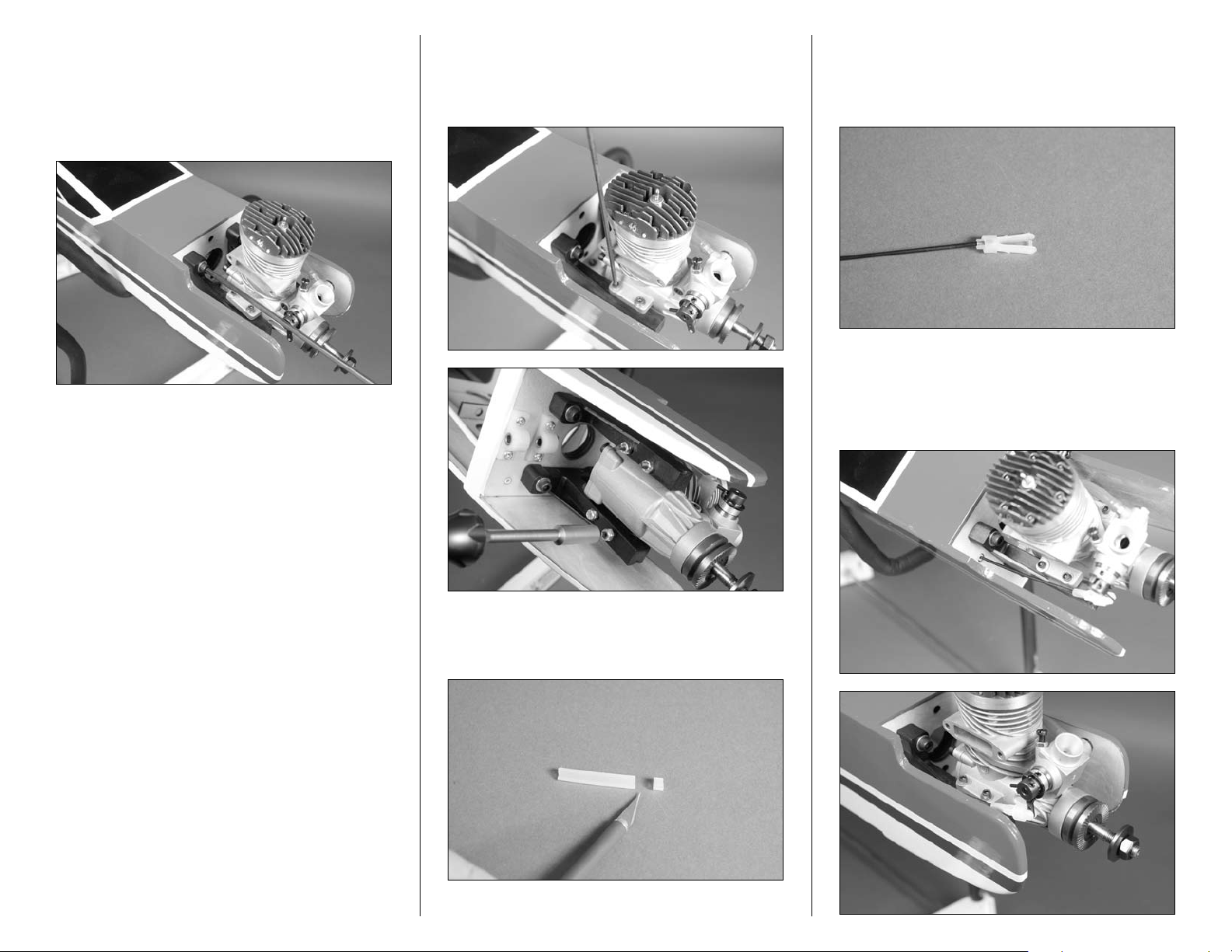

Fuel Tank Installation

Clunk

Vent Line

Top View

Side View

Vent Line (faces top of fuselage)

To Muffler

To Carburetor

Required Parts

Fuselage Fuel tank brace, front

Fuel tank brace, rear 3mm washer (2)

Fuselage hatch Fuel tank (assembled)

3mm x 12mm socket head scew (2)

Required Tools and Adhesives

Threadlock Scissors

Hobby knife with #11 blade Phillips screwdriver: #2

Hex wrench or ball driver: 2.5mm

Step 1

Locate the items necessary to install the fuel tank in the fuselage.

Step 2

Inspect the fuel tank to determine the internal positioning

of the vent line. This is important as the vent line must face

to the top of the fuselage for the engine to run properly.

You may want to place a piece of tape on the tube that

corresponds to the vent line for easier identification later.

Step 3

Insert the fuel tank in the fuselage. Guide the fuel lines

through the hole in the firewall.

Step 4

Guiding the fuel tubes to the top of the fuselage, place the tank

in the fuselage so it rests in the fuselage as shown. The tank

will fit snug against the back of the firewall when installed.

10 Hangar 9 Alpha 40 ARF Assembly Manual

Page 11

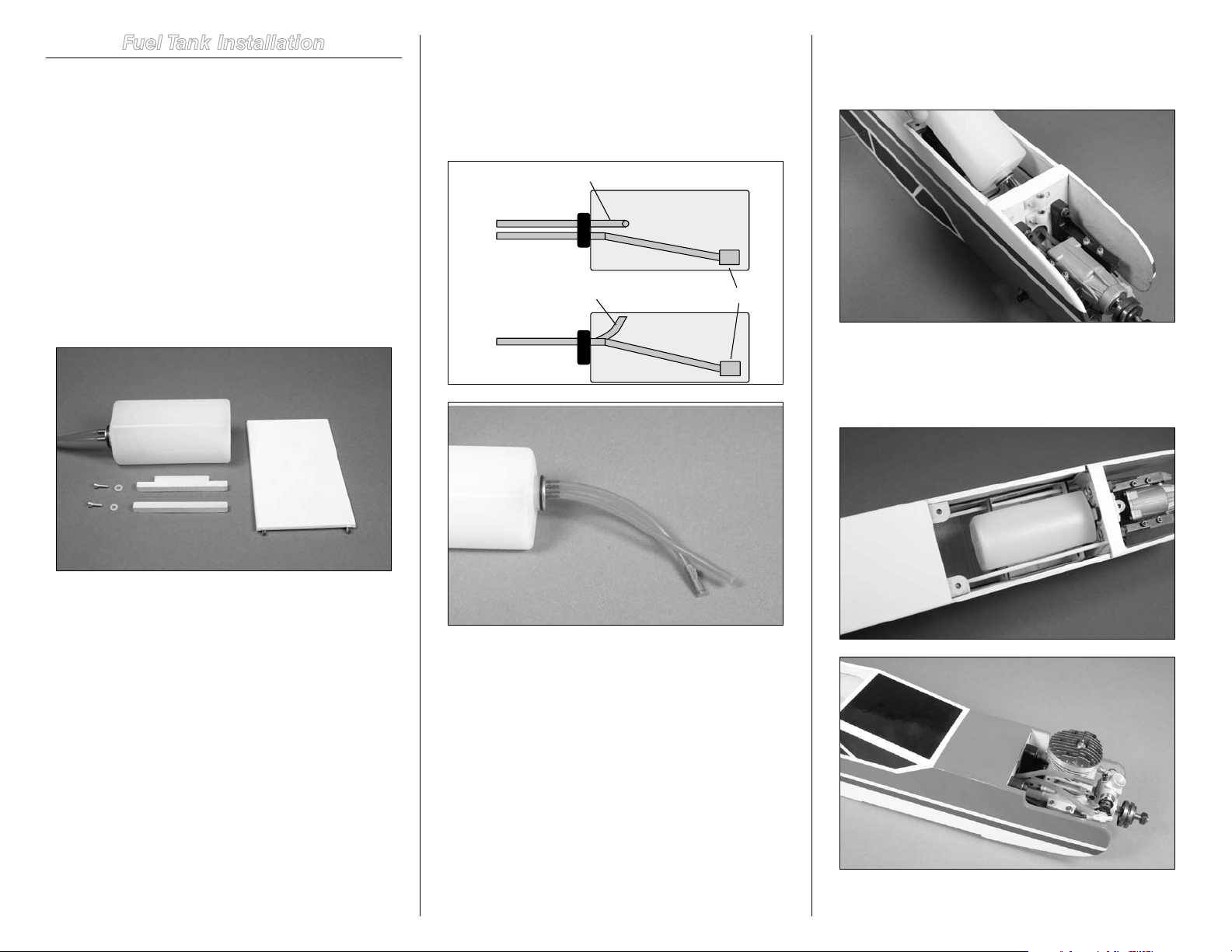

Step 5

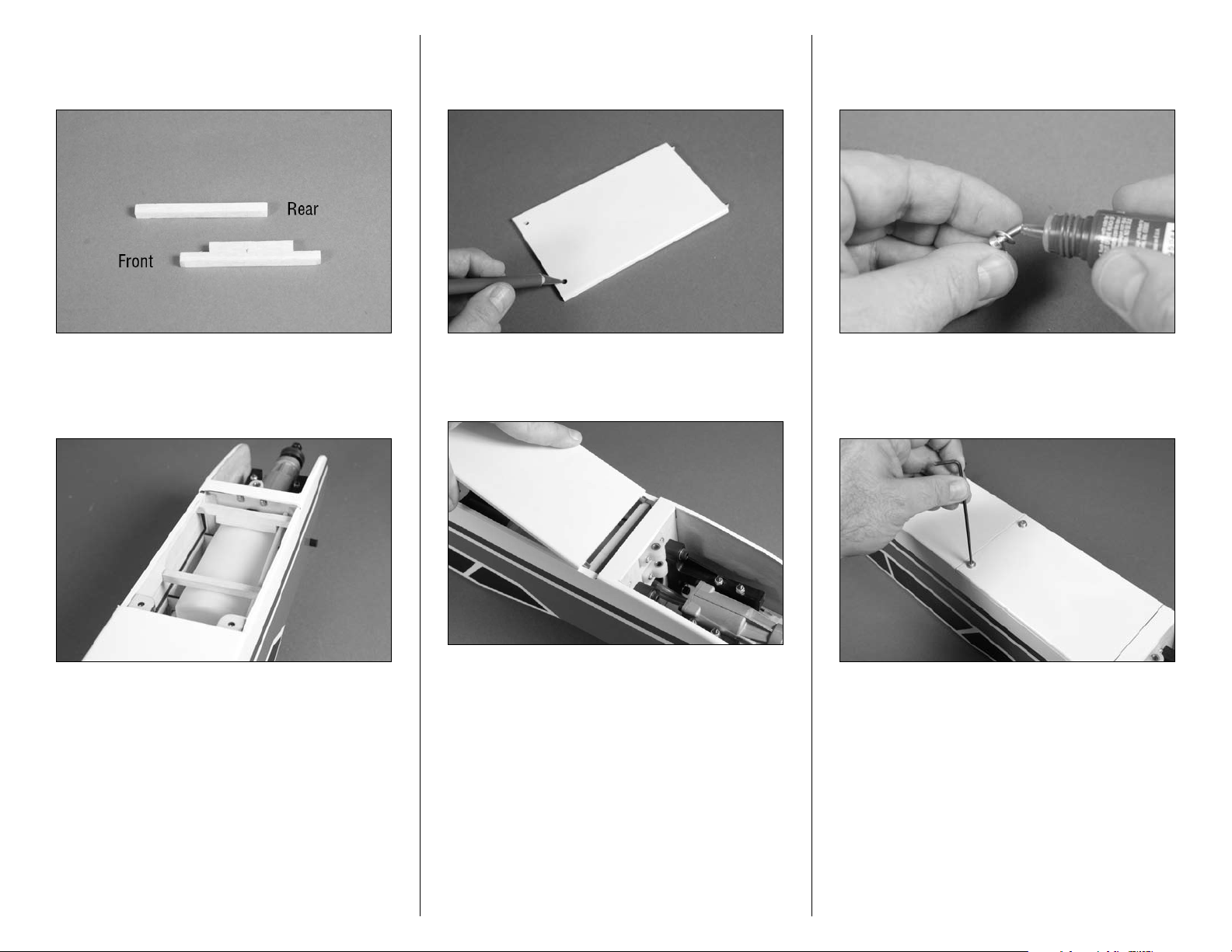

Locate the fuel tank braces. The rectangular piece is the rear

brace, while the shaped one is the front brace.

Step 7

Use a hobby knife with a #11 blade to expose the two holes

for the fuselage hatch mounting screws.

Step 9

Slide a #4 washer on a 3mm x 12mm socket head screw.

Place a drop of threadlock on the screw.

Step 6

Test fit the braces in the fuselage. They will lock into the

sides of the fuselage when installed properly. Once fit, use

medium CA to glue the braces to the fuselage sides.

Step 8

Slide the fuselage hatch in position on the fuselage. The tabs

will lock the front of the hatch in position.

Step 10

Use a 2.5mm hex wrench or ball driver to tighten the

screw. Use two screws and washers to secure the hatch

to the fuselage.

11Hangar 9 Alpha 40 ARF Assembly Manual

Page 12

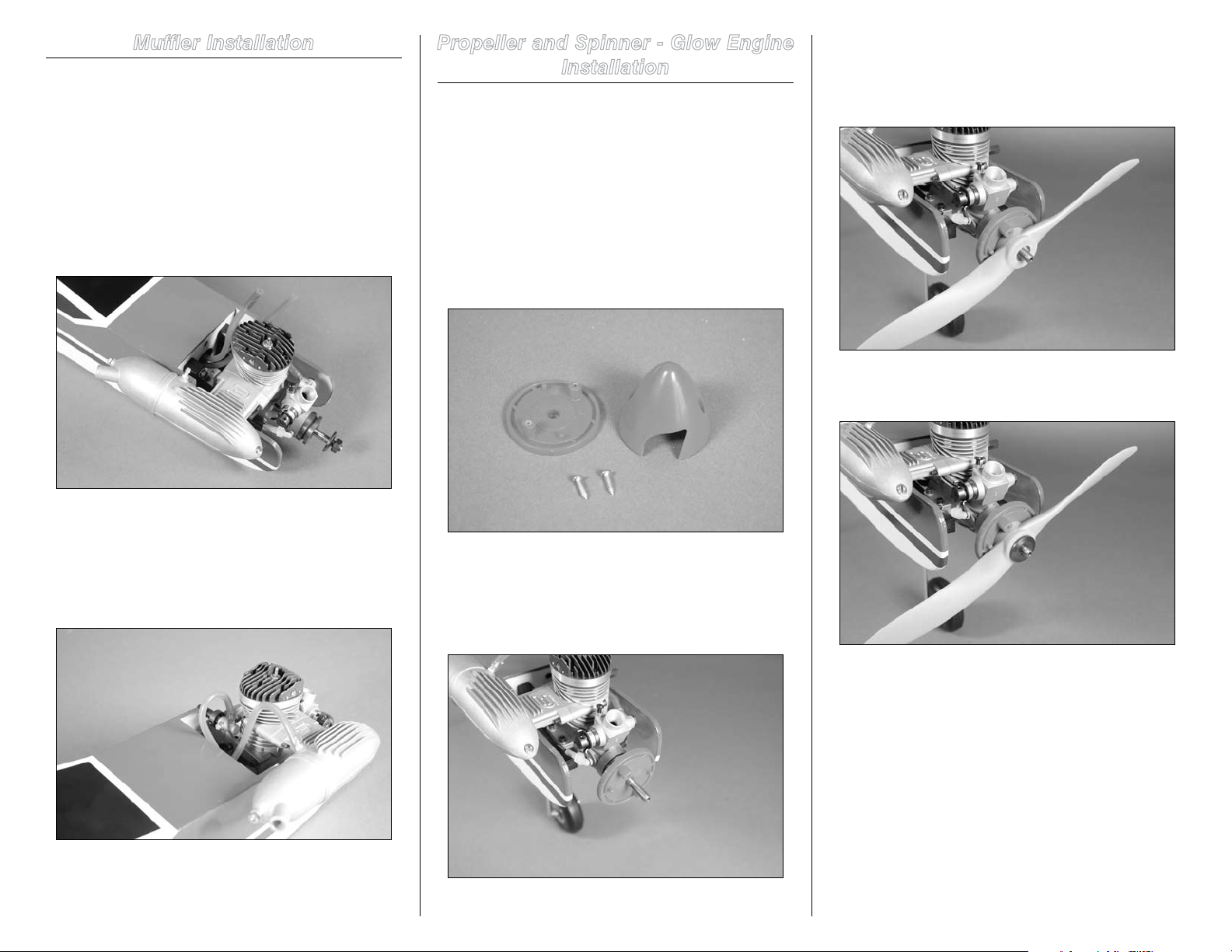

Muffler Installation

Required Parts

Fuselage Muffler

Required Tools and Adhesives

Hobby knife with #11 blade Hex wrench to fit muffler

Step 1

Attach the muffler to the engine using the hardware

provided with the engine. Make sure to follow the engine

manufacturer’s instructions where applicable.

Propeller and Spinner - Glow Engine

Installation

Required Parts

Fuselage assembly Spinner assembly

Propeller

Required Tools and Adhesives

Open end or box wrench: 3/8-inch

Phillips screwdriver: #1

Step 1

Locate the items necessary to install the spinner on your engine.

Step 3

Slide the propeller onto the engine crankshaft. The blades

of the propeller will be positioned against the bosses for the

spinner screws of the spinner backplate as shown below.

Step 4

Slide the propeller washer onto the engine crankshaft.

Step 2

Connect the fuel lines to the carburetor and muffler. The line

from the vent will attach to the muffler, while the line from the

clunk will attach to the carburetor. Use scissors or a hobby

knife and #11 blade to trim the length of the line if necessary

so they don’t interfere with the operation of the engine.

12 Hangar 9 Alpha 40 ARF Assembly Manual

Step 2

Check that the flywheel is fully installed on the engine. It fits

closely to the engine when positioned correctly. Slide the

spinner backplate onto the engine crankshaft so it is tight

against the flywheel.

Page 13

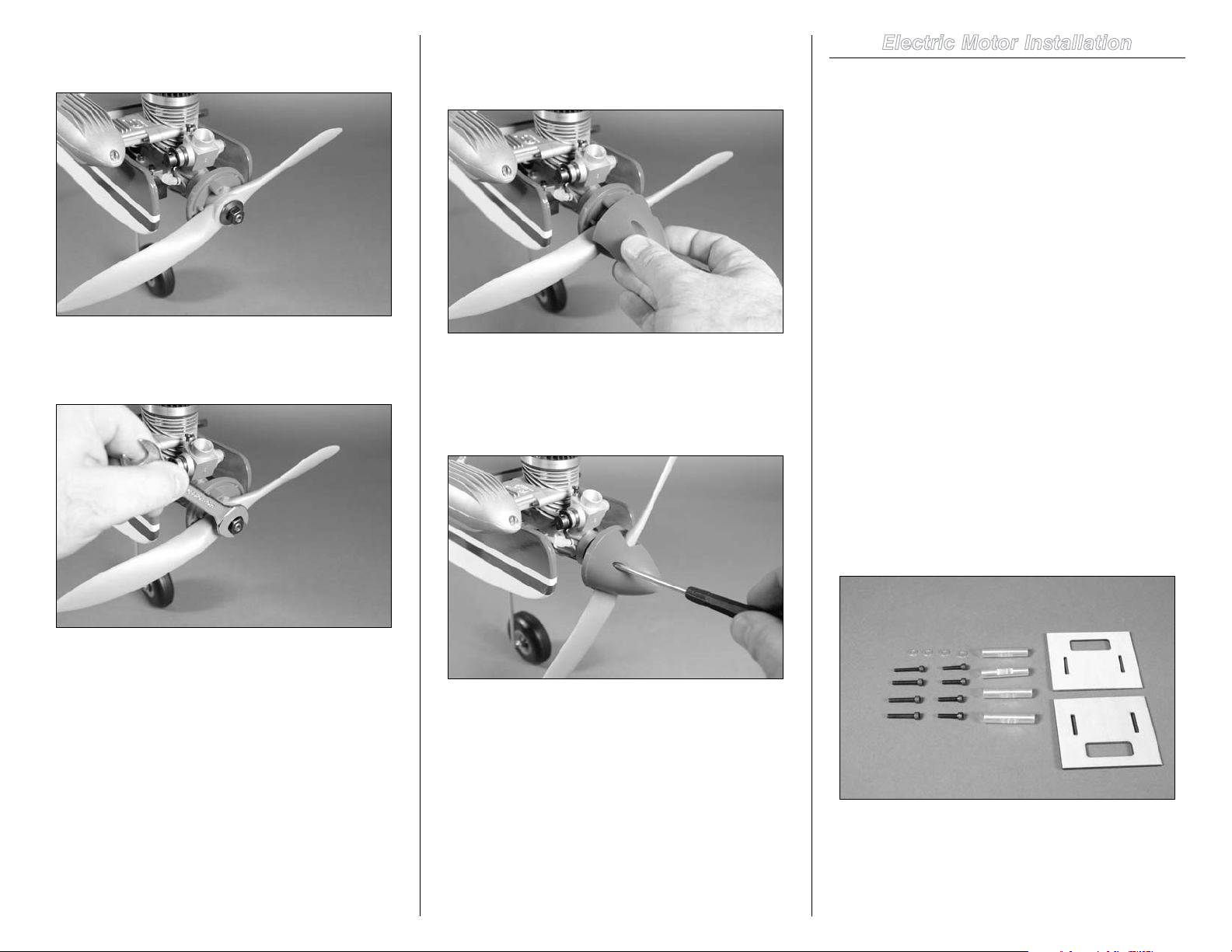

Step 5

Thread the propeller nut onto the engine crankshaft.

Step 6

Use an adjustable wrench to tighten the propeller nut. Secure

the propeller and spinner backplate onto the engine crankshaft.

Step 7

Slide the spinner cone over the propeller. It will fit into the

grooves in the spinner backplate when installed.

Step 8

Use the two 3mm x 10mm sheet metal screws supplied

with the spinner to secure the spinner cone to the spinner

backplate. A #1 Phillips screwdriver will be required to

tighten the screws.

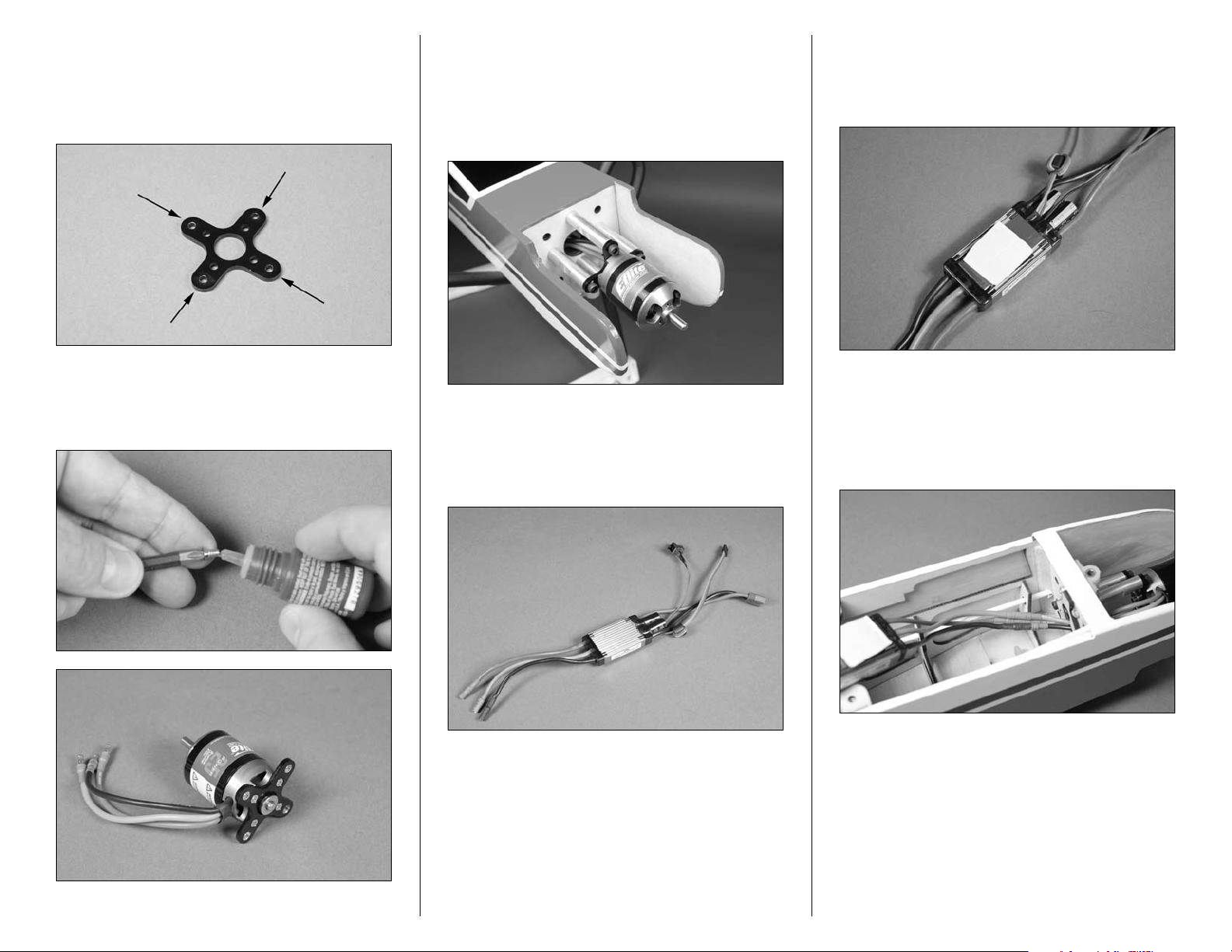

Electric Motor Installation

Required Parts

Fuselage 45mm Motor standoff (4)

#8 washer (4) Battery tray (2)

Fuselage hatch 3mm washer (2)

Motor battery

Electric motor with mount and hardware

Electronic speed control (ESC)

Hook and loop strap (not included)

Hook and loop tape (not included)

3mm x 12mm socket head screw (2)

Motor with mounting hardware

8-32 x 1-inch socket head screw (4)

8-32 x 3/4-inch socket head screw (4)

Required Tools and Adhesives

30-minute epoxy Mixing stick

Threadlock Drill

Open end wrench: 5/16-inch Phillips screwdriver: #1

Drill bit: 11/64-inch (4.5mm)

Hex wrench of ball driver: 9/64-inch, 2.5mm

Important: When tightening the propeller nut, always

use an adjustable wrench, box end wrench or 3/8-inch

drive socket. Using pliers will not allow you to place

enough grip to properly tighten the propeller nut.

Note: Make sure the propeller has not moved from

its position as described back in Step 3. If it has, the

spinner cone will not be able to be installed in the

following steps.

Step 1

Locate the parts necessary to install the electric motor

on the fuselage.

13Hangar 9 Alpha 40 ARF Assembly Manual

Page 14

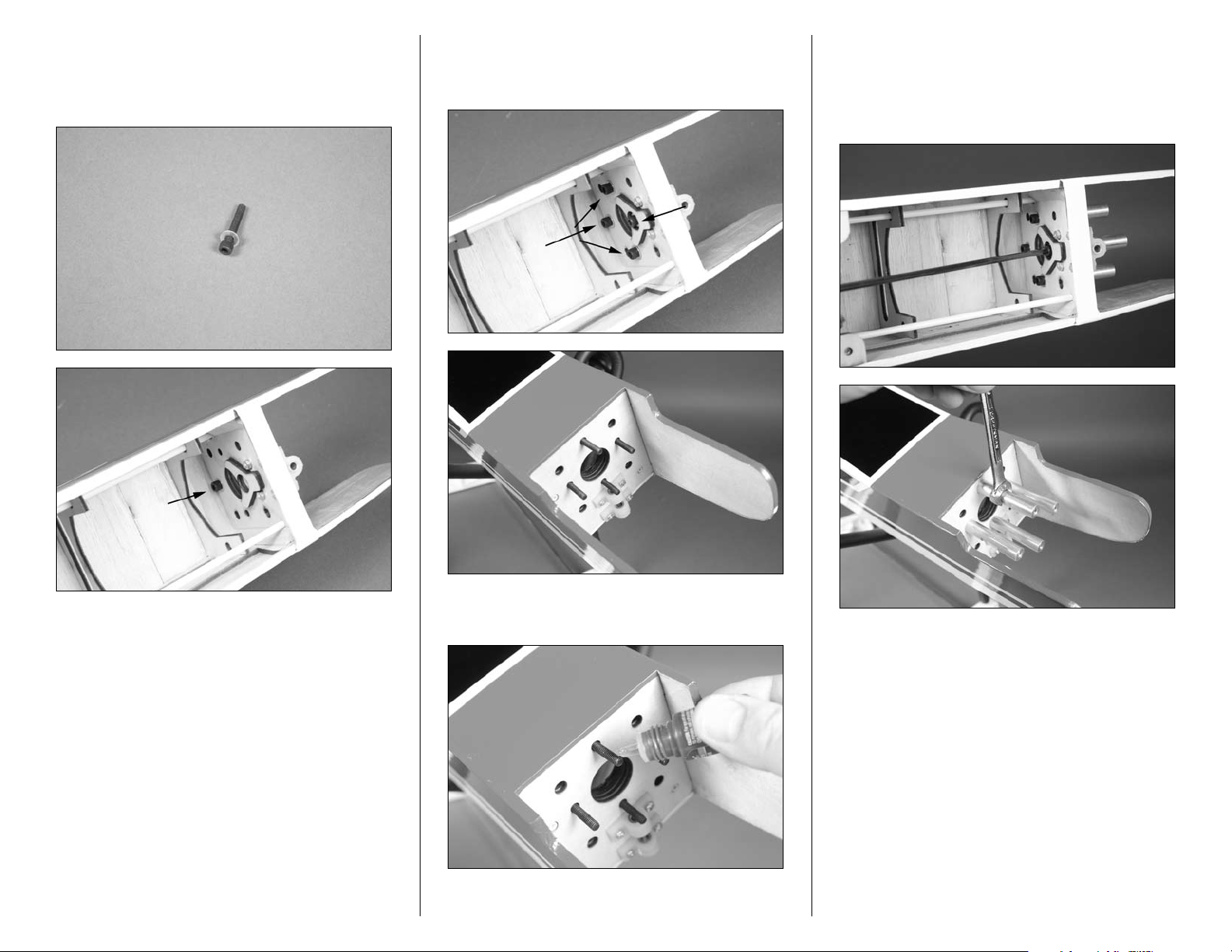

Step 2

Slide a #8 washer on a 8-32 x 1-inch socket head screw.

Insert the screw through the appropriate hole in the firewall

from the inside of the fuselage.

Step 3

Prepare three more 8-32 x 1-inch socket head screws and

insert them into the firewall as shown.

Step 5

Thread a 45mm EP standoff on each of the screws. Use

a 9/64-inch hex wrench or ball driver to tighten the 8-32

socket head screws while holding the standoff with a 5/16inch open end wrench. Install all four standoffs at this time.

Step 4

Place a drop of threadlock on each of the screws.

14 Hangar 9 Alpha 40 ARF Assembly Manual

Page 15

Step 6

Use a drill and 11/64-inch (4.5mm) drill bit to enlarge the

mounting holes in the X-mount. It is highly recommended

to use a drill press as the X-mount can easily be pulled from

your hand if using a hand drill.

Step 8

Use four 8-32 x 3/4-inch socket head screws to attach

the motor to the motor standoffs. Remember to use

threadlock on the screws so they don’t vibrate loose. The

wires from the motor will go into the fuselage through the

large hole in the firewall.

Step 10

Place a piece of hook and loop tape on the bottom of the

speed control. Leave the backing on the mating piece of tape

until instructed to remove.

Step 7

Apply a drop of threadlock on each of the screws used

to attach the X-mount to the motor. Use a #1 Phillips

screwdriver to secure the mount to the motor.

Step 9

Prepare the speed control with the necessary connectors

to connect it to your choice of battery and motor. Follow

the instructions provided with the speed control to

complete this step.

Step 11

Connect the leads from the motor to the speed control. If

you are using E-flite components, the colors will match

from the speed control and motor. If you are using other

components you may need to change the motor wires later

when checking the operation of the motor.

15Hangar 9 Alpha 40 ARF Assembly Manual

Page 16

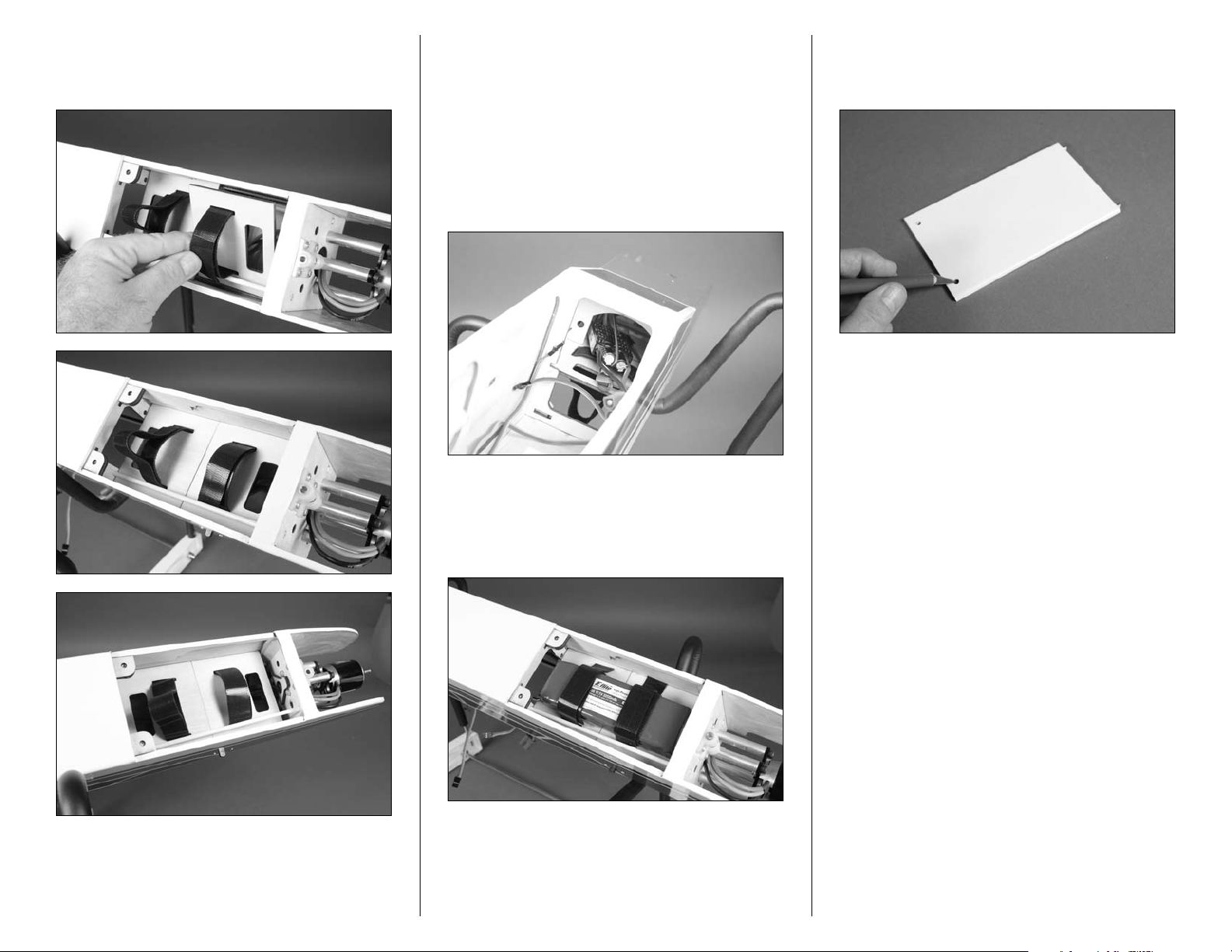

Step 12

Use a hobby knife to remove the covering from the opening

in the side of the fuselage for the speed control switch. Use

the hardware provided with the speed control to mount the

switch in the side of the fuselage.

Step 13

Position the speed control in the fuselage as shown. It will

be secured once the battery trays have been installed.

Step 14

Pass a hook and loop strap (not included) through the slots

in the two battery trays as shown.

Step 15

Insert the first battery tray by angling it in the fuselage as

shown. The tray will then fit into the fuselage where it can be

slid toward the rear of the fuselage.

16 Hangar 9 Alpha 40 ARF Assembly Manual

Page 17

Step 16

The second tray goes in the same as the first, but is

positioned to the front of the fuselage.

Step 17

Once both trays are in the fuselage, use a small amount

of 30-minute epoxy to glue the trays to the sides of the

fuselage. Make sure they are secure so the weight of the

battery does not cause them to come loose.

Step 18

The next step is to remove the backing from the hook and loop

material from the speed control and secure it to the battery

trays. This is tricky and will require patience to accomplish.

Step 19

Use the hook and loop straps to secure the motor battery

in the fuselage. If the battery slides forward or aft in the

fuselage, use a small piece of hook and loop tape between

the tray and battery to prevent it from doing so.

Step 20

Use a hobby knife with a #11 blade to expose the two holes

for the fuselage hatch mounting screws.

17Hangar 9 Alpha 40 ARF Assembly Manual

Page 18

Step 21

Slide the fuselage hatch in position on the fuselage. The

tabs will lock the front of the hatch in position. Slide a #4

washer on a 3mm x 12mm socket head screw. Place a drop

of threadlock on the screw. Use a 2.5mm hex wrench or ball

driver to tighten the screw. Use two screws and washers to

secure the hatch to the fuselage.

Step 22

On the bottom of the fuselage, right behind the rear window,

is an area that can be removed to provide cooling air to pass

through the fuselage to cool the motor battery. Removing

this covering is only necessary if you are not using the

newer Li-Po batteries capable of a 25C discharge rate.

Propeller and Spinner Installation-

Electric Motor

Required Parts

Fuselage assembly Spinner assembly

Propeller Propeller adapter

Required Tools and Adhesives

Phillips screwdriver: #1

Hex wrench or ball driver: 3/32-inch (2mm)

Step 1

Locate the items necessary to install the propeller and

spinner on the motor.

Step 2

Slide the propeller adapter on the motor as shown.

18 Hangar 9 Alpha 40 ARF Assembly Manual

Page 19

Step 3

Slide the spinner backplate onto the engine crankshaft so it

is tight against the flywheel.

Step 4

Slide the propeller onto the engine crankshaft. The blades

of the propeller will be positioned against the bosses for the

spinner screws of the spinner backplate as shown below.

Step 5

Thread the propeller nut onto the engine crankshaft.

Step 6

Use a 3/32-inch or 2.5mm hex wrench or ball driver to

tighten the adapter nut to secure the propeller and spinner

backplate onto the propeller adapter.

Step 7

Slide the spinner cone over the propeller. It will fit into the

grooves in the spinner backplate when installed.

Step 8

Use the two 3mm x 10mm sheet metal screws supplied

with the spinner to secure the spinner cone to the spinner

backplate. A #1 Phillips screwdriver will be required to

tighten the screws.

Note: Make sure the propeller has not moved from

its position as described back in Step 4. If it has, the

spinner cone will not be able to be installed in the

following steps.

19Hangar 9 Alpha 40 ARF Assembly Manual

Page 20

Landing Gear Installation

Required Parts

Fuselage Main landing gear (2)

Nose gear Steering arm

#4 x 3/8-inch wood screw (4) Landing gear strap (2)

2-56 x 16

Required Tools and Adhesives

Felt-tipped pen Drill

Drill bit: 5/64-inch (2mm) Phillips screwdriver: #2

Hobby knife with #11 blade Thin CA

Threadlock Medium CA

Alcohol Paper towel

Hex wrench or ball driver: 1.5mm

Note: The landing gear installation is identical if you are

using a glow engine or electric motor.

3

/4-inch steering pushrod

Step 1

Locate the items necessary to install the nose gear and main

landing gear on your aircraft.

Step 2

Connect the steering arm to the 2-56 x 16

pushrod. Note the position of the steering arm and setscrew

hole in the arm in relationship to how the pushrod is

located. If the pushrod is on the opposite side it will bind the

steering/rudder servo during operation.

3

/4-inch steering

Step 3

Slide the pushrod into the pushrod tube in the fuselage.

Position the steering arm between the block on the firewall

as shown. Make sure the hole for the setscrew faces forward

so it can be accessed.

Step 4

Inspect the nose gear assembly. There is a small notch in

the wire that will align with the hole for the setscrew in the

steering arm.

20 Hangar 9 Alpha 40 ARF Assembly Manual

Page 21

Step 5

Slide the nose gear assembly into the nose gear blocks and

steering arm. Note the direction of the coil spring and that it

faces to the back of the fuselage.

Step 6

Apply a drop of threadlock on the 3mm x 3mm setscrew.

Use the setscrew to secure the steering arm to the nose gear

assembly. The setscrew must be tightened on the notch of

the nose gear wire or it might vibrate loose during flight or

cause the nose gear to twist if the model encounters a poor

landing. Use a 1.5mm hex wrench or ball driver to tighten

the setscrew.

Step 8

Apply a thin coat of medium CA to the slot to seal the

exposed wood. This will keep fuel from soaking into the

wood and causing it to soften over time. Use a paper towel

to wipe away any excess CA. This is not necessary if you are

using an electric power system.

Step 7

Use a hobby knife to remove the covering to expose the

slot on the bottom of the fuselage for the main landing gear

wires. The main gear slot is located 51/2-inches (140mm)

behind the rear edge of the fuselage hatch.

Step 9

Use a hobby knife and #11 blade to bevel the inside edge

of both holes in the main landing gear block. This is

necessary to accept the radius of the bend on the main gear

assemblies, allowing them to fit snug in the slot.

21Hangar 9 Alpha 40 ARF Assembly Manual

Page 22

Step 10

Measure in 7/8-inch (23mm) from each side of the fuselage

and use a felt-tipped pen to draw a line as shown.

Step 12

Use a drill and 5/64-inch (2mm) drill bit to drill the four holes in

the bottom of the fuselage for the landing gear strap screws.

Step 14

Fit the gear to the fuselage. They must fit flush with the

bottom of the fuselage as shown. If not, it may be necessary

to enlarge the bevel made back in Step 9.

Step 11

Position the landing gear strap on the line and center it over the

slot in the fuselage. Use a felt-tipped pen to mark the locations

for the two mounting screws for each landing gear strap.

Step 13

Apply 2–3 drops of thin CA in each hole to harden the

surrounding wood. This will make the screws more secure

and help prevent them from vibrating loose in flight.

Hint: At this time you can remove the lines from the

bottom of the fuselage using rubbing alcohol and a

paper towel.

Step 15

Secure the main landing gear assemblies using the two

landing gear straps and four #4 x 3/8-inch wood screws. Use

a #2 Phillips screwdriver to tighten the screws.

22 Hangar 9 Alpha 40 ARF Assembly Manual

Page 23

Receiver Installation-

Electric Motor Option

Required Parts

Fuselage Receiver

Required Tools and Adhesives

Hook and loop tape

Step 1

Plug the rudder, elevator and throttle servos into the appropriate

ports of the receiver. The 6-inch (152mm) extension should still

be plugged in the aileron port of the receiver.

Step 3

The remote receiver is then mounted to the side of the

fuselage above the elevator servo using hook and loop tape.

Mount it as high as possible in the fuselage for the best

reception from your radio system.

Receiver Installation-

Glow Engine Option

Required Parts

Fuselage Radio tray

#4 x 5/8-inch wood screw Receiver battery

Switch harness Receiver

1/4-inch (6mm) foam (not included)

Required Tools and Adhesives

Phillips screwdriver: #1 Hook and loop tape

Drill bit: 3/32-inch (2.5mm) Drill

Pencil Thin CA

Hobby knife with #11 blade Scissors

Step 1

Locate the hardware necessary to install the radio tray

in the fuselage.

Step 2

Mount the receiver to the bottom of the fuselage using hook

and loop tape.

23Hangar 9 Alpha 40 ARF Assembly Manual

Page 24

Step 2

Slide the radio tray into the notches in the former. The tray will

fit against the rear of the fuel tank to keep it from moving.

Step 3

Use a pencil to mark the support block in the fuselage for the

radio tray screw.

Step 5

Place 2–3 drops of thin CA in the hole. This will harden the

surrounding wood, making the screw less likely to vibrate loose.

Step 4

Remove the radio tray from the fuselage. Use a drill and

3/32-inch (2.5mm) drill bit to drill a hole in the support block

for the screw that will secure the position of the radio tray.

Step 6

Use a hobby knife with a #11 blade to remove the covering

and expose the mounting location for the radio switch.

24 Hangar 9 Alpha 40 ARF Assembly Manual

Page 25

Step 7

Mount the switch to the side of the fuselage using the

hardware included with the switch. Use a #1 Phillips

screwdriver to tighten the screws for the switch.

Step 8

Use scissors to cut a piece of 1/4-inch (6mm) foam. Place

the foam in the bottom of the radio compartment.

Step 9

Plug the throttle, rudder and elevator servos into the

appropriate ports of the receiver. Also connect the battery

to the switch harness and plug the switch harness in the

battery port of the receiver. The 6-inch (152mm) servo

extension should still be plugged into the aileron port of the

receiver. If not, reconnect it at this time.

Step 10

Place the receiver and receiver battery in the fuselage. Use

scissors to cut small pieces of 1/4-inch (6mm) foam to

isolate the receiver and battery from each other, as well as

from the fuselage sides.

Step 11

Use scissors to cut a final piece of 1/4-inch (6mm) foam to

cover the receiver and receiver battery.

Step 12

Slide the radio tray in position. Use a #4 x 5/8-inch wood

screw to secure the tray in position. Use a #1 Phillips

screwdriver to tighten the screw.

25Hangar 9 Alpha 40 ARF Assembly Manual

Page 26

Step 13

Use hook and loop tape to secure the remote receiver above

the throttle servo as shown. Mount the receiver as high in the

fuselage and as far away from the main receiver as possible to

provide the best reception from your radio system.

Wing Dowel Installation

Required Parts

Fuselage assembly Wing dowel (2)

Step 2

Use a hobby knife with a #11 blade to remove the covering

from the fuselage for the wing dowels.

Step 4

Slide the second wing dowel into the pre-drilled holes in the

rear of the fuselage. Center the dowel so it extends equally

from both sides of the fuselage.

Step 5

Apply thin CA into the joint between the dowel and fuselage

to keep it from moving.

Required Tools and Adhesives

Thin CA

Step 1

Locate the wing dowels for your aircraft.

26 Hangar 9 Alpha 40 ARF Assembly Manual

Step 3

Slide the wing dowel into the pre-drilled holes in the front

of the fuselage. Center the dowel so it extends equally from

both sides of the fuselage.

Page 27

Fin and Stabilizer Installation

Required Parts

Fin/Rudder assembly #4 washer (4)

Stabilizer/Elevator assembly Wing nut (2)

3mm x 10mm machine screw (2)

Required Tools and Adhesives

Phillips screwdriver: #1 Threadlock

Hobby knife with #11 blade

Step 1

Locate the fin and stabilizer assemblies and the hardware

necessary to install them on the fuselage.

Step 3

The threaded rods from the fin will fit into the holes that are

pre-drilled in the stabilizer as shown.

Step 5

Apply a drop of threadlock onto each of the threaded rods.

Step 6

Thread the two wing nuts onto the threaded rods to secure

the fin to the stabilizer. Don’t over-tighten the wing nut and

damage the underlying wood.

Step 2

Use a hobby knife with a #11 blade to remove the covering

from the notch at the front of the stabilizer. Also remove the

covering from the pre-drilled holes in the stabilizer.

Step 4

Slide the two #4 washers onto the threaded rods from the

bottom of the stabilizer.

27Hangar 9 Alpha 40 ARF Assembly Manual

Page 28

Step 7

Use a hobby knife to remove the covering from the slot on

the top of the fuselage for the fin.

Step 8

Use a hobby knife with a #11 blade to remove the covering on

the bottom of the fuselage for the stabilizer attachment screw.

Step 9

Slide the fin into position on the fuselage as shown.

o Step 10

Locate a #4 washer and 3mm x 10mm machine screw. Slide

the washer onto the screw, then apply a small amount of

threadlock on the screw.

o Step 11

Insert the screw into the hole in the fuselage and through

the stabilizer to the preinstalled blind nut on the top of the

stabilizer. Use a #2 Phillips screwdriver to tighten the screw.

28 Hangar 9 Alpha 40 ARF Assembly Manual

Page 29

Step 12

Repeat Steps 10 and 11 to install the second screw.

Throttle Linkage Connection

Required Parts

Fuselage Pushrod snap link

Transmitter

Required Tools and Adhesives

Pliers Felt-tipped pen

Drill bit: 5/64-inch (2mm) Pin vise

Diagonal cutters

Note: This section covers the installation and

connection of the throttle linkage. If you have installed

an electric power system you can skip this section of

the manual.

Step 1

Locate the pushrod snap link. This will be used to secure the

pushrod wire to the throttle servo horn.

Step 2

With the radio system on, move the throttle stick and trim on

the transmitter to the center. Remove the throttle servo horn

from the servo. Rotate the horn so the arm that aligns with

the throttle pushrod measures 1/2-inch (13mm) from the

center of the horn, which aligns with the outer hole of the

servo horn.

Step 3

Move the throttle stick to the closed throttle position at the

transmitter. Pull the throttle linkage so the carburetor at the

engine is closed. Use a felt-tipped pen to mark the pushrod

wire where it crosses the hole on the servo horn that is 1/2inch (13mm) from the center of the horn.

Step 4

Use the radio to move the servo to the open throttle position.

Push the linkage to open the carburetor. The line made in the

previous step should align with the same hole on the servo

horn. If the line is further forward than the servo horn, you

will need to use a longer servo horn or connect the clevis at

the carburetor closer to the center of the carburetor. If the

line does not move far enough you will need to use a shorter

servo horn or connect the clevis at the carburetor to a hole

farther away from the center or the arm. Adjust as necessary

so the servo movement is correct for your engine.

Note: If using a computer radio you can use the travel

volume to adjust for minor differences. It is best to set it as

close mechanically to result in linear travel of the throttle.

29Hangar 9 Alpha 40 ARF Assembly Manual

Page 30

Step 5

Once set, use pliers to make a 90-degree bend in the

pushrod wire at the mark made.

Step 6

Use a pin vise and 5/64-inch (2mm) drill bit to enlarge the

hole in the servo horn that has aligned for use with your

linkage position.

Step 7

Remove the servo horn from the servo using a #1 Phillips

screwdriver. Use diagonal cutters to remove any unused

arms from the horn so they don’t interfere with the operation

of the servo.

Step 8

Slide the pushrod wire through the hole in the servo horn.

The horn will fit against the bend in the wire.

Step 9

Slide the pushrod snap link on the wire. Rotate the link so it

snaps on the wire. You may need to use pliers to snap the

link onto the wire.

30 Hangar 9 Alpha 40 ARF Assembly Manual

Page 31

Step 10

Use diagonal cutters to trim the excess wire above the

link so it does not interfere with the operation of the radio

system. Leave a small amount of wire so the pushrod snap

link cannot accidentally slip up and over the wire.

Step 11

Move the throttle stick to the low throttle position. With the

carburetor closed, attach the servo horn on the servo using a

#1 Phillips screwdriver.

Elevator Linkage Installation

Required Parts

Fuselage Safety tubing

Clevis Pushrod snap link

2-56 x 28-inch pushrod wire

Required Tools and Adhesives

Hobby knife with #11 blade Pliers

Phillips screwdriver: #1 Ruler

Diagonal cutters

Step 1

Locate the items necessary to install the elevator linkage.

Step 3

Use a hobby knife to cut a 1/4-inch (6mm) piece from the clear

safety tubing. Slide the tubing onto the clevis, and then thread

the clevis 10-turns on the elevator pushrod wire as shown.

Step 12

Check the operation of the carburetor using the radio

system. The servo should move without any binding at

closed or open throttle. If it does, adjust the clevis at the

carburetor as necessary, or use the radio travel volume to

correct any adjustment issues.

Step 13

If you are going to step away from your model, make sure to

turn off both the transmitter and receiver.

Step 2

Slide the 2-56 x 28-inch pushrod wire into the tube in the

fuselage for the elevator. Make sure the threaded end goes

into the tube first.

31Hangar 9 Alpha 40 ARF Assembly Manual

Page 32

Step 4

Attach clevis

to center hole

Connect the clevis to the center hole of the elevator control

horn. Slide the safety tubing over the forks of the clevis to

prevent it from opening accidentally.

Step 5

With the radio system on, center the stick and trim for

the elevator at the radio. Check that the servo horn on the

elevator servo is centered, and that the arm with the hole

1/2-inch (13mm) from the center of the horn is facing

toward the elevator pushrod wire.

Step 6

Use a ruler to make sure the elevator is centered with the

stabilizer. Use a felt-tipped pen to mark the pushrod wire

where it crosses the hole on the servo horn.

Step 7

Use pliers to bend the pushrod wire 90-degrees at the mark

made in the previous step.

32 Hangar 9 Alpha 40 ARF Assembly Manual

Page 33

Step 8

Use a pin vise and 5/64-inch (2mm) drill bit to enlarge the

hole in the servo horn.

Step 10

Slide the pushrod wire through the hole in the servo horn.

The horn will fit against the bend in the wire.

Step 12

Use diagonal cutters to trim the excess wire above the

link so it does not interfere with the operation of the radio

system. Leave a small amount of wire so the pushrod snap

link cannot accidentally slip up and over the wire.

Step 9

Remove the servo horn from the servo using a #1 Phillips

screwdriver. Use diagonal cutters to remove any unused

arms from the horn so they don’t interfere with the operation

of the servo.

Step 11

Slide the pushrod snap link on the wire. Rotate the link so it

snaps on the wire. You may need to use pliers to snap the

link onto the wire.

Step 13

Secure the elevator servo horn to the elevator servo using

the screw removed from the servo. Use a #1 Phillips

screwdriver to tighten the screw.

Step 14

If you are going to step away from your model, make sure to

turn off both the transmitter and receiver.

33Hangar 9 Alpha 40 ARF Assembly Manual

Page 34

Rudder and Steering Linkage

Installation

Required Parts

Fuselage 180-degree servo horn

Safety tubing Clevis

Pushrod snap link E-clip

Small washer Pushrod connector

3mm x 3mm setscrew Transmitter

2-56 x 28-inch pushrod wire

Required Tools and Adhesives

Drill bit: 5/64-inch (2mm) Pin vise

Felt-tipped pen Pliers

Hobby knife with #11 blade Ruler

Hex wrench or ball driver: 1.5mm

Step 1

Locate the items necessary to install the rudder linkage and to

connect the steering pushrod wire to the rudder servo horn.

Step 2

With the radio system on, center the rudder stick and trim.

Remove the standard servo horn from the rudder servo and

place a 180-degree horn on the rudder servo. The horn will

align perpendicular to the servo centerline as shown. If not,

rotate the arm 180-degrees as there are an odd number of

splines on the servo output and this usually corrects the

alignment issue.

Step 3

Use a pin vise and 5/64-inch (2mm) drill bit to enlarge a hole on

the servo horn that is 9/16-inch (14mm) from the center of the

servo horn on the side closest to the steering pushrod wire.

Step 4

Use a pin vise and 5/64-inch (2mm) drill bit to enlarge a hole

on the servo horn that is 1/2-inch (12mm) from the center of

the servo horn on the side closest to the rudder pushrod tube.

Step 5

Remove the horn from the servo. Insert the pushrod

connector in the outer hole of the servo horn.

34 Hangar 9 Alpha 40 ARF Assembly Manual

Page 35

Step 6

Place the small washer on the opposite side of the horn. The

connector is then secured using a small E-clip. Use pliers to

snap the E-clip in position.

Step 7

Slide the 2-56 x 28-inch pushrod wire into the tube in the

fuselage for the rudder. Make sure the threaded end goes

into the tube first. Use a hobby knife and #11 blade to trim

the covering on the fuselage where the pushrod exits.

Step 8

Use a hobby knife to cut a 1/4-inch (6mm) piece from the clear

safety tubing. Slide the tubing onto the clevis, and then thread

the clevis 10-turns on the rudder pushrod wire as shown.

35Hangar 9 Alpha 40 ARF Assembly Manual

Page 36

Step 9

Attach clevis

to center hole

Connect the clevis to the center hole of the rudder control

horn. Slide the safety tubing over the forks of the clevis to

prevent it from opening accidentally.

Step 10

Place the servo horn back on the rudder servo. Make sure

the horn is aligned correctly as described previously.

Step 12

Remove the rudder servo horn. Use pliers to bend the pushrod

wire 90-degrees at the mark made in the previous step.

Step 11

Use a ruler to make sure the rudder is centered with the

fin. Use a felt-tipped pen to mark the pushrod wire where it

crosses the hole enlarged previously on the servo horn.

Step 13

Slide the pushrod wire through the hole in the servo horn.

The horn will fit against the bend in the wire.

36 Hangar 9 Alpha 40 ARF Assembly Manual

Page 37

Step 14

Slide the pushrod snap link on the wire. Rotate the link so it

snaps on the wire. You may need to use pliers to snap the

link onto the wire.

Step 15

Use diagonal cutters to trim the excess wire above the

link so it does not interfere with the operation of the radio

system. Leave a small amount of wire so the pushrod snap

link cannot accidentally slip up and over the wire.

Step 17

Center the nosewheel so it is aligned with the centerline of

the fuselage. Use a 3mm x 3mm setscrew and 1.5mm hex

wrench to tighten the setscrew that secures the steering

pushrod wire. Make sure to use threadlock on the setscrew.

Step 16

Slide the steering pushrod wire through the pushrod

connector. Use the screw from the servo and a #1 Phillips

screwdriver to attach the horn to the rudder servo.

Note: If you find that your model does not track straight

on the ground, loosen the setscrew to adjust the steering.

Do not use the rudder trim to adjust the steering. Use the

rudder trim for in-flight corrections only.

Step 18

If you are going to step away from your model, make sure to

turn off both the transmitter and receiver.

37Hangar 9 Alpha 40 ARF Assembly Manual

Page 38

Aileron Servo Installation

Required Parts

Wing panel, right Servo with hardware

Clevis (2) Pushrod snap link (2)

2-56 x 6

Safety tubing

Required Tools and Adhesives

Drill bit: 5/64-inch (2mm) Drill

Hobby knife with #11 blade Pin vise

Ruler Pliers

Pencil Thin CA

Phillips screwdriver: #1

1

/8-inch pushrod wire (2)

Step 2

Install the grommets and brass eyelets in the servo. Place the

servo in the wing with the servo output shaft to the trailing

edge of the wing. Use a pencil to transfer the positions for the

servo mounting screws onto the servo mount.

Step 3

Remove the servo from the wing. Use a drill and 5/64-inch

(2mm) drill bit to drill the four holes to mount the servo.

Step 1

Locate the items necessary to install the aileron servo

in the wing.

Hint: Place the drill bit in the drill as far as possible to

avoid accidentally drilling through the top of the wing.

Step 4

Place 2–3 drops of thin CA in each of the holes to harden the

surrounding wood. This will make the screws more secure

and less likely to vibrate loose.

38 Hangar 9 Alpha 40 ARF Assembly Manual

Page 39

Step 5

Use a #1 Phillips screwdriver and the screws provided with

the servo to secure the aileron servo in the wing.

Step 7

Use a ruler and measure 4

the clevis. Use a felt-tipped pen to mark the pushrod wire. Use

pliers to make a 90-degree bend in the pushrod wire as shown.

3

/8-inch (111mm) from the pin in

Step 9

Repeat Steps 6 through 8 to make a second aileron

pushrod wire.

Step 6

Use a hobby knife to cut a 1/4-inch (6mm) piece from the

safety tubing. Slide the tubing onto a nylon clevis. Thread the

clevis 10-turns on a 6-1/8-inch (155mm) threaded pushrod.

Step 8

Measure 3/8-inch (10mm) up from the bend and use

diagonal cutters to trim the pushrod wire as shown.

Step 10

Remove the servo horn from the aileron servo. Use side

cutters to remove the two shorter arms from the servo horn.

39Hangar 9 Alpha 40 ARF Assembly Manual

Page 40

Step 11

Use a pin vise and 5/64-inch (2mm) drill bit to enlarge the

holes in the servo arm that are 1/2-inch (12mm) from the

center of the horn as shown.

Step 12

Plug the aileron servo into the extension inside the fuselage.

Turn on the transmitter and center the aileron stick and trim.

Attach the servo horn to the servo using the screw provided

with the servo and a #1 Phillips screwdriver.

Step 13

Connect the aileron linkages to the holes of the servo horn

that were enlarged in the previous steps. Use the pushrod

snap links for this step.

Wing Assembly

Required Parts

Wing panel (left and right) Aluminum wing tube

Clear tape

Note: The following covers the assembly of the wing

without the use of glue. The wing, when joined in this

method, is very strong and does not need to be glued

together. You will want to purchase additional clear tape

if you plan on breaking the wing down into two pieces

for transportation purposes.

Step 1

Locate the items necessary to join the left and

right wing panels.

40 Hangar 9 Alpha 40 ARF Assembly Manual

Page 41

Step 2

Slide the wing tube into the wing panel as shown. The wing

tube will only slide in halfway, so do not force it in any

further than it will slide easily.

Step 3

Slide the remaining wing panel onto the wing tube.

Step 4

As you slide the wing panels together, make sure the

aluminum pin at the back (trailing edge) of the wing slides

into the hole of the receiving wing panel. Slide the two wing

panels tightly together so there is no gap between the two.

Step 5

Use the supplied clear tape to secure the joint between the

two wing panels. Make sure to apply the tape to both the top

and bottom of the joint.

Step 6

Connect the clevises from the aileron pushrods to the aileron

control horns.

Step 7

Plug the aileron servo into the extension coming from the

aileron port of the receiver. Turn on the radio system and

center the aileron stick and trim. Use a ruler to check that the

aileron are in alignment with the bottom of the wing. If they

are not, thread the clevis in or out as necessary to align the

aileron and wing. Make sure to align both aileron at this time.

41Hangar 9 Alpha 40 ARF Assembly Manual

Page 42

Optional: Gluing the Wing Halves

Required Parts

Wing panel (left and right) Aluminum wing tube

Covering (white) Covering (red)

Required Tools and Adhesives

30-minute epoxy Mixing cup

Mixing stick Epoxy brush

Rubbing alcohol Paper towel

Low-tack tape Covering iron

Step 2

Slide the wing tube into the wing panel as shown. The wing

tube will only slide in halfway, so do not force it in any

further than it will slide easily.

Note: It is not necessary to glue the wing panels

together on your model. This section has been provided

in case you opt to do so. Make sure your vehicle has

enough room to transport the joined wing before joining

the wing panels using this method.

Step 1

Locate the items necessary to join the left and

right wing panels.

Step 4

Slide the remaining wing panel onto the wing tube.

Step 3

Mix 1/2-ounce total (15ML) of 30-minute epoxy. Use an

epoxy brush to apply a thin layer of epoxy to each of the

wing roots as shown.

42 Hangar 9 Alpha 40 ARF Assembly Manual

Page 43

Step 5

As you slide the wing panels together, make sure the pin at

the back (trailing edge) of the wing slides into the hole of

the receiving wing panel. Slide the two wing panels tightly

together so there is no gap between the two.

Step 6

Use a paper towel and rubbing alcohol to remove any epoxy

that seeps from the joint between the two wing panels.

Step 7

Use tape (low-tack tape suggested) to keep the two wing

panels tight against each other until the epoxy is fully cured.

Step 8

After the epoxy has fully cured, use a covering iron to apply

the covering to the joint of the wing. Use the red covering

on the bottom of the wing, and the white covering on the

top of the wing.

Step 9

Connect the clevises from the aileron pushrods to the aileron

control horns. The alignment of the ailerons will be checked

later in this manual.

Step 10

Plug the aileron servo into the extension coming from the

aileron port of the receiver. Turn on the radio system and

center the aileron stick and trim. Use a ruler to check that the

aileron are in alignment with the bottom of the wing. If they

are not, thread the clevis in or out as necessary to align the

aileron and wing. Make sure to align both aileron at this time.

43Hangar 9 Alpha 40 ARF Assembly Manual

Page 44

Wing Installation

Required Parts

Wing Fuselage

Rubber band (10)

Step 1

Locate the rubber band to secure the wing to the fuselage.

Step 2

Locate the aileron extension that is inside the fuselage. Align

the colors from the aileron servo lead with the extension so

they match, then plug them together.

Step 3

Start securing the wing to the fuselage by installing two of

the rubber bands.

Hint: Always start with the cross rubber bands. This

will keep the wing from twisting on the fuselage when

installing the remaining rubber bands.

Step 4

Install a second set of rubber bands on the wing

as shown.

Step 5

Continue installing a total of six or more of the rubber bands,

alternating the direction of each set until they have all been

installed.

Hint: Always end the rubber band installation by

installing the cross rubber bands last. They will help in

keeping all the other rubber bands in position on the

wing dowels.

Hint: After flying, store your rubber bands in a bag with

a small amount of baby powder. This will soak up the fuel

that is on the rubber bands, making them last longer.

44 Hangar 9 Alpha 40 ARF Assembly Manual

Page 45

Checking the Control Surface

Movement

Required Parts

Transmitter Assembled airframe

The control direction has been set at the factory. This

section has been provided in case any servos or control

surfaces are replaced so the control direction can be

checked at a later date.

CHECKING THE ELEVATOR

Check the movement of the elevator with the radio system.

Pushing the elevator/aileron stick (right stick on the

transmitter) forward will make the airplane elevator move

down. This will cause the aircraft to pitch down while in flight.

CHECKING THE AILERONS

Check the movement of the aileron using the transmitter.

When the aileron/elevator stick is moved left, the left aileron

will move up and the right aileron will move down. This will

cause the aircraft to roll left in flight.

CHECKING THE RUDDER

Check the movement of the rudder using the transmitter.

When the left stick is moved left, the rudder should also

move left. This will cause the aircraft to turn left while on the

ground and to yaw left while in flight.

Check the movement of the elevator with the radio

system. Pulling the elevator/aileron stick (right stick on the

transmitter) back will make the airplane elevator move up.

This will cause the aircraft to pitch up in flight.

Check the movement of the aileron using the transmitter.

When the elevator/aileron stick is moved right, the right

aileron will move up and the left aileron will move down.

This will cause the aircraft to roll right in flight.

Check the movement of the rudder using the transmitter.

When the rudder/throttle stick (left side of the transmitter)

is moved right, the rudder should also move right. This will

cause the aircraft to turn right while on the ground and to

yaw right while in flight.

45Hangar 9 Alpha 40 ARF Assembly Manual

Page 46

Checking the Throttle Operation

Required Parts

Fuselage assembly Transmitter

THROTTLE CLOSED

Move the throttle stick and trim down to the fully closed

position as shown. The carburetor should close without

binding the throttle servo. If the servo binds, you will need to

adjust the clevis at the carburetor by threading it in or out to

eliminate any binding.

THROTTLE OPEN

Move the throttle stick and trim up or to the fully open

position as shown. The carburetor should open without

binding the throttle servo. If the servo binds, you will need to

adjust the clevis at the carburetor by threading it in or out to

eliminate any binding.

THROTTLE SET TO IDLE

Move the throttle stick down to the fully closed position. Move

the trim lever upward to open the carburetor roughly 1/16inch (1.5mm). This will be the idle position for your engine.

The idle will be fine-tuned at the field so the engine will idle

reliably without stalling for slow flight and landing procedures.

46 Hangar 9 Alpha 40 ARF Assembly Manual

Page 47

Balancing Your Alpha ARF

In order for your Alpha 40 ARF to fly correctly, you will

need to check the balance of the plane with the fuel tank

empty. This is done by supporting the aircraft either using

your fingers or by using a balancing stand. Not checking the

balance can result in an aircraft that is difficult to fly, which

can lead to the possibility of crashing your model.

Marking the Balance Point

The first step in balancing your Alpha 40 ARF is to mark the

location for the balance point. The ideal balance point for the

Alpha ARF is 23/4–3 inches (70–76mm) back from the leading

edge against the fuselage. If your plane is only slightly out

of balance, try placing the balancing stand towards the nose

or tail by 1/8-inch (3mm) and recheck the balance. If it looks

good and sits level, then you’re good to go.

Balanced Correctly

Nose Heavy – Add Weight to Tail

Adding Weights to Correct the Balance

Due to manufacturing differences, it is possible that the Alpha

40 ARF may not be balanced properly. Weights can be added

to either the tail or the nose of your Alpha ARF if it does not

balance properly. Stick-on weights (Self Stick Weight, 6 oz

HAN3626) available at your local hobby store are the easiest

to use, and come in sizes that are easily placed on your plane.

Add just enough weight as necessary to balance your plane.

Once the weight has been added, make sure it is secure and

will not fall off in flight.

Lifting the Model and Observations

Make sure the Alpha ARF is balanced using either your

fingers or a balancing stand. Place or lift the airplane so it is

supported at the marks made in the previous step. The plane

will rest level when balanced correctly. If not, weights must

be added to correct any balancing problems.

Tail Heavy – Add Weight to Nose

47Hangar 9 Alpha 40 ARF Assembly Manual

Page 48

Control Throws

Step 1

Check the battery voltage on both the transmitter and

the receiver battery packs. Do not fly below 4.3V on the

transmitter if you are using a Spektrum transmitter that uses

4-cells to power the transmitter. Do not fly below 9.5V on the

transmitter if you are using a JR or Spektrum transmitter that

uses 8-cells to power the transmitter. Do not fly if the receiver

pack is at or below 4.7V. To do so may crash your aircraft.

Step 2

Check the movement of the elevator with the radio system.

Moving the elevator stick toward the bottom of the

transmitter will make the airplane elevator move up.

Step 3

Check the movement of the ailerons with the radio system.

Moving the aileron stick right will make the right aileron

move up and the left aileron move down.

Step 4

Use a ruler to adjust the throw of the elevator, ailerons

and rudder.

Aileron High Rate

Up 3/8-inch (10mm) (14 degrees)

Down 3/8-inch (10mm) (14 degrees)

Aileron Low Rate

Up 1/4-inch (6mm) (8 degrees)

Down 1/4-inch (6mm) (8 degrees)

Elevator High Rate

Up 1/2-inch (13mm) (16 degrees)

Down 1/2-inch (13mm) (16 degrees)

Elevator Low Rate

Up 5/16-inch (8mm) (10 degrees)

Down 5/16-inch (8mm) (10 degrees)

Rudder High Rate

Left 7/8-inch (22mm) (20 degrees)

Right 7/8-inch (22mm) (20 degrees)

Rudder Low Rate

Left 1/2-inch (13mm) (11 degrees)

Right 1/2-inch (13mm) (11 degrees)

Note: Measurements are taken at the inner or widest

point on the control surface.

These are general guidelines measured from our own flight

tests. You can experiment with higher rates to match your

preferred style of flying.

Note: Travel Adjust, Sub-Trim and Dual Rates are

not listed and should be adjusted according to each

individual model and preference.

Once all control throws are set, make sure the

safety tubing is slid over the forks of the clevises to

prevent them from opening accidentally in ight.

Maintaining Your Model

The following is a check list you should follow every time you

have completed a flying session with your model. Doing so will

keep your aircraft in the best flying condition.

Clean Up

After a long flying session with your model, you will want to

clean it up before loading it into your vehicle to head home.

Use cleaner and a paper towel to wipe down the exterior of

your plane, removing the fuel residue. Remember, a clean

plane will last longer since the fuel won’t be allowed to soak

into any exposed wood.

Checking the Propeller

Check to make sure the propeller is tightly secured to the

engine. If not, remove the spinner and use a crescent wrench

to tighten it back down. If you have had any not-so-great

landings, you will want to inspect the propeller for any

damage. Small nicks and scratches can quickly become

fractures, causing the propeller to be unsafe for flight.

Always carry a few spare propellers so a damaged propeller

can be replaced at the field, increasing your flying time per

trip to the field.

Checking the Clevises

Inspect the aileron, elevator and rudder clevises to make

sure they are connected and in good working order. If you

find a clevis is showing signs of wear or broken, replace it

with a new clevis. Also check the nylon connectors at the

servo for any wear or damage. If they look worn or in bad

shape, replace them as well.

Checking the Control Horns

Inspect the control horns to make sure they have not

crushed the wood of the control surface. If so, remove the

control horn screws to remove the control horn. Place 2–3

drops of thin CA into each of the screw holes. In addition,

use a T-pin to poke small holes in the covering in the area

where the control horn mounts, then saturate the area with

thin CA. This will harden the wood and give the control

horns a solid surface to be mounted to.

Checking the Wheel Collars

Check the setscrews on the wheel collars for the main and

tail wheel to make sure they are not loose. Use a 1.5mm hex

wrench to tighten the setscrews. It is suggested if they loosen

frequently to remove them, apply threadlock to the setscrews,

then secure the wheel collars back into position. The threadlock

and hex wrench are included in the kit for this purpose.

48 Hangar 9 Alpha 40 ARF Assembly Manual

Page 49

Check the Muffler Bolts

Use a 2.5mm hex wrench (Evolution 2-stroke) or box wrench

(Saito 4-stroke) to make sure the hardware holding the

muffler onto the engine is tight and has not vibrated loose

during flight.

Check the Engine Mount Bolts

Remove the spinner and propeller from the engine. Remove

the exhaust stacks from the fuselage, then remove the

cowling from the fuselage. Remove the muffler from the

engine, and then use a Phillips screwdriver to make sure the

four bolts securing the engine to the mount are tight.

Flight Preparations

Flight preparations must be checked each time you travel to

the flying field. Because your model will encounter a variety of

situations, it is best to keep an eye on the various components

of your model to keep it in the best flying condition.

Checking the Frequency

When using a 2.4GHz radio system, follow the guidelines for

use of these radio systems at your particular field.

Checking the Controls

Before starting your engine, check to make sure the controls

are operating in the correct directions and the linkages and

surfaces are not binding anywhere. Also look at the clevises

and clevis retainers to make sure they are secure and will not

come loose or fail in flight.

Fueling your Model

Fill the fuel tank with the proper fuel. Fill the tank by

connecting the fuel pump to the line going to the needle

valve or to the fuel dot on the side of the cowling.

Disconnect the fuel line attached to the pressure fitting of the

muffler; your tank is full when fuel begins to run out of the

pressure line. Reconnect the fuel lines to the needle valve

assembly or insert the plug into the fuel dot and connect the

line to the muffler.

Note: It is very important to reconnect the lines to the

correct place. If they are reconnected incorrectly, the

engine will not run properly.

Safety Do’s and Don’ts for Pilots

• Ensure your batteries have been properly charged prior to

your initial flight.

• Keep track of the time the system is turned on so you will

know how long you can safely operate your system.

• Consult local laws and ordinances before choosing a

location to fly your aircraft.

• Perform a ground range check prior to the initial flight

of the day. See the “Daily Flight Checks Section” for

information.

• Check all control surfaces prior to each takeoff.

• Do not fly your model near spectators, parking areas or

any other area that could result in injury to people or

damage of property.

• Do not fly during adverse weather conditions. Poor

visibility can cause disorientation and loss of control of

your aircraft. Strong winds can cause similar problems.

• Do not point the transmitter antenna directly toward the

model. The radiation pattern from the tip of the antenna is

inherently low.

• Do not take chances. If at any time during flight

you observe any erratic or abnormal operation, land

immediately and do not resume flight until the cause of

the problem has been ascertained and corrected. Safety

can never be taken lightly.

Dual Rate Recommendations

• We recommend that the rudder dual rate be set to Low