Page 1

GB

61

INSTRUCTIONS

Installation

31 31A 32 32A 33T

Page 2

GB

62

Quality approval

The stove has been tested by the

Swedish National Testing and

Research Institute and meets

the applicable regulations for

CE approval and the stricter

requirements for P marking.

Certificate number for

P Marking: 0112/ 07.

Manufacturer’s assurance

Manufacture of the product

has taken place in accordance

with those documents which are

the basis for the relevant type

approval certification and the

required manufacturing checks.

Requirements for flue

The chimney must be dimensioned for at least 350° C for

both top connection directly

upwards and connection directly

backwards from the rear of the

stove.

Handöl 30 is a Swan marked

wood burning stove.

As the premier stove

manufacturer in Sweden,

we at NIBE Brasvärme are

committed to Swan marking

our stoves. Choosing to Swan

mark our products is one aspect

of our vision to be a company

of the future with equally high

quality standards regarding the

environment.

Certifcate number 378-001.

Certifierad

Certifikat nr

0112/07

NOTE!

Notify the local building authorities of the new installation

Report installation of a stove to your local authority.

The owner of the house is personally responsible for ensuring

compliance with the mandatory safety requirements and must

have the installation approved by a qualified inspector.

Your local chimney sweep must also be informed about the

installation as this will affect the routines for regular chimneysweeping services.

EU-declaration

of conformity

Product covered by this declaration

Product type Stove fired by fixed fuel

Type designation Handöl 30-series

Type acc. to standard SS-EN 13240

Intended for use Heating of living accomodation

Fuels Wood logs

Special conditions None

Manufacturer

Name NIBE AB/NIBE Brasvärme

Address Box 134, Skulptörvägen 10, SE-285 23 MARKARYD

Place of manufacture Markaryd

Manufacturing check by approved organisation

Name Swedish National Testing and Research Institute AB

Address Box 857, SE-501 15 BORÅS

Report no / date -/-

Niklas Gunnarsson

Business area manager NIBE Stoves

Appendices

4--!('3) )-.''.%*))-.,/.%*)-

HANDÖL

In accordance with standards below

marking was affixed:

European Standard:

SE Quality Certification, P-marked:

NO Standard NS 3059:

DE and AT Standard DIN 18.891 and

Art 15a B-VG:

Type:

Nominal Output:

Fuel:

Minimun draught:

Flue gas temerature:

Energy efficiency:

Emission of CO in cumbustion products:

Distance to cumbustible wall (mm):

Follow the user’s instructions and use only recomended fuel

NIBE AB Box 134 SE-285 23 MARKARYD SWEDEN

2007

EN 13240

Cert no 0112/07

SINTEF 110-0275

RRF-40 07 13 90

Handöl 31/31A/32/32A

5 kW

Wood

12 Pa

280°C

78%

0,14%

Behind 150

Beside 450

Corner 150

HANDÖL

In accordance with standards below

marking was affixed:

European Standard:

SE Quality Certification, P-marked:

NO Standard NS 3059:

DE and AT Standard DIN 18 891

and Art 15a B-VG:

Type:

Nominal Output:

Fuel:

Minimun draught:

Flue gas temerature:

Energy efficiency:

Emission of CO in cumbustion products:

Distance to cumbustible wall (mm):

Follow the user’s instructions and use only recomended fuel

NIBE AB Box 134 SE-285 23 MARKARYD SWEDEN

2007

EN 13240

Cert no 0112/07

SINTEF 110-0275

RRF-40 07 13 90

Handöl 33T

5 kW

Wood

12 Pa

280°C

78%

0,14%

Behind 100

Beside 415

Corner 100

378

001

N

O

R

D

I

C

E

C

O

L

A

B

E

L

Page 3

GB

63

TABLE OF CONTENTS

General 64

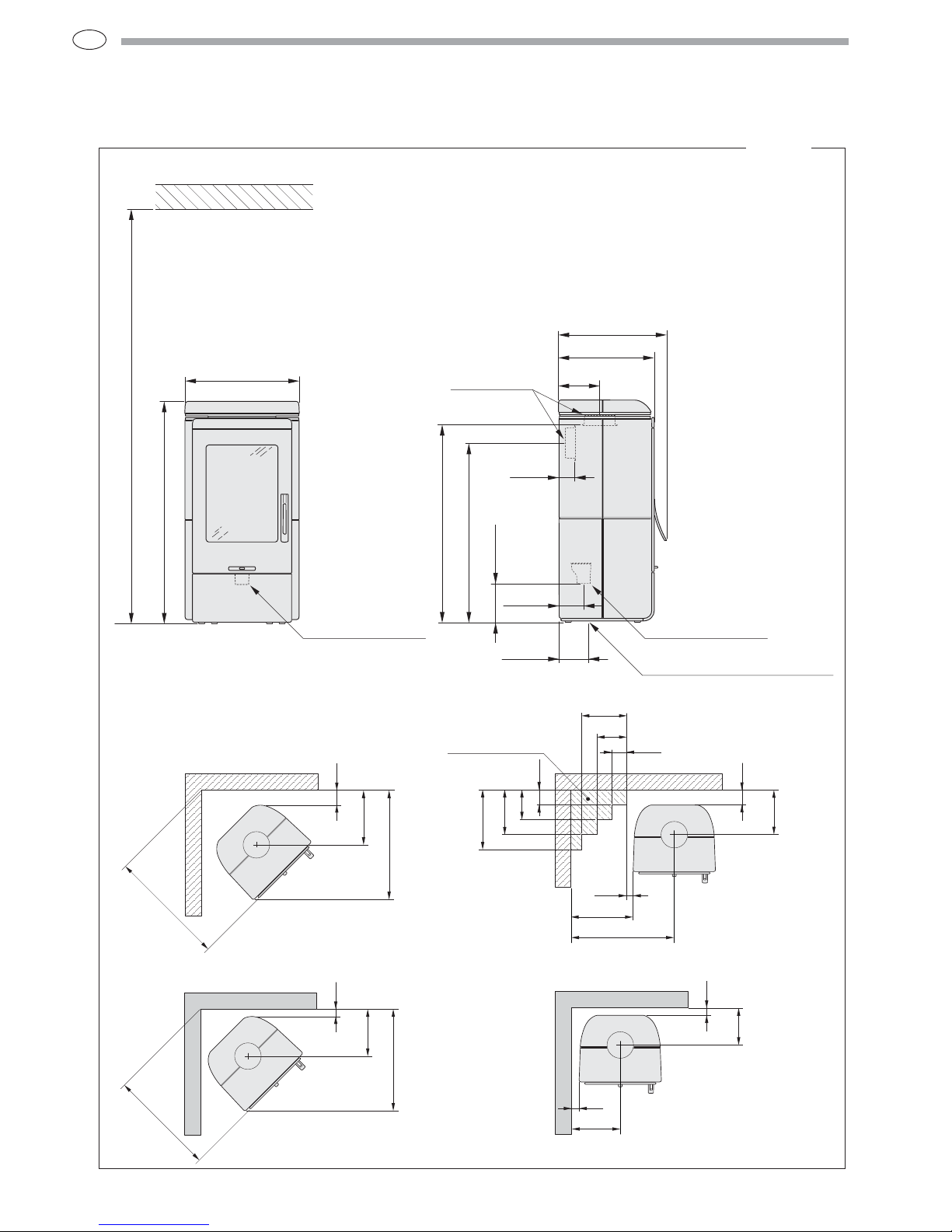

Installation distance to walls and ceiling 65

Supply of combustion air 67

Removing the loose components 68

Connection to the chimney 70

Installing the surround, H31/31A/H32/H32A 72

Installing the surround, H33T 74

Installing accessories · Base 76

Installing accessories · Drawer 77

Installing accessries · Wood compartment 79

DEAR HANDÖL OWNER

We welcome you to the Handöl family and hope that you will

gain much pleasure from your stove. We understand that you

place high demands on both quality and design. As a new

owner of a stove from Handöl you have a stove with timeless

design and a long lifetime.

The stove combustion is also environmentally friendly and

efficient for the best heat production.

Read the installation instructions carefully before you begin

installation and the separate lighting and user instructions

before you light the fire.

WARNING!

The stove becomes very hot when lit

During operation, certain surfaces of the stove

become very hot and can cause burn injury if

touched. Be aware of the strong heat radiated

through the hatch glass. Placing flammable

material closer than the safe distance

indicated may cause a fire. Pyre lighting

can cause quick gas ignition with the risk of

damage to property and personal injury.

Page 4

GB

64

Eldstadsbeklädnad

Rosterreglage

Asklåda

Förbränningsluftsreglage

Brasbegränsare

General

This manual contains

instructions about how

the Handöl 30 series

must be assembled and

installed.

To guarantee the function and safety of the stove we

recommend that it is installed by a professional. Our Handöl

agents can recommend a suitable installer.

Instructions for lighting and use are also supplied with the

stove. Read them carefully and keep them safe for future use.

The stove is type approved and must be connected to a chimney

dimensioned for at least 350°C, the external connection

diameter is Ø150 mm. Supply air from the open air should be

used as combustion air.

Building application

Before installing a stove or erecting a chimney it is necessary

for you to apply for planning permission from your local

authority. Ask your local authority for advice regarding building

regulations and the application.

Structural support

Check that the wood joists are strong enough to bear the weight

of the stove and chimney. The stove and chimney can usually be

placed on a normal wooden joist in a single occupancy house if

the total weight does not exceed 400 kg.

Hearth plate

To protect the floor from any embers the stove must be placed

on a hearth plate. If the floor under the stove is flammable, it

must be protected by a non-flammable material which covers at

least 300 mm to the front and 100 mm on each side.

The hearth plate can consist of natural stone, concrete or 0.7

mm metal. As an accessory, the hearth plate is available in

painted steel.

Chimney

The stove requires a draft in the chimney of at least –12 Pa. The

draught is affected both by the length and area of the chimney,

and by how well sealed it is. Minimum recommended chimney

length is 3.5 m and a suitable cross section area is 150-200 cm²

(140-160 mm in diameter). Carefully check that the chimney is

sealed and that there is no leakage around soot hatches and flue

connections.

Note that a flue with sharp bends and horizontal routing reduces

the draught in the chimney. Maximum horizontal flue is 1 m,

on the condition that the vertical flue length is at least 5 m. It

must be possible to sweep the full length of the flue and the soot

hatches must be easily accessible.

ANVISNING

31 31A 32 32A

33T

installations

I

nstallationsanvisning 2

Installasjonsanvisning xx

I

nstallationsanleitun

g xx

Installation instruction xx

eldnings

instruktion

H

30

Eldningsinstruktion 2

Heizinstruktionen 5

Fyringsinstruksjon 9

Lighting Instructions 13

Fyringsvejledning 17

Instructions d’allumage 21

Lämmity sohjeet 25

Istruzioni per l’accensione 28

Stookinstructies 32

HANDÖL

Technical data

Output 3-7 kW

Nominal output 5 kW

Efficiency level 80%

Model 31 31A 32 32A 33T

Weight (kg) 128 128 128 128 250

Width (mm) 480 480 480 480 550

Depth (mm) 450 450 450 450 460

Height (mm) 1025 1025 1025 1025 1080

The connection’s external diameter is Ø150 mm.

Type approved in accordance with:

European standard EN-13240

Swedish environmental and quality marking,

P-marking cert. no. 0112/07

Norwegian standard NS 3059, SINTEF 110-0275

German standard DIN 18.891, RRF-40 07 13 90

Fire-box surround

Grate shuttle

Ash-pan

Log guard

Air supply control

Type plat e

Page 5

GB

65

480

Tilluftsstos Ø64

1025

2000

Brännbart tak

513

452

189

Tilluftsstos Ø64

Hål i gjuten fotplatta Ø115

A 956

B 865

D 189

C 60

E 103

F 134

Utv. Ø150

392

Brännbar vägg

150

745

817

289

Brännbar vägg

100

450

400

300

100

300

200

100

690

Tillåtet område för

brännbart material

292

Brandmur

50

645

676

239

Brandmur

50*

50

290

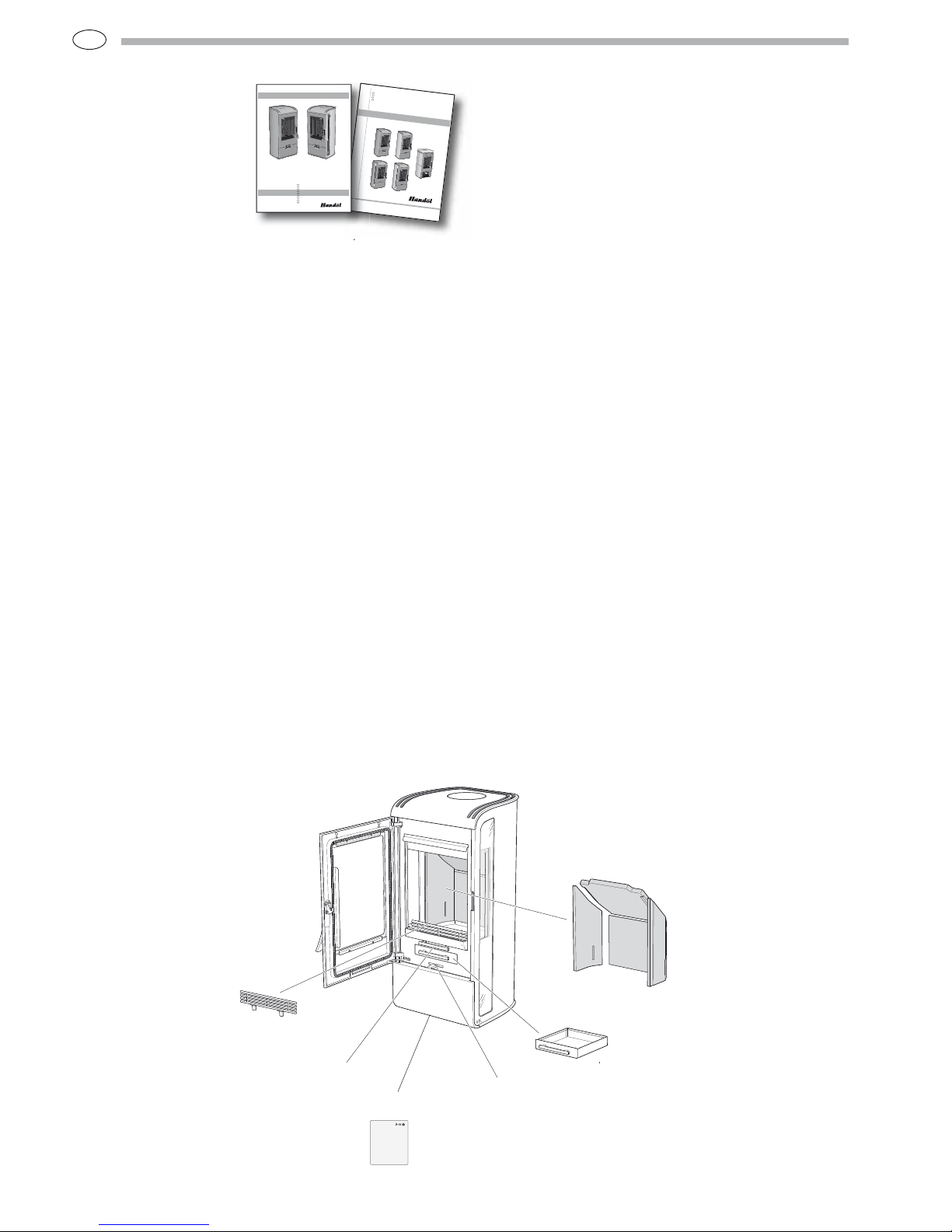

Installation distance to walls and ceiling

Position the stove on a hearth plate and check that the installation distances given

in the diagrams are met. The minimum distance between the stove opening and

combustible parts of the building or décor must be at least 1 m.

When top connecting a steel flue please refer to the relevant manufacturer’s

installation instructions. Observe the safety distances to combustible material that

steel flues require.

H31, H31A och H32 H32A

* To prevent the discolouring of paint ed fire walls, we recommend a side distance the same as for the combustible wall.

A = height from floor to chimney connection

B = height from floor to c /c smoke outlet rear

C = distance from back to smoke outlet rear

D = height from floor to air inlet

E= distance from back to c/ c air inlet

F= distance from back to c /c hole in cast foot plate

Combustible ceiling

Combustible wall

Fire-retardant wall of brick or concrete

Permitted area for

combustible material

.

Combustible wall

Fire-retardant wall of brick or concrete

Air inlet Ø64

Hole in cast foot plate Ø115

Air inlet Ø64

Page 6

GB

66

551

Tilluftsstos Ø64

1073

2000

Brännbart tak

523

462

199

Tilluftsstos Ø64

Hål i gjuten fotplatta Ø120

A 956

B 868

D 189

C 75

E 117

F 141

Utv. Ø150

366

Brännbar vägg

100

732

781

289

Brännbar vägg

100

415

43

300

200

100

300

400

200

100

690

Tillåtet område för

brännbart material

248

Brandmur

50*

50

326

316

Brandmur

50*

682

710

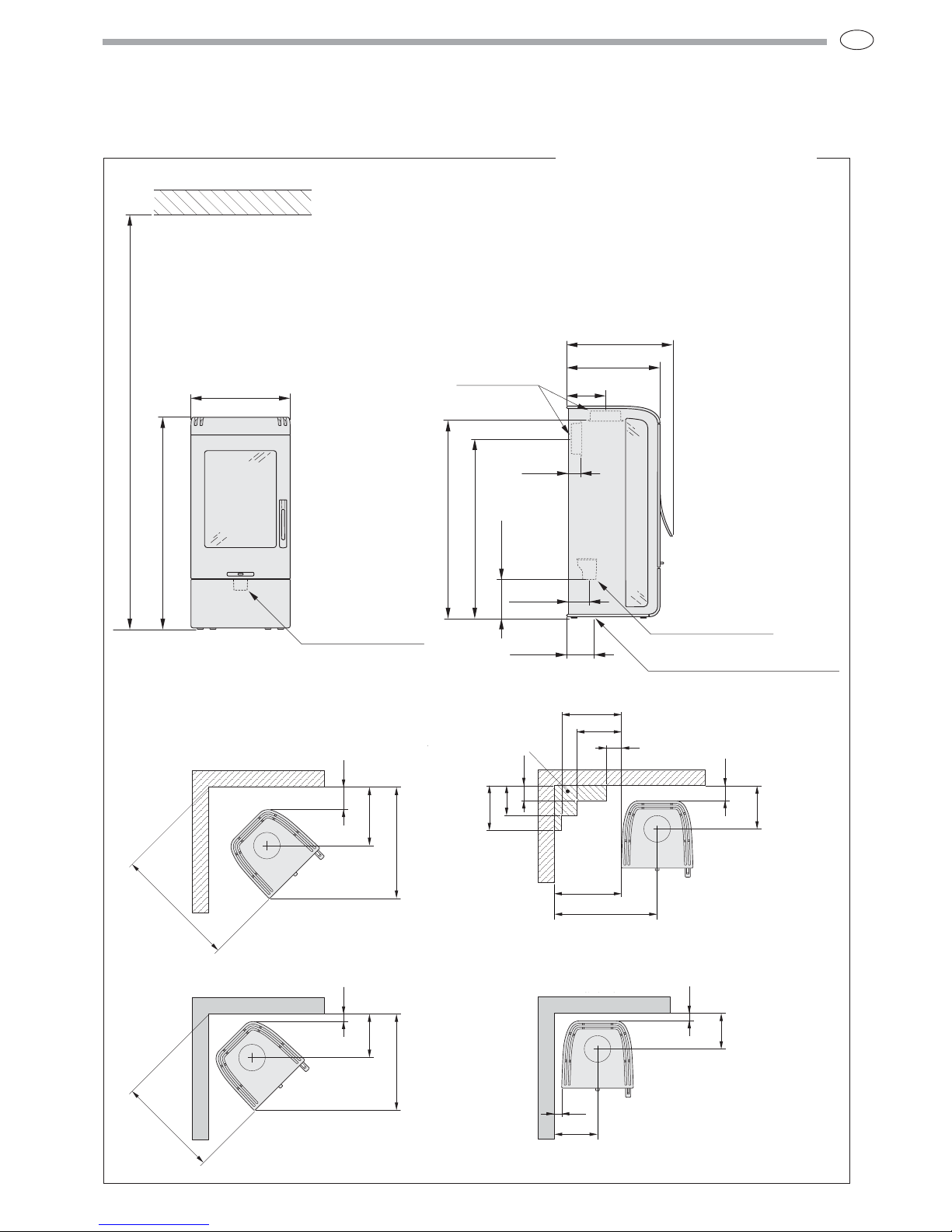

Installation distance to walls and ceiling

Position the stove on a hearth plate and check that the installation distances

given in the diagrams are met. The minimum distance between the stove

opening and combustible parts of the building or décor must be at least 1 m.

When top connecting a steel flue please refer to the relevant manufacturer’s

installation instructions. Observe the safety distances to combustible material

that steel flues require.

* To prevent the discolouring of paint ed fire walls, we recommend a side distance the same as for the combustible wall.

Permitted area for

combustible material.

Combustible wall

Fire-retardant wall of brick or concrete

Combustible wall

Fire-retardant wall of brick or concrete

H33T

A = height from floor to chimney connection

B = height from floor to c /c smoke outlet rear

C = distance from back to smoke outlet rear

D = height from floor to air inlet

E= distance from back to c/ c air inlet

F= distance from back to c /c hole in cast foot plate

Combustible ceiling

Air inlet Ø64

Hole in cast foot plate Ø120

Air inlet Ø64

Page 7

GB

67

Supply of

combustion air

Combustion air can be provided directly via a duct

from outside, or indirectly via a vent in the outer

wall of the room where the stove is to be placed.

The amount of combustion air used for combustion

is approximately 25 m

3

/h.

Some installation alternatives are shown to the

right. .

The air duct connection on the stove has an

external diameter of Ø64 mm.

In hot areas the duct should be insulated with 30

mm mineral wool covered with a moisture inhibitor

(plastic). It is important that the lead-in between

the pipe and the wall (or floor) is sealed using

jointing compound. When duct routing for further

than 1 m the pipe diameter must be increased to

100 mm and a correspondingly larger wall vent

must be selected.

A 1 m length of condensation insulated ducting for

combustion air is available as an accessory.

HK

HK

HK

HK

30 mm

Knock out

To insert the combustion air hose, tap out the

knockout from the back panel and leg using a

hammer, remember to protect the floor.

Page 8

GB

68

Removing the loose components

Unpacking

Before the stove is used, it must be inspected by an

authorised chimney sweep.

Read the Instructions for Lighting the Handöl 30 series

before lighting the fire for the first time.

Sweeping

When sweeping, the smoke baffle must be

lifted out, on the Handöl 30 series this can be

done by lifting the smoke baffle and removing

the side piece. Lift the smoke baffle out and

remove the remaining sections. Handle the

parts with care.

Page 9

GB

69

Heat deflector

The heat deflector is removed by lifting the front

edge and then pulling it out slightly. Lower it

so that it is below the insert and then withdraw

it. Assembly takes place in the reverse order.

Ensure that the rear lugs are secured in the slits

on the upper leg as illustrated above.

Self-closing hatch

The stove has a spring to close the hatch automatically.

The spring is above the heat deflector. The closing force

of the hatch can be adjusted by moving the spring between

the three notches on the lever. After adjustment, the heat

deflector must be reinstalled. The angle of the stove also

affects the closing force of the spring.

If the spring force seems weak

despite the spring being mounted at

the end of the lever, the angle of the

stove should be checked.

Type plates

Two type plates are supplied with

the stove. One for the insert and

one for the surround kit.

Place these plates on the lower

heat deflector as illustrated. On

the model with the drawer, the

type plates can be mounted inside

the drawer.

Page 10

GB

70

Refer to the chimney installation instructions. The

following describes how the chimney system is

connected to the stove.

The stove body is prepared for top connection on delivery.

When connecting from the rear, the cover and connection

must be swapped around.

Top connection to the chimney

When connecting to the top, the whole stove surround must

be installed before installation of the chimney can begin.

Installation of the surrounds for the respective models is

described later on in these installation instructions.

The start pipe is placed over the connection on the insert.

Make sure that the gasket on the connection is intact and

in position. The stop washer is positioned over the collar on

the start pipe. Remove the small securing plate from the cuff

and thread the cuff over the stop washer. The cuff must rest

against the top of the stove. Then install the remaining parts

of the chimney and finally lock the cuff using the securing

plate. The cuff covers the lower section of the start pipe and

facilitates any service work.

Connection to the chimney

It is important that the cast top is installed on the stove before the

chimney is installed.

Cuff lock

Chimney mantle

Cuff

Stop washer

Start pipe

1

2

Page 11

GB

71

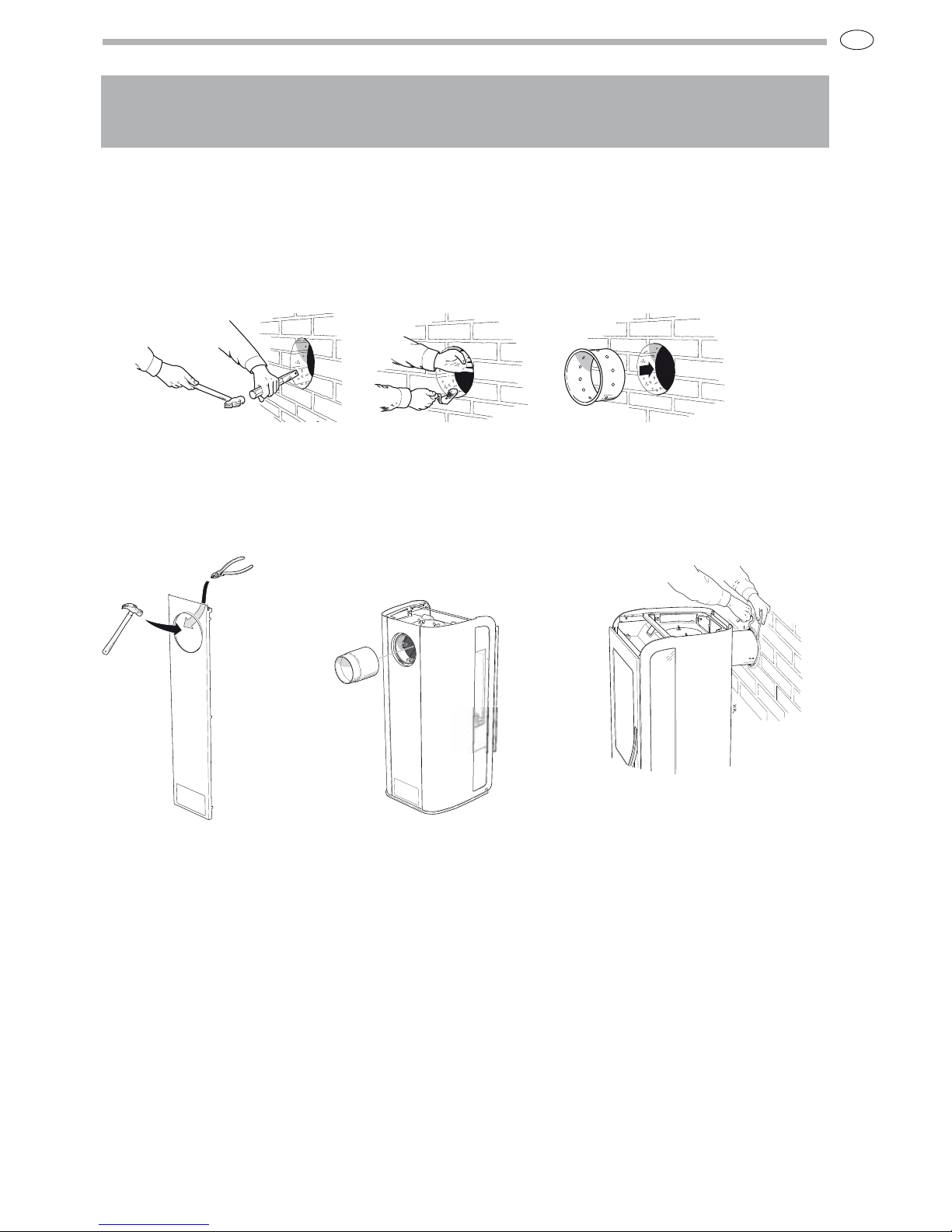

Cut a hole approximately 180 mm in

diameter.

Then cement in a wall connector with

fire proof mortar (not supplied).

Let the mortar dry before the stove is

connected to the chimney.

Tap out the knock out in the

rear panel using a hammer and

cut the heat deflector on the

rear side of the back panel

LEK

LEK

Mount the back plate and install

the connection pipe on the

connection.

Make sure that the gasket does

not work loose from its position.

Installation of the surrounds

for the respective models is

described later on in these

installation instructions.

Seal between the connection

pipe and the connector in the

wall using fire rope. If further

sealing material is required, heatresistant sealant may be used.

Connection to the chimney

Rear connection to a masonry chimney

Mark out the centre for making a hole in the wall to the

flue. Check that the connection height in the chimney breast

corresponds to the height of the connection pipe from the stove.

Page 12

GB

72

Installing the surround

Handöl 31/31A

Handöl 32/32A

s 5NPACKTHESURROUNDKITANDTOPFROMTHE

packaging.

s 2EADTHROUGHTHEENTIRESECTIONREGARDING

installation of the surround. Satisfy yourself that

no components are missing or were defective on

delivery. Handle the parts with care.

s /NTHE(ANDÚL!THEGLASSONBOTHTHE

insert and the surround must be cleaned before

installation.

s 0LACETHESTOVEONTHEHEARTHPLATEANDCHECKTHE

installation distances.

Place these side plates on the lugs in the cast iron

foot as illustrated. Hold the plates so that they do

not tip and become damaged.

Aluminium model

Important: Remove the

protective plastic from along

the rear bent edge before

installing the rear panel.

Remove the protective plastic

once the stove has been

assembled. It is important

to remove all the protective

plastic. Ensure that your hands

are clean to avoid leaving marks on the aluminium sides.

Cleaning

Cleaning must always be carried out with care and on cold panels.

Wipe with a damp cloth and dishwashing detergent and wipe dry

using a clean and dry cotton cloth. For tougher marks, stainless

steel cleaning agent can be used.

Control the top frame as illustrated to fix the sides.

1 2

Page 13

GB

73

Screw the top frame into place on the body

2 1

Place the back panel on the cast feet lugs and carefully

raise the top frame so that the sides do not fall. Guide

in the back panel so that the lugs fix in the side panel

slits

Take out the valence and bend down the small tabs using

pliers so that they fit in the grooves in the top frame.

Place the cast iron top and cover in position.

Check that the top is in line with the sides and door.

4

3

5 6

Page 14

GB

74

Installing the surround

Handöl 33T

s 5NPACKTHESURROUNDKITANDSOAPSTONEKITFROMTHE

packaging.

s 2EADTHROUGHTHEWHOLESECTIONREGARDINGINSTALLINGTHE

surround. Satisfy yourself that no components are missing

or were defective on delivery. Handle the soapstone with

care. In particular sharp edges are vulnerable to knocks.

s 0LACETHESTOVEONTHEHEARTHPLATEANDCHECKTHE

installation distances.

1

2

Place the soapstone holders and back plate in the lugs on the

cast iron foot and attach them to the top frame.

Important! If the stove is to be rear connected

this must be done before the soapstones are hung

in position. If the stove is to be top connected this

must be carried out before the whole surround is

installed.

Apply beads of silicone to the edge between the profiles

and the support plates. Carefully hang the two lower

stones in place. Note that the lower stones have a

rounded edge which is turned downwards unlike the

upper stones which have bevelled edges both upwards

and downwards.

Page 15

GB

75

4

3

5

6

Apply beads of silicone to the edge of the profiles and the

lowest stones. Also apply a blob, near the inside, over the

joint between the lower stones. Hang the upper stones in

position and apply silicone to the edge of the profiles.

Adjust the soapstone panels to each other, door and back.

Screw the top frame into place. Start with the front screws.

Screw the door extension into the door. Leave a 2 mm

gap between the door extension and the door. Slide

down the valence inside the front of the body and

allow the tabs to clamp against the sides of the body.

Apply six small blobs of silicone to each side of the

soapstone sides. Position the top discs and apply eight

small blobs of silicone to the upper side. Then place the

two-piece soapstone top on top of the top discs. Depending

on whether the stove has a rear connection or top

connection, a cover panel or cover ring is used.

Page 16

GB

76

Installing accessories · Base

Base

Take out the components.

When installing the base,

the lower knockout in the

back panel must always be

removed for the supply of

convection air.

Press the front into the snap

fasteners as illustrated.

Position the left hand section

under the stove and screw it into

place as illustrated.

Carry out the equivalent on the

right hand side

1

2

Page 17

GB

77

Drawer

Take out the components.

Installing accessories · Drawer

Remove the front plastic screws in the drawer

rails and discard them. Insert the screws in the

hole of the rail as illustrated. The second screw

is inserted in the rear section. Hold the rail as

far out as possible and angle the front section

downwards whilst you tighten the screws.

When installing the

drawer, the lower

knockout in the back

panel must always be

removed for the supply of

convection air.

1

Page 18

GB

78

Installing accessories · Drawer

Align the drawer mounting as illustrated so that the

drawer mounting notches come under the drawer rail

lugs.

Screw the drawer mounting into place at the front end

using the star screws as illustrated.

Install the drawer on the pull-out unit using the four Allen

screws. Adjust the drawer so that it is centrally positioned in

relation to the hatch and then tighten the screws.

Screw the drawer into place in the cast iron front using

the Allen screws.

2

3

4

5

Page 19

GB

79

Wood compartment

Take out the components.

Installing accessories · Wood compartment

Screw the mounting plate to the cast iron

parts with the Allen screws supplied.

Attach the cast iron component as illustrated

and insert it under the stove. Adjust the pieces

with the Allen screws so that they are in line

with the hatch.

1 2

Page 20

GB

80

IAV SE-EX 0811-4 511941

NIBE AB/ NIBE BRASVÄRME · Box 134 · 285 23 Markaryd

www.handol.eu

Nibe Brasvärme reserves the right to change colours,

materials, dimensions and models at any time without

special notice. Your dealer can provide you with the

latest information.

Loading...

Loading...