Hamworthy Trigon

ST1 Solar Pump Station

Installation, Commissioning,

Operation & Service Instructions

IMPORTANT NOTE

THESE INSTRUCTIONS MUST BE READ

AND UNDERSTOOD BEFORE INSTALLING,

COMMISSIONING, OPERATING OR

SERVICING EQUIPMENT

Customer After Sales Services

Telephone: 01202 662555 E-mail: service@hamworthy-heating.com Fax: 01202 662522

Technical Enquiries

To supplement the detailed technical brochures, technical advice on the application and use of products in the Hamworthy

Heating range is available from our technical team in Poole and our accredited agents.

Site Assembly

Hamworthy offer a service of site assembly for many of our products where plant room access is restricted. Using our trained staff

we offer a higher quality of build and assurance of a boiler built and tested by the manufacturer.

Commissioning

Commissioning of equipment by our own engineers, accredited agents or specialist sub-contractors will ensure the equipment is

operating safely and efciently.

Service Contracts

Regular routine servicing of equipment by Hamworthy service engineers inspects the safety and integrity of the plant, reducing the

risk of failure and improving performance and efciency. Service contracts enable you to plan and budget more efciently.

Breakdown service, repair, replacement

Hamworthy provide a rapid response breakdown, repair or replacement service through head ofce at Poole and accredited

agents throughout the UK.

Spare Parts

We offer a comprehensive range of spare parts, providing replacement parts for both current and discontinued products. Delivery

options are available to suit you. Please refer to our website for more details.

Hamworthy Trigon

ST1 Solar Pump Station

Installation, Commissioning,

Operation & Service Instructions

NOTE: THESE INSTRUCTIONS MUST BE READ AND UNDERSTOOD BEFORE

INSTALLING, COMMISSIONING, OPERATING OR SERVICING THIS EQUIPMENT.

THE TRIGON ST1 SOLAR PUMP STATION COMPLIES WITH ALL RELEVANT EUROPEAN DIRECTIVES.

PUBLICATION NO. 500001281

ISSUE ‘A’

JUNE 2013

HAMWORTHY HEATING LTD

Page

TRIGON SOLAR THERMAL

i

1

500001281/A

HAMWORTHY TRIGON

INSTALLATION AND

OPERATION MANUAL

SOLAR PUMP STATION ST1

Customer Service Centre

Hamworthy Heating Limited

Fleets Corner, Poole,

Dorset BH17 0HH l

0DNO0201 Installation-Operation ST1 Solar Pump Station 1

1 General information

Item no. 0DNO0201

Translation of the original instructions

We reserve the right to make technical changes without notice!

Printed in Germany – Copyright by Hamworthy

2 Installation-Operation ST1 Solar Pump Station 0DNO0201

1 General information

Contents

1

General information ......................................................................................................... 4

1.1 About these instructions ............................................................................................... 4

1.2 About this product ........................................................................................................ 4

1.3 Designated use ............................................................................................................ 5

Safety instructions ........................................................................................................... 6

2

3

Assembly and installation [installer] .................................................................................. 8

4

Commissioning [installer] ............................................................................................... 11

4.1 Flushing and filling the solar circuit ............................................................................. 12

4.2 Preparations before flushing ....................................................................................... 14

4.3 Flushing and filling ..................................................................................................... 14

4.4 Setting the solar installation (only for standard solar pumps) ...................................... 17

Maintenance [installer] ................................................................................................... 18

5

5.1 Draining the solar installation ..................................................................................... 18

5.2 Disassembly ............................................................................................................... 18

Spare parts [installer] ..................................................................................................... 19

6

6.1 ST1 Solar Pump Station ............................................................................................. 19

Controller extension .............................................................................................................. 20

20

Technical data

7

..............................................................................................................

.

7.1 Pressure drop characteristics ST1 Solar Pump Station .............................................. 21

Function check valves [installer] ..................................................................................... 22

8

9

Commissioning report ....................................................................................................

2

4

0DNO0201 Installation-Operation ST1 Solar Pump Station 3

1 General information

1 General information

Carefully read these instructions before installation and commissioning. Save these

instructions in the vicinity of the installation for future reference.

.1 About these instructions

1

These instructions describe the installation, commissioning, function and operation of the

TRIGON ST1 Solar Pump Station. The chapters called [installer] are intended for installers only.

For other components of the solar thermal system such as collectors, tanks, expansion vessels

and controllers, please refer to the instructions for that component.

.2 About this product

1

The station is a premounted fitting group checked for leakage used to circulate the solar fluid in

the solar circuit. It is mounted on a wall bracket and fixed with clips. The solar station is

optionally equipped with a controller. It contains important fittings and safety devices for the

operation of the installation:

• Ball valves in the flow line (1.1) and return line (5.1)

• Check valves in the flow (1.1) and return ball valves (5.1)

• Thermometers in the flow (5.2) and

return line (1.2)

• Pressure gauge to display the installation pressure (1.6)

• Flowmeter to display the flow rate (3.3)

• Ball valve to reduce the flow rate (3.1)

• Solar pressure relief valve (1.3)

• De-aerator to easily vent the solar circuit (4.2)

• Drain (3.2) and fill valves (1.4) with hose connectors

4 Installation-Operation ST1 Solar Pump Station 0DNO0201

1 General information

1.3 Designated use

The solar station may only be used as a pump station in the solar circuit taking into

consideration the technical limit values indicated in these instructions. Due to its design the

station must be mounted and operated as described in these instructions!

Improper usage excludes any liability claims.

Flow

1.3

5.2

4.2

Return

1.4

5.1 1.1

1.6

1.5

1.2

2

3.2

3.1

4.1

3.3

3.4

When the sun shines, the collector can become very hot. The solar fluid

in the circuit can heat up to more than 100 °C.

Only flush and fill the solar circuit when the collector temperatures are

below 70 °C.

0DNO0201 Installation-Operation ST1 Solar Pump Station 5

2 Safety instructions

2 Safety instructions

The installation and commissioning as well as the connection of electrical components require

technical knowledge commensurate with a recognised vocational qualification as a fitter for

plumbing, heating and air conditioning technology, or a profession requiring a comparable level

of knowledge [installer]. The following must be observed during installation and commissioning:

• relevant local and national regulations

• accident prevention regulations of the professional association

• instructions and safety

• use appropriate personal and protective equipment eg safety glasses, gloves, etc...

instructions mentioned in this manual

WARNING

Danger of scalding due to vapour escape!

With pressure relief valves there is risk of scalding due to vapour escape. During

installation, check the local conditions and if a discharge line must be connected

to the safety group.

Observe the instructions regarding the pressure relief valve.

The pressures calculated by the installation planner for the expansion

vessel and the operating pressure of the installation must be set.

CAUTION

Risk of burns!

The valves, fittings and the pump may heat up to more than 100 °C during

operation.

The shell must remain closed during operation.

6 Installation-Operation ST1 Solar Pump Station 0DNO0201

2 Safety instructions

CAUTION

Personal injury and damage to property due to overpressure!

By closing the two ball valves in the primary circuit you isolate the pressure relief

valve from the heat exchanger. A rise in temperature in the storage tank will

cause high pressures and could result in personal injury or damage to property!

Only close the ball valves for service and maintenance.

NOTICE

Material damage due to mineral oils!

Mineral oil products cause lasting damage to seals made of EPDM, whereby the sealant

properties are lost. We do not assume liability nor provide warranty for damage to property

resulting from sealants damaged in this way.

It is imperative to avoid that EPDM gets in contact with substances containing mineral

oils.

Use a lubricant based on silicone or polyalkylene and free of mineral oils such as

Unisilikon L250L and Syntheso Glep 1 of the Klüber company or a silicone spray.

0DNO0201 Installation-Operation ST1 Solar Pump Station 7

3 Assembly and installation [installer]

3 Assembly and installation [installer]

NOTICE

Material damage due to high temperatures!

Install the at a sufficient distance from the collector field, since the solar fluid may

be very hot near the collector. It may be necessary to install an intermediate tank in order to

protect the expansion vessel.

pump station

1. Remove the station from the packaging.

2. Remove the insulating front shell.

3. Copy the mounting holes of the solar station besides

the thermometers to the mounting surface.

4. Drill the holes and mount the solar station to the wall

with the enclosed wall plugs and screws.

8 Installation-Operation ST1 Solar Pump Station 0DNO0201

3 Assembly and installation [installer]

5. Connect the solar station to the installation:

5.1 flow from the collector field

1.1 return to the collector field

4.1 flow to the storage tank

3.4 return from the storage tank

6. Connect the pipe for the expansion vessel below the

pressure gauge [1.5] and fix the bracket for the

expansion vessel.

7. Pressurise the expansion vessel as specified by the

manufacturer and connect the expansion vessel.

Observe the separate instructions regarding the

expansion vessel!

8. Check all screw connections and tighten them if

necessary.

Optionally available!

0DNO0201 Installation-Operation ST1 Solar Pump Station 9

3 Assembly and installation [installer]

WARNING

Risk to life and limb due to electric shock!

Prior to commencing electrical work on the controller, disconnect the mains

plug from the mains

Only after completing all installation work, flushing and filling, plug the

mains plug of the controller into a socket! This avoids an unintentional start

of the motors.

9. Connect the pump and the sensors to the controller.

The assembly of the solar station is completed and you

can put the station into operation.

10 Installation-Operation ST1 Solar Pump Station 0DNO0201

4 Commissioning [installer]

4 Commissioning [installer]

Observe the following safety instructions regarding the commissioning of the station:

WARNING

Risk of burning and scalding!

The fittings can heat up to more than 100 °C. Therefore, do not clean or fill the

system with the collectors heated (intense sunshine). Please note that hot solar

fluid can leak from the pressure relief valves in case of too high system pressure!

During venting the solar fluid may escape as vapour and cause scalding!

Only flush and fill the installation when the collector temperatures are

below 70 °C when wearing appropriate personal and protective equipment.

NOTICE

Risk of frost!

It often happens that the solar thermal system cannot be completely drained after flushing.

Thus, there is risk of frost damage when flushing with water. Therefore, do only use the solar

fluid used later to flush and fill the solar installation.

Use a water and propylene glycol mixture with max. 40% of propylene glycol as a solar

fluid.

NOTICE

Note regarding the commissioning sequence

When putting the system into operation, first fill the heating circuit and then the solar circuit.

This guarantees that heat that may possibly be absorbed by the collectors during

commissioning can be dissipated.

NOTICE

Note regarding the expansion vessel

To prevent that the dirt particles in the solar thermal system are flushed into the expansion

vessel, some manufacturers recommend to disconnect the expansion vessel from the solar

circuit before flushing and filling. Please observe the instructions of the manufacturer.

0DNO0201 Installation-Operation ST1 Solar Pump Station 11

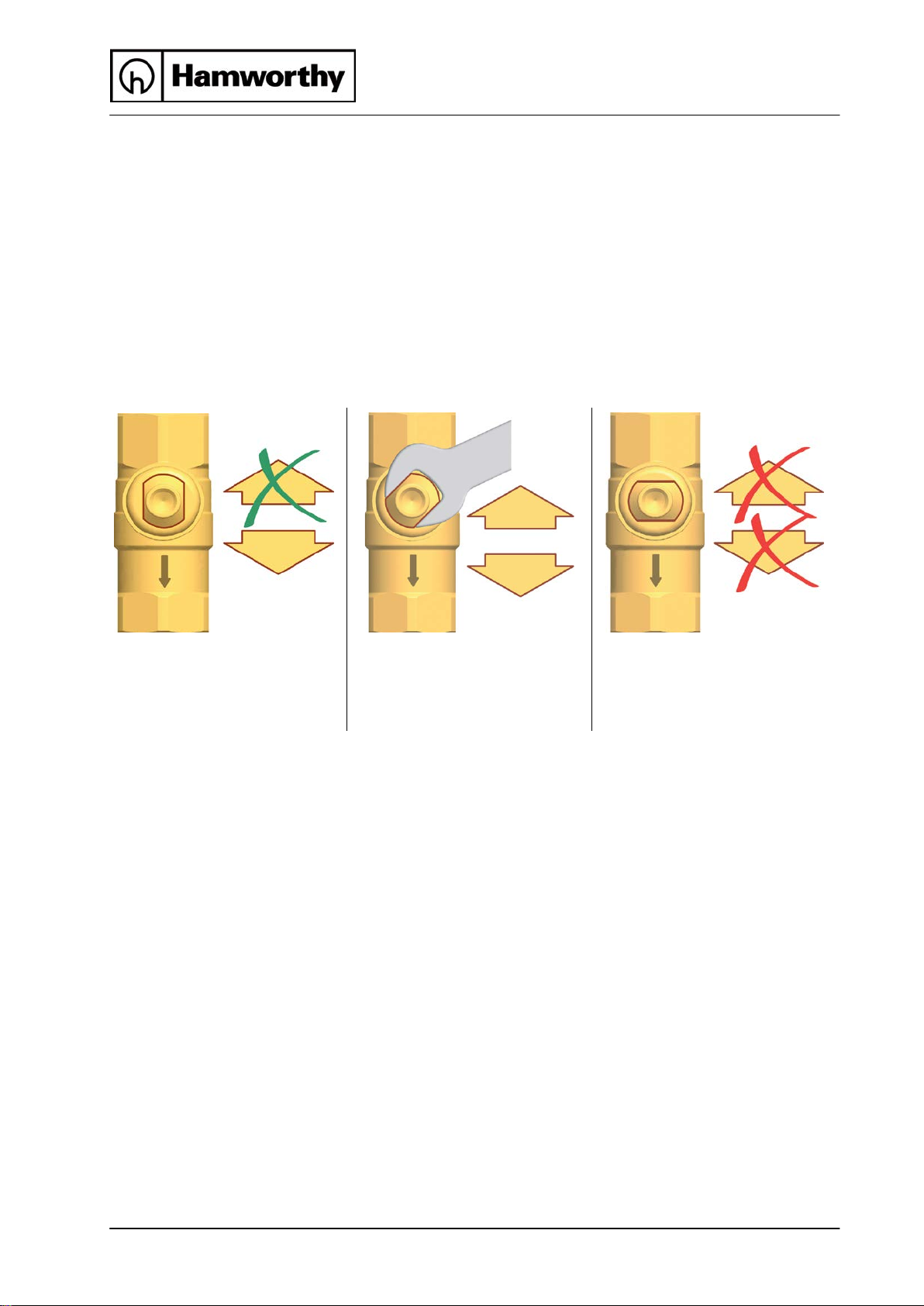

4 Commissioning [installer]

flow only in flow direction.

flow in both directions.

no flow.

4.1 Flushing and filling the solar circuit

The fill and drain valves required to flush and fill are integrated in the solar station.

To flush the dirt particles out of the installation, only use flush and fill stations with fine filters.

Ball valve with integrated flow check valve (1.2 and 5.2)

(normal flow direction in the figure below: downwards)

0° 45° 90°

Check valve is operating,

Check valve is not operating,

Ball valve closed,

12 Installation-Operation ST1 Solar Pump Station 0DNO0201

4 Commissioning [installer]

De-aerator

The de-aerator with manual vent valve is used to vent the solar

installation. To ensure perfect deaeration of the solar circuit, the flow

velocity must be at least 0.3 m/s in the flow line.

Pipe diameter [mm] Flow rate at 0.3 m/s

∅ outside ∅ inside l/h l/min

15 13 ~ 143

~ 2.4

18 16 ~ 217 ~ 3.6

22 20 ~ 339 ~ 5.7

The air liberated from the solar fluid is collected in the upper part of the de-aerator and can be

released at the vent plug [4.2].

WARNING

Danger of scalding due to vapour escape!

The escaping fluid can have a temperature of more than 100 °C and cause

scalding.

Carefully open the vent plug and close it again, as soon as medium

escapes.

enting the solar installation after commissioning

V

At the beginning, vent the solar installation daily and then weekly or monthly,

depending on the vented air quantity. Thus, an optimum operation of the solar

installation is ensured. Check the system pressure after venting and increase it to the

specified operating pressure, if necessary.

0DNO0201 Installation-Operation ST1 Solar Pump Station 13

4 Commissioning [installer]

4.2 Preparations before flushing

4.3 Flushing and filling

The solar circuit is flushed in the direction of

flow.

1. Disconnect the expansion vessel from the

solar installation. Please observe the

instructions of the manufacturer.

2. Turn the check valve in the flow ball

valve [5.2] to operating position

(0°, see page 12).

3. Close the return ball valve [1.2]

(90°, see page 12).

4. The ball valve [3.1] must be open.

5. Connect the filling pump to the solar

station:

- Pressure hose to the fill valve [1.4]

- Flush hose to the drain valve [3.2]

1. Open the fill and drain valves [1.4|3.2].

2. Put the flush and fill station into operation

and flush the installation until clear solar

fluid exits.

Vent the solar installation several times at

the vent plug of the de-aerator [4.2] until

the solar fluid exits without bubbles

(see page 13).

14 Installation-Operation ST1 Solar Pump Station 0DNO0201

4 Commissioning [installer]

3. To vent the pump stroke, slowly open the

return ball valve [1.2] (0°, see page 12).

4. Close the drain valve [3.2] with the filling

pump running and increase the system

pressure to max. 5 bars. The system

pressure can be read on the pressure

gauge. Close the fill valve [1.4] and switch

off the pump of the flush and fill station.

Consider the pressure relief valve (6 bars)!

5. Check the pressure gauge to see whether

the system pressure reduces and eliminate

leaks where necessary.

6. Reduce the pressure at the drain

valve [3.2] to the operating pressure.

7. Connect the expansion vessel to the solar

circuit and set the operating pressure of the

solar system by means of the flush and fill

station (for the required operating pressure,

see instructions of the expansion vessel).

8. Close the fill and drain valves [1.4|3.2].

9. Turn the check valve in the return ball

valve [1.2] to operating position

(0°, see page 12).

0DNO0201 Installation-Operation ST1 Solar Pump Station 15

4 Commissioning [installer]

WARNING

Risk to life and limb due to electric shock!

Check if the sensors and the pumps are properly connected to the

controller and if the controller housing is closed. Only then should the

mains plug of the controller be plugged into a socket.

10. Connect the optional controller to the mains and

set the solar circuit pump in the manual mode to

Max. according to the controller instructions. Let

the solar circuit pump run at maximum rotation

speed for at least 15 minutes.

Meanwhile vent the solar installation several times

at the vent plug of the de-aerator until the solar

fluid exits without bubbles (see page 12).

If necessary, increase the system pressure to the

11. Remove the hoses of the flush and fill station and

screw the sealing caps onto the fill and drain

valves.

The sealing caps only serve to protect the valves

against dirt. They are not designed to take up high

system pressures. The ball valves must be closed.

12. Only for standard solar pumps:

Continue at point "4.4 Setting the solar installation"

only for PWM pumps:

Mount the insulating front shell. Switch the

controll

er to automatic mode (see controller

instructions).

16 Installation-Operation ST1 Solar Pump Station 0DNO0201

4 Commissioning [installer]

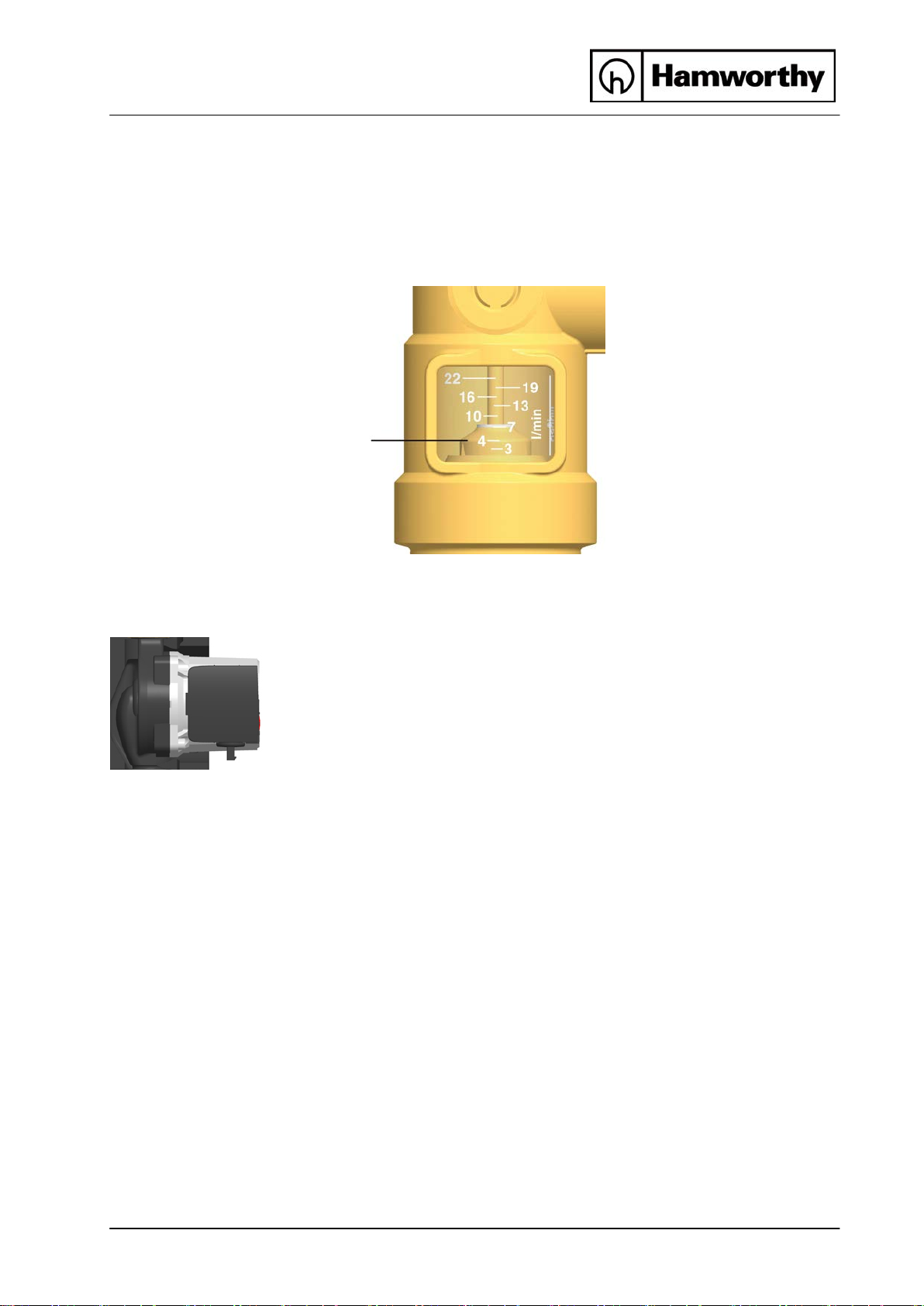

Scale DN 20:

Round edge

Example:

about 4 l/min

Three speed solar pump

4.4 Setting the solar installation (only for standard solar pumps)

Observe the specifications of the collector manufacturer for the correct adjustment of the

flow rate.

3 – 22 l/min

Reading edge =

of the float

Optional controllers:

1. Set the pump P1 to Max. in the manual mode of

the controller to set the maximum flow rate. The

controller sets the corresponding rotation speed.

If necessary, the flow rate can be adjusted at the

ball valve [3.1].

2. Mount the insulating front shell to the station.

3. Switch the controller to automatic mode

DeltaSol BS/2 (Standard controller)

(see controller instructions).

DelatSol M (Advanced controller)

The commissioning of the solar installation is now complete. Please fill in completely the

commissioning report on page 25.

0DNO0201 Installation-Operation ST1 Solar Pump Station 17

5 Maintenance [installer]

5 Maintenance [installer]

5.1 Draining the solar installation

1. Switch off the controller and make sure that a

restart is not possible.

2. Open the check valves in the flow and return ball

valve [5.2|1.2], by turning them to a 45° position

(45°, see page 12).

3. Connect a heat-resistant hose to the lowest drain

valve of the solar installation (or to drain valve [3.2]).

Make sure that the solar fluid is collected in a heatresistant container.

WARNING

Danger of scalding due to hot solar fluid!

The escaping fluid may be very hot.

Place and fix the heat-resistant collecting container so that people

standing nearby are not endangered when the solar installation is being

emptied.

4. Open the drain valve at the lowest point of the solar thermal system.

5. To accelerate draining of the solar circuit, you can open the bleeding device,

if present, at the highest point of the solar thermal system.

6. Dispose of the solar fluid observing the local regulations.

.2 Disassembly

5

1. Drain the solar thermal installation as described above.

2. Disconnect the pipe joints with the solar thermal system.

3. To remove the solar station from the mounting plate, pull

the clips to the side using a screwdriver.

4. Pull out the station towards the front.

18 Installation-Operation ST1 Solar Pump Station 0DNO0201

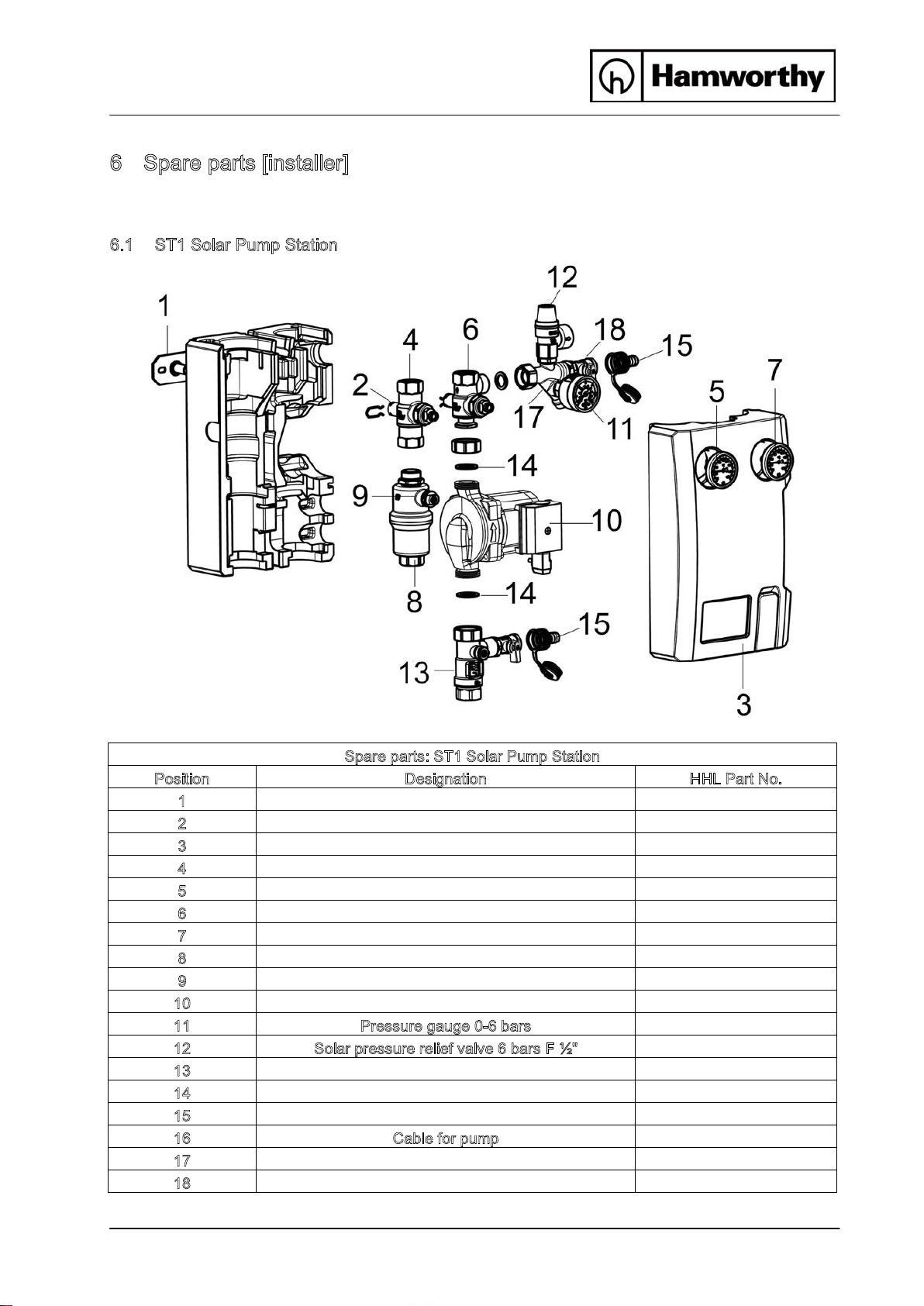

6 Spare parts [installer]

Spare parts: ST1 Solar Pump Station

Position

Designation

HHL Part No.

1

Wall bracket

073336

2

Fixation clip (x 5)

073071

3

Front and back insulating shell made of EPP

073786

4

Ball valve with check valve, return from collector

073085

5

Thermometer, return from collector (red)

073787

6

Ball valve with check valve, flow towards collector

073072

7

Thermometer, flow towards collector (blue)

073788

8

De-aerator

073344

9

Vent plug

073789

10

Pump Wilo Star-ST 15/7 ECO-3

073068

11

Pressure gauge 0-6 bars

073790

12

Solar pressure relief valve 6 bars F ½"

073404

13

Flowmeter 3-22 l/min ST1

073792

14

Sealing set ST1

073347

15

Drain connection

073346

16

Cable for pump

073348

17

Counter cross

18

Fill and drain valve

6 Spare parts [installer]

In case of a complaint, please send us the completely filled commissioning report on page 25.

.1 ST1 Solar Pump Station

6

n.c.

n.c.

0DNO0201 Installation-Operation ST1 Solar Pump Station 19

7 Technical data

Dimensions ST1 Solar Pump Station

7 Technical data

Height (with controller extension)

560 mm

Height (without controller extension) 383 mm

Width (with insulation) 334 mm

Depth (with insulation) 150 mm

Centre distance flow/return 100 mm

Pipe connections ¾" internal thread

Connection for expansion vessel ¾" external thread, flat sealing

Outlet pressure relief valve ¾" internal thread

Operating data

Max. admissible pressure PN 10

Max. operating temperature 120 °C

Max. short-time temperature 160 °C, < 15 minutes

Max. propylene glycol content 40 %

Equipment

Pressure relief valve 6 bars

Pressure gauge 0 – 6 bars

Check valves 2 x 200 mm wc, can be opened

Flowmeter 3-22 l/min

Material

Valves and fittings Brass

Gaskets EPDM

Check valves Brass

Insulation EPP, l = 0.041 W/(m K)

0DNO0201 Installation-Operation ST1 Solar Pump Station 20

7

Technical data

7.1 Pressure drop characteristics ST1 Solar Pump Station

Pressure [m wc]

Flow rate [l/h]

Pressure [kPa]

Installation-Operation ST1 Solar Pump Station 0DNO0201

21

8 Function check valves [installer]

8 Function check valves [installer]

Within their application range, the check valves in this station prevent unwanted gravity

circulation. The efficiency of the check valves depends on:

• the installation height

• the temperature difference between the storage tank and the collector

• the type of heat transfer medium

In the diagram below you can see whether the check valves integrated in the station are

sufficient. If the check valves are not sufficient, you need to install additional components to

prevent gravity circulation. You can mount components such as syphons ("heat traps"), 2-way

valves (zone valves) or additional check valves.

Example:

• The station comprises two check valves (2 x 200 mm wc = 400 mm wc).

• You use a mixture of water and 40% of propylene glycol as a solar fluid.

• The installation height between the collector and the storage tank is 10 m.

Circulation

Installation height in m

Solar fluid

Result:

The check valves prevent gravity circulation up to a temperature difference of about 62 K.

If the temperature difference between the collector and the tank is larger, the difference in

density of the solar fluid will be so large, that the check valves are pushed open.

Temperature difference storage tank/collector in K

0DNO0201 Installation-Operation ST1 Solar Pump Station 22

8 Function check valves [installer]

Do you need to know it exactly?

The density of the solar fluid decreases with rising temperature. In high installations with large

temperature differences, the difference in density will cause gravity circulation. This circulation

can cool down the storage tank.

Calculation example: Δp = Δρ * g * h

Collector temperature: 5 °C Density solar fluid ρ1 = 1042 kg/m³

Storage tank temperature: 67 °C Density solar fluid ρ2 = 1002.5 kg/m³

Δρ = ρ1 - ρ2 = 39.5 kg/m³

g = 9.81 m/s²

Installation height h = 10 m

Δp = 3875 Pa = 395 mm wc

The two check valves in the station (2 x 200 mm wc) are sufficient for an installation height of

10 m and a temperature difference between the collector and the tank of up to 62 K.

23 Installation-Operation ST1 Solar Pump Station 0DNO0201

9 Commissioning report

Installation operator

Location of installation

Collectors (number / type)

Collector surface m²

9 Commissioning report

Installation height m

(Difference in height between

station and collector field)

Pipes ⌀ = mm l = m

Venting (collector field) Manual vent valve Automatic deaerator

No Vented

De-aerator

(station) Vented

Solar fluid (type) % glycol

Antifreeze tested up to: °C

Flow rate l/m

Station

Serial numbers

Pump (type)

Pump speed level (I, II, III)

Controller

System pressure mbars

Software version

Expansion vessel (type)

Initial pressure mbars

Pressure relief valve Checked

Check valves Checked

Plumbing company Date, signature

Restrictor

position:

0DNO0201 Installation-Operation ST1 Solar Pump Station 24

10 Commissioning report

0DNO0201 Installation-Operation ST1 Solar Pump Station 25

10 Commissioning report

26 Installation-Operation ST1 Solar Pump Station 0DNO0201

10 Commissioning report

0DNO0201 Installation-Operation ST1 Solar Pump Station 27

Hamworthy Heating Accredited Agents

Southern Ireland (Sales & Service)

HEVAC Limited

Naas Road, Dublin 12, Ireland

tel: 00 353 141 91919 fax: 00 353 145 84806

email: info@hevac.ie

Northern Ireland (Sales & Service)

HVAC Supplies Limited

Unit A6, Dargan Court, Dargan Crescent, Belfast BT3 9JP

tel: 028 9077 7737

email: hvacsupplies@btconnect.com

Scotland (Sales & Service)

McDowall Modular Services

2 Penson Road, Queenslie Industrial Estate, Glasgow, G33 4AG

tel: 0141 336 8795 fax: 0141 336 8954

email:

MMS.McDowallModularServices@hamworthy-heating.com

North East England (Service)

Allison Heating Products

12 Sunnyside Lane, Cleadon Village, Sunderland SR6 7XB

tel: 0191 536 8833 fax: 0191 536 9933

email: allison.heating@gmail.com

Hamworthy Heating Customer Service Centre

Sales

tel: 01202 662552

email: sales@hamworthy-heating.com

Technical Enquiries

tel: 01202 662505

email: technical@hamworthy-heating.com

Servicing

tel: 01202 662555

email: service@hamworthy-heating.com

Spares

tel: 01202 662525

email: spares@hamworthy-heating.com

British engineering excellence from Hamworthy Heating;

the commercial heating and hot water specialists.

Customer Service Centre

Hamworthy Heating Limited,

Wessex House,

New Fields Business Park,

Stinsford Road,

Poole,

Dorset,

BH17 0NF

Telephone: 01202 662500

Fax: 01202 662522

Email: service@hamworthy-heating.com

Website: www.hamworthy-heating.com

Hamworthy reserves the right to make changes and improvements which may necessitate alteration to the specication without prior notice.

Loading...

Loading...