Hammond Leslie 3300 P, Leslie 3300 WP Service Manual

SERVICE M ANU AL

SUZUKI MUSICAL INST.MFG.CO.,LT D.

*#//10&

.'5.+'2

.'5.+'92

SEP.2009

CAUTION !

see safety notice inside

LESLIE3300WP

LESLIE3300P

2-25-12 , RYOKE, NAKAKU, HAMAMATSU, 43 0- 08 52 JAPAN

Great care has been taken in the design and manufacture of this product to assure that no shock hazard exists on any exposed

metal parts. Internal service operations can expose the technician to hazardous line voltages and accidentally cause these

voltages to appear on exposed metal parts during repair or reassembly of product components. To prevent this, work on these

products should only be performed by those who are thoroughly familiar with the precautions necessary when working on this

type of equipment.

To protect the user, it is required that all enclosure parts and safety interlocks be restored to their original condition and the

following tests be performed before returning the product to the owner after any service operation.

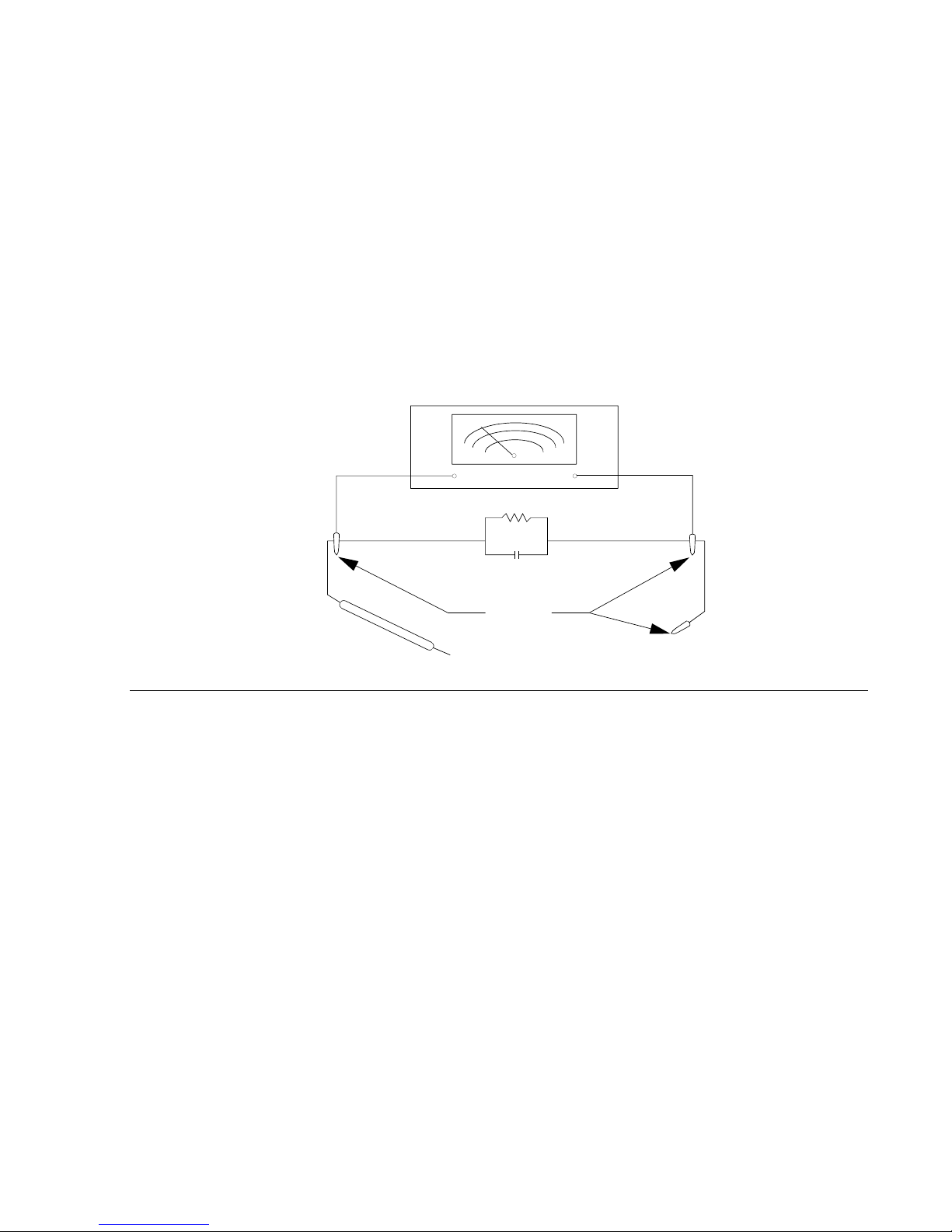

Plug the AC line cord directly into a line voltage AC receptacle (do not use an isolation transformer for this test) and turn the

product on. Connect the network (as shown below) in series with all exposed metal parts and a known earth ground such as a

water pipe or conduit. Use an AC Voltmeter of 5,000 ohms per volt or higher sensitivity to measure the voltage drop across the

network. Move the network connection to each exposed metal part (metal chassis, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the voltage drop across the network. Reverse the line plug and repeat the measurements. Any

reading of 4 volts RMS or more is excessive and indicates a potential shock hazard which must be corrected before returning

the product to the user .

SAFETY NOTIC E

CAUTIO N

Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the

equipment manufacturer. Discard used batterie s according to manufacturer's instructions.

Advarsell

Lithiumbatteri. Eksplosionsfare ved fejlagtig håndering.

Udskiftning må kun ske med batteri as samme fabriket og type.

Lebér det brugte batteri tilbage til leverandoren.

Norge: ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskif tning benyttes kun batteri som anbefalt av appa ratfabrikanten.

Brukt batteri returneres apparatleverandoren.

Sverige:

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller et ekvivalent typ som

rekommenderes av apparattillverkaren,

Kassera använt batteri enlig fabrikantens instruktion.

Finland:

VAROITUS

Paristo voi räjähtää, jos se on virheeliseeti ansennettu

Vaihda p aristo ainoastaan laitevalmistajan suosittelemaan

tyyppoonn, Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

VOM

AC SCAL E

10K

2W

0.01MF

CERA MIC RF

BYPASS CAP

TEST CLIPS

CONNECTE D TO K NO WN

EARTH GROUND

TEST

PROBE

TO EXPOSED METAL PARTS

#3300P

#3300WP

-Table of Contents-

1

2

3-1,3- 2

4

5

6-1,6- 2

7

8-1

8-2

8-3

9-1~9-3

10-1~10-7

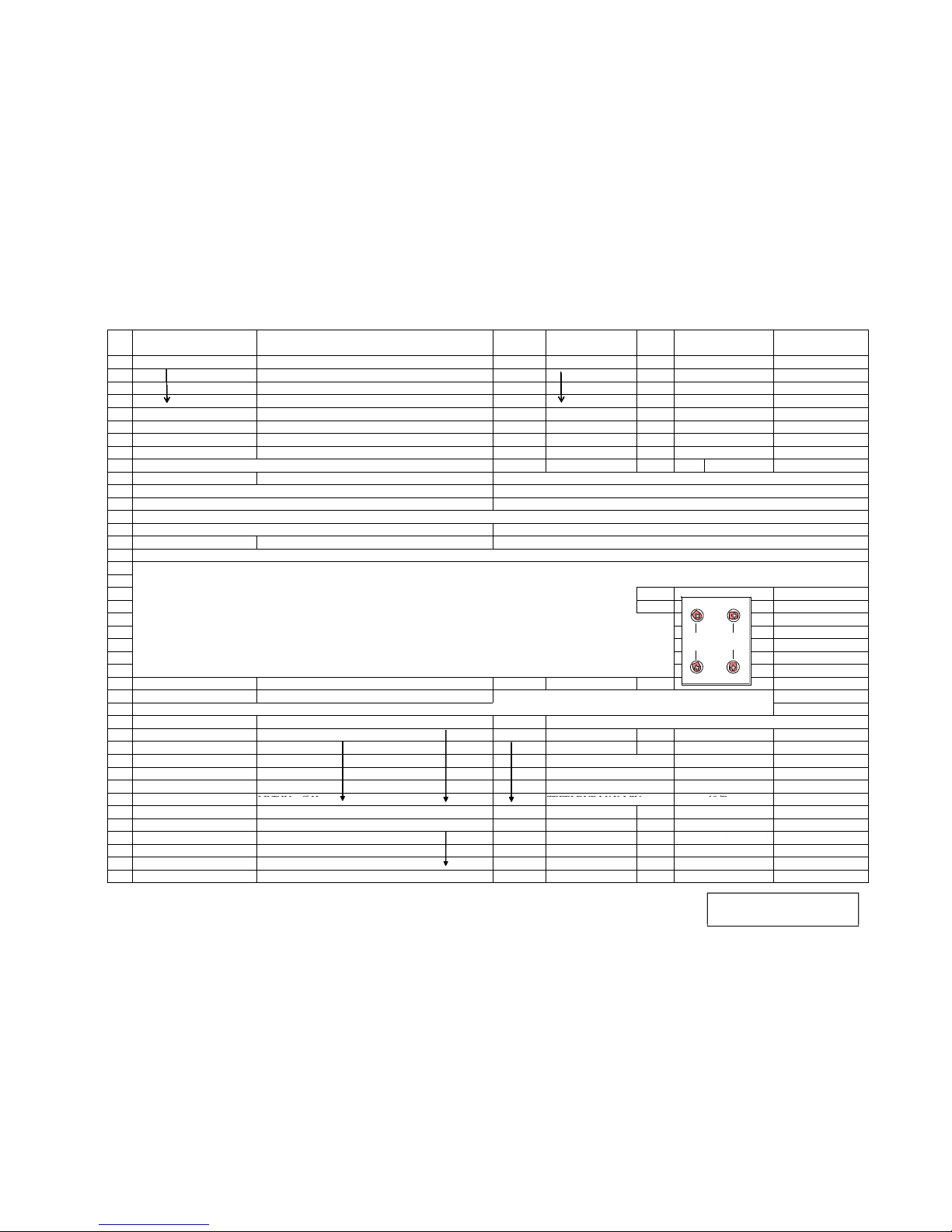

1.SPECIFICATIONS

2.B LOCK DIAGRAM

3.DISASSEMBLY PROCEDURE

4.TEST AND ADJUSTMENT

5.WIRI NG CONNECTION

6.WIRING CHART

7.PRI NTED WIRI NG BOARD ASS'Y LIS T

8.SCHEMATICS

PWH-74C

PAH-74B

CTH-37A

9.TECHNICAL DESCRIPTI ON

10.PARTS LIST

-1-

1.SPECIFICATIONS

TYP E

POWER OUTPUT

SPEAKER

OVERDRIVE

CONTROL

MOTOR

ROTORADJUST

LED

TERMINAL

POWER CONSUMP T ION

DIMENSION

WEIGHT

OPTIONAL

:1-Channel(Rotary Channel Only) REAL 2-Rotor

:HORN Rotor 80 W,DRUM Roto r 22 0 W

(TOTAL POWER 300W)

:ROTARY H ORN DRIVER H e a v y -Duty 100 W,

WOOFER 38cm Massive15"(38cm)

:VACUUM TUBE 12AX7X1

TUBE DRIVE LEVEL, TU BE ON /OFF,TUBE MODE

:EQ BASS, MIDDLE,TREBLE

VOLUME,H ORN LEVEL, SUB WOOFER VOLUME

:BRUSH L ESS DC MOTORx2

:HORN RI SE TIME,FA L L TIME, SLOW SPEED, FA ST SPEED

DRUM RISE TI ME, FALL TIME, SLOW SPEED,FAST SPEED

:FAST,SLOW,STOP

:LESLIE 11PIN SOCKET with STATIONARY L,R THROUGH OUTPUT,

LESLIE 8PI N,LINE INPUT,L INE OUT/ SU B WOOFER OU T

FOOT SWITCH (SLOW/FAST/STOP) AC INPUT

:AC 100V,120V,220~240V,230~240V, 210W

:63(W)x52(D)x90(H)cm

:57kg

:LESLIE CABLE 11 PIN(LC11-7M)

LESLIE CABLE 8PIN(LC8-7M )

FOOT SWITCH FS-9H

1) Horn Driver

2) Power Board

3) Preamp. Board

4) SP Spacer ass'y

5) WR-HZ144-A

6) Upper motor & Bearing ass'y : Pan head machine screw M4x20 fixing the driver mount --> Changed to M4x16

Changes from Leslie 3300

*

: Changed to PA-D50Z made by P.AUDIO

: PWH-72A --> Changed to PWH-74C

: PAH-74A --> Changed to PAH-74B

: Changed to SP Sp acer P

: Sleeve added to the terminal for the driver

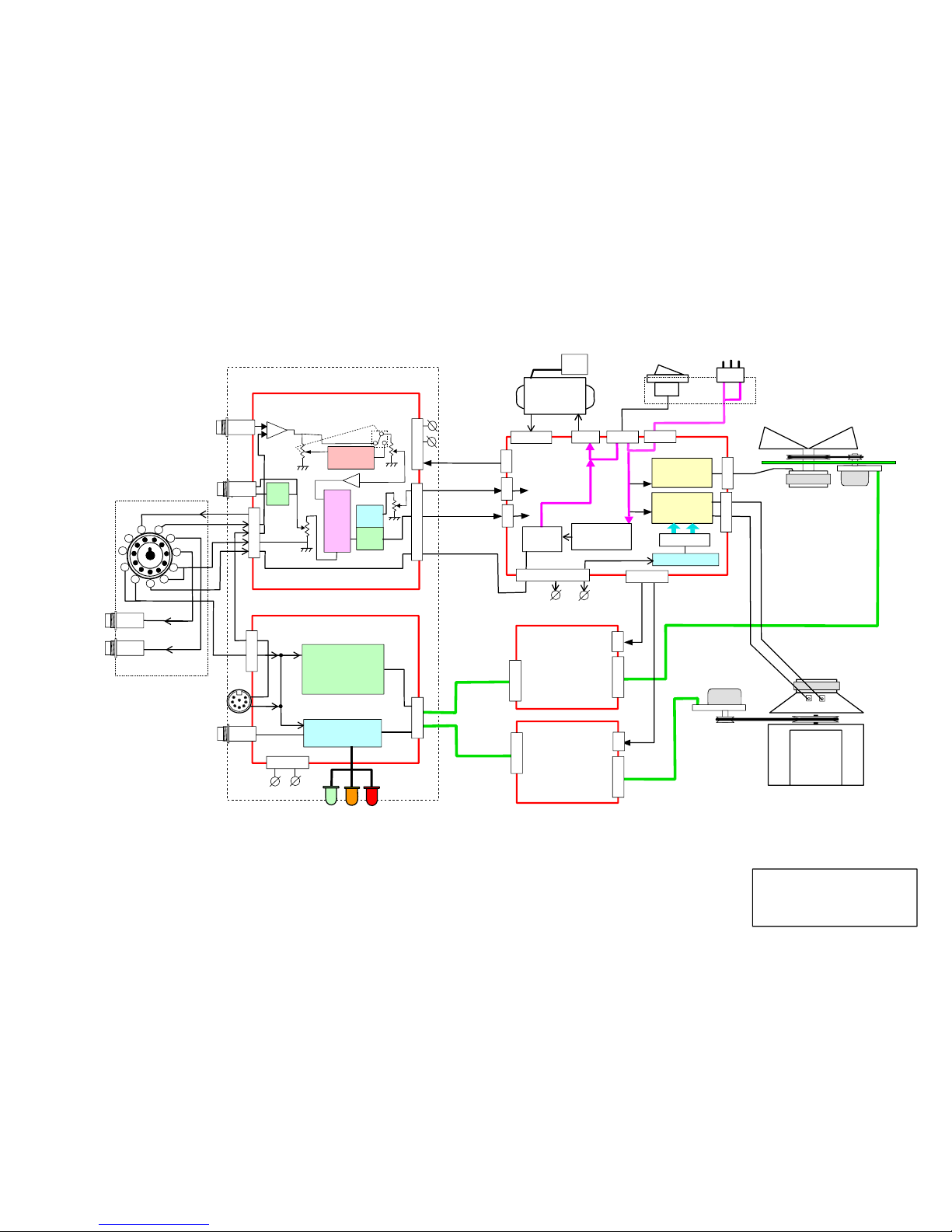

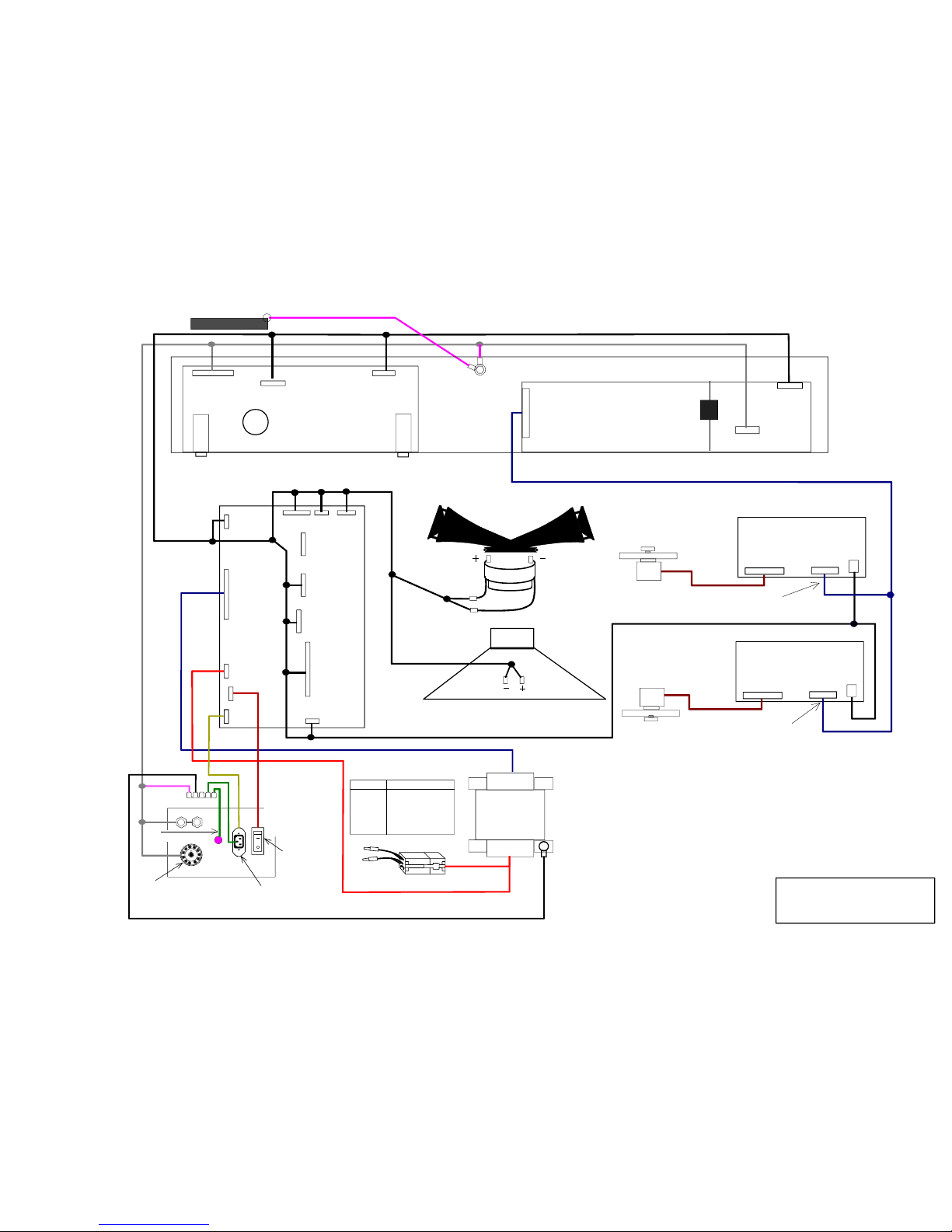

DC SER VO

MOTOR 1

ROTARY

HORN

HORN

DRIVER

SPEAKER

15"WOOFER

DC SER VO

MOTOR 2

DRUM

ROTOR

2.BLOC K DIAGRAM

#3300P, #3300W P

#3300P

#3300WP

POWER SUPPLY

& POWER A MP

TUBE PREAMP

PWH-74C

PAH-74B

CTH -37A

LGH-43A

LGH-43A

CONTROL PANEL

Power SW PANEL

Powe r SW

PANEL

MOTOR SPEED

CONTROLLER

MOTOR

DRIVER 1

MOTOR

DRIVER 2

LINE IN

SUB WOOFER

/ LINE OUT

Stationary-L OUT

Stationary-R OUT

POWER

TRANS

EPH-123

SLOW /FAST/S TOP

FOOT SW

REMOTE

POWER ON

RELAY

1 - Rotary sig. IN

2 - Stationary-L IN

3 - Stationary-R IN

4 - Audio GND

5 - Control GND

6 - Power ON

7 - LE S.FAST

8 - LE S.SLOW

11- +15V OUT

Rotar y SIG

SLOW / F AST

S/F

8PIN ROT SIG

+24V

P.S.

+24V

P.S.

+15V

+15V

-15V

80W HORN

POWER AMP

220W BTL

POWER A MP

+37V TUBE P.S .

HORN SIG

BASS SIG

+15V

-15V

+15V

-15V

EPH-122 SUB TRANS

for POWER RELAY

AC INLET

POWER

SWITCH

J110

J106

J107

J109

J108

J112

C

N

3

CN2

CN1

CN1

CN2

CN3

LESLIE 11PIN

LESLIE 8PIN

FAST SLOW STOP

SPEED I ND. LED

1

11

10

9

8

7

6

5

4

3

2

POWER O N

J303

J302

J101

J111

J103

J102

J301

Voltage

Select

Plug

Primary

IC1A

MIX AMP

IC1B

Tube Drive

Level

VOLUME

Tube MODE

SUB

WOOFER

VOLUME

HORN

LEVEL

JK3

JK4

JK2

JK1

Tube 12AX7

HPF

LPF

LPF

BASS

MID

TREBLE

3BAND

EQ

IC3B

U1

U6,Q5 Thermo Sensor

U2

IC2

LED1

LED2

LED3

IC3C

IC3A,D

U2 HORN/DRUM

Speed, Rise & Fall

Time Control

U1 CPU

Motor Control

J201

J205

Cooling Fan

J202

J104

#3300P

#3300WP

#3300P, #3300W P

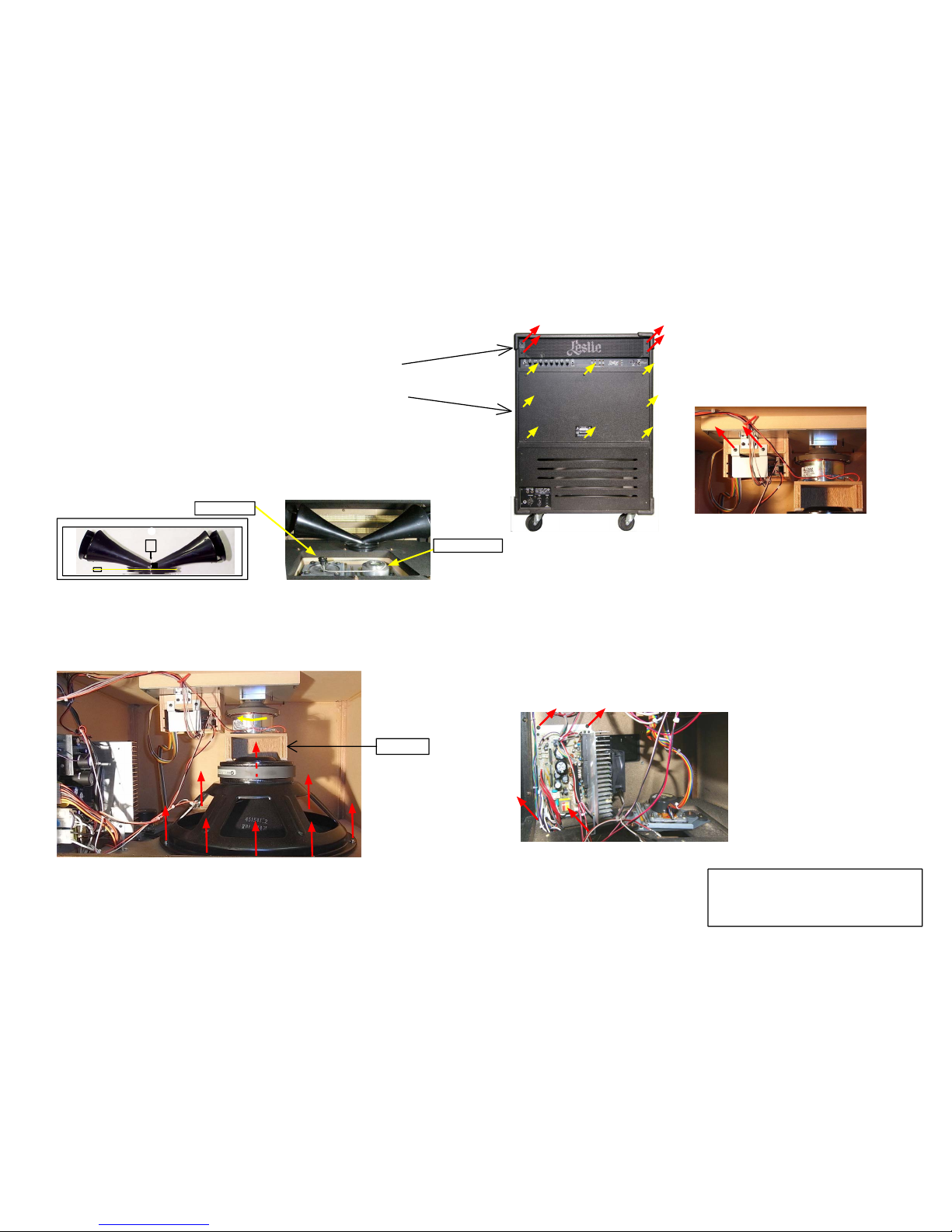

3.DISASSEMBLY PROCEDURE

3. DISASSEMBLY PROCEDURE

#3300P, #3300W P

1/2

2.Remove the Middle Rear Panel.

Remove the 8 tapping screws(type-1 truss,Ø4x30),then remove the Middle Rear Panel.

1.Remove the Upper Rear Cover.

Remove the 4 tapping screws(type-1 truss, Ø4x16),then remove the U pper Rear Cover.

NOTE: Unplug the Power Cable from the u nit before disassembling it.

3. Procedure to change the Horn Rotor Belt..

Locate a sm all Philips screwdriver (of maximum total length 8.5cm).Drop the Belt by tilting in

the Motor. Next r emove the 2 small screws (bind M3x16 for fixing the Horn R otor) and remove

the Horn from the Bearing.

Place the new Belt around the Bearing Ass'y and after mounting the Horn Rotor,

lift it onto the Motor Pulley and the Horn.

Fig. 3

Motor Pull ey

Bearing Ass'y

6. Remove the Motor Drive PWB.

Remove the Cover Bracket of the Motor Cover Ass'y by removing the 2 tapping scr ews (type-1 bind,

Ø3x10).

Slide and remove the PWB with the Connector from the Cover.

Keep track of the wiring for the UP Motor and the Low Motor.

(They are Similar in appearance but not interchangeable.)

Fig. 7

4. Procedure to replace the Horn Driver:

Pull out the "SP Spacer" (between the Horn D river and the Woofer Speaker).

Remove the con necting leads from the horn driver.

Rotate the Driver Unit to the left and remove it from the Upper Horn Motor Ass'y.

Be careful not to pinch your finger s between the Woofer Magnet and the Horn Driver.

(as the ma gnetic pull from the woofer magnet is strong.)

5. Removing th e 15" Woofer Spea ker.

Remove the 8 scr ews W Sems (P=3 M4x30).

Place a thick piece of cardboa rd etc. between the Magnets of the Speaker a nd the

Horn Driver and avoid both Magnets from sticking together.

7. Remove the PWH -74C.

First remove the wiring(s) from the PWB.

Next rem ove the 4 tapping screws (type-1 truss, Ø4x16);

(2 are horiz ontal on the top, 1 is on the bottom,

and another fixes the heat-sink bracket).

Fig. 6

Fig. 1,2

Fig. 4,5

SP Spa cer

#3300P

#3300WP

#3300P, #3300W P

3. DISASSEMBLY PROCEDURE

2/2

Fig. 12-E

Fig 12-D,E

Fig. 12-C

Link Drive

Pin.

9. Remove the Bottom Rear panel.

Pull the panel up from the unit after removing the 4 tapping screws (type-1 truss,

Ø4x30). Slide it down when remounting.

Fig 10-1

Fig 10-2

10. Removing the Power Switch Panel.

Remove the 3 tapping screws (type-1 truss, Ø4x16) (2 horiz ontal,

1 vertical).

If necessary, r emove the 2 GND wirings inserted to the Faston termina l.

Turn the U P Bearing Ass' y.

11. How to change the wide Drum Rotor Belt.

First remove the Belt by tilting in the Lower Motor. After removing the

2 screws W Sems (P=3, M4x30), turn and detach the UP Bearing Ass'y

from the Ca binet.

Take out the Belt from the opening of this Cabinet, and replace it with a

new one.

12. Remove the Drum Rotor.

NOTE: Don't let an unexperienced service staff remove the Drum Rotor.

It requires a certain level of technique to put the shaft into the

Lower Bea ring Ass'y at th e assembly.

A, Remove the 15" Spea ker and the Power Switch Panel.

B, Pull out the UP Bear ing Ass'y from th e Pulley Ass'y.

C, Pull out th e rubber Link Drive (for conducting the rotation of the pulley

to the rotor) from the Rotor Pin,

D, Slowly take it out from the Drum Rotor by turning

the Pulley and the Shaft.

E, When the Shaft is pu lled out from the Lower Bea ring Ass'y, move the Drum Rotor

to the front.

F, Then slide it from underneath the Horn Driver, and take out the Shaft from the

Rotor. Finally, take out the Drum Rotor from the Cabinet.

Fig 11

Shaft and Pulley Ass'y

LOW ER Bea ring ASS'Y

Fig. 9

#3300P

ADJUSTM

RISE

TIME

FALL

TIME

HORN

DRUM

1. a

DC Power Supply Check +15V PWH-74C J110-6

b

-15V J110-1

DC +15V ±5%

DC -15V ±5%

STEP

NOTESUBJECT TEST POINT

ENT

POINT

SPECIFICATIONSETTING INPUT

b

15V

J110 1

c

+37V MAIN VOLUME 0: J111-4

d

+24V J112-3,4

DC 15V

±5%

DC +40V ±4V

DC +24V ±1V

e

LESLIE 11PIN DC OUT Check LES11P -PIN11,(GND)

f

Remote Power ON Check Power SW OFF Short PIN6 -PIN 4

DC +15V ±5%

Power ON

RISE

TIME

FALL

TIME

HORN

DRUM

2.

Resetting Rotation Speed to Factory Settings

Switch ON the power, pressing the Foot SW, and wait for 5 sec. Check the STOP LED (RED) slowly flashes and the HORN and the DRUM ROTOR turns at SLOW.

RISE

TIME

FALL

TIME

HORN

DRUM

a

SLOW SPEED Adjustment: Adjust SLOW by the TRIMMER on the panel

.

Turn the HORN side, so the FAST (GRN) LED turns on

. As

the rotation approaches the standard, it flashes

.

Turn the DRUM side, so the SLOW (ORG) LED turns on. (40±3rpm*)

Press on the Foot SW and switch the Motor to FAST, and wait until the Brake LED (RED) turns on.

RISE

TIME

FALL

TIME

HORN

DRUM

b

FAST SPEED Adjustment: Adjust FAST by the TRIMMER on the panel

.

Turn the DRUM side, so the SLOW (ORG) LED turns on. (400±10rpm*)

Turn the HORN side, so the FAST (GRN) LED turns on

. As

the rotation approaches the standard, it flashes

.

RISE

TIME

FALL

TIME

HORN

DRUM

c

3.

Check the RISE TIME and the FALL TIME of the HORN and the DRUM. (See the figure on the right)

'

After checking, switch OFF the power and switch it ON again for normal operation.Turn the DRUM side, so the SLOW (ORG) LED turns on

.

RISE

TIME

FALL

TIME

HORN

DRUM

3-1

HORN RISE TIME (SLOW -> FAST)

approx. 2.5 ±0.5 sec. at 10 o'clock pos

iti

on

3-2 HORN FALL TIME (FAST -> SLOW) approx. 2.5 ± 0.5 sec. at 9 o'clock position

3-3 DRUM RISE TIME (SLOW -> FAST) approx. 8 ± 1.5 sec. at 11 o'clock position

RISE

TIME

FALL

TIME

HORN

DRUM

3-4

DRUM FALL TIME (FAST

->

SLOW)

approx. 8 ± 1.5 sec. at the center

If not at these tolerances, adjust by the TRIMMER.

If the TRIMMER must be turned more than 30 degrees from the standard position A malfunction is present.

RISE

TIME

FALL

TIME

HORN

DRUM

4

CHECK Power AMP .

Set TUBE MODE, BASS, MID, TREBLE, HORN LEVEL at the center.

TUBE DRIVE LEVEL is TUBE OFF; SUB WOOFER VOL is MAX

RISE

TIME

FALL

TIME

HORN

DRUM

a

TUBE ON

/

OFF CHEC

K

MAIN VOLUME: Grade 2 Adjust the VR9 of the PAH74B so as to not change the output at the TUBE ON/OFF

b

WOOFER SP LINE IN 800Hz 80mV LINE IN PWH-74C J104-2,4 (LINE OUT 15mVrms)

c

HORN SP LINE IN 8kHz PWH-74C J102-1

600mV rms ±30mV

550mV rms ±6mV

RISE

TIME

FALL

TIME

HORN

DRUM

c

SUB WOOFER OUT LINE IN 80Hz

d

TONE VR Check LINE IN 80Hz BASS VR MAX-MIN

e

LINE IN 2kHz MID VR MAX-MIN

+4dB,-17dB

+4.5dB,-6.5dB

SUBWOOFER OUT JAC

K

130mV rms ±12m

V

RISE

TIME

FALL

TIME

HORN

DRUM

f

LINE IN 8kHz TREBLE VR MAX-MIN

5.

CHECK the Noise MAIN VOLUME: MAX

±10dB

RISE

TIME

FALL

TIME

HORN

DRUM

a

Woofer SP- Noise Level PWH-74C J104-2

b

Woofer SP+ Noise Level PWH-74C J104-4

c

HORN SP Noise Level PWH-74C J102-1

1.0mV max (IEC"A"net)

1.0mV max (IEC"A"net)

1.5mV max (IEC"A"net)

RISE

TIME

FALL

TIME

HORN

DRUM

#3300P, #3300WP

RISE

TIME

FALL

TIME

HORN

DRUM

4.TEST AND ADJUSTMENT

RISE

TIME

FALL

TIME

HORN

DRUM

5.WIRING CONNECTION

#3300P, #3300W P

#3300P

#3300WP

POWER

SWITCH

AC INLET

GND TERMINAL

PANEL

Earth

11PIN

100V

120V

220V

240V

00106-00241

00106-00242

00106-00243

00106-00244

Par t No.

Volts

Voltage Select Plug

Secondary

Primar y

POWER SW PANEL

BLK

Horn Driver

Woofer

CONTROL PANEL

WR-HZ144-D

WR-HZ144-A

WR-HZ144-A

WR-HZ144-E

WR-HZ144-D

REAR COVER

WR-HZ144-G 2/2

WR-HZ144-B

WR-HZ144-D

WR-HZ144-A

MOTOR CABLE

MOTOR CABLE

PANEL GND

J301

5P

6P

7P

PAH-74B

Tube PreAmp

J302

J303

EPH-123

PWH-74C

Power

J106

J107

J108

J109

J112

J110

J113

J103

3P

4P

2P

8P

5P

5P

10P

4P

J111

3P

J101J102

J105

J104

4P

4P

2P

3P

UPPER MOTOR ASSY

LOWER MOTOR ASSY

J205

8P

J204

J203

J202

5P

J201

6P

CTH-37A

Motor Control

LGH-43A 1

Motor Driver

CN2

CN1

CN3

9P 10P

2P

LGH-43A 2

Motor Driver

CN2

CN1

CN3

9P 10P

2P

WR-HZ144-G 1/2

RED

White

Red

POWER

TRANS

Red

5PIN

R Red

L White

Pink

5PIN

Pink

Black

Red

Black

CN3

CA UTION !!

CN3

CA UTION !!

WR-HZ144-C

Loading...

Loading...