Hammond Power Solutions RM Series General Product Line Information

SECTION 3 LINE REACTORS

The RM Line Reactor . . .

CORE

The quality and performance of a line reactor is

fundamentally dependant on its ability to withstand

harmonics and transients in what is clearly a difcult

environment. The bonding and clamping techniques

of the gapped core also signicantly impacts its

performance characteristics.

HPS has paid particular attention to these

basics to ensure both reliable and consistent

performance.

Core materials, manufacturing and assembly

processes have been carefully evaluated to produce

optimum losses and sound levels necessary for this

product.

COILS

Conductors are

precision wound for

optimum short

circuit withstandability

and electrical balance

are used throughout

the RM line. Choice

of conductors, winding

techniques and cooling

ducts are precisely

selected to assure the

highest continuous,

reliable performance.

INSULATION

SYSTEM

permissible continuous ambient temperature of

60°C. These temperature tests are all measured at

150% rated 60 Hz current. For further information on

temperature rises, please consult our sales ofces.

VPI IMPREGNATION

Every reactor is fully VPI vacuum and pressure

processed with VT (vinyl-toluene) Polyester Resin.

This modern, vinyl-toluene based resin with its

thicker build, offers signicant benets for electrical,

mechanical and thermal properties.

This impregnation process and material results

in a much improved dielectric constant, dissipation

factor, bonding

strength and dielectric

breakdown (volts per

mil) than any other

impregnation material

including the more

traditional oil modied

epoxies and varnishes.

Vacuum

impregnation is

considered vital for the

integrity of electrical

equipment located

in such sensitive

locations. The core

and coil assembly is

nished with a clear

resin.

TERMINATIONS

SECTION 3

HPS Line Reactors are designed to meet the

most difcult temperature environments. On units

up to 160 amps, RM line reactors have a 115°C

temperature rise designed for 200°C Insulation

Class. This results in a permissible 24 hour

maximum ambient of 50°C and an average of 40°C

continuously.

On units larger than 160 amps, Class 220

Insulation is used throughout with a maximum

© Hammond Power Solutions Inc.

Custom connections are provided for in several

ways. Finger-proof-terminal blocks are provided on

three model ranges, and terminal pads are supplied

on higher current ratings. Refer to the dimensional

summary for details. All connections are brazed to

ensure electrical integrity.

93

Data subject to change without notice.

SECTION 3

. . . Features of Construction

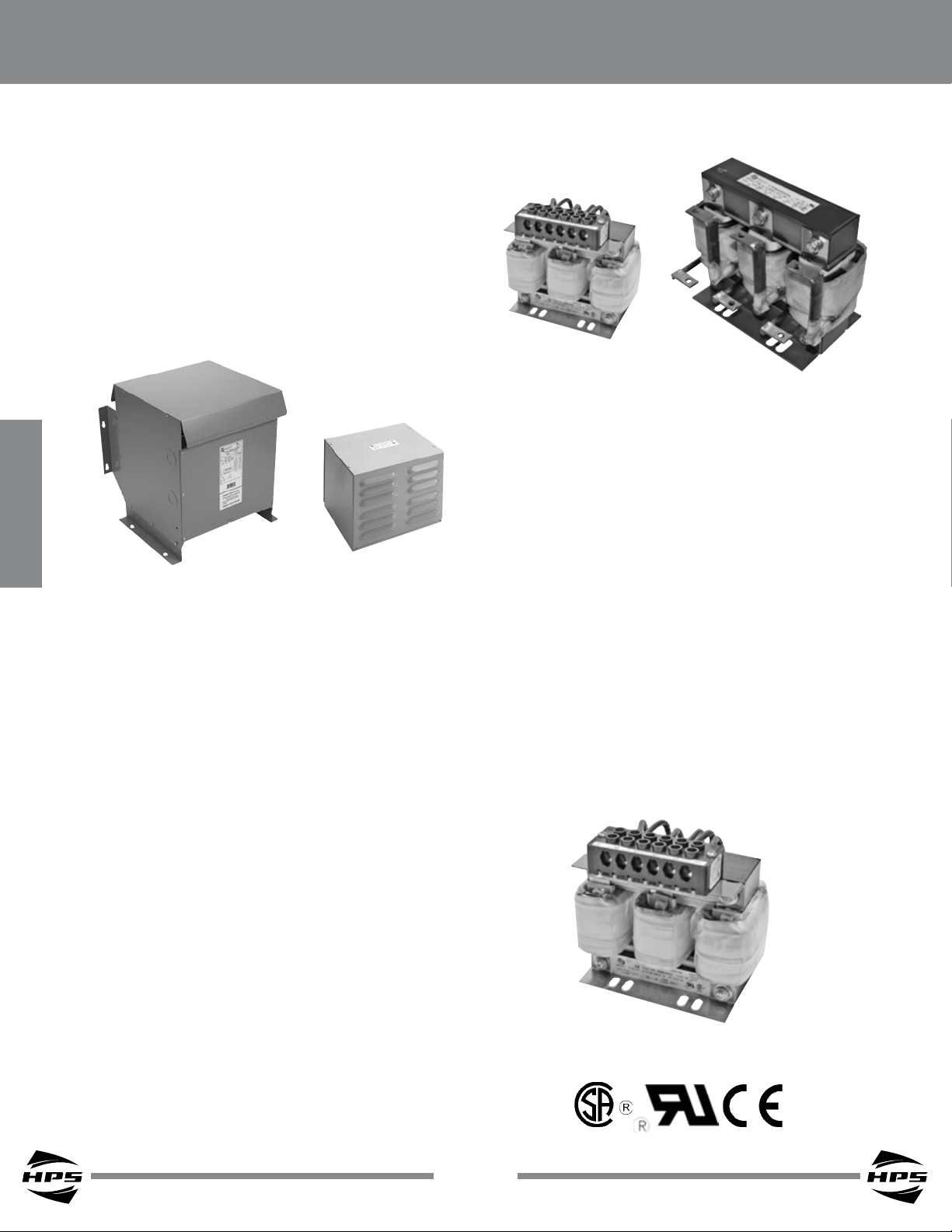

ENCLOSURES

Enclosed reactors are standard as either NEMA

2 or 3R. Units in NEMA 3R enclosures are suitable

for oor or wall mounting. Wall mounting is available

on NEMA 3R units up to 600 lbs. Please consult

customer service for details.

Enclosures are nished with a 7 stage

phosphate process with baked enamel ANSI 61 grey.

RM SERIES

This approval is inclusive to 2000 amps and 8.6

kV class, and may be of interest for any special

applications.

Our products are built in accordance with

and meet UL 508, UL 506 and CSA C22.2 NO.66

standards.

SECTION 3

QUALITY CONTROL

Every reactor is production line tested in

accordance with the requirements for UL, ANSI,

NEMA and CSA. This conrms that every unit meets

our highest expectations for Quality Assurance.

Additionally, line reactors have been short

circuit tested at a certied laboratory to conrm the

withstandability of our reactors to short circuits that

may be present in a distribution system. Tests were

done in accordance with ANSI C57.12.91 at 25 times

rated current for 2 seconds. Those test results are

available upon request successfully withstanding

this test ensured that the RM line reactor will survive

power stresses such as short circuits that may be

present in a distribution circuit.

UL and CSA CERTIFICATION

INPUT AND OUTPUT SIDE REACTORS

HPS three phase Line Reactors are designed

for both the input and output side of variable speed

drives including Insulated Gate Bipolar Transistor

(IGBT) type inverters.

SPECIALS

For special applications or for any features that

you may require beyond the standard line listed,

please contact our sales ofces.

A vital assurance for our customers is the

approval of this product line to national standards.

Our open and enclosed style reactors are

recognized by UL and certied by CSA as follows:

UL File No.: E61431

CSA File No.: LR3902

© Hammond Power Solutions Inc.

94

Data subject to change without notice.

Loading...

Loading...