Page 1

IMAGETEAM™ 2020/4620

Area Imager Cordless System

™

System Manual

Page 2

Disclaimer

Hand Held Products, Inc. (“Hand Held Products”) reserves the right to make

changes in specifications and other information contained in this document

without prior notice, and the reader should in all cases consult Hand Held

Products to determine whether any such changes have been made. The

information in this publication does not represent a commitment on the part of

Hand Held Products.

Hand Held Products shall not be liable for technical or editorial errors or

omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material.

This document contains proprietary information which is protected by copyright.

All rights are reserved. No part of this document may be photocopied,

reproduced, or translated into another language without the prior written consent

of Hand Held Products.

© 2005 Hand Held Products, Inc. All rights reserved.

Web Address: www.handheld.com

Microsoft Pocket PC 2002, Windows, Windows NT, Windows 2000, Windows ME,

Windows XP, ActiveSync, Outlook, and the Windows logo are trademarks or registered

trademarks of Microsoft Corporation.

The Bluetooth® word mark and logos are owned by Bluetooth SIG, Inc.

Page 3

Statement of Agency Compliance

The IT2020-5B/IT4620 system meets or exceeds the requirements of all

applicable standards organizations for safe operation. However, as with any

electrical equipment, the best way to ensure safe operation is to operate them

according to the agency guidelines that follow. Please read these guidelines

carefully before using your IT2020-5B/IT4620 system.

Regulatory and Safety Approvals for the IT2020-5B/

IT4620

Parameter Specification

USA FCC Part 15, Class B

Canada ICES-003

European Community EN 55022 (CISPR 22) Class B

EN60950

EN60825-1

EN55024:1998

FCC Class B Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class

B digital device pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. If this equipment does

cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• •Reorient or relocate the receiving antenna.

• •Increase the separation between the equipment and receiver.

• •Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• •Consult the dealer or an experienced radio or television technician for help.

Page 4

If necessary, the user should consult the dealer or an experienced radio/

television technician for additional suggestions. The user may find the following

booklet helpful: “Something About Interference.” This is available at FCC local

regional offices. Hand Held Products, Inc. is not responsible for any radio or

television interference caused by unauthorized modifications of this equipment

or the substitution or attachment of connecting cables and equipment other than

those specified by Hand Held Products, Inc. The correction is the responsibility

of the user. Use only shielded data cables with this system.

In accordance with FCC 15.21, changes or modifications not expressly

approved by the party responsible for compliance could void the user’s authority

to operate the equipment.

This device and its antenna must not be co-located or operating

in conjunction with any other antenna or transmitter. To maintain

!

compliance with FCC RF exposure guidelines for body-worn

operation, do not use accessories that contain metallic

components and ensure that the device is at least 15mm (0.6

inches) from the body.

Canadian Compliance

This Class B digital apparatus compiles with Canadian ICES-003. Operation is

subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

3. To prevent radio interference to the licensed service, this device is intended

to be operated indoors and away from windows to provide maximum

shielding. Equipment (or its transmit antenna) that is installed outdoors is

subject to licensing.

Cet appareil numérique de la Classe B est conforme à la norme NMB-003 du

Canada.

CE Compliance

The CE mark on the product indicates that the system has been tested

to and conforms with the provisions noted within the 89/336/EEC

Electromagnetic Compatibility Directive and the 73/23/EEC Low Voltage

Directive.

Complies with:

EN55022:1998 (for ITE emissions)

EN55024:1998 (for ITE immunity), including CISPR 22B:1997

EN61000-4-2:1995

EN61000-4-3:1995

Page 5

For CE-related inquiries, please contact:

Hand Held Products, Inc.

Nijverheidsweg 9

5627 BT Eindhoven

The Netherlands

Hand Held Products shall not be liable for use of our product with equipment

(i.e., power supplies, personal computers, etc.) that is not CE marked and does

not comply with the Low Voltage Directive.

Regulatory Approvals for Bluetooth Radio Devices

RF devices are designed to comply with the most current applicable standards

on safe levels of RF energy developed by the Institute of Electrical and

Electronics Engineers (IEEE) and the American National Standards Institute

(ANSI) and have been recommended for adoption by the Federal

Communications Commission (FCC).

Parameter Specification

RF Approvals

U.S.A. FCC Part 15.247

Canada RSS 210

Bluetooth Radio Device R&TTE Compliance Statement

The IT2020-5B and IT4620 are in conformity with all essential requirements of

the R&TTE Directive (1999/5/EC). This equipment has been assessed to the

following standards:

Parameter Specification

R&TTE EN 300 328-2:2000

EN 301 489-1 (2002-08)

EN 301 489-17 (2002-08)

EN 60950:2000

EN 50361:2001

This product is marked with in accordance with the Class II product

requirements specified in the R&TTE Directive, 1999/5/EC.

The equipment is intended for use throughout the European Community.

Page 6

Bluetooth Qualified Product

Bluetooth Qualified Body approved as a Bluetooth Class II radio.

UL and cUL Statement

UL listed UL1950 and CSA 22.2 No.950. cUL listed UL1950 and CSA 22.2 No

950.

LED Safety Statement

This device has been tested in accordance with EN60825-1 LED safety, and has

been certified to be under the limits of a Class 1 LED device.

TÜV Statement

TÜV or GS marked to EN60950 and EN60825-1.

C-Tick Statement

Conforms to AS/NZS 3548. C-Tick number: N10410.

Mexico

Certified

Patents

Please refer to the IT4620 packaging for patent information.

Solids and Water Protection

The IT4620 has a rating of IP41, immunity of foreign particles and dripping

water.

Page 7

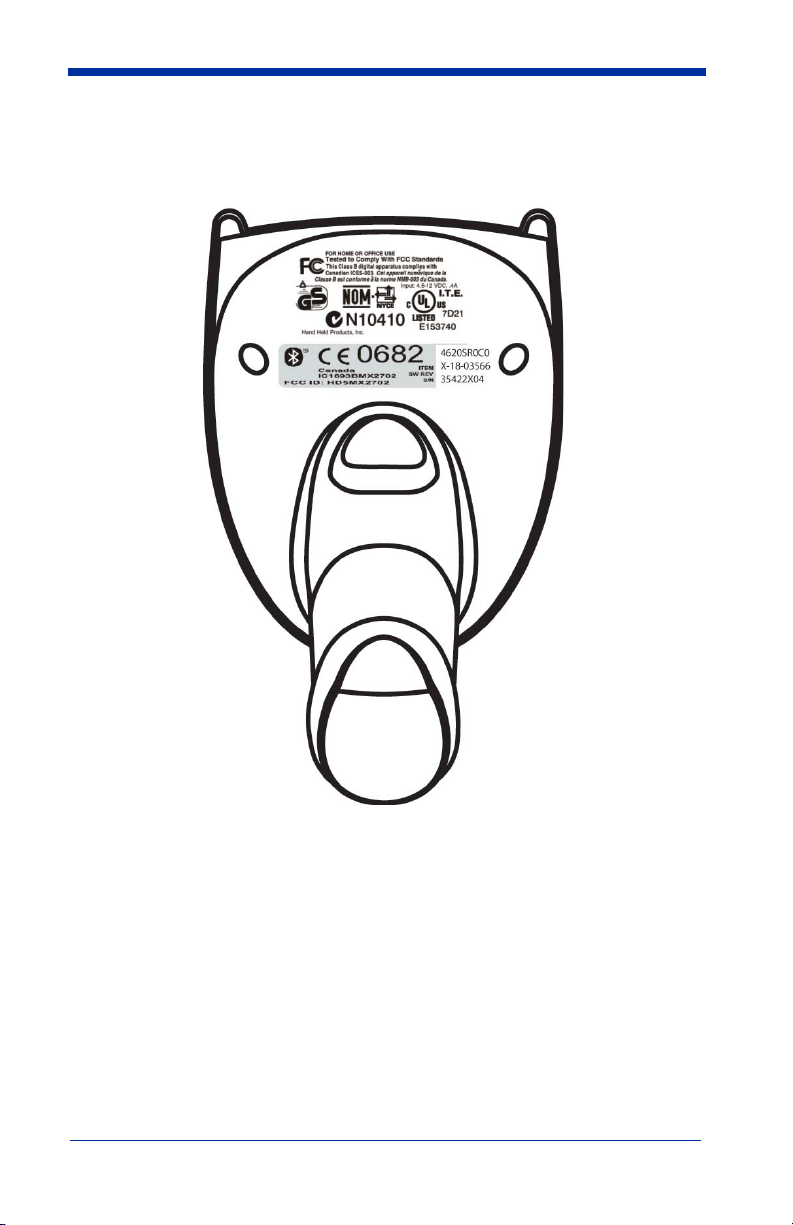

Required Safety Labels

IT4620

www.handheld.com

B

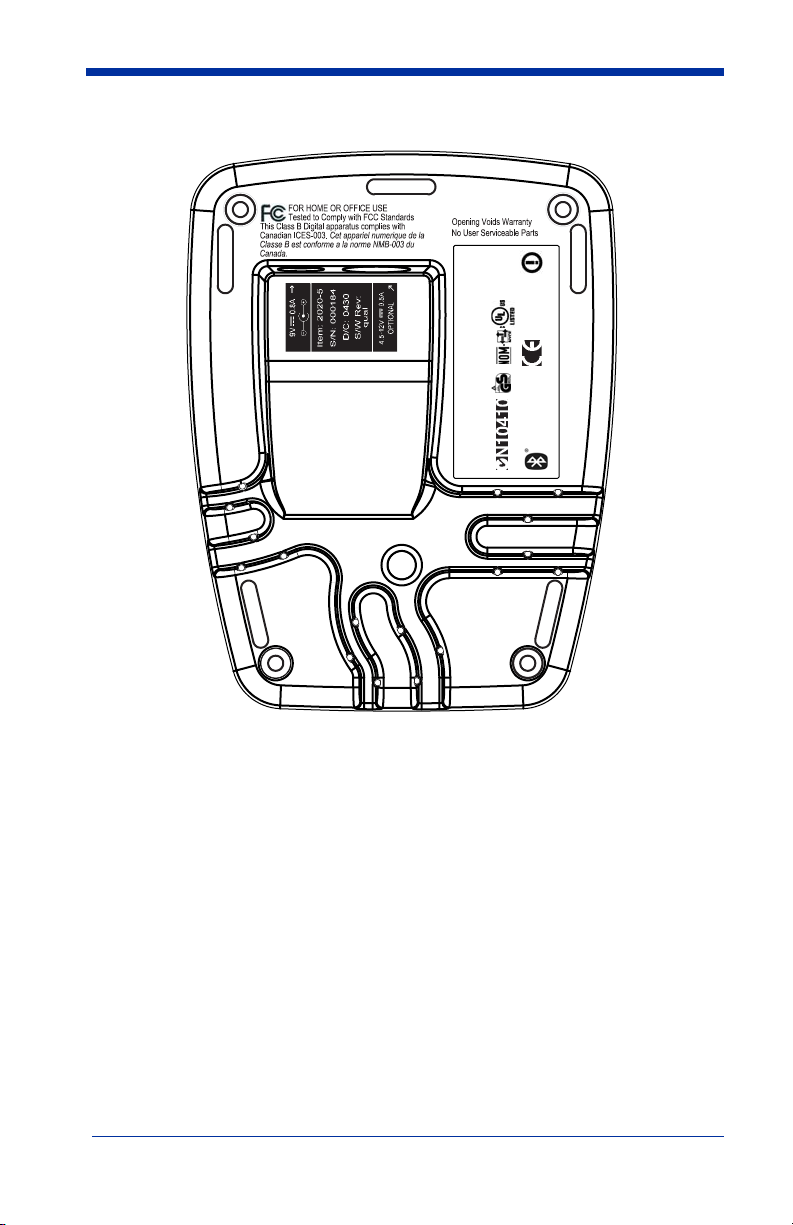

Page 8

IT2020-5B

'

'

B

.c

3

YROS

mo

5131YN,s

nI

c.

,stc

dl

e

u

hd

dorP

n

l

laFs

a

h.

d

leH

www

e

letaenak

d

n

a

H

S

"anihC

047351E

.E

12D7

.

SECCA

T.I

ni

2860

edaM"

gnidnePstnetaPn

B

2072

B2

0

X

72XM5D

M

B396

g

1

ie

C

ro

I

H

:DI

FdnaSU

ada

C

naC

CF

Page 9

Table of Contents

Chapter 1 - Getting Started

About This Manual ............................................................... 1-1

Unpacking the System .......................................................... 1-2

IT4620 Models...................................................................... 1-2

Cordless System: Main Components.................................... 1-2

About the Battery.................................................................. 1-3

Proper Disposal of the Battery.............................................. 1-4

Connecting the Base When Powered by Host

(Keyboard Wedge)............................................................. 1-4

Connecting the Base with USB ............................................ 1-5

Connecting the Base with RS-232 Serial Port...................... 1-6

Connecting the Base with Serial Wedge .............................. 1-7

Linking Imager to Base ........................................................ 1-8

Communication Between the Cordless System and

the Host................................................................................. 1-9

Reading Techniques............................................................ 1-10

Chapter 2 - Programming the Interface

Introduction........................................................................... 2-1

Plug and Play ........................................................................ 2-1

Keyboard Wedge Connection............................................... 2-1

Laptop Direct Connect ................................................... 2-1

RS-232............................................................................ 2-2

Wand Emulation Plug & Play ........................................ 2-2

IBM 4683 Ports 5B, 9B, and 17 Interface ............................ 2-3

IBM SurePos......................................................................... 2-4

USB PC or Macintosh Keyboard ................................... 2-4

USB HID........................................................................ 2-5

USB Com Port Emulation.............................................. 2-5

Serial Wedge......................................................................... 2-6

Resetting the Standard Product Default Settings:

Current Application Work Group ...................................... 2-7

Resetting the Standard Product Default Settings: All

Application Work Groups.................................................. 2-7

i

Page 10

Programming the Interface - Terminal ID Method............... 2-8

Supported Terminals............................................................. 2-9

Keyboard Country .............................................................. 2-11

Keyboard Style ................................................................... 2-13

Keyboard Modifiers............................................................ 2-14

RS-232 Baud Rate........................................................ 2-16

RS-232 Word Length: Data Bits, Stop Bits, and Parity2-17

RS-232 Receiver Time-Out.......................................... 2-18

RS-232 Handshaking ................................................... 2-18

Host ACK Selection..................................................... 2-19

Host ACK Enable......................................................... 2-20

Wand Emulation ................................................................. 2-21

Wand Emulation Connection ....................................... 2-21

Wand Emulation Data Block Size................................ 2-22

Wand Emulation Delay Between Blocks..................... 2-23

Wand Emulation Overall Checksum............................ 2-23

Wand Emulation Transmission Rate............................ 2-24

Wand Emulation Polarity............................................. 2-24

Wand Emulation Idle ................................................... 2-25

Chapter 3 - Basic System Operation

Cordless Base........................................................................ 3-1

RF (Radio Frequency) Module Operation............................ 3-1

Cordless Imager.................................................................... 3-1

System Conditions................................................................ 3-2

Linking Process.............................................................. 3-2

Imager Is Out of Range.................................................. 3-2

Imager Is Moved Back Into Range ................................ 3-2

Out of Range and Back into Range with Data Accumulation

Mode On......................................................................... 3-2

Base Charge Mode................................................................ 3-3

Beeper and LED Sequences and Meaning............................ 3-4

IT4620 LED Sequences and Meaning ........................... 3-4

IT2020-5B LED Sequences and Meaning ..................... 3-4

Imager Modes ....................................................................... 3-5

Unlinking the Imager ..................................................... 3-5

ii

Page 11

Single Imager Operation ....................................................... 3-5

Locked Link Mode - Single Imager ............................... 3-5

Open Link Mode - Single Imager................................... 3-6

Override Locked Imager ................................................ 3-6

Multiple Imager Operation ................................................... 3-6

Imager Name......................................................................... 3-7

Imager Report ....................................................................... 3-8

Application Work Groups..................................................... 3-8

Application Work Group Selection................................ 3-9

Resetting the Standard Product Default Settings: All

Application Work Groups ................................................ 3-10

Resetting the Standard Product Default Settings:

Current Application Work Group..................................... 3-10

Using the Imager with Bluetooth Devices .......................... 3-11

Changing Bluetooth PIN Code.....................................3-11

Out-of-Range Alarm ........................................................... 3-12

Duration........................................................................3-12

Alarm Sound Type ....................................................... 3-12

Data Accumulation Mode ................................................... 3-13

Chapter 4 - Output

Good Read Indicators ........................................................... 4-1

Beeper – Good Read....................................................... 4-1

Beeper Volume – Good Read......................................... 4-1

Beeper Pitch – Good Read ............................................. 4-2

Beeper Duration – Good Read ....................................... 4-2

LED – Good Read .......................................................... 4-2

Number of Beeps – Good Read...................................... 4-3

Good Read Delay.................................................................. 4-3

User-Specified Good Read Delay......................................... 4-3

Serial Trigger Modes ............................................................ 4-4

Manual/Serial Trigger, Low Power................................ 4-4

Scan Stand Mode .................................................................. 4-6

Scan Stand Symbol......................................................... 4-6

iii

Page 12

Presentation Mode ................................................................ 4-6

Presentation LED Behavior after Decode ...................... 4-7

Presentation Sensitivity.................................................. 4-7

Hands Free Time-Out ........................................................... 4-7

Reread Delay ........................................................................ 4-8

User-Specified Reread Delay ............................................... 4-8

LED Power Level ................................................................. 4-9

Illumination Lights ............................................................... 4-9

Aimer Delay........................................................................ 4-10

User-Specified Aimer Delay ........................................ 4-10

Aimer Mode........................................................................ 4-11

Centering............................................................................. 4-11

Decode Search Mode.......................................................... 4-13

Output Sequence Overview ................................................ 4-14

Output Sequence Editor ............................................... 4-16

Require Output Sequence............................................. 4-16

Multiple Symbols ............................................................... 4-17

No Read .............................................................................. 4-17

Print Weight........................................................................ 4-18

Video Reverse..................................................................... 4-18

Working Orientation........................................................... 4-19

Chapter 5 - Data Editing

Prefix/Suffix Overview......................................................... 5-1

To Add a Prefix or Suffix: ............................................. 5-2

To Clear One or All Prefixes or Suffixes:...................... 5-3

To Add a Carriage Return Suffix to all Symbologies .... 5-3

Prefix Selections............................................................. 5-4

Suffix Selections ............................................................ 5-4

Function Code Transmit................................................. 5-4

Intercharacter, Interfunction, and Intermessage Delays ....... 5-5

Intercharacter Delay ....................................................... 5-5

User Specified Intercharacter Delay .............................. 5-6

Interfunction Delay ........................................................ 5-6

Intermessage Delay ........................................................ 5-7

Chapter 6 - Data Formatting

iv

Page 13

Data Format Editor Introduction........................................... 6-1

To Add a Data Format.................................................... 6-1

Other Programming Selections ...................................... 6-2

Data Format Editor Commands...................................... 6-2

Data Format Editor......................................................... 6-5

Data Formatter................................................................ 6-5

Alternate Data Formats .................................................. 6-6

Chapter 7 - Symbologies

All Symbologies ................................................................... 7-2

Message Length Description................................................. 7-2

Codabar ................................................................................ 7-3

Codabar Start/Stop Characters....................................... 7-3

Codabar Check Character............................................... 7-4

Codabar Concatenation .................................................. 7-5

Codabar Message Length ............................................... 7-5

Code 39 ................................................................................ 7-6

Code 39 Start/Stop Characters ....................................... 7-6

Code 39 Check Character............................................... 7-7

Code 39 Message Length ............................................... 7-7

Code 39 Append............................................................. 7-8

Code 32 Pharmaceutical (PARAF) ................................ 7-8

Full ASCII ...................................................................... 7-9

Code 39 Code Page ...................................................... 7-10

Interleaved 2 of 5 ............................................................... 7-10

Check Digit................................................................... 7-11

Interleaved 2 of 5 Message Length .............................. 7-11

Code 93 .............................................................................. 7-12

Code 93 Message Length ............................................. 7-12

Code 93 Code Page ...................................................... 7-13

Code 2 of 5 ......................................................................... 7-13

Code 2 of 5 Message Length........................................ 7-13

IATA Code 2 of 5 .............................................................. 7-14

IATA Code 2 of 5 Message Length ............................. 7-14

Matrix 2 of 5 ...................................................................... 7-15

Matrix 2 of 5 Message Length ..................................... 7-15

v

Page 14

Code 11 .............................................................................. 7-16

Check Digits Required ................................................. 7-16

Code 11 Message Length ............................................. 7-16

Code 128 ............................................................................ 7-17

ISBT 128 Concatenation.............................................. 7-17

Code 128 Message Length ........................................... 7-18

Code 128 Code Page .................................................... 7-18

Telepen .............................................................................. 7-18

Telepen Output............................................................. 7-19

Telepen Message Length.............................................. 7-19

UPC-A ............................................................................... 7-19

UPC-A Check Digit ..................................................... 7-20

UPC-A Number System............................................... 7-20

UPC-A Addenda .......................................................... 7-20

UPC-A Addenda Required........................................... 7-21

UPC-A Addenda Separator .......................................... 7-21

UPC-A/EAN-13

with Extended Coupon Code .......................................... 7-21

UPC-E0 .............................................................................. 7-22

UPC-E0 ........................................................................ 7-22

UPC-E0 Expand........................................................... 7-22

UPC-E0 Addenda Required ......................................... 7-23

UPC-E0 Addenda Separator ........................................ 7-23

UPC-E0 Check Digit.................................................... 7-23

UPC-E0 Number System ............................................. 7-24

UPC-E0 Addenda......................................................... 7-24

UPC-E1 .............................................................................. 7-24

EAN/JAN-13 ..................................................................... 7-25

EAN/JAN-13 Check Digit ........................................... 7-25

EAN/JAN-13 Addenda ................................................ 7-26

EAN/JAN-13 Addenda Required................................. 7-26

EAN/JAN-13 Addenda Separator ................................ 7-26

ISBN Translate............................................................. 7-27

vi

Page 15

EAN/JAN-8 ........................................................................ 7-27

EAN/JAN-8 Check Digit.............................................. 7-27

EAN/JAN-8 Addenda................................................... 7-28

EAN/JAN-8 Addenda Required................................... 7-28

EAN/JAN-8 Addenda Separator .................................. 7-28

MSI .................................................................................... 7-29

MSI Check Character ................................................... 7-29

MSI Message Length.................................................... 7-30

Plessey Code ...................................................................... 7-30

Plessey Message Length............................................... 7-30

RSS-14 ............................................................................... 7-31

RSS Limited .......................................................................7-31

RSS Expanded ................................................................... 7-32

RSS Expanded Message Length................................... 7-32

PosiCode ............................................................................ 7-33

PosiCode Message Length ........................................... 7-33

Trioptic Code ..................................................................... 7-34

Codablock F ....................................................................... 7-34

Codablock F Message Length ...................................... 7-35

Code 16K ........................................................................... 7-35

Code 16K Message Length .......................................... 7-35

Code 49 .............................................................................. 7-36

Code 49 Message Length ............................................. 7-36

PDF417 .............................................................................. 7-37

PDF417 Message Length ............................................. 7-37

MicroPDF417 .................................................................... 7-37

MicroPDF417 Message Length.................................... 7-38

EAN•UCC Composite Codes ............................................ 7-38

UPC/EAN Version ....................................................... 7-39

EAN•UCC Composite Code Message Length ............. 7-39

vii

Page 16

EAN•UCC Emulation ........................................................ 7-40

TCIF Linked Code 39 (TLC39) ......................................... 7-40

Postal Codes ....................................................................... 7-41

Postnet.......................................................................... 7-41

Planet Code .................................................................. 7-42

British Post................................................................... 7-42

Canadian Post............................................................... 7-42

Kix (Netherlands) Post................................................. 7-43

Australian Post ............................................................. 7-43

Japanese Post................................................................ 7-43

China Post .......................................................................... 7-44

China Post Message Length ......................................... 7-44

Korea Post .......................................................................... 7-45

Korea Post Message Length......................................... 7-45

QR Code ............................................................................ 7-46

QR Code Message Length ........................................... 7-46

Data Matrix ........................................................................ 7-47

Data Matrix Message Length ....................................... 7-47

MaxiCode .......................................................................... 7-48

MaxiCode Message Length.......................................... 7-48

Aztec Code ......................................................................... 7-49

Aztec Code Message Length........................................ 7-49

Aztec Runes ................................................................. 7-49

Chapter 8 - Imaging Commands

Image Snap - IMGSNP......................................................... 8-1

IMGSNP Modifiers........................................................ 8-1

Image Ship - IMGSHP.......................................................... 8-2

IMGSHP Modifiers........................................................ 8-3

Intelligent Signature Capture - IMGBOX ............................ 8-7

IMGBOX Modifiers....................................................... 8-7

RF Default Imaging Device.................................................. 8-9

Chapter 9 - OCR Programming

OCR Fonts ........................................................................... 9-2

OCR ...................................................................................... 9-2

viii

Page 17

U.S. Currency Font .............................................................. 9-3

MICR E13 B Font ................................................................ 9-3

SEMI Font ............................................................................ 9-4

OCR Templates..................................................................... 9-4

Creating an OCR Template ............................................ 9-5

Stringing Together Multiple Formats

(Creating “Or” Statements) ............................................ 9-7

OCR User-Defined Variables ............................................... 9-7

Reading Multi-Row OCR............................................... 9-8

OCR Check Character........................................................... 9-9

OCR Modulo 10 Check Character ................................. 9-9

OCR Modulo 36 Check Character ............................... 9-10

OCR User-Defined Check Character.................................. 9-10

Weighting Options ....................................................... 9-11

OCR ISBN Application Example ....................................... 9-13

OCR Template Codes ......................................................... 9-14

Chapter 10 - Interface Keys

Keyboard Function Relationships....................................... 10-1

Supported Interface Keys.................................................... 10-3

Chapter 11 - Utilities

To Add a Test Code I.D. Prefix to All Symbologies .......... 11-1

Reset Imager ....................................................................... 11-1

Show Software Revision.....................................................11-1

Show Data Format .............................................................. 11-1

Imager Report ..................................................................... 11-2

Imager Address ................................................................... 11-2

Base Address....................................................................... 11-2

Resetting the Standard Product Default Settings:

Current Application Work Group..................................... 11-2

Resetting the Standard Product Default Settings: All

Application Work Groups ................................................ 11-3

Test Menu ........................................................................... 11-3

Visual Menu 2003...............................................................11-3

Installing Visual Menu 2003 from the Web................. 11-4

ix

Page 18

Quick*View........................................................................ 11-5

Installing Quick*View from the Web .......................... 11-5

Chapter 12 - Serial Programming Commands

Conventions ........................................................................ 12-1

Menu Command Syntax ..................................................... 12-1

Query Commands......................................................... 12-2

Concatenation of Multiple Commands ........................ 12-2

Responses..................................................................... 12-3

Examples of Query Commands ................................... 12-3

Trigger Commands ............................................................. 12-4

Resetting the Standard Product Default Settings:

Current Application Work Group .................................... 12-5

Resetting the Standard Product Default Settings: All

Application Work Groups................................................ 12-5

Menu Commands................................................................ 12-6

Programming the Interface ................................... 12-6

Basic System Operation ........................................ 12-9

Output Selections ................................................ 12-10

Prefix/Suffix Selections ...................................... 12-12

Data Formatter Selections .................................. 12-13

Symbologies ....................................................... 12-13

Imaging Default Commands ............................... 12-22

Image Snap ......................................................... 12-22

Image Snap (continued) ...................................... 12-23

OCR Selections ................................................... 12-25

Chapter 13 - Product Specifications

IT4620 Product Specifications ........................................... 13-1

IMAGETEAM 2020-5B Product Specifications................ 13-2

Chapter 14 - Maintenance

Repairs ................................................................................ 14-1

x

Page 19

Maintenance........................................................................ 14-1

Cleaning the Imager’s Window.................................... 14-1

Inspecting Cords and Connectors................................. 14-1

Replacing the IT2020-5B Interface Cable: .................. 14-2

Troubleshooting Base ......................................................... 14-2

Chapter 15 - Customer Support

Product Service and Repair................................................. 15-1

Technical Assistance........................................................... 15-2

Limited Warranty ......................................................... 15-3

Appendix A

Symbology Chart ................................................................. A-1

ASCII Conversion Chart (Code Page 1252)........................ A-4

Code Page Mapping of Printed Bar Codes .......................... A-6

xi

Page 20

xii

Page 21

1

Getting Started

The IMAGETEAM™ 4620 cordless scanning system consists of one IT2020-5B

base and one IT4620 Cordless Area Imager. Up to seven imagers may be linked

to one base. The IT4620 marks a new performance level for hand held area

imagers. The IT4620 hand held area imager is powered by Hand Held Products

Adaptus

delivers aggressive read rates and depths of field on 1D, stacked linear, and

matrix codes. This aggressiveness applies even in challenging reading

environments where low lighting conditions and poor quality might make it

difficult to read bar codes. Adaptus Imaging Technology ensures your

investment will continue to supply years of use by reading any bar codes you

require, now or in the future.

Designed for today’s demanding retail and commercial environments, the

IT4620 offers a superior reading range and image quality, durability, and the

ability to read poor quality bar codes. The IT4620 is comfortable to hold, easy to

use, rugged, and excellent for retail applications, as well as for all general

scanning and imaging applications.

The cordless system is an economical, durable solution for a wide variety of

portable data collection applications. The cordless system features:

• a tough, ergonomic thermoplastic housing for comfort and durability.

• an advanced two-way spread-spectrum radio, Bluetooth

• a wide range of interfaces: keyboard wedge, wand emulation, RS-232

• visible and audible feedback for confirmation of a successful decode.

• a rechargeable battery designed to operate through a whole work day.

The cordless system can be programmed for many communication parameters

and input/output protocols compatible to the host, as well as advanced data

editing and formatting.

TM

Imaging Technology. The performance of Adaptus technology

technology

terminals, USB, and legacy decoders.

®

wireless

About This Manual

This User’s Guide provides installation and programming instructions for the

IMAGETEAM 4620. Product specifications, dimensions, warranty, and

customer support information are also included.

Hand Held Products bar code imagers are factory programmed for the most

common terminal and communications settings. If you need to change these

settings, programming is accomplished by scanning the bar codes in this guide.

An asterisk (*) next to an option indicates the default setting.

IMAGETEAM™ 2020/4620 System Manual 1 - 1

Page 22

Unpacking the System

After you open the shipping carton containing the product, take the following

steps:

• Check to make sure everything you ordered is present.

• Save the shipping container for later storage or shipping.

• Check for damage during shipment. Report damage immediately to the

carrier who delivered the carton.

IT4620 Models

Models Description

IT2020-5B Base: Keyboard wedge, TTL level 232, TTL level 232

serial wedge, IBM 4683, wand emulation, USB keyboard,

USB HID, USB retail (IBM SurePOS)

4620SR0C1B Cordless Area Imager - Green aimer

4620SF0C1B Cordless Area Imager - Green aimer

Cordless System: Main Components

Battery Contained in Handle

1 - 2 IMAGETEAM™ 2020/4620 System Manual

Page 23

About the Battery

Use only the Li-ion battery packs provided by Hand Held Products. The

use of any battery pack not sold by Hand Held Products will void your

!

warranty and may result in damage to your unit.

Power is supplied to the cordless imager by a rechargeable battery that is

integrated in the imager handle. Each imager is shipped with a battery.

Product Specifications

beginning on page 13-1

.)

(See

Charging Information

The battery is designed to charge while the imager is positioned in the cordless

base unit. Refer to "IT2020-5B LED Sequences and Meaning" on page 3-4 for

an interpretation of the Charge Status indicators.

• Place the imager in the base that is connected to an appropriate power

supply.

Battery Recommendations

• Batteries are shipped approximately 30% to 60% charged and should be fully

charged for maximum charge capacity.

• The battery is a lithium ion cell and can be used without a full charge, as well

as can be charged without fully discharging, without impacting the battery life.

There is no need to perform any charge/discharge conditioning on this cell

type battery.

• Do not disassemble the battery. There are no user-serviceable parts in the

battery.

• Keep the base connected to power when the host is not in use.

• Replace a defective battery immediately since it could damage the IT4620.

• Don’t short-circuit a battery or throw it into a fire. It can explode and cause

severe personal injury.

• Although your battery can be recharged many times, it will eventually be

depleted. Replace it after the battery is unable to hold an adequate charge.

• If you are not sure if the battery or charger is working properly, send it to Hand

Held Products or an authorized Hand Held Products service center for

inspection.

IMAGETEAM™ 2020/4620 System Manual 1 - 3

Page 24

Proper Disposal of the Battery

When the battery has reached the end of its useful life, the

battery should be disposed of by a qualified recycler or

hazardous materials handler. Do not incinerate the battery or

dispose of the battery with general waste materials. You may

send batteries to Hand Held Products (postage paid). The

shipper is responsible for complying with all federal, state, and

local laws and regulations related to the packing, labeling,

Product Service Department (page 15-1) for recycling or disposal information.

Since you may find that your cost of returning the batteries significant, it may be

more cost effective to locate a local recycle/disposal company.

manifesting, and shipping of spent batteries. Contact the

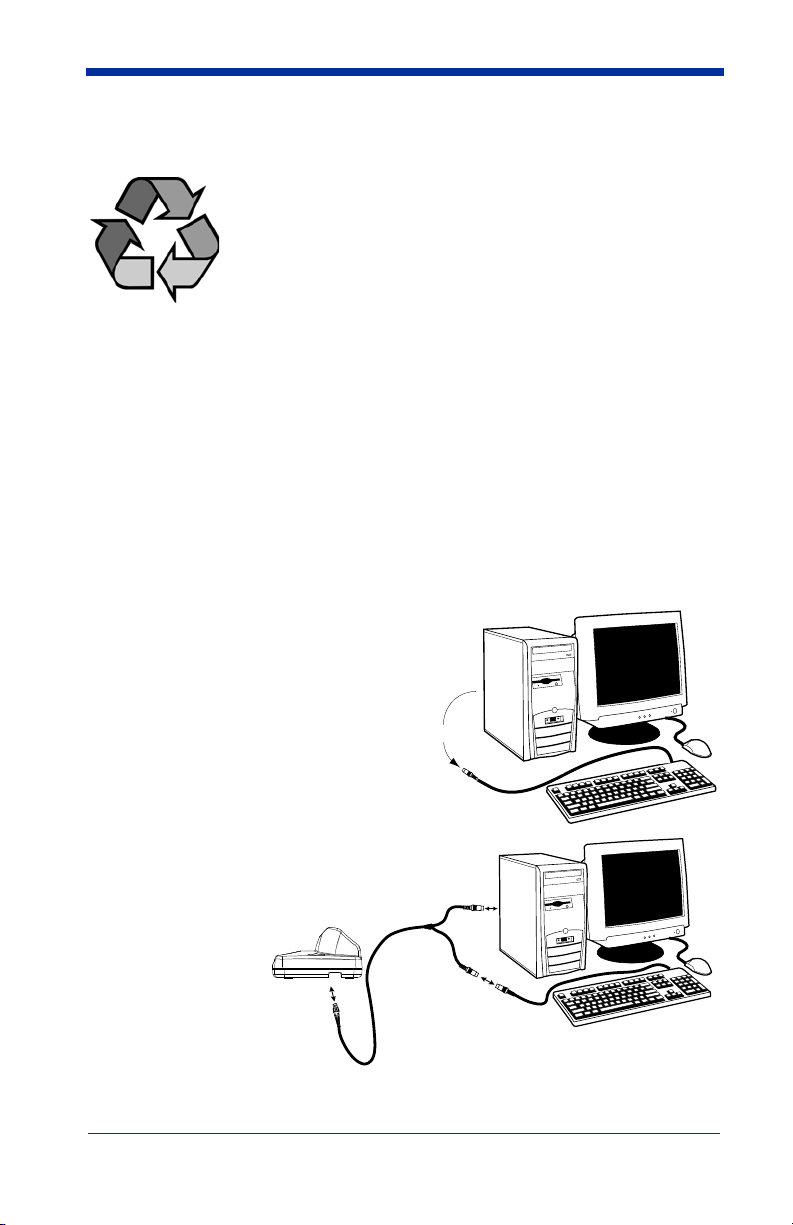

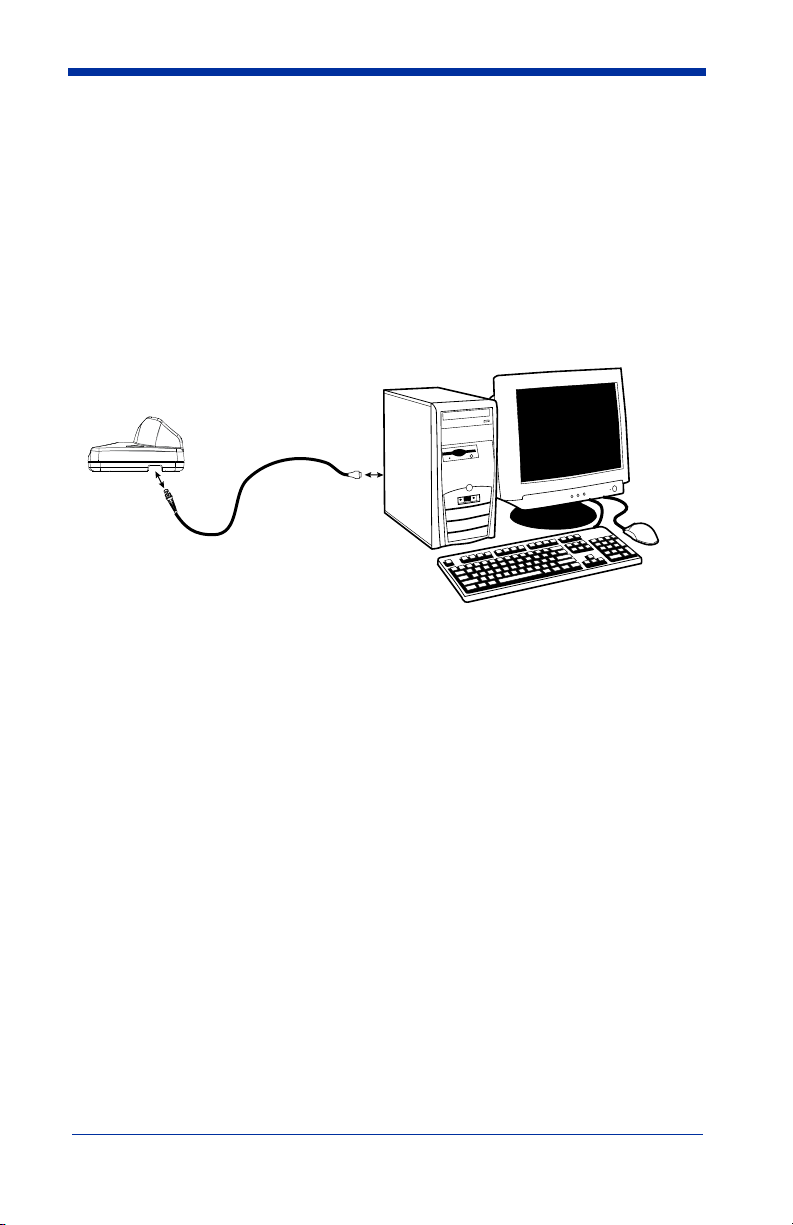

Connecting the Base When Powered by Host (Keyboard Wedge)

A base can be connected between the keyboard and PC as a “keyboard wedge,”

plugged into the serial port, or connected to a portable data terminal in wand

emulation or non decoded output mode. The following is an example of a

keyboard wedge connection:

1. Turn off power to the terminal/computer.

2. Disconnect the keyboard cable

from the back of the terminal/

computer.

Disconnect

3. Connect the

appropriate

interface cable

to the base and

to the terminal/

computer and

keyboard.

4. Turn the

terminal/

computer power

back on.

1

3

2

1 - 4 IMAGETEAM™ 2020/4620 System Manual

Page 25

5. Program the base for the keyboard wedge interface. See "Keyboard Wedge

Connection" on page 2-1.)

6. Verify the base operation by scanning a bar code from the Sample Symbols

in the back of this manual.

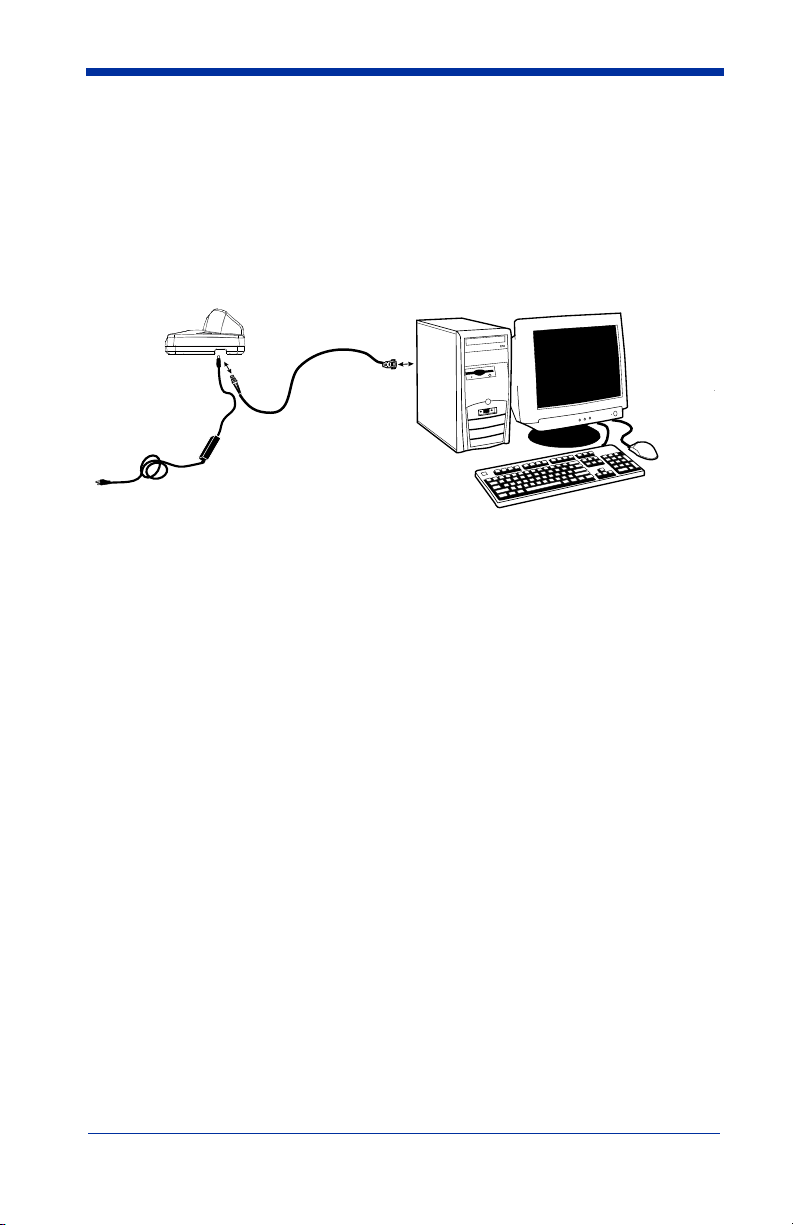

Connecting the Base with USB

A base can be connected to the USB port of a computer.

1. Connect the appropriate interface cable to the base and to the computer.

2. Program the base for the USB interface by scanning the appropriate

programming bar code.

3. Verify the base operation by scanning a bar code from the Sample Symbols

in the back of this manual.

For additional USB programming and technical information, refer to the Hand

Held Products “USB Application Note,” available at www.handheld.com

.

IMAGETEAM™ 2020/4620 System Manual 1 - 5

Page 26

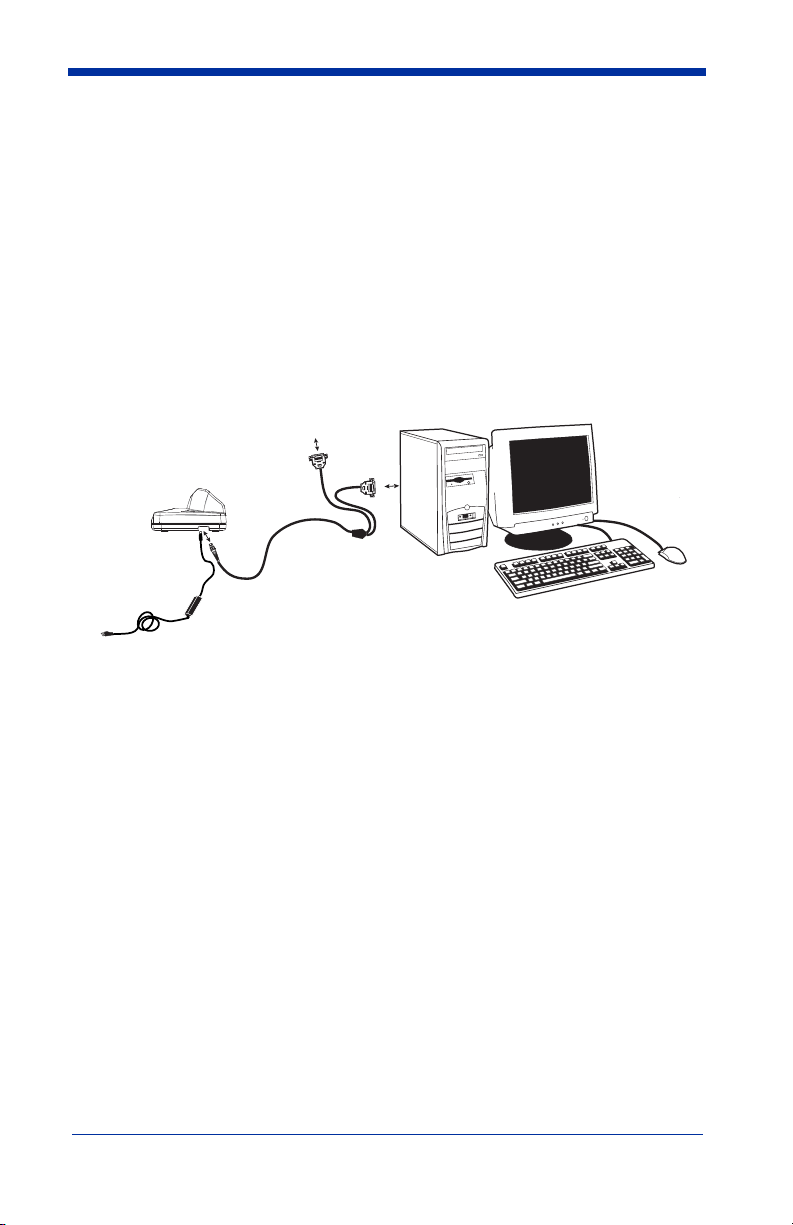

Connecting the Base with RS-232 Serial Port

1. Turn off power to the terminal/computer.

2. Connect the appropriate interface cable to the base.

Note: For the base to work properly, you must have the correct cable for your

type of terminal/computer.

3

2

4

2

5

3. Unplug the mouse or keyboard from the computer. Plug the mouse or

keyboard into the power tap on the imager cable.

4. Plug the power tap into the mouse or keyboard port.

5. Plug the serial connector into the serial port on your computer. Tighten the

two screws to secure the connector to the port.

6. Once the imager has been fully connected, power up the computer.

5

4

3

1 - 6 IMAGETEAM™ 2020/4620 System Manual

Page 27

Connecting the Base with Serial Wedge

The IT2020-5B uses TTL signal levels to wedge into an RS-232 serial network.

Use only IT2020-5B serial wedge cables to prevent damage to the base. Refer

to RS-232 Baud Rate on page 2-16 to set the baud rate and communications

protocol.

1. Turn off power to the computer.

2. Disconnect the existing serial cable from the computer.

3. Connect the appropriate interface cable to the base.

Note: For the base to work properly, you must have the correct cable for your

type of computer.

Other device

5

4

6

4. Plug the serial connector into the serial port on your computer. Tighten the

two screws to secure the connector to the port.

5. Plug the other serial connector into the other device connection and tighten

the two screws.

6. Plug the power supply barrel connector to the base, and plug the power

supply into the AC source.

7. Once the base has been fully connected, power up the computer.

IMAGETEAM™ 2020/4620 System Manual 1 - 7

Page 28

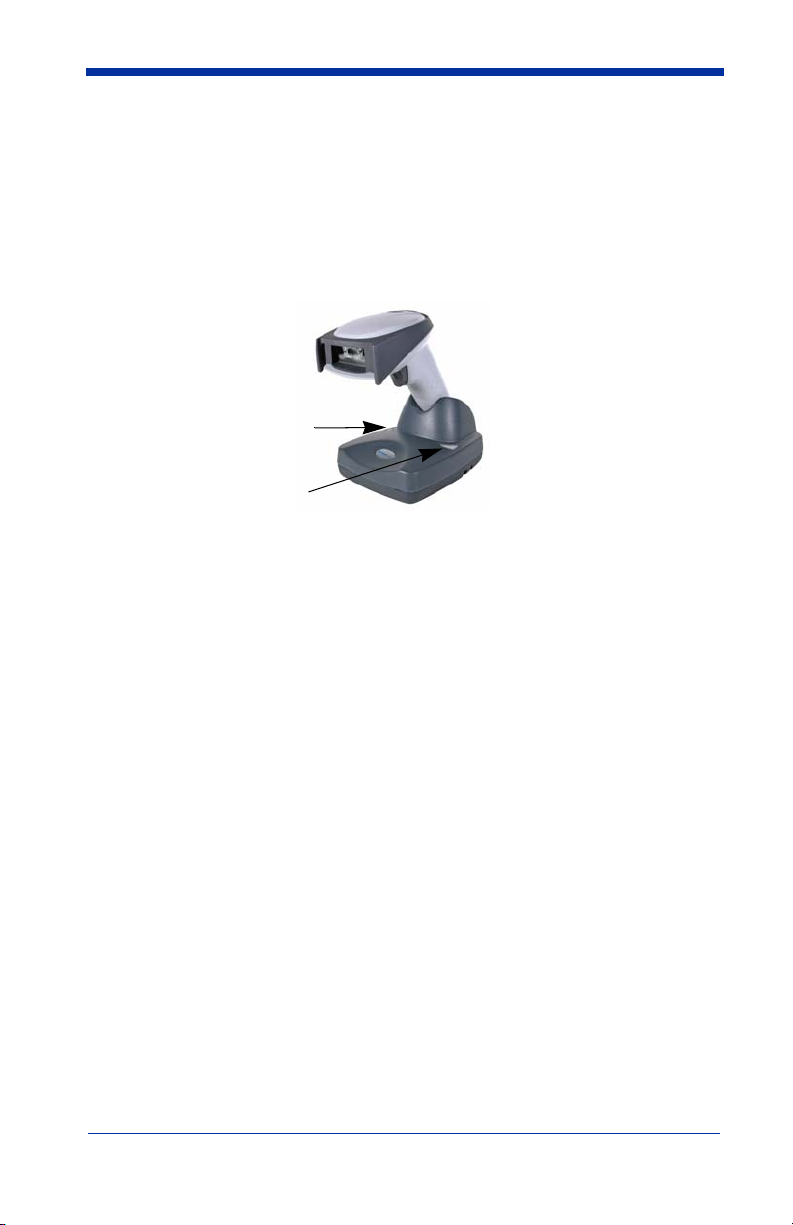

Linking Imager to Base

When newly shipped or defaulted to factory settings, the base and imager are not

linked. Once the imager is placed into the base, the software automatically links

the imager and the base. If the imager and base have previously been linked,

you do not receive any feedback. If this is the first time that the imager and base

are linked, both devices emit a short chirp when their radios link. At this point,

you are set to one imager to one base.

IT4620 Imager

Green LED

Red LED

1. Provide power to the base.

2. Place the IT4620 into the base. The imager and base link.

3. To determine if your cordless system is set up correctly, scan one of the

sample bar codes in the back of this manual. If the imager provides a single

good read beep and the green LED lights, the imager has successfully linked

to the base. If you receive a triple error beep and the red LED lights, the

imager has not linked to the base.

IT2020-5B Cordless Base

1 - 8 IMAGETEAM™ 2020/4620 System Manual

Page 29

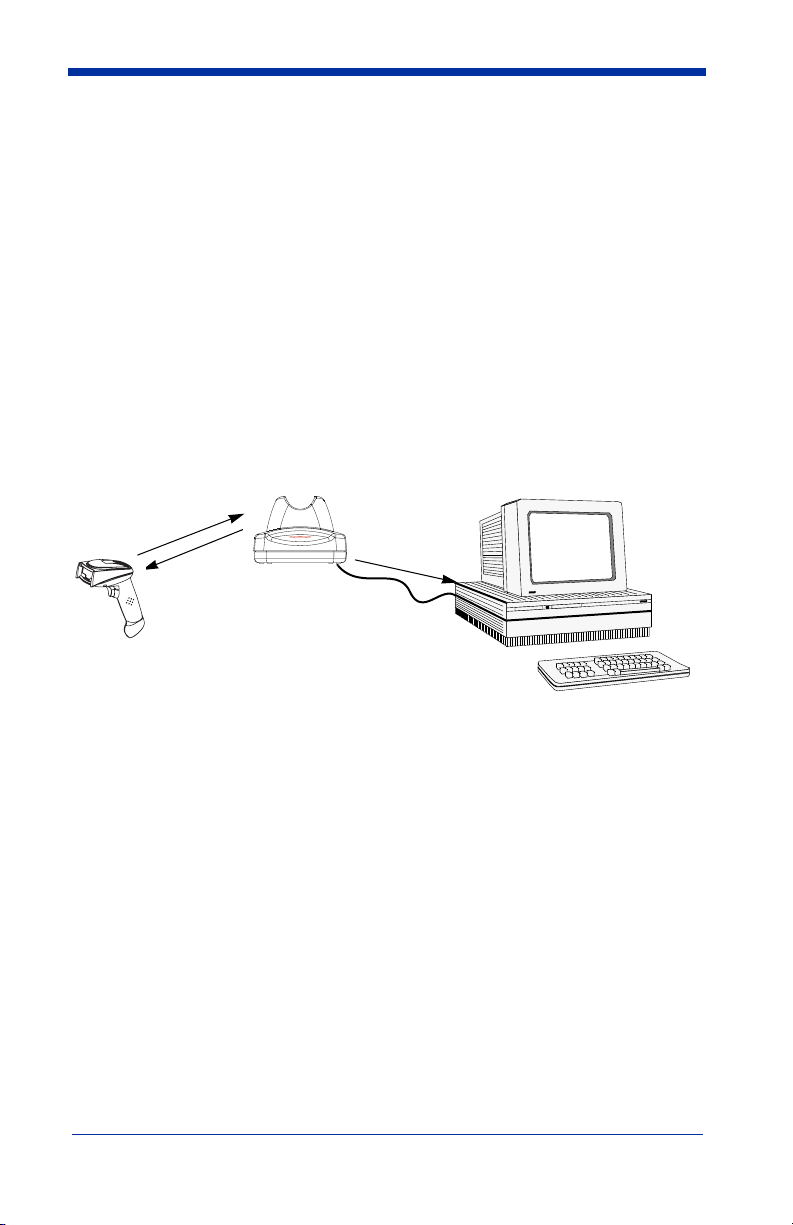

Communication Between the Cordless System and the Host

The cordless imager provides immediate feedback in the form of a “good read”

indication (a green LED on the imager and an audible beep) after a bar code is

scanned correctly and the base has acknowledged receiving the data. This is

possible since the cordless system provides two-way communication between

the imager and the base.

When data is scanned, the data is sent to the host system via the base unit.

Confirmation from the host system or the base indicates that the data sent was

received by the host. The cordless imager recognizes data acknowledgement

(ACK) from the base unit. If it cannot be determined that the data has been

properly sent to the base, the imager issues an error indication. You must then

check to see if the scanned data was received by the host system.

3) Base sends

d

a

e

R

d

o

o

G

)

1

e

s

a

b

m

o

f

r

K

C

A

)

2

data to host

IMAGETEAM™ 2020/4620 System Manual 1 - 9

Page 30

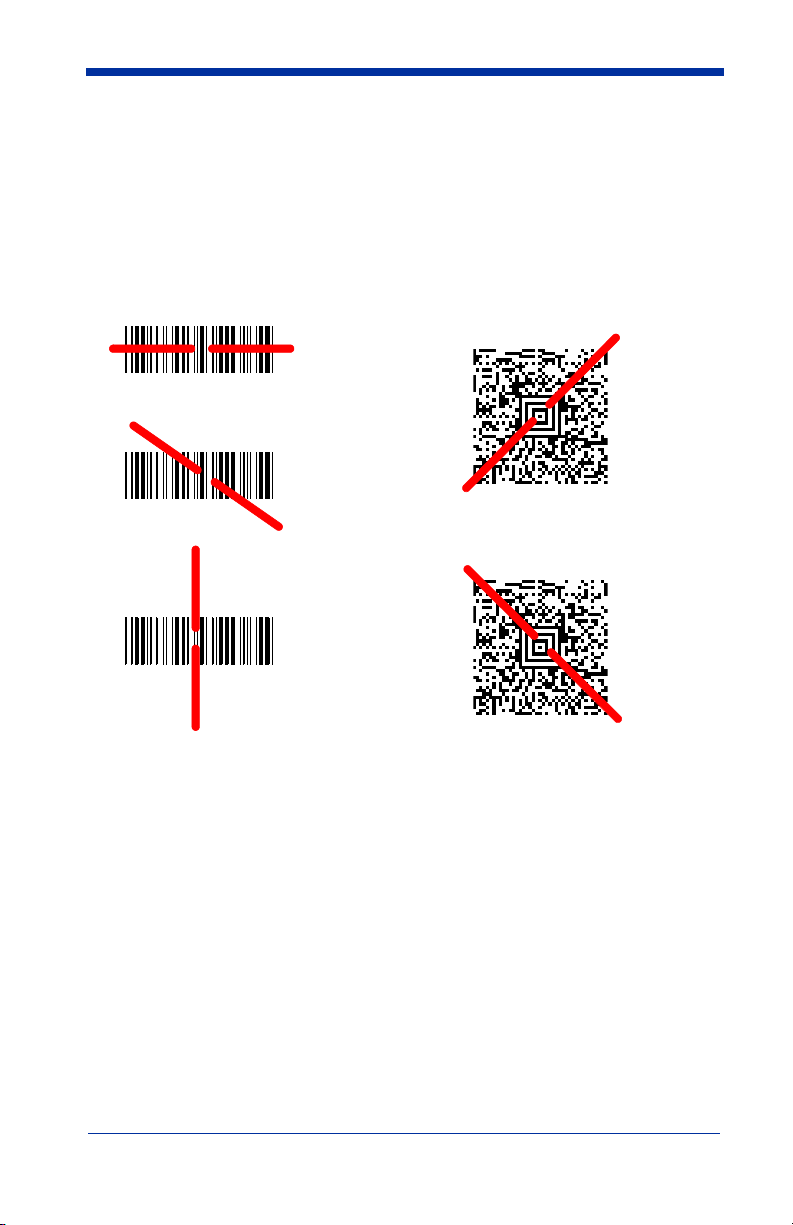

Reading Techniques

The imager has a view finder that projects a bright red or green aiming beam that

corresponds to the imager’s horizontal field of view. The aiming beam should be

centered over the bar code, but it can be positioned in any direction for a good

read.

Linear bar code 2D Matrix symbol

The aiming beam is smaller when the imager is closer to the code and larger

when it is farther from the code. Symbologies with smaller bars or elements (mil

size) should be read closer to the unit. Symbologies with larger bars or elements

(mil size) should be read farther from the unit. To read single or multiple symbols

(on a page or on an object), hold the imager at an appropriate distance from the

target, pull the trigger, and center the aiming beam on the symbol. If the code

being scanned is highly reflective (e.g., laminated), it may be necessary to tilt the

code up 15° to 18° to prevent unwanted reflection.

1 - 10 IMAGETEAM™ 2020/4620 System Manual

Page 31

2

Programming the Interface

Introduction

Chapter 1 describes connecting the base to the computer with the appropriate

interface cable. This chapter describes how to program your system for the

desired interface.

Plug and Play

Plug and Play bar codes provide instant imager set up for commonly used

interfaces.

Note: After you scan one of the codes, power cycle the host terminal to have the

interface in effect.

Keyboard Wedge Connection

If you want your system programmed for an IBM PC AT and compatibles

keyboard wedge interface with a USA keyboard, scan the bar code below.

Keyboard wedge is the default interface.

Note: The following bar code also programs a carriage return (CR) suffix.

IBM PC AT and Compatibles

with CR suffix

Laptop Direct Connect

For most laptops, scanning the Laptop Direct Connect bar code allows

operation of the imager in parallel with the integral keyboard. The following

Laptop Direct Connect bar code selects terminal ID 03, programs a carriage

return (CR) suffix and turns on Emulate External Keyboard (page 2-14).

Laptop Direct Connect

with CR suffix

IMAGETEAM™ 2020/4620 System Manual 2 - 1

Page 32

RS-232

The RS-232 Interface bar code is used when connecting to the serial port of a

PC or terminal. The following RS-232 Interface bar code also programs a

carriage return (CR) and a line feed (LF) suffix, baud rate, and data format as

indicated below. It also changes the trigger mode to manual.

Option

Baud Rate 115200 bps

Data Format 8 data bits, no parity bit, 1 stop bit

Setting

RS-232 Interface

Wand Emulation Plug & Play

In Wand Emulation mode, the imager decodes the bar code then sends data in

the same format as a wand imager. The Code 39 Format converts all

symbologies to Code 39.

The Same Code Format transmits UPC, EAN, Code 128 and Interleaved 2 of 5

without any changes, but converts all other symbologies to Code 39.

The

Wand Emulation Plug & Play Code 39 Format

terminal ID to 61. The

code sets the terminal ID to 64. These Plug & Play bar codes also set the

Transmission Rate to 25 inches per second, Output Polarity to black high, and

Idle State to high. (If you want to change the terminal ID

any other imager settings, please refer to Introduction on page 2-1.)

Wand Emulation

Plug & Play

(Code 39 Format)

Wand Emulation Plug & Play Same Code Format

bar code below sets the

only

, without changing

Wand Emulation

Plug & Play

Same Code

bar

2 - 2 IMAGETEAM™ 2020/4620 System Manual

Page 33

IBM 4683 Ports 5B, 9B, and 17 Interface

Scan one of the following “Plug and Play” codes to program the IT4620 for IBM

4683 Port 5B, 9B, or 17.

Note: After scanning one of these codes, you must power cycle the cash

register.

IBM 4683 Port 5B Interface

IBM 4683 Port 9B

HHBCR-1 Interface

IBM 4683 Port 17 Interface

IBM 4683 Port 9B

HHBCR-2 Interface

Each bar code above also programs the following suffixes for each symbology:

Symbology Suffix

EAN 8 0C

EAN 13 16

UPC A 0D

UPC E 0A

Code 39 00 0A 0B

Interleaved 2 of 5 00 0D 0B

Code 128 * 00 0A 0B

Code 128 ** 00 18 0B

* Suffixes programmed for Code 128 with IBM 4683 Port 5B, IBM 4683 Port 9B HHBCR-1,

and IBM 4683 Port 17 Interfaces

**Suffixes programmed for Code 128 with IBM 4683 Port 9 HHBCR-2 Interface

IMAGETEAM™ 2020/4620 System Manual 2 - 3

Page 34

IBM SurePos

Scan one of the following “Plug and Play” codes to program the IT4620 for IBM

SurePos (USB Hand Held imager) or IBM SurePos (USB Tabletop imager).

Note: After scanning one of these codes, you must power cycle the cash

register.

IBM SurePos

(USB Hand Held Imager)

Each bar code above also programs the following suffixes for each symbology:

Interface

IBM SurePos

(USB Tabletop Imager)

Interface

Symbology

EAN 8 0C

EAN 13 16

UPC A 0D

UPC E 0A

Code 39 00 0A 0B

Interleaved 2 of 5 00 0D 0B

Code 128 00 18 0B

Suffix

USB PC or Macintosh Keyboard

Scan one of the following codes to program the IT4620 for USB PC Keyboard or

USB Macintosh Keyboard. Scanning these codes adds a CR and LF, along with

selecting the terminal ID (USB PC Keyboard - 124, USB Macintosh Keyboard -

125).

USB Keyboard (PC)

USB Keyboard (Mac)

2 - 4 IMAGETEAM™ 2020/4620 System Manual

Page 35

USB HID

Scan the following code to program the IT4620 for USB HID bar code imagers.

Scanning this code changes the terminal ID to 131.

USB HID Bar Code Imager

USB Com Port Emulation

Scan the following code to program the IT4620 to emulate a regular RS-232based Com Port. If you are using a Microsoft® Windows® PC, you will need to

download a driver from the Hand Held Products website (www.handheld.com).

The driver will use the next available Com Port number. Apple® Macintosh

computers recognize the imager as a USB CDC class device and automatically

uses a class driver. Scanning the code below changes the terminal ID to 130.

USB COM Port Emulation

Note: No extra configuration (e.g., baud rate) is necessary.

CTS/RTS Emulation

CTS/RTS Emulation On

* CTS/RTS Emulation Off

ACK/NAK Mode

ACK/NAK Mode On

* ACK/NAK Mode Off

IMAGETEAM™ 2020/4620 System Manual 2 - 5

Page 36

Serial Wedge

To set up the serial wedge terminal ID, use the serial terminal ID 050 and follow

the instructions on page 2-1. Make sure that all of the communication

parameters match on all of the connected devices. Choosing Both sends

scanned data to P1 and P2. Default = P1.

* P1

P2

Both P1 and P2

2 - 6 IMAGETEAM™ 2020/4620 System Manual

Page 37

Resetting the Standard Product Default Settings:

Current Application Work Group

If you aren’t sure what programming options are in your imager, or you’ve

changed some options and want the standard product default settings restored,

scan the

code below.

The Menu Commands starting on page 12-6 list the factory default settings for

each of the commands (indicated by an asterisk (*) on the programming pages).

Note: Scanning this bar code also causes both the imager and the base to

Standard Product Default Settings: Current Application Group

perform a reset and become unlinked. Refer to "Imager Modes" on

page 3-5 for additional information.

Standard Product Default Settings:

Current Application Group

bar

Resetting the Standard Product Default Settings: All Application Work Groups

The following bar code defaults all of the work groups to the factory settings.

Standard Product Default Settings:

All Application Groups

The Menu Commands starting on page 12-6 list the standard product default

settings for each of the commands (indicated by an asterisk (*) on the

programming pages).

IMAGETEAM™ 2020/4620 System Manual 2 - 7

Page 38

Programming the Interface - Terminal ID Method

If your interface is not a standard PC AT, refer to Supported Terminals on page

2-9 through page 2-10, and locate the Terminal ID number for your PC. Scan the

Terminal ID bar code below, then scan the numeric bar code(s) from the

Programming Chart inside the back cover of this manual to program the imager

for your terminal ID. Scan Save to save your selection.

For example, an IBM AT terminal has a Terminal ID of 003. You would scan the

Terminal ID bar code, then 0, 0, 3 from the Programming Chart inside the back

cover of this manual, then Save. If you make an error while scanning the digits

(before scanning Save), scan the Discard code on the Programming Chart, scan

the Terminal ID bar code, scan the digits, and the Save code again.

Note: The default interface is Keyboard Wedge (Term ID = 003).

Terminal ID

Save

Note: After scanning one of these codes, you must power cycle your computer.

2 - 8 IMAGETEAM™ 2020/4620 System Manual

Page 39

Supported Terminals

Ter minal Model(s)

DDC 3496, 3497, 122 key

DDC 3496, 3497, 102 key

DEC VT510, 520, 525 (PC style)

DEC VT510, 520, 525 (DEC style

LK411)

Esprit 200, 400

Heath Zenith PC, AT

Heath Zenith

HP Vectra

HP Vectra

IBM XT

IBM PS/2 25, 30, 77DX2

IBM AT, PS/2 30–286, 50, 55SX, 60,

70, 70–061, 70–121, 80

IBM 102 key 3151, 3161, 3162, 3163, 3191,

3192, 3194, 3196, 3197, 3471,

3472, 3476, 3477

IBM 122 key 3191, 3192, 3471, 3472

IBM 122 key 3196, 3197, 3476, 3477, 3486,

3482, 3488

IBM 122 key 3180

IBM 122 key 3180 data entry keyboard

IBM DOS/V 106 key PC & Workstation

IBM SurePOS USB Hand Held Imager

IBM SurePOS USB Tabletop Imager

IBM Thinkpad 360 CSE, 340, 750

IBM Thinkpad

IBM Thinkpad 365, 755CV

I/O 122 key 2676D, 2677C, 2677D

ITT 9271

Lee Data IIS

NEC 98XX Series

Olivetti M19, M200

Olivetti M240, M250, M290, M380,

P500

RS-232 TTL

Serial Wedge

Silicon Graphics Indy, Indigoll

Terminal

ID

005

071

084

104

005

003 *

090

003 *

023

001

002

003 *

006

007

008

024

114

102

128**

129**

097

106

003 *

008

007

007

103

001

003

000

050

005

IMAGETEAM™ 2020/4620 System Manual 2 - 9

Page 40

Supported Terminals

Ter minal Model(s)

Telex 88 key 078, 078A, 79, 80, 191, 196,

Telex 88 key Data Entry Keyboard

Telex 102 key 078, 078A, 79, 80, 191, 196,

Telex 122 key 078, 078A, 79, 80, 191, 196,

USB COM Port Emulation

USB PC Keyboard

USB Mac Keyboard

USB HID POS

Wand Emulation (Code 39

Format)

Wand Emulation (Same

Code Format)

* Default for IT2020-5B models

**It is best to use the Plug and Play bar codes, beginning on page 2-1 to program these

interfaces, rather than scanning the terminal ID listed in this table.

1191,1192, 1471, 1472, 1476,

1477, 1483

1191,1192, 1471, 1472, 1476,

1477, 1483

1191,1192, 1471, 1472, 1476,

1477, 1482, 1483

Terminal

ID

025

112

045

046

130

124**

125**

131**

061

064

2 - 10 IMAGETEAM™ 2020/4620 System Manual

Page 41

Keyboard Country

Scan the appropriate country code below to program the keyboard for your

country. As a general rule, the following characters are supported, but need

special care for countries other than the United States:

@ | $ # { } [ ] = / ‘ \ < > ~

* United States

Brazil

Czechoslovakia

Belgium

Canada (French)

Denmark

Finland (Sweden)

France

Germany/Austria

Greece

Hungary

Israel (Hebrew)

IMAGETEAM™ 2020/4620 System Manual 2 - 11

Page 42

Keyboard Country (continued)

Italy

Netherlands (Dutch)

Poland

Romania

Latin America

Norway

Portugal

Russia

SCS

Slovakia

Spain

Sweden

Switzerland (German)

2 - 12 IMAGETEAM™ 2020/4620 System Manual

Page 43

Keyboard Country (continued)

Turkey F

U.K.

Keyboard Style

Turkey Q

This programs keyboard styles, such as Caps Lock and Shift Lock.

Regular.

Regular

Caps Lock

Shift Lock

to U.S. keyboards).

Automatic Caps Lock

software tracks and reflects if you have Caps Lock on or off (AT and PS/2 only).

This selection can only be used with systems that have an LED which notes the

Caps Lock status.

is used when you normally have the Caps Lock key off.

* Regular

is used when you normally have the Caps Lock key on.

Caps Lock

is used when you normally have the Shift Lock key on (not common

Shift Lock

is used if you change the Caps Lock key on and off. The

Default =

Automatic Caps Lock

IMAGETEAM™ 2020/4620 System Manual 2 - 13

Page 44

Autocaps via NumLock

Germany, France) where the Caps Lock key cannot be used to toggle Caps

Lock. The NumLock option works similarly to the regular Auotcaps, but uses the

NumLock key to retrieve the current state of the Caps Lock.

bar code should be scanned in countries (e.g.,

Autocaps via NumLock

Emulate External Keyboard

keyboard (IBM AT or equivalent).

Note: After scanning the Emulate External Keyboard bar code, you must power

cycle your computer.

should be scanned if you do not have an external

Emulate External Keyboard

Keyboard Modifiers

This modifies special keyboard features, such as CTRL+ ASCII codes and Turbo

Mode.

Control + ASCII Mode On:

control characters for values 00-1F. Refer to Keyboard Function

Relationships, page 10-1 for CTRL+ ASCII Values.

Control + ASCII Mode On

Turbo Mode:

drops characters, do not use Turbo Mode.

The imager sends characters to a terminal faster. If the terminal

The imager sends key combinations for ASCII

Default = Off

* Control + ASCII Mode Off

Default = Off

Turbo Mode On

* Turbo Mode Off

2 - 14 IMAGETEAM™ 2020/4620 System Manual

Page 45

Numeric Keypad Mode:

numeric keypad.

Numeric Keypad Mode On

Default = Off

Sends numeric characters as if entered from a

* Numeric Keypad Mode Off

Automatic Direct Connect Mode:

IBM AT style terminal and the system is dropping characters.

Automatic Direct

Connect Mode On

This selection can be used if you have an

* Automatic Direct Connect

Mode Off

Default = Off

IMAGETEAM™ 2020/4620 System Manual 2 - 15

Page 46

RS-232 Baud Rate

Baud Rate sends the data from the imager to the terminal at the specified rate.

The host terminal must be set for the same baud rate as the imager.

Default = 115,200.

300

600

1200

2400

4800

9600

19200

38400

57,600

* 115,200

2 - 16 IMAGETEAM™ 2020/4620 System Manual

Page 47

RS-232 Word Length: Data Bits, Stop Bits, and Parity

Data Bits

application requires only ASCII Hex characters 0 through 7F decimal (text, digits,

and punctuation), select 7 data bits. For applications which require use of the full

ASCII set, select 8 data bits per character.

Stop Bits

Parity

Default = None.

7 Data, 1 Stop, Parity Even

sets the word length at 7 or 8 bits of data per character. If an

Default = 8.

sets the stop bits at 1 or 2.

provides a means of checking character bit patterns for validity.

7 Data, 1 Stop, Parity Odd

7 Data, 2 Stop Parity None

Default = 1.

7 Data, 1 Stop, Parity None

7 Data, 2 Stop, Parity Even

7 Data, 2 Stop, Parity Odd

8 Data, 1 Stop, Parity Even

* 8 Data, 1 Stop, Parity None

8 Data, 1 Stop, Parity Odd

IMAGETEAM™ 2020/4620 System Manual 2 - 17

Page 48

RS-232 Receiver Time-Out

The unit stays awake to receive data until the RS-232 Receiver Time-Out

expires. A manual or serial trigger resets the time-out. When an RS-232

receiver is sleeping, a character may be sent to wake up the receiver and reset

the time-out. A transaction on the CTS line will also wake up the receiver. The

receiver takes 300 milliseconds to completely come up. Change the RS-232

receiver time-out by scanning the bar code below, then scanning digits from the

inside back cover of this manual, then scanning

seconds.

Default = 0 seconds (no time-out - always on).

RS-232 Receiver Time-Out

Save

. The range is 0 to 300

RS-232 Handshaking

RS-232 Handshaking allows control of data transmission from the imager using

software commands from the host device. CTS/RTS operates in mode 2. When

this feature is turned

is turned

character (DC3, hex 13) to the imager. To resume transmission, the host sends

the XON character (DC1, hex 11). Data transmission continues where it left off

when XOFF was sent.

On

, the host device suspends transmission by sending the XOFF

RTS/CTS On

Off

, no data flow control is used. When Data Flow Control

Default = RTS/CTS, XON/XOFF and ACK/NAK Off

.

* RTS/CTS Off

XON/XOFF On

* XON/OFF Off

ACK/NAK On

* ACK/NAK Off

2 - 18 IMAGETEAM™ 2020/4620 System Manual

Page 49

Host ACK Selection

Some applications require that the host terminal (or server) approve or reject

incoming bar code data and notify the operator of these actions. These

applications require that the host maintain control over the response indicators

emitted from the source imager. Turning the Host ACK selection on, configures

the cordless system imagers to respond to commands from the host system.

The following criteria must be met for the Host ACK to work correctly:

• The cordless system must be configured for “Host Port RS-232” (Terminal ID

= 000)

• RTS/CTS is defaulted off. You must enable it if the host system requires it.

• Host ACK must be enabled (page 2-20).

• System performance degrades when using Host ACK at rates lower than

9600.

• The host terminal software must be capable of interpreting the bar code data,

make decisions based on the data content, and send out appropriate escape

commands to the source imager.

Escape commands are addressed to the source imager via “Application Work

Groups.” Once a command is sent, all imagers in a group respond to that

command. Because of this situation, it is recommended that each imager is

assigned to its own group in host ACK mode.

The commands to which the imager responds are listed on page 2-21. The

<ESC> is a 1B in hex. A typical command string is y <ESC> x, where “y” is the

application work group number, “<ESC> x” is the escape command, and the

comma is the terminator

Commands may be strung together to create custom response sequences. An

example of a command string is listed below.

0<ESC>4<ESC>5<ESC>6,

The above example will make an imager in application work group zero beep low,

medium, high.

Once Host ACK is enabled, the system works as follows:

• The imager reads a code and sends data to the base/host system. No audible

or visual indication is emitted until you receive an escape command. The

imager read illumination goes out upon a successful read.

• Imager is suspended until 1) a valid escape string is received from the host

system (via the base) or 2) the imager “times out.”

• Once condition 1 or 2 above has been met, the imager is ready to scan again,

and the process repeats.

Time out is indicated by three rapid beeps at the same pitch. A time out occurs

if the source imager does not receive a valid escape command in 10 seconds. If

a time out occurs, the operator should check the host system to understand why

a response to the imager was not received.

.

IMAGETEAM™ 2020/4620 System Manual 2 - 19

Page 50

d

a

e

R

d

o

o

G

)

1

a

B

:

K

C

A

)

4

Host ACK Enable

Host ACK On

2

a

d

r

e

g

a

m

I

o

t

e

s

o

t

t

s

o

H

:

K

C

A

)

3

t

s

o

h

o

t

a

t

e

s

a

B

s

d

n

e

s

e

s

a

B

)

* Host ACK Off

2 - 20 IMAGETEAM™ 2020/4620 System Manual

Page 51

IT2020-5B Host Escape Commands

Command Action

<ESC> a Indicate as if successful menu change made

<ESC> b Indicate as if unsuccessful menu change made

<ESC> 1

<ESC> 2

<ESC> 3

<ESC> 4 One beep at low volume

<ESC> 5 One beep at medium volume

<ESC> 6 One beep at high volume

<ESC> 7 Indicate as successful decode and communication to host.

<ESC> 8 Indicate as unsuccessful decode and communication to host.

Illuminate green LED for 135 milliseconds (followed by at least 70 mSecs.

dark time when multiple blinks)

Illuminate green LED for two seconds (followed by at least 500 mSecs.

dark time when multiple blinks)

Illuminate green LED for five seconds (followed by at least 500 mSecs.

dark time when multiple blinks)

Wand Emulation

Wand Emulation Connection

The Wand Emulation Connection bar codes should be used if you want to

change the terminal ID

recommend using Wand Emulation Plug & Play bar codes to program your

imager to emulate a wand reader. The Wand Emulation Plug & Play bar codes

change other parameters, in addition to changing the terminal ID. Please refer

to Wand Emulation Plug & Play on page 2-2 for further information.

In Wand Emulation mode, the imager decodes the bar code then sends data in

the same format as a wand imager. The Code 39 Format converts all

symbologies to Code 39.

The Same Code Format transmits UPC, EAN, Code 128 and Interleaved 2 of 5

without any changes, but converts all other symbologies to Code 39. 2D

symbologies are converted to Code 128.

only

, without changing any other imager settings. We

IMAGETEAM™ 2020/4620 System Manual 2 - 21

Page 52

The

Code 39 Format

Code Format

Code 39 Format

bar code sets the terminal ID to 64.

bar code below sets the terminal ID to 61, and the

Wand Emulation Data Block Size

Default = Code 39 Format.

Same

Same Code Format

This transmits the data in smaller blocks to prevent buffer overflow.

20

* 40

60

80

Default = 40.

2 - 22 IMAGETEAM™ 2020/4620 System Manual

Page 53

Wand Emulation Delay Between Blocks

This sets the delay time between data blocks.

5ms

150ms

Default = 50ms.

* 50ms

500ms

Wand Emulation Overall Checksum

When this option is turned on, a computed check character is added at the end

of the entire message. The check character is the character which when

Exclusive-OR’d with every preceding character of the message yields a result of

0x00 (00H).

Wand Emulation Overall

Default = Off.

Checksum On

* Wand Emulation Overall

Checksum Off

IMAGETEAM™ 2020/4620 System Manual 2 - 23

Page 54

Wand Emulation Transmission Rate

The Transmission Rate is limited by the terminal’s ability to receive data without

dropping characters.

10

40

120

200

Default = 25 inches/second.

* 25

80

150

Wand Emulation Polarity

The Polarity can be sent as standard with black bars high, or reversed with white

bars high.

Default = Black High.

* Black High

White High

2 - 24 IMAGETEAM™ 2020/4620 System Manual

Page 55

Wand Emulation Idle

The idle describes the state of the imager when no data is being transmitted.

When in Wand Emulation mode, you must set the imager’s idle state to match

the idle state for the device to which the imager is connected.

* Idle High

Default = Idle High

Idle Low

.

IMAGETEAM™ 2020/4620 System Manual 2 - 25

Page 56

2 - 26 IMAGETEAM™ 2020/4620 System Manual

Page 57

3

Basic System Operation

Cordless Base

The cordless base provides the link between the cordless imager and the host

system. The base contains an interface assembly and an RF communication

module. The RF communication module performs the data exchange between

the cordless imager and the interface assembly. The control assembly

coordinates the central interface activities including: transmitting/receiving

commands and data to/from the host system, performing software activities

(parameter menuing, visual indicator support, power-on diagnostics), and data

translation required for the host system.

The base also is the imager’s battery charger. Refer to "Base Charge Mode" on

page 3-3 for additional information.

RF (Radio Frequency) Module Operation

The cordless system uses a state-of-the-art two-way Bluetooth radio to transmit

and receive data between the imager and the base. Designed for point-to-point

and multipoint-to-single point applications, the radio operates using a license

free ISM band, which sends relatively small data packets at a fast data rate over

a radio signal with randomly changing frequencies, makes the cordless system

highly responsive to a wide variety of data collection applications and resistant

to noisy RF environments. Bluetooth Class 2 power level provides range of 33

feet (10m) depending on the environment.

Cordless Imager

The cordless imager enables fast and accurate bar code scanning using a noncontact area imager.

The imager is comprised of an area imager, a decode/control assembly, and an

RF communication module. The scan engine performs the bar code image

illumination and sensing. The decode/control assembly coordinates the central

communication activities including: capturing and decoding the bar code image

data, performing software activities (parameter menuing, visual indicator

support, low battery indication), and data translation required for the host system.

The RF communication module performs the data exchange between the imager

and the base.

IMAGETEAM™ 2020/4620 System Manual 3 - 1

Page 58

System Conditions

The components of the cordless system interact in specific ways as you

associate an imager to a base, as you move an imager out of range, bring an

imager back in range, or swap imagers between two cordless systems. The

following information explains the cordless system operating conditions.

Linking Process

Once an imager is placed into the base, the imager’s battery charge status is

checked, and software automatically detects the imager and links it to the base

depending on the selected link mode.

Imager Is Out of Range

The cordless imager is in communication with its base, even when it is not

transmitting bar code data. Whenever the imager can’t communicate with the

base for a few seconds, it is out of range. If the imager is out of range and you

scan a bar code, the imager issues a triple beep indicating no communication

with the base. In addition, your imager and base can sound an alarm if

programmed to emit an alarm. Refer to "Out-of-Range Alarm" on page 3-12.

Imager Is Moved Back Into Range

The imager re-links if the imager or the base have been reset or out of range. If

the imager re-links, you will hear a single chirp when the re-linking process

(uploading of the parameter table) is complete.

Out of Range and Back into Range with Data Accumulation Mode On

The imager may store a number of symbols (approximately 500 UPC symbols,

others may vary) when out of range and then send them to the base when back

in range. You will not hear a communication error beep in this mode, but you will

hear a short buzz when you pull the trigger if the radio communication is not