Page 1

R

SCANTEAM 3700 CCD

Page 2

Disclaimer

Welch Allyn, Data Collection, Inc. (d/b/a Hand Held Products) reserves the right to make changes in

specifications and other information contained in this document without prior notice, and the reader should in all

cases consult Hand Held Products to determine whether any such changes have been made. The information in

this publication does not represent a commitment on the part of Hand Held Products.

Hand Held Products shall not be liable for technical or editorial errors or omissions contained herein; nor for

incidental or consequential damages resulting from the furnishing, performance, or use of this material.

This document contains proprietary information which is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced, or translated into another language without the prior

written consent of Hand Held Products.

E2000 Welch Allyn Data Collection, Inc. All rights reserved.

Web Address: www.handheld.com

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

FCC Class B Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio or television technician for help.

Caution: Any changes or modifications made to this device that are not expressly

approved by Welch Allyn, Inc. may void the user’s authority to operate the equipment.

Note: To maintain compliance with FCC Rules and Regulations, cables connected to this device must

be shielded cables, in which the cable shield wire(s) have been grounded (tied) to the connector shell.

Canadian Notice

This equipment does not exceed the Class B limits for radio noise emissions as described in

the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites

applicables aux appareils numeriques de la classe B prescrites dans le Reglement sur le

brouillage radioelectrique edicte par le ministere des Communications du Canada.

The word SCANTEAM, the SCANTEAM logo, and the Welch Allyn logo are trademarks of Welch Allyn, Inc.

Throughout this manual, trademarked names may be used. Rather than put a trademark (TM) symbol in every

occurrence of a trademarked name, we state that we are using the names only in an editorial fashion, and to the

benefit of the trademark owner, with no intention of infringement.

Page 3

The CE mark on the product indicates that the system has been tested to and

conforms with the provisions noted within the 89/336/EEC Electromagnetic

Compatibility Directive and the 73/23/EEC Low Voltage Directive.

For further information, please contact:

Welch Allyn Ltd.

1st Floor

Dallam Court Dallam Lane

Warrington, Cheshire WA2 7LT

England

Welch Allyn shall not be liable for use of our product with equipment

(i.e., power supplies, personal computers, etc.) that is not CE marked and

does not comply with the Low Voltage Directive.

Patents

The SCANTEAM 3700 product is covered by the following U.S. Patent: 5,932,862. Other U.S. and foreign patents pending.

Page 4

Page 5

TABLE OF CONTENTS

Disclaimer

Agency Compliance

Chapter 1 SCANTEAM 3700 Description

Section Page

1.1 Introduction 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SCANTEAM 3700 Hardware Description 1–1. . . . . . . . . . . . . . . .

1.2.1 Interface Port 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Nonvolatile Memory 1–2. . . . . . . . . . . . . . . . . . . . . . . .

1.3 SCANTEAM 3700 Software Description 1–2. . . . . . . . . . . . . . . . .

Chapter 2 System Hardware Description

Section Page

2.1 Introduction 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 General Characteristics of the 3700 2–2. . . . . . . . . . . . . . . . . . . . .

2.2.1 Mechanical Layout of the 3700 2–2. . . . . . . . . . . . . .

2.2.2 Single Modular Connector Port 2–3. . . . . . . . . . . . . .

2.2.3 Audible Indicator 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Mounting Inserts 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Operating Theory 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Scanner/Host Communication 2–4. . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Communications Port 2–4. . . . . . . . . . . . . . . . . . . . . .

2.4.2 Asynchronous ASCII Interface 2–4. . . . . . . . . . . . . . .

2.4.3 Hardwire Pinouts 2–5. . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Power Requirements 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Set–Up and Installation

Section Page

3.1 Introduction 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 General Preparation for Use 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Set–Up Procedure for Evaluation of the 3700 3–2. . . . . . . . . . . .

3.3.1 Preparation 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Set–up Procedure 3–3. . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Installation in the Host Instrument 3–4. . . . . . . . . . . . . . . . . . . . . . .

i

Page 6

Chapter 4 Configuring the SCANTEAM 3700

Section Page

4.1 Preparation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Command Conventions 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Operational Commands 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Configuration Commands 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Configuration Status Query Commands 4–15. . . . . . . . . . . . . . . . .

4.6 Default Operating Parameters 4–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Service/Technical Assistance

Section Page

5.1 Maintenance 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Troubleshooting Guide 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Troubleshooting Hints 5–1. . . . . . . . . . . . . . . . . . . . . .

5.2.2 Diagnostic Procedure 5–2. . . . . . . . . . . . . . . . . . . . . .

5.2.3 Troubleshooting Checklist 5–2. . . . . . . . . . . . . . . . . .

5.3 Obtaining Factory Service 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Service Under Warranty 5–4. . . . . . . . . . . . . . . . . . . .

5.3.2 Out of Warranty Service 5–4. . . . . . . . . . . . . . . . . . . .

5.4 SCANTEAM 3700 Removal/Replacement 5–5. . . . . . . . . . . . . . .

ii

Page 7

Appendices

A CCD Operation and Bar Code Scanning

A.1 Objectives A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Scanning and Decoding a Bar Code Symbol A–1. .

A.3 Bar Code Basics and Scanning Techniques A–4. . .

B Technical Specifications

B.1 Scanner Performance B–1. . . . . . . . . . . . . . . . . . . . . .

B.2 Optical Specifications B–1. . . . . . . . . . . . . . . . . . . . . .

B.3 Electrical Specifications B–3. . . . . . . . . . . . . . . . . . . .

B.4 Environmental Specifications B–4. . . . . . . . . . . . . . . .

B.5 Mechanical Specifications B–5. . . . . . . . . . . . . . . . . .

B.6 Bar Code Label Specifications B–5. . . . . . . . . . . . . . .

B.7 SCANTEAM 3700 Interface Cable B–6. . . . . . . . . . .

C Serial Commands Summary

C.1 Configuration Commands C–1. . . . . . . . . . . . . . . . . . .

C.2 Operational Commands C–2. . . . . . . . . . . . . . . . . . . .

C.3 Configuration Status Query Commands C–2. . . . . . .

C.4 Default Configuration Settings C–3. . . . . . . . . . . . . . .

D ASCII Conversion Table

Glossary

Index

SCANTEAM 3700 Limited Warranty

iii

Page 8

List of Tables

Table Page

4.1 SCANTEAM 3700 Code ID Values 4–7. . . . . . . . . . . . . . . . . . . . . .

5.1 SCANTEAM 3700 Troubleshooting Checklist 5–2. . . . . . . . . . . . .

List of Illustrations

Figure Page

2.1 Basic System Operation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 3700 Fixed Mount CCD Dimensions 2–2. . . . . . . . . . . . . . . . . . . .

2.3 Basic Scanner/Decoder Operation 2–3. . . . . . . . . . . . . . . . . . . . . .

3.1 SCANTEAM 3700 Identification Label 3–2. . . . . . . . . . . . . . . . . . .

3.2 Mounting Dimensions for the 3700 3–5. . . . . . . . . . . . . . . . . . . . . .

3.3 Examples of SCANTEAM 3700 Barcode Orientation 3–6. . . . . .

3.4 SCANTEAM 3700 Pitch, Skew & Tilt Tolerance 3–7. . . . . . . . . . .

3.5 Specular Reflection Interference 3–7. . . . . . . . . . . . . . . . . . . . . . . .

3.6 Scanner Illumination Clearance 3–8. . . . . . . . . . . . . . . . . . . . . . . .

A.1 Main Elements of the 3700 CCD Bar Code System A–1. . . . . . .

A.2 SCANTEAM 3700 Timing Sequence A–3. . . . . . . . . . . . . . . . . . . .

iv

Page 9

Preface

Intended Audience

This manual is written for users familiar with serial data communications. An

understanding of integrated circuitry and bar code technology is recommended.

Overview of the Technical Manual

Chapter 1 provides a brief description of SCANTEAM 3700 software and hardware.

Chapter 2 discusses the system’s hardware, including connectors, ports, and power

requirements.

Chapter 3 explains how to set up and install your 3700 Machine Mount CCD.

Chapter 4 describes the default operating and configuration parameters and explains

how to change these to meet your specific needs using serial commands sent through the

host RS–232 communications interface. Explains how to use the configuration status

query commands.

Chapter 5 explains how to obtain service and technical assistance.

Appendix A is a guide to CCD operation, bar code basics and scanning techniques.

Appendix B provides information about scanning performance, optical, electrical,

environmental, mechanical and bar code label specifications.

Appendix C lists the configuration, operational and configuration status query serial

commands. The default configuration settings are also listed.

Appendix D provides an ASCII conversion chart.

v

Page 10

Related Publications

Reading Between the Lines: An Introduction to

Bar Code Technology

Craig K. Harmon and Russ Adams

1989 Helmers Publishing Inc.

174 Concord Street

Peterborough, NH 03458

(603) 924–9631

The Bar Code Book: Reading, Printing, and

Specification of Bar Code Symbols

Roger C. Palmer

1989 Helmers Publishing Inc.

174 Concord Street

Peterborough, NH 03458

(603) 924–9631

Handbook of Bar Coding Systems

Harry E. Burke

1984 NCR Corporation

Van Nostrand Reinhold Company, Inc.

115 Fifth Avenue

New York, New York 10003

Automatic ID Resource Catalog

AIM USA Publications

634 Alpha Drive

Pittsburgh, PA 15238–2802

Fax: 412–963–8753

Phone: 412–963–8588

AIM “Guidelines on Symbology Identifiers,” “Uniform Symbology Specifications”

(USS), and other AIM resources from the address above.

vi

Page 11

SCANTEAM 3700 DESCRIPTION

1.1 Introduction

The Hand Held Products SCANTEAM 3700 is a fixed mount CCD bar code scanner

with integral decoder for easy integration into host equipment. Typical host equipment

with bar code requirements satisfied by the 3700 include automated clinical chemistry

analyzers, pharmaceutical label verification systems, industrial automation equipment,

robotic systems, materials handling equipment, library systems, point of sale terminals

and office equipment.

The 3700 features Hand Held Products’ time–proven decoding algorithms in a

microprocessor–controlled bar code scanner/decoder and offers configurable operating

parameters, providing you with the capability to tailor the 3700 to your present

requirements and the flexibility to meet your future application requirements.

The following features are available with every SCANTEAM 3700:

• Economical, reliable, safe CCD scanning technology

• Audible indicator configurable for good read or no read

• True RS–232 data communications with RTS/CTS, XON/XOFF, ACK/NAK

• Autodiscrimination of 6 bar code symbologies

• 100 scans per second (standard); other scan rates available

• Flexible scan trigger configurations

• Decoder configurable for high security

• Scan voting to ensure bar code data integrity

• Automatic read timeout

• Ease of configuration through RS–232 interface

1

1.2 SCANTEAM 3700 Hardware Description

The SCANTEAM 3700 housing is molded ABS formed to enclose the optics platform

and electronics. Standard housing width is 3.5 inches (88.9mm). The housing length is

2.9 inches (73.7mm) and the height is fixed at 1.05 inches (26.7mm).

The scanner uses red (660 nm wavelength) LED’s to illuminate the bar code label. A

high resolution CCD (charge coupled device) is used as an image or reading sensor. A

trigger signal can direct the 3700 to read the bar code. The trigger signal may originate

from the scanner itself, from a host serial communications program, or from a hardware

object sensor. The scanned code is converted to a digital signal in the scanner, then

decoded and sent to the host computer or system. Scan width and focal point of the

optics may be customized to the particular requirements of your application.

SCANTEAM 3700 Description 1–1

Page 12

Communication is achieved using full duplex, asynchronous serial ASCII through a

bidirectional RS–232 connection to the host system. The host defines or sets the

configurable features and controls the operation of the 3700. The 3700’s configuration

may be stored in non–volatile memory.

Note: In this manual, the term “host” refers to any computer that communicates with the

SCANTEAM 3700 through its RS–232 port. During the configuration procedure, the host

can be the main computer which controls the entire application, or can be a PC which has

been connected to the 3700 for just that purpose. The terms “host instrument,” “host

equipment,” and “host device” all refer to the system in which the 3700 has been

integrated and which communicates with, controls and configures the operating features.

1.2.1 Interface Port

The SCANTEAM 3700 has one port for I/O and Power. The port is a 10 pin RJ11

modular female connector. Hardwire connection to the scanner motherboard is available

for additional features Pin assignments and function descriptions are presented in

Appendix B. Cables are available from Hand Held Products for evaluation of the 3700.

Hand Held Products can provide custom cables for host integration. A modular

connector was chosen as the standard configuration for ease in servicing the scanner once

installed..

1.2.2 Nonvolatile Memory

The 3700 contains nonvolatile FLASH memory which is used to store operating

parameters configured by means of host serial commands. This memory is easily

reconfigurable to modify or add symbologies, as well as to modify or add serial

commands to emulate a currently installed scanner.

1.3 SCANTEAM 3700 Software Description

SCANTEAM 3700 software employs Hand Held Products’ time–proven decoding

algorithms, controls the microprocessor functions, selects the scanner ports, decodes the

bar codes, and formats the serial output messages.

The 3700 standard default parameters can be easily reconfigured to meet most scanning

requirements. Application–specific features and options are configurable through the

RS–232 communications link to the host system.

The 3700 can be configured to autodiscriminate among the following bar code

symbologies and their variations: Codabar, Code 39, Code 128, Interleaved 2 of 5, UPC

and EAN. Most common bar code options, such as validating symbol length and

optional check character, are supported and easily selected. Symbologies can be added

from Hand Held Products’ library of decoding algorithms.

In addition to decoding selections; data output formats, such as preamble and postamble

strings, and operating parameters are also configurable through the host RS–232 serial

communications connection.

1–2 SCANTEAM 3700 Description

Page 13

SYSTEM HARDWARE DESCRIPTION

2.1 Introduction

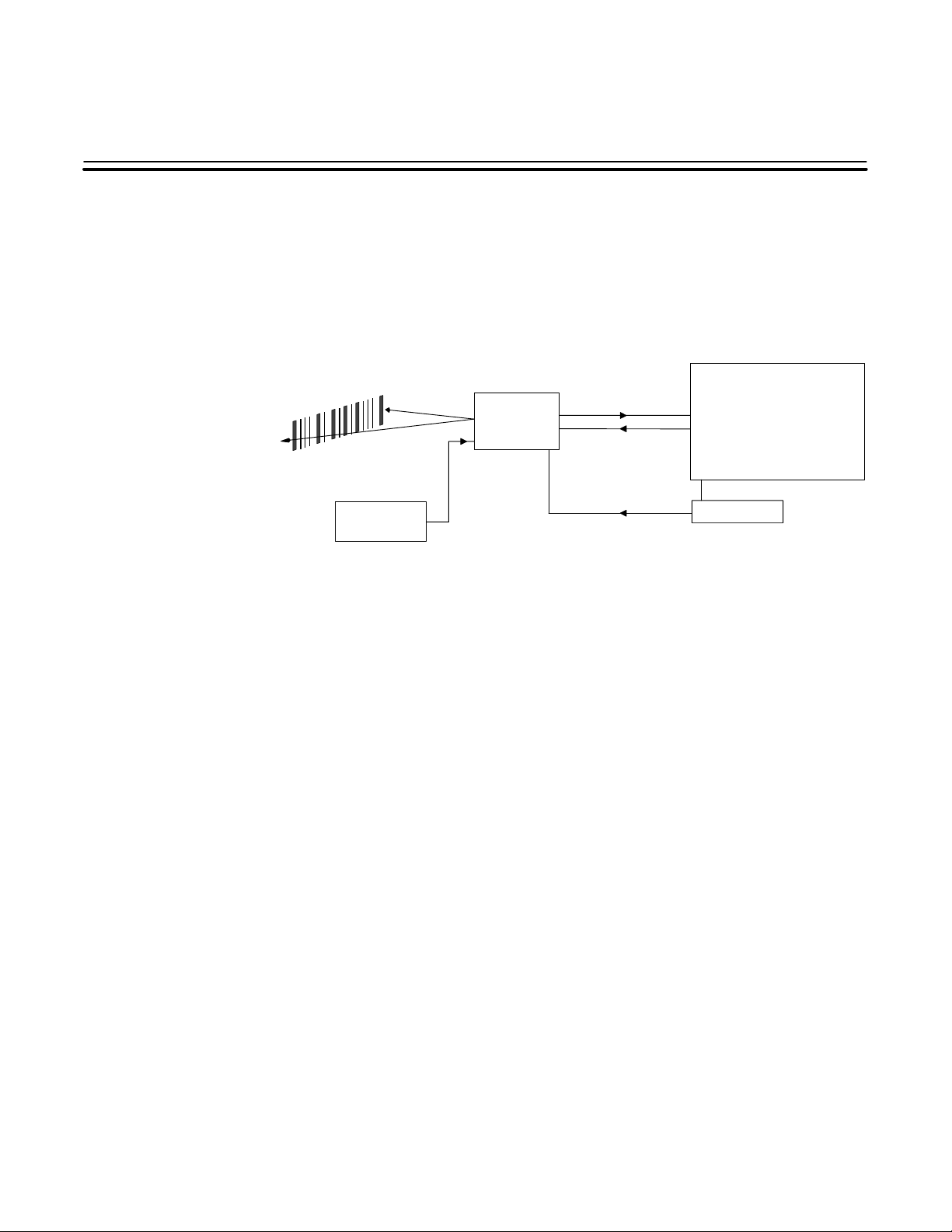

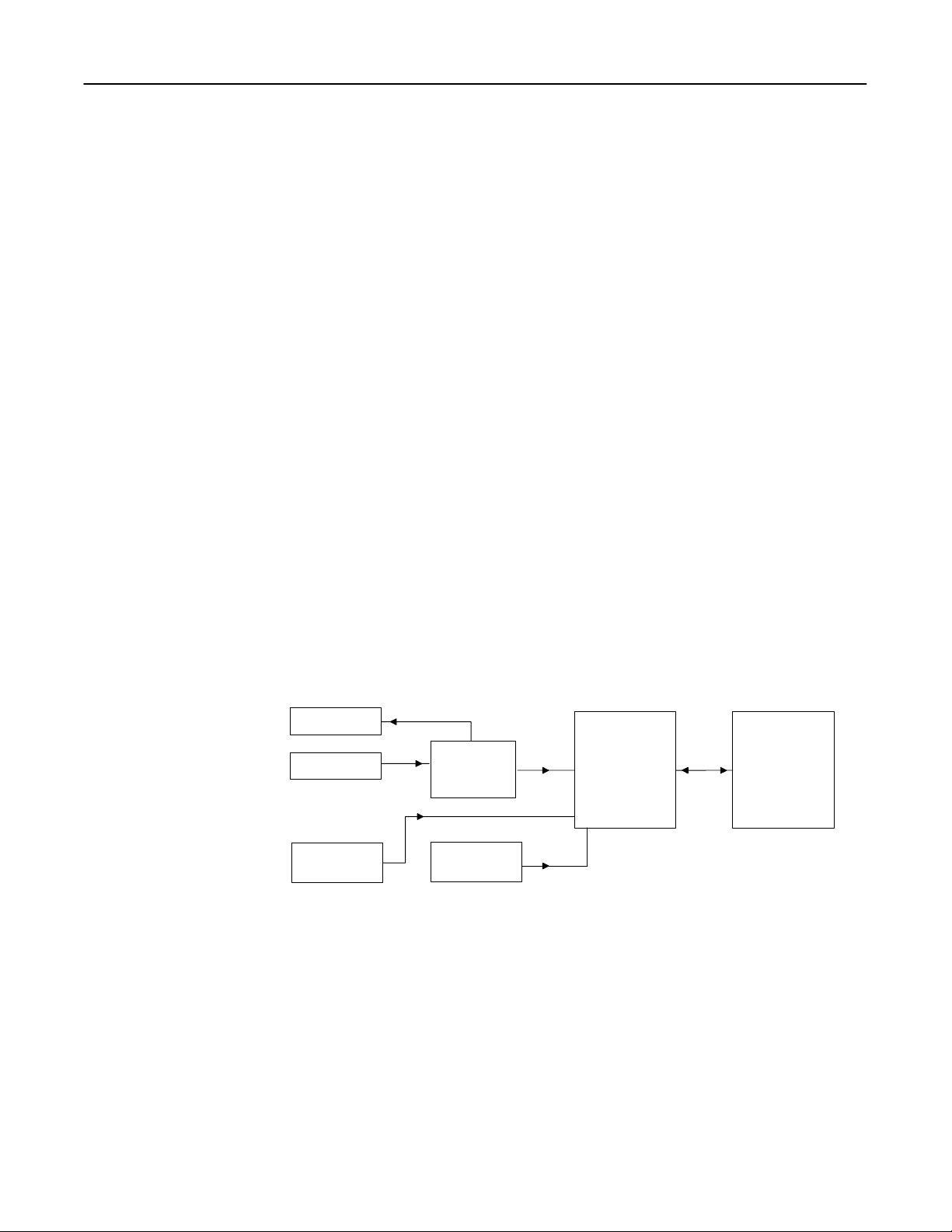

The major components of the system are the SCANTEAM 3700 Machine Mount CCD

and the host instrument or equipment. Electrical power is generally supplied to the 3700

Machine Mount CCD by the host system. Figure 2.1 shows the functional relationships

between the components of the basic system.

SCANTEAM

3700

Machine

Mount CCD

Asynchronous

Communication

2

Host System

Auxiliary Trigger

Bar Code

Provides Data Input

Aux Trigger

Triggers Decoder

Device

(Optional)

Scanning Circuitry ✺

Scans Bar Code

Decoder

Enables Scanning Circuitry

Reads Bar Code

Sends Decoded Bar Code

to Host

✺ Scanning circuitry is internal to 3700.

Figure 2.1 Basic System Operation

Power Supply

Host Application

Supplies Power to 3700 (typically)

Sends Configuration Commands

Sends Operational Commands

Sends Configuration Status Query

Commands

Sends Software Trigger Signal

(Optional)

System Hardware Description 2–1

Page 14

2.2 General Characteristics of the 3700

2.2.1 Mechanical Layout of the 3700

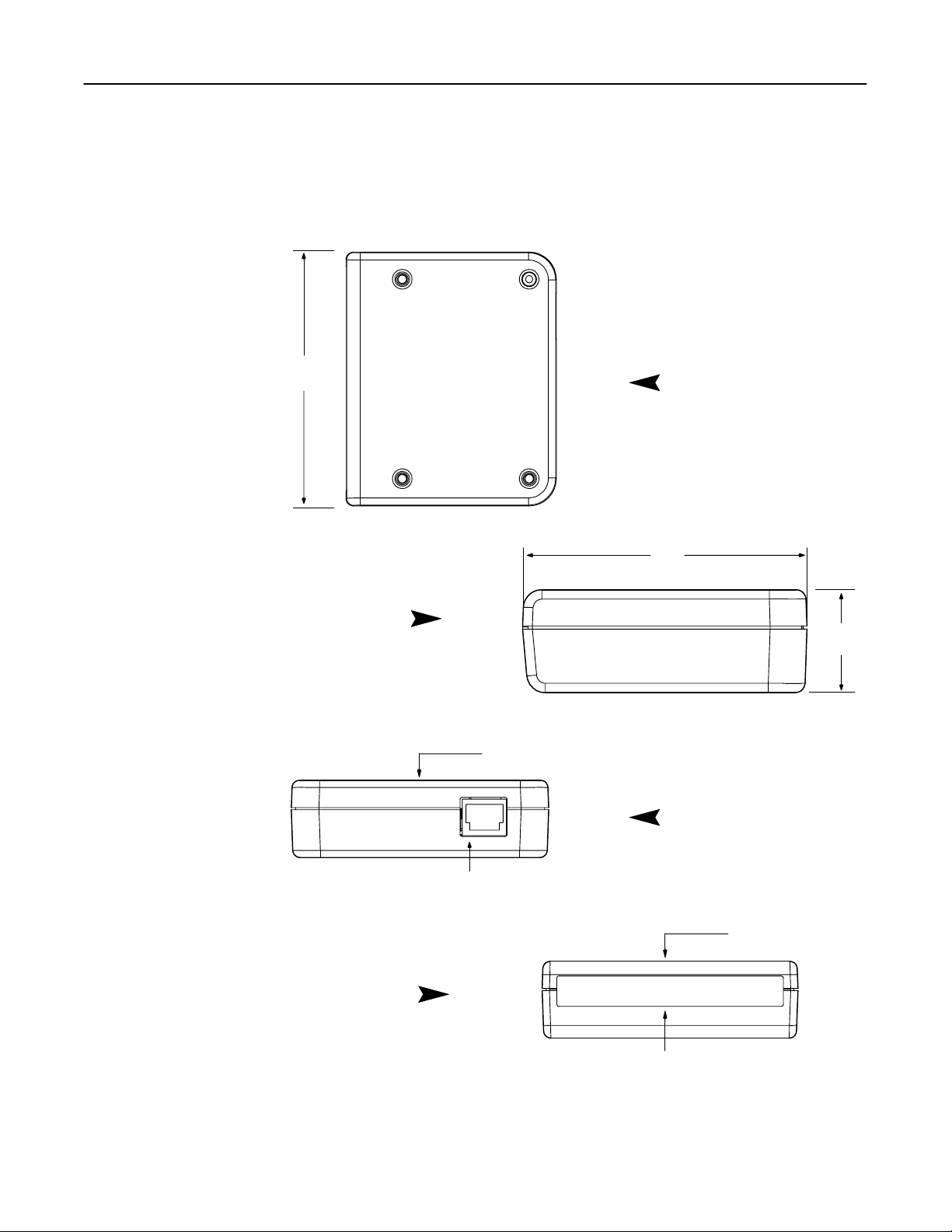

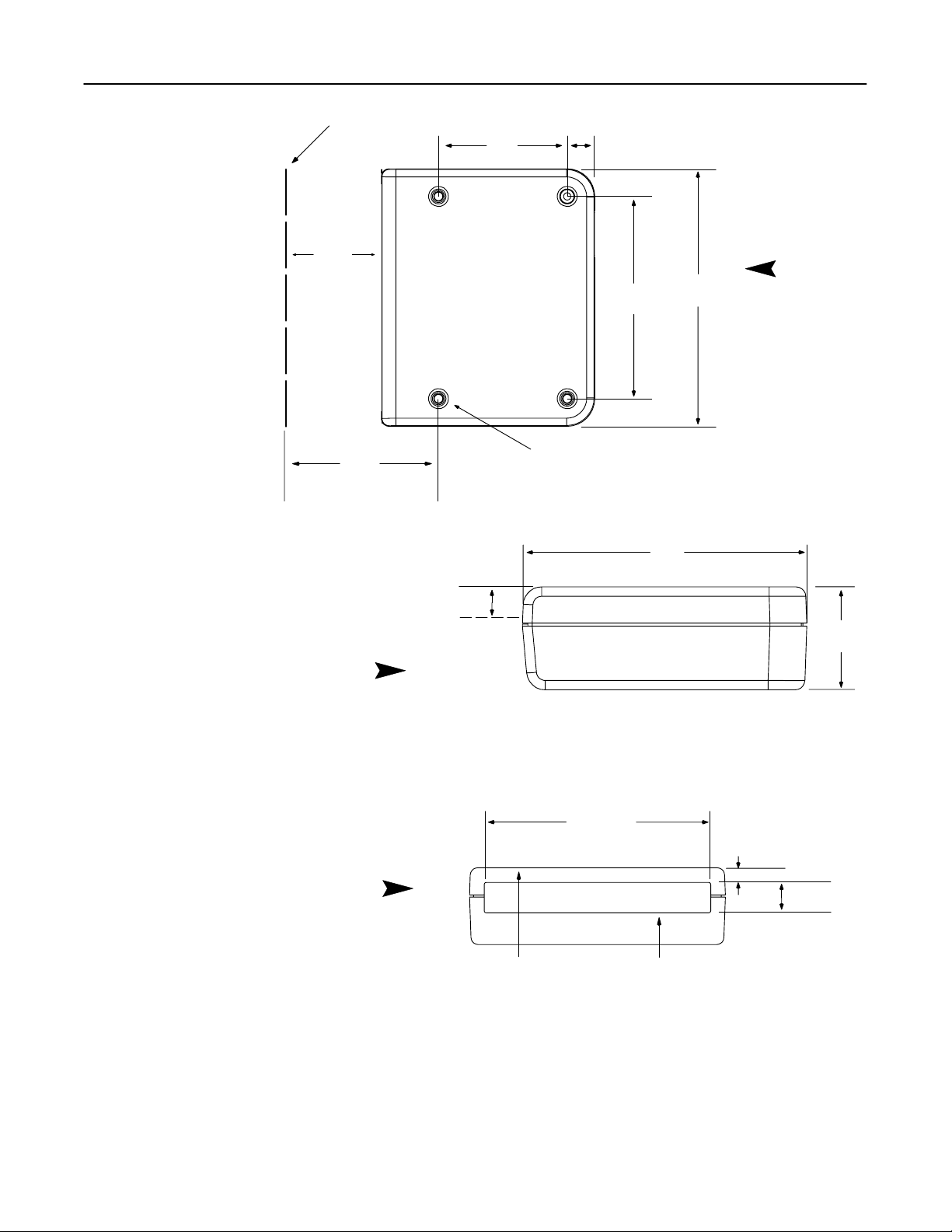

Figure 2.2 shows several views of the SCANTEAM 3700 Machine Mount CCD,

including general dimensions, the location of connectors, and the scanner window.

3.5”

[88.9]

Top View

2.9”

[73.7]

Side View

Front View

millimeters in brackets [mm]

Mounting Surface

Interface Port

(I/O Communications and Power)

Back View

Scanner Window

1.05”

[26.7]

Mounting Surface

2–2 System Hardware Description

Figure 2.2 3700 Fixed Mount CCD Dimensions

Page 15

2.2.2 Single Modular Input /Output /Power Port

The interface port is an 8–pin female modular connector used for attaching the

Asynchronous Serial Communications Interface Cable. Allows triggering capability (at

pin 2) for an external triggering device, such as an object sensor or a switch. Power and

ground connections are also on this port.

2.2.3 Audible Indicator

The beeper can be disabled by using a configuration command. Refer to Chapter 4 for

information on setting configuration commands. The beeper also sounds on power–up or

reconfiguration as an audible self–check of software configuration.

2.2.4 Mounting Inserts

Inserts are molded into the housing to retain mounting screws. Inserts are available for

metric (3.5) or SAE (#6–32) screws.

2.3 Operating Theory

Figure 2.3 presents a block diagram of the basic SCANTEAM 3700 Machine Mount

CCD operation.

The SCANTEAM 3700 Machine Mount CCD looks for data input from the scanning

circuitry, which includes the LED reflector (illuminates the bar code target), the CCD

sensor and imaging lens (focuses the scattered optical energy from the bar code symbol),

and the peak detectors and comparator (generates a digital representation of the bar code

symbol to send to the microprocessor). Refer to Appendix A, CCD Operation and Bar

Code Scanning, for a detailed explanation of 3700 scanning circuitry operation. When

the 3700 sees a trigger, a read cycle is started. The read cycle is completed when a bar

code is read or the read timeout expires.

LED Reflector

CCD Sensor

Auxiliary Trigger

(Optional)

LED Pulse Generator

Peak Detectors

and Comparator

Second Scanner

Digital Input

(Optional)

Decode

RS–232

Communications

Figure 2.3 Basic Scanner/Decoder Operation

Note: A trigger can be a hardware trigger, such as an object sensor, or a software command,

such as a serial trigger command or continuous read trigger mode command, from the

host. Refer to chapter 4 for description of serial trigger and trigger mode commands..

During a read cycle, the 3700 evaluates scanner data for a valid bar code symbol. If a

valid bar code symbol is seen, data is placed into the output queue where it may be

transmitted to the host through the RS–232 communications port. The 3700 can

optionally be configured to send a “No Read” message when a read cycle times out.

System Hardware Description 2–3

Page 16

2.4 Scanner/Host Communication

The RS–232 communications interface of the 3700 is used for entering configuration

commands from a PC or host instrument for specific application requirements. The

communications I/O port also sends decoded bar code data to the host.

2.4.1 Communications Port

The communications port connector for the 3700 is an 8–pin female modular socket for

interfacing to the host system or other communications device. Communications

between the host system and the 3700 occur using an Asynchronous ASCII protocol.

Refer to Appendix B for a complete description of pin assignments of the RS–232

communications port.

Caution: Do not use a host communications cable with more wires connected than are

required for the application. Damage to equipment within the system may result if

the communications connection is improperly wired.

2.4.2 Asynchronous Serial ASCII Interface

The Asynchronous serial ASCII Interface operates in Full Duplex Mode. Software

configuration parameters (see Chapter 4) control Baud Rate, Parity, Data Bits, Stop Bits,

Xon/Xoff, ACK/NAK, RTS/CTS, and Pre/Postambles.

Baud rate is a means of expressing data transmission speed, where “baud” equals the

number of signal events per second (roughly equivalent to bits per second). Parity is a

means of checking character bit patterns for validity by confirming if they contain an

Even or Odd number of “1”s. The communications port can be configured to operate at

baud rates of 600, 1200, 2400, 4800, 9600, 19200, and 38400, with even, odd, or no

parity.

Data bits refers to the number of bits used to encode each ASCII character in a data

message. Stop bits refers to the number of stop bits appended to each character. The

communications port can be configured to send 7 or 8 data bits, with 1 or 2 stop bits.

Note: For proper operation the 3700 must be configured for the same baud rate, parity, number

of data bits, and number of stop bits as the connected RS–232 host device.

Xon/Xoff are control characters that refer to ASCII characters “DC1” and “DC3,”

respectively. If enabled, Xon/Xoff is a method to control data flow in the following

manner. Whenever its buffers approaches full, the device receiving communications data

sends an “Xoff” to stop data transmission. The transmitting device stops data

transmission. When its buffer approaches empty, the receiving device sends “Xon” and

the transmitting device starts sending data again. The receiving device refers to the host

instrument. Likewise, the transmitting device refers to the 3700.

Note: The SCANTEAM 3700 will respond to XON and XOFF characters from the host, but will

not send these characters.

2–4 System Hardware Description

Page 17

ACK/NAK are ASCII characters that allow the receiving device to tell the sending

device to repeat a data message that contains errors. If enabled, the 3700 expects to

receive an ACK (positive acknowledgement of data transmission) or a NAK (negative

acknowledgement of data transmission) from the host after each message is sent. If a

NAK is received, the 3700 repeats the message. After three attempts to transmit have

been made, with successive NAK from the host, the 3700 will discard the message. The

3700 responds to communication from the host with an ACK or NAK.

Pins are available at the I/O Port to support RTS/CTS handshaking. The RTS/CTS

feature may be enabled or disabled in the scanner software configuration. During

communications, the 3700 will raise RTS and wait for CTS before each transmission. In

applications where the host system does not support “handshaking,” the CTS line may be

left unconnected and the 3700 will pull it to the active state. Alternately, if CTS is left

unconnected, RTS/CTS can be disabled by configuration command.

Preambles and postambles are optional ASCII strings that precede and are appended to

each data message sent by the 3700. Typical preamble and postamble strings would

include the ASCII control characters STX (start of text), ETX (end of text), CR (carriage

return) and LF (line feed). An identification character to indicate the type of bar code

read and source scanner port is included in the standard scanner software configuration.

2.4.3 Hardwire Pinouts

The following signals not related to communications are available by hardwiring to the

motherboard (factory ordered with all cable requirements). See Appendix B for the full

lising of available pinouts.

• Pin 1 Boot Strap

• Pin 2 Dig In – Auxiliary

• Pin 3 Reset

• Pin 4 IND – Good Read

Auxiliary Trigger

The scanned data input can be controlled by an external triggering device connected to

the Trigger/Enable line (pin 2 of the Communications port). The actual trigger can be as

simple as a foot actuated relay switch and as sophisticated as an optical sensor.

The Trigger/Enable line action depends on output mode, as follows:

• Bar/Space Output Mode – continuous scan while active

• ASCII Output Mode – read while active – transmit on timeout.

System Hardware Description 2–5

Page 18

2.5 Power Requirements

DC operating voltage is +5 volts and consumes approximately 200 milliamps when

scanning. Refer to Appendix B for a complete description of voltage range, current

consumption levels, and pin assignments.

2–6 System Hardware Description

Page 19

SET–UP AND INSTALLATION

3.1 Introduction

This chapter explains the SCANTEAM 3700 Machine Mount CCD set–up for use in the

design lab and a brief description of installation in a host instrument. The set–up

procedures are intended for a technician or design engineer to explore the functions and

features of the 3700 Machine Mount CCD in a hands–on setting, before the 3700 is

embedded in host equipment. The section on installation in a host instrument includes

the general mounting dimensions of the 3700.

Set–up and installation includes unpacking the unit, checking for possible damage during

shipment, and connecting the Machine Mount CCD to the host system. The host system

in the design lab will typically be a PC/DOS microcomputer with an RS–232

communications port and a serial communications program. Otherwise, the host system

is the instrument or equipment the 3700 is intended to be embedded in.

A Hand Held Products representative will provide application support if needed. Refer

to Chapter 5 for Hand Held Products’ service and technical assistance phone number(s).

3

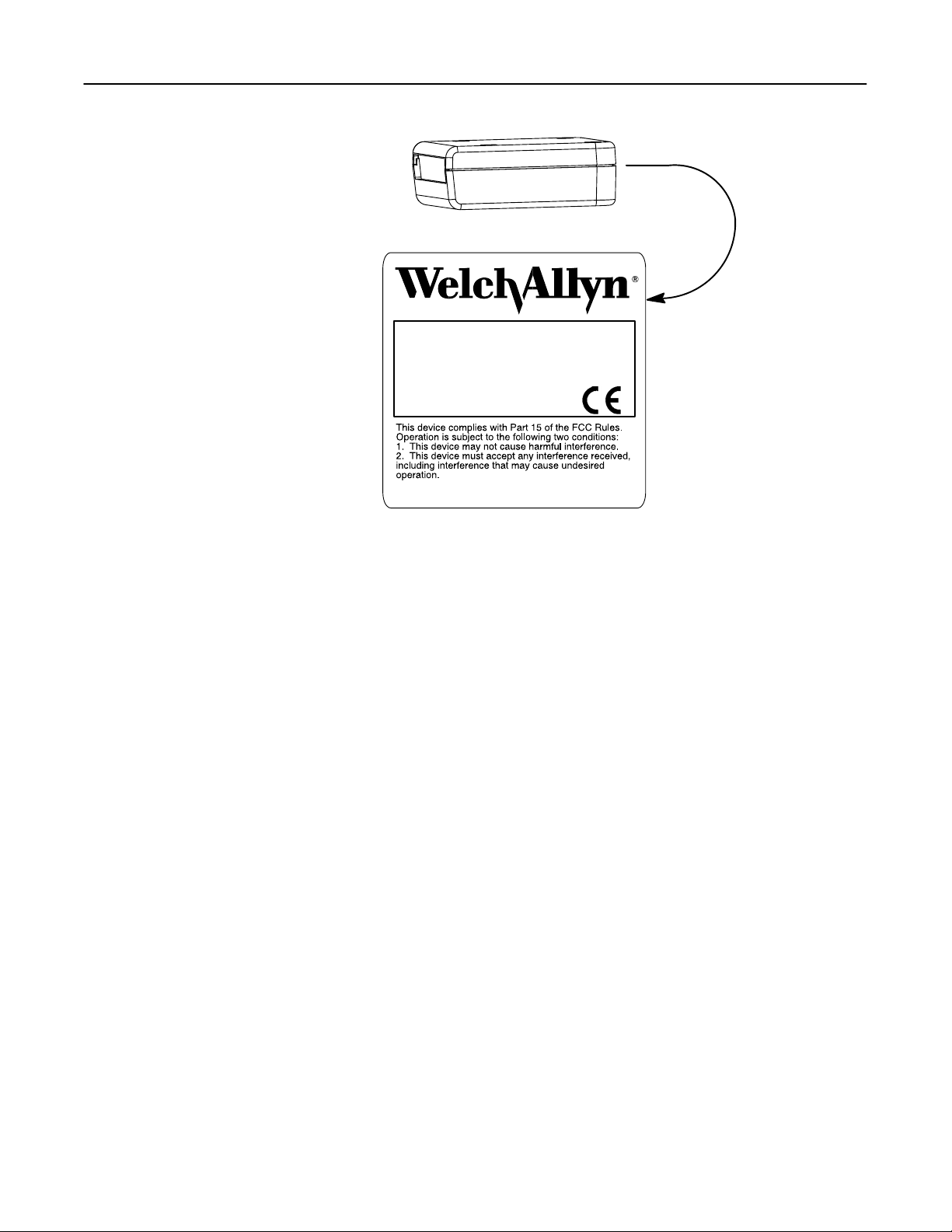

3.2 General Preparation for Use

Upon receipt, open the carton. Keep the shipping carton since this should be used in the

event the scanner ever needs to be returned to the factory for service or repair.

Check the part numbers and confirm that each item on the packing list has been supplied.

Check that the scanner model number and any other companion products are the ones

ordered for your application. The scanner model and serial numbers are on the

identification label attached to the scanner enclosure. Refer to Figure 3.1. You may

want to record these numbers for easy reference when communicating with Hand Held

Products or your Sales Representative.

Thoroughly inspect the 3700 to determine if any damage has occurred during shipment.

Any damage should be reported immediately to the carrier that delivered the 3700.

Damage claims due to handling during shipping should be placed directly with the

carrier. Hand Held Products will quote for repair of shipment damage (refer to Chapter

5), but the final claim and negotiations with the carrier are the responsibility of the

purchaser.

When all the components of your order have been identified and checked, prepare the

3700 for service using the procedures provided in the following sections (for set–up in a

design lab or for installation in host equipment). To assure proper operation and prevent

possible damage to the 3700 or your host system, perform the following set–up

procedures in the sequence in which they are presented.

Note: Before starting the set–up or installation procedure, set the host system or computer

power switch to the “OFF” position.

Set–Up and Installation 3–1

Page 20

Enlarged View of Label

ST3700

NEAR CONTACT DECODED OUTPUT

ITEM# 3700-XYZ

SOFTWARE# 31203795-XYZ

DATE - S/N H-04-1234

MADE IN USA PATENT 5,294,783

www.welchallyn.com

Figure 3.1 SCANTEAM 3700 Identification Label

3.3 Set–up Procedure for Evaluation of the 3700

Caution: The 3700 contains static sensitive components. The 3700 has been designed for

internal protection against damage due to discharge. Precautions should be taken

to protect against static discharge to the 3700.

3.3.1 Preparation

Interface cables for evaluating the 3700 are available from Hand Held Products. Hand

Held Products also offers 110VAC and 220VAC to 5VDC power supplies for the 3700.

If you wish to construct your own cables, Appendix B lists the 3700 port pin

assignments.

Set–up Checklist

• SCANTEAM 3700 CCD Scanner

• SCANTEAM 3700 Input/Output/Power Cable

• 5 VDC Power Supply

• Computer with Serial I/O Port

• For I/O: may need a 25 pin to 9 pin convertor

(Refers to step 4 in 3.3.2 Set–up Procedure.)

• For I/O: may need a Null Modem adapter

(Refers to step 4 in 3.3.2 Set–up Procedure.)

• Terminal Emulation Software

(Refers to step 6 in 3.3.2 Set–up Procedure.)

3–2 Set–Up and Installation

Page 21

3.3.2 Set–up Procedure

This procedure will verify that bar code scanning and communications between the host

and the 3700 has been established.

To setup serial communications to the scanner

1) Connect the RS–232 communications (I/O) cable between the 3700 and the PC

serial port. (You may require a 25 pin to 9 pin converter and Null Modem adapter.

Contact your Hand Held Products sales representative or distributor for assistance.)

2) Connect power to the 3700. The scanner should beep once.

3) Start serial communications software program, such as PCTools Desktop (Central

Point Software), on the PC.

4) On the PC, set up the serial communications program to match the 3700 default

values:

• Baud rate = 9600

• Parity = Even

• Stop Bits = One

• Data Bits = Seven

5) The default factory scanner configuration for the SCANTEAM 3700 requires a

serial command from a host to trigger a scan. Change the trigger mode to

“Continuous Read, Send Once, Clear on Timeout” by typing <Kg , 1>. The elapsed

time between the typing of each character should not exceed 5 seconds. The

illumination LEDs should light in response to the command.

6) Confirm communications to the 3700 with the test label below. Observe that the

LED reflector is illuminated. Scan the test label“ABC123” below. The default

scanner configuration for preamble is Port ID and Code ID. Default postamble is

CR (carriage return) and LF (line feed). Observe within 3 seconds the message

“1bABC123” on the PC.

• “1” = Port ID

• “b ” = Code ID (Code 39 code ID is “b”)

• “ABC123” = The bar code label

A B C 1 2 3

This completes set–up of the SCANTEAM 3700 Machine Mount CCD for evaluation.

You are now ready to configure the 3700 to explore the functions and features.

Instructions for configuring the 3700 using configuration and operational commands are

provided in Chapter 4, Configuring the SCANTEAM 3700.

Set–Up and Installation 3–3

Page 22

3.4 Installation in the Host Instrument

Caution: The 3700 contains static sensitive components. Precautions must be taken to

eliminate potential static discharge to the 3700.

Installation in the host instrument includes the following activities:

1) Power down the host system or instrument.

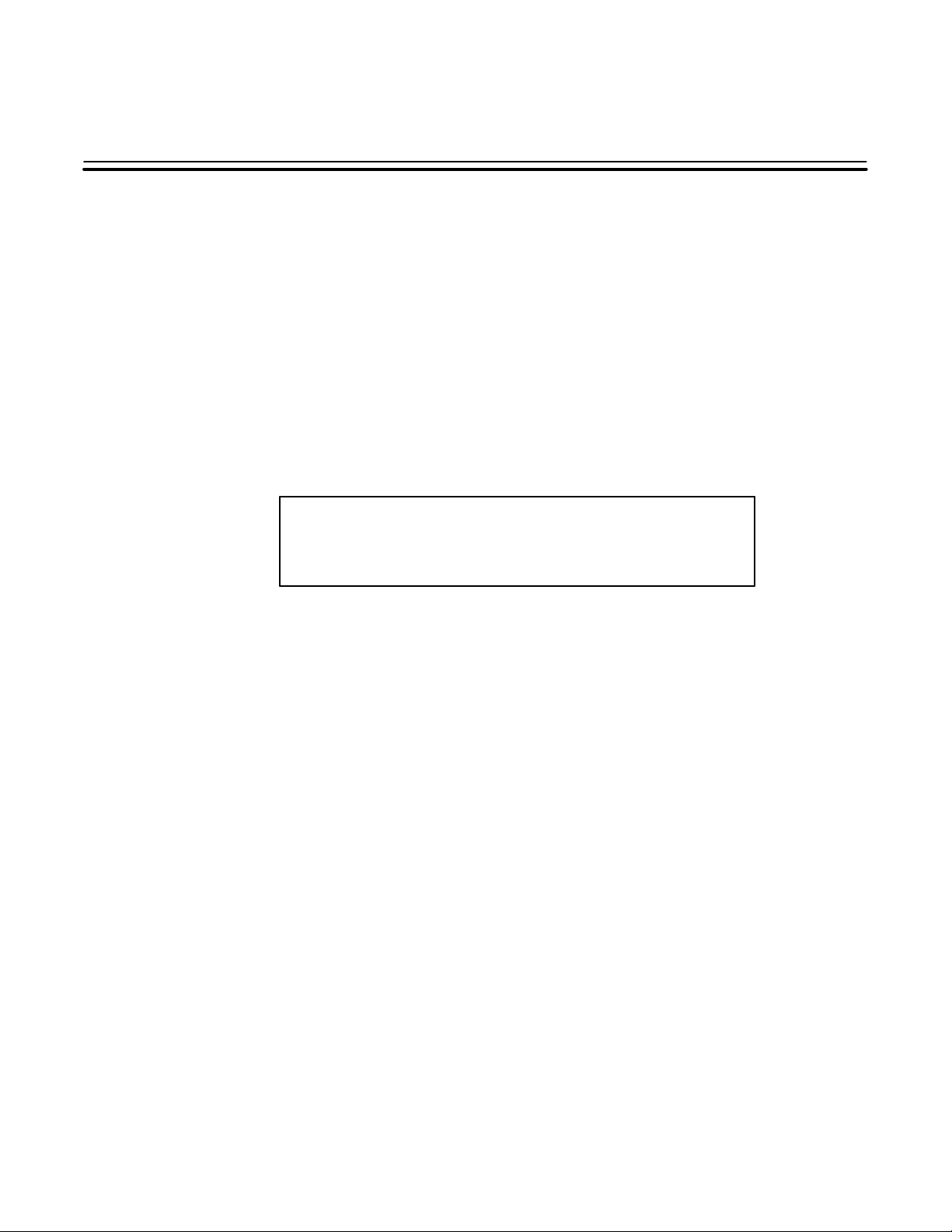

2) Mount the SCANTEAM 3700 in the host instrument. The 3700 has four mounting

holes (threaded inserts). Be sure to allow access to all cable connections. Figures

3.2 and 3.3 show the general dimensions for mounting the 3700.

3) Connect the 3700 RS–232 Communication Port to the host system I/O.

4) If applicable, connect your object sensor or hardware triggering device to the 3700.

5) Power up the host system or instrument.

3–4 Set–Up and Installation

Page 23

Focal Plane

REF

1.95”

[49.5]

1.75”

[44.5]

.375”

[9.5]

2.75”

[69.9]

3.5”

[88.9]

Top View

2.73”

[69.3]

Nominal Optics Center Line

Side View

Front View

.31” [7.9]

✺

Mounting Screw Location #6–32 UNC–2B or M3.5 (4 Places)

2.9”

[73.7]

1.05”

[26.7]

✺ Installation should provide adjustment to align the optical center line

on the intended target. This adjustment should account for tolerance

variation in the 3700 scanner, as well as the host equipment.

3.1” [78.7]

.2” [5.1]

.42” [10.7]

millimeters in brackets [mm]

Figure 3.2 Mounting Dimensions for the 3700

Mounting Surface

Scanner Window

Set–Up and Installation 3–5

Page 24

The 3700 Machine Mount CCD may be oriented in any way so that the beam scanning

path moves across the bar code as shown in Figure 3.3. Bar code presentation to the

scanner is important for successful scanning of the label. The first requirement is that the

beam scan path cross all bars on the label, as well a 0.25 inch quiet zone before and after

the code. The Automatic Identification Manufacturers (AIM), the industry association,

has defined orientation of the bar code label according to Figure 3.4.

Bar Code Target Moving

Perpendicular to Scan Beam

Optical Light Center Line

Mounting Surface

Optical Light Center Line

Mounting Surface

Bar Code Target Moving

Parallel to Scan Beam

Front View

Indicates relative direction

of bar code target movement

Mounting Surface

Figure 3.3 Examples of SCANTEAM 3700 Barcode Orientation

3–6 Set–Up and Installation

Page 25

PITCH OR ROLL

Rotation about the Y–axis ±7°

R

TILT

Rotation about the Z–axis

controlled by bar code

length and height

Figure 3.4 SCANTEAM 3700 Pitch, Skew and Tilt Tolerance

Bar Code Label

R

SKEW OR YAW

Rotation about the X–axis ±30°

(0 to –10° specular

reflection interference

✺ See Figure 3.5

Bar Code Label

THE ABOVE DEFINITIONS ARE FROM AIM SPECIFICATIONS

✺)

R

Bar Code Label

Rear View

R = Rotation

Bar

Code

Target

–30°

–10°

.31” [7.9]

Nominal Optics

Center Line

+30°

0°

Specular Zone

(Operation in the Specular Zone must be avoided)

Figure 3.5 Specular Reflection Interference

Set–Up and Installation 3–7

Mounting Surface

SCANTEAM

3700

Page 26

– NOM –

Focal Plane

3.5”

[88.9]

3.1”

[78.7]

1.55”

[39.4]

2°

15°

27°

.61”

[15.5]

.2”

[5.1]

2.4”

[61]

Minimum clearance required for

=

scanner illumination of target. [

Receive path/area. [

=

Top View

[ Illumination area is larger than receive area.

This completes installation of the SCANTEAM 3700 Machine Mount CCD in a host

instrument. You are now ready to configure the 3700 for your particular application.

Instructions for configuring the 3700 using configuration and operational commands are

provided in Chapter 4, Configuring the SCANTEAM 3700.

3–8 Set–Up and Installation

Side View

2°

millimeters in brackets [mm]

Figure 3.6 Scanner Illumination Clearance

Page 27

CONFIGURING THE SCANTEAM 3700

4.1 Preparation

This chapter provides instructions for configuring the software in the SCANTEAM 3700

Machine Mount CCD. The configuration process allows you to change the operating

parameters of the scanner software to explore the functions of the 3700. The

user–defined configuration is stored in volatile RAM memory and can be changed by the

user.

All communication between the host system and the 3700 Machine Mount CCD is

through the RS–232 communications interface using an Asynchronous ASCII protocol.

The host system sends commands one at a time to the 3700. During the configuration

process, there is no acknowledgement or other response from the 3700. It is important to

enter commands accurately. If a command is sent erroneously to the 3700, you may

terminate that command and send the command again. You may send configuration

status query commands to obtain a status listing of the configuration selections.

For detailed instructions on preparing the SCANTEAM 3700 for configuration, refer to

section 3.3, Set–up Procedure for Use in the Design Lab, or section 3.4, Installation in

the Host Instrument.

4

The application–specific features that can be modified using the RS–232 communication

line include the following:

• Auditory feedback for operator

• Bar code symbology may be disabled for security reasons

• Communications parameters

• Data message options

• Decoding enabled or disabled

• Fully configurable bar code symbologies and their options

• Triggering options.

Configuring the SCANTEAM 3700 4–1

Page 28

4.2 Command Conventions

The following conventions apply when entering configuration commands:

• Actual serial configuration command entries are highlighted in bold to distinguish

them from descriptive text.

• Spaces shown within command strings must not be included in the actual string;

they are for clarity only.

• Commas shown in command strings are used as item separators and are required as

place holders; except for trailing commas in abbreviated strings, which are not

required.

• Where a selection in a command string is indicated to be more than one character

(for example, the time value in the Read Timeout command) commas are never used

to separate the characters within that item.

Command Format

The command format contains the following, with the exception of two commands ✺:

• < data string >

The data string is the serial command. Send the hexadecimal equivalent of each ASCII

value when programming the 3700 from the host. An ASCII conversion chart is

provided in Appendix D.

The following three sections, 4.3, 4.4 and 4.5, explain the operational, configuration and

configuration status query commands, providing the ASCII and equivalent hex characters

for command definitions.

Note: In order to provide compatibility with drivers already written for the SCANTEAM 7300,

configuration commands that deal with multiple scanner ports in the SCANTEAM 7300

are also recognized by the SCANTEAM 3700 Machine Mount CCD. These commands

may contain port–specific data not relevant to the 3700. This extra data will be accepted,

but ignored. These items are identified in the command descriptions by a pound sign (#).

✺ The two commands, DC2 and DC4 for enabling and disabling decoding, do not

follow the above command format. They are single character commands which do

not need the “<” before or the “>” after the data byte.

4–2 Configuring the SCANTEAM 3700

Page 29

4.3 Operational Commands

Five operational commands recognized by the SCANTEAM 3700 are:

<A> – resets the 3700

DC4 – disables bar code scanning

DC2 – enables bar code scanning

<1> – serial trigger

<Z> – saves current configuration in non–volatile memory.

Explanations, ASCII and hex characters for the operational commands follow.

Reset Command <A>

COMMAND

ASCII Hex Characters

Reset <A> 3C 41 3E

Sending the operational command <A> causes the 3700 to reset. After reset the 3700

will operate according to the last configuration saved in non–volatile memory. If a valid

configuration cannot be retrieved from memory, the 3700 will operate according to the

default configuration.

Disable Decoding Command DC4

COMMAND

ASCII Hex Characters

Disable Decoding DC4 14

This is a single character command. Sending the operational command DC4 will cause

the 3700 to stop looking at bar code data.

Enable Decoding Command DC2

COMMAND

ASCII Hex Characters

Enable Decoding DC2 12

This is a single character command. Sending the operational command DC2 will allow

the 3700 to decode according to its current configuration.

Note: DC4 and DC2 are ASCII control characters. With a terminal emulation program running

on a PC, send a DC4 by holding down the CTRL key while pressing the “T” key. Send a

DC2 by holding down the CTRL key while pressing the “R” key.

Configuring the SCANTEAM 3700 4–3

Page 30

Serial Trigger Command <1>

COMMAND

ASCII Hex Characters

Serial Trigger <1> 3C 31 3E

Sending the operational command <1> sends a serial trigger to scanner port “1.” If the

Trigger Mode for Port “1” is set to allow serial triggers, the 3700 enables the Machine

Mount CCD and attempts to read a bar code.

Trigger Mode, a configuration command, is described in section 4.4.

Serial Trigger Command <2>

COMMAND

ASCII Hex Characters

Serial Trigger <2> 3C 32 3E

Sending the operational command <2> sends a serial trigger to scanner port “2.” If the

Trigger Mode for Port “2” is set to allow serial triggers, the 3700 enables the auxilliary

wand input port. The hardware configuration to support this port is optional.

Save Configuration Command <Z>

COMMAND

ASCII Hex Characters

Save Configuration <Z> 3C 5A 3E

Sending the operational command <Z> causes the current configuration to be saved in

non–volatile memory.

4–4 Configuring the SCANTEAM 3700

Page 31

4.4 Configuration Commands

Fifteen configuration commands recognized by the SCANTEAM 3700 are:

Ka – sets communication port

Kd – sets preamble

Ke – sets postamble

Kf – sets communications protocol

Kg – sets trigger mode

Kh – sets read timeout

Kk – sets no read message

Km – sets votes

Kp – sets Code 39

Kq – sets Codabar

Kr – sets I 2 of 5

Ks – sets UPD A/E and EAN 8/13

Kt – sets Code 128

Ku – sets beeper mode

Kv – scan rate

Explanations and ASCII characters for the configuration commands follow.

Note: The commands in this section are shown in ASCII format only. Refer to Appendix D for

an ASCII conversion chart.

Format for a Configuration Comand

<K mode_global , mode_port_1 , mode_port_2>

(2)

(3) (4) (5)

(1)

(1) Configuration commands start with “<” and end with “>.”

(2) Configuration commands include “K” as the start of the command text string. The

“K” must be upper case.

(3) The next letter in the command string defines the function and must be lower case.

(4) Where applicable, the “mode_global” portion of the command defines the selection

for the particular command (for both scanner inputs) unless specified otherwise in

the following mode portions of the command.

(5) “Mode_port_1” and “mode_port_2” refer to the configuration for the particular

scanner input. The 3700 CCD is port 1, and so is controlled by Mode 1. A second

(optional) external digital scanner input is configured as Mode 2.

Note: Default configuration indicated by asterisk “*” following default configuration. Default

options (if applicable) will follow in parenthesis.

(6) No more than five (5) seconds may pass between keystrokes or the decoder will not

recognize the command as a single string of characters.

(7) If an incorrect keystroke is entered, end the string with a “>” and enter the string

over from the beginning.

Configuring the SCANTEAM 3700 4–5

Page 32

Set Communications Port Command Ka

COMMAND

<Ka baud, parity, stop bits, data bits>

Parameter ASCII Option

Baud 0 600

1 1200

2 2400

3 4800

4 9600 *

5 19,200

6 38,400

Parity 0 none

1 even *

2 odd

Stop Bits 0 one *

1 two

Data Bits 0 seven *

1 eight

Sending the configuration command Ka sets the communications port parameters. Baud

rate, parity, stop bits and data bits may be selected. For example, if you wanted to set the

baud rate to 2400, the parity to none, the stop bits to two, and the data bits to eight; you

would send the following command: <Ka 2, 0, 1, 1>. If you only wanted to set the

baud rate to 4800, leaving the other parameters unchanged, you could send the following

abbreviated command: <Ka 3>. If you only wanted to set the stop bits to two, leaving

the other parameters unchanged, you could send the following command: <Ka , , 1>.

The default setting is 9600 baud, even parity, one stop bit, and seven data bits.

Tip: The Ka command does not become effective until the 3700 is reset. Since reset

causes the 3700 to use the configuration saved in non–volatile memory, the Ka

command should be followed by a Save Configuration command <Z> and a Reset

command <A>.

4–6 Configuring the SCANTEAM 3700

Page 33

Set Preamble Command Kd

COMMAND

<Kd enable, data>

Parameter ASCII Option

Enable 0 no

1 yes * (Port ID, Code ID)

Data one to four ASCII characters

Sending the configuration command Kd sets the preamble characters. The preamble

option may be enabled or disabled; if enabled, up to four preamble characters may be

defined. Any ASCII character can be specified except NUL, ACK, NAK, DC1, DC2,

DC3, DC4 or DEL. The character SUB should only be used as the first character in a

pair, with the second character being either a 1 or a 2. SUB 1 causes the 3700 to include

the Port ID in the preamble, while SUB 2 specifies that the Code ID should be included.

Table 4.1 lists the Code ID values. The default setting is preamble enabled, Port ID and

Code ID characters sent with data strings.

Tip: When character pairs SUB 1 and SUB 2 are specified in the preamble, the SUB

characters are not counted toward the maximum number of ASCII characters

allowed (four).

Code ID Value

Definition

a Codabar

b

e

j

Code 39

Interleaved 2 of 5

Code 128

c UPC

d

SPACE

EAN

No code

Table 4.1 SCANTEAM 3700 Code ID Values

Configuring the SCANTEAM 3700 4–7

Page 34

Set Postamble Command Ke

COMMAND

<Ke enable, data>

Parameter ASCII Option

Enable 0 no

1 yes * (CR, LF)

Data one to four ASCII characters

Sending the configuration command Ke sets the postamble characters. The postamble

option may be enabled or disabled; if enabled, up to four postamble characters may be

defined. Any ASCII character can be specified except NUL, ACK, NAK, DC1, DC2,

DC3, DC4 or DEL. The character SUB should only be used as the first character in a

pair, with the second character being either a 1 or a 2. SUB 1 causes the 3700 to include

the Port ID in the postamble, while SUB 2 specifies that the Code ID should be included.

Port ID is always 1. Table 4.1 lists the Code ID values. The default setting is postamble

enabled, CR and LF characters sent with data strings.

Tip: When character pairs SUB 1 and SUB 2 are specified in the postamble, the SUB

characters are not counted toward the maximum number of ASCII characters

allowed (four).

4–8 Configuring the SCANTEAM 3700

Page 35

Set Communications Protocol Command Kf

COMMAND

<Kf mode>

Parameter ASCII Option

Mode 0 Disable RTS/CTS *

Disable XON/XOFF *

Disable ACK/NAK *

Mode 1 Enable RTS/CTS

Disable XON/XOFF

Disable ACK/NAK

Mode 2 Disable RTS/CTS

Enable XON/XOFF

Disable ACK/NAK

Mode 3 Enable RTS/CTS

Enable XON/XOFF

Disable ACK/NAK

Mode 4 Disable RTS/CTS

Disable XON/XOFF

Enable ACK/NAK

Mode 5 Enable RTS/CTS

Disable XON/XOFF

Enable ACK/NAK

Mode 6 Disable RTS/CTS

Enable XON/XOFF

Enable ACK/NAK

Mode 7 Enable RTS/CTS

Enable XON/XOFF

Enable ACK/NAK

Sending the configuration command Kf sets the communications protocol. The default

setting is Mode 0, with RTS/CTS, XON/XOFF, and ACK/NAK disabled.

Configuring the SCANTEAM 3700 4–9

Page 36

Set Trigger Mode Command Kg

COMMAND

<Kg mode_global, mode_port_1, mode_port_2, #>

Parameter ASCII Option

Mode 0 Continuous Read

Mode 1 Continuous Read, Send Once, Clear on Timeout

Mode 2 External Trigger, Read While Active

Mode 3 External Trigger, Read Once

Mode 4 Serial Trigger

Mode 5 Serial Trigger or External Trigger,

Read Once *

Sending the configuration command Kg sets the trigger mode. The command string is

interpreted left to right. For example, if you send the following command: <Kg 4, 0>,

both ports will be set to mode 4, then port 1 changes back to mode 0. Likewise, if you

send the following command: <Kg , 0, 4>, port 1 is set to mode 0 and port 2 is set to

mode 4. Both commands have the same end result; port 1 will be in continuous read

mode and port 2 will be in serial trigger mode. The default setting is Mode_global 5,

selecting a serial trigger or an external trigger, one read.

Tip 1: Careful consideration must be taken when configuring multiple ports to a

continuous trigger mode. The 3700 decodes from only one port at a time. With

multiple ports triggered, the 3700 will select each in turn and attempt to read. If

no bar code label is present at the selected port, the 3700 will wait for read

timeout to expire before stepping to the next port. If read timeout is set to a value

near or greater than the time it takes a bar code label to pass by a scanner, then

the label will often be missed.

Set Read Timeout Command Kh

COMMAND

Parameter

Mode 0 Timeout Ends a Read Attempt * (150)

Time one to five ASCII digits,

Sending the configuration command Kh sets the read timeout. One to five ASCII digits

in the range of 10 to 65,000 determine the number of 10ms increments of time that the

3700 will, once triggered, wait while attempting to read from a port. For example, if you

wanted to set port 1 to timeout ends a read attempt after 100ms; you would send the

following command: <Kh , , 0, 10>. Port 2 is not changed. The default setting is

Mode_global 0 and Time_global 150 (150 x 10 msec = 1.5 seconds).

4–10 Configuring the SCANTEAM 3700

<Kh mode_global, time_global, mode_port_1, time_port_1,

mode_port_2, time_port_2, #, #>

ASCII Option

range of 10 to 65000

Page 37

Set No Read Message Command Kk

COMMAND

<Kk enable, data>

Parameter ASCII Option

Enable 0 no

1 yes * (NR)

Data one to seven ASCII characters

Sending the configuration command Kk sets the no read message. Any ASCII character

can be specified except NUL, ACK, NAK, DC1, DC2, DC3, DC4 or DEL. The default

setting is NR (no read).

Tip: The No Read Message is not sent for scanner ports that are configured for a

continuous trigger mode.

Set Votes Command Km

COMMAND

<Km data_global, data_port_1, data_port_2, #>

Parameter

ASCII Option

Data one or two ASCII digits

range of 1 to 31 * (3, 1)

Sending the configuration command Km sets the votes. One or two ASCII digits in the

range of 1 to 31 determine the number of consecutive identical decodes required for a

valid read. A selection of 1 means that no voting will take place. The default setting is

Data_port_1, 3 and Data_port_2, 1, which means voting is set to 3 for port 1 and set to 1

for port 2.

Tip: When using the voting feature for additional decode security, a value of three is

generally adequate in most applications.

Configuring the SCANTEAM 3700 4–11

Page 38

Set Code 39 Command Kp

COMMAND

<Kp enable, require checksum, send checksum, minimum

length, maximum length>

Parameter

ASCII Option

Enable 0 no

1 yes *

Require Checksum 0 no *

1 yes

Send Checksum 0 no *

1 yes

Minimum Length Set from 1 to 48 * (1)

Maximum Length Set from 1 to 48 * (48)

Sending the configuration command Kp sets Code 39 and all its parameters:

enable/disable, require checksum, send checksum, minimum length, and maximum

length. The default setting is Code 39 enabled, doesn’t require or send checksum,

minimum length 1, and maximum length 48.

Set Codabar Command Kq

COMMAND

<Kq enable, send start/stop, minimum length, maximum

length>

Parameter

ASCII Option

Enable 0 no

1 yes *

Send Start/Stop 0 no

1 yes *

Minimum Length Set from 1 to 60 * (6)

Maximum Length Set from 1 to 60 * (60)

Sending the configuration command Kq sets Codabar and all its parameters:

enable/disable, send start/stop, minimum length, and maximum length. The default

setting is Codabar enabled, send start/stop, minimum length 6, and maximum length 60.

4–12 Configuring the SCANTEAM 3700

Page 39

Set I 2 of 5 Command Kr

COMMAND

<Kr enable, require checksum, send checksum,

minimum length, maximum length>

Parameter

ASCII Option

Enable 0 no *

1 yes

Require Checksum 0 no *

1 yes

Send Checksum 0 no *

1 yes

Minimum Length Set from 2 to 80 * (6)

Maximum Length Set from 2 to 80 * (80)

Sending the configuration command Kr sets I 2 of 5 and all its parameters:

enable/disable, require checksum, send checksum, minimum length, and maximum

length. The default setting is I 2 of 5 disabled, doesn’t require or send checksum,

minimum length 6, and maximum length 80.

Tip 1: To require a fixed length, set the minimum and maximum lengths to the same

value.

Tip 2: An Interleaved 2 of 5 symbol must always have an even number of characters

encoded in it. However, if you have configured the 3700 to require a checksum but

not send the checksum, the 3700 will reduce the number of characters output by

one to an odd value. The minimum and maximum lengths will be checked after

the checksum is removed and so must be set to allow a symbol length that is one

less than actually encoded in the label to be read.

Set UPC A/E, EAN 8/13 Command Ks

COMMAND

<Ks enable UPC, enable EAN>

Parameter ASCII Option

Enable UPC 0 no

1 yes *

Enable EAN 0 no

1 yes *

Sending the configuration command Ks sets UPC A/E and EAN 8/13 to enable or

disable. The default setting is UPC A/E and EAN 8/13 enabled.

Configuring the SCANTEAM 3700 4–13

Page 40

Set Code 128 Command Kt

COMMAND

<Kt enable, minimum length, maximum length>

Parameter ASCII Option

Enable 0 no

1 yes *

Minimum Length Set from 1 to 80 * (1)

Maximum Length Set from 1 to 80 * (80)

Sending the configuration command Kt sets Code 128 and all its parameters:

enable/disable, minimum length, and maximum length. The default setting is Code 128

enabled, minimum length 1, and maximum length 80.

Set Beeper Mode Command Ku

COMMAND

<Ku mode_global, mode_port_1, mode_port_2, #>

Parameter

ASCII Option

Mode 0 Disable beeper *

Mode 1 Enable beeper on valid read

Mode 2 Enable beeper on failed read

Sending the configuration command Ku sets the beeper mode. For example, if you

wanted to enable the beeper for good reads on port 1; you would send the following

command: <Ku , 1>. The default setting is Mode_global 0, with beeper disabled.

Set Scan Rate Command Kv

COMMAND

<Kv rate, reserved, reserved>

Parameter

ASCII Option

Rate 0 50 scans per second

Rate 1 100 scans per second

Rate 3 200 scans per second

The Kv command has been retained in the 3700 for compatibility with the SCANTEAM

3600, but the 3700 scan rate is fixed at the time of manufacture and cannot be changed

by the Kv command. The <Kv?> status request (see next section) will report the scan

rate setting.

4–14 Configuring the SCANTEAM 3700

Page 41

4.5 Configuration Status Query Commands

The configuration status query commands are used to obtain a status listing of the

configuration command selections. You may request a listing of the entire series of

individual configuration status messages or you may request the status of a single

configuration status message be output to your host system or terminal. Descriptions and

ASCII characters for the configuration commands follow.

Note: The commands in this section are shown in ASCII format only. Refer to Appendix D for

an ASCII conversion chart.

The following command causes the entire series of individual configuration status

messages to be output to the host system:

<?> – configuration query.

Fifteen configuration status query commands recognized by the SCANTEAM 3700 are:

<Ka?> – communications port status

<Kd?> – preamble status

<Ke?> – postamble status

<Kf?> – communications protocol status

<Kg?> – trigger/enable mode status

<Kh?> – read timeout status

<Kk?> – no read message status

<Km?> – votes status

<Kp?> – Code 39 status

<Kq?> – Codabar status

<Kr?> – Interleaved 2 of 5 status

<Ks?> – UPC, EAN status

<Kt?> – Code 128 status

<Ku?> – beeper status

<Kv?> – scan rate status

Each configuration query will cause the current status of the selected option to be output

in a format identical to the configuration command string itself, except that global fields

are excluded. For example, if the trigger mode_global is set to 5 <Kg?> will result in

<Kg , 5, 5> being output by the 3700.

Except for the Communication Port Command, configuration commands take effect

immediately upon receipt by the 3700. Therefore most configuration commands can be

verified as having been received by the 3700 by immediately following the command

with a status query. For the Communications Port Command to become effective, the

command must be followed by a <Z><A> (save configuration and reset the 3700

commands) since the port is only initialized upon a reset. Since the 3700 reports the

current configuration of the port itself, the status query <Ka?> will not indicate if a

Communications Port Configuration Command has been received correctly until the

<Z><A> has been received.

All status output strings will include the current preamble and postamble. Thus if the

preamble is set to DC1 and the postamble to DC3 then a postamble status query <Ke?>

will result in the output string DC1<Ke1,DC3>DC3. The receiving system must be able

to handle the embedded DC3 and not treat it as the termination of the string.

Configuring the SCANTEAM 3700 4–15

Page 42

4.6 Default Operating Parameters

The SCANTEAM 3700 is configured at the Hand Held Products factory with standard

(default) operating parameters. The default configuration can be used as is or changed

(reconfigured) by downloading new parameters over an RS–232 communications line

from a host instrument. The default configuration settings are listed below.

Default Configuration Settings

• ACK / NAK Disabled

• Baud Rate 9600

• Beeper Mode Disable beeper

• Data Bits 7

• No Read Message “NR”

• Parity Even

• Postamble CR LF

• Preamble Port ID Code ID

• Read Timeout Timeout ends a read attempt, 1.5 seconds

• RTS/CTS Disabled

• Stop Bit 1

• Trigger Mode Serial Trigger or External Trigger, Read Once

• Votes Voting set to 3 for port 1 and set to 1 for port 2

• XON/XOFF Disabled

Default Configuration: Symbology Settings

• Codabar Enabled

Send Start/Stop Yes

Minimum Length 6

Maximum Length 60

• Code 39 Enabled

Require Checksum No

Send Checksum No

Minimum Length 1

Maximum Length 48

• Code 128 Enabled

Minimum Length 1

Maximum Length 80

• I 2 of 5 Disabled

Require Checksum No

Send Checksum No

Minimum Length 6

Maximum Length 80

• UPC A/E, EAN 8/13 Enabled

4–16 Configuring the SCANTEAM 3700

Page 43

SERVICE/TECHNICAL ASSISTANCE

5.1 Maintenance

The Hand Held Products SCANTEAM 3700 Machine Mount CCD Bar Code Scanner

and Decoder is designed to provide reliable and efficient operation, requiring no routine

maintenance. The 3700 has no moving physical parts. Convection air flow serves to

cool the unit. Maintenance, therefore is related to troubleshooting and replacement of the

3700 Machine Mount CCD.

Troubleshooting procedures are described in the following section. Section 5.4 provides

procedures for removing and replacing a SCANTEAM 3700 Machine Mount CCD.

5.2 Troubleshooting Guide

This section describes procedures for identifying problems that prevent the SCANTEAM

3700 from operating normally. Field repair procedures include the following:

• Power supply troubleshooting

• 3700 Machine Mount CCD troubleshooting

5

5.2.1 Troubleshooting Hints

If there is no power to the 3700 Machine Mount CCD, check the following:

• Host power supply output to the 3700. Check that the output voltage from the host

is +5 VDC. If the voltage isn’t present or is out of range, there may be a problem

with power distribution from the host system. Appendix B provides the specific

voltage range.

• If there is no output voltage, check to be sure the host instrument power switch is set

to “ON”; if this switch is on and there is no output voltage, there may be a problem

with the host power supply.

• Check all cables for secure connections and continuity (with an ohm/volt/meter).

Warning: Only a qualified person should attempt to replace a power supply.

Service/Technical Assistance 5–1

Page 44

5.2.2 Diagnostic Procedure

The SCANTEAM 3700 Machine Mount CCD may be reset to the last saved

configuration parameters by issuing a Reset Command. (A list of these parameters may

be found on in section 4.6 and C.4.)

• To perform a Reset Command, send an <A> serial command to the 3700. This

action causes all data in memory to be erased and the current user configuration

parameters to be loaded from non–volatile memory. In the absence of a user

configuration, the default configuration is loaded into memory. This action allows

the user to clear memory of any corrupt data from scanned data.

5.2.3 Troubleshooting Checklist

Problem

3700 does not scan.

3700 is not reading bar

code.

Beeper does not come on.

Data is not transmitted.

Possible Cause

1) Loose I/O communications cable.

2) Trigger mode not configured correctly.

3) Not triggered.

1) Bar code symbol type is disabled.

2) Symbol length is out of range.

3) Symbol does not contain a valid

checksum character.

4) Bar code is bad, damaged or out of spec.

5) Window is scratched or dirty.

1) 3700 is not decoding.

2) Good read is disabled.

1) Loose I/O communications cable.

2) 3700 is waiting for clear to send (CTS).

3) 3700 is waiting for XON.

Solution

1) Connect cable.

2) Configure the 3700 for the proper trigger

mode and read timeout value.

3) Provide trigger consistent with the trigger

mode configuration.

1) Enable the symbology.

2) Configure the 3700 for correct length.

3) Configure the 3700 to not require checksum

or use a label with a valid checksum.

4) Replace bar code.

5) Clean window.

1) See “3700 is not reading bar code.”

2) Configure the 3700 for desired good read

operation.

1) Connect cable.

2a) Have the receiving equipment generate CTS.

2b)Disconnect CTS signal allowing the 3700 to

force CTS to the active state.

3a) Send an XON to the 3700.

3b)Configure the 3700 to disable XON.

Data message is missing

or garbled.

Baud rate, parity, stop bits or data bits is

wrong.

Table 5.1 SCANTEAM 3700 Troubleshooting Checklist

5–2 Service/Technical Assistance

Configure the 3700 for the proper

communications parameters.

Page 45

5.3 Obtaining Factory Service

Hand Held Products provides service for all its products through a service center located

at its manufacturing facilities in Skaneateles, New York. To obtain warranty or

non–warranty service, return the unit to Hand Held Products (postage paid) with a copy

of the dated purchase record attached.

In the United States, please contact the Hand Held Products’ Product Service Department

at the address/telephone number listed below to obtain a Return Material Authorization

number (RMA #).

Main Office

Welch Allyn Data Collection, Inc. (d/b/a Hand Held Products)

4619 Jordan Road

P.O. Box 187

Skaneateles Falls, New York 13153–0187

Product Service Department

Telephone: (315) 685–4278 or 685–4360

Fax: (315) 685–4156

For service in Europe, please contact your Hand Held Products’ representative (at the

address that follows) or your local distributor.

European Office

Hand Held Products, Ltd.

Hondsruglaan 87 D

5628 DB Eindhoven

The Netherlands

Telephone: Int+ 31 40 242 4486

Fax: Int+ 31 40 242 5672

United Kingdom Office

Hand Held Products (UK) Ltd.

Dallam Court

Dallam Lane

Warrington

Cheshire WA2 7LT

United Kingdom

Telephone: Int+44 (0) 1 925 240055

or Int+353 1 216 0070

Fax: Int+44 (0) 1 925 631280

or Int+353 1 295 6353

For service in Asia, please contact your Hand Held Products’ representative (at the

address that follows) or your local distributor.

Asia/Pacific Office

Hand Held Products

10/F Tung Sun Commercial Centre

194–200 Lockhart Road

Wanchai, Hong Kong

Telephone: Int+852–2511–3050 or 2511–3132

Fax: Int+852–251–1355

For service in Japan, please contact your Hand Held Products’ representative (at the

address that follows) or your local distributor.

Service/Technical Assistance 5–3

Page 46

Japan Office

Hand Held Products

Bon Marusan 8F

3–5–1 Kanda–Jinbocho

Chiyoda–ku

Tokyo 101, Japan

Telephone: Int+81–3–5212–7392

Fax: Int+81–3–3261–7372

For service in Latin America, please contact your Hand Held Products’ representative (at

the address that follows) or your local distributor.

Latin America Office

Hand Held Products

5150 North Tamiami Trail

Suite 302

Naples, FL 34103–2821

Telephone: (941) 263–7600

Fax: (941) 263–9689

5.4 Help Desk

If you need assistance installing or troubleshooting your scanner, please call your

Distributor or the nearest Hand Held Products technical support office:

North America:

Telephone: (315) 685–2476 (8 a.m. to 6 p.m. EST)

Fax number: (315) 685–4960

E–mail: support@handheld.com

Europe:

Telephone–

European Ofc: Int+31 40 242 4486

U.K. Ofc: Int+44 1925 240055

E–mail: support@handheld.com

Asia:

Telephone: Int+852–2511–3050 or 2511–3132

E–mail: support@handheld.com

5.3.1 Service Under Warranty

All Welch Allyn bar code products carry a one (1) year warranty (from date of

shipment). The specific Limited Warranty coverage for the SCANTEAM 3700 Machine

Mount CCD is described near the end of this manual. Warranty service may be obtained

by contacting the Welch Allyn Customer Service Group.

5.3.2 Out Of Warranty Service

Factory service is also available for out of warranty products on a time and materials or

fixed price basis. The scanner/decoder should be returned (postage paid) for repair only

after obtaining a Return Material Authorization (RMA) from a Customer Service

Representative. When out of warranty product service is required, you will be advised of

a “not to exceed” price for repair when the Return Material Authorization is requested.

5–4 Service/Technical Assistance

Page 47

The following information is required to process an RMA for the product and should be

available for the Service Representative. It is located on the manufacturers label attached

to the box the SCANTEAM 3700 was shipped in.

Model Number

Serial Number

Date of Manufacture

Note: The Welch Allyn Customer Service Group cannot accept materials that are returned

without an RMA number.

When out of warranty service is required the Customer Service Representative will

request a Purchase Order Number in the amount of the “not to exceed” price for repair.

However, customers will be billed only for the actual service costs.

5.4 SCANTEAM 3700 Removal/Replacement

The application intention of the 3700 makes it a component of the host controlled

instrument. Power to the host system must be turned off before removing the 3700

Machine Mount CCD. Removing the 3700 involves reversing the steps that you

followed during installation (Chapter 3).

Caution: Some circuits in the 3700 Machine Mount CCD are sensitive to electrostatic

discharge. Be sure you are properly grounded before removing the 3700 from the

host system.

Note: Set the host instrument power switch to the “OFF” position.

Step 1: Disconnect the data communications/ power cable between the 3700 Machine

Mount CCD and the host system (see Chapter 2, Figure 2.2 for the exact

location of the port on the 3700).

Step 2: Using a screwdriver, remove the mounting screws, if applicable, from the 3700

Machine Mount CCD.

Step 3: Remove the 3700 Machine Mount CCD and place it immediately into an

antistatic container or an antistatic bag.

This completes the 3700 Machine Mount CCD removal procedure. For replacement

vinstructions, please follow the set–up and installation procedures in Chapter 3.

Service/Technical Assistance 5–5

Page 48

5–6 Service/Technical Assistance

Page 49

CCD OPERATION AND BAR CODE SCANNING

A.1 Objectives

This appendix describes:

• Reading and decoding a bar code symbol.

• Overview of how the SCANTEAM 3700 works, including a scanner diagram with

the main decoding elements listed.

• In–depth discussion of the operation of the scanner, including a block diagram and

discussion of the internal parts of the scanner, and a timing sequence diagram.

• Bar code basics and scanning tips.

A.2 Scanning and Decoding a Bar Code Symbol

The body of the SCANTEAM 3700 houses all the scanning elements, and

decoding/interface elements. Refer to Figure A.1.

A

LED

Reflector

Bar

Code

Symbol

Aperture

Lens

LED Pulse

Generator

CCD

Sensor

Bar Code

Label

Image

Decoding/Interface

Power Supply,

Digitizing,

Microprocessor,

Signal

Processing,

and Control

Circuitry

Cable

Modular

Connector

Pixel

Array

Figure A.1 Main Elements of the 3700 CCD Bar Code System

The SCANTEAM 3700 performs the following steps when scanning and decoding a bar

code symbol:

1. The scanner turns the LEDs (Light Emitting Diodes) inside the scanner ON, and the

light from the LEDs illuminate the bar code symbol.

CCD Operation and Bar Code Scanning A–1

Page 50

2. The black bars on the symbol absorb the LED light, while the white spaces scatter

the LED light.

3. A portion of the scattered light re–enters the scanner’s optical system and is detected

by the pixels of the CCD (Charged Coupled Device).

4. The CCD converts the returned light into a sequence of electrical pulses with

amplitude proportional to the energy level of the scattered light.

5. The digitizer converts the analog light signal to a bit serial representation of the bar

code symbol. The width of the binary signal pulse being proportional to the width of

the bars and spaces of the bar code symbol.

6. The Decoding Circuitry decodes the digitized pulses into characters of data

representative of the bar code symbol.

7. After a successful decode is complete, a beeper is sounded (if enabled to indicate a

Good Read). The decoded information is transmitted to the host.

8. Depending upon the trigger chosen, the scanner either continuously initiates another

scan cycle or waits for the next trigger to scan.

LED Reflector

The bar code symbol is illuminated with a bank of LEDs with a proprietary reflector.

The LEDs are pulsed, strobing illumination, to stop relative motion of the scanner and

the label.

CCD Sensor

The optical energy scattered from the bar code symbol is focused with a custom lens onto

the pixel array of the CCD sensor.

The switching transients from the CCD are removed with analog filters. This filtered

signal is then an analog representation of scattered light incident on the CCD.

Peak Detectors and Comparator

The positive and negative peak detectors retain the signal level associated with the

minimum black and maximum white reflectances respectively. The comparator

threshold is then set at a point between the black and white peak reflectance levels. The