Page 1

SECTION 1

CONTROL TRANSFORMER SELECTION

INDUSTRIAL CONTROL

TRANSFORMERS

Selecting a Control Transformer

requires that you have first hand

knowledge of the application for the

transformer and that you understand

some basic terms related to the

selection process. By using the following information, you will be sure to

select the HPS Control Transformer

which best meets your application.

Th e H P S I m per a tor Se r ies

machine tool control transformers

SECTION 1

are specifically designed for high

inrush applications requiring reliable

output voltage stability. Designed to

meet industrial applications where

electromagnetic devices such as

relays, solenoids, etc. are used, the

HPS Imperator series transformers

ma ximi ze inrush capa bility and

ou tput volt age regulatio n when

electromagnetic devices are initially

energized.

To select the proper transformer,

three characteristics of the load

circuit must first be determined.

They are total steady-state (sealed)

VA, total inrush VA, and inrush load

power factor.

1 (A). The total steady state

“sealed” VA is the amount of VA

that the transformer must supply

to the load circuit for an extended

length of time. Simply add the total

steady-state VA of all devices in your

control circuit. The operating VA data

of these components is available

from the manufacturers.

1 (B). The total inrush VA

is th e amoun t of VA that the

transformer must supply for all

components in the control circuit

which are energized together.

Some consideration to the start-up

sequence may be required. Inrush VA

should be obtained from the device

manufacturer.

1 (C). The inrush load power

factor is difcult to determine without

detailed vector analysis of all the

control circuit components. Such

information is not generally available.

Therefore, HPS is recommending

that a value of 40% power factor

be utilized. Although some other

control transformer manufacturers

still recommend a power factor of

only 20%, HPS, through recent tests

conducted on many popular brands

of control devices has determined

that the 40% power factor value is

more accurate.

Once the above circuit variables

have been determined, transformer

selection is a six (6) step process.

SIX EASY STEPS

1. Determine what your Primary

(supply) and Secondary (output)

voltage requirements are, as well

as your required frequency (i.e. 60

Hz)

2. Calculate the Total Sealed VA

of your circuit. (See Step A)

3. Now ca lculate the Inrush

VA by add ing the inru sh VA of

all components being energized

together. Remember to add the

sealed VA of all components that do

not have inrush VA, (lamps, timers

etc.) as they do however present

a load to the transformer during

maximum inrush. If the inrush for

the components in your circuit are

not known, assume a 40% Inrush

Power Factor.

4. Calculate the Total Inrush VA

using one of the two methods:

A. Total Inrush VA =

(VA sealed)2 + (VA inrush)

OR

B. Total Inrush VA =

VA Sealed + VA Inrush

Note: method B will result in a slightly

larger transformer being selected.

For VA sealed denition please refer to 1 (A).

For VA inrush denition please refer to 1 (B).

2

5. If the nominal supply voltage

does not uctuate more than 5%,

then reference the 90% secondary

voltage column in the Regulation

Data Table for the correct VA

rating.

If th e supp l y voltage varies

upwards of 10%, the 95% secondary

voltage column should be used to

size the transformer.

C u r re n t s ta n d ar d s r eq u i re

electromagnetic devices to operate

rel i ably at a minimum of 85%

of their rated voltage. However,

contact life may be affected with

continuous start-ups at that voltage

level. Therefore, the minimum 85%

secondary voltage column should

only be used as a reference.

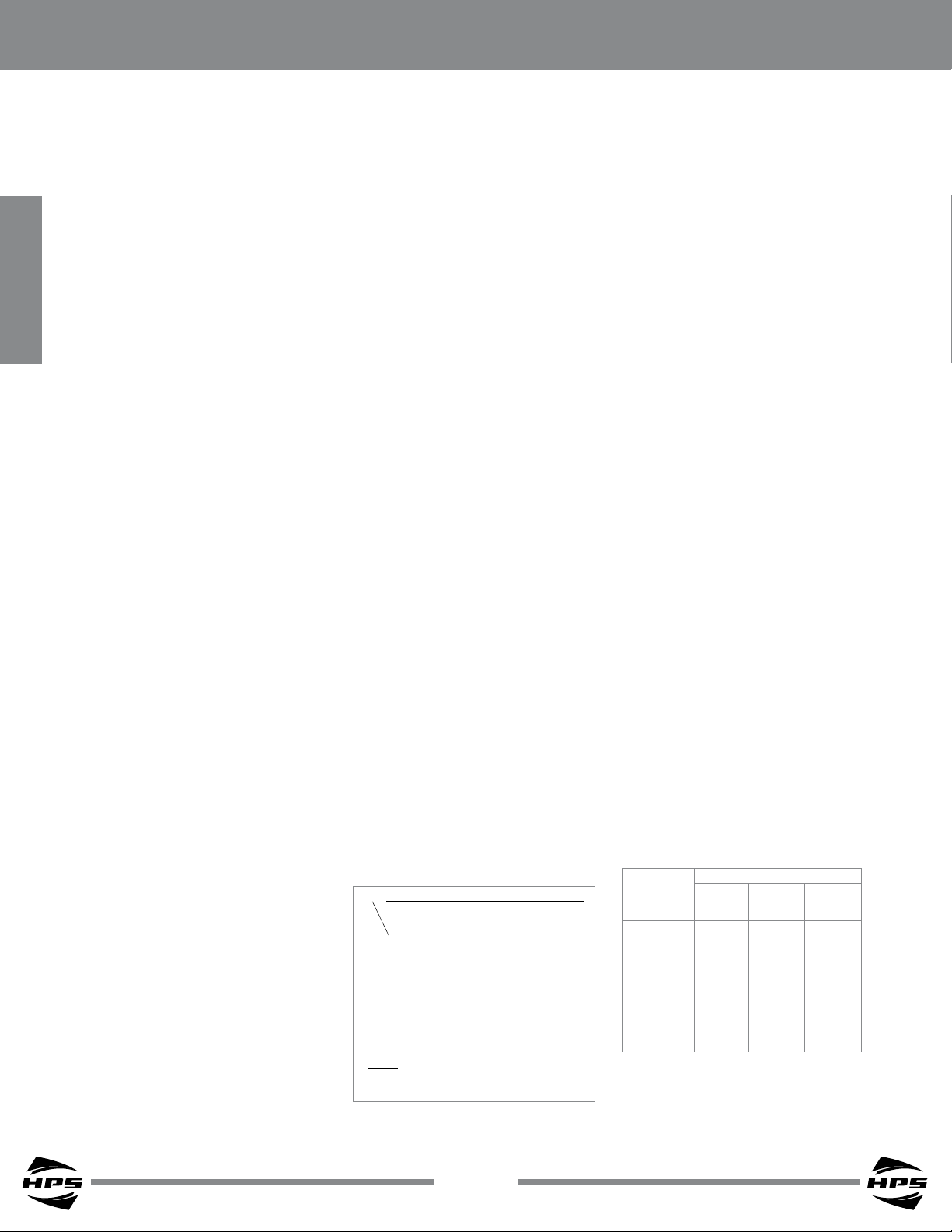

6. Using the regulation data tables

below, select the appropriate VA

rated transformer:

A) With a continuous VA rating that

is equal to or greater than the value

in Step 2.

B) With a maximum inrush VA

equal to or greater than the value

obtained in Step 4.

To determine the correct HPS

Transformer and its Catalog Number,

just refer to the tables in this catalog

for the voltage ratings, frequency

and corresponding VA required.

“HPS IMPERATOR” TRANSFORMERS

REGULATION DATA TABLE

Continuous VA Inrush VA @ 40% Power Factor

Transformer 85% 90% 95%

Nameplate Secondary Secondary Secondary

Rating Voltage Voltage Voltage

50

75

100

150

250

350

500

750

1000

1500

2000

3000

5000

It is recommended that a Control Transformer be

sized at a 40% Power Factor. Some components

in a circuit, such as electromagnetic devices,

typically operate at that level due to their

inherently lower power factor. Selecting a

transformer at 40% Power Factor will more than

adequately size the unit for all the various loads

in the circuit.

330

350

620

895

1596

2464

3939

6422

9842

12797

17833

37406

55629

259

258

467

699

1229

1889

2854

4778

7102

9018

12656

26217

38788

192

170

321

512

880

1345

1819

3228

4530

5489

7865

15940

23601

© Hammond Power Solutions Inc.

32

Data subject to change without notice.

Page 2

SECTION 1

HPS IMPERATOR

SECTION 9

HPS ImperatorTM Series Control Transformer - Applications

TM

The Perfect Solution

The HPS Imperator series of machine tool industrial

control transformers are specically designed to meet the

high inrush industrial applications where electromagnetic

components such as relays, solenoids etc. are used.

With 11 standard voltage groups, a VA range from 50VA to

5000VA and available with standard secondary and optional

primary fuse kits, the HPS Imperator series from HPS

provides the perfect solution for any applications.

Superior Quality and Value

The HPS Imperator series design, utilizing superior

insulation systems and being constructed with high quality

silicon steel laminations for optimum performance, will meet

or exceed cUL and CE standards.

Backed by an industry leading LIFETIME warranty, the HPS

Imperator industrial control transformer line offers superior

performance, quality and value.

Innovative Design

The HPS Imperator series is a unique, fresh and

innovative compact design that provides the ideal

solution for any industrial control application and will

change the way the industrial machine tool industry looks

at the control transformer.

The HPS Imperator’s unique terminal block design

(patent pending) allows for the quick and easy

installation of standard secondary or optional primary

13/32” x 1 1/2” midget/type CC fuse clips on every unit.

This is the simplest and most inexpensive fusing

installation provided on any industrial control transformer

in the market today.

The windings and internal terminations of the HPS Imperator are encapsulated, which protects them from moisture, dirt and other airborne contaminants. The custom

molded coil covers with their unique ‘n shaped’ design

combine superior transformer cooling properties with a

clean bold look.

The HPS Imperator utilizes custom serrated terminals, in

combination with standard SEMS washer screws making

assembly easier and quicker to install; and provides superior connection strength when connecting with bare, solid

or stranded wire. It also allows for ring or spade termination connectors.

SECTION 1

STANDARDS

HPS Industrial and Machine Tool Control and Instrument Transformers meet or

exceeds the standards established by UL, IRC, ANSI, NEMA.

Standard File # VA Size

UL (ANSI/UL 506) E50394 All PH

IEC 61558 All PH (excluding PH***AJ & PH***AR)

NEMA (ST-1) All PH

At HPS, we rate the VA capacity of our transformers at the output ..... where it counts.

Other transformer manufacturers rate their capacity on the input side of the

transformer, which can result in a 5% to 20% lower actual VA at the output.

© Hammond Power Solutions Inc.

33

Data subject to change without notice.

Page 3

SECTION 1 HPS IMPERATOR

Fe a t u r e s & Be n e f i t s

TM

• 600V class, machine tool rated industrial control transformers

• 11 standard multi primary and secondary voltage groups available

• 50/60 Hertz (60Hz on PH***AJ & PH***AR)

• VA range from 50 to 5000

SECTION 1

• Superior insultation system

• 50-150VA, temperature rise 55°C, insulation class 105°C

• 250-1500VA, temperature rise 80°C, insulation class 130°C

• 2000-5000VA, temperature rise 115°C, insulation class 180°C

• Constructed with high quality silicon steel laminations that provide

optimum performance and reliability

• Encapsulated coils

molded cover, protects coils and terminations from moisture, dirt and other

industrial airborne contaminants.

• Mounting Feet: made of heavy steel and welded or bolted to the core, these

mounting feet provide superior strength in a compact design.

• Termination: combination slot/Philips #6 screw, complete with SEMS washer

(suitable for 18 AWG to 14 AWG solid or 14 AWG stranded wire)

• Standard SEMS washers - supplied on all units up to and including 1500VA

• Standard secondary fuse kits -utilizing 13/32” x 1 1/2” midget/type CC fuse clips

(supplied with all units up to and including 1500VA)

• Optional primary fuse kits available utilizing 13/32” x 1 1/2” midget/type CC fuse

clips

• Optional nger safe terminal covers available on all units up to and including

1500VA

• UL Listed (approved for U.S. and Canada)

• CE Mark standard on all molded units up to and including 1500VA

(excluding PH***AJ & PH***AR)

• LIFETIME Warranty (Limited)

• RoHS Compliant

1

1

(up to and including 1500VA) encased in a custom injection

2

(available on all units up to and including 1500VA)

1

special voltages and VA sizes available upon request

2

excluding PH750PG, PH1000PG, PH750MLI, PH1000MLI

© Hammond Power Solutions Inc.

Warranty

Lifetime

34

Data subject to change without notice.

Page 4

SECTION 1

SECTION 9

Fe a t u r e s & Be n e f i t s Co n t i n u e d

Terminal connection numbers molded into

terminal block and correspond to nameplate and

wiring diagrams, makes connecting the HPS

Imperator quick and simple.

Innovative terminal block

design (patent pending)

provides for easy hook-up and

installation of fuse clips.

HPS IMPERATOR

Standard secondary and optional

primary fuse kits utilizing 13/32” x 1 1/2”

midget/type CC fuse clips provide an

economical solution to your fusing

requirements (fuses not available).

TM

SECTION 1

Optional removable nger safe

terminal covers available on all units

up to and including 1500VA.

© Hammond Power Solutions Inc.

Custom injection molded coil cover with its

unique “n shaped” design combines superior cooling properties with a clean, bold look.

35

Made of heavy steel and

welded or bolted to the

core, these mounting feet

provide superior strength

in a compact design.

Data subject to change without notice.

Loading...

Loading...