HANBELL RC2-100, RC2-930 Installation Manual

HANBELL COMPRESSOR

INSTALLATION & START-UP GUIDE

RC2-100 TO RC2-930

Rev M.5.2

WARNING! NO OIL is shipped in compressor.

Compressor must NEVER be run backwards.

These Safeties ARE Required at Startup to Maintain Hanbell Warranty

a)

Motor Module Trip (INT69HBY): Open for 1 second

b)

Low Oil Level Float Trip: Open for 30-60 seconds

c)

Unsafe Suction: Less than 5 psi for 3 seconds

d)

Low Differential Pressure: Less than 65 psi for 60 seconds (Oil Psi – Suction Psi)

e)

Unsafe Differential Pressure: Less than 35 psi for 5 seconds (Oil Psi – Suction Psi)

f)

Low Discharge Superheat: Less than 25°F for 300 seconds

Revision – 10/02/19

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

2

Th

Date

Author

Description of Changes

Update Manual to REV H

Updated / Added Solenoid Installation & Alignment Pictures

M. Schreiber

Update Manual to REV J

Added Hanbell Flooded Type Compressor with Oil Separator

Update Manual to Rev L

Inserted Table of Contents

Update Manual to Rev M

Updated images Hanbell VFD & Solenoids

DEW

DEW

DEW

DEW

e MCS Commitment: Our commitment is to provide practical solutions for the industry’s needs and to be both a

leader and a partner in the effective use of microprocessor controls.

(W

ebsite contains product descriptions, manuals, software releases and troubleshooting aids among others)

All information contained within this document is considered to be proprietary information of M ic ro Co ntr ol Sy stem s, I nc. No

information or data from thi s d ocu ment sha ll b e published, used, reprod uced, tr ans mitted, or disclosed to others outside your

organization without the prior expressed written consent of Micro Control Systems, Inc. This document and the information

contained herein shall be treated as proprietary. Reasonable provisions shall be provided to ensure that this information

remains proprietary by your employees, agents and other personnel that may have access to this document.

Revision:

Updated Hanbell Liquid Injection Piping

12/03/12

M. Schreiber / X. Beltran

ATTENTION: Step Control Loading Plate Design In RC2 Series

Added Revision Chart

12/06/12

05/24/13

06/13/13

6/18/13

11/04/14

7/30/15

8/27/15

11-16-16

04-18-17

11-27-17

M. Schreiber

M. Schreiber

K. Mitchell

X. Beltran

DEW

Update Manual to REV I

Added Hanbell Compressor Picture

Updated Hanbell Liquid Injection Piping

Update Manual to REV K

Updated Hanbell Liquid Injection Piping

Updated wiring of electrical power terminals

Added rotation of compressor

Updated Installation Procedures (Liquid Injection Solenoid)

Updated INT69HBY diagnose wiring diagram

Updated Hanbell Flooded Type diagr

Update Manual to Rev N

Update page 11

Update section 13

Replace dwg pg 6, 7,9, 212. 22

Add Warranty Maintenance Info in back

Edits to pages 11,12,13 picked up from App097

ams

12-28-17

09-05-17

DEW

DEW

add POE OIL Warning

Add Note on Economizer, Drawing

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

3

Table of Contents

Compressor Crate Unpacking & Inspection ....................................................................................................... 4

Compressor Safety Instructions ......................................................................................................................... 5

Installation Procedures ...................................................................................................................................... 5

Recommended Liquid Injection Piping ............................................................................................................... 6

Screw Compressor Wiring Procedures .............................................................................................................. 7

INT69HBY ....................................................................................................................................................... 12

Maintenance Area Requirement ...................................................................................................................... 18

Compressor Piping .......................................................................................................................................... 20

Electrical Wiring ............................................................................................................................................... 20

Pre-Start-up Procedure .................................................................................................................................... 21

Start-up Procedure .......................................................................................................................................... 25

Recommended Safety Settings ....................................................................................................................... 25

Hanbell with VFD ............................................................................................................................................. 26

Solenoids ........................................................................................................................................................ 27

Slide Amp Calculation...................................................................................................................................... 34

Handling POE Oil Information .......................................................................................................................... 39

Warranty / Maintenance Information ................................................................................................................ 40

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

4

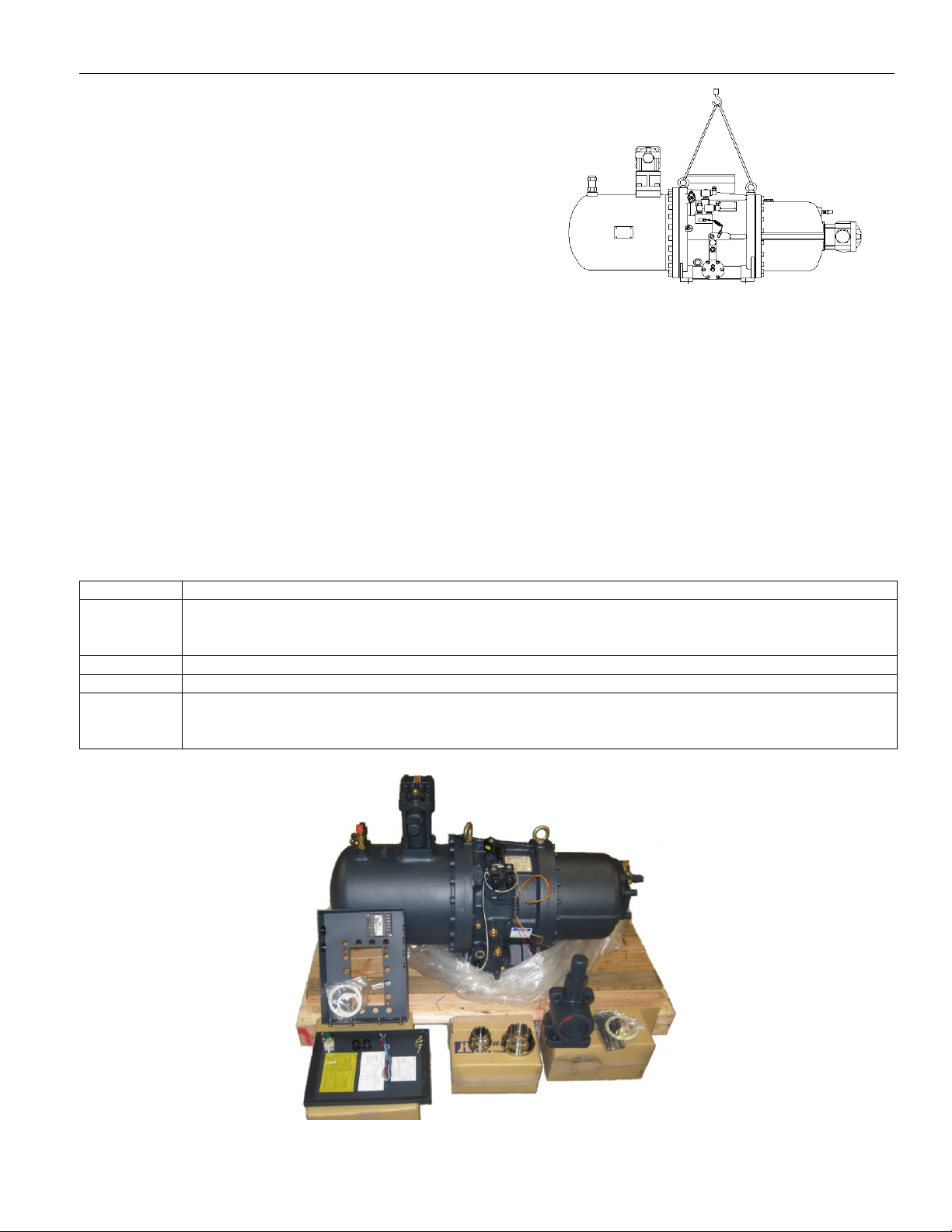

1.

Qty

Description

1

Stop Valve Assembly

bonnet

1

Discharge bushing connector

1

Suction bushing connector

1

Motor Terminal Junction Box Assembly

(refer to Figure 4-B)

Compressor Crate Unpacking & Inspection

1.1.

Inspect crate and compressor for any shipping

damage.

1.2.

The compressor is in an easy open crate, cut straps

and lift off crate top from base.

1.3.

Use either steel cable or safety ropes to lift the

compressor, see Figure 1. The cable should be

capable of holding up to a minimum of 2 tons.

Use caution while lifting the compressor

⇒ Make sure that the steel cable does not touch the Solenoid Valves, Capillary, Oil Heater, Discharge

T

emperature Sensor and or Power Terminals, e tc. to prevent damage.

⇒ Use only steel cable or safety ropes to lift the compressor; make sure that the cabl e/r ope has the

pr

oper strength to lift the compressor.

⇒ Keep the compressor horizontal while lifting.

1.4.

Check compressor nameplate for correct model and voltage designation.

1.5.

To facilitate customer installation requirements, the parts listed in Table 1 are factory supplied in separate boxes

located in the compressor terminal box or packed in the compressor shipping container. Please verify that you

have received all accessory parts.

Table 1: Compressor Accessories & Service Valve Parts

Figure 1

Lifting Compressor with Steel Cable

1 stop valve, 2 gaskets, 1 charging valve, 4 bolts, 1 half union connector, 1 flare nut, 1 flare seal

1 terminal box, 1 motor protection, 2 plastic terminal plugs, 1 reset button, 4 wires

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

5

2.

Compressor Safety Instructions

2.1.

Follow recognized safety procedures and practices.

2.2.

In order to prevent the penetration of moisture, air or impurities, the compressor has been charged with Nitrogen

gas. Do not remove any compressor bolts or fittings until the factory supplied holding charge has been relieved

2.3.

Do not apply any power to the compressor unless all valves are open and solenoids are energized (suction /

discharge, service valves, economizer and oil shut off valves).

2.4.

Do not operate or provide any electrical power to the compressor unless the terminal box cover is in place and

secured. Measurements of the current and voltage during running conditions must be taken at other points in the

power supply.

2.5.

Do not remove terminal box cover until all electrical sources have been disconnected.

WARNING: Failure to follow these instructions could result in serious personal injury.

3.

Installation Procedures

3.1.

Holding Charge: The screw compressor is factory supplied with 7 psig (0.5 bar) holding charge of nitrogen gas.

The internal pressure must be relieved before attempting to remove any compressor fittings or parts. Relieve the

holding charge by removing the threaded cap on the low pressure Schrader connection fitting and depressing

the internal Schrader stem.

CAUTION: This compressor may contain trace amounts of oil. Do not relieve the holding charge or open th e c o mp resso r p ot s u nt i l i t i s re ad y t o b e co n n ect ed t o a closed dry system . Excessive moisture may shorten compressor life.

3.2.

Installation of the Compressor Electr ical Terminal Box: Four bolts located on the top of the electrical terminal

box cover mount the electrical terminal box; it is adjustable to the cable hole direction to meet the power cables’

optional connection direction from the chiller.

3.3.

Oils: Adding and removing oil is done through the Drain valve located on the solenoid side of compressor. The

compressor has no oil and is not charged with oil. When adding or doing a complete change, use only the

listed Hanbell approved oils. POE oils readily absorb moisture and cause acid formation in the system.

Keep oil exposure to the atmosphere to a minimum.

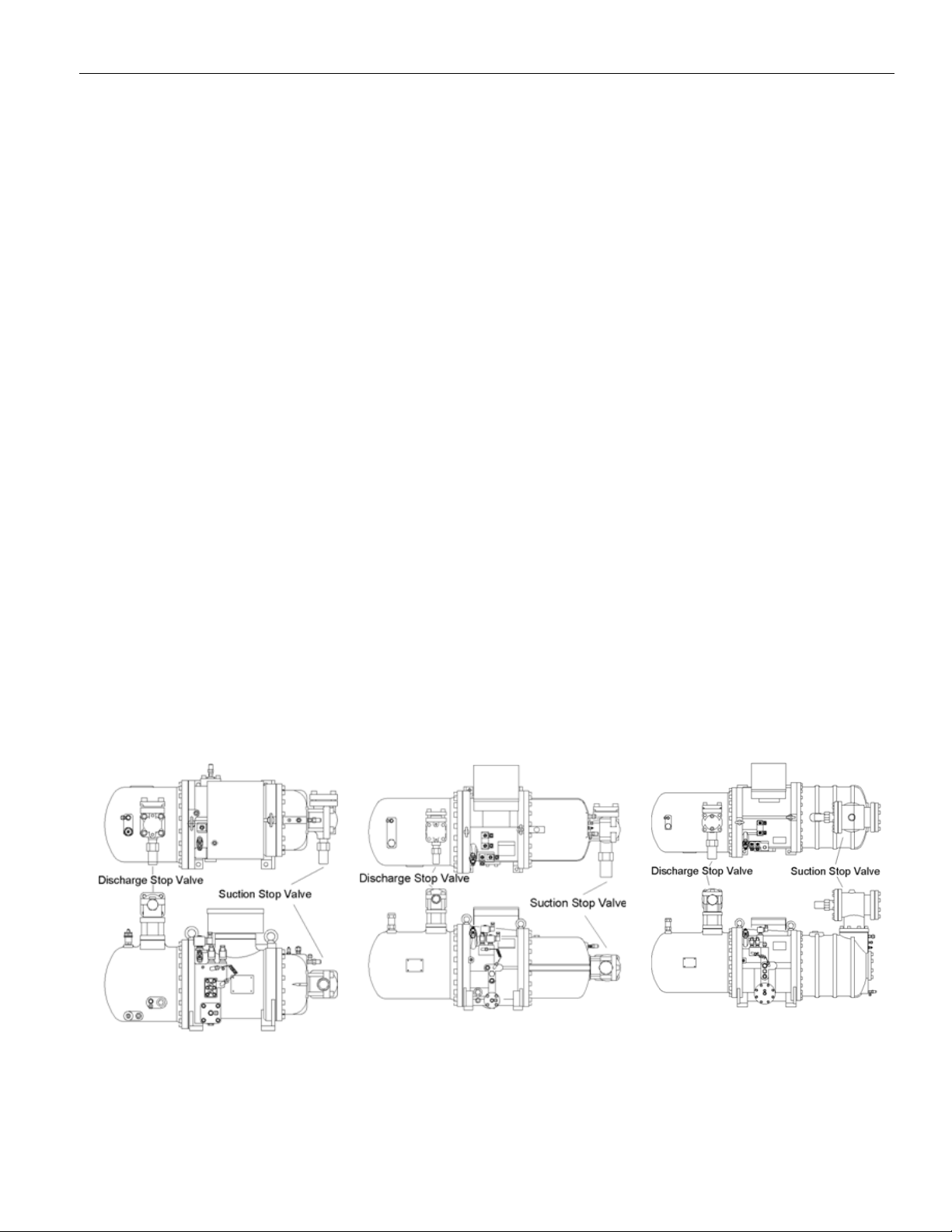

3.4.

Installation of the Service/Stop Valve: Unpack the service/stop valve’s box then check against the list on the

outside of the box to ensure correct parts. Be sure that all parts inside the carton are clean. Use the four bolts to

secure the service/stop valve. Use PTFE sealer to seal the adapter while tightening it. Please refer to Figure 5-A

for space requirements for future service and maintenance needs.

3.5.

Service/stop Valve Recommended Connection

Figure 3-A RC2-100, 140 & 180

Figure 3-B RC2-170, 200~580 & 620

Figure 3-C RC2-610, 710~930

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

6

3.6.

Liquid Injection Solenoid Valve and Expansion Valve (Required, Not included with compressor): The

liquid injection system may be piped, but it is necessary to consider the required space for adjustment of the

expansion valve while testing or running the compressor. Please refer to installation guide in the following

section for connection points.

3.7.

PTC Discharge Temperature Protection: Each compressor comes standard with three PTC sensors in the

motor windings and one located at the discharge port. A motor module (INT69HBY) is installed in the electrical

terminal box. Refer to Figure 4-B showing the connection of motor and discharge PTCs in series to the motor

module corresponding terminal blocks.

4.

Recommended Liquid Injection Piping

Note A: It is necessary to adjust the Ball Valve to feed small amounts of liquid (drops) to the

compressor motor.

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

7

5.

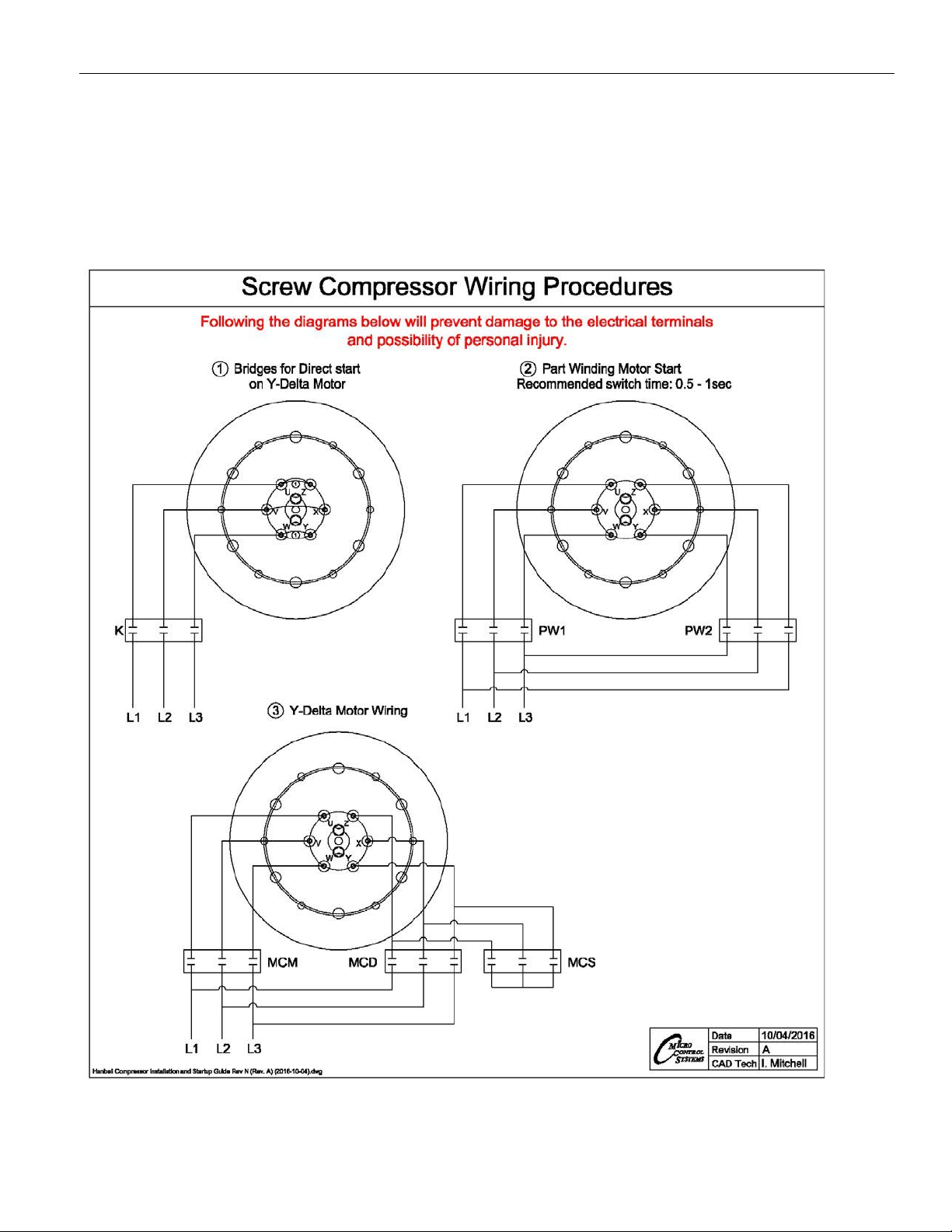

Screw Compressor Wi rin g Procedures

Following the diagrams below will prevent damage to the electrical terminals and the

possibility of personal injury.

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

8

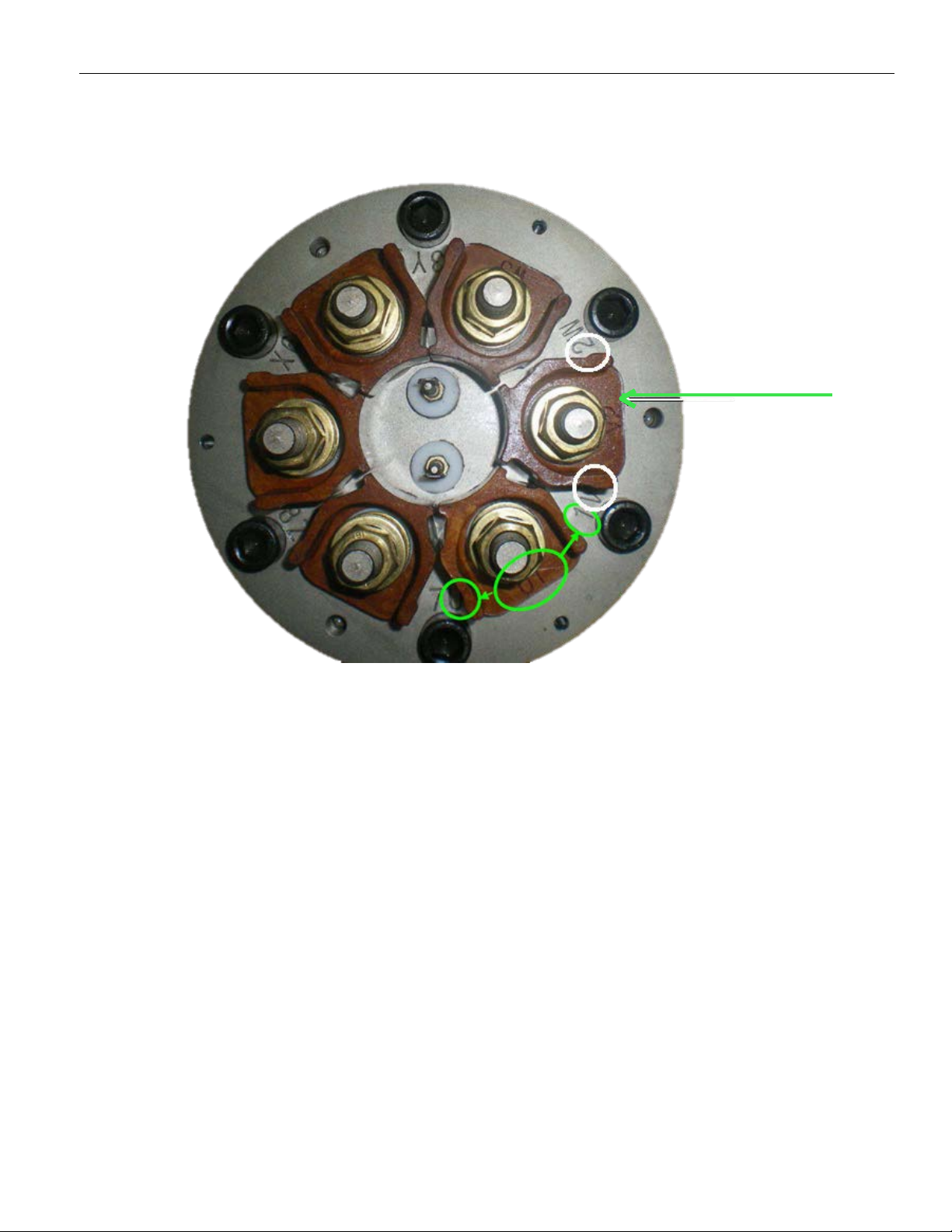

The method to tell the terminals (V-Phase)

1. By alphabet: Refer to the alphabet beside each terminal bolt in a star-delta motor.

2. By numbers: Refer to the number beside each bolt in a PWS motor.

Terminal

V2

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

9

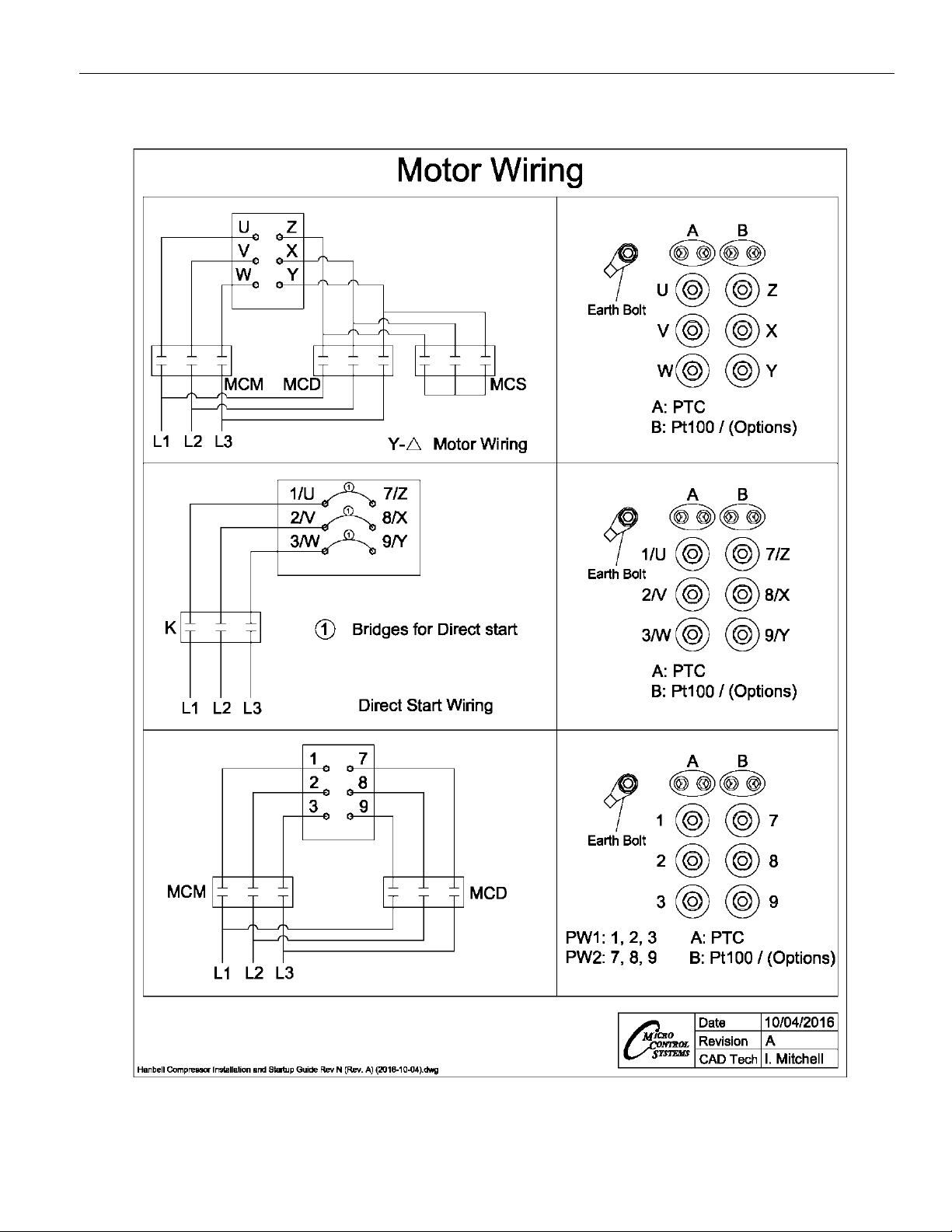

Figure 5-A Motor Wiring

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

10

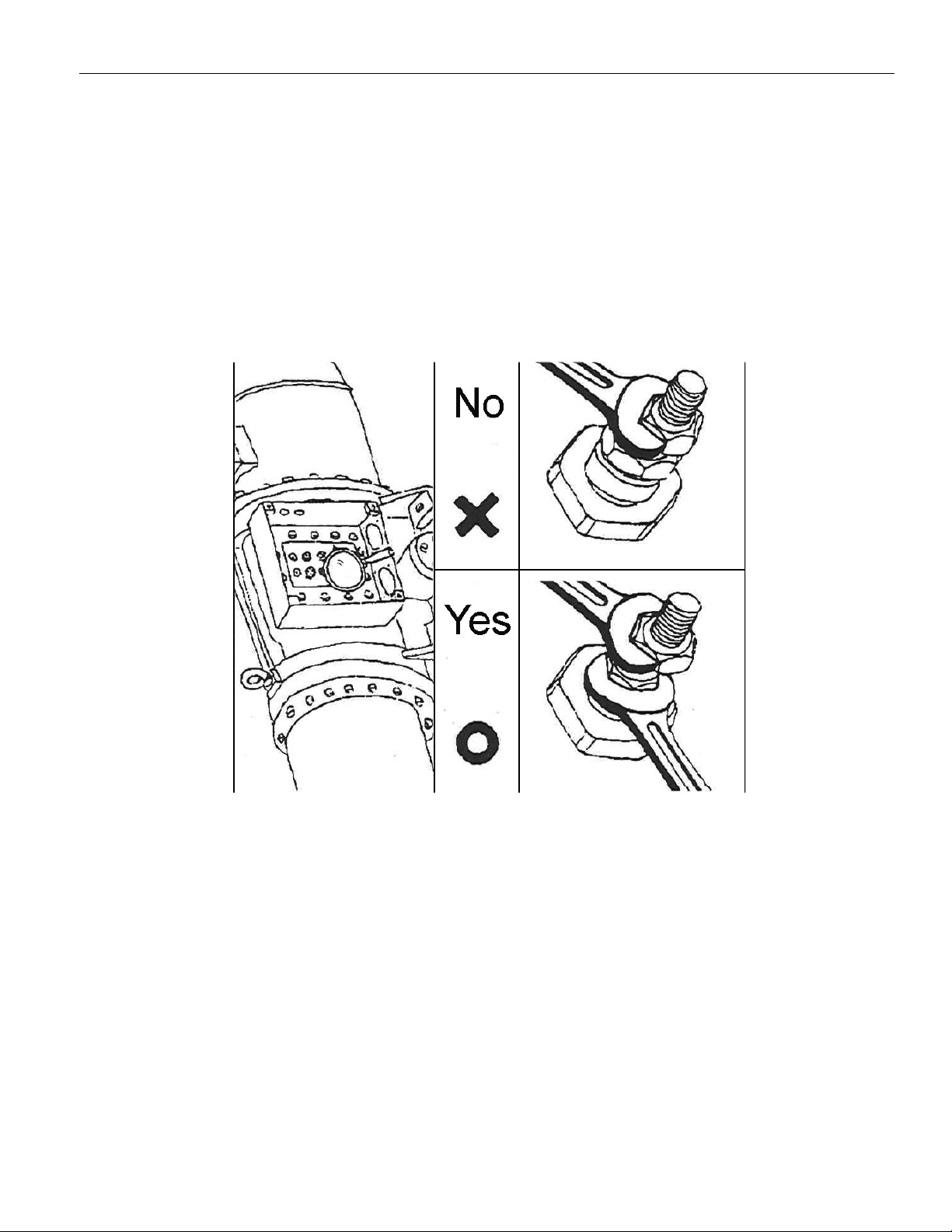

5.1.

Electrical Power Terminals

The power terminals of Hanbell compressors are made from ceramic materials and well insulated

more than 1000MΩ. Be careful connecting the wiring and follow the list below.

⇒ The ceramic part on the power terminal should not be tighten by hitting otherwise the insulation of

the power terminal could be degraded.

⇒ Follow the drawing shown below for the wiring to prevent the power terminal from being damaged.

⇒ The setting of the torque wrench for tightening the copper nut of the terminal bolts should be set less

than 500 kg-cm (36 pound/inch)

The insulation of the ceramic power terminals are very easily degraded by water, so DO NOT take

the leakage test by immersing the whole compressor in the water. Shut down the chiller first for

service if the insulation valve of the power terminal is lower than 5MΩ.

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

11

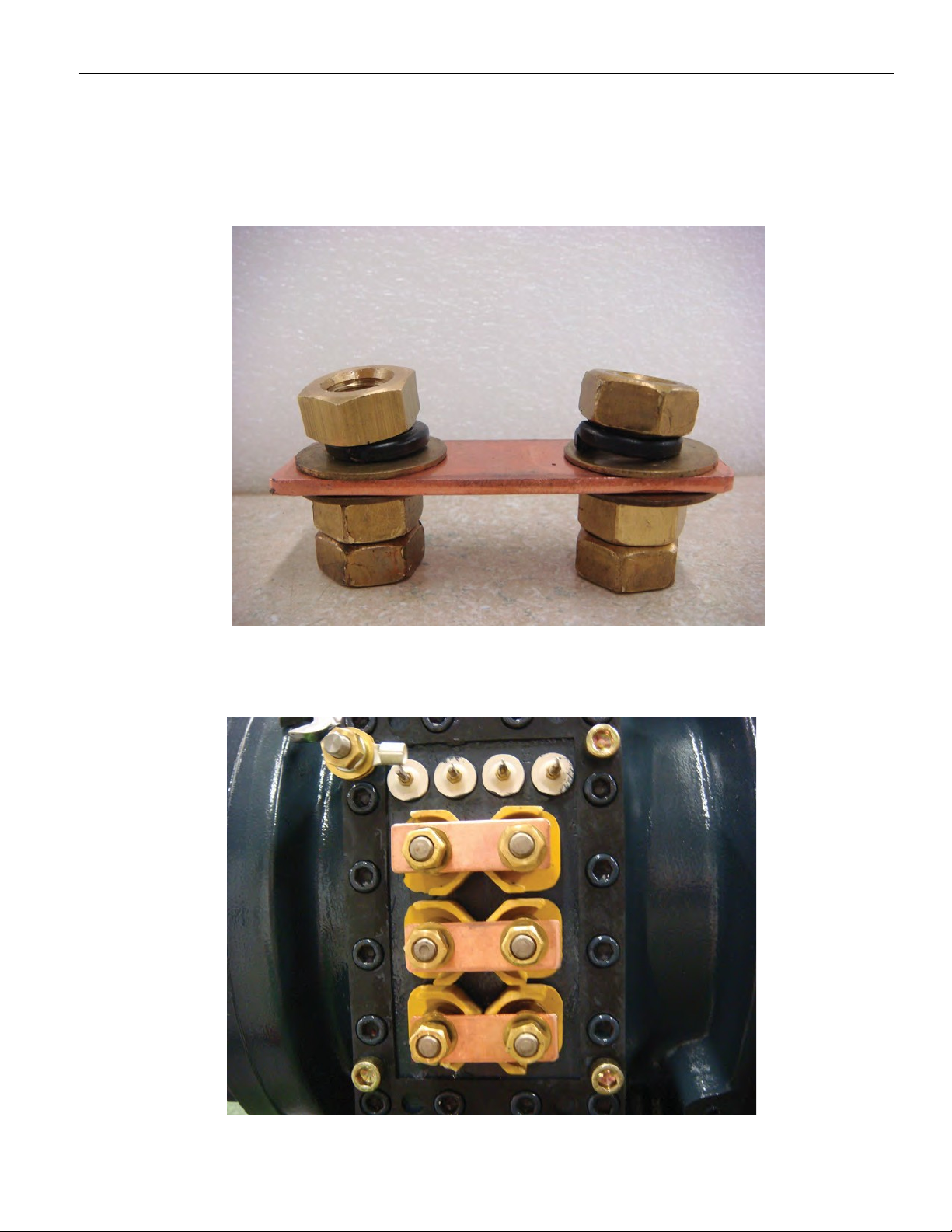

5.2.

Across the Line Jumper Bar Installation

Photo shows extra nuts installed under jumper bar for

clearance of power bolt Insulation.

Connect line voltage directly on Terminal post.

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

12

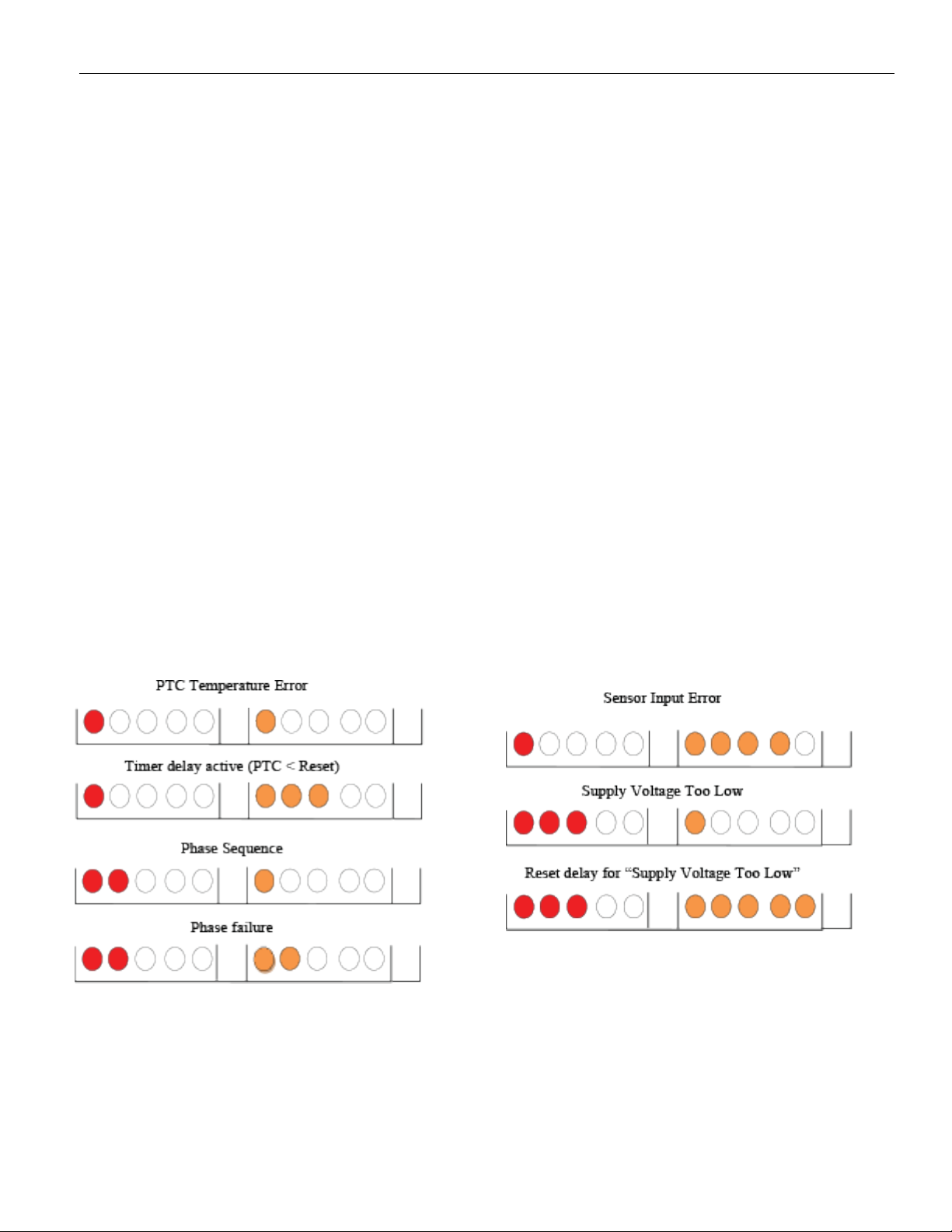

RED

ORANGE

RED

ORANGE

6.

Description - INT69HBY DIAGNOSE

Hanbell supplies INT69 HBY Diagnose for motor protection with monitoring functions of phase loss, phase

sequence, motor temperature, and discharge temperature. The module has built in flash codes that are helpful for diagnosing safety faults.

In order t o pr otect th e c om pr e s s or , e ac h RC 2 series compressor has been built with three PTC temperature

sensors inside the motor coil and one at the discharge port neck of the compressor. These sensors are connected to the motor module to monitor coil temperature and discharge temperature. Up to 9 sensors can be

connected in series and used with one module.

If the temperature in one of the positions monitored exceeds nominal response temperature of the respective

PTC thermistor (230° F, 4.5 ohms ±20%), the sensor resistance increases and the module trips (M1 and M2

open). The failure results in a lockout. The module resets when the response temperature drops 3kΩ(when

temp

decreases below 212°F, 2.75 ohms ±20%). 5 min delay for the first PTC failure, 60 min delay for the 2

ure, latching lockout for the 3

to prevent nuisance trips from brief reverse rotation.

Phase failure (loss) and Phase sequence safety trips result in a first time lockout. Phase sequence monitoring is active 1 second after motor start for 10 seconds. Phase loss is monitored 1 second after motor start till

motor stop.

nd

rd

within 24 hour period. Monitoring is inactive for 20 seconds after motor stop

fail-

Lockout and time delay can be cancelled by interrupting power to the module for 5 second’s. An optional

power supply reset button can be added to electrical connection box.

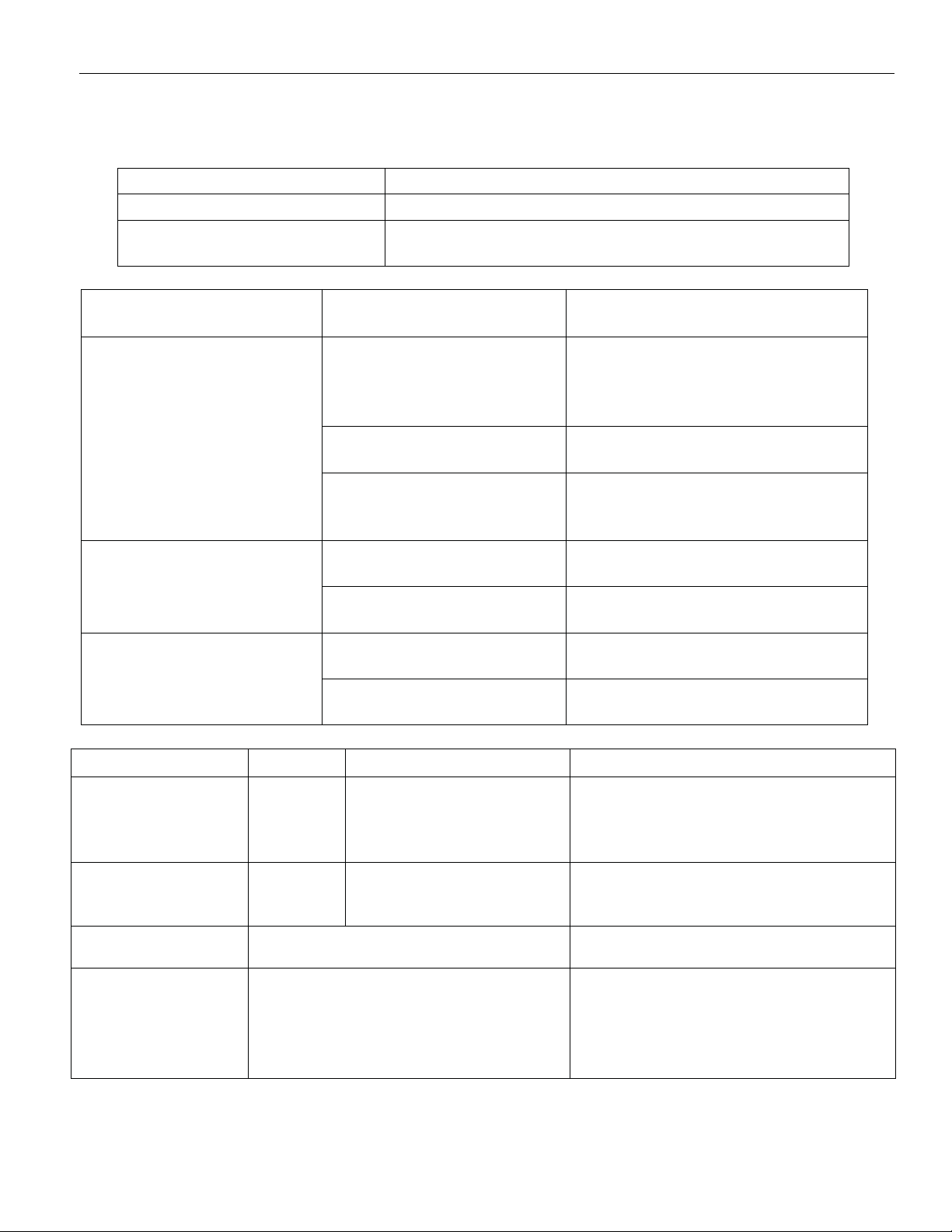

Flash Codes

COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

13

Green lit

Compressor Operational

Green flashing

Compressor Running

Red/Orange flashing

Error, Compressor is switched off; for description see

table below

1st flashing sequence

(Red LED)

2nd flashing sequence

(Orange LED)

Description

1

1 Motor temperature;

ture exceeded

3

Motor temperature;

Reset delay after static switch off

4

Motor temperature;

circuit or short circuit

2

1

Motor voltage;

Incorrect phasesequence

2

Motor voltage;

Phase failure/asymmetry

3

1

General;

Supply voltage too low

5

General;

Reset delay after “General” error

Error

Active

Condition

Time delay

Motor temperature

Always

Rtrip 4,5kΩ ±20%

1. / 24h 5min 2. / 24h 60min

Operation cycle

Always

>3 switch off within 30s

5min

Phase sequence

1s after motor start for 10s

Locked out

Phase loss

1s after motor start till motor stop,

trips from brief reverse rotation.

Locked out

Flash Code Overview

Static switch off,

Permissible winding te mpera-

Sensor input detected open

static trip

Rreset 2,75kΩ ±20%

limitation

failure

monitoring is inactive for 20 seconds after

motor stop to prevent nuisance

3. / 24h locked out

Time delay starts after cooling down

Loading...

Loading...