Page 1

Quick Check® 200 Series

User’s Guide

Page 2

Disclaimer

Hand Held Products, Inc. (“Hand HeldProducts”) reserves the right to make

changes in specifications and other information contained in this document

without prior notice, and the reader should in all cases consult Hand Held

Products to determine whether any such changes have been made. The

information in this publication does not represent a commitment on the part of

Hand Held Products.

Hand Held Products shall not be liable for technical or editorial errors or

omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright. All

rights are reserved. No part of this document may be photocopied, reproduced,

or translated into another language without the prior written consent of Hand

Held Products.

© 2001-2005 Hand Held Products, Inc. All rights reserved.

Web Address: www.handheld.com

®

Microsoft

CE

Visual C++®, Windows® 95, Windows® 98, Windows® 2000, Windows

®

, and Windows NT® are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Other product names mentioned in this document may be trademarks or

registered trademarks of other companies and are the property of their respective

owners.

The CE mark on the product indicates that the system has been tested

to and conforms with the provisions noted within the 89/336/EEC

Electromagnetic Compatibility Directive and the 73/23/EEC Low Voltage

Directive.

For further information please contact:

Hand Held Products, Inc.

Nijverheidsweg 9

5627 BT Eindhoven

The Netherlands

Hand Held Products shall not be liable for use of our product with equipment (i.e.,

power supplies, personal computers, etc.) that is not CE marked and does not

comply with the Low Voltage Directive.

Page 3

Statement of Agency Compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

FCC Class A Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

Caution: Any changes or modifications made to this device that are not

expressly approved by Hand Held Products may void the user's authority to

operate the equipment.

Note: To maintain compliance with FCC Rules and Regulations, cables

connected to this device must be shielded cables, in which the cable shield

wire(s) have been grounded (tied) to the connector shell.

Canadian Notice

This equipment does not exceed the Class A limits for radio noise emissions as

described in the Radio Interference Regulations of the Canadian Department of

Communications. (ICES-003)

Le present appareil numerique n'emet pas de bruits radioelectriques depassant

les limites applicables aux appareils numeriques de la classe A prescrites dans

le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada. (ICES-003)

Page 4

Page 5

Table of Contents

1. About This Manual..................................................................... 1

Conventions........................................................................................................ 1

QC200 “Low Battery” Warning ........................................................................ 1

2. Overview...................................................................................... 3

Unpacking .......................................................................................................... 4

Charging the Battery.......................................................................................... 4

Command Code “Quick Start” .......................................................................... 5

3. Detailed Operation...................................................................... 7

Using the QC200................................................................................................ 9

Power ON/OFF.................................................................................................. 9

Reflectance Scale Calibration.......................................................................... 10

Initial Power Up Default Settings .................................................................... 10

4. Configuration/Programming.................................................... 13

Codes/Symbology Options................................................................................ 13

“Application”/Model Options.......................................................................... 16

Model Selections: ..................................................................................... 17

“Tests” Options................................................................................................ 17

“Config.” Options............................................................................................ 19

5. Symbol Testing & Scan Results................................................ 21

Test Result Details............................................................................................ 23

Dimensional Parameters.......................................................................... 23

Reflectance Parameters............................................................................ 25

Format Parameters .................................................................................. 26

6. Printer Printout Samples.......................................................... 29

7. Special Functions ..................................................................... 33

Reflectometer Mode.......................................................................................... 33

Command Code Programming......................................................................... 33

8. Quick Check Maintenance....................................................... 37

Battery Charging..............................................................................................37

Scanner Tip Cleaning.......................................................................................37

Reflectance Calibration Page Replacement..................................................... 37

Troubleshooting................................................................................................ 38

i

Page 6

9. Single Scan To Result (SSTR).................................................. 39

10. Printer Information .................................................................. 41

Saving Data...................................................................................................... 41

Reviewing printouts.......................................................................................... 41

Using a printer ................................................................................................. 44

Print your work ................................................................................................ 44

Save data when a printer is not connected....................................................... 45

Review data from the last scan:........................................................................ 45

Print or delete stored data: .............................................................................. 45

Stop printing..................................................................................................... 46

Using the QCP and QCHSP............................................................................. 46

Setup the QCP or QCHSP:............................................................................... 47

Install or replace the QCP or QCHSP paper roll:........................................... 47

Remove ribbon cartridge from the QCP or QCHSP........................................ 49

Connect the QCP or QCHSP to the Quick Check............................................ 50

Perform a QCP or QCHSP self-test:................................................................ 50

Troubleshooting the QCP or QCHSP .............................................................. 50

Turn on and off the QCSSP.............................................................................. 52

Setup the QCSSP.............................................................................................. 52

Install or replace the QCSSP paper roll:......................................................... 52

Perform a QCSSP self-test ............................................................................... 53

Troubleshooting the QCSSP............................................................................. 53

11. Customer Support ..................................................................... 57

Obtaining Factory Service ............................................................................... 57

Online Product Service and Repair Assistance........................................ 58

Technical Assistance ........................................................................................ 58

Online Technical Assistance..................................................................... 59

Limited Warranty ............................................................................................. 59

ii

Page 7

1. About This Manual

This manual contains information on the Quick Check® 200 Series.

• Quick Start Command Code

• Detailed Operation

• Configuration / Programming

• Symbol Testing / Scan Results

• Printer Printouts

• Special Functions

• Quick Check Maintenance

• Single Scan to Result (SSTR)

Conventions

This manual uses several special symbols to refer to the controls on the

instrument. The following table shows the symbols and their descriptions.

Symbol Description

POWER or Scroll [<>] or

Select

Represents a button on the Quick Check

unit

-Specs- or OK-to-Scan Shows the LED display on the Quick

♦

Check unit

Indicates steps to follow to perform a

procedure

QC200 “Low Battery” Warning

The Quick Check® 200 Series dynamically checks the condition of its battery

when turned on and during menu cycles. If any test falls below a specified limit,

the LCD will show “Low Battery” (and the unit “beeps” five times) as a warning

that the battery’s charge may be deteriorating. The QC200’s microprocessor

“sets” a system “flag” or “pointer” that indicates a degraded condition was

measured for that particular test. With this “flag” set, further cycling of the menu

1

Page 8

or attempts to scan will automatically bring about additional “Low Battery”

indications.

This testing sequence has a power drain than normal scan or single menu

functions. This protects the user by insuring a low battery indication before total

unit power failure occurs, thus preserving proper unit operation. It is possible for

an intermittent “false” low to be detected and reported due to variations in battery

condition, temperature, component efficiency and rapid cycle time. When “Low

Battery” is indicated, the operator should turn their QC200 off, allow one or two

minutes for the battery to recover and then turn it back on. This sequence clears

the Low Battery “flag” or “pointer”. If the “Low Battery” indication returns

immediately on power up, then the unit should be recharged. If not, the QC200

can continue to be used.

The QC200 can be recharged before the warning is seen. Alternately, it can be

left connected to the charger when not in use. To extend battery life, battery

manufacturers recommend you fully charge the unit, use it till the “Low Battery”

indication is seen repeatedly, and then fully recharge before continued use.

2

Page 9

2. Overview

The Quick Check® 200 Series is one of the Hand Held Products family of Quick

Check bar code quality assurance devices. The Quick Check

®

200 Series is fully

portable and compatible with all major bar code symbologies. It is effectively two

instruments in one, both an easy-to-use Pass/Fail quick tester and a powerful

measuring tool for detailed testing and analysis of those same symbols.

®

Testing criteria within the Quick Check

200 Series is based on the American

National Standard X3.182-1990 “Bar Code Print Quality Guideline.” The Quick

Check family of bar code verifiers was designed specifically to fully implement

this guideline guaranteeing symbol compliance to the standard. They provide a

baseline in measurement accuracy against which all verifiers, new and old,

should be judged.

The QC200 series determines print quality, wide to narrow ratios, print contrast

and reflectance parameters, decodes and verifies character format as called for

by application specifications. The quality information from the Quick Check

®

200

Series is presented through an easy to read liquid crystal display (LCD), light

emitting diodes (LEDs), audible tones and through its optional accessory printer.

The knowledge gained using the Quick Check

®

200 Series measurement modes

is invaluable in educating the user about the critical optical characteristics of bar

code symbols.

®

The Quick Check

200 Series can verify the quality of:

• EAN/UPC family of symbols with or without addendum

• Code 39 with or without check character

• Interleaved 2 of 5 with or without check character

• Codabar/USS Codabar with or without check character

• Code 128 with all modes and characters displayed

• MSI Code

• Code 16K

• IATA 2 of 5

• Regular 2 of 5

3

Page 10

Unpacking

When you first receive your Quick Check® 200 Series unit, you should carefully

unpack it. Before attempting to use the instrument, inspect the contents of the

package for any shipping damage. If there is evidence of shipping damage,

please keep ALL packing materials and contact the delivery carrier AS SOON AS

POSSIBLE for claim procedure. Confirm that you have the following items:

QC200 Series model number ordered.

AC Charger

User’s Guide

Manual Pack with:

Test Symbols

Warranty Card

Gauge Ruler

“X” Dimension Ruler

Please fill out the Warranty Card immediately. Also make a note of the serial

number of the unit and the date purchased.

Charging the Battery

NOTE: The battery you received with your Quick Check® 200 unit may be

discharged. Prior to initial use, the batteries should be charged for at least six (6)

hours. The Quick Check

NiCad rechargeable battery pack. It is not intended to be powered directly from

an adapter or AC outlet. The Quick Check

make maximum use of its battery power. As a result, the unit will operate for a

minimum of one (1) hour on a properly charged battery pack.

®

200 unit is designed to operate only using the supplied

®

200 Series verifier is designed to

!!! WARNING!!!

DO NOT CONNECT YOUR QUICK CHECK TO ITS CHARGER OR PRINTER

UNLESS A BATTERY PACK IS INSTALLED. TO DO SO WILL DAMAGE THE

UNIT AND VOID ITS WARRANTY!! ALL UNITS HAVE HAD A PACK

INSTALLED AT THE TIME OF MANUFACTURE.

USE ONLY A HAND HELD PRODUCTS SUPPLIED NICAD TYPE

RECHARGEABLE BATTERY PACK. USE OF OTHER PACKS OR BATTERIES

AND ATTEMPTS TO RECHARGE THESE BATTERIES COULD CAUSE THE

BATTERIES TO EXPLODE, CAUSING DAMAGE TO THE UNIT AND

POSSIBLE PERSONAL INJURY!! DAMAGE CAUSED BY ATTEMPTS TO

RECHARGE OTHER THAN THE SPECIFIED HAND HELD PRODUCTS QC200

4

Page 11

SERIES BATTERY PACK WILL VOID ANY AND ALL QUICK CHECK® 200

SERIES WARRANTIES.

To charge the batteries:

1. Plug the AC charger into the power jack on the end of the Quick Check unit.

2. Plug the AC charger power unit into an appropriate VAC wall outlet.

3. Charge the batteries for a minimum of six (6) hours.

After allowing the proper battery charge time, your Quick Check will be ready for

operation.

If you experience any problems during this set up procedure, carefully review the

above steps and try again. If you still have problems, contact your dealer or

Hand Held Products for assistance.

Command Code “Quick Start”

The Quick Check® 200 Series is a complete, self-contained handheld bar code

verifier. Though we recommend you become thoroughly familiar with the device

and this manual before use, those familiar with bar code verification can easily

set-up and use the QC200 within a matter of minutes (after it has been unpacked

and initially charged) following the next steps:

1. Carefully unpack and inspect the unit. (See section titled UNPACKING for

details)

2. Plug the QCAC charger into the QC200 and an AC wall outlet and charge

the unit for a minimum of six hours. (See sectional titled CHARGING THE

BATTERY for details)

3. After charging, turn the unit on by pressing and releasing the POWER

button. You should hear four beeps indicating the unit is ready.

4. Next, select one of the following pre-printed “Quick Start” Command Codes

appropriate for your use of the QC200, carefully place the tip of the QC200

on the Command Code of choice and scan the code.

5. The unit will respond with four beeps and return to the start up, ready to

scan state.

6. You have now totally programmed your QC200 and are ready to scan your

sample codes. After each scan, the custom LCD display will show decode,

symbology type, PCS or ANSI grade, bar growth/shrinkage indication and

any parameter areas where errors exist. If the code has passed all tests,

one beep will be heard and the green LED will flash. If errors have been

found, three beeps will be heard, the red LED will flash and one or more of

the parameter areas will be lit on the LCD (DIM, REF and /or FMT) to show

in what test criteria area(s) the fault exists.

Detailed information on proper scanning techniques and unit use can be found

throughout this manual. If you have any problems during your “Quick Start,”

5

Page 12

please refer to the rest of this manual or call Hand Held Products’ Customer

Support.

NOTE: Display Orientation (Right Handed vs. Left Handed) and Printer Interface

selection ARE NOT set using the Command Code. Factory default settings for

these are “Right Handed” and “QCHSP”.

.

6

Page 13

3. Detailed Operation

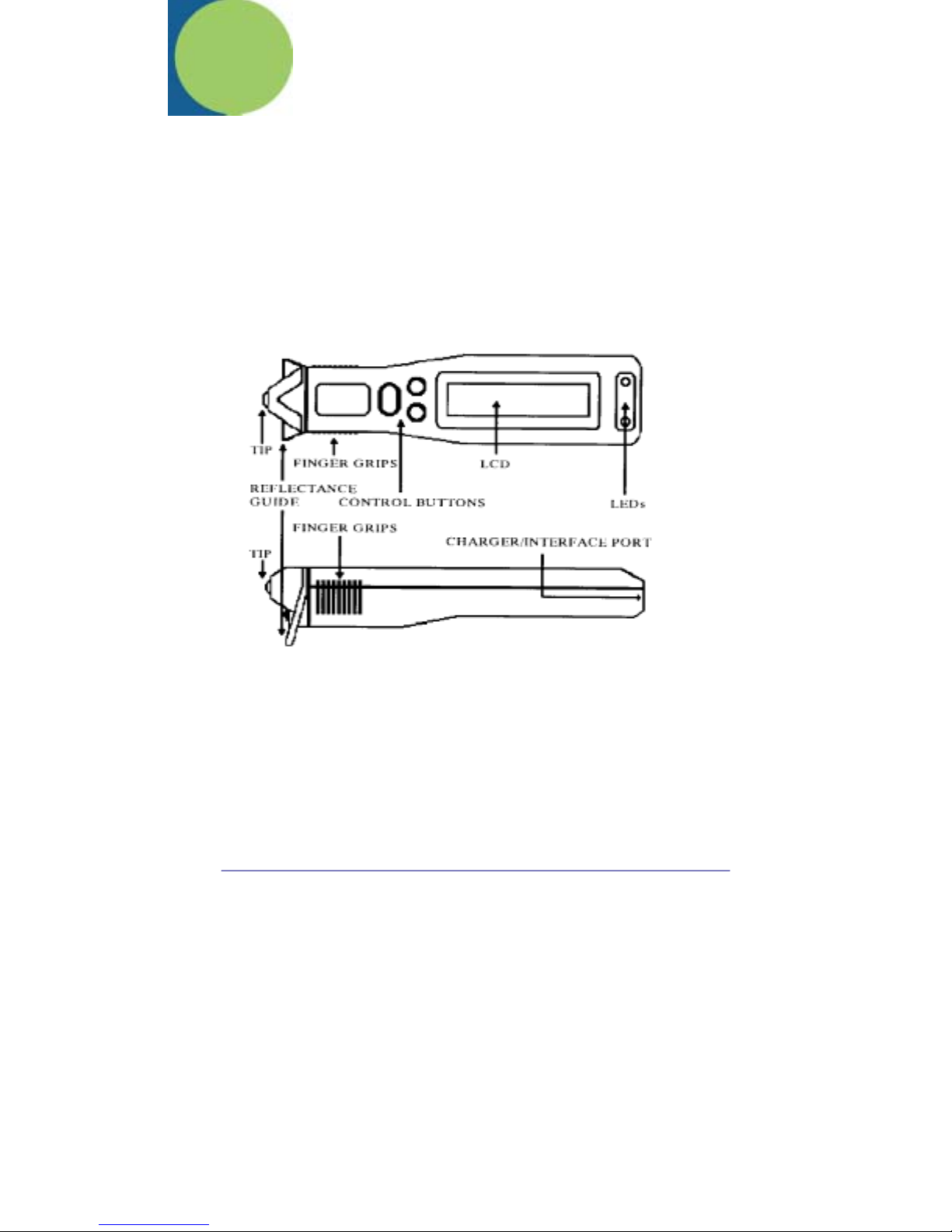

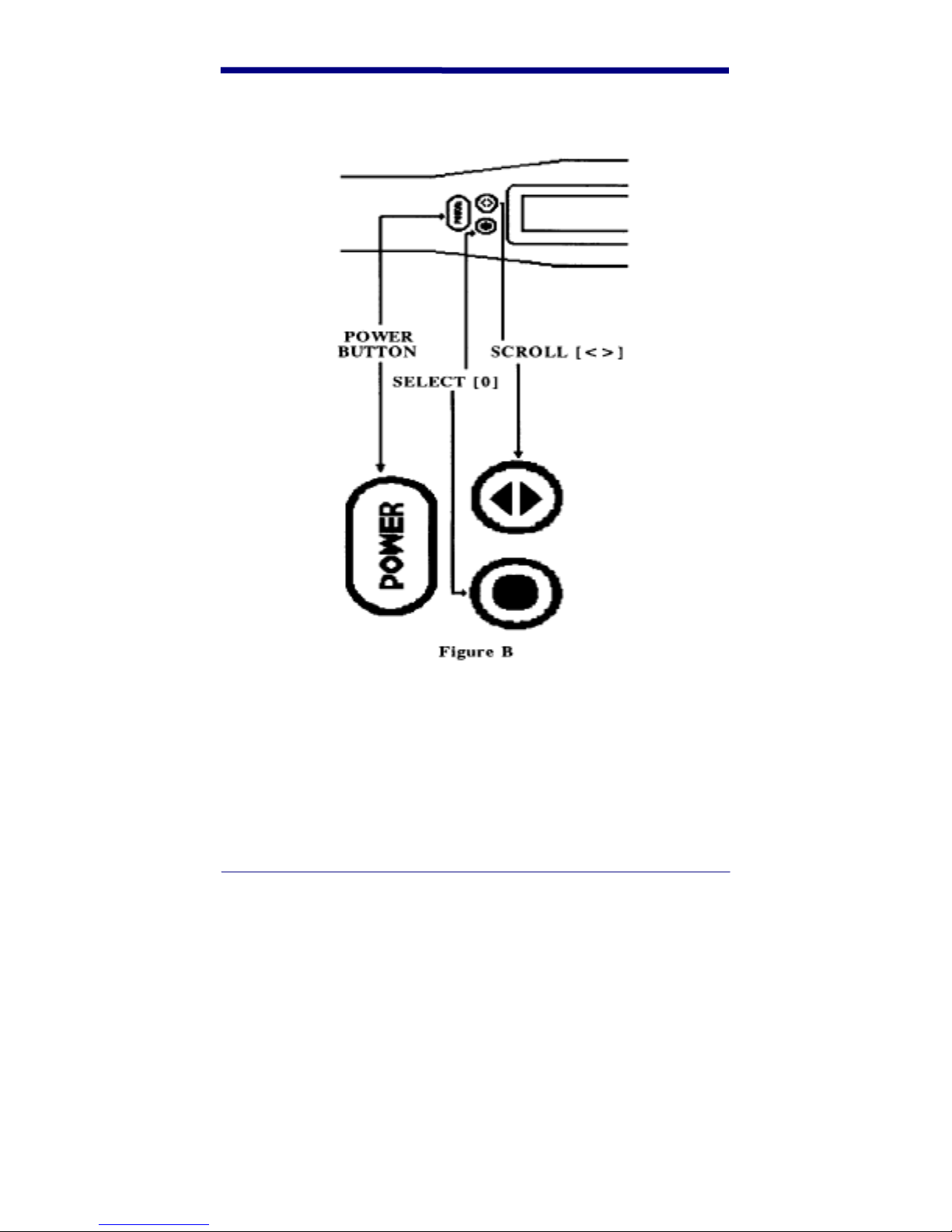

The Quick Check® 200 Series is a complete, self-contained handheld bar code

verifier. The top panel features include a “POWER” button a “SELECT” button

[0], a “SCROLL” [<>] button, a red and a green colored LED and a custom, multifunction, liquid crystal display (LCD). On the bottom of the instrument is the

Serial Number label as well as two of the three case screws that must be

removed for access to the internal battery. (WARNING: DO NOT attempt to

replace the battery pack without first contacting Hand Held Products’ Service

Department!) A port on the end allows connection to a recharger or optional

printer. The following figures show the unit’s layout.

Figure A

7

Page 14

Quick Check® 200 Control Buttons

8

Page 15

Using the QC200

Before you turn the unit on and select a mode of operation, you should review

the following to learn how to properly scan a bar code with it.

To scan a bar code:

1. Hold the QC200 as you would a pen or pencil. The raised “finger grip

ridges” on each side of the case near the optics/scanning tip are guides for

finger placement.

2. Press the optics tip lightly against the surface to be scanned in the clear

area (quiet zone) on either side of the bar code symbol. To maintain a

proper scanning angle, be sure both the optics tip and the “reflectance

guide” are flat on the surface to be scanned.

3. At about the same speed with which you would quickly underline one of the

sentences in this text, and without interruption, move the QC200 evenly

across the center (or approximate center) of the bar code.

4. Listen for a long beep tone quickly followed by a short beep tone signifying a

good read. Note that a long beep followed by three short beeps indicates an

error condition exists in the symbol scanned.

NOTE: Practice your scanning technique until you can successfully scan each of

the supplied test symbols on each attempt. Some of the supplied test symbols

have “intentional errors” in them to show the user how error conditions are

reported.

Power ON/OFF

The Quick Check® 200 Series is turned on by pressing the POWER button, to

which it responds by emitting four quick beeps and first displays:

[QC2xx aa/lll]

where “xx” identifies the model number, “aa” is the aperture size designation in

“mils” (one thousandths of an inch) and “lll” is the spectral response or

wavelength of illumination in nanometers. If there are stored print records (and

the unit is connected to a Quick Check

the display then changes to:

[BUF xx% Ful>]

or it may read “LOW BATTERY!” or “RECALIBRATE!” if charging or reflectance

calibration is needed.

®

AC Charger or Printer interface cable),

9

Page 16

The Quick Check® 200 Series shuts itself off after about a minute of inactivity.

Alternately, the operator can shut the instrument off by pressing the button for

about two seconds, until it beeps and clears the display.

Reflectance Scale Calibration

The first time you use the unit or charge the battery pack and periodically during

normal operation, the Quick Check

calibrated. Remove the QC200 Reflection Calibration Page (QCRFPG) from the

manual and, with the unit at the proper scanning angle (so it rests on its

“reflectance guide”), CAREFULLY scan the reference target symbol 10 times.

Note that your first scan will yield a “triple” beep (one long, two short) as well as

your tenth scan.

®

200 Series reflectance scale should be

NOTE: TO INSURE MAXIMUM REFLECTANCE-SCALE ACCURACY FOR THE

HIGHEST ACCURACY IN DATA COLLECTION, YOUR QUICK CHECK

PERFORMS A CONSISTENCY TEST WHILE THE TEN CALIBRATION SCANS

ARE MADE. IF, DURING THOSE SCANS, IT DETECTS REFLECTANCE

READINGS SIGNIFICANTLY DIFFERENT FROM THE PREVIOUS ONES

RECORDED, IT WILL AGAIN “BEEP” THREE (3) TIMES AND THE LCD WILL

PROMPT YOU TO AGAIN BEGIN THE REFLECTANCE CALIBRATION

PROCEDURE. IF DURING THE MEASUREMENT OF A SAMPLE SYMBOL AN

“XX” or “- -“ IS DISPLAYED OR PRINTED A REFLECTANCE VALUE, AND

OUT OF RANGE READING HAS BEEN MADE. THE UNIT SHOULD BE

RECALIBRATED AND THE SAMPLE SHOULD BE RESCANNED.

Initial Power Up Default Settings

The Quick Check® 200 Series powers up in whatever operating mode it was last

left in. To facilitate “getting started”, we have programmed the QC200 so that it

will default, the first time it is powered up and calibrated, to the settings listed.

The many possible variations available to the QC200 user will be outlined in later

sections of this guide.

All codes Active (Auto-discrimination)

Those Codes are:

Code 39

Interleaved 2 of 5

EAN/UPC 100% Magnification

Codabar

Code 128

MSI

16K

10

Page 17

Other Configuration Settings:

“NormalAccur” – Normal Accuracy

“Trad’l P/F” – Traditional Tolerance Testing

“Avg DMargin” – Hand Held Products Averaged Decodability Margin

“Ltr. Grades” – If ANSI is invoked, Letter Grades used

“Right Handed” – LCD Right Hand Orientation

“HS Printer” – Printer Interface set for Hand Held Products QCHSP

An explanation of each of the above default settings can be found in the

CONFIGURATION/PROGRAMMING section.

11

Page 18

12

Page 19

4. Configuration/Programming

The Quick Check® 200 Series auto-recognizes or “autodiscriminates” seven bar

code symbologies - - Codabar, Code 39, Interleaved 2/5, EAN/UPC, Code 128,

MSI Code and Code 16K - - or alternately can check that symbols conform under

any or all of several applications specifications; AIAG, BOOKLAND, CCBBA,

Comp Tia/CTIA, SCC, SISAC, U.P.C.-COUPON CODE, dependent upon the

QC200 Model. The QC200 also has a number of operator selectable test and

configuration options. The QC200 user can program their unit for all of these

options in two distinct ways. One is by simply scanning a specialized Code 128

called a Command Code. Predetermined Command Codes were used in the

QC200 Quick Start section of this manual and are explained in a later section.

The QC200’s options can also be programmed manually.

®

The “heart” of the operation and manual programming of the Quick Check

Series is centered around its “Select” and “Scroll” buttons. All functions with the

QC200 are controlled by their use. Generally, pressing the Select [0] Button

moves the user from menu “level” to menu “level”. Pressing of the Scroll [<>]

Button allows the user to pick an option within these levels. At the end of the

manual are menu “flow charts” of the QC200 menu sequences. An explanation

of what programmable selections are available follows.

200

Codes/Symbology Options

The Quick Check® 200 Series symbology selection configuration is set and

controlled from within the QC200’s programming menu structure, this is entered

after power up by pressing the Select [0] Button two times as demonstrated

through the next steps:

On power up, [Qc2xx aa/lll] is displayed.

If you press the Scroll [<>] Button the results of the last scan is displayed (the

QC200 always stores the last sample scan). If you press the Select [0] Button

the following is displayed:

[Reflectom’r>]

This is the QC200’s static Reflectometer option, which is described later in this

manual. Pressing the Select [0] Button again bypasses this and changes the

LCD to:

13

Page 20

[- Specs - >]

The “>” indicates to the user that pressing the Scroll [<>] Button will allow them to

select between the different code “specifications” (generic symbologies vs.

applications) preprogrammed into the QC200. If you press Scroll [<>] here, you

are put into the “Codes” (generic symbologies) mode with a resulting LCD of:

[ - Codes - >]

Here you will be allowed to make certain modifications in the testing criteria used

for the generic symbologies. These choices are also accepted or by-passed

using the Select [0] and Scroll [<>] buttons. Pressing Select [0] will bring up the

first set of options:

Codabar Options displayed on the LCD are:

[USS – Codabr>] or [Trad Codabr>]

This choice is between the original constant character width Codabar font (with

Monarch’s original print tolerances applied) and the compatible “rationalized” font

described in AIM’s USS – Codabar specification (with the appropriate USS

tolerances applied). NOTE: An “x” shown during Codabar decoding indicates a

missing stop/start character.

Code 39 Options displayed on the LCD are:

[Cod39 no Ck>] or [Code39 w/Ck>]

This choice is whether to test for Code 39’s optional Mod 43 Check Character

(see AIM USS for Code 39).

Interleaved 2/5 Options displayed on the LCD are:

[Int25 no Ck>] or [Int25 w/Ck>]

This choice is again whether to test for an optional Interleaved 2/5 Mod Check

Character.

UPC/EAN/JAN Options displayed on the LCD are:

[UPC/EAN x.x>] where “x.x” represents a UPC/EAN magnification factor.

The possible choices are .80, .85, .90, .95, 1.0, 1.2, 1.4, 1.6, 1.8 or 2.0 and are

cycled through by repeatedly pressing the Scroll [<>] Button. The default setting

is 1.0 or 100%.

Code 128 Options displayed on the LCD are:

[Cd128 Modes>] or [Cd128 Messg>]

This choice is whether or not to have Special Extra Characters displayed and

printed within the encoded message that show Code 128’s Starting Mode, Mode

14

Page 21

Changes and Shifts. Normally this information is totally transparent to the user

but it may assist in analyzing reading or printing problems.

When scanning Code 128 in the “Show Modes” setup, the LCD display and the

printer “show” Code 128’s “Special Extra Characters” as well as information on

the symbol’s check digit. Because of the nature of some of these characters,

they are represented by special character “strings” as shown in the following

table.

CODE 128 CHARACTER TRANSLATION TABLE

CHARACTER LCD PRINTER CHARACTER LCD PRINTER

00(NUL) 0 <NL> 15(NAK) 15 <NK>

01(SOH) 1 <SH> 16(SYN) 16 <SY>

02(STX) 2 <SX> 17(ETB) 17 <EB>

03(ETX) 3 <EX> 18(CAN) 18 <CN>

04(EOQ) 4 <ET> 19(EM) 19 <EM>

05(ENQ) 5 <EQ> 1A(SUB) 1A <SB>

06(ACK) 6 <AK> 1B(ESC) 1B <ES>

07(BEL) 7 <BL> 1C(FS) 1C <FS>

08(BS) 8 <SC> 1D(GS) 1D <GS>

09(HT) 9 <HT> 1E(RS) 1E <RS>

0A(LF) A <LF> 1F(US) 1F <US>

0B(VT) B <VT> 7F(DEL) * <DL>

0C(FF) C <FF>

0D(CR) D <CR> FCN1 F1 <F1>

0E(SO) E <SO> FCN2 F2 <F2>

0F(SI) F <SI> FCN3 F3 <F3>

10(DLE) 10 <DE> FCN4 F4 <F4>

11(DC1) 11 <D1> Mode A A <A:>

12(DC2) 12 <D2> ModeB B <B:>

13(DC3) 13 <D3> ModeC C <C:>

14(DC4) 14 <D4> Shift Sh <Xh>

* - No “special” displayed character for <DEL>

Code 16K Options displayed on the LCD are:

[Cd16K Modes>] or [Cd16K Messg>]

Selection here is similar to that described under Code 128. When scanning a

Code 16K symbol, the QC200 reports quality information on each individual row

of the code. After the appropriate number of rows has been decoded, the QC200

will also output the complete Code 16K encoded message. Note that Code 16K

uses many of the same special character “strings” as those listed for Code 128.

An additional character, the “Pad” character is shown as Pd on the LCD and

printouts.

15

Page 22

MSI Code Options displayed on the LCD are:

[MSI NoUsrCk>] or [MSI Mod10Ck>] or [MSI Mod11CK>]

which allows the selection of no user specified second check digit or a user

specified second check digit of either the Modulo 10 or Modulo 11 type.

NOTE: The MSI “System” Check Digit, which is inherent to the code, is displayed

on the Quick Check’s LCD line after decode. In some cases it may not be shown

as a “human readable” digit on printed samples.

If, after the initial LCD output of “- Codes - >”, the Scroll [<>] Button is pressed

twice, the operator is then prompted to select an application specification.

“Application”/Model Options

A QC200 is preprogrammed with Industry Applications according to the Model

selected. These application tests not only test the codes for generic print quality

parameters, as applied by the applications, but also test for application specific

formats, check characters and data identifiers. The selection of an application is

accomplished by turning on the QC200.

[QC2xx aa/lll] where “xx” identifies the model number.

Continue by pressing the Select [0]button two (2) times.

[ - Specs - >] is displayed.

Press the Scroll [<>] button

[ - Codes - >] is the next display.

Continue by pressing the Scroll [<>] button until the Industry Application of choice

is display. (message displays for each application are listed below.) Then press

the Select [0] button to accept this Industry Application. NOTE: Only one (1)

Industry Application may be selected at a time.

The available Industry Applications to select from include;

AIAG [ - - AIAG - - >] – Automotive applications

BOOKLAND [ - Bookland - >] – Book applications

CCBBA [ - CCBBA - >] – Blood Bank applications

Comp Tia/CTIA/ABCD [ - - ABCD - - >] – Computer applications

HIBCC [ - HIBCC - >] – Health Care applications

LOGMARS [ - LOGMARS - >] – Government applications

SCC[ - - - SCC - - - >] – Retail (SCS/ITF, EAN-128, UCC 128 Serial)

16

Page 23

SISAC [ - SISAC - >] – Serial Coding applications

U.P.C. [ Coupon Code >] – Coupon Coding applications

If additional user information must be input when an application is selected, the

user will be prompted to do so after the Select button [0] has been pressed.

Those applications need additional input follow:

AIAG the user must indicate whether they are the “supplier” of the bar code or

the “customer” receiving the bar code (the AIAG application specification adjusts

acceptance criteria accordingly).

[AIAG Custmr >] or [AIAG Supplr >]

Pressing the Select [0] Button accepts the choice, the Scroll [<>] Button

bypasses.

SCC This application requires the entry of a magnification factor for the

Interleaved 2/5 symbols to be tested (thereby setting appropriate tolerances!).

The user steps through the choices (>75%, 74%, 70%, 66%, 62%, 58%, 54%,

50%) using the Scroll [<>] Button. Selection is made using the Select [0] Button.

BOOKLAND As with the UPC/EAN/JAN codes mentioned earlier, the Bookland

codes (which are based on those symbols) require input of a magnification factor.

Again, the possible choices are .80, .85, .90, .95, 1.0, 1.2, 1.4, 1.6, 1.8 or 2.0 and

are cycled through by repeatedly pressing the Scroll [<>] Button. Default is 1.0

or 100%.

Model Selections:

QC200 – Symbologies only

QC210 – Retail Model. Symbologies plus retail/book industry applications.

(SCC;BOOKLAND;SISAC)

QC220 – Health Model. Symbologies plus health industry applications.

(SCC;HIBSS;CCBBA)

QC230 – Industrial/Government Model. Symbologies plus

industrial/government.(LOGMARS;AIAG;ABDC/CTIA;SCC)

QC250 – All Industry Applications plus Symbologies

“Tests” Options

After Power up and pressing the Select [0] Button three times, you are brought to

the “Test” Programming Sections:

17

Page 24

[ - Tests - >]

Pressing the Scroll [<>]Button once at this point will access the area of the

QC200’s programming where test procedures are determined. Use of the Select

[0] and Scroll [<>] buttons here will allow you to select the unit's pass/fail level

criteria (Traditional vs. ANSI), use of a higher level of statistical accuracy for

measurement of each scan path (NormalAccur vs. ExtendAccur), type of

Decodability calculation to use (Avg DMargin vs. Decodability) and whether,

when ANSI is the pass/fail criteria, letter or number grading is used (Ltr. Grades

vs. Num. Grades). An explanation of these possible selections follow.

“Trad’l P/F” vs. “ANSI PrQual> A” / “ANSI PrQual> B”/ “ANSI PrQual?

C”/”ANSI PrQual> D” The Quick Check

®

200 Series can apply Pass/Fail

criteria based on either the “Traditional” bar code print tolerances and PCS

measurements or the “Graded” methodology specified in the ANSI Standard “Bar

Code Print Quality – Guideline” X3.182. Upon any measurement scan, the

QC200 beeps either once to indicate a passing symbol or three (3) times to

indicate failure of one or more tests. Choose here whether to apply Traditional

Pass/Fail criteria -- PCS value and Print Tolerances – or the graded <A> through

<F> criteria and scales from ANSI’s Print Quality Guideline.

®

“NormalAccur” vs. “ExtendAccur” The Quick Check

200 Series is capable of

scanning in a “Normal Accuracy” mode as well as in “Extended Accuracy”. In the

“Extended Accuracy” Mode, ALL individual parameter measurements and results

are averaged over eight (8) successive scans of a given scan path of the symbol

under test, greatly reducing reading variability due to variations in scanning

motion and minor scan path variations. This is not to be confused with ANSI’s

recommended ten (10) scan symbol average, where ten (10) individual symbol

scans have their final scan grade averaged.

“Avg DMargin” vs. “Decodability” “Decodability” is an ANSI graded measure

of how close a given scan comes to a reference decode failure due to variations

in the bar and/or space widths. The Quick Check

®

200 Series has the ability to

analyze a symbol using “Decodability Margin” (Avg DMargin in the QC200) as

well as true “ANSI” Decodability (Decodability in the QC200). “Decodability

Margin” is the character-averaged value of Decodability. Decodability is what

percentage of the symbology’s safe decoding margin is left for the scanner after

printing errors. Lower margin values and corresponding lower grades indicate an

increased susceptibility to decoding failure due to scanning errors such as, for

example, acceleration or bar or space size deviations. NOTE: Variations in scan

speed affects ANSI Decodability. When hand scanning set this option to “Avg

DMargin”. “Decodability” (ANSI Decodability) should only be used by those

who have a very consistent and smooth scanning action or with automated

scanning. The QC200 will “measure” your scanning and prompt you to “Scan

Faster”, “Scan Slower” or “Scan Evenly” if it detects gross variations in your scan

rates.

18

Page 25

“Ltr. Grades” vs. “Num. Grades” When the QC200 has been set to an ANSI

grade for its test criteria, the user can have that ANSI grade reported as a letter

or as a number ( 4.0=A, 3.0=B, 2.0=C, 1.0=D and 0.0=F) by selection either “Ltr.

Grades” or “Num. Grades” here.

“Config.” Options

After Power up and pressing the Select [0] Button four times, you are brought to

the “Config.” Programming Section:

[ - Config. - >]

Pressing the Scroll [<>] Button once at this point will access the area of the

QC200’s programming where reporting configuration is determined. Use of the

Select [0] and Scroll[<>] Buttons here will allow you to select the unit’s LCD

orientation (Left Handed vs. Right Handed), raise or lower the beeper pitch or

effect volume (Raise Pitch in single steps or Lower Pitch in single steps), select

the Hand Held Products QC printer (HS Printer, VHS Printer or Std Printer) and

finally save the settings in non-volatile RAM for future use. An explanation of

these possible selections follows:

“Left Handed” vs. “Right Handed” The QC200’s custom LCD display can have

its text and read-outs oriented for either a left handed or right handed user. This

automatic “flipping” of the LCD image makes the unit easy to use and read by all

operators. Selection of either orientation is done here by pressing the Scroll [<>]

Button.

“Raise Pitch” Repeated pressing of the Scroll[<>] Button increases the

pitch/volume of the QC200 beeper.

“Lower Pitch” Repeated pressing of the Scroll[<>] Button increases the

pitch/volume of the QC200 beeper.

®

“Std Printer” vs. “HS Printer” vs. “VHS Printer” . The Quick Check

Series supports all three of Hand Held Products’ accessory printers. The QCP,

QCHSP and QCSSP printer interface software is selected here by pressing the

Scroll [<>] Button until the desired setting is shown on the LCD.

To save these settings and the other previous selected options, the user again

presses the Select [0] Button after leaving the desired accessory printer selection

on the LCD. This brings the following message to the LCD:

[SaveSetngs?>]

Pressing the Select [0] Button will by-pass this (effectively answering “NO”), but

pressing the Scroll [<>] Button will accept it, changing the LCD to:

200

19

Page 26

[**Confirm**>]

This gives the user a last chance to change their minds and abort the changes.

Again, pressing Select [0] will by-pass it, but pressing Scroll[<>] will accept it

changing the LCD to:

[ - Busy! - ] then to [Version yyyy] and finally to [QC2xx aa/lll]

as the non-volatile memory is updated. The “yyyy” represents the base

software’s “checksum”. This number can be used by Hand Held Products’

Service Department when identifying a QC200. (If the Select [0] Button is

pressed after “SaveSetngs?>” or “**Confirm**>”, the LCD changes automatically

to the “Version yyyy” message.

20

Page 27

5. Symbol Testing & Scan Results

The Quick Check® 200 Series acquires data during a measurement scan utilizing

the new software-intensive “ScanProfile” methodology as specified in ANSI’s

“Bar Code Print Quality Guideline” (ANSI x3.182). (NOTE: In all cases, the

more smooth and slow the scan, the more accurate the results.) the user may be

prompted with a series of beeps (one long and three short) and one of the

following displays:

[Scan Slower!] or [Scan Evenly!] or [Scan Faster!]

indicating that the scan was either too fast, too uneven/erratic or too slow for

proper data collection. A practiced, more deliberate and smooth rescan should

be made to insure accurate results.

Both pass/fail testing and detailed measurements on a given symbol are

obtained simply by scanning across it with the QC200. The most accurate

results will be obtained by starting just outside the quiet zone and scanning in a

single, smooth motion with the optics tips and reflectance guide “foot” lightly

touching the symbol surface. Practice helps! A successful measurement will be

signaled by beeping, a blinking green (pass) or red (fail) LED and the display

showing results such as:

21

Page 28

If in Traditional P/F Test Mode. When in ANSI Grading Test Mode, the PCS

value shown is replaced with an ANSI letter grade or its numerical equivalent.

A symbol that consistently produces no beeping is either fatally out-of-spec or of

an unknown or unprogrammed bar code symbology.

The QC200’s customer LCD display shows the user a complete synopsis of the

scan results. The information shown includes the decode of the symbol’s

encoded characters (dot matrix characters in the middle of the LCD), the

symbology type (across the LCD top), the PCS or ANSI Grade (on the right when

in the Right Handed viewing orientation), an indication of bar growth/shrinkage

(small arrows to the extreme left of the LCD when in the Right Handed viewing

orientation) and in what parameter any error may have occurred (the key words

DIM, REF and/or FMT will light just to the left of the symbol decode, when in the

Right Handed viewing orientation).

If the encoded message in a bar code symbol exceeds 12 characters, the right

most character of the display will be a “right arrow” (>). In that case, pressing the

Scroll[<>] Button will “scroll” the encoded message and allow the remainder of

the message, in 11 character portion, to be viewed.

As mentioned above, uniform bar growth or shrinkage is displayed by a vertical

series of “arrows” on the LCD. One “arrow” will remain lit to indicate the average

bar width error in relation to traditional print tolerance allowances. When

centered between the “+” and “-“ on the label, the bar growth/shrinkage is at a

minimum. As the arrow position moves toward the “-”, increasing amount of

shrinkage is seen. Conversely, a move toward the “+” indicates bar growth.

When the arrow directly across from either the “+” or “-“ is lit, traditional bar width

tolerances have been exceeded. There are seven arrows in the scale.

With each test scan of a symbol, the QC200 also indicates the sample’s pass/fail

status with a characteristic “beep” pattern. One long beep with ONE short

indicates that the symbol passes the appropriate battery of tests. One long beep

with THREE short beeps indicates that it fails in some regard. Thus pass/fail

testing proceeds by simply scanning symbols and listening for a triple beep.

Upon any failure, the LCD indicates the parameter area where the failure

occurred. These areas are indicated by a three-letter abbreviation.

DIM = a DIMENSIONAL parameter error

REF = a REFLECTANCE (contrast) parameter error

FMT = a FORMAT parameter error

In a symbol with multiple errors, you will have more than one of the above

indicators lit. Exact details of the failure can be obtained by following the

procedures in the section that follows.

22

Page 29

When in the ANSI Grading mode, every tenth measurement of a given symbol

(or every eightieth measurement if also in Extended Accuracy mode) will

cause the results message for the last scan to be replaced with:

[**g/aa/lll**] x.x

reflecting the ANSI Symbol Grade (average of the ten Scan Grades per ANSI

procedures). In this display, “g” is the ANSI Grade (A,B,C,D or F), “aa” is the

verifier’s aperture size, “lll” is the verifier’s spectral response and “x.x” is the

numerical value the ANSI letter grade was derived from.

Test Result Details

Dimensional Parameters

After a successful scan is made, detailed results in the Dimensional Parameters

area are accessed by first pressing the Select [0] Button once. This will produce

the display:

[Dim’l Data>] P (or F)

Either the “P” or “F” will be shown to indicate if the symbol under test passed or

failed the Dimensional Parameters. Pressing the Scroll [<>] Button will move you

into the Dimensional Parameters details. The order the displays are shown

changes dependent upon whether the QC200 is set for “Traditional” or “ ANSI”

testing criteria (though in each case all the same displays are shown). For this

document, the order used with “Traditional” test criteria is illustrated, with the first

display showing:

[AvgBar x.xxX] P (or F)

AvgBar is the average bar print error. It is the value or amount of average bar

growth or shrinkage in the measured symbol relative to its X dimension. This

value is compared against Traditional print tolerance criteria with the “P” of “F”

showing compliance or non-compliance. Pressing the Scroll [<>] Button again

changes the display to:

[W/N Ratio x.xx] P (or F)

W/N Ratio is the wide-to-narrow ratio and is measured for those symbologies

where it is meaningful, namely Code 39, Interleaved 2/5 and USS-Codabar;

otherwise, it is not displayed. This value is compared against either generic limit

(1.8 to 3.2) or a target fixed value (e.g., 2.5 + 0.2) to determine if it passes or

fails. An out-of-range W/N ratio is considered a dimensional error under BOTH

Traditional and Graded testing criteria.

23

Page 30

Another press of the Scroll [<>] Button will display (ONLY IF applicable errors

have been found) certain Global Threshold, Reference Decode or Reference

Algorithm failure messages such as:

[GloThrsFAILS] F or [RefDcod FAIL] F or [RefAlgoFAILS] F

Global Threshold ANSI’s Symbol Grading methodology requires foremost that

a global reflectance threshold set simply at the halfway point between R(min) and

R(max) should “find” every bar and space in the symbol. The Quick Check

®

200

Series uses the ANSI prescribed methodology for precise edge location and

indicates when the global threshold requirement has not been met. “Reference

Decode or Algorithm” ANSI’s Graded symbol testing criteria requires that a

given scan be decodable using certain “reference” algorithms, else the scan fails.

Similarly, certain application specifications call for specific formats, checks or

characters that must be in the symbol. The Quick Check

®

200 Series employs

advanced decoding schemes to test the necessary reference decoding and

algorithms. If any errors are encountered, a failure is indicated appropriately.

If errors were not found in these areas, the next display would read:

[D Margin xx%] Grade or [Decod’ty xx%]Grade

Decodability/Decodability “Margin” Decodability is a Graded measure of how

close a given scan comes to a reference decode failure due to variations in bar

and space widths. The Quick Check

®

200’s “Avg DMargin” is the characteraveraged value of Decodability. Decodability is what percentage of the

symbology’s safe decoding margin is left for the scanner after printing errors.

Lower margin values and corresponding lower grades indicate an increased

susceptibility to decoding failure due to scanning errors such as, for example,

acceleration or bar or space size deviation. Decodability “Margin” is stated as “D

Margin” in the QC200’s LCD Dimensional Details display and ANSI decodability

is listed as “Decod’ty”.

If the Scroll [<>] Button is again pressed, various other Dimensional Parameter

errors might be displayed next. Examples of these follow:

[BAD QuietZon] F -- Indicates insufficient Quiet Zone width

[WIDE IC Gap] F -- Indicates the InterCharacter Gap is too wide

[BAD StrtStop] F -- Indicates either the Start or Stop Characters are bad

[BAD GuardPat] F – Indicates that the Guard Bar Pattern in a UPC/EAN/JAN

symbol is bad

[BAD Separatr] F – Indicates a bad Separator Pattern

Pressing the Scroll [<>] Button again produces the display:

24

Page 31

[Total xxx”X”]

Total xxx”X” indicates the total symbol width expressed in “X” dimensions.

“Formally” a bar code symbol’s width includes the quiet zones, however the value

presented here is a calculated count of the number of “X” dimensions from the

starting bar through the ending bar of the scanned symbol. The operator can use

this value and the symbol’s actual measured width to calculate X. By pressing

Scroll [<>] again, the display becomes:

[Calc “X”? 0]

The “X” DIMENSION can now be calculated by first pressing the Select [0]

Button (pressing Scroll [<>] will by-pass this operation) giving the following

display:

[SymLen=0.--“]

By then entering the symbol’s width as measured with the supplied ruler in

decimal inches (e.g., 1.24), the operator provides the key parameter for

calculating X. To change the value of “0.--“, press the Scroll [<>] Button. This

increments the first digit from “0” to “9”. When the desired digit is shown, press

Select [0] to accept and move to the next digit. After all three are filled in, the

Quick Check® 200 series then calculates the X Dimension and displays it in the

following manner:

[X is x.xxxx”]

If 0.00 is entered, the X remains uncalculated. The “total” width of any EAN/UPC

symbol is that of the main symbol, ignoring a possible addendum.

Reflectance Parameters

After a successful scan is made, detailed results in the Reflectance Parameters

area are accessed either by first stepping through the Dimensional Details as

shown above or by pressing the Select [0] Button twice. This will produce the

display:

[Refl Data >] P (or F)

Again, either the “P” or “F” will be shown to indicate if the symbol under test

passed or failed the Reflectance Parameters. Pressing the Scroll [<>] Button will

move you into the Reflectance Parameters details. The order of the displays are

shown changes dependent upon whether the QC200 is set for “Traditional” or

“ANSI” testing criteria (though in each case all the same displays are shown).

For this document, the order used with “Traditional” test criteria is illustrated, with

the first display showing:

[PCS xx%] P (or F)

and then pressing the Scroll [<>] Button again will give:

25

Page 32

[Rl:Rd xx:xx%] P (or F)

Print Contrast Signal (PCS), Light Reflectance (Rl) and Dark Reflectance

(Rd) are all “Traditional” measures of symbol contrast. PCS is based on the

reflectance of light areas, Rl and dark areas, Rd. These values are determined

using a definition of Rl and Rd as the Peak Light and Peak Dark points seen

during the scan. Thus Rl = R(max) and Rd = R(min) in current terminology. The

Traditional pass/fail criteria are PCS > 75% with Rl > 25% and Rd <30%. NOTE:

IF DURING THE MEASUREMENT OF A SAMPLE SYMBOL AN “XX” IS

DISPLAYED OR PRINTED AS A Rl, Rd or PCS REFLECTANCE VALUE, AND

“OUT OF RANGE” READING HAS BEEN MADE.THE QC200 SHOULD BE

RE-CALIBRATED AND THE SAMPLE SHOULD BE RESCANNED. Again

pressing the Scroll [<>] Button will change the display to:

[SymContr xx%] Grade

Symbol Contrast (SC) is a Graded measure of the difference between the

highest reflectance value R(max) and lowest reflectance value R (min) seen

during a measurement scan. Another press of the Scroll [<>] Button changes the

display to show:

[Rmin/Rmx xx%] Grade

Rmin/Rmx has an additional Pass/Fail (Grade “A” or “F”) requirement that it be

at or below 50%. Press the Scroll [<>] Button again to get:

[Modul’n xx%] Grade

Modulation (MOD) is an ANSI graded criterion equal to Edge Contrast (min)

divided by Symbol Contrast.

[Edge(mn) xx%] Grade

Edge Contrast Minimum (Ecmin or Edge(mn)) is the minimum value of Edge

Contrast (EC) seen during a measurement scan. Edge Contrast (EC) is the

reflectance difference between an adjacent bar and space. The Pass/Fail

requirement (Grade “A” or “F” here is that the EC(min) be >15%. Another press

of the Scroll [<>] Button brings us to the final Reflectance parameter detail of:

[Defects xx%] Grade

Defects is the Graded measure of the maximum Element Reflectance Non-

uniformity (noise WITHIN any element due to spots, voids, etc.) normalized to

symbol Contrast.

Format Parameters

After a successful scan is made, detailed results in the Format Parameters area

are accessed either by first stepping through the Dimensional and Reflectance

Details as shown above or by pressing the Select [0] Button three (3) times.

26

Page 33

[Msg Format >] P (or F)

Either the “P” or “F” will be shown to indicate if the symbol under test passed or

failed the Format Parameters. Pressing the Scroll [<>] Button will move you into

the Format Parameters details. The order the displays are shown changes

dependent upon whether the QC200 is set for “Traditional” or “ANSI” testing

criteria (though in each case all the same displays are shown). For this

document, the order used with “Traditional” test criteria is illustrated. If an

Application Specification has been activated, the normal sequence will be

superseded by the following display:

[APPL *Type*]

where APPL will be the appropriate Application and Type will be any possible

sub-identifier within that application. Repeated pressing of the Scroll [<>] Button

will then show any other application specific errors such as:

[BAD Source]

and will finally come to:

[MsgLength xx] P (or F)

Message Length is the length of an encoded message. The length may need to

be checked against an application-specified length restriction. Another press of

the Scroll [<>] Button displays:

[No Check Chr] P or

[ChkChr Checks] P or

[ChkChr Fails] F

Check Characters may be mandatory under a bar code symbology

specification, required by the user or by an application specification: either,

neither, or both! The display screen will reflect the requirement and the result.

Repeated pressing of the Scroll [<>] Button will reveal any additional error

situations such as:

[BAD Symbology] F if a wrong code type is found.

At this point (or any other point during the scrolling of results), pressing the

Select [0] Button will cycle the QC200 into its “Store” (if not hooked to a printer)

or “Print” (if hooked to a printer) sequence. The print sequence is explained in

Section 6.

27

Page 34

28

Page 35

6. Printer Printout Samples

[Store Data?>]

When a printer is not attached or is turned off, you are asked if you wish to store

the measured results in a 20-scan print buffer. Pressing the

Scroll [<>] Button will store the scan. The buffer’s contents can later be dumped

to the printer. When a QC200, that has stored data, is hooked to a printer and

the QC200 is then turned on, the first display will be a query on whether or not to

dump the stored information. NOTE: The QC200 will also “see” the QCAC

Charger as a “printer” when it is connected.

[Print Data?>]

When a printer is attached to the Quick Check® 200, you are asked if you wish to

print the most recent scan. Pressing the Scroll [<>] Button will cause the current

testing results to be printed and the following display will show:

[ - Busy ! - ]

NOTE: Printing can be halted after starting by momentarily pressing the POWER

button on the QC200. Printing will stop as soon as the printer’s internal buffer is

clear.

29

Page 36

Printout Samples

All of the measurements obtained during a measurement scan are saved in a

temporary buffer. When a printer is not connected those measurements can be

transferred to a 20-scan print buffer as described above. When a printer is

attached and powered, it produces a listing of full measurement details. From a

QCP or QCHSP, the printout would look similar to the following

\\\Quick Check® 200\\\

660 nm, 06 mil Scanner

UPC-A: 100% Mag. Factor

021200074424

Avg Bar Err = +.04X OK!

DecodeMargin = 92% <A>

Symbol Total = 095 “X”

Prnt Contr Sig = 94% OK!

Reflect (Light) = 75% OK!

Reflect (Dark) = 03% OK!

Symbol Contrst = 72% <A>

R(min)/R(max) = 04% <A>

Modulation = 79% <A>

EdgeContr(min) = 57% <A>

“Defects” = 05% <A>

Message Length = 11 OK!

Check Charctr Passes OK!

Traditional Tests <PASS>

Bar Growth: IN TOL (+)

“P C S” – OK

Traditional Tests - PASS -

Format Tests - PASS -

ANSI Parameters <A>

Dimension Checks <P>

Format Checks <P>

Profile QualityGrade <A>

30

Page 37

From a QCSSP, a typical printout would look more like the following:

Quick Check® 200 –

660 nm, 06 mil Scanner

Code 39

*+A123B4C5D6E711*

AvgBar = +.05 X OK! W/N Ratio = 2.9 OK!

DecodMargn = 88% <A> Symbol Totals 264X

PCS = 90% OK! R(L) = 79% OK! R(D) = 07% OK!

SymbolContr = 72% <A> R(mn)/R(mx) = 09% <A>

Modulation = 61% <B> EdgeCtr(mn) = 44% <A>

“Defects” = 04% <A>

Msg Length = 15 OK! -No-Check Character

Bar Growth: IN TOL

“P C S” : OK

Traditional Tests -PASS-

Format Tests -PASS-

ANSI Parameters: <B>

Dimension Checks: <P>

Format Checks: <P>

Profile Quality Grade is <B>

For all printers, on the tenth scan of a given symbol (or eightieth scan if in

“Extended Accuracy” mode), a message similar to the following will be appended

to the normal printout.

31

Page 38

For the QCP and QCHSP:

***************************

* Symbol Quality Grade *

* Avg 4.0 = > A/06/660*

***************************

And from the QCSSP:

*****************************************************

****

Symbol Quality Grade: Avg 3.0 = > B/06/660

*****************************************************

****

Each result shown in the printout is information also available on the display as

previously described. Having the wrong printer setting, if encountered, may

cause printing difficulties. This is set within the “Config.” Menu as explained

previously.

Printing can also be initiated in either a single (“on demand”) or continuous

(“auto-print”) print mode by use of the Printer Control Command Codes found

later in this manual.

NOTE: Printing can be halted after starting by momentarily pressing the

POWER button on the QC200. Printing will stop as soon as the printer’s internal

buffer is clear.

32

Page 39

7. Special Functions

The Quick Check® 200 series can be set to a special “static” reflectance

measurement function (Reflectometer Mode). This mode is especially useful in

investigating the underlying optical characteristics of bar code symbols. The

Reflectometer Mode, along with the Command Code mode is covered below.

Reflectometer Mode

This menu selectable Special Function is entered by pressing the Scroll [<>]

Button when [Reflectom’r>] is present on the LCD. Then in this special

reflectometer mode, the reflectance “seen” by the QC200’s optics is continuously

displays as both a two digit reflectance percentage and on a graphic bar graph

as soon as the mode is invoked.

Here the xx% and the graphic bar graph (or “gas gauge”) represent a reflectance

value of 00% to 100% from the static reflectometer. This mode is not

“memorized” when the unit is shut off. When turning the unit back on after power

down, it will be necessary to re-establish the Reflectometer Mode if needed. For

these values to be meaningful and consistent, it is critical first that reflectance

calibration have been performed recently and second that the QC200 be held

with its “reflectance foot” and optics tip both touching the sample to maintain the

proper angle.

Command Code Programming

The Quick Check® 200 series has the unique ability to be “pre-programmed” by

the user by scanning a specially encoded code 128 symbol. This symbol will

automatically make all the selections normally made by the user stepping

through the normal menu sequence. This is particularly useful if the user has

one or two particular setups that they are constantly switching between.

Samples of Command Codes, such as the Command Code to “reset” the QC200

back to all generic default settings, are included with each unit.

NOTE: Display orientation (Right Handed vs. Left Handed) and Printer Interface

selection ARE NOT set using the Command Code. Factory default settings for

these are “Right handed” and “QCHSP”.

Users with one of the accessory Quick Check® Printers can produce a Command

Code of their QC200’s present set-up by following the next steps;

First be sure your Quick Check

the proper interface selection has been made and both are turned on. Next,

®

200 is connected to a Quick Check® Printer, that

33

Page 40

locate the Special Features Bar Code Menu in the back of this manual. On this

Menu sheet are two codes, Command Code “Unlocked” and Command Code

“Locked”. Scanning either will result in the Quick Check

®

Printer printing the

specialized code 128 you can use for rapid one step programming of your

QC200.

The Command Code “Locked” code allows the user to add a feature to the

Command Code that will “lock” the menu programming after that code is scanned

the first time. This prevents access to reprogramming of the unit by the casual

user. The “lock” can not be removed unless the user scans another, previously

prepared, Command Code that does not have the “lock” function in it, such as

the “reset” Command Code supplied in this manual. (NOTE: Before actually

using this code, label it along the line provided with a description and make a

copy of it on your office copier. This helps improve the bar code quality. Making

a “reduced size” copy will help also.)

These codes are also produced by Hand Held Products. Contact Customer

Administration at Hand Held Products about this service. It will be necessary to

make the following selections;

OPERATING MODE

Extended Accuracy (8-Scan/Scan path average)

ON(ExtendAccur) or OFF(NormalAccur)

Decodability (choose one)

Hand Held Products’ Decodability Margin (Avg DMargin)

ANSI’s (Decodability)

Pass/Fail Criteria (choose one)

“Traditional” P/F (Trad’l P/F) or

ANSI Grades – D, C, B, or A

ANSI Grading by LETTER or NUMBER (choose one)

Letter Grades (Ltr.Grades)

Number Grades (Num. Grades)

Program Menu Lock

On or Off

Reflectometer Mode

On or Off

34

Page 41

SPECIFICATION

Generic Codes vs. Application Spec (choose one)

Generic Codes (if selected an Application cannot also be selected)

Code 39 Yes or No and Mod Check? Yes or No

Interleaved 2 of 5 Yes or No and Mod Check? Yes or No

UPC/EAN/JAN Yes or No

Magnification Factor?_ _ _ (Default is 100)

Choices – 080/085/090/095/100/120/140/160/180/200

Codabar Yes or No

Traditional Codabar? Yes or No

USS Codabar? Yes or No

Code 128 Yes or No and Modes or Messages (choose one)

MSI Code Yes or No

User Check Digit? Yes or No

Mod 10 or Mod 11? (choose one)

Code 16K Yes or No and Modes or Messages? (choose one)

Application Specification

CCBBA Yes or No

HIBCC Yes or No

AIAG Yes or No

Bookland Yes or No

SISAC Yes or No

Logmars Yes or No

CompTia/CITA(ABCD) Yes or No

SCC Yes or No

I 2/5 mag factor? _ _ _ (default 075)

35

Page 42

36

Page 43

8. Quick Check Maintenance

Battery Charging

Charging the battery pack > > when the batteries require recharging, the LOW

BATTERY!! Prompt will flash on the LCD. The unit will not allow further scans

until it has been turned off and the batteries recharge to a level above the

operational minimum. The batteries will only recharge when the Quick Check is

not in use.

To charge the batteries in the unit:

1. Plug the QC charger into the power jack on the end of the Quick Check.

2. Plug the AC charger power cube into an appropriate VAC wall outlet.

3. Charge the batteries for a minimum of six (6) hours.

After following the proper battery charging time, your Quick Check will be ready

for operation.

Scanner Tip Cleaning

Occasionally the scanner tip and its optically clear window may become partially

obstructed by ink, paper fibers or other deposits. To insure reliable scanning,

you should check the tip periodically and clean it if dirty.

To clean the scanner tip:

1. With the Quick Check turned off, lightly dust the tip with a soft camel’s

hairbrush or equally soft device.

2. If ink or deposits are still evident, using a mild cleaning solution and soft

applicator (cotton swab), wipe the tip to clean.

NOTE: Damaged wand tips may be replaced. Contact the Customer

Administration or Service Department for details.

Reflectance Calibration Page Replacement

The Reflectance Calibration Page that comes with your Quick Check® 200 is

used for setting the unit’s reflection calibration point. This page is a precision

made standard. If it should become physically damaged or dirty, it should be

replaced in order to insure proper operation of the unit. Contact Customer

Administration at Hand Held Products to order replacements.

37

Page 44

Troubleshooting

If your Quick Check fails to operate properly after following all operation

instructions carefully, do not open the case or attempt to repair. This will void the

warranty. Contact Hand Held Products for assistance.

38

Page 45

9. Single Scan To Result (SSTR)

Hand Held Products’ Single Scan To Result (SSTR) feature allows the user to

quickly and easily access test results using the following SSTR bar codes,

without having to step through each of the QC200’s individual result menu steps.

After a test scan is completed, the user can find the result they are interested in

by simply scanning the appropriate SSTR Code. If another result is required,

simply scan that SSTR code.

You can set the QC200 to display a particular parameter as the default “first

message” after each test scan by scanning the “INSTALL” SSTR Code, then the

SSTR Code that you desire as your default and finally scanning the “SAVE

SETTINGS” SSTR Code twice.

By installing the “First Failure” SSTR Code as the default, your QC200 will

display as its default first message, whichever parameter fails “first” on a test

scan. The order of test/failure is the same order as that of the parameters listed

in a QC200 printout. See the “PRINTOUTS” section of this manual.

Installing the “Decode” SSTR Code will reset the QC200 to factory default report

settings.

NOTE: All parameter test results are still accessible by using the QC200’s

Select [0] and Scroll [<>] buttons as outline in the “TEST RESULT

DETAILS” section of this manual.

39

Page 46

40

Page 47

10. Printer Information

Saving Data

When you scan a bar code symbol, and you do not have a printer connected to

the Quick Check, or it is connected by not turned on, the Quick Check can save

the measured data in its temporary buffer. You can send scan results to this

temporary buffer by using special Print/Store Codes or stepping through the

menus. Later you can send this data to a printer.

When a printer is attached to the Quick check and turned on, you can print the

results stored in the buffer or, if the buffer is empty, the current results, using the

special Print/Store Codes or stepping through the menus.

When you turn on the Quick Check and the buffer has stored data or you fill the

buffer during use, the display will tell you. You can print or delete the stored

records. Instructions are provided later in this section.

Reviewing printouts

The Quick Check can print to three Quick Check printers. The printouts from the

QCP and QCHSP look similar while the printout from the QCSSP looks different.

Both types are shown in the Figure 10-1.

Figure 10-1 QCP and QCHSP Printers

41

Page 48

Figure 10-2, QCP and QCHSP printout

\\\Quick Check® 200\\\

660 nm, 06 mil Scanner

UPC-A: 100% Mag. Factor

Avg Bar Err = +.04X OK!

DecodeMargin = 92% <A>

Symbol Total = 095 “X”

Prnt Contr Sig = 94% OK!

Reflect (Light) = 75% OK!

Reflect (Dark) = 03% OK!

Symbol Contrst = 72% <A>

R(min)/R(max) = 04% <A>

Modulation = 79% <A>

EdgeContr(min) = 57% <A>

“Defects” = 05% <A>

Message Length = 11 OK!

Check Charctr Passes OK!

Traditional Tests <PASS>

Bar Growth: IN TOL (+)

Traditional Tests - PASS -

Format Tests - PASS –

ANSI Parameters <A>

Dimension Checks <P>

Format Checks <P>

Profile Quality Grade <A>

021200074424

“P C S” – OK

42

Page 49

Figure 10-3. QCSSP printout

AvgBar = +.05 X OK! W/N Ratio = 2.9 OK!

DecodMargn = 88% <A> Symbol Totals 264X

PCS = 90% OK! R(L) = 79% OK! R(D) = 07% OK!

SymbolContr = 72% <A> R(mn)/R(mx) = 09% <A>

Modulation = 61% <B> EdgeCtr(mn) = 44% <A>

Msg Length = 15 OK! -No-Check Character

Quick Check® 200 –

660 nm, 06 mil Scanner

Code 39

*+A123B4C5D6E711*

“Defects” = 04% <A>

Bar Growth: IN TOL

“P C S” : OK

Traditional Tests -PASS-

Format Tests -PASS-

ANSI Parameters: <B>

Dimension Checks: <P>

Format Checks: <P>

Profile Quality Grade is <B>

43

Page 50

Using a printer

The Quick Check supports three different Hand Held Products serial printers:

• Quick Check Printer (QCP)

• Quick Check High Speed Printer (QCHSP)

• Quick Check Super Speed Printer (QCSSP)

The QC and QCHSP are both impact printers. The QCSSP is a thermal printer

with high quality output.

When you first receive your printer, you should carefully unpack it. Before

attempting to use it, inspect the contents of the package for any shipping

damage. If there is evidence of damage, please keep ALL packing materials and

contact the delivery carrier as soon as possible for claim procedure.

Confirm that you have the following items:

• printer

• QCSSP, one roll of thermal paper

• QCP and QCHSP, one roll of paper

• QCSSP, AC power cord

QCP and QCHPS, Power Supply

For maximum printer performance, follow these general precautions for any type

of printer:

• Never place the printer where it is exposed to direct sunlight.

• Never apply power while you are plugging or unplugging an input

connector.

• Do not print without paper or a ribbon as this may damage the print head.

• Do not subject the printer to temperatures below 5°C or above 40°C

during operations, or to a sudden change in temperature.

• Insert the connectors so that a slight pressure seats the cable properly.

Never force the connectors as this could damage the cable.

Print your work

1. Connect your printer to the Quick Check and turn both units on.

2. Scan a bar code symbol.

3. Scan the appropriate special Print/Store Code. The Codes are located at the

back of this manual. There are four codes, one for each type of Quick Check

printer and one for a PC printer. The Quick Check sends your data to the

printer and begins printing.

44

Page 51

Save data when a printer is not connected

1. Scan a bar code symbol.

2. Scan the appropriate special Print/Store Code. The Codes are located at the

back of this manual. There are four codes, one for each type of Quick Check

printer and one for a PC printer. You can save results from up to 25 scans in

this buffer and then connect the printer and print your results.

OR

3. Press Select [0] four times or until Store Data? appears. Press Select [0]

again to store the data. The data is stored in the temporary buffer. You can

save results from up to 25 scans in this buffer. When you connect a printer

and turn it on, you can print the data.

Review data from the last scan:

1. If the Quick Check is turned off, turn it on.

The message, BUF XX% Ful appears.

2. Press Scroll [<>]

The message, Print Bufr? appears.

3. Review the data, press Scroll [<>]

Information from the last bar code scanned appears.

Print or delete stored data:

1. Connect your printer to the Quick Check and turn on both units.

2. Turn on Quick Check.

The message, Buf XX% Ful appears.

3. Press Scroll [<>].

The message, Print Bufr? appears.

4. To print the stored data, press Scroll [<>] twice. After you press Scroll [<>]

once, the message, **Confimr** appears. The Quick Check sends the data

to the printer. After you press Scroll [<>] a second time, the message –

Busy!- appears.

OR

5. To delete the stored data, press Select [0] twice. After you press Select [0]

once, the message, Dump Buffr? appears. After you press Select [0] a

second time, the message, **Confimr** appears.

45

Page 52

Stop printing

1. During printing, press and momentarily hold the power switch on the Quick

Check. Printing stops when the printer’s internal buffer is clear.

OR

2. Wait until the printer stops automatically.

Using the QCP and QCHSP

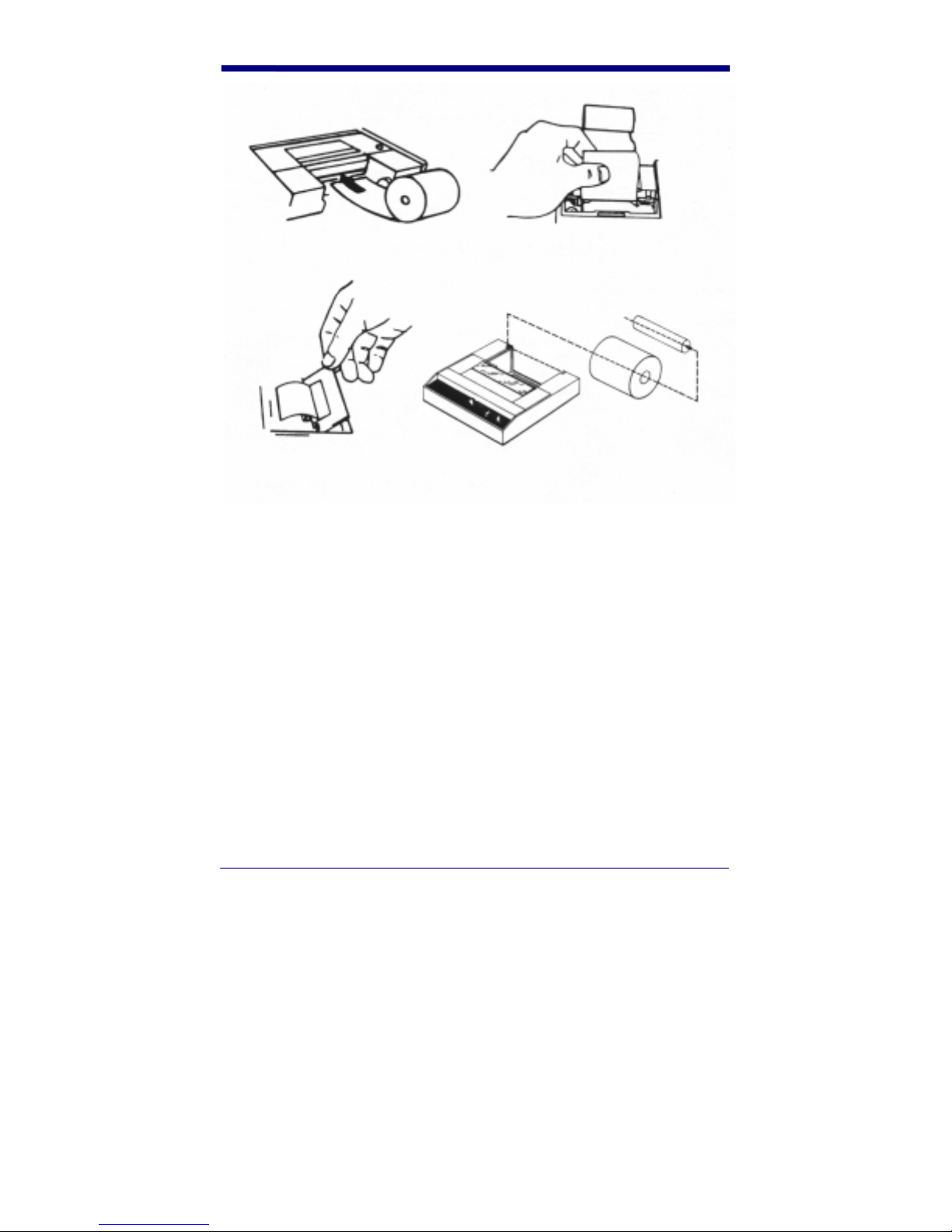

The QCP and QCHSP are shown in Figure 10-4.

Figure 10-4. QCP and QCHSP

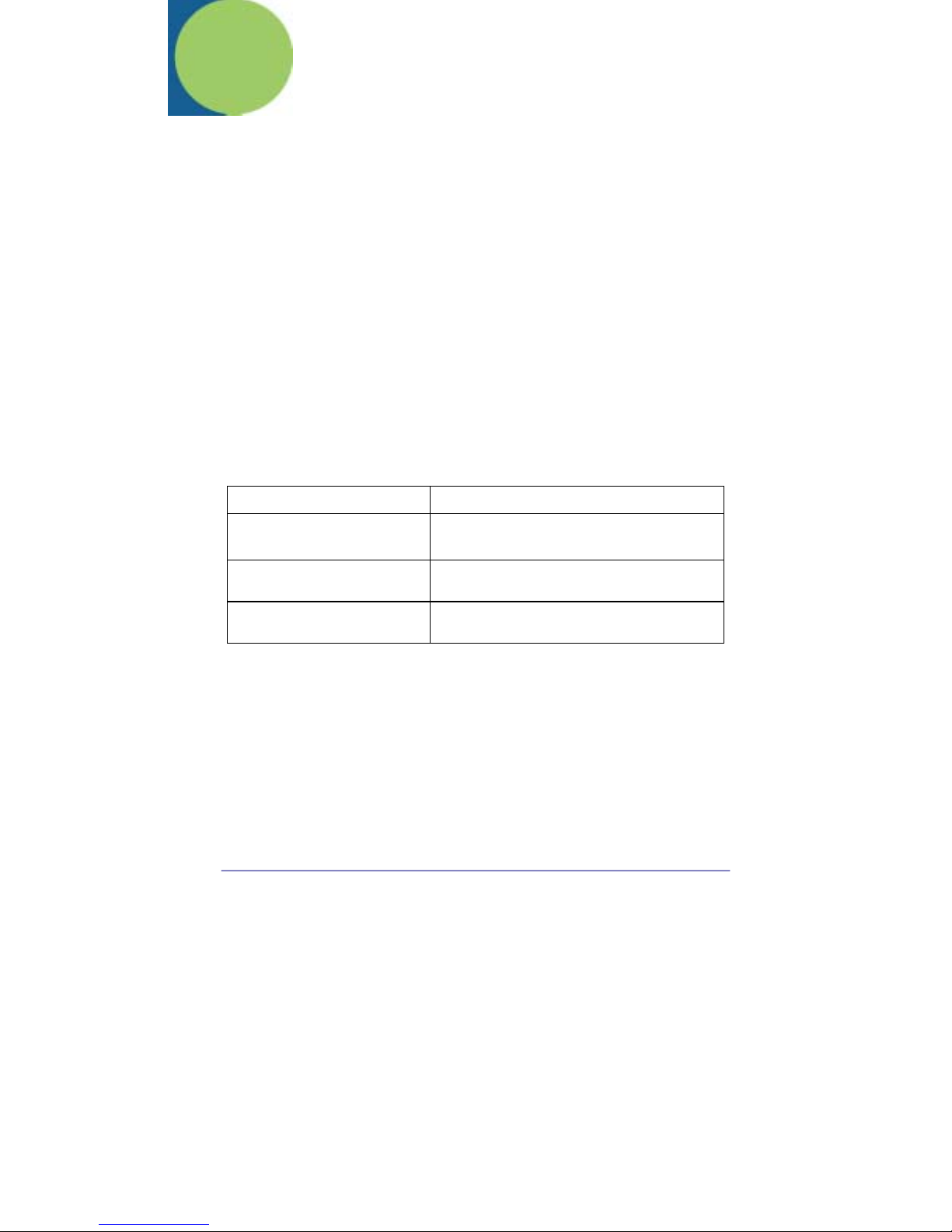

A three-position power switch on the printer’s front panel determines its function

as described in the following table.

46

Page 53

Switch Position Function

Down Left Off

Center On

Down Right Paper Feed