Dorchester DR-SA Range

of Hot Water Storage Heaters

Open Flue, Direct Gas Fired Hot Water

Storage Heaters with Automatic Ignition

for Domestic Hot Water Installations

Installation, Commissioning

and Servicing Instructions

DORCHESTER DR-SA 16, 19 MODELS

NATURAL GAS I

LPG I

2H

3+

NOTE: THESE INSTRUCTIONS MUST BE READ AND UNDERSTOOD BEFORE INSTALLING,

COMMISSIONING, OPERATING OR SERVICING EQUIPMENT.

THIS WATER HEATER IS FOR USE ON GROUP H NATURAL GAS (2ND FAMILY) I2H OR

LPG (3RD FAMILY) I3+. PLEASE ENSURE RELEVANT INFORMATION REQUIRED WITHIN

DOCUMENT IS FOUND RELATING TO SPECIFIC GAS TO BE FIRED BEFORE FIRING

HEATER.

THIS WATER HEATER COMPLIES WITH ALL RELEVANT EUROPEAN DIRECTIVES.

PUBLICATION NO. 500001135

ISSUE ‘F’

APRIL 2012

2

3

CONTENTS PAGE

1. GENERAL 4

1.1 Description .............................................................................................................................................................4

1.1.1 Delivery ..................................................................................................................................................................4

1.1.2 Options ...................................................................................................................................................................4

1.2 Technical description ..............................................................................................................................................6

1.2.1 Gas control valve ...................................................................................................................................................6

1.2.2 Control panel ..........................................................................................................................................................6

1.2.3 Operation of the water heater ................................................................................................................................6

1.2.4 Combustion products discharge safety device.......................................................................................................7

1.3 Technical information .............................................................................................................................................7

1.3.1 Dimensions ............................................................................................................................................................7

1.3.2 Technical data ........................................................................................................................................................8

2. FOR THE INSTALLER 9

2.1 Installation ..............................................................................................................................................................9

2.1.1 Regulations and Related Documents.....................................................................................................................9

2.1.2 Water circulation system ......................................................................................................................................10

2.1.3 Gas connection ....................................................................................................................................................12

2.1.4 Draught diverter ...................................................................................................................................................12

2.1.5 Flue system ..........................................................................................................................................................12

2.1.6 Electrical connection ............................................................................................................................................12

2.2 Commissioning .....................................................................................................................................................12

2.3 Removing and replacing the control panel front cover .........................................................................................13

2.4 Setting the gas pressure ......................................................................................................................................13

2.5 Temperature regulation ........................................................................................................................................14

2.6 Converting to another type of gas ........................................................................................................................14

2.7 Maintenance.........................................................................................................................................................14

2.7.1 Sacricial anode ...................................................................................................................................................14

2.7.2 Cleaning ...............................................................................................................................................................14

2.7.3 Inspection of the internal waterside surfaces .......................................................................................................14

2.7.4 Spare parts...........................................................................................................................................................15

2.8 Condensation .......................................................................................................................................................15

2.9 Important warning ................................................................................................................................................15

3. FOR THE USER 15

3.1 Instructions for use ...............................................................................................................................................15

3.2 Fault nding..........................................................................................................................................................16

APPENDIX 1 ............................................................................................................................................................................17

Connection diagram Dorchester DR-SA 16 & 19 .....................................................................................................................17

4

1. GENERAL

1.1 Description

Construction of the Dorchester DR-SA heaters is in

accordance with the European standards for gas red

water heaters for sanitary use (EN 89). The heaters

comply with the European Directive for Gas Appliances

and are permitted to bear the CE mark.

1.1.2 Options

The Dorchester DR-SA heaters can be supplied with

additional variations, either ready tted or for on-site

assembly.

a) LPG – The heaters can be supplied adjusted for use

on propane or butane – see section 2.7. It is important

that the heater is correctly adjusted for the gas to be

red.

It is an open-ue appliance without a fan and with

combustion products discharge safety device (category

B

). The heaters are suitable for use with a working

11BS

pressure of up to 8 bar but on un-vented systems this is

limited to 5.5 bar due to the pre-set of the un-vented kit.

The cylindrical tank is made from sheet steel containing

one vertically placed ue tube.

For protection against corrosion, the inside of the tank is

glass lined. The tank is also tted with one magnesium

anode for extra protection against corrosion. A thick

insulating layer between the tank and the steel jacket

helps to reduce heat loss.

When the heater is completely lled with water, the

system is under continuous water pressure. When hot

water is drained from the heater, cold water immediately

enters the heater. For effective heat transfer, four ue

bafes are included in the ue tube. Heat from the ue

gases is transferred to the water by means of radiation

and convection. The ue gases are discharged by natural

thermal draught (see gure 1).

Dead legs on a hot water installation are undesirable.

Where possible they must be avoided. Where the

inclusion on the system of a dead leg is unavoidable the

following restrictions must be applied:

- For pipes not exceeding 19 mm inside diameter;

maximum length of dead leg permitted 12.0 metres;

- For pipes exceeding 19 mm but not exceeding

25 mm inside diameter; maximum length of dead leg

7.5 metres;

- For pipes with an inside diameter exceeding 25 mm;

maximum dead leg 3.0 metres.

b) Un-vented supply – The heaters can be supplied

with a purpose designed and sized un-vented kit

comprising pressure reducing valve, non-return

valve, expansion vessel, expansion relief valve and

temperature/pressure relief valve, to enable the heater

to be coupled directly to the mains water.

c) Top to Bottom Recirculation – In order to give

enhanced temperature control to aid compliance with

HSE guidance and Health Technical Memoranda,

a pump circulation kit can be supplied comprising

230 volt single phase pump, pipe work and sufcient

ttings to connect between the hot water ow and the

bottom drain connection.

d) Electrical Anode Protection - The electrical

conductivity of water, measured in micro siemens per

centimetre, is an important parameter in sacricial

anode protection. The lower the value, the less

effective the magnesium anode becomes.

In areas where the conductivity is likely to be less than

200 ¼ µ/cm, it is recommended that the magnesium

anode be replaced with an electrically powered inert

anode that requires an uninterrupted electrical supply

to its control unit. A kit (normally factory tted) can be

supplied comprising anode, additional control panel

and interconnecting wiring.

1.1.1 Delivery

All Dorchester heaters are factory assembled and

delivered individually packed and shrouded in polythene

on a wooden pallet. Within the packaging, wrapped

separately is the draught diverter complete with the

combustion products discharge safety device attached by

its capillary sensor. A separate package is included that

contains the installers kit, a ½” manual gas shut off valve,

a ¾” drain valve with Tee and plug, a special ¾” NPT to

BSP threaded nipple and a plastic cover for the drain cutout in the casing.

5

11

14

15

16

17

1

2

3

4

5

6

9

7

13

10

12

8

AOS 1120

Figure 1 - Cross-section of the heater

1) Draught diverter

2) Hot water outlet

3) Insulation

4) Flue tube

5) Glass lined tank

6) Gas control valve

7) Control panel

8) Inspection cover plate

9) Intermittent pilot burner and ame probe

10) Cold-water inlet (c/w inlet tube)

11) Combustion products discharge safety device.

12) T&P valve connection

13) Outer casing

14) Flue bafe

15) Magnesium anode

16) Drain valve and secondary return connection

17) Main burner.

6

1.2 Technical description

1129

1.2.3 Operation of the water heater

1.2.1 Gas control valve

The water heater is equipped with a gas control valve

c/w burner control that regulates the ow of gas to the

burner. To improve ignition the opening mechanism of

the gas control valve is tted with a delay (softlite). The

gas control valve is suitable for gases of the second and

third family. The maximum inlet pressure is 60 mbar. The

pilot system has an automatic spark ignition that make

sure that the burner ignites consistently when there is a

demand for hot water.

1.2.2 Control panel

The temperature control for the water heater is housed

in the control panel (See gure 2). For safety reasons,

heaters are tted with two thermostats: a control

thermostat is adjustable between 40°C and 80°C and a

safety thermostat is pre-set to 90°C. The control panel

is also tted with an ON/OFF switch (I/0). At setting “I”,

the gas control is activated on the basis of heat demand

from the control thermostat. At setting “0” the heater is

switched off.

Normal operation

When there is a demand for heat a waiting period

of about 1 second elapses before the built-in spark

generator and pilot gas valve are switched on. The

ignition spark lights the pilot burner and the ame probe

detects the resulting ame. Almost immediately after the

pilot ame is detected, sparking stops and the main gas

valve is opened. The pilot ame lights the main burner.

The unit is now in operation. When the water in the unit

reaches the set temperature the thermostat switches the

burner off.

Ignition failure

If the ame is not established within the safety period of

25 seconds the automatic ignition controller locks out.

The lamp on the reset button in the control panel shows a

lockout when lit. Pushing the reset button must manually

reset the heater. If the ame is lost during normal run, the

automatic ignition controller repeats the start sequence.

Figure 2 - Top view of the heater

A) Hot water outlet

B) Cold water inlet

1) Electrical connection

2) ON/OFF switch

3) Ignition controller reset button

4) Control thermostat knob

5) Safety thermostat reset button.

7

1.2.4 Combustion products discharge safety

device

The heater has been tted with a combustion products

discharge safety device. It is the function of the safety

device to prevent ue gases from the water heater

entering the room where the water heater has been

placed, instead of passing through the ue to outside

atmosphere. The gas supply is disconnected as soon as

hot gases owing over the sensor activate the device.

After the cause of the re-entry of ue gases has been

traced the device can be put back into operation by

pressing its reset button. If this failure occurs frequently,

this indicates that the ue suffers from down draught

conditions. It is recommended that a competent person

carry out the necessary remedial action.

Important

The combustion products discharge safety device must

never be put out of operation. Re-entry of ue gases to

the building could be harmful and cause poisoning or

death.

1.3 Technical information

1.3.1 Dimensions

The ue pipe must at least have the same diameter as

the spigot on the water heater (dimension G).

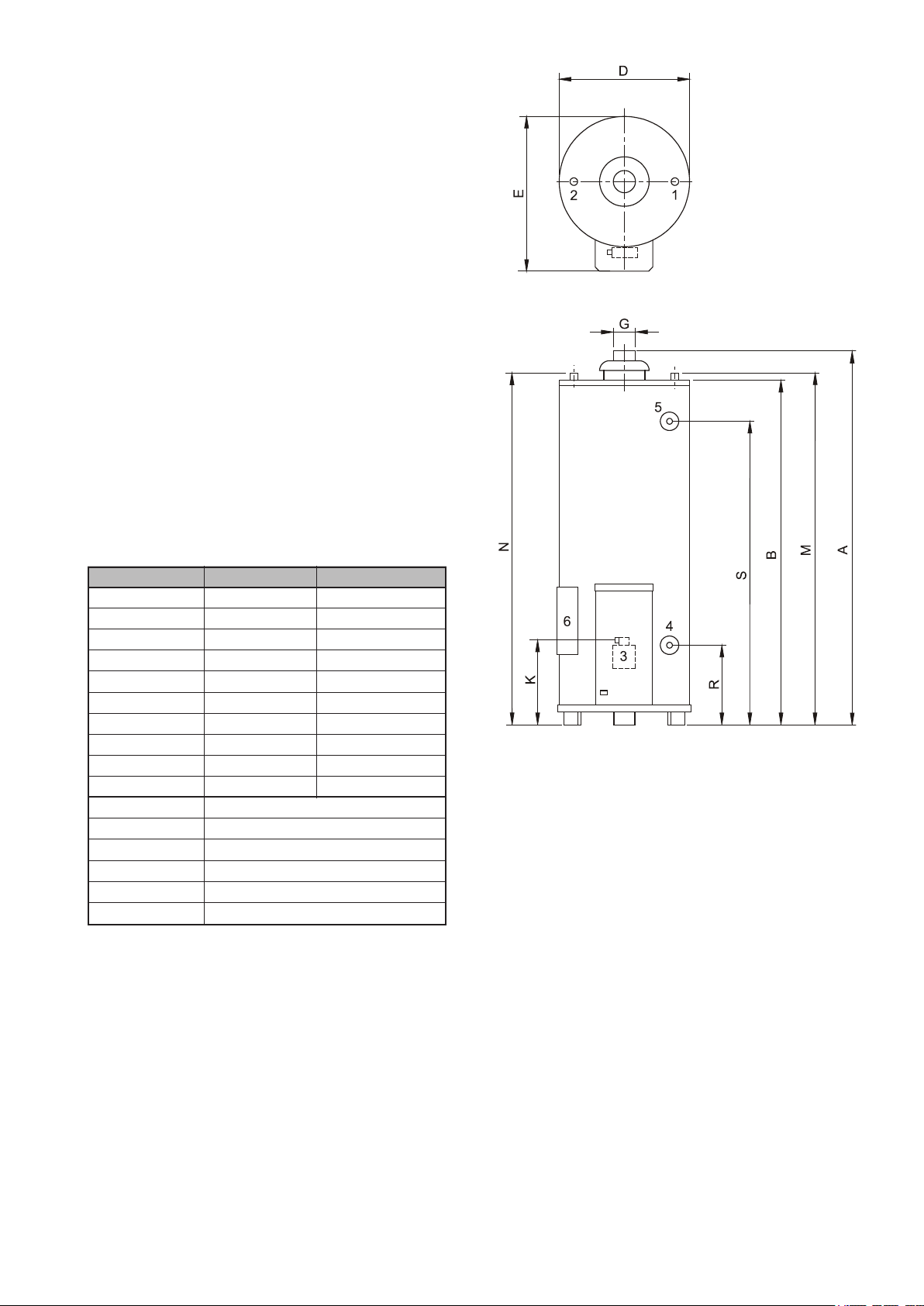

Dimensions DR-SA 16 DR-SA 19

A 1585 1780

B 1450 1640

D 645 675

E 770 775

G 130 130

K 340 340

M 1505 1685

N 1505 1685

R 285 285

S 1280 1460

1 Cold water inlet

2 Hot water outlet

3 Gas control valve

4 Drain valve

5 T&P valve tapping

6 Access door opening

All dimensions are given in mm. (rounded off to 5mm).

See gure 3.

Figure 3 - Dimensions

1) Cold water inlet

2) Hot water outlet

3) Gas control valve

4) Drain valve

5) T&P valve tapping

6) Access door opening

8

1.3.2 Technical data

Device category II2H3+

Description Unit DR-SA 16 DR-SA 19

DATA G20 – 20 mbar:

Nominal output kW 18.9 20.1

Nominal load (gross) kW 24.7 26.2

Supply pressure (G20) mbar 20 20

Burner pressure (G20) mbar 12.0 7.9

Gas consumption (G20)* m

Diameter main orice (G20) mm 3.90 4.50

Diameter pilot orice (G20) mm 0.56 / 0.41 0.56 / 0.41

Heating time ∆T = 45 K min 43 55

DATA G30 – 30 mbar:

Nominal output kW 18.9 20.1

Nominal load (gross) kW 24.1 25.6

Supply pressure (G30) mbar 30 30

Gas consumption (G30)* kg/h 1.8 1.9

Diameter main orice (G30) mm 2.30 2.35

Diameter pilot orice (G30) mm 0.23 0.23

Heating time ∆T = 45 K min 43 55

3

/h 2.4 2.5

DATA G31 – 37 mbar:

Nominal output kW 17.6 19.1

Nominal load (gross) kW 22.5 24.5

Supply pressure (G31) mbar 37 37

Gas consumption (G31)* kg/h 1.6 1.8

Diameter main orice (G31) mm 2.30 2.35

Diameter pilot orice (G31) mm 0.23 0.23

Heating time ∆T = 45 K min 43 55

GENERAL:

Storage capacity litres 278 372

Water connections ** 1-11.5 NPT 1¼-11.5 NPT

Gas connection Rp 1/

2

Rp 1/

2

Drain valve ¾”-14NPT ¾”-14NPT

Anode ¾”-14NPT ¾”-14NPT

T&P-plug ¾”-14NPT ¾”-14NPT

Maximum operating pressure bar 8 8

Maximum operating pressure un-vented bar 5,5 5,5

Nominal operating pressure un-vented bar 3,5 3,5

Empty weight kg 122 149

* Gas consumption at 1013,25 mbar and 15 °C

** For a leak proof connection to an NPT thread, a coupling with threads to ISO 228/1 can be used

9

Electrical connenction

Electrical supply Frequency Fuse

230 V AC 50 Hz 5 A

Ionisation current

The minimum ionisation current is 0.9 micro-Amperes DC.

Below this current the burner controller will assume no ame

is present. When in normal operation, the ionisation current

will be about 1.2 to 1.3 micro-Amperes DC when only the

pilot ame is burning.

(Adjust the main burner pressure to zero to be able to

measure under this condition).

With pilot and main burner in operation, the ionisation

current will be approx. 6.0 to 6.3 micro-Amperes DC.

Ionisation current can be measured by connecting a

universal meter in series with the connection to the ame

probe. Make sure meter is set for Direct Current. Alternating

Current gives no information about the system’s behaviour.

2. FOR THE INSTALLER

2.1 Installation

This water heater must be tted in a location that will permit

the provision of an approved ue system and adequate

ventilation.

A service clearance of 50 cm at the sides and rear of the

unit and 100 cm at the front of the unit must be allowed

for ease of servicing. Adequate distance must be allowed

between the top of the unit and any obstruction or ceiling to

allow the ue bafe and anode to be inspected, cleaned or,

in the case of the anode, replaced if necessary.

The water heater must stand on a level surface resistant

to heat, insulated in accordance with local by laws and

Building Regulations and with sufcient strength to support

the weight of the unit when full of water.

The heater must stand on its feet as supplied and the

space beneath the bottom casing kept clear as this is the

path for combustion air to enter the heater.

This water heater must not be installed in a bathroom,

bedroom or in a cupboard opening on to such rooms.

This water heater must not be installed in any area where

ammable materials are used or stored.

Insufcient ventilation may give rise to a risk of re,

explosion or suffocation. If in doubt consult the national

and local regulations governing the installation of gas

appliances or local gas service organisation.

2.1.1 Regulations and Related Documents

Gas Safety Installations and Use Regulations 1998,

(as amended). It is law that competent persons, in

accordance with the above regulations install all gas

appliances. Failure to install appliances correctly could

lead to prosecution. It is in your own interest, and that of

safety, to make sure that this law is complied with.

The installation of the boiler MUST be in accordance with

the relevant requirements of the Gas Safety Regulations,

Building Regulations, IEE Regulations and the Water

Supply (water ttings) Regulations.

The installation must also be in accordance with any

relevant requirements of the HSE, local gas region and

local authority and the relevant recommendations of the

following documents: -

British Standards

BS 6891: Specication for the installation of low-pressure

gas pipe work of up to 28 mm (R1) in domestic premises (2

family gas). For larger installations see IGE/UP/2 below.

BS 6798: Specication for installation of gas-red boilers

of rated input not exceeding 70 kW net.

BS 6644: Specication for installation of gas-red hot

water boilers of rated inputs between 70 kW and 1.8 MW

nd

(net) (2

BS 6700: Specication for design, installation, testing and

maintenance of services supplying water for domestic use

within buildings and their curtilages.

BS EN 806-2: Specication for installations inside

buildings conveying water for human consumption.

Part 2: Design.

BS 5546: Specication for installation of hot water

supplies for domestic purposes, using gas-red

appliances of rated input not exceeding 70 kW.

BS 5440: Installation and maintenance of ues and

ventilation for gas appliances of rated input not exceeding

70 kW net (1

Part 1: Flues. Part 2: Ventilation.

Institute of Gas Engineers and Managers Publications

IGE/UP/1 Soundness testing and purging of industrial and

commercial gas installations.

IGE/UP/1A Soundness testing and direct purging of

small low-pressure industrial and commercial natural gas

installations.

and 3rd family gases).

st

, 2nd and 3rd family gases).

nd

IGE/UP/2 Gas installation pipe work, boosters and

compressors on industrial and commercial premises.

IGE/UP/10 Installation of gas appliances in industrial and

commercial premises. Part 1: ued appliances.

CIBSE Publications:- “CIBSE Guide”

Section B4 : Water Service Systems.

Some chemicals produce vapours that can cause

rapid failure of main and pilot burners and storage

tanks if they are drawn into the combustion air

supply.

10

1105

Therefore if this water heater is to be used to supply

hot water to:

- hairdressers,

- dry cleaners,

- industrial degreasing processes or any other area

where compounds containing halogens are used

and stored, care must be taken that all primary and

secondary air is drawn from outside atmosphere free

of these contaminants. For further advice contact

Hamworthy Heating Limited.

2.1.2 Water circulation system

Dorchester water heaters are suitable for connection to

vented, un-vented and pumped pressurised systems.

In each case appropriate valves and ttings must be used

to make sure the system complies with the requirements

of the water ttings and appropriate

building regulations.

When tting it is essential the rules of ‘good practice’ are

applied at all stages of installation.

Water quality

The water heater is intended for heating drinking water.

The drinking water must comply with the regulations

governing drinking water for human consumption.

The table gives an overview of the specications.

Drain connection

The ttings for the drain are supplied in the installation kit

stuck to the wooden pallet. Select the hexagon nipple and

screw the thread nearest the groove in the nipple into the

heater drain opening using suitable sealant.

Fit the plastic cover over the nipple and push up tight to

the heater before assembling any other parts.

Note: the hexagon nipple is a thread adapter between

¾” NPT (nearest the groove cut into the hexagon) and ¾”

BSPT. Arrange the tee, plug and drain as shown in

gure 4. The actual orientation of the tee may depend on

whether a system return is required and whether a top to

bottom circulator kit is to be tted.

Vented systems (See gure 5)

Water composition

Hardness

(alkaline earth ions)

> 1.00 mmol/l:

• German hardness > 5.6 °dH

• French hardness > 10.0 °fH

• English hardness > 7.0 °eH

• > 100 mg/l CaCO3

Conductivity > 125 μS/cm

Acidity (pH value) 7.0 < pH value < 9.5

Note: If the water specications deviate from those

stated in the table, then the tank protection cannot be

guaranteed.

Important

Where water softeners are used on the hot water supply,

make sure that the hardness remains between 60 and

100 ppm CaCO3. In soft water areas with conductivity

less than 200 μS/cm, the electrically powered anode

system must be used.

Figure 5 –

Connection diagram vented systems

Figure 4

If the water heater is to be connected to a cold feed tank

or cistern the hot water supply pipe must include an open

vent. Ideally the vent pipe must be linked to a separate

tundish/drain or else to discharge over the cold water feed

tank. The cold feed cistern must have an actual capacity

of greater volume than the hourly recovery rate of the

water heater(s) that it supplies.

The minimum actual capacity is 50 gallons or 227 litres.

3) Safety valve

4) Stop valve

5) Non-return valve

6) Circulation pump

9) Drain valve

10) Manual Gas valve

11) Stop valve

14) Hot water draw off points

17) 3-way venting valve

A ) Cold water supply

B) Hot water outlet

C) Circulation pipe

D) Gas supply

E) Overow pipe

11

Un-vented system (see gure 6)

1119

To install a Dorchester water heater on an un-vented cold

water supply system a kit of valves and ttings (WRAS

approved) must be used. Installation must be carried out

generally as shown on gure 6.

Figure 6 - Connection diagram un-vented systems

1) Manual gas valve

2) Stop valve

3) Expansion vessel

4) T&P safety valve

5) Non return valve

6) Circulation pump

7) Drain valve

8) Pressure reducing valve

9) Expansion valve

A) Gas supply

B) Hot water delivery

C) Cold water inlet

D) Hot water taps

E) Return circulation

12

2.1.3 Gas connection

The gas supply to this appliance must be installed in

accordance with BS 6891 and IGE/ UP/1,1A and 2.

Fit the 1/2” manual gas shut off valve, supplied with this

unit, immediately before the gas control valve. No heat

or soldered joints must be applied in the vicinity of the

gas control valve, as this could cause damage to the

control. All connections and joints must be tested for gas

soundness.

2.1.4 Draught diverter

The draught diverter, supplied separately in the delivery

crate, MUST be tted to the top of the heater in an

unmodied condition before connecting the ue system.

The sensor of the combustion products discharge safety

device is pre-tted to the draught diverter so care must be

taken not to damage the capillary and thermostat. With

the sensor facing forward, place the draught diverter over

the ue tube and make sure the three legs engage with

the slots in the top casing.

To complete the installation of the combustion products

discharge safety device, remove the two screws from the

top casing, position the bracket with the pre-assembled

thermostat over the holes and re-apply screws.

Complete the electrical circuit by connecting the two-pin

plug to its appropriate socket on the top casing. If the

safety device operates, the heater will shut down and only

restart when the temperature of the sensor has dropped

sufciently for the button on the thermostat to be reset.

Important

The combustion products discharge safety device must

never be put out of operation.

Re-entry of ue gases to the building could be harmful

and cause poisoning or death.

2.1.5 Flue system

The water heater must be tted with a ue system

connected to the draught diverter. The ue pipe must rise

for at least 50 cm. vertically before the inclusion of any

bends. If a horizontal run of ue is required this must be

kept to the minimum length possible and incorporate a

rise of 6 cm. per metre of run.

The ue system must be self-supporting and incorporate

a removable section close to the heater to enable the

diverter and ue gas bafe to be removed for cleaning.

The materials used for the ue system must be non-

combustible, mechanically robust and resistant to internal

and external corrosion. Combustible materials in the

vicinity of the heater and ue shall not exceed 65°C

during heater operation. The ue shall not be closer

than 50 mm to any combustible material, except where

it passes through such material with a non-combustible

sleeve when the air gap may not be less than 25 mm.

All ues must terminate in free air space approx.

1,5 metres from any vertical surface of structure i.e.

chimneystacks, roof parapets, etc. If an existing chimney

or ue is to be used this must be swept clean and be

free of debris before an approved liner is installed and

connected to the water heater.

2.1.6 Electrical connection

An accredited electrical installation company must carry

out all electrical connections in accordance with IEE

regulations. The appliance must be connected to the

mains by means of a permanent electrical connection.

A Fused isolator must be tted between the permanent

connection and the water heater. The cable must have

3 cores of at least 1.0 mm

for the electrical supply are indicated by the symbol for

earth, N for neutral and L for live. Always check with a

voltage tester that the live and the neutral have been

connected correctly in the electrical supply. The electrical

supply must comply with the requirements below:

Electrical supply Frequency Fuse

230 V AC 50 Hz 5 A

The maximum power consumption is 25 W.

See appendix 1 electrical diagram for more information.

2

. The connecting terminals

2.2 Commissioning

Filling the water heater

1. Close the drain valve.

2. Open the cold-water stop valve to the water heater

and open all taps where hot water can be drained to

remove air. The water heater is lled as soon as cold

water ows from all taps.

3. Close all hot water taps.

Putting into operation

1. Check to see if the heater is lled with water

by running a little to waste from a hot water tap

connected to the system.

2. Make sure that the ON/OFF switch is in OFF position.

3. Make sure gas supply is fully purged of air and turn on

manual gas valve.

4. Switch the mains isolator to ‘ON’. Make sure that

power is correctly supplied to the unit. Use a voltage

tester to check that the live is to “L” and neutral to “N”.

(Flame detection is phase sensitive).

5. When rst starting, the controller can be in the ‘lock

out’ condition: depress the reset button to free the

control. (After manual reset, an extended pre-purge/

waiting time will occur).

6. Switch the ON/OFF switch into ON position. If the pilot

fails to ignite within 25 seconds the controls will go

to lock out and the reset button will need to be reset

(wait 15 seconds before attempting reset). It may be

necessary to repeat the lighting sequence a number

of times if all the air has not been purged from the gas

supply.

7. The main burner pressure must be checked once the

heater has operated for 10 to 20 minutes (see 2.4).

8. Set the temperature regulator to the required setting

(60°C is maximum recommended).

Note: If, during normal use, the reset button is

pressed, the gas valves will close and the automatic

ignition controller will start a new sequence after the

reset button is released.

Shut down

Note: The water heater must only be turned off when

hot water will not be required for an extended period (e.g.

holidays); otherwise it must be left on.

To shut down put the ON/OFF switch into OFF position.

13

2.3 Removing and replacing the control

panel front cover

Removing the cover (see gure 7)

1. Remove the screw at the top centre of the control

panel.

2. Push the cover upwards until the hooks at the lower

end clear the burner access opening and base tray.

3. Pull the lower end of the cover slightly forward.

4. Pull the cover down until the top edge is clear of the

control panel and then remove.

Replacing the cover (see gure 7)

1. Place the top of the cover inside the rim of the control

panel and push it up as far as possible.

2. Position the bottom hooks inside the burner access

opening and over the rim of the base tray.

3. Push the cover downwards until the lower hooks

engage and the top screw holes align.

4. Replace the screw in the top centre of the cover.

2.4 Setting the gas pressure

The gas pressure has been set to the correct value at the

factory but it must be checked again at commissioning

and during the once a year and every year maintenance

by adopting the following procedure:

1. Shut down the heater by switching the ON/OFF switch

to OFF.

2. If the control panel front cover is in place, remove it

(see 2.3).

3. Locate the lower pressure test point at the right hand

rear of the gas control valve. Loosen the screw a turn

and connect a manometer to measure the burner

pressure.

4. Switch the heater ‘ON’ and allow the burner to ignite

and stabilize.

5. Check the burner pressure for the gas being red,

against the requirement on the data plate or see

1.3.2. If necessary, reset the pressure by means of

the burner pressure adjusting screw located under

the metal cover screw adjacent to the pressure test

points. Turning it anti-clockwise reduces burner

pressure. Turning it clockwise increases burner

pressure.

6. Shut down the heater, remove the manometer,

tighten the pressure test point screw, and replace the

adjustment screw cover and the control panel front

cover.

7. Restart the heater.

Figure 7 - Removing and replacing the control panel

front cover

14

2.5 Temperature regulation

With the system operational, the amount of cold water that

is added is equal to the amount of hot water used. The gas

control valve automatically regulates the gas supply. The

main burner will ignite as soon as the thermostat senses a

reduction in water temperature. The main burner will shut

down as soon as the preset temperature is achieved. At

high water temperatures there is more scale build-up in the

heater. It is recommended therefore, that the thermostat is

set no higher than 60°C as the accumulation of scale will

be minimised.

2.6 Converting to another type of gas

Must conversion of the heater from natural gas to LPG

or vice versa be required, it must only be carried out by

a qualied competent person and only items from the

approved conversion kit must be used.

It will be necessary for the main and pilot injectors to be

changed to those sized for the gas to be red and for the

burner pressure to be adjusted (see 1.3.2).

Adopt the following procedure:

1. Turn the heater off. Close the manual gas shut off valve

and switch off the electrical supply at the local isolator.

2. Remove the burner assembly (see 2.8.2).

3. Replace the injectors with the correct injectors from

the conversion set.

4. Set the correct burner pressure for the gas to be red,

see sections 1.3.2 & 2.4.

For conversion from natural gas to LPG, the burner

pressure adjusting screw on the gas control valve

must be screwed in clockwise as far as it will go.

For conversion from LPG to natural gas, the burner

pressure adjusting screw must be backed off anticlockwise until the correct burner pressure is obtained.

2.7 Maintenance

Important: Due to the variable chemical nature of

distributed water supplies, it is recommended that, in

addition to the once a year and every year internal

inspection and cleaning, this heater is inspected for scale

deposition and anode loss within a maximum of three

months following initial commissioning and the frequency of

subsequent inspections adjusted accordingly.

Failure to install in accordance with the relevant Hamworthy

Heating Installers Guides and to carry out the above

recommendations may compromise appliance warranties.

Regular once a year and every year maintenance by a

qualied competent person is recommended. Although

cleaning of the ue is not necessary every year, it is

important that all controls and safety features are checked

for correct operation.

WARNING: Before proceeding with any maintenance,

isolate the electrical supply to the heater being serviced

and turn off the manual gas shut-off valve.

2.7.1 Sacricial anode

Note: On no account remove the magnesium anode

without checking to make sure that the heater is fully

isolated and the pressure removed.

1. Close the stop valve in the cold water supply pipe.

2. Open the nearest hot water tap in order to allow the

pressure to drop from the water heater and the pipes.

Run a hose to a convenient drain and open the drain

valve. Either drain sufcient water to enable the anode

to be removed or completely drain the heater if an

internal inspection is to be carried out.

3. The heater is tted with a single magnesium anode

that hangs vertically within the vessel and is located

behind the cold-water inlet. Release and unscrew

the anode with a suitable socket (27mm A/F) and

withdraw.

4. Check the anode and if it has been reduced

in diameter by 60% or more at any point on its

length it must be replaced. Always replace with an

anode of the correct size and type. When ordering

replacements always quote model and serial

numbers.

It is recommended that Permabond A131 WRAS

approved sealant or equivalent must be used to seal

the anode into the tank.

The anode must be in direct metal-to-metal contact

with the heater tank to protect it. It is therefore

recommended that electrical continuity between tank

and anode be checked with an appropriate instrument

immediately following replacement.

5. Check for water leaks.

2.7.2 Cleaning

WARNING: some of these items will be hot if the heater

has been ring immediately prior to disassembly.

1. Remove the control panel front cover, see section 2.3

and the inner front panel, see section 2.5,

2. Disconnect the gas burner feed pipe, the pilot burner

feed pipe and the two electrical cables (HT and ame

probe) from the gas control valve.

3. Remove the complete burner assembly.

4. Clean the burner with a soft brush.

5. Check the pilot burner, ignition electrode and ame

probe. Clean or replace as necessary.

6. Disconnect the ue adjacent to the draught diverter

(a maintenance joint must have been provided for

this purpose) and remove the draught diverter taking

care to disconnect the combustion products discharge

safety device. Withdraw the ue bafe vertically.

Check the combustion chamber, ue tube and ue

bafe and clean as required.

7. Re-assemble in the reverse order and check the

operation. If necessary the burner pressure must be

reset.

2.7.3 Inspection of the internal waterside

surfaces

Make sure the heater is fully empty. Remove the outer

inspection cover (two self tapping screws), the insulation

pad and clean out the door complete with sealing gasket (6

bolts ,13 mm socket). If deposits are apparent, they can be

ushed through the drain by a water jet applied through the

clean out opening.

The tank can also be chemically cleaned but it is advised

that a reputable chemical cleaning company carries this out.

15

Note: Do not use a metal scraper to remove deposits.

You will damage the glass lining.

After cleaning, replace the clean out door with new gasket

if required. Rell heater and check for leaks.

Note: The maintenance of the waterside of the system

may require additional cleaning and disinfecting before

being placed into service. Refer to BS 6700.

6. Make sure the manual gas shut off valve is open.

7. Switch the mains electricity supply to the heater ON.

Set the on/off switch on the heater to ON (1) and

adjust the control thermostat to the desired setting.

8. If the ignition controller rest button is illuminated, wait

30 seconds before pressing the reset button.

9. The heater will now light if heat is required.

2.7.4 Spare parts

To be able to order spare parts it is important to note the

model number of the heater as well as the serial number.

Based on this information the detailed spare parts can be

determined.

2.8 Condensation

If the appliance is lled with cold water or if the hot

water consumption is very high, condensation of ue

gases will occur on the cold surfaces of the combustion

chamber and the ue tube. The water droplets will fall on

the burner and cause a sizzling noise. This is a normal

phenomenon that will disappear as soon as the heater

reaches its normal operating temperature.

2.9 Important warning

The heater must never be placed into operation with a

closed cold water supply! Provision must always be made

for expansion.

3. FOR THE USER

3.1 Instructions for use

If the safety thermostat or the combustion-products

discharge safety-device operates and shuts down the

heater, nd the cause of the fault before you press

the reset button. If in doubt, contact your installer or

Hamworthy Heating Ltd. for advice.

Operation

The gas control valve automatically regulates the gas

supply. The main burner will ignite as soon as the

thermostat senses a reduction in water temperature.

The main burner will shut down as soon as the preset

temperature is achieved. At high water temperatures there

is more scale build-up in the heater. It is recommended

therefore, that the thermostat is set no higher than 60 °C

as the accumulation of scale will be minimised.

Shutting down the heater

To shut the heater off for short periods (i.e. 2 – 3 days),

turn the heater control thermostat to minimum. Wait 2 to 3

minutes and switch the on/off switch to OFF. To switch the

heater off for longer periods, repeat the above and turn

both the local electrical isolator and the manual gas shut

off valve to OFF. Depending on the weather conditions

likely to prevail during the shutdown period, consideration

must also be given to completely draining the heater.

The manual gas shut off valve must not be used except

in emergencies, for long periods of shutdown or during

servicing.

Note: Refer to the data label to conrm for which gas the

heater is adjusted.

Warning: All installations MUST conform to the

relevant Gas Safety and Building Regulations. It is law

that competent persons in accordance with the above

regulations install all gas appliances.

The electrical supply to the heater MUST be switched

OFF before attempting service or maintenance.

This appliance MUST be suitably earthed.

Filling the water heater

1. Close the drain valve.

2. Open the cold water valve to the water heater and

open all hot water taps. The water heater is lled as

soon as cold water ows from all taps.

3. Close all hot water taps.

Lighting instructions

1. Check that the heater is full of water by ensuring water

ows at constant pressure from a hot tap connected to

the heater system.

2. Switch the mains electricity supply to the heater OFF.

3. Turn the heater thermostat to the lowest setting.

4. Press the safety thermostat reset button rmly to

make sure it is reset.

5. Press the combustion products discharge safety

device reset button rmly to make sure it is reset.

Additional safety advice

1. Do not block or obstruct ventilation grilles.

2. If at any time a gas leak is suspected, turn OFF gas

supply – DO NOT use a naked ame – DO NOT use

electrical switches, alarms or lights – DO open

windows – contact your nearest Gas Conveyor ofce

immediately. Generally their telephone number can be

located under GAS in your telephone directory.

3. If you consider the heater to be malfunctioning, turn it

OFF and seek expert advice.

4. To make sure safe and efcient operation at all times,

it is essential that the heater be serviced regularly.

Contact your installer or Hamworthy Heating Ltd for

advice.

16

3.2 Fault nding

Fault Possible Cause Corrective Action

Heater is off or does Control thermostat satised None – heater will light up when

not ignite hot water temperature drops.

No electrical power Make sure electrical supply is

turned on at local isolator and heater on/off

switch. Check 230v supply is present

at the heater.

No gas Make sure all manual gas valves between meter

and heater are turned on fully. Check gas

pressure at the heater.

Burner ignition controller is in lock-out Press the illuminated reset button on

the control panel. If repeated lock-out occurs,

expert investigation is required

Safety thermostat has operated Investigate the cause (control thermostat

set too high, out of calibration or not working,

water circulation incorrect) and rectify before

pressing reset button on control panel

Combustion products discharge Investigate the cause (blocked ue, incorrect

safety device has operated ue, wind conditions, incorrect ventilation)

and rectify before pressing reset button on the

ue thermostat.

Insufcient hot water Temperature set too low Increase control thermostat setting

to higher value (recommended 60°C maximum)

Hot water usage greater Reduce hot water usage and allow time

than heater output for heater to fully recover to set temperature.

Water circulation system Investigate the cause (pump failure, air lock,

not operating correctly pipe blockage) and rectify. If cause not identied,

seek expert advice.

Noisy Ignition Incorrect gas supply pressure Check and set correct pressures

and/or poor ame shape or burner pressure

Dirty pilot and/or main injectors Clean injectors

Water leakage Condensation of ue gases Allow temperature in heater to increase

(see 2.11)

Local pipe work leaking Carefully investigate cause and rectify

Nearby appliance leaking by repair or replacement.

Groundwater seeping

Water heater leaking

17

APPENDIX 1

Connection diagram Dorchester DR-SA 16 & 19

= brown

1

= blue

2

= yellow/green

3

= black

4

= white

5

= red

6

A = Ignition controller

B = ON/OFF switch

C = Pilot burner

D = Spark electrode

E = Flame probe

G = Combustion products

discharge safety device

H = Control thermostat

K = Safety thermostat

M = Reset button

N = Terminal block

P = Terminal block

R = Earth terminals

S = Connector to ignition controller

T = Gas control valve

U = Mains terminal block

V = Tank earth

W = Casing earth

X = Control panel base plate earth

0308 236 R3

Loading...

Loading...