Page 1

DCN

PRO

&

seAN

User's Manual Vol. 1: Sean Funetion

i

01

. lo

Page 2

DCN

PRO

&

seAN

User's

Manual

Vol. 1: Sean

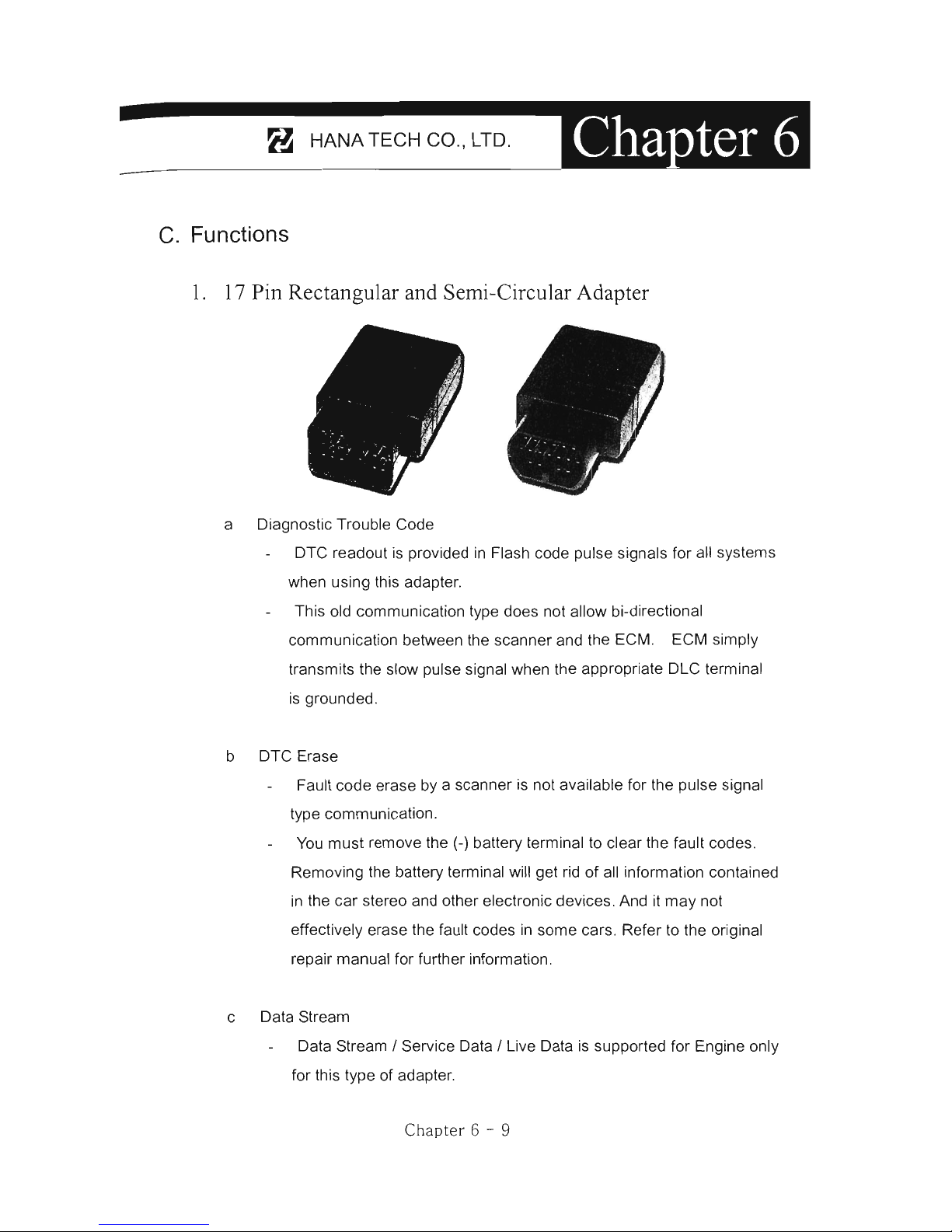

Funetion

o I I o

0000

0000

0000

0000

DDDO

<]-0[>

~

Page 3

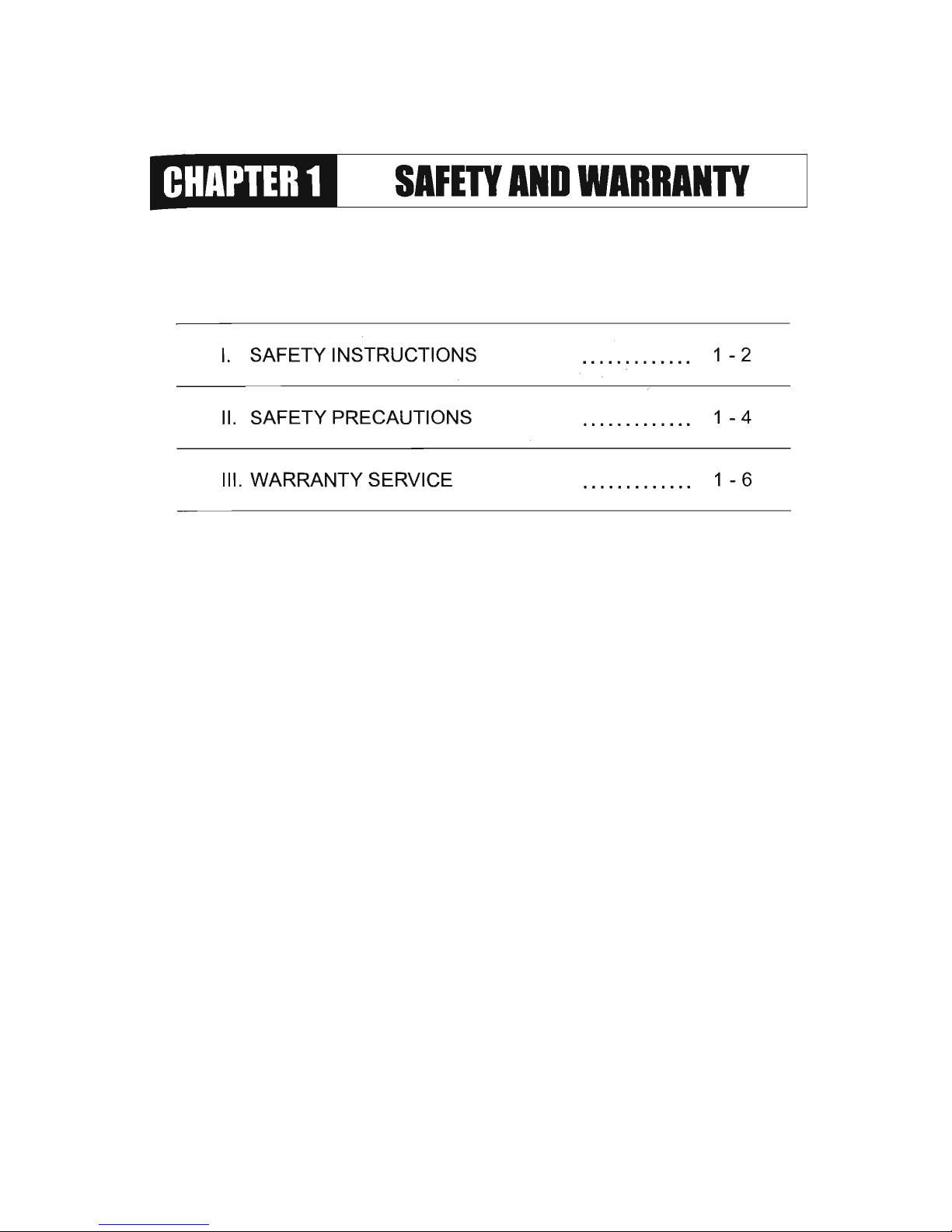

SAFEn

ANO

WARRANTY

1.

SAFETY

INSTRUCTIONS

1 - 2

11.

SAFETY

PRECAUTIONS

1 - 4

111.

WARRANTY

SERVICE

1 - 6

Page 4

8 HANATECH CO., LTD.

Safety

and

Warranty

About this Manual

AII

rights reserved by HAN A TECH Co., Ud., Gumi, Korea.

The contents

of

this manual are the result of cOntributions by dozens

of individuals all who have added their vital expertise and experience to

the evolution of the contents of this manual.

The information contained

in

this manual may contain printing errors

and is subject to change without notice according to product upgrade.

HANA TECH shall not be liable

for

errors contained herein

or

for

incidental or consequential damage

in

connection with the furnishing,

performance, or use of this material.

No part of this manual may be photocopied, reproduced, or translated

to another laRguage

in

any way without the prior written consent of

HANA TECH Co

.,

Ud.

Using this Manual

It

is

recommended that the user become familiar with the

operating procedures, terminologies and information contained

within this user's manual. This will help to increase the user's

effectiveness with this equipment.

Vehicle system familiarity

While this equipment provides very powerful functions with extensive

vehicle coverage, it cannot replace knowledge and skill.

To

get the

most out of this equipment, a full understanding of vehicle systems

is

required.

It

is

recommended that the equipment be used

in

conjunction

with the original service manual for the vehicle being tested.

The equipment

is

designed for use by trained service personnel and

this manual assumes that the service technician who is going to use this

equipment has a familiarity with vehicle electronic control systems,

however, the latest service manuals and bulletins should always be

referenced before using this equipment.

Chapter 1 - 1

Page 5

For DeN Scanners

1.

SAFETY INSTRUCITONS -----------------------

Thank you for purchasing DCN scanners.

To

get the maximum performance of

the equipment, please carefully read this manual first, and keep it at hand.

On delivery inspection

When the equipment is delivered, a check should be made for any damaged or

missing components. If the unit

is

damaged or fails to operate according to the

specifications, contact your local distributor or the manufacturer, HANA TECH CO.,

LTD., Hana bldg. , 80-1 Songjung-dong, Gumi-shi, Kyung-buk Republic of Korea 730-

090.

In

the unlikely event the equipment requires shipping back to the manufacturer,

please use the original packing material.

Safety symbols

The following symbols are used throughout this manual :

&

This mark means that dangerous consequences may

DANGER

arise, with the possibility of death or serious injury

to

the

user, if the machine

is

handled incorrectly.

This mark means dangerous consequences may arise,

&

WARNING

with the possibility of somewhat serious injury to the user

and or damage

to

the machine and facilities, if the

equipment is handheld incorrectly.

SYMBOL Description

This symbol

is

affixed

to

locations on the equipment where

&

the operator should consult corresponding topics

in

this

manual (which are also marked with the

'!\

symbol) before

using relevant functions

of

the equipment.

In

the manual,

this

symbol indicates

explanations

that are particularly

important that the user

is

expected to read the manual before

using the equipment.

---

This symbol represents

DC

(Direct Current)

Chapt

er 1 - 2

,

Page 6

8

HANATECH

CO.,

LTD.

Safety

guideline

In

order to ensure proper operation and satisfactory performance, observe the

cautions listed below.

& DANGER

This equipment

is

designed

to

comply with IEC61

01

O~

1 safety standards, and

has been tested for safety prior to shipment. Excessive high voltage measurement

or improper operation could result

in

personal injury, as well as damage to the

equipment or the vehicle. Please read this manual carefully and be sure that you

understand its contents befare using the equipment.

The manufacturer disclaims all responsibility for any accident except for that

resulting due to defect

in

its product.

~--

--

----.----

-----------

---------------------------~

-----

-

----

!i

\ WARNING

L~

For safety reasons, this equipment should not be used

to

measure circuits carrying more than 30Vrms or 42.4 V peak.

To

avoid electrical accident that could result

in

injury or

death , do not measure voltage

in

excess

of

these limitations.

Maximum rated measurable voltage

is

30Vrms or 42.4V

peak.

Ch<1pter 1 - 3

Page 7

For DeN Scanners

11.

SAFETY PRECAUT10NS -----------------------

DANGER

When an engine is running, keep the workshop area WELL

VENTILATEO or attach a building exhaust removal system

to

the

engine exhaust system. Engines produce carbon monoxide, an

odorless and poisonous gas that causes slower reaction time

and may lead to serious injury or death.

WARNING

Brakes and wheel blocks

Apply the hand brake and block the wheels before using the test

equipment.

It

is

highly recommended

to

block the wheels on

front-wheel drive vehicles beca use the hand brake does not hold

the driving wheels.

Orive Test

Do not drive the vehicle and operate the test equipment at the

same time. Any distraction may cause an accident. Have one

person operate the test equipment

while the other person drives

the vehicle.

-------

--

r~

Never place the test equipment

in

front of you when driving the vehicle because the

test equipment

may

hit your body and cause serious injury when

the air bag inflates.

Do not try to test the SRS air bag system while driving the

vehicle as unintended air bag inflation may result.

Chapt

er 1 - 4

Page 8

8 HANATECH CO.,

LTD.

Engine Compartment

Maintain sufficient clearance between moving components or

belts while using the test equipment

in

the engine compartment.

Moving components and belts may catch loose clothing, test

cables or a part of your body and cause damage or personal

injury.

Electrical Components

Always turn the ignition key OFF when connecting or disconnecting electrical

components unless otherwise instructed.

Vehicle Battery

DeN

equipments are designed to prevent damage from reverse polarity battery cable

connection, however, it is always highly recommended to always ensure correct

polarity terminal connection.

Never lay the test equipment on vehicle battery.

You

may short the terminals and may

cause damage to your body, the test equipment or the battery.

To

avoid damaging the test equipment or displaying false data, make sure the vehicle

battery

is

fully charged and the connections

to

the electronic control module are clean

and tight.

The warning messages aboye and the safety messages contained hereinafter cover

situations Hana Tech

is

aware of. Hana Tech cannot know, evaluate or advise you as

to

al!

of the possible hazards.

You

must make sure that any conditions

or

service

procedures encountered do not jeopardize your personal safety.

Chapter

1 - 5

Page 9

For DeN Scanners

III.

WARRANTY SERVICE

Warranty Period

In

principie, DCN products are warranted

to

the consumer to be free of defects

in

material and workmanship for the period of 3 years after the date

of

purchase.

If the product

is

found defective during this period, the product can be returned to

Hana Tech and will be repaired or replaced free

of

charge.

Freight and repair Cost

For the repair

of

head unit, Hana Tech covers the freight cost for the service during

one year from the date

of

purchase, and you can send the troubled unit

to

your local

distributor without having

to

pay the freight cost.

You

should consult with your local

distributor about the validity

of

remaining warranty period before sending the unit.

For the remaining two years, you are liable for any international cost incurred. Repair

or replacement will be provided free

of

charge.

When the warranty period

is

expired after three years, the customer must pay the

round trip freight and the repair or replacement cost.

Upon delivery

Hana Tech inspects all the ordered product parts and components are included

in

the

package before shipment, and includes the original copy

of

pre-shipment inspection

report

in

the box. As soon as the product

is

delivered to you, please ensure

everything you ordered is properly checked and included referring

to

the pre-shipment

inspection report. If there is anything missing or damaged, you must notify the local

distributor immediately within 3 working days from the delivery date for free

of

charge

replacement

of

the parts.

In

case

of

trouble

If you encounter any malfunction or trouble with the equipment, please refer to the

Trouble Shooting chapter

in

this manual. If the problem cannot

be

solved, please

contact your local distributor for assistance . For early identification

of

a fault or error,

Chélpt

er 1 - 6

Page 10

8

HANATECH

CO.,

LTD.

your local distributor will require the following details:

1.

Symptom

of

problem you are experiencing

2. Serial number of the head unit

3.

Vehicle information: Which specific car were you testing when the problem

occurred - Model name, Model year and system

ID

number if available (for Mitsubishi,

Subaru and Suzuki only: Refer

to

Japanese car chapter for details)

Warranty Void

Even

in

the effective warranty period, if the problem

is

found to be caused by any

of

the followings, Hana Tech charges the cost for round trip freight and actual cost for the

service

to

the customer, and the shipment back

to

the customer will be suspended

until the customer's payment

is

duly made

1.

Evidence

of

improper use

or

application

of

the product ignoring the cautions and

warnings stipulated

in

the

user

's manual

2. Infenfional damage

or

modifications

fo

fhe producf

or

user's attempt

fo

repair

without proper authorization

3.

Any

damage caused

by

Force Majeure including

war

and natural disaster

4.

L08S

of

time, inconvenience and other consequential damage

or

108S

Warranty void seal

In

addition to the above mentioned warranty void conditions, warranty service

is

not

provided

in

case the warranty void seal

is

broken or removed.

If you remove the head unit safety boot, you will see a yellow round sticker covering

one

of

the screw holes

in

the back. Please be careful not to break this seal and never

try

to

open the head unit without direct authorization from the manufacturero

Bought

in

other countries

Only the products properly supplied by the contracted authorized local distributors are

recognizable for free

of

charge warranty service. Any equipment bought outside the

contracted national territory

of

your local distributor will be charged for service.

Chapt

er 1 - 7

Page 11

Page 12

SPECIFICATION

ANO

PARTS

1.

SPECIFICATION

......

... oo'

..........

..

2-1

11.

PART LlST

.................

oo

..

2-3

A.

Head unit and basic supplies

2-3

B.

Basic supplies for DCN-PRO

2-6

C.

Diagnostic Adapters

2-9

D.

Software Cartridges

2 - 16

E.

Spare Parts

2

-17

F. Optional Supplies

2

-18

Page 13

Page 14

______

B_H_A_N_A_T_E_C_H_C_O_",_LT_D_"_--'

__

Specification

and

Parts

1.

S p ec ifi ca

ti

on -----------------------------------

A.

Hardware

CPU: 16bit, 33MHz

RAM: 1 Mbyte (SRAM)

Program Cartridge Memory: 128Mbytes Flash Memory

16M bytes cards for optional packages

Display:

320x 240 Monochrome Graphic LCD with Back Light

Key Pad:

24

membrane keys, embossing type

Serial Port: RS232

Printer: General PC printer

Power: DC 8-18V, 800mA or higher

B.

Environmental Specification

Indoor use only

Operating temperature: Max

50

oC

/ 122°F

Maximum relative humidity: 80% (up to

31

°C/88°F) and 50% (40°C/104°F or

higher)

Installation overvoltage categories: CAT

TI

Maximum measurable voltage:

DC

30V Max

Pollution degree 2

Max" Altitude:

Up

to 2000m

Chapter

2 - 1

Page 15

For DCN Scanners

C.

Oscilloscope Specification

(DCN-PRO

only)

4 Channel

Voltage Division: 0.1V - 20V Div

Time Division: Normal

25/.15

- 20sec

Sampling Rate: 500KHz

/2

channel

Measurable Voltage :

OC

±150V Max

D. Multi-meter Specification

(DCN-PRO

only)

Voltage:

OC

30V Max

Frequency: 1 Hz -

100KHz

Out y Cycle:

O - 99.9%

Current:

±128Amp

Voltage Output:

OC

0.00 - 5.00V

Frequency/Duty Cycle Output: 1.0Hz - 1.0KHz

E.

Mechanical Dimensions

Length: 302.

1111U1

/ 12.1"

Width:

171.91i101

/6.8"

Height: 75 .

7U101

/3.1"

Weight:

1.61

<:g

/

3.51b

(head unit only)

Body Color: Dark Grey

Safety Boot Color: Yellow / Blue / Red

AII

specifications are subject to change without notice for the purpose

of

product

and quality improvement.

Chapter

2 - 2

Page 16

________

__

_

~_

.

_H_A_N_A_T_E_C_H_C_O_.,_U_D_.

___

~

11.

Part

List -----------------------------------------

A.

Head

unit and basic supplies

1.

Head Unit (P/N. 1000-0005)

Made

of

strong ABS resin, each unit has

passed internal impact test before shipment.

As the inner surface

is

coated with anti-

electromagnetic interference material,

it

neither interferes the other electronic

devices nor gets interfered by the other

equipments.

2.

Safety Boot (P/N. 2002-0030)

Flexible plastic cover that protects the head unit from physical,

chemical and electrical damage

Yellow boots are used for DCN-PRO, and blue and red boots are

also available upon distributor's demando

\

/

)

C

hapt

er 2 - 3

Page 17

For

DeN

Scanners

3.

Carry Case (P/N. 3003-0003)

Provides convenient transportation

and the protection

of

the head unit

and other components from outer

physical

impact during

the

transportation and storage. Carry

case

is

provided when purchasing the

head unit and at least one software

package together.

and

dial lock

In

cludes keys

4.

Main Data Link Cable (P/N. 3001-0001)

Connects vehicle side OLC and

OCN

head unit for data transmission.

Connecting parts

on

both ends

are exactly same, therefore,

simply put any one end

to

the

head unit, and then hook the

other end to the vehicle side

OLC after connecting

an

appropriate adaptor

5. Power Cable 1 - Cigarette Lighter (P/N. 3000-0004)

Supplies power to the head unit

from the cigarette lighter socket.

Used when OLC

is

located near

the driver or passenger seat and

power is not

supplied through

OLC.

LEO lights on both ends turn ON

when power is properly supplied.

The metal plunger part

in

the end

of

cigarette lighter connector

is

Ch

apter

2 - 4

Page 18

removable by unscrewing for the fuse replacement.

It

may

become

loose over repeated use, therefore, it

is

highly recommended

to

check if

it

is

tightly screwed frequently . A set

of

plunger parts are included

in

the

basic supplies. Refer to spare parts section hereinafter.

The rated voltage and current for this power cable are 12V a

nd

less than

2A

.

6.

Power

cable 2 - Vehic1e Battery (P/

N.

3000-0005)

Supplies power from the vehicle battery when the OLC is located

in

the engine bay or when using the oscilloscope or multi-meter

functions

Connect each

of

the two

alligator clips

to

the battery

terminal

of

the correct

polarity with caution.

Must be used together with

the Power

Cable 1 . Insert

the cigarette lighter adaptor

of

the Power Cable 1 into the socket,

and connect the other end to the head unit.

Red LEO light turns ON when power

is

properly supplied from the

vehicle battery.

Chapter 2 - 5

Page 19

For DCN Scanners

B.

Basic supplies for

DCN-PRO

l. 4 Channel Oscilloscope Adapter (P/N. 3000-0007)

Collects and delivers electrical

signal from the probes to the

head unit for . oscilloscope,

multimeter and ignition pattern

analysis functions.

Refer to the manual book

2 for

further information

2.

Probes (P/N. 3000-0001)

Obtains and transmits voltage signal from electrical wire or sensor

terminal

to

the main unit for the Oscilloscope, Multimeter and

Primary Ignition Pattern

Analysis functions.

Since DCN-PRO supports up

to 4 channels, 4 probes are

provided together for the

maximum utilization of the

function.

Each probe has rubber bands

of

same color

on

both ends for easier

distinction.

These probes directly get voltage signal by applying a probe needle

into the electric wire, which you have to handle with care. Refer

to

the following warning message.

C

hapt

er 2 - 6

Page 20

_-----8--H-A-N-A-T-E-C-H-C-O-o,-L-T-D-o

------

~...

DANGER

Note that the probe has a needle while the Secondary Ignition Probe does no!.

These probes with needle get electrical signal directly from the wire, therefore,

extending them to high voltage lines

is

extremely dangerous o

Probe with needle Probe without needle

3 o

Secondary

Ignition Probe

(P

/N. 3000-0002)

Applied to the high tension spark plug wires to get the secondary

ignition voltage signal by induction.

The probe has no needle and

the body

is

colored RED for

clear distinction from the

oscilloscope probes that have

needles to measure the

voltage from the wire directly. Refer to the warning message

aboye .

40

# 1

Cylind

er Trigger Pick-up

Clamp

(P/

N.

3000-0003)

Clipped on the spark plug wire to cylinder No. 1 to get the trigger

signal that is used to identify

the correct cylinder number of

each ignition voltage signa!.

Refer to the ignition pattern

analysis section

in

the manual

book 2.

Chapter 2 - 7

Page 21

For

DeN

Scanners

5.

Ground Cable (P/N. 3000-0006)

Used for circuit ground while using Scope , Multi-meter and Ignition

Pattern functions to get more stable and accurate test result.

Highly recommended to

extend this cable to the (-)

terminal of the vehicle battery

always when using these

functions.

Chapter 2 - 8

Page 22

:_---------~--

.

-H-A-N-A-T-E-CH--C-O-.,-U-D-.--~~-

~..

c.

Diagnostic Adapters

Oiagnostic adapters are sold separately, therefore check if all the adapters

you ordered are included

in

the package upon delivery.

There are two types

of

adapters: capsulated and wired types.

Most

of

OCN adapters are capsulated for better durability and storage ,

however, sometimes it

is

difficult or almost impossible to connect the

capsulated adapter to vehicle side OLC when it is located deep inside .

beneath the dashboard. We use wire type adapters for the cars such

as

Hyundai and Kia that we were reported

to

have such connecting difficulties.

Capsule type

l.

OBD2 Standard Adapter

(P/N . 3001-0010)

Used for all OBO generation 2 and EOBO

compatible vehicles . Vehicle side OLC is

generally located near the driver's seat and

most frequently found beneath the dash panel.

2. Toyota / Lexus l7Pin Rectangular

Adapter

(P/N. 3001-0011)

Used for the diagnosis of Toyota and Lexus

of

OBO generation

1.

Vehicle side OLC

of

this type is generally located

in

the engine

compartment.

Chapter 2 - 9

Wire type

Page 23

For DeN Scanners

3. Toyota/Lexus 17Pin Semi-circular Adapter (P/N. 3001-0012)

Also used for the diagnosis

of

Toyota and

Lexus

of

OBO generation 1.

The vehicle side OLC

is

generally found

beneath the dashboard.

Refer to the following warning message

WARNING

.

.'

...

J:

1;-. .-...

~

..

..

f.4

-

:/_

. -

-~--

'

' ,'

........

-'-

.:

.

"" ---

...

..

The appearances of this adapter and

MAZDA

17Pin

adapter

are exactly

same, however, the internal wiring and circuit are different.

Clleck

the

engraved

name

and the

body

color

of the adapter carefully before use.

Improp

er

adapter

connection

may

result

in

serious

malfunction

of

either

control

system

and

DeN

head

unit.

4. Honda 3 Pin Adapter and 2 Pin Jump Wire

(P/N. 3-pin: 3001-0014, 2-pin wire: 3001-0023)

3-pin adapter

is

used for the diagnosis of Honda

cars

of

OBO generat ion 1 that support OTC

read and erase as well

as

data stream.

Older Honda cars have 2-pin OLC that supports

OTC read onl

y.

The jump wire

is

used for these

older cars

to

bridge the 2-pin OLC terminals.

The vehicle s

id

e OLC

is

generally located under

the dashboard or the glove bo

x.

Chapte r 2 -

10

~7.

;""-

Page 24

8 HANATECH ca.,

LTD.

--

----------

------

----------------------------~

5.

Mitsubishi and Hyundai 12Pin Adapter (P/N. 3001-0001)

Used for the communication

with Mitsubishi and Hyundai

cars

of

OBO generation

1.

A wire type adapter

is

provided

as the connecting difficulties

of

capsule type adapter

in

quite a

few Hyundai cars were

reported.

6.

Mitsubishi 12+16pin dual headed adapter (P/N: 3001-0030)

Used for the communication with

Mitsubishi cars with both

of

12-pin

OB01 and 16-pin

OB02

adapters

on-board.

Refer to the Mitsubishi section,

Chapter 6 for

details.

7.

Nissan and Samsung 14Pin Adapter (P/N. 3001-0006)

Used f or t he e ommunication with N issan e ars

of

OBO generation 1 and all Samsung

passenger cars.

Vehicle side OLC

is

generally found under the

dash or inside the fuse box.

8.

Mazda 17Pin Adapter (P/N. 3001-0013)

Used for the communication with Mazda cars

of

OBO generation

1.

Vehicle side OLC

is

generally located

in

the

engine compartment.

Refer to the warning message

in

the next page:

Chélpter 2 -

11

Page 25

For

DeN

Scanners

WARNING

The appearances

of

this adapter and Toyota

17Pin

SEMI-CIRCULAR

adapter

are exactly same, however, the internal wiring and circuit are different. Check

the

engraved

name

and the

body

color

of the adapter carefully before use.

Improper

adapter

connection

may

result

in

serious

malfunction

of

either

control

system

and

DCN head

unit

8.

Subaru 9Pin Adapter (P/N. 3001-00)

Used for the communication with Subaru cars

of

OBO generation

1.

The vehicle side OLC

is

generally located

beneath the dashboard.

9.

GM Daewoo 12Pin Adapter

(P/N. 3001-00)

Used for the communication with Oaewoo cars

of OBO generation

1.

The vehicle side OLC

is

generally located

beneath the glove box, door side.

10. Kia 6Pin Adapter (P/N. 3001-0003)

Used for the communication with old

Kia cars

of

OBO generation 1 .

Only the Diagnostic Trouble Code

reading function

is

available for the

cars with this type

of

adapter as only

the slow pulse signal

is

transmitted

through the vehicle side OLC .

.

~J

,_0

__

~

. -

.

"~

~,,:-~/

,:,

= :

:.

~~,

..

The split wire

of

the adapter

is

to be connected to the ground terminal of

the vehicle side OLC .

Chapt

er 2 - 12

Page 26

__

---------

~---H-A-N-A-T-E-C-H-C

-

O

-.,

-

L-T-D-.

--~

~--

~

••

11.

Kia

20Pin Adapter (P/N. 3001-0004)

Used for the communication with Kia cars

of

OBO generation

1.

OTC read & erase and data stream

functions are available for the cars

with this type

of

adapter.

Refer to the following warning

message.

& WARNING

The appearances

of

Kia 20Pin

adapter

and

Ssangyong

20Pin

Rectangular

I

adapter

are exact ly same, however, the internal wiring and circuit are different. !

Check the

engraved

name

and the

body

color

of

the adaptel· carefully before i

use.

Improper

adapter

connection

may

result

in

serious

malfunction

of

either

control

system

and

DeN

head

unit

12. Ssangyong

20Pin Rectangular Adapter (P/N. 3001-0005)

Used for Ssangyong cars of OBO

generation

1.

Vehicle side OLC

is

located

in

the

engine compartme nt.

Refer to the warning aboye.

13. Ssangyong 14Pin Circular Adapter

(P/N.3001-0007)

Used for old Ssangyong cars of OBO

generation 1.

Vehicle side OLC

is

located

in

the engine

compartment.

Ch;\pt er:2 - 13

Page 27

For

DeN Scanners

14.

Holden 6 Pin

Adapter(P/N.

3001-0023)

Used for Australian Holden

of

OBO

generation

1.

Japanese cars such as Toyota and Nissan

assembled

in

Australia with Holden built

engines

may

have this type of adapter, too.

Vehicle side OLC

is

generally located

beneath the glove box

to

the center facia.

15

. GM Opel 1

OPin

Adapter

(P/N

. 3001-0019)

Used for the communication with

Opel cars

of

OBO generation 1.

Also available with OCN Australian

Holden, South American Opel and

European

packages.

Vauxhall

software

Vehicle side OLC

is

generally

located

in

the fuse box beneath the dashboard or near the parking brake.

16.

Ford 20 Pin

Adapter(P/N.

3001-0020)

Used for the communication with Ford cars

of OBO generation 1, including Australian

and British Fords.

Vehicle side OLC

is

generally located

in

the

fuse box beneath the dashboard.

Chapter

2 - 14

Page 28

8 HANA TECH ca., LTD.

-

----------

--------------------------------

~

17.

OBD2

SAE

11850

Cornmunication Module

(P/N.3001-0025)

To

be used with Ford and Australian

Holden software packages. Enables

DeN

to

communicate with

0802

compliant Ford

and

Holden Gen

111

for

vehicles using SAE

J 1850 communication

protocols including VPW and PWM .

18. Upgrade cable (P/N. 3000-0010)

To

be connected to main data link

cable for updating your

DeN

software by downloading updated

codes from your

pe

. Refer to the

related chapter

in

this manual.

Chapter

2 - 15

Page 29

For

DCN

Scanners

D.

Software Cartridge

Contains vehicle information and operating software for DCN

scanners.

The appearance and measurements for DCN cartridges

complies

with standard PCMCIA, however, inner circuits are

of

Hana Tech's

own designo Therefore, you can neither use it with the other

equipment nor copy its contents to the other standard

PCMCIA .

Various software packages are available on demand by the

combination

of

a variety

of

software. Therefore, please check if each

software cartridge provides the vehicle coverage you have ordered.

WARNING

MAKE

SURE

TO TURN POWER OFF BEFORE REMOVING OR INSERTING

A CARTRIDGE . It

is

extremely dangerous to insert or remove a PCMCIA card

while the head unit

is

turned on. Both PCMCIA card and head unit can be

critically damaged and break down. Always turn power

off

by pressing the

[POWER] key or removing power supply cable from the head unit befare

inserting or removing a PCMCIA card

..

Chapt er 2 - 16

Page 30

_-----B--H-A

-

N-A-T-E-C-H-C-O-.,-L-T-D-.

______

iII'"

E.

Spare Parts

1.

DeN-seAN

Extra

fu

ses

(P/N. 3008-0003)

For the replacement of the fuse located inside

the_

cigarette lighter power cable.

You

can also replace

it

with a fuse

of

which rated current

is

2 Ampere or

less.

Spare

cigarette

lighter

power

cable

plunger

parts

A set

of

spare parts for replacement when

the original parts are lost.

2.

DeN-PRO

Wrench

for

probe

needle

replacement

(P/N. 3008-0002)

•••

A screw driver type

hexagon wrench used

for the

replacement of

the probe needle.

------------

....

1 -

-

Extra

probe

needles

(P/N. 3008-0001)

A couple of short spare needles and

extended needle units.

You

can use any metal sawing

needle when you run out of spare

needles.

Chapter

2 - 17

Page 31

For DeN Scanners

F.

Optional Supplies

l. Current Ampere Meter Clamp

(P/N.3000-0008)

Sold separately for measuring current

ampere . Made by Summit, Korea.

2.

Printer Cable (P/N. 3000-0009)

To

be connected between head unit

RS232 port and printer to enable direct

interface with a PC printer.

Compatible with the printers that support

PCL mode, and Hewlett Packard ® is

highly recommended.

3.

Host-Pro PC Interface Package

Consisted

of

a software installation CD (P/N. 3005-0002), 5 meter

USB cable (P/N. 3000-0014) and communication module (P/N.

3000-0013) that converts RS232 communication to USB.

Enables realtime PC interface

of

DeN

scanners . Refer to

the PC interface section of this

manual and the separate

HOST-PRO user manual for

further information.

Chapt

er 2 - 18

Page 32

OPERATING

DeN-PRO

1.

GETTING STARTED

..........

".o

..

.o

.o

..

3-1

A.

Head unit

3-1

B.

PCMCIACard

3-2

C.

Main OLC Cable

3-4

o. Power Supply

3-5

E. Contrast

3-7

11.

CONTROL KEYS

............

.o

.o.

3-8

A.

Key pad

3-8

B.

Making Selection

in

the menu

3-8

C.

Function keys

3-9

111.

CONFIGURATION

.......................

3 -

11

A.

Software Information

3 -

11

B.

System Test

3

-12

C. Speci

al

Functions 3 - 13

Page 33

Page 34

_---

--

8-

'

_H_A_NA_TE_C

_

H_C_O_"_,

L_T_D_" _--'_

Operating

DeN-PRO

1.

Getting Started---------------------------------

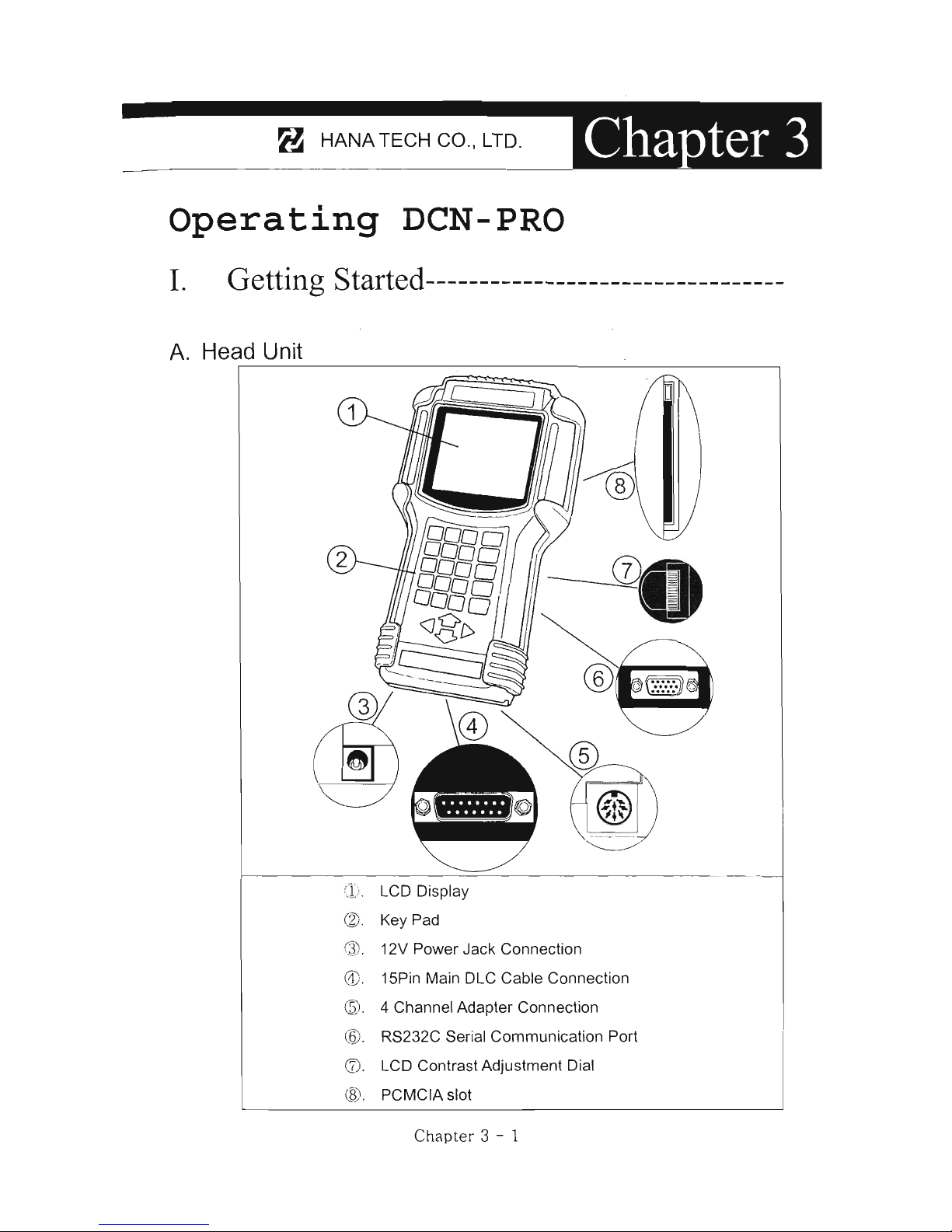

A.

Head Unit

Oí

LCD Display

@ Key Pad

C

J}

12V Power Jack Connection

®

0)

. 15Pin Main DLC Cable Connection

(5:

1. 4 Channel Adapter Connection

(6)

" RS232C Serial Communication Port

(f). LCD Contrast Adjustment Dial

(S).

PCMCIA slot

Ch

apter

3 - 1

Page 35

For DCN Scanners

B.

PCMCIA card

WARNING

Insert or remove PCMCIA card when DCN-PRO power

is

turned

OFF

Serious damage to head unit and PCMCIA card may occur in case of

insertion or removal

of

PCMCIA card while DCN-PRO

is

operating.

l.

Inserti

on

Slowly insert the PCMCIA card into the slot and press firmly until it clic

ks

into

place.

WARNING

Make sure not to insert the PCMCIA card upside down.

The card will not fit into the place when inserted upside down, however, if

you press it too hard applying excessive power, the frame and

connecting pins inside

DCN-PRO may be broken or bent.

Free

of

charge warranty service

is

not provided

in

this case.

Chapter 3 - 2

Page 36

_---

- -8-'

_H_A_N_A_T_E_C_H_C_O_.,_L_T_D

_.

__

2.

Removal

1. Press the eject buUon to release the PCMCIA card from the tight connection with

the inside frame and pins.

2.

Hold the PCMCIA card gentiy and pul! it slowly out

of

the slot.

Chapter 3 -

;\

Page 37

For

DCN Scanners

C.

Main DLC Cable

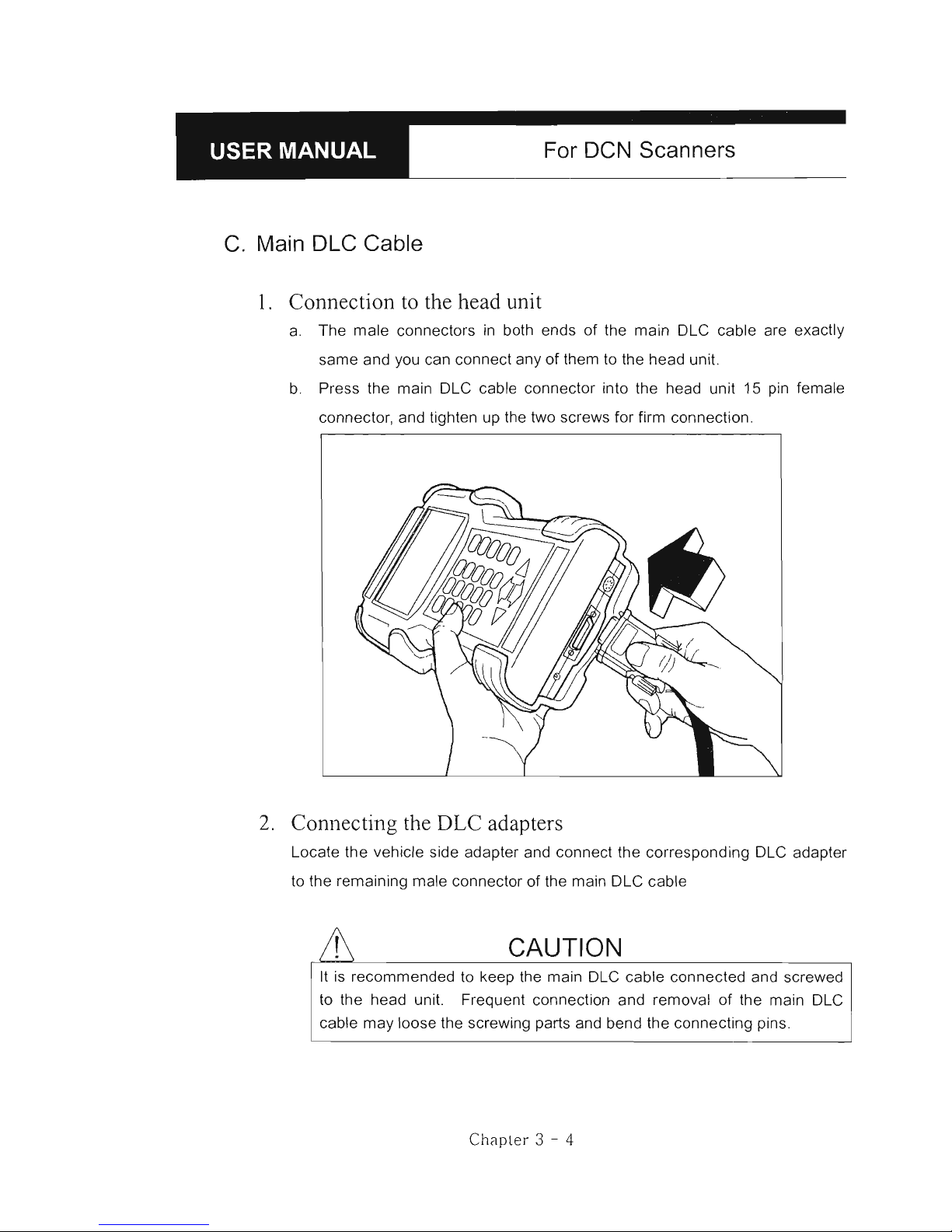

1.

Connection to the head unit

a.

The male connectors

in

both ends

of

the main

OLe

cable are exactly

same and you can connect any

of

them

to

the head unit.

b. Press the main OLe cable connector into the head unit 15 pin female

connector, and tighten up the two screws for firm connection.

2.

Connecting the DLC adapters

Locate the vehicle side adapter and connect the corresponding

OLe

adapter

to

the remaining male connector

of

the main

OLe

cable

CAUTION

It

is

recommended to keep the main OLe cable connected and screwed

to the head unit. Frequent connection and removal

of

the main OLe

cable may loose the screwing parts and bend the connecting pins.

Chapler 3 - 4

Page 38

2

__

----8--H-A-NA-TE-C-H-C-O-.-'

L_T_D_.

__

_

D.

Power supply

l.

Power supplied through DLC adapter

12V battery power

is

supplied through all OLC adapters except GM/Oaewoo

1

OPin

and Mitsubishi/Hyundai 12Pin adapters

2.

Cigarette hghter

a.

Use the cigarette lighter cable when power

is

not supplied through the

OLC adapter.

b. Insert the cigarette lighter connector into the socket, and check

if

the red

LEOs

in

both ends

of

the cable are ON.

c.

Insert the metal power jack into the head unit power socket.

Chélpt er

:3

- 5

Page 39

For

DeN

Scanners

3. Vehicle battery

a. Since the head unit must be placed

in

the engine compartment when

using multimeter, oscilloscope or ignition pattern analysis function,

it

is necessary to get the power from the vehicle battery.

b.

Connect the alligator clips of the battery power cable to the battery

terminals

of

correct polarity. Check the red LED

on

the round

socket turns ON.

c.

Connect the cigarette lighter power cable connector into the battery

power cable socket.

4.

Power

ON

Press the [POWER) key

of

the head unit key pad to turn power ON.

To

turn power OFF, press the [POWER) key for more than 1 second.

Chapter

3 - 6

Page 40

:_-----8

-'

_H_A_N_A_T_E_C_H_C_O_.,_L_T_D_.

------'_

E.

Contrast

a.

The Leo display is sensitive to the temperature.

It

becomes too faint when it

is

cold and too dark when it is hot.

b. If the screen

is

too faint or too dark to read, you can adjust the contrast by

turning the contrast dial in the right side

of

the head unit.

c.

In

case of any trouble with the display, please refer to the Trouble Shooting

chapter

in

this manual.

Chapt

er

3 - 7

Page 41

For DeN Scanners

11.

Control Keys -----------------------------------

A.

Keypad

The keypad is made of chemistry

proofing PVC material that

prevents contamination and

damage from hazardous oily

workshop environment.

The membrane keypad

is

designed and tested

to

maintain

its normal operation over

million time key press for each.

Each key is raised for better

tactile feel. The keypad has total

of

24

keys.

B.

Making selection

in

the menu

1.

Numeric

Keypad

a.

Simply press the corresponding number

b. This

is

available only when you are selecting

an

item

of

which number

is

9 or less. For more than 10, you should locate the highlight ed bar

on

the desired item and press the [ENTER]

key.

Chapter 3 - 8

Page 42

:_-----~-H-A-N-A-T-E-C-H-C-O-.,-LT-D-.---'-

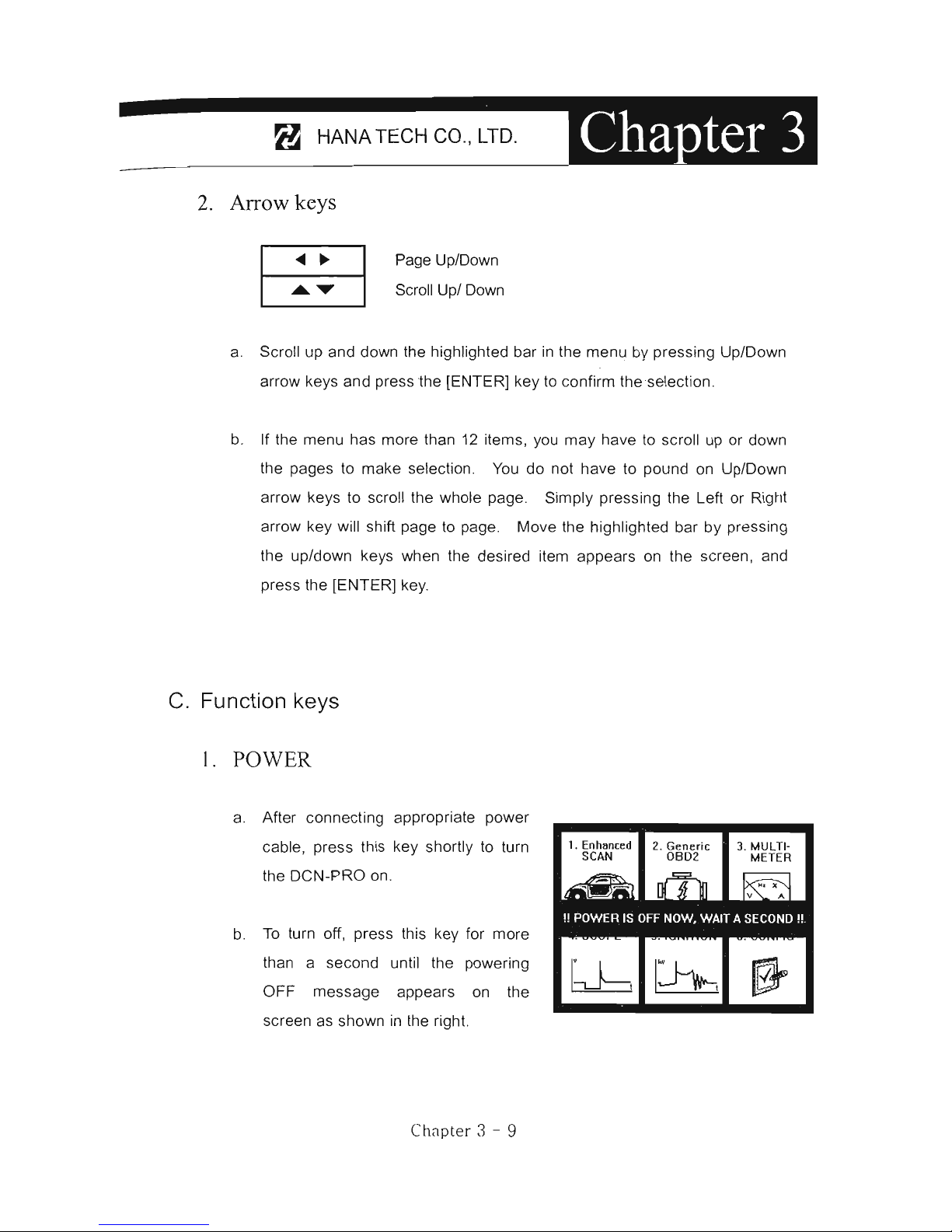

2.

Arrow keys

Page Up/Down

Seroll Up/ Down

a. Seroll up and down the highlighted bar

in

the menu by pressing Up/Down

arrow keys and press

the

[ENTER] key to eonfirm theseleetion.

b. If the menu has more than

12

items, you may have to seroll

up

or down

the pages to make seleetion.

You

do not have to pound

on

Up/Down

arrow keys to seroll the whole page. Simply pressing the Left or Right

arrow key will shift page to page. Move the highlighted bar by pressing

the up/down keys when the desired item appears on the sereen, and

press the [ENTER] key.

C.

Functían keys

1.

POWER

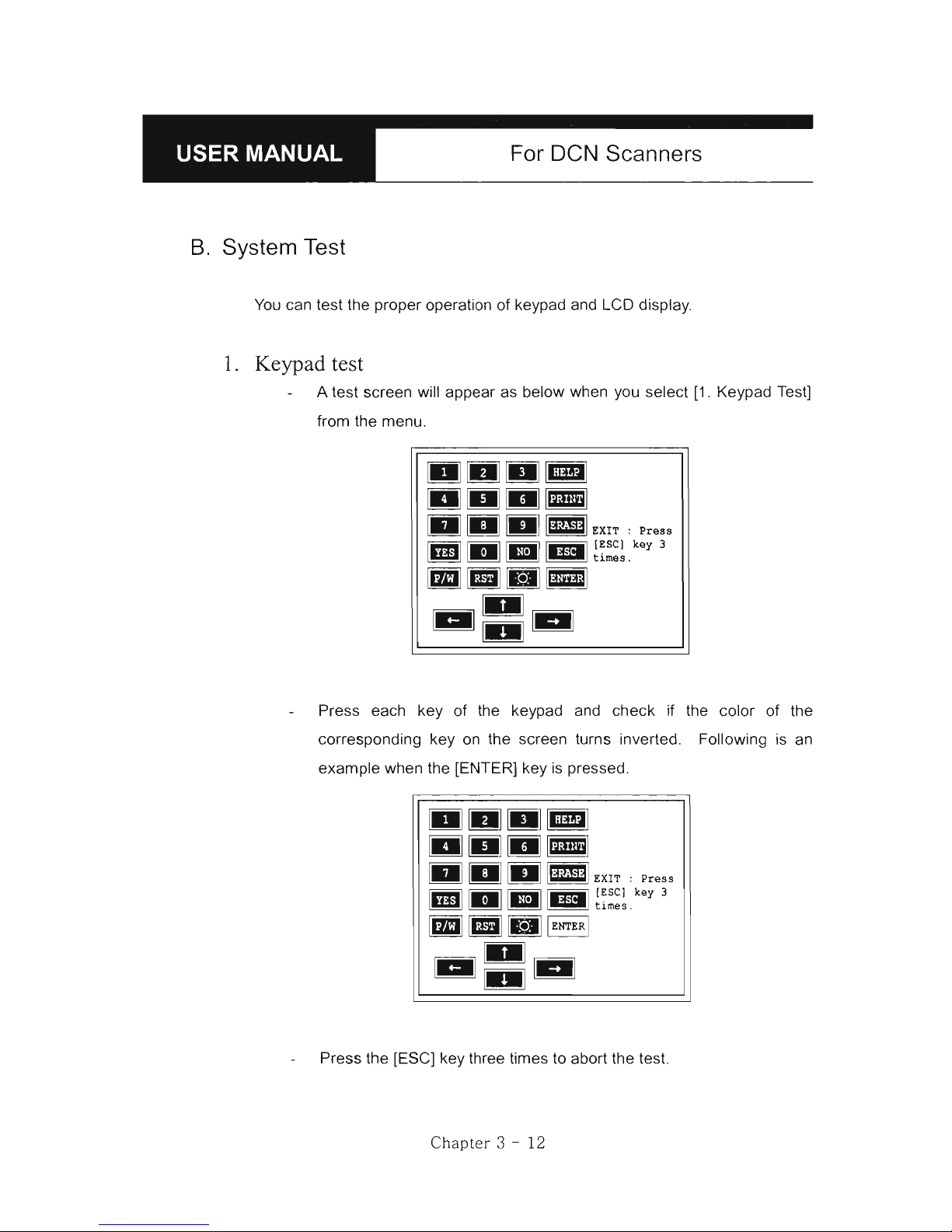

a. After eonneeting appropriate power

cable, press this key shortly to turn

the

DeN-PRO

on.

b.

To

turn off, press this key for more

than a seeond until the powering

OFF message appears

on

the

sereen as shown

in

the right.

C

hC1pt

er 3 - 9

1. Enhllnced

2. Generic

3.

MULTI·

seAN

0802

METER

Page 43

For

DeN

Scanners

2.

Back light

[-:9:-

]

a. LCD module

of

DCN-PRO has an illuminating back panel for better

legibility in dark or shady places.

b. Press this button to turn the back light ON and OFF.

3.

ESC

Used to abort an operation

of

DCN-PRO or move to the upper level menu.

4.

HELP

a. DTC Read

When a trouble code

is

detected, you can press this key to view the

detailed information

of

the DTC.

DTC definition, DTC registration conditions and check points are

provided (For Korean and

Malaysian cars only as

of

May, 2003)

b.

Service Data (Data Stream)

While live data

is

being displayed

on

the screen, select a live data

item by moving the highlighted bar, and press this key to view the

detailed information about the selected item.

Standard

value and technical explanations are provided. (For

Korean and Malaysian cars only as of May, 2003)

5.

PRlNT

a.

When a printer

is

connected to DCN-PRO via printer cable, press this

key to print out the current display : DTC list, a set

of

data stream,

oscilloscope waveform or ignition pattern.

b. Refer to the

Optional Parts section for detailed information on the printer

cable.

Cha

pt

er 3 - 10

Page 44

:

__

---------~---H-A-N-A-T-EC-H--C-O-.,-U-D-.--~~

II!.

Configuration ----------------------------------

Press the [6] key from the initial function menu to proceed to the configuration

menu. You can check the version numbers

of

the software packages contained

in

the PCMCIA card, test the keypad and LCO, set up sound and language

options and download software updates

in

the configuration menu .

1. Enhanced

2.

Generic

3.

MULTI-

seAN

0802

METER

6&I

ID

~

V A

4.

seOPE

5.IGNITION

6.

eONFIG

bb

~

~

CONFIGURATION

l .

SOFTWARE

INFORMATION

2.

SYSTEM

TEST

3.

SPECIAL

FUNCTIONS

System Informatlon

Serial

No

......

70000-000

Model ....... ... DCN-PRO

Languaqe

.......

English

Memory

Card

....

16

MByte

Bootstrap

Code

. . Ver .

300

[2003.4.201

Operating

Code

. . Ver .3 10 [2003.4 .

201

ESC.

HAIN

FUNCTION

[CUSTOHER)

A.

Software Information

When you select [1. SOFTWARE INFORMATION]

in

the configuration menu, a

list of software packages contained

in

the PCMCIA card will appear as below:

SOFTWARE

INFORHATI

ON

SCOPE

V.310

GENERAL

0802

V.201

HYUNDAI

{DOMESTIV.550

HYUNDAI

{NON

USAV.150

KIA

(DQMESTICS)

V.550

KIA

(NON

USA)

V.l50

DAEWOO

VEHICLES

V.550

SSANGYONG

VEHlC

V.550

SAMSUNG

VEHICLE

V.550

2003 .04.20

2003 .04.

1B

2003 .04.29

2003 .

04.29

2003.04 .

21

2003.04.21

2003.04 .

21

2003 .04.

21

2003.04.21

Should you get any update files from your local distributor or from Hana Tech

website , please compare the version number and last update date to check if the

update is necessary.

Chapter 3 -

11

Page 45

For

DeN

Scanners

B.

System Test

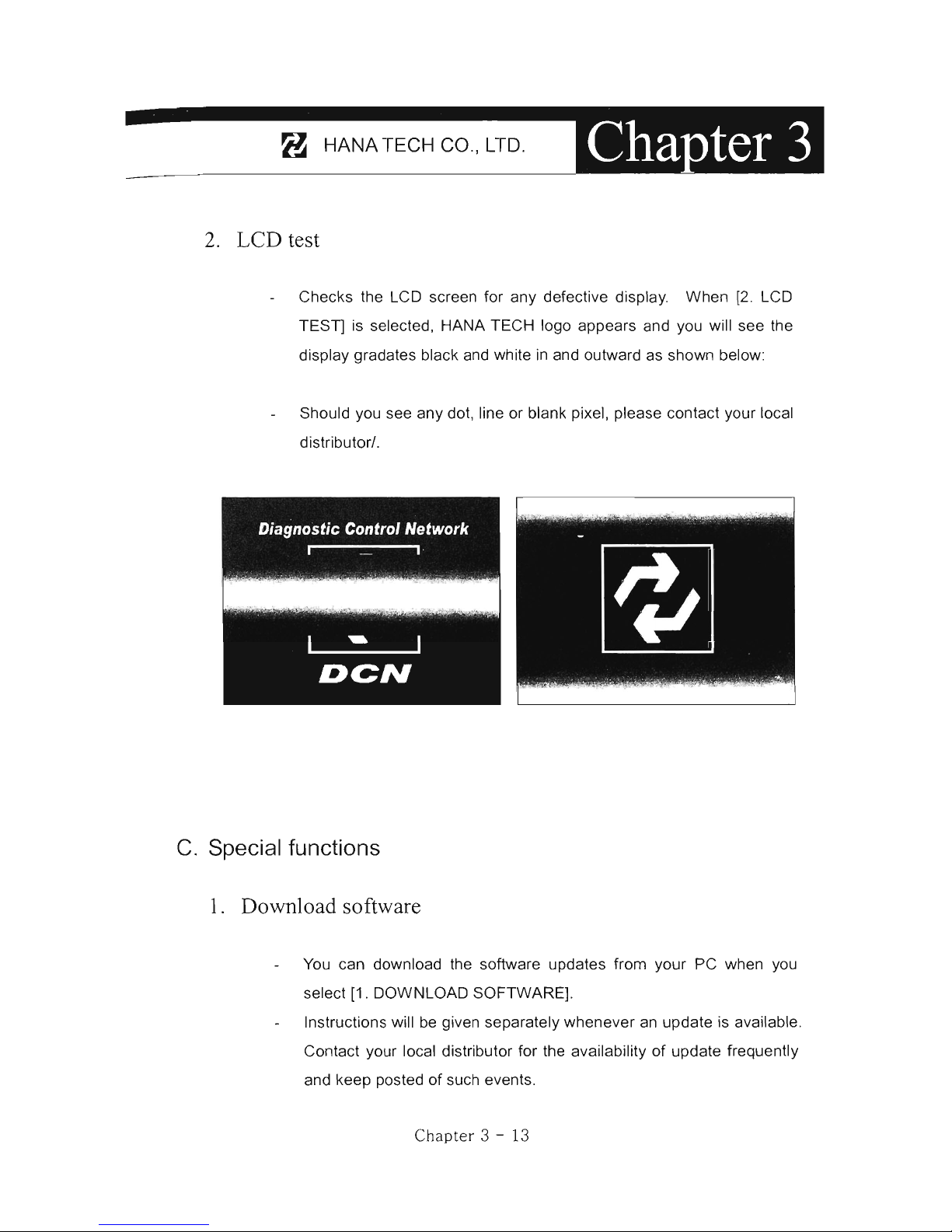

You

can test the proper operation of keypad and LCD display.

1.

Keypad test

A test screen will appear as below when you select [1. Keypad Test]

from the menu.

Press each key

of

the keypad and check if the color of the

corresponding key on the screen turns inverted. Following

is

an

example when the [ENTER] key is pressed.

Press the [ESC] key three times to abort the test.

Chapter 3 - 12

Page 46

:_------

---

~---H-A

-

N-A-T-E

-

C-H-C

-

O

-

.

t

-U-D-.--~~

2.

LCD test

Checks the LCO screen for any defective display. When [

2.

LCO

TEST] is selected, HANA TECH logo appears and you will see the

display gradates black and white in and outward as shown below:

Should you see any dot, line or blank pixel, please contact your local

distributor/.

C.

Special functions

l.

Download software

You can download the software updates from your PC when you

select [1. OOWNLOAO SOFTWARE].

Instructions will be given separately whenever

an

update

is

available.

Contact your local distributor for the availability

of

update frequently

and keep posted

of

such events.

Chapte r 3 - 13

Page 47

For DeN Scanners

2.

Language

3.

Sound

You can select provided language. English and Spanish languages

are available for selection as

of

May, 2003.

Hana Tech

is

translating the menu and messages of DCN-PRO

to

various local languages such as Russian, Arabic and Chinese for

convenience

of

non-English speaking customers, and the each

language will be provided as

an

update when the translati

on

is

completed.

You

can toggle ON and OFF the key sound.

4.

Save Configuration

If you have made any change

in

this [Special Function) menu, you

have to save the configuration

to

make such changes effective.

Press the [4] key to save the changes

in

configuration

Chapter 3 - 14

Page 48

DCN-PRO

FUNCIIONS

1.

DIAGNOSTIC TROUBLE CODE

.............

4-1

A.

DTC Read

4-1

B. DTC Erase

4-4

C.

DTC Help Tips

4-5

11.

CURRENT DATA

.............

4-6

A.

Pulse Signal Type

4-6

B. Serial Communication Type

4-6

C.

Data Freeze

4-7

D.

Data Graph

4-8

E.

Help Tips 4 -

10

111.

ACTUATION

TEST

.............

4 -

11

IV. BLACK BOX

4

-14

V.

CONNECTOR LOCATION

4

-20

Page 49

Page 50

8 HANATECH CO.,

LTD.

DeN-PRO

Functions

The functions you can choose when all the test vehicle details are selected

properly are explained

in

this chapter of the manual. The actual list of

available functions may be différent according to the vehicle you want

to

test.

1.

Diagnostic Trouble Code---------------------

A.

OTC Read

l. Pulse signal type

a.

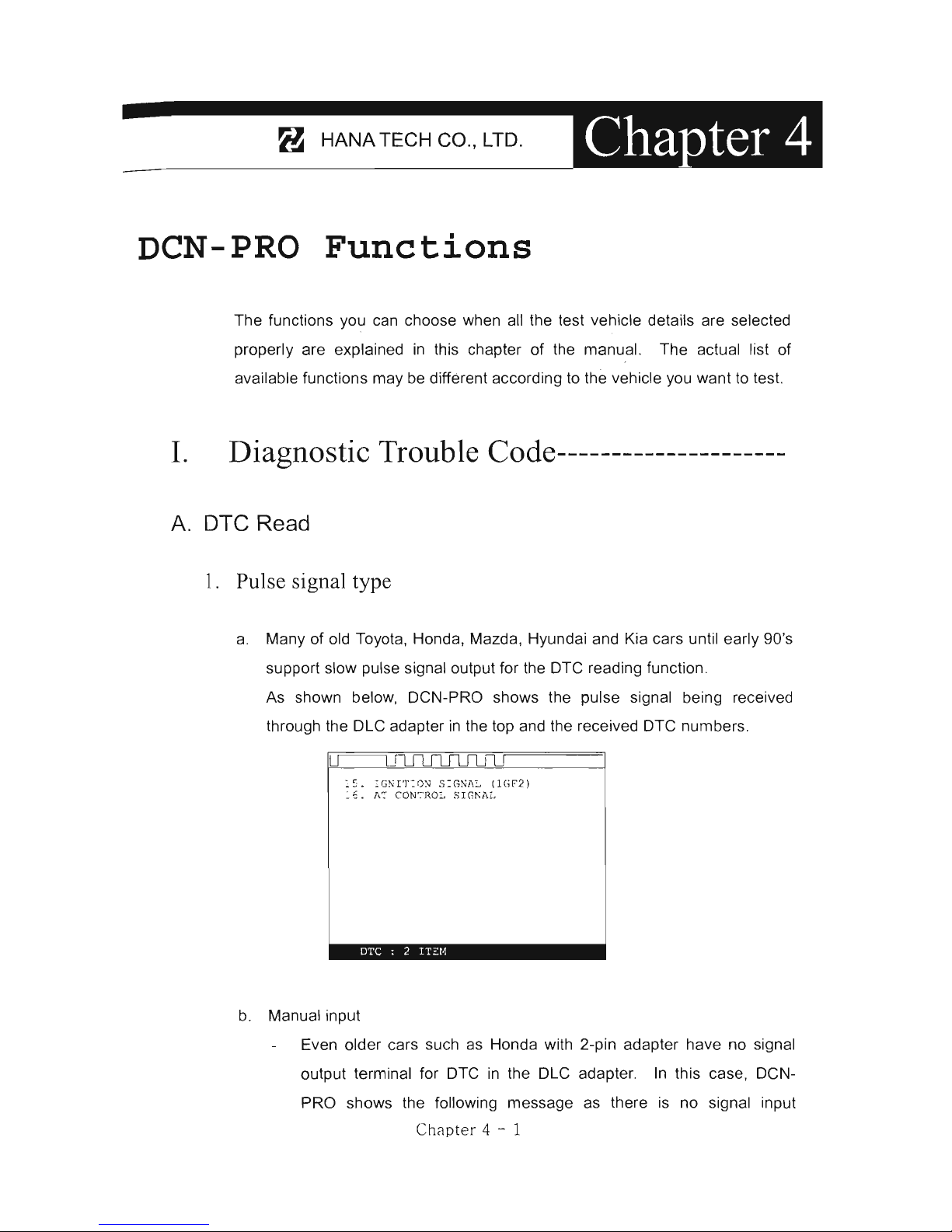

Many of old Toyota, Honda, Mazda, Hyundai and Kia cars until early 90's

support slow pulse signal output for the DTC reading function .

As shown below, DCN-PRO shows the pulse signal being received

through the DLC adapter

in

the top and the received DTC numbers .

'-5. :GNIT:ON

S:GNi\L (1(;,2)

_~. A

~

CON7ROL

5IGKAL

DTC : 2

n=:N

b.

Manual input

Even older cars such as Honda with 2-pin adapter have no signal

output terminal for DTC

in

the DLC adapter.

In

this case, DCN-

PRO shows the following message as there

is

no signal input

Chapter 4 - 1

Page 51

For DeN Scanners

through the adapter.

Rea

d Fl a

sh Code

as

belo

w:

l . I

nsert Diagnostic

Connector.

2 .

Tur

~

Vchicle

Ignition OK.

3.

Read

Oash

Lig~t rlashi~g.

- No OTC: M

ay

be

~o

blir.king

or

b l

inking

fa~

t

4. Inp

ut 2 digit

DTC code

ro

CONTINü~

,

PRESS

(~NTERJ

OTC:

I72r~

•

You

have to count the MIL flashing

on

the dashboard and manually

input the DTC number to DeN-PRO to view the details as below :

INP~T

OTC

N~MBER

: l e

15

. I GNITION

SIGN1IL (lG

F2 )

OTC : 1

1:'

::[,1

Long flash signals count for tens and short signals for ones . Input

two digits for tens and ones

in

sequence using the numeric keypad.

A flash signal for

acode

is

followed by another if there are multiple

trouble

codeso

Blinking signals for all trouble codes flash

in

sequence, and repeat after a pause.

Long signal: X10

Short signal:

X1

I

~

ON

ON

ON

-

-

-

'--

OTe No.

12

Chapter 4 - 2

Page 52

:_-----8-

'

_H_A_N_A_T_EC_H_C_O_"

_LT_D_,

___

_

c. Others

Generally DCN-PRO reads DTC pulse signal from the diagnostic

adapter and shows the DTC number, title and details automatically.

2,

Serial Cornmunication type

a. Most

of

the cars built

in

1990's or later support serial communication with

a scanner, and the DTC

is

read by bi-directional communication.

b. DCN-PRO sends a command

to

the control module to reply with the DTC

numbers stored

in

memory, and the control module replies thereupon.

Chapter

4 - 3

Page 53

For DCN Scanners

B.

DTC Erase (Clear fault code)

l.

Pulse signal type

a.

Pulse signal type does not support bi-directional serial communication,

therefore, a scanner is unable to send a command to the control module

to erase the DTC information from memory.

These old cars require you to remove battery terminal to clean up

diagnostic information from control module memory.

~5. :G~!'r:ox

S:G~A:,

(lG~2)

_

-::.

. l'

..

'"::

cor,l

~I{.O=-. ':;JC~':¡\:,

~~~;()

'./~.; ~.'\~":}-,~,Y

- :-r,HJl. i N.·

\[

t'

O,,:

:~.

~";I:".co

>,;:~

<~.

DTC

: 2 ITEM

Removing the battery terminal wil! get rid

of

al!

information contained

in

the car stereo and other electronic devices. And it may not effectively

erase the fault codes

in

some cars. Refer to the original repair manual

for further information.

Check if DTC information

is

properly removed by reading the trouble

code again after erasing the codeo

2.

Serial communication type

a. DCN-PRO sends a command to the control module

to

erase DTC

information stored

in

memory, and the control module replies thereupon.

b. Check if DTC information

is

properly removed by reading the trouble

code again after erasing the code

Chapter 4 - 4

Page 54

8 HANA TECH

ca

., LTD.

C.

OTC Help tips

a. Help tips are provided when you press the [HELP] key after locating the

highlighted bar on one of the detected trouble code(s). This function

is

available when DCN-PRO detects one or more trouble code(s)

b. Help tips including trouble code definition, conditions and check points

are provided for all Korean cars and Malaysian cars as of May 2003.

Wiring diagrams are

al

so provided for Korean cars

of

2000 model-year or

older.

DIAG~OSTIC

TRO~BLE

CODE

D

.T.C.

~lc.:

IP0

336)

DTe :-:cndi:-.

i(Jn

~

:

Whcn IG

~cy

ON,

cranklng

i s

possib~e

bu~

thc

rcfc

rcncc mark

lS

~ot

withi~

s:.andard

r~ngc whc~

~o:c

tta~

20GRPM

Fails

afc:

Feedbac~

~o~t:ol

sus

pend~

Icile

s~ccd ad

ap~

atlo~

contro

l s t

ops

(R

c~cr~

:0

che

actua

l

val~Q)

U

s~s

~can

val~c

:nste

ad

of id: e

spcc

¿

char

actc

ris

~lc

curve

.

~slng adap~cd ~arget

a~r vo:~~c

~5

prchih

i~cd(Re

fcr~

to the

a

ct~a:

valu

e )

c. Press the [ESC] key to return

to

DTC list.

Chapter 4 - 5

Page 55

For

DCN

Scanners

II.

Current Data -----------------------------------

(= Data Stream, Live Data, Service Data)

A.

Pulse Signal Type

a. Data stream

is

not generally supported for this type

of

old cars because the

speed

of

pulse signal communication

is

too slow to read the data stream

variables.

b.

Some

of

old Toyota cars using

17

-pin rectangular adapter exceptionally

support data readings as the system supports relatively high speed pulse

signal communication.

B.

Serial Communication Type

a.

Most of control systems with serial communication support data stream

function. Select [Current data] from the menu, then the data readings follow.

b.

Some systems like SRS or ABS may be designed not to support data stream

intentionally by the car make while the other systems are supported. A

scanner

is

a passive tool that reads information from the control system, and

it is unable

to

actively generate information that the system does not provide.

C

hCl

pte

r 4 - 6

Page 56

~

___

------_~--_H_A_N_A_T_E_C_H_C_O_.,_L_T_D.----~

C.

Data Freeze

The [Data Freeze] function places the selected data stream variable

on

top

of

the

LeO

screen so that the user can check and compare desired sensor

values continually without having to scroll up and down.

This function

is

different from 'Freeze Frame Data' function

of

Generic OBD2.

1) Step One

Select a desired sensor using the

[~][

~

1 and the

[A][T]

keys.

2) Step Two

Press the [ENTER] key

to

freeze the selected sensor.

i.e

.,

when

02

sensor and MAP sensor are selected and frozen, these

sensor values will

be

placed at the top of the display as below :

SEI(VIC

F.

C

.~T!·

.

02 SENSOR - - - - - -

---

... -

--

~A

P

SE

NSOR --

----------

02

SENSOR - - -

--------

- -

MAP

SENSOR

------------

946

hIR

TE~P SENSOR

-------

1PS

SENSROR

-----

----

- -

SIEP MOTOR

----

- - - - - - - -

BAT~ERY

VOLTAGE ------

-

IGNIT:ON

S:G

NhL

---

- - - -

COOI,~NT

TE~P

SEN

SOR

---

ENG!NE

RP~

------

- - ----

SHOHI

TEr

·:~·~

rUE

L

TR:~'1

- -

~'lrW

39

.

:"

¡,

13

. 2

\1

OFF

82

"C

'!oOr pm

1O

~

1 : GRl,PH 2 : FUL L

ENTER:

F7X

3) S tep Three

Up to five sensors may be frozen at a time. For example, if the Injection

Tim

e,

which can be shown when scrolled down,

is

selected and frozen,

Injection Time value will be placed below the previously frozen

02

and MAP

sensor.

Chapter

4 - 7

Page 57

D.

Data Graph

For

DeN

Scanners

SERVICE

DlITr,

02 SENSOR

-------------

~~p

SENSOR

------------

INJECTIO:-¡ TIHE --- -

----

ENGINE

RPM

-------- - - - -

SHORT

TERM

FUEL

TRIM

- -

LONG TERM

FL:E:"

TRIM

- - -

I

DLE SWITCH -------

- -

--

?OW

ER

STE

ERI

NG

SWITCH

-

lIIR CONCITINER

SWITCH

-

~8:nV

9/J

6

O.2mS

"7

(;0

r'p:~

101

86

8

FF

•

O

FF

OFF

INJECTION

TIME

--------

O.2mS

3TDC

------------

-

-----

lIIr

CONDITIONER

RELlIY

-

1 : GIU, PH 2 :

FULL ENTER

~

O

FF

FIX

DCN PRO provides the [Data Graph) function for more efficient data

analysis.

a When you press the

[1)

key after locating the highlight bar on the desired

sensor, the sensor data graph will be displayed as shown below.

b You can display up to 3 graphs

in

a screen by choosing the sensors as

previously explained [Data Freeze) procedure - Press the [Enter) key

after locating the highlight bar

on

the desired sensor, and then press the

[1)

key.

When

more than 4 sensors are selected, the graphs of upper

three sensors will be displayed.

02 SENSO

R

.........

....

6J

5

mV

,~.

~,

.",n,

,..,n.

J1l\nnutr

THROTTLE

POSmON SEN

SOR

·

425

mV

~~

I

ENGINE

RPM

............

82

7

rpm

--..A

.AI1.ht

'--

1

:

LINE / DOT

PAGE:

1~317

Chapter

4 - 8

Page 58

~

____

------~--_H_AN_A_T_E_C_H_C_O_.,_~_D_.--~~

e For ea

eh

sensor data graph, the name

of

the sensor and its eurrent

value will be simultaneously displayed together.

d To ehange the sensor, go baek to the previous Serviee Data display by

pressing the [Ese] key, and then ehoose other sensors.

e To halt the graph output, press the [ENTER] key. It will resume when

you press the [ENTER] keyagain .

C

hapt

er 4 - 9

Page 59

For

DeN

Scanners

E.

Help

tips

a When you press the [HELP] key after locating the highlight bar

on

a

certain data stream variable, the help message will be displayed. This

works the same for detected Trouble Codes

in

[Self Diagnosis] function.

b Detailed information including conditional standard range on the selected

sensor will be displayed as shown below.

02

SENSOR

-

---

-------

--

523mV

Idlir.g

dgr.t

after

er.gine

sta!"t

(O,'EN

:'002

)

:Approx.450mV-9~OmV

Idling

after

'.'a t·m-

t.:

p (CLOS ED LOOP )

:

Changes

bet',¡eer

. l

OOmV

-

9~OmV

e Press the [ESC] key to go back to the data stream display.

Chapter 4 - 10

Page 60

:_-----8-

,

_H_AN_A_T_E_C_H_C_O_.,_LT_D_._----'_

111.

Actuation Test ---------------------------------

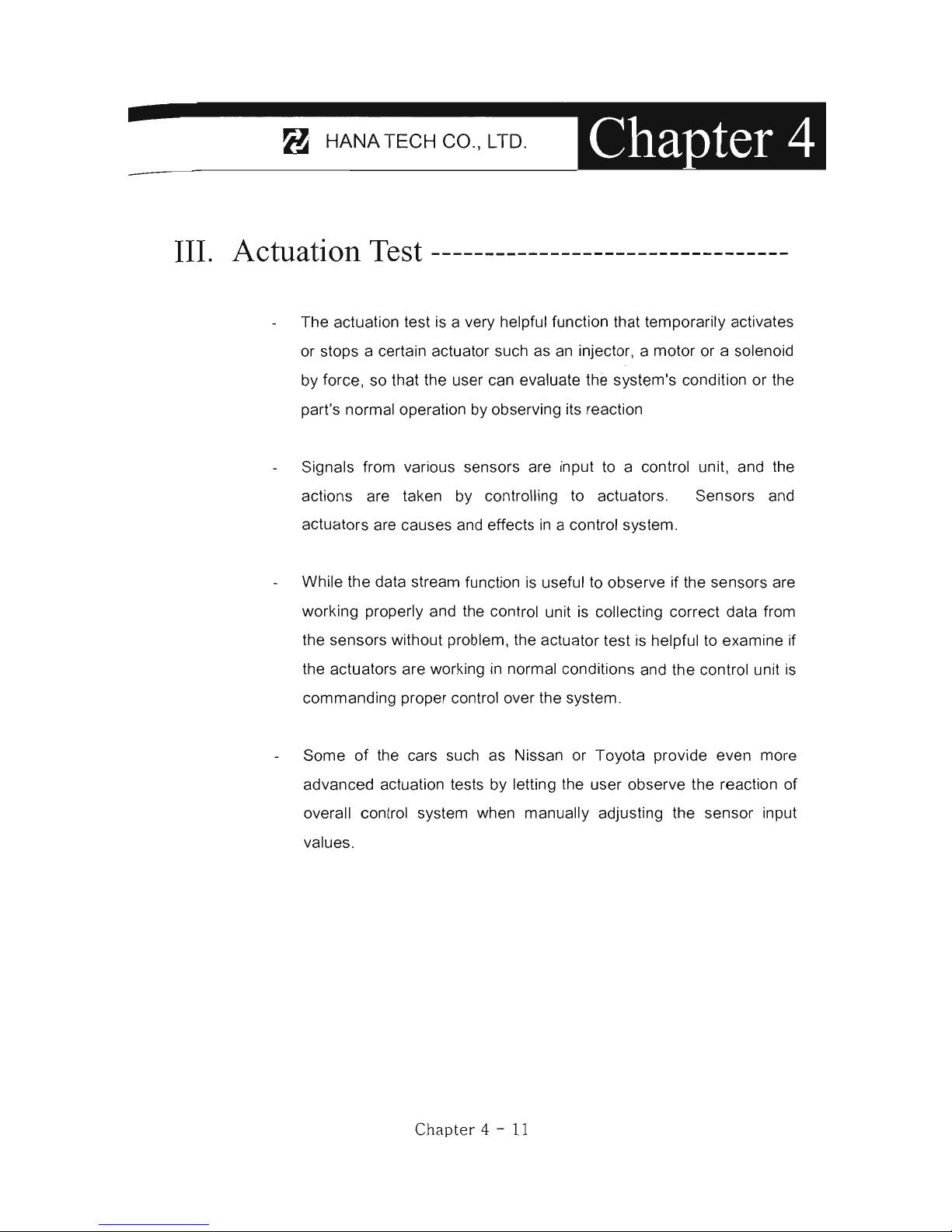

The actuation test

is

a very helpful function that temporarily activates

or stops a certain actuator such as an injector, a motor or a solenoid

by force, so

that

the user can evaluate the system's condition or the

part's normal operation by observing its reaction

Signals from various sensors are input

to

a control unit, and the

actions are taken by controlling to actuators . Sensors and

actuators are causes and effects

in

a control system.

While the data stream function

is

useful to observe if the sensors are

working properly and the control unit

is

collecting correct data from

the sensors without problem, the actuator test

is

helpful

to

examine if

the actuators are working

in

normal conditions and the control unit

is

commanding proper control over the system.

Some

of

the cars such as Nissan or Toyota provide even more

advanced actuation tests by letting the user observe the reaction of

overall control system when manually adjusting the sensor input

values.

Ch

apter

4 -

11

Page 61

For DeN Scanners

A.

Menu Selection

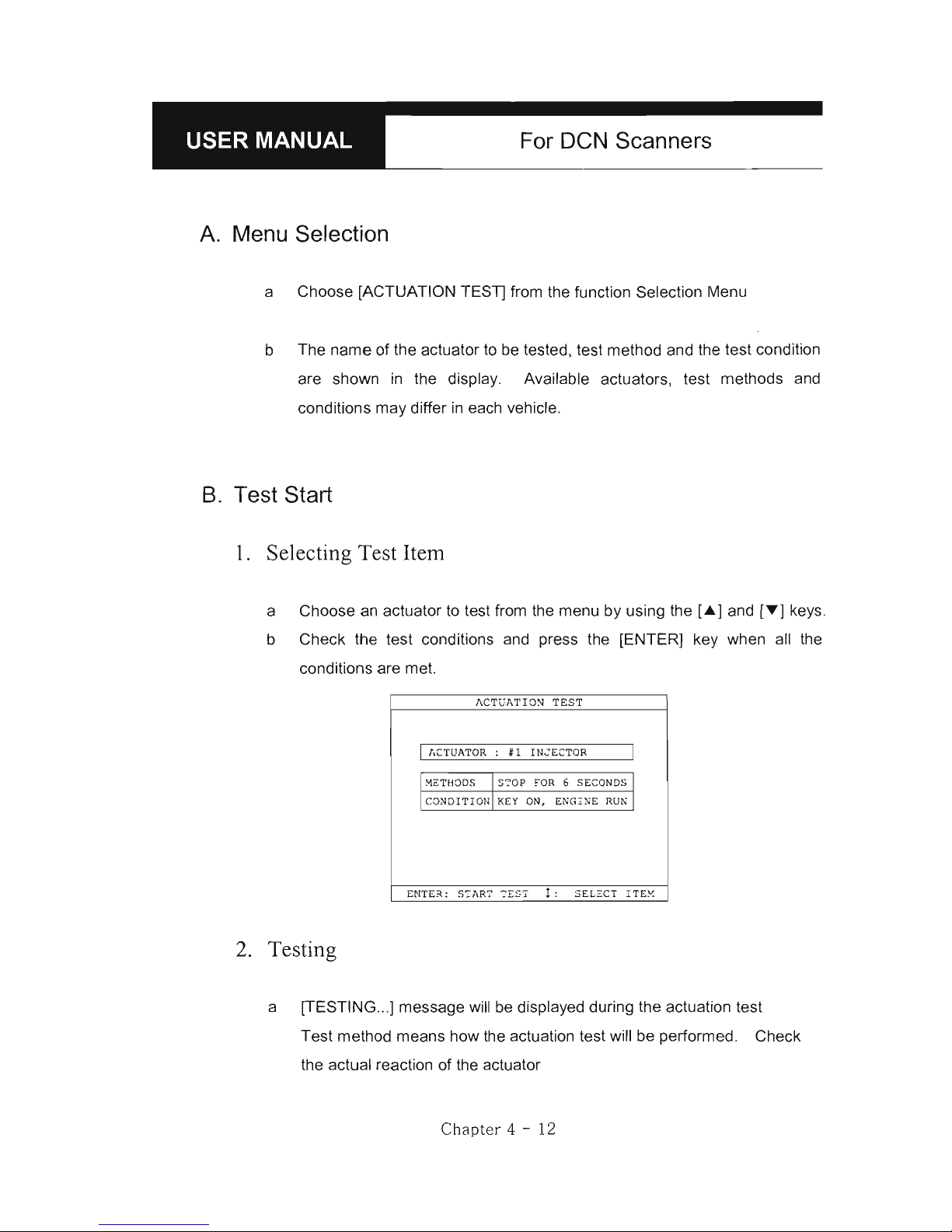

a Choose [ACTUATION TEST] from the function Selection Menu

b The name

of

the actuator to be tested, test method and the test condit i

on

are shown

in

the display. Available actuators , test methods and

conditions may differ

in

each vehicle.

B.

Test Start

l. Selecting Test Item

a Choose an actuator

to

test from the menu by using the [

....

l a

nd

['Yl

keys.

b Check the test conditions and press the [ENTER] key when all the

conditions are met.

I\.CTUI\.TION

TEST

I

r

.CTUATOR

:

#1

IN

.7EC

TOR

I

I ME:THODS

]

S':'OP

FOR

6

SEC

ONDS

J

I

CON

DITIONIK

EY

ON,

ENGINE

R

UN

I

ENTER:

S71\R':'

TES

'l

¡ :

S

EL,,-CT

ITE~

2.

Testing

a [TESTING

...

] message will be displayed during the actuation test

Test method means how the actuation test will be performed. Check

the actual reaction of the actuator

Chap t

er

4 - 12

Page 62

:_- -

--

-B

-

H-A-N-A-T-E-C-H-C-O-.,-LT-D-.---

b

In

the example below , the injector will stop injecting fuel for 6 seconds

while engine is idling, and

it

will make engine stall or unstable.

c Testing a fan or

an

injector

is

easy

to

check the proper reaction as

it

generates distinctive changes

in

vehicle condition such as fan whining or

unstable idling. However, valves or motors are generally tested while

engine is stopped and all you can hear may be a small and unclear

electric buzzing sound. Test

in

a quite place and observe the test

results carefully.

l\CTt)!·.TION TES T

I

~·Ic.:T¡;OCS

J

f.·:-

OP , O R 6

SE.:::ON::J~

:

I

I

CO'DIT:ON[KEY ON, E

NG:

XC

RUX

[

.¡ f. ST '

NG ...

.

I

tETIlOCS

.J

ST

OP F OR 6

SEC

ONDS [

I

coxuITION

I KEY ON, ENG:¡NC RUN I

ENTER: STl\

RI

TES! 1 :

5

EL~C:-

:TE~

d When the test is completed, the [TEST COMPLETE] message will be

displayed. You can choose other actuators by using the [ ... ] and

[T]

keys. Press the [ESC] key

to

quit test mode.

Chapter 4 - 13

Page 63

For DCN Scanners

IV. Black

Box

--------------------------------------

Just like the 'Black Box' or a 'flight recorder'

of

an aircraft, DCN-PRO can

'record' data stream during the vehicle drive test and the recorded data can

be

'retrieved' later for intensive analysis of vehicle's condition.

This Black Box function

is

available with Korean cars only as

of

May 2003,

and scheduled

to

expand its applicable range to all car makes befo re the end

of

year 2003. Please contact your local distributor for the availability of the

update.

A.

Capacity

a During a normal test, the [Data Stream] frames pass by

in

rapid

succession, and cannot be recalled unless the data has been saved.

Thanks to its extensive internal memory, DCN PRO can record up to 700

frames

of

Data Stream for multiple cars.

b By loading the recorded data, you can diagnose sensor data frame

to

frame without missing a single critical momento

c Choose

[#. Black

Bo

x Data] from the [Function Selection Menu].

l.

SEL? CI

AGN

OSIS

2.

SE,W:

CS

DAr l\

] .

i\CT

\':

I\TIO

~

TEST

4.

BLACKBOX

DATA

Ch

apte

r 4 - 14

Page 64

:_----8-

'

_H_A_N_A_T_E_C_H_C_O_.,_L_TD_.

__

_

B.

Memory Check

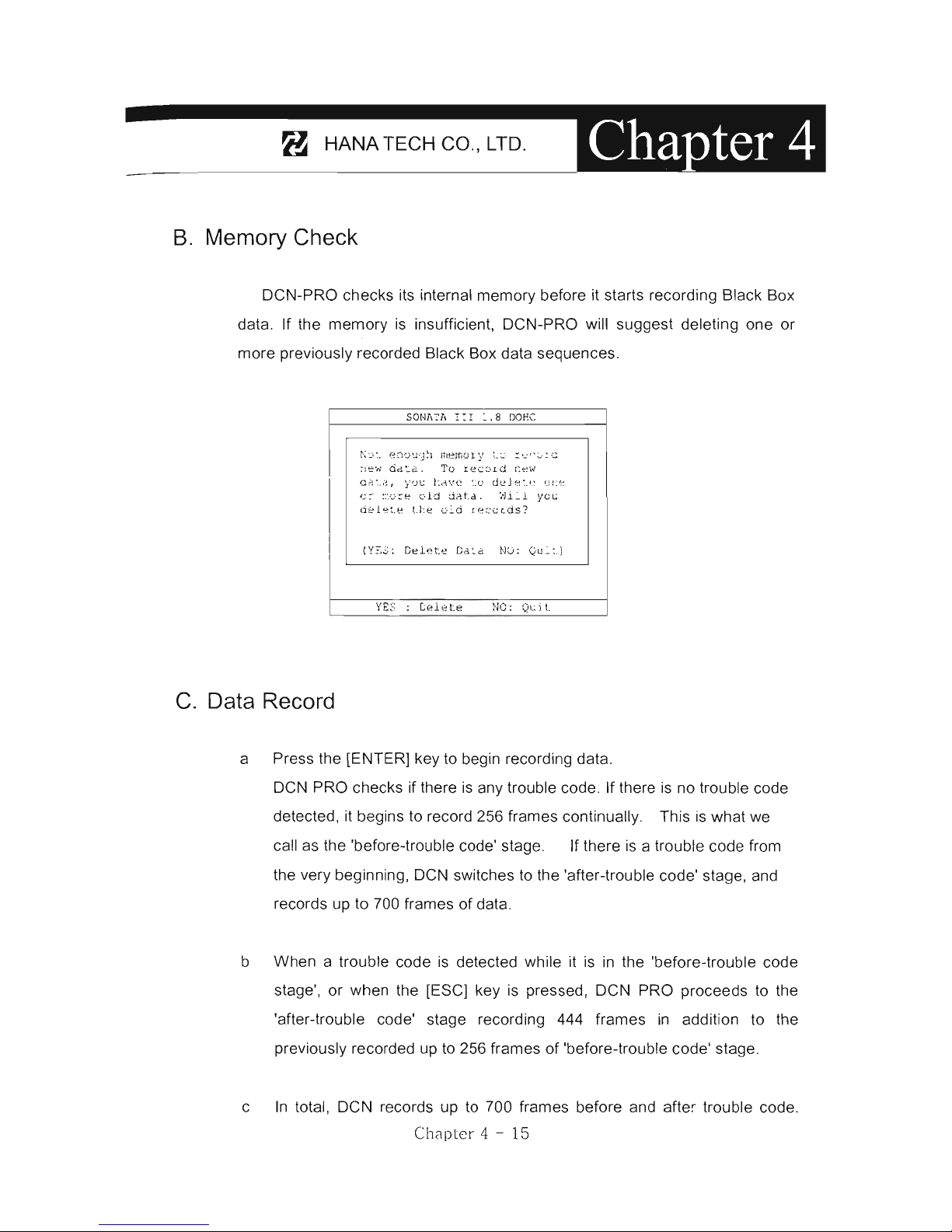

DCN-PRO checks its internal memory befo re it starts recording Black Box

data . If the

memory

is

insufficient, DCN-PRO will suggest deleting one or

more previously recorded Black Box data sequences.

C.

Data Record

SO

NA

el,

1:

1

~

.

8 DOEC

~~:. e~u~g~l

nlem u

ty

t_~ !~C0

;C

;le

w

da~a.

To

record

¡~

e w

a~!·._l~

,

::{D

L:

LA'o/e :

:0 deJe

:.t!

r..JI:~

"!

I

:'~

::".c-

::e

<.."

-1·j

tinta

. ':Ji.i..l

yc~

ci~let.

e

L

hé

oi.

d

t'e~'

(;(ds

?

(Y~3:

Ce l

ete

C

d~a

NU:

Qu:~

)

NO:

QL.:i

L

a Press the [ENTER] key to begin recording data.

DCN PRO checks if there

is

any trouble

codeo

If there

is

no trouble code

detected, it begins to record

256 frames continually. This

is

what we

call

a5

the 'before-trouble eode' 5tage. If there

is

a trouble eode from

the very beginning, DCN switches

to

the 'after-trouble code' stage, and

record s up to 700 frames

of

data.

b When a trouble code is detected while it is

in

the 'before-trouble code

5tage', or when the [ESC] key

is

pressed, DCN PRO proceeds

to the

'after-trouble eode' stage recording 444 frames

in

addition to the

previou51y recorded

up

to 256 frames

of

'before-trouble code' 5tage.

c

In

total,

DeN

record5 up to 700 frames before and after trouble codeo

Ch8pter 4 - 15

Page 65

For

DeN

Scanners

When it reaches 700 frames it automatically stops recordin

g.

BL/\CK

BOX

DI\T/\

02

SENSOR

--------------

624

mV

t17

,¡>

S~l\SOR

----------

- - .-

~16

mr:::J:,¡

/\!R

T

~MP

SENSOR ---

---

- -

3~

' C

TI'S ---

-------------..

- - -

12

¡n'.!

S:SP

MOTOR ----

-------

- -

32

.~\

BI\TTERY

VOLTI\GE --- - - -

--

: 2 .

3V

I

GN!TION SIGNI\L

------

- -

~

FF

COOLANT

TS~:P

SE!,SOR ---

- 92 'C

ENG!NE

RPM --- -

---

- - - - - - 1 10 rpm

IJLE

SWITCH

-------

-----

OK

BEFCRE:

256

/\FTER: 157

DTC

NUM:

2

~SC

: ST

OP

EN':'E

R :

S~LECT

•

d When the frame number reaches 700 or when you press the [ESC) key,

dialog box appears and asks you

to

input the date.

Enter the date and press the [ENTER] key to save the recorded data

to

DCN-PRO memory. Pressing the [ESC) key cancels saving data.

Date format

is

YYYY-MM-DD(Y-year , M-month, D-day), and only

numeric values are available.

BU<:K

BOX

Cl\'1.'1

INPl:-:-

Dr,TA

g

•

MOCEL:

SOIolI\TA

rTI

1.8

DO

EC

DE

VIes:

ENGINE

CONTROL

Di\T

;;:

:

20C3YO

':'

Y03D

oEFORE:

256

I'I\GE

AFT5:R:

2C2

PAGE

Dre

NU~

IBER:

2

t:

~~OVE

SNTER:

SI\

VE

Ese :

CANCE

L

,

~

~

-

'

t'

I J

LE

SWI T

CH

-------

- - -

--

O

~

BEFCRE:

25€-

/\FTE,,:

202

DT

C

N:!M:

2

I

~SC

:

STOP

SNTER : SELSCT

D.

Black Box Data Load

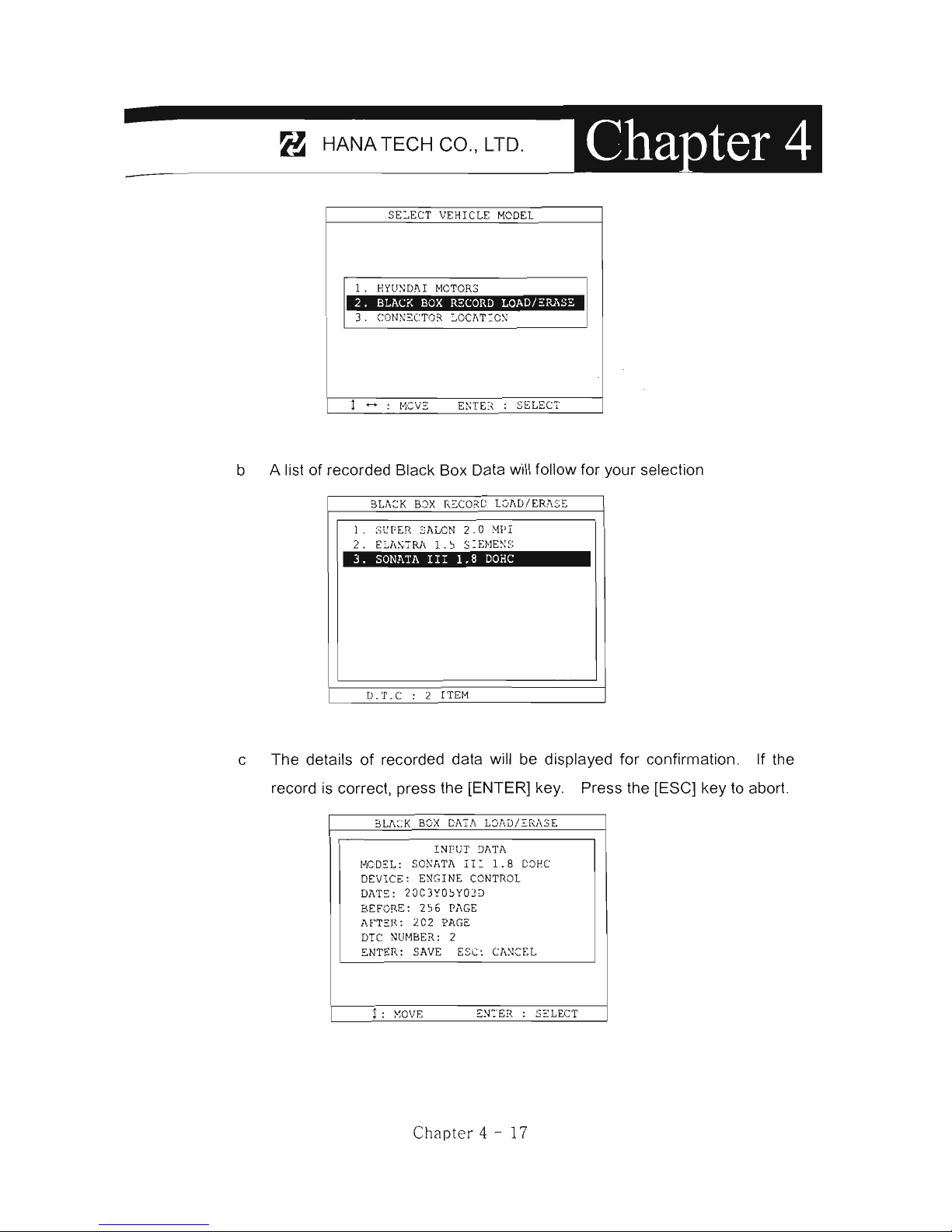

a You can retrieve the saved data by choosing [BLACKBO X RECORD

LOAD / ERASE] from the [Vehicle Model Selection] menu as shown

below:

Chapter

4 - 16

Page 66

:_-----8-

-

H-A-N-A-T-E-C-H-C-O-.,

_LT_D

_.

_----'_

SEL

ECT

VEHICLE

MO

DE:L

l . HYllNDAI

MOTOR

S

2 .

B~ACK

BOX

RECORD

LOAD/~RJ,SZ

E:;TE

7\

SE

LECT

b A list of recorded Black Box Data will follow for your selection

3U\2K

BOX E

CORD

LOl,D/ ER!\

SE

l .

,>U

FER S

ALeN 2.

()

~!PI

2 .

ELM,TRlI

l.

J

S=EJ.1E~:S

3.

SONAéA

IIr

1.8

DOHe

D . T . C 2 1 TEI

"!

c The details

of

recorded data will be displayed for confirmation. If the

record

is

correct, press the [ENTER] key. Press the [ESC] key to

aborto

BL!,~:K

BOX

C1\Tl\

L:::,r,D/!:RlI

SE

INPUT

Dl,TA

HOD"L:

S01>Il,TA

n:

1.8

DOHC

DE:

vrCE:

ENG

I NE CONTR

OL

DlIT

,,:

20C3YO"YOD

BEFORE

:

256

Pl\GE

!\.F"T~R

:

202 P

AGE

DIC

Nm·IBER : 2

ENTER

:

SAVE

Ese:

C

A~KEL

¡ :

}'~OVE

EN:

'ER

:

S"LECT

Chapter

4 - 17

Page 67

For

DeN

Scanners

E.

Loaded Blackbox data

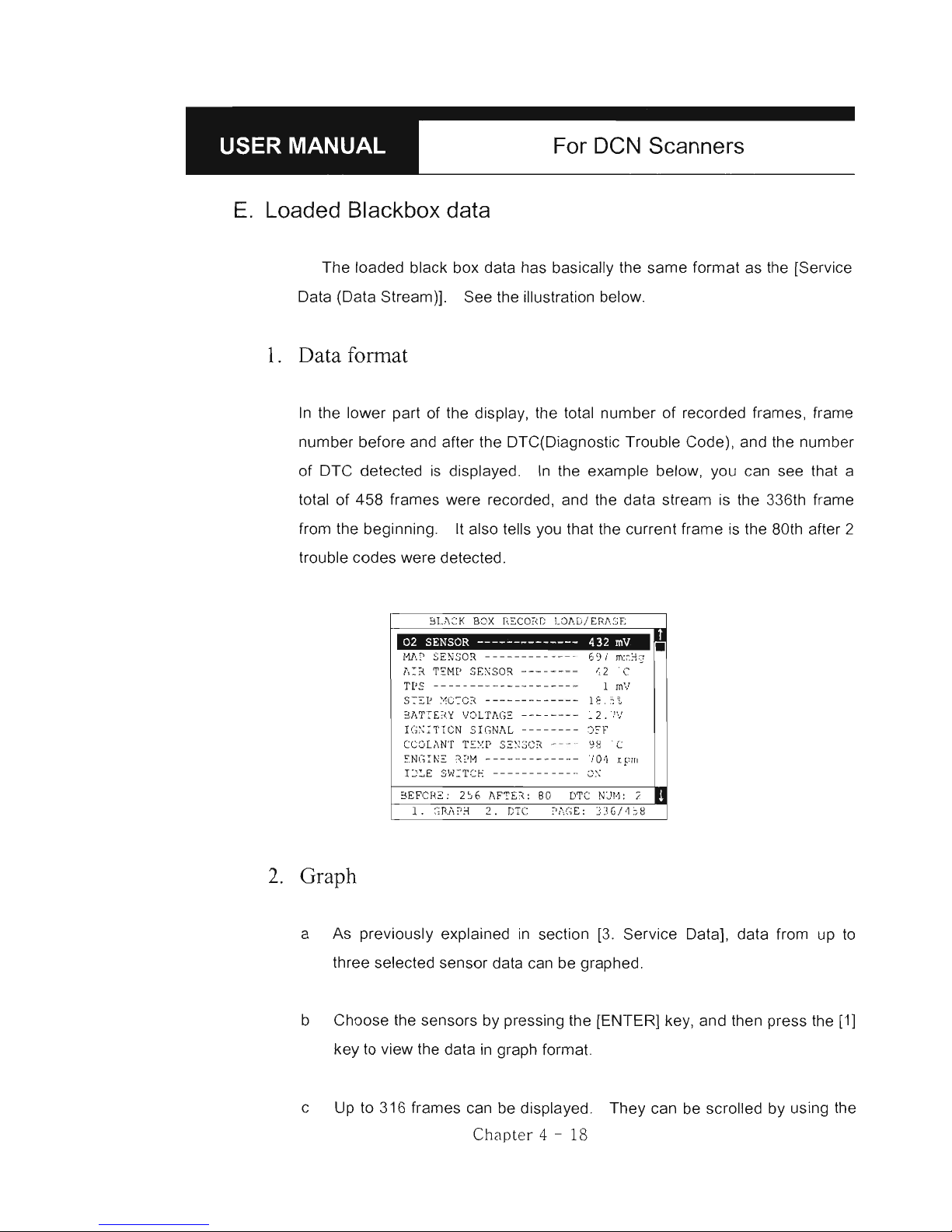

The loaded black box data has basically the same format as the [Service

Data (Data Stream)]. See the illustration below.

l.

Data format

In

the lower part

of

the display, the total number

of

recorded frames, frame

number before and after the DTC(Diagnostic Trouble Code), and the number

of

DTC detected

is

displayed.

In

the example below, you can see that a

total

of

458 frames were recorded, and the data stream is the 336th frame

from the beginning.

It

also tells you that the current frame

is

the 80th after 2

trouble codes were detected.

2.

Graph

02

SENS

OR

--------------

432

mV

1111

I'

SENSOR

-------

-----

-

69

¡

m:c.'-l"

A!~

TEMP

SENSOR ---

----

-

~2'C

TrS ---

-----------------

1

mV

S:~P ~C:OR

-------------le.

5\

31,TTE

" Y VDLT

JI.

GE ------- -~ 2 .

IV

I GNi TION SI

GNAL

- -

------D?P

CCOL

AN!

TSXP

SE~SOR

----

98

' C

EN

GINE

R~ M

---

- -

---

- - - --

701

rpm

IJ~E

SW!TCE -----------_.

OX

3EFCR2:

2~6

AFTE",

80 DTe

N:J

H, 2

•

a As previously explained

in

section [3. Service Data], data from

up

to

three selected sensor data can be graphed.

b Choose the sensors by pressing the [ENTER] key , and then press the [1]

key to view the data

in

graph format.

c Up to 316 frames can be displayed. They can be scrolled by using the

Chapt er 4 - 18

Page 68

:_---------~--

.

-H-A-N-A-T-E-CH--C-O-.,-~-D-.--~~

[Al

and

[~l

keys.

d The dotted line indicates from which frame the sensor values are being

displayed. You can move it left and right with the

[~l

and

[~l

keys.

The frame number

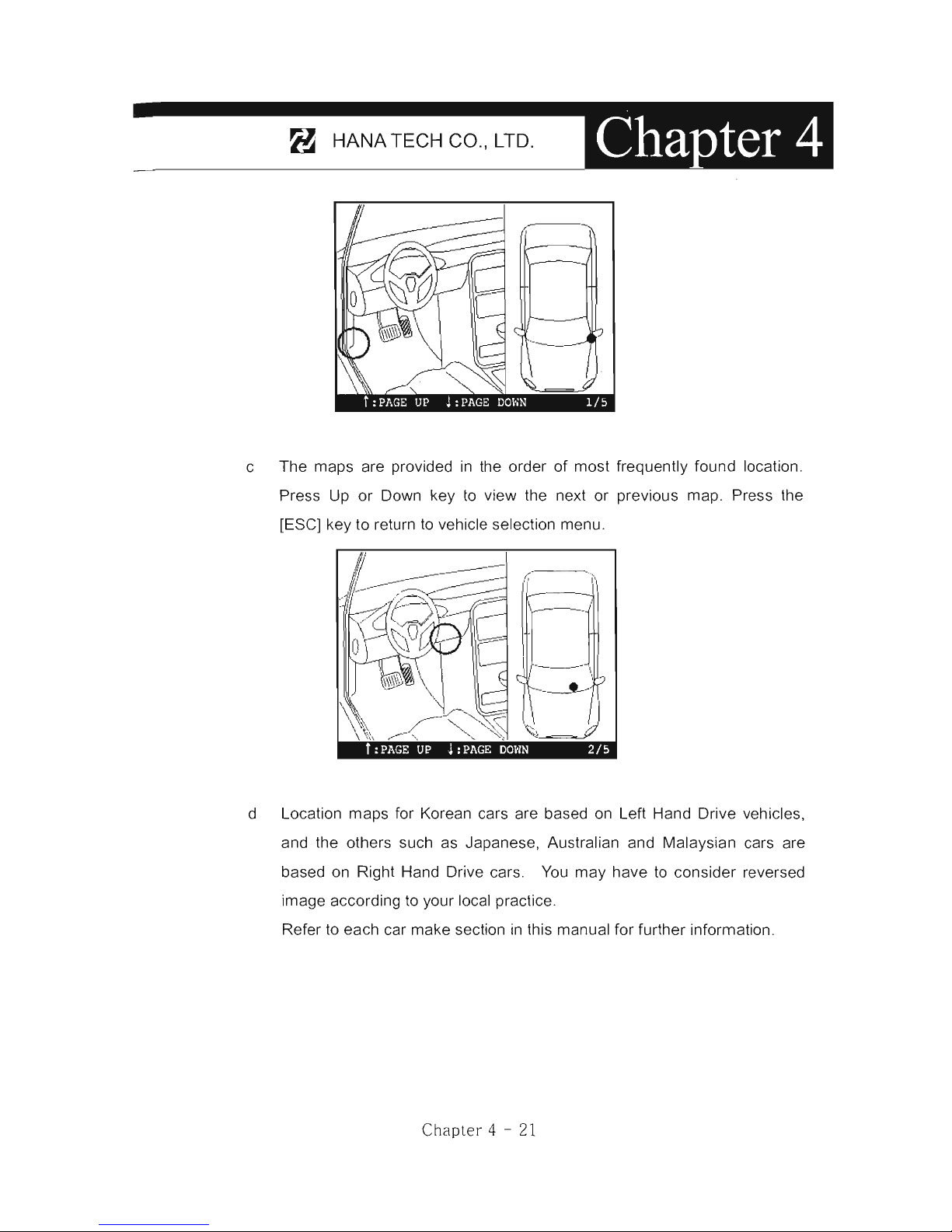

is