Hammond LESLIE 2102, LESLIE 2101 Service Manual

SERVICE MANUAL

SUZUKI MUSICAL INST.MFG.CO.,LTD.

25-12,RYOKE 2-CHOME,HAMAMATSU, JAPAN

~HA<O>

Dec.2002

CAUTION !

see safety notice inside

LESLIE 2102

(SILVER)

LESLIE 2101

(BLACK)

Rotary Unit

Units shown with optional stands.

#2101/ #2102

-Table of Contents-

1

2

3-1,3-2

4

5

6-1,6-2

7

8-1

8-2

8-3~8-5

9

10

11-1~10-3

1.SPECIFICATIONS

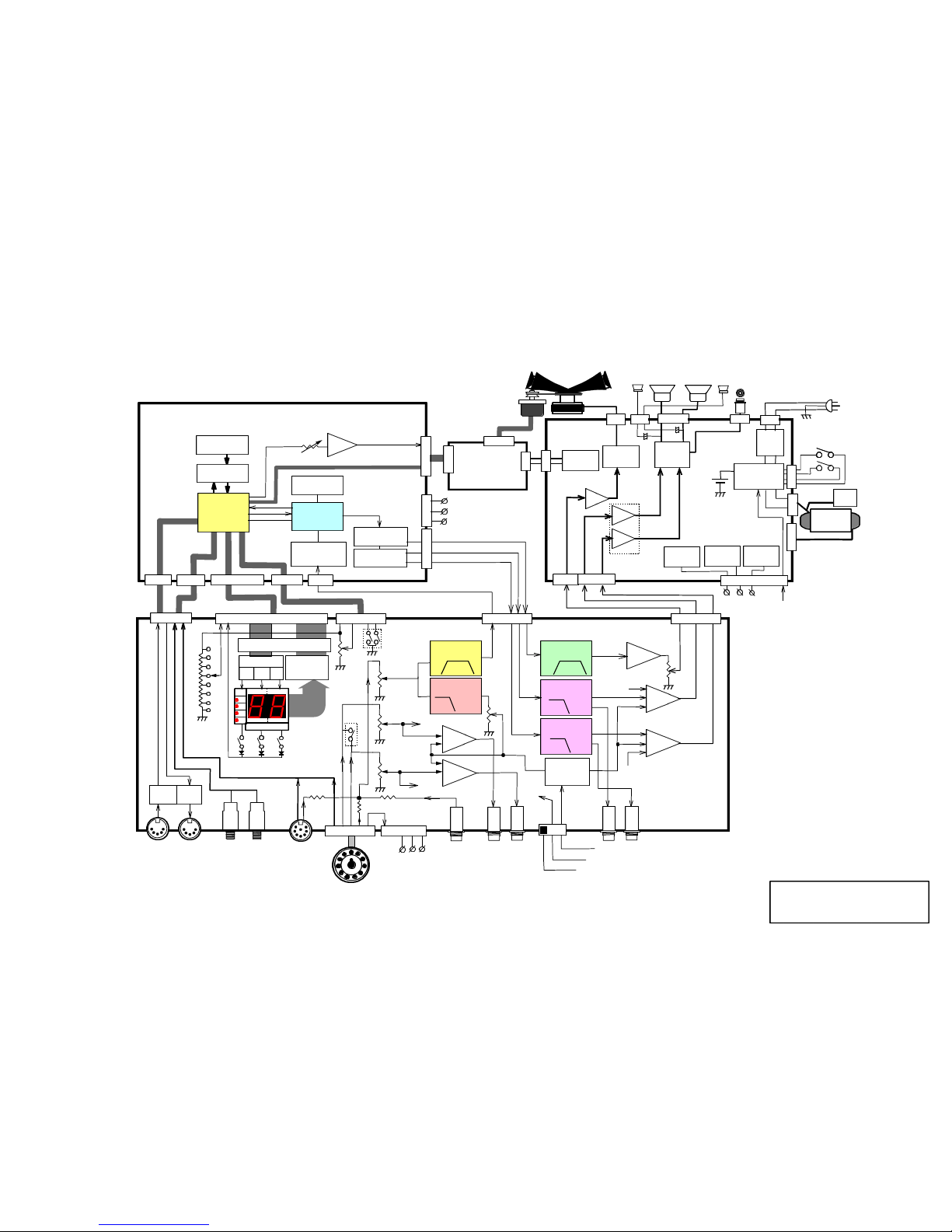

2.BLOCK DIAGRAM

3.DISASSEMBLING PROCEDURE

4.TEST AND ADJUSTMENT

5.WIRING CONNECTION

6.WIRING CHART

7.PRINTED WIRING BOARD ASS'Y LIST

8.SCHEMATICS

PWH-68A

SWH-492A

EFH-237A 1/3~3/3

9.WARNING

10.TECHNICAL DESCRIPTION

11.PARTS LIST

-1-

1.SPECIFICATIONS

TYPE

POWER OUTPUT

SPEAKER

CONTROL

DISPLAY

TERMINAL

POWER CONSUMPTION

DIMENSION

WEIGHT

OPTIONAL

Rotary Unit #2101 (Black) , #2102 (Silver)

: 3-channel (ROTARY, STATIONARY-L , STATIONARY-R)

HORN ROTOR(ACOUSTIC)

LOWER ROTOR(2channel DSP)

: ROTARY HORN 50W, LOWER CH 50WX2

: ROTARY HORN COMPRESSION DRIVERX1,

13cm WOOFERX2.5cm TWEETERX2

: VOLUME:

STA-L , STA-R , ROTARY , OVERDRIVE

8-POSITION FUNCTION SWITCH, VALUE UP/DOWN

PRESET 1-2, MEMORY

CHANNEL MODE:

NORMAL-STA MONO, STA ROT BASS-MUTE

: 7segment 2digit LED display

: LESLIE 11PIN SOCKET , LESLIE 8PIN , ROTARY INPUT ,

FOOT SWITCH 1 (PRESET), FOOT SWITCH 2 (SLOW/FAST/STOP)

LINEOUT(STATIONARY-L, STATIONARY-R, ROTARY-L, ROTARY-R)

MIDI IN, MIDI OUT, REMOTE POWER for #2121

: AC 120V,220-230V,230-240V 190W

: 51(W)X52(D)X33(H)cm

: 23kg

: STATIONARY UNIT #2121, LESLIE CABLE 11PIN (LC11-7M)

LESLIE CABLE 8PIN (LC8-7M),LESLIEY CABLE(LC11Y-7M)

STAND ADAPTER(LSA-21) , FOOT SWITCH FS-9H

+5V Reg.

U3

U1A :BPF

125-12kHz

U7 :24bit DAC

U4 : 128K x 8

MTP ROM

U10 : 20bit ADC

PCM1800E

LED

1

2

3

4

LED5(7seg x 2)

LED Driver

U6 & Q4

COM Driver

Q1 Q2 Q3

U11:24bit DAC

U7

PC900V

Q10

A933S

8bit x 3 Matrix

U1B:LPF

125Hz

U2A

MIX AMP

U2B

MIX AMP

U3A :BPF

700-12kHz

U4A:LPF

1.1kHz

STA-L

U5A:LPF

1.1kHz

Low

Rotor

Lch

Horn Rotor ch

Rotary Channel

Low

Rotor

Rch

U3B

AMP

U14A

DC AMP

VR1 GAIN

OFFSET

MOTOR CONTROL DC

U4B

MIX AMP

U5B

MIX AMP

Power Amplifier

& Power Supply

CPU Control & DSP Effect

PreAmp

& Panel Switch

Power On

Mute Relay

Q1,Q2,RL2

13cm Woofer

Lch Rch

Rch

Tweeter

Power Switch

Lch

Tweeter

Rotary Horn

Brushless DC

Servo Motor

FY815-SD3

U2

POWER AMP

STK402-120

POWER AMP

STK404-130

U1

PWH-68A

SWH-492A

EFH-237A

Motor Driver

FYD815SD3-300

to J110-10

R79 thru R85

Leslie Power On

50W50W

50W

50W

Power On

Mute Relay

Q1,Q2,RL1

+5

ROT BASS

MUTE ON/OFF

Q6, Q7

ROT BASS

LEVEL

VR5

VR4

OVER

DRIVE

COM 0

1

8

SW1

MEM

D1

D2 D3

SW2

FUNC.

SEL.

SW3

PRESET

SELECT

COM 1

COM 2

SW5 VALUE

(Rotary Encoder)

ROT IN

VOLUME

VR1

SW4

FUNCTION

SWITCH

Vref

STA-L

VOLUME

VR2

STA-R

VOLUME

VR3

HORN

LEVEL

VR6

J302

J307

J206

J203

J207 J205

J301J305

J306

J103

LESLIE 11PIN

Bass & Stationary

Line out

L/MONO R

LESLIE 8PIN

J101

Rotary

Line out

Rotary

Line IN

1 2

PRESET SLOW/FAST

FOOT SWITCH

LESLIE SLOW / FAST CONTROL

IN OUT

MIDI

L/MONO R

STA-L

STA-R

STA-R

U8 :64KW x 16bit

DRAM

U3 : 1M SRAM

uPD431000AGW

J303

+12

SW6

SLIDE

SWITCH

NORMAL

STA MONO

BASS & STA

MUTE

SW6-2

SW6-2

-12

J304

J102

C28

C29

J104

J105

Voltage

Select

Plug

BT1 3V

Battery

CR2032

+12

Primary

Secondary

-12

+24V Reg.

U6

POWER

TRANS

EPH-115

+5

from J303

AC LINE FI

LTER

L1,C48 to

C52

Remote DC Out

J110 -10

J106

J108

J109

Remote Power

On Relay RL3

Q3,Q4,Q5

J107

J112

CN3

J208

J202 J201

J204

CN1

CN2

U1 :CPU

H8/3007

+12

-12

+5

U9 : DSP

TMS57070

+12V Reg.

U4

-12V Reg.

U5

J111

2.

BLOCK DIAGRAM

#2101/ #2102

#2101/ #2102

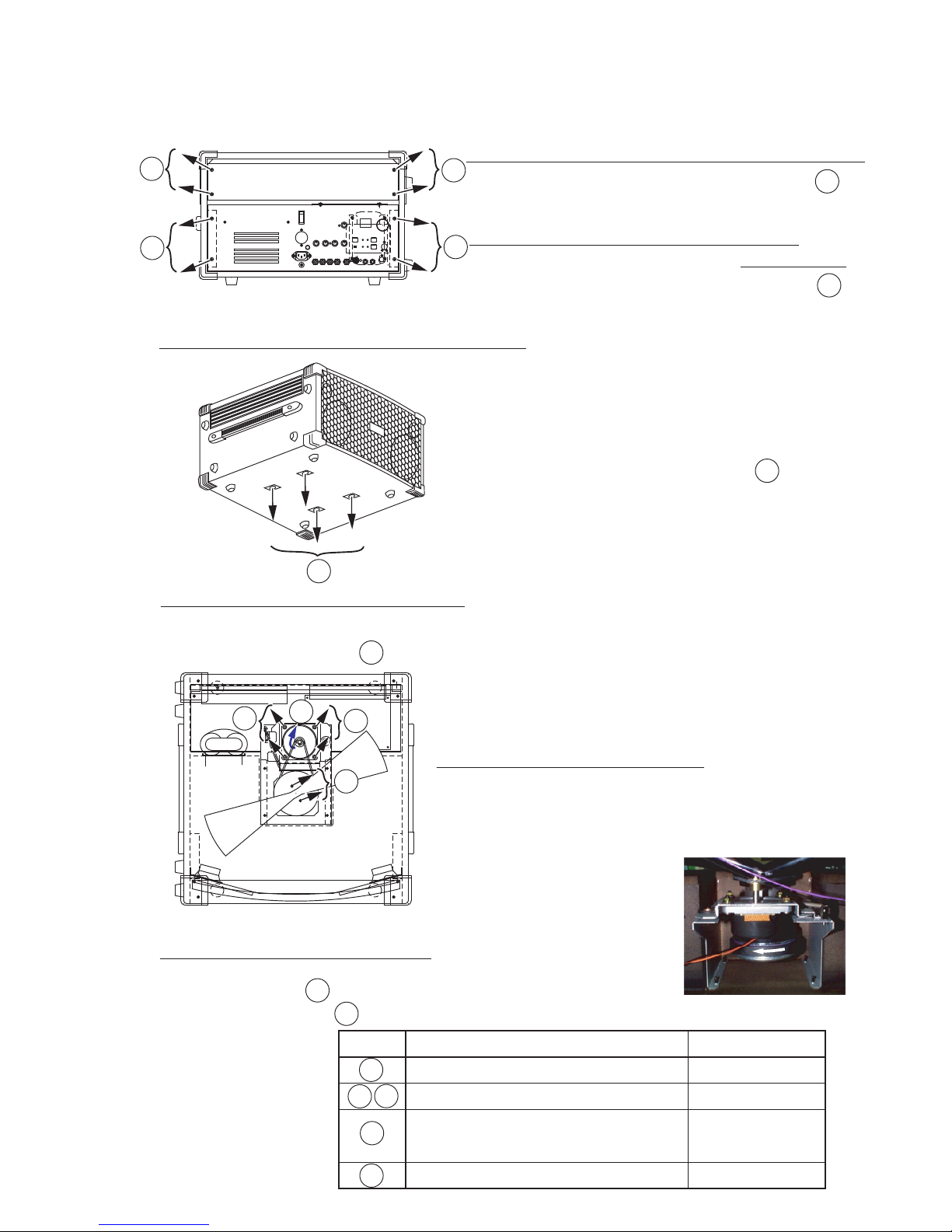

3.DISASSEMBLING PROCEDURE

#2101/ #2102

3-1

B

A

A

B

B

C

D

CAUTION:

<CAUTION>

When reinstalling Motor assembly,make sure that

these screws are tight!

Screw name Part No.

00613-64030

00703-84030

00703-55020

00725-85000

00703-23018

A

a.REMOVAL OF TOP REAR BOARD ASSEMBLY:

Unfasten the four (4) machine screws labeled

in Figure 1 from the rear board.

<FIG.1>

A Tapping,Truss,Ø4x30

Machine screws,W Sems,M4x30

Machine screws,Bind,M5x20

Flange,M5(hexagon nut)

Machine screws,Oval head,M3x18

b.REMOVAL OF BOTTOM REAR PANEL

ASSEMBLY:

Unfasten the four (4) machine screws labeled

in Figure 1 from the rear panel.

<FIG.2>

c.REMOVAL OF ROTARY HORN ASSEMBLY:

Remove the Rear Panel Assembly by following the

procedure outlined in Section b.

Place the Leslie cabinet on it's side which has the

four (4) rubber feet installed on a flat surface.

Unfasten the four (4) machine screws from the

unit as shown in Figure 2.

d.REMOVAL OF MOTOR ASSEMBLY:

1.Remove the Rotary Horn Assembly following the procedure outlined in Section c.

2.Unfasten the four (4) machine screws as shown in Figure 3.

e.REMOVAL OF HORN DRIVER:

Remove the Motor Assembly following the procedure

outlined in Section d.

Disconnect (unplug) the wire assembly from the Driver.

Remove the Horn Driver by rotating the Driver in a

counterclockwise direction.

f.REPLACING THE CLOTH BELT:

1.

2.

3.

C

F

D

E

D

1.

2.

3.

Remove the Rear Panel following the procedure outlined in Section b.

Remove the belt from motor pulley.

Unfasten the four (2) machine screws from the rotary horn after remove the cloth belt as

shown in Figure 3.

E

F

1.

2.

3.

C

<FIG.3>

D

A

F

B

Disconnect the line cord from A.C. Source before disassembling any

portion of this product.

A

B

3-2

#2101/ #2102

A

g.REMOVAL OF SPEAKER GRILLE:

h.SPEAKER REMOVAL:

1.Place the Leslie Cabinet on a flat surface with the top of the Leslie facing up.

2. Unfasten the two (2) screws labeled in Figure 4.

3.Remove the Top Rear Board Assembly by following the procedure outlined in Section a.

4.Remove the speaker grille by gently pushing the grille out from the inside of the cabinet.

1.Remove the Speaker Grille by following the procedure outlined in Section g.

2. To remove the 5cm speaker , unfasten the two (2) screws labeled in Figure 5.

3.To remove the 13cm speaker , unfasten the four (4) screws labeled in Figure 5.

PUSH

A

A

B

C

Screw name Part No.

00613-53025

00613-64012

00613-64016

A Tapping,Bind,Ø3x30,ZnB

A Tapping,Truss,Ø4x12

A Tapping,Truss,Ø4x16

A

B

C

<FIG.4>

<FIG.5>

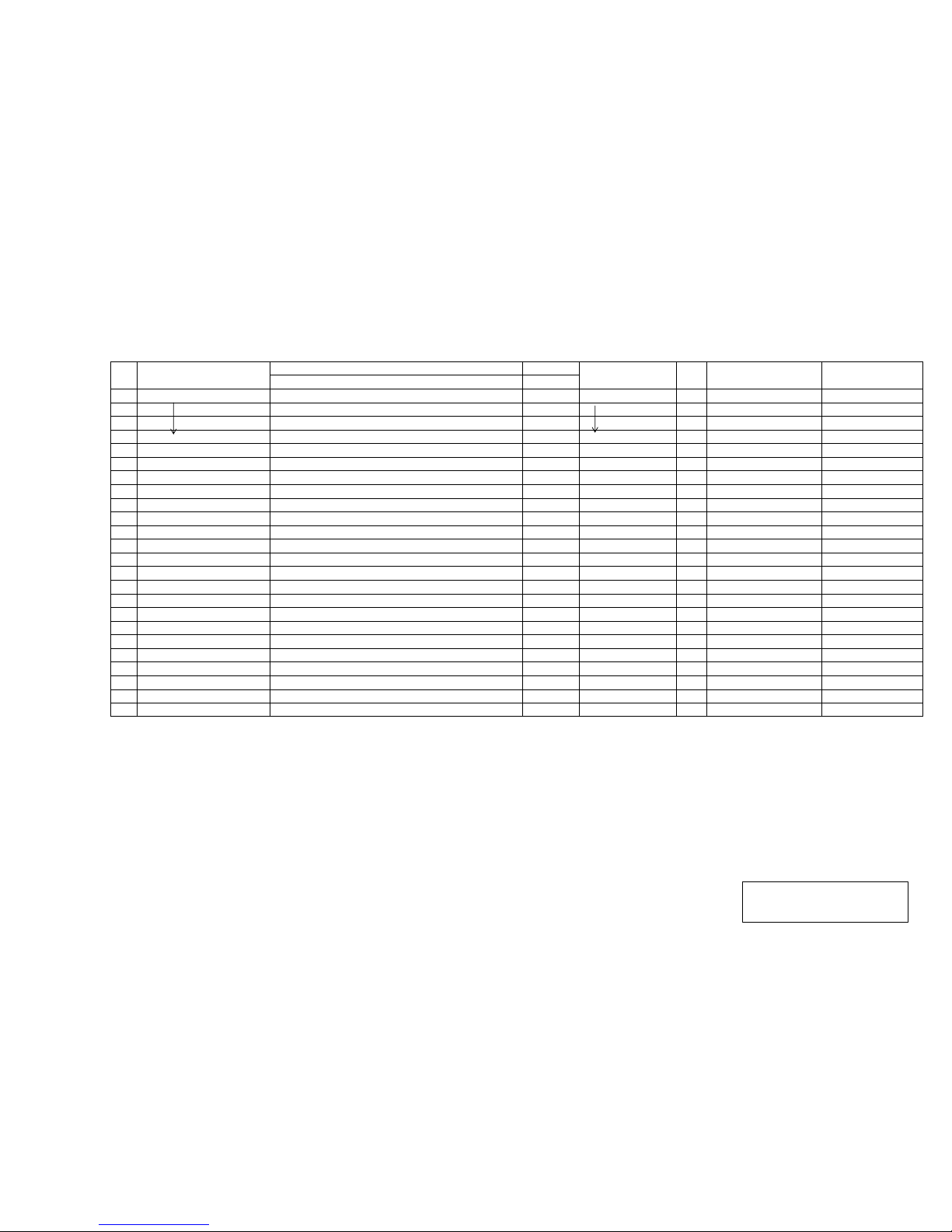

#2101/ #2102

OVERDRIVE VOL : Min.

SETTING INPUT

1. a

DC Poewr Supply +5V PWH-68A J110-7

b

+12V J110-5

c

-12V J110-1

d

+24V J112-3

e

Remote DC OUT Remote DC JACK-Core

f

Remote DC OUT Connect to Leslie 2121 thru DCC-2 cable Remote DC JACK-Core

g

LESLIE 11PIN 11 DC OUT LES11P -PIN11

2. a

Motor Speed Control Voltage LESLIE FAST , Function sw Fast Speed Value : 9 (Preset 1) EFH-237A J208-5 VR-1

* round per mintue of Horn

b

LESLIE SLOW , Function sw Slow Speed Value : 5 (Preset 1) EFH-237A J208-5

3. a

Stationary Lch SP Level STA-L VOL Max 400Hz SINE WAVE 1Vrms LES11PIN-2 PWH-68A J104-2

b

Stationary Rch SP Level STA-R VOL Max 400Hz SINE WAVE 1Vrms LES11PIN-3 PWH-68A J104-4

c

Rotary HORN SP Level ROTARY VOL Max , HORN LEV Max , 1kHz SINE 1Vrms LES11PIN-1 PWH-68A J102-1 Leslie Fast Mode

4. a

Stationary Lch Line out Level STA-L VOL Max 400Hz SINE WAVE 1Vrms LES11PIN-2 STA-L OUT JACK

b

Stationary Rch Line out Level STA-R VOL Max 400Hz SINE WAVE 1Vrms LES11PIN-3 STA-R OUT JACK

c

Rotary Line out Lch Level ROTARY VOL Max , ROT BASS LEV Center, 1kHz 1Vrms LES11PIN-1 ROT OUT-L JACK Leslie Fast Mode

d

Rotary Line out Rch Level ROTARY VOL Max , ROT BASS LEV Center, 1kHz 1Vrms LES11PIN-1 ROT OUT-R JACK Leslie Fast Mode

5. a

Stationary Lch SP Noise Level STA-L,-R,ROTARY VOL Max PWH-68A J104-2

b

Stationary Rch SP Noise Level STA-L,-R,ROTARY VOL Max PWH-68A J104-4

c

Rotary HORN SP Noise Level STA-L,-R,ROTARY VOL Max PWH-68A J102-1

#2101/ #2102

1.0mV max (IEC"A"net)

1.0mV max (IEC"A"net)

19V rms ±2V

19V rms ±2V

15V rms ±1.5V

3.1V rms ±0.4V

4.

3.1V rms ±0.4V

300mV rms ±40mV

350mV rms ±40mV

1.0mV max (IEC"A"net)

TEST AND ADJUSTMENT

DC +12V ±5%

6.60V (400±7rpm)*

0.57±0.05V (36±1rpm)*

DC -12V ±5%

DC +24V ±1V

DC -18V ±1.5V(open)

DC -3.0V ±0.4V(on Load)

DC +5V ±5%

DC +12V ±5%

STEP NOTESUBJECT TEST POINT

ADJUST

MENT

POINT

SPECIFICATION

Loading...

Loading...