Page 1

INSTALLATION, OPERATION AND MAINTENANCE GUIDE

FOR INDOOR/OUTDOOR SINGLE PHASE

FOR INDOOR/OUTDOOR SINGLE PHASE

ENCAPSULATED TRANSFORMERS

ENCAPSULATED TRANSFORMERS

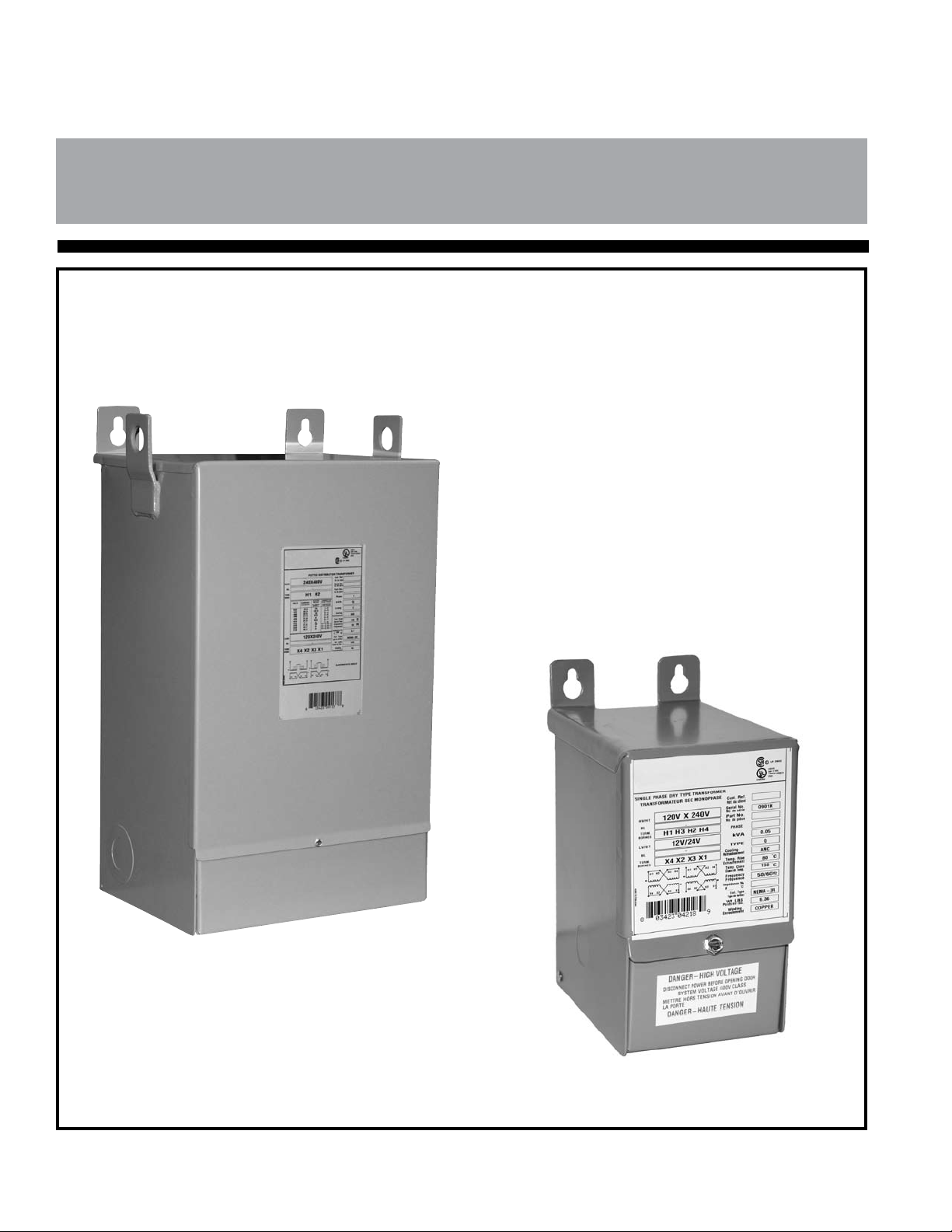

Indoor/Outdoor

Encapsulated Transformers

Single Phase

Up To 50 kVA

*Note: This guide is Trilingual

(English, French, Spanish)*

Literature No.: IOMGE1PH

Issue Date: May 2010

Page 2

Safety Precautions

(1) Do not lift or move a transformer without proper equipment and

experienced personnel.

(2) Do not install the transformer until a full inspection has been

completed.

(3) Use terminals only for electrical connections, and exible connectors

are recommended.

(4) Connections should only be in accordance with the nameplate diagram

or connection drawings.

(5) Make sure all power is disconnected before attempting any work on the

transformer.

(6) Make certain all ground connections are complete and tightened before

energizing the transformer.

(7) Do not attempt to change any taps - primary or secondary, while the

transformer is energized.

(8) Do not change connections when the transformer is energized.

(9) Do not adjust or remove any accessories or cover plates while the

transformer is energized.

Class 1, Division 2, Hazardous Location

Installation Requirements

If this unit is designed for use in Class 1, Division 2, Groups A, B, C & D

hazardous locations then also refer to notes below:

(1) Power, input and output (I/O) wiring must be in accordance with Class 1,

Division 2 wiring methods as per Article 501-10 (b) of the National

Electrical Code.

(2) WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN

TO BE NON-HAZARDOUS.

CONTENTS

General Information 3

Handling 3

Receiving & Inspection 3

Storage 3

Installation 3

Ventilation 4

Accessibility 4

Sound Levels 4

Cable Connections 4

Grounding 4

Inspection Before Energization 5

Operation 5

Maintenance 5

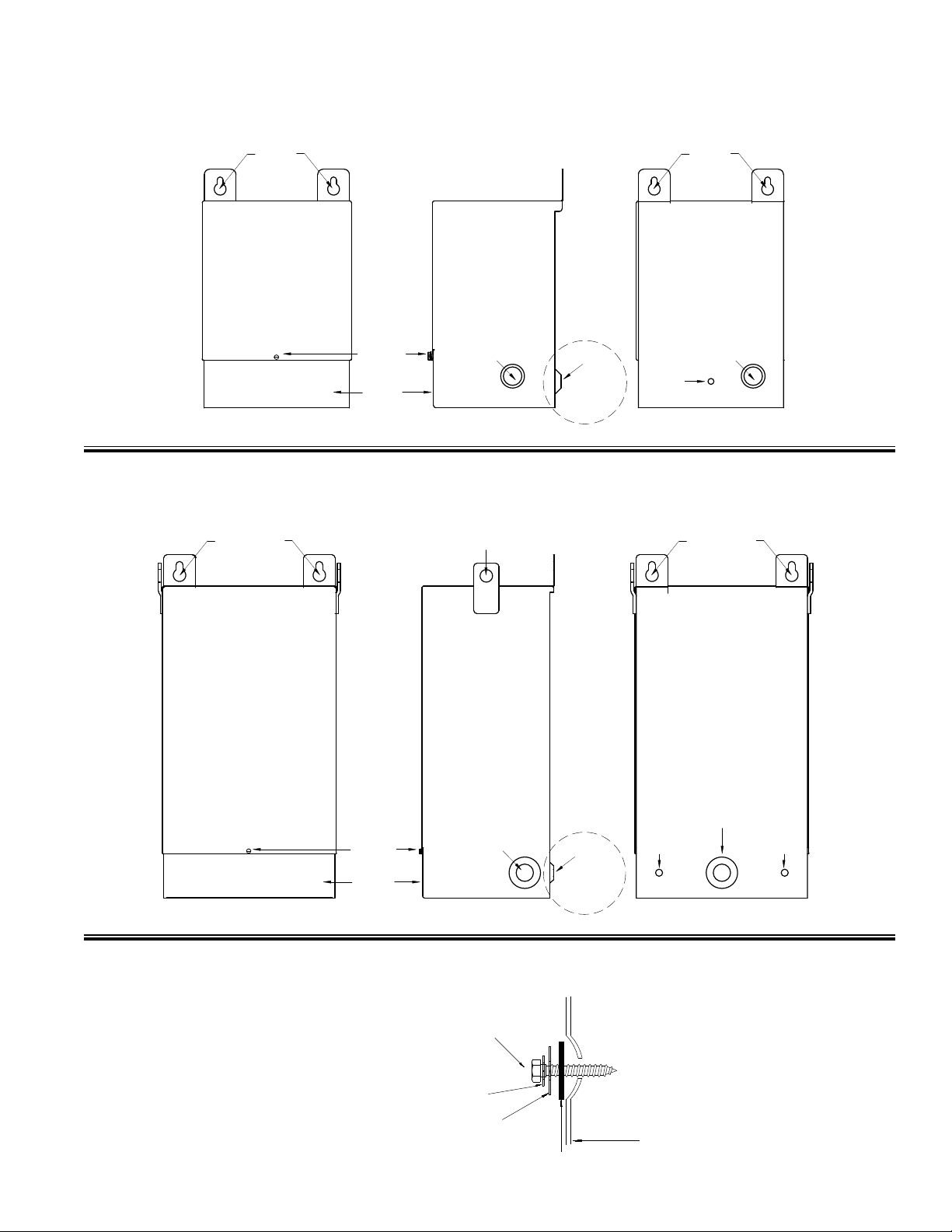

Diagrams 1a, 1b and 2 6

- 2 -

Page 3

INSTALLATION, OPERATION AND MAINTENANCE

OF ENCAPSULATED TRANSFORMERS

GENERAL

Encapsulated transformers are manufactured to

provide optimum performance for a lifetime of

uninterrupted service. Careful attention to the following

instructions is recommended for safe and reliable

operation.

Installation, operation and maintenance of

transformers should be performed by qualied

persons, familiar with electrical apparatus and the

potential hazards involved.

Warning: Danger! There is the potential of electric

shock whenever working in or around electrical

equipment such as transformers. Power must

be shut off before any work is conducted on a

transformer.

As with any electrical device, transformers

must be installed according to the requirements

of the national, and local electrical codes. Refer

to ANSI/IEEE C57-94 may also be referred to for

recommended installation, application, operation and

maintenance of dry-type transformers.

STORAGE

Transformers that will not be immediately

installed and energized, should be stored in a clean

dry environment away from any environmental

airborne contaminants.

It is recommended that transformers be stored in

a heated building, in the original shipping packaging.

INSTALLATION

All encapsulated transformers are supplied with a

NEMA 3R enclosure. NEMA 3R units may be installed

indoors, or outdoors where applicable.

For any outdoor location, the appropriate

applicable codes must be followed including cable

installation and hardware suitable for outdoor service.

Water tight couplings must be used at the knockouts.

Encapsulated transformers must be located in

an upright position on walls, posts, beams or other

locations capable of supporting their weight.

If encapsulated units are to be either stored or

installed outdoors, the unit must be oriented vertically

with the wiring compartment down to prevent the

ingress of moisture.

HANDLING

Transformers are either shipped in cartons or

palletized. The units on pallets can either be lifted via a

forklift truck or hoisted by the lifting lugs provided.

Appropriate lifting equipment should be used

relative to the size of each transformer. No attempt

should be made to lift or move a transformer from any

points on the unit other than those indicated.

Please Note: On units bolted to the pallets,

please remove the shipping bolts located at the top

mounting holes as well as the one(s) located inside the

wiring compartment.

RECEIVING INSPECTION

Immediately after receiving the transformer, it

should be inspected for any transit damage and for

correctness against the shipping documents.

The unit should be examined for any breaks in its

packaging, dented or damaged enclosures or missing

parts from the packing list.

If any damage is noted, a claim should be led

immediately with the carrier and a second copy of

all pertinent information relative to the order and the

circumstances should be led with the local sales

ofce.

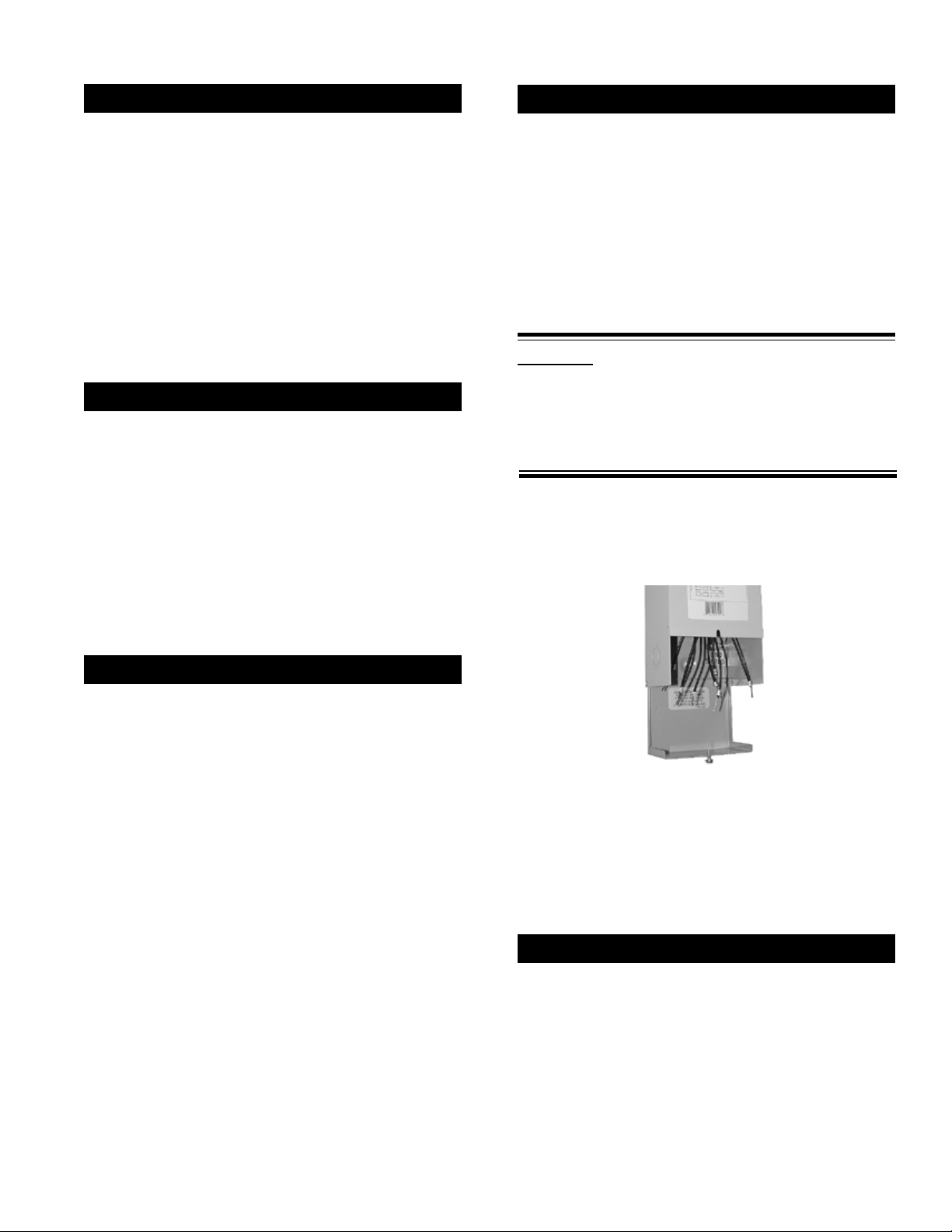

Mounting Instructions (refer to page 6)

1. Select an installation location that is on a

non-combustable surface.

2. The mounting location must allow for air

circulation around the transformer for cooling

purposes. Please refer to the minimum distances

stated in the ventilation section.

3. Using the appropriate mounting template

provided, drill the top two mounting holes on the

mounting surface.

4. Lift the transformer into position and install the top

two mounting bolts.

5. With the transformer hanging on the top two

mounting bolts, level the unit, then with the wiring

compartment cover open, mark and drill the lower

mounting hole(s) into the mounting surface.

6. To provide NEMA 3R protection (protection from

falling rain), the transformer must be mounted

vertically with the mounting tabs facing up.

7. Install the lower mounting bolt, lock washer, at

washer and rubber washer into the lower

mounting hole(s) (refer to Diagram 2).

- 3 -

Page 4

VENTILATION

CABLE CONNECTIONS

Transformers are required to be installed in

an area where they can be cooled by means of the

free circulation of air where the average ambient

temperature is 30°C (86°F) and should not exceed

40°C (104°F) at any time.

Adequate ventilation is essential for transformers

to meet their nameplate kVA capability. All

encapsulated general purpose transformers should be

located at least 2 inches on units up to 10kVA and at

least 4 inches on units over 10kVA, away from walls or

any other obstructions to allow free, clean circulation

of air.

ACCESSIBILTY

accessible for inspection and located accordingly.

However, transformers should not be located in areas

where stored items are likely to interfere with either

natural air convection or the capability to have them

inspected. Passage ways or other areas where people

could be exposed to live parts during inspection should

also be avoided.

Adequate protection should be provided under

any circumstances.

NEC standards require that transformers be

1. Open the wiring compartment by loosening the

cover screw.

2. Terminals should be cleaned and electrical joint

compounds are recommended for use on all

electrical connections.

3. Make the appropriate electrical connection to suit

the desired voltages as per the connection

diagram on the nameplate. This includes the

input connections, output connections and the

ground(s).

WARNING: If this unit is designed for and to be

used in Class 1, Division 2, Groups A, B, C and

D hazardous locations than the power, input and

output (1/0) wiring must be in accordance with

Class 1, Division 2 wiring methods as per Articles

501-10 (b) of the National Electrical Code.

4. Make certain to insulate any unused wire leads

with marrette connectors and electrical tape.

5. Close the wiring compartment and ensure that

the cover screw is tightly secured.

TRANSFORMER SOUND LEVELS

Transformers are an electrically energized

apparatus and by their nature emit sound due to their

component materials.

Transformers are required to meet NEMA

standards for the maximum sound levels permissible.

These sound level standards vary from 40 to 60 DB

and hence, can be an annoyance if located in close

proximity to where people work or reside.

Care should therefore be exercised in selecting

sites for transformers particularly to avoid sensitive

areas like hospitals, classrooms, medical or ofce

facilities.

The following guide lines may be helpful;

Units should be mounted away from corners or

reecting walls or ceilings.

Cable or other exible conduit should be

considered to make connections.

Acoustically absorbing materials could be

considered for walls and ceilings around the unit.

The location of the unit should be located as far

as practical from areas where sound levels could

be considered undesirable.

The connecting cable size is determined from

the line current rating of the transformers primary

and secondary windings. Convenient pre-punched

knockouts are provided on all transformer enclosures,

to facilitate cable entry. (NOTE: potted transformers cannot be

returned if the knockouts have been removed unless the unit has a

manufacturing defect as outlined in the standard warranty policy.)

GROUNDING

All core and coil assemblies are solidly grounded

to the enclosure internally to ensure that all conductive

metal parts have the same potential.

The transformer enclosure in turn should also

be securely and effectively grounded as a safety

precaution. This grounding should be in accordance

with national electrical code standards.

- 4 -

Page 5

INSPECTION BEFORE ENERGIZATION

For the safe and proper operation of the

transformer, we recommend that the following items be

checked for completeness:

a) The insulation resistance, enclosure to primary,

enclosure to secondary and primary to

secondary, should be greater than 10k ohms.

b) Before energizing and connecting any loads,

please measure and verify the output voltage

matches nameplate specications.

c) Ensure correct phase connections. Refer to the

nameplate vector diagram.

d) When windings are connected in parallel (as in

the case of dual voltage primaries), the primary

taps for all coils must be connected to the

identical percentage tap positions to avoid the

shorting of turns. For tap positions, refer to the

nameplate on the transformer.

e) The enclosure should be grounded with the

appropriately sized conductor.

f) The clearance and tightness of all electrical

connections should be checked.

g) For single phase 3-wire 240/120 volt loads, care

must be taken to ensure the neutral current does

not exceed 1/2 of the transformers kVA rating.

OPERATION

For all relatively normal and clean installations,

encapsulated transformers will operate satisfactorily

under normal conditions of energization and load.

For your reference, fully loaded transformers may

be very warm to the touch, particularly on the top of

the unit.

Standards permit the temperatures of the

enclosure to be 65°C over ambient. This represents

normal loading and should not be of concern.

Encapsulated transformers are designed to

operate continuously at their full nameplate kVA rating.

ANSI C57.96 provides guidance for loading

transformers under different conditions including:

Ambient temperatures that are varied from the

ambient temperatures required for transformer

operation.

Short time overload as it relates to time and

temperature and the corresponding loss of life of

the transformer.

Overload that results in a reduction of life

expectancy of the transformer.

If the transformer is experiencing increased

temperatures, the following load characteristics

should be considered immediately:

Rigorous motor starting loads or other impact

type loading for which a specic transformer for

that application is required.

Over-excitation of unit due to excess supply line

voltage or current.

Ambient temperatures above standard.

Overload beyond ANSI C57.96 guidelines.

Harmonic distortions of the supply line voltage

and currents.

MAINTENANCE

Under normal operating conditions and

environments, encapsulated transformers do not

require maintenance. However, periodic care and

inspection is a good practice, particularly if the unit is

exposed to extreme environmental conditions.

Peripheral inspection and external dust and dirt

removal may be carried out while the transformer is

in operation. However, access covers must not be

opened under energized conditions.

The accumulation of ice or snow will not adversly

effect the operation of encapsulated transformers.

However, the accumulation of dust or dirt will effect the

cooling of the transformer and may become a potential

fire hazard.

Internal maintenance must be performed with a

transformer de-energized, isolated and with the

terminals grounded.

The ground connection should be checked to

ensure a low impedance connection.

WARNING: If this unit is designed for and to be

used in Class 1, Division 2, Groups A, B, C, and

D hazardous locations; DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS

- 5 -

Page 6

Upper

Mounting

Holes

Upper

Mounting

Holes

FRONT VIEW SIDE VIEW BACK VIEW

Side Knockout Rear Knockout

Wiring

Compartment

Cover

Wiring

Compartment

Cover

Screw

Mtg. Hole

Lower

Mounting

Hole(s)

(see diagram 2 below)

DIAGRAM 1a: NQ0, NQ1, NQ2, NQ3, NQ4 and NQ5 Series Enclosure Mounting for

Upper

Mounting

Holes

Upper

Mounting

Holes

FRONT VIEW SIDE VIEW BACK VIEW

Side Knockout

Rear Knockout

Wiring

Compartment

Cover

Mtg. Hole

Mtg. Hole

Lower

Mounting

Hole(s)

Wiring

Compartment

Cover

Screw

Lifting Tabs

(see diagram 2 below)

Trans former

Enclo sure

Mount ing

Bolt

Lock

Washe r

Flat

Washe r

Rubbe r

Washe r

Single Phase Encapsulated Transformers.

DIAGRAM 1b: NQ6, NQ6A, NQ7 and NQ8 Series Enclosure Mounting for Single Phase

Encapsulated Transformers.

DIAGRAM 2: Lower wiring compartment mounting hole(s), mounting hardware installation

assembly diagram.

- 6 -

Page 7

GUIDE D’INSTALLATION, DE FONCTIONNEMENT ET D’ENTRETIEN

POUR TRANSFORMATEURS ENCAPSULÉS MONOPHASÉS

POUR TRANSFORMATEURS ENCAPSULÉS MONOPHASÉS

POUR L’INTÉRIEUR ET L’EXTÉRIEUR

POUR L’INTÉRIEUR ET L’EXTÉRIEUR

Transformateurs encapsulés

pour l’intérieur et l’extérieur

Monophasé

Jusqu’à 50 kVA

N° de document : IOMGE1PH

Date de publication : Mai 2010

Page 8

Consignes de sécurité

(1) Ne levez pas et ne déplacez pas un transformateur sans disposer de

l’équipement approprié et de personnel expérimenté.

(2) N’installez pas le transformateur tant qu’une inspection complète n’a pas

été effectuée.

(3) N’utilisez les bornes que pour les branchements électriques. Il est recom

mandéd’utiliserdesconnecteursexibles.

(4) Les branchements doivent respecter le schéma de la plaque signalétique ou les

diagrammes de connexion.

(5) Vériezquelasourced’alimentationestcoupéeavantdecommencerà

travailler sur le transformateur.

(6) Vériezquetouteslesliaisonsàlaterresontcomplètesetsontbienserrées

avant de mettre le transformateur sous tension.

(7) Ne tentez pas de changer des prises (primaires ou secondaires)

lorsque le transformateur est sous tension.

(8) Ne changez pas les branchements lorsque le transformateur est sous tension.

(9) Ne réglez pas et ne retirez pas les accessoires ou les plaques de recou vrement

lorsque le transformateur est sous tension.

Exigences pour l’installation dans

des emplacements dangereux de classe 1, division 2

Si cet équipement est conçus pour une utilisation dans des endroits dangereux

et non dangereux de classe 1, division 2, groupes A, B, C, D, réferrer aussi aux

notes suivants:

(1) L’alimentation ainsi que le câblage d’entrée et de sortie (I/O) doivent être

conformes aux méthodes de cablâge des équipements de division 2 décrites dans

l’article 501-10(b) du Code national de l’électricité.

(2) AVERTISSEMENT - RISQUE D’EXPLOSION - NE PAS DÉBRANCHER CET

ÉQUIPEMENT AVANT D'AVOIR COUPER LE COURANT OU QUE

L'ENDROIT EST CONNU POUR ÊTRE NON DANGEREUX.

TABLE DES MATIÈRES

Informations générales 9

Manutention 9

Contrôle de réception 9

Entreposage 9

Installation 9

Ventilation 10

Accessibilité 10

Niveaux de bruit 10

Branchement des câbles 10

Miseàlaterre 10

Inspection avant la mise sous tension 11

Fonctionnement 11

Entretien 11

Schémas 1a, 1b et 2 12

- 8 -

Page 9

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

DES TRANSFORMATEURS ENCAPSULÉS

INFORMATIONS GÉNÉRALES

Les transformateurs encapsulés sont fabriqués pour

fournir un rendement optimal pendant un cycle de vie de

service continu. Pour un fonctionnement fiable et sans

danger, nous vous recommandons de bien lire les consignes

suivantes.

L’installation, le fonctionnement et l’entretien des

transformateurs doivent être effectués par du personnel

qualiés, familier avec l’appareillage électrique utilisé et des

dangers potentiels qu’il représente.

Avertissement : Danger ! Travailler sur un

transformateur ou autour d'un équipment électrique

similaire présente un risque de choc électrique. Il

est indispensable de mettre hors tension la source

d'alimentation électrique avant d'entreprendre des

travaux sous tension.

Comme pour tout appareil électrique, les transformateurs

doivent être installés en conformité avec les codes nationaux

et locaux de l’électricité. Veuillez egalement vous reporter

a la norme ANSI/IEEE C57-94 pour les recommandations

portant sur l'installation, l'utilisation, le fonctionnement et

l'entretien des transformateurs de type sec.

MANUTENTION

ENTREPOSAGE

Les transformateurs qui ne sont pas immédiatement

installés et mis sous tension doivent être entreposés

dans un endroit propre et sec, à l’abri des contaminants

atmosphériques environnants.

Nous recommandons d’entreposer les transformateurs

dans un immeuble chauffé muni de l'emballage plastiwue

d'origine.

INSTALLATION

Tous les transformateurs encapsulés sont fournis

avec un boîtier NEMA 3R. Les unités NEMA 3R peuvent être

installées à l’intérieur ou à l’extérieur, le cas échéant.

Pour les installations à l’extérieur, les codes en

vigueur qui s’appliquent à l’installation doivent être

respectés, notamment ceux concernant l’installation des

câbles et le matériel convenant à une utilisation extérieure.

Des connecteurs de conduits étanches doivent être utilisés

aux endroits prévus (diaques défonçables).

Les transformateurs encapsulés peuvent être installés

à la verticale sur des murs, des poteaux, des poutres ou

dans d’autres endroits pouvant supporter leur poids.

Si les unités encapsulées sont entreposées ou

installées à l’extérieur, elles doivent être placées à la

verticale, le compartiment de branchement vers le bas, pour

éviter que l’humidité n’y pénètre.

Les transformateurs sont envoyés dans des boîtes ou

en palettes. Les unités sur palettes peuvent être soulevées

à l’aide d’un chariot élévateur à fourche ou levées par les

anneaux de levage fournis.

L’équipement de levage doit être adapté à la taille de

chaque transformateur. En aucun cas, un transformateur

ne doit être soulevé ou déplacé en utilisant d’autres points

d’ancrage que ceux indiqués sur l’appareil.

Remarque : Si le transformateur est xé aux palettes,

retirez les boulons de transport situés dans les orices de

xation supérieurs ainsi le(s) boulon(s) se trouvant dans le

compartiment de branchement.

CONTRÔLE DE RÉCEPTION

Immédiatement après avoir reçu le transformateur, une

inspection doit être effectuée pour vérier la présence de

dommages éventuels survenus durant le transport ainsi que

l’exactitude des documents d’expédition.

L’emballage sera examiné an d’y détecter des bris,

de voir si les boîtiers sont bosselés ou abîmés et si des

pièces inscrites sur le bordereau de marchandises sont

manquantes.

Si des dommages sont constatés, une réclamation

doit immédiatement être effectuée avec le transporteur

et une deuxième copie des renseignements concernant

la commande et les problèmes survenus devrait étre

conservée dans le bureau de vente local.

Instructions de montage (Référez-vous à la page 12)

1. Choisissez pour l’installation un emplacement

dont la surface est non combustible.

2. L’emplacement choisi doit permettre à l’air

de circuler librement pour assurer le

refroidissement de l’appareil. Reportez-vous

aux distances de dégagement minimales

indiquées dans la section Ventilation.

3. En vous servant du gabarit de montage appro

prié, percez les deux trous de xation du haut

sur la surface de xation.

4. Soulevez le transformateur jusqu’à sa position

de montage dénitive et xez les deux boulons

de xation du haut.

5. Ouvrez le couvercle du compartiment de

branchement et marquez le ou les trous

de xation du bas, puis percez la surface de

xation.

6. Pour obtenir une protection NEMA 3R

(protection contre la pluie), il faut monter le

transformateur verticalement, les pattes de

xation vers le haut.

7. Fixez le boulon de xation du bas, la rondelle de

blocage, la rondelle plate et la rondelle de

caoutchouc dans le ou les trous de xation

du bas (voir schéma 2).

- 9 -

Page 10

VENTILATION

BRANCHEMENT DES CÂBLES

Les transformateurs doivent être installés dans un

endroit où ils pourront être refroidis par la circulation de l’air.

La température ambiante moyenne doit être de 30 °C (86 °F)

et ne jamais excéder 40 °C (104 °F).

Une bonne ventilation est indispensable pour que

les transformateurs atteignent la capacité en kVA indiquée

sur leur plaque signalétique. Tous les transformateurs

encapsulés d’usage général doivent être installés à au moins

5 cm (2 po) des murs et autres obstacles pour des unités de

moins de 10 kVA et à au moins 10 cm (4 po) pour des unités

de plus de 10 kVA, pour permettre la libre circulation de l’air

frais.

ACCESSIBILITÉ

Il est prévu par les normes du Code national de

l'électricité que les transformateurs soient accessibles pour

l'inspection et que l'emplacement de l'installation soit choisi

dans cette optique. Ils ne doivent donc pas être installés

dans des locaux renfermant des objets entreposés risquant

de faire obstacle à la circulation de l’air et aux inspections.

Les passages et les endroits dans lesquels des personnes

risquent d’être exposées à des pièces sous tension au cours

de l’inspection doivent également être évités.

Une protection adéquate doit être assurée en toutes

circonstances.

1. Ouvrez le compartiment de branchement en

desserrant la vis du couvercle.

2. Les bornes devraient être nettoyées. Il est

de plus recommandé d’utiliser un produit

d’étanchéité pour raccordements électriques

pour tous les branchements électriques.

3. Effectuez le branchement électrique qui convient

aux tensions désirées en vous conformant au

schéma électrique de la plaque signalétique

(c.-à-d. les branchements pour l’entrée, la sortie

et la mise à la terre).

Avertissement: Si cette unité est conçue pour être

utilisé des endroits dangereux de classe 1, division 2,

groupes A, B, C, D. alors l’alimentation ainsi que le

câblage d’entrée et de sortie (I/O) doivent être

conformes aux méthodes de câblage des équipements

de division 2 décrites dans l’article 501-10 (b) du Code

national de l’électricité.

4. Veillez à bien isoler les ls inutilisés avec des

capuchons de connexion et du ruban isolant.

5. Refermez le compartiment de branchement

et vériez que la vis du couvercle est bien serrée.

NIVEAUX DE BRUIT DU

TRANSFORMATEUR

Les transformateurs sont des appareils alimentés par

l'électricité, et lorsqu'ils sont en fonction, les matériaux qui

sont necessaires à leur construction émettent un certain

bruit.

Les transformateurs doivent respecter les normes

NEMA en matière de niveau sonore. Ces normes varient de

40 à 60 dB, ce qui peut constituer une source de gêne pour

les personnes qui travaillent ou résident à proximité.

Il faut donc choisir avec soin leur emplacement

d’installation et éviter tout particulièrement les zones

sensibles comme les hôpitaux, les écoles, les

établissements médicaux et les bureaux.

Les lignes directrices suivantes pourront se révéler

utiles pour déterminer le bon emplacement d’installation.

Les unités doivent être installées loin des

angles et des murs ou plafonds rééchissants.

Pour les branchements, pensez à utiliser

des câbles ou autres conduits exibles.

Pensez à installer des matériaux acoustiques

absorbants sur les murs et les plafonds se

trouvant autour du transformateur.

Le transformateur doit se trouver aussi loin

que possible des zones pour lesquelles le bruit

pourrait constituer une gêne.

La taille du câble de branchement dépend du courant

nominal des enroulements primaires et secondaires du

transformateur. Des disques defonçables sont fournies avec

tous les transformateurs pour faciliter le passage du câble.

(REMARQUE : les transformateurs encapsulés dont les disques défonçables

ont été retirées ne pourront être retournés sauf si un défaut de fabrication

couvert par la garantie a été détecté.)

MISE À LA TERRE

Toutes les piéces métalliques du noyau-bobines,

non-porteuses de courant, sont reliées à la terre, via le

connecteur de mise à la terre. L'intégrité équipotentielle y

est maintenue.

Pour des raisons de sécurité, le boîtier du

transformateur doit lui aussi être adéquatement relié à la

terre. La mise à la terre doit être effectuée en conformité

avec les normes du Code national électrique.

- 10 -

Page 11

INSPECTION AVANT LA MISE

SOUS TENSION

Pour un fonctionnement adéquat et sans danger du

transformateur, nous recommandons que les éléments

suivants soient également vériés :

a) La résistance d’isolation, de la bobine à l'enroulement

primaire, de la bobine à l'enroulement secondaire

et de l'enroulement primaire au secondaire doit être

supérieure à 10 kilohms.

b) Avant de brancher et de mettre la charge sous tension,

mesurez la tension de sortie pour vérier s’il

correspond aux spécications de la plaque

signalétique.

c) Assurez-vous de brancher les phases conformément

au diagramme vectoriel de la plaque signalétique.

d) Lorsque les enroulements sont branchés en parallèle

(comme dans le cas d’enroulements primaires à

bitension), les prises primaires de toutes les bobines

doivent être branchées au même pourcentage de

positions de prises pour éviter que les spires ne soient

court-circuitées. Pour connaître les positions des

prises, consultez la plaque signalétique du

transformateur.

e) Le boîtier doit être mis à la terre à l’aide d’un

conducteur d’une taille adaptée.

f) Il faut vérier que chaque branchement électrique est

bien serré et sufsamment dégagé.

g) Dans le cas de charges monophasées à 3 conducteurs

de 240/120 volts, il est nécessaire de vérier que le

courant de neutre n’excède pas la moitié du régime

nominal en kVA du transformateur.

FONCTIONNEMENT

Dans tous les cas d’installation normale et bien

réalisée, les transformateurs encapsulés fonctionnent

normalement dans des conditions normales de mise sous

tension et de charge.

Pour votre information, un transformateur chargé peut

s’avérer très chaud au toucher, particulièrement la partie

supérieure de l'appareil.

Les normes permettent que les boîtiers de ce type

d’appareil puissent atteindre jusqu’à 65 °C de plus que la

température ambiante. Cette chaleur indique une charge

normale et ne doit pas vous inquiéter.

Les transformateurs encapsulés sont conçus pour

fonctionner en permanence selon la pleine capacité de kVA

indiquée sur leur plaque signalétique.

ENTRETIEN

Dans des conditions de fonctionnement et des

environnements normaux, les transformateurs encapsulés

ne nécessitent aucun entretien. Il est cependant

recommandé de procéder à un entretien et une inspection

de routine, particulièrement si l’unité est exposée à des

conditions climatiques extrêmes.

Une inspection des éléments externes et un nettoyage

de la poussière et de la saleté accumulées sur le boîtier

peuvent être effectués lorsque le transformateur fonctionne.

Cependant, les couvercles d’accès ne doivent pas être

ouverts lorsque l’appareil est sous tension.

L’accumulation de glace ou de neige ne compromet

pas le fonctionnement des transformateurs encapsulés.

Par contre, l’accumulation de poussière ou de saleté gène

le refroidissement de l’appareil et peut provoquer un risque

d’incendie.

L’entretien interne doit être effectué sur un

transformateur éteint, isolé, et dont les bornes sont

mises à la terre.

Il est nécessaire de vérifier la liaison à la terre pour

garantir que le branchement est de faible impédance.

AVERTISSEMENT - Si cette unité est conçue pour être

utilise des endroits dangereux de classe 1, division

2, groupes A, B, C, D. – NE PAS DÉBRANCHER CET

ÉQUIPEMENT AVANT D'AVOIR COUPER LE COURANT

OU QUE L'ENDROIT EST CONNU POUR ÊTRE NON

DANGEREUX.

Les normes C57.96 de l’ANSI donnent des

directives pour le chargement des transformateurs dans

différentes conditions, notamment :

démarrage de moteur brusque ou autre type de

charge brusque pour lequel un transformateur

spécique pour ce type d'application est requis.

ur-excitation de l’unité à la suite d’une surtension de

l'alimentation ou d'une surcharge.

températures ambiantes supérieures à la

normale.

surcharge supérieure aux directives C57.96

de l’ANSI.

distorsions harmoniques de la tension de la ligne

d'alimentation et du courant.

- 11 -

Page 12

Trous de

montage

supérieurs

Trous de

montage

supérieurs

VUE AVANT VUE LATÉRALE VUE ARRIÈRE

Disque défonçable arrière

Trou de

montage

Trou(s) de

montage

inférieur(s)

(Reportez-vous au diagramme 2, ci-dessous.)

Couvercle du

compartiment de

branchement

Vis du couvercle

du compartiment

de branchement

Disque défonçable latérale

SCHÉMA 1a : Montage du boîtier des séries NQ0, NQ1, NQ2, NQ3, NQ4 et NQ5 pour

Trous de

montage

supérieurs

Trous de

montage

supérieurs

VUE AVANT VUE LATÉRALE VUE ARRIÈRE

Disque défonçable latérale

Disque défonçable arrière

Couvercle du

compartiment de

branchement

Trou de montage

Trou(s) de

montage

inférieur(s)

Vis du couvercle

du compartiment

de branchement

Languettes de soulèvement

Trou de montage

(Reportez-vous au diagramme 2, ci-dessous.)

Boîtier du transformateur

Boulon de fixation

Rondelle de blocage

Rondelle plate

Rondelle de caoutchouc

transformateurs encapsulés monophasés.

SCHÉMA 1b : Montage du boîtier des séries NQ6, NQ6A, NQ7 et NQ8 pour

transformateurs encapsulés monophasés.

SCHÉMA2:Trou(s)dexationinférieur(s)ducompartimentdebranchement,

schémad’assemblagedelaquincailleriedexation.

- 12 -

Page 13

GUÍA DE INSTALACIÓN, OPERACIÓN Y MANTENIMIENTO

TRANSFORMADORES MONOFÁSICOS CON GABINETE

TRANSFORMADORES MONOFÁSICOS CON GABINETE

PARA INTERIORES Y EXTERIORES

PARA INTERIORES Y EXTERIORES

Transformadores con gabinete

para interiores y exteriores

Monofásico

Hasta 50 kVA

N.º de folleto: IOMGE1PH

Fecha de emisión: De mayo de 2010

Page 14

Precauciones de seguridad

(1) No levante ni traslade un transformador sin equipo apropiado ni personal

experimentado.

(2) No instale el transformador hasta que se haya realizado una inspección

completa.

(3) Ut i l ic e ú n i c am e n t e l os te rm i na l e s pa ra co ne x io ne s e l éc t ri ca s .

Serecomiendanconectoresexibles.

(4) Las conexiones solo deben realizarse siguiendo el diagrama de la placa de

identicaciónolosdiagramasdeconexión.

(5) Asegúrese de que toda la energía esté desconectada antes de iniciar cualquier

trabajo en un transformador.

(6) Asegúrese de que todas las conexiones a tierra estén completas y ajustadas antes

de dar energía al transformador.

(7) No intente cambiar ninguna derivación, primaria o secundaria, mientras el

transformador esté energizado.

(8) No cambie las conexiones cuando el transformador esté bajo excitación.

(9) No ajuste ni retire ningún accesorio ni cubierta protectora mientras el

transformador está energizado.

Sitio peligroso de clase 1, división 2

Requisitos para la instalación

Si esta unidad es diseñada para uso en locaciones peligrosas Clase 1, División 2,

GruposA,B,C&D,entoncesreérasetambiénalasnotassiguientes:

(1) El cableado de energía, entrada y salida (I/O, por sus siglas en inglés) debe cumplir

con los métodos de cableado de clase 1, división 2, de acuerdo con el Artículo

501-10 (b) del Código Eléctrico Nacional.

(2) ADVERTENCIA - PELIGRO DE EXPLOSIÓN - NO DESCONECTE EL EQUIPO A MENOS

QUE SE HAYA APAGADO LA ENERGÍA O QUE EL ÁREA NO SEA PELIGROSA.

CONTENIDO

Información general 15

Manipulación 15

Recepción e inspección 15

Almacenamiento 15

Instalación 15

Ventilación 16

Accesibilidad 16

Niveles de ruido 16

Conexiones de cables 16

Conexión a tierra 16

Inspección antes de la energización 17

Operación 17

Mantenimiento 17

Diagramas 1a, 1b y 2 18

- 14 -

Page 15

INSTALACIÓN, OPERACIÓN Y MANTENIMIENTO

DE LOS TRANSFORMADORES CON GABINETE

GENERAL

Los transformadores con gabinete se fabrican para

brindar un rendimiento óptimo con una vida útil de servicio

ininterrumpido. Se recomienda seguir al pie de la letra las

siguientes instrucciones para lograr una operación segura y

conable.

La instalación, la operación y el mantenimiento de

los transformadores deben ser realizados por personas

calicado, que tengan conocimiento sobre aparatos eléctricos

y los posibles riesgos que conllevan.

Advertencia: ¡Peligro! Existe el riesgo de descarga

eléctrica cuando trabaja con o cerca de equipos

eléctricos como los transformadores. Se debe

desconectar la energía antes de realizar cualquier

trabajo en un transformador.

Al igual que con cualquier dispositivo eléctrico, los

transformadores se deben instalar de acuerdo con los

requisitos de los códigos eléctricos nacionales y locales.

También puede consultar la norma ANSI/IEEE C57-94 para

conocer las pautas recomendadas de instalación, aplicación,

operación y mantenimiento de transformadores de tipo seco.

MANIPULACIÓN

Los transformadores se envían en cajas de cartón o

en tarimas. Las unidades en las tarimas se pueden elevar

con un montacargas o se pueden levantar con las argollas

de elevación provistas.

Se debe utilizar equipo de elevación apropiado para el

tamaño de cada transformador. No se debe intentar elevar

ni trasladar un transformador desde ningún otro punto de la

unidad que no sean los puntos indicados.

Tenga en cuenta: En las unidades atornilladas a las

tarimas, retire los pernos de envío que se encuentran en

los oricios de montaje superiores y los que se encuentran

dentro del compartimiento de cableado.

INSPECCIÓN DE RECEPCIÓN

Inmediatamente después de recibir el transformador,

se debe inspeccionar para detectar cualquier daño

transitorio y para vericar la exactitud de los datos en

comparación con los documentos de envío.

Se debe examinar la unidad para detectar cualquier

rotura en el embalaje, abolladura o daño en los recintos o

piezas faltantes de la lista de empaquetado.

Si se observa algún daño, se debe presentar un

reclamo de inmediato ante la empresa de transporte y

una segunda copia ante la ocina local de ventas con

toda la información pertinente con respecto al pedido y las

circunstancias.

ALMACENAMIENTO

Los transformadores que no se instalarán y

energizarán de inmediato, se deben guardar en un ambiente

seco y limpio, alejados de cualquier contaminante ambiental

en suspensión.

Se recomienda guardar los transformadores en un

lugar con calefacción, en su embalaje de envío original.

INSTALACIÓN

Todos los transformadores con gabinete vienen

provistos de un recinto NEMA 3R. Las unidades NEMA 3R

se pueden instalar en interiores, exteriores o donde sea

necesario.

Para una ubicación en exteriores, se deben seguir los

códigos aplicables adecuados, que incluyen la instalación de

los cables y el equipo apropiado para el servicio exterior. Se

deben usar acoplamientos herméticos en los troqueles.

Los transformadores con gabinete se deben ubicar en

posición vertical apoyados en paredes, postes, vigas u otros

lugares que puedan soportar el peso.

Si las unidades encapsuladas se van a guardar

o instalar en exteriores, la unidad se debe orientar

verticalmente con el compartimiento de cableado hacia

abajo para impedir el ingreso de humedad.

Instrucciones de montaje (Reerase a la página 18)

1. Seleccione un lugar para la instalación que esté

sobre una supercie no inamable.

2. La ubicación de montaje debe permitir la

circulación de aire alrededor del transformador

para que pueda enfriarse. Consulte las distancias

mínimas especicadas en la sección de ventilación.

3. Con la plantilla de montaje apropiada que viene con

el equipo, perfore dos oricios de montaje superior en

la supercie de montaje.

4. Levante el transformador hasta colocarlo en su

posición e instale los dos pernos de montaje superiores.

5. Con el transformador colgando sobre los dos pernos

de montaje superiores, nivele la unidad y luego, con el

compartimiento de cableado abierto, marque y perfore

los oricios de montaje inferiores en la supercie de

montaje.

6. Para brindar protección NEMA 3R (protección contra

lluvia), el transformador debe estar montado

verticalmente con las lengüetas de montaje orientadas

hacia arriba.

7. Instale el perno de montaje inferior, la arandela de

presión, la arandela plana y la arandela de goma en

el oricio de montaje inferior (ver Diagrama 2).

- 15 -

Page 16

VENTILACIÓN

Los transformadores se deben instalar en una área

donde se puedan enfriar mediante la libre circulación de aire

y donde la temperatura ambiente promedio sea de 30°C

(86°F) y no supere los 40°C (104°F) en ningún momento.

La ventilación adecuada es esencial para que los

transformadores alcancen la capacidad de kVa que gura

en la placa de identicación. Todos los transformadores con

gabinete para usos generales se deben ubicar por lo menos

a 2 pulgadas (5 cm) en las unidades de hasta 10 kVa y a por

lo menos 4 pulgadas (10 cm) en las unidades superiores a

10 kVa, alejados de paredes o de otras obstrucciones para

permitir la libre y despejada circulación de aire.

ACCESIBILIDAD

sean accesibles para la inspección y que se ubiquen

adecuadamente para tal n. Sin embargo, los

transformadores no se deben ubicar en áreas donde

es probable que los elementos almacenados intereran

con la convección natural del aire o con la capacidad de

inspeccionarlos. También se deben evitar los pasillos u

otras áreas donde la gente pueda estar expuesta a piezas

energizadas durante la inspección.

Se debe proporcionar protección adecuada bajo

cualquier circunstancia.

Las normas NEC exigen que los transformadores

CONEXIONES DE CABLES

1. Abra el compartimiento de cableado aojando el

tornillo de la cubierta.

2. Los terminales se deben limpiar, y se recomienda

usar compuestos de empalme eléctrico en todas las

conexiones eléctricas.

3. Realice las conexiones eléctricas apropiadas para

adaptarse a los voltajes deseados de acuerdo con el

diagrama de conexión que gura en la placa de

identicación. Esto incluye las conexiones de entrada,

de salida y la conexión a tierra.

PELIGRO: Si esta unidad es diseñada para o va ser

usada en, locaciones peligrosas Clase 1, División 2,

Grupos A, B, C & D, entonces las conexiones eléctricas

de entrada y salida deben estar de acuerdo con los

métodos de conexión para Clase 1, División 2, según los

Artículos 501-10 (b) del Código Nacional de Electricidad.

4. Asegúrese de aislar todos los cables conductores no

utilizados con conectores Marrette y cinta aisladora.

5. Cierre el compartimiento de cableado y verique que

el tornillo de la cubierta esté rmemente ajustado.

NIVELES DE RUIDO

DEL TRANSFORMADOR

Los transformadores son aparatos energizados

eléctricamente y por su naturaleza emiten ruidos debido a

sus materiales componentes.

Los transformadores deben cumplir las normas NEMA

para los niveles máximos de ruido permitidos. Estos niveles

de ruido varían de 40 a 60 DB, y por lo tanto, pueden ser

molestos si se encuentran en las inmediaciones de los

lugares donde viven o trabajan personas.

Se debe tener cuidado al elegir los sitios para los

transformadores, especialmente para evitar áreas sensibles

como hospitales, escuelas, centros médicos u ocinas.

Las siguientes pautas pueden ser útiles.

Las unidades deben montarse alejadas de

esquinas o de paredes o cielorrasos que

produzcan reejos.

Los cables u otros conductos exibles deben

tenerse en cuenta para realizar conexiones.

Los materiales absorbentes acústicamente se podrían

tener en cuenta para las paredes y los cielorrasos

alrededor de la unidad.

La unidad debe ubicarse lo más alejada posible

de las áreas donde los niveles de ruido podrían

considerarse indeseables.

El tamaño del cable de conexión se determina con la

potencia de corriente de línea de los bobinados primarios

y secundarios de los transformadores. Se suministran

prácticos troqueles previamente perforados en todos los

recintos de los transformadores para facilitar la entrada de

los cables.

devolver si se han retirado los troqueles, a menos que la unidad

tenga un defecto de fabricación, como se describe en la política de

garantía estándar).

(NOTA: Los transformadores envasados no se pueden

CONEXIÓN A TIERRA

Todos los conjuntos de núcleo y bobina se conectan

sólidamente a tierra al recinto, en forma interna, para

garantizar que todas las piezas metálicas conductoras

tengan el mismo potencial.

El recinto del transformador también debe tener

una conexión a tierra segura y ecaz como precaución

de seguridad. Esta conexión a tierra debe cumplir con las

normas de los códigos eléctricos nacionales.

- 16 -

Page 17

INSPECCIÓN ANTES DE LA

ENERGIZACIÓN

Para la operación segura y apropiada del

transformador, recomendamos vericar que se hayan

completado los siguientes pasos:

a) La resistencia del aislamiento, el recinto hasta el

primario, el recinto hasta el secundario y del primario

al secundario, debe ser superior a 10 k ohmios.

b) Antes de energizar y conectar cualquier carga, mida y

verique que el voltaje de salidacoincida con las

especicaciones de la placa de identicación.

c) Verique que las conexiones de fase sean correctas.

Consulte el diagrama vectorial de la placa de

identicación.

d) Cuando los bobinados se conectan en paralelo (como

en el caso de primarios de doble voltaje), las

derivaciones primarias de todas las bobinas se deben

conectar en las posiciones de derivación con

porcentaje idéntico para evitar el cortocircuito de

las marchas. Para conocer las posiciones de

derivación, consulte la placa de identicación

del transformador.

e) El recinto debe estar conectado a tierra con el

conductor del tamaño apropiado.

f) Se debe vericar que todas las conexiones eléctricas

respeten la distancia de seguridad y que estén

ajustadas.

g) Para las cargas monofásicas, de 3 hilos, de 240/

120 voltios, se debe tener cuidado para garantizar

que la corriente neutra no supere 1/2 de la potencia

de kVA de los transformadores.

Si el transformador presenta aumento de temperatura,

se deben considerar de inmediato las siguientes

características de carga:

Cargas de arranque del motor rigurosas u otra carga

de tipo impacto para la cual se requiere un

transformador especíco para esa aplicación.

Excitación excesiva de la unidad debido a un exceso

del voltaje o la corriente de la línea de alimentación.

Temperaturas ambiente superiores a las estándar.

Sobrecarga superior a la indicada en las pautas

ANSI C57.96.

Distorsiones armónicas del voltaje y las corrientes

MANTENIMIENTO

En condiciones normales de funcionamiento y

ambientales, los transformadores con gabinete no requieren

mantenimiento. Sin embargo, es una buena práctica realizar

el cuidado y la inspección periódica, especialmente si la

unidad está expuesta a condiciones ambientales extremas.

La inspección periférica y la remoción del polvo

y la suciedad externa se deben realizar mientras el

transformador está en funcionamiento. Sin embargo, no se

deben abrir las cubiertas de acceso si el transformador está

energizado.

La acumulación de hielo o nieve no afectará

negativamente el funcionamiento de los transformadores

con gabinete. Sin embargo, la acumulación de polvo o

suciedad afectará el enfriamiento del transformador y podría

representar un riesgo de incendio.

OPERACIÓN

Para todas las instalaciones relativamente normales

y limpias, los transformadores con gabinete funcionarán

satisfactoriamente en condiciones normales de energización

y carga.

Para su referencia, los transformadores totalmente

cargados pueden estar muy calientes al tacto,

especialmente en la parte superior de la unidad.

Las normas permiten que las temperaturas del recinto

sean de 65ºC con respecto a la temperatura ambiente.

Esto representa una carga normal y no debe ser motivo de

preocupación.

Los transformadores con gabinete están diseñados

para operar en forma continua a la potencia total de kVA que

gura en la placa de identicación.

La norma ANSI C57.96 ofrece pautas para la carga de

transformadores en diferentes condiciones, entre ellas:

Temperaturas ambiente que varían de

las temperaturas ambientes exigidas para la

operación de transformadores.

Sobrecarga de corta duración que se relaciona

con el tiempo y la temperatura y la

correspondiente pérdida de la vida útil del

transformador.

Sobrecarga que provoque la reducción de

la expectativa de vida útil del transformador.

El mantenimiento interno se debe realizar con un

transformador desenergizado, aislado y con los

terminales con conexión a tierra.

Se debe verificar la conexión a tierra para garantizar

que sea una conexión de baja impedancia.

PELIGRO: Si esta unidad es diseñada para o va ser

usada en, locaciones peligrosas Clase 1, División 2,

Grupos A, B, C & D, NO DESCONECTE EL EQUIPO

A NO SER QUE LA ELECTRICIDAD HAYA SIDO

DECONECTADA O HASTA ESTAR SEGURO QUE EL

AREA ES FUERA DE PELIGRO.

- 17 -

Page 18

Orificios

superiores

de montaje

Orificios

superiores

de montaje

VISTA POSTERIOR

VISTA LATERAL

VISTA FRONTAL

Cubierta del

compartimiento

de cableado

Tornillo de la

cubierta del

compartimiento

de cableado

Troquel lateral

Agujero(s)

inferior(es)

de montaje

Agujero de

montaje

Troquel trasero

(ver Diagrama 2 abajo)

DIAGRAMA 1a: Montaje de recintos de serie NQ0, NQ1, NQ2, NQ3, NQ4 y NQ5 para

Orificios

superiores

de montaje

VISTA FRONTAL VISTA LATERAL VISTA POSTERIOR

Troquel lateral

Troquel trasero

Cubierta del

compartimiento

de cableado

Agujero de montaje

Agujero(s)

inferior(es)

de montaje

Tornillo de la

cubierta del

compartimiento

de cableado

Lengüetas de elevación

Orificios

superiores

de montaje

Agujero de montaje

(ver Diagrama 2 abajo)

Recinto del transformador

Perno de montaje

Arandela de presión

Arandela plana

Arandela de goma

transformadores con gabinete monofásicos.

DIAGRAMA 1b: Montaje de recintos de serie NQ6, NQ6A, NQ7 y NQ8 para

transformadores con gabinete monofásicos.

DIAGRAMA2: Oriciosdemontajeinferioresdelcompartimientodecableado,

diagrama del conjunto de instalación del equipo.

- 18 -

Loading...

Loading...