Page 1

Quick Check® 600/800 Series

Bar Code Verifiers

™

User’s Guide

Page 2

Disclaimer

Hand Held Products, Inc. (“Hand Held Products”) reserves the right to make

changes in specifications and other information contained in this document

without prior notice, and the reader should in all cases consult Hand Held

Products to determine whether any such changes have been made. The

information in this publication does not represent a commitment on the part of

Hand Held Products.

Hand Held Products shall not be liable for technical or editorial errors or

omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright. All

rights are reserved. No part of this document may be photocopied, reproduced,

or translated into another language without the prior written consent of Hand

Held Products.

© 2001-2007 Hand Held Products, Inc. All rights reserved.

Web Address: www.handheld.com

For European Community Users

Hand Held Products complies with Directive 2002/69/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL of 27 January 2003 on waste electrical

and electronic equipment (WEEE).

Waste Electrical and Electronic Equipment Information

This product has required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health and

the environment, if not properly disposed.

In order to avoid the dissemination of those substances in our environment and

to diminish the pressure on the natural resources, we encourage you to use the

appropriate take-back systems for product disposal. Those systems will reuse or

recycle most of the materials of the product you are disposing in a sound way.

The crossed out wheeled bin symbol informs you that the product should

not be disposed of along with municipal waste and invites you to use the

appropriate separate take-back systems for product disposal.

If you need more information on the collection, reuse, and recycling systems,

please contact your local or regional waste administration.

You may also contact your supplier for more information on the environmental

performances of this product.

Page 3

Table of Contents

Chapter 1 - Getting Started

About This Guide ................................................................. 1-1

Unpacking the Quick Check 600/800 Verifier ..................... 1-2

Noting the Verifier’s Features........................................ 1-3

Specifications........................................................................ 1-7

Installing the Batteries .......................................................... 1-7

Charging the Batteries.................................................... 1-8

Turning the Unit On and Off.......................................... 1-9

Calibrating the Quick Check 600/800 Verifier ............ 1-12

Properly Scanning With the Unit ................................. 1-13

Cleaning the Wand....................................................... 1-14

Accessories and Options .............................................. 1-14

Chapter 2 - Quick Start Guide

Chapter 3 - Changing the Settings

Changing the Specifications ................................................. 3-1

Symbologies................................................................... 3-2

Symbology Specifications.............................................. 3-3

Magnification Factor...................................................... 3-4

Expand U.P.C./EO ......................................................... 3-4

Check Options................................................................ 3-4

Modes Shown................................................................. 3-4

Character Font & Tolerances ......................................... 3-5

Wide-to-Narrow Ratio ................................................... 3-6

Fixed Message Length ................................................... 3-6

Industry Applications ..................................................... 3-7

Changing the Test Criteria.................................................... 3-8

Scan Grade ..................................................................... 3-8

Decodability ................................................................... 3-9

ISO/IEC grades .............................................................. 3-9

Number of Scans ............................................................ 3-9

i

Page 4

Changing the Scanning Options ......................................... 3-10

Beeper Pitch ................................................................. 3-11

Extended Accuracy ...................................................... 3-11

Decode Direction ......................................................... 3-11

Changing the Output Options ............................................. 3-12

Display Options............................................................ 3-12

Parameter Result Lines ................................................ 3-12

Print Options ................................................................ 3-13

AutoPrint/Store ............................................................ 3-13

Scan Profile .................................................................. 3-14

Resetting the Default Settings ............................................ 3-15

Locking the Settings ........................................................... 3-15

Using a Command Code..................................................... 3-16

About Command Codes ............................................... 3-16

Choosing a Command Code......................................... 3-18

Customized Command Codes...................................... 3-18

Chapter 4 - Reviewing Scan Data

Reviewing Scan Results ....................................................... 4-1

Scan Grades .......................................................................... 4-1

ISO/IEC Symbol Grade.................................................. 4-2

Reviewing a Scan Example .................................................. 4-5

LED Display ......................................................................... 4-7

Audio Sounds........................................................................ 4-8

Reviewing the Dimensional Parameters............................... 4-9

Errors in Dimensional Parameters ................................. 4-9

Calculating X ............................................................... 4-10

Reviewing the Reflectance Parameters .............................. 4-11

Errors in Reflectance Parameters ................................ 4-12

Reviewing the Format Parameters...................................... 4-14

Errors in Format Parameters ........................................ 4-14

Reviewing Messages.................................................... 4-15

Using SSTR Codes to Review Data............................. 4-16

Using the Quick Check Verifier as a Reflectometer .......... 4-17

ii

Page 5

Chapter 5 - Saving and Printing

Saving Data........................................................................... 5-1

Checking the Print Buffer During Operation........................ 5-1

Printing Data ......................................................................... 5-2

Deleting Stored Data............................................................. 5-3

Interfacing With a Computer.......................................... 5-4

Reviewing the Printouts ................................................. 5-4

Printing Guidelines ............................................................... 5-6

Using the QCP or QCHSP.............................................. 5-6

Troubleshooting the QCP or QCHSP........................... 5-11

Chapter 6 - Background Information

General Bar Code Information.............................................. 6-1

Symbology Specifications .................................................... 6-2

Symbologies ................................................................... 6-2

Symbology Characteristics ................................................... 6-4

How a Bar Code Verifier Works .......................................... 6-6

Additional Information ......................................................... 6-7

Chapter 7 - Using DataMatch

Understanding the DataMatch Feature ................................. 7-1

Downloading DataMatch ...................................................... 7-1

Structuring and Loading the Database.................................. 7-1

Selecting the DataMatch Feature .......................................... 7-4

Reviewing DataMatch Results.............................................. 7-5

Chapter 8 - Using a Quick Check 800 Verifier

Using the Quick Check 800 Verifier with a QC3800V Linear

Imager ................................................................................ 8-1

General Operation .......................................................... 8-1

Reflectance-Based Information...................................... 8-2

ScanProfile Output ......................................................... 8-2

Percent Decoded/Scanned Mode.................................... 8-2

iii

Page 6

Chapter 9 - Error, Application, and Type Messages

Chapter 10 - Flow Charts

Chapter 11 - SSTR Codes

Chapter 12 - Special Codes

Chapter 13 - Unrecognized Symbols

Unrecognized Symbols....................................................... 13-1

Chapter 14 - Customer Support

Troubleshooting.................................................................. 14-1

Technical Assistance .......................................................... 14-1

Online Technical Assistance............................................... 14-2

For Further Information...................................................... 14-2

Product Service and Repair ................................................ 14-2

Online Product Service and Repair Assistance .................. 14-3

Limited Warranty................................................................ 14-3

iv

Page 7

1

Getting Started

About This Guide

This manual contains information on the Quick Check® 600/800 Series Bar

Code Verifiers. It describes all the features and functions of the Quick Check

600/800 Verifier and all the industry applications that can be enabled on the

Quick Check 600/800 Verifier. Your particular Quick Check Verifier may have

fewer applications.

This manual is organized into the following chapters:

Chapter 1 Getting Started

Chapter 2 Quick Start Guide

Chapter 3 Changing the Settings

Chapter 4 Reviewing Scan Data

Chapter 5 Saving and Printing

Chapter 6 Background Information

Chapter 7 Using DataMatch

Chapter 8 Using a Quick Check 800 Verifier

(Specific to the Quick Check 800 Verifier

Chapter 9 Error, Application, and Type Messages

Chapter 10 Flow Charts

Chapter 11 SSTR Codes

Chapter 12 Special Codes

Chapter 13 Unrecognized Symbols

Chapter 14 Customer Support

only

)

Quick Check® 600/800 Series User’s Guide 1 - 1

Page 8

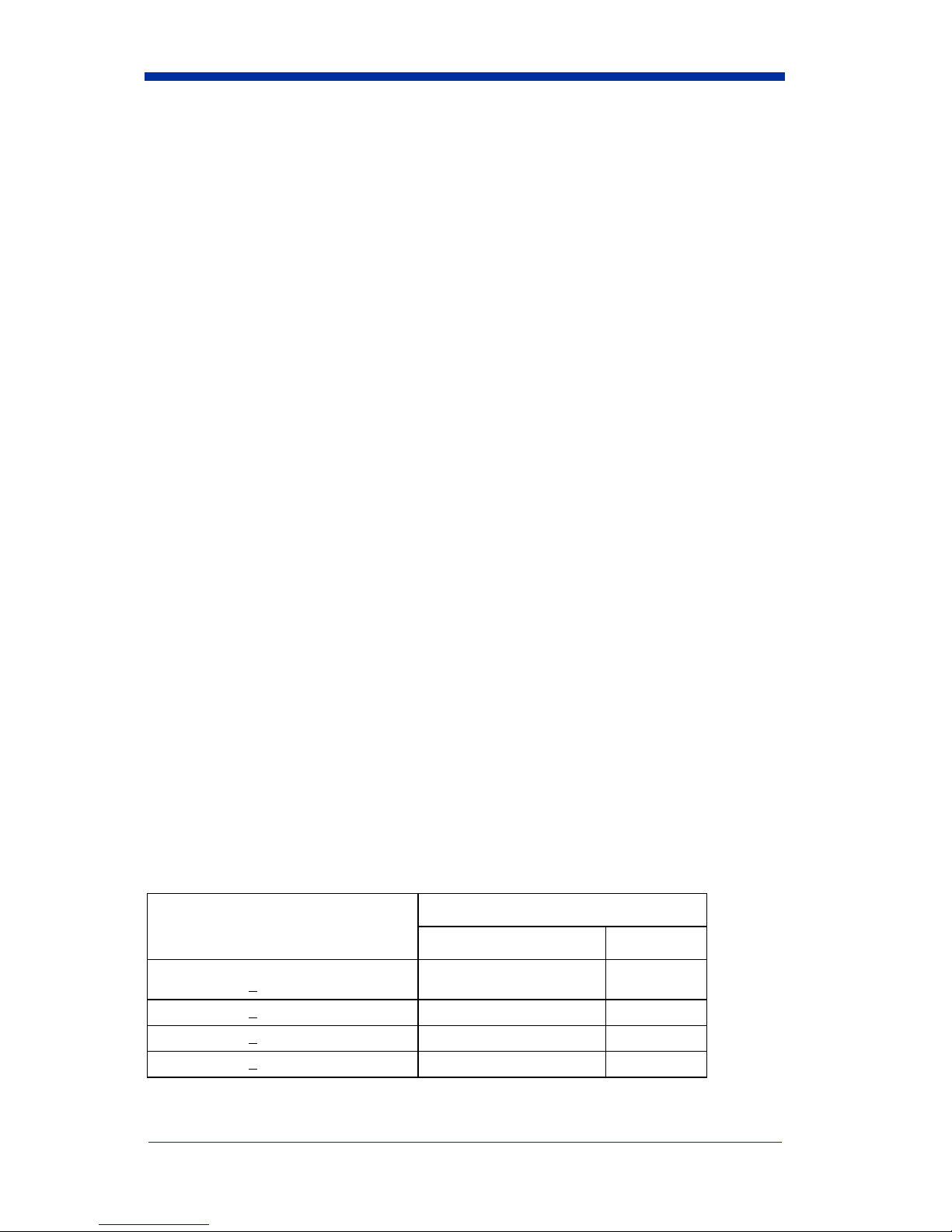

This manual uses several special symbols to refer to the controls on the

instrument. The following table shows the symbols and their descriptions.

Symbol Description

POWER or SELECT

or ↑, ↓, ←, →

Scan or Low Battery

♦

Some terms used in this manual may differ slightly from the terms used in the

Quick Check Verifier software menus due to space restrictions. The following

table shows these terms.

Term in manual Term in software

W/N WN

U.P.C.

(Universal Product Code)

Represents a button on the Quick Check

Verifier unit

Shows the LED display on the Quick Check

unit

Indicates steps to follow to perform a

procedure

UPC

Unpacking the Quick Check 600/800 Verifier

When you first receive your Quick Check 600/800 Verifier, you should unpack it

carefully. Before attempting to use the instrument, inspect the contents of the

package for any shipping damage. If there is evidence of damage, please keep

all packing materials and contact the delivery carrier as soon as possible for

claim procedure.

Confirm that you have the following items:

• Quick Check 600/800 Verifier

• Wand scanner (specific to the QC600 series)

• Linear Imager (specific to the QC800 series)

• AC Charger

• Four “AA” NiCad batteries

• Quick Check 600/800 Verifier User’s Guide

(this publication)

• Manual Package containing:

Test Symbols

Warranty Card

Gauge Ruler

1 - 2 Quick Check® 600/800 Series User’s Guide

Page 9

“X” Dimension Ruler

QCRFPG Calibration Reflectance Bar Code Page

If you do not have all these items, contact your sales representative.

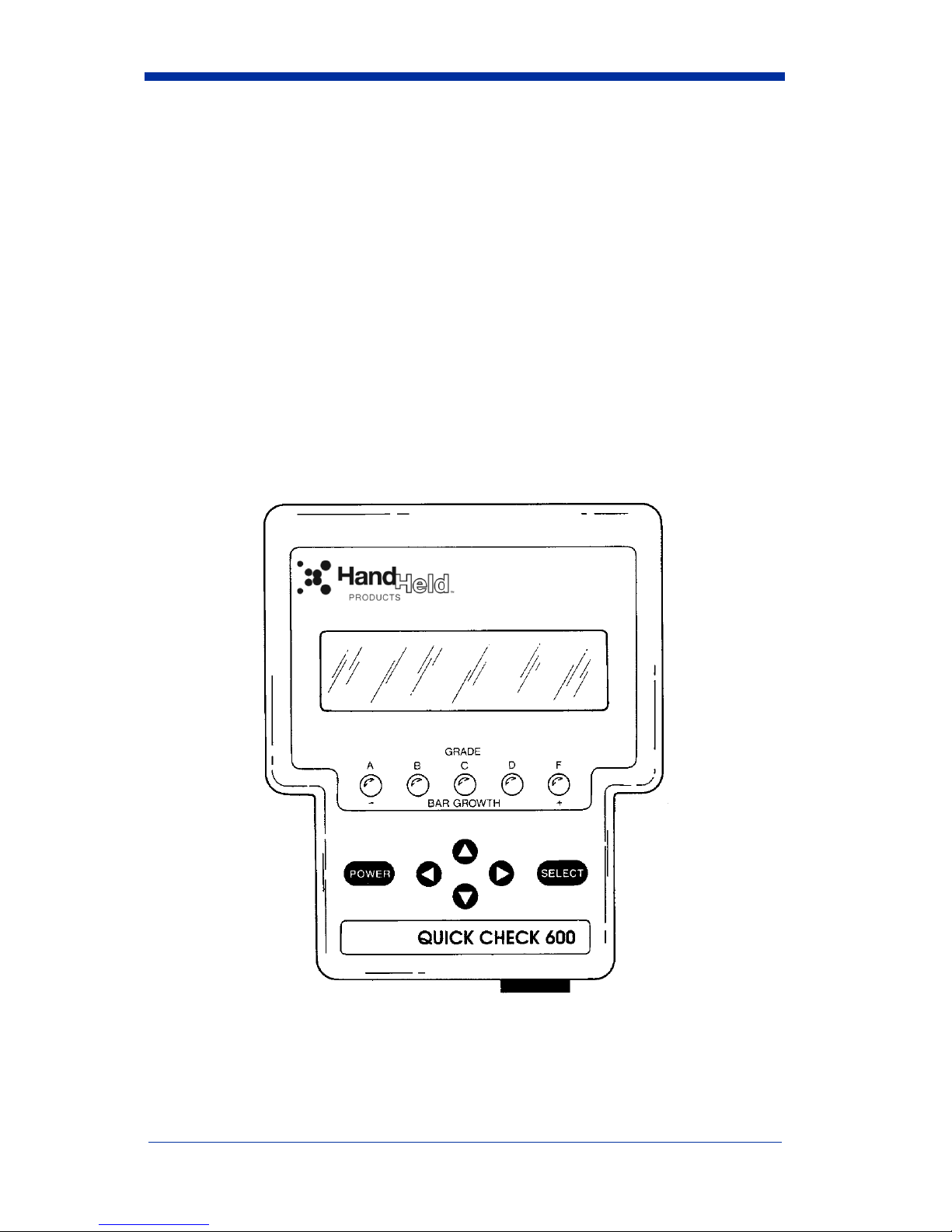

Noting the Verifier’s Features

The Quick Check 600/800 Verifier is a full-featured bar code verifier compatible

with all major linear bar code symbologies. It is suitable for desktop use in the

office and is easily carried for portable verification in the field. It is both a quick

and easy to use pass/fail tester for bar code symbols and a powerful measuring

tool for detailed testing of these same symbols.

All the information you need to interpret overall symbol quality is available. The

Quick Check 600/800 Verifier unit is housed in a compact and lightweight impact

resistant case.

Quick Check® 600/800 Series User’s Guide 1 - 3

Quick Check 600/800 Verifier

Page 10

The symbologies tested by the verifier include

•EAN/UPC

• Code 39

• Interleaved 2 of 5

• Code 128

• Code 93

• Codabar

• Code 11

• Code 16K

• Code 49

•MSI

•IATA 2 of 5

• Interleaved 2 of 5

Each model of the Quick Check 600/800 Verifier is capable of testing either all,

none, or different sets of industry applications. If you are not sure which

applications are available on your unit, refer to "Changing the Specifications" on

page 3-1 of this manual to display a list of available applications. Industry

standard symbols (applications) tested by the Quick Check 600/800 Verifier

include:

•AIAG

• CTIA/ABCD

• LOGMARS

•HIBC

• CCBBA

•SISAC

•SCC

• BOOKLAND

• Coupon Code

The Quick Check 600/800 Verifier provides the following types of scan data:

• Type of symbology verified

• ISO/IEC and traditional print quality results

• Uniformity in bar guard size (UPC)

• Data string identifiers

• Application identifiers

• Function characters

• Data check characters

• Bar/Space dimensional indication and measurement

• Wide/Narrow ratio measurement

• Character format verification

• Quiet zone tests

• With a printer, hardcopy results and ISO/IEC scan profiles

•Profile

1 - 4 Quick Check® 600/800 Series User’s Guide

Page 11

You can customize the settings for specifications, test criteria, scanning options,

and output options to your preferences. These options are described in

3, Changing the Settings

.

Chapter

Display

The liquid crystal display (LCD) provides four lines of text, each with up to 20

characters per line. The four lines allow you to quickly and easily review a large

amount of scan data and view a variety of options. Some text, such as the word

“SCAN,” is displayed in a larger size for easier reading. Each scan grade and

the resulting ISO/IEC symbol grade appear in a large letter or number on the right

of the display.

While the scan and symbol grade look the same, the difference is clear. The

second line of a symbol grade display states it is a symbol grade, either running

or final. For additional information, refer to

Chapter 4, Reviewing Scan Data

LEDs

If you set the verifier to evaluate symbols using traditional methods, the lightemitting diodes (LEDs) indicate bar growth and shrinkage. If you set the verifier

to use ISO/IEC evaluation criteria, the LEDs display the ISO/IEC grade. For your

convenience, the display option feature called LEDs allows you to select ISO/IEC

test criteria, yet have the LEDs display bar growth rather than pass or fail. See

"Changing the Output Options" on page 3-12 for additional information.

Buttons

You can review the software selections using the four arrow buttons (↓,↑,←,→)

and the SELECT button. The arrows allow you to move the on-screen cursor. If

the scan data length exceeds the display length, a right-hand arrow appears as

the right character of the display. Press → to review the additional data and then

press ← to restore the original display.

Audio Sound

An audio signal gives you a quick indication if a scan passes or fails the current

test. You can change the pitch/volume of these beeps. After a scan, one beep

indicates that the symbol passes an appropriate battery of tests, while three

beeps indicate that it fails in some regard.

Special Features

In addition, the Quick Check 600/800 Verifier has a database feature. You can

connect the verifier to your computer and download a database into the verifier.

While scanning, the verifier can provide additional information about the scanned

code; for example, the name of the product. More information about the

database feature is provided in

Chapter 7, Using DataMatch

.

Quick Check® 600/800 Series User’s Guide 1 - 5

Page 12

The Quick Check 600/800 Verifier also supports two customized operational

modes: Reflectometer mode and Command Code function. In the Reflectometer

mode, the unit operates as a free-running reflectometer. "Using the Quick Check

Verifier as a Reflectometer" on page 4-17 contains information about

reflectometer mode. The Command Code is a specially structured bar code

symbol that offers a unique way for you to quickly program the settings.

3, Changing the Settings

manual contains separate and versatile bar code menus to Single-Scan-toResult (SSTR) Codes or to customize the unit (Command Code).

, contains instructions on changing the settings. This

Chapter

Ports

The ports on the back of the unit connect to a recharging unit or to a printer

interface cable. The smaller port is for charging the unit. The larger port

connects to RS-232 serial communication devices, such as Hand Held Products’

QCPand QCHSPprinters.

The port on the front of the unit connects to the pen or mouse wand scanner. A

wand scanner holder, on the back of the unit, secures the wand when it is not in

use.

1 - 6 Quick Check® 600/800 Series User’s Guide

Page 13

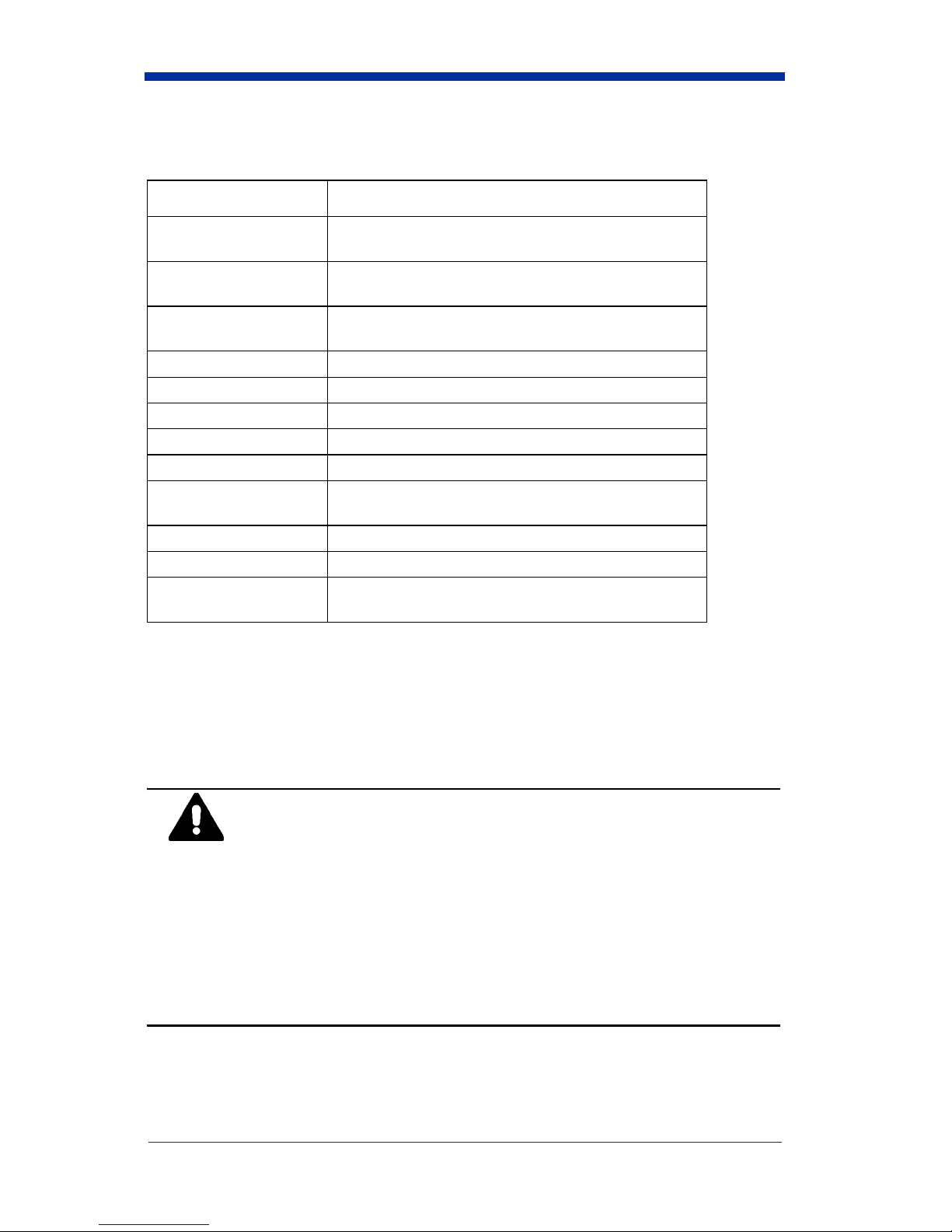

Specifications

Item Specification

Dimensions

Weight

Temperature

Humidity 5% to 95% RH non condensing

Sealability Designed to meet NEMA 1

Regulatory approvals FCC - Class A limits

Display 4 x 20 characters/line LCD

Keypad 6-button: POWER, SELECT, ↑, ↓, ←, →

Audible signal

LED indicators Five tri-colored LEDs

Batteries Four “AA” NiCad

Data Buffer

4.30”W x 2.75”H x 5.25”D

(10.9 cm W x 7.0 cm H x 13.3 cm D)

1.0 lb. (454 g) with wand attached and batteries

installed

Storage: -20° to 70°C

Operational: 0° to 50°C

Volume/tone adjustable beeper

(includes volume off position)

32 KB; the onboard memory can store data and scan

profiles.

Installing the Batteries

The Quick Check 600/800 Verifier is shipped with four “AA” NiCad rechargeable

batteries. You must install the batteries in the unit before you use it. The

batteries may be discharged and need to be charged.

You must install the four NiCad rechargeable batteries in the

Quick Check 600/800 Verifier before you connect the charger or

WARNING

the printer to the unit. If you do not install the batteries first, you

may damage the unit and consequently void the warranty. Use

only the supplied batteries. If you use other types of batteries

(such as alkaline) and attempt to recharge them, you could

cause the batteries to explode, damage the unit, and possibly

cause a personal injury. Damage caused by attempts to

recharge any batteries, except those supplied with the unit, voids

any and all Quick Check 600/800 Verifier warranties.

Quick Check® 600/800 Series User’s Guide 1 - 7

Page 14

♦ To Install the Batteries

1. Slide off the battery cover on the bottom of the unit.

2. Insert the four batteries into the compartment, matching the “+” on the

battery ends with the “+” on the bottom of the compartment, and press each

battery into place.

3. Slide the battery cover back in place.

Charging the Batteries

The Quick Check 600/800 Verifier uses rechargeable batteries. An AC charger

is supplied to recharge these batteries. The Quick Check 600/800 Verifier is

intended to be powered from the batteries, not directly from an adapter or AC

outlet. With a set of properly charged batteries, the unit operates continuously

for a minimum of 1.5 hours. When not in use, you can leave the unit connected

to the charger. To extend the battery life, battery manufacturers recommend you

fully charge the unit, use it until the batteries are

fully charge the batteries.

A Low Battery message on the bottom line of the opening display may appear

when you power up your Quick Check 600/800 Verifier or during use. When this

message appears, you cannot scan bar code symbols, but you can perform other

operations, such as changing the settings. If you turn the unit off and then on

again, the Low Battery message may disappear momentarily, but reappears

when the batteries are discharged more.

completely

discharged, and then

Low Battery message appears before the battery is completely

The

discharged to preserve proper unit operation. However, this message may

appear for a variety of other reasons including variations in battery power,

temperature, component efficiency, or rapid cycle time. If your battery has not

lasted for a continuous hour and a half of operation, and you suspect a low

not

battery is

the message reappears immediately on power up, the batteries are discharged

and you should recharge the unit. If the message does not reappear, you can

continue to use the unit. If you think there is a problem with your batteries,

contact Hand Held Products.

the cause for the message, turn the unit off and then on again. If

♦ To charge the batteries:

1. Turn off the verifier.

2. Plug the AC charger into the port on the back of the unit.

3. Plug the AC charger into a VAC wall outlet.

4. The batteries start charging. If you have completely discharged the

batteries, charge them for a minimum of 12 hours. If the batteries are

partially discharged, charge them for less time.

5. After charging, remove the AC charger from the unit. The verifier is ready for

use.

1 - 8 Quick Check® 600/800 Series User’s Guide

Page 15

Turning the Unit On and Off

When you turn on the verifier, it contains the settings stored from the last time

you changed them.

Chapter 3, Changing the Settings

describes these settings

and provides instructions for changing them.

The verifier shuts itself off after a minute of inactivity to conserve battery power.

You can also turn the unit off at any time. When you turn off the unit, the setting

options you selected are automatically saved. There is no need for a separate

save command.

Insert the wand scanner into the port on the front of the unit.

♦ To turn on the unit:

1. Press the POWER button.

The unit emits four quick beeps and displays the opening screen. The upper

lines of the opening display show the Quick Check 600/800 Verifier model

number. The bottom line of the opening display provides a variety of

information. If the bottom line of the opening display states:

Low Battery, then charge the batteries as described previously.

•

Recalibrate, then calibrate the unit as described later in this

•

chapter.

• Other information as described below. Review it and then scan a bar

code symbol.

• If the unit was set to verify an industry application (rather than

symbologies) before being turned off, the bottom line of the opening

display shows the name of the application that was in use.

If the unit was set to verify symbologies before being turned off, the bottom

line shows the spectral response of the wand scanner connected to the unit,

such as 660 nanometers (nm) and the wand aperture size for the unit such as

6 mils (one thousandth of an inch).

"Accessories and Options" on page 1-14 describes the available wands. The

wavelength and aperture described are necessary to obtain the proper

symbol grade.

If the unit was set to use the database feature before being turned off, the

bottom line shows the term DATABASE.

X Dimension

inches (mm)

0.004 (0.102)<

0.007 (0.178)<

0.013 (0.330)<

0.025 (0.635)<

X<0.007 (0.178) 0.003 (0.076) 03

X<0.013 (0.330) 0.005 (0.127) 05

X<0.025 (0.635) 0.010 (0.254) 10

X 0.020 (0.508) 20

Quick Check® 600/800 Series User’s Guide 1 - 9

Measuring Aperture

Diameter inches (mm) Number

Page 16

Note: 6 mil (0.006 inch) diameter aperture is recommended for EAN/UPC.

2. The display that follows the opening screen depends on two conditions:

whether a printer is available, and how the AutoPrint/Store feature is set. If

the first line of the display states:

No Printer Attached, then refer to step 2.a

•

•

Print Buffer, then refer to step 3.

2.a If a

2.b To continue obtaining scan results with the AutoPrint/Store feature

No Printer Attached message appears, it indicates that

a printer is not available to the verifier; that is, the verifier is not connected to a printer, or the verifier is connected to a printer but the

printer is turned off. The second line of this display provides both the

percent of the memory used for the stored records and the number of

scan records in the memory. If there are no stored records, both values are zero.

Depending on the status of the AutoPrint/Store feature (on or off),

you have different ways to respond to this display.

If the AutoPrint/Store feature is set to On

• Continue with the AutoStore

• Clear

• Change

The cursor is at the asterisk next to the term

AutoStore

setting

display and are automatically stored in the memory. The previously

stored results remain in the memory.

On, press SELECT. After a scan, the results appear on the

.

(the default), you can:

Continue with

2.c To clear (delete) the records stored in the memory, press ↓ to place

the cursor on the asterisk next to the term

SELECT. The stored results and the result from the last scan are

deleted from the Quick Check 600/800 Verifier’s memory.

2.d To change the AutoPrint/Store feature setting to

→ to place the cursor on the asterisk next to the term

then press SELECT. The Change settings printout options display

appears. Press → to change the setting to

results appear on the display, but are not automatically stored in the

memory. The previously stored results remain in the

memory.

Clear and then press

Off, press ↓ and

Change and

Off. After a scan, the

1 - 10 Quick Check® 600/800 Series User’s Guide

Page 17

If the AutoPrint/Store feature is set to Off, you can:

• Continue

•Clear

• Continue with AutoStore

The cursor is at the asterisk next to the term

2.e To continue obtaining scan results with the AutoPrint/Store feature

setting

display but are not automatically stored in the memory. The previously stored results remain in the memory.

2.f To clear (delete) the records stored in the memory,

press → to place the cursor on the asterisk next to the term

and then press SELECT. The stored results and the results from the

last scan are deleted from the Quick Check 600/800 Verifier’s memory.

2.g To continue obtaining scan results but change the Auto Print/Store

feature setting to

to the terms

After a scan, the results appear on the display and are automatically

stored in the memory. The previously stored results remain in the

memory.

3. If a

Print Buffer message appears, it indicates a printer is available

(the Quick Check 600/800 Verifier is connected to a printer that is turned on)

and the Auto Print/Store feature setting is

provides both the percent of the memory used for the stored records and the

number of scan records in the memory. If there are no stored records, both

values are zero. You can

Off, press SELECT. After a scan, the results appear on the

On, press ↓ to move the cursor to the asterisk next

Continue w/AutoStore and then press SELECT.

On. The second line of this display

Continue.

Clear

• Continue

•Print

•Clear

The cursor is at the asterisk next to the term

3.a To continue obtaining scan results, press SELECT. The opening

display appears. You can then scan a symbol. The scan results

print on the printer. The previously stored results remain in the memory.

3.b To print the stored records, press ↓ to place the cursor on the asterisk next to

Once printed, the stored results are removed from the Quick Check

600/800 Verifier’s memory, however, the results from the last scan

remaining in the buffer. (Press ← at the opening menu to display the

last scan’s results.)

Print. Then press SELECT. The stored records print.

Continue.

Quick Check® 600/800 Series User’s Guide 1 - 11

Page 18

3.c To clear (delete) the records stored in the memory, press ↓ and → to

place the cursor on the asterisk next to the term

press SELECT. The stored results and the result from the last scan

are deleted from the Quick Check 600/800 Verifier’s memory.

Clear and then

♦ To turn off the unit:

1. Press and hold down POWER for about two seconds until the unit beeps

once and clears the display.

OR

Let the unit turn itself off.

If the unit is connected to a charger, it turns off after ten

minutes of inactivity. If the unit is not connected to a charger, it turns off after

one minute of inactivity.

Note: If the unit turned itself off and you want to review the results of the last

←

scan, press POWER to turn on the unit and then press

from the last scan appear.

. The results

Calibrating the Quick Check 600/800 Verifier

Even though the verifier is calibrated at the factory, you should calibrate it before

its first use to ensure its accuracy. For continued accuracy, periodically calibrate

the unit during normal operation. You calibrate the unit using a reflectance page

that is included in the pack of accessories. Each page has a serial number on it.

For accurate calibration and data collection, you scan the reflectance page ten

times and the Quick Check 600/800 Verifier performs a consistency test. If it

passes, the unit is calibrated.

If, during the measurement of a symbol, a scan reflectance value of

appears on the display or on a printout, an out-of- range reading was recorded.

Recalibrate the unit and then rescan the symbol.

The reflectance page is a precision standard made of photographic materials. If

it becomes physically damaged or dirty, replace it to insure proper calibration. To

order a new reflectance page, contact your sales representative.

XX or — —

♦ To calibrate the Quick Check 600/800 Verifier:

1. Using the proper scan technique, scan the reflectance symbol from the

accessory pack. You will hear a long beep followed by two short beeps after

the first good scan, and the LCD displays

-9- More Scans!

2. Continue to scan the reflectance page for a total of ten good scans. After

each good scan, a single beep sounds and the display indicates how many

good scans you need to obtain. After the tenth good scan, three beeps

sound and the message

Target

appears. To scan, set the wand scanner on a symbol’s quiet zone.

appears. When you lift the scanner up, the opening display

.

Now Lift the Scanner Up off the

REFLECTANCE CALIBRATION

1 - 12 Quick Check® 600/800 Series User’s Guide

Page 19

Three beeps (one long followed by two short beeps) sound if the unit detects

reflectance readings significantly different from the previously recorded

ones. You may be scanning too slowly, too quickly or unevenly, or using an

improper scan angle. A message appears and prompts you to begin again.

Continue scanning using the recommended scanning technique until the unit

is calibrated.

Properly Scanning With the Unit

Variations in scan rates and angles can affect bar code verification. Before you

begin collecting data, review and practice the recommended method for

whichever configuration you are using, the pen wand or the mouse wand.

♦ To scan properly using a pen wand:

1. Turn on the verifier and confirm that it is operational (that is, does not need to

be charged or calibrated).

2. Hold the pen wand as you would a pen or pencil, placing your fingers on

each side of the foot near the tip.

3. Lightly touch the scanner tip against either quiet zone (clear area) of the bar

code. You have the proper scanning angle when the tip and the reflectance

guide are flat on the scan surface. (If the unit does not respond, press

POWER.)

4. At about the same speed with which you would quickly underline a sentence

in this manual, and without interruption, gently drag the tip across the center

of the bar code. You do not need to press the tip on the bar code. Gentle

pressure on the tip will not scratch the contacted surface.

5. Listen for audible tones.

• If you hear a long beep tone followed by a short tone, it signifies a good

read.

• If you hear a long beep and then three short beeps, the unit detects an

error in the scanned symbol.

• If one of these messages appears

please!;

technique accordingly. If a symbol consistently produces no beeping,

it is either fatally out of spec or it is not one of the symbologies

programmed on the unit.

• If you receive a message about a bad quiet zone, you may have

started scanning too close to the first bar. Rescan the symbol, starting

a little farther away from the first bar.

6. Practice your scanning technique until you can successfully scan, on the first

attempt, each of the test symbols supplied with the verifier.

or more evenly, please!; adjust your scan

slowly, please!; faster,

♦ To scan properly using a mouse wand:

1. Turn on the Quick Check 600/800 Verifier and confirm that it is operational

(that is, does not need to be charged or calibrated).

Quick Check® 600/800 Series User’s Guide 1 - 13

Page 20

2. Hold the mouse wand as you would a computer mouse, placing your fingers

on each side of the mouse near the front.

3. Lightly pass the mouse wand over either quiet zone (clear area) of the bar

code. If the unit does not respond, press POWER.

4. At about the same speed with which you would quickly underline a sentence

in this manual, and without interruption, gently pass the mouse wand across

the center of the bar code. You do not need to press the mouse on the bar

code.

5. Listen for audible tones.

• If you hear a long beep tone followed by a short tone, it signifies a good

read.

• If you hear a long beep and then three short beeps, the unit detects an

error in the scanned symbol.

• If one of these messages appears,

please!;

technique accordingly. If a symbol consistently produces no beeping,

it is either fatally out of spec or it is not one of the symbologies

programmed on the unit.

• If you receive a message about a bad quiet zone, you may have

started scanning too close to the first bar. Rescan the symbol, starting

a little farther away from the first bar.

6. Practice your scanning technique until you can successfully scan, on the first

attempt, each of the test symbols supplied with the verifier.

or more evenly, please!; adjust your scan

slowly, please!; faster,

Cleaning the Wand

Occasionally the scanner tip or window may become partially obstructed by ink,

paper fibers, or other particulate deposits (such as wax or varnish). To ensure

reliable scanning, you should periodically check and, if necessary, clean the tip

with a soft cloth.

Note: Damaged tips for the pen wand should be replaced. Consult your dealer

or Hand Held Products’ Customer Service Department for details.

Accessories and Options

Hand Held Products supplies a variety of accessories and options for the Quick

Check 600/800 Verifier. The items indicated by an asterisk are supplied with the

verifier.

Item/DescriptionOrder code

Charger & Batteries

*Quick Check 600/800 Verifier AC Charger . . . . . . . . . QCAC = 110 VAC

QCAC 220B = 220 VAC UK

QCAC 220A = 220 VAC Europe

*NiCad Rechargeable batteries (set of four “AA” size) . . . . . . . . . . QCB

1 - 14 Quick Check® 600/800 Series User’s Guide

Page 21

Documentation

*QC600/800 User’s Guide & Programming Manual . . . . QC600-800-UG

*QC600/800 Reflectance Page . . . . . . . . . . . . . . . . . . . . . . . . . QCRFPG

Printers

QC Standard Speed Dot Matrix Printer . . . . QCP68-USA/QCP68-EURO

QC High Speed Dot Matrix Printer . . QCHSP68-USA/QCHSP68-EURO

Printer supplies

Power supply for QCP & QCHSP Printers. . . . . . . . . . . . . . . . . . QCPAC

Printer ribbon for QCP & QCHSP . . . . . . . . . . . . . . . . . . . . . . . . . QCPR

Printer paper for QCP & QCHSP (4 roll/pack). . . . . . . . . . . . . . . . QCPP

Interface cable for QC600/800 to QCP or QCHSP . . . . . . . . . . . . QCPC

Wand Scanner

QCIW05V Pen Wand 5 mil visible red . . . . . . . . . . . . . . . . . . . . . .622301

QCIW06V Pen Wand 6 mil visible red . . . . . . . . . . . . . . . . . . . . . .622302

QCIW10V Pen Wand 10 mil visible red . . . . . . . . . . . . . . . . . . . . .622299

QCMWI03 Mouse Wand 3 mil infrared . . . . . . . . . . . . . . . . MOUSE3MIR

QCMWV03 Mouse Wand 3 mil visible red . . . . . . . . . . . . MOUSE3MVR

QCMWI05 Mouse Wand 5 mil infrared . . . . . . . . . . . . . . . . MOUSE5MIR

QCMWV05 Mouse Wand 5 mil visible red . . . . . . . . . . . . MOUSE5MVR

QCMWI06 Mouse Wand 6 mil infrared . . . . . . . . . . . . . . . . MOUSE6MIR

QCMWV06 Mouse Wand 6 mil visible red . . . . . . . . . . . . MOUSE6MVR

QCMWI10 Mouse Wand 10 mil infrared . . . . . . . . . . . . . . MOUSE10MIR

QCMWV10 Mouse Wand 10 mil visible red . . . . . . . . . . MOUSE10MVR

QCMWI20 Mouse Wand 20 mil infrared . . . . . . . . . . . . . . MOUSE20MIR

QCMWV20 Mouse Wand 20 mil visible red . . . . . . . . . . MOUSE20MVR

Quick Check® 600/800 Series User’s Guide 1 - 15

Page 22

1 - 16 Quick Check® 600/800 Series User’s Guide

Page 23

2

Quick Start Guide

If you are familiar with bar code verifiers, this section will get you up and running

in a few minutes. We assume the factory defaults are in effect.

1. Install the batteries Chapter 1

• Slide off battery cover on the bottom of unit.

• Insert four batteries into compartment, matching “+” on battery ends

with “+” in case.

• Slide battery cover back in place.

2. Charge the batteries Chapter 1

• Plug AC charger into port on back of unit.

• Plug charger into a VAC wall outlet.

• Charge completely discharged batteries at least 12 hours; charge low

charge batteries less time.

• After charging, remove AC charger from unit.

3. Turn on the verifier Chapter 1

•Press POWER. Unit emits four quick beeps.

If unit displays:

• RECALIBRATE, calibrate unit. Go to step 4.

• LOW BATTERY!, charge batteries. Go to step 2.

• NO PRINTER ATTACHED... records may be stored in buffer. Use

arrow keys to select an option. Either continue to scan using current

AutoPrint/Store setting, clear (delete) records, or change AutoPrint/

Store setting to

• PRINT BUFFER... records are stored in buffer. Use arrow keys to

select an option. Either continue to scan and leave records in buffer,

print records, or clear (delete) records. Go to step 5.

• SCAN, go to step 5.

• QUICK-CHECK Opening Menu, go to step 5.

4. Calibrate the unit Chapter 1

• Scan reflectance page if you’re using either a pen or mouse wand.

Three beeps (one long, two short) sound after a good scan.

• Continue to scan page for ten good scans.

5. Scan the bar code symbol Chapter 3

Off (not store data). Go to step 5. Chapter 5

• The scan grade display appears. (Extended Accuracy setting default

is off).

• To obtain final symbol grade, scan symbol nine more times (# Scan/

Symbol setting default is 10).

6. Review the scan results Chapter 4

Quick Check® 600/800 Series User’s Guide 2 - 1

Page 24

• The standard decode display appears.

• Use arrow keys to view data

OR

Scan SSTR Codes to view data.

7. Print your scan results Chapter 3

• If the Quick Check 600/800 Verifier is connected to a printer and it is

turned on, results print automatically (AutoPrint/Store setting default is

On).

• If a printer is not connected or is turned off, results are stored in buffer.

8. Review the option settings: Chapter 3

• If data parameters are not customized the way you want, press

SELECT to display Print Results menu and then press Ø three times

to change the settings.

2 - 2 Quick Check® 600/800 Series User’s Guide

Page 25

3

Changing the Settings

There are four types of options on the Quick Check 600/800 Verifier you can

customize: specifications (applications and symbologies), test criteria, scanning

options, and output options. Each option has several items that you can turn on,

turn off, or change a value. This section describes all the selectable option

settings.

You can easily review and change the settings using SELECT and the ↑, ↓, ←

and → buttons. You save settings by displaying their name and then making the

changes you want. A separate save command is not necessary. You can exit

the settings menu at any point and scan a bar code symbol by placing the wand

tip or the mouse wand on a quiet zone and scanning or by pressing POWER.

It may be useful to create a customized Command Code for each type or set type

of operations you perform. When you need to perform another procedure, just

scan the Command Code that contains those settings. Refer to instructions for

making and using a Command Code starting on "Using a Command Code" on

page 3-16. Sometimes you may want to change just one or two of the settings,

but not create a new Command Code that differs only slightly from the one you

frequently use. You can easily change settings after you use a Command Code.

Chapter 10, Flow Charts

changes you can make and how to access each of them using the menus.

contains a flow chart that displays all the settings

Changing the Specifications

The Quick Check 600/800 Verifier specification section consists of the industry

application standards and symbologies. The Quick Check 600/800 Verifier can

verify the quality of the following symbologies and industry application standards:

Symbologies

• EAN/UPC

• Code 39

• Interleaved 2 of 5

• Code 128

• Code 93

• Codabar

• Code 11

• Code 16K

• Code 49

• MSI Code

• IATA 2 of 5

• Regular 2 of 5

Industry Applications

• AAIG

• Comp Tia

• LOGMARS

• SCC

• HIBCC

• CCBBA

• SISAC

• BOOKLAND

• Coupon Code

Quick Check® 600/800 Series User’s Guide 3 - 1

Page 26

Symbologies

You can enable (turn on) the symbologies available on your Quick Check 600/

800 Verifier so they are recognized. When a symbology is enabled, you can

modify some of its test parameters. "Symbology Specifications" on page 3-3 lists

the parameters you can modify and their factory installed defaults. The

parameters are described after the table.

3 - 2 Quick Check® 600/800 Series User’s Guide

Page 27

Symbology Specifications

Symbology

EAN/UPC

Code 39

Interleaved

2 of 5

Code 128

Code 93

Codabar

Code 11

Parameters (defaults are in bold)

Enable: On or off

Magnification factor: (080/085/090/100/105/110/115/120/130/140/150/

160/180/200)

Expand U.P.C.-EO: Yes or No

Enable: On or off

Check Character: None or Checked

Fixed W/N: None or a value between 1.4 and 3.9 +

Fixed Msg Len*: None or a value between 1 and 49 characters

Enable: On or off

Check Digit: None or Checked

Fixed W/N: None or a value between 1.4 and 3.9 +

Fixed Msg Len*: None or a value between 1 and 78 digits

Enable: On or off

Modes Shown? Yes or No

Fixed Msg Len*: None or a value between 1 and 70 characters

Enable: On or off

Fixed Msg Len*: None or a value between 1 and 80 characters (from

Code 39 set)

Enable: On or off

Character Font & Tolerances: Trad’l ,”USS” or ISO/IEC’83

Fixed W/N: None or a value between 1.4 and 3.9 +

Fixed Msg Len*: None or a value between 1 and 61 digits

Enable: On or off

1 or 2 check digits

Fixed Msg Len*: None or a value between 1 and 80 digits

0.2

0.2

0.2

Code 16K

Code 49

MSI Code

IATA 2 of 5

Regular 2 of 5

Enable: On or Off

Modes Shown? Yes or No

Fixed Msg Len*: None or up to 154 characters, full symbol

Enable: On or Off

Fixed Msg Len*: None or up to 49 alpha (81 numeric characters, full

symbol

Enable: On or Off

User Check: None, Mod 10 or Mod 11

Fixed Msg Len*: None or a value between 1 and 50 digits

Enable: Yes or No

Enable: Yes or No

Enable: Checked or None

* The message length specification for each symbology is listed. Although you can enter

any value between 0 and 255, the unit does not decode more than the values indicated by

the specification.

Quick Check® 600/800 Series User’s Guide 3 - 3

Page 28

Magnification Factor

The Magnification (Mag) Factor applies to the EAN/UPC symbologies. By setting

the size of the bar code symbols that you test, you define appropriate tolerances.

You can select a mag factor from the following values: 80%, 90%, 95%, 100%,

105%, 110%, 115%, 120%, 125%,130%, 140%, 150%, 160%, 180% or 200%.

The default is 100%.

Expand U.P.C./EO

The Yes setting for this parameter allows you to expand the compressed U.P.C.

code. When you expand the scan data, the digits are shifted to the left and +

appears on the display to indicate that additional data is available for your review.

The No setting for this parameter presents the data in zero suppression format.

Check Options

The check character, check digit and UserCheck are optional characters or digits

in some symbologies that are placed in a predetermined position in a symbol.

You can use them to validate that the correct data has been decoded.

Check characters in a symbol may be mandated by a bar code symbology

industry specification, by you, by both, or not at all. Refer to the relevant

industry’s publication for specific information on check characters.

• When you select Checked, the verifier looks for and checks the check

character or digit.

• When you select None, the verifier does not look for the check character or

digit. None is the default setting.

Selected symbologies offer additional options:

• Code 39 contains an optional Mod 43 check character.

• Interleaved 2 of 5 contains an optional 3-1-3-1 weighted check digit.

• MSI Code can contain a second check digit (UserCheck), either the Modulo

(Mod) 10 or Modulo (Mod) 11.

Modes Shown

This parameter allows you to have additional information appear on the display

and on the printout. This information includes special extra characters and

control characters within the encoded message. Having this extra information

displayed may help you analyze reading or printing problems. In Code 128, for

example, you can display starting mode, mode changes and shifts. Code 16K

allows you to display similar additional characters.

3 - 4 Quick Check® 600/800 Series User’s Guide

Page 29

The Yes setting for this parameter is the default. Some of the extra characters

are represented by special character “strings” as shown in the following

Character Translation Table. When you select the No setting, this information

does not appear on the display or the printout.

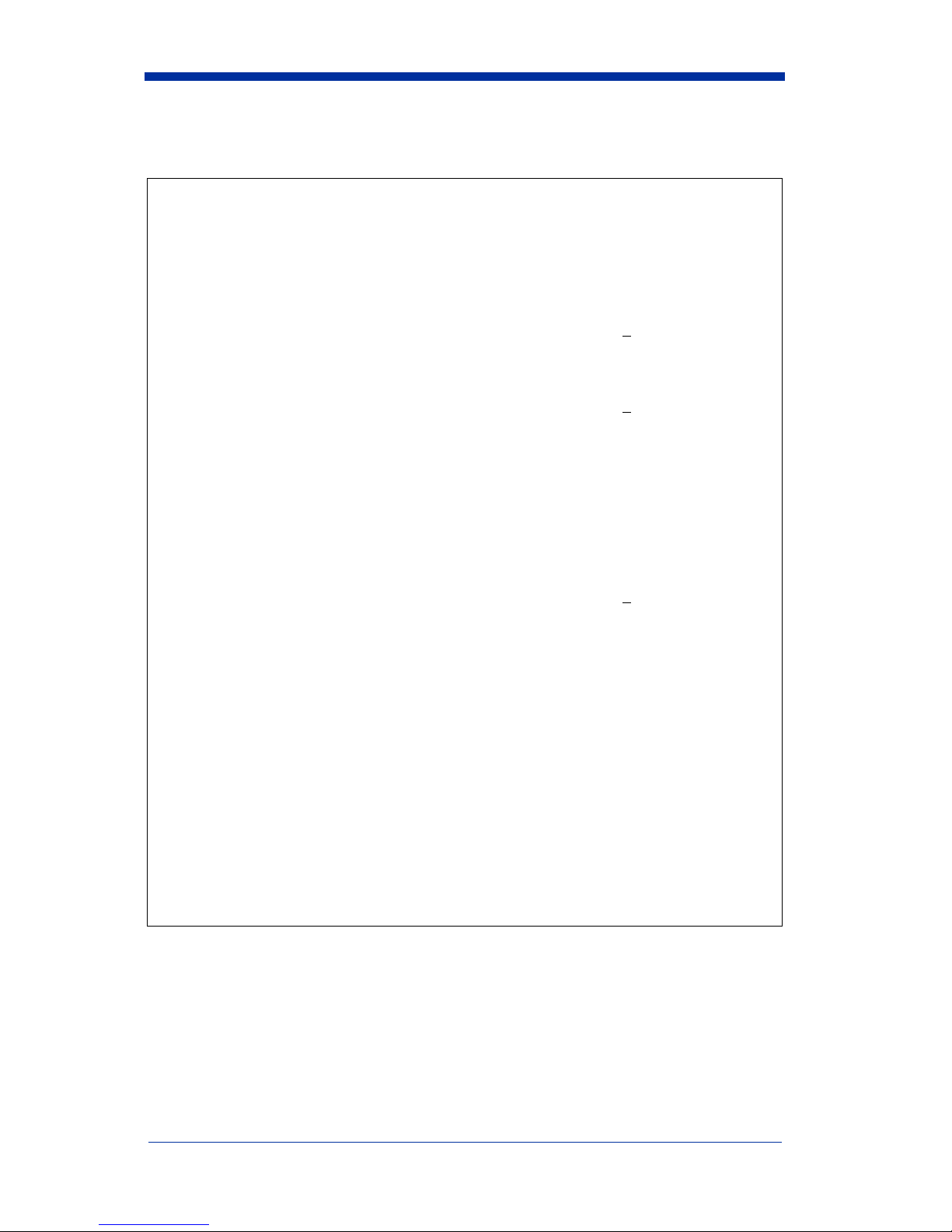

Character Translation Table

(Code 128, Code 16K, and Code 49)

Character

00(NUL)

01(SOH)

02(STX)

03(ETX)

04(EOT)

05(ENQ)

06(ACK)

07(BEL)

08(BS)

09(HT)

0A(LF)

0B(VT)

0C(FF)

0D(CR)

0E(SO)

0F(SI)

10(DLE)

11(DCI)

12(DC2)

13(DC3)

14(DC4)

On

LCD

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

10

11

12

13

14

On

Printout

<NL>

<SH>

<SX>

<EX>

<ET>

<EQ>

<AK>

<8L>

<BS>

<HT>

<LF>

<VT>

<FF>

<CR>

<SO>

<SI>

<DE>

<D1>

<D2>

<D3>

<D4>

Character

15(NAK)

16(SYN)

17(ETB)

18(CAN)

19(EM)

1A(SUB)

1B(ESC)

1C(FS)

1D(GS)

1E(RS)

1F(US)

7F(DEL)

FCN1

FCN2

FCN3

FCN4

Mode A

Mode B

Mode C

Shift

Pad**

On

LCD

15

16

17

18

19

1A

1B

1C

1D

1E

1F

*

F1

F2

F3

F4

A

B

C

Sh

Pd

On

Printout

<NK>

<SY>

<EB>

<CN>

<EM>

<SB>

<ES>

<FS>

<GS>

<RS>

<US>

<DL>

<F1>

<F2>

<F3>

<F4>

<A:>

<B:>

<C:>

<Sh>

Pd

* No “special” character is displayed for <DEL>.

** For Code 16K only.

Character Font & Tolerances

Codabar supports two options for Character font and tolerances.

• Trad’l (Traditional Codabar) uses traditional print tolerances based on

Monarch’s original print tolerances. This is the default setting.

• USS Codabar uses the ISO/IEC 1983 MH10.8M standards.

Refer to Codabar and ISO/IEC publications for specific information on print

tolerances.

Quick Check® 600/800 Series User’s Guide 3 - 5

Page 30

Wide-to-Narrow Ratio

The wide-to-narrow ratio (W/N) applies to symbologies with two

element widths, including Codabar, Interleaved 2 of 5, and Code 39. “W/N” is the

ratio of wide to narrow elements. Only one symbology can have a W/N ratio at

a time. The range of values is 1.4 to 3.9 ± 0.2.

Fixed Message Length

You can set a Fixed Message Length for any symbology except EAN/UPC, but

only one symbology can have a fixed message length at a time. You can enter

the message length for any value between 0 and 255. "Symbology

Specifications" on page 3-3 lists the message length specification for each

symbology.

♦ To modify the symbology options:

1. Display the menu that begins with

then SELECT).

Print Results (press POWER and

2. Set the cursor on the asterisk next to

SELECT.

A menu that begins with

3. With the cursor on the asterisk next to

A menu that begins with

4. With the asterisk next to

A list containing the names of the first four available

symbologies appears. Next to each symbology name is either the term

OFF indicating its enable status. To review the entire list, press ↑ or ↓

or

and hold it down, or press ↑ or ↓ and let up each time. The names of the

additional available symbologies appear.

5. To change the enable status of a symbology, position the cursor next to the

symbology name and press SELECT. For all the symbologies except Code

93 and Code 49, a new menu appears with the name of the symbology on

top and a list of parameters that you can change.

With the cursor on the asterisk next to

symbology enable status changes between

• To change a parameter, use ↓ to move the cursor to the asterisk next

to the name of the first parameter.

• To change a numeric value such as the magnification factor, press →

to move the cursor from the asterisk to the parameter value, then

press ↑ or ↓ until the value you want appears.

• To change a selection such as

→ or SELECT.

• To return to the previous menu, press POWER.

Specifications appears.

Symbologies appears.

Symbologies, press SELECT.

Change Settings and then press

Specifications, press SELECT.

ON

ENABLE, press → or SELECT. The

Yes and No.

Yes/No or Checked!/None, press

When you exit any menu, all the displayed parameter choices are saved.

3 - 6 Quick Check® 600/800 Series User’s Guide

Page 31

6. To change which symbology has a W/N Ratio:

•Press ↑ or ↓ to set the cursor on the asterisk next to Fixed W/N Ratio

and then press SELECT. A menu appears with Fixed W/N Ratio on

top and asks you to choose the symbology name and the ratio

amount.

• To choose the symbology, press SELECT or → to move the cursor

from the asterisk next to Symbgy to the name of the specific

symbology. You can set the W/N ratio for only one symbology at a

time. Now press ↑ or ↓ to display the symbology that you want to have

a fixed W/N ratio.

• To save the selection, press SELECT or ← to move the cursor back

to the asterisk next to Symbgy.

• To set the fixed W/N ratio amount, press ↓ to move the cursor to the

asterisk next to Ratio. Then press SELECT or → to move the cursor

to the numeric value. Use ↑ or ↓ to display the value you want. The

value can range from 1.4 to 3.9 ± 0.2.

• To save the selection, press SELECT or ← to move the cursor back

to the asterisk next to Ratio.

• To return to the previous menu, press POWER.

7. To change which symbology has a fixed message length:

•Press ↑ or ↓ to set the cursor on the asterisk next to Fixed Len and

then press SELECT. A menu appears with Fixed Message Length on

the top and asks you to choose the symbology name and the specific

length.

• To choose the symbology, press SELECT or → to move the cursor

from the asterisk next to Symbgy to the name of the specific

symbology. Now press ↑ or ↓ to display the symbology that you want

to have a fixed message length.

• To save the selection, press SELECT or ← to move the cursor back

to the asterisk next to Symbgy.

• To set the specific length, press ↓ to move the cursor to the asterisk

next to Length. Then press SELECT or → to move the cursor to the

numeric value. Now press ↑ and

length can range from 0 to 255 characters. (See "Symbology

Specifications" on page 3-3.)

• To save the selection, press SELECT or ← to move the cursor back

to the asterisk next to Length.

• To return to the previous menu, press POWER.

8. To change other symbologies and their parameters, repeat

step 5. on page 3-6.

↓ to display the value you want. The

• To return to the previous menu, press POWER.

• To scan a symbol, set the wand on the symbol’s quiet zone.

Industry Applications

You can enable only one application at a time. Your verifier may not have all the

applications installed in it.

Quick Check® 600/800 Series User’s Guide 3 - 7

Page 32

♦ To select an application:

1. Display the menu that begins with Print Results (press POWER and

SELECT).

2. Set the cursor on the asterisk next to Change Settings and then press

SELECT.

A menu that begins with Specifications appears.

3. With the asterisk next to Specifications, press SELECT.

A menu that begins with Symbologies appears.

A list containing the term Symbologies and the names of the applications

appears. The application that is currently enabled has a ← to the right of the

name. If a → is to the right of the term Symbologies, no application is enabled.

4. To enable another application, set the cursor next to the application name

and then press SELECT.

• When you select AIAG, SCC, Coupon Code or

BOOKLAND, you are prompted to provide additional

information. AIAG asks if you want Supplier or Customer. Use ↑ and

↓ to set the cursor on the asterisk next to the term you want and then

press SELECT.

• When you select SCC for the SCS/ITF, Coupon Code and BOOKLAND, you are prompted to provide a magnification factor. Use ↑ and

↓ to display the magnification factor you want to use and then press

SELECT.

5. To return to the previous menu, press POWER.

To scan a symbol, set the wand on the symbol’s quiet zone.

Changing the Test Criteria

The test criteria apply to the standards used to evaluate the scanned symbols.

You can select the following items:

• ISO/IEC scan grade or pass/fail criteria for traditional parameters

• Character averaged decodability or ISO/IEC Decodability

• ISO/IEC grades in letters or numbers

• Number of scans used to determine the final ISO/IEC Symbol Grade

Scan Grade

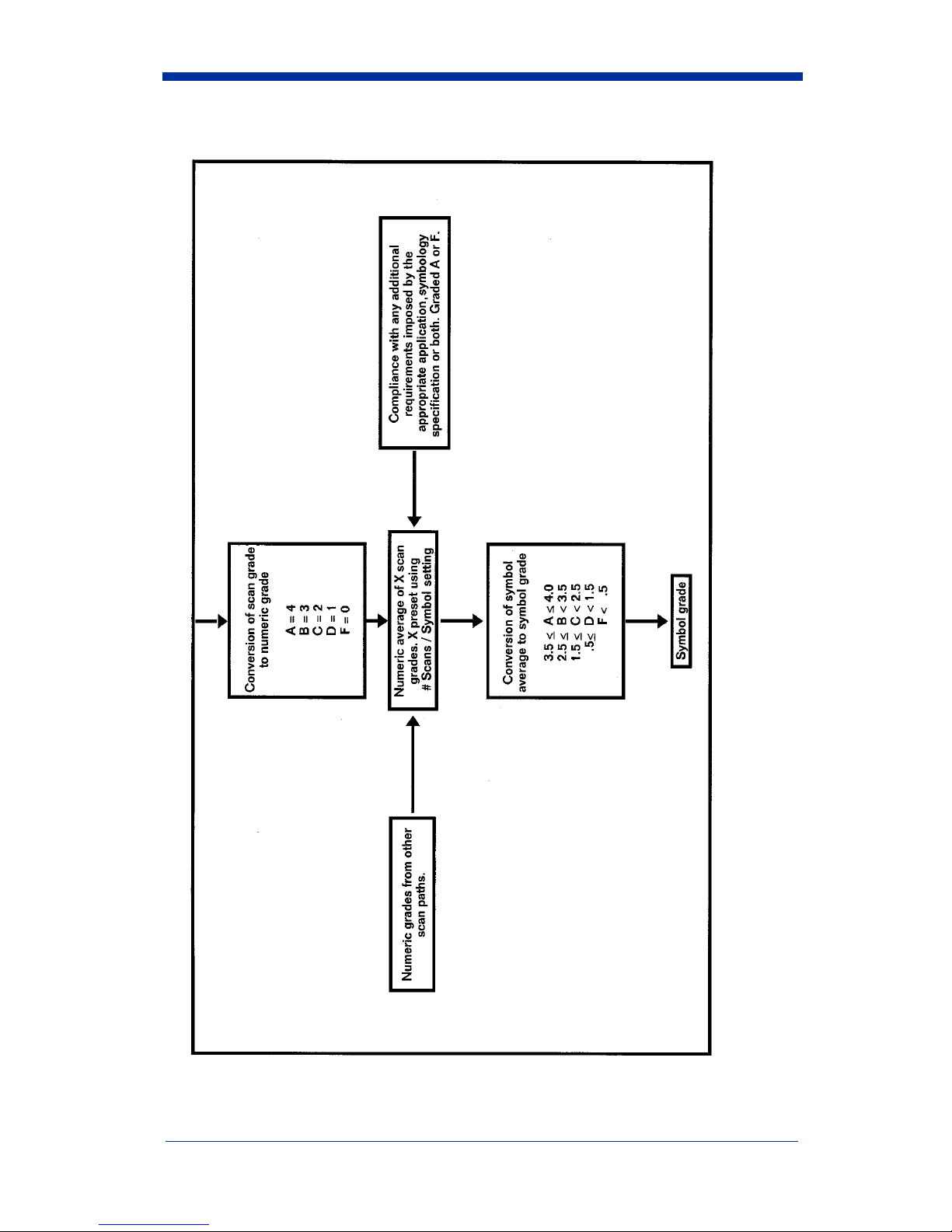

The Quick Check 600/800 Verifier acquires data using the ScanProfile

Methodology specified in the ISO/IEC’s “Bar Code Print Quality Guideline.” The

verifier then evaluates the acquired data and provides a scan grade (also called

a scan profile grade).

The default number of scans used to obtain the scan grade is one (with Extended

Accuracy set to Off). You can obtain an averaged scan grade when the

Extended Accuracy scanning option is On (set to a value >1).

3 - 8 Quick Check® 600/800 Series User’s Guide

Page 33

You can obtain the scan grade result in two ways:

• Set the verifier to use traditional print quality parameters to make a pass/fail

judgment about the symbol and provide detailed

measurements.

• Set the verifier to use ISO/IEC methods to judge the symbol and report an

ISO/IEC scan grade of A, B, C, D or F. The default setting is ISO/IEC scan

grade C.

All the test criteria options are available for you to select regardless of which scan

grade method (ISO/IEC or traditional) you selected. For example, if you select

the traditional pass/fail criteria, you can view and change the ISO/IEC grade

letter or number option, even though it has no affect on the traditional criteria you

selected.

Decodability

Decodability is the percentage of the symbology’s safe decoding margin

available for the scanner after printing errors. Lower margin values and

corresponding lower grades indicate an increased susceptibility to decoding

failure due to scanning errors. Scanning variations, such as acceleration, cause

bar or space deviations due to uneven, too fast or too slow scanning and could

yield lower margin values.

You can choose the decodability method you want to use — ISO/IEC

Decodability or character averaged decodability (Avg):

• ISO/IEC Decodability is a graded measure of how close a given scan comes

to a reference decode failure due to variations in bar and/or space widths.

The default setting is ISO/IEC decodability.

• Avg is the character-averaged value of decodability and is referred to as “D

Margin” on a Quick Check 600/800 Verifier printout.

ISO/IEC grades

For all symbologies, and most of the applications, you can view the test results,

ISO/IEC scan grade and ISO/IEC symbol grades reported as letters (A, B, C, D,

or F) or as numbers (4, 3, 2, 1, or 0). The default setting is letters, with A=4, B=3,

C=2, D=1, and F=0. For some applications, such as AIAG, the grade level is

specified by the application and you cannot change it. If you set an incorrect

grade level, the application resets the correct one.

Number of Scans

You use the #Scans/Symbol setting to specify the number of individual scan

grades that you want used to calculate the final symbol grade. The term

“#Scans/Symbol” is shorthand for the number of scan grades used to determine

the final symbol grade. For further discussion and comparison to scan grades,

refer to "Reviewing Scan Results" on page 4-1.

You can select from the following settings: 1 through 10, 12, 15, 20, 30, 50, 100

and Var. The default #Scans/Symbol setting is 10.

Quick Check® 600/800 Series User’s Guide 3 - 9

Page 34

Consider the symbol grade as the average resulting from scans you take from all

over the symbol. The ISO/IEC standard requires you to obtain ten scans of each

symbol.

For example, you might sample the symbol at ten different paths in the symbol

— four in the upper portion, two in the middle and four in the lower portion.

Multiple scans of the same symbol across different scan paths take advantage

of the vertical redundancy of bar codes and give you a more accurate value of

the symbol’s overall print quality.

♦ To change the test criteria:

1. Display the menu that begins with Print Results (press POWER and then

SELECT).

2. Set the cursor on the asterisk next to Change Settings and then press

SELECT. A menu that begins with Specifications appears.

3. Set the cursor on the asterisk next to Test Criteria and then press SELECT.

A menu that begins with Passing appears.

• To change the pass/fail criteria, set the cursor on the asterisk next to

the term Passing and then press SELECT or →. The cursor moves to

the right of Passing. Press ↑ and ↓ until the grade (Trad’l, ISO/IEC

“A,” ISO/IEC “B,” ISO/IEC “C,” ISO/IEC “D,”) you want appears. To

save the selection, press SELECT, POWER or ←. The cursor moves

back to the asterisk next to Passing.

• To change the Decodability, set the cursor on the asterisk next to

Decodability and then press SELECT or →. The setting changes

between ISO/IEC and Avg.

• To change the Grades, set the cursor on the asterisk next to Grades

and then press SELECT or →. The setting changes between Letters

and Numbers.

• To change the number of scans used to determine the final ISO/

IEC Symbol Grade, set the cursor on the asterisk next to #Scans/

Symbol and then press SELECT or →. The cursor moves to the right

of the terms #Scans/Symbol. Press ↑ and ↓ until the numeric value

you want (1 through 10, 12, 15, 20, 30, 50, 100 or Var) appears. To

save the selection, press SELECT or ←. The cursor moves back to

the asterisk next to #Scans/Symbol.

When you exit any menu (press POWER), all the displayed parameter

choices are saved.

4. To return to the previous menu, press POWER.

To scan a symbol, set the wand on the symbol’s quiet zone.

Changing the Scanning Options

The scanning options apply to the general operation of the Quick Check 600/800

Verifier. You can change the following options:

3 - 10 Quick Check® 600/800 Series User’s Guide

Page 35

• Beeper Pitch (raise or lower)

• Extended Accuracy

• Decoding direction (both ways or forward only)

Beeper Pitch

You can change the pitch of the verifier’s beeper. Higher pitches seem to sound

louder. You can also turn off the tone. The default is 16. The range includes Off

and 1 through 31.

Extended Accuracy

The Extended Accuracy setting is the number of scans of the same symbol,

taken at the same path in the symbol, that yields the scan grade.

• With Extended Accuracy on, individual parameter measurements and results

are averaged over successive scans of the symbol. Using the extended

accuracy mode greatly reduces reading variability due to variations in

scanning motion and minor scan path variations. When Extended Accuracy

is on, you select the number of scans for the averaged result from 2 through

10, 12, 15, 20, 30, 50 and 100.

• When Extended Accuracy is off (set to one), each scan of the symbol gives

the measured results. The default is Extended Accuracy turned off.

When you scan a symbol with Extended Accuracy on, a numeric counter appears

on the display telling you how many additional scans of the same path you must

obtain. After you satisfy the setting, the scan grade appears. If you do not scan

the same symbol within five seconds, the unit assumes you do not want to satisfy

the Extended Accuracy setting you chose and displays the scan results from that

individual scan. If you scan a different symbol after your first scan, the Extended

Accuracy counter resets.

For further discussion and comparison of scan grade to symbol grade, refer to

Chapter 4, Reviewing Scan Data

.

Decode Direction

You can set the Quick Check 600/800 Verifier to read bar code symbols from leftto-right, called “forward only,” or from either direction, called “Both Ways.” The

BothWays setting (default) makes scanning easier and more flexible than

forward-only scanning.

♦ To change the scanning options:

1. Display the menu that begins with Print Results (press POWER and

SELECT).

2. Set the cursor on the asterisk next to Change Settings and then press

SELECT.

A menu that begins with Specifications appears.

Quick Check® 600/800 Series User’s Guide 3 - 11

Page 36

3. Set the cursor on the asterisk next to Scanning Options and then press

SELECT.

A menu that begins with Beeper Pitch appears.

4. To make any necessary changes:

• To change the beeper pitch, set the cursor on the asterisk next to

Beeper and then press SELECT or →. The cursor moves to the right

of the term Pitch. Press ↑ and ↓ until you hear the beeper pitch you

want. To save the selection, press SELECT or ←. The cursor moves

back to the asterisk next to Beeper.

• To change the Extended Accuracy setting, set the cursor on the

asterisk next to Extended Accur and press SELECT or →. The cursor

moves to the right of Accur. Press ↑ and ↓ until the number of scans

you want for the average appears. To save the selection, press

SELECT or ←. The cursor moves to the asterisk next to Extended.

• To change the decoding direction setting, set the cursor on the

asterisk next to Decoding and then press SELECT or →. The setting

changes between BothWays and FwdOnly!.

• When you exit any menu, all the displayed parameter choices are

saved.

5. To return to the previous menu, press POWER.

To scan a symbol, set the wand on the symbol’s quiet zone.

Changing the Output Options

The output options include the display options and the print options.

Display Options

The display options include:

• Upper Parameter Result Line display

• Lower Parameter Result Line display

• Error Override display

• LEDs either display ISO/IEC Grade or indicate bar growth or loss

The display options allow you to set the two types of results that are most

important to you in the upper and lower parameter result lines so they appear

immediately after a scan. (The upper parameter result line is the third line of the

display and the lower line is the fourth or bottom line of the display.) Then, by

pressing a few buttons, you can review all the other results.

Parameter Result Lines

On the parameter lines, you can display either the result defaults set at the

factory, or results you select.

• For traditional pass/fail criteria, the factory-set defaults are PCS and AvgBar.

• For ISO/IEC criteria, the factory-set defaults are Decodability and Modulation.

3 - 12 Quick Check® 600/800 Series User’s Guide

Page 37

Additional results you can display and the criteria used include:

• Symbol type

• Wide-to-narrow ratio (traditional)

• Light reflectance (traditional and ISO/IEC)

• Dark reflectance (traditional and ISO/IEC)

• Symbol contrast (ISO/IEC)

• Reflectance minimum/maximum (ISO/IEC)

• Edge contrast minimum (ISO/IEC)

• Defects (ISO/IEC)

• Message length

• Bar growth (traditional)

Error override allows you to set the verifier to replace the default or user-selected

Upper and Lower Parameter Result lines with any error information or messages

that might result from the bar code scan analysis. If more than two errors result

from a scan, the first two appear on the display and you can scroll the display to

view the other errors. The default for Error Override is NO.

When you select ISO/IEC criteria, you can use the LED’s display feature to set

the LEDs to indicate bar growth/loss or pass/fail grade and result grade. In

addition, when you select ISO/IEC criteria, the five multi-colored LEDs normally

indicate symbol pass or fail based on the ISO/IEC criteria. With the LED feature

set to Bar Growth, the LEDs provide information on bar growth or loss, just as

they would if you selected traditional pass/fail test criteria.

Print Options

The print options allow you to select:

• Printer type (QCP or QCHSP)

• Printout form (long or short)

• Automatic options — automatically print data when the unit is connected to a

printer and turned on, automatically store data when the unit is not connected

to a printer

• Auto Print/Store with or without Profile

You can use any one of the three optional accessory hardcopy printers, but you

need to select the printer before you try to print. Supported printers include:

• QCP (standard printer)

• QCHSP (High-Speed Printer)

Refer to

printers.

Chapter 5, Saving and Printing

for more information about these

AutoPrint/Store

The AutoPrint/Store option automatically prints or stores your data:

• When you have the AutoPrint/Store feature turned on and a printer connected

to your verifier and turned on, your scan results print automatically. You

cannot store results when a printer is connected and turned on.

Quick Check® 600/800 Series User’s Guide 3 - 13

Page 38

• When you have the AutoPrint/Store feature turned on, but no printer is

connected to your verifier, or your printer is connected, but is turned off, your

scan results are automatically stored in the verifier’s memory.

• When you have the AutoPrint/Store feature turned off, after each scan you

need to instruct the verifier to print your data (if a printer is connected and

turned on) or to store your data (if a printer is not connected or is turned off).

The default is setting for AutoPrint/Store is ON.

Scan Profile

The Quick Check 600/800 Verifier allows you to print the scan profile which is a

record of the reflectance values seen by a scanner as it moves across a symbol.

The scan profile is the basis of ISO/IEC evaluation and is usually presented in a

graphic form.

• When you use the AutoPrint/Store feature with Profile, you can choose to

have the scan results stored so you can later print a graphic scan profile on a

printout.

• When you use AutoPrint/Store without Profile, the raw data is not stored.

♦ To change the output options:

1. Display the menu that begins with Print Results (press POWER and then

SELECT).

2. Set the cursor on the asterisk next to Change Settings and then press

SELECT. A menu that begins with Specifications appears.

3. Set the cursor on the asterisk next to Output Options and then press

SELECT. A menu that contains Display Options and Printout Options

appears.

4. To change the display options:

• To change the display options, set the cursor on the asterisk next to

Display Options and then press SELECT. A menu with four display

options selections appears.

• To change the data displayed in the upper (3rd line) or the lower (4th

line) parameter result line, set the cursor on the asterisk next to

UpperLine and then press SELECT or →. The cursor moves to the

right of the term. Press ↑ and ↓ until the name of the data that you

want to show up on the parameter result line appears. To save the

selection, press SELECT or ←. The cursor moves back to the asterisk

next to the term.

• To change the error override feature, set the cursor on the asterisk

next to Error Override and then press SELECT or → until the setting

you want, YES (Y) or NO (N), appears.

• To change what the LEDs indicate, set the cursor on the asterisk next

to LEDs and then press SELECT or → until the setting you want, P/F

Criteria or Bar Growth!, appears.

•Press POWER to return to the menu that contains Display Options

and Printout Options.

3 - 14 Quick Check® 600/800 Series User’s Guide

Page 39

5. To change the printout options:

• To change the printout options, set the cursor on the asterisk next to

Printout Options and then press SELECT. A menu with the printout

options selections appears.

• To change the printer type, set the cursor on the asterisk next to

Printer Type and then press SELECT or → until the setting you want,

QCP or QCHSP, appears.

• To change the printout form, set the cursor on the asterisk next to

Printout and then press SELECT or → until the setting you want, Long

or Short, appears.

• To change the AutoPrint and Store setting, set the cursor on the

asterisk next to AutoPrint/Store and then press SELECT or → until the

setting you want, On or Off appears. If you set the AutoPrint and Store

setting On, you may want to use it with or without Profile. To change

the Profile settings, set the cursor on the asterisk next to w/Profile?.

Press SELECT or → until the setting you want, Yes or No, appears.

6. To return to the previous menu, press POWER.

To scan a symbol, set the wand on the symbol’s quiet zone.

Resetting the Default Settings

If you make changes to your Quick Check 600/800 Verifier’s settings, you can

easily reset them to the factory installed defaults.

♦ To reset a unit:

1. Scan the special “Reset All Options” code located in

Codes

2. Recalibrate the unit.

Refer to

. The unit reinstalls the factory default settings.

Chapter 2, Quick Start Guide

for instructions.

Chapter 12, Special

Locking the Settings

After you set all the options (specifications, test criteria, scanning options and

output options) on the Quick Check 600/800 Verifier, you can “lock” the unit so

that you or others cannot accidentally change the settings during routine use. If