Operating manual

Vacuum valve (weight loaded)

12504/ 12818, 12819

1

General ............................................................................................................................................................. 1

2 Safety Information ............................................................................................................................................ 2

3 Delivery, Completeness, Storage ...................................................................................................................... 3

4 Installation, Operation, Maintenance ............................................................................................................... 3

5 Additional Equipment ..................................................................................................................................... 11

1 General

1.1 Manufacturer

Albert Handtmann Armaturenfabrik GmbH & Co. KG

Arthur-Handtmann-Str. 11; D-88400 Biberach

Tel.: +49(0) 73 51/3 42-0; Fax: +49(0) 73 51/ 3 42-44 80

E-Mail: sales.fittings@handtmann.de

1.2 Proper application

Vacuum valves are used in the food, beverage, pharmaceutical and chemical industries.

They are suitable for the protection of tanks and other closed systems against negative

pressure.

During installation, operation and maintenance please pay attention to the generally

accepted safety regulations as well as to the operating instructions.

1.3 Misuse

Misuse is:

• Application in different operating conditions as intended for the specific type.

• Installation, operation and maintenance by unqualified staff.

• Any unauthorized modification of the valve or a valve component.

• On-observance of the operating instructions.

Any misuse will automatically lead to a loss of right to claim under guarantee as well as

any liability.

1.4 Duties of operator

The operator has to make sure that:

• The valve/component is operated properly and only in functional condition.

• The legal requirements are kept during operation and maintenance.

• Only sufficiently qualified and authorized staff maintain the valve/component.

• The staff responsible for operation and maintenance know and obey the

operating instructions and in particular the safety advice.

• The safety and warning signs remain on the valve/component and are

always legible.

1 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

strictly have to be obeyed.

Vacuum valve (weight loaded)

12504/ 12818, 12819

2 Safety Information

Notice and Safety

The following safety advice is an addition to existing national regulations and laws for

accident prevention. Existing regulations and laws for accident prevention always have to

be adhered to. Pay attention to the specific regulations and laws in your country.

The safety advice does not take into account:

• Coincidences and events that may occur during assembly, operation and

maintenance.

• Local safety regulations in responsibility of the operator.

Basic safety advice

Requirements for a proper function of the valve/component:

• Proper transportation and storage

• Installation and setting into operation by authorized staff

• Operation according to these operating instructions – proper application

• Proper and regular maintenance

WARNING

Warning – general dangers!

To avoid danger for health and life the following safety instructions

• Assembly and setting into operation only by qualified staff.

• Instruction and supervision by the operator.

• Keeping of technical and electrical data as specified in the operating instructions.

• Guarantee the electric safety of external devices.

• Keep legal regulations.

Non-observance may lead to the following dangers:

• Malfunction of the valve/component respectively of the plant.

• Danger for persons due to electrical, mechanical and chemical affects.

• Danger for the environment due to possible leakage of dangerous media.

2019-02-08 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2 / 13

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

3 Delivery, Completeness, Storage

• Check the data of the delivery note for factual correctness and the material for

completeness. We regret that money cannot be refunded after purchase.

• Always check the material for transport damages. Possible damages have

to be informed immediately.

• Store the material in a dry place and if possible in its original packaging.

4 Installation, Operation, Maintenance

Wichtiger Hinweis !

• Valve/component suitable for vertical installation.

• Valves with standard weight open at a negative pressure of 3-5 mbar.

Pressure compensation to ambient pressure by air draw in.

The valve will be closed by the counter pressure of the weight.

• Valves with pneumatic lifting open only at a limited counter pressure, i.e. tank

inside pressure. This pressure may not exceed 0.2 bar.

This may cause a malfunction of the valve.

• During the CIP process the pneumatic lifting should be activated only, if the tank

is depressurized. Other-wise, there will be explosion-like pressure

compensation, due to the escaping medium. This mixture of gas and CIP

liquid is splashed into the environment.

• The lifting itself can be performed according to the process requirements. The

duration of lifting should be about 5-20 seconds and can take place during different

cleaning steps. To prevent too strong splashing, the opening gap on the valve can

be adjusted via the stroke on the pneumatic cylinder or lifting takes place during

the startup phase of the pump with reduced power.

Further information can be found in the INFO sheet - IB_CIP lifting VV-SV.02

• During assembly/disassembly please pay attention to the operating instructions

respectively to the type plate or type marking.

DANGER

Danger – General risk!

Lifting the valve during CIP and low tank inside pressure (p < 0.2 bar) causes splashing of

penetrating CIP liquid.

An increasing tank inside pressure can be caused by thermal expansion of the CIP

medium during circulation or by pre-stressing of the tank with CO2/gas.

– Stop spraying of the tank before lifting the valve or de-pressurize the tank.

– Use fully closed splash guard.

3 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

4.1 Assembly instructions

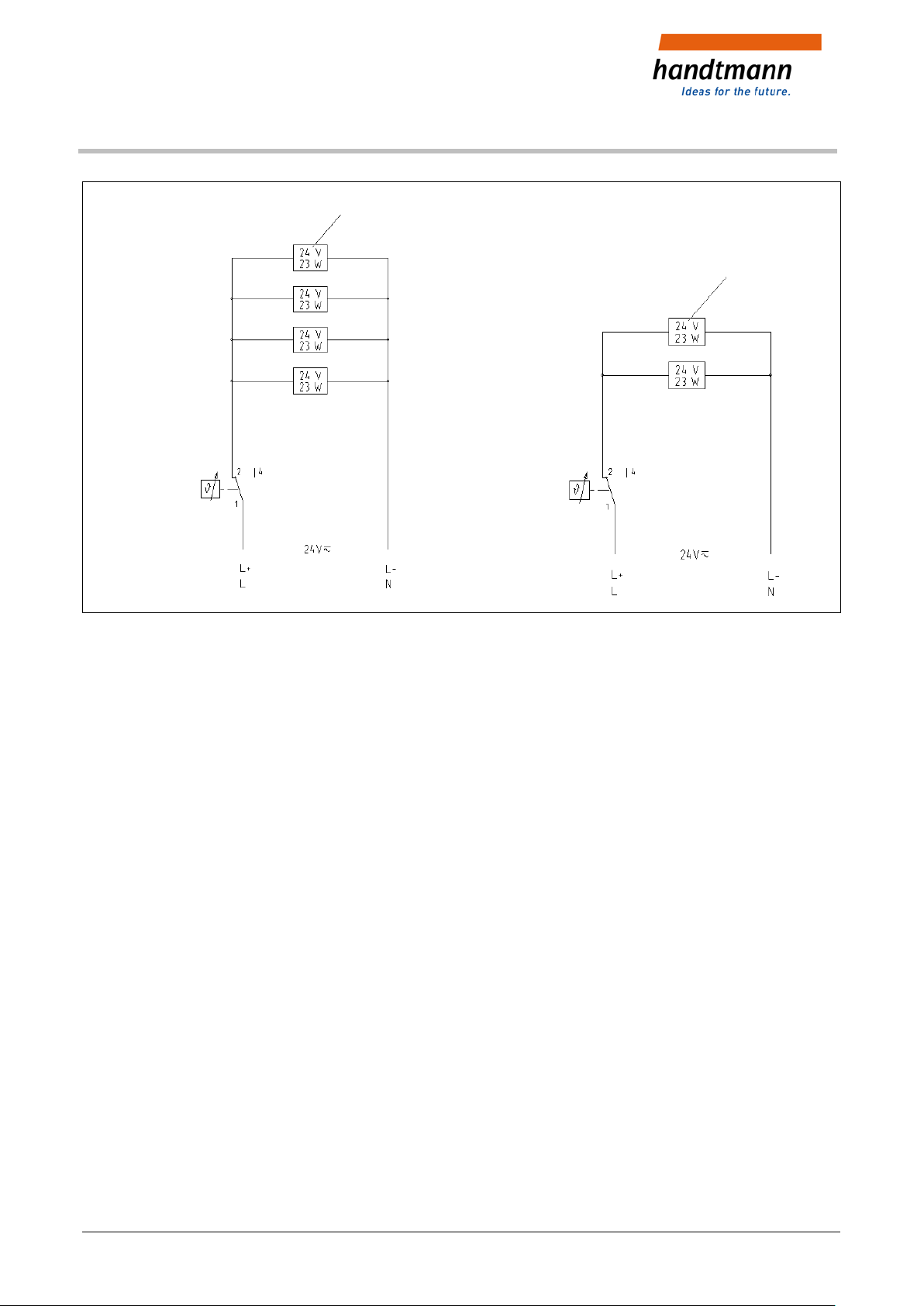

Execution with heating device:

• The heating insets may only be connected according to attached scheme.

Pay attention to the connecting voltage!

• Do not remove the heating inset from the flange during function test

(heating capacity). It may get damaged by overheating.

Execution with external cleaning:

• The external surface of the valve cone is able to be cleaned by an optional

mounted spray pipe.

In this case it is necessary to lift the valve cone. Otherwise the CIP liquid is

damming up within the cylindrically splash guard and runs off through the

drainage drilling to the tank surface (cleaning time 10s, CIP pressure 2 bar).

Execution with lifting device:

• Pneumatic lifting cylinder for function test and for lifting the valve cone

during CIP. The stroke of the lifting cylinder is factory preset.

So the stroke of the valve cone is limited to about 3 mm.

With too large stroke, the emerging splash amount increases.

• Suitable for treated compressed air, max. 6 bar.

• Throttle of air inlet has to be adjusted upon setting into operation.

• Compressed air supply: air hose Ø 6/4.

2019-02-08 Albert Handtmann Armaturenfabrik GmbH & Co. KG 4 / 13

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

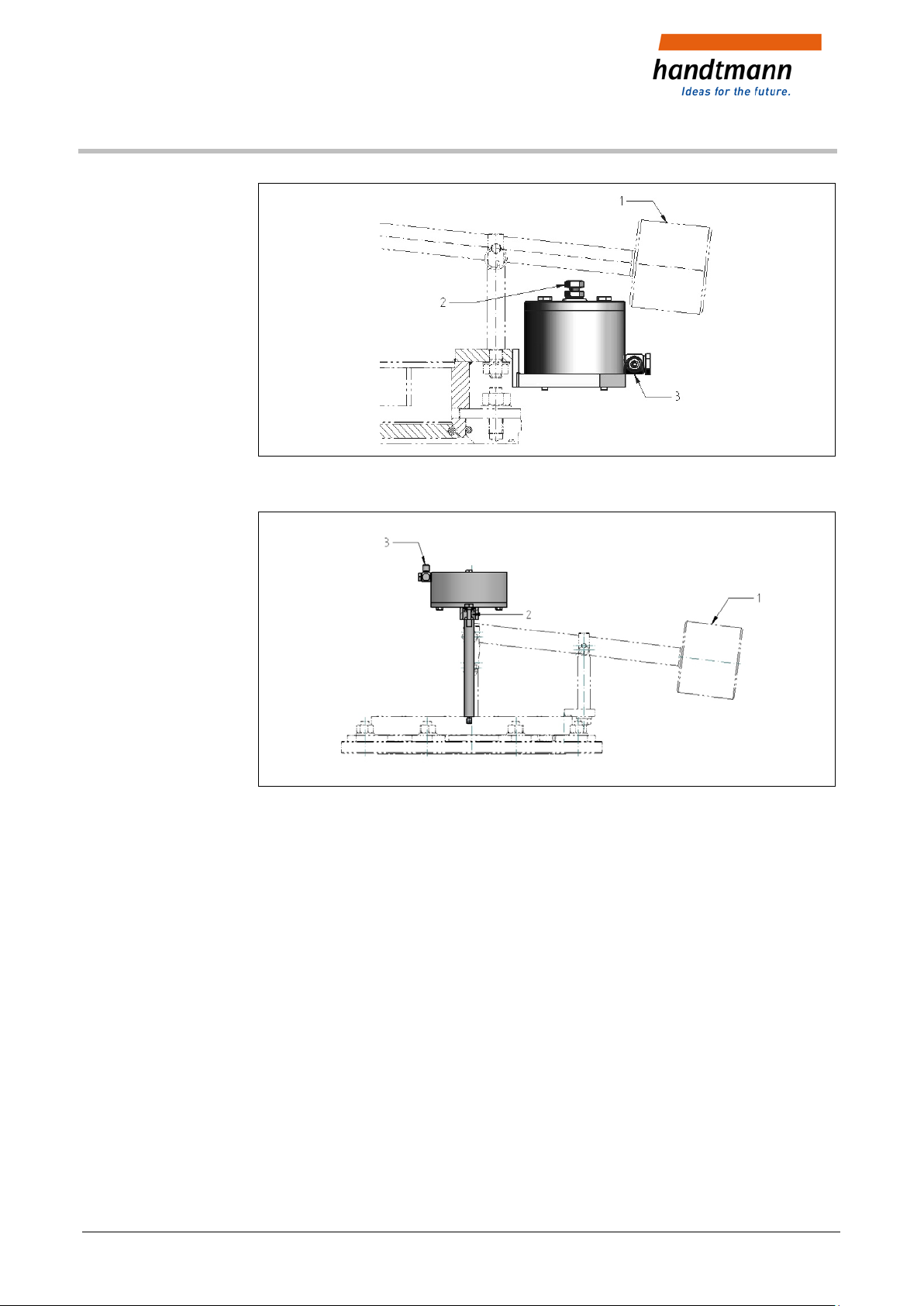

Fig. 1: Schematic representation with lifting device DN 150 – DN 200

Fig. 2: Schematic representation with lifting device für DN 300 – DN 400

1 Counter weight

2 Lifting adjustment

3 Compressed air supply

5 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

Execution with splash guard - Type 12818

Fig. 3: Schematic representation DN 80 – 400

1 Vacuum valve

2 Splash guard

Execution with splash guard and jet pipe – Type 12819

Fig. 4: Schematic representation DN 80 – 400

1 Vacuum valve

2 Splash guard

2019-02-08 Albert Handtmann Armaturenfabrik GmbH & Co. KG 6 / 13

3 Jet pipe

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

4.2 Operation

Type 12504

Construction with stainless steel valve disk DN 80 – DN 400

• Keep the valve clean.

• Lift the valve cone from time to time.

• Exchange the O-ring (1) carefully.

• Avoid any damages at the valve seat.

• Protect vacuum valves from any force influence from outside.

Any damage may affect the function.

• Admissible temperature: 125°C

Fig. 5: with stainless steel valve cone

1 O-ring

2 O-ring (flange)

3 Guiding band

4 Heating inset

7 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

4.3 Maintenance

• Maintain the valve carefully, avoid any damages.

• Dismount the valve.

• Exchange the O-rings (1), (2) and the guiding band (3), do not distort.

Clean the grooves and sealing area.

– The maintenance should be executed at regular intervals of min. every year.

Depending on the operating conditions of the valves, these intervals may be

shorter.

– During maintenance pay attention to the assembly and safety instructions.

– Any maintenance work may be carried out only in a depressurized system.

4.4 Identification of components

All vacuum valves (VV) must be provided with permanent identification of the component.

– Standard vacuum valves are provided with a setting value (4 mbar) specified by us

(opening pressure range 3-5 mbar)

– Special vacuum valves (with special weight) are provided with a

customer-specific setting value.

They also include the identifying letter “S” before the manufacturing №.

Explanation of the identification:

Numerical

code

Allocation 1 2 3 4 5 6

1 Manufacturer

2 Vacuum valve

3 Valve type

4 Nominal width / DN [mm]

5 Set negative pressure p [mbar]

6 Year of manufacture with manufacturing № or “S“ with manufacturing №

AH VV xxxxx xxx yyy xx / xxxxx

AH VV xxxxx xxx yyy xx / S xxxxx

2019-02-08 Albert Handtmann Armaturenfabrik GmbH & Co. KG 8 / 13

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

4.5 Seals

4.6 Spare parts

Fig. 6: Type 12504

10 O-ring

20 O-ring

30 Guiding band

DN 12504 12818 12819

80 012504.00080LE 012504.00080LE 012504.00080LE

100 012504.00100LE 012504.00100LE 012504.00100LE

150 012504.00150LE 012504.00150LE 012504.00150LE

200 012504.00200LE 012504.00200LE 012504.00200LE

300 012504.00300LE 012504.00300LE 012504.00300LE

400 012504.00400LE 012504.00400LE 012504.00400LE

LE - EPDM

9 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

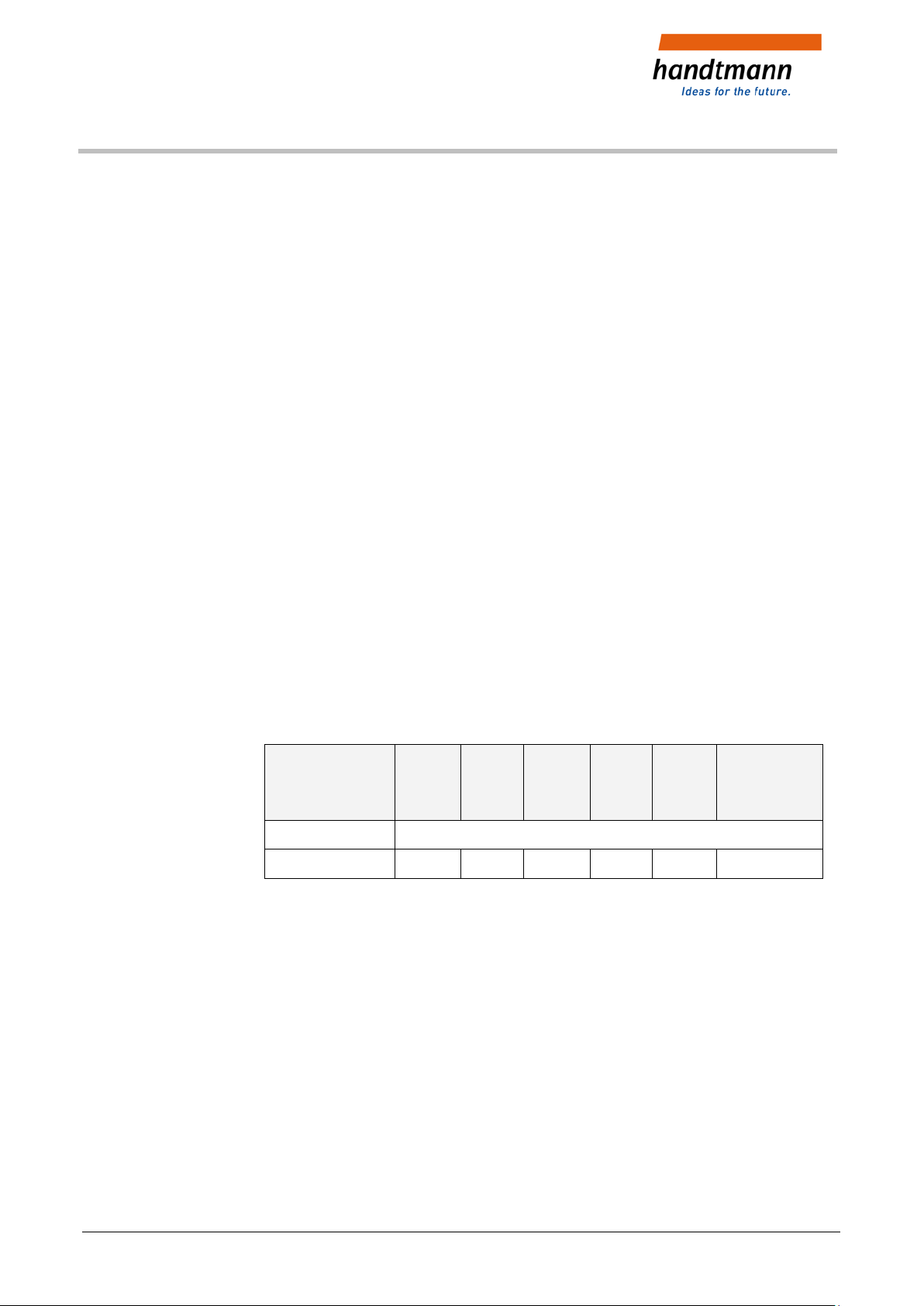

4.7 Performance diagram

15.000

14.000

13.000

12.000

11.000

10.000

9.000

8.000

7.000

6.000

5.000

[Nm³/h]

flow capacity

4.000

3.000

2.000

1.000

DN 400

DN300

DN 200

DN 150

DN 100

DN 080

0

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

vacuum pressure [mbar-g]

Fig. 7: 12504, DN 80 – DN 400

Conversion: 1 mbar >> 10 mmWS >> 100 Pa >> 0.1 KPa

2019-02-08 Albert Handtmann Armaturenfabrik GmbH & Co. KG 10 / 13

BA_012504.15_EN

Vacuum valve (weight loaded)

12504/ 12818, 12819

5 Additional Equipment

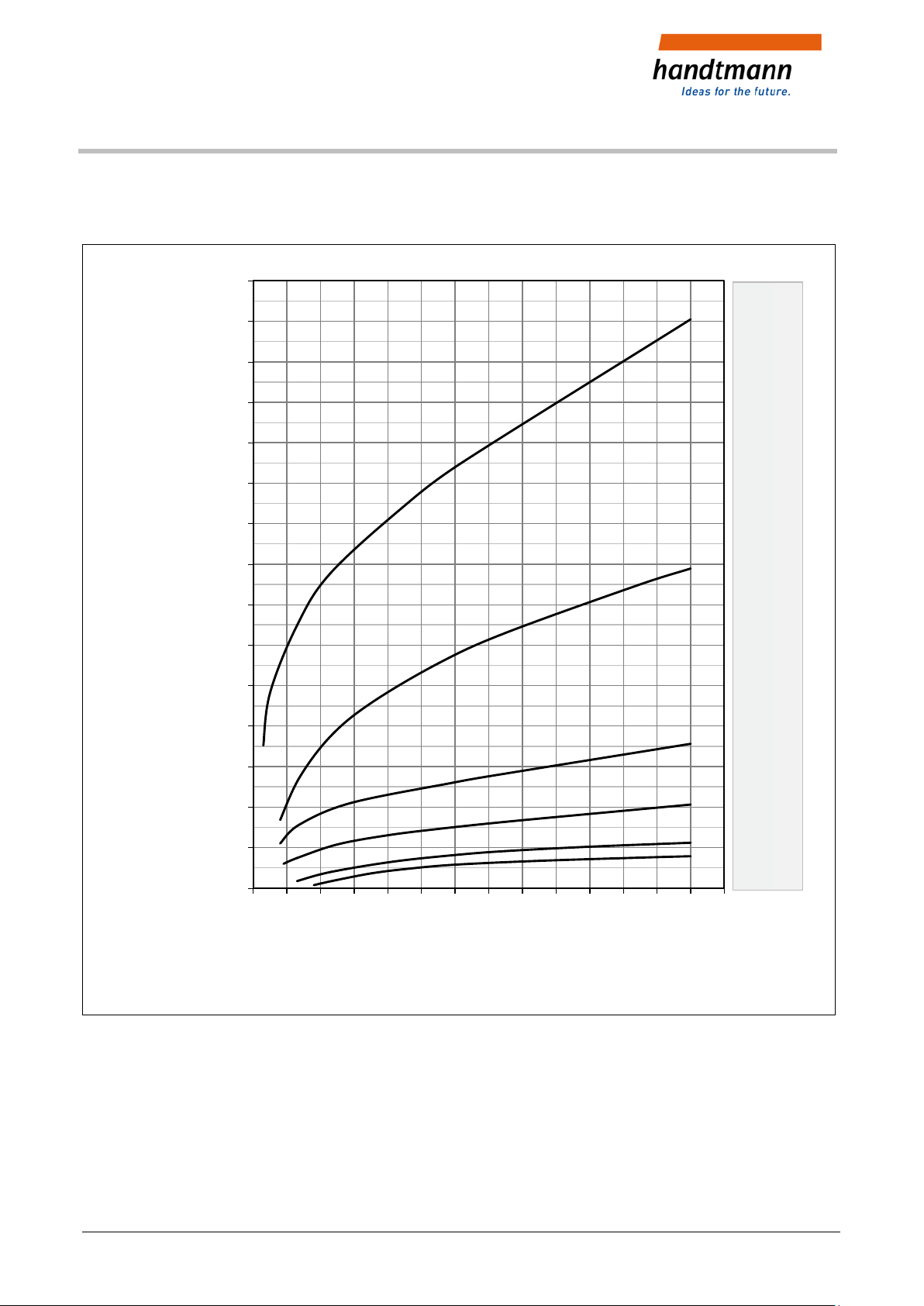

Proximity s witch, induc tive

5.1 Proximity switch, inductive

Type make contact (NO); № 106220 BES M12EE-PSC40B-S04G,

Nominal switching distance

>> with trip cam material steel

>> with trip cam material stainless steel 2,8 mm even

Supply current U 10 ...30 VDC

No-load current bedämpft / unbedämpft max. 10 mA/max. 5 mA

Operating current 200 mA

Potential drop U max. 2,5 V

Switching frequency 200 Hz

Reserve battery protection yes

4 mm even

Short-circuit proof yes

Construction size M12x1

Casing material Stainless steel

Temperature range - 25° C ... + 85° C

Enclosure rating IP 68

Indicator Multi-hole – LED

Fig. 8: Dimensions and connection scheme PNP

11 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

Heating inset Ø 6,5 x 40

Heating inset Ø 6,5 x 40

Vacuum valve (weight loaded)

12504/ 12818, 12819

5.2 Heating insets

Heating insets

DN

400 11 125E 33 24 184 8 24 23 105373

300 11 125E10 24 138 6 24 23 105373

200 11 125E30 24 92 4 24 23 105373

150 11 125E31 24 46 2 24 23 105373

100 11 125E31 24 46 2 24 23 105373

Connection-

scheme №

Connection

voltage

Volt

Heating

capacity

Watt

Quantity

Rated power:

Volt Watt

Part №

80 11 125E31 24 46 2 24 23 105373

Temperature

control unit

Temperature

control unit

Fig. 9: E 33, DN 400 E 10, DN 300

2019-02-08 Albert Handtmann Armaturenfabrik GmbH & Co. KG 12 / 13

BA_012504.15_EN

Heating inset Ø 6,5 x 40

Heating inset Ø 6,5 x 40

Vacuum valve (weight loaded)

12504/ 12818, 12819

Temperature

control unit

Temperature

control unit

Fig. 10: E 30, DN 200 E31, DN 80 - DN150

Abb. 11:

13 / 13 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-02-08

BA_012504.15_EN

Loading...

Loading...