Page 1

FCC Part 15.209

Transmitter Certification

Test Report

FCC ID: VC3-RF5X10

FCC Rule Part: 15.209

ACS Report Number: 07-0074-15C

Manufacturer: Hanchett Entry Systems, Inc.

Model(s): RF5010-IA, RF5010-EA, RF5210-IA, RF5210-EA

Installation Guide

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Page 2

Cutout Template

Installation Instructions

®

RF5010 and RF5210

HYBRID ELECTRIC STRIKES: OUTSWING VERSIONRF5010 and RF52010: OUTSWING VERSION

HES, Inc.

22630 N. 17th Ave.

Phoenix, AZ 85027

800-626-7590

14

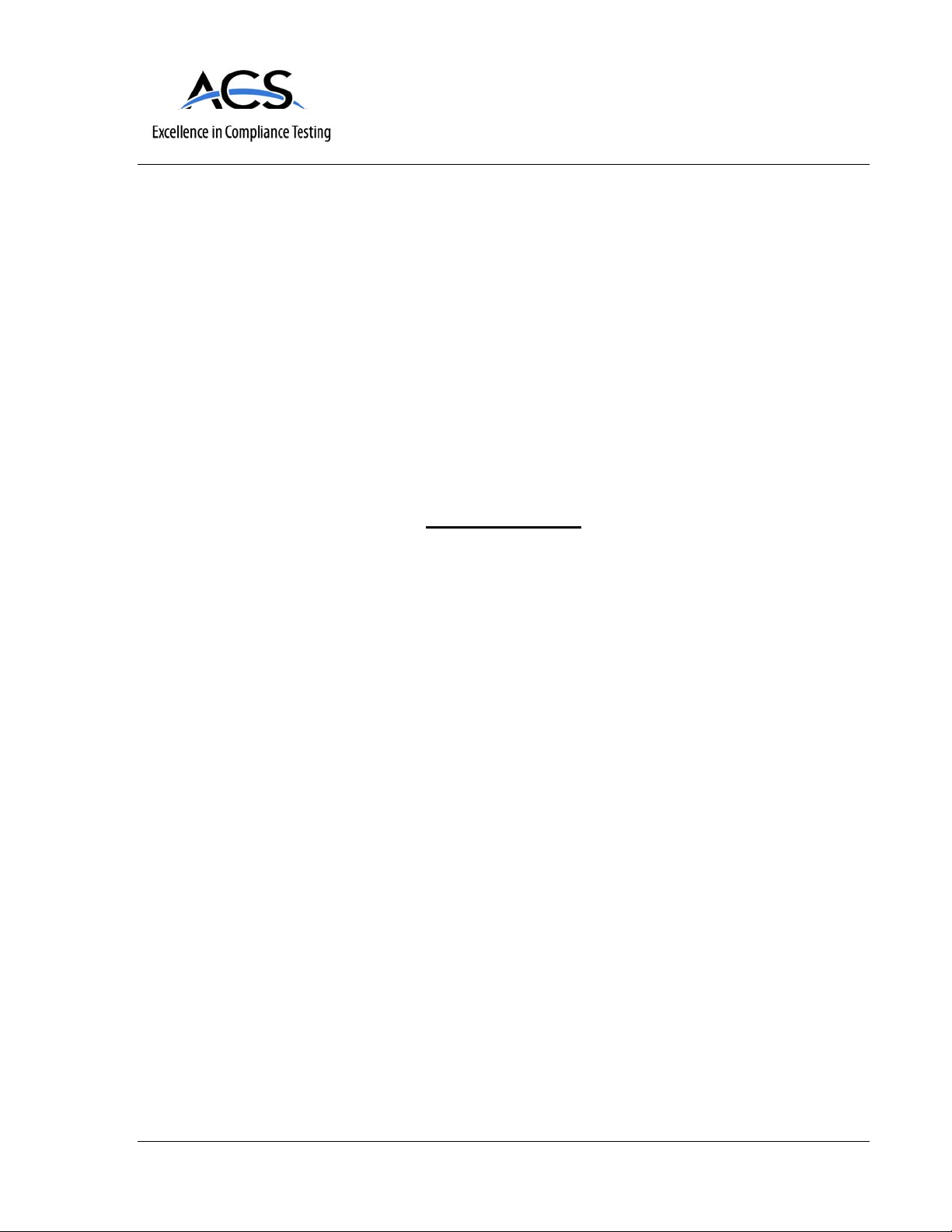

RF5010 or RF5210 with 501 Faceplate

1-1/4” x 4-7/8” Square Corner Faceplate

ANSI Metal Jamb Installation

1-1/4"

RF5010: 11/16"

RF5210: 13/16"

43

46

32

4 -1/8"

105

3 -3/8"

86

3/8"

10

Door Position Switch Hybrid Electric Strike

4 -7/8"

124

Outswing Version

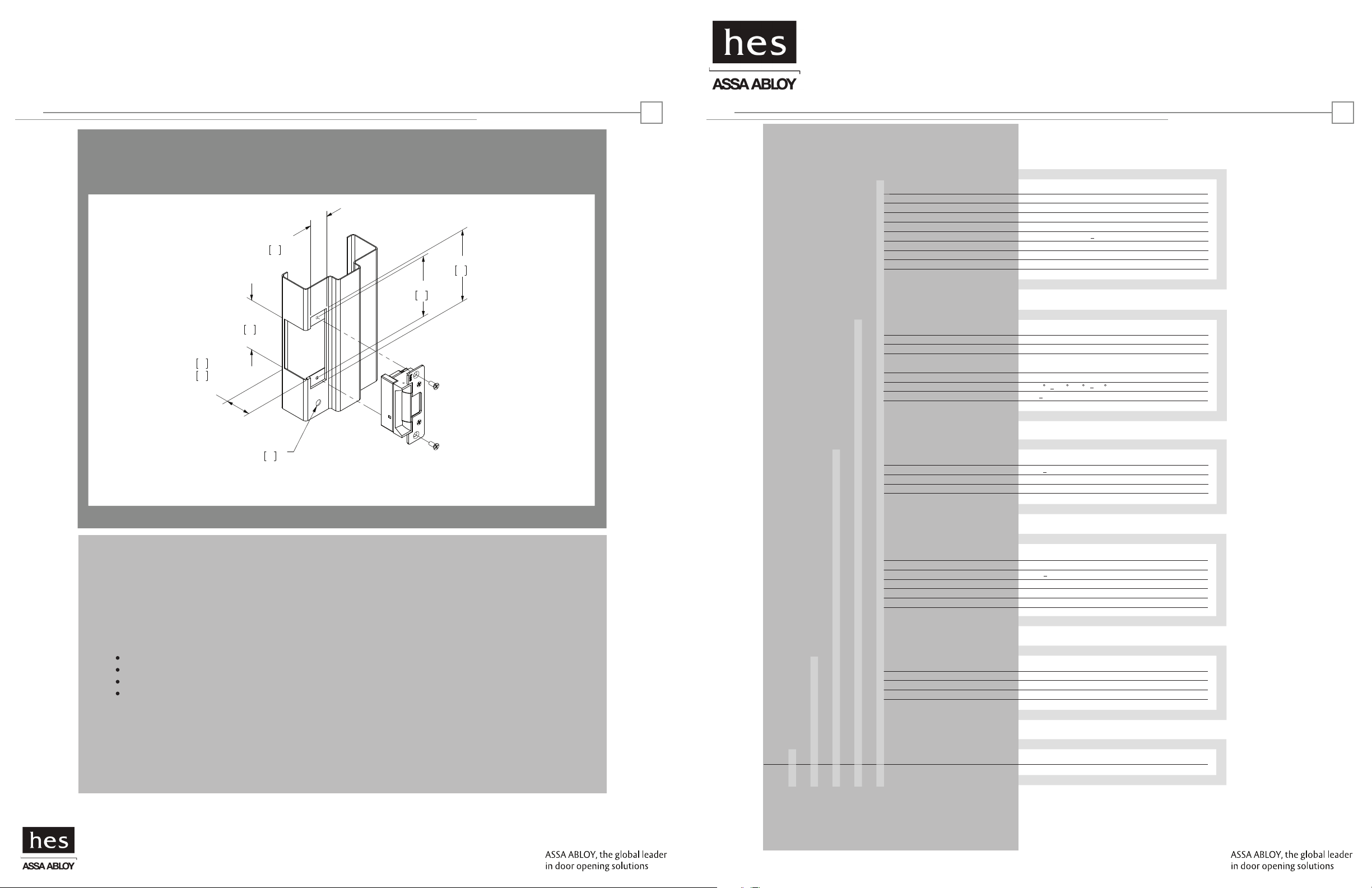

Product

Description

Dimensions

Orientation

Compatibility

Access Control Systems

Proximity Cards

Frequency

Indicators

Supervision

Integrated Electric Strike and Proximity Card Reader

See page 4

Non-handed, Reversible

Open Architecture

Interfaces with Wiegand Protocol Systems

Supports HID 26 39 Bit Formats

Supports HID 125 KHz Credentials

Red/Green LED and Buzzer

Door Position Switch and Latchbolt Monitor

Applications

Frames

Trim Enhancer

Locks

Latchbolts Released*

Environment

Temperature

Humidity

Steel, Aluminum, Wood

Included

Cylindrical

RF5010: Accomodates up to 5/8" Latchbolt

RF5210: Accomodates up to 3/4" Latchbolt

Not Recommended for Outdoor use

32 F 150 F (0 C 65 C)

5 95%, Non-condensing

Electrical

Reader Module

Operating Voltage 10 14VDC

Operating Current 125 mA Max. at 12VDC

Electric Strike Module 250mA @12VDC

Warning: Changes or modification to this device not expressly approved by HES, Inc. could void the user’s authority to

operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a class [B] digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help

This class [B] digital apparatus meets all requirements of the Canadian interference Causing Equipment Regulations.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

Cet appareillage numérique de la classe [B] répond à toutes les exigences de l’inerférencé canadienne causant des

réglements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui

peut causer l’opération peu désirée.

0000000000.002 rev A

®

© 2007 HES, Inc.

Cable Detail

Reader Module

Distance to Host

Recommended Type

Electric Strike Module

Distance to Power

Recommended Type

Certifications

Compliance

Security

Warranty

*

Faceplate options accommodate

various keeper and latchbolt

actions. For more detail, contact

HES tech support

at 800-626-7590

HID is a registered trademark of HID Corporation.

500 ft. Max.

18 22 AWG (Dependent on Distance) Stranded and Shielded

See Page 3

See Page 3

FCC Part 15 (USA and Canada)

UL 1034, Burglary-Resistant Listed

ANSI/BHMA 156.31, Grade 1

MEA New York City Accepted

Lifetime Waranty

Page 3

Product Components

Installation Directions

RF5010 and RF5210: OUTSWING VERSION RF5010 and RF5210: OUTSWING VERSION

1

Hybrid Electric Strike

2

Pigtail Connectors (8 pin and 4 pin)

3

Faceplate (sold separately)

4

#12-24 Mounting Screws (included with faceplate)

5

#8-32 Faceplate Screws (included with faceplate)

8

6

Trim Enhancer (optional)

7

Trim Enhancer Screws

8

Door Position Switch, Press-Fit Magnet

and 10” Connector Cable (2 pin)

1

Access Control System

Control Panel and Power Supply

(By others)

2

2

3

CAUTION! Before connecting any device at the installation site, verify that there is 12VDC input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage outside the electrical

specifications outlined on page 1 may cause severe damage to the unit and will void the warranty.

Prepare Frame

1. Prepare door jamb for hybrid electric strike per the appropriate template detail (see page 4). Be sure to allow enough

Finishing Installing

8. Attach the faceplate to the hybrid electric strike, using the

#8-32 screws provided.

room behind the strike in the cutout to avoid pinching any

wires.

9. Install the trim enhancer on the hybrid electric strike (if

needed to cover any extra space).

2. Drill a 3/8” hole for the door position switch per the appropriate template detail (see page 4). Note that the door position

switch may be positioned as desired, within limits of its 10”

10. Install the hybrid electric strike in jamb cutout, using

#12-24 screws provided (or wood screws where necessary).

connector. Next, drill a matching 3/8” hole in the door and

install the press-fit magnet so that it comes into contact with

the door position switch.

11. Tighten the #10-32 screws holding the mounting tabs

(when applicable).

3. Install mounting tabs (sold separately as P/N 152) when

applicable, using #10-32 screws.

Testing and Operation

6

Wiring Diagram

8 Pin Connector (Reader Module)

Red (+) Board Power 10 - 14 VDC

Black ( ) Board Power

Green Data 0

White Data 1

Yellow LED/Buzzer

Blue Not Used

Orange Not Used

Brown Not Used

- -

12. When power is supplied to the hybrid electric strike, the

7

3

Connect Components and Wiring

4. Check that the wires running from the host control panel

and/or power supply are correct for the components and

distance (see Wiring Diagram on page 2 and Wire Gauge

4

Diagram below). Connect the two pigtails provided (8 pin and

4 pin) to these wires. Note that a linear power supply is

recommended.

5. Connect and mount the door position switch, routing its 10”

cable from the door position switch to the hybrid electric

strike.

5

6. Plug the loose end of the door position switch cable into the

2 pin connector on the bottom of the hybrid electric strike.

LED should flash green three times, while the beeper simulta-

neously beeps. The LED should then turn red. This sequence

indicates that the micro-controller is operating properly.

13. Present a Proximity ID card to the reader/antenna. The LED

will turn green, while the beeper beeps once. This indicates

that the card was read successfully.

14. Simultaneously, the keeper should click open. This

indicates that communication between the host and the

hybrid electric strike is operational.

15. For further testing of communication with the host, consult

the manual for the host control panel or the site’s system

administrator.

7. Connect the wire bundle on the side of the hybrid electric

strike to the pigtails/wire back to the host control panel. Check

4 Pin Connector (Strike Module)

Gray (+) Strike Power 12 VDC

Violet ( ) Strike Power

Tan Common

Pink Door Closed and Latch Engaged

any pertinent information from the access control system

installation guide or manual.

2 Pin Connector (Door Position Switch)

Wire plugs into Hybrid Electric Strike

Wire Gauge Diagram

12VDC @ 250 mA

Max. One-way Distance Voltage Drop/100’ Recommended AWG

800’

500’

300’

200’

120’

100’ or less

0.16

0.25

0.40

0.64

1.01

1.6

12 Gauge

14 Gauge

16 Gauge

18 Gauge

20 Gauge

22 Gauge

Page 4

Cutout Template

Installation Instructions

®

RF5010 and RF5210

HYBRID ELECTRIC STRIKES: INSWING VERSIONHYBRID ELECTRIC STRIKES: INSWING VERSION

HES, Inc.

22630 N. 17th Ave.

Phoenix, AZ 85027

800-626-7590

14

5/8"

17

RF5000 or RF5200 with 501 Faceplate

RF5000 or RF5200 with 501 Faceplate

RF5010 or RF5210 with 501 Faceplate

1-1/4” x 4-7/8” Square Corner Faceplate

1-1/4” x 4-7/8” Square Corner Faceplate

1-1/4” x 4-7/8” Square Corner Faceplate

ANSI Metal Jamb Installation

ANSI Metal Jamb Installation

ANSI Metal Jamb Installation

1-1/4"

32

1-5/16"

33

3 -3/8"

86

RF5010: 11/16"

RF5210: 13/16"

1"

25

17

21

3/8"

10

4-1/8"

105

4- 7/8"

124

Inswing Version

Product

Description

Dimensions

Orientation

Compatibility

Access Control Systems

Proximity Cards

Frequency

Indicators

Supervision

Electric Strike and Proximity Card Reader with

Antenna Module Mounted Separately in Frame

See page 4

Non handed, Reversible

Open Architecture

Interfaces with Wiegand Protocol Systems

Supports HID 26 39 Bit Formats

Supports HID 125 KHz Credentials

Red/Green LED and Buzzer

Door Position Switch and Latchbolt Monitor

Applications

Frames

Trim Enhancer

Locks

Latchbolts Released*

Environment

Temperature

Humidity

Steel, Aluminum, Wood

Included

Cylindrical

RF5010: Accomodates up to 5/8" Latchbolt

RF5210: Accomodates up to 3/4" Latchbolt

Suitable for Exterior Doors

32 F 150 F (0 C 65 C)

5 95%, Non-condensing

Electrical

Reader Module

Operating Voltage 10 14VDC

Operating Current 125 mA Max. at 12VDC

Electric Strike Module 250mA @12VDC

Reader/Antenna Door Position Switch Hybrid Electric Strike

Warning: Changes or modification to this device not expressly approved by HES, Inc. could void the user’s authority to

operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a class [B] digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help

This class [B] digital apparatus meets all requirements of the Canadian interference Causing Equipment Regulations.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

Cet appareillage numérique de la classe [B] répond à toutes les exigences de l’inerférencé canadienne causant des

réglements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui

peut causer l’opération peu désirée.

0000000000.001 rev A

®

© 2007 HES, Inc.

Cable detail

Reader Module

Distance to Host

Recommended Type

Electric Strike Module

Distance to Power

Recommended Type

Certifications

Compliance

Security

Warranty

*

Faceplate options accommodate

various keeper and latchbolt

actions. For more detail, contact

HES tech support

at 800-626-7590

HID is a registered trademark of HID Corporation.

500 ft. Max.

18 22 AWG (Dependent on Distance) Stranded and Shielded

See Page 3

See Page 3

FCC Part 15 (USA and Canada)

UL 1034, Burglary-Resistant Listed

ANSI/BHMA 156.31, Grade 1

MEA New York City Accepted

Lifetime Waranty

Page 5

Product Components

Installation Directions

RF5010 and RF5210: INSWING VERSION RF5010 and RF5210: INSWING VERSION

1

Hybrid Electric Strike

2

Pigtail Connectors (8 pin and 4 pin)

3

Faceplate (sold separately)

4

#12-24 Mounting Screws (included with faceplate)

5

#8-32 Faceplate Screws (included with faceplate)

6

24” Cable (connecting reader/antenna and strike)

11

10

9

Wiring Diagram

8 Pin Connector (Reader Module)

Red (+) Board Power 10 -14 VDC

Black ( ) Board Power

Green Data 0

White Data 1

Yellow LED/Buzzer

Blue Not Used

Orange Not Used

Brown Not Used

- -

7

Reader/Antenna Body

8

#6-32 Reader/Antenna Screws

9

Reader/Antenna Cover

10

Trim Enhancer (optional)

11

Trim Enhancer Screws

12

Door Position Switch, Press-Fit Magnet

and 10” Connector Cable (2 Pin)

12

6

7

8

4 Pin Connector (Strike Module)

Gray (+) Strike Power

Violet ( ) Strike Power 12 VDC

Tan Common

Pink Door Closed and Latch Engaged

1

2

3

4

5

2 Pin Connector (Door Position Switch)

Wire plugs into Hybrid Electric Strike

Access Control System

Control Panel and Power Supply

(By others)

2

3

CAUTION! Before connecting any device at the installation site, verify that there is 12VDC input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage outside the electrical

specifications outlined on page 1 may cause severe damage to the unit and will void the warranty.

Prepare Frame

1. Prepare door jamb for hybrid electric strike per the appropriate template detail (see page 4). Be sure to allow enough

Finishing Installing

11. Attach the faceplate to the hybrid electric strike, using the

#8-32 screws provided.

room behind the strike in the cutout to avoid pinching any

wires.

12. Install the trim enhancer on the hybrid electric strike (if

needed to cover any extra space).

2. Drill a 1” diameter hole for reader/antenna per the appropriate template detail (see page 4). Note that the reader/antenna

may be positioned as desired, within limits of the 24”cable.

3. Drill a 3/8” hole for the door position switch per the appropriate template detail (see page 4). Note that the door position

13. Install the hybrid electric strike unit in jamb cutout, using

#12-24 screws provided (or wood screws where necessary).

14. Tighten the #10-32 screws holding the mounting tabs

(when applicable).

switch may be positioned as desired, within limits of its 10”

connector. Next, drill a matching 3/8” hole in the door and

install the press-fit magnet so that it comes into contact with

the door position switch.

4. Install mounting tabs (sold separately as P/N 152) when

applicable, using #10-32 screws.

Testing and Operation

15. When power is supplied to the hybrid electric strike, the

LED should flash green three times, while the beeper simulta-

neously beeps. The LED should then turn red. This sequence

indicates that the micro-controller is operating properly.

Connect Components and Wiring

16. Present a Proximity ID card to the reader/antenna. The LED

will turn green, while the beeper beeps once. This indicates

5. Check that the wires running from the host control panel

that the card was read successfully.

and/or power supply are correct for the components and

distance (see Wiring Diagram on page 2 and Wire Gauge

Diagram below). Connect the two pigtails provided (8 pin and

4 pin) to these wires. Note that a linear power supply is

17. Simultaneously, the keeper should click open. This

indicates that communication between the host and the

hybrid electric strike is operational.

recommended.

18. For further testing of communication with the host, consult

6. Connect and mount the door position switch, routing its 10”

cable from the door position switch to the hybrid electric

the manual for the host control panel or the site’s system

administrator.

strike.

7. Plug the loose end of the door position switch cable into the

2 pin connector on the bottom of the hybrid electric strike.

Wire Gauge Diagram

8. Connect the 24” cable to the reader/antenna (check labels to

insure that you connect the correct end). Then, install the

reader/antenna in the frame, using the #6-32 screws provided.

Snap on the reader/antenna cover and pull the 24”cable

through to the hybrid electric strike.

9. Plug the loose end of the 24” cable into the 7 pin connector

on the side of the hybrid electric strike.

10. Connect the wire bundle on the top of the hybrid electric

strike to the pigtails/wire back to the host control panel. Check

Max. One-way Distance Voltage Drop/100’ Recommended AWG

800’

500’

300’

200’

120’

100’ or less

12VDC @ 250 mA

0.16

0.25

0.40

0.64

1.01

1.6

12 Gauge

14 Gauge

16 Gauge

18 Gauge

20 Gauge

22 Gauge

any pertinent information from the access control system

installation guide or manual.

Loading...

Loading...