Page 1

INSTALLATION, OPERATION AND MAINTENANCE GUIDE

FOR INDOOR/OUTDOOR DRY-TYPE TRANSFORMERS

FOR INDOOR/OUTDOOR DRY-TYPE TRANSFORMERS

WHICH UTILIZE A NH SERIES, NJ1, NJ2, NJ3 OR NJ4 ENCLOSURE

WHICH UTILIZE A NH SERIES, NJ1, NJ2, NJ3 OR NJ4 ENCLOSURE

*Note: This guide is Trilingual

(English, French and Spanish)*

Literature No.: IOMGDDI

Issue Date: May 2010

Page 2

Safety Precautions

(1) Do not lift or move a transformer without proper equipment and experienced personnel. On

some larger kVA distribution transformers, lifting provisions are provided on the inside of the

enclosure on the core & coil.

(2) Do not off-load the transformer until a full inspection has been completed.

(3) Use terminals only for electrical connections. Flexible connectors are recommended for bus

connections. The transformer terminals are not designed to support the weight of supply or load

cables. Uni-strut supports can be added in the eld providing proper clearances are maintained.

(4) Connections should only be in accordance with the nameplate diagram or connection drawings.

(5) Make sure all power is disconnected before attempting any work on a transformer or inside of

control box and ground all windings.

(6) Make certain all ground connections, line terminals and selected taps are complete and tighened

before energizing the transformer.

(7) Do not attempt to change any taps - primary or secondary, while the transformer is energized.

(8) Do not change connections when the transformer is energized.

(9) Do not tamper with control panels, alarms, interlocks or control circuits.

(10) Do not adjust or remove any accessories or cover plates while the transformer is energized.

No supply cables should come in contact with the core or any live part except the terminal that it

is intende for.

CONTENTS

General 3

Handling 3

Receiving & Inspection 3

Storage 3

Installation 3

Ventilation 4

Accessibility 4

Transformer Sound Levels 4

Cable Connections 4

Grounding 5

Inspection Before Energization 5

Operation 5

Maintenance 6

Dry-out of Transformers 6

Accessories 6

Appendix A 7

Appendix B 8

Figure 1 9

Figure 2 10

Figure 3 11

Notes 12

- 2 -

Page 3

INSTALLATION, OPERATION AND MAINTENANCE

OF DRY-TYPE TRANSFORMERS

GENERAL

Dry-type transformers are manufactured to

provide optimum performance for a lifetime of

uninterrupted service. Careful attention to the following

instructions is recommended for safe and reliable

operation.

Installation, operation and maintenance of

transformers should be performed by authorized

persons, familiar with electrical apparatus and the

potential hazards involved.

Warning: Danger! There is the potential of

electric shock whenever working in or

around electrical equipment such as

transformers. Power must be shut off

before any work is conducted on a

transformer.

As with any electrical device, transformers must

be installed according to the requirements of the

national and local electrical codes. Refer to ANSI/IEEE

C57-94 may also be referred to for recommended

installation, application, operation and maintenance of

dry-type transformers.

HANDLING

Transformers are palletized and can either be

lifted via a forklift truck or hoisted by the lifting lugs

provided.

Appropriate lifting equipment should be used

relative to the size of each transformer. For safety

purposes and to protect the transformer, spreader bars

are recommended.

No attempt should be made to lift or move a

transformer from any points on the unit other than

those indicated. Refer to Figures 1 and 2 (pages 9 and

10).

RECEIVING & INSPECTION

Immediately after receiving the transformer, it

should be inspected for any transit damage and for

correctness against the shipping documents.

The unit should be examined for any breaks in its

packaging, dented or damaged enclosures or missing

parts from the packing list.

If any damage is noted, a claim should be led

immediately with the carrier and a second copy of all

pertinent information relative to the order and the

circumstances should be led with the local sales

ofce.

If this examination of the unit takes place

outdoors, caution should be exercised such that

inclement weather would not present further hazard.

STORAGE

Transformers that will not be immediately

installed and energized, should be stored in a clean

dry environment away from any environmental

airborne contaminants.

It is recommended that transformers be stored in

a heated building with the protective plastic wrap still

installed.

INSTALLATION

Enclosures are designed and approved

in accordance with specications

CSA 22.2 No. 47 (General Purpose),

CSA 22.2 No. 94 (Specialty Enclosures),

NEMA 250 and UL 50.

For IEC enclosure equivalents please see

IEC 60529 (Enclosure Classications

Designations).

a) Indoor/Outdoor Dry-Type Transformers with

Enclosures

Most dry-type transformers are supplied with

either a type 3R, 4 or 12 enclosure. Units may be

installed indoors, or outdoors where applicable. If

equipped with a type 1 enclosures, these units are for

indoor use only.

Ventilated enclosures are recommended for

indoor installation but may also be installed outdoors

where weather conditions allow a type 3R ventilated

enclosure to be installed.

For any outdoor location, the appropriate

applicable codes must be followed including cable

installation and hardware suitable for outdoor service.

Water tight couplings must be used at the

knockouts and any holes in the enclosure must be

drilled below any un-insulated live parts, (below LV

terminals).

Dry-type transformers may be located in an

upright position on walls, oors, posts, beams or other

- 3 -

Page 4

locations capable of supporting their weight with the

proper accessories attached. Refer to Appendix B

(page 8) for wall mounting kits.

Conventional open ventilated dry-type

transformers have a bottom screen for air convection.

When transformers are mounted above the ground

surface a catcher plate should be installed under each

transformer as a safety precaution against any hot

particles that may fall through the screen in the event

of a faulted condition. Refer to Appendix B (page 8).

It is important that ventilated transformers be

installed in a dry area where the ambient air is clean

and free of dust, dirt, corrosive fumes, moisture, heat

or other adverse conditions. Transformers should not

be installed in such a place having the possibility of

water logging inside the enclosure.

In the event that a transformer has been

subjected to moisture or dampness before installation,

ensure that it is completely cleaned and dried before

energization. The blowing of warmed air through the

transformer is recommended to dry internal

components. Refer to the section on dry-out of

transformers.

b) Indoor/Outdoor Transformers with Non-

Ventilated Type 4, 4X or 12 Enclosures.

However, transformers should not be located in

areas where stored items are likely to interfere with

either natural air convection or the capability to have

them inspected. Passage ways or other areas where

people could be exposed to live parts during

inspection should also be avoided.

Adequate protection should be provided under

any circumstances.

TRANSFORMER SOUND LEVELS

Transformers are an electrically energized

apparatus and by their nature emit sound due to their

component materials.

Transformers are required to meet NEMA

standards for the maximum sound levels permissible.

These sound level standards vary from 40 to 60 DB

and hence, can be an annoyance if located in close

proximity to where people work or reside.

Care should therefore be exercised in selecting

sites for transformers particularly to avoid sensitive

areas like hospitals, classrooms, medical or ofce

facilities.

The following guidelines may be helpful:

Transformers equipped with non-ventilated type

4, 4X or 12 enclosures maybe located either indoors or

outdoors in any similar location noted above. Nonventilated enclosed transformers, although slightly

larger, offer much greater protection against a variety

of elements such as dust, dirt, snow, moisture, rain

etc.

For any outdoor location, the appropriate

applicable codes must be followed including cable

installation and hardware suitable for outdoor service.

VENTILATION

Transformers are required to be installed in an

area where they can be cooled by means of the free

circulation of air where the average ambient

temperature is 30°C (86°F) and should not exceed

40°C (104°F) at any time.

Adequate ventilation is essential for transformers

to meet their nameplate kVA capability. All general

purpose transformers should be located away from

walls or any other obstructions (at least 6 inches when

oor mounted and 4 inches when wall mounted) to

allow free, clean circulation of air through the

ventilation openings or around a non-ventilated unit.

ACCESSIBILITY

NEC standards require that transformers be

accessible for inspection and located accordingly.

Units should be mounted away from corners or

reecting walls or ceilings.

Cable or other exible conduit should be

considered to make connections.

All dry-type transformers are provided with

isolation rubber mounts between the core and

coil assembly and the enclosure. However,

sound absorbing vibration isolators may also be

installed between the transformer and its

mounting surface.

Acoustically absorbing materials could be

considered for walls and ceilings around the

unit.

The location of the unit should be located as

far as practical from areas where sound levels

could be considered undesirable.

CABLE CONNECTIONS

The connecting cable size is determined from the

line current rating of the transformers primary and

secondary windings and may be selected from the

information in Appendix A (page 7). Cables rated for at

least 90°C (194°F) is recommended as are ALC9CU

lugs.

Convenient pre-punched knockouts are provided

on all ventilated transformer enclosures up to 150 kVA

- 4 -

Page 5

three phase and 100 kVA single phase, to facilitate

cable entry.

For non-ventilated transformers, pre-punched

knockouts are not provided and the appropriate cable

connector suitable for the application must be used.

Please refer to gures 1 and 2 (pages 9 and 10)

for cable entry locations.

Warning: Never attempt to change connections or taps unless the transformer is

de-energized and all windings grounded.

Side entry of cables is recommended as it leaves

the ventilated areas unobstructed.

Cable connection lugs of plated copper or

aluminum may be used to connect to the transformer

terminals. Terminals should be cleaned and electrical

joint compounds are recommended for use on all

electrical connections.

Refer to the transformer nameplate for primary

and secondary voltage connection combinations and

primary and/or secondary tap positions as applicable.

Transformers received from the factory will have

tap leads installed on the nominal, or 100%, voltage

position. The balance of the tap positions will still be

coated with impregnation material and insulation.

To change taps, it is necessary to remove this

insulation by gently removing the protective coating

from the surface appropriately. The surface of the tap

lead should be clean and coated subsequently with

electrical compound.

NOTE: After installation of cables and

connectors, a minimum of 1” clearance

must be maintained from energized parts

to all case parts.

GROUNDING

secondary and primary to secondary, should be

greater than 10k ohms.

b) Before energizing and connecting any loads,

please measure and verify the output voltage

matches nameplate specications.

c) Ensure correct phase connections. Refer to the

nameplate vector diagram.

d) The load on a delta secondary winding with a 120

volt center tap should not exceed the normal

current rating of the winding. This center tap is

designed for a max. of 5% of the nameplate kVA.

e) When windings are connected in parallel (as in

the case of dual voltage primaries), the primary

taps for all coils must be connected to the

identical percentage tap positions to avoid the

shorting of turns. For tap positions, refer to the

nameplate on the transformer.

f) The enclosure should be grounded with the

appropriately sized conductor.

g) The total load among all the phases should be

balanced as much as possible for optimum

performance of the transformers windings.

Any three phase or single phase load may be

connected to the transformer but the kVA loading

on each phase must not exceed 1/3 of the

nameplate kVA rating.

h) The clearance and tightness of all electrical

connections should be checked.

i) If there is any reason to suspect that the

transformer has been exposed to moisture during

transit or storage, it should be checked for

dryness before energization. This can be done by

making an insulation resistance test. Dry-out

procedures are on page 6.

All core and coil assemblies are solidly grounded

to the enclosure internally to ensure that all conductive

metal parts have the same potential.

The transformer enclosure in turn should also be

securely and effectively grounded as a safety

precaution.

This grounding should be in accordance with

national electrical code standards.

INSPECTION BEFORE ENERGIZATION

For the safe and proper operation of the

transformer, please check and verify the following:

a) The insulation resistance, core to primary, core to

OPERATION

For all relatively normal and clean installations,

dry-type transformers will operate satisfactorily under

normal conditions of energization and load.

For your reference, fully loaded dry-type

transformers may appear warm to the touch,

particularly on the cover of the unit.

Standards permit the temperatures of the cover

to be 65°C (149°F) over ambient. This represents

normal loading and should not be of concern.

Dry-type transformers are designed to operate

continuously at their full nameplate kVA rating.

ANSI C57.96 provides guidance for loading

- 5 -

Page 6

transformers under different conditions including:

Ambient temperatures that are varied from the

ambient temperatures required for transformer

operation.

Short time overload as it relates to time and

temperature and the corresponding loss of life of

the transformer.

Overload that results in a reduction of life

expectancy of the transformer.

If the transformer is experiencing increased

temperatures, the following load characteristics

should be considered immediately:

Rigorous motor starting loads or other impact

type loading for which a specic transformer for

that application is required.

Over-excitation of unit due to excess supply line

voltage or current.

Maintenance would include internal cleaning,

tightening of links and bolted connections, servicing

and inspection of auxiliary devices.

Air ducts should be free of any accumulation of

dust and debris and any bolted connections of

terminals must be in good condition.

Vacuuming or blowing of compressed air from

the top down is an accepted practice for removing dust

from the ducts of a transformer coil. Low pressure, dry

air should be used to avoid further contamination of

the windings by foreign material.

The ground connection should also be checked

to ensure a low impedance connection. The

accumulation of ice, snow or any other object blocking

the ventilation should be cleaned up immediately

during the operation of the transformer.

On outdoor units where filters have been

installed, being exposed to the outside atmosphere

can cause the filters to get dirty quickly. A periodic

check of the filters will help avoid filter clogging and

thus transformer overheating. Also, never run the

transformer without the filters properly in place.

Ambient temperatures above standard.

Overload beyond ANSI C57.96 guidelines.

Harmonic distortions of the supply line voltage

and currents.

If overheating is noted, any attempt to add

supplemental fan cooling must be in accordance with

factory installation guidelines. Incorrectly installed fans

can misdirect the airow and cause serious

deterioration of the insulation life in a transformer coil.

Dry-type transformers can be shut down and

stored for extended periods of time without any

deterioration. Care must be exercised to clean and dry

units prior to energization, as previously outlined.

MAINTENANCE

Under normal operating conditions and

environments, dry-type transformers do not require

maintenance. However, periodic care and inspection is

a good practice particularly dependent on the

environmental conditions in which the unit is installed.

Peripheral inspection and external dust removal

may be carried out while the transformer is in

operation. However, access covers must not be

opened under energized conditions.

Internal maintenance must be performed

with a transformer de-energized, isolated

and with the terminals grounded.

DRY-OUT OF TRANSFORMERS

In the event that transformers have been

exposed to moisture such as condensation or rain, it is

advisable to dry-out any unit prior to energization.

Drying may be accomplished by using any hot or

warmed air, radiant heat or internal heat that is

directed through the windings. Heated air should be

allowed to rise up through the windings for a minimum

of twenty four (24) hours after the evidence of

condensation is no longer visible.

Transformers that have been exposed to ood

conditions, direct rain or sprinklers, may not be able to

be dried out appropriately. Contact the transformer

manufacturer for appropriate action.

ACCESSORIES

Dry-type distribution transformers are available

with a number of accessories to facilitate installation.

Consult your local dealer or distributor for the

purchase of any of the items which may be carried in

inventory.

1) Wall Mounting Brackets

Encapsulated transformers have integral wall

mounting capabilities for units up to 285 lbs. Units over

285 lbs. must be oor mounted only.

Ventilated dry-type transformers are normally

designed to be oor mounted only. However, some

ventilated units up to 51kVA are supplied in enclosures

that have integral wall mounting capabilities. These

units can be conveniently mounted on walls, beams or

- 6 -

Page 7

poles.

Conventional open ventilated dry-type

transformers have a bottom screen for air convection.

When transformers are mounted above the ground

surface a catcher plate should be installed under each

transformer as a safety precaution against any hot

particles that may fall through the screen in the event

of a faulted condition. Refer to Appendix B (page 8).

2) Sound Isolation Pads

APPENDIX A

AMPACITY RATINGS FOR CONNECTIONS

A. For a single phase transformer

Line Amperes = volt-amperes

line volts

B. For a three phase transformer

All dry-type transformers have rubberized sound

absorbing pads mounted internally between the core

and coil assembly and the enclosure.

For maximum absorption of vibration and

emission of sound, additional sound isolation pads are

recommended for installation between the transformer

and the mounting surface.

These molded neoprene and steel plate

assemblies virtually eliminate vibration noise between

the transformer and the mounting surface.

Consult the manufacture’s catalog for the part

number of the correct isolation pad required

3) Connectors

Connectors for the installation of dry-type

transformers are readily available. These connectors

are suitable for either copper or aluminum cable.

Connectors should be sized and installed in

accordance with your local electrical code

requirements using the best practices to ensure safe

and reliable operation. Cable surfaces should be

cleaned and electrical compound should be used for

all joints.

Selecting Connectors

a) Determine the primary current for the required

transformer from the Appendix A.

b) Similarly, determine the secondary current rating

for the transformer from Appendix A.

c) For 120/240 voltage connections the current

should be based on 240 volts.

d) For 240/480 volt connections, the current should

be based on 480 volts.

Line Amperes = volt amperes

3 X line Volts

Full Load Current Table

Single Phase Transformer

Current in Amperes

kVA

Rating 120V 240V 416V 480V 600V

3 25.0 12.5 7.21 6.25 5.00

5 41.6 20.8 12.0 10.4 8.33

7.5 62.5 31.2 18.0 15.6 12.5

10 83.3 41.6 24.0 20.8 16.6

15 125 62.5 36.0 31.2 25.0

25 208 104 60.0 52.0 41.6

37.5 312 156 90.1 78.1 62.5

50 416 208 120 104 83.3

75 625 312 180 156 125

100 833 416 240 208 166

150 1250 625 360 312 250

167 1391 695 401 347 278

250 2083 1041 600 520 416

333 2775 1387 800 693 555

Full Load Current Table

Three Phase Transformer

Current in Amperes

kVA

Rating 208V 240V 380V 416V 480V 600V

2 5.55 4.81 3.03 2.77 2.40 1.92

3 8.32 7.21 4.55 4.16 3.60 2.88

6 16.6 14.4 9.11 8.32 7.21 5.77

9 24.9 21.6 13.6 12.4 10.8 8.66

15 41.6 36.0 22.7 20.8 18.0 14.4

30 83.2 72.1 45.5 41.6 36.0 28.8

45 124 108 68.3 62.4 54.1 43.3

75 208 180 113 104 90.2 72.1

112.5 312 270 170 156 135 108

150 416 360 227 208 180 144

225 624 541 341 312 270 216

300 832 721 455 416 360 288

450 1249 1082 683 624 541 433

500 1387 1202 759 693 601 481

600 1665 1443 911 832 721 577

750 2081 1804 1139 1040 902 721

- 7 -

Page 8

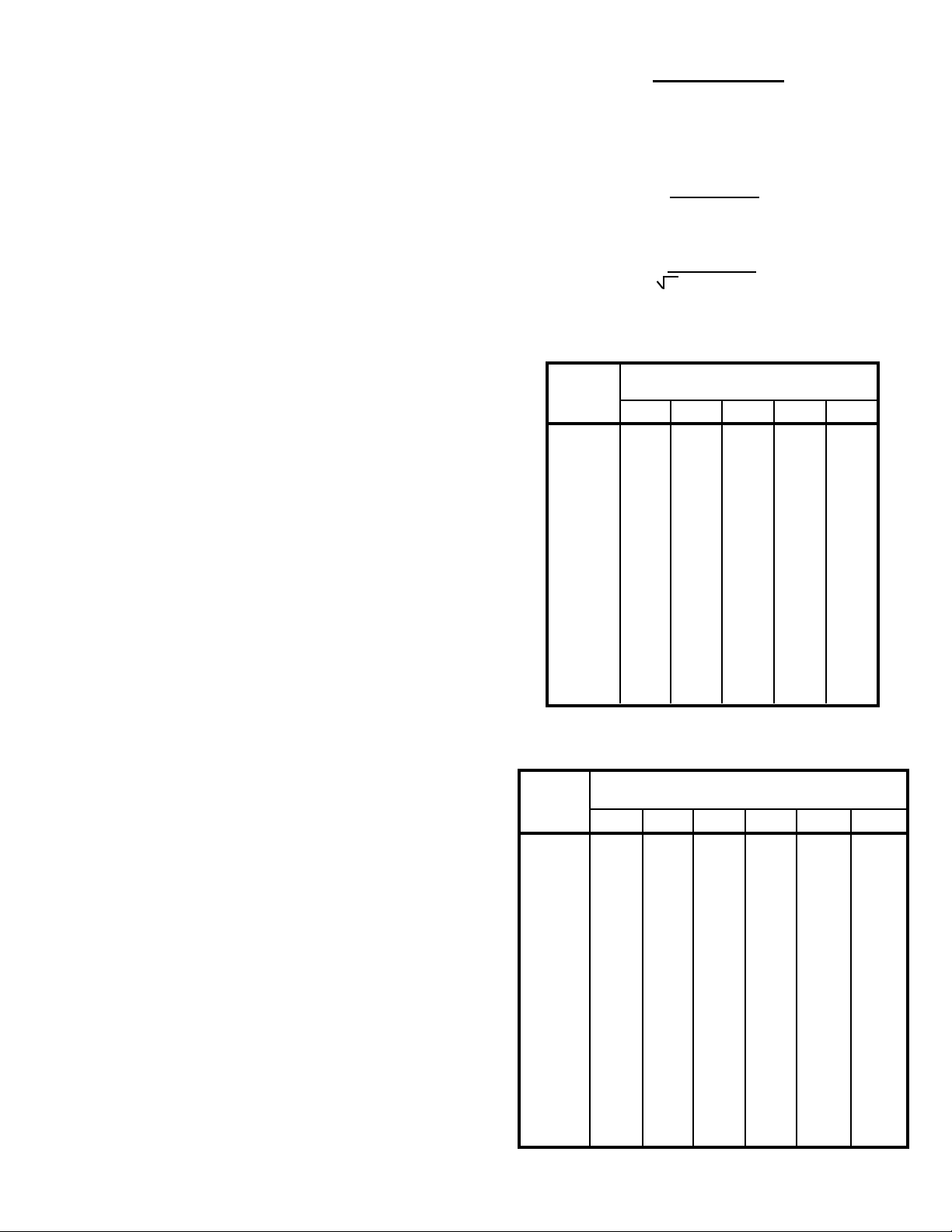

APPENDIX B

LOCATION OF WALL MOUNTING BRACKETS AND CATCHER PLATES

FOR NH3 SERIES TYPE 3R ENCLOSURES

Optional Wall

Mounting Bracket

Catcher Plate

Where Local Code Requires

Catcher Plate

Where Local Code Requires

APPENDIX B

LOCATION OF WALL MOUNTING BRACKETS AND CATCHER PLATES

FOR NH5 & NH6 SERIES TYPE 3R ENCLOSURES

Wall Mounting

Hole Locations

Optional Ceiling

Mounting Bracket

Catcher Plate

Where Local Code Requires

Floor/Ceiling Mounting

Hole Locations

- 8 -

Page 9

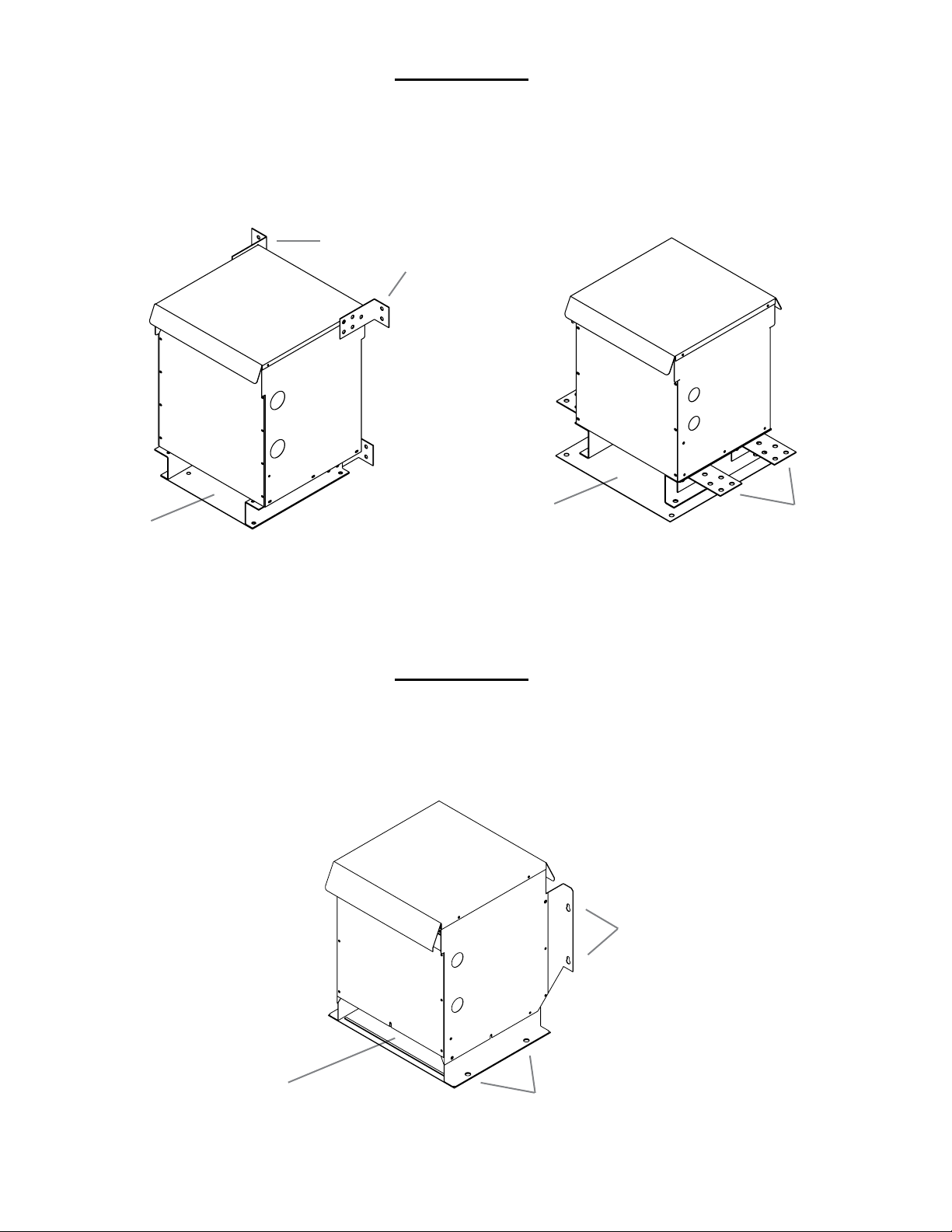

FIGURE 1

Typical Type 3R, NH Series Ventilated Enclosure Assembly for Three Phase and Single

Phase Transformers.

Notes:

Handling - units are designed to be raised by a fork lift from underneath the pallet. Final positioning of the unit 1.

with the pallet removed can be via a fork lift under the transformer with the forks between the channels.

Shipping - units are shipped on pallets which are to be removed at installation. 2.

Installation - This transformer can be installed indoor or outdoor providing a degree of protection against falling 3.

rain, sleet and external ice formation.

All general purpose/drive isolation transformers should be located away from walls or any other obstructions at 4.

least 6 inches when oor mounted and 4 inches when wall mounted.

DO NOT block bottom ventilation area.5.

Removable front

access panel

Position fork

lift under pallet

Cable entrance

knockouts (2 per side)

For nal positioning

with pallet removed,

fork lift points are under

the transformer

- 9 -

Page 10

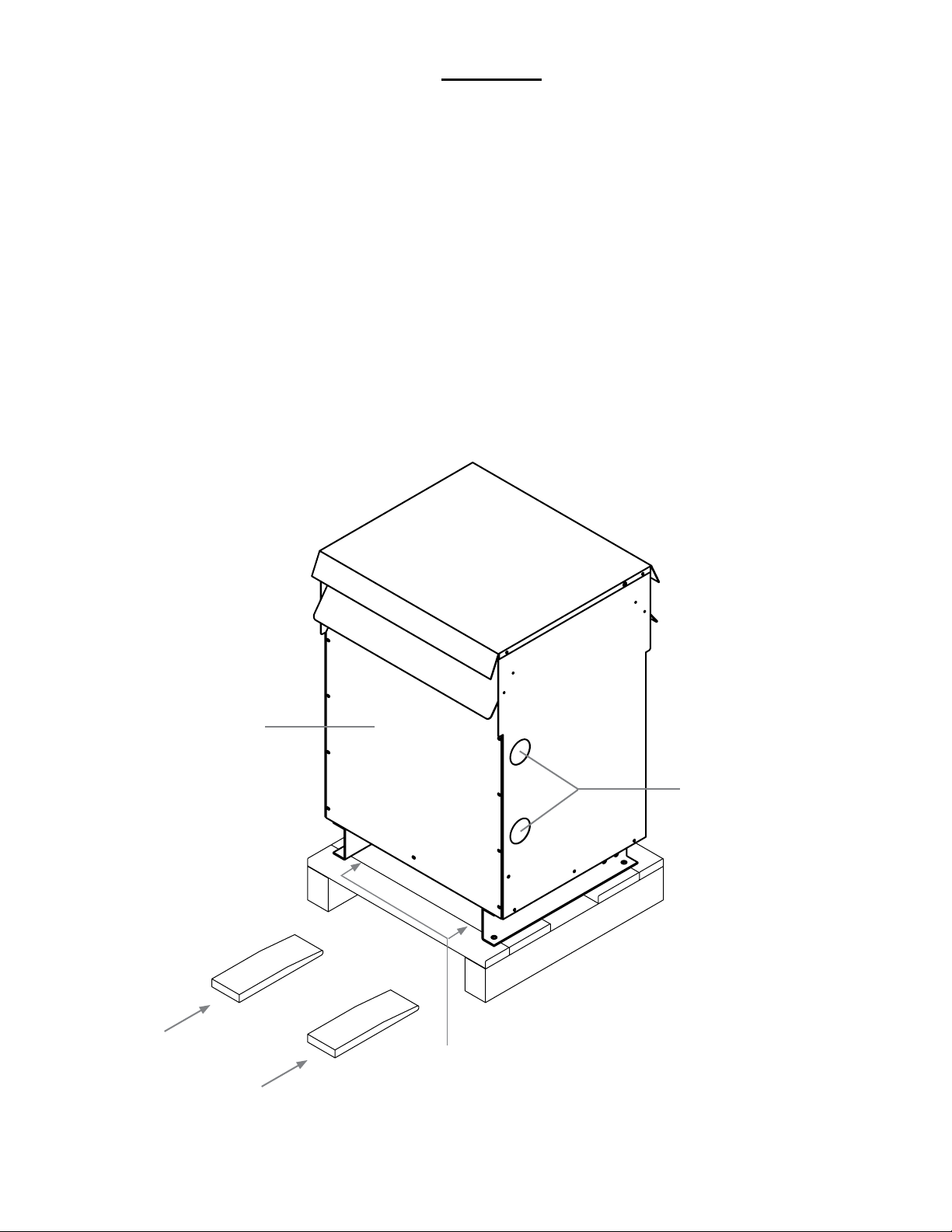

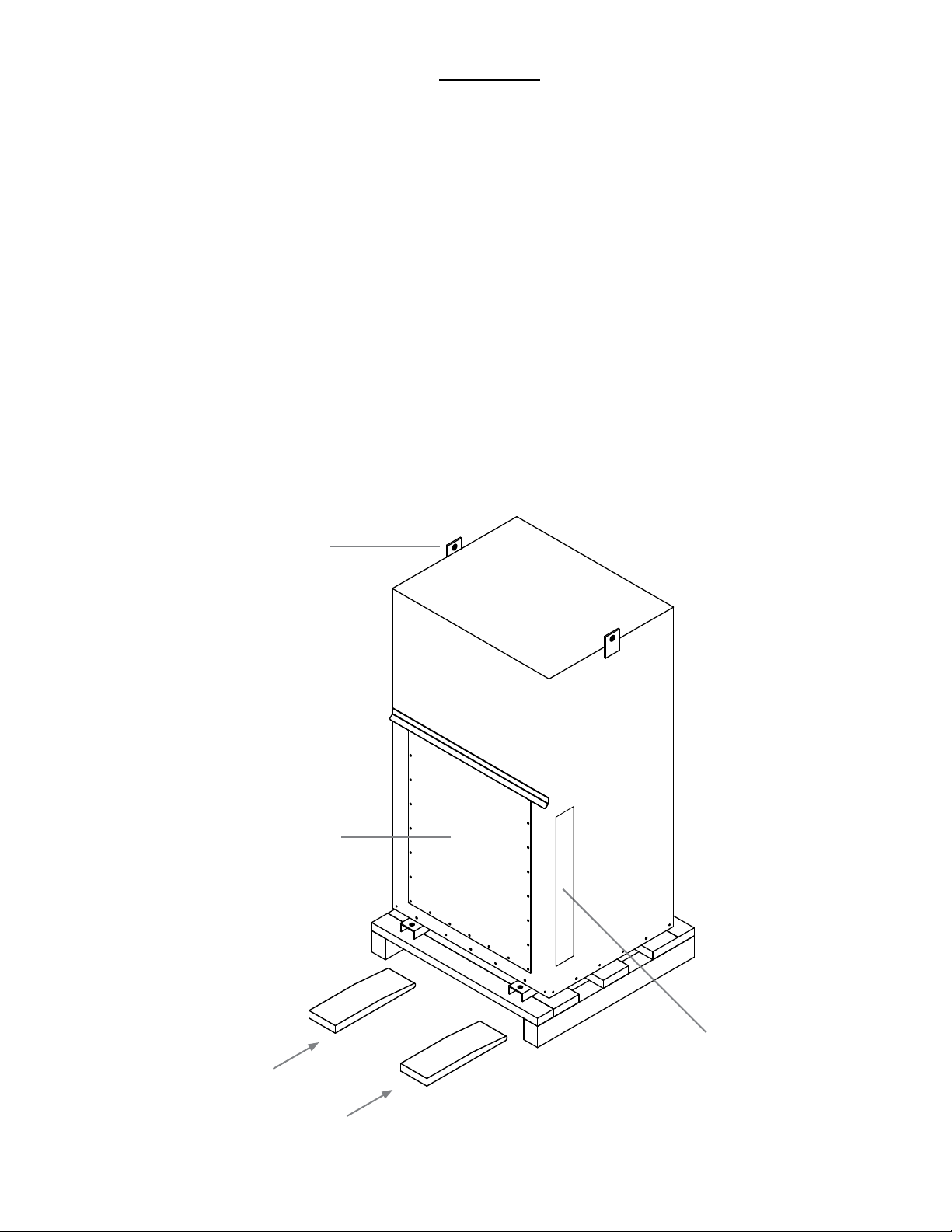

FIGURE 2

Typical Type 3R, NJ Series Ventilated Enclosure Assembly for Three Phase or Single Phase

Transformers.

Notes:

Handling - units are designed to be raised by a fork lift from underneath the pallet. Final positioning of the unit 1.

with the pallet removed can be via a fork lift under the transformer with the forks between the channels. (Note:

for transformers weighing greater than 2350 lbs should be lifted by removing the top panel and

accessing the lifting provisions on top of the top of the core and coil.)

Shipping - units are shipped on pallets which are to be removed at installation. 2.

Installation - This transformer can be installed indoor or outdoor providing a degree of protection against falling 3.

rain, sleet and external ice formation.

All general purpose/drive isolation transformers should be located away from walls or any other obstructions at 4.

least 6 inches when oor mounted and 4 inches when wall mounted. (Note: These enclosures are not intended

to be wall mounted. They may be mounted on a customer supplied platform.)

DO NOT block bottom ventilation area.5.

Removable front

access panel

Position fork

lift under pallet

Recommended cable

entry location (both

sides). Refer to

outline drawing for

exact dimensions.

For nal positioning with pallet

removed, fork lift points are

under the transformer. Forks

must be inserted all the way

through the depth.

- 10 -

Page 11

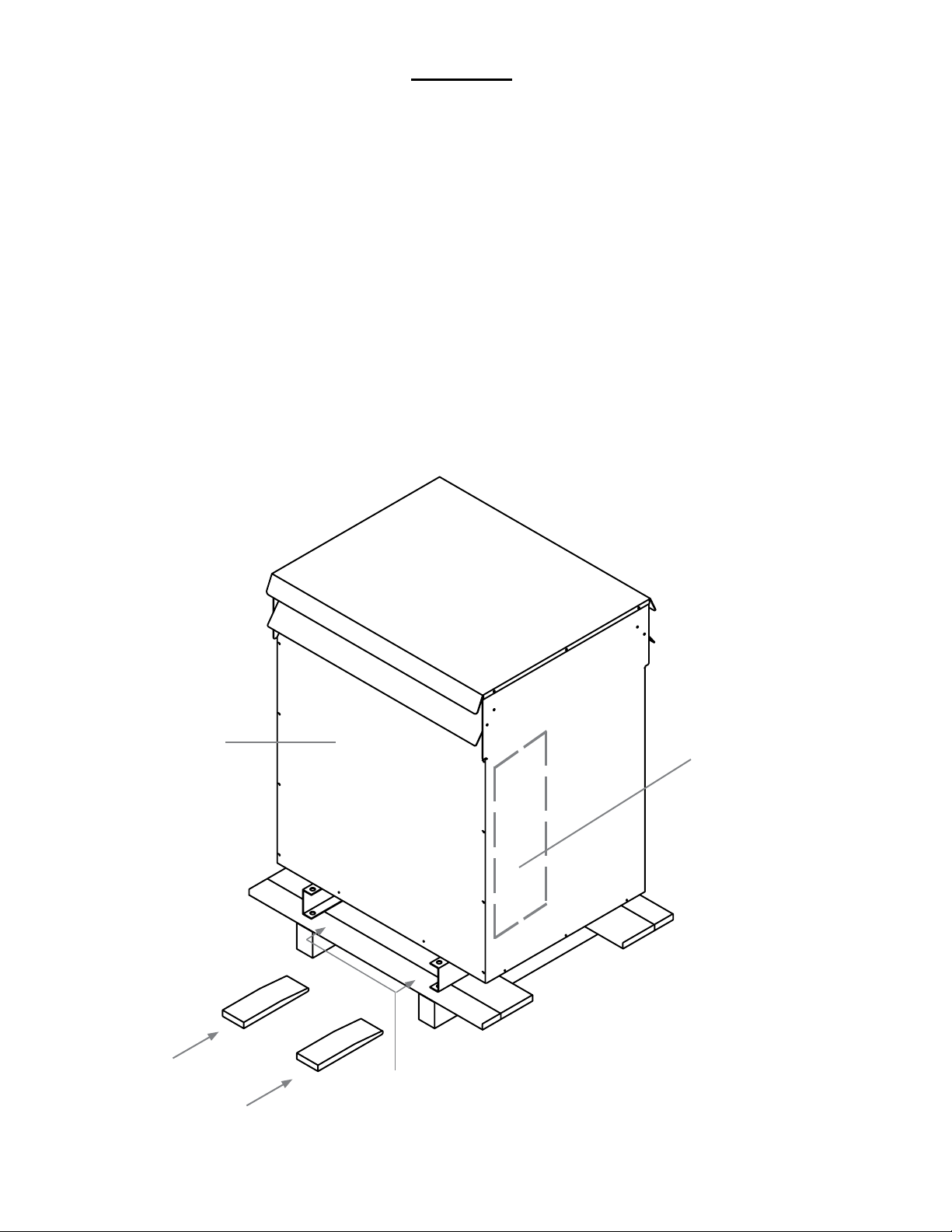

FIGURE 3

Typical Type 4 & 12, NH Series Non-Ventilated Enclosure Assembly for Three Phase or

Single Phase Transformers.

Notes:

Handling - units are designed to be raised by a fork lift from underneath the pallet. Final positioning of the unit 1.

with the pallet removed can be via a fork lift under the transformer with the forks between the channels.

Shipping - units are shipped on pallets which are to be removed at installation. 2.

Installation - This is a non-ventilated indoor or outdoor enclosure designed primarily to provide a degree of 3.

protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, hose-directed water and that will

be undamaged by the external formation of ice on the enclosure. It is suitable in areas where exposure to large

amounts water from any direction is possible. (Note: not submersible)

All general purpose/drive isolation transformers should be located away from walls or any other obstructions at 4.

least 6 inches when oor mounted and 4 inches when wall mounted.

Lifting Hook

Removable front

access panel

Position fork

lift under pallet

Recommended cable entry location

(either side). Refer to outline

drawing for exact dimensions.

- 11 -

Page 12

Notes

Page 13

GUIDE D'INSTALLATION, DE FONCTIONNEMENT ET

D'ENTRETIEN

POUR LES TRANSFORMATEURS A SEC INTÉRIEUR/EXTÉRIEUR

POUR LES TRANSFORMATEURS À SEC INTÉRIEUR/EXTÉRIEUR

UTILISANT UN BOÎTIER DE LA SÉRIE NH, NJ1, NJ2, NJ3 OU NJ4

UTILISANT UN BOÎTIER DE LA SÉRIE NH, NJ1, NJ2, NJ3 OU NJ4

N° de document: IOMGDDI

Date de publication: Mai 2010

Page 14

Consignes de sécurité

(1) Ne levez pas et ne déplacez pas un transformateur sans disposer de l'équipement approprié et du personnel

expérimenté. Sur certaines unités de grandes dimensions, les dispositifs de levage sont situés à l'intérieur du

boîtier sur le noyau-bobines.

(2) Ne déchargez pas le transformateur tant qu'une inspection complète n'a pas été exécutée.

(3) N'utilisez les bornes que pour les branchements électriques. Il est recommandé d'utiliser des connecteurs

exibles pour les connexions sur barre. Les bornes du transformateur ne sont pas conçues pour supporter le

poids des câbles d'entrée ou de sortie. Des supports de type "Uni-Strut" peuvent être ajoutés au site en s'assurant de rencontrer les distances électriques.

(4) Les branchements doivent respecter le schéma de la plaque signalétique ou les diagrammes de connexion.

(5) Vériez que la source d'alimentation est coupée avant de commencer à travailler sur un transformateur ou à

l'intérieur de la boite de jomction Mettre tous les enroulements à la terre.

(6) Vériez que toutes les liaisons à la terre, les bornes d'entrée et de sortie et les prises sélectionnées sont com-

plètes et sont bien serrées avant de mettre le transformateur sous tension.

(7) Ne tentez pas de changer des prises (primaires ou secondaires), alors que le transformateur est sous tension.

(8) Ne changez pas les branchements lorsque le transformateur est sous excitation.

(9) N'altérez pas les panneaux de commande, les alarmes, les verrouillages ni les circuits de commande.

(10) Ne réglez pas et ne retirez pas les accessoires ou les plaques de recouvrement lorsque le transformateur est

sous tension. Les câbles d'entrée et de sortie ne doivent pas venir en contact avec le noyau ou toutes autres

parties vivantes sauf les bornes conçues à cette n.

TABLE DES MATIÈRES

Informations générales 15

Manutention 15

Contrôle et inspection 15

Entreposage 15

Installation 15

Ventilation 16

Accessibilité 16

Niveaux de bruit du transformateur 16

Branchement des câbles 16

Mise à la terre 17

Inspection avant la mise sous tension 17

Fonctionnement 17

Entretien 18

Séchage des transformateurs 18

Accessoires 18

Appendice A 19

Appendice B 20

Figure 1 21

Figure 2 22

Figure 3 23

Notes 24

- 14 -

Page 15

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

DES TRANSFORMATEURS DE TYPE SEC

INFORMATIONS GÉNÉRALES

Les transformateurs de type sec sont fabriqués

pour fournir un rendement optimal pendant une durée de

vie utile sans interruption. Il est recommandé de porter

une attention particulière aux consignes suivantes an

d'obtenir un fonctionnement able et sûr.

L'installation, le fonctionnement et l'entretien des

transformateurs doivent être effectués par du personnel

autorisé, familier avec l'appareillage électrique utilisé et

des dangers potentiels qu'il représente.

Avertissement : Danger! Travailler sur un

transformateur ou autour d'un équipement

électrique similaire présente un risque de choc

électrique. Il est indispensable de mettre hors

tension la source d'alimentation électrique

avant d'entreprendre des travaux sous tension.

Comme pour tout appareil électrique, les transformateurs doivent être installés en conformité avec les

codes nationaux et locaux de l'électricité. Veuillez

également vous reporter à la norme ANSI/IEEE C57-94

pour les recommandations portant sur l'installation,

l'utilisation, le fonctionnement et l'entretien des transformateurs de type sec.

MANUTENTION

conservée au bureau de vente local.

Si l'examen de l'appareil a lieu à l'extérieur, il faut

prendre les précautions nécessaires an que des

conditions météorologiques inclémentes ne présentent

pas davantage de risques.

ENTREPOSAGE

Les transformateurs qui ne sont pas immédiatement

installés et mis sous tension doivent être entreposés

dans un endroit propre et sec, à l'abri des contaminants

atmosphériques environnants.

Il est recommandé d'entreposer les transformateurs

dans un immeuble chauffé muni de l'emballage plastique

d'origine.

INSTALLATION

Les boîtiers sont conçus et approuvés

selon les normes CSA C22.2 No 47(usage

général), CSA22.2 No 94 (usage spécial),

NEMA 250 et UL50.

Pour un boîtier équivalent sous CEI, voir

la norme IEC60259 (Classication des

boîtiers).

Les transformateurs sont posés sur palettes

pouvant être soulevées à l'aide d'un chariot élévateur à

fourche ou levées par les anneaux de levage fournis.

L'équipement de levage doit être adapté à la taille

de chaque transformateur. Il est recommandé d'utiliser

des barres d'écartement pour les besoins de sécurité et

de protection du transformateur.

En aucun cas, un transformateur ne doit être

soulevé ou déplacé en utilisant d'autres points d'ancrage

que ceux indiqués sur l'appareil. Veuillez vous reporter

aux gures 1 et 2.

CONTRÔLE ET INSPECTION

Immédiatement après avoir reçu le transformateur,

une inspection doit être effectuée pour vérier la présence de dommages éventuels survenus durant le

transport ainsi que l'exactitude des documents

d'expédition.

L'emballage sera examiné an d'y détecter des bris,

de voir si les boîtiers sont bosselés ou abîmés et si des

pièces inscrites sur le bordereau de marchandises sont

manquantes.

Si des dommages sont constatés, une réclamation

doit immédiatement être effectuée avec le transporteur et

une deuxième copie des renseignements concernant la

commande et les problèmes survenus devrait être

a) Transformateurs de type sec pour intérieur et

extérieur avec boîtiers

La plupart des transformateurs de type sec sont

munis d'un boîtier type 3R, 4 ou 12. Les appareils

peuvent être installés à l'intérieur ou à l'extérieur, le cas

échéant. S'ils sont munis d'un boîtier type 1, ils doivent

être utilisés seulement à l'intérieur.

Les boîtiers ventilés sont recommandés pour être

installés à l'intérieur, mais ils peuvent également être

installés à l'extérieur lorsque les conditions atmosphériques permettent l'installation d'un boîtier avec aération de

type 3R.

Pour les installations à l'extérieur, les codes en

vigueur qui s'appliquent à l'installation doivent être

respectés, notamment ceux concernant l'installation des

câbles et le matériel convenant à une utilisation

extérieure.

Des connecteurs de conduits étanches doivent être

utilisés aux endroits prévus (disques défonçables) et pour

toutes autres ouvertures. Si des trous sont percés sur les

parois du boîtier, ils doivent être faits en dessous des

parties sous tension non isolées (sous les bornes B.T.).

Il est possible de poser les transformateurs de type

sec debout contre un mur, un plancher, un poteau, une

poutre ou un autre endroit pouvant supporter leur poids

avec les accessoires adéquats xés. Veuillez vous

- 15 -

Page 16

reporter à l'appendice B (page 20) pour les jeux de

montage mural.

Les transformateurs de type sec ventilés conventionnels sont dotés d'une grille inférieure pour la convection de l'air. Lorsque les transformateurs sont installés

au-dessus du sol, une plaque de captage devrait être

installée sous chaque transformateur par mesure de

sécurité contre les particules chaudes risquant de passer

à travers la grille dans le cas d'une défaillance. Veuillez

vous reporter à l'appendice B (page 20).

Il est important d'installer les transformateurs

ventilés dans un endroit sec où l'air ambiant est propre et

exempt de poussières, saletés, émissions corrosives,

humidité, chaleur ou autres conditions nocives. Les

transformateurs ne doivent pas être installés dans un lieu

où il y a un risque de pénétration d'eau dans le boîtier.

Dans le cas où un transformateur aurait été soumis

à de l’humidité avant son installation, assurez-vous de

bien le nettoyer et de le sécher avant de le mettre sous

tension. Il est recommandé de soufer de l’air chaud

dans le transformateur an de sécher les composants

internes. Veuillez vous reporter à la rubrique de séchage

des transformateurs.

b) Transformateurs pour intérieur et extérieur

avec boîtiers Type 4, 4X ou 12 sans aération.

Les transformateurs équipés de boîtiers type 4,

4X ou 12 sans aération peuvent être installés à l’intérieur

comme à l’extérieur à l’un des endroits indiqués ci-dessus. Les transformateurs à boîtier sans aération, bien que

légèrement plus grands, procurent une protection bien

plus grande contre une variété d’éléments, notamment la

poussière, la saleté, la neige, l’humidité, la pluie, etc.

Pour les installations à l’extérieur, les codes en

vigueur qui s’appliquent à l’installation doivent être

respectés, notamment ceux concernant l’installation des

câbles et le matériel convenant à une utilisation

extérieure.

VENTILATION

locaux renfermant des objets entreposés risquant de faire

obstacle à la circulation de l’air et aux inspections. Les

passages et les endroits dans lesquels des personnes

risquent d’être exposées à des pièces sous tension au

cours de l’inspection doivent également être évités.

Une protection adéquate doit être assurée en toutes

circonstances.

NIVEAUX DE BRUIT DU

TRANSFORMATEUR

Les transformateurs sont des appareils alimentés

par l’électricité, et lorsqu′ils sont en fonction, les matériaux qui sont nécessaires à leur construction émettent un

certain bruit.

Les transformateurs doivent respecter les normes

NEMA en matière de niveau sonore. Ces normes varient

de 40 à 60 dB, ce qui peut constituer une source de gêne

pour les personnes qui travaillent ou résident à proximité.

Il faut donc choisir avec soin leur emplacement

d’installation et éviter tout particulièrement les zones

sensibles comme les hôpitaux, les écoles, les établissements médicaux et les bureaux.

Les lignes directrices suivantes pourront se

révéler utiles pour déterminer le bon emplacement

d’installation.

Les unités doivent être installées loin des angles et

des murs ou plafonds rééchissants.

Pour les branchements, pensez à utiliser des

câbles ou autres conduits exibles.

Tous les transformateurs de type sec sont munis

de coussinets d′insonorisation caoutchoutés

installés entre le noyau-bobines et le boîtier.

Cependant, il est aussi possible d′installer d′autres

coussinets d′insonorisation entre le transformateur

et sa surface de montage.

Les transformateurs doivent être installés dans un

endroit où ils pourront être refroidis par la circulation de

l’air. La température ambiante moyenne doit être de 30

°C (86 °F) et ne jamais excéder 40 °C (104 °F).

Une bonne ventilation est indispensable pour que

les transformateurs atteignent la capacité en kVA indiquée sur leur plaque signalétique. Tous les transformateurs à usage général doivent être éloignés des murs ou

de toutes autres obstructions (au moins 15,24 cm (6 po)

lorsqu’ils sont installés au plancher et de 10,16 cm (4 po)

lorsqu’ils sont installés au mur) an de permettre la

circulation de l’air propre à travers les interstices d’aération ou autour d’un appareil sans aération.

ACCESSIBILITÉ

Il est prévu par les normes du Code national de

l’électricité que les transformateurs soient accessibles

pour l’inspection et que l’emplacement de l’installation

soit choisi dans cette optique.

Ils ne doivent donc pas être installés dans des

Pensez à installer des matériaux acoustiques

absorbants sur les murs et les plafonds se trouvant

autour du transformateur.

Le transformateur doit se trouver aussi loin que

possible des zones pour lesquelles le bruit pourrait

constituer une gêne.

BRANCHEMENT DES CÂBLES

Le calibre des câbles de branchement dépend du

courant nominal des enroulements primaires et secondaires du transformateur. Les informations pertinentes se

trouvent à l’appendice A (page 19). Il est recommandé

d’utiliser des câbles supportant une température d’au

moins 90 °C (194 °F) ainsi que des cosses ALC9CU.

Des disques défonçables sont fournies sur tous les

transformateurs à boîtier ventilé jusqu’à 150 kVA tripha-

sés et 100 kVA monophasés an de faciliter le passage

du câble.

Les transformateurs non ventilés ne sont pas munis

de disques défonçables; vous devez utiliser un connec-

- 16 -

Page 17

teur de câble approprié pour l’utilisation.

Veuillez vous reporter aux gures 1 et 2 (page 9 et

10) pour l’emplacement du passage de câble.

Avertissement : Ne remplacez jamais des

branchements ni des prises, sauf si le transformateur est débranché et que toutes les

bobines sont mises à la terre.

Il est recommandé de passer les câbles sur le côté

an d’éviter d’obstruer les aires de ventilation.

Des prises de connexion de câble plaquées cuivre

ou aluminium peuvent être utilisées pour brancher les

bornes des transformateurs. Les bornes doivent être

nettoyées et il est recommandé d’utiliser de la pâte à

joints pour application électrique sur tous les

branchements.

Veuillez vous reporter à la plaque signalétique du

transformateur pour connaître les combinaisons de

tension primaire et secondaire ainsi que l’emplacement

des prises primaires et/ou secondaire si applicable.

Les ls de prise des transformateurs livrés d’usine

seront positionnés sur la tension nominale ou 100 %. Les

autres emplacements des prises seront recouverts d’un

matériel d’imprégnation et d’un isolant.

Pour déplacer les prises, vous devez retirer l’isolant

en soulevant délicatement la couche protectrice de la

surface. Vous devez nettoyer le l de la prise et l’enduire

ensuite d’une pâte à joints.

REMARQUE : Après l’installation des câbles

et des connecteurs, il faut maintenir un écartement d’au moins 2,5 cm (1 po) entre les

parties sous tension et toutes les parties du

boîtier.

MISE À LA TERRE

Toutes les piéces métalliques du noyau-bobines

non-porteuses de courant, sont reliées à la terre, via le

connecteur de mise à la terre. L′intégrité équipotentielle y

est maintenue.

Pour des raisons de sécurité, le boîtier du transformateur doit lui aussi être adéquatement relié à la terre.

La mise à la terre doit être effectuée en conformité

avec les normes du Code national électrique.

INSPECTION AVANT LA MISE

SOUS TENSION

Pour un fonctionnement adéquat et sans danger du

transformateur, veuillez vérier ce qui suit :

a) La résistance d’isolation, de la bobine à l’enroule-

ment primaire, de la bobine à l’enroulement

secondaire et de l’enroulement primaire au secondaire doit être supérieure à 10 k ohms.

b) Avant de brancher et de mettre la charge sous

tension, mesurez la tension de sortie pour vérier si

elle correspond aux spécications de la plaque

signalétique.

c) Assurez-vous de brancher les phases conformé-

ment au diagramme vectoriel de la plaque

signalétique.

d) La charge de l’enroulement delta secondaire

comportant une prise centrale de 120 volts ne doit

pas dépasser le courant nominal normal de l’enroulement. Cette prise centrale est conçue pour recevoir

un maximum de 5 % des kVA indiqués.

e) Lorsque les enroulements sont branchés en

parallèle (comme dans le cas d’enroulements

primaires à bitension), les prises primaires de toutes

les bobines doivent être branchées au même

pourcentage de positions de prises pour éviter que

les spires ne soient court-circuitées. Pour connaître

les positions des prises, consultez la plaque signalétique du transformateur.

f) Le boîtier doit être mis à la terre à l’aide d’un

conducteur de calibre approprié.

g) Dans la mesure du possible, la charge doit être

répartie également entre les phases pour assurer le

bon fonctionnement des enroulements du

transformateur.

Toute charge triphasée ou monophasée peut être

branchée au transformateur; toutefois, la charge en

kVA de chaque phase ne doit pas excéder 1/3 du

régime nominal en kVA indiqué sur la plaque

signalétique.

h) Il faut vérier que chaque branchement électri-

que est bien serré et que le dégagement autour de

chaque partie vivante est sufsant.

i) S’il existe un risque quelconque que le transforma-

teur a été soumis à de l’humidité pendant le transport ou l’entreposage, assurez-vous qu’il est bien

sec avant de le mettre sous tension. Ceci peut être

exécuté en faisant un test d’induction de résistance.

Les procédures de séchage se trouvent à la page

18.

FONCTIONNEMENT

Dans tous les cas d’installation normale et bien

réalisée, les transformateurs de type sec fonctionnent

normalement dans des conditions normales de mise sous

tension et de charge.

Pour votre information, un transformateur de type

sec à pleine charge peut s’avérer très chaud au toucher,

particulièrement la partie supérieure de l’appareil.

Les normes permettent que les boîtiers de ce type

d’appareil puissent atteindre jusqu’à 65 °C (149 °F) de

plus que la température ambiante. Ceci représente une

charge normale et ne doit pas vous inquiéter.

Les transformateurs de type sec sont conçus pour

- 17 -

Page 18

fonctionner en permanence selon la pleine capacité de

kVA indiquée sur la plaque signalétique.

Les normes C57.96 de l′ANSI donnent des directives

pour le chargement des transformateurs dans

différentes conditions, notamment :

les températures ambiantes différentes des tempé-

ratures à respecter pour un bon fonctionnement du

transformateur;

la surcharge brève en fonction du temps et de la

température, ainsi que la perte de vie utile du

transformateur;

la surcharge entraînant une réduction de la vie utile

du transformateur.

Si le transformateur subit une augmentation de la

température, les éléments de charge suivants doivent

être immédiatement examinés :

démarrage de moteur brusque ou autre type de

charge brusque pour lequel un transformateur

spécique pour ce type d'application est requis;

sur-excitation de l′unité à la suite d′une surtension

de l′alimentation ou d′une surcharge;

températures ambiantes supérieures à la normale;

surcharge supérieure aux directives C57.96 de

l’ANSI;

distorsions harmoniques de la tension de la ligne

d’alimentation et du courant.

En cas de surchauffe, l’ajout de ventilateur de

refroidissement complémentaire doit respecter les

directives d’installation de l’usine. Une mauvaise

installation de ventilateurs peut mal diriger la

circulation de l’air et entraîner une détérioration

réduisant la durée de l’isolant dans la bobine du

transformateur.

Les transformateurs de type sec peuvent être

arrêtés et entreposés pour des périodes prolongées sans

subir de détérioration. Il faut soigneusement nettoyer et

sécher les appareils avant de les mettre sous tension,

comme indiqué préalablement.

ENTRETIEN

L′entretien interne doit être effectué sur un

transformateur éteint, isolé et dont les bornes

sont mises à la terre.

La maintenance comprend le nettoyage interne, le

serrage des barrettes et des connexions boulonnées,

l’entretien et l’inspection des dispositifs auxiliaires.

Les conduits d’air doivent être exempts de toute

accumulation de poussières et de saleté. Les connexions

boulonnées des bornes doivent être en bon état.

Une pratique acceptée consiste à aspirer ou à

soufer de l’air comprimé de haut en bas an d’enlever la

poussière dans les conduits d’une bobine de transforma-

teur. Il faut soufer de l’air sec à basse pression an

d’éviter de contaminer davantage les enroulements avec

des matériaux étrangers.

Il est nécessaire de vérifier également la liaison à la

terre pour garantir que le branchement est de faible

impédance. Il faut enlever immédiatement toute accumulation de glace, de neige ou toute autre matière pouvant

obstruer l’aération pendant le fonctionnement du

transformateur.

Les filtres des appareils pour l’extérieur exposés

aux conditions climatiques peuvent rapidement se salir.

Une vérification régulière des filtres permettra d’éviter

que le filtre se bouche et, par conséquent, que le transformateur surchauffe. D’autre part, il ne faut jamais faire

fonctionner le transformateur sans que les filtres soient

bien en place.

SÉCHAGE DES

TRANSFORMATEURS

Dans le cas où un transformateur a été exposé à de

l’humidité, condensation ou pluie, il est conseillé de

sécher l’appareil avant de le mettre sous tension.

Il est possible d’exécuter le séchage en utilisant de

l’air chaud ou réchauffé, de la chaleur rayonnante ou un

chauffage interne dirigé à travers les enroulements. Il faut

continuer à envoyer de l’air chauffé dans les enroulements pendant au moins vingt-quatre (24) heures après

avoir constaté qu’il n’y a plus de condensation visible.

Il peut être difcile de sécher correctement des

transformateurs ayant été soumis à une inondation, de la

pluie directe ou des gicleurs. Veuillez communiquer avec

l′usine an de connaître la marche à suivre.

Dans des conditions de fonctionnement et des

environnements normaux, les transformateurs de type

sec ne nécessitent aucun entretien. Il est cependant

recommandé de procéder à un entretien et à une inspection de routine en fonction des conditions climatiques

sous lesquelles l’appareil sera installé.

Une inspection des éléments externes et un

nettoyage de la poussière accumulée sur le boîtier

peuvent être effectués lorsque le transformateur fonctionne. Cependant, les couvercles d’accès ne doivent pas

être ouverts lorsque l’appareil est sous tension.

plusieurs accessoires an de faciliter l’installation.

Veuillez consulter votre détaillant ou distributeur pour

l’achat de ces articles pouvant être en magasin.

1) Supports de montage mural

montage mural intégré pour des appareils pesant jusqu’à

123,3 kg (285 lb). Les appareils pesant plus de 123,3 kg

ACCESSOIRES

Les transformateurs de type sec sont offerts avec

Les transformateurs encapsulés sont équipés de

- 18 -

Page 19

(285 lb) doivent uniquement être montés au sol.

Les transformateurs de type sec ventilés sont,

généralement, conçus pour un montage au sol uniquement. Cependant, certains appareils ventilés jusqu’à 51

kVA sont pourvus de boîtiers dotés de supports de

montage mural intégrés. Ces appareils peuvent être

montés sur des murs, des poutres ou des poteaux.

Les transformateurs de type sec ventilés conventionnrls sont dotés d’une grille inférieure pour la convection de l’air. Lorsque les transformateurs sont installés

au-dessus du sol, une plaque de captage devrait être

installée sous chaque transformateur par mesure de

sécurité contre les particules chaudes risquant de passer

à travers la grille dans le cas d’une défaillance. Veuillez

vous reporter à l’appendice B (page 20).

APPENDICE A

COURANT ADMISSIBLE POUR

BRANCHEMENTS

A. Pour un transformateur monophasé

Courant de ligne = Volt-ampères

Tension de ligne

B. Pour un transformateur triphasé

Courant de ligne = Volts-ampères

3 X Tension de ligne

2) Coussinets d’insonorisation

Tous les transformateurs de type sec sont équipés

de coussinets d’insonorisation caoutchoutés installés

entre le noyau-bobines et le boîtier.

An d’assurer une absorption maximale des

vibrations et du bruit, il est recommandé d’installer

d’autres coussinets d’insonorisation entre le transformateur et la surface de montage.

Ces plaques moulées en néoprène et acier éliminent virtuellement le bruit de vibration entre le transformateur et la surface de montage.

Veuillez consulter le catalogue du fabricant pour

obtenir le numéro de pièce du coussinets requis.

3) Connecteurs

Les connecteurs pour l’installation de transformateurs de type sec sont facilement utilisables. Ces connecteurs conviennent autant pour les câbles en aluminium

que ceux en cuivre.

La taille et l’installation des connecteurs doivent

respecter les exigences du code de l’électricité en

appliquant les meilleures pratiques an d’assurer un

fonctionnement able et sûr. Les surfaces des câbles

doivent être nettoyées et il faut utiliser une pâte à joints

pour application électrique sur tous les branchements.

Choix des connecteurs

a) Déterminez le courant primaire pour le transforma-

teur requis à l’appendice A.

b) D’autre part, déterminez le courant secondaire pour

le transformateur requis à l’appendice A.

c) Le courant pour les branchements à 120/240 de

tension doit être basé sur 240 volts.

d) Le courant pour les branchements à 240/480 volts

doit être basé sur 480 volts.

Tableau de courant en pleine charge du

transformateur monophasé

kVA

Nominal 120 V 240 V 416 V 480 V 600 V

3 25,0 12,5 7,21 6,25 5,00

5 41,6 20,8 12,0 10,4 8,33

7,5 62,5 31,2 18,0 15,6 12,5

10 83,3 41,6 24,0 20,8 16,6

15 125 62,5 36,0 31,2 25,0

25 208 104 60,0 52,0 41,6

37,5 312 156 90,1 78,1 62,5

50 416 208 120 104 83,3

75 625 312 180 156 125

100 833 416 240 208 166

150 1 250 625 360 312 250

167 1 391 695 401 347 278

250 2 083 1 041 600 520 416

333 2 775 1 387 800 693 555

Courant en ampères

Tableau de courant en pleine charge du

transformateur triphasé

kVA

Nominal 208 V 240 V 380 V 416 V 480 V 600 V

2 5,55 4,81 3,03 2,77 2,40 1,92

3 8,32 7,21 4,55 4,16 3,60 2,88

6 16,6 14,4 9,11 8,32 7,21 5,77

9 24,9 21,6 13,6 12,4 10,8 8,66

15 41,6 36,0 22,7 20,8 18,0 14,4

30 83,2 72,1 45,5 41,6 36,0 28,8

45 124 108 68,3 62,4 54,1 43,3

75 208 180 113 104 90,2 72,1

112,5 312 270 170 156 135 108

150 416 360 227 208 180 144

225 624 541 311 312 270 216

300 832 721 455 416 360 288

450 1 249 1 082 683 624 541 433

500 1 387 1 202 759 693 601 481

600 1 665 1 443 911 832 721 577

750 2 081 1 804 1 139 1 040 902 721

Courant en ampères

- 19 -

Page 20

APPENDICE B

EMPLACEMENT DES SUPPORTS DE MONTAGE MURAL ET PLAQUES DE CAPTAGE

POUR LES BOÎTIERS TYPE 3R DE LA SÉRIE NH3

Support de montage

mural en option

Plaque de captage

lorsque requis par le code local

Plaque de captage

lorsque requis par le

code local

Support de montage

au plafond en option

APPENDICE B

EMPLACEMENT DES SUPPORTS DE MONTAGE MURAL ET PLAQUES DE CAPTAGE

POUR LES BOÎTIERS TYPE 3R DES SÉRIES NH5 et NH6

Points de xation mural

Plaque de captage

lorsque requis par le code local

Points de xation pour

montage au sol ou au plafond

- 20 -

Page 21

FIGURE 1

TYPE 3R typique, boîtier avec aération série NH pour les transformateurs triphasés et monophasés.

Notes :

1. Manutention - les appareils sont construits de manière à pouvoir être soulevés par la palette au moyen d'un

chariot à fourche. Le positionnement nal de l'appareil lorsque la palette est retirée peut se faire avec le chariot à

fourche dont les fourches sont glissées entre les canaux du transformateur.

2. Expédition - les appareils sont transportés sur palettes qui seront retirées au moment de l'installation.

3. Installation - ce transformateur peut être installé à l'intérieur ou à l'extérieur avec une certaine protection contre la

pluie, la fonte des neiges et la formation de glace externe.

4. Les transformateurs doivent être éloignés des murs et de toutes autres obstructions au moins de 15,24 cm (6 po)

lorsqu'ils sont installés au plancher et de 10,16 cm (4 po) lorsqu'ils sont installés au mur.

5. NE BLOQUEZ PAS l'aération inférieure.

Panneau d'accès

avant

Placez le chariot à fourche

sous la palette

Passage de câble

avec disques

défonçables (2 par côté)

Les points pour les fourches

sont sous le transformateur

pour le positionnement nal

sans la palette

- 21 -

Page 22

FIGURE 2

TYPE 3R typique, boîtier avec aération série NJ pour les transformateurs triphasés ou monophasés.

Notes :

1. Manutention - les appareils sont construits de manière à pouvoir être soulevés par la palette au moyen d'un

chariot à fourche. Le positionnement nal de l'appareil lorsque la palette est retirée peut se faire avec le chariot à

fourche dont les fourches sont glissées entre les canaux du transformateur. (Note: Pour les transformateurs

ayant un poids supdérieur à 2350 lbs, ceux-ci doivent être levés en utilisant les dispositifs de levage

situés sur le dessus du noyau-bobines. Vous devez d’abord soulever le panneau de dessus du boîtier.)

2. Expédition - les appareils sont transportés sur palettes qui seront retirées au moment de l'installation.

3. Installation - ce transformateur peut être installé à l'intérieur ou à l'extérieur avec une certaine protection contre la

pluie, la fonte des neiges et la formation de glace externe.

4. Les transformateurs doivent être éloignés des murs et de toutes autres obstructions au moins de 15,24 cm

(6 po) lorsqu'ils sont installés au plancher et de 10,16 cm (4 po) lorsqu'ils sont installés au mur. (Note: Ces boîtiers

ne sont pas conçus pour etre ancrés directement à un mur. Ils peuvent cependant être installés sur une

plateforme fournie par le client.)

5. NE BLOQUEZ PAS l'aération inférieure.

Panneau d'accès

avant

Placez le chariot à

fourche sous la palette

Emplacement

recommandé pour le

passage des câble

(deux côtés).

Reportez-vous au

diagramme pour les

dimensions exactes.

Les points pour les fourches sont sous

le transformateur pour le

positionnement nal avec la palette

retirée. Les fourches doivent être

insérées la pleine profondeur du boîtier.

- 22 -

Page 23

FIGURE 3

TYPE 4 et 12 typique, boîtier sans aération série NH pour les transformateurs triphasés ou

monophasés.

Notes :

1. Manutention - les appareils sont construits de manière à pouvoir être soulevés par la palette au moyen d'un

chariot à fourche. Le positionnement nal de l'appareil lorsque la palette est retirée peut se faire avec le chariot à

fourche dont les fourches sont glissées entre les canaux du transformateur.

2. Expédition - les appareils sont transportés sur palettes qui seront retirées au moment de l'installation.

3. Installation - ceci est un boîtier sans aération pour intérieur ou extérieur conçu principalement pour offrir une

certaine protection contre les chutes de saletés, pluie, neige fondante, neige, poussières soufées, éclaboussures

ou arrosage d'eau pouvant être endommagé par la formation externe de glace sur le boîtier. Convient aux

endroits particulièrement exposés à de grandes quantités d'eau provenant de toutes directions. (Remarque : n'est

pas submersible)

4. Les transformateurs doivent être éloignés des murs et de toutes autres obstructions au moins de 15,24 cm

(6 po) lorsqu'ils sont installés au plancher et de 10,16 cm (4 po) lorsqu'ils sont installés au mur.

Crochet de levage

Panneau d'accès

avant

Placez le chariot à

fourche sous la palette

Emplacement recommandé pour le

passage du câble (un des deux côtés).

Reportez-vous au diagramme pour les

dimensions exactes.

- 23 -

Page 24

Notes

Page 25

GUÍA DE INSTALACIÓN, OPERACIÓN Y

MANTENIMIENTO

PARA TRANSFORMADORES TIPO SECO DE USO EN

PARA TRANSFORMADORES TIPO SECO DE USO EN

INTERIORES/EXTERIORES QUE UTILIZEN GABINETES SERIE

INTERIORES/EXTERIORES QUE UTILIZEN GABINETES SERIE

NH, NJ1, NJ2, NJ3 O NJ4

NH, NJ1, NJ2, NJ3 O NJ4

N.º de folleto: IOMGDDI

Fecha de emisión: De mayo de 2010

Page 26

Precauciones de seguridad

(1) No levante ni traslade un transformador sin equipo apropiado ni personal experimentado. En algunos trans-

formador de distribución mayor capacidad. see proveen dispositivos de elevación en el conjunto de núcleo y

bobinas

(2) No instale el transformador hasta que se haya realizado una inspección completa.

(3) Utilice únicamente terminales para conexiones eléctricas. Se recomiendan conectores exibles para las

conexiones en barras colectoras. Las terminals del transformador no estan diseñadas para soportar el peso del

cableado de alimentación o de carge. Largueros de soporte pueden ser agregados en el campo cuidando de

que se mantengan las distancias de separación adecuadas.

(4) Las conexiones solo deben realizarse siguiendo el diagrama de la placa de identicación o los diagramas de

conexión.

(5) Asegúrese de que toda la energía esté desconectada y de que todos los embobinados esten conectados a

tierra, antes de iniciar cualquier trabajo en un transformador o adentro del panel de control.

(6) Asegúrese de que todas las conexiones a tierra estén completas y ajustadas antes de energizar el

transformador.

(7) No intente cambiar una derivación primaria o secundaria mientras el transformador está energizado.

(8) No cambie las conexiones cuando el transformador esté energizado.

(9) No altere los paneles de control, las alarmas, los interruptores de seguridad ni los circuitos de control.

(10) No ajuste ni retire accesorios ni cubiertas protectoras mientras el transformador esté energizado. Ningun cable

de alimentación debe tener contacto con el núcleo o cualquier parte viva, excepto con la terminal que se debe

conectar.

CONTENIDO

General 27

Manipulación 27

Recepción e inspección 27

Almacenamiento 27

Instalación 27

Ventilación 28

Accesibilidad 28

Niveles de ruido del transformador 28

Cables de conexión 28

Conexión a tierra 29

Inspección antes de la energización 29

Operación 29

Mantenimiento 30

Secado de los transformadores 30

Accesorios 30

Apéndice A 31

Apéndice B 32

Figura 1 33

Figura 2 34

Figura 3 35

Notas 36

- 26 -

Page 27

INSTALACIÓN, OPERACIÓN Y MANTENIMIENTO

DE LOS TRANSFORMADORES DE TIPO SECO

GENERAL

Los transformadores de tipo seco se fabrican para

brindar un rendimiento óptimo para un servicio in

interrompido de provida. Se recomienda seguir al pie de

la letra las siguientes instrucciones para lograr una

operación segura y conable.

La instalación, la operación y el mantenimiento de

los transformadores deben ser realizados por personas

autorizadas, que tengan conocimiento sobre aparatos

eléctricos y los posibles riesgos que conllevan.

Advertencia: ¡Peligro! Existe el riesgo de

descarga eléctrica cuando trabaja con o

cerca de equipos eléctricos como los

transformadores. Se debe desconectar la

energía antes de realizar cualquier trabajo

en un transformador.

Al igual que con cualquier dispositivo eléctrico, los

transformadores se deben instalar de acuerdo con los

requisitos de los códigos eléctricos nacionales y locales.

También puede consultar la norma ANSI/IEEE C57-94

para conocer las pautas recomendadas de instalación,

aplicación, operación y mantenimiento de

transformadores de tipo seco.

MANIPULACIÓN

Si este examen de la unidad se realiza en

exteriores, hay que tener precaución para que las

inclemencias del tiempo no presenten mayor peligro.

energizarán de inmediato se deben guardar en un

ambiente limpio y seco, alejados de todo contaminante

ambiental en suspensión.

lugar con calefacción, con el envoltorio de plástico

protector todavía colocado.

ALMACENAMIENTO

Los transformadores que no se instalarán ni

Se recomienda guardar los transformadores en un

INSTALACIÓN

Los gabinetes están diseñados y

aprobados de acuerdo con las

eapecicaciones CSA 22.2 No. 47

(Propósitos Generales), CSA 22.2 No. 94

(Gabinetes Especiales), NEMA 250 y

UL 50.

Para IEC gabineles equivalentes por favor

reérase a IEC60529 (Designación y

clasicación de Gabinetes).

Los transformadores se envían en tarimas y se

pueden elevar con un montacargas o se pueden levantar

por las argollas de elevación provistas.

Se debe utilizar equipo de elevación apropiado para

el tamaño de cada transformador. Con nes de seguridad

y para proteger el transformador, se recomienda el uso

de barras separadoras.

No se debe intentar levantar ni trasladar un

transformador desde ningun punto en la unidad distinto

de los puntos indicados. Consulte las Figuras 1 y 2

(pag.33-34).

RECEPCIÓN E INSPECCIÓN

Inmediatamente después de recibir el

transformador, debe ser inspeccionado para detectar

cualquier daño de traslado y para vericar la exactitud de

los datos en comparación con los documentos de envío.

Se debe examinar la unidad para detectar cualquier

rotura en el embalaje, abolladura o daño en los

gabinetes, o piezas faltantes de la lista de empaquetado.

Si se observa algún daño, se debe presentar un

reclamo de inmediato ante la empresa de transporte y

una segunda copia ante la ocina local de ventas con

toda la información pertinente con respecto al pedido y

las circunstancias.

a) Transformadores de tipo seco para interior/exterior

con gabinete

La mayoría de los transformadores de tipo seco

vienen provistos de un gabinete tipo 3R, 4 ó 12. Las

unidades se pueden instalar en interiores, exteriores o

segón aplique. Si están equipadas con un gabinete tipo

1, estas unidades son para uso interior únicamente.

Se recomiendan los gabinetes con ventilación para

instalación en interiores, pero también se pueden instalar

en exteriores en lugares en que las condiciones

climáticas permiten que se instale un gabinete con

ventilación de tipo 3R.

Para una ubicación en exteriores, se deben seguir

los códigos aplicables adecuados, que incluyen la

instalación de los cables y el equipo apropiado para el

servicio exterior.

Se deben de usar acoplamientos herméticos y

cualquier oricio en el gabinete debe perforapse por

debajo de cualquier parte viva sin aislamiento (debajo de

las termina les de bajo voltaje).

Los transformadores de tipo seco pueden ubicarse

en posición vertical apoyados en paredes, pisos, postes,

vigas u otros lugares que puedan soportar el peso con

los accesorios apropiados colocados. Consulte el

Apéndice B (pag.32) para ver los equipos de montaje de

paredes.

- 27 -

Page 28

Los transformadores de tipo seco convencionales

con ventilación abierta tienen una pantalla inferior para la

entrada del aire. Cuando los transformadores se montan

por encima de la supercie de la tierra, debe instalarse

una placa receptora debajo de cada transformador como

precaución de seguridad contra cualquier partícula

caliente que pueda caer por la pantalla en caso de

alguna condición defectuosa. Consulte el Apéndice B

(página 32).

Es importante que los transformadores ventilados

se instalen en un área seca donde el aire del ambiente

sea limpio y sin polvo, suciedad, gases corrosivos,

humedad, calor u otras condiciones adversas. Los

transformadores no deben instalarse en lugares que

tengan la posibilidad de ingreso de agua en el caja.

En caso de que un transformador haya estado

expuesto a la humedad antes de la instalación,

asegúrese de que esté totalmente limpio y seco antes de

la energización. Se recomienda el soplo de aire caliente

por el transformador para secar los componentes

internos. Consulte la sección que habla del secado de los

transformadores.

b) Transformadores para interior/exterior con

gabinetes TIPO 4, 4X o 12 sin ventilación.

Los transformadores equipados con gabinetes tipo

4, 4X o 12 sin ventilación pueden colocarse en interiores

o exteriores en cualquier ubicación similar a la

mencionada anteriormente. Los transformadores con

gabinetes sin ventilación, si bien son ligeramente más

grandes, ofrecen una protección mucho mayor contra

varios elementos, entre ellos polvo, suciedad, nieve,

humedad, lluvia, etc.

Para una ubicación en exteriores, se deben seguir

los códigos aplicables adecuados, que incluyen la

instalación de los cables y el equipo apropiado para el

servicio exterior.

VENTILACIÓN

Los transformadores se deben instalar en una área

donde se puedan enfriar mediante la libre circulación de

aire y donde la temperatura ambiente promedio sea de

30 °C (86 °F) y no supere los 40 °C (104 °F) en ningún

momento.

La ventilación adecuada es esencial para que los

transformadores cumplan con la capacidad de kVA que

gura en la placa de identicación. Todos los

transformadores para usos generales deben estar

ubicados alejados de paredes u otras obstrucciones (al

menos 15,24 cm [6 pulgadas] cuando se montan en el

piso y 10,16 cm [4 pulgadas] cuando se montan en la

pared) para permitir la circulación limpia y libre de aire

por las aberturas de ventilación o alrededor de la unidad

para las unidades sin ventilación.

ACCESIBILIDAD

Las normas NEC exigen que los transformadores

sean accesibles para la inspección y que se ubiquen

adecuadamente para tal n.

Sin embargo, los transformadores no se deben

ubicar en áreas donde es probable que los elementos

almacenados intereran con la convección natural del

aire o con la facilidad de inspeccionarlos. También se

deben evitar los pasillos u otras áreas donde la gente

pueda estar expuesta a piezas energizadas durante la

inspección.

Se debe proporcionar protección adecuada bajo

cualquier circunstancia.

NIVELES DE RUIDO DEL

TRANSFORMADOR

Los transformadores son aparatos energizados

eléctricamente que, por su naturaleza y debido a los

materiales que los componen, emiten ruidos.

Los transformadores deben cumplir con las normas

NEMA para los niveles máximos de ruido permitidos.

Estos niveles de ruido varían de 40 a 60 DB y, por lo

tanto, pueden ser molestos si se encuentran en las

inmediaciones de los lugares donde residen o trabajan

personas.

Por consiguiente, se debe tener cuidado al elegir

los sitios de ubicación para los transformadores,

especialmente para evitar áreas sensibles como

hospitales, escuelas, centros médicos u ocinas.

Las siguientes pautas pueden ser útiles:

Las unidades deben montarse alejadas de

esquinas o de paredes reectantes o cielorrasos.

Los cables u otros conductos exibles deben

tenerse en cuenta para realizar conexiones.

Todos los transformadores de tipo seco vienen

con montajes de goma para aislamiento entre el

conjunto de núcleo y bobina y el gabinete. Sin

embargo, aisladores de vibración que absorben el

ruido también pueden instalarse entre el

transformador y su supercie de montaje.

Se pueden tomar en cuenta materiales

abosorbentes acusticamente, para ser instalados

en paredes y cielosrasos alrededor de la unidad.

La unidad debe ubicarse lo más alejada posible de

las áreas donde los niveles de ruido podrían

considerarse indeseables.

CONEXIÓN DE LOS CABLES

El tamaño del cable de conexión se determina con

la corriente de línea de los embobinados primario y

secundario del transformador y puede seleccionarse con

la información que aparece en el Apéndice A (página

31). Se recomiendan que los cables sean para al menos

90 °C (194° F), ya que los conectores son ALC9CU.

Se suministran prácticas perforaciones

premarcadas para tubería en todos los gabinetes para

los transformadores ventilados trifásicos de hasta 150

kVA y monofásicos de 100 kVA para facilitar la entrada de

- 28 -

Page 29

los cables.

Para los transformadores sin ventilación, no se

suministran perforaciones premarcadas para tubería y se

debe utilizar el cable conector apropiado para la

aplicación.

Consulte las guras 1 y 2 (páginas 33-34) para ver

las ubicaciones de la entrada de los cables.

Advertencia: No intente cambiar las

conexiones o las derivaciones a menos que el

transformador esté desenergizado y todos las

bobinas estén conectados a tierra.

Se recomienda que la entrada de los cables sea

lateral, ya que evita que se obstruyan las áreas

ventiladas.

Se pueden usar conectores de cable, recubiertos

de cobre o aluminio para conectarse a las terminales del

transformador. Los terminales deben limpiarse y se

recomienda el uso de compuestos para conexiones

eléctricas en todas las conexiones eléctricas.

Consulte la placa de identicación del

transformador para ver las combinaciones de conexión

para los voltaje primario y secundario y las posiciones

para las derivaciónes del primario y/o secundario, según

sea el caso.

Los transformadores recibidos de fábrica deberán

tener los cables conductores conectados en la posición

de la derivación de voltaje nominal o 100%. El resto de

las posiciones de derivación estarán recubiertas de

material para impregnación y de aislamiento.

Para cambiar las derivaciones, es necesario quitar

ligeramente la cubierta protectora de la supercie de

manera apropiada y retirar dicho aislamiento. La

supercie del cable conductor de derivación debe estar

limpia y recubrirse posteriormente con un compuesto

eléctrico.

NOTA: Después de la instalación de los

cables y los conectores, se debe mantener un

espacio mínimo de separación de 2,54 cm (1

pulgada) entre las partes energizadas y todas

las partes del gabinete.

CONEXIÓN A TIERRA

Para la operación segura y apropiada del

transformador, verique lo siguiente:

a) La resistencia del aislamiento, desde el núcleo

hasta el primario, desde el núcleo hasta el

secundario, y desde el primario hasta el secundario,

debe ser superior a 10k ohmnios.

b) Antes de energizar y conectar cualquier carga, mida

y verique que el voltaje de salida coincida con las

especicaciones de la placa de identicación.

c) Verique que las conexiones de fase sean

correctas. Consulte el diagrama vectorial de la placa

de identicación.

d) La carga de un embobinado secundario delta con

una derivación central de 120 voltios no debe

superar la corriente normal para el embobinado.

Esta derivación central está diseñada para un

máximo del 5% de los kVA que guran en la placa

de identicación.

e) Cuando los embobinados se conectan en paralelo

(como en el caso de primarios de doble voltaje), las

derivaciones del primario de todas las bobinas se

deben conectar en las posiciones de derivación con

porcentaje idéntico para evitar el cortocircuito de las

vueltas. Para conocer las posiciones de derivación,

consulte la placa de identicación del transformador.

f) El gabinete debe estar conectado a tierra con el

conductor del tamaño apropiado.

g) La carga total entre todas las fases debe

equilibrarse lo más posible para un óptimo

rendimiento de las bobinas de los transformadores.

Cualquier carga trifásica o monofásica puede