INSTRUCTION MANUAL

2600W & 3000W

BLOW VAC

Model No: THEV2600 -- Product No: 193823002

Model No: THEV3000 – Product No: 193824002

ASSEMBLY REQUIRED

SAVE THESE INSTRUCTIONS

SPARES & SUPPORT: 01793 333212

Please read & understand this manual, paying particular attention to the safety instructions,

before use.

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

Subject to change without notice.

29-03-2017

CONTENTS

SPECIFICATION

IMPORTANT INFORMATION

GENERAL SAFETY INSTRUCTIONS

KNOW YOUR MACHINE

INTENDED USE

SET UP & PREPARATION FOR OPERATION

GENERAL OPERATION

MAINTENANCE & STORAGE

TROUBLE SHOOTING

NOTES PAGE

PARTS LISTS & DIAGRAM

EC DECLARATION OF CONFORMITY

WARRANTY

If you require any assistance with regards to the contents or operation of your machine, please

contact us:

Tel: 01793 333212 - Monday to Friday 8.00am to 5.30pm

(excl. Bank Holidays)

Email: customerservice@handydistribution.co.uk

SPECIFICATION

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

Model THEV2600

Product No. 193823002

Motor Rated Power 230V-240V, 50Hz

Motor Power 2600 W 3000 W

Protection Class II – Double Insulated

Speed 14000 min 6000-14000 min

Max Air Speed 270 km/h

Air Flow 720 m³/h

Collector Capacity 45L

Electric Cable Length 6 m

Mulching Ratio 10:1

Guaranteed Sound Power Level 102 dB(A)

Vibration 4.0 m/s² = K: 1.5 m/s²

THEV3000

193824002

150-270 km/h

10 m

IMPORTANT INFORMATION

WARNING

Read this instruction manual carefully before operating this machine. Make sure that you are familiar

with the controls and properly operate the machine. Following these instructions can reduce the risk

of fire, electric shock and personal injury.

IF NOT USED PROPERLY THIS MACHINE CAN BE DANGEROUS!

This machine can cause serious injury to the operator and others, the warning and safety instructions

must be followed to ensure reasonable safety and efficiency in using this product. The operator is

responsible for following the warning and safety instructions in this manual and on the machine.

Never use the product unless the grass box or guards are correctly positioned.

DESIGNED FOR DOMESTIC USE ONLY.

The Blow Vac is designed for use in private gardens, whose annual use does not generally exceed 50

hours and that are primarily used for blowing or vacuuming leaves and other garden cuttings, but not

in public facilities, parks or sports grounds and not for agricultural or forestry use.

Compliance with this manual supplied by the manufacturer is a prerequisite for the proper usage of

the machine. The operating manual contains servicing and maintenance instructions as well as

directions for use.

TRAINING

Read the instructions carefully: Be familiar with the controls and the proper use of the equipment.

Never allow children or people unfamiliar with these instructions to use the product. Local

regulations can restrict the age of the operator.

Never operate while people, especially children, or pets are nearby.

Keep in mind that the operator or user is responsible for accidents or hazards involving the machine

that occur to other people or their property.

GENERAL SAFETY INSTRUCTIONS

It is important that you read and understand the owner’s manual and labels affixed to the

machine. Learn its application and limitations as well as the specific potential hazards. Retain

these instructions for future reference. The operator is responsible for following the warnings &

instructions in this manual and on the product.

Read & understand operator’s manual

before using the machine. Failure to

follow instructions could result in

death or serious injury.

Wear gloves to protect your hands

Whenever the machine is in use,

safety glasses must be worn to

safeguard against flying objects.

Hearing protection must also be used

to protect the operators hearing.

Rotating parts can contact or entangle

Traumatic amputation or severe

Check your machine before turning it

working order. Frequently check to

see that foreign objects are removed

from the tool area before turning it

on. Replace damaged, missing or

Before working or undertaking any

servicing or cleaning of the machine,

ensure the electrical cable is removed

Moving Parts

hands, feet, hair, clothing or

accessories.

laceration can result

on. Keep guards in place and in

failed parts before using it.

from the power source.

15m

DANGER

CAUTION

Face masks are also recommended to

avoid inhalation of debris.

Wear appropriate close fitting closing

at all times, to avoid suction into the

machine

Keep all bystanders & animals at least

15 metres away from the machine

during operation.

If approached, stop the machine

immediately.

Indicates an imminently hazardous

situation which, if not avoided, will

result in serious injury.

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

WARNING

CAUTION

Double Insulated – II

Do not expose to rain or damp

conditions

Safety alert symbol. Used to alert you

to potential personal injury hazards.

Obey all safety messages that follow

this symbol to avoid possible injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in serious injury.

Used without the safety alert symbol,

indicates a potentially hazardous

situation which, if not avoided, may

result in property damage.

According to the European directive 2012/19/EU for Waste Electrical and Electronic

Equipment and its implementation into national law, electrical and electronic

equipment that are no longer usable must be collected separately and disposed of

in an environmentally correct manner.

STAY ALERT

Do not operate the machine while under the influence of drugs, alcohol, or any medication that

could affect your ability to use it properly. Do not use this machine when you are tired or distracted

from the job at hand. Be aware of what you are doing at all times. Use common sense.

AVOID DANGEROUS CONDITIONS

Make sure there is adequate surrounding workspace. Cluttered areas invite injuries.

Keep your work area clean with sufficient light. Keep the area around the machine clear of

obstructions, grease, oil, rubbish and other debris which could cause persons to fall onto moving

parts.

INSPECT YOUR MACHINE

Check all bolts, nuts, and screws for tightness before each use, especially those securing guards and

drive mechanisms. Vibration during use, may cause these to loosen.

Form a habit of checking to see that all other tools/equipment are removed from the working area

before turning it on.

Replace damaged, missing or failed parts before using it. Warning labels carry important

information. Replace any missing or damaged warning labels.

DRESS PROPERLY

Do not wear loose clothing, gloves, scarfs, neckties or jewellrey (rings, wrist watches), which can be

caught in moving parts. Protective electrically non-conductive gloves and non-skid heavy duty

footwear are highly recommended when working. Wear a face or dust mask if the operation is dusty.

Always wear safety glasses/goggles and/or face shields. Everyday eyeglasses have only impact

resistant lenses; they are not safety glasses/goggles. Wear protective hair covering to contain long

hair, preventing it from getting caught in machinery.

AVOID ELECTRICAL SHOCK

Check that the electric circuit is adequately protected and that it corresponds with the power,

voltage and frequency of the motor. Check that there is a ground connection, and a regulation

differential switch further up the circuit. Ground the machine. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. Never open the pushbutton box on

the motor. Should this be necessary, contact a qualified electrician. Make sure your fingers do not

touch the plug’s metal prongs when plugging or unplugging the machine.

KEEP BYSTANDERS AND CHILDREN AWAY

Keep unauthorised persons a minimum distance of 15 metres away from the machine. If

approached, stop the machine immediately. Do not allow children to handle, climb on or in the

machine.

DO NOT OVERREACH

Keep proper footing and balance at all times when using the machine. Never stand on the

machine. Serious injury could occur if the machine is tipped or if the moving parts are

unintentionally contacted. Do not store anything above or near the machine, where anyone might

stand on the machine to reach them.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Keep hands & feet out of the way of all moving parts. Do not place any part of your body or any

tool e.g. in the machine during operation.

DO NOT FORCE TOOL

Always work within the rated capacity. Do not use the machine for a purpose for which it was not

intended.

NEVER LEAVE MACHINE RUNNING UNATTENDED

Do not leave the machine unattended until it has come to a complete stop.

MAINTAIN YOUR MACHINE WITH CARE

Clean the machine immediately after use. Keep the machine clean to ensure it operates to its full &

safest performance. When maintaining this machine, only the manufacturer’s original replacement

parts should be used. The use of non-original manufacturer parts may invalidate your warranty.

PROTECT THE ENVIRONMENT

Take left over materials to an authorised collection point or follow the stipulations in the country

where the machine is used. Do not discharge into drains, soil or water.

STORE IDLE EQUIPMENT

When not in use, the machine should be stored in a dry location. Keep the machine away from

children and others not qualified to use it.

PREPARATION

▪

Always wear appropriate footwear, such as work boots, and trousers when operating the

machine. Do not operate the equipment when barefoot or wearing open sandals. Always wear

safety goggles or safety glasses with side shields when operating the product.

▪

Thoroughly inspect the area where the equipment is to be used and remove all objects which can

be thrown by the machine.

▪

Before using, always visually inspect to see that the is not worn or damaged. Replace worn or

damaged parts before future use.

▪

Do not operate the machine while under the influence of alcohol or drugs.

▪

Never operate the machine whilst standing on wet surfaces. This could cause you to slip while

using.

ELECTRICAL SAFETY

▪

Power plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce

risk of electric shock.

▪

Avoid unintentional starting. Always check that the switch is in Off position before plugging in the

product to the power supply. Do not carry a plugged in product with your finger on the switch.

▪

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

▪

Do not expose the product to rain or wet conditions.

▪

Water entering an appliance will increase the risk of electric shock.

▪

Electrical power should be supplied via a residual current device (RCD) with a tripping current of

not more than 30 mA.

▪

Before use, check the supply and extension cord for signs of damage or aging. If the cord becomes

damaged during use, disconnect the cord from the supply immediately. Do not touch the cord

before disconnecting the supply. Do not use the product if the cord is damaged or worn.

▪

If you need to use an extension cable, ensure it is suitable for outdoor use and has a current

capacity rating, sufficient to supply your product. Check it before every use for damage, always

uncoil it completely, during use because coiled cables can overheat. Damaged extension cables

should not be repaired; they should be replaced with an equivalent type.

▪

Make sure the power cable is positioned so that it cannot be damaged, will not be stepped on,

tripped over or otherwise subjected to damage or stress.

▪

Never pick up or carry the product by the electric cable.

▪

Never pull by the power cord to disconnect from the power supply.

▪

Keep the power cord away from heat, oil and sharp edges.

▪

Make sure voltage is correct for your product. A nameplate on the product indicates the product’s

voltage. Never connect the product to an AC voltage that differs from this voltage.

▪

Always ensure the cord from the handlebar to the mower body is never trapped, pinched or

otherwise damaged during assembly or handle folding. Never apply power to the mower if this

cable is damaged. Return to authorised service centre for professional repair.

OPERATION

▪ Only operate the machine in daylight or in good artificial light.

▪ Avoid operating the equipment in wet conditions.

▪ Always be sure of your footing on slopes. Exercise extreme caution when changing direction on

slopes.

▪ Never run while using the machine, always walk.

▪ Use extreme caution when reversing or pulling the product towards you.

▪ Never operate the product with defective guards, or without safety devices, for example

deflectors and/or collection bag, in place.

▪ Do not put hands or feet near or under rotating parts. Keep clear of the discharge opening at all

times.

Stop the motor and disconnect the electrical plug from the power source:

✓ before clearing blockages or unclogging the chute;

✓ before checking, cleaning or working on the machine;

✓ after striking/collecting a foreign object, inspect the product for damage and make repairs

before restarting and operating,

✓ if machine starts to vibrate abnormally (check immediately).

▪ Shut the motor off and wait until the motor and the fan come to a complete stop before

removing the collection bag or suction tubes.

▪ Watch for holes, ruts, or bumps. Tall grass can hide obstacles.

▪ Do not use near drop-offs, ditches or embankments. The operator could lose footing or balance.

▪ Be alert and turn the machine off if children enter the area.

▪ Never tamper with safety devices. Check their proper operation regularly.

MAINTENANCE AND STORAGE

▪

Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

▪

Replace worn or damaged parts for safety.

▪

Keep the machine free of grass, leaves, or other debris build-up, when being stored for any length

of time.

▪

Allow the machine to cool before storing.

▪

Grass catcher components are subject to wear, damage, & deterioration, which could expose

moving parts or allow objects to be thrown. Frequently check & replace them with the

manufacturer’s recommended parts, when necessary.

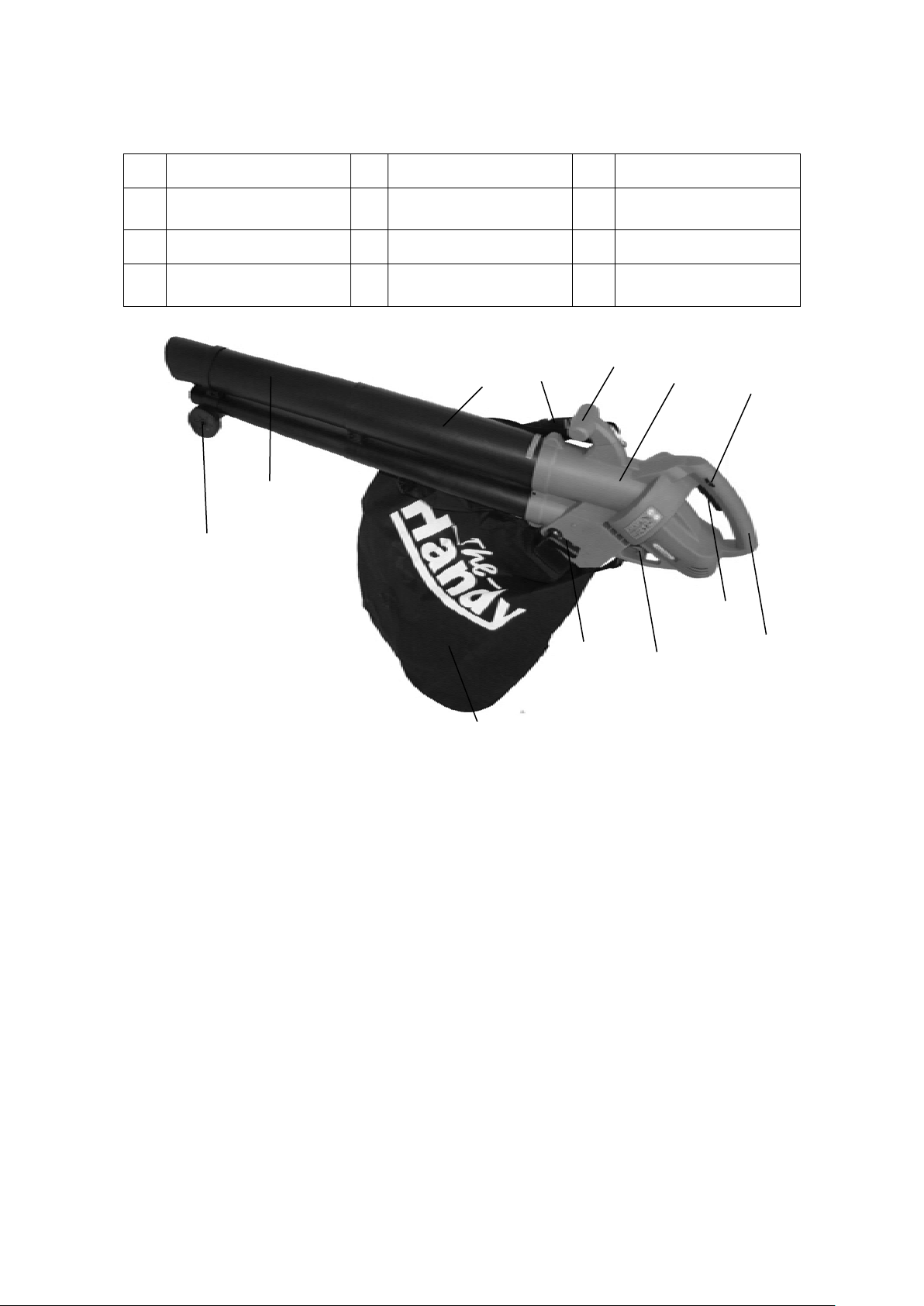

KNOW YOUR MACHINE

1

Rear Handle

2

Trigger

3

Main Body

4

Front Handle

5

Cable Restraint

6

Blow/Vac Switch

Adjuster

7

Top Tube

8

Bottom Tube

9

Collection Bag

10

Shoulder Strap

11

Wheel Kit

(THEV3000 only)

12

Variable Speed Adjuster

(THEV3000 only)

4 2 3

1 5 6 7 8 9

10

11

12

INTENDED USE

WORKING PLAN

• The Blow Vac is only suitable for domestic use and can be used only for processing light, dry

garden waste materials such as leaves, grass cuttings, clippings, small twigs and pieces of paper.

• NEVER use to vac, blow or shred heavy sharp or flammable materials such as metal, stones,

branches, fir cones, glass, barbecue coals, cigarette ends, dust, gravel, soil or liquids

• Blow material to a safe collection point, away from stones and other hard debris, which could

damage the mulching fan and collection bag of the machine.

• It is not advised to vacuum wet material as this may clog the exits, tubes and mulching fan.

• Limit the amount of time the product is used continuously to a maximum of 30 minutes per

session.

• Leave the machine to rest between sessions for between 5-10 minutes.

• Total amount of work performed per day with the machine, should be limited to 120 minutes

maximum.

• Continuous use of the machine can cause “Repetitive Stress Injury (RSI)”. If you feel discomfort,

redness or swelling of your hands and fingers or any other body part, consult your doctor.

• Check local regulations for sound level and hours of operation constraints.

SET UP & PREPARATION

FOR OPERATION

Follow the operating instructions step-bystep and use the pictures provided as a visual

guide to easily assemble the machine.

Please ensure that you have all the below

necessary parts, before commencing with

the assembly. To assemble, you will require a

cross head (Philips) screwdriver.

With your Handy Blow Vac, you will receive:

1x Instruction Manual

1x Handy Blow Vac

1x Collection Bag

1x Wheel Assembly (THEV3000 only)

1x Front Handle

1x Shoulder Strap & Clasp

2x Tubes

2x Large Screw

1x Small Screw (THEV3000 only)

In the unlikely event that you are missing a

component, please do contact us on 01793

333212, option 2 or email

customerservice@handydistribution.co.uk

for assistance.

Insert both tubes into the main body and

screw together with the large screw.

FRONT HANDLE

Insert the front handle into the recess in the

top of the main body, with the handle

pointing towards the end of the tubes.

ASSEMBLY

TUBES

Connect the top suction tube to the bottom

suction tube ensuring the securing tabs are

housed correctly. Screw them together with a

large screw.

To assist with the handle fitting flush with the

main housing, it may be necessary to loosen

the two casing screws, by 2 complete turns

and apply downward pressure to insert.

Tighten the two screws when housed.

COLLECTION BAG

Hook the front securing clasp of the collection

bag onto the bottom suction tube.

Hook the rear securing clasp of the collection

bag onto the main body.

It will snap into place, with inward pressure

being applied to the two ribbed tabs on the

front and back of the neck.

Ensure the zip fastener is closed on the

collection bag!

Slip the square opening of the collection bag

onto the square opening of the main body.

SHOULDER STRAP

The shoulder strap is attached to the machine

using the metal triangular clip. Unscrew and

fix this to the small moulded ring on the top

handle and tighten.

WHEEL ASSEMBLY (THEV3000 only)

Slide the wheel kit assembly over the large

and smaller tube until the ridge is reached.

Secure with the small screw, ensuring it

secures the two collars together and the

wheel assembly does not slip off the tubes.

CABLE RESTRAINT

Thread the cable through the restraint,

forming a loop as shown.

Ensure that there is sufficient slack in the

cable.

POWER CONNECTION

WARNING!

Before operating the Blow Vac, ensure the

tubes are fixed in position and the collection

bag is secure before connecting to the mains

electricity supply.

To reduce the risk of injuries, always switch

off the motor and pull out the mains plug

before working on the machine.

The product can be connected to any socket

(with 230-240V alternating current). We

recommend to always use the appliance via a

Residual Current Device (RCD) with a tripping

current of max. 30mA.

1. Mains leads on electrical garden

equipment are particularly susceptible to

insulation damage. The causes of this

include the following:

❖ Damage through crushing, if the mains

lead becomes stuck under doors or

windows.

❖ Cracks caused by ageing of the insulation

sheath.

❖ Kinks caused by incorrect fastening of the

mains lead.

2. Damaged mains lead should not be used

under any circumstances as they may

cause fatal injuries due to a damaged

insulation sheath.

3. Always check the plug and cable and

make sure they are in good condition

before operation.

GENERAL OPERATION

WARNING!

In some countries regulations define at what

time of the day and on what day’s machines

can be used and what restrictions apply!

WARNING!

If the product vacuums a foreign object stop

the motor! Switch the product off,

disconnect it from the power supply and let

it cool down. Inspect the product thoroughly

for damage! Have any damage repaired

before restarting!

WARNING!

If the machine vibrates unusually during

operation it may indicate that it is damaged!

The product should be inspected and

repaired immediately!

▪ Check the product, its power cord and

plug as well as accessories for damage

before each use. Do not use the product if

it is damaged or shows wear.

▪ Double check that accessories are

properly connected.

▪ Ensure that the air vents are always

unobstructed and clear. Clean them if

necessary with a soft brush. Blocked air

vents may lead to overheating and

damage the product.

▪ Switch the product off immediately if you

are disturbed while working by other

people entering the working area. Always

let the product come to complete stop

before releasing the handle.

▪ Do not overwork yourself. Take regular

breaks to ensure you can concentrate on

the work and have full control over the

product.

▪ Make sure that the area to be vacuumed

is clear of stones, sticks, wire or other

objects that could damage the mulching

fan, causing the machine to be

unbalanced, or the collection bag.

▪ It is recommended that the items to be

vacuumed are blown to a safe area for

vacuuming.

▪ Do not work with this product on a wet

debris because it may stick to the the

product, preventing the proper collection

and discharge of collected material, and

could also cause you to slip and fall.

▪ Do not try to vacuum material which is

too big for the suction tubes to accept.

▪ Adjust the variable power Move the

product at an appropriate speed. Do not

move it too fast or the discharge opening

may get blocked and the engine may

overload.

▪ Pay special attention when changing

direction.

▪ Adjust the length of the shoulder strap to

suit and hold the machine with both

hands (one on the top handle, one on the

rear handle).

STARTING

The On/Off trigger is located on the underside

of the rear handle and is operated by

squeezing the trigger upwards.

STOPPING

The product will automatically stop once the

trigger is released.

USING AS A BLOWER:

Move the switch to the blower setting and

move the Blow Vac gently from side to side a

few centimetres above ground level.

WARNING!

Never point the Blow Vac at people or

animals and take extra care when using near

sand, soil, loose gravel or shingle.

USING AS A VACUUM

Move the switch to the vac/shredder setting.

Switch on and move the machine over the

debris slowly.

Suction power decreases when the bag is full

so ensure that it is emptied regularly.

Before emptying, disconnect the Blow Vac

from the mains.

When you have finished vacuuming, return

the switch to the blow mode to remove any

material still lodged in the suction tubes.

VARIABLE POWER SWITCH

(THEV3000 only)

The variable power switch is located on the

left hand side of the machines rear handle.

This controls the speed for both vacuum and

blow options.

This facility is useful around graveled and

barked areas.

MAINTENANCE &

STORAGE

WARNING!

Before carrying out any repairs or servicing

work, you must ensure that the product

has been disconnected from the power

supply. Repairs and maintenance work other

than those described within this instruction

manual may be performed only by an

authorised service agent.

SERVICE & STORAGE

▪ Regularly check for obvious defects, such

as loose, dislodged or damaged fixings

and worn or damaged components.

▪ Check that covers and guards are

undamaged and correctly fitted. Carry out

necessary maintenance or repairs before

using the product.

▪ If the device should happen to fail despite

the care taken in manufacturing and

testing, the product should be returned to

your retailer.

▪ Do not clean the product while it is

running.

▪ Ensure that all the fastening elements

(screws, nuts, etc.) are tight at all times,

so that you can safely work with the

product.

▪ Check the product frequently for signs of

wear. Replace worn or damaged parts.

▪ Store your product in a dry place.

▪ Clean the product with a brush or cloth.

Do not use any solvents or water to

remove dirt.

▪ Shake out the collection bag thoroughly,

turn inside out and brush the bag out.

▪ You may wash a soiled bag by hand, using

a mild detergent, but ensure it is

thoroughly dry before re-using.

▪ If the zip becomes stiff to use, rub with

dry soap.

▪ The component that is subject to most

wear is the mulching fan and collection

bag. You should therefore check the

condition of them both at regular

intervals. If worn or damaged, they must

be replaced immediately.

HANGER

The hanger has been supplied to allow the user to store their Handy Blow Vac, conveniently and off

the ground.

Find a suitable position in your dry storage area (shed, garage, store room) and position high

enough, that the Blow vac is away from the floor, heat or direct sunlight. Ideally, a level (spirit or

laser) should be used to ensure the hanger is positioned level. Secure with the four fixing screws

supplied, (if suitable for the material attached to).

mains electric supply, remove both

and ensure material is not blocking

The fan needs to be replaced by an

tear or machines that are damaged

mains electric supply, remove both

and ensure material is not blocking

TROUBLE SHOOTING

WARNING!

Only perform the steps described in these instructions!

All further inspection, maintenance and repair work must be performed by an authorised service

specialist!

Contact your local authorised service dealer if the problem cannot be solved by yourself!

WARNING!

If the product does not perform properly, makes unusual sounds, the motor does not start or stop

as described, the cutting device does not work properly, or any other irregularity or malfunction

occurs, do not attempt to repair the product by yourself. Please contact customer services or your

local authorised service dealer.

Before attempting any of the below actions, ensure the machine is removed from the electrical

supply.

PROBLEM POSSIBLE CAUSE FAULT CORRECTION

Not connected to power supply Connect to power supply

Power cord or plug is defective Check by a specialist electrician.

Will not start.

Material not being

vacuumed correctly

Machine is vibrating

violently

Suction tubes blocked or clogged

The fan has become unbalanced

Fuse in plug failed

Motor or switch defect

(DO NOT VACUUM WET

MATERIAL)

Air vents are blocked Clean the air vents

due to the impact of a foreign

object e.g. a stone or gravel.

Replace with new 13A fuse

Return machine to retailer.

Switch to blow mode and clear

blockage.

If does not resolve, remove from

suction tubes and collection bag

the machines openings.

approved service dealer. Please

note that this will not be covered

under the warranty, as the

warranty does not cover wear and

Blow/Vac Switch does not

work

Switch flap is blocked by

material/debris

by the user.

Switch to blow mode and clear

blockage.

If does not resolve, remove from

suction tubes and collection bag

the machines openings.

38

PARTS DIAGRAM – THEV2600 (193823002)

ITEM

PART NO

DESCRIPTION

QTY 6 TH100-30

Suction Tube Lower

1 7 TH100-27

Suction Tube Upper

1 8 TH100-29

ST4.2*50 B Screw

2

9

TH100-2

Front Handle Assembly (Black)

1

10

1

11 1 12

TH100-3

ST4.2*15 B Screw

23

13

TH100-6

Shoulder Clasp

1

14

Shoulder Strap

1

15

TH100-301010063

Right Housing (GM) (ABS)

1

16

TH100-8

Switch Spring

1

17

TH100-9

Switch

1

18

TH100-104030045

ST3*18 A Screw

2

19

TH100-10

Micro Switch

1

20

TH100-11

Capacitor

1

21

TH100-4070204

Motor Assembly (Two Flat Sides)

1

22

TH100-12

Rubber Gasket

2

23

TH100-103010118

Fan Pad

1

24

TH100-301019237

Motor Bracket

1

25

TH100-104030335

M4*12 Bolt

2

26

TH100-301019200

Fan (Two Flat Sides)

1

27

TH100-16

M8 Lock Nut

1

28

TH100-17

Insulated Cap

1

29

TH100-18

Cable Clamp

1

30

TH100-19

Cable Sleeve

1

31

TH100-20

Terminal Block

1

32

TH100-21

Cable with BS Plug

1

33

TH100-301010064

Left Housing (GM) (ABS)

1

34

TH100-23

Blow/Vac Switch

1

35

TH100-24

Air Block Board

1

36

TH100-26

Inner Collar Bush

1

37

TH100-28

Collection Bag Assembly

1

38

TH100-HANGER

Hanger

1

39

TH100-HANGERSCREWS

Hanger Screws

4

PARTS LIST – THEV2600 (193823002)

38

PARTS DIAGRAM – THEV3000 (193824002)

ITEM

Handy Part No.

Handy Description

Qty

1

TH100-32

Wheel Bracket Kit

2 2 2 3 2 4 2 5 1 6 TH100-30

Suction Tube Lower

1 7 TH100-27

Suction Tube Upper

1 8 TH100-29

ST4.2*50 B Screw

2

9

TH100-2

Front Handle Assembly (Black)

1

10 1 11 1 12

TH100-3

ST4.2*15 B Screw

23

13

TH100-6

Shoulder Clasp

1

14

Shoulder Strap

1

15

TH100-301010063

Right Housing (GM) (ABS)

1

16

TH100-8

Switch Spring

1

17

TH100-9

Switch

1

18

TH100-104030045

ST3*18 A Screw

2

19

TH100-10

Micro Switch

1

20

TH100-4100134

Capacitor (Variable Speed)

1 set

21

TH100-4070204

Motor Assembly (Two Flat Sides)

1

22

TH100-12

Rubber Gasket

2

23

TH100-103010118

Fan Pad

1

24

TH100-301019237

Motor Bracket

1

25

TH100-104030335

M4*12 Bolt

2

26

TH100-301019200

Fan (Two Flat Sides)

1

27

TH100-16

M8 Lock Nut

1

28

TH100-17

Insulated Cap

1

29

TH100-18

Cable Clamp

1

30

TH100-19

Cable Sleeve

1

31

TH100-20

Terminal Block

1

32

TH100-21

Cable with BS Plug

1

33

TH100-301010062

Left Housing (Variable) (GM) (ABS)

1

34

TH100-23

Blow/Vac Switch

1

35

TH100-24

Air Block Board

1

36

TH100-26

Inner Collar Bush

1

37

TH100-28

Collection Bag Assembly

1

38

TH100-HANGER

Hanger

1

39

TH100-HANGERSCREWS

Hanger Screws

4

PARTS LIST – THEV3000 (193824002)

EC DECLARATION OF CONFORMITY

We Handy Distribution Ltd - SN3 5HY (Importer) declare that the product:

Designation: 2600 Watt Electric Garden Blow Vacuum

Model(s): THEV2600

Product Number: 193823002

Type/Serial No: As per rating label on machine

Complies with the following directives:

2006/42/EC – Machinery Directive

The conformity assessment procedure followed was in accordance with

EN 60335-1:2012+A11:2014, EN 50636-2-100:2014, EN 62233:2008

Notified Bodies:

Interlek Testing Services Shanghai

Address(es):

Building No. 86, 1198 Qinzhou Road (North), Caohejing Development Zone,

Shanghai 200233, P.R China

Guaranteed Sound Power Level:

(LWA) 102 dB(A)

Vibration Measurement

4.0 m/s² = K: 1.5 m/s²

Authorised signatory & technical file holder

Date:

07/12/2016

Signature:

Name:

Mr Simon Belcher

Position:

Managing Director

Company:

Handy Distribution Ltd

Address:

Murdock Rd, Dorcan, Swindon, Wiltshire, SN3 5HY.

EC DECLARATION OF CONFORMITY

We Handy Distribution Ltd - SN3 5HY (Importer) declare that the product:

Designation: 3000 Watt Electric Garden Blow Vacuum

Model(s): THEV3000

Product Number: 193824002

Type/Serial No: As per rating label on machine

Complies with the following directives:

2006/42/EC – Machinery Directive

The conformity assessment procedure followed was in accordance with

EN 60335-1:2012+A11:2014, EN 50636-2-100:2014, EN 62233:2008

Notified Bodies:

Interlek Testing Services Shanghai

Address(es):

Building No. 86, 1198 Qinzhou Road (North), Caohejing Development Zone,

Shanghai 200233, P.R China

Guaranteed Sound Power Level:

(LWA) 102 dB(A)

Vibration Measurement

4.0 m/s² = K: 1.5 m/s²

Authorised signatory & technical file holder

Date:

07/12/2016

Signature:

Name:

Mr Simon Belcher

Position:

Managing Director

Company:

Handy Distribution Ltd

Address:

Murdock Rd, Dorcan, Swindon, Wiltshire, SN3 5HY.

GJ HANDY & CO LTD USER WARRANTY POLICY

Users Statement of Warranty

Each new machine is warranted against defective material or assembly of material under normal

usage. The warranty applies to the original purchaser and covers faulty parts and the labour involved

in replacing and repairing those parts, which are of original manufacture.

Period of Warranty

All Webb & Webb Pro machines plus Sanli engines.

a) 2 years from the original date of sale to the first domestic user.

b) 90 days from the original date of sale to the professional/commercial user.

c) 90 days from the original date of sale when used for hire.

d) A reduced warranty period of 90 days applies to those items which are subject to normal wear

and tear (e.g. but not limited to wheels, tyres, cutter bars, cylinders, blades, belts, cables, grass

bags, spark plugs).

e) Engines as per the manufacturer’s warranty statement which will be supplied with the machine.

f) 90 days from the original date of purchase for Replacement Spare Parts (unless normal wear &

tear component, which are covered for 30 days).

g) All machines’ must be serviced within the first 12 months from the original date of purchase to

comply with the warranty, failure to do so will invalidate the 2nd year of the warranty.

All Handy, Mowerland and Q-Garden products.

a) 1 year from the original date of sale to the first domestic user.

b) 90 days from the original date of sale to the professional/commercial user.

c) 90 days from the original date of sale when used for hire.

d) A reduced warranty period of 90 days applies to those items which are subject to normal wear

and tear (e.g. but not limited to wheels, tyres, cutter bars, cylinders, bottom blades, belts,

cables, collection bags, spark plugs).

e) Engines as per the manufacturer’s warranty statement which will be supplied with the machine.

f) 90 days from the original date of purchase for Replacement Spare Parts (unless normal wear &

tear component, which are covered for 30 days).

All warranty repairs must be undertaken by an authorised service dealer. These dealers have been

accredited by GJ Handy & Co Ltd and agree to only use genuine parts and follow our repair

procedures.

GJ HANDY & CO LTD USER WARRANTY POLICY

Not covered by this warranty

a) The warranty policy does not cover any depreciation or damages caused by ordinary wear,

rusting or corrosion, lack of correct maintenance or operation, misuse, abuse, lack of

transportation or accident.

b) The warranty policy does not cover any costs necessary for the standard periodic maintenance

services instructed by the operator’s manual, or service parts replacement which would include

oil, filters, tyres, belts, brake linings, fuses, blades, seals and other service parts unless it can be

proven that the item has evidence of faulty manufacture.

c) The warranty policy will not cover failure or damage caused as a result of parts or accessories

being modified without the written approval of GJ Handy & Co Ltd.

d) The warranty policy will not cover the unit if non-genuine parts have been fitted and as a result

damage has occurred to the unit.

e) The warranty policy is non-transferable and is only applicable to the original purchaser.

Disclaimer

a) This warranty is only a remedy for defect of products. GJ Handy & Co Ltd will never warranty in

terms of the merchantability or the fitness for a particular purpose.

b) No person is authorised to make any warranties, representations or promises, expressed or

implied, on behalf of GJ Handy & Co Ltd, or to modify the terms conditions or limitation of this

warranty policy in any way.

c) Neither GJ Handy & Co Ltd nor any company affiliated with GJ Handy & Co Ltd shall be liable in

any event or manner whatsoever for incidental or consequential damages or injuries, including,

but not limited to, loss of crops, loss of profit, out of pocket expenses or profits, rental of

substitute equipment or other commercial losses.

General

a) Most warrantable failures show up within the first few weeks of use. These failures are usually

straightforward and warranty assessment is relatively easy.

b) Failures relating to cutter decks and belts need careful investigation, as the cause may not

always be straightforward. Look for damage to blades and pulleys especially when the cutter

belt or blade boss have snapped or cracked as this could be due to impact damage.

c) Customers should always refer to the operator/instruction manual when any disputed problem

arises, you will find most areas covered within the manual.

Version 04 (10-16)

NOTES

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

NOTES

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

equipment

For spares or support of your Handy product,

please contact us:

Tel: 01793 333212

Email: customerservice@handydistribution.co.uk

Monday – Friday 8.00am to 5.30pm

(excl. Bank Holidays)

To see our range of garden machinery & equipment visit:

www.thehandy.co.uk

Making gardening easier & affordable since 1938

Distributed by Handy Distribution, Murdock Road, Dorcan, Swindon, SN3 5HY

Loading...

Loading...