Page 1

User’s Guide

User’s Guide

User’s Guide

User’s Guide

User’s Guide

User’s Gu ide

™

IMAGETEAM™ 4400/4700

2D Series

Hand Held Imager

User’s Guide

Page 2

Statement of Agency Compliance

This device complies with part 15 of the FCC Rule s. Operation is subject to the

following two conditi ons: (1) this device may not cause harm ful interference, and

(2) this device must accep t any interference rec eived, including interfere nce that

may cause undesired operation.

FCC Class B Compliance State ment

This equipment h as been teste d and f ound t o comp ly with the li mits for a Class

B digital device p ursuant to par t 15 of the FCC Rules. These lim its are design ed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determ ined by turning the equip ment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving ante nna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio or television technician for

help.

Caution: Any changes or modifications made to this device that are not

expressly approved by Welch Allyn Data Collection, Inc. may void the user’s

authority to operate the equipment.

Note: To maintain compliance with FCC Rules and Regulations, cables

connected to this device must be

wire(s) have been grounded (tied) to the connector shell.

shielded

cables, in which the cable shield

Canadian Notice

This equipment does not exce ed the Class B limits for radio noise emissions as

described in th e Radio Interference Regula tions o f the Canad ian Departm ent of

Communications.

Le present appareil num erique n’emet pas de bruits radioelectriques depassant

les limites applicables aux app areils num eriques de la classe B pre scrites dans

le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

CDRH Laser Safety Statement

This product complies with US DHHS 21 CFR J Part 1040.10. This product is a

CLASS II LASER PRODUCT with a maximum output of 1.0 mW at 670

nanometers and continuous wave.

EN 60825-1 Laser Safety Statement

This product is classified as a CLASS 2 LASER PRODUCT with a maximum

output of 1.0 mW at 670 nanome ters per EN 608 25-1:1994 , Issue 2, June 1 997.

Page 3

The CE mark on the product indicates that the system has be en tested

to and conforms with the provisions noted within the 89/336/EEC

Electromagnetic Compatibility Directive and the 73/23/EEC Low

Voltage Directive.

For further information please contact:

Welch Allyn Ltd.

Block 1, Bracken Business Park

Sandyford, C o. Dublin

Ireland

or

Welch Allyn Ltd.

1st Floor

Dallam Court Dallam Lane

Warrington, Cheshire WA2 7LT

England

Welch Allyn Data Collection, Inc. shall not be liable for use of our product with

equipment (i.e ., power supplies, p ersonal computers, et c.) that is not CE mar ked

and does not comply with the Low Voltage Directive.

Patents

The IMAGETEAM 4400/4700 products are covered by one or more of the

following U.S. P atents: 5,420,409 , 5,780,834, 5,723, 853; 5,723,868; 5,8 25,006;

5,900,613; 5,929,418. Other U.S. and foreign patents pending.

Scan on Demand is covered by the following patent: 5,463,214.

Image Sensor Containment System is covered by the following patent:

5,838,495.

Disclaimer

Welch Allyn Data Collection, Inc. reserves the right to make changes in

specifications and other information contained in this document without prior

notice, and the reader should in all cases consult Welch Allyn Data Collection,

Inc. to determine whether any such changes have been made. The information

in this publication does not represent a commitment on the part of Welch Allyn

Data Collection, Inc.

Welch Allyn Data Collection, Inc. shall not be liable for technical or editorial

errors or omissions contained herein; nor for incidental or consequential

damages resulting from the furnishing, performance, or use of this material.

This docume nt contains pr oprietary information wh ich is pro tected by copyr ight.

All rights are reserved. No part of this document may be photocopied,

reproduced , or translated into another language w ithout the prior written consent

of Welch Allyn Data Collection, Incorporated.

1999-2000 Welch Allyn Data Collection, Inc. All rights reserved.

Welch Allyn Data Collection, Inc. Web Address: http://dcd.welchallyn.com

Page 4

Page 5

Chapter 1 - Introduction and Installation

About the Hand-Held 2D Imager ......................................... 1-1

Unpacking the Imager....... ...................................... .............. 1-2

IT4400 Imager Identification................................................ 1-3

IT4700 Imager Identification................................................ 1-4

Laser and LED Safety........................................................... 1-5

Connecting the Scanner When Powered by Host

(Keyboard W edg e)......... ........................... ......................... 1-6

Reading Techniques.............................................................. 1-7

Depth of Field Charts.... ........................... ............................. 1-8

Chapter 2 - Programming

Introduction........................................................................... 2-1

Reset Factory Settings .......................................................... 2-2

Status Check ......... ................................................................ 2-2

All Symbologies ............................................................. ...... 2-3

Revision Selections... ....................................... ..................... 2-3

Terminal Interface ................................................................ 2-4

Supported Termin als Chart.................. ................ ................. 2-5

Keyboard Country ................................................................ 2-6

Keyboard Style ..................................................................... 2-7

Keyboard Modifiers.............................................................. 2-8

Keyboard Function Relationships......................................... 2-9

Connecting the Scanner to a Serial Port ............................. 2-10

Communication Settings..................................................... 2-11

Parity ............................................................................ 2-11

Baud Rate.................................................. ................... 2-12

Word Length Data Bits ........................................ ........ 2-13

Word Length St o p Bits... ............... ............................... 2-13

Hardware Flow Control................................................ 2-14

Software Flow Control................................................. 2-14

Serial Triggering .......................................................... 2-15

Power Saving Mode.. .... ...................................................... 2-16

Power Hold Mode. ........................... ........................... ........ 2-16

i

Page 6

LED Power Level................................................................2-17

LED Flashing......................................................................2-17

Aimer Delay........................................................................2-18

Aimer Timeout....................................................................2-18

Aimer Interval.....................................................................2-19

AutoTrigger.........................................................................2-20

Scan Stand...........................................................................2-20

Scan Stand LE D In ten sity...... .......................................2-20

Scan Stand Lig hts....... ..................................................2-21

Presentation Mo de...............................................................2-21

Presentation Reread Delay......................... ...................2-21

Presentation Default .....................................................2-21

Presentation Aimer......... ..............................................2-22

Zoom ...................................................................................2-22

Zoom Placement........ ............... ....................................... ....2-23

Beeper Volum e.................. ...................................... ............2-24

Power Up Beeper ................................................................2-24

Output Sequence Beeper .....................................................2-24

Beep On Decode .................................................................2-25

Beeper Default................... .... ................ .......................2-25

Intercharacter, Interfunction,

and Intermessage Delays ..................................................2-26

Intercharacter Delay ......................... ...........................2-26

Interfunction Delay ......................................................2-27

Intermessage Delay ......................................................2-28

Prefix/Suffix Ov erview............ ........................... ................2-29

Adding a Prefix or Suffix .............................................2-30

Add a Carriage Return Suffix to All Symbologies ......2-31

Add a Code I.D. Prefix to All Symbologies ................2-31

Add an AIM I.D. Prefix to All Symbologies ...............2-31

Prefix Entries................................................................2-32

Suffix Entries.................. ........................... ...................2-32

Symbology Chart ................................................................2-33

Decimal to Hex to ASCII Conversion Chart.......................2-34

ii

Page 7

Data Format Editor Overview.............................................2-35

Format Editor Commands.............................................2-36

Data Format Editor .......................................................2-38

Data Formatter..............................................................2-39

Require Data Format.....................................................2-39

Show Data Formats.......................................................2-39

Alternate Data Formats.................................................2-40

Output Sequence Overview.................................................2-41

Require Output Sequence .............................................2-43

Output Sequence Editor ................................................2-44

Multiple Symbols ................................................................2-45

No Read......... ...................................... ................................2-45

Print Weight ........................................................................2-46

Chapter 3 - Symbologies

Introduction ...........................................................................3-1

Codabar .................................................................................3-2

Start/Stop Characters ......................................................3-2

Message Len gth..... .... .... .... ... .... ................ .... ............... ...3 -2

Check Character..... ........................... .............................. 3-3

Code 39..................................................................................3-4

Start/Stop Characters ......................................................3-4

Message Len gth..... .... .... .... ... .... ................ .... ............... ...3 -4

Full ASCII..................................... ..................................3-5

Check Character..... ........................... .............................. 3-6

Interleaved 2 of 5...................................................................3-7

Message Len gth..... .... .... .... ... .... ................ .... ............... ...3 -7

Check Digit............ ....................................... ..................3-8

Iata 2 of 5...............................................................................3-9

Message Len gth..... .... .... .... ... ................ .... ............... .... ...3 -9

Code 93................................................................................3-10

Message Len gth..... .... .... .... ... ................ .... ............... .... .3-10

Code 128..............................................................................3-11

Message Len gth..... .... .... .... ... ................ .... ............... .... .3-11

ISBT ....................................................................................3-12

iii

Page 8

EAN/JAN 8.........................................................................3-13

Check Digit............................ .......................................3-13

EAN/JAN 13.......................................................................3-14

Check Digit............................ .......................................3-14

EAN Addenda.....................................................................3-15

UPC A...................................... ...........................................3-16

Check Digit............................ .......................................3-16

Number System ............................................................3-16

UPC E0....... ............................................................. ............3-17

Check Digit............................ .......................................3-17

Number System ............................................................3-17

Version E Expand.........................................................3-18

UPC E1....... ............................................................. ............3-18

UPC Addenda......................................................................3- 18

RSS-14 ................................................................................3-19

RSS-14 Limited....................................................... ............3-19

RSS-14 Expanded ................. ...................................... ........3-20

Message Len gth.......... .... ... .... .... ................ ............... ....3-20

Codablock ...........................................................................3-21

Message Len gth.......... .... ... .... .... ................ ............... ....3-21

PDF417 ...............................................................................3-22

Message Len gth.......... .... ... .... .... ................ ............... ....3-22

Micro PDF417.....................................................................3-23

Message Len gth.......... .... ... .... .... ................ ............... ....3-23

Code 49 ...............................................................................3-24

Message Len gth.......... .... ... .... .... ................ ............... ....3-24

Composite Codes ................................................................3-25

Message Len gth.......... .... ... .... .... ................ ............... ....3-25

U.S. Postal Service POSTNET Code..................................3-26

Planet Code.........................................................................3-26

British Post Office 4 State Code ........................................3-26

Canadian 4 State Code ........................................................3-26

Dutch Postal Code...............................................................3-26

Australian 4 State Code.......................................................3-27

Japanese Postal Service.......................................................3-27

QR Code................ ..............................................................3-28

Message Len gth.......... .... ... .... .... ................ ............... ....3-28

iv

Page 9

Data Matrix..........................................................................3-29

Message Len gth..... .... .... .... ... .... ................ .... ............... .3-29

MaxiCode ............................................................................3-30

Message Len gth..... .... .... .... ... .... ................ .... ............... .3-30

Structured Carrier Message Only .................................3-31

Aztec Code ..........................................................................3-32

Message Len gth..... .... .... .... ... .... ................ .... ............... .3-32

VeriCode .............................................................................3-33

VeriCode Size...............................................................3-34

Test Menu........................................................ ....................3-35

2D Scan Diagnostics ............ .... ... .... .... ................ ... .............3- 35

Chapter 4 - OCR P r ogramming

Introduction ...........................................................................4-1

OCR.......................................................................................4-2

Creating OCR Templates ......................................................4-3

Creating an OCR Template.............................................4-3

Stringing Together Multiple Formats

(Creating “Or” Statements).............................................4-5

Creating a User-Defined Variable ..................................4-6

Adding an OCR Chec k Character. ..................................4-6

OCR Template Codes .....................................................4-7

Chapter 5 - Default Charts

Communication (RS-232) Selections .............................5-1

Imager Selectio ns.................. ........................... ...............5 -1

Prefix/Suffix Selections ........... ........................... ...........5 -2

Data Formatter Selections...............................................5-2

Output Sequence Selections............................................5-2

Linear Symbologies........................................................5-3

Postal Symbology Selections..........................................5-5

2D Matrix Selections .................... .... .... .... .... ... .... .... .... ...5 -5

v

Page 10

Chapter 6 - Quick*View

Quick*View Demonstration Software Instructions ..............6-1

Setting Up the Imager and the Quick*View Software...6-1

Installing Quick *View from the Web................. ..................6-2

Using the Quick* View Sof tware ................................ ..........6 -3

Electronic Parts Manufacturing Demonstration .............6-6

Patient Registration Demonstration................................6-8

Bills of Lading Demonstration .......................................6-9

Load New Imager Software..........................................6-14

Serial Programming Commands...................................6-15

Status Check ..........................................................6-17

Output Selections ..................................................6-17

Communication Settings .......................................6-18

Imager Selectio ns ........................... .......................6-19

Output Selections ..................................................6-20

Prefix/Suffix Se lectio ns ................. ............... ........6-20

Data Formatter Selections .....................................6-21

Output Sequence Selections ..................................6-21

Linear Symbology Selections ...............................6-21

Stacked Symbology Selections .............................6-25

Postal Symbology Selections ................................6-25

2D Matrix Symbology Selections ...... ...................6-26

Chapter 7 - Visual Menu

Visual Menu Introduction.....................................................7-1

Installing Visual Menu fr om the Web.......... ................ ..7-2

Chapter 8 - Interface Keys

Chapter 9 - Product Specifications & Pinouts

Product Specifications.......................... .................................9-1

Cable Pinouts ........................................................................9-3

RS-232 Output, external power (IT4400 and IT4700)...9-3

IT4400 Dimensions...............................................................9 -4

IT4700 Dimensions...............................................................9 -5

vi

Page 11

Chapter 10 - Maintenance & Troubleshooting

Repairs.................................................................................10-1

Maintenance ........................................................................10-1

Replacing the Interface Cable.......................................10-2

Troubleshooting...................................................................10-4

Application Support......................................................10-5

Chapter 11 - Customer Support

Obtaining Factory Service...................................................11-1

Limited Warranty ................................................................11-3

Sample Symbols

Programming Chart

vii

Page 12

viii

Page 13

1

Introduction an d In sta llation

About the Hand - He ld 2D Imager

The hand-held 2D Imager is an economical, durable solution for a wide variety

of data collection appl ications. The Imager features the following:

• A tough, ergonomic thermoplastic housing for comfort and durability.

• Omni-directional reading of a variety of printed symbols, including the

most popular linear and 2D matrix symbologi es.

• Advanced binary optics for ease of aiming and framing labels.

• RS-232, keyboard wedge, and laser emulation communication outputs.

• The ability to captur e and do wnload image s to a PC for signatu re captur e

software applications, and PC-based decoding.

• The ability to read single line OCR-A and OCR-B fonts.

About this Manual

This user’s guide p rovides installation instr uctions for the hand-held Image r. The

chapters contain the following information:

Chapter 1 Unpacking and installing the Imager

Chapter 2 Programming selections

Chapter 3 Symbology programming selection s

Chapter 4 OCR programming

Chapter 5 Default settings

Chapter 6 Quick*View software infor mation and serial program ming

commands

Chapter 7 Visual Menu softwar e

Chapter 8 Interface Keys

Chapter 9 Product specification s and conne ctor pi nout li stings

Chapter 10 Maintenance and troub leshooting

Chapter 11 Customer support, service information, and warranty

1 - 1

Page 14

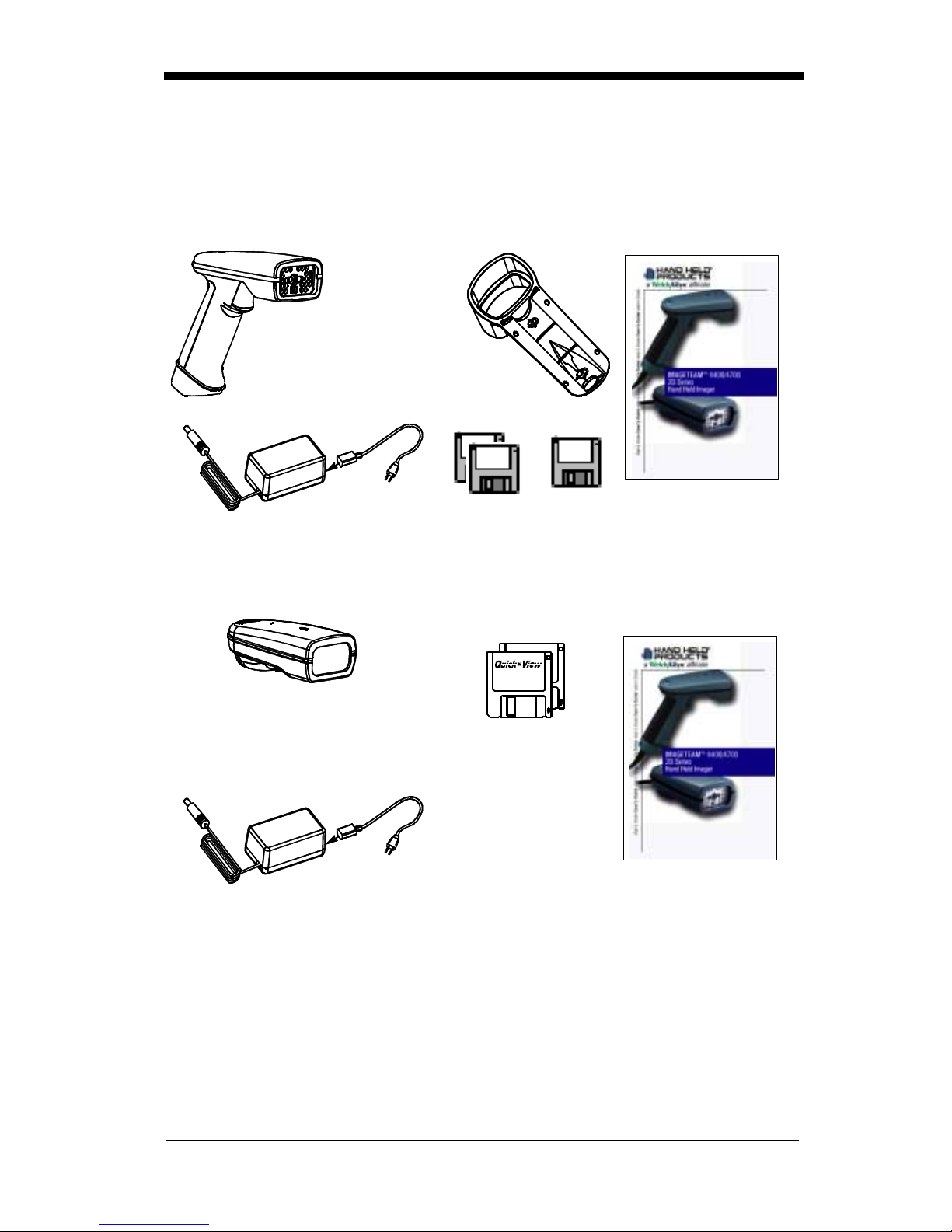

Unpacking the Imager

Open the carton. The shipping carton or container should contain:

IMAGETEAM 4400:

IMAGETEAM 4400

Hand Held Imager

Holder

Universal Power Supply

and Power Cable

IMAGETEAM 4700:

IMAGETEAM 4700

Hand Held/Fixed

Mount Imager

Quick*View

Visual Menu

User’s Guide

Demonstration

Diskettes

Demonstration

Diskettes

User’s Guide

Universal Power Supply

and Power Cable

• Check to make sure everything you ordered is present.

• Save the shipping container for later storage or shipping.

• Check for damage during shipment. Report damage immediately to the

carrier who delivered the carton.

1 - 2

Page 15

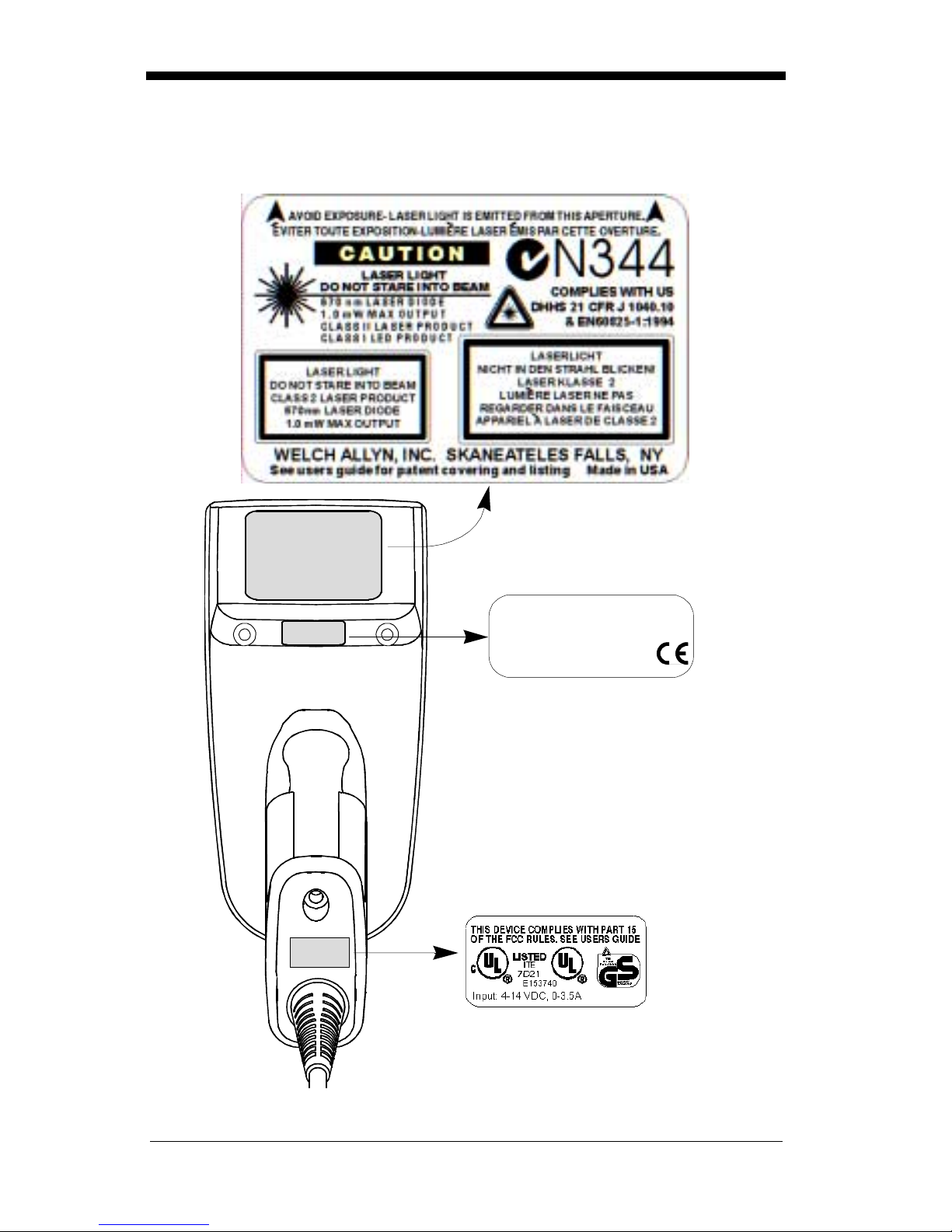

IT4400 Imager Ide ntifi cation

Enlarged View of Label

Model# = 4400XX-XX

Manufactured = July 1999

Seria l # = P-12- 34567

S/W = 34567001/4400

Hand Held IT4 400 I mag er

Bottom View

1 - 3

Page 16

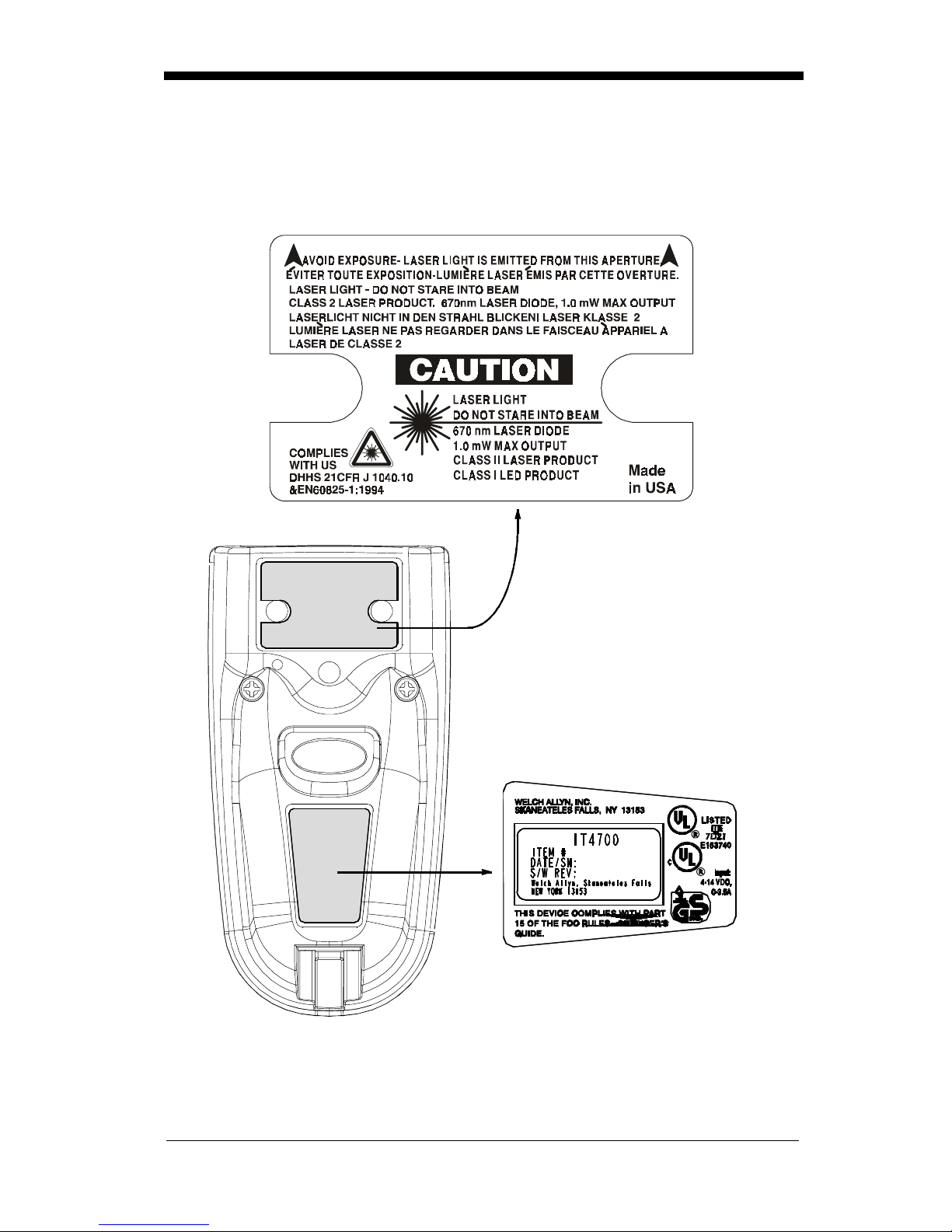

IT4700 Imager Ide ntifi cation

Enlarged View of Label

Hand Held IT4700 Imager

Bottom View

1 - 4

Page 17

Laser and LED Safety

The Laser A iming subsystem p rojects 670 nm laser light onto the bar code target

to define the optical field of view. The projected pattern consists of a central

cross and four 90 de gree corner sections. T his pattern is gener ated by a lens and

diffractive component positioned at the output of the enclosed laser diode. This

projected pattern assists the operator to frame the bar code being scanned.

The Good Read Indicator and the LED Illumination Array have been tested in

accordance with the spe ci ficati on “Safety of Laser Products” EN 60825-1:1994,

Issue 2, June 1997 and found to satisfy the requirements of Class 1. Class 1

optical systems are consi dered safe under r easonably foreseeab le cond itions of

operation. The Aiming Laser has been tested in accordance with the

specification “Safety of Laser Products” EN 60825-1:1994, Issue 2, June 1997

and found to satisfy the requirements of Class 2. Class 2 systems are

considered to emit visible radiation in the wavelen gth range from 400 nm to 700

nm. Eye protection is normally afforded by aversion responses including the

blink reflex. It is recommended that you do not stare into the beam or cause

others to stare into the beam.

1 - 5

Page 18

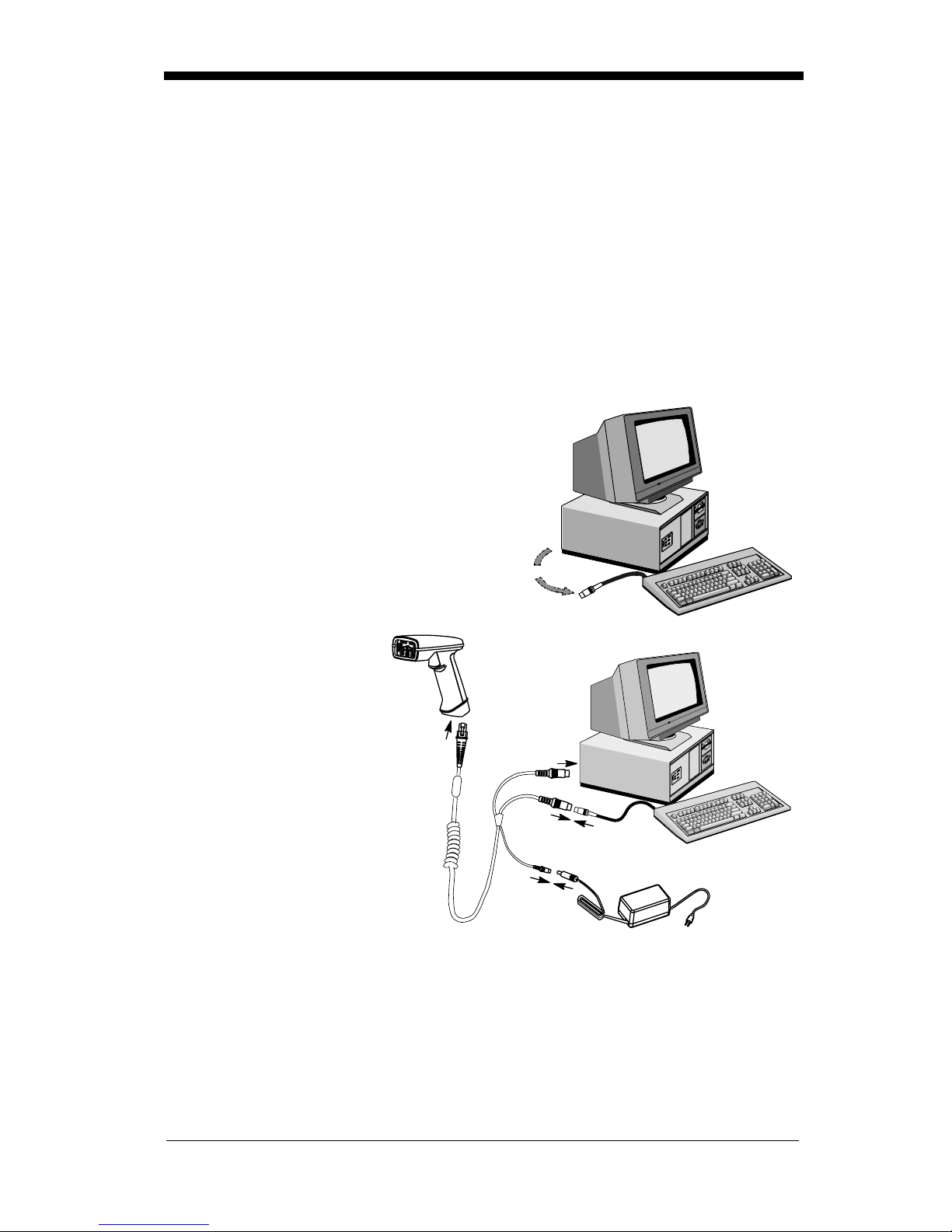

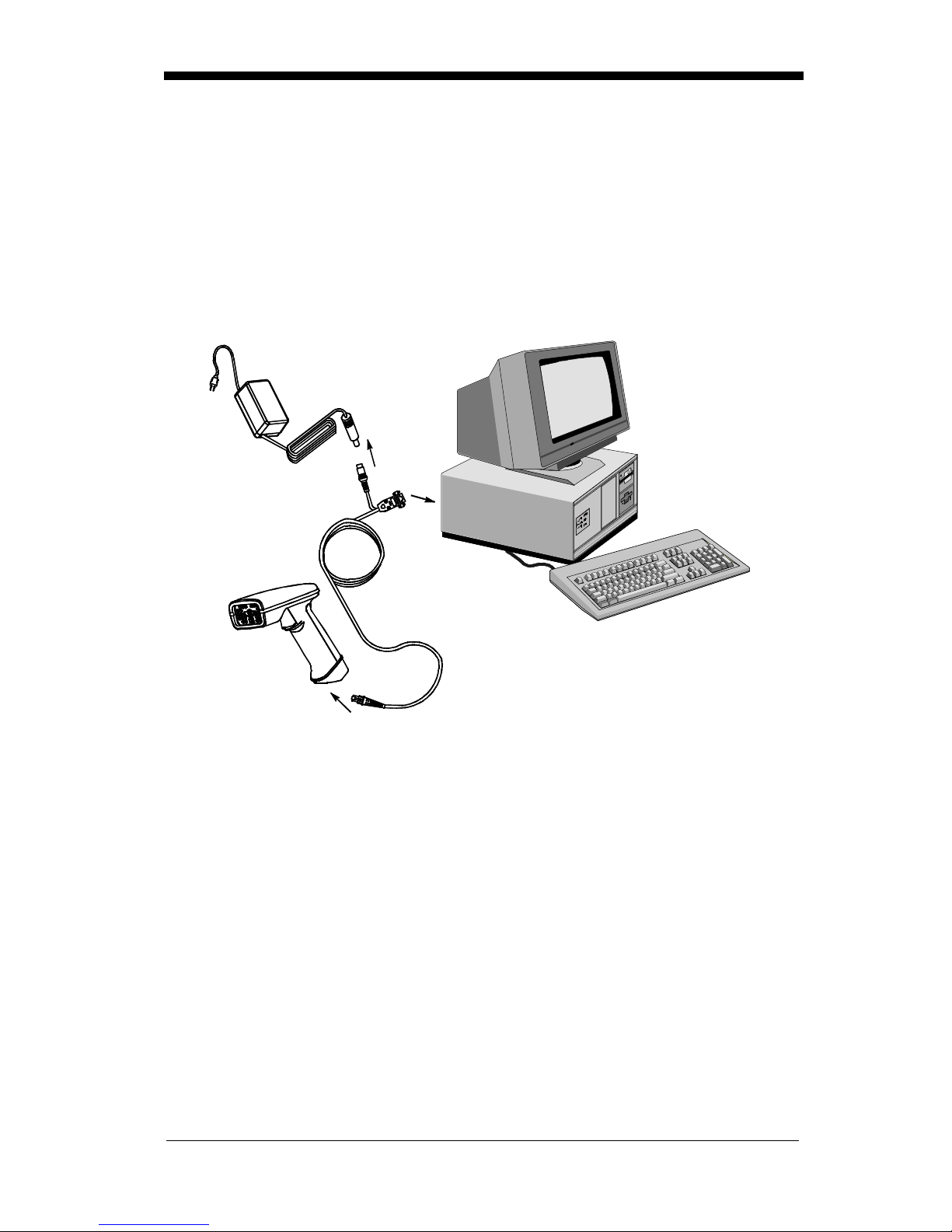

Connecting the Scanner When Powered by Host

(Keyboard Wedge)

A scanner can be connected between the keyboard and PC as a “keyboard

wedge,” plug ged into the s erial p ort, or conn ected to a por table data terminal in

wand emulation or non decoded output mode.

Note: Only un its ordered from the factory with keyboar d wedge capability can be

connected as keyboard wedge units.

The following is an example of a keyboard wedge connection:

1. Turn off power to the terminal/computer.

2. Disconnect the keyboard cable from

the back of the terminal/computer.

Disconnect

3. Connect the appropriate interface cable to

the scanner and to the

terminal/

computer. The scanner will beep twice.

4. Turn the terminal/computer power back on.

5. Verify the scanner

operation by scanni ng

a bar code from the

back cover of this

manual. The scanner

will beep once.

The scanner is now connected and read y to communicate with your terminal/PC.

You must program the scanne r for your inter face befor e bar code data can be

transmitted to your terminal/PC. If you are using the scanner as a keyboard

wedge, see"Terminal Interface" on page 2-4. If the scanner is connected via a

serial port, turn to "Connecting the Scanner to a Serial Port" on page 2-10.

1

3

2

4

1 - 6

Page 19

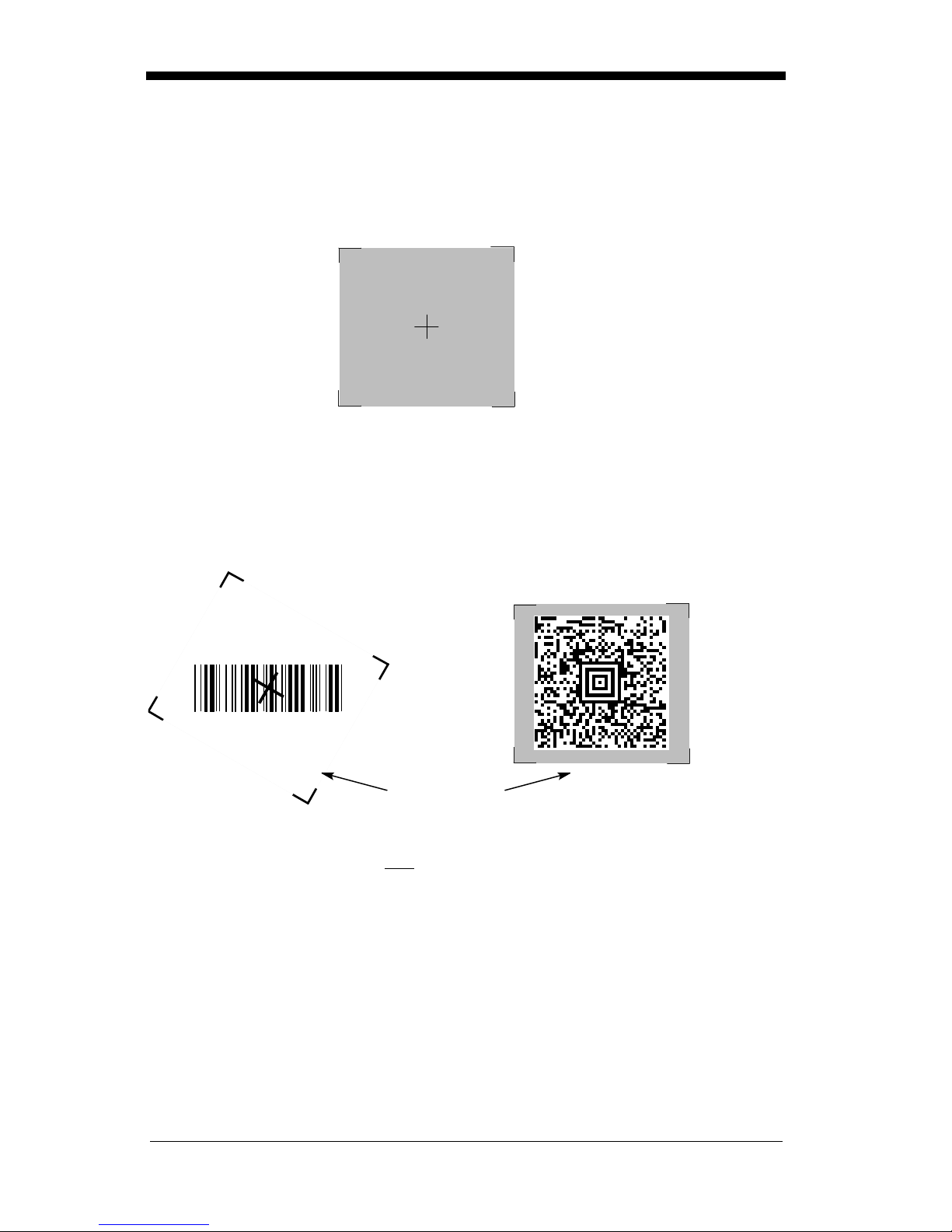

Reading Techniques

The hand-held Ima ger has a view finder (shown be low) wh ich is similar to those

on cameras. The view finder allows you to position the code within the field of

view.

The illustration below shows where to aim the red illuminated beam over the

symbol for a good read. Center the symbology in the view finder. The entire

symbology must be within the view finder (aiming beam). The view finder

changes size as you move the Imager closer to or farther away from a code.

Linear bar code 2D Matrix symbol

Note: The symbols can be in any orientation for the Imager to read.

The view finder is smaller when the Imager is closer to the code and larger when

it is farther from the code. Symbologies with smaller bars or elements (mil size)

should be read closer to the unit. Symbologies with la rger bars or elements (m il

size) should be read f arthe r from th e unit. (see "Depth of Field Charts "on page

1-8.) To read single or multiple symbols (on a page or on an object), hold the

Imager at an appropr iate distance fro m the target, pull the trigger , and center the

view finder cross hairs on the symbol.

View Finder

(Aiming Beam)

1 - 7

Page 20

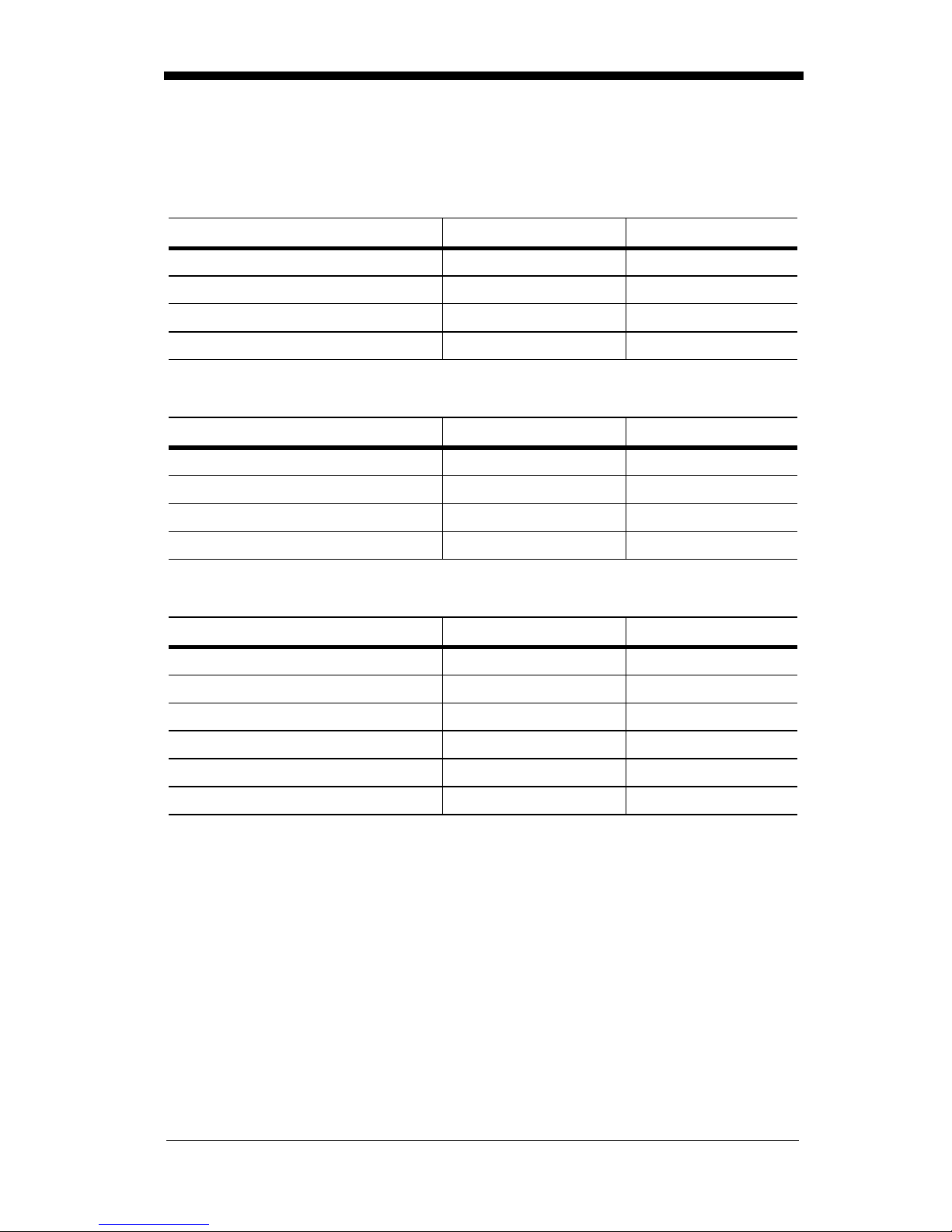

Depth of Field Charts

Depth of Fiel d for High Densi ty Imager (2" No mina l Focus)

Code Size Near Distance Far Distance

QR 6.6 mil (0.017 cm) 1.7 inches (4.3 cm) 2.4 inches (6.1 cm)

Data Matrix 6.6 mil (0.017 cm) 1.7 inches (4.3 cm) 2.4 inches (6.1 cm)

Linear 4 mil (0.01 cm) 1.6 inches (4.1 cm) 2.5 inches (6.4 cm)

OCR 6 pt. (20 cpi) 2 inches (5.1 cm) 3.5 inches (8.9 cm )

Depth of Field for High Density10 Imager (3" Nominal Focus)

Code Size Near Distance Far Distance

QR 10 mil (0.025 cm) 2.0 inches (5.1 cm) 4.0 inches (10.2 cm)

Data Matrix 10 mil (0.025 cm) 2.0 inches (5.1 cm) 3.5 inches (8.9 cm)

Linear 5 mil (0.013 cm) 2.75 inches (7.0 cm) 3.75 inches (9.5 cm)

OCR 12 pt. (12 cpi) 2 inches (5.1 cm) 5 inches (12.7 cm)

Depth of Fiel d for Long Range Imager (5" Nominal Focus)

Code Size Near Distance Far Distance

Linear 7.5 mil (0.019 cm) 3.0 inches (7.6 cm) 5.0 inches (12.7 cm)

Linear 10 mil (0.025 cm) 2.5 inches (6.4 cm) 4.75 inches (12.1 cm)

Linear 15 mil (0.038 cm) 2.0 inches (5.1 cm) 7.5 inches (19.1 cm)

Data Matrix 15 mil (0.038 cm) 2.5 inches (6.4 cm) 4.0 inches (10.2 cm)

Aztec or QR 15 mil (0.038 cm) 3.5 inches (8.9 cm) 5.0 inches (12.7 cm)

Maxicode 35 mil (0.089 cm) 2.0 inches (5.1 cm) 9.0 inches (22.9 cm)

1 - 8

Page 21

2

Programming

Introduction

Use this section to progra m the hand-held Imager.

This programming section contains the following menuing selections:

• General Sel ections

• Terminal Interface Selections

• Keyboard Selections

• Communication Set tings

• Imager Selection s

• Output Selections

• Prefix/Suffix Selections

• Data Formatter Selections

• Output Sequence Selections

2 - 1

Page 22

Reset Factory Settings

All operating parameters are stored in nonvolatile memory resident in the

Imager, wher e they are permanently retai ned in the event of a power inte rruption.

When you receive you r Imager, certa in operating param eters have already b een

set. These are the factory defaults, indicated by the symbol “✱” on the

programming menu pages (beneath the default program ming symbo l). Default

charts begin on page 5-1.

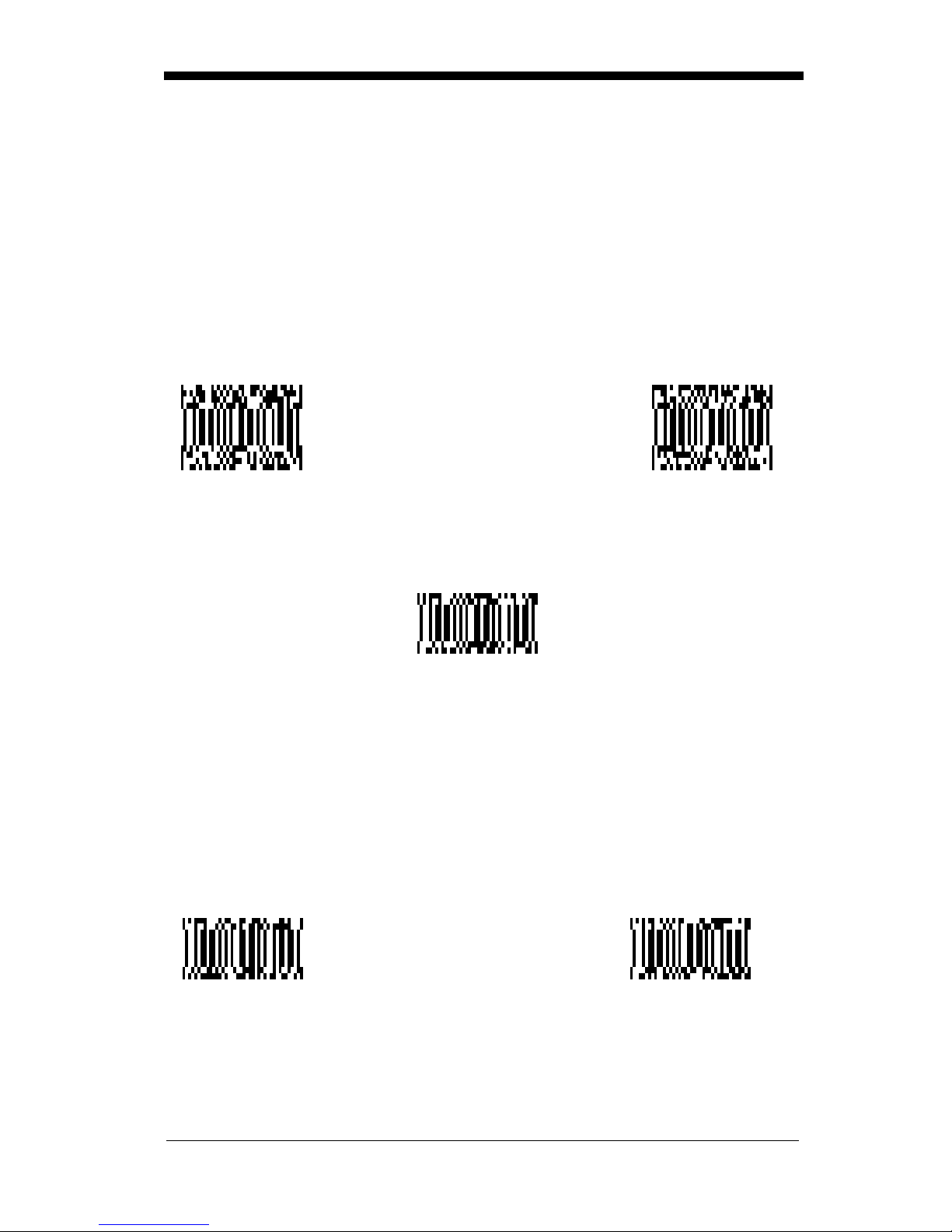

Depending on yo ur model, sca n one of the fo llowing ba r codes to set th e imag er

to the o riginal factory settings, cle aring any p rogramming changes you may have

made.

HD

LR

HD10

Status Check

Read the Show S oftware Re vision symbol to tran smit the soft ware revisi on level

to the host terminal. The software revision will be printed out as

“REV_SW:$ProjectRevision: 1.xx$;REV _WA:31204734-xxx.”

Read the Show Data Formats symbol to transmit t he existing D ata Format Edito r

formats. One format per line will be printed out.

Show Software

Revision

2 - 2

Show Data Formats

Page 23

All Symbologies

If you want to decode all the symbologies allowable for your scanner, scan the

All Symbologies On code.

All Symbologies

On

All Symbologies

Off

Revision Select i ons

Both the following pro gramming codes would not nor mally be needed unless you

have a problem with the unit. An Application Support Representative may

request the boot code or power P C revision information in orde r to trouble shoot

a problem.

Boot Code RevisionPower PC Revision

2 - 3

Page 24

Terminal Interface

IMAGETEAM 44 00 and 4700 scann ers are factory progr amm ed for a keyboar d

wedge interface to an IBM PC AT with a USA keyboard. If this is your interface

and you do not need to modify the settings, skip to page 2-16 for Imager

Selections.

If your interface is not a standard PC AT, refer to the "Supported Terminals

Chart" on page 2-5 and locate the Terminal ID number for your PC. Scan the

Terminal ID bar code below, then scan the numeric bar code(s) on the inside

back cover of this manual to program the scanner for your terminal ID. Scan

Save to save your selection.

For example, an IBM PS/2 terminal has a Terminal ID of 002. You would scan

the Ter minal ID bar code, then 0, 0, 2 from the inside back cover, then Save. If

you m ake an error wh ile scanning the digits (before scanning Save), scan the

Discard code on the back cover and scan the digits and the Save code again.

Factory Default = 03

Terminal ID

Save

2 - 4

Page 25

Supported Terminals Chart

Terminal Model(s)

Terminal

DEC PC433 SE (Portable PC) 003

DELL Latitude (Portable PC) 003

DTK 486 SLC (Portable PC) 003

Fujitsu Stylistic (Portable PC) 003

HHLC (Code 128 Emulation)

089

IBM PC X 001

IBM PS/2 25, 30, 77DX2 002

IBM

IBM

IBM

IBM

AT, PS/2 30-286, 50, 55SX, 60, 70, 003,

70-061, 70-121, 80

AT Compatibles Keyboard Emulation

(Non-wedge)

Thinkpad 360 CSE, 34, 750

(P ortable PC)

Thinkpad 365 , 755 CV

(P ortable PC)

003

097

003

IBM AT Thinkpad 106

Midwest Micro Elite TS 30 PS (Portable PC) 003

Mitak 4022 (Portable PC) 003

Olivetti M19, M24, M28, M200 001

I.D.

*

Olivetti M240, M250, M290, M380, P500 003

Reliasys TR 175 003

RS-232 TTL 000

Televideo 990, 995, 9060 002

Texas Instruments Extensa 560CD (Portable PC) 003

Toshiba 2600 (Portable PC) 003

Toshiba Satellite T1960, T2130, CS (Portable PC) 003

Zenith Z-note (Portable PC) 003

* This capability is not available for the IT4700. Contact the factory if this capability is

needed for the IT4700.

Note: These interfaces are available only for units that have 1 megabyte of

program me mory. The software revision indicate s the memory s ize. If you

are not certain of your unit’s memory, please contact Welch Allyn’s

Application Support (see page 10-5).

2 - 5

Page 26

Keyboard Country

Scan the Program Keyboard Country bar code below, then scan the numeric

bar code(s) from the inside back cover, then the Save bar code to program the

keyboard for your country. As a general rule, the following characters are not

supported by the scanner for countries other than the United States:

@ | $ # { } [ ] = / ‘ \ < > ~

Keyboard Country

Country Code Scan Country Code Sc an

Belgium.....................1 Italy........................5

Denmark...................8 Norway...................9

Finland......................2 Spain......................10

France ......................3 Switzerland............6

Germany/Austria....... 4 USA

Great Britain .............7

(Default)

.........0

2 - 6

Save

Page 27

Keyboard Style

This programs keyboard styles, such as Caps Lock and Shift Lock.

Default =

Regular.

Regular

Caps Lock

Shift Loc k

to U.S. keyboards.)

Automa tic Caps Lo ck

software tracks and r eflects if you have Caps Lock on or of f (AT and PS/2 only).

This selection can only be used with systems that have an LED which notes the

Caps Lock status.

Emulate E xte rnal Keyb oa rd

keyboard (IBM AT or equivalen t), but sh ould not be use d for laptops. To connect

the scanner to a laptop, use "Automatic Direct Connect Mode On"on page 2-8.

is used when you normally have the Caps Lock key off.

is used when you normally have the Caps Lock key on.

is used when you normall y have the Shift Lock key on. ( Not common

is used if you cha nge the Caps Lo ck key on and off. T he

should be scanned if you do no t have an exter nal

* Regular Caps Lock

Shift Lock

Automatic

Caps Lock

Emulate External

Keyboard

2 - 7

Page 28

Keyboard Modifiers

This modifies special keyboard features, such as CTRL+ A SCII codes and Turbo

Mode.

Control + ASCII Mode On

control characters for values 00-1F. Refer to "Keyboard Function

Relationship s" on page 2-9 for CTRL+ ASCII Values.

Control + ASCII

Mode On

Turbo Mode

use with IB M AT onl y.) If th e terminal drops character s, do not u se Turbo M ode.

- The scanner send s character s to an IB M AT term inal faster. (Fo r

- The scanner sends key combinations for ASCII

Default = Off

* Control + ASCII

Mode Off

Default = Off

Turbo Mode On

Numeric Keyp ad Mod e

numeric keypad.

Default = Off

- Sends numeric characters as if entered from a

* Turbo Mode Off

Numeric Keypad

Mode On

Automatic D ir ect Conn ect

keyboard is disabled when you plug in the scanner. This selection can also be

used if you h ave an IBM AT style terminal a nd the system is drop ping characters.

Default = Off

Automatic Direct

Connect Mode On

2 - 8

* Numeric

Keypad Mode Off

- Use this selection if you are using a laptop whose

* Automatic Direct

Connect Mode Off

Page 29

Keyboard Func tion Re lationships

The following Keyboard Function Code, Hex/ASCII Value, and Full ASCII

“CTRL”+ relationships apply to all terminals that can be used with the scanner.

Function Code HEX/ASCII Value Full ASCII “CTRL” +

NUL 00 2

SOH 01 A

STX 02 B

ETX 03 C

EOT 04 D

ENQ 05 E

ACK 06 F

BEL 07 G

BS 08 H

HT 09 I

LF 0A J

VT 0B K

FF 0C L

CR 0D M

SO 0E N

SI 0F O

DLE 10 P

DC1 11 Q

DC2 12 R

DC3 13 S

DC4 14 T

NAK 15 U

SYN 16 V

ETB 17 W

CAN 18 X

EM 19 Y

SUB 1A Z

ESC 1B [

FS 1C \

GS 1D ]

RS 1E 6

US 1F -

2 - 9

Page 30

Connecting the Scanner to a Serial Port

6. Turn off power to the terminal/computer.

7. Connect the interface cable to the scanner.

8. Connect the interface cable to the 5 or 14 VDC power supply and plug in the

power supply. The scanner will beep twice.

9. Connect the interface cable to the terminal/computer.

Power Supply

1

10. Turn the terminal/computer power back on.

11. Verify the scanner operation by scanning a bar code from the back cover of

this manual. The scanner will beep once.

The scanner is now connected and read y to communicate with your terminal/PC.

Turn to "Communication Settings" on page 2-11 to program the communication

parameters for a serial inter face.

2

3

Interface Cable

2 - 10

Page 31

Communicat ion Settings

<Default All RS-232 Communication Settings>

Parity

Parity provides a means of checking character bit patterns for validity. The

Imager can be configured to operate under Mark, Space, Odd, Even, or No

(None) parity options. The host terminal must be set up for the same parity as

the Imager, to ensure reliable communication.

Mark

Odd

Space

Even

* None

2 - 11

Page 32

Baud Rate

This sets the baud rate from 300 bits pe r second to 115,200 bits per second (see

next page). Programming baud rate causes the data to be sent at the specified

rate. The host terminal must be set to the same baud rate as the Imager to

ensure reliable communication.

300 600

1200

19200

2400

96004800

* 38400

2 - 12

Page 33

Baud Rate,

57600 115200

continued

Word Le ngth Data Bits

You can set t he Word Lengt h at 7 or 8 bits of da ta per character. If an applicatio n

requires only ASCII Hex characters 0 through 7F decimal (text, digits, and

punctuation), select 7 data bits. For applications requiring use of the full ASCII

set, select 8 data bits per character.

7 Data Bits

Wo rd Le ngth Stop Bits

Word Length can be set to one or two stop bits.

* 1 Stop Bit

* 8 Data Bits

2 Stop Bits

2 - 13

Page 34

Hardware Flow Control

When hardware flow control is on, the software checks for a CTS signal before

sending data. This option is useful when your application supports the CTS

signal.

On

* Off

Software Flow Control

This allows control of data transmission from the Imager using software

commands from the host device. When this feature is turned off, no data flow

control is used. When Data Flow Control is turned on, the host device suspen ds

transmission by sending the XOFF character (DC3, hex 13) to the Imager. To

resume transmission, the host sends the XON character (DC1, hex 11). Data

transmission continues where it left off when XOFF was sent.

On

* Off

2 - 14

Page 35

Serial Triggering

This provides a means of sending a serial trigger command to s tart and stop

decoding. When this feature is turned off, the Imager will not respond to serial

trigger commands. When serial triggering is turned on, the Imager requires a

serial trigger chara cter to activate scanning and deco ding. The unit continues to

scan and decode bar codes unt il the Trigger Off character turn s off the scanner,

or a time out occurs.

On th e " Deci mal to Hex to ASCII Conversion Chart" on page 2-34, find the hex

characters you want to use to turn the trigger on and off. Locate the decimal

values for those characters and scan the 2 digits for each one from the

Programming Chart in the back of this manual.

When Serial T riggering is On, the defa ult Trigger On decim al character is 18 (hex

12, DC2), and the default Trigger Off decimal character is 20 (hex 14, DC4).

* OffOn

Trigger On ‡ Trigger Off ‡

‡ A one to three digit decimal number and Save are required after reading

this programming symbol. See "Decimal to Hex to ASCII Conversion

Chart" on page 2-34, and the Programming Chart (inside back cover).

* Trigger Defaults

2 - 15

Page 36

Power Sav i ng Mode

This provides control of the Imager’s power consumption, as follows:

Low Power

attempt

during the read attempt, and powers down after the image capture is complete.

Medium Power

enhances motion tolerance.

trigger is pulled, going into a “doze” (low power) state after each read attempt.

The Imager powers down ten seconds after the image capture is complete.

Normal Power

trigger is pulled. The Imager doesn’t go into a “doze” state after each read

attempt, but m ay power down a fter two minutes if Power Hold Mode is turned Off.

Low Power Medium Power

draws low LED current during image capture, allowing one read

only

for each tri gger pull. The Ima ger is less tolerant of ha nd movement

draws a normal LED current during image capture which

Medi um Power

draws a normal LED current, attempting to read as long as the

attempts to read as long as the

Power Hold Mode

Power Hold On keeps the Imager in a ready to read state. To conserve power,

this selection may be turned

two minutes. When you are ready to use the Imager again, restore power by

pressing the trigge r.

On * Off

2 - 16

* Normal Power

Off

and the unit will power down if not used within

Page 37

LED Power Level

This selection allows you to adjust LED brightness.

Off

is used when no illumination is needed.

sufficient.

High

(the default) is the brightest setting.

Low

is used if low illumination is

Off

* High

Low

LED Flashing

If LED Flashing is turned off, the average current draw is increased and the

aiming light won’t illuminate while the scanner reads a bar code.

Off † * On

† If LED Flashing is turned off, the average current draw is increased and

the view finder won’t illuminate duri ng the rea ding phase.

2 - 17

Page 38

Aimer Delay

The aimer delay allows a delay time for the operator to aim the scanner before

the picture is taken. Use these codes to set the time between when the trigger

is pulled and when th e picture is taken. During t he delay time, the aiming light

will appear, but the LEDs won’t turn on until the delay time is over.

200 milliseconds

* Off

(no delay)

400 milliseconds

Aimer Timeout

Use this selection to set a timeout (in second s) of the Imager’s aiming light when

the device is not reading a bar code.

Default setting = 60 seconds

‡ A one- to three digit number and Save are required after reading this

programming symbo l. Refer to the Programming Chart (inside back

cover).

2 - 18

Set Timeou t ‡

Page 39

Aimer Interval

Aimer Interval turns off the aiming light, or programs the aimer to come on at

certain intervals when re ading symbols with the scanner. You may program the

scanner to use t he aimer Every Read, Ever y Second Read, or Every Thir d Read.

You may also pr ogram th e scanner to use the a imer ever y “x” reads, by e ntering

a number from 0 to 999 to indica te “x.”

Off

Every Second Read

* Every Read

Every Third Read

‡ A one- to three digit number and Save are required after reading this

programming symbo l. Refer to the Programming Chart (inside back

cover).

Every “x” Reads

‡

2 - 19

Page 40

AutoTrigger

Two AutoTrigger Modes are available: Scan Stand and Presentation Mode.

When a unit is in Scan Stand mode, the LED shines at the symbol on the base

of the stand which te lls it to rem ain idle. When a different cod e is pre sented, the

Imager is triggered to read the new code.

Presentation mode is fo r those applications where a scan stand will not work, i.e.,

when large packages mu st be scann ed. To program the devi ce for presentat ion

mode, refer to "Prese ntation Mod e" on page 2-21.

Scan S tand

This selection programs the Imager to work in a Scan Stand.

On* Off

Scan Stand LED Intensity

This sets the idle LED intensity when the Imager is in Scan Stand mode. When

a unit is in Scan Stand mode, the LED shines at the symbol on the base of the

stand which tel ls it to remain idle. Wh en a different code is present ed, the Imager

is triggered to read the new code. If the Imager has difficulty going back to

reading the Scan St and’s fixed cod e, for instance, in a low lig hting situation, you

may want to adjust the Scan Stand LED Intensity. A two digit number between

15 and 75 must be input after the Scan Stand LED Intensity prog rammi ng code

is scanned. A 15 corresponds to the lowest intensity level, and a 75 corre sponds

to the highest intensity level. 15 is the default setting.

Note that when the unit is triggered to read a code, the unit uses the LED power

level specified through "LED Power Level" on page 2-17.

Set Scan Stand LED Intensity

2 - 20

Page 41

Scan Stand Lights

You can turn off the scanner li ght when the imager is in idle mode in a scan stand.

* OnOff

Presentation Mode

This programs the scanner to work in Presentation Mode.

Default = Off.

On* Off

Presentation Reread Delay

This sets the time period before the scanner can read the

second time. Setting a reread delay protects against accidental rereads of the

same bar code. Longer delays are effective in minimizing accidental rereads at

POS (point of sale). Us e shorter delays i n applicatio ns where repet itive bar code

scanning is required. Entries are in milliseconds, up to 10,000.

Default = 500.

Presentation R ere ad Delay

same

bar code a

Presentation Def ault

Defaults all presentation mode settings.

Presentation Reread Delay 500 ms (1/2 sec.), Presentation Aimer On.

Defaults

Presentation Default

=

Presentation Mode Off,

2 - 21

Page 42

Presentation A imer

You can turn on or off the scanner’s aiming light when the device is not reading

a bar code.

Off

* On

Zoom

Use Zoom to zoom in and read smaller m atr ix codes. The zoom selection does

not affect reading of linear bar codes. The factory default setting is Off. (High

Density scanners are programmed with the zoom turned on when shipped from

the factory. If you scan the LR Factory Default Settings code on page 2-2, the

zoom will be turned off.)

On

* Off

2 - 22

Page 43

Zoom P l acement

This lets you positi on the r ead area (crosshairs ) of the Ima ger wh en it is in zo om

mode. The Zoom Vertical moves the crosshairs vertically, and the Zoom

Horizontal move them hor izonta lly, as illustr ated below :

Note: When zoom is turn ed on, the field of view of the Imag er is reduced, making

it more difficult for the Imager to read large matrix symbols.

Zoom Horizon tal

3 4 5 6

3

4

5

6

Zoom Vertical

After the Zoom Placement code below is scanned, you must scan a 1 digit code

(inside ba ck cover) to enter the zoom positi on you want. The default for both

vertical and horizon tal placement is 4, wh ich centers the crosshairs in the fi eld of

view.

Zoom Vertical

Zoom Horizontal

Note: The default setting for the H D Imager is a Zo om Verti cal of 6 and, for the

HD10, the default setting is a Zoom Vertical of 5.

2 - 23

Page 44

Beeper Volume

Off

Medium

Power Up Beeper

Low

* High

* On

Off

Output Sequence Bee per

If you are using an Outpu t Sequence (see "Output Seq uence Overview" on page

2-41), you may want to hear a beep after each bar code as it is read. Scan

Output Sequence Beeper On to enable this feature, or Off to disable it.

* On

Off

2 - 24

Page 45

Beep On Decode

If you want the scanner to beep each time it reads a bar code, le a v e t h is setting

On. If you don’t want it to beep on each read, but do want it to beep for other

events, set this selection to Off.

* On

Beeper Default

Defaults all beep er setti ngs.

On, Output Sequence Beeper On, Beep On Read On.

Defaults

=

Beeper Defaul t

Beeper Volume High, Pow er Up B eeper

Off

2 - 25

Page 46

Intercharacter, Interfunction,

and Intermessage Delays

Some terminals dr op information (ch aracters) if data comes thr ough too quickly.

Intercharacter, interfunction, and intermessage delays slow the transmission of

data, which increases data integrity.

Each delay is composed of a 5 millisecond step. You can program up to 99 steps

(of 5 ms each).

Intercharacter Delay

This is a delay of up to 495 milliseconds (in multiples of 5) placed between the

transmission o f each character of scanned data. You can pr ogram up to 99 steps

(of 5 ms each). Scan the Intercharacter Delay bar code below, then scan the

number of steps, and the SAVE bar code from the inside back cover.

Note:

To remove this delay, scan the Intercharacter Delay bar code, then set the

number of steps to 00. Scan the SAVE bar code from the inside back cover.

If you make an error while scanning the digits (before scanning Save),

scan Discard on the back cover and scan the correct digits and Save

again.

Prefix Scanned Data Suffix

1 2345

Interchara cter Delay

Intercharacter Delay

2 - 26

Page 47

Interfunction Delay

This is a delay of up to 495 milliseconds (in multiples of 5) placed between the

transmission of each segm ent of the message string . You can program up to 99

steps (of 5 ms each). Scan the Interfunction Delay bar code below, then scan

the number of steps, and the SAVE bar code from the inside back cover.

Note: If you make an error while scanning the digits (before scanning Save),

scan Discard on the back cover and scan the correct digits and Save

again.

Prefix Scanned Data Suffix

1 2345STX HT CR LF

Interfunction D elays

Interfunction Delay

To remove this dela y, scan the Interfunction Delay bar code, the n set the number

of steps to 00. Scan the SAVE bar code from the inside back cover.

2 - 27

Page 48

Intermessage Delay

This is a delay of up to 495 milliseconds (in multiples of 5) placed between each

scan transmission. You can program up to 99 steps (of 5 ms each). Scan the

Intermessage Delay bar code below, then scan the number of steps, and the

SAVE bar code from the inside back cover.

Note:

To remove this delay, scan the Intermessage Delay bar code, then set the

number of steps to 00. Scan the SAVE bar code from the inside back cover.

If you make an error while scanning the digits (before scanning Save),

scan Discard on the back cover and scan the correct digits and Save

again.

2nd Scan Transmission1st Scan Transmission

Intermessage Delay

Intermessage Delay

2 - 28

Page 49

Prefix/Suffix Overview

When a bar code is scanned, additional information is sent to the host computer

along with the bar code data. This group of bar code data and additional,

user-define d data is called a “message str ing.” The selection s in this section are

used to build the user-def ined data into the message string.

Prefix and Suffix char acters are data characters that can be sent before and after

scanned data. You can specify if they should be sent with all symbologies, or

only with specific symbologies. The following illustration shows the breakdown

of a message string:

Prefix Scanned Data Suffix

1-10

alpha

numeric

characters

variable

length

1-10

alpha

numeric

characters

Points to Keep In Mind

• It is not necessary to build a message string. The selections in this

chapter are only used if you wish to alter the default settings.

prefix = None. Default suffix = None

• A prefix or suffix may be added or cleared from one symbology or all

symbologies.

• You can add any prefix or suffix from the "Decimal to Hex to ASCII

Conversion Chart" on page 2-34, plus Code I.D. and Aim I.D.

• You can string together several entries for several symbologies at one

time.

• Enter prefix es and suffixes in the orde r in which you want th em to appear

on th e output.

.

Default

2 - 29

Page 50

Adding a Prefix or Suffix

1. Scan the Add Prefix (page 2-32) or Add Suffix symbol (page 2-32).

2. Determine the 2 digit Hex value from the "Symbology Chart "on page 2-33

for the symbology to which you want to apply the prefix or suffix.

3. Scan the 2 hex digits from the Programming Chart inside the back cover or

scan 9, 9 for all symbologies.

4. Determine the hex value from the "Symbology Chart "on page 2-33 for the

prefix or suffix you wish to enter.

5. Scan the 2 digit hex value from the Programming Chart inside the back

cover.

Note:

Note:

6. Scan Save to exit and save, or scan Discard to exit without saving.

Repeat Steps 1-6 to add a prefix or suffix for another symbology.

Example: Add a Suff ix to a specific symbolo gy

To send a CR (carriage return )Suffix for UPC only:

1. Scan Add Suffix.

2. Determine the 2 digit hex value from the "Symbology Chart" on page 2-33 for

3. Scan 6, 3 from the Programming Chart (inside back cover).

4. Determine the hex value from the "Decimal to Hex to ASCII Conversion

5. Scan 0, D from the Programming Chart (inside back cover).

6. Scan Save, or scan Discard to exit without saving.

Repeat Steps 4 and 5 for every prefix or suffix character.

To add the Code I.D., scan 5, C, 8, 0.

To add AIM I.D., scan 5, C, 8, 1.

To add a backslash (\), scan 5, C, 5, C

UPC.

Chart" on page 2-34 for the CR (carriage return).

.

Clearing One or All Prefixes or Suffixes

You can clear a single prefix or suffix, or clear all prefixes/suffixes for a

symbology. When you Clear One Prefix (Suffix), the specific character you

select is deleted from the symbology you want. When you Clear All Prefixes

(Suffixes), all the prefixes or suffixes for a symbology are deleted.

1. Scan the Clear One Prefix or symbol.

2. Determine the 2 digit Hex value from the "Symbology Chart "on page 2-33

for the symbology from which you want to clear the prefix or suffix.

3. Scan the 2 digit hex va lue from the Prog ramming Chart inside the back cover

or scan 9, 9 for all symbologies.

Your change is automatically saved.

2 - 30

Page 51

Add a Car riage Ret ur n Suffi x to A l l Symbologies

Scan the following bar code if you wish to add a Carriage Return Suffix to all

symbologies at once. This action first clears all current suffixes, then programs

a carriage retur n suffix for al l symbol ogies.

Add CR Suffix

All Symbologies

Add a Code I .D. Prefix to All Symb ologies

This selection allows you t o turn on ( or off) tr ansmission of a Code I.D. b efore the

decoded symbology. (See the "Symbology Chart"on page 2-33 for the single

character cod e that identifies each symbology.) This acti on first clears all current

prefixes, then programs a Code I.D. prefix for all symbologies.

Add Code ID Prefix

All Symbologies

Add an AIM I.D. Prefix to All Symbologies

This selection a llows you to tu rn on (or o ff) transmission o f an AIM I.D. before the

decoded symbology. (See the "Symbology Chart"on page 2-33 for the single

character cod e that identifies each symbology.) This acti on first clears all current

prefixes, then pro gram s an AIM I.D . prefix f or all symbolo gi es.

Add AIM ID Prefix

All Symbologies

(See AIM Guidelines on Symbology Identifiers for more information on the AIM

symbology ID characters.)

2 - 31

Page 52

Prefix Ent rie s

Add Prefix †

Suffix Entrie s

Add Su f fi x †

Clear One Prefix †

Clear All Prefixes

Clear One

Suffix †

† One or more two digit numbers and Save are required after reading this

programming symbol. Refer to the Programming Chart (inside back cover).

Exit Selections

Save Discard

2 - 32

Clear All Suffixes

Page 53

Symbology Char t

Symbology

Australian 4 State

Aztec Code

BC412**

BPO 4 State

Canadian 4 State

Codabar

Codablock-F

Code 39

Code 49

Code 93/93i

Code 128

Code Z**

Data Ma trix

EAN

Iata 2 of 5

CodeIDAIMIDHex

ID

A[X41

z[z7A

g[X67

B[X42

C[X43

a[F61

q[O71

b[A62

l[T6C

i[G69

j[C6A

u[X75

w[d77

d[E64

f[R66

Symbology

Interleaved 2 of 5

Japanese Postal

Kix (Dutch) Postal

Maxicode

Micro PDF417

No Read

OCR

PDF417

Planet Code

Postnet

QR C ode

RSS/Composites

UPC

Vericode**

All Symbologies

CodeIDAIMIDHex

e[l65

J[X4A

K[X4B

x[U78

R[L52

o[Y6F

r[L72

L[X4C

P[X50

s[Q73

y[e79

c[E63

v[V76

†

ID

9C

99

Note: Prefix/Suffix entries for specific symbologies override the universal (All

Symbologies, 99) entry.

†

All Symbologies: Prefix/Suffix programming only!

** Not available in standard product. Only available when ordered in custom

firmware

2 - 33

Page 54

Decimal to Hex to ASCII Conversion Chart

Dec. Hex ASCII Dec. Hex ASCII Dec. Hex ASCII Dec. Hex ASCII

0 00 NUL 32 20 SP 64 40 @ 96 60 ‘

1 01 SOH 33 21 ! 65 41 A 97 61 a

2 02 STX 34 22 “ 66 42 b 98 62 b

3 03 ETX 35 23 # 67 43 C 99 63 c

4 04 EOT 36 24 $ 68 44 D 100 64 d

5 05 ENQ 37 25 % 69 45 E 101 65 e

6 06 ACK 38 26 & 70 46 F 102 66 f

7 07 BEL 39 27 ‘ 71 47 G 103 67 g

8 08 BS 40 28 ( 72 48 H 104 68 h

9 09 HT 41 29 ) 73 49 l 105 69 i

10 0A LF 42 2A * 74 4A J 106 6A j

11 0B VT 43 2B + 75 4B K 107 6B k

12 0C FF 44 2C , 76 4C L 108 6C l

13 0D CR 45 2D - 77 4D M 109 6D m

14 0E SO 46 2E . 78 4E N 110 6E n

15 0F SI 47 2F / 79 4F O 111 6F o

16 10 DLE 48 30 0 80 50 P 112 70 p

17 11 DC1 49 31 1 81 51 Q 113 71 q

18 12 DC2 50 32 2 82 52 R 114 72 r

19 13 DC3 51 33 3 83 53 S 115 73 s

20 14 DC4 52 34 4 84 54 T 116 74 t

21 15 NAK 53 35 5 85 55 U 117 75 u

22 16 SYN 54 36 6 86 56 V 118 76 v

23 17 ETB 55 37 7 87 57 W 119 77 w

24 18 CAN 56 38 8 88 58 X 120 78 x

25 19 EM 57 39 9 89 59 Y 121 79 y

26 1A SUB 58 3A : 90 5A Z 122 7A z

27 1B ESC 59 3B ; 91 5B [ 123 7B {

28 1C FS 60 3C < 92 5C \ 124 7C |

29 1D GS 61 3D = 93 5D ] 125 7D }

30 1E RS 62 3E > 94 5E ^ 126 7E ~

31 1F US 63 3F ? 95 5F _ 127 7F DEL

2 - 34

Page 55

Data Format Editor Overview

The Data Format Edi tor selections are used to edit scanned data. For example,

you can use the Data Format Editor to insert characters at certain points in bar

code data as it is scanned.

It is not necessary to use the Data Format Editor. A set of defaults for the data

format is already programmed in the scanner. The selections in the following

pages are used on ly if you wish t o alter the defau lt settings.

setting = none.

If you ha ve changed da ta format setti ngs, and wish to clear all formats and return

to the defaults, scan the Default Data Format code.

To Add a Data Format

1. Scan the Enter Data Format symbol (page 2-38).

2. Primary/Alternate Fo rmat

Determine if this will be your primary data format, or one of 3 alternate formats. (Alternate formats allow you “single shot” capability to scan one bar

code using a different data format. After the one bar code has been read,

the scanner reverts to the primary data format. See "Alternate Data

Formats" on page 2-40.) If you are progra mming the primary for mat, scan 0.

If you are programming an alternate format, scan 1, 2, or 3, depending on

the alternate format you are programming.

Default Data Format

3. Terminal Type

Refer to the "Supported Terminals Chart"on page 2-5 and locate the Terminal ID number for your PC. Scan three numeric bar codes on the inside back

cover to program the scanner for your terminal ID (you must enter 3 digits).

For example, scan 0 0 3 for an AT wedge.

4. Code I.D.

On page 2-33, find the symbology to which you want to apply the data format. Locate the Hex value for that symbology and scan the 2 digit hex value

from the Programm ing Chart.

5. Length

Specify what length (up to 9999 character s) of d ata will be a cceptable fo r this

symbology. Scan the four digit data length from the Programming Chart.

(Note: 50 characters is entered as 0050. 9999 is a universal number, indicating all lengths.)

6. Editor Commands

Refer to the "Format Editor Commands" on page 2-36. Scan the symbols

that represent the command you want to enter. 94 alphanumer ic characters

may be entered for each symbology data format.

7. Scan Save to save your entries.

2 - 35

Page 56

Other Programming Selections

• Clear One Data Format

This deletes one data format for one symbology. If you are clearing the

primary format, scan 0. If you are clearing an alternate format, scan 1, 2,

or 3, depending on the alternate format you are clearing. Scan the

Terminal Type (refer to the "Supported Terminals Chart"on page 2-5),

Code I.D. and the length of the format you want to delete. That length

data format for that symbology is deleted and all other formats are

unaffected.

• Save

This exits, saving any Data Format changes.

• Discard

This exits without saving any Data Format changes.

Format Editor Comma nds

Send Commands

F1 Send all characters followed by “xx” key or function code, starting from

current cursor position .

ASCII code, see "Decimal to Hex to ASCII Conversion Chart" on page 2-

34.)

F2 Send “nn” character s followe d by “xx” key or function code, starting from

current cursor position.

value (00-99) f or the number of char acters and xx stands for the hex value

for an ASCII code. See "Decimal to Hex to ASCII Conversion Chart" on

page 2-34.)

F3 Send up to but not including “ss” character (Search and Send) starting

from current curso r positi on, leavi ng cursor pointing to “ss” character

followed by “xx” key or function code.

stand for the hex values for ASCII codes, see "Decimal to Hex to ASCII

Conversion Chart" on page 2-34.)

F4 Send “xx” character “nn” time s (Inse rt) leaving cursor in current cursor

position.

see "Decimal to Hex to ASCII Conversio n Char t" on page 2-34, and nn is

the numeric value (00-99) for the number of times it should be sent.)

E9 Send all but the last “nn” characters, starting from the current curs or

position.

of characters that will not be sent at the end of the message.)

Syntax = F4xxnn

Syntax = E9nn

Syntax = F1 xx

Syntax = F2nnxx

(xx stands for the hex valu e for an ASCII code,

(nn is the numeric value ( 00- 99) f or the number

(xx stands for the he x value fo r an

(nn stands for the numeri c

Syntax = F3ssxx

(ss and xx both

Move Commands

F5 Move the cursor ahead “nn” characters from current cursor position.

Syntax = F5nn

of characters the c ursor should be move d ahead.)

F6 Move the cursor back “nn” characters from current cursor position.

Syntax = F6nn

of characters the cursor should be moved back.)

F7 Move the cursor to the beginning of the data string.

EA Move the cursor to the end of the data string.

2 - 36

(nn stands for the numeric value (00-99) for the number

(nn stands for the numeric value (00-99) for the number

Syntax = F7.

Syntax = EA

Page 57

Search Commands

F8 Search ahead for “xx” character from current cursor position, leaving

cursor pointing to “xx” character.

Syntax = F8xx

(xx stands for the hex

value for an ASCII code, see "Decimal to Hex to ASCII Conversion

Chart" on page 2-34.)

F9 Search back for “xx” chara cter from current curso r position, leaving cu rsor

pointing to “xx” cha racter.

Syntax = F9x x

(xx stands for the hex value for

an ASCII code, see " Decimal to H ex to AS CII Conversion Chart" on page

2-34.)

E6 Search ahead for the l ast instance of “xx” characte r from the curre nt cursor

positio n, then inc rement cursor.

Syntax = E6xx

(xx stands for the hex

value for an ASCII code, see "Decimal to Hex to ASCII Conversion

Chart" on page 2-34.)

E7 Search back for the last instance of “xx” character from the current curso r

positio n, then inc rement cursor.

Syntax = E7xx

(xx stands for the hex

value for an ASCII code, see "Decimal to Hex to ASCII Conversion

Chart" on page 2-34.)

Miscellaneous Commands

FB Suppress all occurrences of up to 15 different characters, starting at the

current cursor position, as the cursor is advanced by other commands.

When the FC command is encountered, the suppress function is

terminated. The cursor is not moved by the FB command. Syntax =

FBnnxxyy . .zz where nn is a count o f the number suppress characte rs in

the list and xxyy .. zz is the list of characters to be suppressed. (xx stands

for the hex value for an ASCII code, see "Decimal to Hex to ASCII

Conversion Chart" on page 2-34.)

FC Disable suppress f ilter a nd clear a ll suppr essed character s.

Syntax = FC.

E4 Replaces up to 15 characters in the data string with user specified

characters. Replacement continues until the E5 command is

encountered.

Syntax = E4nnxx1xx2yy1yy2...zz1zz

where nn is the tota l

2

count of both character s to be repl aced plus replacem ent characte rs; xx1

defines characters to be replaced and xx2 defines replacement

characters, continuing through zz1 and zz2.

E5 Terminates character replacement.

Syntax = E5.

FE Compare character in current cursor position to the character “xx.” If

characters are equal, increment cursor. If characters are not equal, no

format match.

Syntax = FExx

(xx stands for the hex value for an ASCII

code, see "Decimal to Hex to ASCII Conversion Chart" on page 2-34.)

EC Check to make sure there is a numeric character at the current cursor

position. If character is not numeric, format is aborted.

Syntax = EC

ED Check to make sure there is a non-numeric ch aracter at the cu rrent cursor

position. If character is numeric, format is aborted.

Syntax = ED

.

.

2 - 37

Page 58

Data Format Editor

See page 2- 35 through page 2-37 for a descrip tion of Data Fo rmat selections an d

commands.

Enter Data Format † Default

Data Format

(none)

Clear One

Data Format †

Exit Selections

Clear All

Data Formats

Save Current

Data Format Changes

Discard Current

Data Format Changes

† One or more two digit numbers and Save are required after reading this

programming symbol. Refer to the Programming Chart (inside back cover).

2 - 38

Page 59

Data Formatter

When Data Forma tter is turned off, the bar cod e data is output to the host as read

(including prefixes and suffixes).

* On Off

Require Data Format

When Data F ormatter is r equired, al l input data must conform to a n edited f ormat

or the scanner does not transmit the input data to the host device.

Required

Show Data Formats

Read the Show Data Formats bar c ode to transmit the existing data formats.

One format per line is printed out.

Show Data Formats

2 - 39

Page 60

Alternate Data Formats

Alternate form ats allow you “single shot” capability to scan one bar code using a

different data format than your primary format. When data formats are

programmed (see page 2-35), y ou m ust input whet her you a re progr amming t he

primary format, or an alternate format numbered 1, 2, or 3.

An alternate format is initiated by scanning one of the 3 alternate format bar

codes below. The scanner will scan the next bar code, formatting the d ata with

the selected alternate format, then revert immediately to the primary format.

Alternate

Data Format 1

Alternate

Data Format 2

Alternate Data Format 3

2 - 40

Page 61

Output Sequence Ov erview

Require Output Sequence

When turned off, the bar code data will be o utput to the host as the Imager

decodes it. When turned on , all output data must conf orm to an ed ited sequence

or the Imager will not transmit the output data to the host device.

Note: This selection is unavailable when the Multiple Symbols Selection is

turned on.

Output S equ ence Editor

This programming selection allows you to program the Imager to output data

(when scanning more than one symbol) in whatever order your application

requires. Reading the

Universal v alues, shown b elow. These are the defaults. Be certain you want to

delete or clear all formats before you read the

Note: To make Outpu t Sequence Editor selections, you’ll n eed to know the co de

I.D., code length, a nd characte r match(es) yo ur appl ication req uires. Use

the Alphanumeric symbols (inside back cover) to read these options.

To Add an Output Sequence

1. Scan the Enter Sequence symbol (see "Output Sequence Editor "on page

2-44).

Default Sequence

symbol programs the Imager to the

Default Sequence

symbol.

2. Code I.D.

On the "Symbology Chart"on page 2-33, find the symbology to which you

want to apply the output sequence form at. Locate the Hex value for that

symbology and scan the 2 digit hex value from the Programming Chart

(inside back cover).

3. Length

Specify what length (up to 99 99 character s) of data output will be acceptable

for this symbology. Scan the four digit data length from the Programming

Chart. (Note: 50 characters is entered as 0050. 9999 is a universal number, indicating all lengths.)

4. Character Match Seque nce s

On the "Decimal to Hex to ASCII Conversion Chart" on page 2-34, find the

Hex value that represents the character(s) you want to match. Use the Programming Chart to read the alphanumeric combination that represents the

ASCII characters. (99 is the Universal number, indicating all characters.)

5. End Output Sequence Editor

Scan F F to enter an Output Sequence for an addi tiona l symbo logy, or Save

Current Sequence Changes to save your entries.

Other Progr amm i ng Selections

• Discard Current Sequence Changes

This exits without saving any Output Sequence changes.

2 - 41

Page 62

Output Sequence Example

In this example , you are sca nning Codabar, Code 128, and Code 39 ba r cod es,

but you want the scanner to output Code 39 1st, Code 128 2nd, and Codabar

3rd, as shown below.

A - Code 39

B - Code 128

C-123456789B

Note: To use this example, you must tur n on Codabar start/stop cha racters (see

page 3-2).

You would set up the sequence editor with the following command line:

SEQBLK62999941FF6A999942FF61999943FF

The breakdown of the command line is shown below:

SEQBLKsequence editor start command

62 code identifier for Code 39

9999code length that must match for Code 39, 9999 = all lengths

41 start character match for Code 39, 41h = “A”

FF t erm ination stri ng for first code

6A code identifier for Code 128

9999code length that must match for Code 128, 9999 = all lengths

42 start character match for Code 128, 42h = “B”

FF t ermin ation string for second code

61 code identifier for Codabar

9999code length that must match for Codabar, 9999 = all lengths

43 start character match for Codabar, 43h = “C”

FF t erm ination stri ng for third code

2 - 42

Page 63

Require Output Sequence

When an outpu t sequence is Re quired, all o utput data must confor m to an edit ed

sequence or the scanner will not transmit the output data to the host device.

When it’s On/Not Required, the scanner will attempt to get the output data to

conform to an edited sequ ence, but if it cannot, the scanner transmits all outp ut

data to the host device as is.

When the output sequence is Off, the bar code data is output to the host as the

scanner decodes it.

Note: This selection is unavailable when the Multiple Symbols Selection is

turned on.

Required On/Not Required

Off

2 - 43

Page 64

Output Sequence Editor

Enter Sequence † Default Sequence

Exit Selections

Save Current

Output Sequence Cha nges

Discard Current