Page 1

INS TRUCTIONS

26T 26K

Installation

Page 2

GB

74

Quality approval

The stove has been tested by SP

Technical Research Institute of

Sweden and complies with current

CE marking regulations and the

more stringent requirements for

P marking. Certificate number

for P marking: 220312

Manufacturer’s declaration

This product has been

manufactured in accordance with

the documents that constitute the

basis for approval certification

and the relevant criteria for

production control.

Flue requirements

For backward connections from

the rear of the stove and upward

connections from the top of the

stove, the chimney must be able

to withstand temperatures of at

least 350°C.

The Handöl 26 is a Swan

marked wood burning stove.

As the premier stove

manufacturer in Sweden, we at

Nibe Brasvärme are committed

to Swan marking our stoves. Our

commitment to producing stoves

that meet the requirements of

the Swan eco-label is part of our

vision to be a forward-looking

company with high quality goals

when it comes to the environment

too. Eco-label certification no.

378-001.

Certifierad

Certifikat nr

220312

NOTE! Always contact your local authority planning office

before installing a stove.

The owner of the house is personally responsible for ensuring

compliance with the mandatory safety requirements and must have

the installation approved by a qualified inspector.

Your local chimney sweep must also be informed about the

installation as this will affect the routines for regular chimneysweeping services.

378

001

N

O

R

D

I

C

E

C

O

L

A

B

E

L

WARNING!

Some of the surfaces become very hot when the stove is in

use and can cause burn injuries if touched. Please also be aware

of the strong heat radiated through the hatch glass. Placing

inflammable material closer than the safe distance indicated may

cause a fire. Pyre lighting can cause quick gas ignition with a risk

of damage to property and personal injury.

EC declaration of

conformity

Manufacturer

Name NIBE AB

Address Box 134, Skulptörvägen 10, SE-285 23 MARKARYD

Place of manufacture Markaryd, Sweden

Product covered by this declaration

Product type Stove fired by solid fuel

Type designation Handöl 20-series

Type acc. to standard EN 13240 annex ZA

Intended for use Heating of living accomodation

Fuels Wood logs

Special conditions None

CE-marking

Nominal output: 6 kW

Fuel type: Wood logs

Flue gas temperature: 250° C

Energy eciency: 79%

Emission of CO: 0,09%

Safety measurments for

Handöl 20-series: Distance to adjacent combustible materials:

Handöl 24, 26K, 26T

Behind 100 mm, beside 600 mm

Manufacturing check by approved organisation

Notified body No. 0402

Name Swedish National Testing and Research Institute AB

Address Box 857, SE-501 15 BORÅS

Appendix

• Lighting and Installation Instructions

Niklas Gunnarsson

Business area manager NIBE Stoves

www.handol.eu

Page 3

GB

75

CONTENTS

General information 76

Installation distances to walls and ceiling 77

Supply of combustion air 79

Hearth plate, sweeping 80

Chimney connection 81

Installing the surround 82

Installing soapstone /tiles, low model 84

Installing soapstone /tiles, tall model 86

Installing accessories ·baking oven 92

Installing accessories · heat tank 94

DEAR HANDÖL OWNER!

May we take this opportunity to welcome you to the Handöl family.

We hope your new stove will give you a great deal of pleasure.

Your choice of a Handöl stove is testimony to the high standards

you demand in terms of quality and design and you can rest

assured that this stove with its timeless design will be an integral

part of your home for many years.

The stove is not only an efficient source of heat but is

environmentally-friendly as well.

Please read through these instructions carefully before

starting installation work, and study the separate User/Lighting

Instructions before lighting a fire for the first time.

Page 4

GB

76

Eldstadsbeklädnad

Rosterreglage

Asklåda

Förbränningsluftsreglage

Brasbegränsare

ANVISNING

26T 26K

ins talla tion s

Installationsanvisning 2

Installasjonsanvisning 25

Installationsanleitung 49

Installation instruction 73

SE

NO

GB

DE

BAV SE/EX 0601-2

511299

Eldningsinstruktion och bruksanvisning för Handöl 20-serien 2

Heizinstruktionen und Gebrauchsanweisungen für Kaminöfen

von Handöl 20 5

Fyringsinstruksjon og bruksanvisning for Handöl 20-serien 8

Fyringsvejledning og brugsanvisning for Handöl 20-serien 11

Istruzioni per l’accensione e consigli per l’uso delle stufe-caminetto

Handöl serie 20 14

Instructions d’allumage et mode d’emploi de la série Handöl 20 17

Stookinstructies en gebruiksaanwijzing voor de Handöl 20-serie 20

Lighting and Maintenance Instructions for Handöl 20 23

Handöl 20-sarjan lämmitys- ja käyttöohje 26

SE

DE

NO

DK

IT

FR

NL

GB

FI

HANDÖL

In accordance with standards below

marking was affixed:

European Standard:

SE Quality Certification, P-marked:

NO Standard NS 3059:

DE and AT Standard DIN 18.891 and

Art 15a B-VG:

Type:

Nominal Output:

Fuel:

Minimun draught:

Flue gas temerature:

Energy efficiency:

Emission of CO in cumbustion products:

Distance to cumbustible wall (mm):

Follow the user’s instructions and use only recomended fuel

NIBE AB Box 134 SE-285 23 MARKARYD SWEDEN

2007

EN 13240

Cert no 0112/07

SINTEF 110-0275

RRF-40 07 13 90

Handöl 31/31A/32/32A

5 kW

Wood

12 Pa

280°C

78%

0,14%

Behind 150

Beside 450

Corner 150

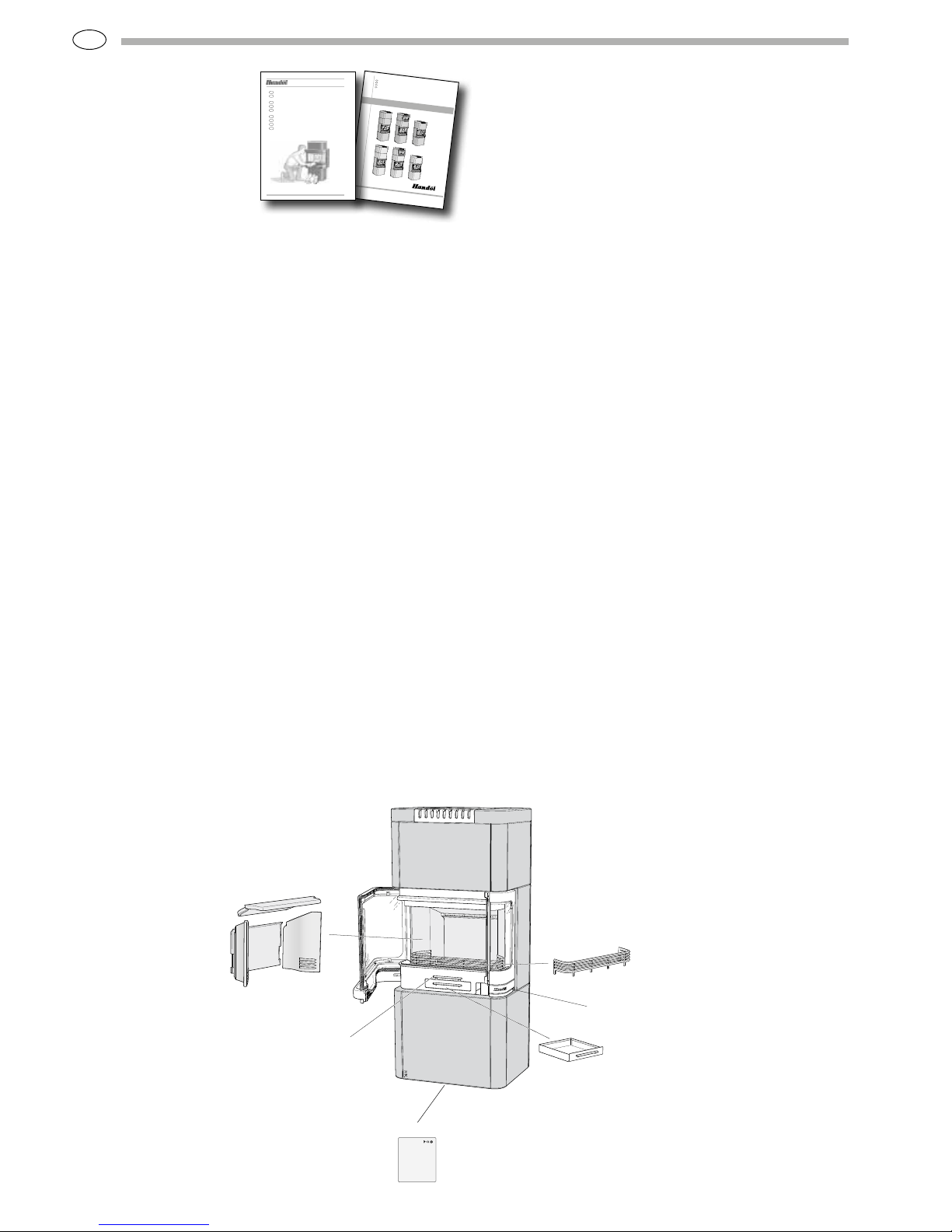

Type plate

Log guard

Fire-box surround

Ash-pan

Grate shuttle

Air supply control

Building application

Before installing a stove or erecting a chimney, you must apply

to your local planning authority for planning permission. We

recommend you contact your local planning office for advice on

building regulations and applying for planning permission.

Structural support

Check that the wood joists are strong enough to bear the weight

of the stove and chimney. The stove and chimney can usually

be placed on a normal wooden joist in a self-contained house

provided the total weight does not exceed 400 kg.

Hearth plate

The stove must be placed on a hearth plate to protect the floor

from any embers. If the floor under the stove is combustible, it

must be protected with a minimum of 12 mm of non-combustible

material that covers at least 300 mm of the floor in front of the

stove door and 100 mm on each side.

Chimney

The draught in the chimney must generate a negative pressure

of at least 12 Pa. The draught is affected both by the length

and cross-sectional area of the chimney, and by how well sealed

it is. The shortest recommended chimney length is 3.5 metres.

The cross-sectional area must be 150-200 cm² (140-160 mm

in diameter). Carefully check that the chimney is sealed and

that there is no leakage around soot hatches and flue pipe

connections.

Note that the draught in the chimney is reduced in a flue with

sharp bends and horizontal sections. A horizontal flue length of

up to 1 metre is permissible, provided that the vertical flue is

at least 5 metres high. It must be possible to sweep the entire

length of the flue and the soot hatches must be easily accessible.

Technical data

Output 3-9 kW

Nominal output 6 kW

Efficiency rating up to 80%

Model H26T/K Tall H26T Low H26K Tall H26K Low

Weight (kg) 470 420 240 240

Widthd (mm) 580 580 580 580

Depth (mm) 462 462 462 462

Height (mm) 1622 1312 1622 1312

Weight H26T with baking oven: 480 kg

Weight H26K with baking oven: 265 kg

Weight Heat tank (Optional accessory for H26 T/K Tall): 120 kg

Air duct connection, external diameter Ø150 mm.

Type approved in accordance with:

European standard EN-13240

Swedish environmental and quality marking, P-marking cert. no.

220306

Norwegian standard NS 3059, SINTEF 110-0223

German standard DIN EN 13240, RRF 4005900

General

information

This manual contains

instructions on how the

Handöl 20 series must be

assembled and installed.

In order to be able to guarantee the performance and

safety of the stove, we recommend that it is installed by a

professional. Our Handöl agents can recommend suitable

installers. For information about our agents, please visit our

website www.handol.se

Instructions for use and how to light the stove correctly are

also supplied with the stove. We recommend that you read

these instructions carefully and keep them safe for future use.

The stove is type approved and must be connected to a chimney

able to withstand temperatures of at least 350°C. The diameter

of the external connection is 150 mm. Air should be supplied

from outside for use as combustion air.

Page 5

GB

77

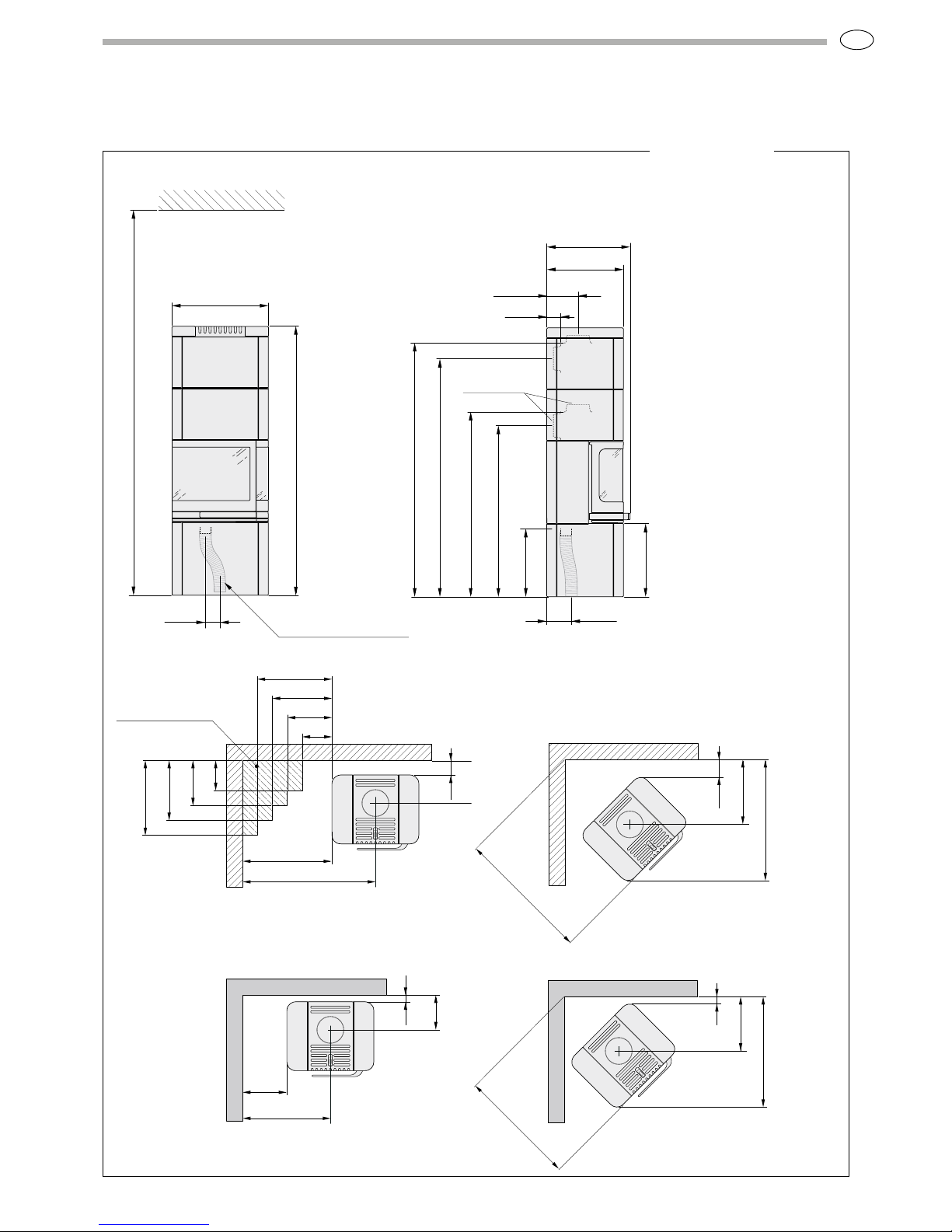

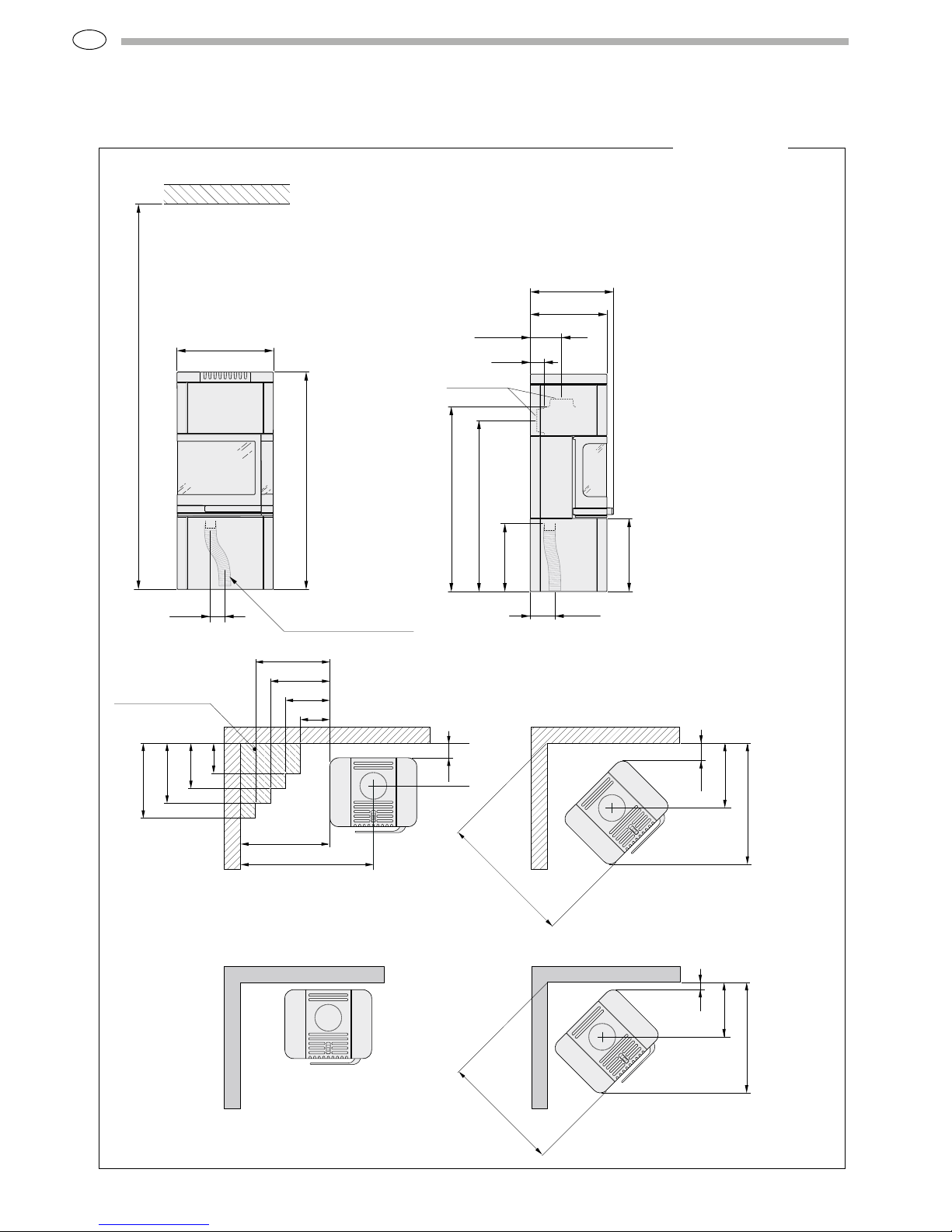

1622

582

2300

G 90

Combustible roof

Combustion air hose

(accessory)

442

E 150

A 1116

1435*

B 1033

F 410

1532*

C 188

D 85

502

462

Utv. Ø150

288

100

600

890

500

400

300

200

300

400

500

200

Combustible wall

Permitted area for

combustible material

435

120

890

810

Combustible wall

H26T/K High

* Used when ins talling optional b aking oven

** To prevent discolouration of painted firewalls, we r ecommended the same side distance as to combustible walls.

238

50

300**

590

Fire-retardant wall of

brick or concrete

365

50

795

740

Fire-retardant wall of

brick or concrete

A = height from floor to upward chimney connection

B = height from floor to c /c rear chimney connection

C = dista nce from back to c/c upward chimney connection

D = distance from back to rear chimney conne ction

E = distance from back to hole in base pla te

F = height from floo r to air inlet (410 mm)

G = distance to hole in ba se plate

Position the stove on a

hearth plate and check that

the installation distances

shown in the diagrams are

met. There must be at least

1 metre between the stove

opening and combustible

parts of the building or décor.

When installing a stove with

a top flue connection to a

steel chimney, please refer to

the relevant manufacturer’s

installation instructions.

Observe the safety distances

to combustible material

required for the steel

chimney.

Installation distances to walls and ceiling

Page 6

GB

78

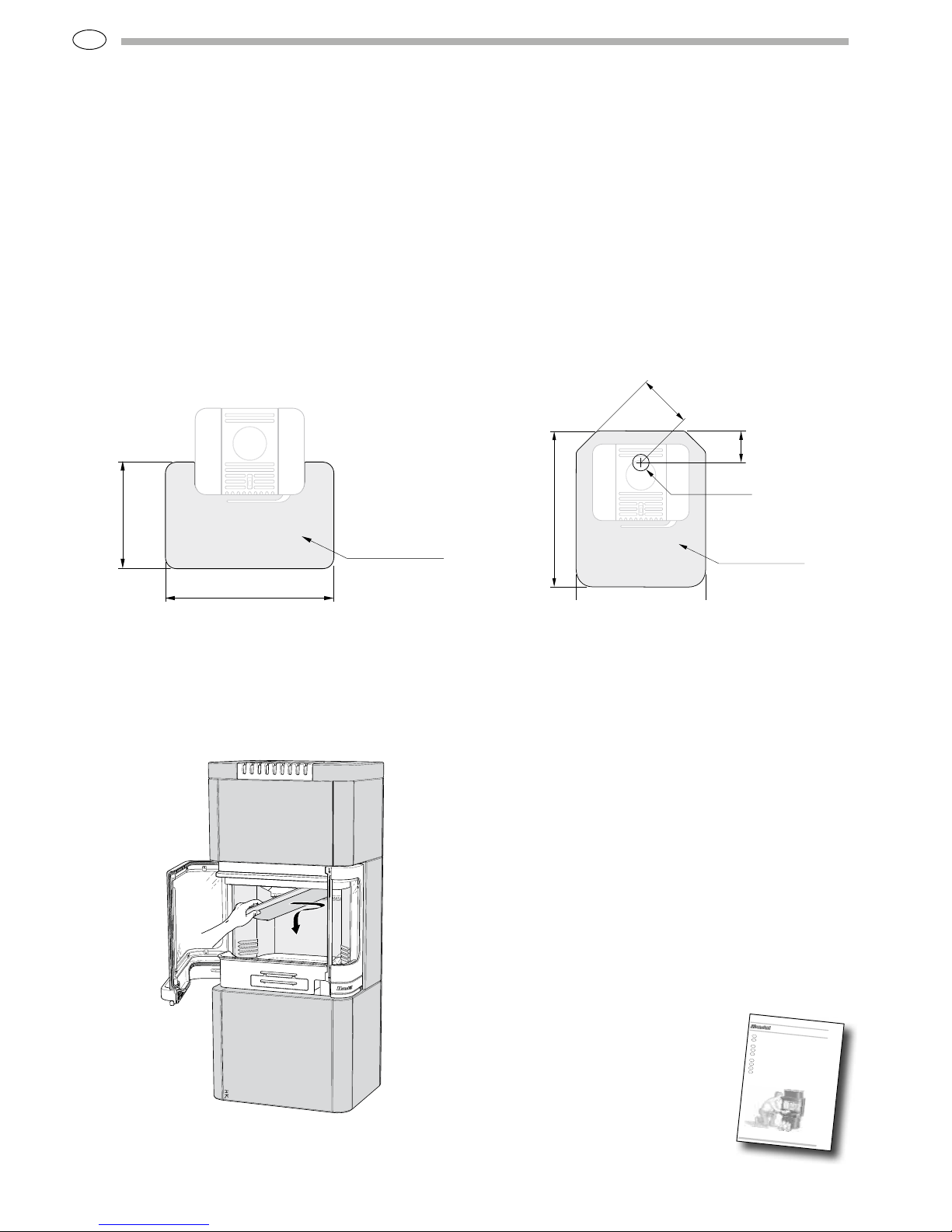

1312

582

2300

G 90

Combustible roof

Combustion air hose

(accessory)

442

E 150

A 1116

B 1033

F 410

C 188

D 85

Ø150

502

462

* To prevent discolouration of painted firewalls, we r ecomm ende d the same side dista nce as to combustible walls.

A = height from floor to upward chimney connection

B = height from floor to c /c rear chimney connection

C = dista nce from back to c/c upward chimney connection

D = distance from back to rear chimney conne ction

E = distance from back to hole in base pla te

F = height from floo r to air inlet (410 mm)

G = distance to hole in ba se plate

288

100

600

890

500

400

300

200

300

400

500

200

Combustible wall

Permitted area for

combustible material

435

120

890

810

Combustible wall

Fire-retardant wall of

brick or concrete

365

50

795

740

Fire-retardant wall of

brick or concrete

H26T/K Low

Position the stove on a

hearth plate and check

that the installation

distances shown in the

diagrams are met. There

must be at least 1 metre

between the stove opening

and combustible parts of

the building or décor.

When installing a stove

with a top flue connection

to a steel chimney,

please refer to the

relevant manufacturer’s

installation instructions.

Observe the safety

distances to combustible

material required for the

steel chimney.

Installation distances to walls and ceiling

Page 7

GB

79

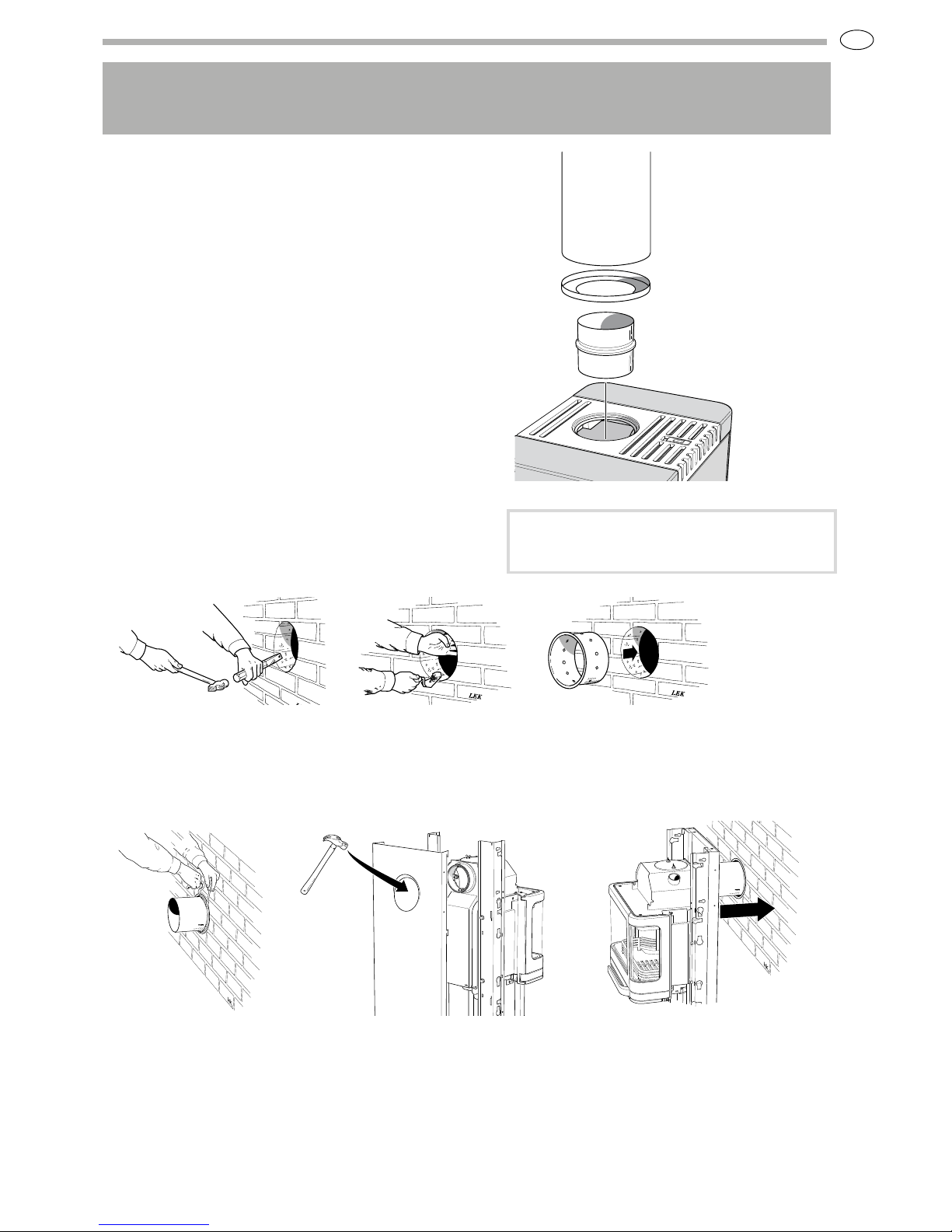

HK

HK

HK

HK

30 mm

For this type of connection, first remove the vent

screen over the back plate’s air intake.

When connecting an air supply through the floor,

first remove the knockout in the base plate and

hearth plate (if any).

Supply of combustion

air

Combustion air can be supplied through a duct

directly from outside, or indirectly through a

vent in the outer wall of the room where the

stove is installed. The amount of air required for

combustion is approximately 25 m

3

/hr.

The illustrations to the right show various

installation alternatives.

The external diameter of the air duct connection

on the stove is 64 mm.

In heated areas, the duct must be insulated with

30 mm of mineral wool covered with a moisture

inhibitor (construction plastic). It is important

to seal carefully around the duct where it passes

through the wall or floor. Use jointing compound.

If the duct is longer than 1 metre, the diameter of

the duct must be increased to 100 mm and the size

of the wall vent must be increased correspondingly.

A condensation-insulated combustion air hose (1

metre) is available as an accessory.

Page 8

GB

80

Before the stove is used, it must be inspected by an

authorised chimney sweep.

Read the Instructions for Lighting the

Handöl 20 series before lighting the

fire for the first time.

Sweeping

Before sweeping any of the stoves in the

Handöl 20 series, the smoke baffle must be

lifted out. This is easily done by lifting and then

pushing the baffle to the side.

The prefabricated metal hearth plates in the Handöl 20 series have a

hole through which the combustion air hose can pass. Please note that

the illustrations below show the position of the hole in the hearth plate

and not the air inlet on the stove. If connecting an air supply from the

floor, a flexible hose must be used. See illustrations on pages 77 and 78.

190

940

Ø125

Eldstadsplan

320

Hearth plate for the Handöl 20 series (optional)

BAV SE/EX 0601-2

511299

Eldningsinstruktion och bruksanvisning för Handöl 20-serien 2

Heizinstruktionen und Gebrauchsanweisungen für Kaminöfen

von Handöl 20 5

Fyringsinstruksjon og bruksanvisning for Handöl 20-serien 8

Fyringsvejledning og brugsanvisning for Handöl 20-serien 11

Istruzioni per l’accensione e consigli per l’uso delle stufe-caminetto

Handöl serie 20 14

Instructions d’allumage et mode d’emploi de la série Handöl 20 17

Stookinstructies en gebruiksaanwijzing voor de Handöl 20-serie 20

Lighting and Maintenance Instructions for Handöl 20 23

Handöl 20-sarjan lämmitys- ja käyttöohje 26

SE

DE

NO

DK

IT

FR

NL

GB

FI

570

900

Eldstadsplan

Glass hearth plate Metal hearth plate

Hearth plate

Hearth plate

Page 9

GB

81

When installing the chimney, please refer to the chimney

installation instructions. The chimney is connected to the stove

as described below.

The insert comes from the factory ready for top connection. When

connecting from the rear, the cover and connection must be swapped

around.

Top connection to the chimney

If connecting from the top, the whole stove surround must be installed

before installation of the chimney can begin.

The start pipe is placed over the connection on the insert. Make sure

that the gasket on the connection is intact and in position. The stop

washer is positioned over the collar on the start pipe. Install the

remaining parts according to the instructions for the chimney.

Chimney connection

Important! If connecting from the top, the hot air

grate must be installed before the chimney.

!

Chimney mantle

Stop washer

Start pipe

Rear connection to a masonry

chimney

Mark out the centre for making a hole in the wall to the flue.

Check that the connection height in the chimney breast is

the same as the height of the connection pipe from the stove.

Make a hole with a diameter of

approx. 180 mm.

Then cement the wall connector

with fireproof mor tar (not

supplied with the product).

Let the mortar dry before the

stove is connected to the chimney.

Move the stove back into place.

Make sure that the connector

gasket does not work loose from

its position. If further sealing

material is required, heatresistant sealant may be used.

Slide the connection pipe into

the wall connector and seal the

joint with sealing rope.

Use a hammer to tap out the

knockout in the back plate.

Hang the back plate into place

on the side profiles as explained

later in these instructions.

Page 10

GB

82

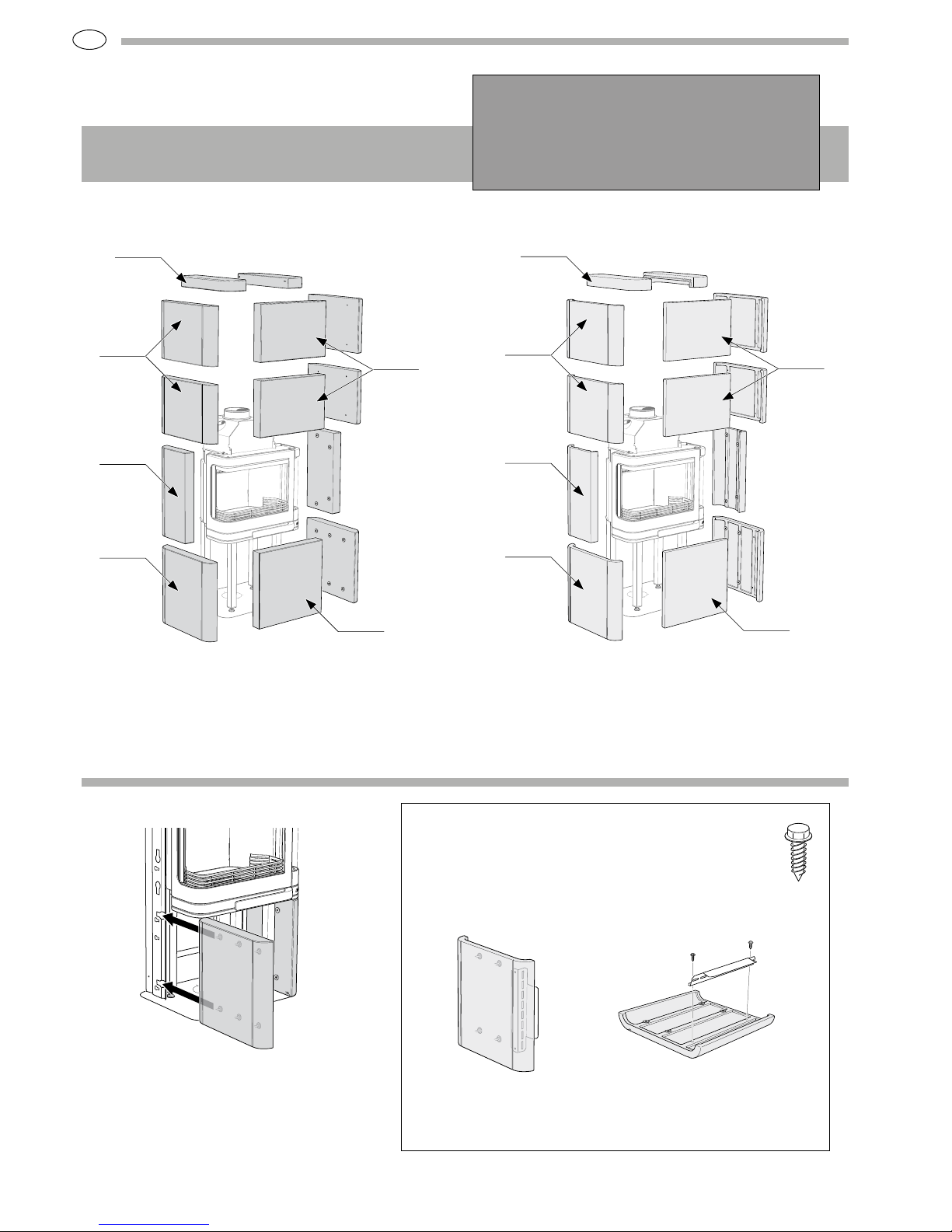

Installing the surround

Handöl 26 T Tall/Low

Handöl 26 K Tall/Low

Type plates

Two type plates are supplied with the stove. One for the

insert and one for the surround kit. Place these plates on

the guide plate as illustrated.

Centre marking chimney

Position the insert and adjust the feet so that the distance

from the guide plate up to the rear edge of the door is

445 mm.Check that the insert is vertically straight.

Position the guide plate according to the installation dimensions

and ensure that it is horizontal. Note that the rear edge of the

guide plate must be 5 mm inside the rear side of the stove.

Remove the insert from the packing and unpack

the surround kit. Read through the whole section on how to install the surround. Check that no

parts are missing or are defective on delivery.

Page 11

GB

83

Tall

Low

Tall

Low

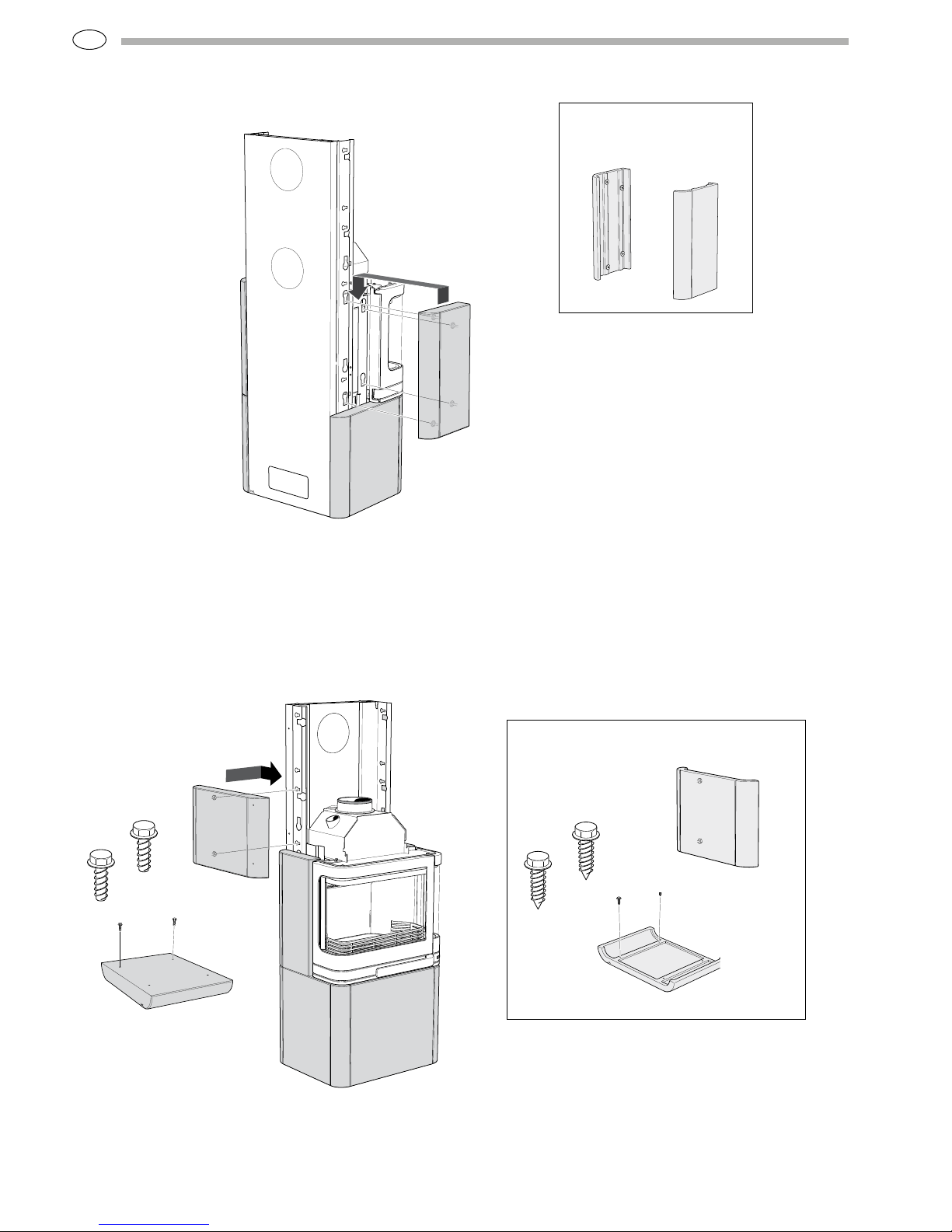

Install the back plate by hanging it in the holes on the side profiles. If the

stove is to be rear connected, this must be done at this stage. Use the upper

outlet on a tall model only if installing a baking oven. Otherwise, use the

lower outlet.

Assemble the rear side profiles with two screws (M6x20) each. Check

that the profiles are resting against the base plate and are vertically

straight. If necessary, use washers between the insert and side profiles to

straighten them.

Page 12

GB

84

TILE

Lower side stone

Assembly

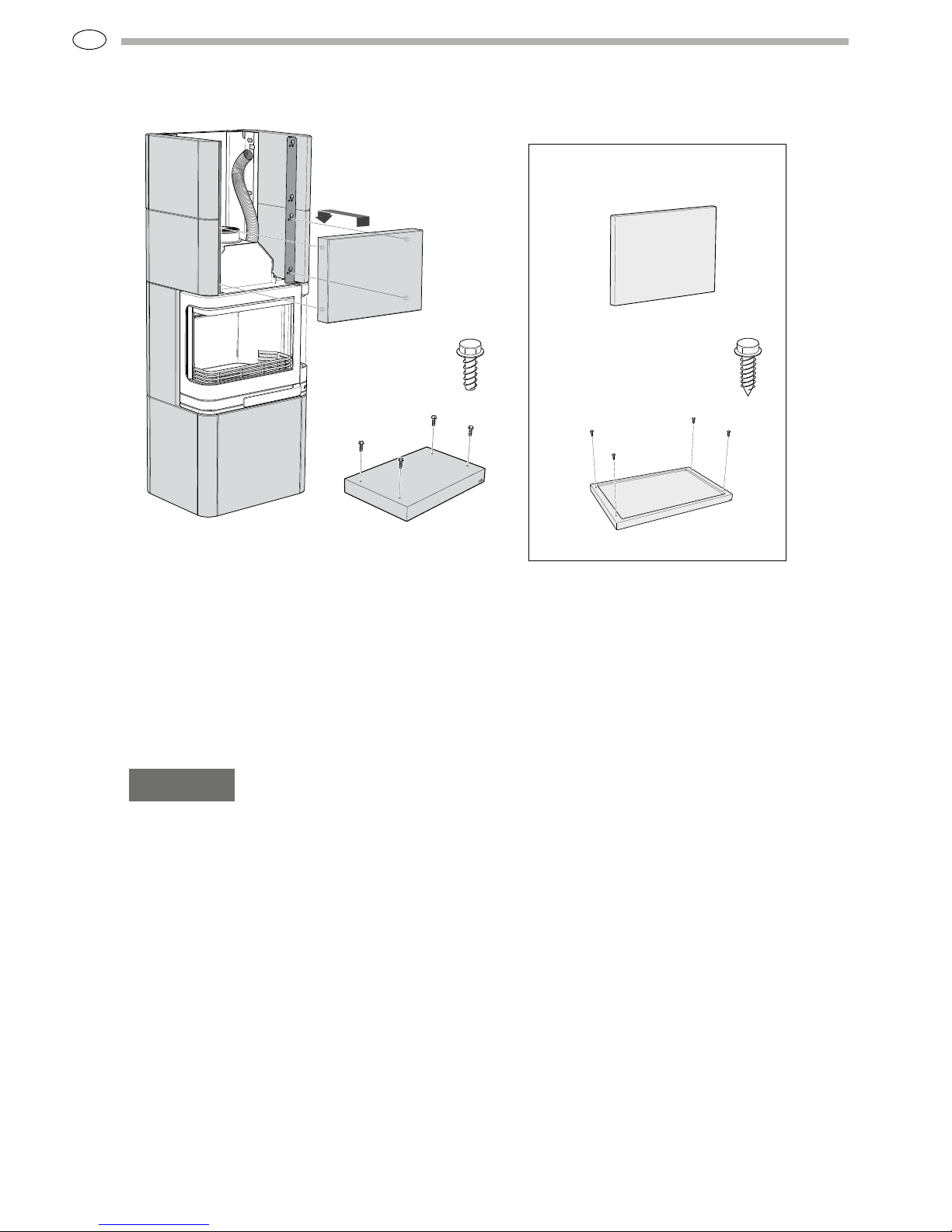

Soapstone and tile stoves are installed in more

or less the same way. These illustrations show

installation of a soapstone model, along with

smaller illustrations of corresponding tiles and

profiles.

H26T Low/H26K Low

Installing tiles

Installing soapstone

403872

Top stone

403871

Upper side stone

403868

Upper front stone

403870

Middle side stone

403869

Lower side stone

403867

Lower front stone

403882

Top stone

403881

Upper side stone

403878

Upper front stone

403880

Middle side stone

403879

Lower side stone

403877

Lower front stone

General information

The stove must be placed on a level and horizontal surface to

ensure that the rows are even and straight, so that the tiles do

not become misaligned or the gaps between them too large.

While you are installing the stove, make sure that all the

stones/tiles are level and that each row is of uniform height

along its length.

Remember that the stones/tiles must be handled with care.

They are easily scratched and sharp edges are vulnerable to

knocks. You should also be careful not to crack the stones/

tiles when screwing in screws.

For the tile model, first screw

two profiles firmly into the lower

side plates. Insert them in the

same way as for the soapstone

model.

Make quite certain that the

rear side profiles are vertically

straight. Push in the lower side

stones from the front so that

their suspension plates hook

into the horizontal keyholes of

the side profiles. Make sure that

there is a 5 mm gap between the

stone and the lower edge of the

door.

Page 13

GB

85

TILE

Middle side stone

TILE

Lower front

stone

H26T Low/H26K Low

Check that the

type plates are in

place.

Hang the middle side

stones into place using

the keyholes in the side

profiles. Then tighten the

screw that is holding the

front side profile in the

insert.

Hook the front side profile onto the

lower side stone’s suspension plate and

secure its upper edge with screws in

both the insert and side profile. Do not

tighten the screw in the insert until the

second layer of side stones are in place.

Install the two, lower front profiles on the lower

front stone so that they are edge to edge with the

short sides of the stone. Insert the front stone

between the lower side stones so that they are

locked into place by the front stone’s profiles.

Page 14

GB

86

TILE

Upper side stone

H26T Low/H26K Low

TILE

Upper front

profile

TILE

Upper front stone

Secure screws into the

upper front stone leaving

4-5 mm between the screw

flange and the soapstone.

Hang the stone into place in

the keyholes and allow it to

rest against the bent edge

of the side profile. Check

that it is at the same height

as the side stones and then

tighten the screws.

Screw the upper front profiles

securely into place in the side stones.

Press the profile upwards so that its

bent edge is against the lower edge of

the side stone.

Secure screws into the

upper side stones leaving

4-5 mm between the

screw flange and the

stone. Then insert them

into the smaller keyholes

in the side profiles and

check that they are level

before finally tightening

the screws.

Page 15

GB

87

H26T Low/H26K Low

TILE

Top stone

Damper

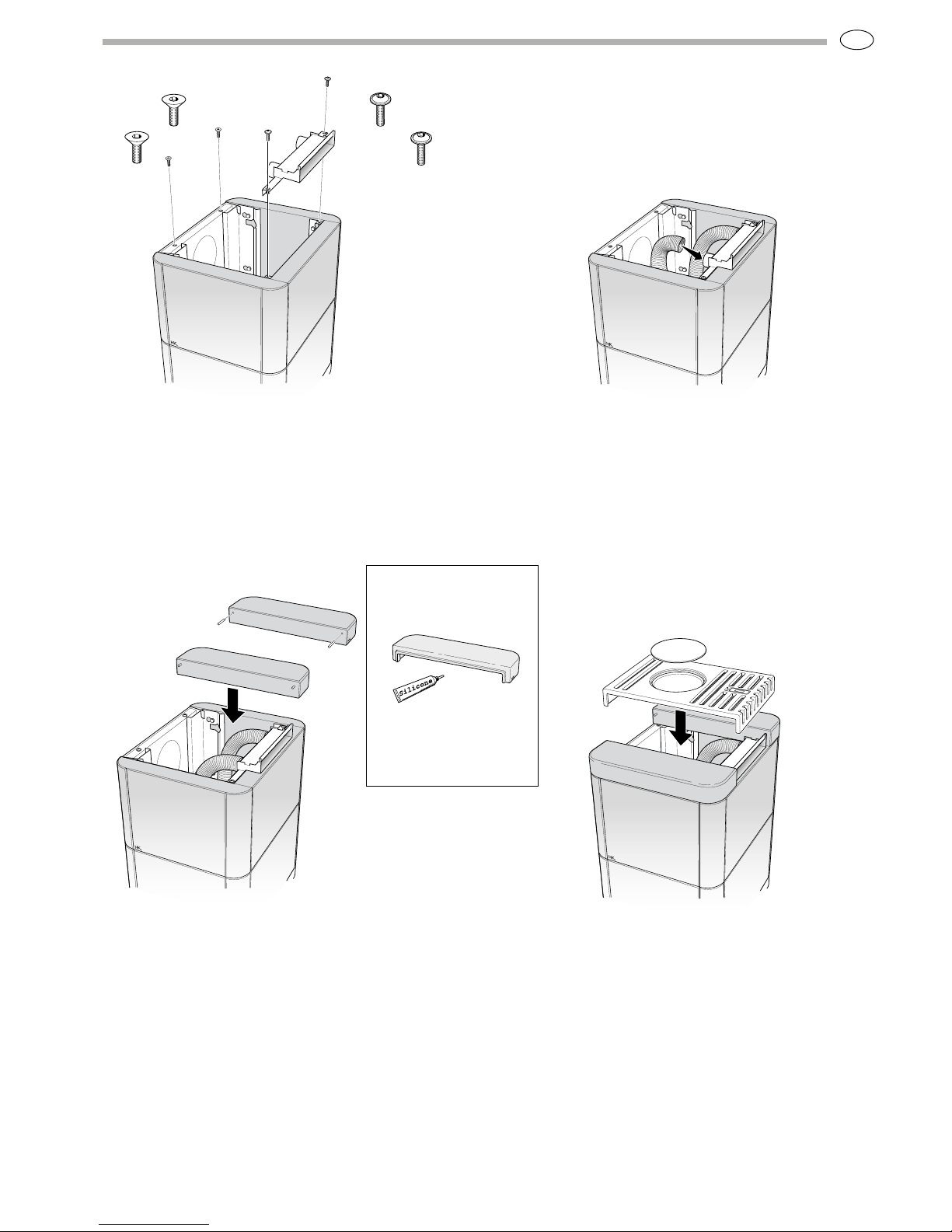

The top grate damper is regulated using the

control on the top. When the damper is open,

the heated air flows into the room and spreads

the heat. When the damper is closed, a greater

amount of heat is stored in the soapstone, which

releases the heat more slowly and over a longer

period.

Apply a few small drops

of silicone beneath the

tile top to hold it in place.

Carefully place the grate so that it rests on the

pins or the cast edge of the tile top. Check that

the damper can be opened and closed properly.

Position the top stones on top of

the stove. Pins are placed in the

soapstone top for the grate to

rest on.

Position the adjusting screws on the top of the

back plate and screw them down so that the screw

heads are level with the top surface of the upper

side stones.

Screw the convection box securely into the upper

front profiles. Then connect the aluminium hoses

to the convection box.

Place the base plate of the heat tank on the top of the insert. Then place the tank stones as illustrated and push the aluminium

hoses through the holes in the tank stone and down into the convection pipes on the top of the insert. Handle the hoses with care to

ensure they do not crack.

Page 16

GB

88

403882

403881

403880

403877

403878

403879

403872

403871

403870

403867

403868

403869

TILE

Lower side stone

H26T High/H26K High

Installing tiles

Assembly

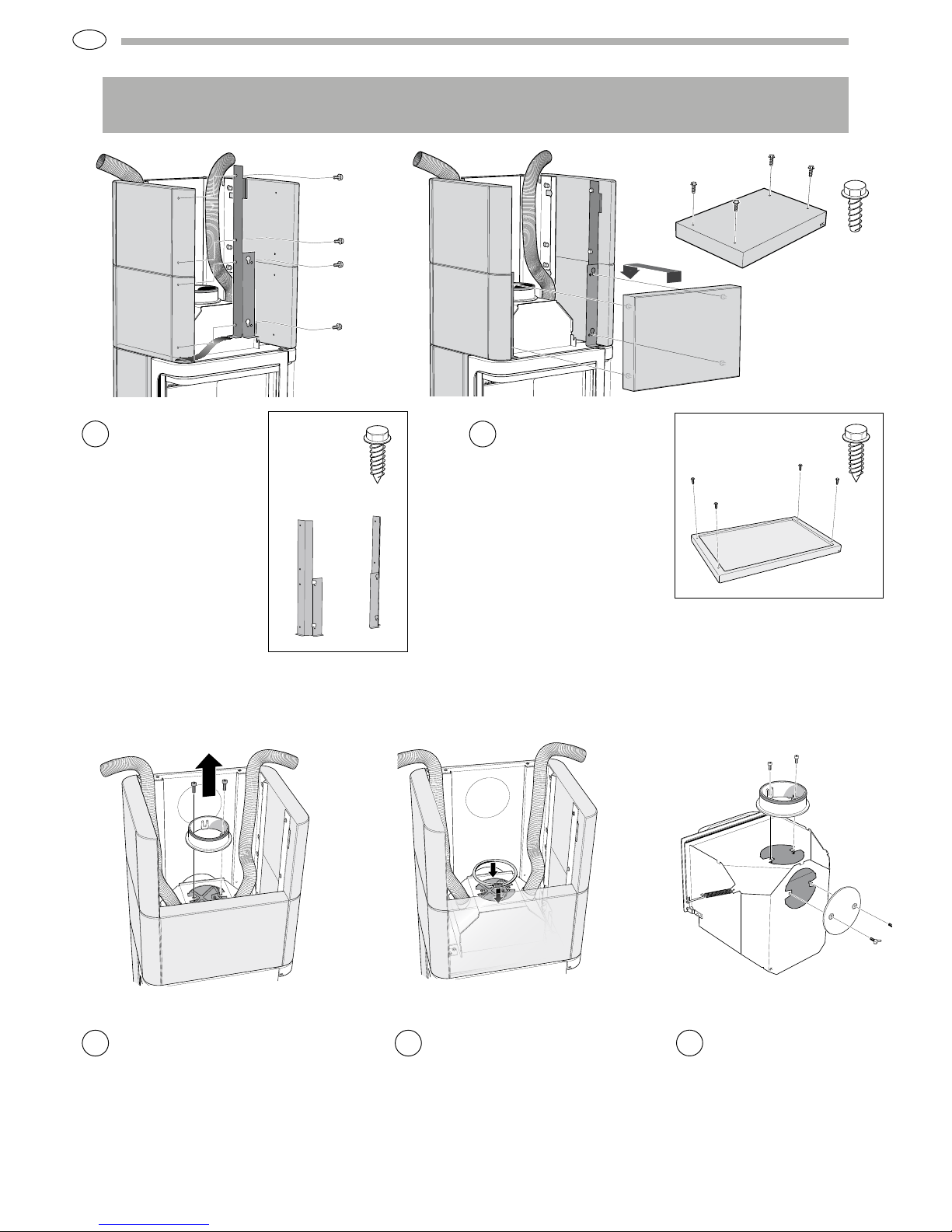

Soapstone and tile stoves are installed in

more or less the same way. These illustrations

show installation of a soapstone model, along

with smaller illustrations of corresponding

tiles and profiles.

Installing soapstone

For the tile model, first screw two profiles firmly

into the lower side plates. Insert them in the same

way as for the soapstone model.

Make quite certain that the rear side profiles

are vertically straight. Push in the lower side

stones from the front so that their suspension

plates hook into the horizontal keyholes of the

side profiles. Make sure that there is a 5 mm

gap between the stone and the lower edge of

the door.

General information

The stove must be placed on a level and horizontal surface to

ensure that the rows are even and straight, so that the tiles do

not become misaligned or the gaps between them too large.

While you are installing the stove, make sure that all the stones/

tiles are level and that each row is of uniform height along its

length.

Remember that the stones/tiles must be handled with care. They

are easily scratched and sharp edges are vulnerable to knocks.

You should also be careful not to crack the stones/tiles when

screwing in screws.

Page 17

GB

89

TILE

Lower front stone

H26T High/H26K High

Hook the front side profile onto the lower

side stone’s suspension plate and secure

its upper edge with screws in both the

insert and side profile.

Do not tighten the screw in the insert

until the second layer of side stones are

in place.

Install the two, lower front profiles on the lower front stone

so that they are edge to edge with the short sides of the

stone.

Insert the front stone between the lower side stones so that

they are locked into place by the front stone’s profiles.

Page 18

GB

90

TILE

Upper side stone

H26T High/H26K High

TILE

Middle side stone

Secure two (2) screws into the upper side stones leaving

4-5 mm between the screw flange and the stone.

Then insert them into the smaller keyholes in the side

profiles and check that they are level before finally

tightening the screws.

Hang the middle side stones into place

using the keyholes in the side profiles. Then

tighten the screw that is holding the front

side profile in the inser t.

Page 19

GB

91

TILE

Upper front

profile

H26T High/H26K High

>> If installing optional

baking oven, go to

page 92.

Screw the upper front profiles securely into place in the side stones. Press

the profile upwards so that its bent edge is against the lower edge of the

side stone.

Slide the end of the flexible

aluminium hoses down into the

convection pipes on the top of

the insert. (Not when installing

optional heat tank)

Mount the remaining upper side

stones in the same way.

Page 20

GB

92

TILE

Upper front stone

>> If installing optional heat

tank, go to page 94.

H26T High/H26K High

Secure screws into the upper front stone leaving 4-5

mm between the screw flange and the soapstone.

Hang the stone into place in the keyholes and allow it to

rest against the bent edge of the side profile.

Check that it is at the same height as the side stones and

then tighten the screws.

Mount the last front stone in the same way.

Page 21

GB

93

TILE

Top stone

H26T High/H26K High

Damper

The top grate damper is regulated using the control on

the top. When the damper is open, the heated air flows

into the room and spreads the heat. When the damper

is closed, a greater amount of heat is stored in the

soapstone, which releases the heat more slowly and over a

longer period.

Apply a few small drops

of silicone beneath the

tile top to hold it in place.

Final assembly instructions

Carefully place the grate so that it

rests on the pins or the cast edge

of the tile top.

Check that the damper can be

opened and closed properly.

Position adjusting screws on the top of the back

plate and screw them down so that the screw heads

are level with the upper side stones. Slacken the

uppermost screws on the corner profiles. Position the

screen so that it is resting on the corner profiles and

then tighten the screws to secure the screen in place.

Then mount the convection box on the screen.

Screw the convection box securely into the upper

front profiles.

Position the top stones on top of

the stove. Pins are placed in the

soapstone top for the grate to

rest on.

Then connect the aluminium

hoses to the convection box.

Page 22

GB

94

H26T High/H26K High

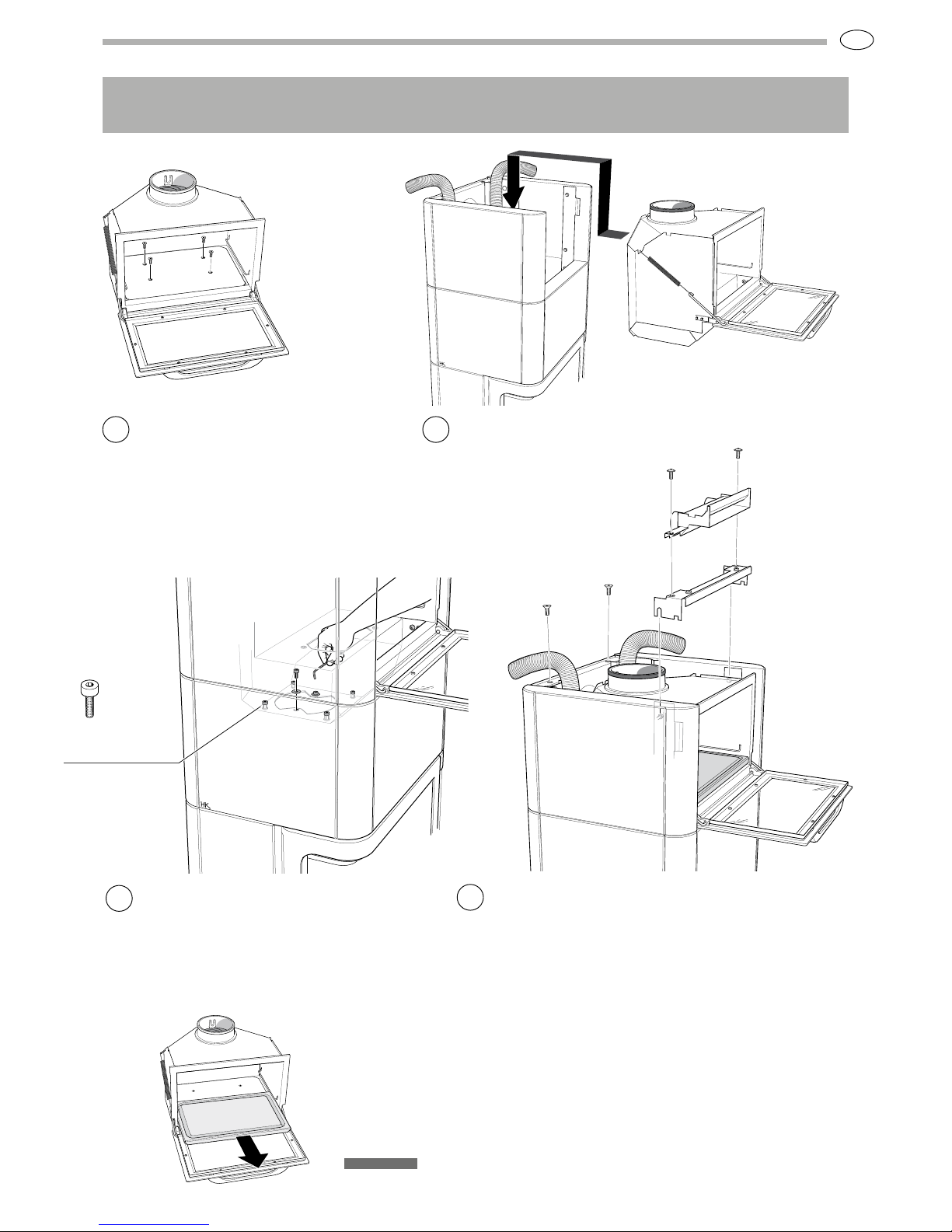

Installing the baking oven (accessory)

TILE

Upper front

profile

TILE

Front stone

Place the sealing ring so that

it is centered over the hole on

the top of the insert. Press the

aluminium hoses into the back

corners so that they are not in the

way of the baking oven.

If connecting upwards,

move the pre-assembled

lid on the baking oven

top to the back.

Remove the connector from

the top of the insert and secure

it onto the back or top of the

oven, depending on whether the

chimney is to be connected from

the rear or directly upwards.

Hang the stone into place in

the keyholes and allow it to

rest against the bent edge

of the side profile. Check

that it is at the same height

as the side stones and then

tighten the screws.

Secure screws into the

front stone leaving 4-5 mm

between the screw flange

and the soapstone.

Securely screw the

corner profiles that are

packed together with

the baking oven into the

upper side stones.

Press the profile

upwards so that its bent

edge is against the lower

edge of the side stone.

1

2

3 4

5

Page 23

GB

95

Justerskruvar

9

H26T High/H26K High

>> Turn to page 91 for final assembly instructions

Installing the baking oven (accessory)

Stone hearth

The hearth at the bottom of the baking oven can be lifted out and washed. If

necessary, rub the surface with a fine sandpaper to restore its appearance. Both sides

of the hearth can be used. When using the stone hearth, it is important to remember

that the stone becomes much hotter than the air in the baking oven. Any food that

spills on the aluminium walls of the oven should be wiped off immediately to prevent it

from burning onto the surface.

Adjusting screw

Position the screen so that it is resting on the corner profiles.

Slacken the uppermost screws on the corner profiles and fasten

the screen into these. Screw the convection box to the screen

and connect the aluminium hoses.

Screw the baking oven onto the insert using the

screws and washers provided. There should be

about 6 mm between the lower edge of the door and

the front stone. Check that the oven is straight. If

necessary, use the four adjusting screws to straighten

it. (Screw the lid back into place in the base of the

baking oven. Place the oven hearth on top.)

Carefully lift the baking oven in

and place it on the insert. Check

that the sealing ring has not

moved out of position.

Remove the lid at the bottom

of the oven.

8

6 7

Page 24

GB

96

>> Turn to page 91 for final assembly instructions

H26T High/H26K High

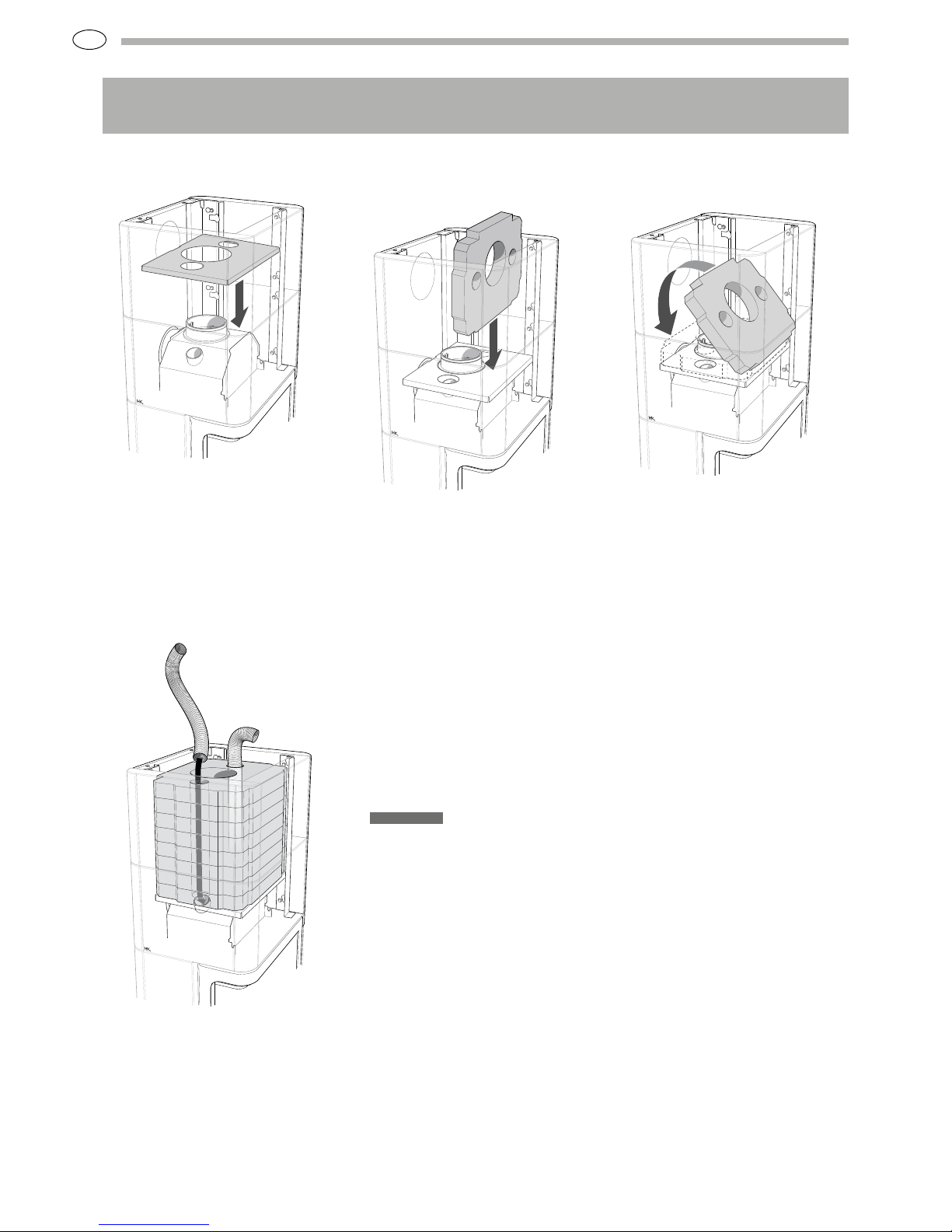

Installing the heat tank (accessory)

IAV SE-EX 1019-3 811008

Place the base plate of the heat tank on the top of the

insert. Then place the tank stones as illustrated and push

the aluminium hoses through the holes in the tank stone

and down into the convection pipes on the top of the insert.

Handle the hoses with care to ensure they do not crack.

Page 25

IAV SE-EX 1019-3 811008

NIBE AB/ NIBE STOVES · Box 134 · 28 5 23 Marka ryd, Sw eden

ww w.han dol.s e

NIBE Stoves re serves the right to change colours,

materials, dime nsions a nd models at any time without

special notice. Your dealer can provide you with the

lates t infor mation. The stoves shown in brochur es

may also f eature optional acc essories or eq uipment.

Loading...

Loading...