Page 1

0

CONTENTS

1. Compressor’s characteristics ............................................................................................................................. 2

2. Compressor specification .................................................................................................................................... 3

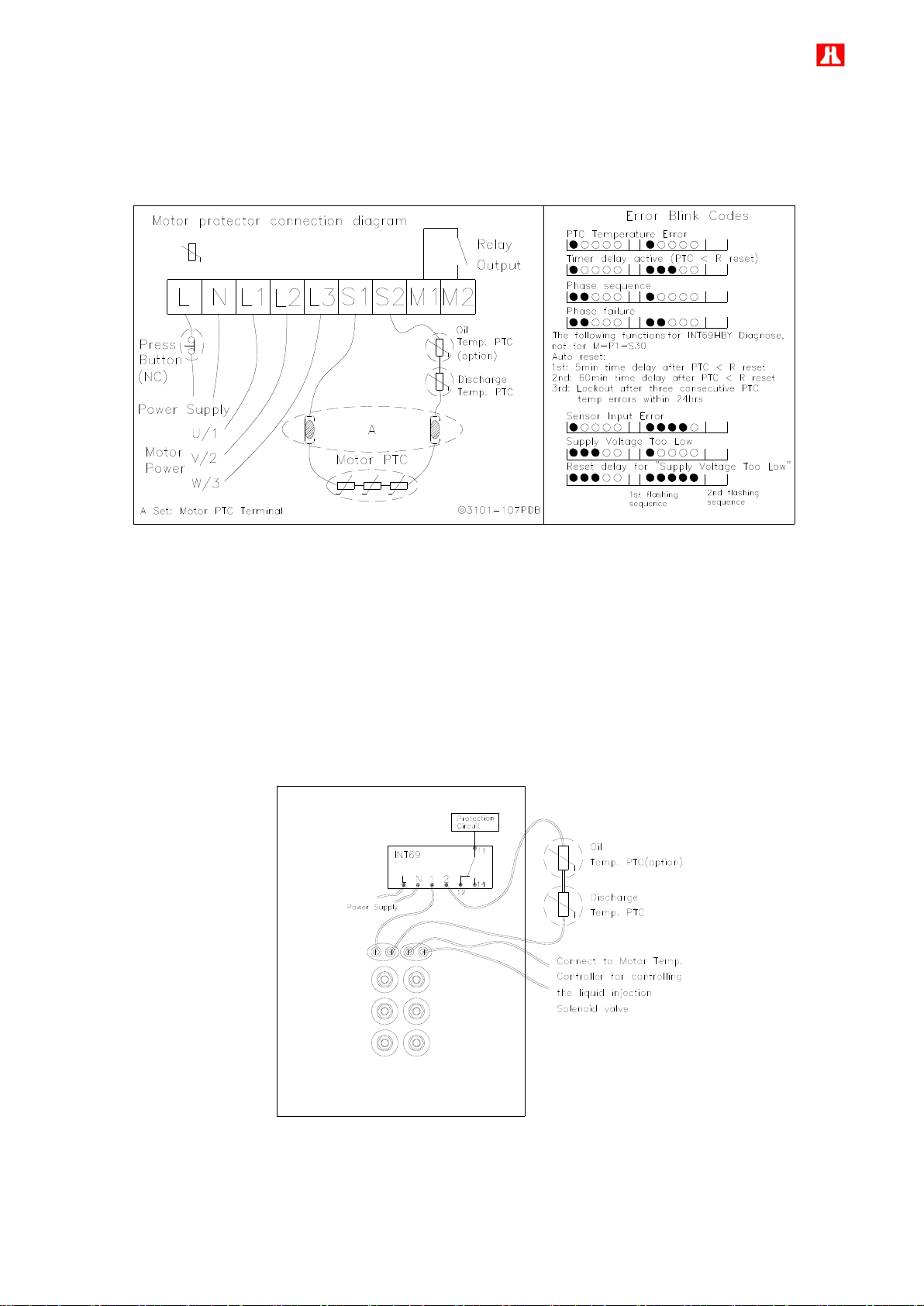

2.1 Design specification .................................................................................................................................... 3

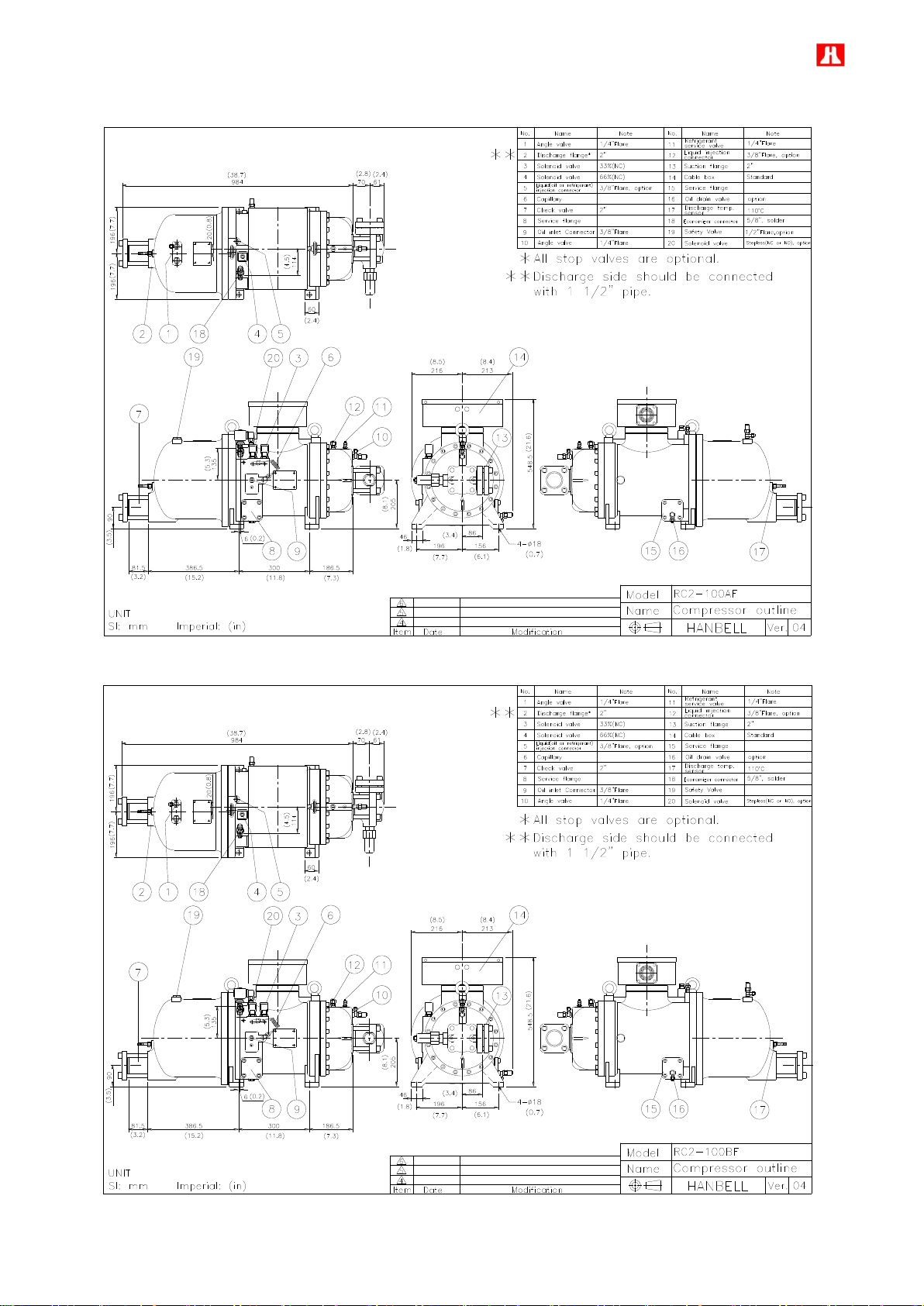

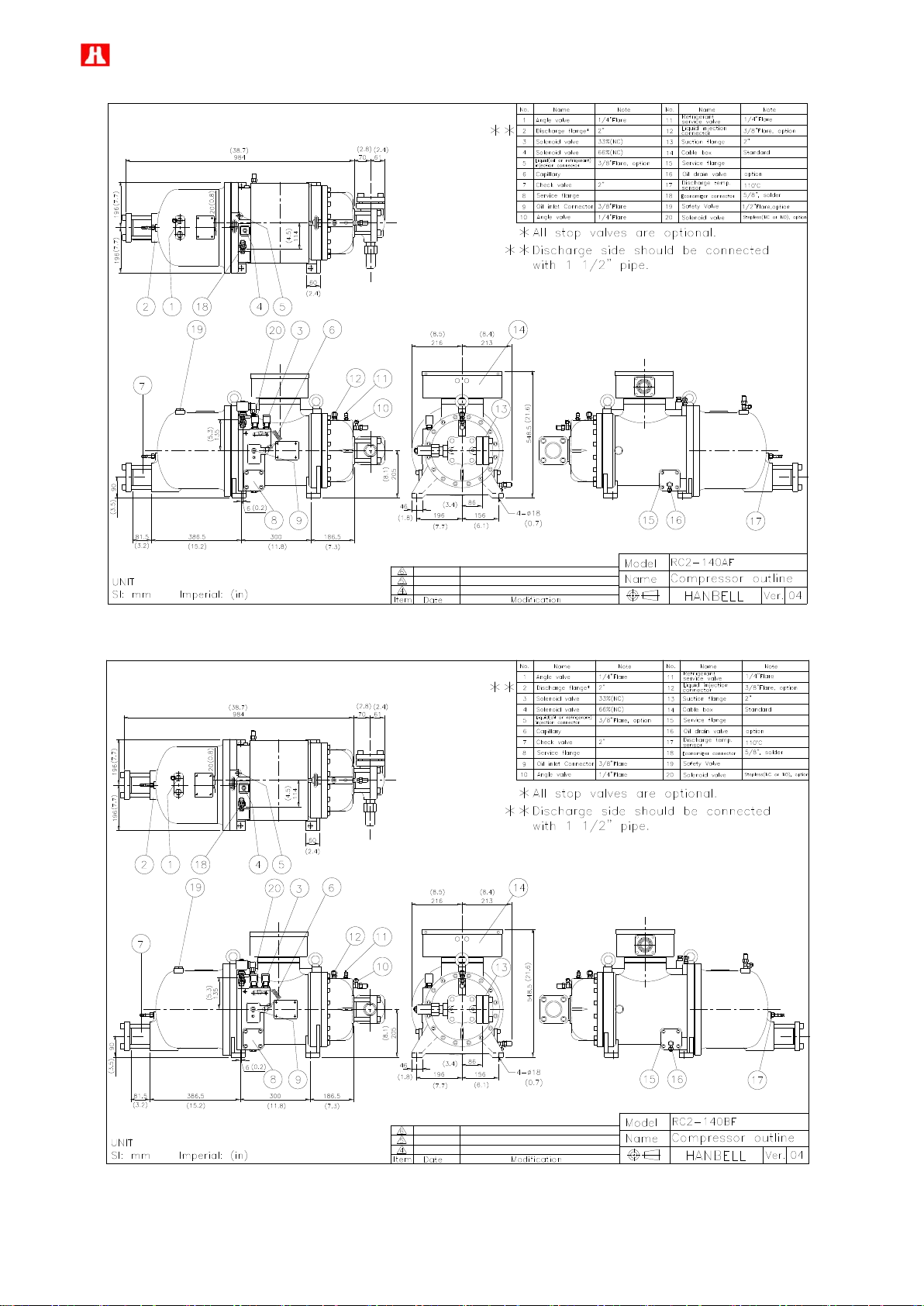

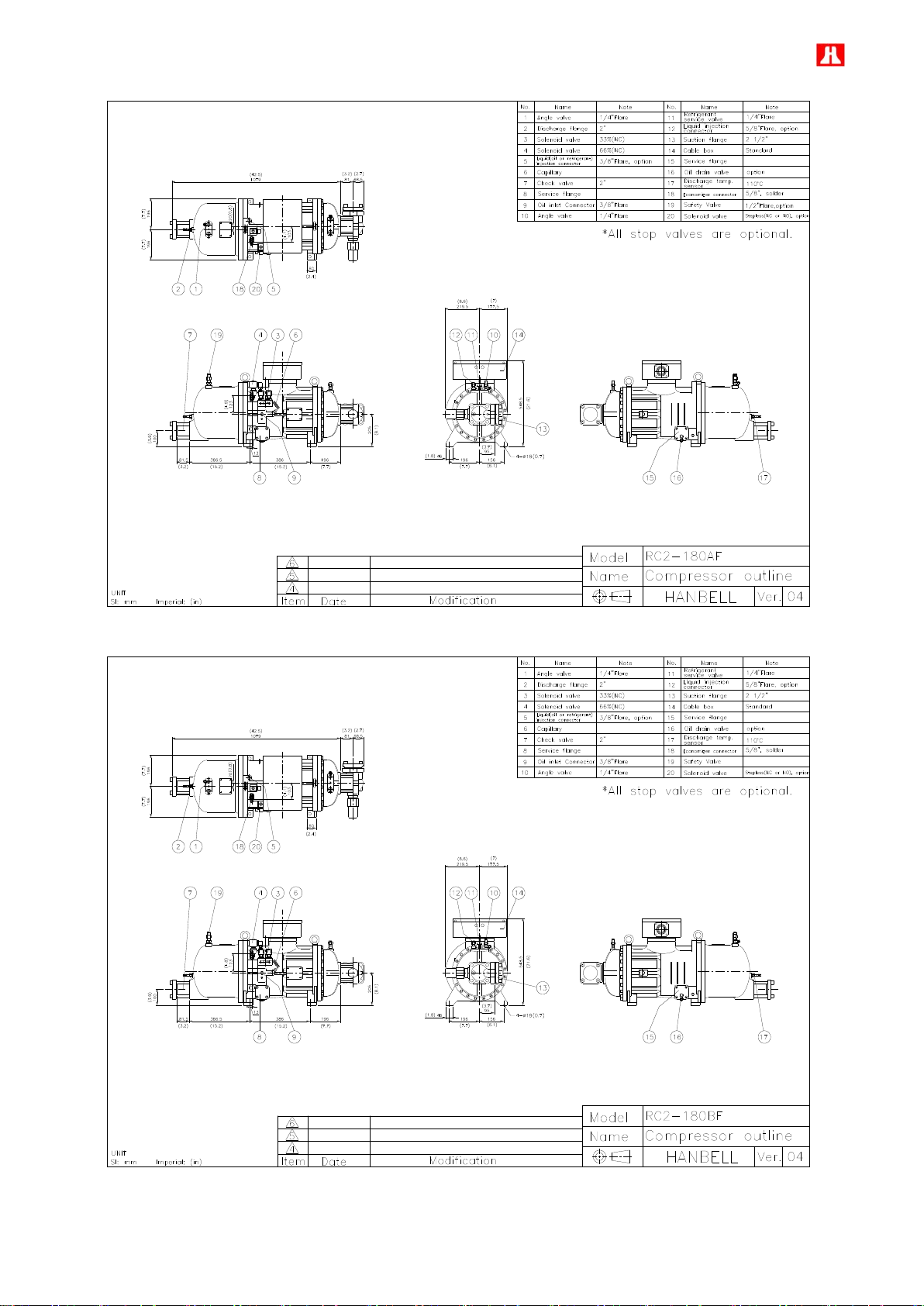

2.2 Compressor outline ..................................................................................................................................... 5

2.3 Compressor construction ......................................................................................................................... 28

2.4 Capacity control system ........................................................................................................................... 30

2.5 Compressor application limits ................................................................................................................. 33

2.6 Compressor design feature ...................................................................................................................... 35

2.7 MCC and LRA ............................................................................................................................................. 37

3. Compressor handling and Installation ............................................................................................................. 41

3.1 Compressor handling ............................................................................................................................... 41

3.2 Mounting the compressor ........................................................................................................................ 41

4. Lubricant .............................................................................................................................................................. 64

4.1 Pre-cautions in changing of oil ................................................................................................................ 64

4.2 Changing of oil .......................................................................................................................................... 65

4.3 Lubricants table ......................................................................................................................................... 66

5. Electrical data and design ................................................................................................................................. 67

5.1 Motor design .............................................................................................................................................. 67

5.2 Compressor protection devices .............................................................................................................. 69

5.3 Power supply ............................................................................................................................................. 69

5.4 Selection of magnetic contactor .............................................................................................................. 71

5.5 Grounding .................................................................................................................................................. 71

6. Compressors accessories ................................................................................................................................. 72

6.1 Compressors standard and optional accessories ................................................................................. 72

6.2 Description of accessories ....................................................................................................................... 73

7. Operation and trouble shooting ........................................................................................................................ 87

7.1 Compressor start-up ................................................................................................................................. 87

7.2 System adjustment .................................................................................................................................... 89

7.3 Compressor stop ....................................................................................................................................... 91

7.4 Troubleshooting ........................................................................................................................................ 92

7.5 Compressor checking list......................................................................................................................... 95

8. System applications ........................................................................................................................................... 96

8.1 General application ................................................................................................................................... 96

8.2 Economizer application .......................................................................................................................... 109

8.3 Important notice to compressor application ........................................................................................ 112

8.4 Example of installation ........................................................................................................................... 113

Appendix 1. Compressor noise level .................................................................................................................. 116

Page 2

1

Introduction

The Hanbell RC2-F series semi-hermetic twin-screw compressor inherits all the quality and experience of our

RC2 series compressor. The RC2-F series compressor is developed especially for application with Freon in

flooded system or refrigeration field. With a built-in high operating load design and advanced 5 to 6 Patented

Screw Rotor Profile, each compressor has high efficiency and reliability in all operating condition. Each unit is

carefully manufactured and inspected by high precision THREAD SCREW ROTOR GRINDING MACHINE, CNC

MACHINING CENTER, and 3-D COORDINATE MEASURING MACHINE. Each compressor at HANBELL also

follows the ISO 9001 certification quality system which assures the best quality control and production process to

customers. RC2-F series compressor has 27 models RC2-100~RC2-1530, with displacement (50/60Hz) from 98

/ 1 18 m3/hr to 1539 / 1847 m3/hr.

The RC2-F series compressors use high quality bearings which resulted in longer bearing life compare to

competitors. These bearings provide strong support to screw rotors especially for the heavy duty application.

Oil/Refrigerant injection port can be utilized when external cooling is needed at chamber. This can keep the

compression chamber at proper discharge temperature and ensures sufficient oil viscosity for moving parts

lubrication. Economizer port can be used to reach higher cooling capacity and working efficiency especially at high

pressure ratio working condition or at very low evaporating temperature. All these new designs guarantee that the

compressor has the best reliability, longest bearing life and easiest regular maintenance work.

This Technical Manual contains all basic information about dimensions, handling, installation, operation, trouble

shooting, and system application. It is highly recommended that the content of this manual should be read carefully

prior to handling, installing, and operating the RC2-F compressor in order to prevent any unwanted damage on it.

For any technical issue related to RC2-F series compressor, please contact HANBELL or local distributors/agents

for more information and assistance.

Page 3

2

1. Compressor’s characteristics

1-1 Multi country (Taiwan, China, USA, England) patented high efficiency 5 to 6 asymmetrical rotor profile.

1-2 Precise volume control system

Steps or continuous capacity control system are available.

1-3 Economizer applications

Economizer port is a standard accessory for RC2-F series screw compressor.

Floating type medium pressure (Economizer returned pressure) design, no matter if compressor work at full

load or partial load condition, always can track the best medium pressure value, it means economizer could

develop the maximum efficiency during the operation.

1-4 Applicable with:R-134a, R-407C, R22, R404A, R507A.

1-5 Resistant to high load condition with long life bearing design

1-6 PTC temperature thermistor for the protection of

(1) High motor coil temperature

(2) High discharge temperature

(3) High oil temperature (optional)

1-7 Low vibration and low noise.

1-8 High efficiency oil separator, low-pressure drop, external connection.

Page 4

3

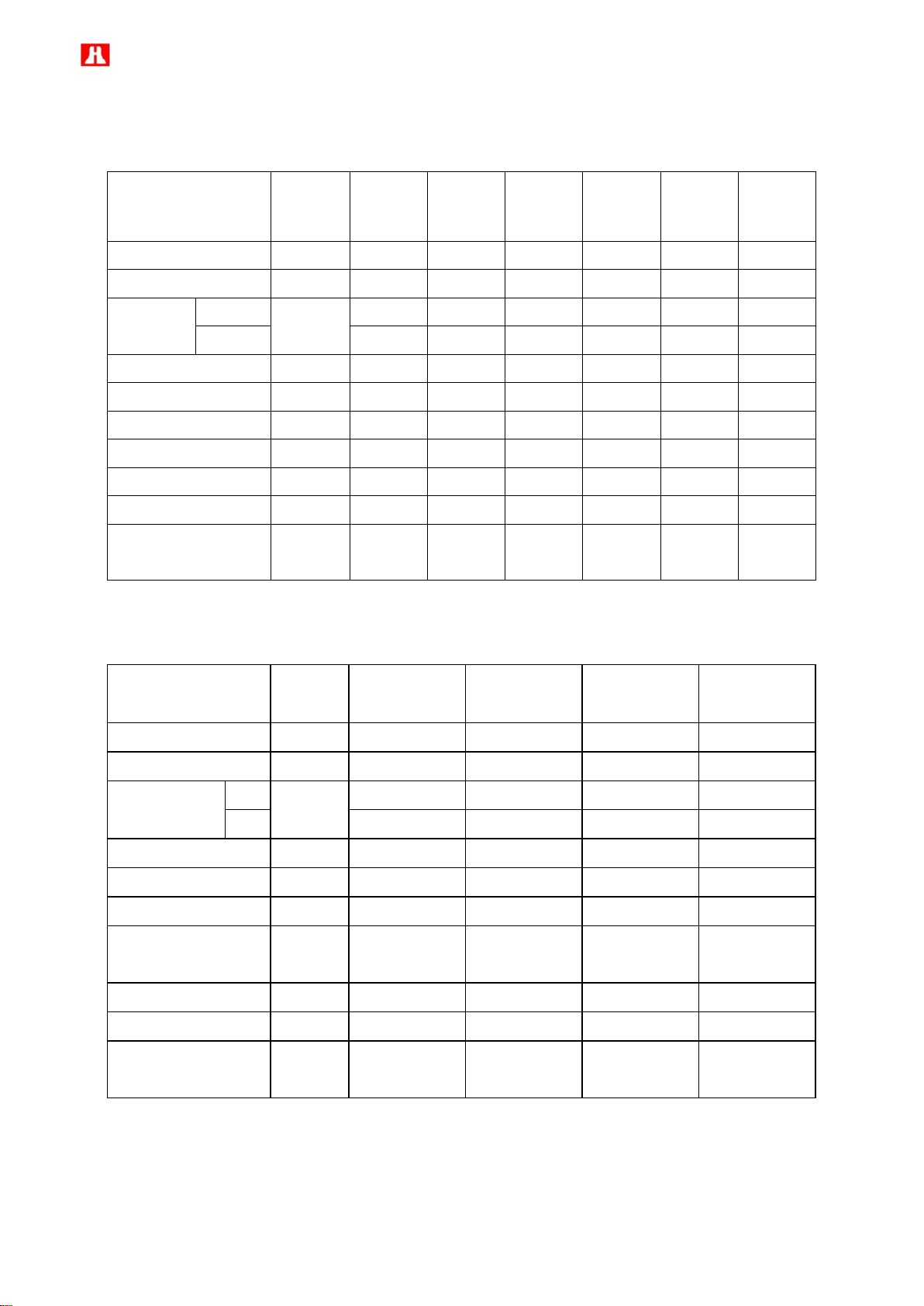

2. Compressor specification

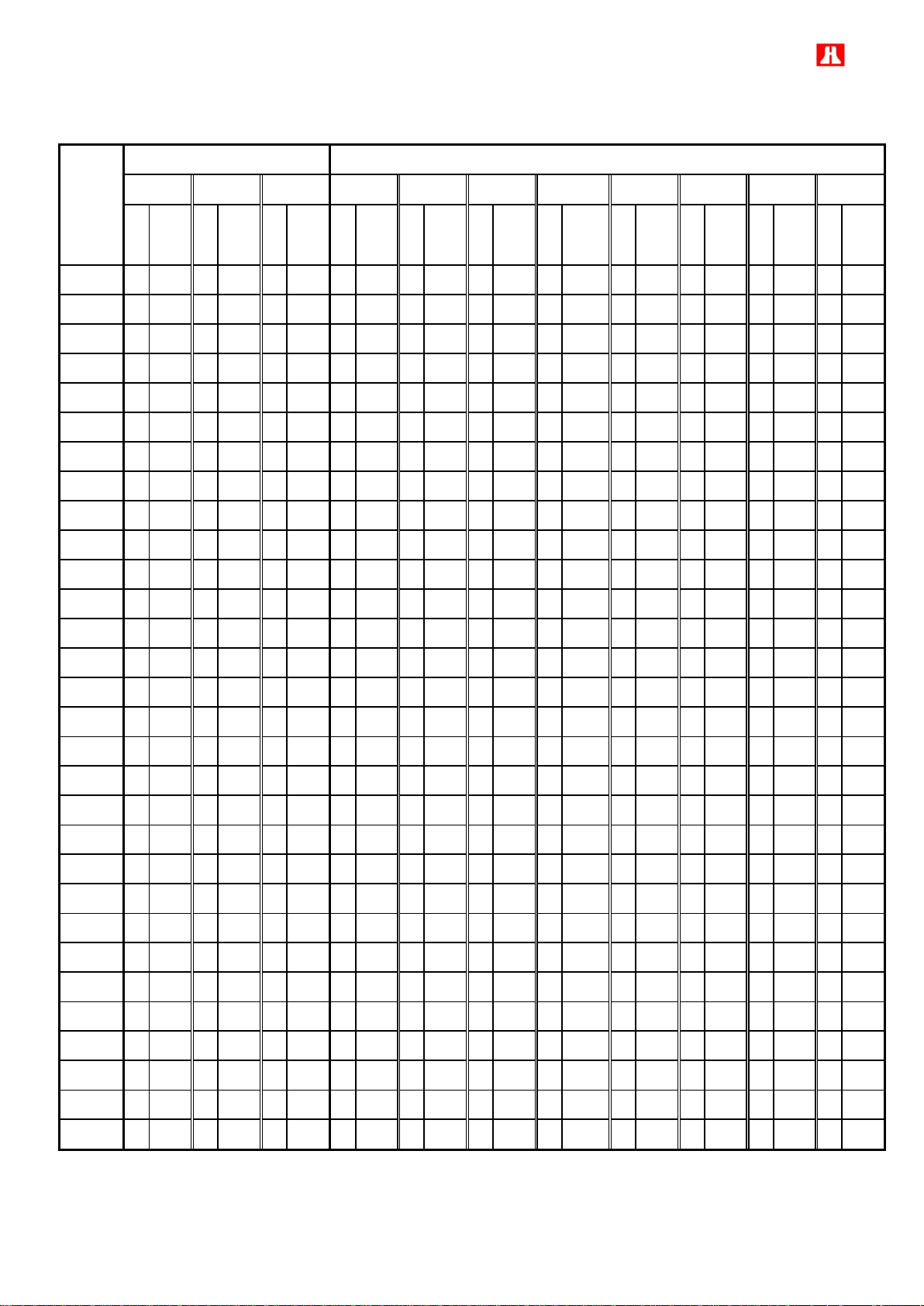

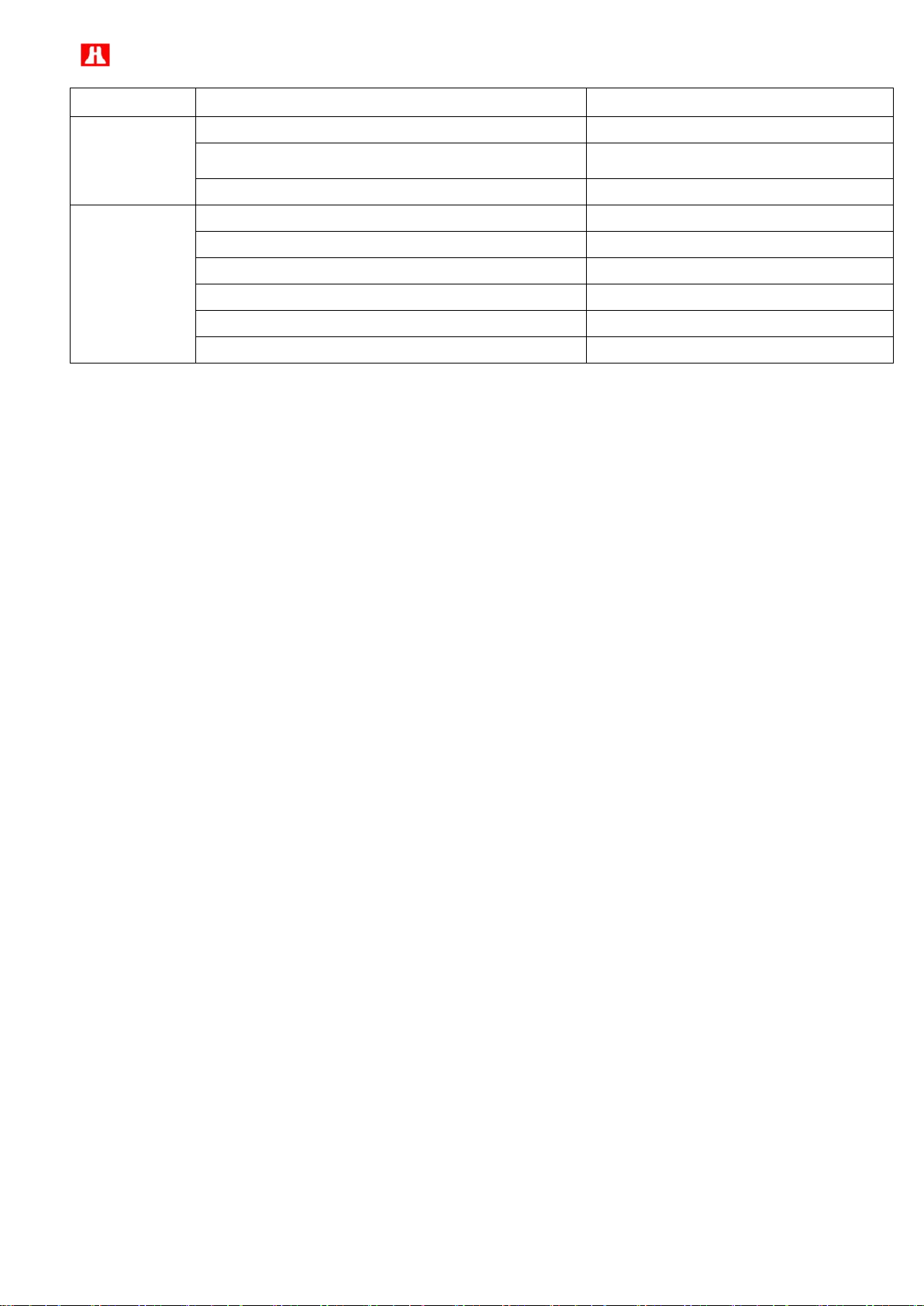

MODEL

COMPRESSOR

MOTOR

Hydrostatic Pressure

Test

Weight

Displacement 60 /

50Hz

Rated

Speed

VI

Cap. Control (%)

Type

Nominal

Hp

Starting

Voltage (V)

Insulation

Protection

m3/hr

60 / 50Hz

STEP

STEPLESS

60Hz

50Hz

60Hz

50Hz

Kg/cm2G

kg

RC2-100AF

118/98

3550/2950

2.2

2.6

3.0

3.5

4.8

33, 66, 100

33~100

3 Phase, 2 Pole, Squirrel Cage, Induction Motor

23

19

Y-△

PWS

DOL

208

220

230

380

440

460

480

575

380

400

415

Class F

PTC Protection

42

260

RC2-140AF

165/137

33, 66, 100

33~100

32

26

265

RC2-180AF

216/180

33, 66, 100

33~100

42

35

365

RC2-200AF

233/193

25, 50, 75, 100

25~100

45

37

405

RC2-230AF

277/230

35, 50, 75, 100

35~100

53

44

530

RC2-260AF

309/257

25, 50, 75, 100

25~100

59

49

535

RC2-300AF

352/293

25, 50, 75, 100

25~100

67

56

580

RC2-310AF

371/308

35, 50, 75, 100

35~100

71

59

565

RC2-320AF

384/320

25, 50, 75, 100

25~100

72

60

595

RC2-340AF

407/339

35, 50, 75, 100

35~100

77

64

600

RC2-370AF

440/366

35, 50, 75, 100

35~100

84

70

610

RC2-410AF

490/407

25, 50, 75, 100

25~100

93

78

380

440

460

480

575

730

RC2-430AF

512/425

25, 50, 75, 100

25~100

100

84

735

RC2-470AF

567/471

25, 50, 75, 100

25~100

108

90

800

RC2-510AF

611/508

35, 50, 75, 100

35~100

117

98

760

RC2-550AF

660/549

25, 50, 75, 100

25~100

126

105

820

RC2-580AF

702/583

35, 50, 75, 100

35~100

131

109

805

RC2-620AF

745/619

35, 50, 75, 100

35~100

137

114

Y-△

DOL

850

RC2-710AF

858/713

35, 50, 75, 100

35~100

158

131

1050

RC2-790AF

952/791

30, 50, 75, 100

30~100

175

146

1140

RC2-830AF

993/825

30, 50, 75, 100

30~100

183

152

1150

RC2-930AF

1117/929

35, 50, 75, 100

35~100

212

176

1180

RC2-1020AF

1223/1017

25, 50, 75, 100

25~100

227

189

1500

RC2-1130AF

1350/1122

25, 50, 75, 100

25~100

248

206

1520

RC2-1270AF

1521/1268

25, 50, 75, 100

25~100

286

238

2100

RC2-1530AF

1847/1539

25, 50, 75, 100

25~100

331

275

2200

2.1 Design specification

a. RC2-AF

Page 5

4

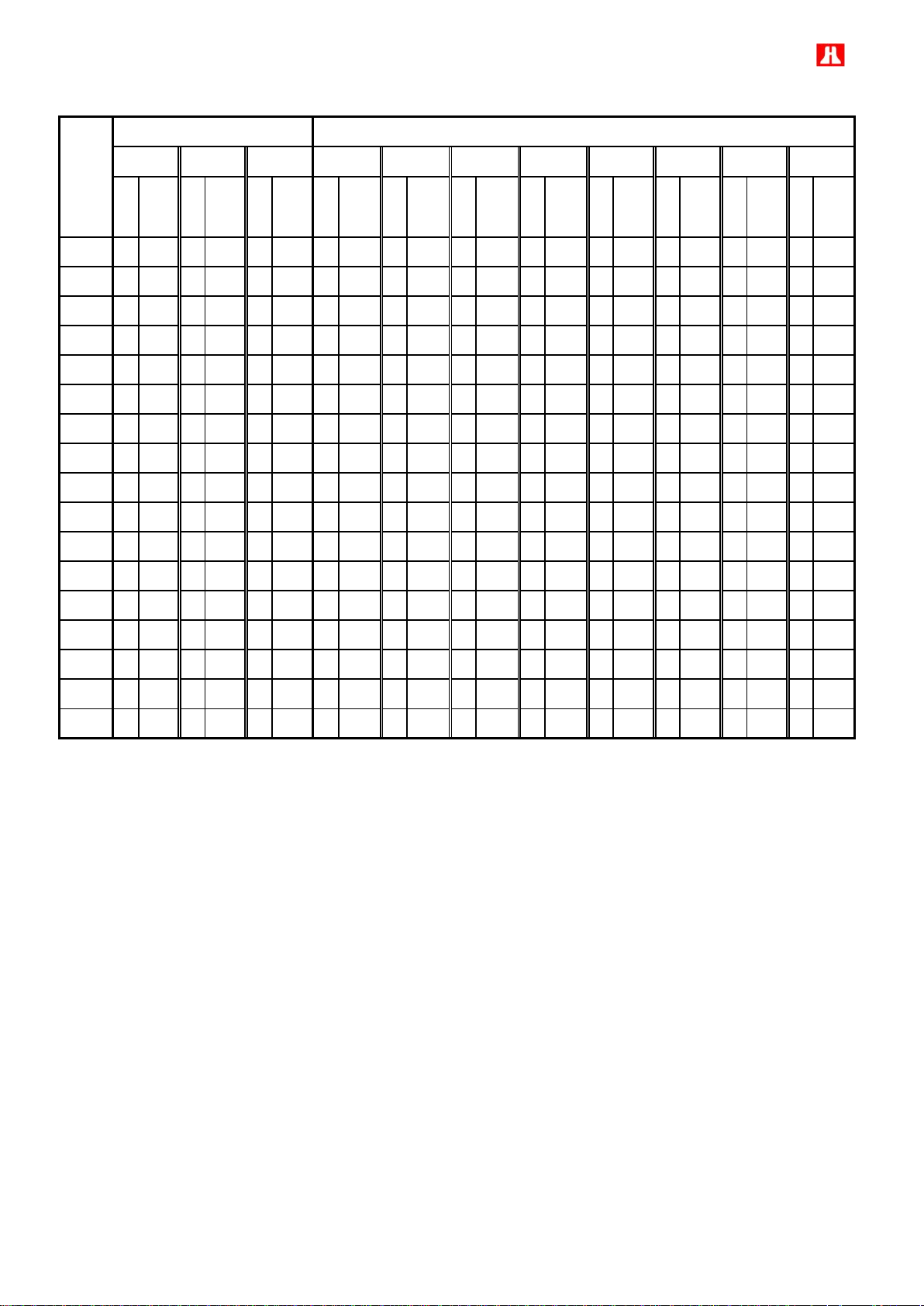

MODEL

COMPRESSOR

MOTOR

Hydrostatic

Pressure Test

Weight

Displacement 60 /

50Hz

Rated

Speed

VI

Cap. Control (%)

Type

Nominal

Hp

Starting-Up

Voltage (V)

Insulation

Protection

m3/hr

60 / 50Hz

STEP

STEPLESS

60Hz

50Hz

60Hz

50Hz

Kg/cm2G

kg

RC2-100BF

118/98

3550/2950

2.2

2.6

3.0

3.5

4.8

33, 66, 100

33~100

3 Phase, 2 Pole, Squirrel Cage, Induction Motor

38

31

Y-△

PWS

DOL

208

220

230

380

440

460

480

575

380

400

415

Class F

PTC Protection

42

265

RC2-140BF

165/137

33, 66, 100

33~100

50

41

270

RC2-180BF

216/180

33, 66, 100

33~100

66

55

390

RC2-200BF

233/193

25, 50, 75, 100

25~100

70

58

415

RC2-230AF

277/230

35, 50, 75, 100

35~100

53

44

535

RC2-260BF

309/257

25, 50, 75, 100

25~100

90

75

540

RC2-300BF

352/293

25, 50, 75, 100

25~100

107

89

600

RC2-310BF

371/308

35, 50, 75, 100

35~100

110

91

570

RC2-320BF

384/320

25, 50, 75, 100

25~100

114

94

600

RC2-340BF

407/339

35, 50, 75, 100

35~100

121

101

620

RC2-370BF

440/366

35, 50, 75, 100

35~100

130

108

640

RC2-410BF

490/407

25, 50, 75, 100

25~100

146

121

380

440

460

480

575

740

RC2-470BF

567/471

25, 50, 75, 100

25~100

170

141

810

RC2-510BF

611/508

35, 50, 75, 100

35~100

183

152

780

RC2-550BF

660/549

25, 50, 75, 100

25~100

195

162

850

RC2-580BF

702/583

35, 50, 75, 100

35~100

210

175

840

RC2-620BF

745/619

35, 50, 75, 100

35~100

220

183

Y-△

DOL

880

RC2-710BF

858/713

35, 50, 75, 100

35~100

250

208

1080

RC2-790BF

952/791

30, 50, 75, 100

30~100

276

230

1180

RC2-830BF

993/825

30, 50, 75, 100

30~100

290

234

1215

RC2-930BF

1117/929

35, 50, 75, 100

35~100

334

278

1240

RC2-1020BF

1223/1017

25, 50, 75, 100

25~100

357

297

1540

RC2-1130BF

1350/1122

25, 50, 75, 100

25~100

393

327

1560

RC2-1270BF

1521/1268

25, 50, 75, 100

25~100

471

392

2200

RC2-1530BF

1847/1539

25, 50, 75, 100

25~100

534

443

2300

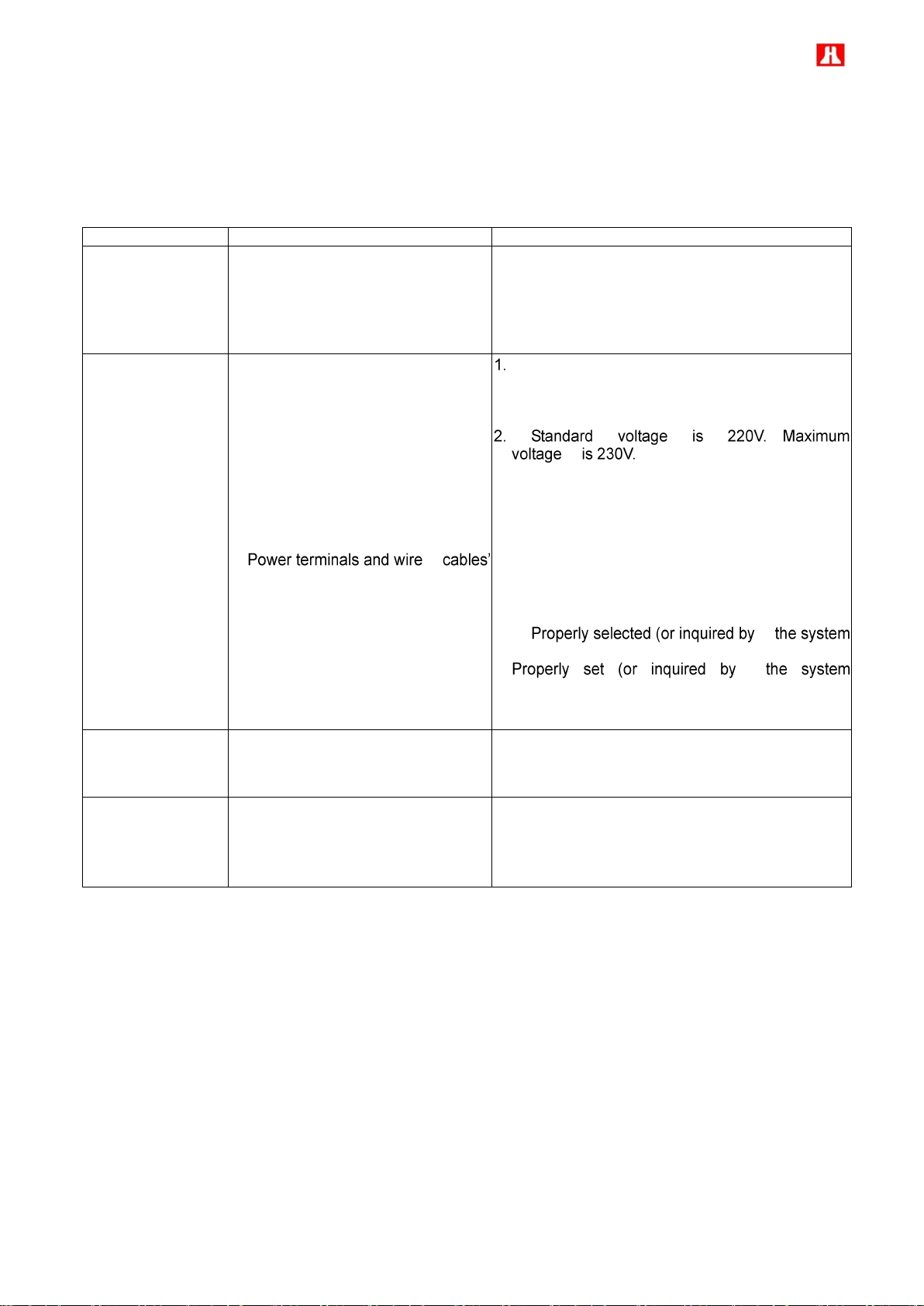

b. RC2-BF

Nominal Horse Power:

All above Nominal Hp are not equal to the maximum compressors Hp; Please refer to Hanbell selection software’s

output for the rated current, Maximum Continuous Current-M.C.C according to various working condition while

selecting the contactor, cable, fuse and wire, etc…

Page 6

5

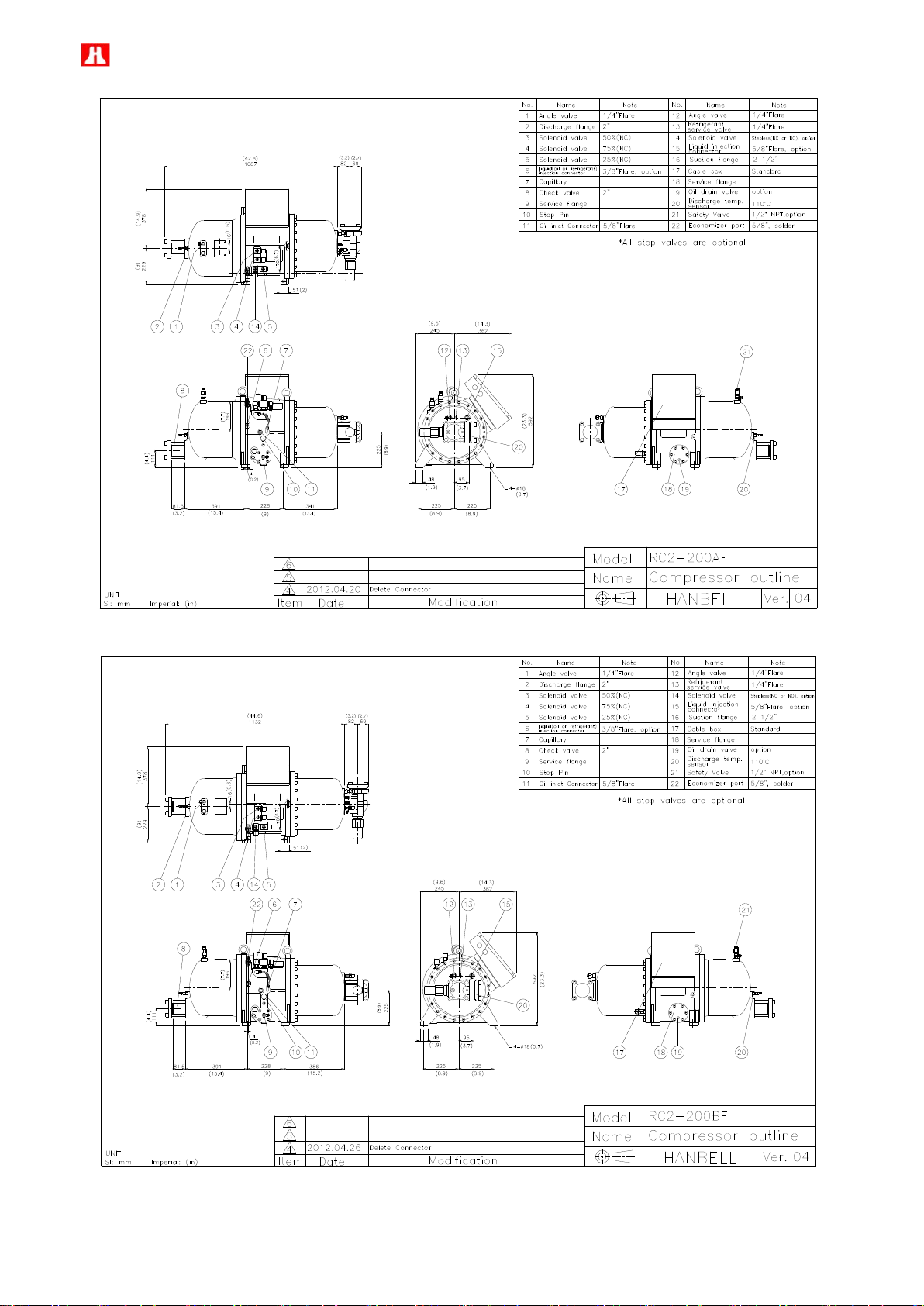

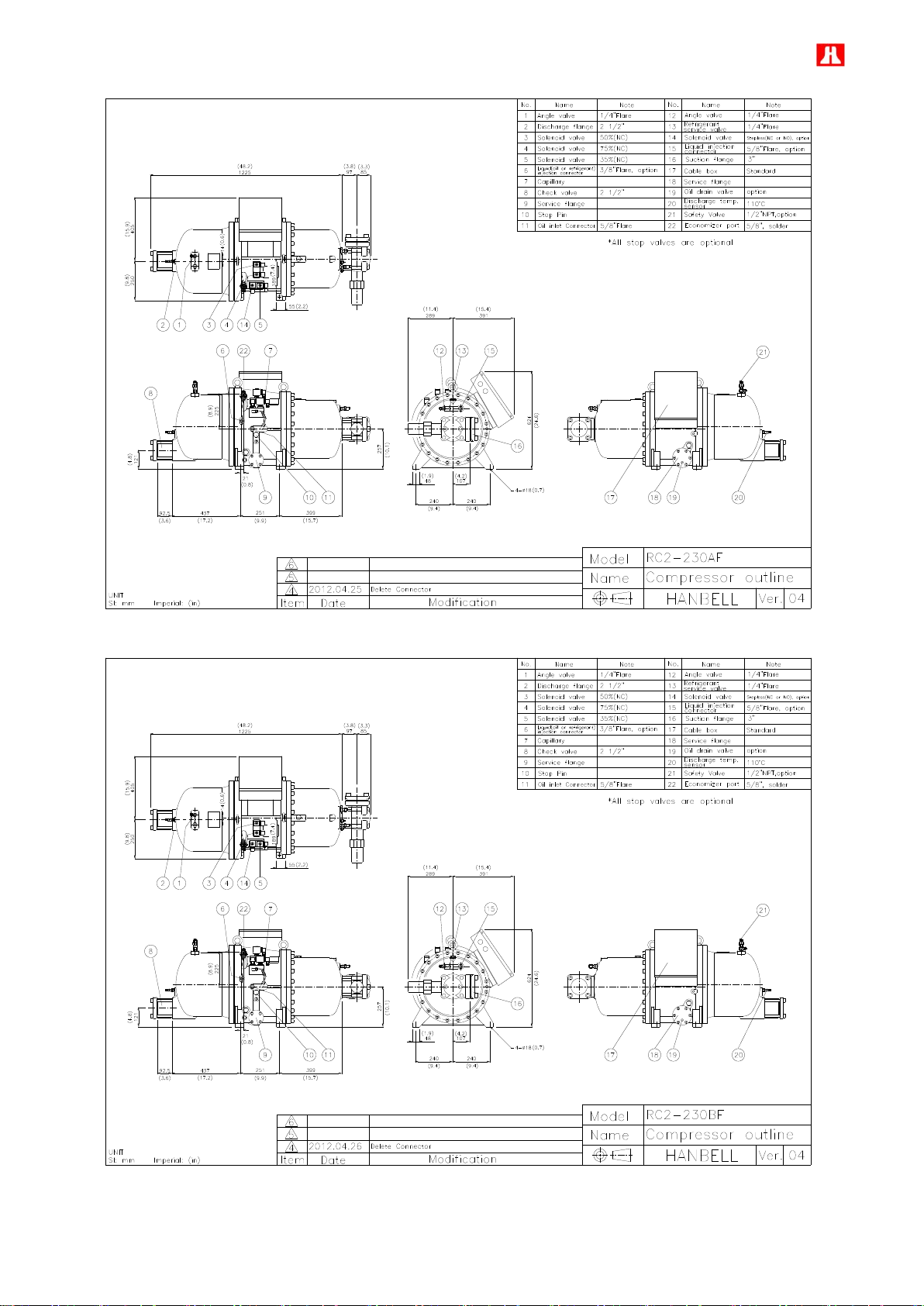

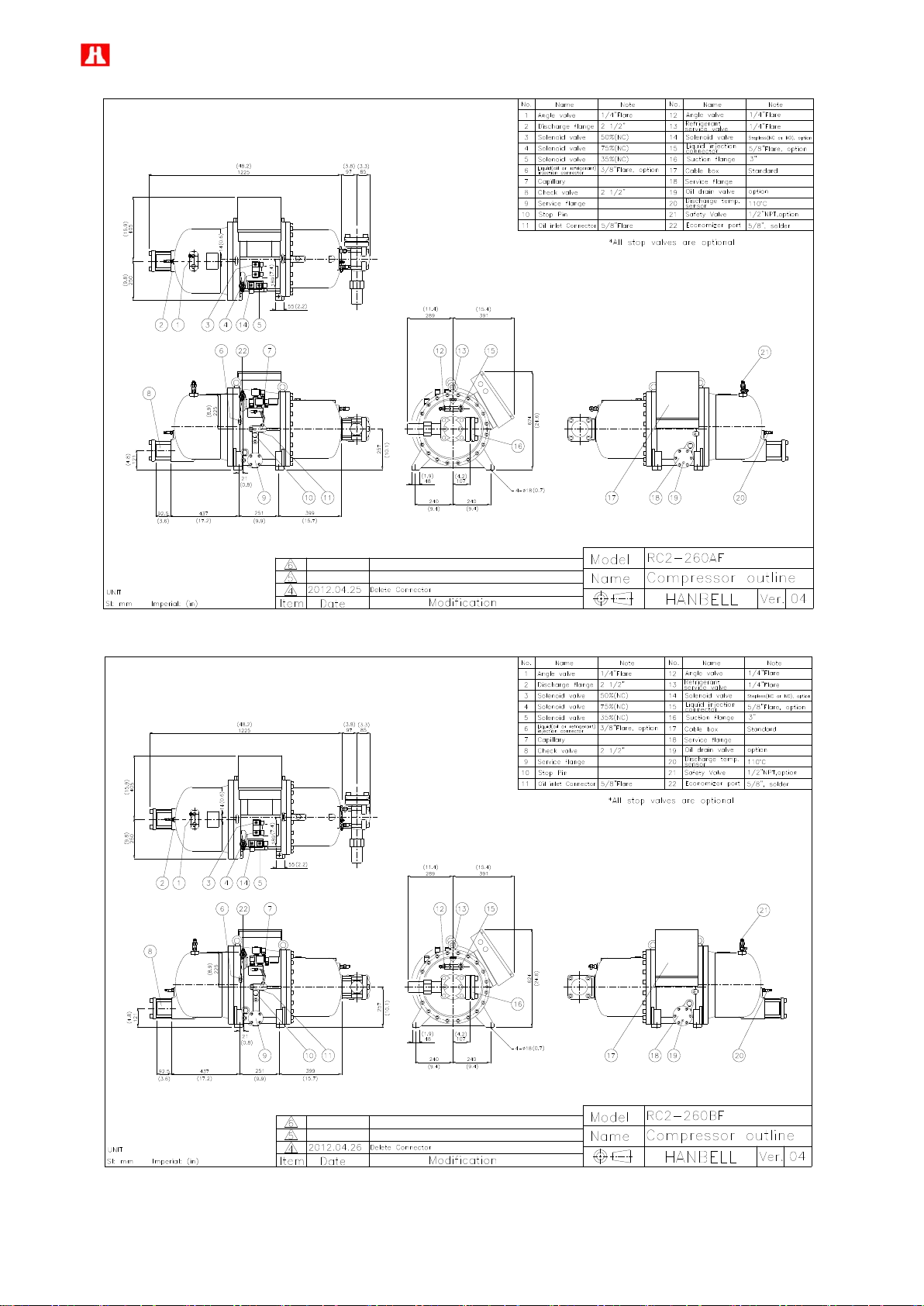

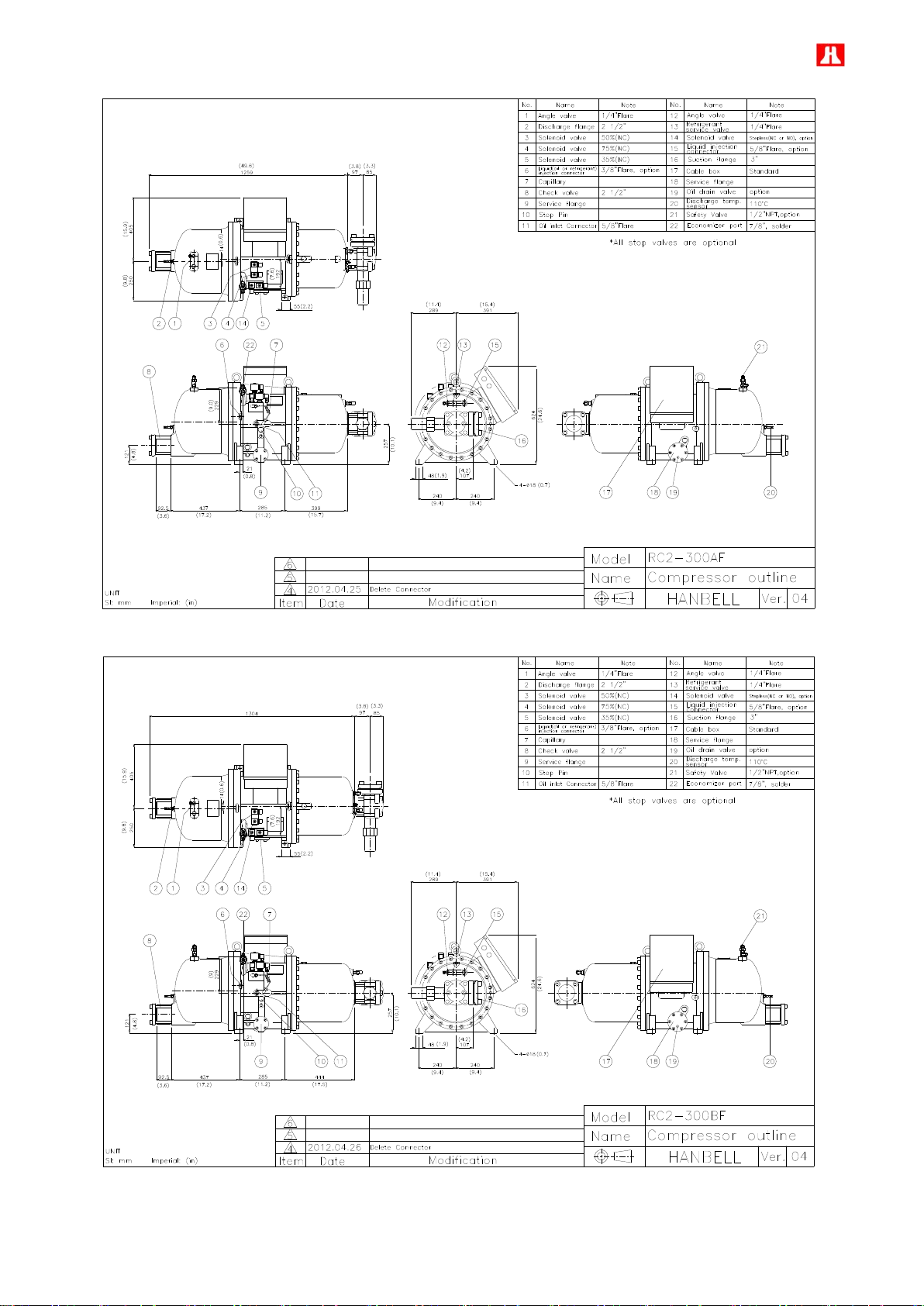

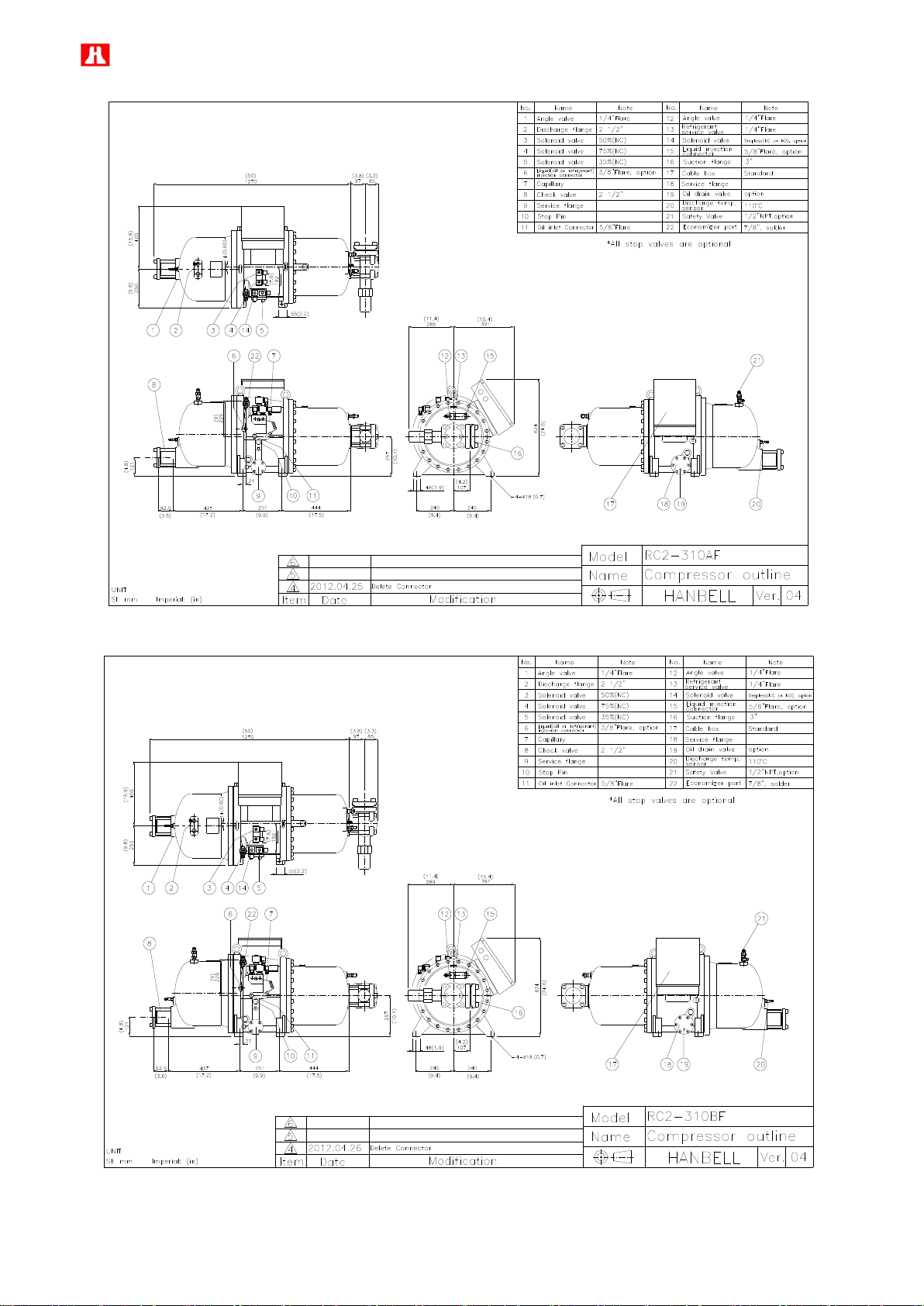

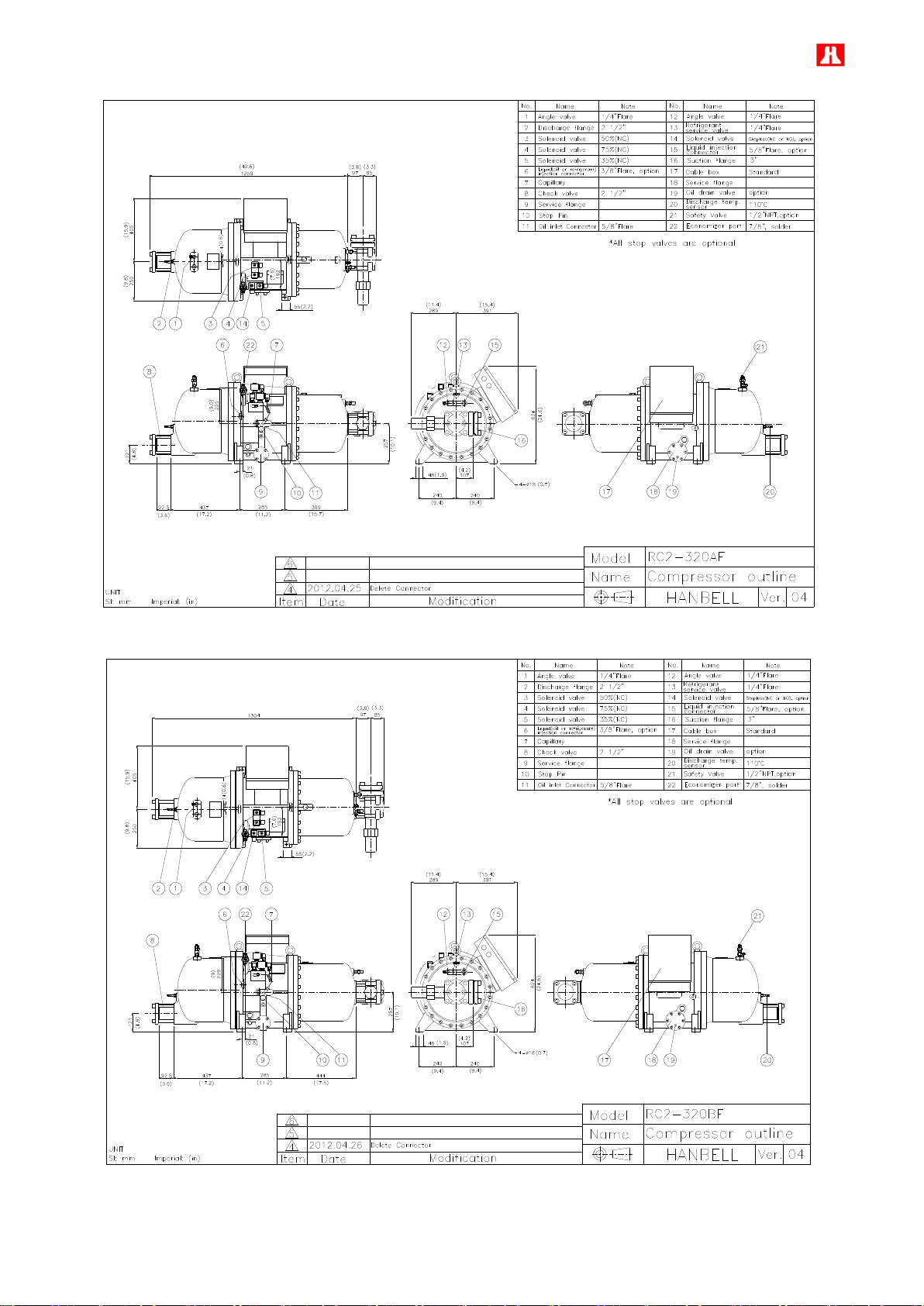

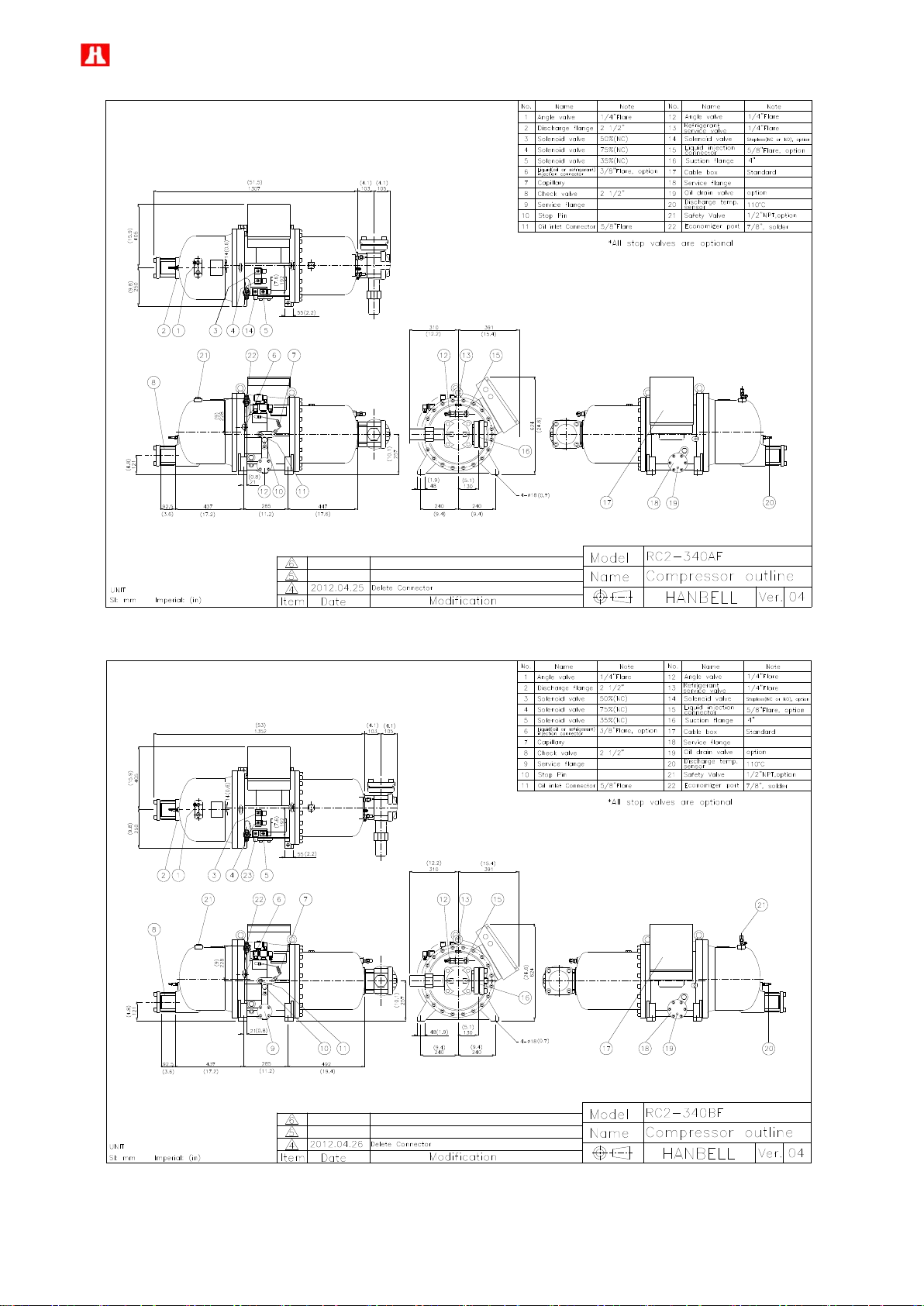

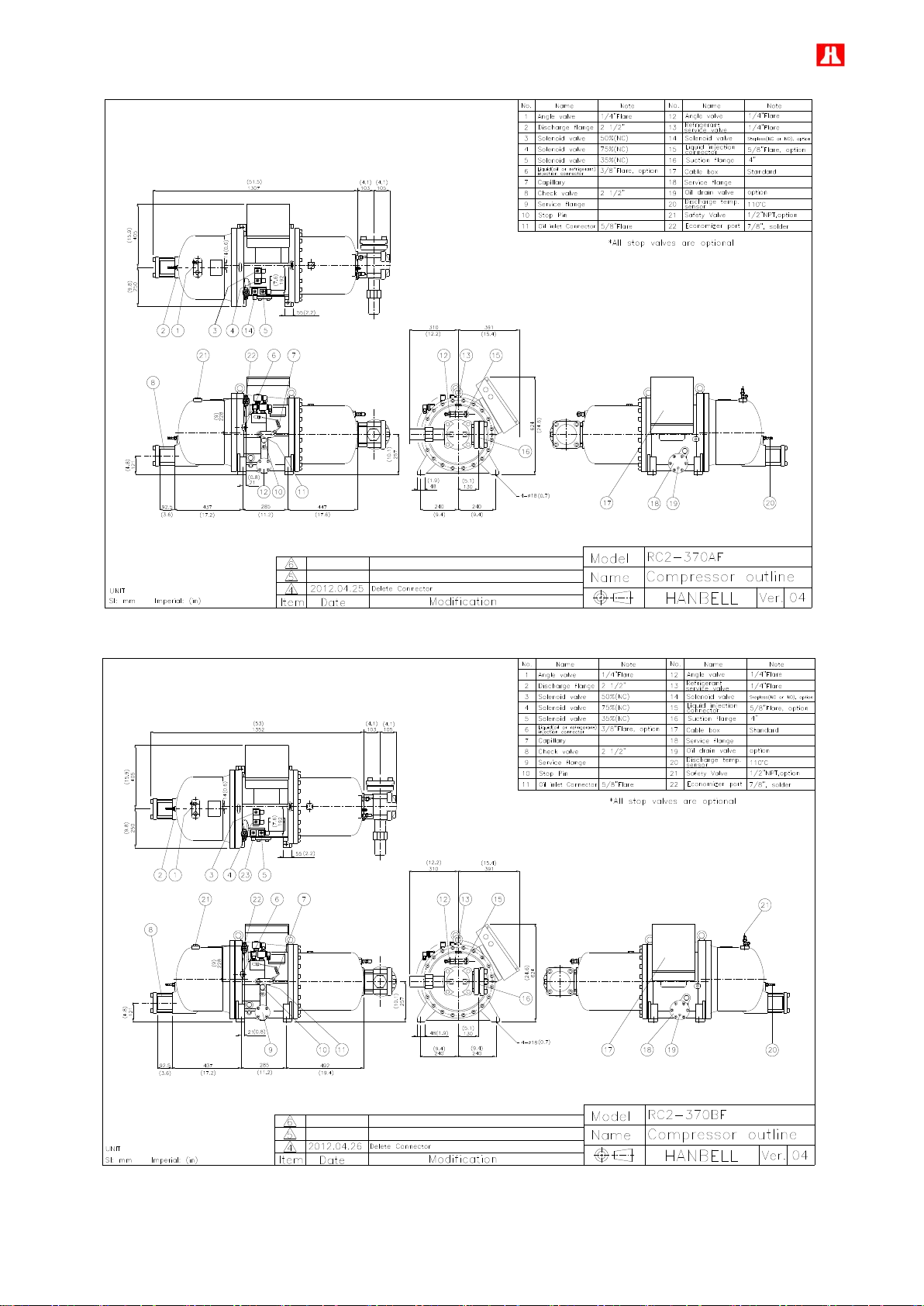

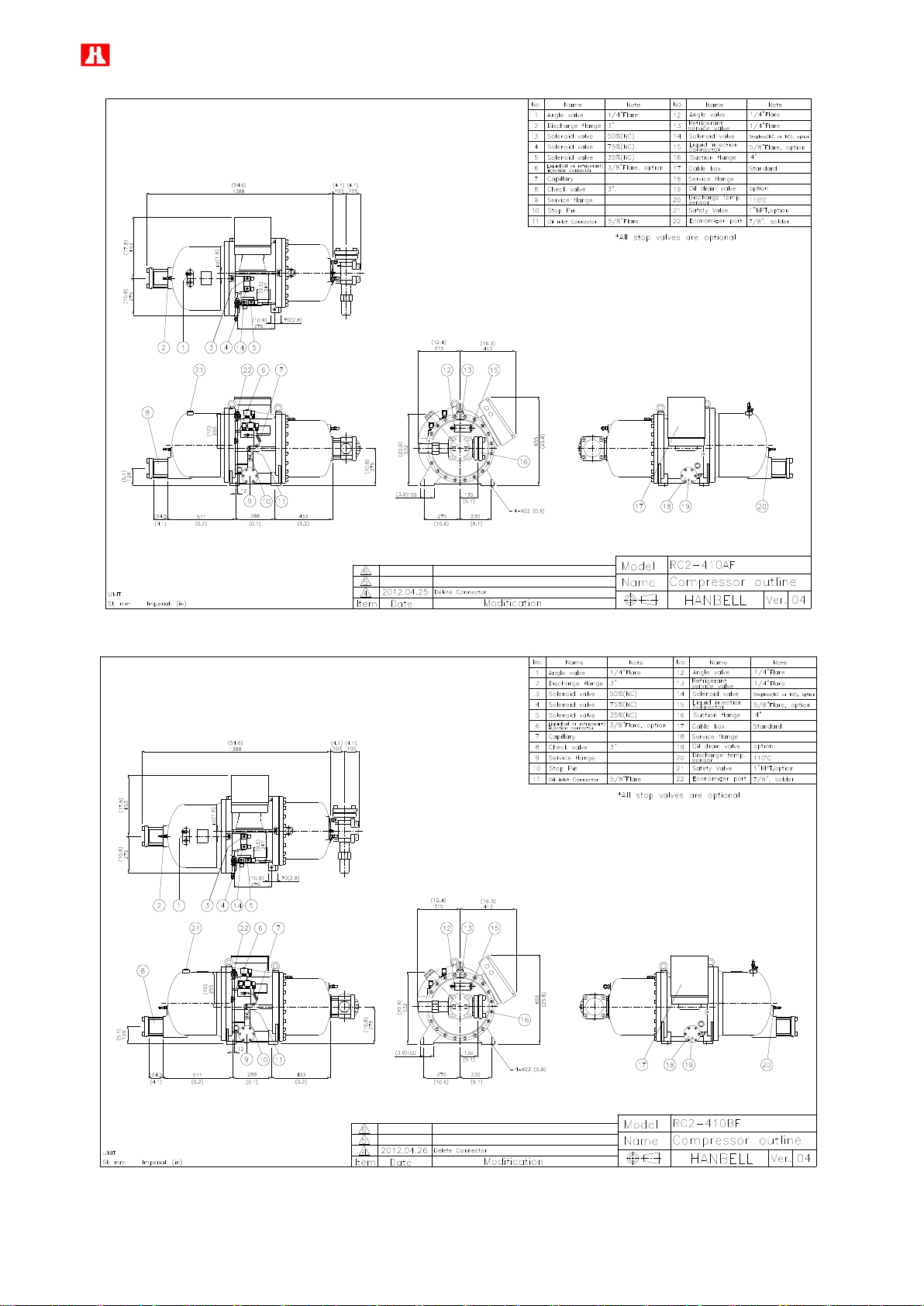

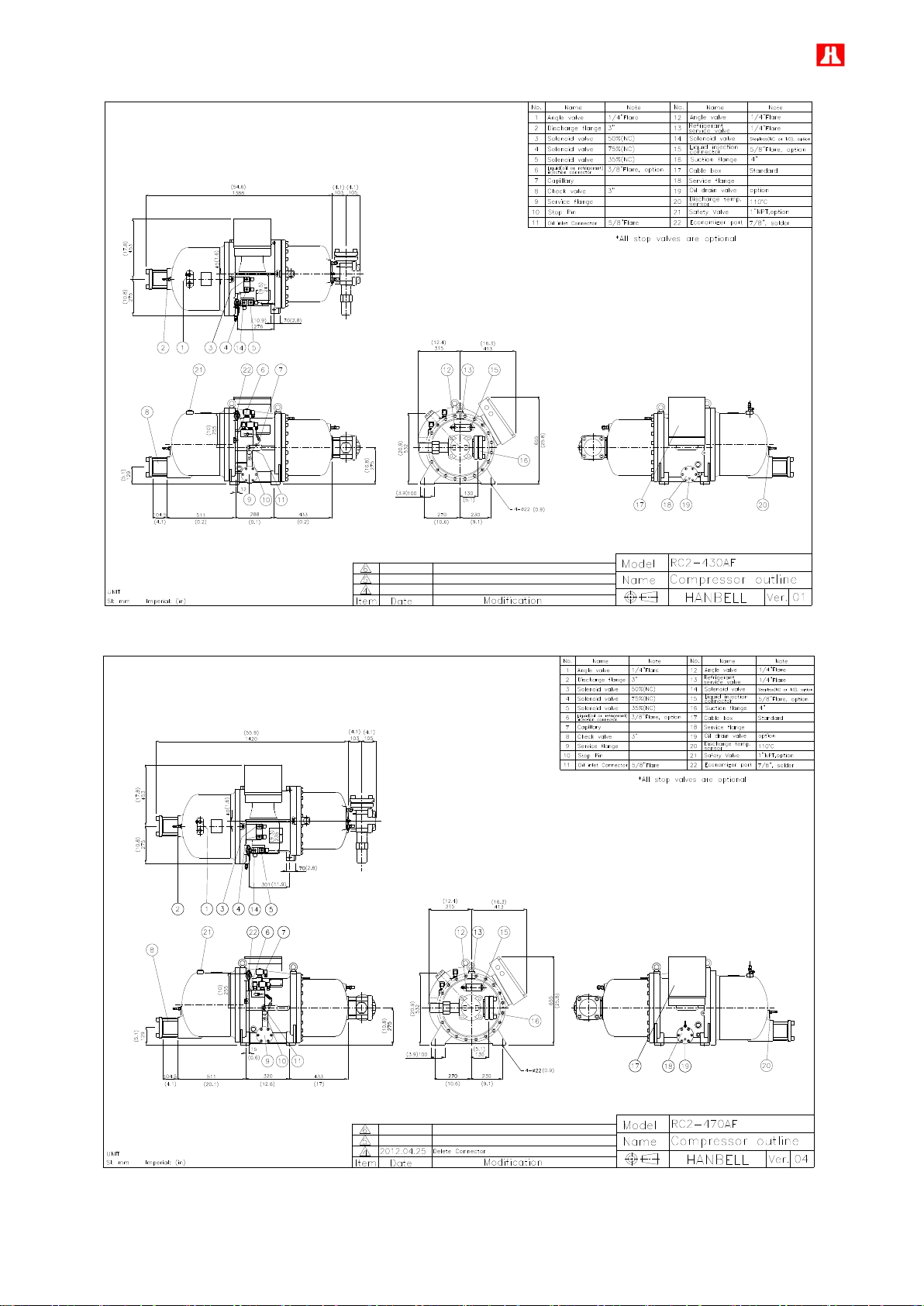

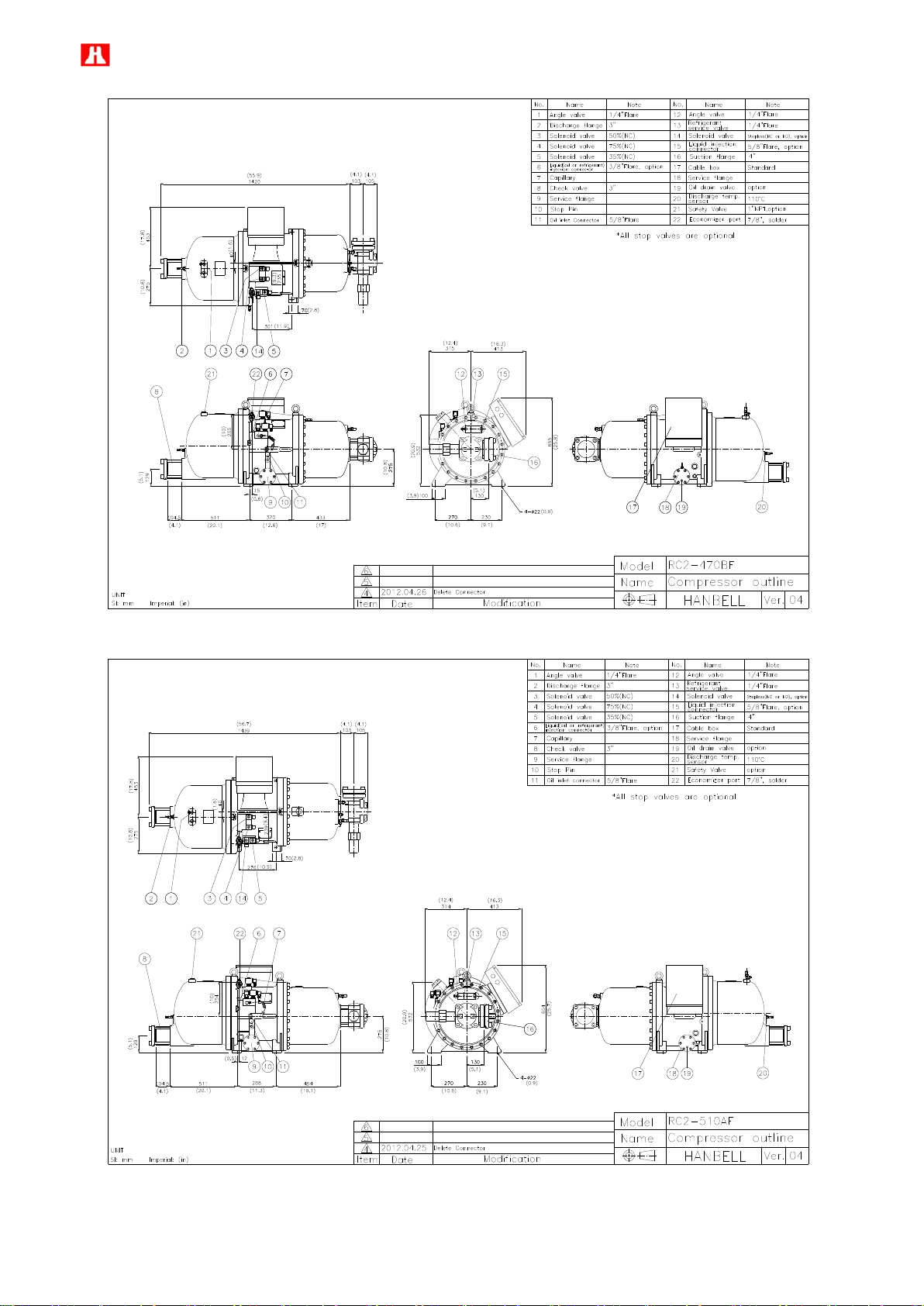

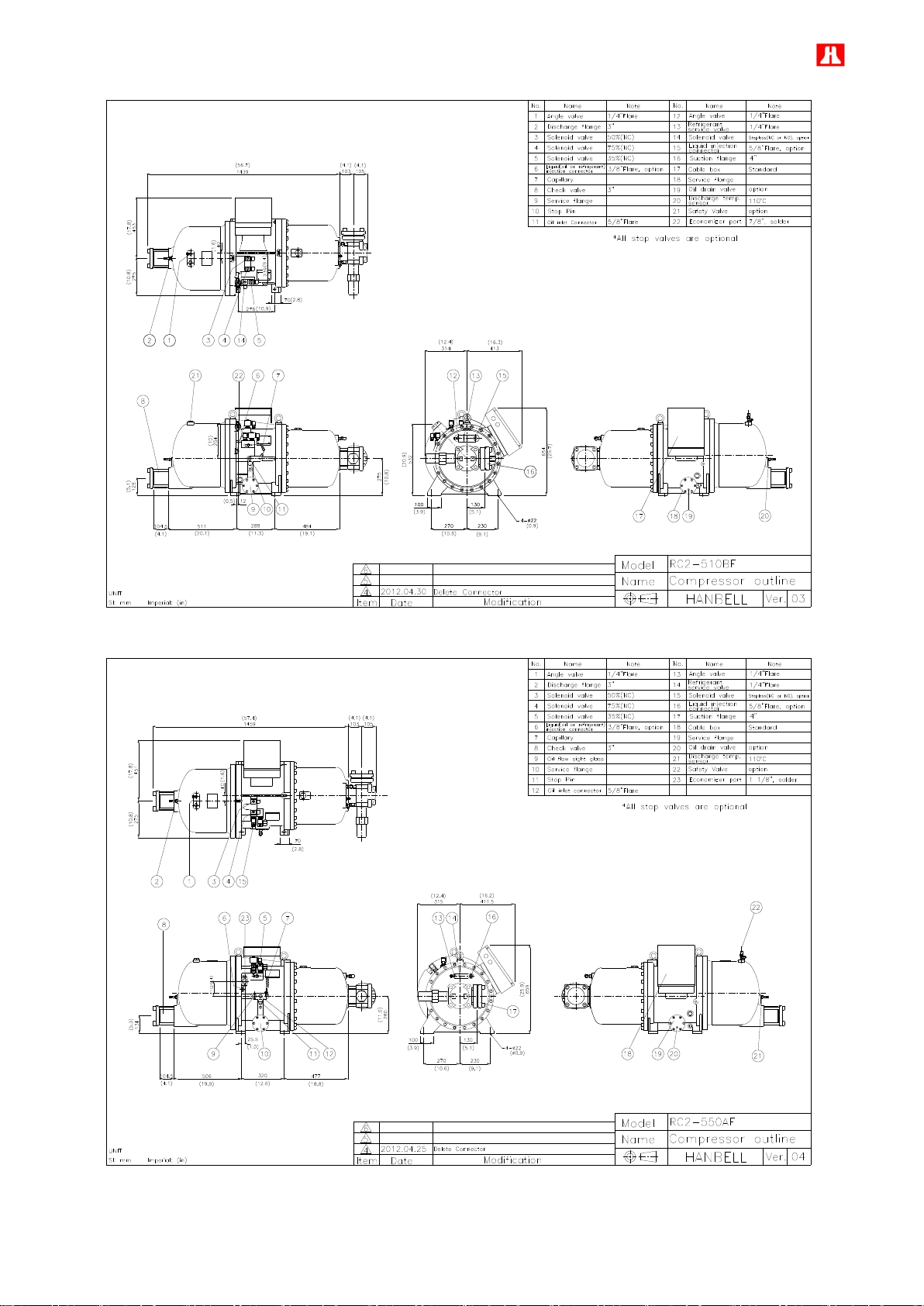

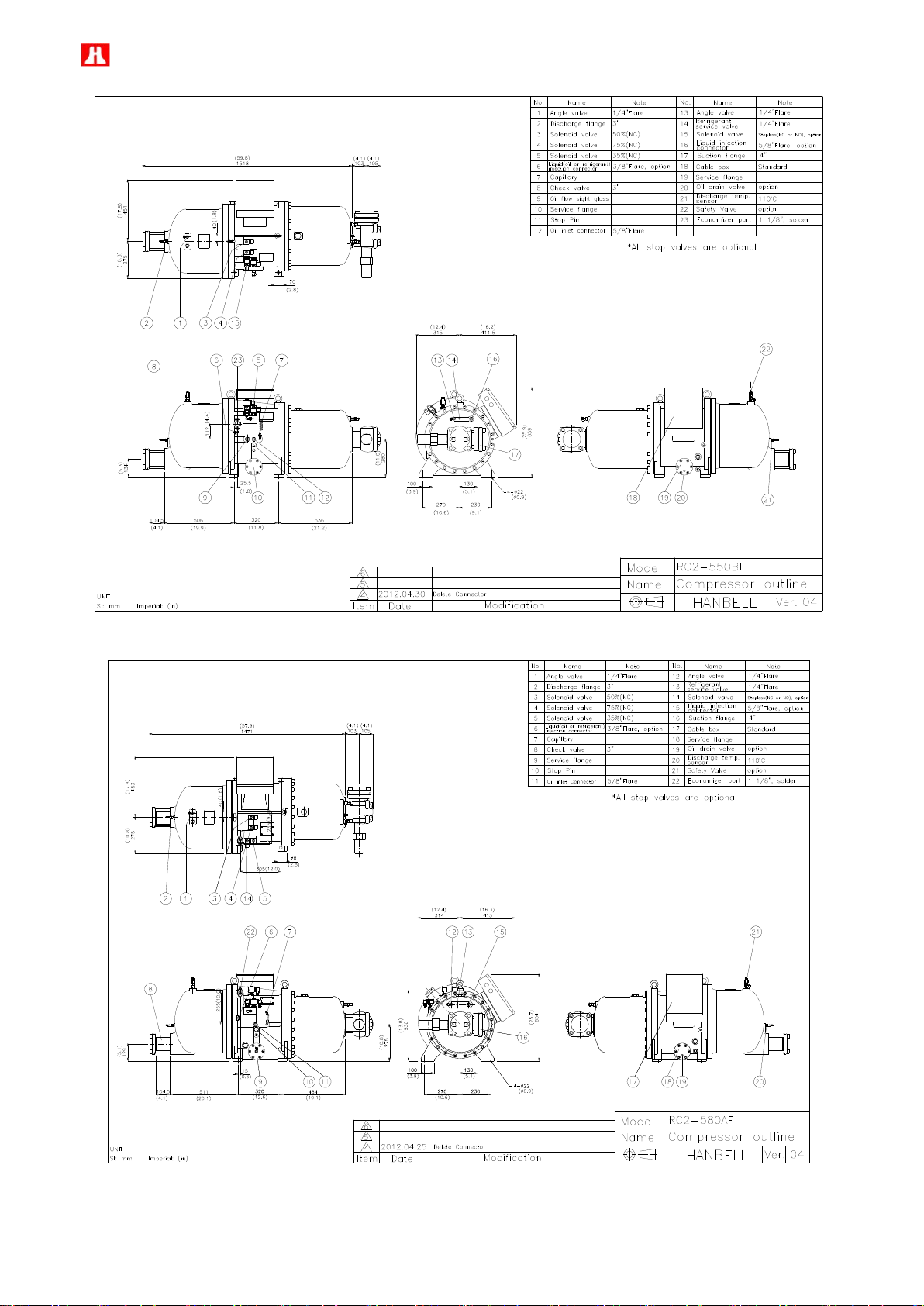

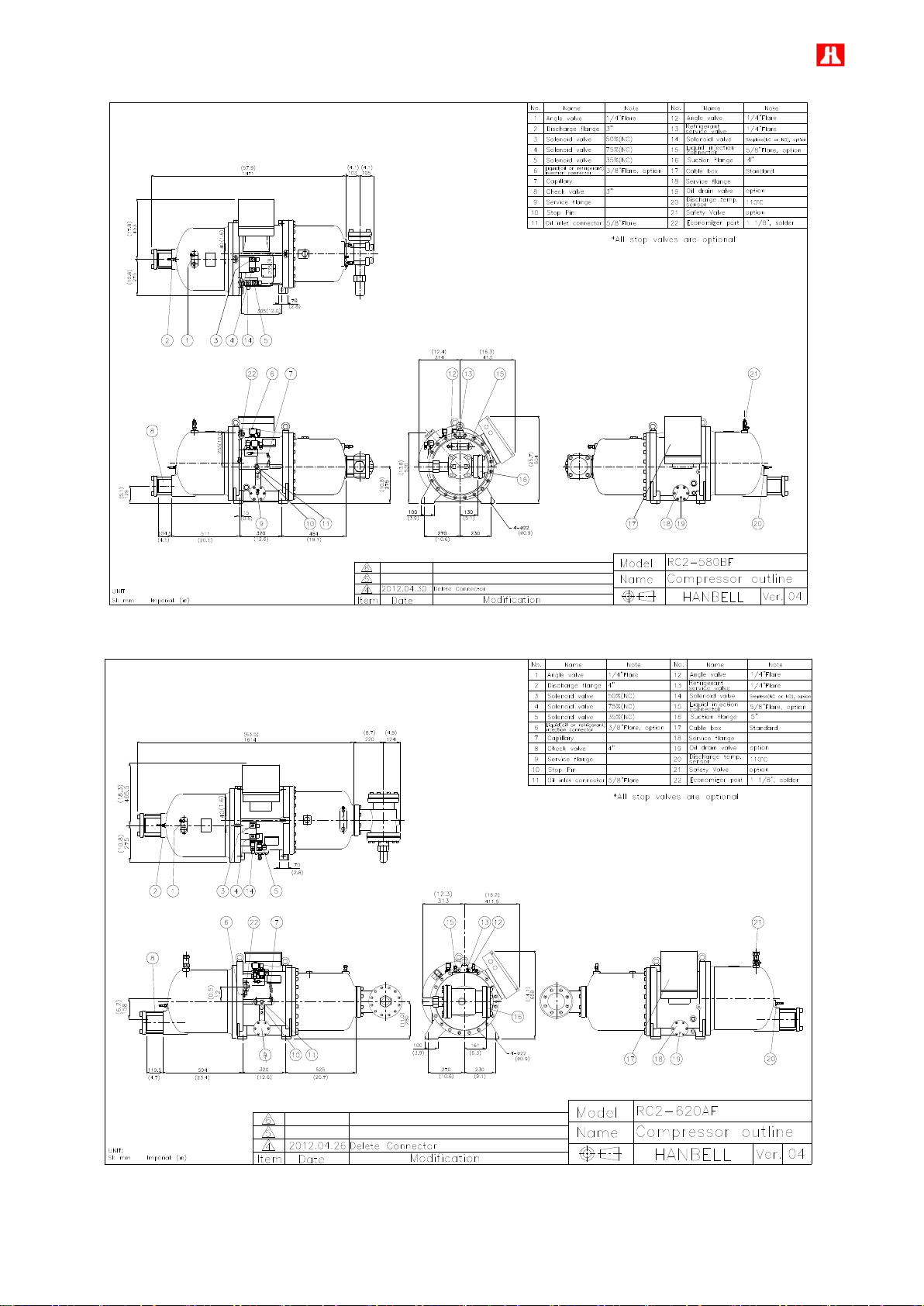

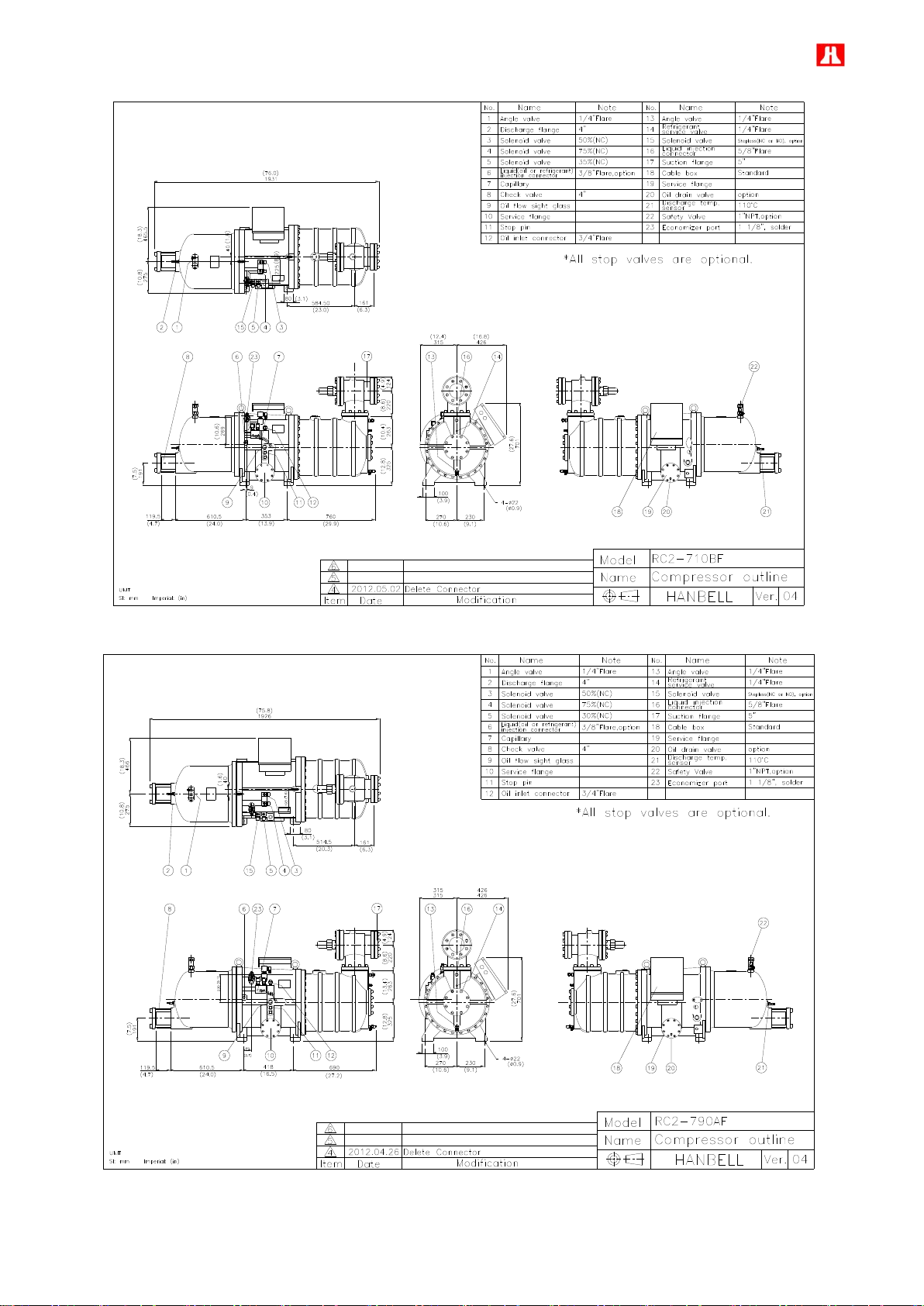

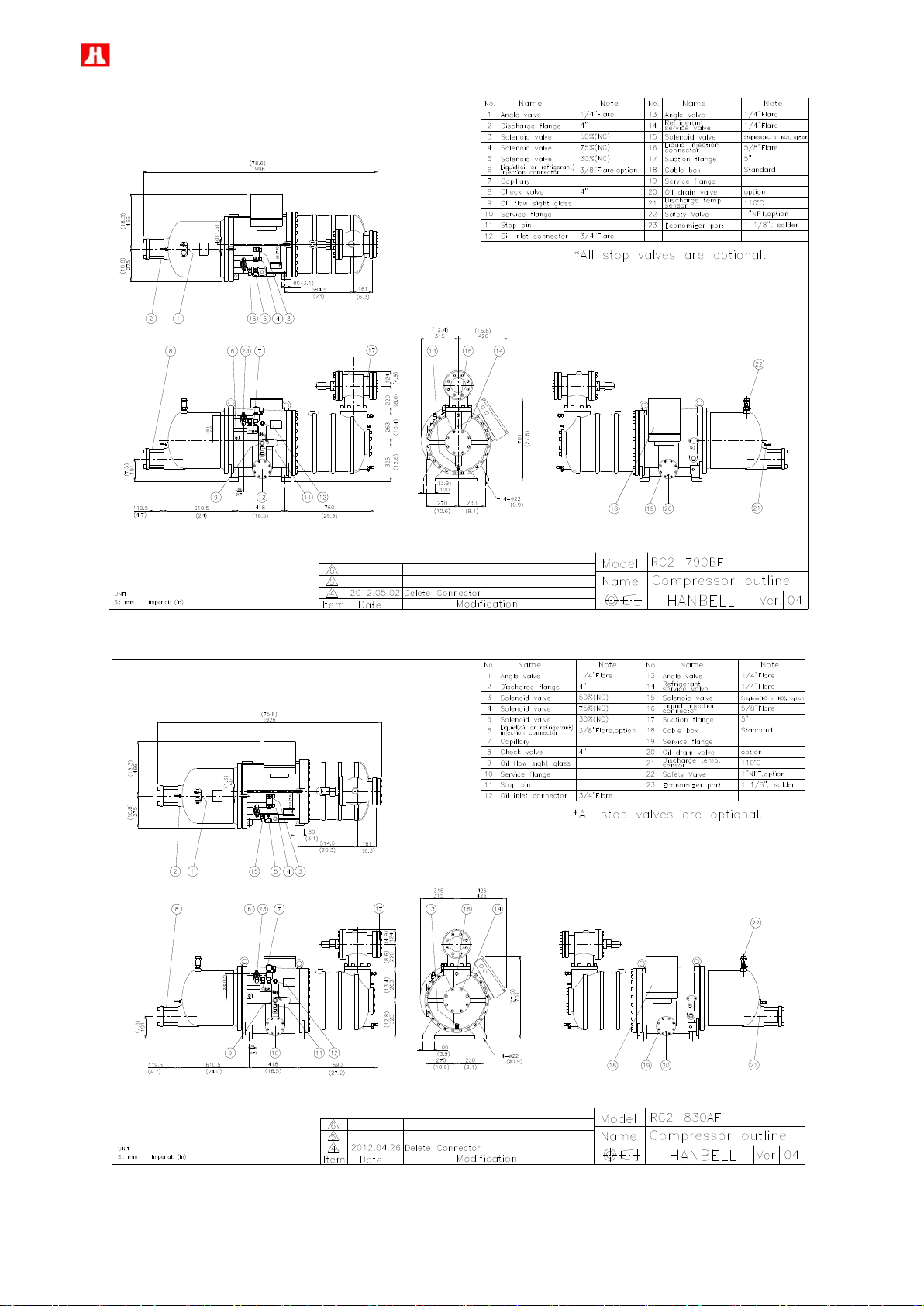

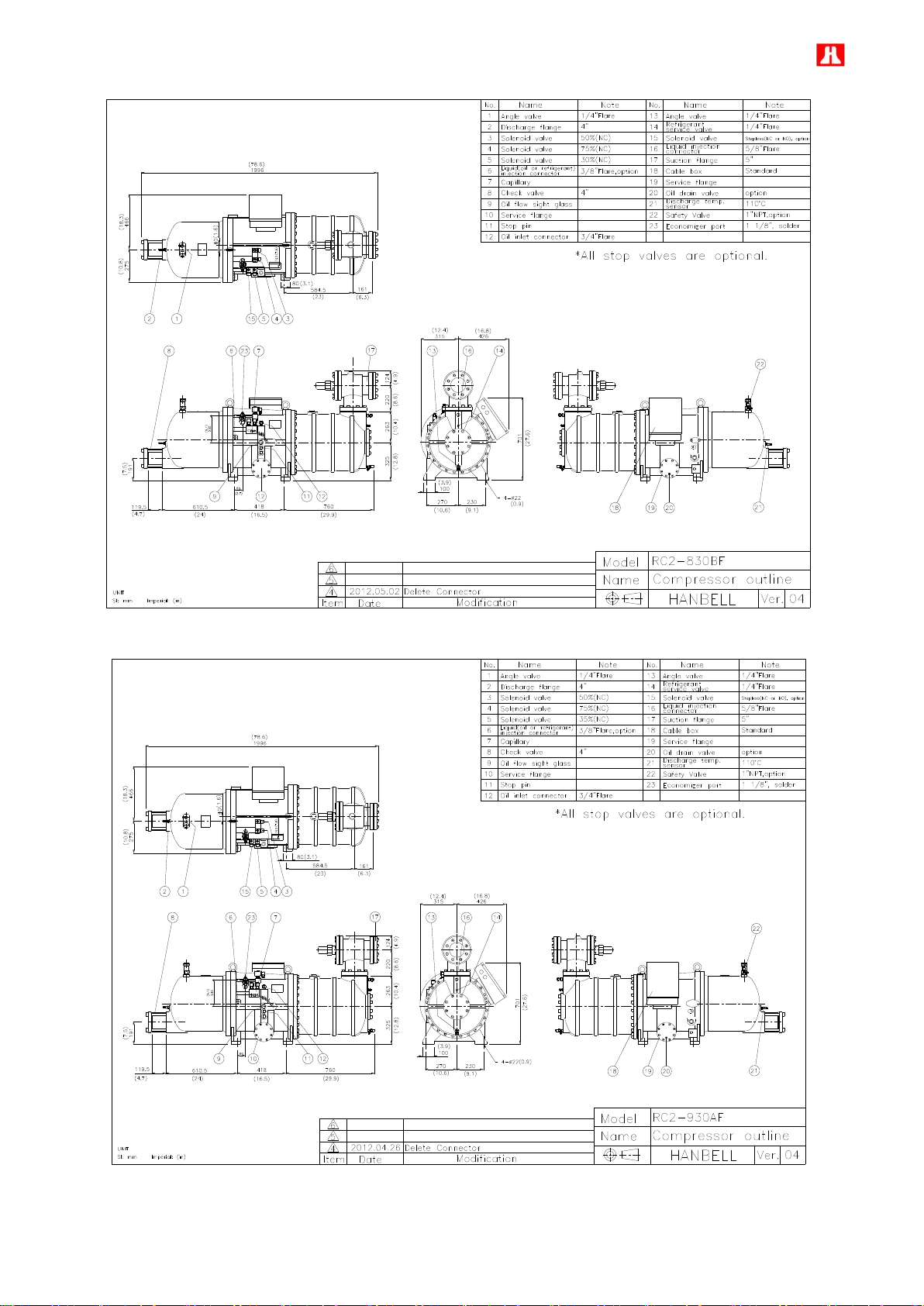

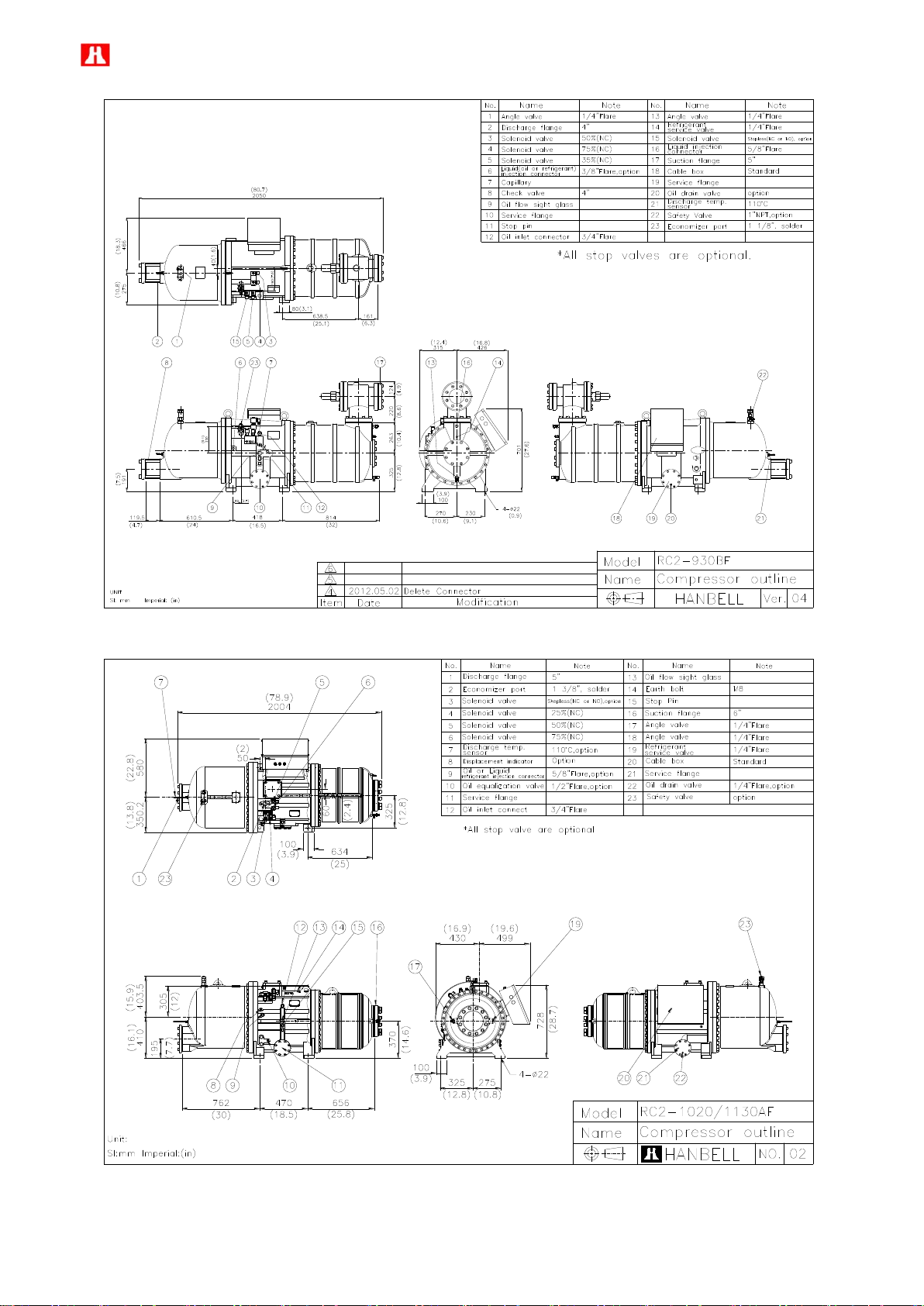

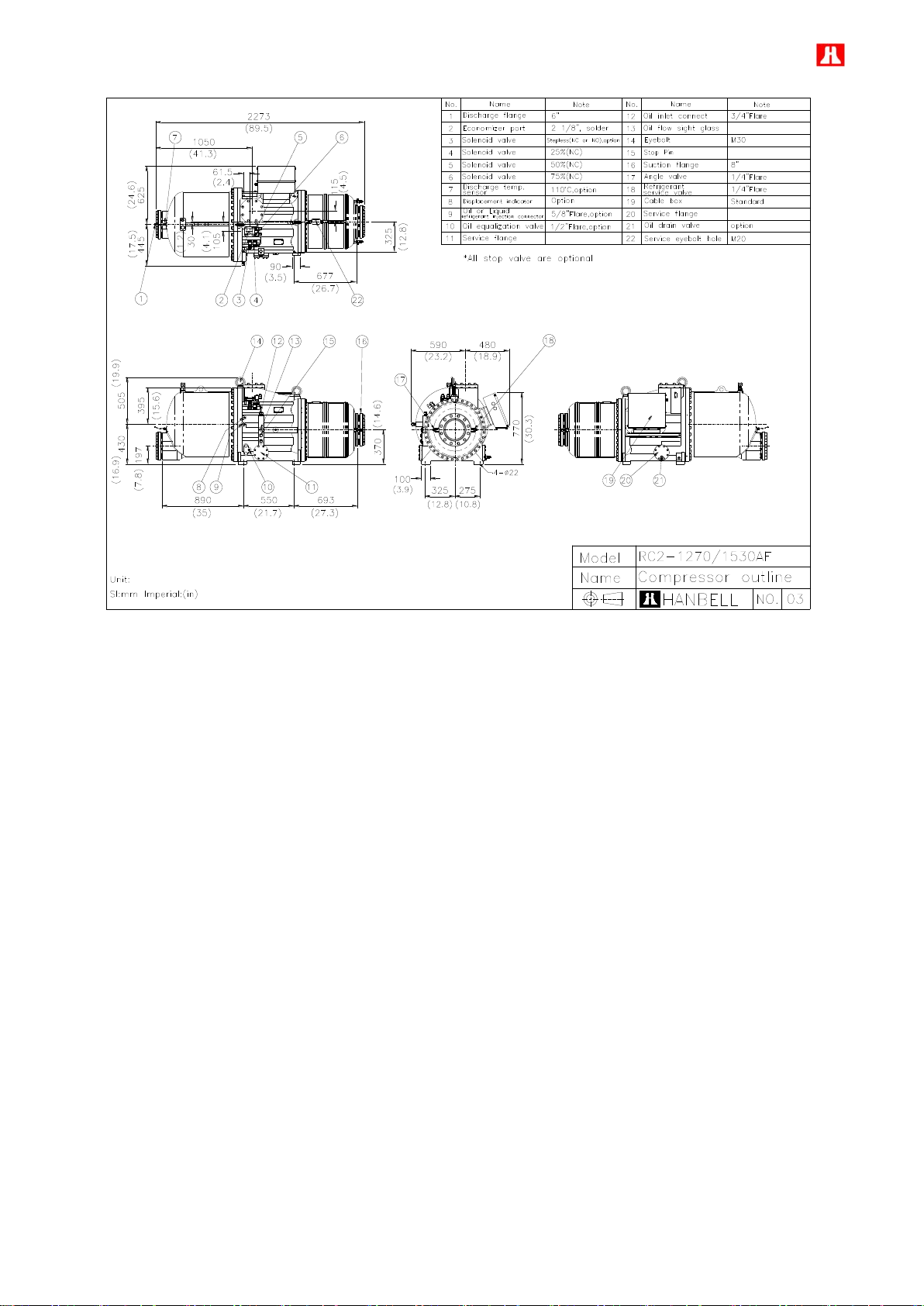

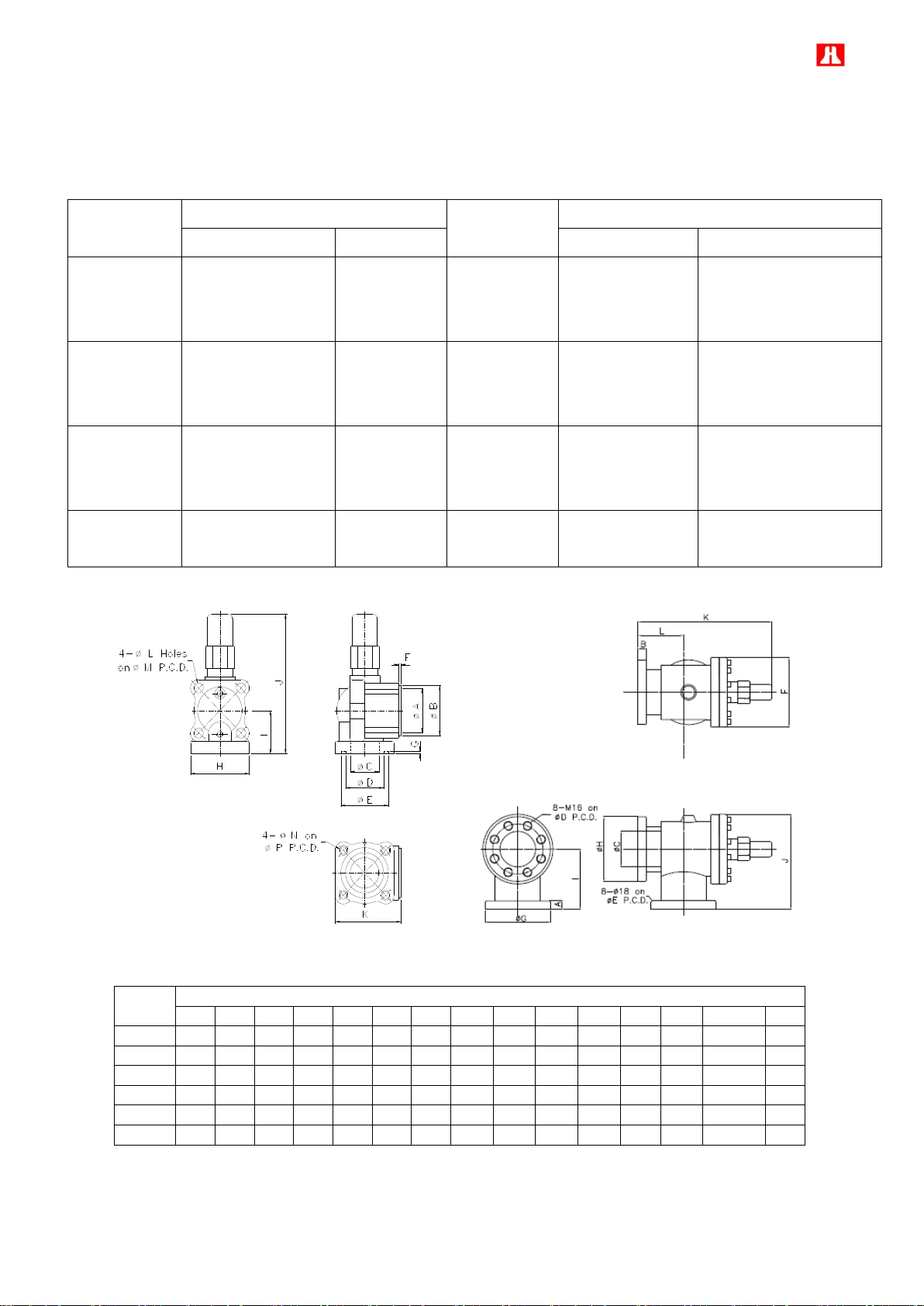

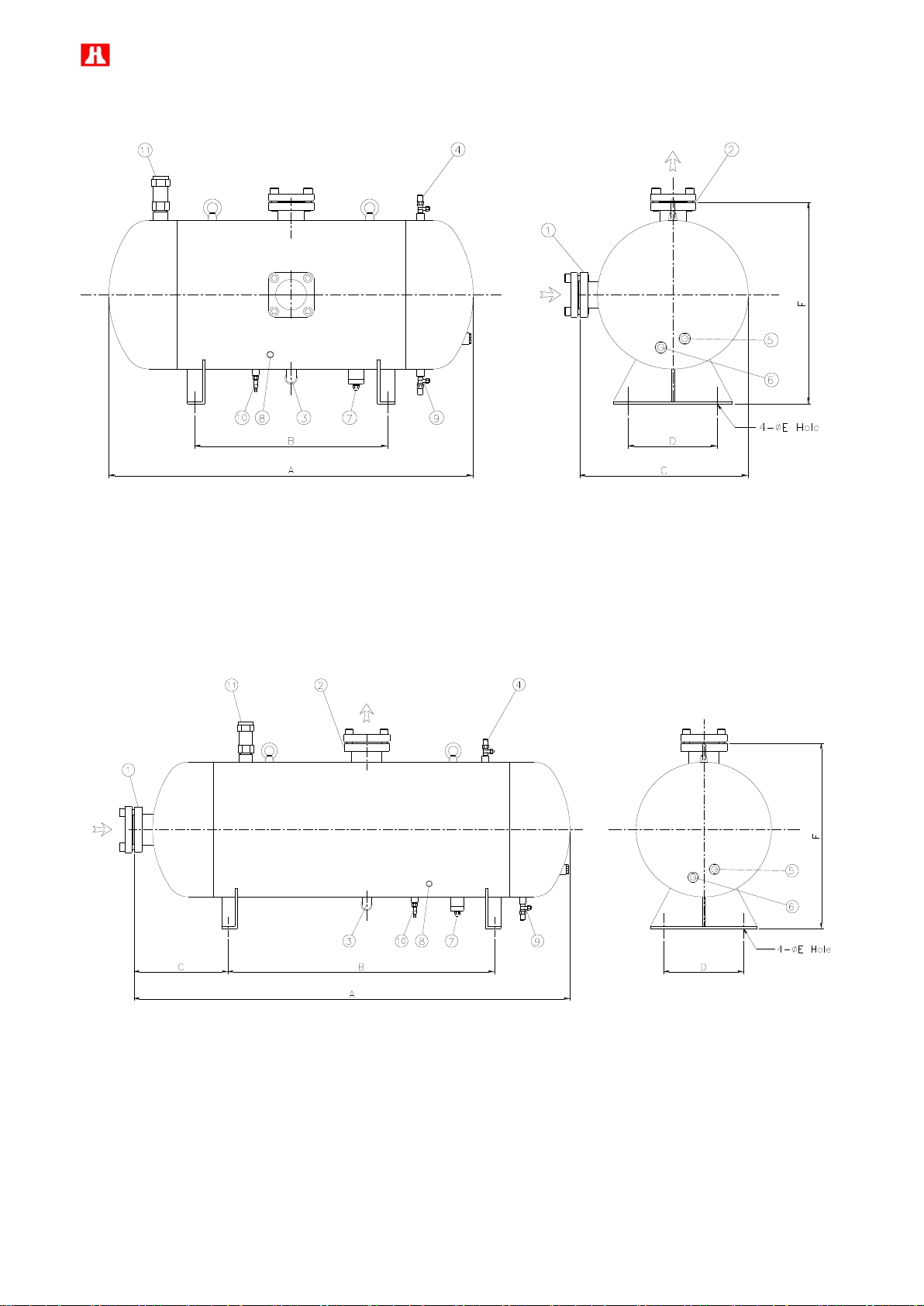

2.2 Compressor outline

Page 7

6

Page 8

7

Page 9

8

Page 10

9

Page 11

10

Page 12

11

Page 13

12

Page 14

13

Page 15

14

Page 16

15

Page 17

16

Page 18

17

Page 19

18

Page 20

19

Page 21

20

Page 22

21

Page 23

22

Page 24

23

Page 25

24

Page 26

25

Page 27

26

Page 28

27

Note: For RC2-1020BF, RC2-1130BF, RC2-1270BF and RC2-1530BF outline drawing, please refer to those of

RC2-1020AF, RC2-1130AF, RC2-1270AF, and RC2-1530AF

Page 29

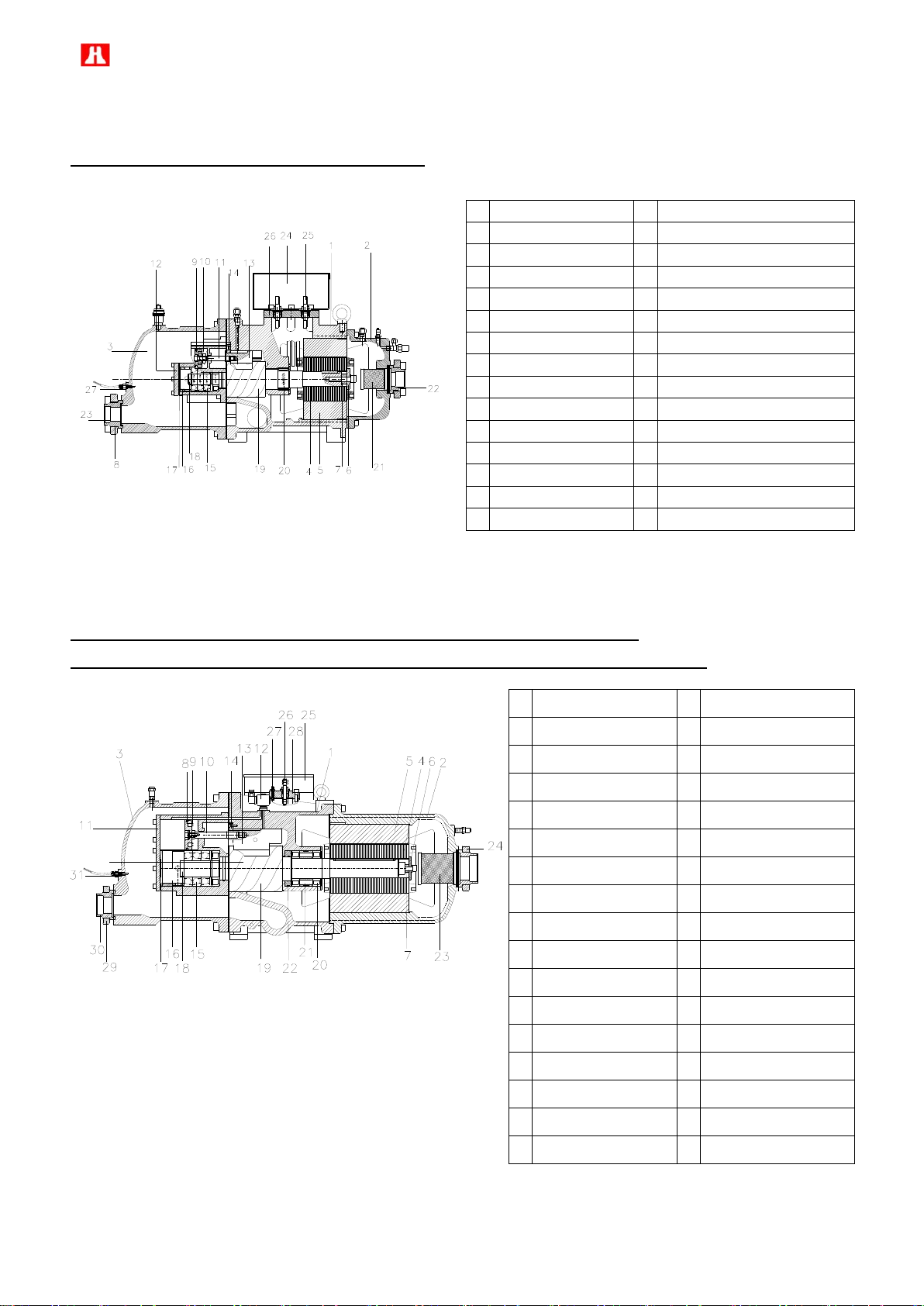

28

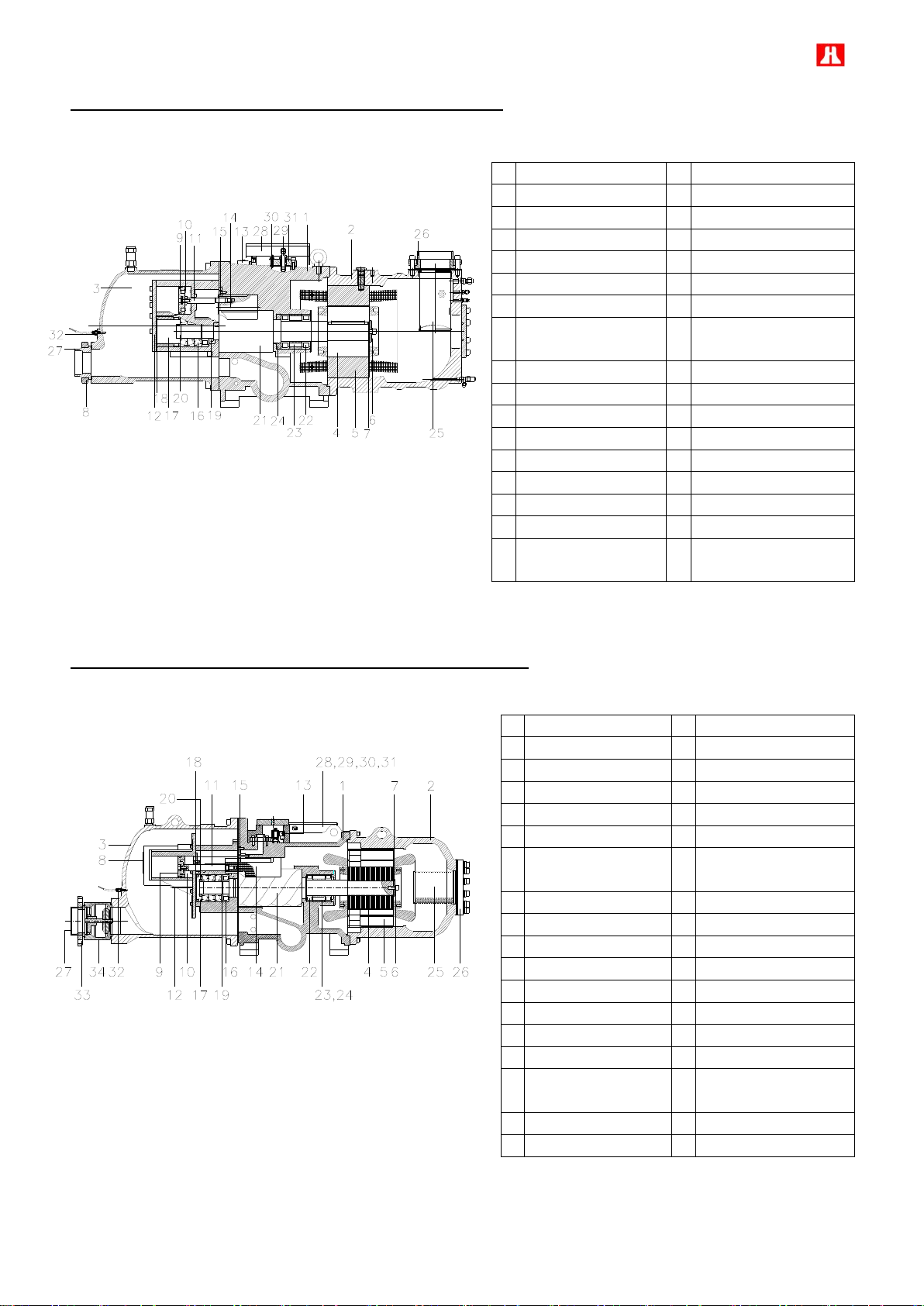

No.

Description

No.

Description

1

Compressor casing

15

Discharge bearings

2

Motor casing

16

Discharge fixed ring

3

Discharge casing

17

Disc spring

4

Motor rotor assembly

18

Bearing slot nut

5

Motor stator assembly

19

Male rotor

6

Motor rotor washer

20

Suction bearings

7

Motor rotor spacer ring

21

Suction filter

8

Discharge connect flange

22

Suction flange

9

Piston

23

Discharge flange bushing

10

Piston ring

24

Cable box

11

Piston rod

25

Power bolt

12

Bearing seat cover plate

26

Terminal cover plate

13

Modulation slide valve

27

PTC discharge temperature sensor

14

Slide valve key

No.

Description

No.

Description

1

Compressor casing

17

Disc spring

2

Motor casing

18

Bearing slot nut

3

Discharge casing

19

Male rotor

4

Motor rotor assembly

20

Suction bearings

5

Motor stator assembly

21

Suction bearings

inner/outer spacer ring

6

Motor rotor washer

22

Oil guiding ring

7

Motor rotor spacer ring

23

Suction filter

8

Piston

24

Suction flange

9

Piston ring

25

Cable box

10

Piston rod

26

Power bolt

11

Bearing seat cover plate

27

Thermostat terminals

12

Modulation solenoid

valve

28

Terminal cover plate

13

Modulation slide valve

29

Discharge connect flange

14

Slide valve key

30

Discharge flange bushing

15

Discharge bearings

31

PTC discharge

temperature sensor

16

Discharge fixed ring

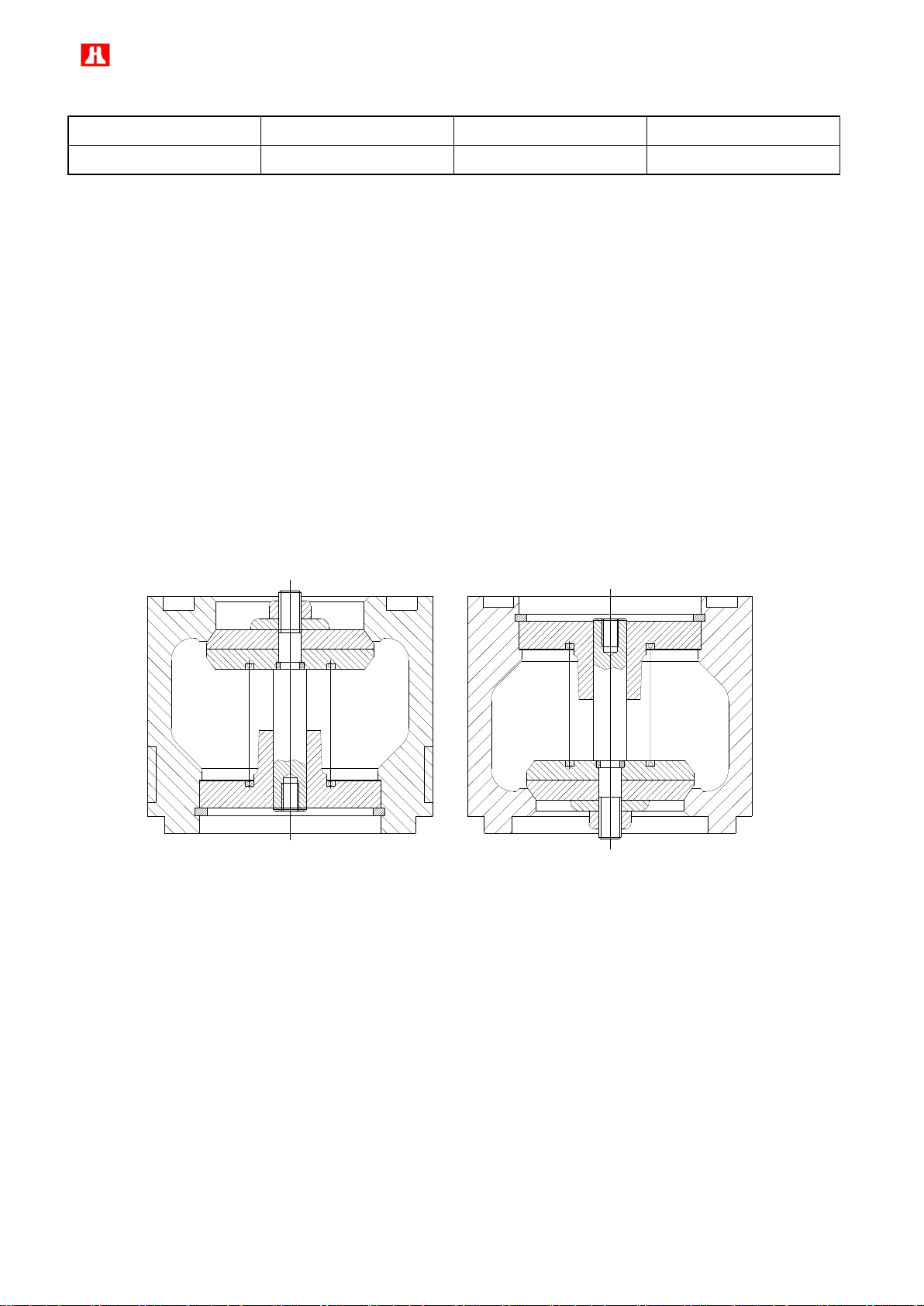

2.3 Compressor construction

RC2-100, RC2-140, RC2-180 F type Construction

RC2-200, RC2-230, RC2-260, RC2-300, RC2-310, RC2-320, RC2-340, RC2-370,

RC2-410, RC2-430, RC2-470, RC2-510, RC2-550, RC2-580, RC2-620 F type Construction

Page 30

29

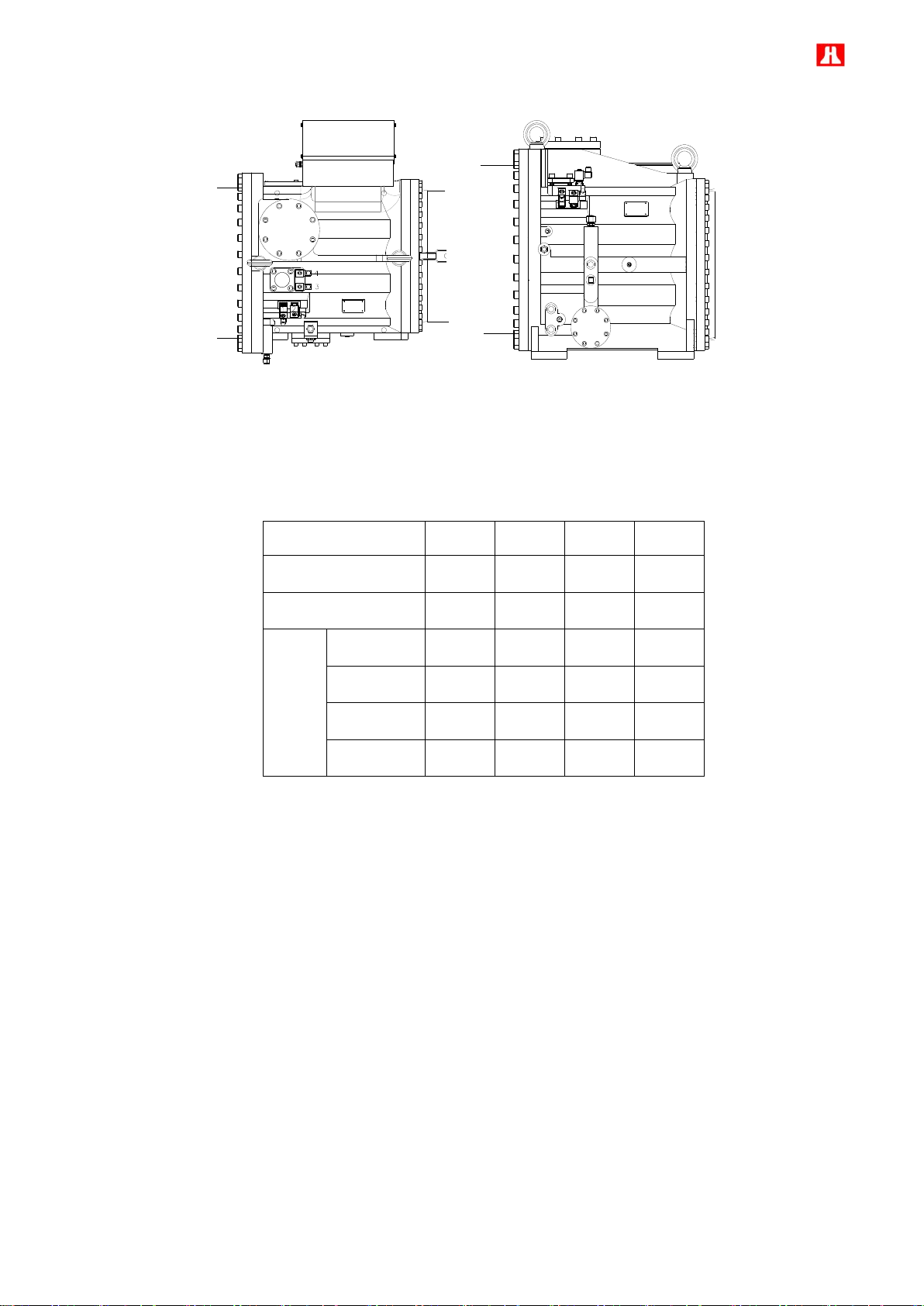

RC2-710, RC2-790, RC2-830, RC2-930 F type Construction

No.

Description

No.

Description

1

Compressor casing

17

Discharge fixed ring

2

Motor casing

18

Disc spring

3

Discharge casing

19

α-Balance piston

4

Motor rotor assembly

20

Bearing slot nut

5

Motor stator assembly

21

Male rotor

6

Motor rotor washer

22

Suction bearings

7

Motor rotor spacer ring

23

Suction bearings inner/outer

spacer ring

8

Discharge connect flange

24

Oil guiding ring

9

Piston

25

Suction filter

10

Piston spring

26

Suction flange

11

Piston rod

27

Discharge flange bushing

12

Bearing seat cover plate

28

Cable box

13

Modulation solenoid valve

29

Power bolt

14

Modulation slide valve

30

Thermostat terminals

15

Slide valve key

31

Motor cable cover plate

16

Discharge bearings

32

PTC discharge temperature

sensor

No.

Description

No.

Description

1

Compressor casing

18

Disc spring

2

Motor casing

19

Balance piston

3

Discharge casing

20

Bearing slot nut

4

Motor rotor assembly

21

Male rotor

5

Motor stator assembly

22

Suction bearings

6

Motor rotor washer

23

Suction bearings inner/outer

spacer ring

7

Motor rotor spacer ring

24

Oil guiding ring

8

Muffler

25

Suction filter

9

Piston

26

Suction flange

10

Piston spring

27

Discharge flange bushing

11

Piston rod

28

Cable box

12

Bearing seat cover plate

29

Power bolt

13

Modulation solenoid valve

30

Thermostat terminals

14

Modulation slide valve

31

Motor cable cover plate

15

Slide valve key

32

PTC discharge temperature

sensor

16

Discharge bearings

33

Discharge connect flange

17

Discharge fixed ring

34

Check valve

RC2-1020, RC2-1130, RC2-1270, RC2-1530 F type Construction

Page 31

30

1

2

4

3

2.4 Capacity control system

The RC2-F series screw compressors are equipped with either 3-steps/4-steps or continuous (step-less) capacity

control system. Both capacity control systems consist of a modulation slide valve, piston rod, cylinder, piston and

piston rings. The slide valve and the piston are connected by a piston rod. The principle of operation is using the oil

pressure to drive the piston in the cylinder. The lubrication oil flows from the external oil separator through the oil

filter to the main oil inlet port and then fills into the cylinder due to the positive oil pressure force which is bigger

than the spring force plus the force from high pressure gas. The positive pressure differential causes the piston to

move toward the loading direction in the cylinder. When the slide valve moves toward the loading direction, the

effective suction volume increased in the compression chamber. This means the displacement of refrigerant gas

also increases, as a result the refrigeration capacity also increases. However, when any of the step solenoid valve

(for 4-step capacity control system) is opened, the high pressure oil in the cylinder bypasses to the suction side,

which causes the piston and the slide valve move toward the unloading direction, and then some of the refrigerant

gas bypasses from the compression chamber back to the suction end. As a result, the refrigeration capacity

decreases because of the reduction of displacement of refrigerant gas flowing in the system.

The piston spring is used to push the piston back to its original position, i.e. minimum load position in order to

reduce the starting current for the next starting-up. If the compressor started at full load capacity it may result in

over current start. The modulation solenoid valves are controlled by a micro controller or temperature switch to

modulate the piston position smoothly with stable output of capacity.

If the oil filter cartridge or modulation solenoid valves are not working well in the capacity control system, this may

result in the abnormality and ineffectiveness of the capacity control system. Before stopping the compressor,

HANBELL strongly recommends that the unloading solenoid valve of step-less control system or minimum load

solenoid valve of 3/4 steps control system should be kept opened for 30~60 seconds so that oil pressure in the

cylinder can be released. When starting the compressor next time, the slide is at its minimum load position for a

light duty start.

The capacity control solenoid valves of different models are equipped as the pictures shown below. Please refer

to the pictures and description for the detail of capacity control logic.

RC2-100F/140F/180F RC2-200F~RC2-930F

Page 32

31

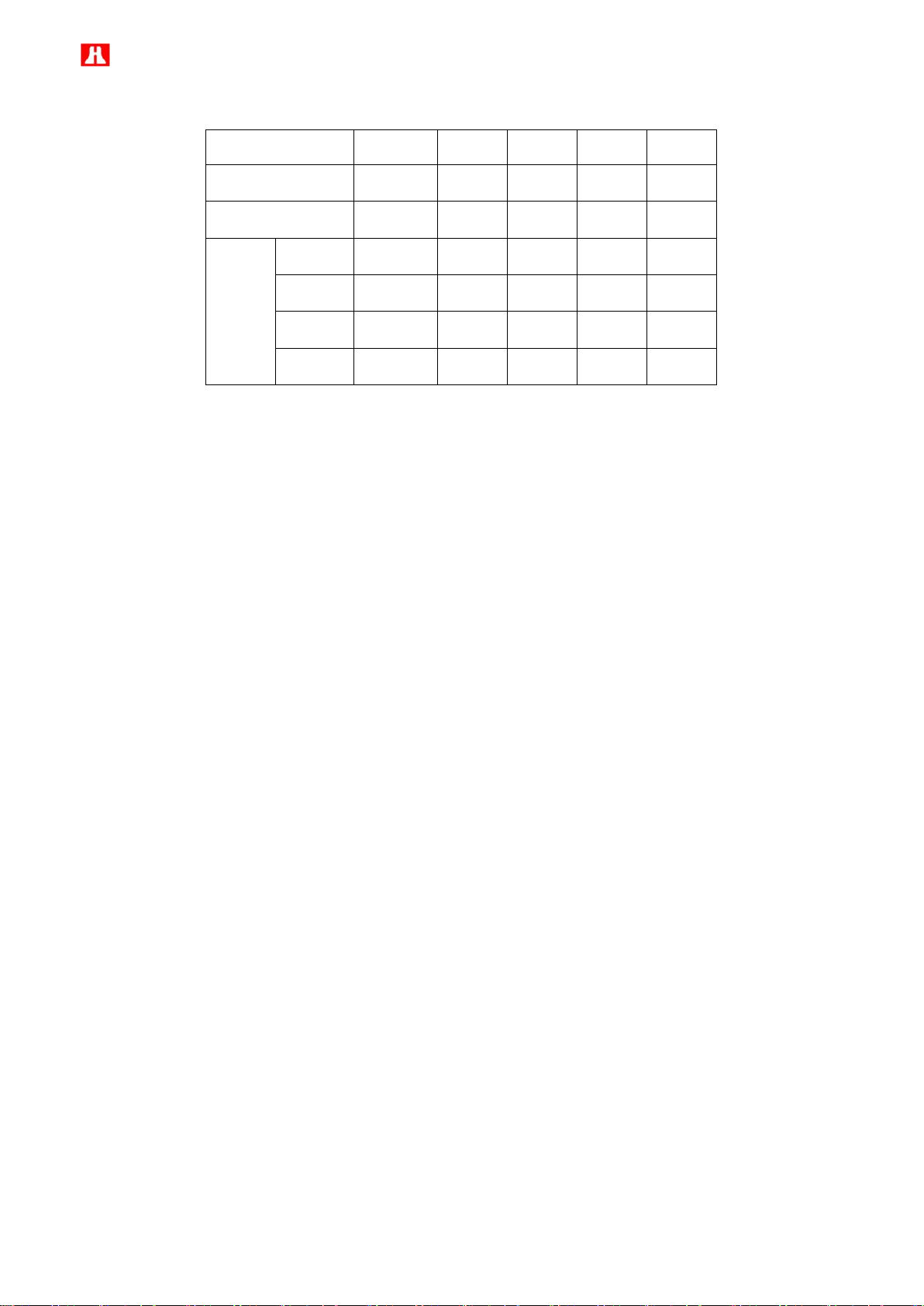

Top view Side view

Solenoid Valve

1 2 3

4

Normal Open / Normal Close

--

NC

NC

NC

Standard / Optional

--

STANDARD

STANDARD

STANDARD

Control

Logic

S %

(Start)

--

ON

OFF

OFF

M1 %

(66% or 50%)

--

OFF

ON

OFF

M2 %

(75%)

--

OFF

OFF

ON

F %

(Full Load / 100%)

--

OFF

OFF

OFF

RC2-1020F ~ RC2-1530F

3 or 4 steps capacity control

Note:

ON : Solenoid valve energized

OFF: Solenoid valve not energized

Warning:If the S % ( start ) capacity is essential to be kept running for a long time, the problem of oil return,

motor cooling and high discharge temperature and other problem should be considered seriously to prevent

inappropriate operation of the compressor which may damage it.

Page 33

32

Solenoid Valve

1 1 2 3 4

Normal Open / Normal Close

NO

NC

NC

--

--

Standard / Optional

OPTIONAL

STANDARD

STANDARD

--

--

Control

Logic

Start

ON

OFF

ON

--

--

Loading

OFF

ON

OFF

--

--

Unloading

ON

OFF

ON

--

--

Hold /

Stable

ON

OFF

OFF

--

--

Stepless capacity control

Note:

ON : Solenoid valve energized

OFF: Solenoid valve not energized

In continuous capacity control system, two normally close solenoid valve are equipped as standard. These two

solenoid valves are controlled by the chiller temperature controller, hence refrigeration capacity can be modulated

between S (start) %100% continuously. The exactness of temperature control depends on the precision of

temperature sensor.

The timer resolution of control system, affects the capacity control’s speed. Hanbell recommends setting the timer

resolution between 0.1~1second to have a precise capacity control. If the resolution is set more than 1 second,

then it is recommended to add a flow control device to obtain a smooth capacity control.

Page 34

33

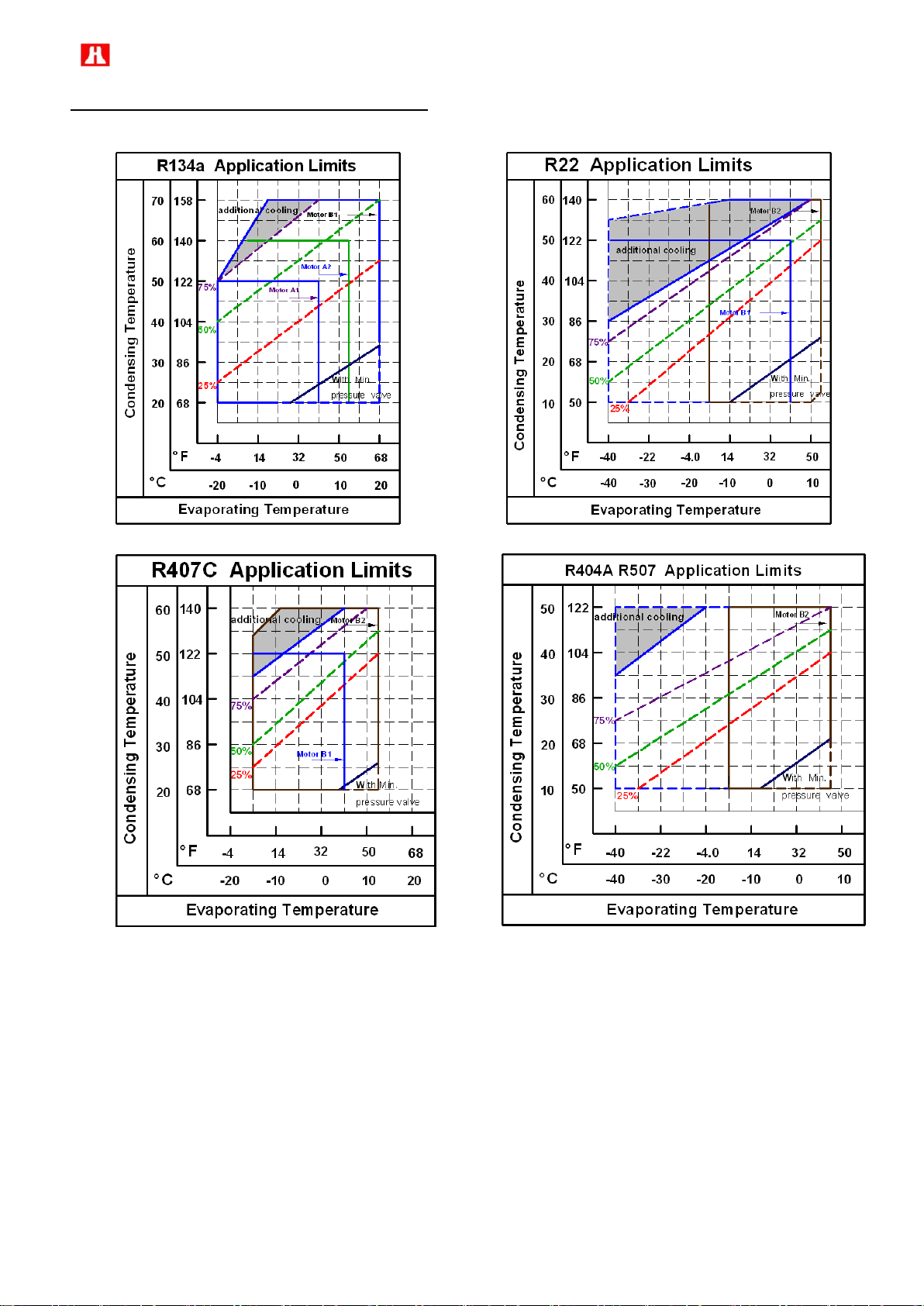

2.5 Compressor application limits

Compressor Operating Limits vary significantly with the type of refrigerant used. The operating limits shown below

are based on saturated suction and discharge operating conditions. For continuous operation over extended

periods of time, it is important to operate the compressor within these limits to maintain proper compressor life.

Operating at extra low saturated suction temperature, may cause oil management problem, and operating at extra

high saturated condensing temperature may shorten the compressor life due to insufficient compressor chamber

cooling or oil supply for lubrication.

a. Application limits of RC2-100F~RC2-930F are described on the respective refrigerant charts.

Page 35

34

b. Application limits of of RC2-1020F~RC2-1530F are described on the respective refrigerant charts.

Note :

1. When Hanbell screw compressor operates in partial or full load within limits, temperature of motor coil and

discharge will rise concurrently. In order to keep compressor running safely, Hanbell recommends using the

following additional cooling methods :

(1) Oil cooler. (2) Liquid injection to chamber. (3) Liquid injection to motor.

Please refer to Hanbell selection software for calculation and chapter 9—application for design reference.

2. The minimum discharge superheat is recommended to be kept 10°k higher than the condensing temperature

( normally discharge superheat is around 20°K for R-134a,R404A, R507A and 30°K for R22, R407C) to avoid

liquid filling back to compressor and lubrication failure. According to EN12900, the minimum suction

superheat is 10°k and liquid sub-cooling is 0°k.

Page 36

35

V

Pd

Pd'

V

Pd<Pd'

P

Pd, Pd'

V

Pd=Pd'

P

Pd>Pd'

Pd'

Pd

P

3. Hanbell recommends monitoring oil pressure differential by pressure differential switch passively or by

Gcmkg2/

Gcmkg2/

Under compression (CR > Pi)

Over compression (CR < Pi)

CR = Pi

Loss of work

Loss of work

1

2

3

4

Ps

1

2

3

4

Ps

Ps

2

3

4

1

additional oil pump actively and keep it 4

over the suction pressure for adequate seal, lubrication

and capacity control. This is very important especially when the condensing temperature is low and the

evaporating temperature is high like the application in water-cooled flooded chillers and normally its high-low

pressure differential tends to be less than 4

. In this kind of situation, installation of oil pump is

recommended to ensure sufficient oil supply.

4. All models’ motor cooling are by refrigerant returned from evaporator. If compressors run continuously at

partial load below 50%, failure of motor coils might happen due to insufficient motor cooling. Therefore,

Hanbell emphasizes installation of liquid injection system to motor to make sure adequate cooling at motor

coils for safe running of compressors.

5. Contact with Hanbell to verify potential operating conditions outside the limits shown.

2.6 Compressor design feature

2.6.1 Compressor volume ratio

The Volume ratio (Vi) of the compressor can be defined as the ratio of suction volume of gas divided by discharge

volume of gas of the compressor. The volume ratio directly affects the internal compression ratio or Pi of the

compressor. A low Vi compressor corresponds to a low compression ratio compressor and high Vi compressors

are used on higher compression ratio systems. In the equation below, in order to avoid over or under compression,

the system compression ratio (CR) should be equal to the compressor internal compression ratio (Pi). If CR is not

equal to Pi, it would cause extra compensation of work / power of compressor and also decrease C.O.P. Refer

also to the P-V (pressure – volume) diagram below to show the relation.

CR =

Pd/Ps

Pi = Vi

k

Vi = Vs/Vd

Where: CR: system compression ratio Pi: internal compression ratio

Vi: internal volume ratio Pd: system pressure (absolute pressure)

Pd’: discharge pressure (absolute pressure) Ps: suction pressure (absolute pressure)

Vs: suction volume Vd: discharge volume K: refrigerant specific heat ratio

Page 37

36

B - B' View

A - A' View

P2

P1

P2

A'

B

A

P1

PART LOAD

FULL LOAD

Vi 2.6

Vi 3.5

Note:

1. Hanbell recommends using selection program to get the suggested Vi because inappropriate Vi selection will

cause higher power consumption, vibration and discharge temperature.

2. When compressor running below 70% capacity, because the slide is partially inside the compression chamber

and results the inappropriate Vi, the system will suffer higher discharge temperature. Therefore Hanbell

recommends not running compressor under partial load in a long time.

To ensure compressor performs in a high efficiency condition and prevent from additional power loss, built-in Vi is

designed for all models ( Vi = 2.2, 2.6, 3.0, 3.5, 4.8 ), so the customer could select the suitable Vi according to

different working condition. Please refer to Hanbell selection software to get the recommended Vi for different

working condition.

Built-in fixed type Vi

2.6.2 Floating type medium pressure ( for application with economizer)

Normally, a fix type medium pressure compressor when combine with economizer, the economizer can only

develop their effect in full load condition or closed to full load condition.

RC2-F series uses floating medium pressure design, the floating mechanical design is shown in the next drawing.

Economizer can be functioned not only in full load condition, but also in partial load condition. The economizer can

reach the best medium pressure value and develops the maximum efficiency.

Floating type medium pressure explanation

Medium pressure’s position will vary as shown in the above drawing. When the slide is at full load position, the

medium pressure is P1. When the slide is at partial load position, the medium pressure is P2.

Page 38

37

2.7 MCC and LRA

Model

50Hz

60Hz Unit: Ampere

380V

400V

415V

208V

220V

230V

380V

440V

460V

480V

575V

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

RC2-100AF

53

58/175

50

60/ 180

49

55/165

115

127/380

109

117/350

104

120/360

63

70/210

55

58/175

52

60/180

50

55/165

42

48/145

RC2-140AF

73

77/230

70

80/240

67

73/220

160

175/525

151

153/460

145

160/480

88

97/290

76

77/230

72

80/240

69

73/220

58

63/190

RC2-180AF

97

103/310

92

108/325

89

98/295

213

230/690

202

198/595

193

207/620

117

125/375

101

103/310

96

108/325

92

98/295

77

85/255

RC2-200AF

103

103/310

98

108/325

94

98/295

226

230/690

214

198/595

204

207/620

124

125/375

107

103/310

102

108/325

98

98/295

82

85/255

RC2-230AF

124

160/480

117

167/500

113

155/465

270

360/1080

256

302/905

244

315/945

148

200/600

128

160/480

122

167/500

117

155/465

98

125/375

RC2-260AF

138

160/480

131

167/500

126

155/465

302

360/1080

286

302/905

273

315/945

165

200/600

143

160/480

137

167/500

131

155/465

109

125/375

RC2-300AF

155

200/600

147

208/625

142

180/540

340

462/1385

322

375/1125

308

392/1175

186

245/735

161

200/600

154

208/625

147

180/540

123

157/470

RC2-310AF

163

200/600

155

208/625

149

180/540

360

462/1385

341

375/1125

326

392/1175

197

245/735

170

200/600

163

208/625

156

180/540

130

157/470

RC2-320AF

167

200/600

158

208/625

153

180/540

366

462/1385

346

375/1125

331

392/1175

200

245/735

173

200/600

165

208/625

158

180/540

132

157/470

RC2-340AF

178

230/690

169

240/720

163

218/655

388

503/1510

367

460/1380

351

480/1440

213

270/810

184

230/690

176

240/720

168

218/655

140

182/545

RC2-370AF

194

230/690

185

240/720

178

218/655

426

503/1510

403

460/1380

386

480/1440

233

270/810

202

230/690

193

240/720

185

218/655

154

182/545

RC2-410AF

216

233/700

205

243/730

198

230/690

- - - - -

-

260

273/820

224

233/700

215

243/730

206

230/690

172

183/550

RC2-430AF

230

233/700

218

243/730

211

230/690

- - - - -

-

277

273/820

239

233/700

229

243/730

219

230/690

183

183/550

RC2-470AF

248

270/810

236

282/845

227

265/795

- - - - -

-

300

328/985

259

270/810

248

282/845

238

265/795

198

220/660

RC2-510AF

271

270/810

258

282/845

248

265/795

- - - - -

-

327

328/985

282

270/810

270

282/845

259

265/795

216

220/660

RC2-550AF

292

292/875

277

305/915

267

283/850

- - - - -

-

350

372/1115

302

292/875

289

305/915

277

283/850

231

250/750

RC2-580AF

304

292/875

288

305/915

278

283/850

- - - - -

-

365

372/1115

316

292/875

302

305/915

289

283/850

242

250/750

RC2-620AF

317

407/1220

301

428/1285

290

387/1160

- - - - -

-

381

482/1445

329

407/1220

315

428/1285

301

387/1160

252

323/970

RC2-710AF

365

447/1340

347

467/1400

334

432/1295

- - - - -

-

439

583/1750

379

447/1340

363

467/1400

348

432/1295

290

373/1120

RC2-790AF

404

477/1430

384

498/1495

370

457/1370

- - - - -

-

486

643/1930

420

477/1430

402

498/1495

385

457/1370

321

388/1165

RC2-830AF

422

522/1565

401

545/1635

387

495/1485

- - - - -

-

507

728/2185

438

522/1565

419

545/1635

402

495/1485

335

462/1385

RC2-930AF

490

663/1990

465

693/2080

448

617/1850

- - - - -

-

589

823/2470

509

663/1990

487

693/2080

466

617/1850

389

555/1665

RC2-1020AF(A1)

360

583/1750

342

613/1840

330

537/1610

434

763/2290

374

583/1750

358

613/1840

343

537/1610

287

493/1480

RC2-1020AF(A2)

536

753/2260

510

793/2380

491

690/2070

645

945/2835

557

753/2260

533

793/2380

510

690/2070

426

635/1905

RC2-1130AF(A1)

395

583/1750

375

613/1840

362

537/1610

475

763/2290

410

583/1750

393

613/1840

376

537/1610

314

493/1480

RC2-1130AF(A2)

588

753/2260

559

793/2380

538

690/2070

709

945/2835

612

753/2260

585

793/2380

561

690/2070

468

635/1905

RC2-1270AF(A1)

457

753/2260

434

793/2380

419

690/2070

550

943/2830

475

753/2260

455

793/2380

436

690/2070

364

635/1905

RC2-1270AF(A2)

682

888/2665

648

935/2805

624

782/2345

820

1168/3505

708

888/2665

677

935/2805

649

782/2345

542

717/2150

RC2-1530AF(A1)

517

753/2260

491

793/2380

474

690/2070

623

943/2830

538

753/2260

514

793/2380

493

690/2070

411

635/1905

RC2-1530AF(A2)

770

888/2665

732

935/2805

705

782/2345

927

1168/3505

800

888/2665

766

935/2805

734

782/2345

613

717/2150

Refrigerant : R134a (Y-△)

Page 39

38

Model

50Hz

60Hz Unit: Ampere

380V

400V

415V

208V

220V

230V

380V

440V

460V

480V

575V

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

(Y/△)

RC2-100BF

69

77/230

65

80/240

63

73/220

151

175/525

142

153/460

136

160/480

82

97/290

71

77/230

68

80/240

65

73/220

54

63/190

RC2-140BF

91

103/310

87

108/325

84

98/295

199

230/690

188

198/595

180

207/620

109

125/375

94

103/310

90

108/325

86

98/295

72

85/255

RC2-180BF

121

155/465

115

162/485

110

148/445

263

362/1085

249

310/930

238

323/970

144

192/575

124

155/465

119

162/485

114

148/445

95

127/380

RC2-200BF

128

155/465

122

162/485

117

148/445

282

362/1085

266

310/930

255

323/970

154

192/575

133

155/465

127

162/485

122

148/445

102

127/380

RC2-230BF

153

230/690

146

240/720

140

218/655

336

503/1510

318

460/1380

304

480/1440

184

270/810

159

230/690

152

240/720

146

218/655

122

182/545

RC2-260BF

171

230/690

163

240/720

157

218/655

376

503/1510

355

460/1380

340

480/1440

206

270/810

178

230/690

170

240/720

163

218/655

136

182/545

RC2-300BF

193

260/780

183

272/815

177

263/790

424

653/1960

401

520/1560

384

543/1630

232

343/1030

200

260/780

192

272/815

184

263/790

153

223/670

RC2-310BF

203

260/780

193

272/815

186

263/790

446

653/1960

421

520/1560

403

543/1630

244

343/1030

211

260/780

201

272/815

193

263/790

161

223/670

RC2-320BF

207

260/780

196

272/815

189

263/790

456

653/1960

431

520/1560

413

543/1630

250

343/1030

216

260/780

206

272/815

198

263/790

165

223/670

RC2-340BF

220

345/1035

209

360/1080

201

313/940

483

720/2160

457

662/1985

437

692/2075

264

407/1220

228

345/1035

218

360/1080

209

313/940

175

272/815

RC2-370BF

241

345/1035

229

360/1080

221

313/940

529

720/2160

500

662/1985

478

692/2075

289

407/1220

250

345/1035

239

360/1080

229

313/940

191

272/815

RC2-410BF

268

292/875

254

305/915

245

283/850

- - - - -

-

323

372/1115

279

292/875

267

305/915

256

283/850

214

250/750

RC2-470BF

310

407/1220

294

428/1285

284

387/1160

- - - - -

-

372

482/1445

321

407/1220

307

428/1285

294

387/1160

246

323/970

RC2-510BF

336

443/1330

319

463/1390

308

417/1250

- - - - -

-

406

535/1605

350

443/1330

335

463/1390

321

417/1250

268

382/1145

RC2-550BF

336

443/1330

319

463/1390

308

417/1250

- - - - -

-

406

535/1605

350

443/1330

335

463/1390

321

417/1250

268

382/1145

RC2-580BF

377

443/1330

358

463/1390

345

417/1250

- - - - -

-

454

535/1605

392

443/1330

375

463/1390

359

417/1250

300

382/1145

RC2-620BF

393

503/1510

374

527/1580

360

468/1405

- - - - -

-

473

627/1880

409

503/1510

391

527/1580

375

468/1405

313

422/1265

RC2-710BF

453

663/1990

430

693/2080

415

617/1850

- - - - -

-

545

823/2470

471

663/1990

450

693/2080

432

617/1850

360

555/1665

RC2-790BF

498

743/2230

473

777/2330

456

682/2045

- - - - -

-

598

958/2875

516

743/2230

494

777/2330

473

682/2045

395

600/800

RC2-830BF

534

785/2355

508

827/2480

489

863/2590

- - - - -

-

643

1067/3200

555

785/2355

531

827/2480

509

863/2590

425

658/1975

RC2-930BF

620

875/2625

589

915/2745

567

955/2865

- - - - -

-

746

1247/3740

644

875/2625

616

915/2745

591

955/2865

493

765/2295

RC2-1020BF(B1)

611

888/2665

580

935/2805

559

782/2345

735

1168/3505

635

888/2665

607

935/2805

582

782/2345

486

717/2150

RC2-1020BF(B2)

684

1085/3255

650

1142/3425

626

920/2760

823

1290/3870

710

1085/3255

680

1142/3425

651

920/2760

544

868/2605

RC2-1130BF(B1)

671

888/2665

637

935/2805

614

782/2345

806

1168/3505

697

888/2665

666

935/2805

638

782/2345

533

717/2150

RC2-1130BF(B2)

766

1085/3255

728

1142/3425

702

920/2760

922

1290/3870

796

1085/3255

762

1142/3425

730

920/2760

609

868/2605

RC2-1270BF(B1)

777

1085/3255

738

1142/3425

711

920/2760

934

1290/3870

807

1085/3255

772

1142/3425

740

920/2760

617

868/2605

RC2-1270BF(B2)

864

1338/4015

820

1160/3480

791

1213/3640

1038

1573/4720

896

1338/4015

857

1160/3480

821

1213/3640

686

1292/3875

RC2-1530BF(B1)

878

1085/3255

834

1142/3425

804

920/2760

1056

1290/3870

912

1085/3255

873

1142/3425

836

920/2760

698

868/2605

RC2-1530BF(B2)

996

1393/4180

946

1195/3585

912

1263/3790

1199

1633/4900

1035

1393/4180

990

1195/3585

949

1263/3790

792

957/2870

Refrigerant : R22, R407C, R404A (Y-△)

Page 40

39

Refrigerant : R134a (PWS)

Model

50Hz

60Hz Unit: Ampere

380V

400V

415V

208V

220V

230V

380V

440V

460V

480V

575V

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

RC2-100AF

53

79/165

50

84/175

49

74/155

115

170/355

109

156/325

104

166/345

63

86/190

55

79//165

52

84/175

50

74/155

42

62/130

RC2-140AF

73

108/225

70

113/235

67

101/210

160

238/495

151

211/440

145

221/460

88

125/160

76

108/225

72

110/230

69

101/210

58

79/165

RC2-180AF

97

155/310

92

163/325

89

145/290

213

338/675

202

305/610

193

320/640

117

185/370

101

155/310

96

163/325

92

145/290

77

118/235

RC2-200AF

103

155/310

98

163/325

94

145/290

226

338/675

214

305/610

204

320/640

124

185/370

107

155/310

102

163/325

98

148/295

82

118/235

RC2-230AF

124

303/505

117

285/475

113

267/445

270

645/1075

256

618/1030

244

573/955

148

360/600

128

303/505

122

285/475

117

267/445

98

237/395

RC2-260AF

138

303/505

131

285/475

126

267/445

302

645/1075

286

618/1030

273

573/955

165

360/600

143

303/505

137

285/475

131

267/445

109

237/395

RC2-300AF

155

350/565

147

329/530

142

322/520

340

822/1325

322

763/1230

308

704/1135

186

428/690

161

350/565

154

329/530

147

322/520

123

273/440

RC2-310AF

163

350/565

155

329/530

149

322/520

360

822/1325

341

763/1230

326

704/1135

197

428/690

170

350/565

163

329/530

156

322/520

130

276/445

RC2-320AF

167

350/565

158

329/530

153

322/520

366

822/1325

346

763/1230

331

704/1135

200

428/690

173

350/565

165

329/530

158

322/520

132

276/445

RC2-340AF

178

462/710

169

423/650

163

410/630

388

943/1450

367

868/1335

351

920/1415

213

546/840

184

462/710

176

423/650

168

410/630

140

358/550

RC2-370AF

194

462/710

185

423/650

178

410/630

426

943/1450

403

868/1335

386

920/1415

233

546/840

202

462/710

193

423/650

185

410/630

154

358/550

RC2-410AF

216

475/730

205

497/765

198

429/660

- - - - -

-

260

553/850

224

475/730

215

497/765

206

429/660

172

374/575

RC2-430AF

230

475/730

218

497/765

211

429/660

- - - - -

-

277

553/850

239

475/730

229

497/765

219

429/660

183

374/575

RC2-470AF

248

571/840

236

598/880

227

513/755

- - - - -

-

300

677/995

259

571/840

248

598/880

238

513/755

198

439/645

RC2-510AF

271

571/840

258

598/880

248

513/755

- - - - -

-

327

677/995

282

571/840

270

598/880

259

513/755

216

439/645

RC2-550AF

292

615/905

277

646/950

267

596/875

- - - - -

-

350

779/1145

302

615/905

289

646/950

277

595/875

231

476/700

RC2-580AF

304

615/905

288

646/950

278

595/875

- - - - -

-

365

779/1145

316

615/905

302

646/950

289

595/875

242

476/700

Page 41

40

Model

50Hz

60Hz Unit: Ampere

380V

400V

415V

208V

220V

230V

380V

440V

460V

480V

575V

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

MCC

LRA

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

(△/△△)

RC2-100BF

69

108/225

65

113/235

63

101/210

151

238/495

142

211/440

136

221/460

82

125/260

71

108/225

68

113/235

65

101/210

54

82/170

RC2-140BF

91

155/310

87

163/325

84

145/290

199

338/675

188

305/610

180

320/640

109

185/370

94

155/310

90

163/325

86

145/290

72

118/235

RC2-180BF

121

225/425

115

239/450

110

207/390

263

480/905

249

444/840

238

466/880

144

254/480

124

225/425

119

239/450

114

207/390

95

172/325

RC2-200BF

128

225/425

122

239/450

117

207/390

282

480/905

266

445/840

255

466/880

154

254/480

133

225/425

127

239/450

122

207/390

102

172/325

RC2-230BF

153

350/565

146

329/530

140

322/520

336

822/1325

318

763/1230

304

704/1135

184

428/690

159

350/565

152

329/530

146

322/520

122

273/440

RC2-260BF

171

462/710

163

423/650

157

410/630

376

943/1450

355

868/1335

340

920/1415

206

546/840

178

462/710

170

423/650

163

410/630

136

358/550

RC2-300BF

193

507/780

183

497/765

177

481/740

424

1260/1940

401

1121/1725

384

1004/1545

232

614/945

200

507/780

192

497/765

184

481/740

153

403/620

RC2-310BF

203

507/780

193

497/765

186

481/740

446

1261/1940

421

1121/1725

403

1004/1545

244

614/945

211

507/780

201

497/765

193

481/740

161

403/620

RC2-320BF

207

507/780

196

497/765

189

481/740

456

1261/1940

431

1121/1725

413

1004/1545

250

614/945

216

507/780

206

497/765

198

481/740

165

403/620

RC2-340BF

220

663/1020

209

640/985

201

608/935

483

1628/2505

457

1342/2065

437

1495/2300

264

777/1195

228

663/1020

218

640/985

209

608/935

175

527/810

RC2-370BF

241

663/1020

229

640/985

221

608/935

529

1628/2505

500

1342/2065

478

1495/2300

289

777/1195

250

663/1020

239

640/985

229

608/935

191

527/810

RC2-410BF

268

615/905

254

646/950

245

595/875

- - - - -

-

323

779/1145

279

615/905

267

646/950

256

595/875

214

476/700

RC2-470BF

310

870/1280

294

915/1345

284

826/1215

- - - - -

-

372

1030/1515

321

870/1280

307

915/1345

294

826/1215

246

690/1015

RC2-510BF

336

952/1400

319

996/1465

308

891/1310

- - - - -

-

406

1142/1680

350

952/1400

335

996/1465

321

891/1310

268

816/1200

RC2-550BF

336

952/1400

319

996/1465

308

891/1310

- - - - -

-

406

1142/1680

350

952/1400

335

996/1465

321

891/1310

268

816/1200

RC2-580BF

377

952/1400

358

996/1465

345

891/1310

- - - - -

-

454

1142/1680

392

952/1400

375

996/1465

359

891/1310

300

816/1200

Refrigerant : R22, R407C, R404A (PWS)

Page 42

41

3. Compressor handling and Installation

3.1 Compressor handling

After the compressor arrives at the warehouse, check the crate if it is kept in good condition and check all the

compressor accessories and the shipping documents to see if there is any discrepancy. Be noted that the

compressor is charged with 0.5~1 bar nitrogen, so release the inner pressure before loosing any parts on the

compressor is very important.

Each HANBELL screw compressor is fully tested at the factory where every precaution and care is taken to make

sure that the compressor is in perfect condition. When lifting the compressor, it is recommended to use a steel

chain or steel cable as shown in the next page. The safety rope can also be used if it is proofed to resist the

compressor weight.

Make sure that the chains, cables, ropes or other lifting equipment are properly positioned to avoid possible

damage to the compressor or its accessories. Keep the compressor in horizontal position when lifting, and avoid

the compressor from crashing or falling on the ground, hitting the wall or any other event that may damage it or its

accessories.

3.2 Mounting the compressor

The installation of the compressor in the refrigeration system should be made accessible and make sure that the

chiller base or site is far enough from the heat source to prevent heat radiation. The compressor should also be

installed as close as possible to the electrical power supply for easier connection and must keep good ventilation

and low humidity condition in the site. Make sure that the frame or supporter is strong enough to prevent

excessive vibration and noise while the compressor are running and must reserve enough space for compressors’

future overhauling work.

Page 43

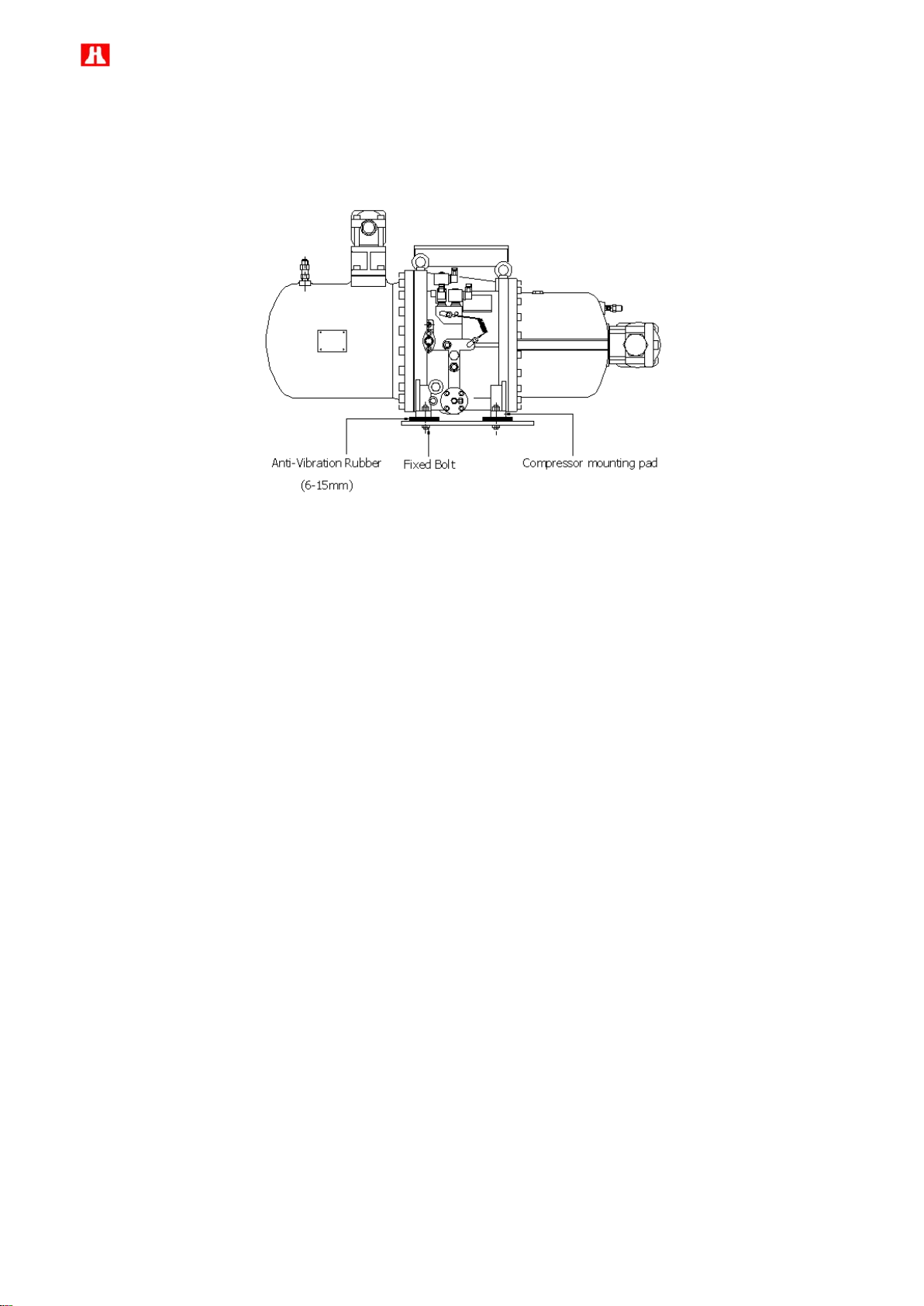

42

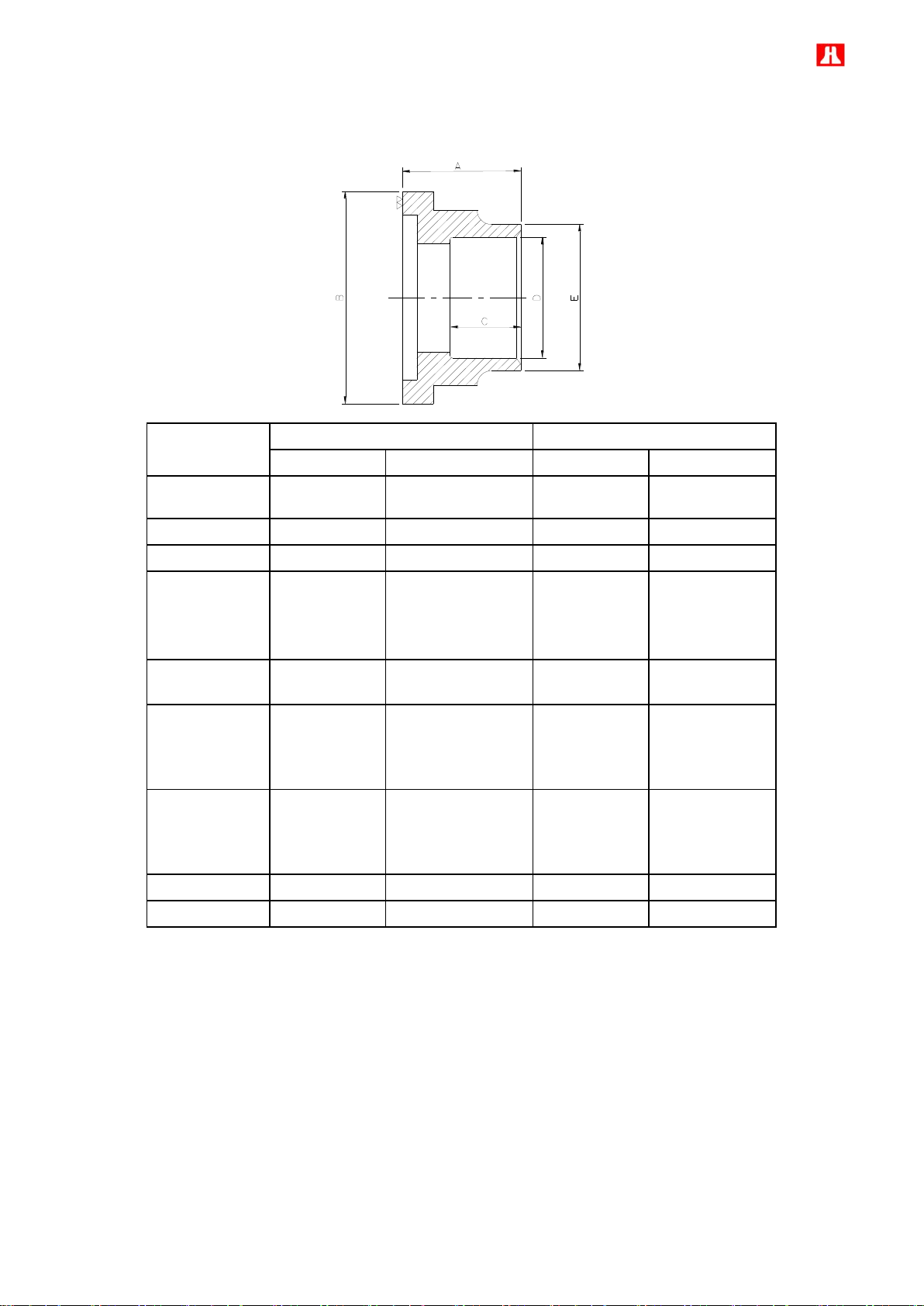

The compressor must be installed horizontally and in order to prevent excessive vibration transferred by the

structure and piping of the chiller while in operation, the cushion or anti-vibration pad should be installed. The

installation of the anti-vibration pad is shown in the figure below. The screws should only be tightened until slight

deformation of the rubber pad is visible.

Attention on the compressor piping works

The unsuitable piping works done to the compressor could cause abnormal vibration and noise which might

damage the compressor. Take notice to the following points to prevent this situation:

1. Cleanliness of the system should be kept after welding the piping to avoid any swarf or debris contained inside

the system as it may cause serious damage to the compressor during operation.

2. In order to reduce the vibration on the piping tubes, it is recommended to use copper tube to be the suction and

discharge piping tubes. Copper tubes are better to minimize the vibration in the piping while the compressor is in

operation. In case steel tubes are used in piping system, then the suitable welding works are very important to

avoid any stress in the piping. This inner stress can cause harmonic vibration and noise which will reduce the

compressor life. If a large-caliber copper tube is not easily accessible and a steel tube is used instead in suction

port, Hanbell recommends using a copper tube in discharge port to minimize abnormal vibration and noise.

3. Remove the oxidized impurities, swarf or debris caused by welding in the piping tubes. If these foreign matters

are sunk into the compressor, the oil filter might be clogged resulting in the malfunctioning of lubrication system,

bearings and capacity control system.

4. Suction and discharge flanges are forged steel and it can be welded directly with piping connectors. After

welding the flanges and pipes, it must be cooled down by ambient air. Do not use water to cool it down. Water

quenching is prohibited.

Page 44

43

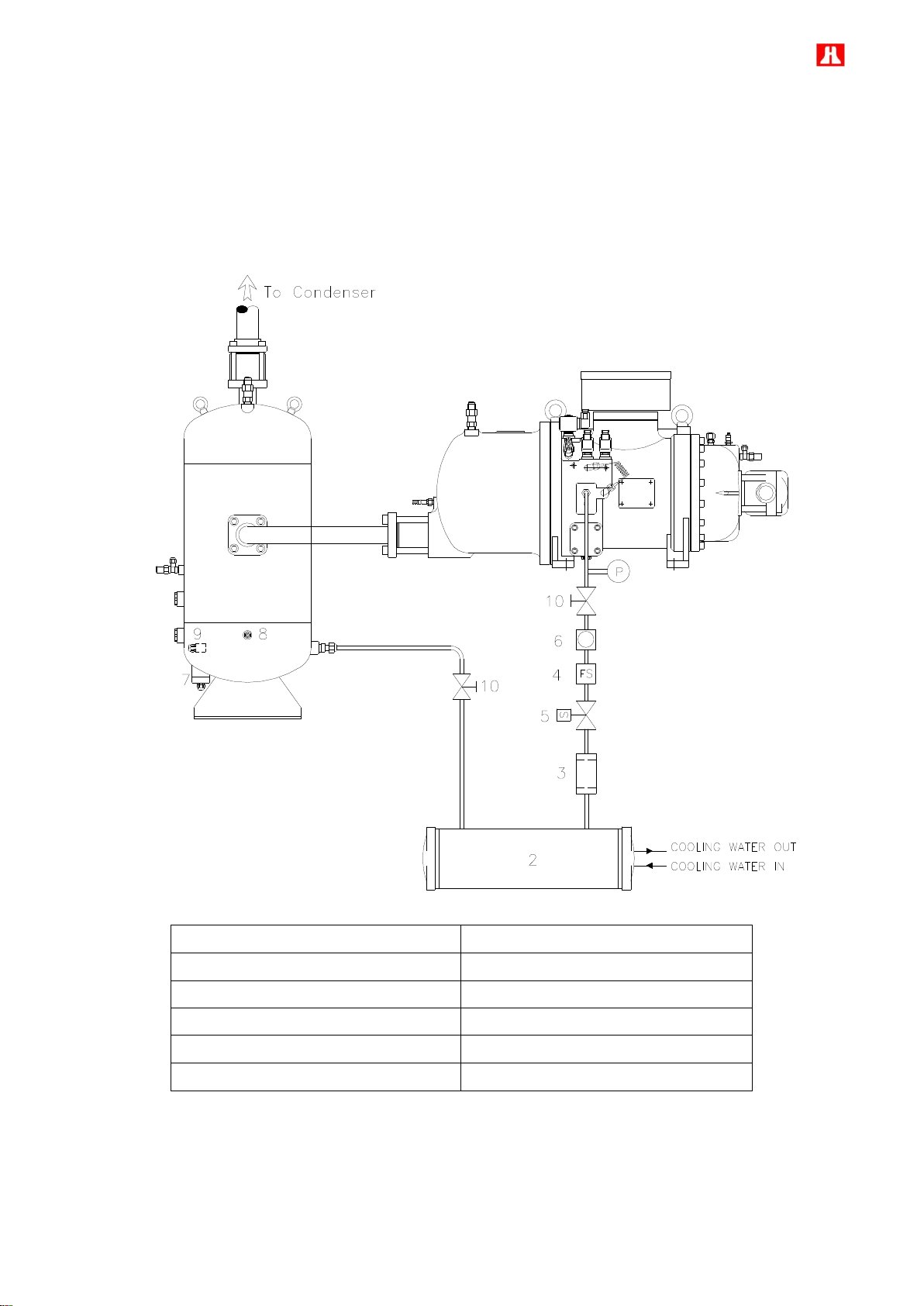

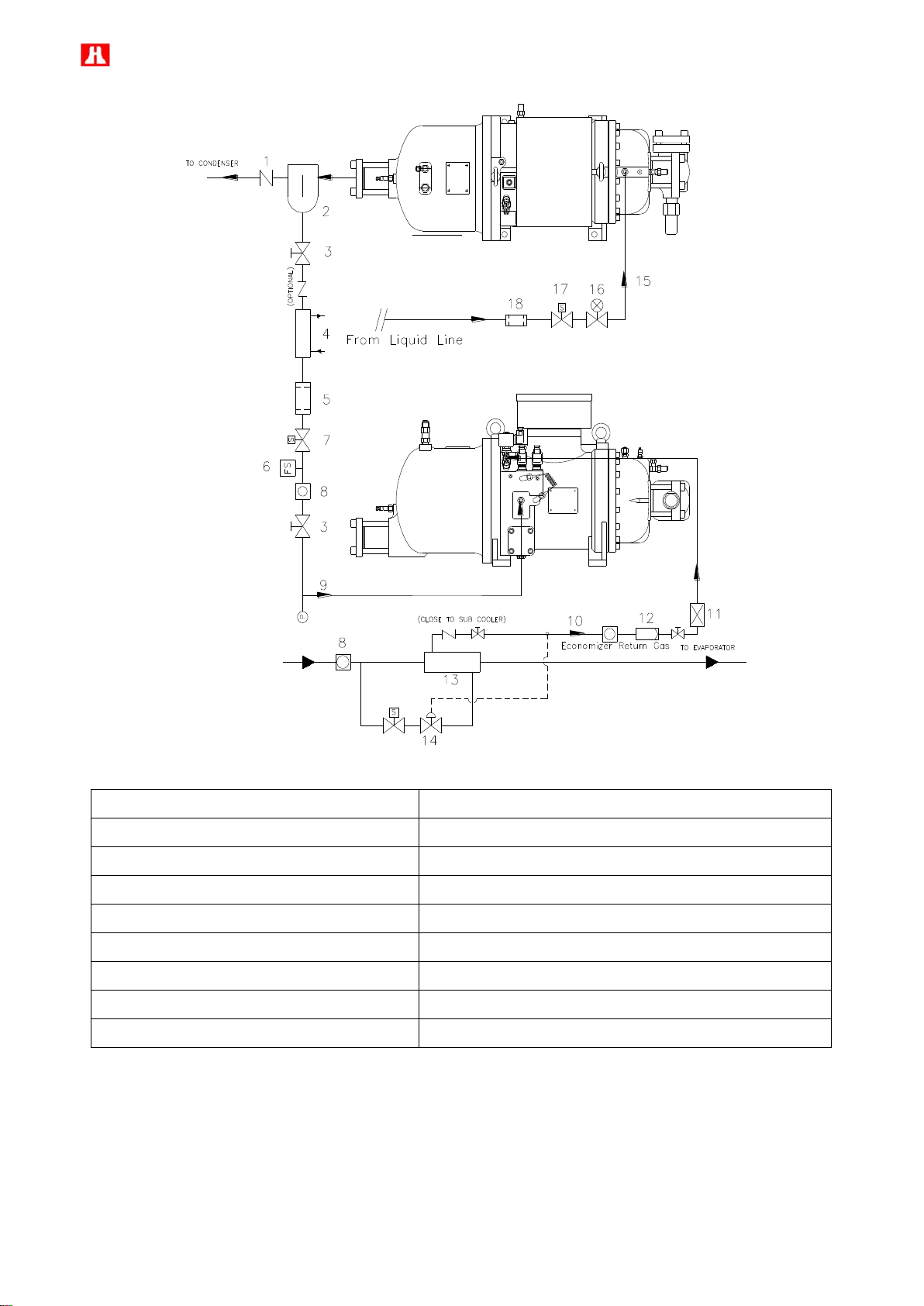

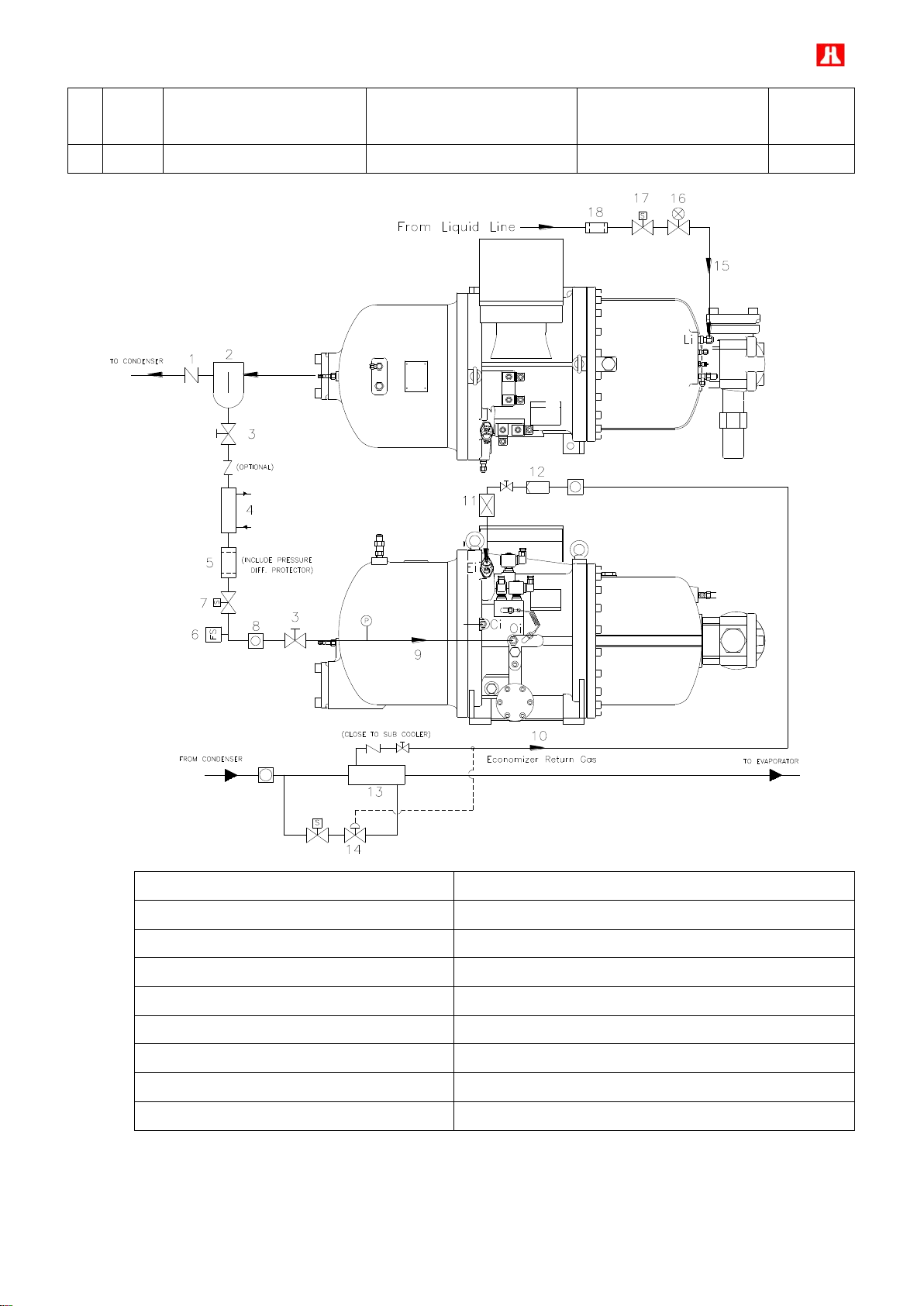

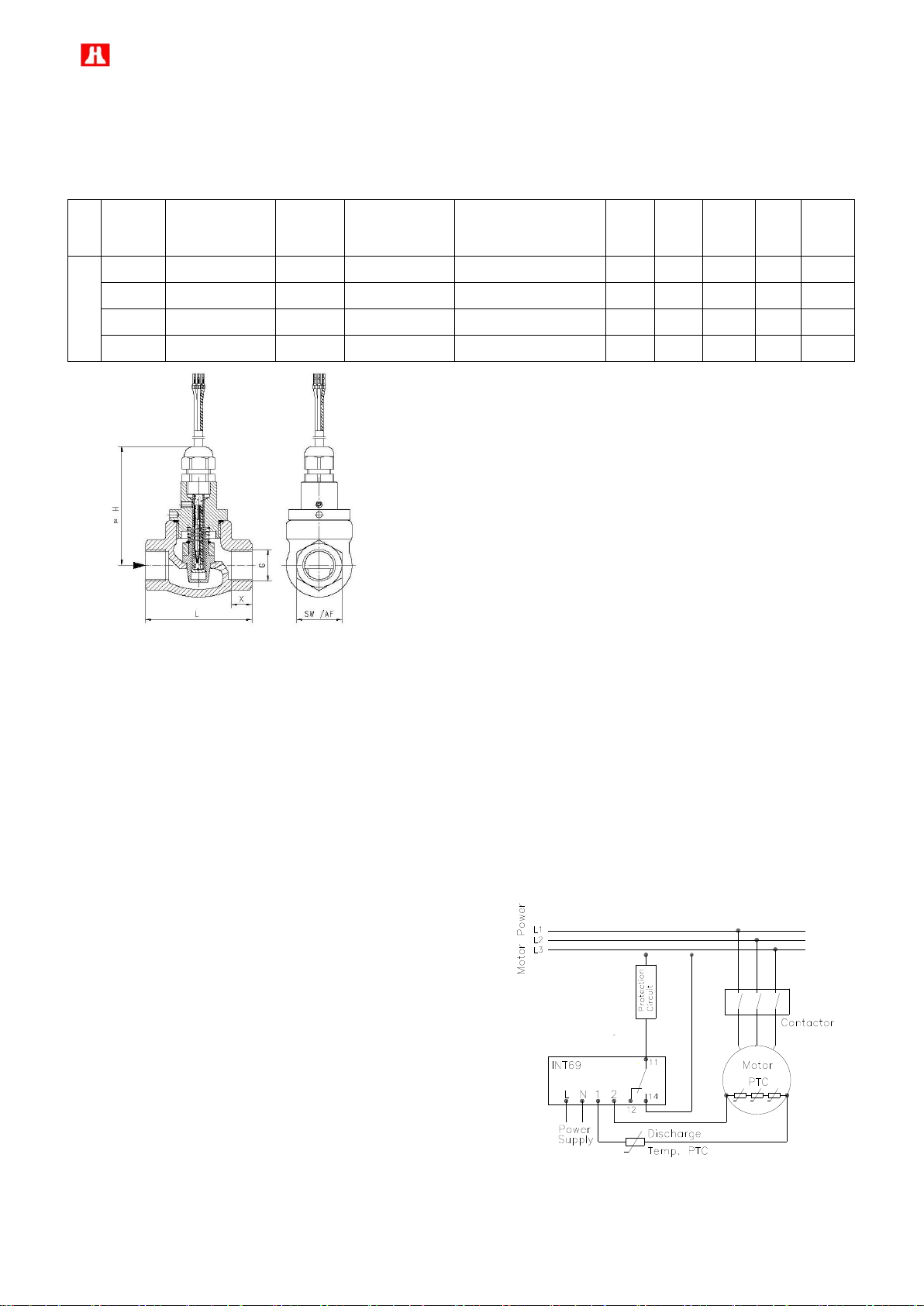

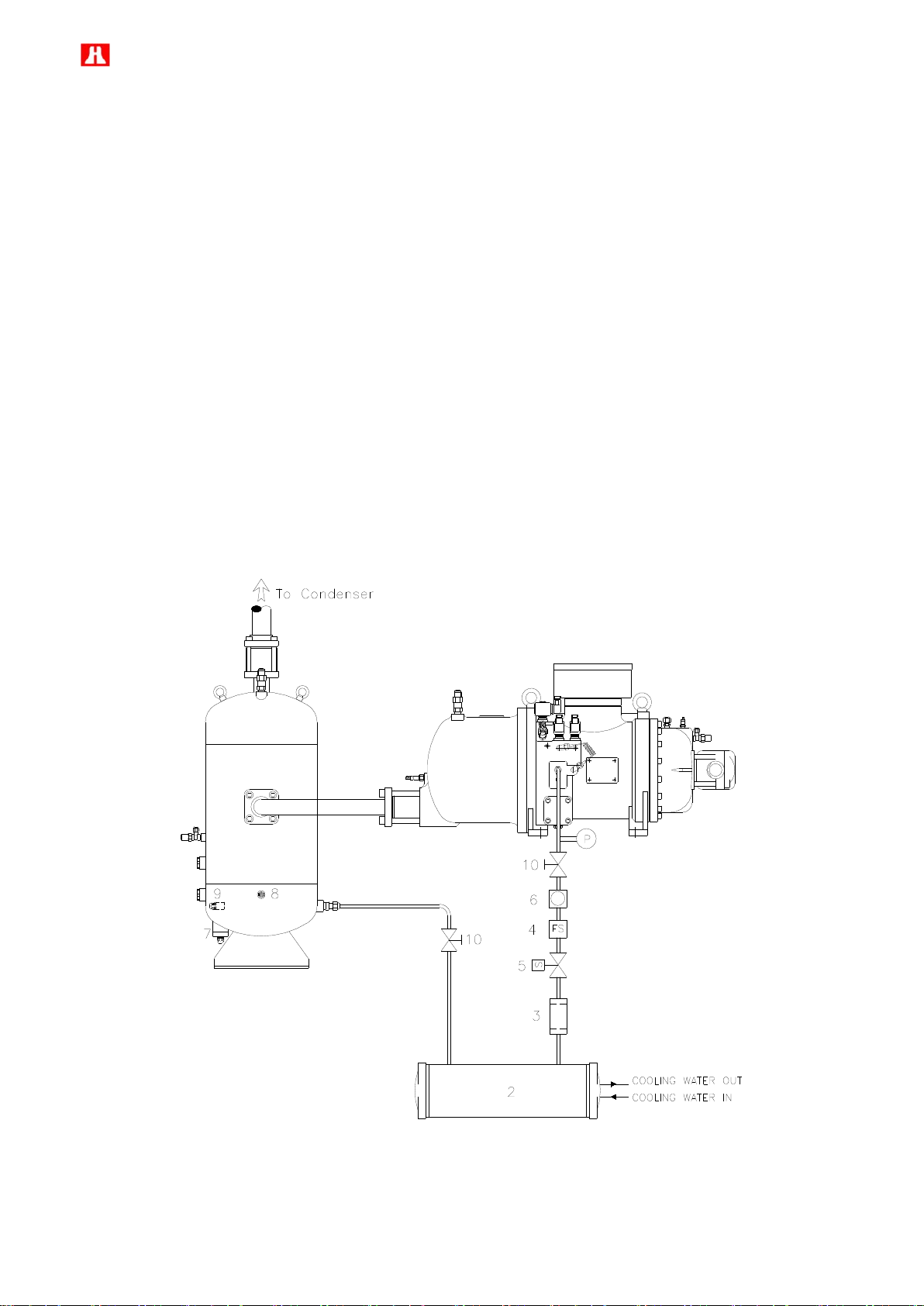

Model : RC2-100F、RC2-140F、RC2-180F

1. External oil separator

7. Oil level switch

2. Oil cooler

8. Oil temperature sensor

3. Oil filter

9. Oil heater

4. Lubricant flow switch

10. Stop valve

5. Solenoid valve

11. Compressor

6. Sight glass

(1) Installation of lubricant circuit

To obtain high oil filtering efficiency, low pressure drop and non-interruption with lubricant supply system, the oil

separator is built outside the compressor. The installation of lubricant circuit is a very important issue during the

installation of the compressor. So before starting, make sure to read carefully all the instructions contain inside

this manual, and make sure that each step is done in accordance with the specification.

Note:Please refer to the selection software for the capacity of liquid injection or oil cooler and following

recommendation to install oil cooler, oil injection system and economizer.

Page 45

44

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

A

-

- - -

O

Ci

Oi

Ei

Li

1. Check valve

8. To principal return oil port Oi

2. External oil separator

9. To medium pressure (Economizer return port) Ei

3. Stop valve

10. Oil cooler

4. Oil filter

11. Muffler

5. Lubricant flow switch

12. Suction strainer

6. Oil solenoid valve

13. Expansion valve

7. Sight glass

14. Sub-cooler

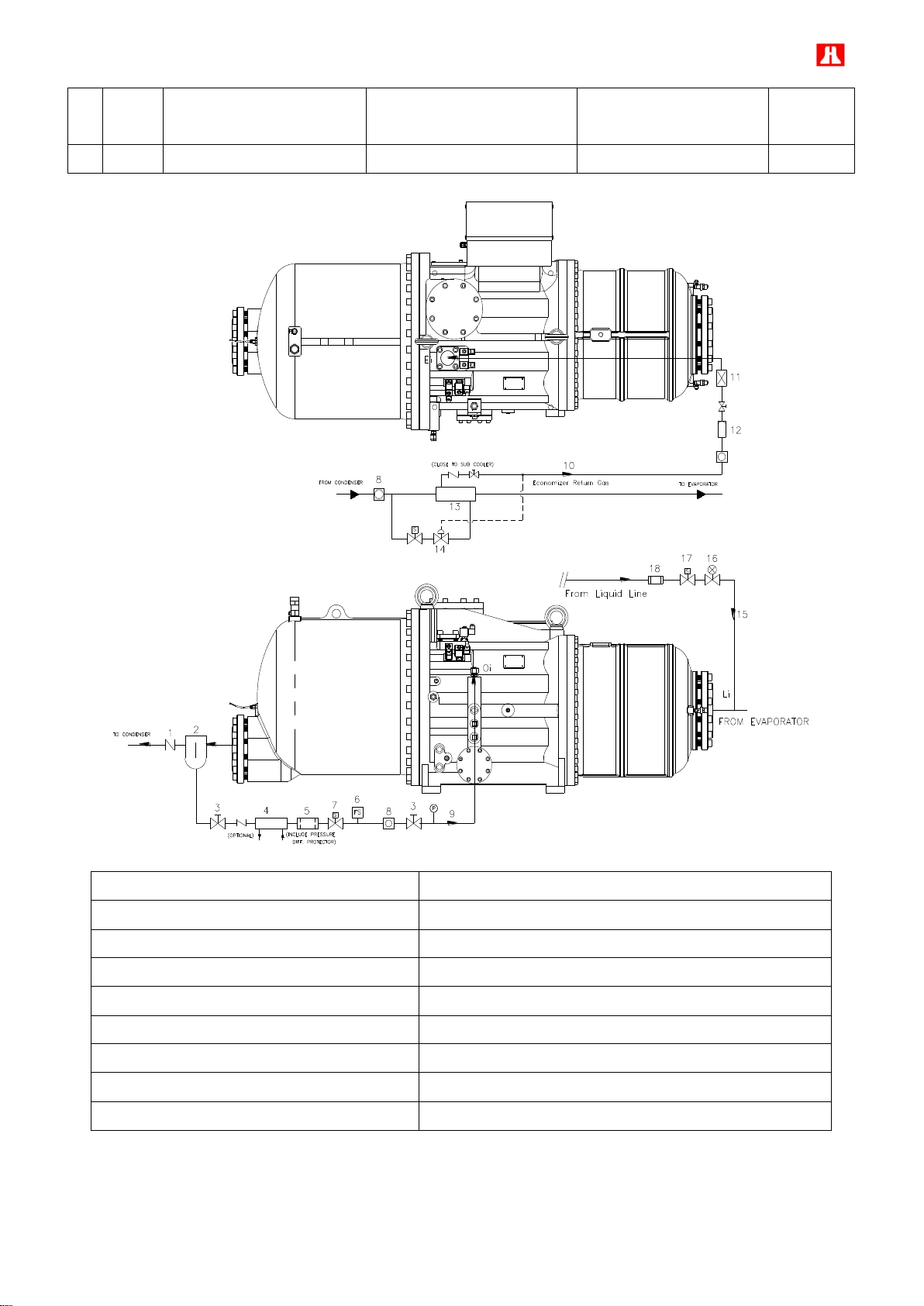

(2) Lubricant circuit, Liquid injection system and economizer connection diagram

Page 46

45

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

B

O

O - O

O

Ci

Oi

Ei

Li

Page 47

46

It

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

C

O

-

O

O

O

1. Check valve

11. Cooling compressor’s chamber port Ci

2. External oil separator

12. To medium pressure (economizer return port) Ei

3. Stop valve

13. Liquid injection to motor winding port Li

4. Oil cooler

14. Liquid injection solenoid valve

5. Oil filter

15. Liquid injection expansion valve

6. Oil flow switch

16. Liquid line filter

7. Oil solenoid valve

17. Muffler

8. Sight glass

18. Strainer

9. To principal oil return port Oi

19. Sub-cooler

10. Adjustable flow valve

20. Expansion valve

Page 48

47

Ci

Oi

Ei

Li

1. Check valve

12. To cooling down compression chamber port Ci

2. External oil separator

13. Liquid line filter

3. Stop valve

14. Liquid injection to motor winding port Li

4. Oil cooler

15. Liquid injection solenoid valve

5. Oil filter

16. Liquid injection expansion valve

6. Lubricant flow switch

17. Liquid line filter

7. Oil solenoid valve

18. To medium pressure (economizer return port) Ei

8. Sight glass

19. Muffler

9. To principal return oil port

20. Strainer

10. Liquid injection solenoid valve

21. Sub-cooler

11. Liquid injection expansion valve

22. Expansion valve

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

D

O

-

-

O

O

Page 49

48

1. Check valve

10. To medium pressure (economizer return port) Ei

2. External oil separator

11. Muffler

3. Stop valve

12. Strainer

4. Oil cooler

13. Sub-cooler

5. Oil filter

14. Expansion valve

6. Lubricant flow switch

15. Liquid injection to motor winding port Li

7. Oil solenoid valve

16. Liquid injection to expansion valve

8. Sight glass

17. Liquid injection to solenoid valve

9. To principal return oil port Oi

18. Liquid line filter

Ci

Oi

Ei

Li

Page 50

49

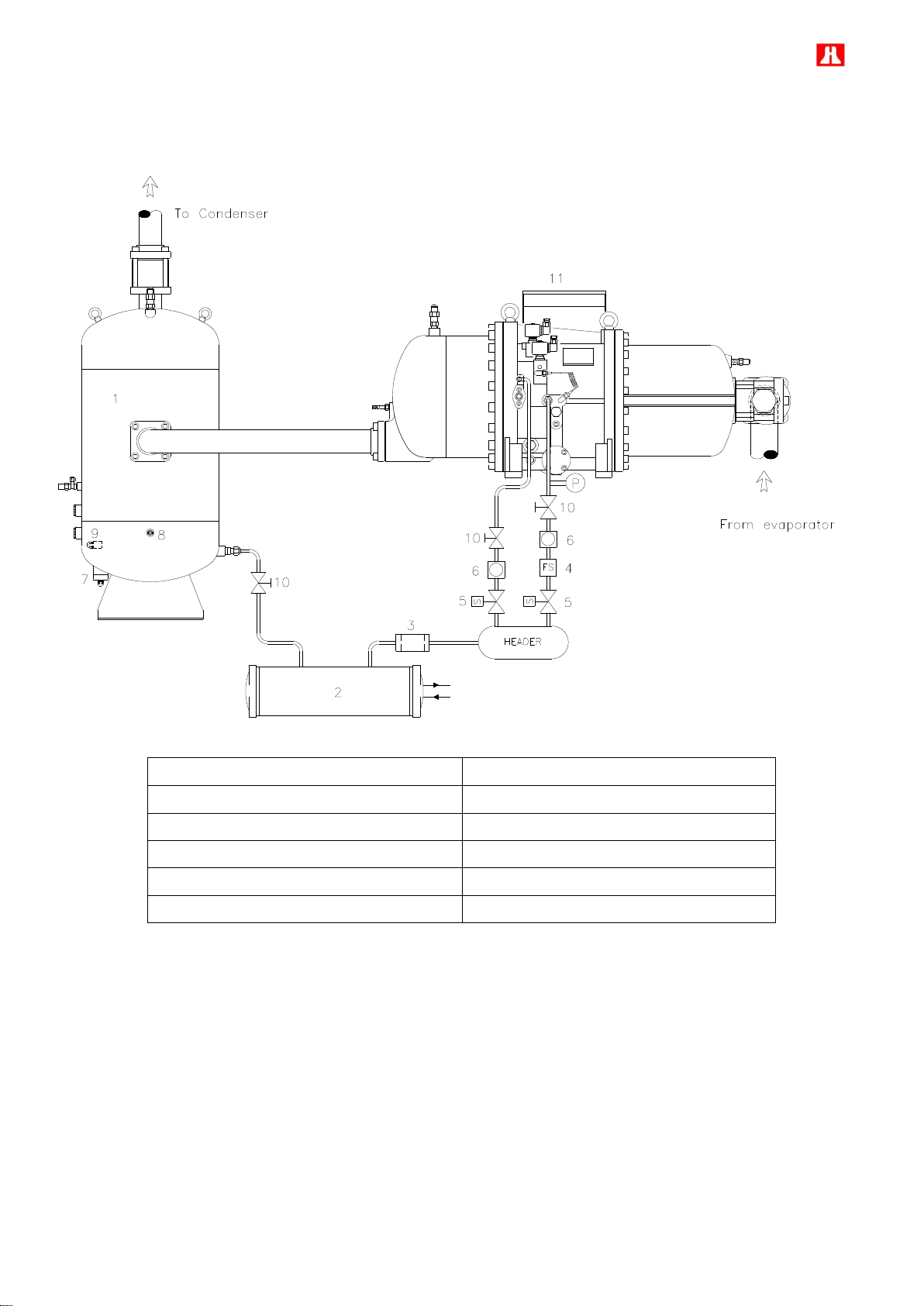

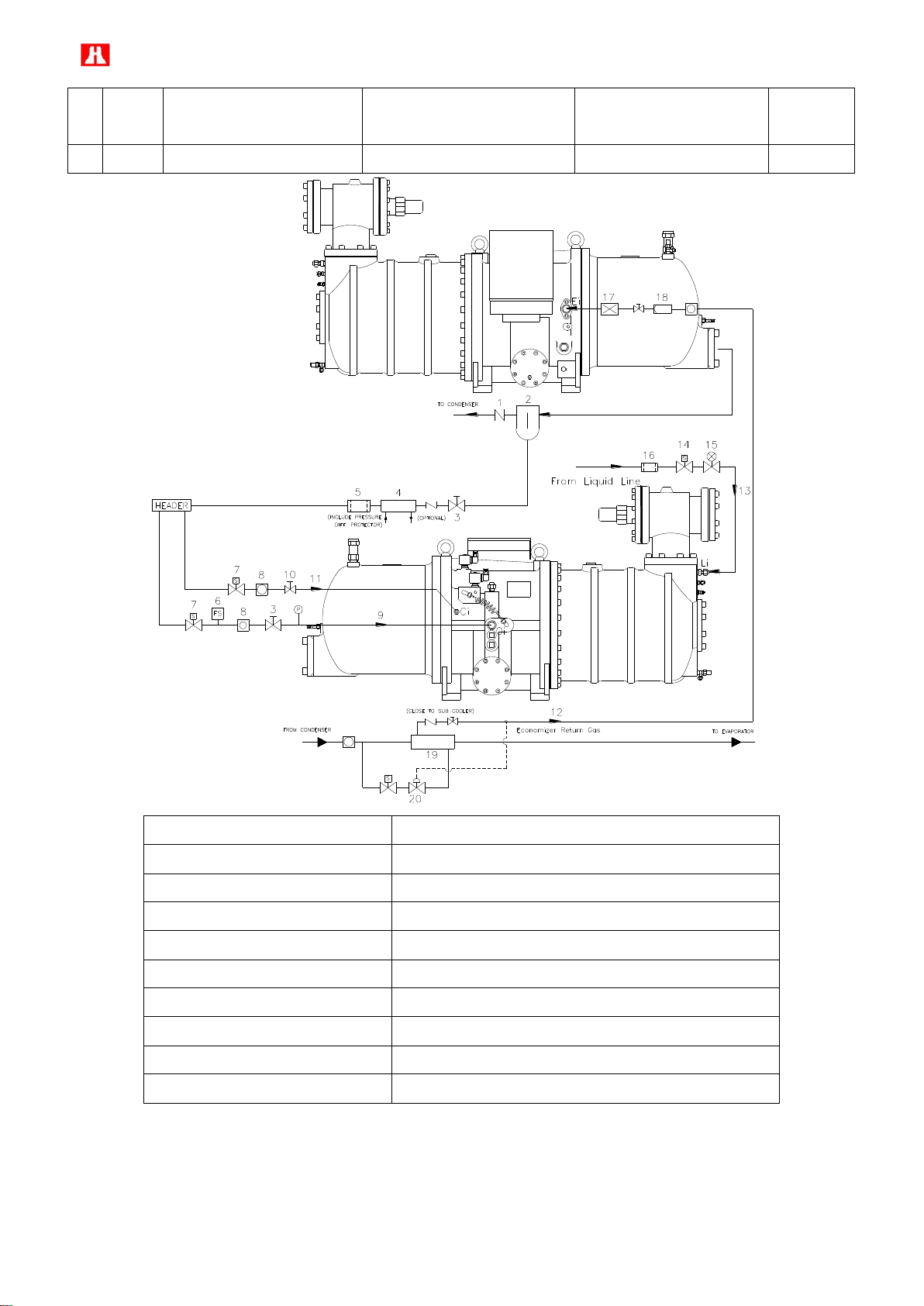

Model : RC2-200F ~ RC2-620F

1. External oil separator

7. Oil level switch

2. Oil cooler

8. Oil temperature sensor

3. Oil filter and cartridge

9. Oil heater

4. Lubricant flow switch

10. Manually adjustable flow valve

5. Oil solenoid valve

11. Compressor

6. Sight glass

(1) Installation of lubricant circuit

Page 51

50

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

A

-

- - -

O

1. Check valve

8. To principal return oil port Oi

2. External oil separator

9. To medium pressure (Economizer return port) Ei

3. Stop valve

10. Oil cooler

4. Oil filter

11. Muffler

5. Lubricant flow switch

12. Suction strainer

6. Oil solenoid valve

13. Expansion valve

7. Sight glass

14. Sub-cooler

(2) Lubricant circuit, Liquid injection system and economizer connection diagram

Page 52

51

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

B

O

O - O

O

1. Check valve

11. Cooling compressor’s chamber port Ci

2. External oil separator

12. To medium pressure (economizer return port) Ei

3. Stop valve

13. Liquid injection to motor winding port Li

4. Oil cooler

14. Liquid injection solenoid valve

5. Oil filter

15. Liquid injection expansion valve

6. Oil flow switch

16. Liquid line filter

7. Oil solenoid valve

17. Muffler

8. Sight glass

18. Strainer

9. To principal oil return port Oi

19. Sub-cooler

10. Adjustable flow valve

20. Expansion valve

Page 53

52

Item

Oil cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

C

O - O

O

O

1. Check valve

12. To cooling down compression chamber port Ci

2. External oil separator

13. Liquid line filter

3. Stop valve

14. Liquid injection to motor winding port Li

4. Oil cooler

15. Liquid injection solenoid valve

5. Oil filter

16. Liquid injection expansion valve

6. Lubricant flow switch

17. Liquid line filter

7. Oil solenoid valve

18. To medium pressure (economizer return port) Ei

8. Sight glass

19. Muffler

9. To principal return oil port

20. Strainer

10. Liquid injection solenoid valve

21. Sub-cooler

11. Liquid injection expansion valve

22. Expansion valve

Page 54

53

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

D

O

-

-

O

O

1. Check valve

10. To medium pressure (economizer return port) Ei

2. External oil separator

11. Muffler

3. Stop valve

12. Strainer

4. Oil cooler

13. Sub-cooler

5. Oil filter

14. Expansion valve

6. Lubricant flow switch

15. Liquid injection to motor winding port Li

7. Oil solenoid valve

16. Liquid injection to expansion valve

8. Sight glass

17. Liquid injection to solenoid valve

9. To principal return oil port Oi

18. Liquid line filter

Page 55

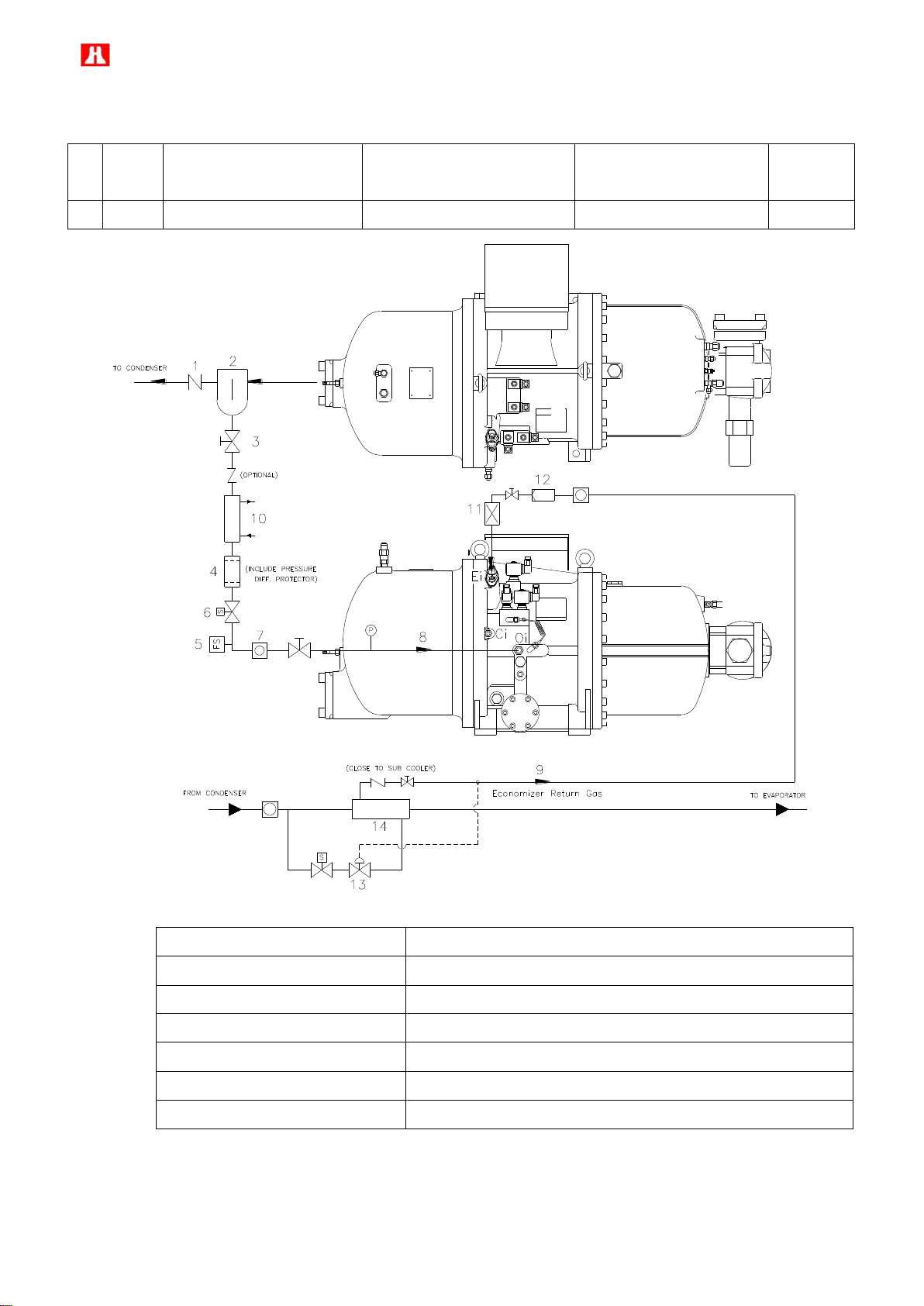

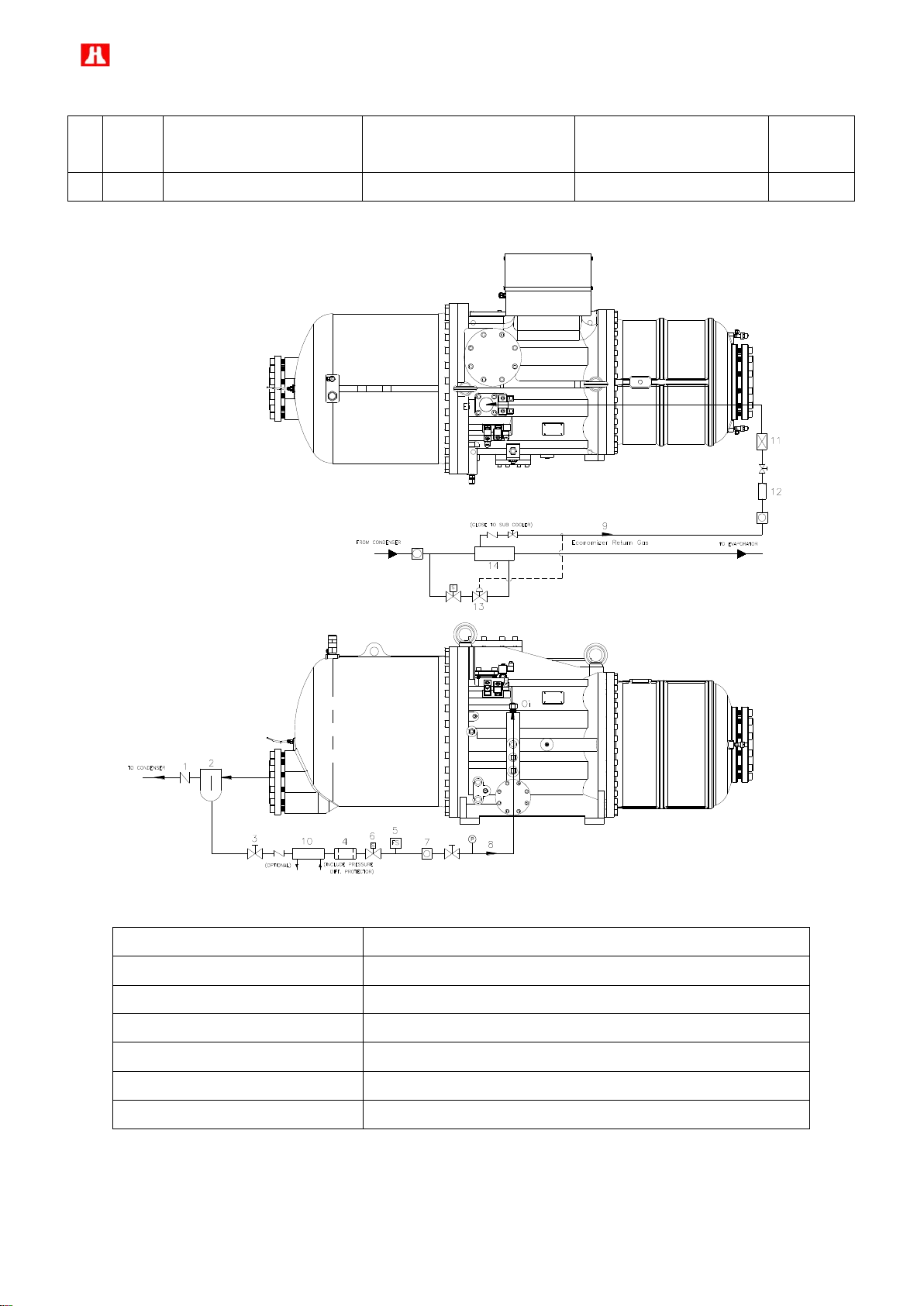

54

1. External oil separator

7. Oil level switch

2. Oil cooler

8. Oil temperature sensor

3. Oil filter and cartridge

9. Oil heater

4. Lubricant flow switch

10. Manually adjustable flow valve

5. Oil solenoid valve

11. Compressor

6. Sight glass

Model : RC2-710F ~ RC2-930F

(1) Installation of lubricant circuit

Page 56

55

(2) Lubricant circuit, Liquid injection system and economizer connection diagram

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

A

-

- - -

O

1. Check valve

8. To principal return oil port Oi

2. External oil separator

9. To medium pressure (Economizer return port) Ei

3. Stop valve

10. Oil cooler

4. Oil filter

11. Muffler

5. Lubricant flow switch

12. Suction strainer

6. Oil solenoid valve

13. Expansion valve

7. Sight glass

14. Sub-cooler

Page 57

56

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

B

O

O - O

O

1. Check valve

11. Cooling compressor’s chamber port Ci

2. External oil separator

12. To medium pressure (economizer return port) Ei

3. Stop valve

13. Liquid injection to motor winding port Li

4. Oil cooler

14. Liquid injection solenoid valve

5. Oil filter

15. Liquid injection expansion valve

6. Oil flow switch

16. Liquid line filter

7. Oil solenoid valve

17. Muffler

8. Sight glass

18. Strainer

9. To principal oil return port Oi

19. Sub-cooler

10. Adjustable flow valve

20. Expansion valve

Page 58

57

Item

Oil cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

C

O - O

O

O

1. Check valve

12. To cooling down compression chamber port Ci

2. External oil separator

13. Liquid line filter

3. Stop valve

14. Liquid injection to motor winding port Li

4. Oil cooler

15. Liquid injection solenoid valve

5. Oil filter

16. Liquid injection expansion valve

6. Lubricant flow switch

17. Liquid line filter

7. Oil solenoid valve

18. To medium pressure (economizer return port) Ei

8. Sight glass

19. Muffler

9. To principal return oil port

20. Strainer

10. Liquid injection solenoid valve

21. Sub-cooler

11. Liquid injection expansion valve

22. Expansion valve

Page 59

58

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

D

O

-

-

O

O

1. Check valve

10. To medium pressure (economizer return port) Ei

2. External oil separator

11. Muffler

3. Stop valve

12. Strainer

4. Oil cooler

13. Sub-cooler

5. Oil filter

14. Expansion valve

6. Lubricant flow switch

15. Liquid injection to motor winding port Li

7. Oil solenoid valve

16. Liquid injection to expansion valve

8. Sight glass

17. Liquid injection to solenoid valve

9. To principal return oil port Oi

18. Liquid line filter

Page 60

59

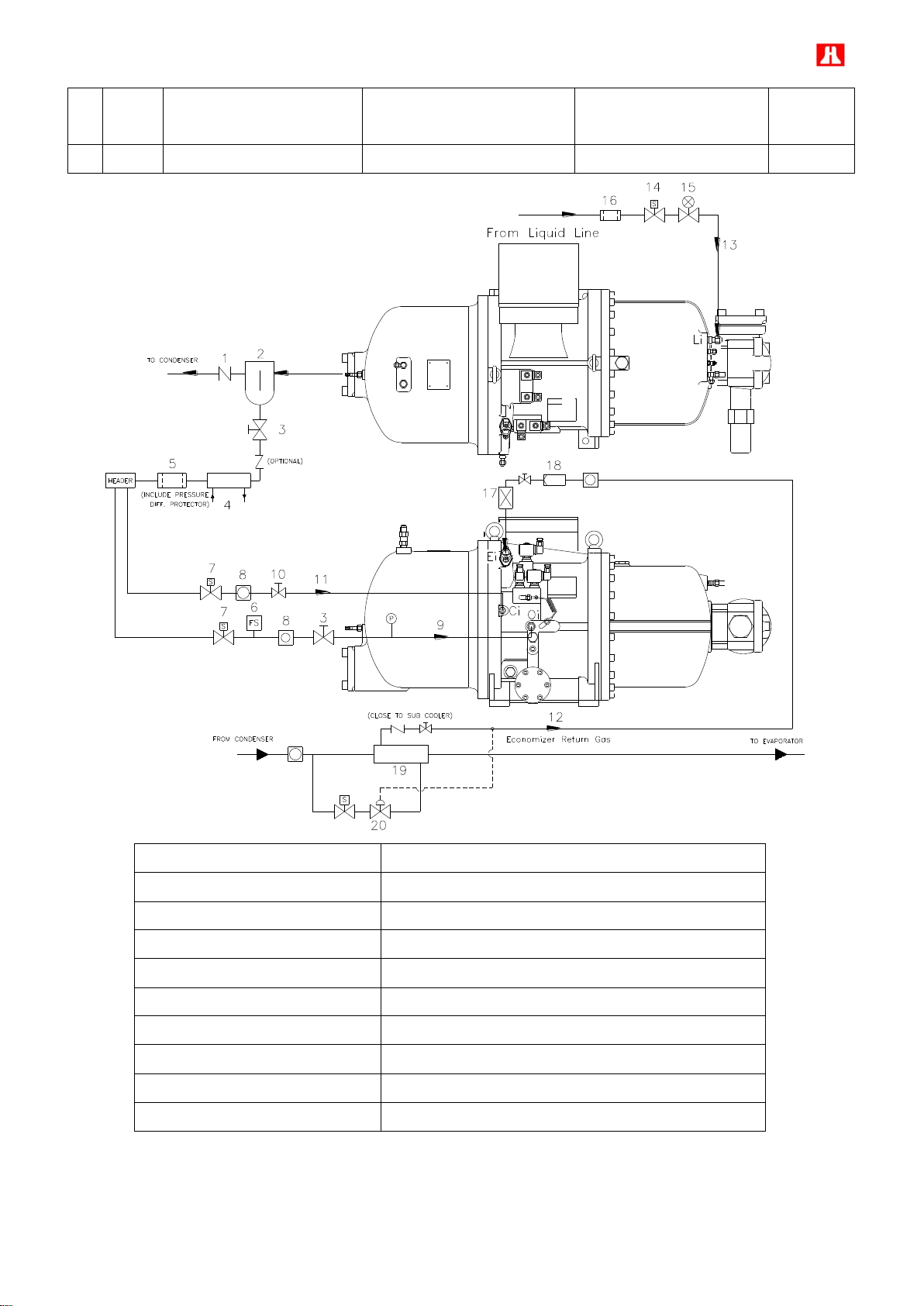

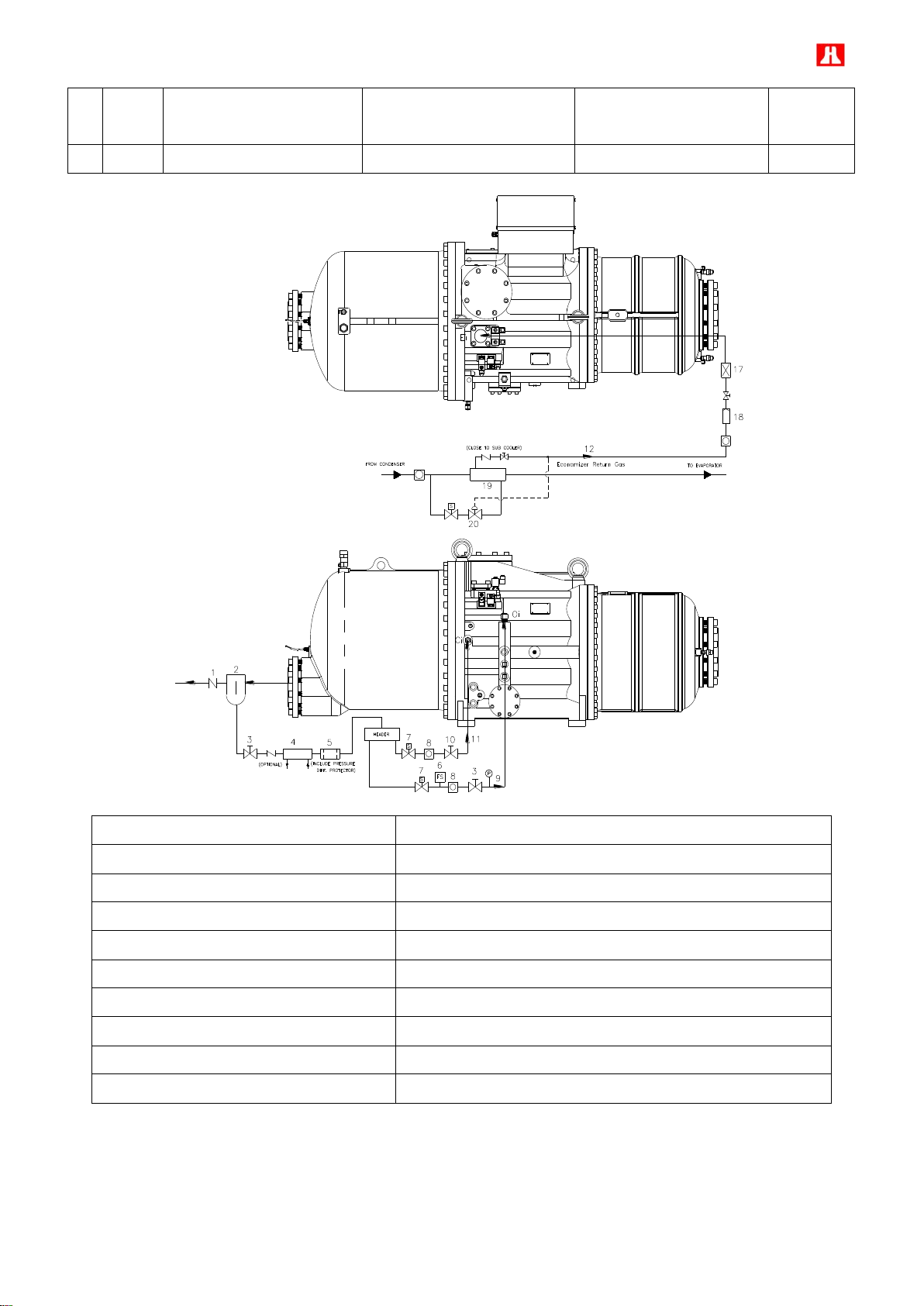

Model : RC2-1020F ~ RC2-1530F

1. External oil separator

7. Oil level switch

2. Oil cooler

8. Oil temperature sensor

3. Oil filter and cartridge

9. Oil heater

4. Lubricant flow switch

10. Manually adjustable flow valve

5. Oil solenoid valve

11. Compressor

6. Sight glass

(1) Installation of lubricant circuit

Page 61

60

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

A

-

- - -

O

1. Check valve

7. To principal return oil port Oi

2. External oil separator

8. To medium pressure (Economizer return port) Ei

3. Stop valve

9. Oil cooler

4. Oil filter

10. Muffler

5. Lubricant flow switch

11. Suction strainer

6. Oil solenoid valve

12. Expansion valve

7. Sight glass

13. Sub-cooler

(2) Lubricant circuit, Liquid injection system and economizer connection diagram

Page 62

61

Item

Oil

cooler

Oil injection into

compression chamber

Liquid injection into

compression chamber

Liquid injection for cooling

motor winding

Economizer

B

O

O - O

O

1. Check valve

11. Cooling compressor’s chamber port Ci