Hanbell RC2-100AF, RC2-140AF, RC2-200AF, RC2-230AF, RC2-260AF Series Manual

...

0

CONTENTS

1. Compressor’s characteristics ............................................................................................................................. 2

2. Compressor specification .................................................................................................................................... 3

2.1 Design specification .................................................................................................................................... 3

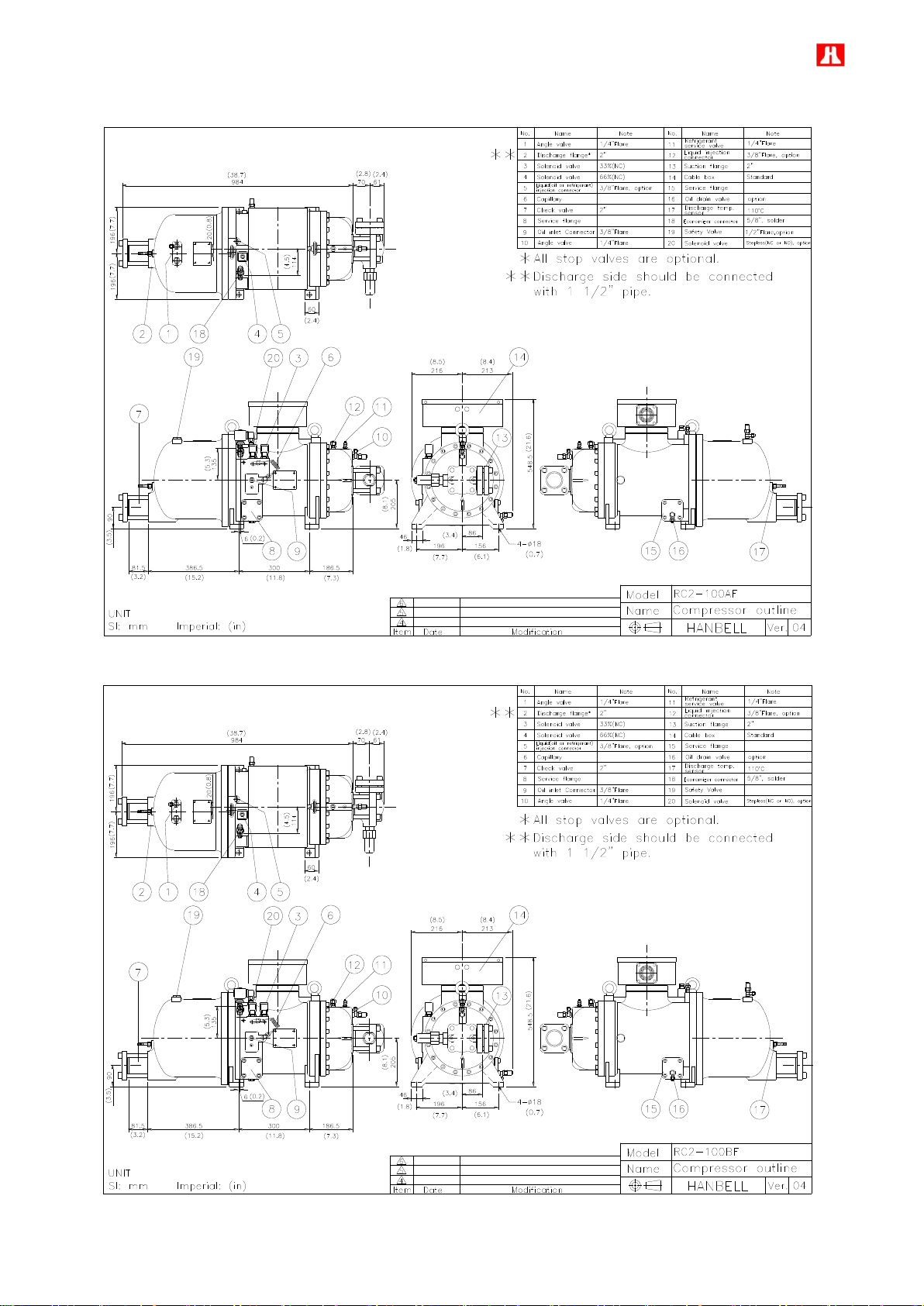

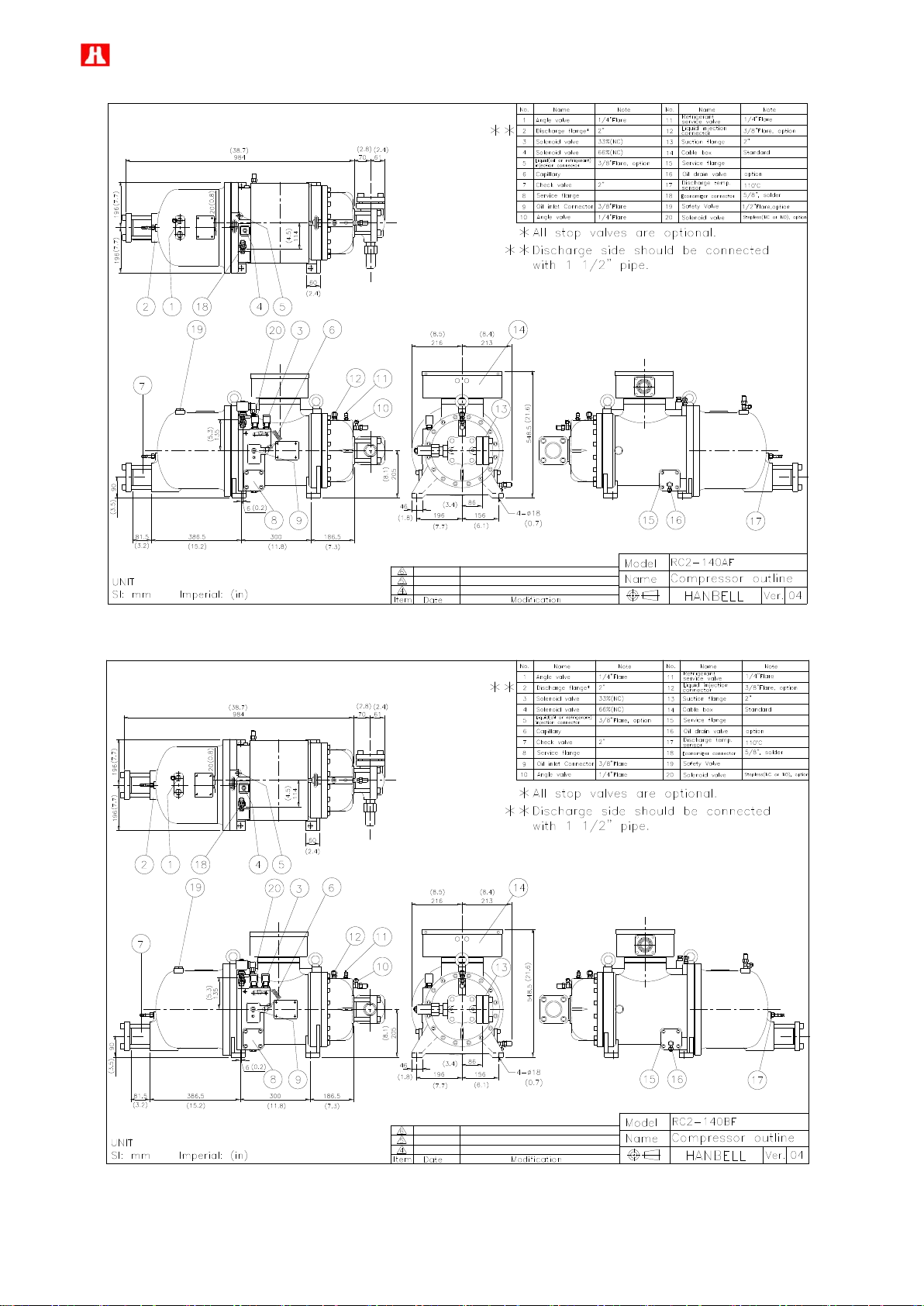

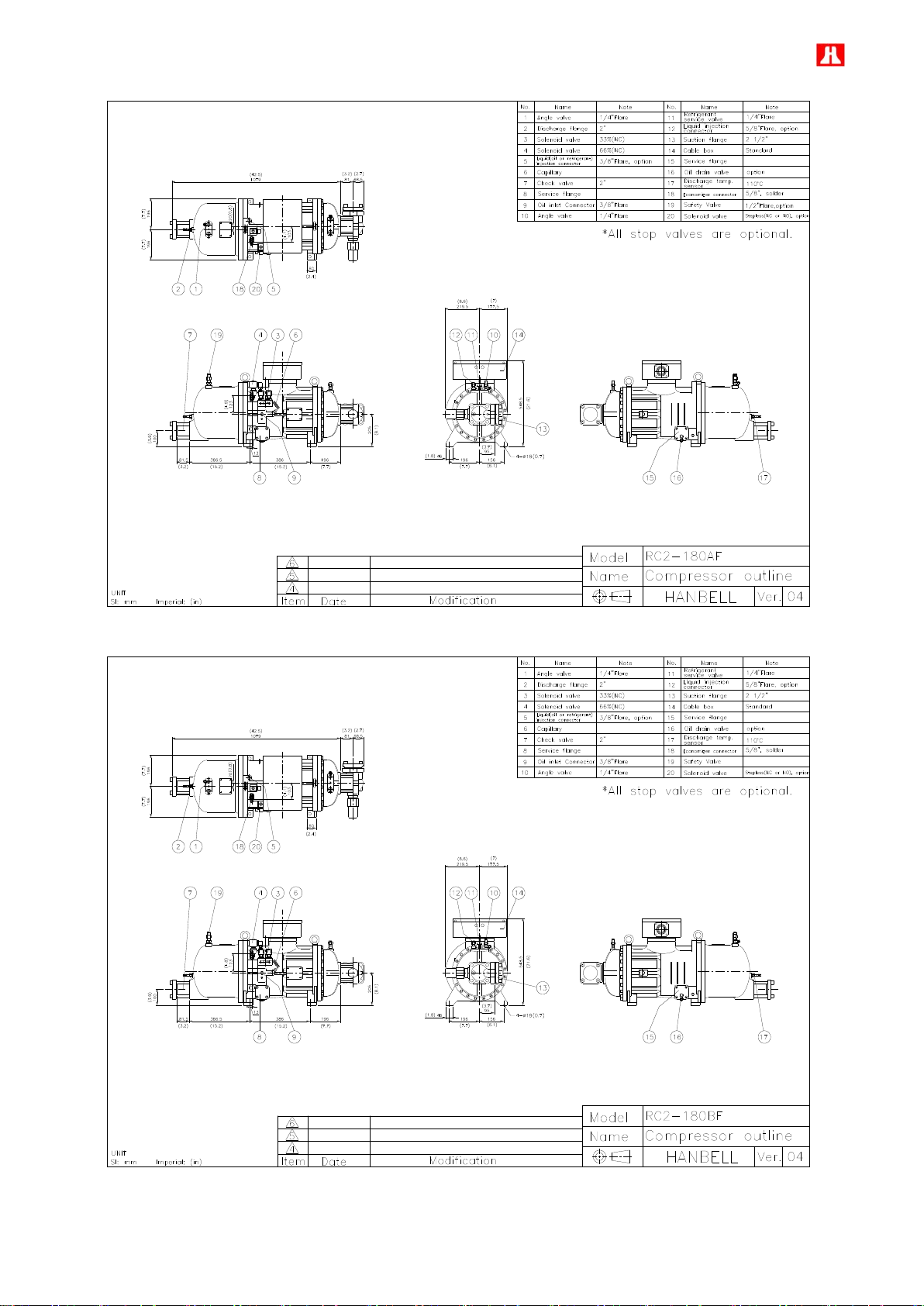

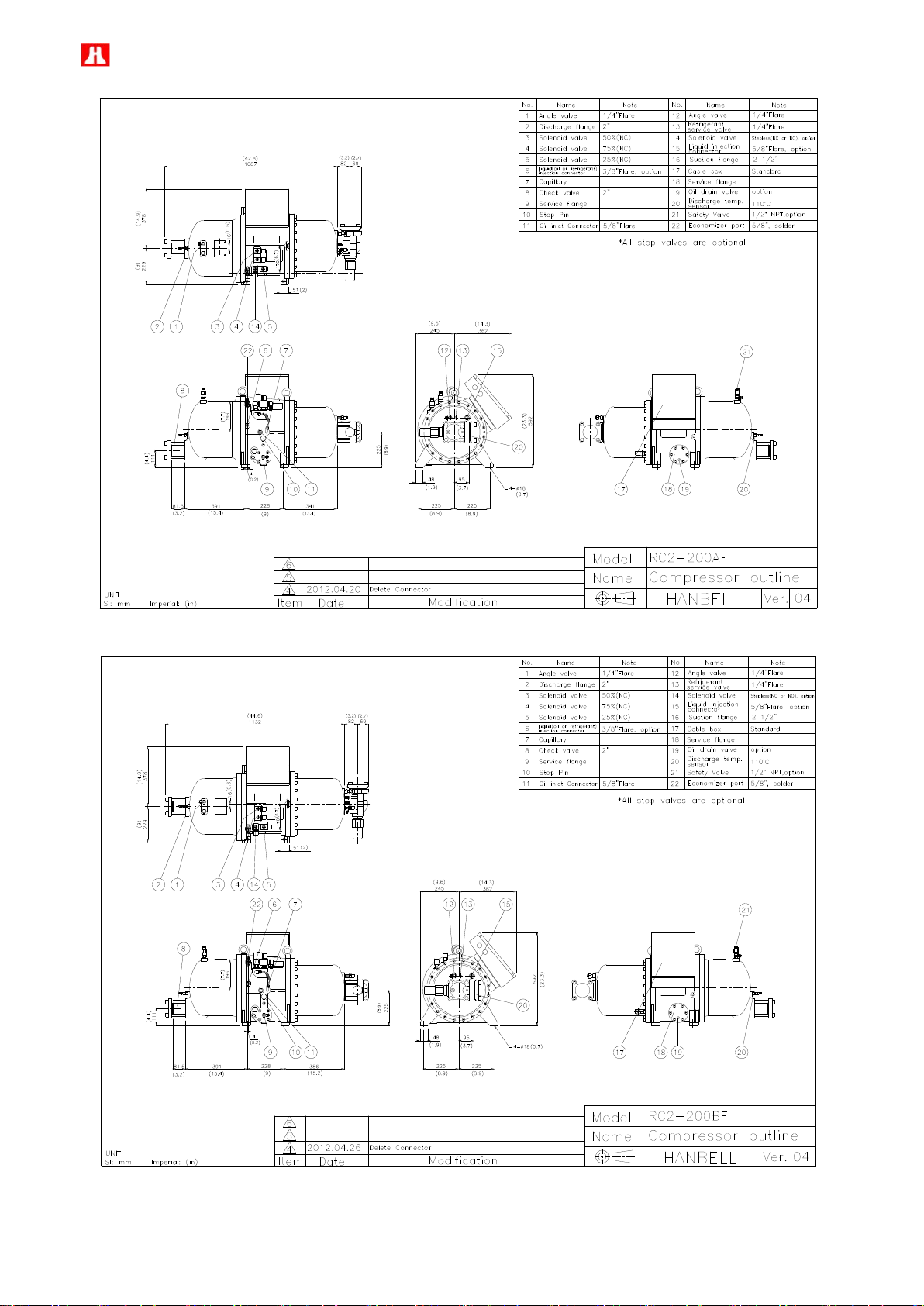

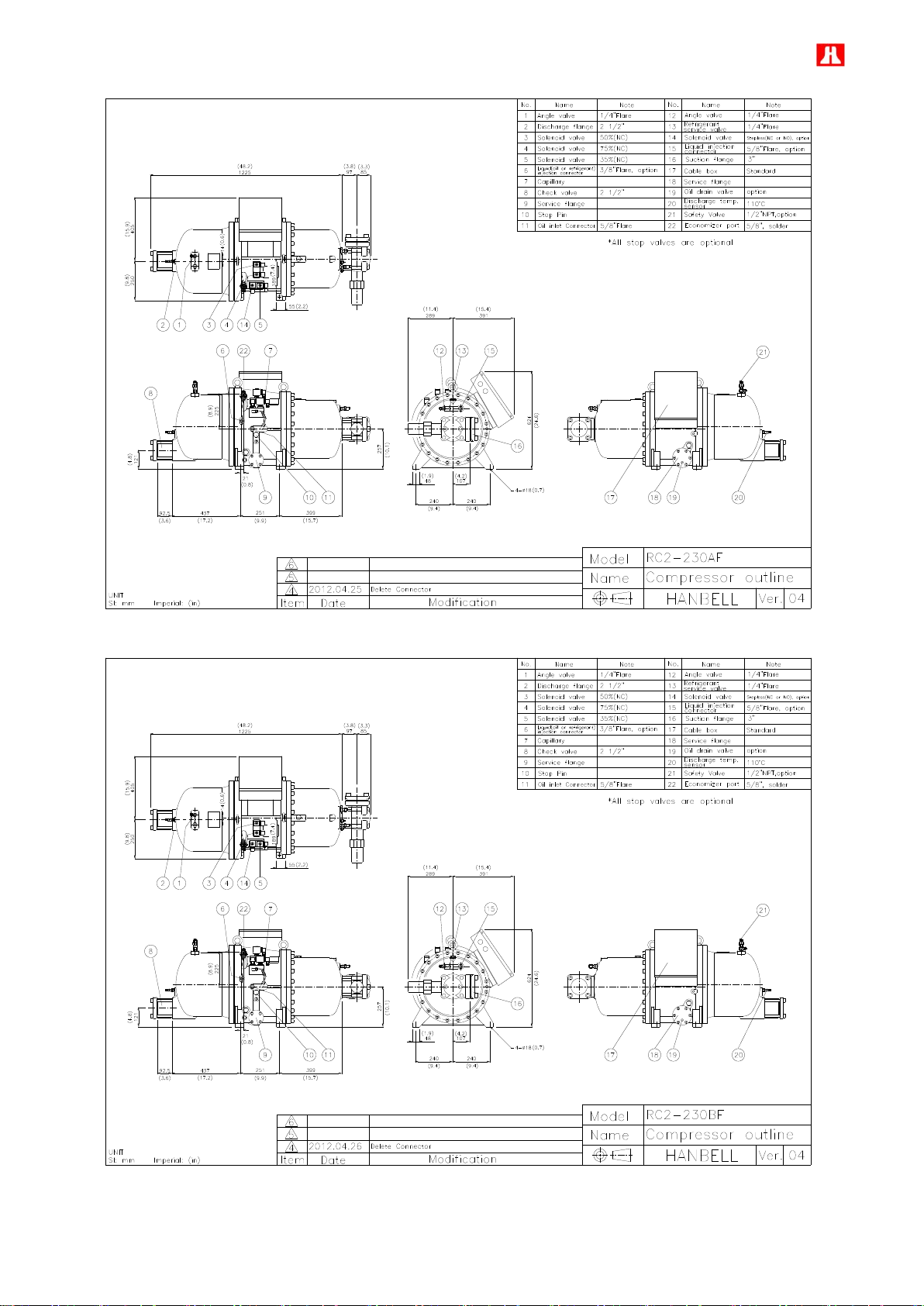

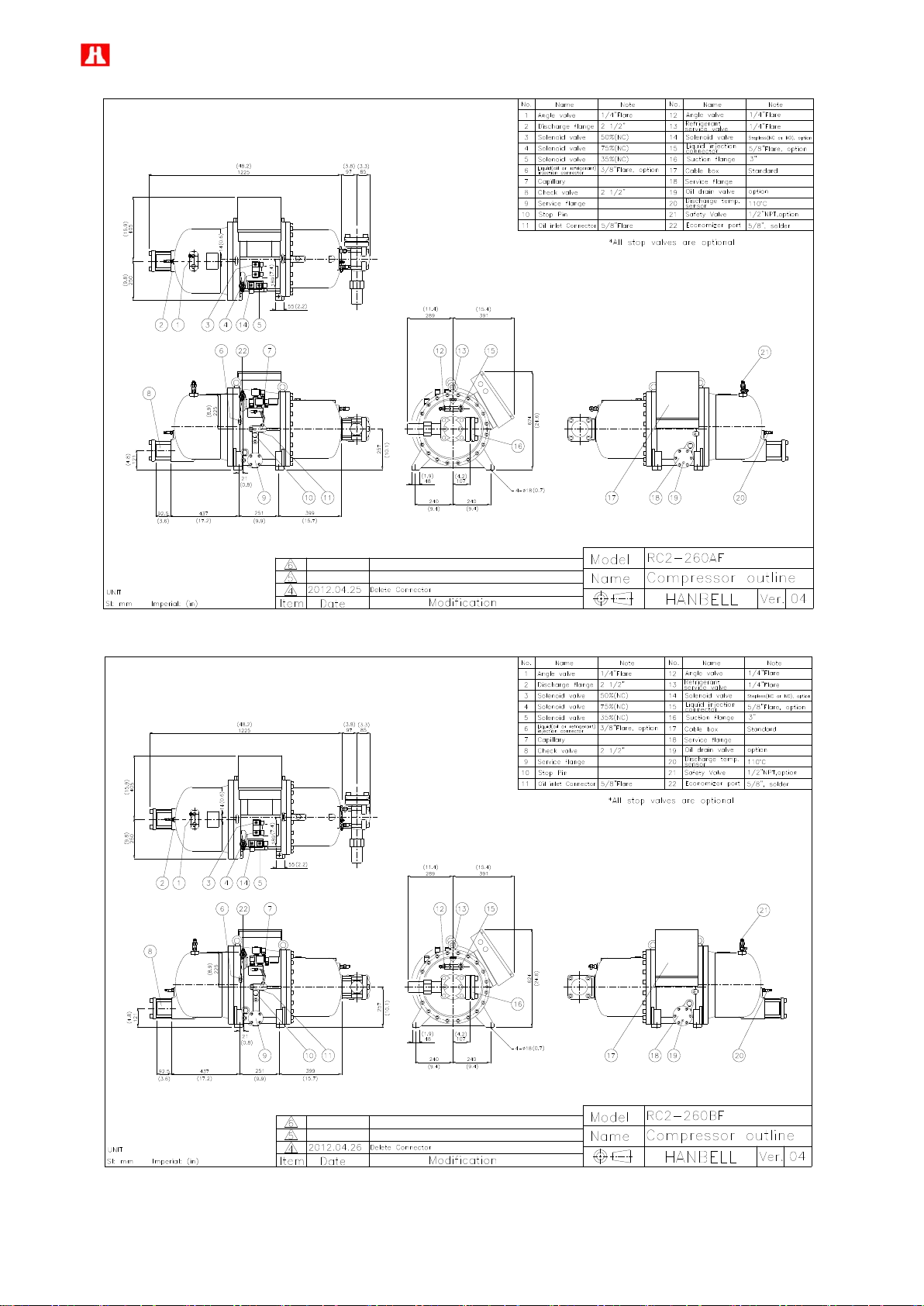

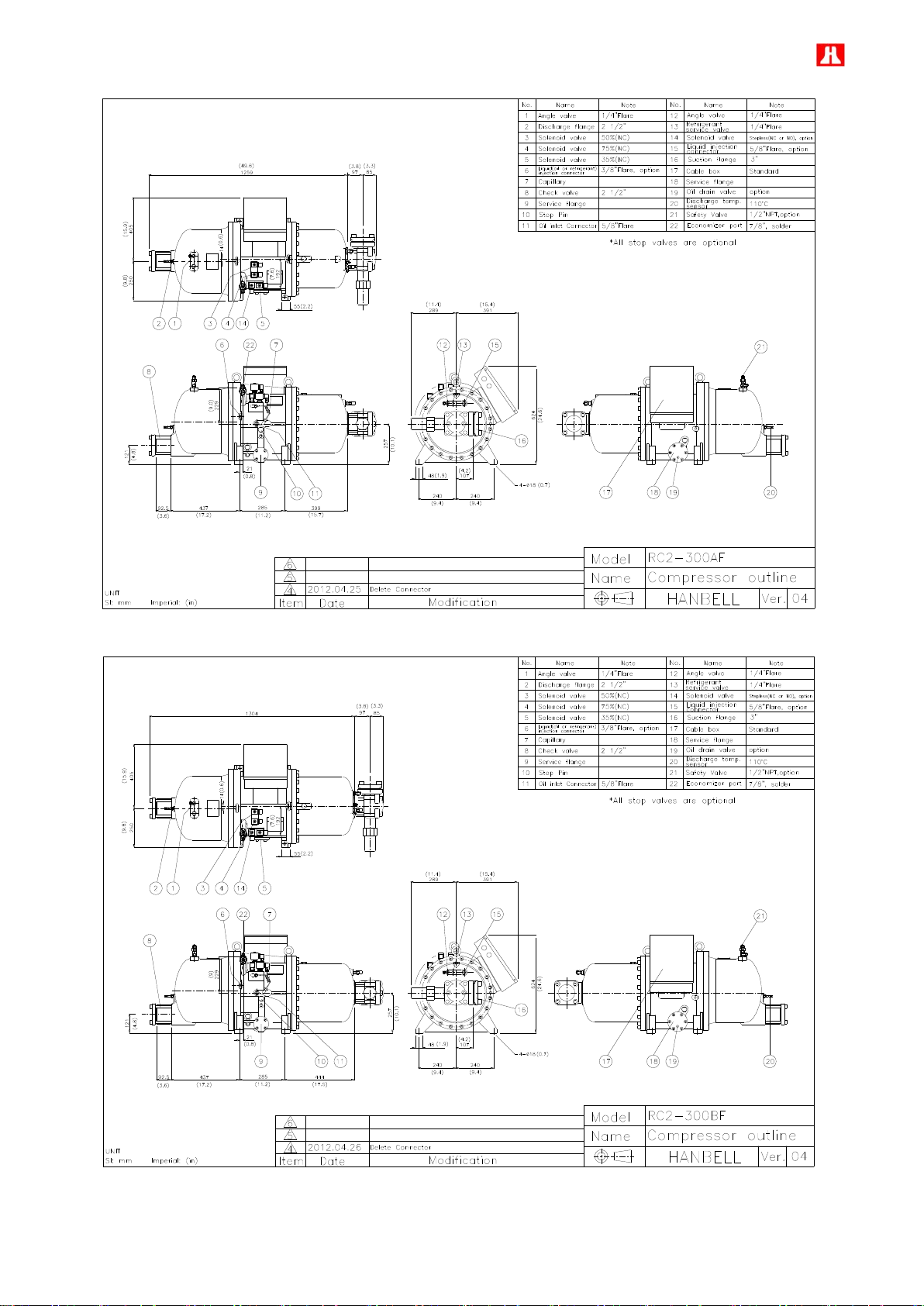

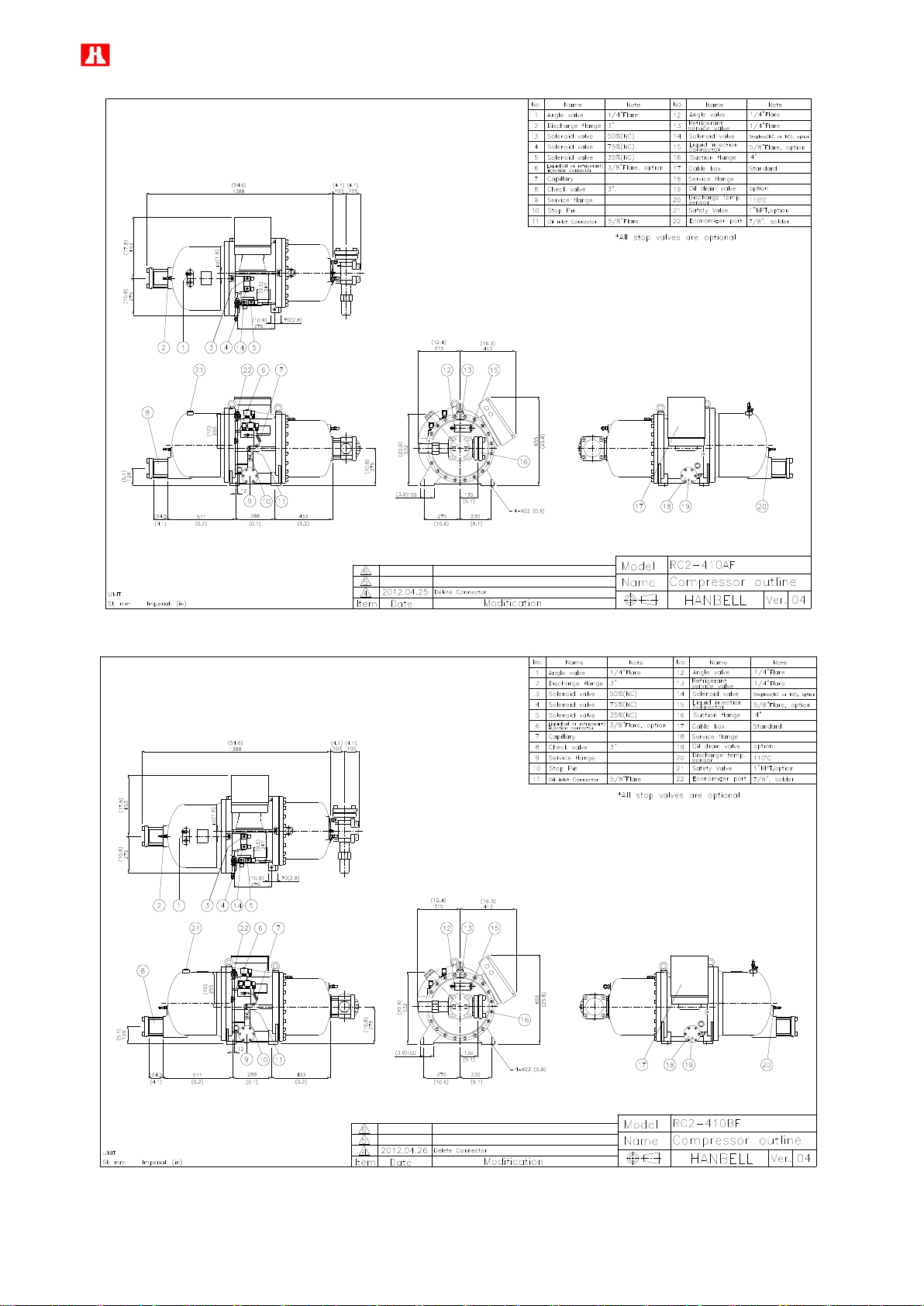

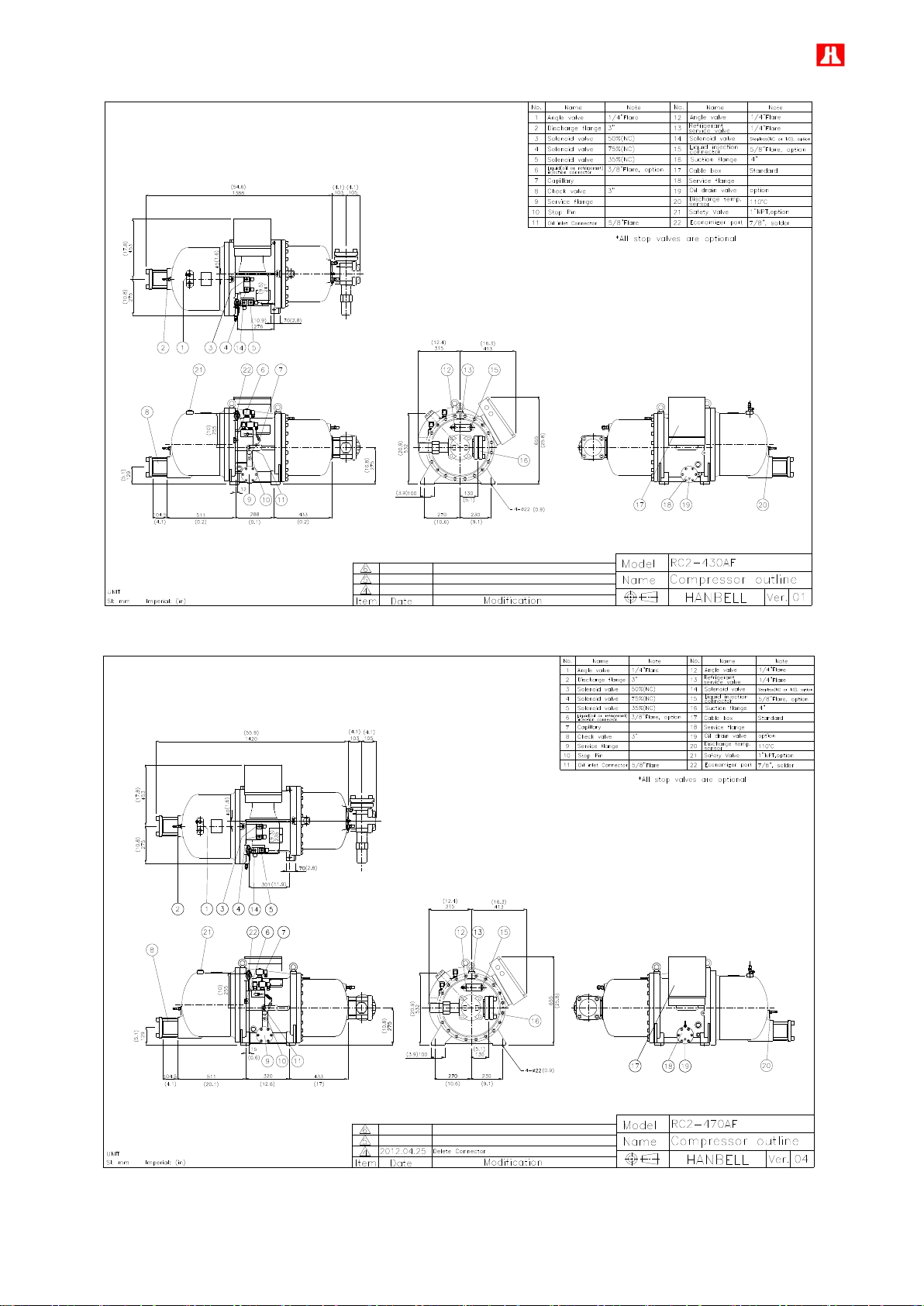

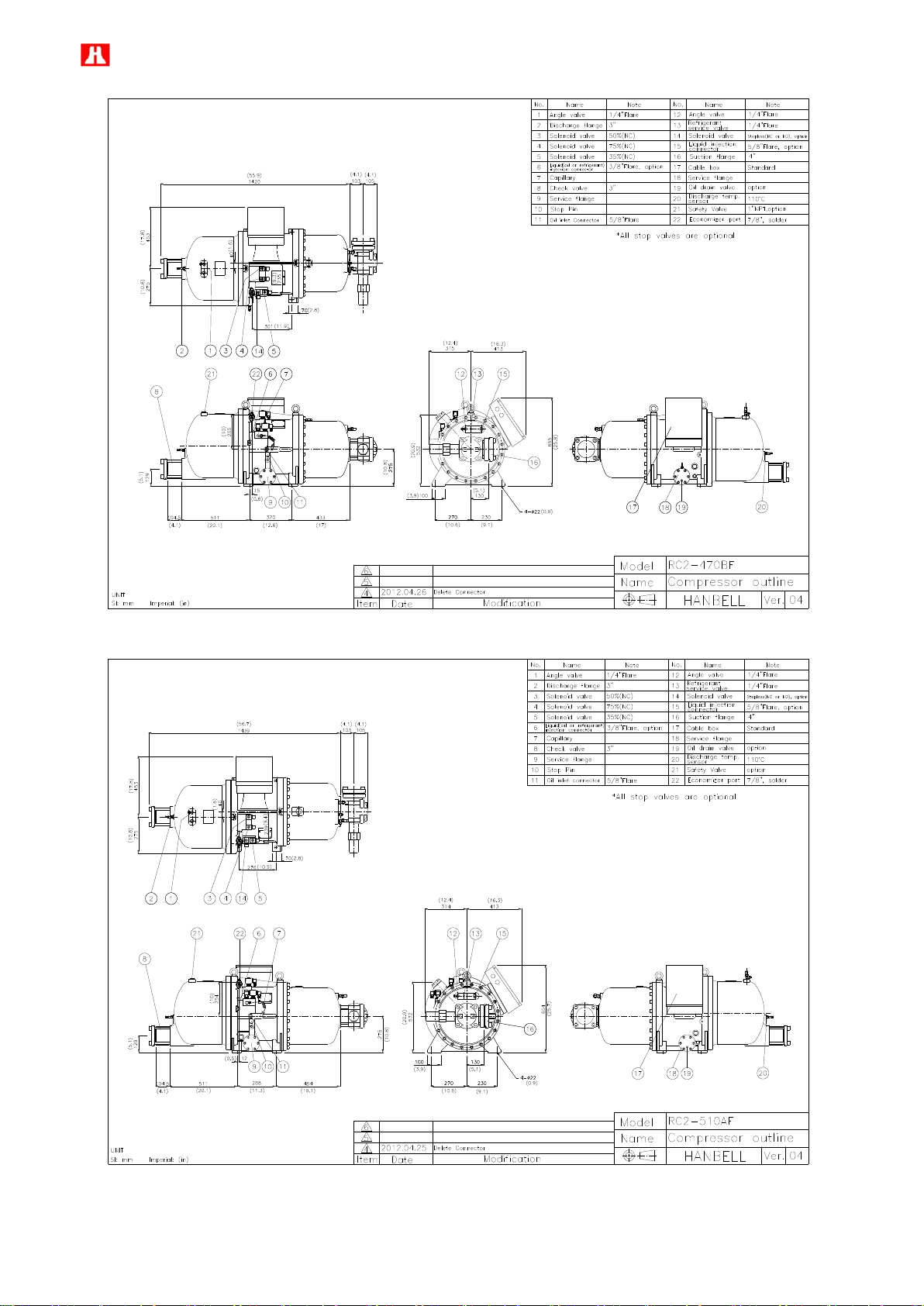

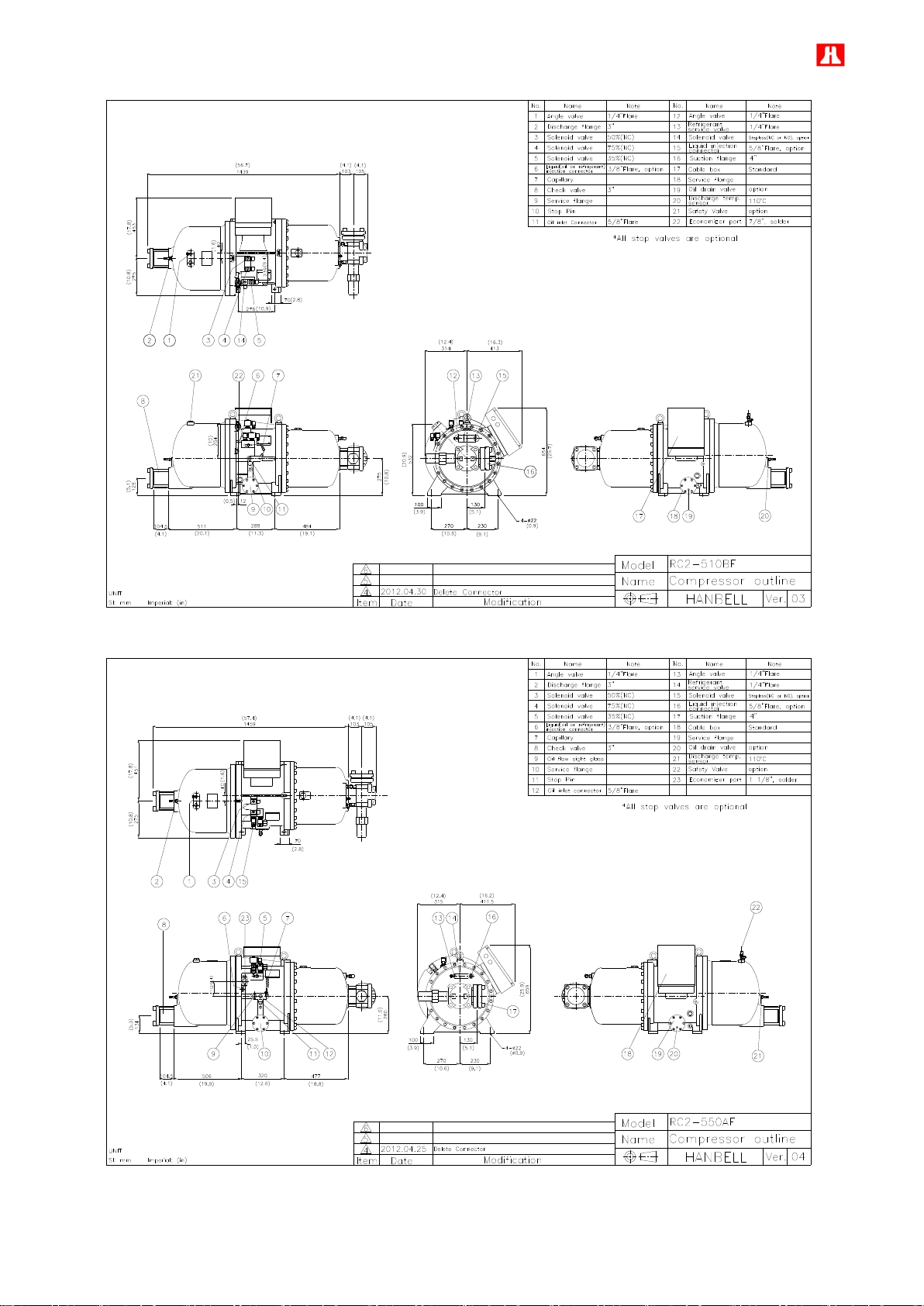

2.2 Compressor outline ..................................................................................................................................... 5

2.3 Compressor construction ......................................................................................................................... 28

2.4 Capacity control system ........................................................................................................................... 30

2.5 Compressor application limits ................................................................................................................. 33

2.6 Compressor design feature ...................................................................................................................... 35

2.7 MCC and LRA ............................................................................................................................................. 37

3. Compressor handling and Installation ............................................................................................................. 41

3.1 Compressor handling ............................................................................................................................... 41

3.2 Mounting the compressor ........................................................................................................................ 41

4. Lubricant .............................................................................................................................................................. 64

4.1 Pre-cautions in changing of oil ................................................................................................................ 64

4.2 Changing of oil .......................................................................................................................................... 65

4.3 Lubricants table ......................................................................................................................................... 66

5. Electrical data and design ................................................................................................................................. 67

5.1 Motor design .............................................................................................................................................. 67

5.2 Compressor protection devices .............................................................................................................. 69

5.3 Power supply ............................................................................................................................................. 69

5.4 Selection of magnetic contactor .............................................................................................................. 71

5.5 Grounding .................................................................................................................................................. 71

6. Compressors accessories ................................................................................................................................. 72

6.1 Compressors standard and optional accessories ................................................................................. 72

6.2 Description of accessories ....................................................................................................................... 73

7. Operation and trouble shooting ........................................................................................................................ 87

7.1 Compressor start-up ................................................................................................................................. 87

7.2 System adjustment .................................................................................................................................... 89

7.3 Compressor stop ....................................................................................................................................... 91

7.4 Troubleshooting ........................................................................................................................................ 92

7.5 Compressor checking list......................................................................................................................... 95

8. System applications ........................................................................................................................................... 96

8.1 General application ................................................................................................................................... 96

8.2 Economizer application .......................................................................................................................... 109

8.3 Important notice to compressor application ........................................................................................ 112

8.4 Example of installation ........................................................................................................................... 113

Appendix 1. Compressor noise level .................................................................................................................. 116

1

Introduction

The Hanbell RC2-F series semi-hermetic twin-screw compressor inherits all the quality and experience of our

RC2 series compressor. The RC2-F series compressor is developed especially for application with Freon in

flooded system or refrigeration field. With a built-in high operating load design and advanced 5 to 6 Patented

Screw Rotor Profile, each compressor has high efficiency and reliability in all operating condition. Each unit is

carefully manufactured and inspected by high precision THREAD SCREW ROTOR GRINDING MACHINE, CNC

MACHINING CENTER, and 3-D COORDINATE MEASURING MACHINE. Each compressor at HANBELL also

follows the ISO 9001 certification quality system which assures the best quality control and production process to

customers. RC2-F series compressor has 27 models RC2-100~RC2-1530, with displacement (50/60Hz) from 98

/ 1 18 m3/hr to 1539 / 1847 m3/hr.

The RC2-F series compressors use high quality bearings which resulted in longer bearing life compare to

competitors. These bearings provide strong support to screw rotors especially for the heavy duty application.

Oil/Refrigerant injection port can be utilized when external cooling is needed at chamber. This can keep the

compression chamber at proper discharge temperature and ensures sufficient oil viscosity for moving parts

lubrication. Economizer port can be used to reach higher cooling capacity and working efficiency especially at high

pressure ratio working condition or at very low evaporating temperature. All these new designs guarantee that the

compressor has the best reliability, longest bearing life and easiest regular maintenance work.

This Technical Manual contains all basic information about dimensions, handling, installation, operation, trouble

shooting, and system application. It is highly recommended that the content of this manual should be read carefully

prior to handling, installing, and operating the RC2-F compressor in order to prevent any unwanted damage on it.

For any technical issue related to RC2-F series compressor, please contact HANBELL or local distributors/agents

for more information and assistance.

2

1. Compressor’s characteristics

1-1 Multi country (Taiwan, China, USA, England) patented high efficiency 5 to 6 asymmetrical rotor profile.

1-2 Precise volume control system

Steps or continuous capacity control system are available.

1-3 Economizer applications

Economizer port is a standard accessory for RC2-F series screw compressor.

Floating type medium pressure (Economizer returned pressure) design, no matter if compressor work at full

load or partial load condition, always can track the best medium pressure value, it means economizer could

develop the maximum efficiency during the operation.

1-4 Applicable with:R-134a, R-407C, R22, R404A, R507A.

1-5 Resistant to high load condition with long life bearing design

1-6 PTC temperature thermistor for the protection of

(1) High motor coil temperature

(2) High discharge temperature

(3) High oil temperature (optional)

1-7 Low vibration and low noise.

1-8 High efficiency oil separator, low-pressure drop, external connection.

3

2. Compressor specification

MODEL

COMPRESSOR

MOTOR

Hydrostatic Pressure

Test

Weight

Displacement 60 /

50Hz

Rated

Speed

VI

Cap. Control (%)

Type

Nominal

Hp

Starting

Voltage (V)

Insulation

Protection

m3/hr

60 / 50Hz

STEP

STEPLESS

60Hz

50Hz

60Hz

50Hz

Kg/cm2G

kg

RC2-100AF

118/98

3550/2950

2.2

2.6

3.0

3.5

4.8

33, 66, 100

33~100

3 Phase, 2 Pole, Squirrel Cage, Induction Motor

23

19

Y-△

PWS

DOL

208

220

230

380

440

460

480

575

380

400

415

Class F

PTC Protection

42

260

RC2-140AF

165/137

33, 66, 100

33~100

32

26

265

RC2-180AF

216/180

33, 66, 100

33~100

42

35

365

RC2-200AF

233/193

25, 50, 75, 100

25~100

45

37

405

RC2-230AF

277/230

35, 50, 75, 100

35~100

53

44

530

RC2-260AF

309/257

25, 50, 75, 100

25~100

59

49

535

RC2-300AF

352/293

25, 50, 75, 100

25~100

67

56

580

RC2-310AF

371/308

35, 50, 75, 100

35~100

71

59

565

RC2-320AF

384/320

25, 50, 75, 100

25~100

72

60

595

RC2-340AF

407/339

35, 50, 75, 100

35~100

77

64

600

RC2-370AF

440/366

35, 50, 75, 100

35~100

84

70

610

RC2-410AF

490/407

25, 50, 75, 100

25~100

93

78

380

440

460

480

575

730

RC2-430AF

512/425

25, 50, 75, 100

25~100

100

84

735

RC2-470AF

567/471

25, 50, 75, 100

25~100

108

90

800

RC2-510AF

611/508

35, 50, 75, 100

35~100

117

98

760

RC2-550AF

660/549

25, 50, 75, 100

25~100

126

105

820

RC2-580AF

702/583

35, 50, 75, 100

35~100

131

109

805

RC2-620AF

745/619

35, 50, 75, 100

35~100

137

114

Y-△

DOL

850

RC2-710AF

858/713

35, 50, 75, 100

35~100

158

131

1050

RC2-790AF

952/791

30, 50, 75, 100

30~100

175

146

1140

RC2-830AF

993/825

30, 50, 75, 100

30~100

183

152

1150

RC2-930AF

1117/929

35, 50, 75, 100

35~100

212

176

1180

RC2-1020AF

1223/1017

25, 50, 75, 100

25~100

227

189

1500

RC2-1130AF

1350/1122

25, 50, 75, 100

25~100

248

206

1520

RC2-1270AF

1521/1268

25, 50, 75, 100

25~100

286

238

2100

RC2-1530AF

1847/1539

25, 50, 75, 100

25~100

331

275

2200

2.1 Design specification

a. RC2-AF

4

MODEL

COMPRESSOR

MOTOR

Hydrostatic

Pressure Test

Weight

Displacement 60 /

50Hz

Rated

Speed

VI

Cap. Control (%)

Type

Nominal

Hp

Starting-Up

Voltage (V)

Insulation

Protection

m3/hr

60 / 50Hz

STEP

STEPLESS

60Hz

50Hz

60Hz

50Hz

Kg/cm2G

kg

RC2-100BF

118/98

3550/2950

2.2

2.6

3.0

3.5

4.8

33, 66, 100

33~100

3 Phase, 2 Pole, Squirrel Cage, Induction Motor

38

31

Y-△

PWS

DOL

208

220

230

380

440

460

480

575

380

400

415

Class F

PTC Protection

42

265

RC2-140BF

165/137

33, 66, 100

33~100

50

41

270

RC2-180BF

216/180

33, 66, 100

33~100

66

55

390

RC2-200BF

233/193

25, 50, 75, 100

25~100

70

58

415

RC2-230AF

277/230

35, 50, 75, 100

35~100

53

44

535

RC2-260BF

309/257

25, 50, 75, 100

25~100

90

75

540

RC2-300BF

352/293

25, 50, 75, 100

25~100

107

89

600

RC2-310BF

371/308

35, 50, 75, 100

35~100

110

91

570

RC2-320BF

384/320

25, 50, 75, 100

25~100

114

94

600

RC2-340BF

407/339

35, 50, 75, 100

35~100

121

101

620

RC2-370BF

440/366

35, 50, 75, 100

35~100

130

108

640

RC2-410BF

490/407

25, 50, 75, 100

25~100

146

121

380

440

460

480

575

740

RC2-470BF

567/471

25, 50, 75, 100

25~100

170

141

810

RC2-510BF

611/508

35, 50, 75, 100

35~100

183

152

780

RC2-550BF

660/549

25, 50, 75, 100

25~100

195

162

850

RC2-580BF

702/583

35, 50, 75, 100

35~100

210

175

840

RC2-620BF

745/619

35, 50, 75, 100

35~100

220

183

Y-△

DOL

880

RC2-710BF

858/713

35, 50, 75, 100

35~100

250

208

1080

RC2-790BF

952/791

30, 50, 75, 100

30~100

276

230

1180

RC2-830BF

993/825

30, 50, 75, 100

30~100

290

234

1215

RC2-930BF

1117/929

35, 50, 75, 100

35~100

334

278

1240

RC2-1020BF

1223/1017

25, 50, 75, 100

25~100

357

297

1540

RC2-1130BF

1350/1122

25, 50, 75, 100

25~100

393

327

1560

RC2-1270BF

1521/1268

25, 50, 75, 100

25~100

471

392

2200

RC2-1530BF

1847/1539

25, 50, 75, 100

25~100

534

443

2300

b. RC2-BF

Nominal Horse Power:

All above Nominal Hp are not equal to the maximum compressors Hp; Please refer to Hanbell selection software’s

output for the rated current, Maximum Continuous Current-M.C.C according to various working condition while

selecting the contactor, cable, fuse and wire, etc…

5

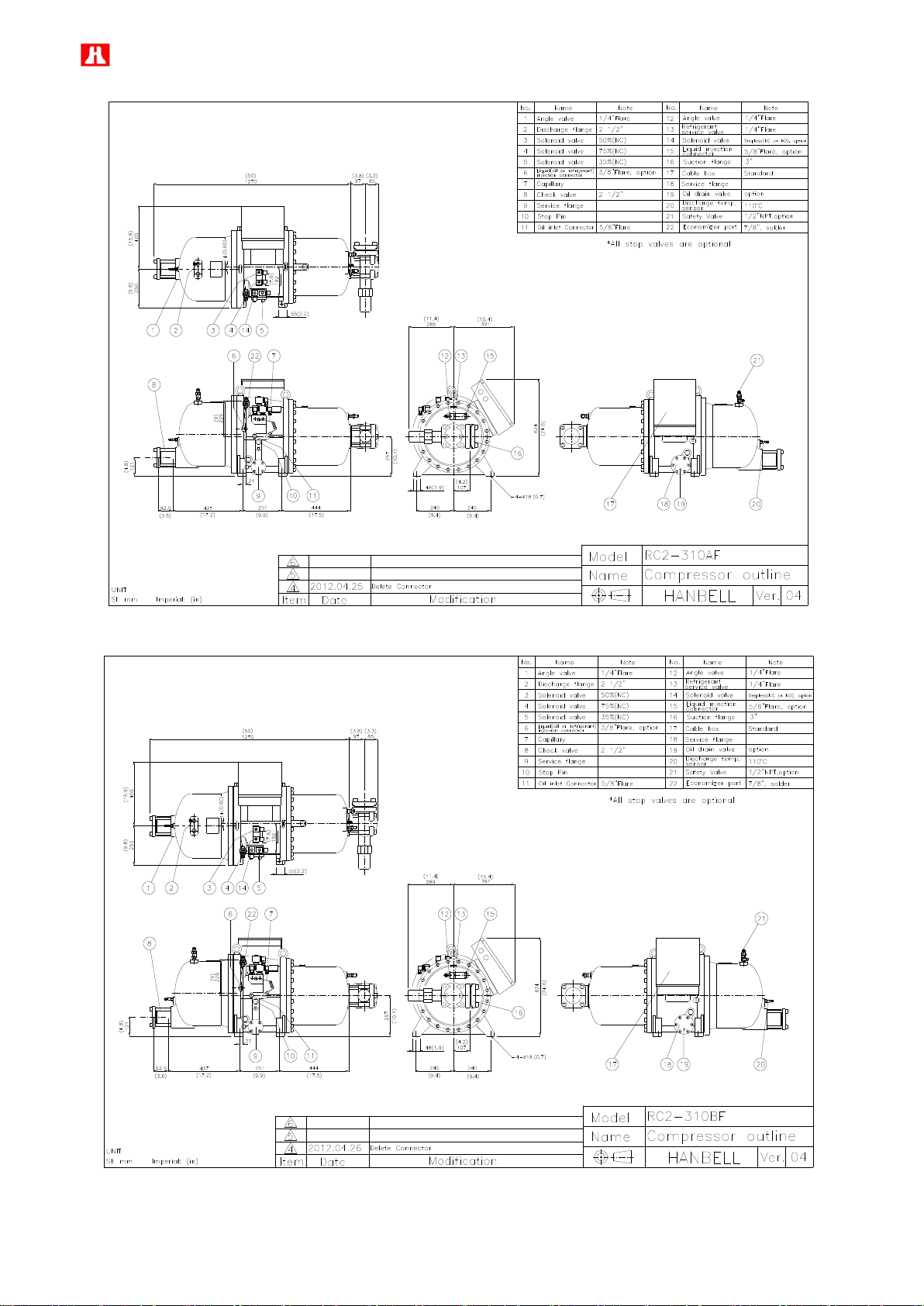

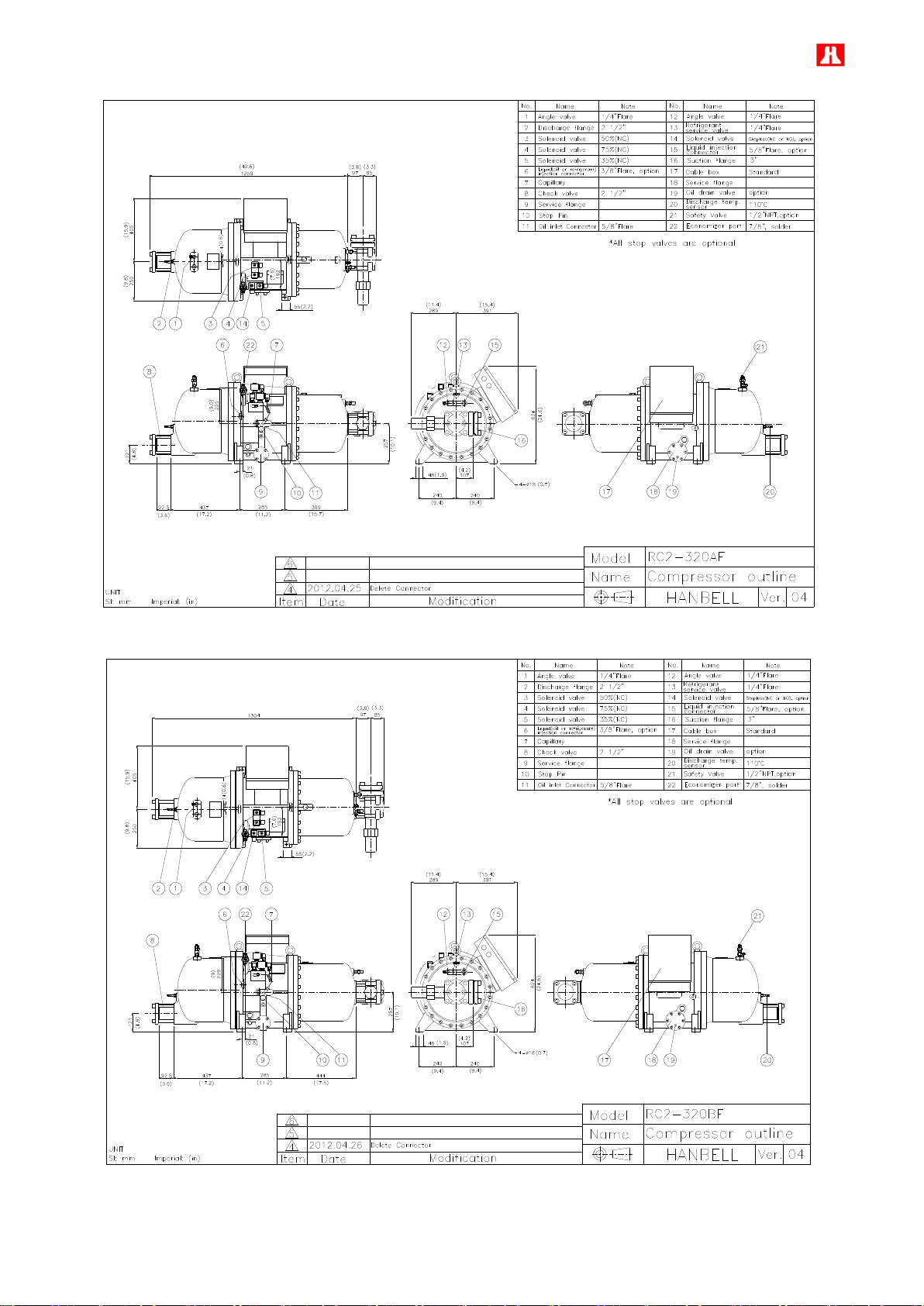

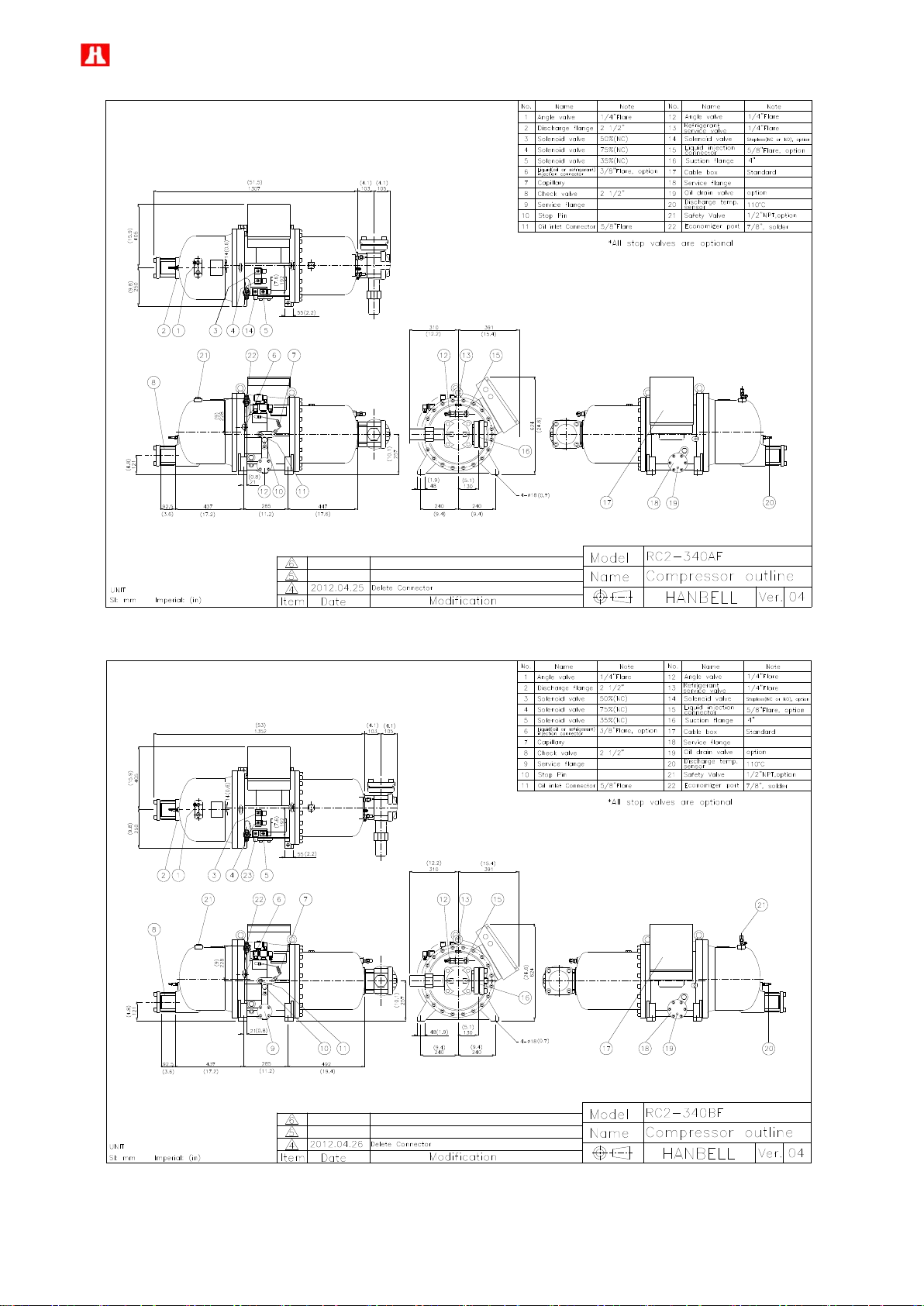

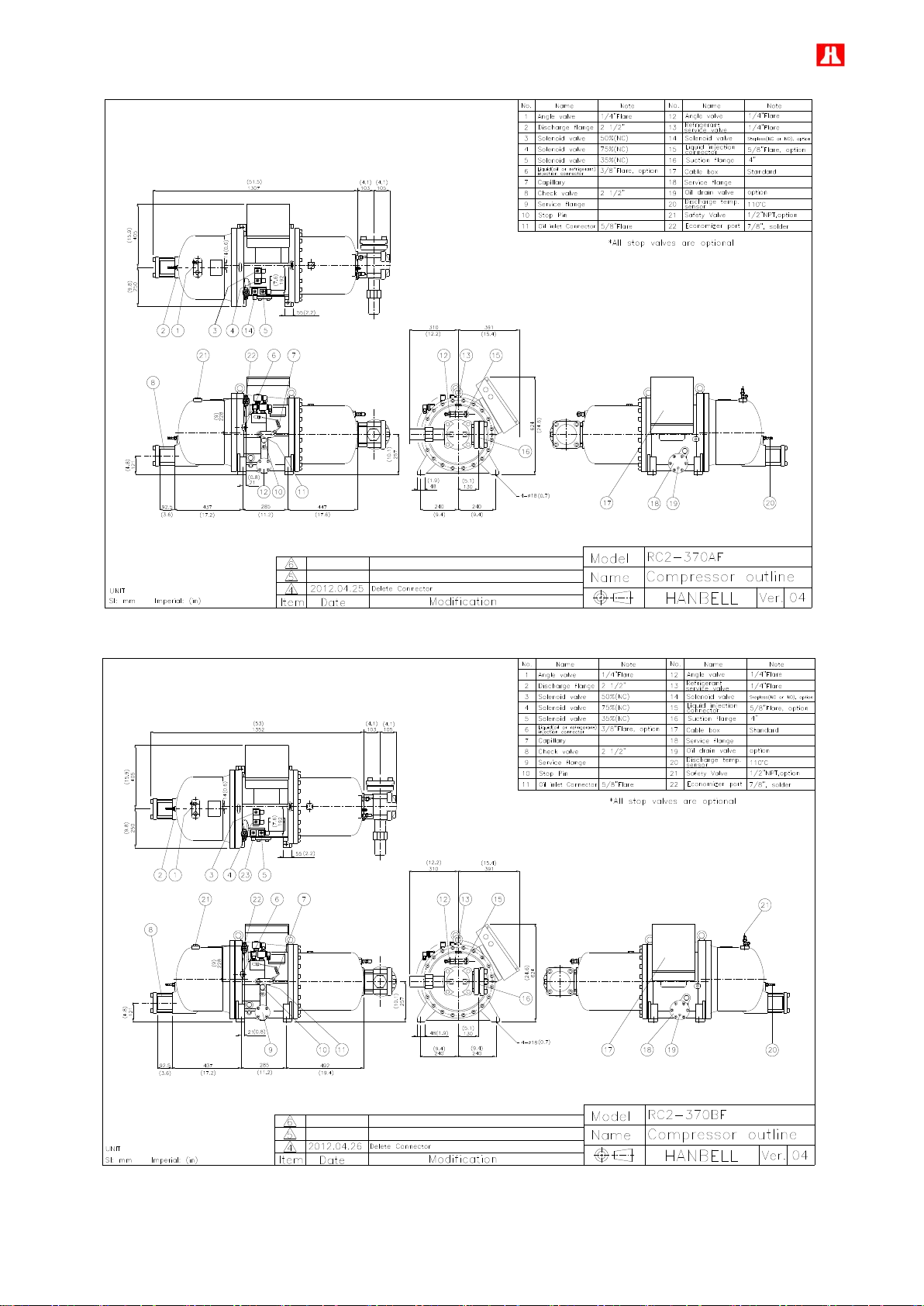

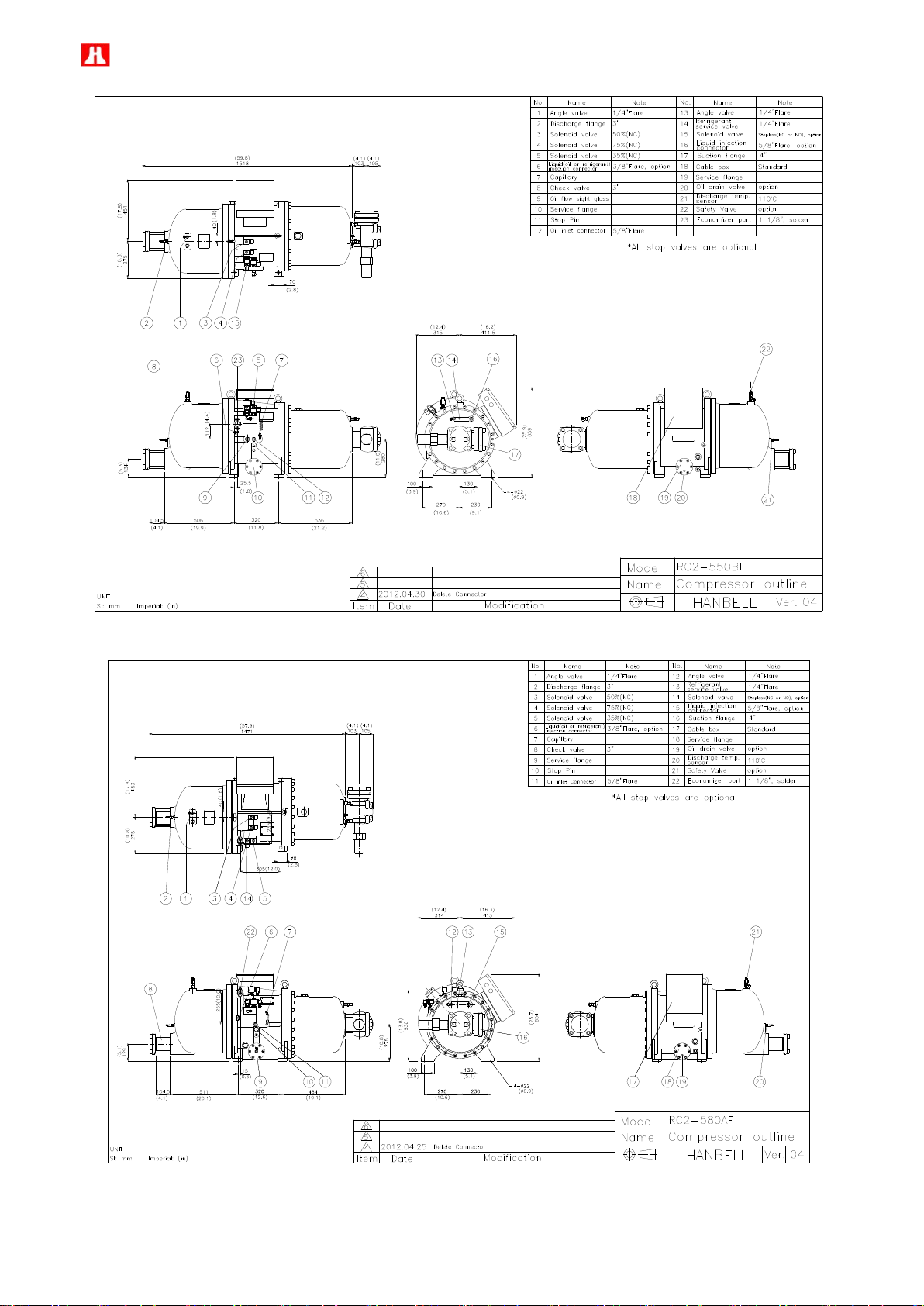

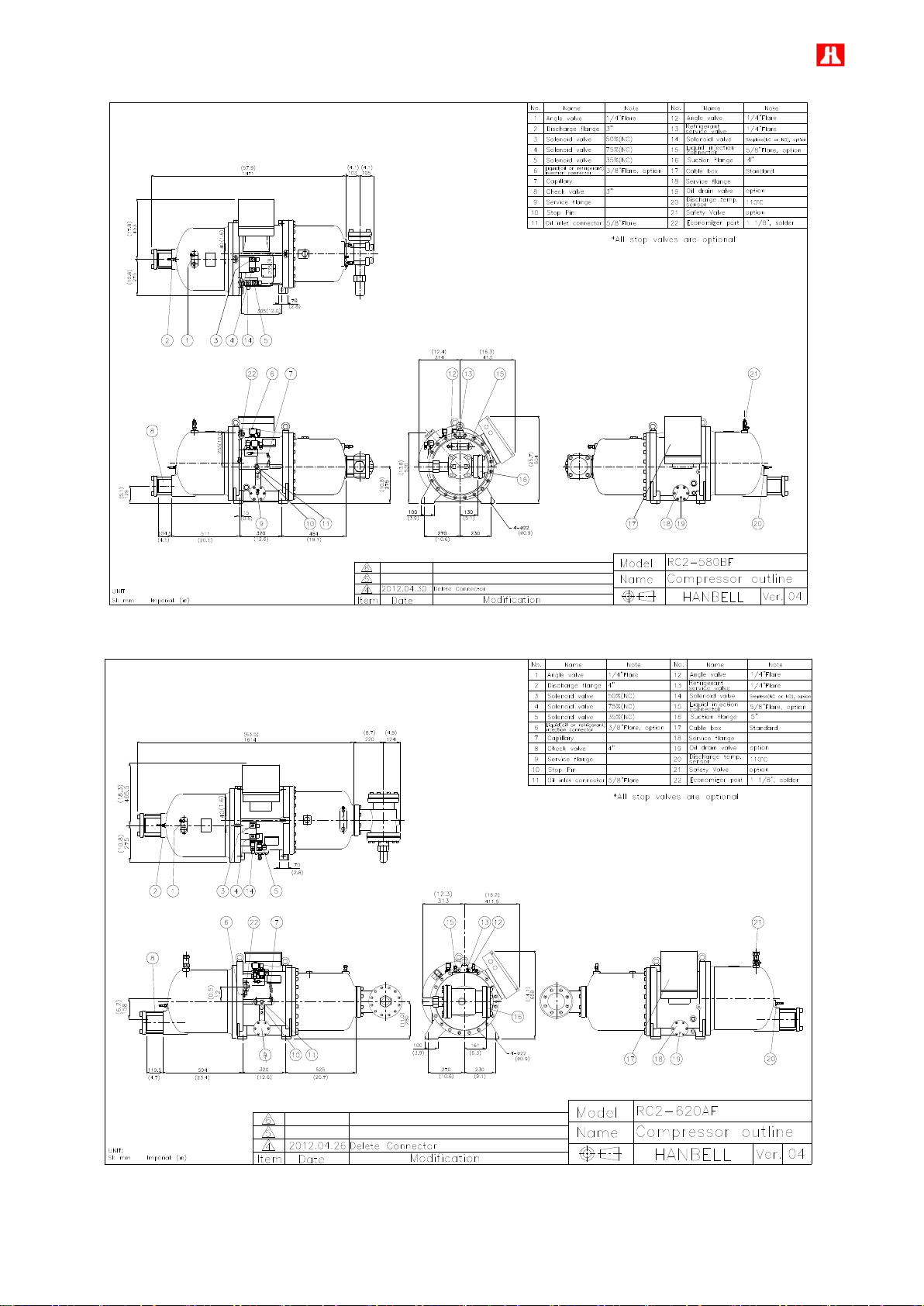

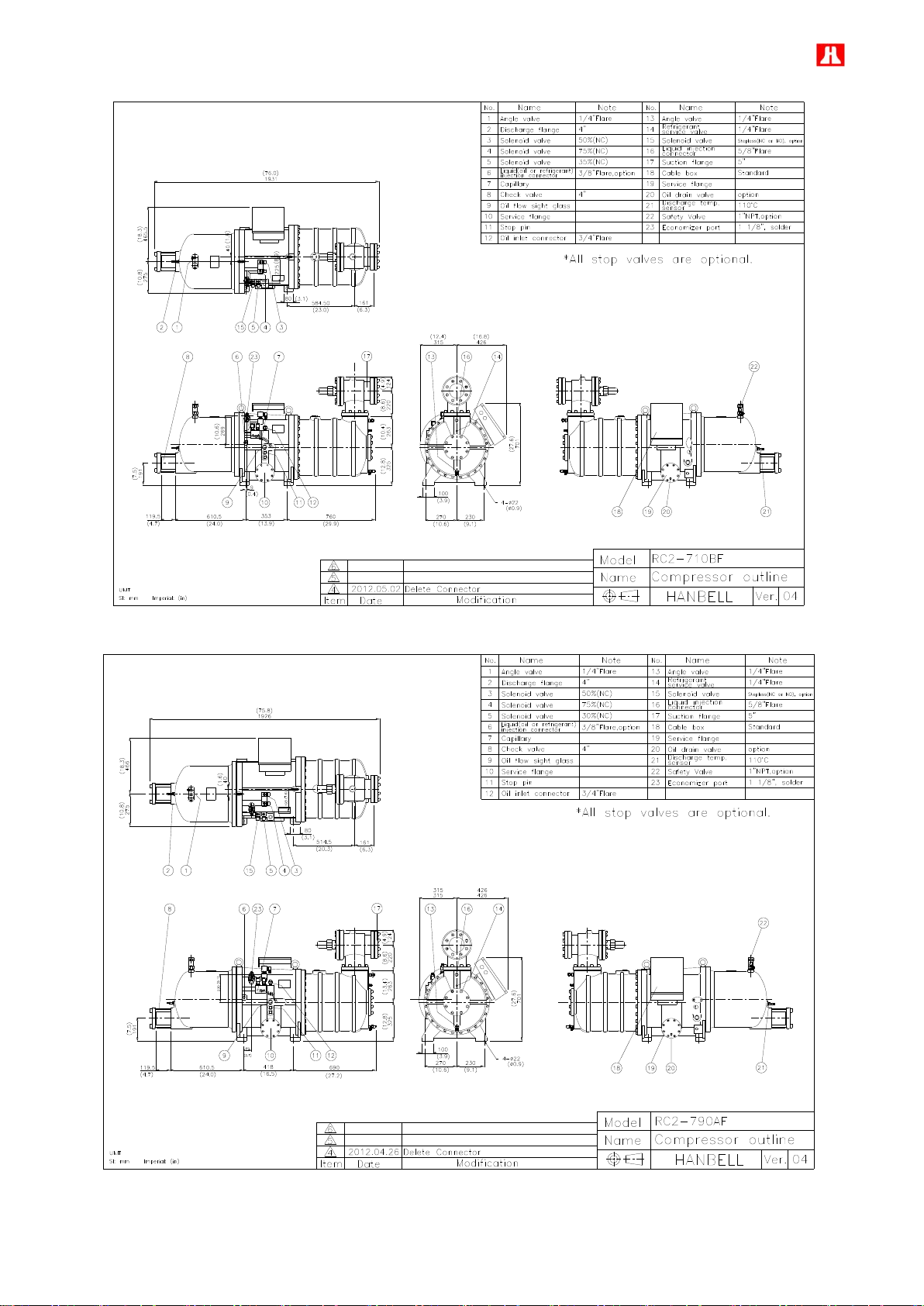

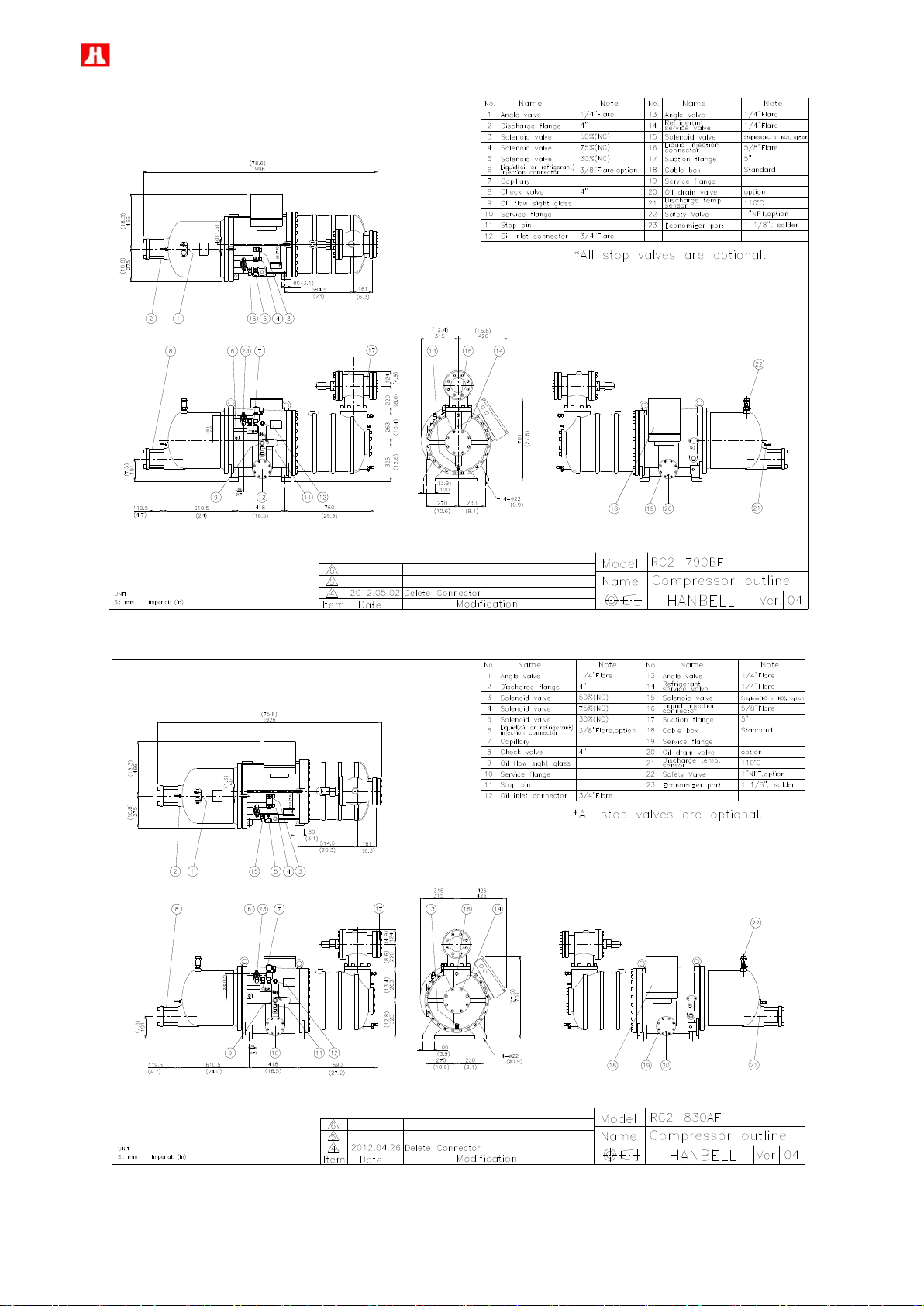

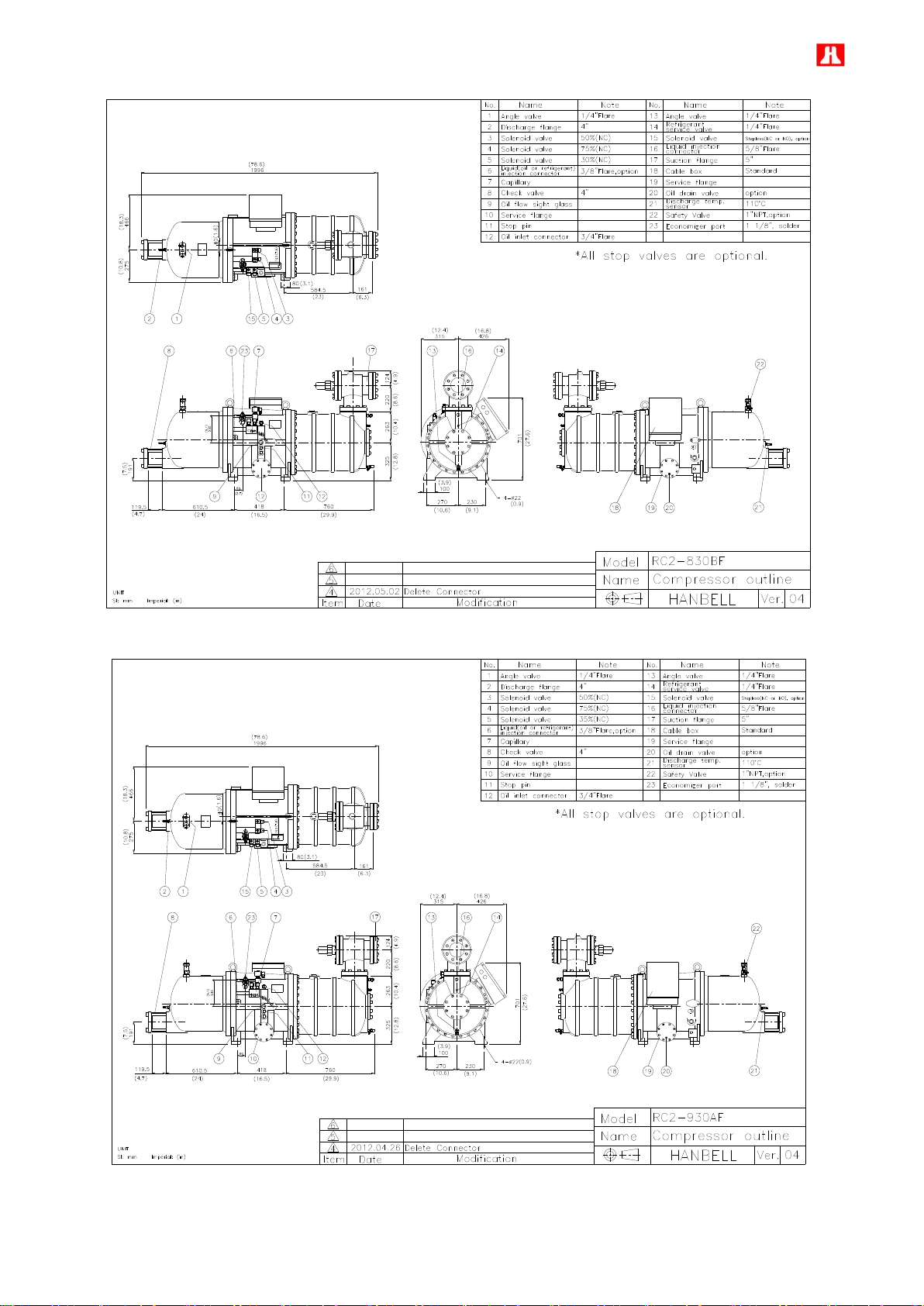

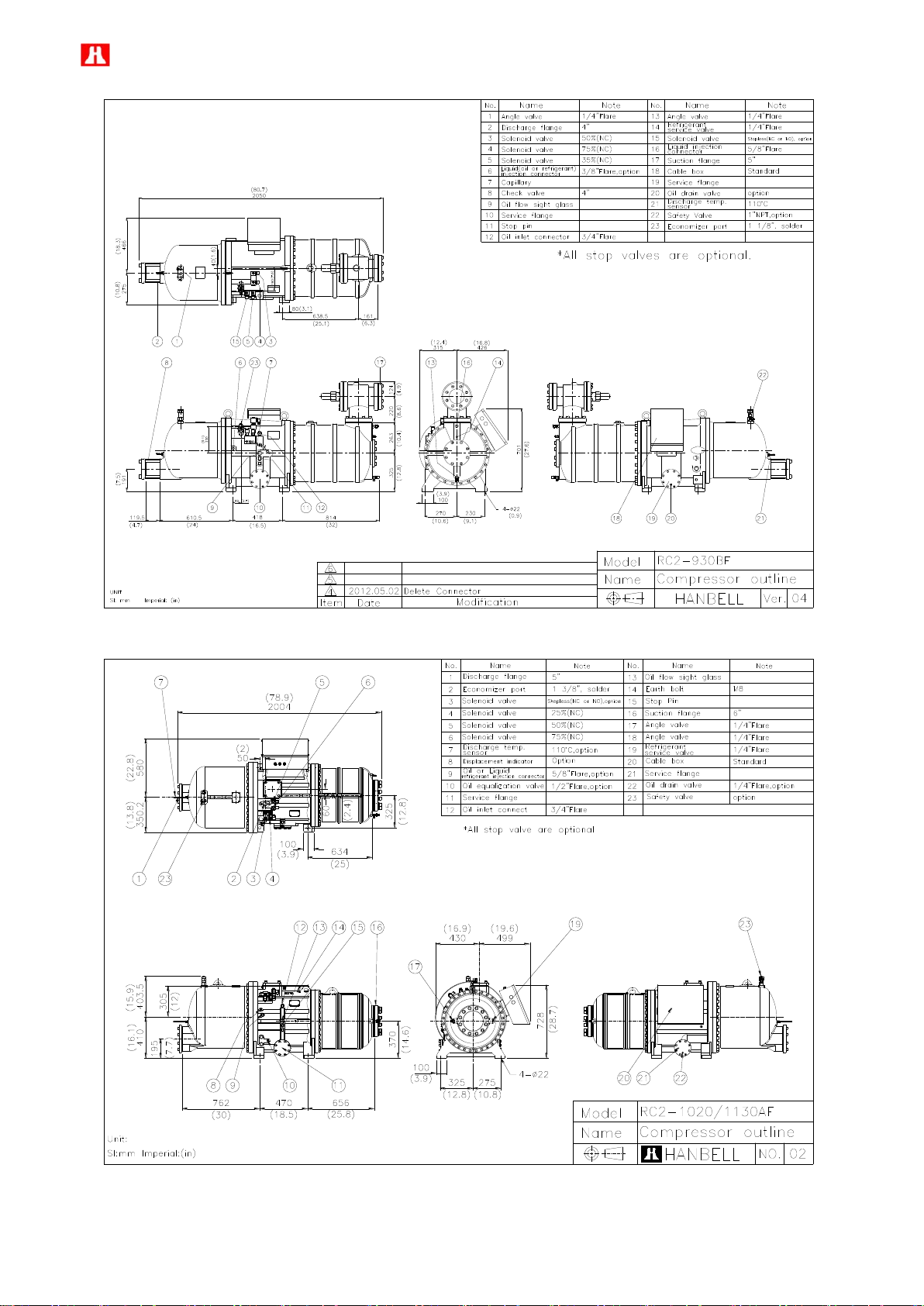

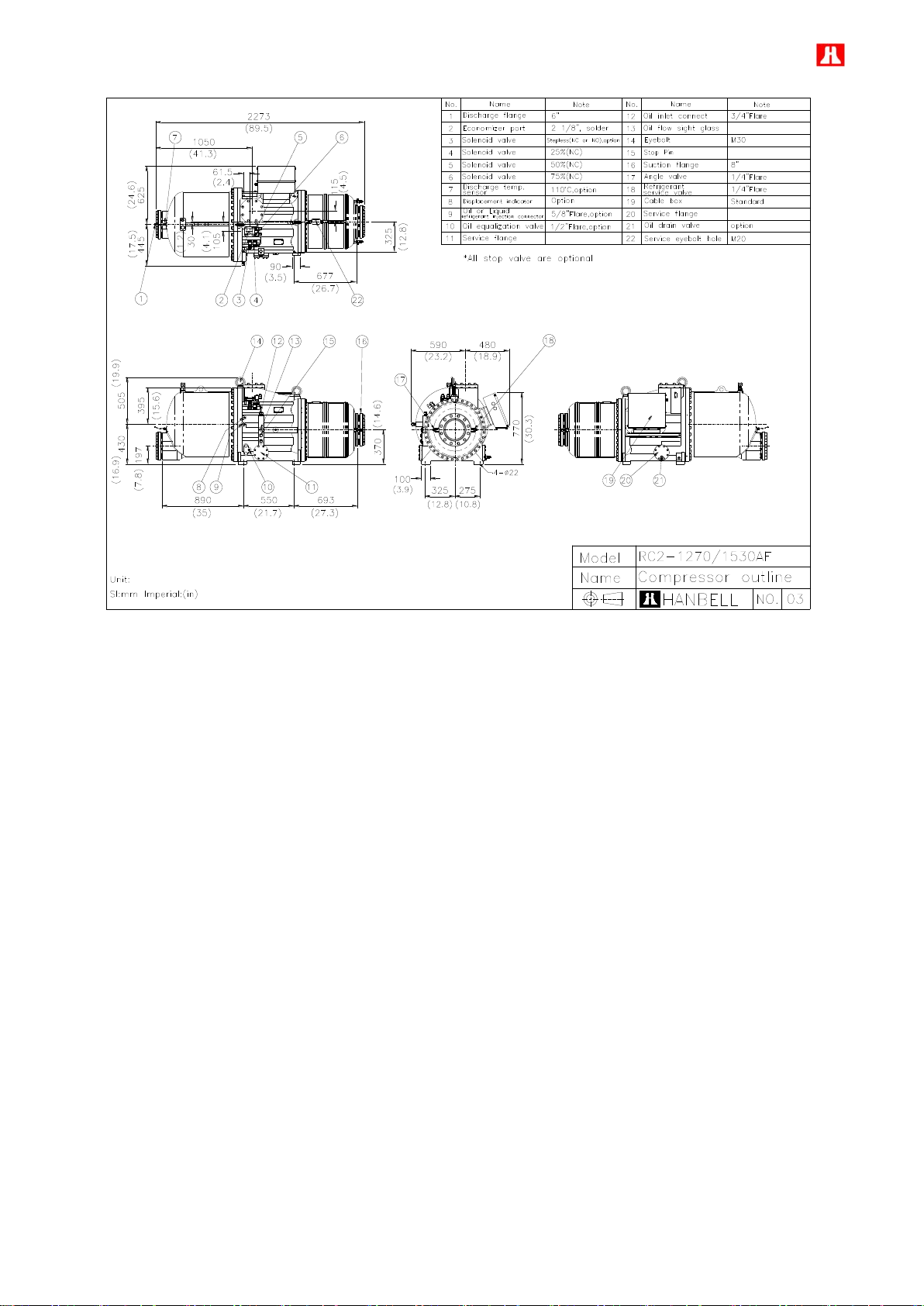

2.2 Compressor outline

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Note: For RC2-1020BF, RC2-1130BF, RC2-1270BF and RC2-1530BF outline drawing, please refer to those of

RC2-1020AF, RC2-1130AF, RC2-1270AF, and RC2-1530AF

28

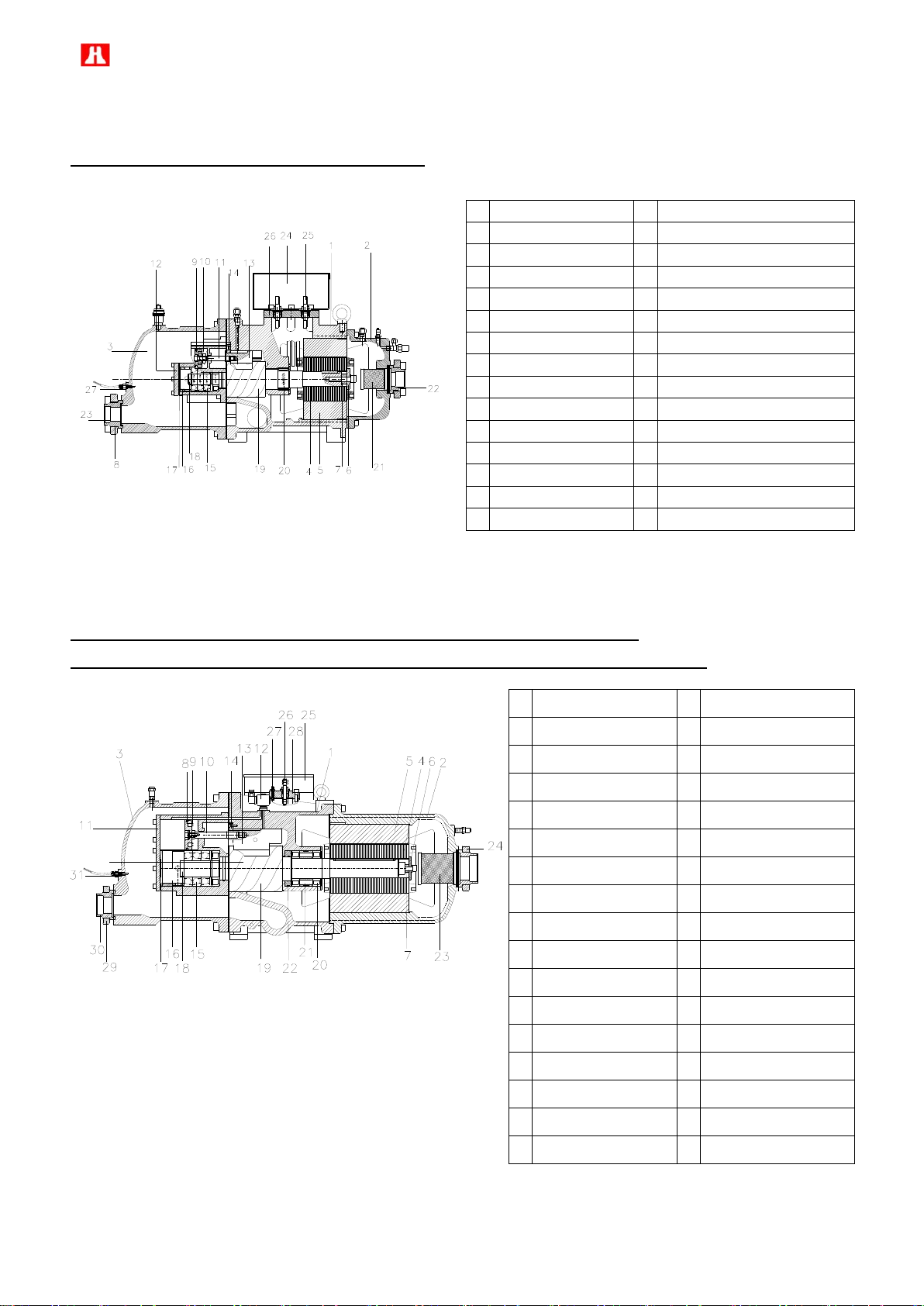

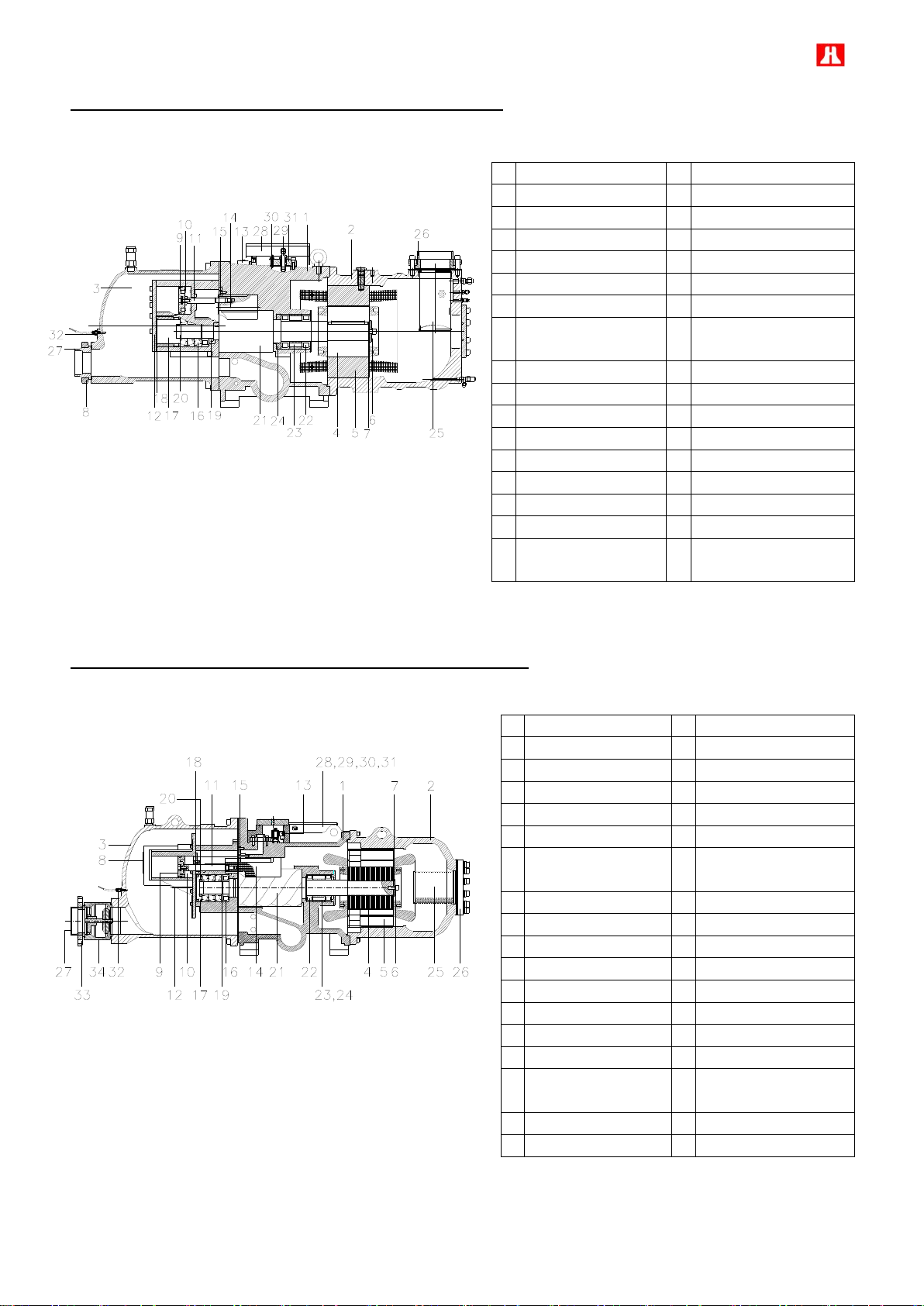

No.

Description

No.

Description

1

Compressor casing

15

Discharge bearings

2

Motor casing

16

Discharge fixed ring

3

Discharge casing

17

Disc spring

4

Motor rotor assembly

18

Bearing slot nut

5

Motor stator assembly

19

Male rotor

6

Motor rotor washer

20

Suction bearings

7

Motor rotor spacer ring

21

Suction filter

8

Discharge connect flange

22

Suction flange

9

Piston

23

Discharge flange bushing

10

Piston ring

24

Cable box

11

Piston rod

25

Power bolt

12

Bearing seat cover plate

26

Terminal cover plate

13

Modulation slide valve

27

PTC discharge temperature sensor

14

Slide valve key

No.

Description

No.

Description

1

Compressor casing

17

Disc spring

2

Motor casing

18

Bearing slot nut

3

Discharge casing

19

Male rotor

4

Motor rotor assembly

20

Suction bearings

5

Motor stator assembly

21

Suction bearings

inner/outer spacer ring

6

Motor rotor washer

22

Oil guiding ring

7

Motor rotor spacer ring

23

Suction filter

8

Piston

24

Suction flange

9

Piston ring

25

Cable box

10

Piston rod

26

Power bolt

11

Bearing seat cover plate

27

Thermostat terminals

12

Modulation solenoid

valve

28

Terminal cover plate

13

Modulation slide valve

29

Discharge connect flange

14

Slide valve key

30

Discharge flange bushing

15

Discharge bearings

31

PTC discharge

temperature sensor

16

Discharge fixed ring

2.3 Compressor construction

RC2-100, RC2-140, RC2-180 F type Construction

RC2-200, RC2-230, RC2-260, RC2-300, RC2-310, RC2-320, RC2-340, RC2-370,

RC2-410, RC2-430, RC2-470, RC2-510, RC2-550, RC2-580, RC2-620 F type Construction

29

RC2-710, RC2-790, RC2-830, RC2-930 F type Construction

No.

Description

No.

Description

1

Compressor casing

17

Discharge fixed ring

2

Motor casing

18

Disc spring

3

Discharge casing

19

α-Balance piston

4

Motor rotor assembly

20

Bearing slot nut

5

Motor stator assembly

21

Male rotor

6

Motor rotor washer

22

Suction bearings

7

Motor rotor spacer ring

23

Suction bearings inner/outer

spacer ring

8

Discharge connect flange

24

Oil guiding ring

9

Piston

25

Suction filter

10

Piston spring

26

Suction flange

11

Piston rod

27

Discharge flange bushing

12

Bearing seat cover plate

28

Cable box

13

Modulation solenoid valve

29

Power bolt

14

Modulation slide valve

30

Thermostat terminals

15

Slide valve key

31

Motor cable cover plate

16

Discharge bearings

32

PTC discharge temperature

sensor

No.

Description

No.

Description

1

Compressor casing

18

Disc spring

2

Motor casing

19

Balance piston

3

Discharge casing

20

Bearing slot nut

4

Motor rotor assembly

21

Male rotor

5

Motor stator assembly

22

Suction bearings

6

Motor rotor washer

23

Suction bearings inner/outer

spacer ring

7

Motor rotor spacer ring

24

Oil guiding ring

8

Muffler

25

Suction filter

9

Piston

26

Suction flange

10

Piston spring

27

Discharge flange bushing

11

Piston rod

28

Cable box

12

Bearing seat cover plate

29

Power bolt

13

Modulation solenoid valve

30

Thermostat terminals

14

Modulation slide valve

31

Motor cable cover plate

15

Slide valve key

32

PTC discharge temperature

sensor

16

Discharge bearings

33

Discharge connect flange

17

Discharge fixed ring

34

Check valve

RC2-1020, RC2-1130, RC2-1270, RC2-1530 F type Construction

Loading...

Loading...