1

-~-------

HQ-110A

COM'MUNICATIONS

RECEIVER

\

\

\

j

--lll

I

II

!I

I

,

-""'"

""

............

"--.

"'"

.

...

'

'

~

""',

...

...

-

~

I::

I -

I

L-

~I

TECHNICAL

DESCRIPTION

AND

OPERATING

INSTRUCTIONS

_

"",\

"-

\.

\~

\)

»

l\

,

/'

.!(

\

//

/

.'

k'

. I

Hammarlund

Manufacturing Company

A

Giannini Scientific Co.

53 West 23rd Street, New

York

10,

N.

Y.

Export Department: 13 East 40th Street, New

York

16,

N.

Y.

MANUAL

PART

NO,

41383-1

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

TIlE

HQ-IIOA

COMMUNICATIONS

RECEIVER

INSTRUCTION

AND

SERVICE

INFORMATION

FOR RECEIVERS STARTING WITH SERIAL #8900

,

ESTABLISHED

1910

ISSUE I

In

order

to

receive

the

full

unconditional

gO-day

warranty

against

defective

material

and

workmanship

in

this

receiver,

the

warranty

card

must

be

filled

out

and

mailed

within

two

weeks

of

purchase.

Please

refer

to

serial

number

of

warranty

in

correspondence.

I

,-.

THE

HAMMARLUND MANUFACTURING

CO.

A GIANNINI SCIENTIFIC

CO.

53

West 23rd Street New

York

10,

N.

Y.

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

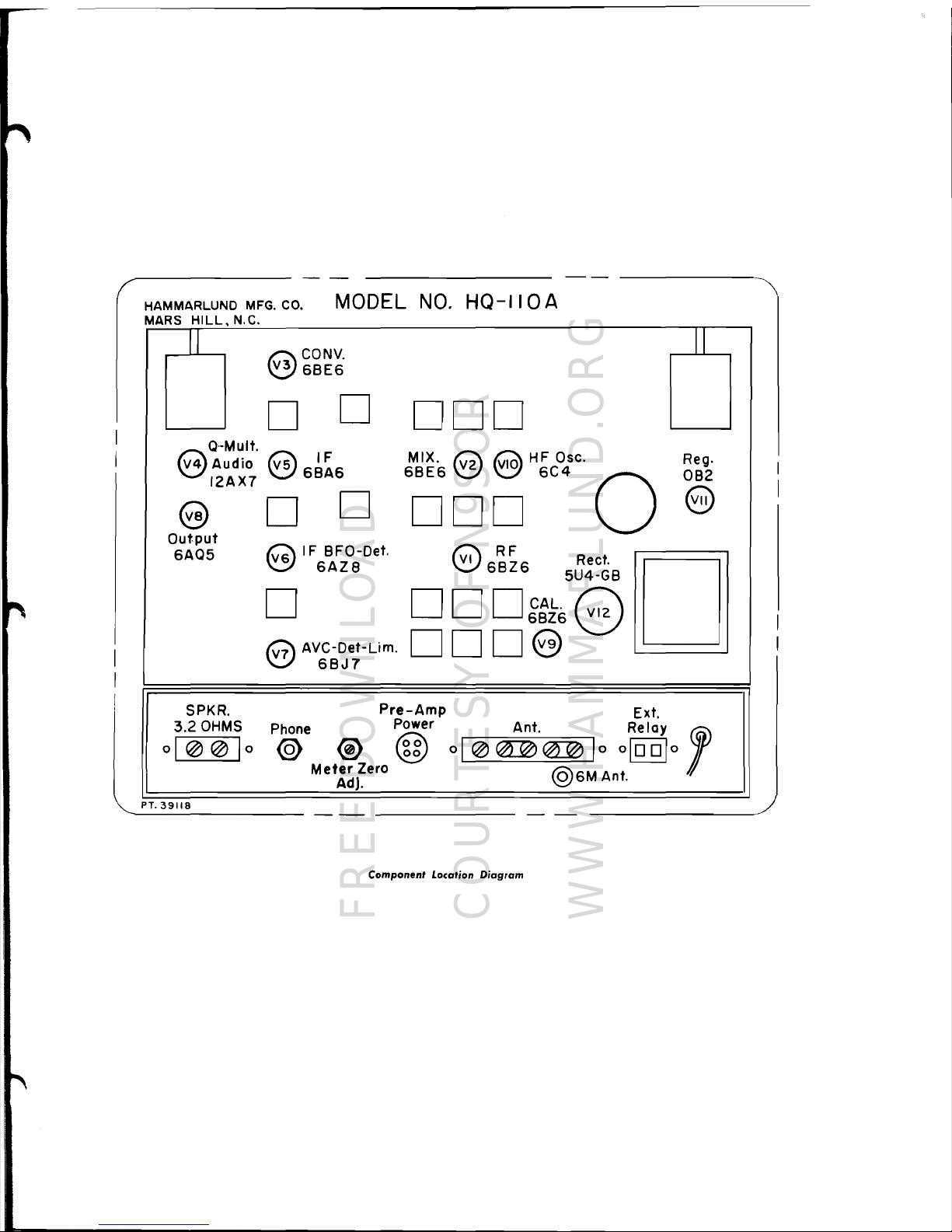

m

Figure

J.

The HQ- JJ

OA

Communications

Receiver

TUBE

COMPLEMENT

Symbol

VI

V2

V3

V4

V5

V6

V7

V8

V9

VIO

VII

VI2

Type

6BZ6

6BE6

6BE6

I2AX7

6BA6

6AZ8

6BJ7

6AQ5

6BZ6

6C4

OB2

5U4-GB

Tube

Pentode

Pentagrid

Converter

Pentagrid

Converter

Twin

Triode

Pentode

Triode-Pentode

Triple

Diode

Pentode

Pentode

Triode

Gas

Filled

Diode

Twin

Diode

Function

RF

Amplifier

Mixer

Converter

Q-Multiplier,

First

AF

Amplifier

First

IF

Amplifier

Linear

Detector-Second

IF

Amplifier,

BFO

Detector, Noise

Limiter,

AVC

AF

Output

Crystal

Calibrator

Oscillator

HF

Oscillator

Voltage

Regulator

Rectifier

11

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

-

INTRODUCTION

The

Hammarlund

HQ-110A

is

an

all-new

amateur

communications

receiver

representing

entirely

new

concepts

in

electrical

and

mechanical

design.

It

will

provide

years

of

top

performance

with

minimum

maintenance.

The

HQ-110A

has a self-contained

power

supply

operating

from a 60

cps,

105-125

volt

AC

source.

Power

consumption

is

80

watts.

The

Hammarlund

HQ-110AC

incorporates a telechron

automatic

electric

clock-timer

in

its

design.

The

ex-

port

model,

HQ-llOAE,

now

available,

will

operate

from a 50

or

60

cps,

115-230

volt

AC

source,

5ee

Fig-

ure

13

for

Wiring

Instructions.

The

HQ-110A

is a superheterodyne

receiver

with

a

frequency

coverage

of

the

amateur

bands

as

follows:

160

meter

band,

1.8

to

2.0

mc,

calibrated

in

5

KC

divisions.

30

meter

band,

3.5

to

4.0

mc,

calibrated

in

5

KC

divisions.

40

meter

band

7.0

to

7.3

mc,

calibrated

in

5

KC

divisions

20

meter

band,

14.0

to

14.4

mc,

calibrated

in

5

KC

divisions

IS

meter

band,

21.0

to

21.6

mc,

calibrated

in

10

KC

divisions.

10

meter

band,

23.0

to

30.0

mc,

calibrated

in

20

KC

divisions.

6

meter

band,

50.0

to

54.0

mc,

calibrated

in

50

KC

divisions.

A 2

Meter

scale

is

provided

for

use

with a converter

which

has

an

output

in

the 6 meter

band.

Double

conversion

is

employed

for

the

40, 20,

IS,

10

and

6

meter

bands.

A

single

control

provides

extremely

fine

tuning

for

the

separation

of

crowded

signals. A very

high

sig-

nal-to-noise

ratio,

plus

the

famous

Hammarlund

noise

limiter

circuit,

permits

full

use

of

the

receiv-

er's

excellent

sensitivity

on

the

weakest

signal.

A

Q-Multiplier

is

provided

for

varying

the

selectivity

of

the

receiver.

A

new

audio

output

circuit

feature

is

the

Auto-Re-

sponse,

which

automatically

narrows

and

widens

the

frequency

range

of

the

audio

output,

according

to

the

gain

required.

This

feature

permits

higher

fidel·

ity

reception

on

stronger

signals,

while

providing

the

sharp

cutoff

required

in

receiving

communica-

tions

under

adverse

conditions. A second

advantage

of

the

Hammarlund

Auto-Response

is

the

rapid

damping

of

the

audio

power

in

the

speaker

voice

coil

which

greatly

minimizes

undesirable

speaker

"hangover."

The

receiver

may

be

used

with

either

speaker

or

headphones.

Fast

acting AVC

maintains

a

constant

audio

level.

Adequate

filtering

practically

eliminates

AC

power

ripple.

The

HQ-110A

is

equipped

with a stable

beat

fre-

quency

oscillator

which

provides

the

operator

with

a

continuous

range

of

audio

tones

when

receiving

telegraphic

code

signals.

When

used

in

conjunction

with

the

Q-Multiplier,

single

signal

reception

is

assured.

A 100

KC

crystal-controlled

oscillator

is

incorpor-

ated

to

provide

100

KC

check

points

for

precise

cali-

bration

on

all

seven

bands.

A

linear

detector

is

provided

for

the

optimum

re-

ception

of

55B

and

CW

signals.

An

"5"

.meter

is

provided

to

obtain

accurate

read-

ings

on

received

phone

signals

and

to

assure

"on-

the-nose"

tuning. A send-receive

switch

is

provided

to

silence

the

receiver

while

transmitting.

Large,

comfortable

controls

in

logical

groupings

are

provided

for

greatest

operating

ease.

The

new

futur-

istic

front

panel

is

clearly

marked

to

permit

full

at-

tention

to

the

operation

at

hand.

The

HQ-110A

was

designed

with

you

in

mind. You'II

have

many

hours

of

pleasure

and

use

in

operating

this

truly

fine

communications

instrument.

1

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

In

~

75FT

OVERALL--

RECEIVER

A

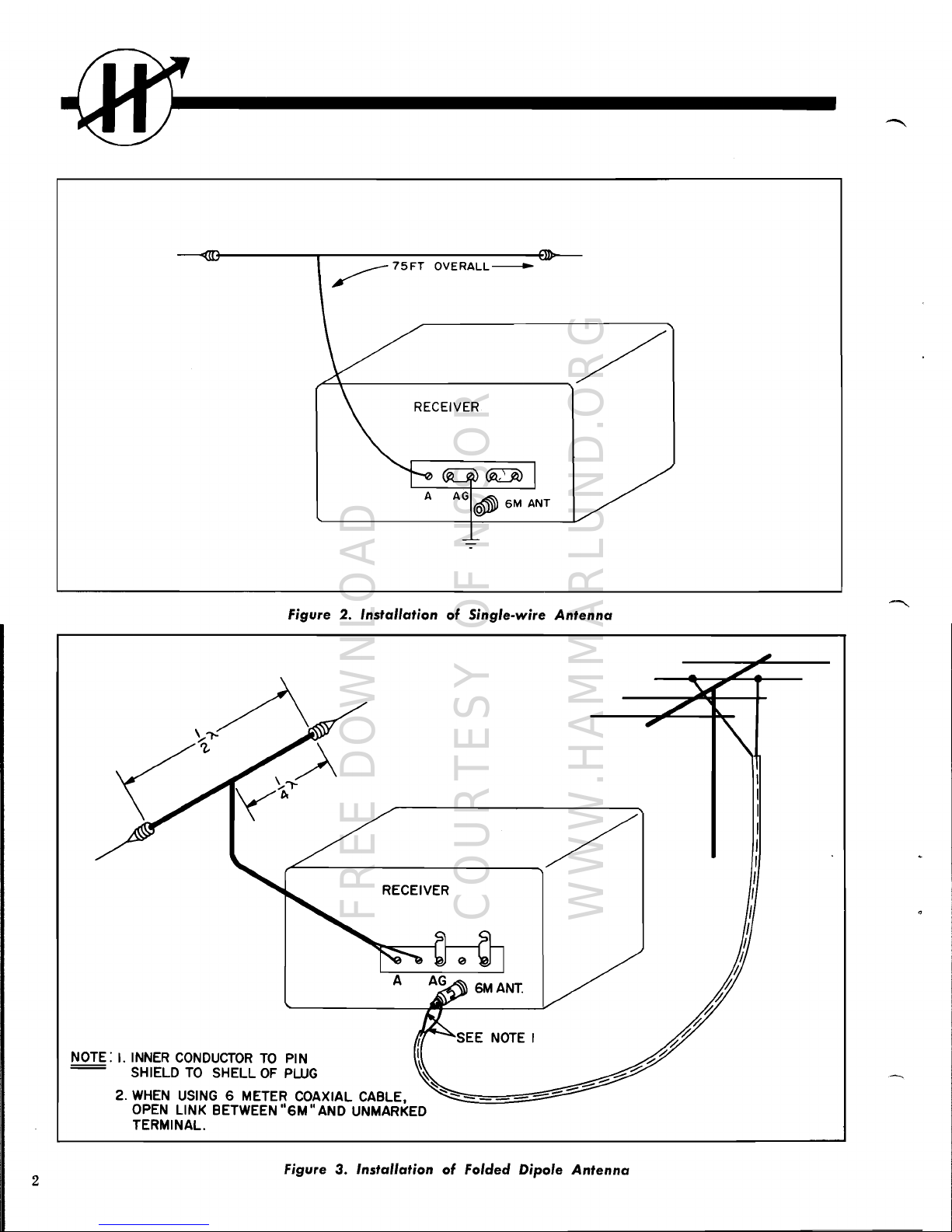

Figure 2. Installation

of

Single-wire

Antenna

NOTE: I.

INNER

CONDUCTOR

TO

PIN

= SHIELD

TO

SHELL

OF

PWG

2.

WHEN

USING

6 METER COAXIAL CABLE,

OPEN

LINK BETWEEN

"6M"

AND

UNMARKED

TERMINAL.

Figure

3.

Installation

of

Folded Dipole

Antenna

2

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

------------0

INSTALLATION

UNPACKING

Unpack

the

receiver

carefully.

Make

sure

the

tubes,

associated

tube

shields

and

pilot

lamps

are

in

place.

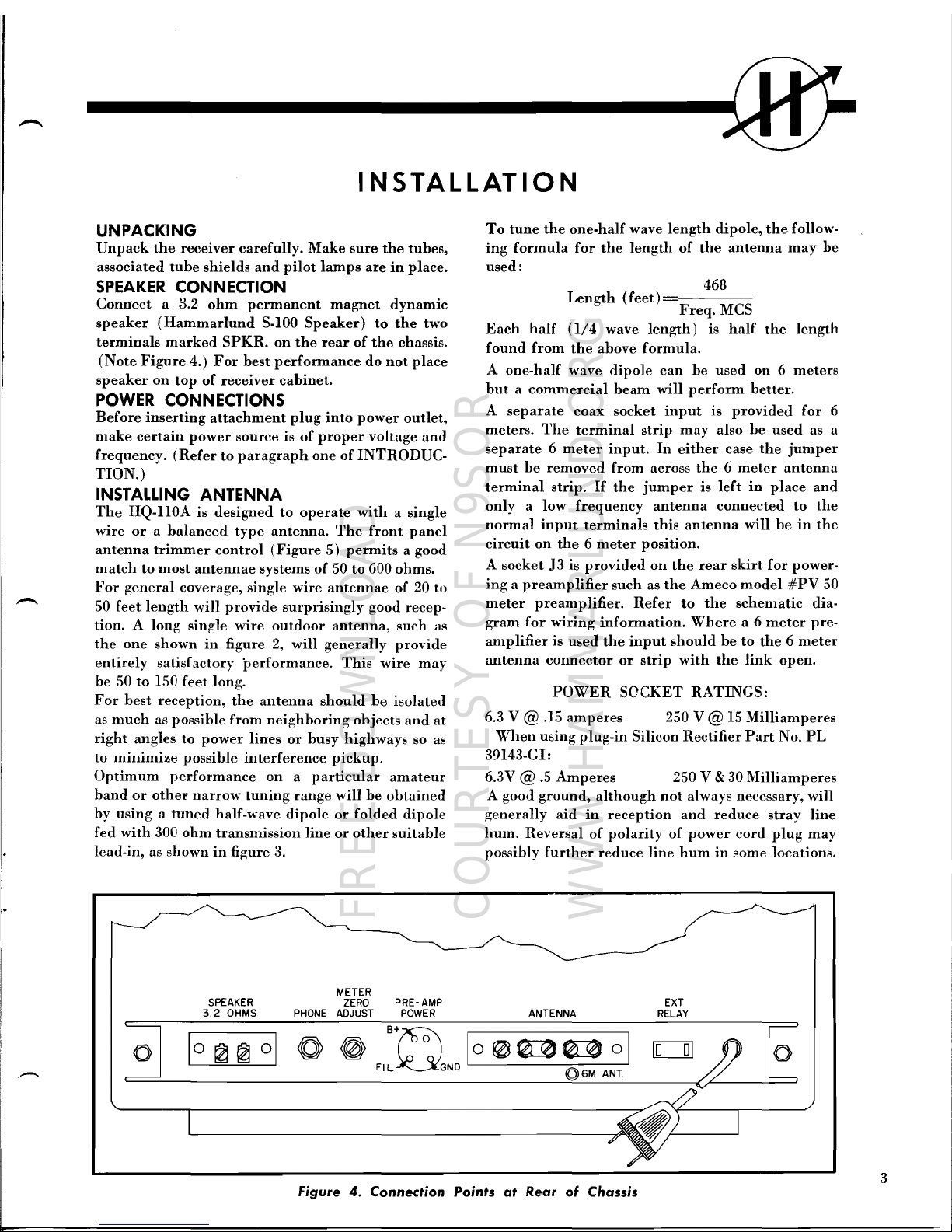

SPEAKER

CONNECTION

Connect

a 3.2

ohm

permanent

magnet

dynamic

speaker

(Hammarlund

S-100

Speaker)

to

the

two

terminals

marked

SPKR.

on

the

rear

of

the

chassis.

(Note

Figure

4.)

For

best

performance

do

not

place

speaker

on

top

of

receiver

cabinet.

POWER CONNECTIONS

Before

inserting

attachment

plug

into

power

outlet,

make

certain

power

source

is

of

proper

voltage

and

frequency.

(Refer

to

paragraph

one

of

INTRODUC-

TION.)

INSTALLING ANTENNA

-

The

HQ-IIOA

is

designed

to

operate

with a single

wire

or a balanced

type

antenna.

The

front

panel

antenna

trimmer

control

(Figure

5)

permits a good

match

to

most

antennae

systems

of

50

to

600

ohms.

For

general

coverage,

single

wire

antennae

of

20

to

50

feet

length

will

provide

surprisingly

good

recep-

tion. A long

single

wire

outdoor

antenna,

such

as

the

one

shown

in

figure

2,

will

generally

provide

entirely

satisfactory

performance.

This

wire

may

be

50

to

150

feet

long.

For

best

reception,

the

antenna

should

be

isolated

as

much

as

possible

from

neighboring

objects

and

at

right

angles

to

power

lines

or

busy

highways

so as

to

minimize

possible

interference

pickup.

Optimum

performance

on a particular

amateur

band

or

other

narrow

tuning

range

will

be

obtained

by

using a tuned

half-wave

dipole

or

folded

dipole

fed

with

300

ohm

transmission

line

or

other

suitable

lead-in,

as

shown

in

figure

3.

To

tune

the

one-half

wave

length

dipole,

the

follow-

ing

formula

for

the

length

of

the

antenna

may

be

used:

468

Length

(feet)

Freq.

MCS

Each

half (1/4

wave

length)

is

half

the

length

found

from

the

above

formula.

A

one-half

wave

dipole

can

be

used

on 6 meters

but a commercial

beam

will

perform

better.

A

separate

coax

socket

input

is

provided

for

6

meters.

The

terminal

strip

may

also

be

used

as a

separate 6 meter

input.

In

either

case

the

jumper

must

be

removed

from

across

the 6 meter

antenna

terminal

strip.

If

the

jumper

is

left

in

place

and

only a low

frequency

antenna

connected

to

the

normal

input

terminals

this antenna

will

be

in

the

circuit

on

the 6 meter

position.

A

socket

J3

is

provided

on

the

rear

skirt

for

power-

ing a preamplifier

such

as

the

Ameco

model

#PV

50

meter

preamplifier.

Refer

to

the

schematic

dia-

gram

for

wiring

information.

Where

a 6

meter

pre-

amplifier

is

used

the

input

should

be

to

the 6 meter

antenna

connector

or

strip

with

the

link

open.

POWER

SOCKET

RATINGS:

6.3 V @ .15

amperes

250 V @ 15

Milliamperes

When

using

plug-in

Silicon

Rectifier

Part

No.

PL

39143-GI:

6.3V

@

.5

Amperes

250 V & 30

Milliamperes

A

good

ground,

although

not

always

necessary,

will

generally

aid

in

reception

and

reduce

stray

line

hum.

Reversal

of

polarity

of

power

cord

plug

may

possibly

further

reduce

line

hum

in

some

locations.

,...-..

o

SPEAKER

32

OHMS PHONE

METER

ZERO

ADJUST

PRE - AMP

POWER

ANTENNA

EXT

RELAY

o

3

Figure

4.

Connection Points

at

Rear

of

Chassis

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

I

1-1

1

2

13--"';"'---

12

---~---!!i!.o=:!

!!::!::::i!+--

3

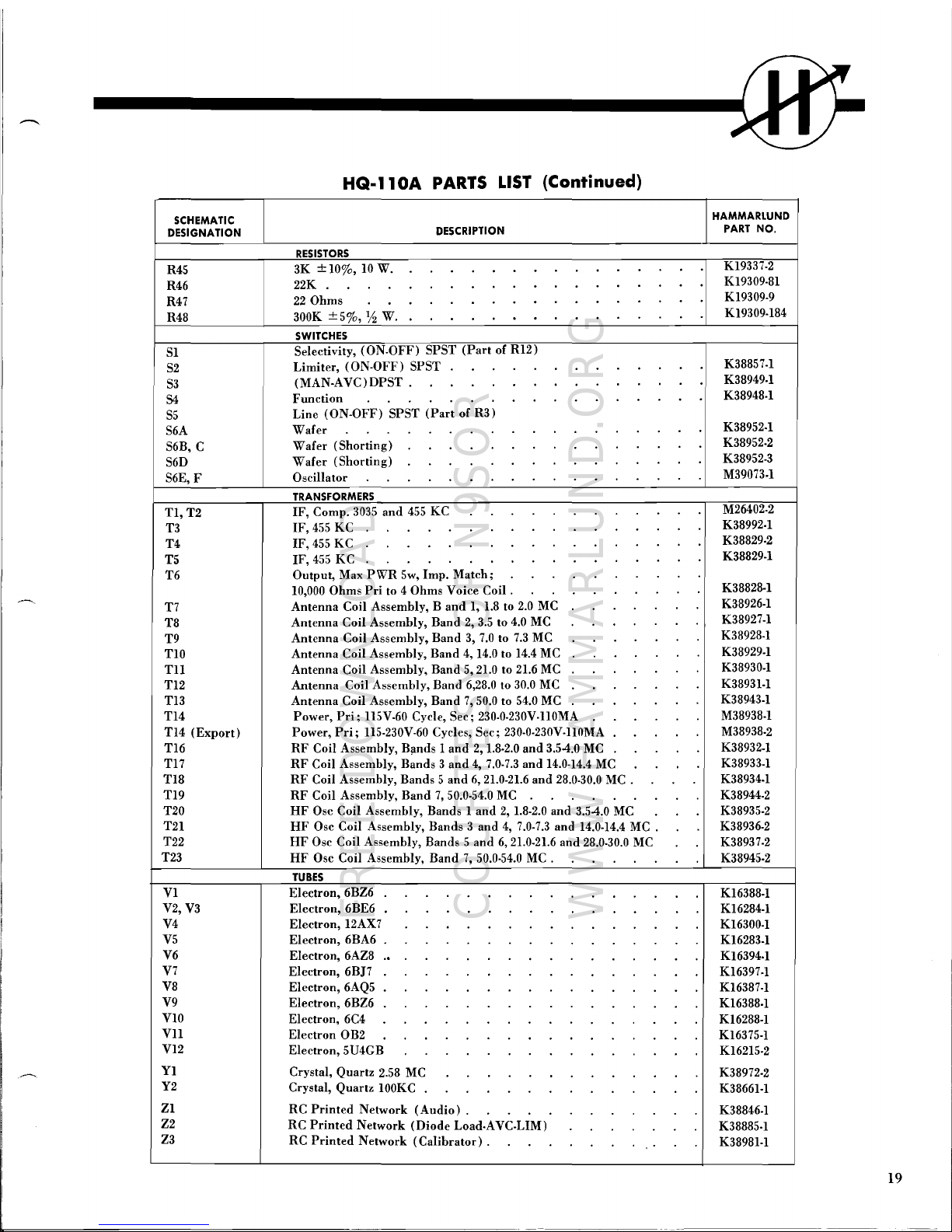

INDEX

NO.

2

3

4

5

6

7

11

10

CONTROL

CAL

SET

Control

"s"

Meter

(Carrier

Level)

FREQ.

Control (Q-MultipIier)

SELECTIVITY

Control (Q-MultipIier)

FUNCTION

Switch

AUDIO

GAIN

Control

LIM

Switch (Noise

Limiter)

9 8

INDEX

NO.

8

9

10

11

12

13

14

7

6 5

CONTROL

TUNING

RANGE

Switch

(Band

Selector)

MAN-AVC Switch

SENSITIVITY

Control

TUNING

Control

ANTENNA Trimmer

CW

PITCH

Control

(Beat

Frequency

Oscilla-

tor)

Telechron

Automatic

Clock

(Timer)

Figure

5.

Location

of

Controls

4

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

OPERATION

AM

RECEPTION

For

AM

reception

the

position

of

the

controls

should

be

as

follows:

FUNCTION

Switch

_._

Receive

(REC)

TUNING

RANGE

Switch

.. ..5et

to

desired

frequency

range

MAN

- A

VC

Switch

__

_ AVC

FREQ.

Control

_

Set

pointer

to

triangular

marker

CAL

SET

Control

.Set

to

vertical

marker

LIM

Switch

_

As

required

TUNING

Control

_

Tune

for

highest

"s"

meter

reading

on

signal

ANTENNA

Trimmer

Tune

for

highest

"s"

meter

reading

on

signal

SELECTIVITY

Control

Fully

counter-

clockwise*

SENSITIVITY

Control

._

Fully

clockwise**

AUDIO

GAIN

Control

_._

Adjust

for

required

level***

*Normally

for

AM

reception,

the

Q-Multiplier

is

switched

OFF

(fully

counterclockwise)

for

maximum

bandwidth.

However,

the

Q-Multi-

plier

may

be

useful

in

eliminating

interference

from

closely

adjacent

signals

at

some

sacrifice

in

the

fidelity.

The

bandwidth

is

narrowed

by

clockwise

rotation

of

the

SELECTIVITY

con-

trol

**For

normal

AM

reception,

the

SENSITIVITY

control

is

fully

clockwise.

The

"s"

meter

calibra-

tion

holds

only

in

this

position

on AVC

opera-

tion.

In

the

presence

of

extremely

strong

signals,

the

SENSITIVITY

control

may

be

reduced

to

prevent

overloading.

***A feature

of

the

audio

system

is

the

variable

negative

feedback

employed.

Maximum

feed-

back

is

provided

at

low

settings

of

the

AUDIO

GAIN

control

for

the

best

quality

reception

of

strong

signals. As

the

AUDIO

GAIN

control

is

increased,

the

feedback

decreases

so

that

on

re-

ception

of

weak

signals

additional

selectivity

is

provided

by

the

audio

system.

This

results

in

an

increased

signal-to-noise

ratio. A further

advan-

tage

is

the

critical

damping

of

the

speaker

for

elimination

of

speaker

"hangover."

This

up-

grades

the

reception

of

speech

and

decreases

the

noise

output

of

the

receiver. A further

advantage

is

the

reduction

of

distortion

at

low

settings

of

the

AUDIO

GAIN

control.

CODE

SIGNAL

RECEPTION

For

CW

code

reception

the

position

of

the

controls

should

be

as

follows:

FUNCTION

Switch

__

_CW-SSB

TUNING

RANGE

Switch

_Set

to

desired

frequency

range

MAN

- A

VC

Switch

_

MAN

FREQ.

Control

_

Set

pointer

to

triangular

marker*

CAL

SET

Control

5et

to

vertical

marker

CW

PITCH

Control

__

Pointer

on

tri-

angular

marker

for

zero

beat

tuning

and

then

offset

either

left

or

right

for

desired

pitch

TUNING

Control

__

Tune

for

zero

beat

ANTENNA

Trimmer

..

.....

_Tune

for

maximum

response

SELECTIVITY

Control

"ON"

and

advanced

as

required

**

SENSITIVITY

Control

Adjust

for

desired

output

level

AUDIO

GAIN

Control

_

Clockwise

to

12

or

2

o'clock

position

*The

FREQ.

control

will

peak

the

selectivity

curve

to

the

left

or

right

over

the

pass

band

of

the

IF

amplifier

permitting a high

degree

of

the

control

of

selectivity

for

closely

adjacent

interfering

signals.

**The

broadest

position

of

the

SELECTIVITY

control

(corresponding

to

a 6

db

bandpass

of

3

KCS)

is

with

the

control

turned

clockwise

just

sufficiently

to

operate

its

switch.

This

puts

the

Q-Multiplier

in

operation.

Further

clockwise

rotation

of

the

control

narrows

the

bandwidth

until a position

is

reached,

just

short

of

oscilla-

tion,

where

the

bandwidth

is

of

the

order

of

100

cycles.

The

control

should

be

adjusted

below

the

point

of

oscillation

and

to

the

desired

band-

width

as

required

by

interference.

SSB

RECEPTION

For

SSB

reception

the

position

of

the

controls

should

be

as follows:

FUNCTION

Switch

_ _ CW-SSB

TUNING

RANGE

Switch

_.5et

to

desired

frequency

range

MAN-A

VC

Switch

_ __.MAN

FREQ.

Control

__

Set

pointer

to

triangular

marker

CAL

SET

Control

Set

to

vertical

marker

5

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

IIi

TUNING

Control

Tune

for

maximum

clarity

ANTENNA

Trimmer

.Tune

for

maximum

response

SELECTIVITY

Control

_

"ON"

but

not

advanced

beyond

switch

*

SENSITIVITY

Control

_

As

required

**

AUDIO

GAIN

Control

Clockwise

to

12

or

2

o'clock

position

****

CW

PITCH

Control

_

Approximately

1

division

left

or

right****

*The

SELECTIVITY

control

should

only

be

advanced

beyond

the

switch

"ON"

position

if

required

to

increase

the

selectivity

due

to

interference.

**The

SENSITIVITY

control

should

be

advanced

only

sufficiently

to

provide

the

required

output.

The

use

of a minimum

SENSITIVITY

control

setting

insures

that

no

overload

distortion

oc-

curs

in

the

receiver.

***Operating

with

the

AUDIO

GAIN

control

advanced

1/2

to

2/3

rotation

insures

sufficient

power

output

while

permitting

the

reduced

SENSITIVITY

operation

described

above.

****The

CW

PITCH

control

is

set

approximately

1

division

to

the

right

or

left

of

the

triangular

marker,

depending

on

whether

the

upper

or

the

lower

side

band,

respectively,

is

transmitted.

The

CW

PITCH

control

is

adjusted

for

maxi-

mum

clarity,

once

the

signal

has

been

tuned

in.

There

will

be a correct

setting

of

this

control

for

each

sideband

and

once

these

two

settings

are

determined,

they

should

be

noted

for

future

use

in

SSB

reception.

CALIBRATE

For

dial

calibration

checking,

the

FUNCTION

switch

is

set

at

the

CAL

position

and

the

other

COH-

troIs

should

be

set

as

listed

under

CODE

SIGNAL

RECEPTION.

The

receiver

is

aligned

with

the

CAL

SET

control

set

at

the

vertical

marker

and

should

be

closely

correct.

The

CAL

SET

control

is

used

to

accurately

reset

the

dial

indicator

lines

if

they

are

found

to

be

slightly

off

calibration

at

any

point

on

the

dials

where

correct

calibration

is

desired.

The

receiver

is

tuned

to

produce a zero

beat

response

with

the

PITCH

control

set

at

the

triangular

marker,

on

any

100

KCS

multiple

in

the

desired

band.

The

CAL

SET

control

is

then

used

to

reset

the

dial

indicator

to

the

correct

marker.

If

the

dial

calibration

should

be

foun-d

to

be

beyond

the

range

of

the

CAL

SET

control,

the

HF

Oscillator

will

re-

quire

readjustment

(see

under

SERVICE

AND

RE-

ALIGNMENT)

.

On

switching

from

the

CW-SSB

position

to

the

CAL

position,

an

increase

in

level

will

be

noticed.

This

is

done

deliberately

to

provide

additional

gain

for

the

higher-order

harmonics

of

the

100

KCS

crystal

calibrator,

regardless

of

whether

the

receiver

is

in

MAN

or AVC

position.

Note

As

only

the

amateur

bands

are

covered

by

this

receiver

it

is

not

possible

to

compare

the

100

KCS

freq.

calibrator

against

WWV.

The

100

KCS

crystal-controlled

oscillator

has

been

accurately

set

at

the

factory.

This,

plus

the

fact

that a very

low

drift

.005%

crystal

is

employed,

will

insure

sufficient

accuracy

for

all

practical

purposes.

For

those

who

desire

frequency

ac-

curacy

of

the

crystal

calibrator

in

the

order

of

cycles,

the

procedure

outlined

on

Page

14

should

be

employed.

EXTERNAL

RELAY

CONNECTION

A

standard

power

receptable

is

provided

on

the

rear

apron

of

the

chassis

for

the

connection

of

an

ex-

ternal

relay-operated

switch.

This

receptacle

accom-

modates a standard

power

plug

and

when

so

used

the

SEND

position

of

the

FUNCTION

SWITCH

is

not

used.

A

jump~r

plug,

provided

for

normal

without

relay

switching,

is

removed

from

the

recep-

tacle

when

using

the

relay

switching.

The

usual

antenna

change-over

relay

equipped

with

a

set

of

normally

closed

contacts

is

suggested.

The

choice

of

this

relay

will

depend

on

the

particular

antenna

system

involved,

such

as

whether

a co-ax

relay

or

one

for

open

wire

line

is

employed.

In

either

case

the

extra

set

of

contacts

to

control

the

receiver

will

be

necessary.

TELECHRON

AUTOMATIC

CLOCK-TIMER

If

your

receiver

is

equipped

with

the

built-in

Tele-

chron

Automatic

Clock-Timer,

the

following

in-

structions

should

be

noted:

Every

radio-frequency

device

is

stable

only

at

pre-

determined

operating

temperatures.

In

order

to

eliminate

waiting

for

the

receiver

to

warmup

to

operating

temperature,

the

Telechron

Timer

auto-

matically

turns

on

the

receiver

ahead

of

anticipated

operating

time.

This

is

accomplished

by

setting

the

6

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

--

hand

of

the

timer

(small

knob

at

rear

of

receiver)

to

approximately

one-half

hour

before

operating

time.

The

front

panel

control

under

Timer

is

then

set

to

"Auto"

position.

The

function

switch

is

set

to

REC.

The

receiver

is

then

automatically

turned

on

at

the

desired

time.

The

clock

hands

are

set

by

the

rear

knob.

"Push

in"

and

turn

the

knob

to

set

the

switch

timing

hand

and

"pull

out"

and

turn

the

knob

to

set

the

clock

hands.

The

front

switch

is

set

to

AUTO

and

the

function

switch

is

set

to

REC.

when

it

is

desired

to

use

the

automatic

clock

switch

for

pre-warming

the

receiver

before

operation

or

for

use

as

an

alarm

to

turn

the

receiver

on

to a pre-tuned

station.

To

use

the

function

switch

normally,

the

clock

switch

should

be

left

in

the

ON

position.

The

clock

will

continue

to

run

as

long

as

the

re-

ceiver

line

cord

is

connected

to

the

power

outlet,

and

is

extremely

useful

for

checking

sign-in

periods

and

schedules.

If

your

receiver

is

not

equipped

with

the

standard

Telechron

Automatic

Clock-Timer,

and

you

would

care

to

have

the

accessory

added,

The

Clock

Kit,

with

full

installation

instructions,

may

be

pur-

chased

from

your

local

Hammarlund

dealer.

Instructions

for

connecting

the

standard

clock·timer

are

as

indicated

in

figure

12.

The

Export

Model

Clock-Timer

HQ-110AE

is

now

available

from

your

local

Hammarlund

Dealer.

This

automatic

Clock-Timer

will

operate

from

a 50-60

CPS,

115-230

Volt

AC

source.

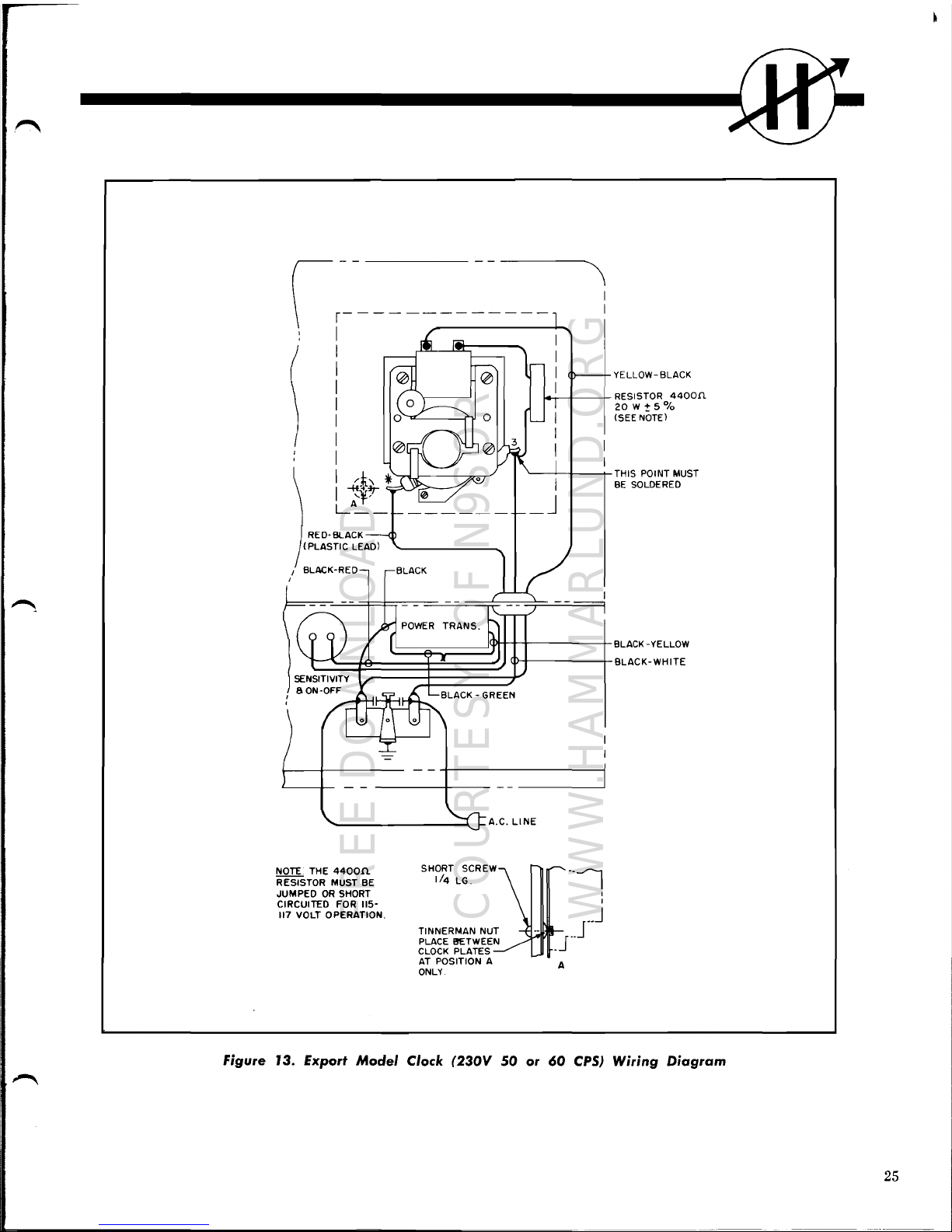

Instructions

for

con-

necting

the

export

model

Clock-Timer

are

as

indi-

cated

in

Figure

13.

CIRCUIT THEORY

The

HQ-110A is a

superheterodyne

receiver

cover-

ing

the

6, 10, 15, 20, 40,

80.and

160

meter

amateur

frequency

bands.

Double

conversion

is

employed

in

the 6 through

40

meter

bands.

Twelve

tubes

are

used,

including

the

Rectifier

and

Voltage

Regulator

of

the

self-contained

power

supply.

The

circuitry

of

the

receiver

includes

a 100

KCS

crystal

calibrator,

a

Q-Multiplier

for

full

control

of

selectivity,

an

effec-

tive

noise

limiter

and a separate

highly

stable

Beat

Frequency

Oscillator.

PRESELECTION

The

antenna

input

coupling

and

RF

amplifier

stage

provide

the

necessary

preselection

and

gain

for

high

performance

and

rejection

of

undesired

signals.

The

high

signal

level

at

the

mixer

grid,

V2,

contributes

to a favorable

signal-to-noise

ratio.

Both

grid

and

plate

circuits

of

the

RF

stage

are

tuned;

individual

tuning

coils

are

selected

for

each

band.

The

antenna

compensating

capacitor,

adjustable

from

the

front

panel,

permits

the

receiver

to

be

resonated

for

optimum

performance

with

the

par-

ticular

antenna

in

use.

CONVERTER

STAGE

A

high

degree

of

oscillator

stability

is

attained

by

the

use

of a separate

mixer

(6BE6),

V2,

and

an

in-

dependent

oscillator

(6C4),

VI0.

The

output

signal

from

RF

amplifier,

VI,

is

hetero-

dyned

with

the

output

of

the

local

high

frequency

oscillator,

VlO,

and

electronically

combined

within

the

mixer

tube,

V2.

On

the

80

and

160

meter

bands,

the

local

oscillator

is 455

KCS

above

the

signal

frequency.

On

the

10

to

40

meter

bands,

the

local

HF

Oscillator

is 3035

KCS

above

the

signal

fre-

quency.

On

the

6'meter

band,

the

local

HF

Oscilla-

tor

is 3035

KCS

below

the

signal

frequency.

When

operating

in

the 6 to

40

meter

bands,

the

dif-

ference

frequency

of

3035

KCS

is

heterodyned

with

the

output

of

the

2580

KCS

crystal

controlled

oscil-

lator

and

electronically

combined

within

the

con-

verter

tube,

V3,

to

produce

the

455

KCS

final

inter-

mediate

frequency.

Low-loss

tube

sockets,

low-loss

phenolic,

temperature

compensating

capacitors,

and

stable,

coaxial

glass

trimmer

all

contribute

to

oscillator

stability.

Addi-

tional

frequency

stability

is

attained

by

applying

regulated

voltage

to

the

oscillator

circuit

and

by

the

rugged

construction

of

the

entire

HF

oscillator

sec-

tion

assembly.

Q·MULTIPLIER

The

Q-Multiplier

circuit

employed

in

this

receiver

provides a means

of

peaking

any

signal

within

the

pass

band

of

the

IF

amplifier.

The

degree

of

peak-

ing

is

controlled

by

the

SELECTIVITY

control.

The

bandwidth

varies

from 3 KCS

with

the

SELECTIV.

ITY

control

switch

just

"ON"

to

approximately

100

7

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

cps

with

the

control

just

below

the

oscillation

point.

If

interference

is

experienced

caused

by

two

stations

operating

very

close

to

one

another,

the

Q-Multi-

plier

may

be

employed

under

these

circumstances

to

minimize,

if

not

eliminate,

the

interference

by

the

improved

selectivity

or'

the

decreased

bandwidth

proper

adjustment

will

provide.

The

proper

use

of

the

Q-Multiplier

can

actually

enhance

many

times

the

results

obtained

with

the

receiver.

In

view

of

this,

it

is

suggested

that a little

time

be

spent

in

learning

just

how

to

properly

adjust

the

Q-Multi-

plier

frequency

and

selectivity

controls

under

differ·

ent

receiving

conditions.

As

the

Q.Multiplier

SELECTIVITY

control

is

advanced, a decided

de-

crease

in

noise

will

be

apparent.

This

is

due

to

the

narrowing of

the

pass

band.

On

AM

pbone

signals

this

control

will

usually

be

between

the 7 and

II

o'clock

positions.

The

FREQUENCY

control

should

then

be

adjusted

for

clarity

of

signal

or

for

minimum

adjacent

channel

interference.

The

SELECTIVITY

control

may

be

advanced

progres-

sively

more

for

SSB

and

CW

reception.

The

more

this

control

is

advanced,

the

more

critical

the

set-

ting

of

the

FREQUENCY

control

becomes.

The

CW

PITCH

control

will

also affect

the

Q-Multiplier

FREQUENCY

control

setting.

Advancing

the

SELECTIVITY

control

too

far

will

cause

the

Q-

Multiplier

to

oscillate.

This

should

be

avoided

and

the

best

setting

of

this

control

for

CW

reception

is

just

below

the

oscillation

point,

where

maximum

peaking

occurs.

The

Q-Multiplier

is a

very

handy

tool

in

the

hands

of

an

experienced

operator

and,

unfortunately,

it

is

beyond

the

scope

of

this

instruc.

tion

manual

to

attempt

to

be

more

definite

than

we

have.

IF

AMPLIFIER

Nine

stable

tuned

circuits,

in

three

stages

of

IF

am-

plification,

V3, V5,

and

V6A,

contribute

to

sensi-

tivity

and

selectivity.

On

the

80

and

160

meter

bands,

the

Intermediate

frequency

is 455 KCS.

On

the 6 to

40

meter

bands,

the

first

conversion

is

to

an

Intermediate

frequency

of

3035 KCS,

employing

two

tuned

circuits

and

the

second

conversion

is

to

the

455

KCS

Intermediate

frequency

employing

seven

tuned

circuits.

Iron

core

permeability-tuned

transformers

improve

performance

and

add

to

the

ease

of

adjustment.

AVC

SYSTEM

Automatic

Volume

Control

minimizes

fading

and

signal

strength

variations

by

controlling

the

gain

of

the

RF

stage,

VI,

and

the

IF

stage, V5. As a

result,

a

comfortable

and

constant

level

of

audio

is

main-

tained.

The AVC

voltage

for

the

RF

Amplifier

tube,

VI,

is

provided

with a delay

voltage

which

prevents

the

AVC

from

operating

on

the

RF

Amplifier

tube

on

extremely

weak

signals,

thus

maintaining

the

maximum

sensitivity

and

signal-to-noise

ratio.

"5"

METER

(CARRIER

LEVEL)

The

"S",

or

Tuning,

Meter

is

provided

to

assist

in

tuning

and

to

give

an

indication

of

relative

signal

strength.

Because

the

meter

readings

are

propor-

tional

to

AVC voltage,

it

is

operative

only

in

the

AVC

position

and

on

AM

reception.

In

the

MAN

position

of

the

MAN-A

VC

switch,

the

meter

pointer

will

not

indicate

the

signal

strength.

However,

the

meter

pointer

will

assume

various

positions,

includ.

ing

slightly

off scale,

depending

on

the

setting

of

the

SENSITIVITY

control

and

the

FUNCTION

switch.

In

any

operating

position

of

the

FUNCTION

switch,

receiver

overload

is

indicated

by a reverse

reading

of

the

meter.

The

meter,

which

is

calibrated

to

40

db

over

S-9, is

factory

adjusted

so

that a signal

input

of

approxi-

mately

50

microvolts

gives a

reading

of

S-9.

Each

"s"

unit

indicates

a 6

db

increase,

equivalent

to

doubling

signal

strength.

Should

meter

readjust-

ment

be

necessary:

1.

Set

FUNCTION

switch

to

REC.

2.

Set

front

panel

SENSITIVITY

control

to

"10."

3.

With

receiver

off,

mechanically

zero

pointer

with

a fine

screwdriver.

4.

With

AVC

on

and

the

ANT.

terminals

shorted,

adjust

the

pointer

to

zero

with

ZERO

AD}

potentiometer

R19.

DETECTOR

AND

NOISE

LIMITER

One

section

of

the

6BJ7

tube,

V7, is

used

for

the

sec-

ond

detector

and

AVC

system

for

the

IF

amplifier.

This

system

produces a minimum

of

distortion.

8

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

+4

+2

0

-2

-4

..

-6

.!

u

>.

-9

(,)

0

0

-10

0

-

E

-12

0

~

tIl

-14

a

-16

-18

-20

-22

10

~1

I-Ill~

~

I:

~.

~

....

.,~

IIIl

_.

~

,..

,

,~

~

"'IIIl

"

,

L

..

/

,

,

.......

~

.#

"

,

~

4

~

I~~

~

•

,

II....

~r

HQ-llOA

Audio

Characteristic

.,~

A--Max.

AF

Gain

Control

If

IJ

B ---

AF

Gain

Approx.

25%

of

rotation

I~

from

Min.

Simulating

Average

J

Setting

for

local

Broadcast

~

Stations

(IV

at

Antenna

Input)

Output

at

1000

CPS = 500

MW

,

A

Input

.10 V Across

AF

Gain

Control

Con-

~

stant

J

B

Input

1.4 V Across

AF

GAIN

Control

Con-

I'.

stant

If

A

10

1

10

3

Frequency

in

Cycles

Per

Second

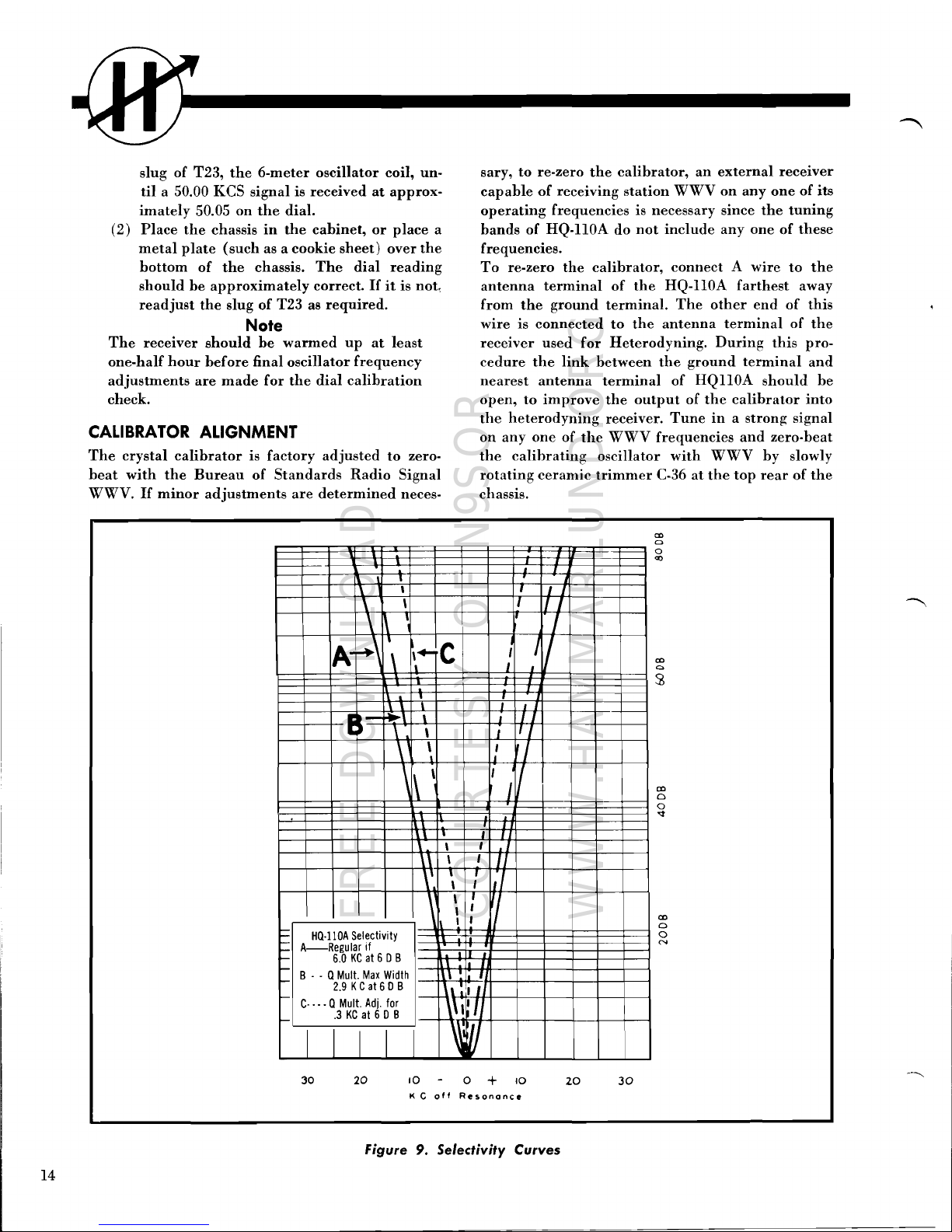

Figure 6.

Auto-Response

Curve

One

section

of

the

V7

operates

as a series,

self·ad·

justing

noise

limiter.

It

will

reduce

automobile

ig-

nition

and

other

types

of

impulse

noise

to a minimum.

Intelligibility

is

not

affected

by

the

noise

limiter,

although

it

may

be

switched

off

if

desired.

The

third

section

of

the

V7

provides

delayed AVC

for

tbe

RF

amplifier

tube.

BEAT

FREQUENCY

OSCILLATOR

(BFO)

The

triode

section

of

the

(6AZ8) V6B is

used

for

the

beat

frequency

oscillator.

The

CW

PITCH

con·

trol

is

used

to

vary

the

beat

tone.

Each

calibration

division

of

this

control

represents

approximately

1000 cycles.

When

receiving

single

side

band

trans-

mission,

the

generally

accepted

procedure

of

setting

the

beat

frequency

oscillator

approximately

2000

cycles

above

or

below

zero

beat

should

be

employed.

In

other

words,

if

the

beat

frequency

oscillator

CW

PITCH

control

is

set

two

degrees

clockwise

or

coun-

terclockwise

from

the

center

position,

optimum

single

side

band

reception

will

usually

be

obtained.

Whether

the

beat

frequency

oscillator

control

will

be

set

clockwise

from

zero

beat

will

depend

on

whether

upper

or

lower

side

band

is

being

trans-

mitted.

If

the

beat

frequency

oscillator

is

on

the

wrong

side

of

zero

beat,

it

will

be

impossible

to

obtain

intelligibility

of

the

single

side

band

signal

when

the

dial

is

tuned

very

slowly

through

the

single

side

band

signal.

Should

such a condition

arise,

merely

rotate

the

CW

PITCH

control

from

the

two

degrees

counterclockwise

to

the

two

degrees

clockwise

position

and

then

very

carefully

adjust

the

tuning

for

intelligible

speech.

Here

again

ex-

perience

is

the

best

teacher.

The

stability

of

both

the

high

frequency

oscillator

employed

in

this

receiver

plus

the

excellent

mechanical

rigidity

will

provide

excellent

single

side

band

reception.

Refer

to

the

above

paragraph

on

the

Q-Multiplier

for

im-

proved

single

side

band

reception.

CRYSTAL

CALIBRATOR

A

(6BZ6)

tube,

V9, a

hermetically

sealed

quartz

crystal

unit

and

associated

components,

provide

a

highly

stable

100

KC

crystal-controlled

oscillator.

9

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

An

adjustable

ceramic

trimmer

capacitor

is

pro-

vided

for

accurately

adjusting

the

oscillator

fre-

quency

against

an

external

standard

frequency

such

as

WWV.

It

provides

signal

markers

at

100

KC

in-

tervals

throughout

the

tuning

range

of

the

receiver.

I.INEAR

DETECTOR

The

pentode

section

of

the

(6AZ8)

V6A

functions

as a

linear

detector

for

CW

and

SSB

reception,

re-

sulting

in a clear

undistorted

beat

note

on

CW

and

greater

ease

of

tuning

and

freedom

from

interfer-

ence

on

SSB

reception.

AUDIO

AMPLIFIER

The

first

audio

stage

is a

resistance

coupled

voltage

amplifier

employing

the

other

section

of

the

(I2AX7)

V4B.

The

audio

output

stage

is a

(6AQ5)

beam

power

amplifier,

V8,

providing

an

undistorted

output

level

of

at

least

one

watt.

SUGGESTED

PROCEDURE

FOR

EI.IMINATING

COMMON

TROUBLES

1.

Most

of

the

trouble

that

has

developed

has

been

due

to

one

or

more

defective

tubes.

In

the

event

your

receiver

has

excessive

hum

or

erratic

"S"

meter

operation,

the

two

tuhes

most

likely

to

cause

this

condition

is V7

in

the

schematic

dia-

gram

on

Page

19

of

our

Instruction

Manual,

this

is a

6Bj7

or

V6A,

the

6AZ8

tube

type

may

also

develop

internal

shorts.

2.

Failure

of

the

"Q"

multiplier

to

operate

prop-

erly

or

another

possible

source

of

excessive

hum

may

be

due

entirely

to

the

12AX7,

V4A

and

V4B,

since

this

is a

combined

"Q"

multiplier

tube

and

first

audio

amplifier.

Please

do

not

rely

too

much

on

testing

the

tubes

in a tube

tester

unless

they

are

completely

dead,

when

internal

shorting

occurs,

there

is a

possibility

that a tube

tester

will

not

prove

reliable.

This

is

due

to

the

fact

that

most

tube

testers

do

not

pro-

vide a means

of

testing

excessive

heater

to

cath-

ode

leakage,

which

is

the

most

common

cause

of

hum

complaints.

It

is

therefore,

suggested

that

any

suspicious

tube

be

replaced

with a new

one,

sinc~

this

is

by

far

the

best

method

of

defi.

nitely

eliminating

this

possible

cause

of

com·

plaint.

3.

Excessive

oscillator

drift

which

would

be

most

noticeable

on

all

of

the

high

frequency

bands

plus a microphonic

condition

is

usually

the

re-

sult

of a poor

type

6C4

high

frequency

oscillator

or

VI0

in

the

schematic

diagram.

This

tube

is

also

capable

of

producing a poor

beat

note

that

may

have a ripple

in

it,

especially

noticeable

on

the

high

frequency

bands.

4.

Excessive

drift

can

also

be

attributed

to a poor

6BE6

employed

in

position

V2.

In

addition,

the

6BE6

employed

in

V2

can

also

cause

hum

modu-

lation

which

will

be

most

noticeable

on

the

two

high

frequency

band~.

Sometimes

merely

inter-

changing

the 2 6BE6

tubes

employed

in

Posi-

tions

V2

and

V3

may

produce a noticeable

im-

provement.

If

this

is

not

the

case,

we

would

sug-

gest

the

purchase

of

another

6BE6.

5.

It

is

normal

for

less

output

to

be

obtained

in

the

CW

ISSB

position

than

in

the

Receive

or

Cali-

brate

position.

To

compensate

for

the

slight

loss

in

level,

merely

advance

the

audio

control

should

this

be

required.

CALI

BRA

TION COMPLAINTS:

Please

remember

that

the

100

kc

calibrator

was

built

into

the

HQ-IIOA

receiver

as a

means

of

de-

tecting

dial

error.

The

incorporation

of

the

100

kc

crystal

oscillator

does

not

mean

that

you

will

find

the

100

kc

markers

exactly

at

100

kc

intervals,

inso-

far

as

dial

reading

are

concerned.

Obviously,

if

the

100

kc

calibrator

would

line

up

at

each

of

the

100

kc

dial

markers,

there

would

be

no

point

in

incor-

porating

the

100

kc

crystal

calibrator.

Dial

error

in

the

order

of 5 to

10

kc

for

the

lower

frequency

bands,

and

25

to

50

kc

error

on

the

10

and 6 meter

bands,

is

within

our

production

tolerance.

The

pro-

cedure

for

correcting

frequency

deviations

in

excess

of

those

previously

specified

will

usually

involve

only a minor

adjustment

of

the

high

frequency

oscillator

trimmer

capacitor.

Please

refer

to

Pages

II

thru

14

of

your

instruction

manual

where

the

various

alignment

points

are

clearly

indicated.

All

of

the

oscillator

trimmer

ad-

justments

are

clearly

marked

in

figure

8,

and

obvi-

ously

the

proper

trimmer

for

the

particular

band

is

the

only

adjustment

to

make.

Please

be

sure,

there-

fore,

before

attempting

to

make

minor

frequency

(Continued

on

page

20)

10

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

SERVICE

AND ALIGNMENT

PROCEDURE

NOTE

Before

servicing

this

receiver,

disconnect

from

power

source

and

remove

all

lead·

wires

attached

to

terminal

connections

at

rear

of

chassis

apron.

Carefully

turn

the

receiver

up

onto

the

front

panel

face

on a smooth

clean

surface.

Remove

the

two

No.

10

hex

machine

screws

at

the

extreme

ends

of

the

chassis

apron

at

the

rear

of

the

cabinet,

and

the

knob

from

the

clock

adjustment

shaft

if

receiver

is

so

equipped.

Lift

cabinet

straight

up

and

off

of

chassis.

To

reassemble,

use

reverse

procedure.

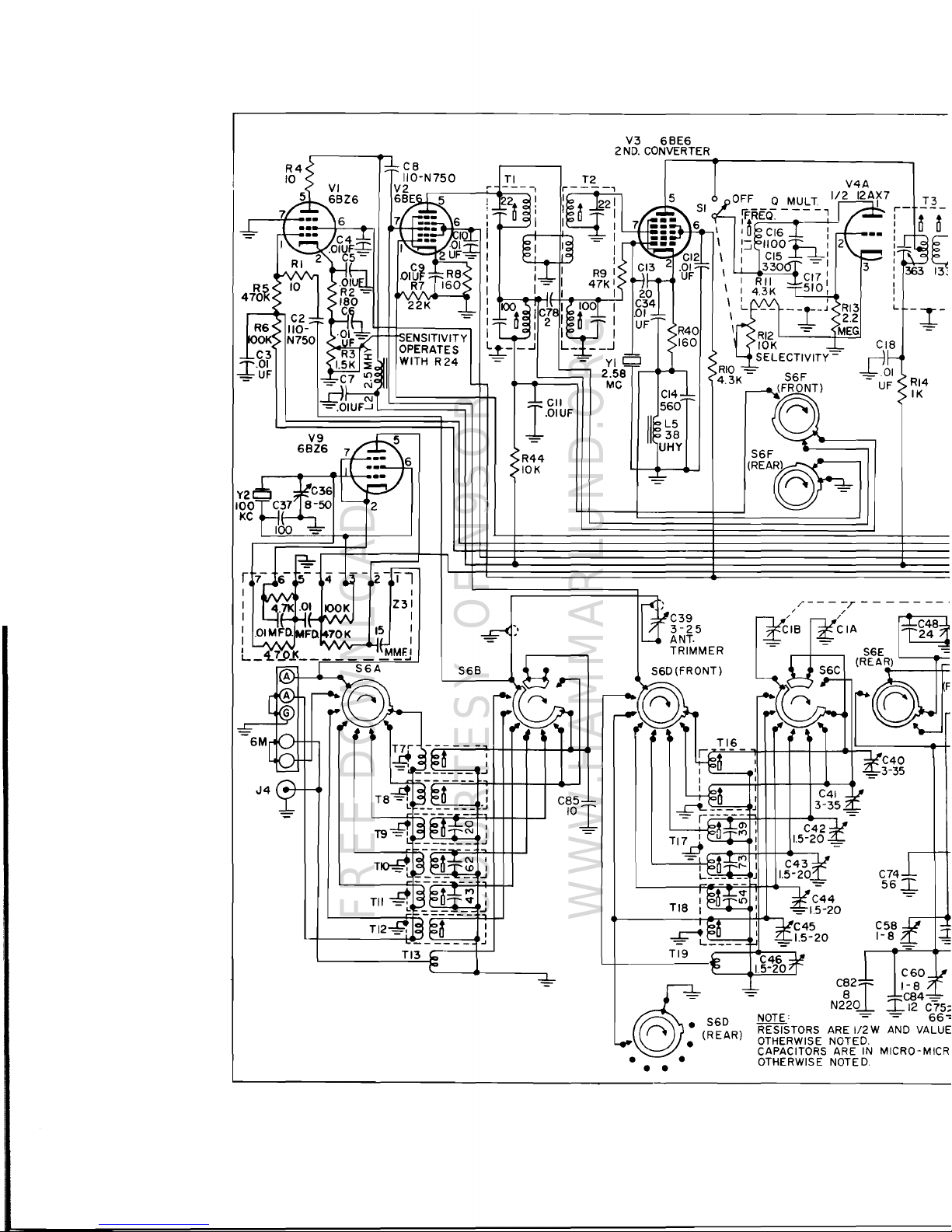

ADJUST

OSC SLUGS AND

TRIMMERS

AT

INDICATED

FREQUENCIES

FROM

TOP

ANTENNA

ADJUSTMENTS

RF

ADJUSTMENTS -MCS

CRYSTAL

IF

ADJUST-

MENTS

455

KCS

/21

7 1.8

TOP

SLUG

\

28

14

3.5

BOTTOM SLUG

3.5

21

MCS

CALIBRATOR

TRI

MMER

C36

/28

7.0

VI2

7 14

21

28

OSCILLATOR

ADJUSTMENTS

MCS

TOP BOTTOM

1.8

3.5

\ 2 4

7.3

14.4

21.6

30

54/

IF

ADJUSTMENTS

455

KCS

TOP

HF

OSCILLATOR

MCS

3035

KCS

BOTTOM

Figure 7. Top

View

of Chassis

II

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

IF

ALIGNMENT

Note

Use a

non-metallic

alignment

tool.

such

as

General

Cement

Co. No. 5097,

or

equal.

a.

Connect

the

output

cable

of

a 455

KCS

unmodu-

lated,

signal

generator

to

the

bus

lead

of

the

(6BE6)

V2

mixer

grid.

The

frequency

accuracy

of

the

generator

may

be

checked

with

sufficient

precision

by

picking

up

its

second

harmonic

(910

KCS)

in

any

receiver

whose

calibration

at

910

KCS

has

been

checked

as

correct

and

then

adjust-

ing

the

generator

frequency.

b.

Connect

a DC

vacuum

tube

voltmeter,

set

for

negative

voltage

reading

to

terminal 2 of

the

T5

IF

transfonner

and

chassis

ground.

c.

Set

the

receiver

controls

as follows:

CAL

SET

control

on

marker

FUNCTION

switch

on

REC.

Tuning

dial

on

1.8

mc

Noise

limiter

(LM)

switch

on

OFF

AUDIO

GAIN

control

at

minimum

SELECTIVITY

control

OFF

TUNING

RANGE

switch

on

1.8 - 2.0

mc

MAN

• AVC

switch

on

MAN.

SENSITIVITY

control

on 3 from

maximum

d.

During

alignment,

adjust

the

generator

output

and

the

SENSITIVITY

control

to

prevent

over-

loading.

Final

adjustment

should

be

made

with

the

SENSITIVITY

control

at

approximately

the

RF

/,-------------------,

2 4

7.3

14.4

21.6

30

54

OSC

50

MCS

RF

50

MCS

Figure 8. Bottom

View

of

Chassis

.1

12

FREE DOWNLOAD

COURTESY OF N9SOR

WWW.HAMMARLUND.ORG

third

indice

from

its

maximum

(clockwise)

posi-

h.

All

RF

and

oscillator

slug

adjustments

are

made

tion.

Adjust

each

of

the

three

IF

transformers,

from

the

top

of

the

shield

cans. 50-54

mcs,

RF

T3,

T4

and

T5,

for

maximum

meter

reading.

coils

do

not

have

slugs.

The

RF

coil

of

this

hand

Topside

adjustments

are

secondaries

or

grid

cir-

is

"knifed"

for

adjustment

of

inductance. A slight

cuits;

hottom

of

chassis

adjustments

are

prima-

spreading

of

the

turns

decreases

the

inductance.

rie

or

plate

circuits.

Adjust

the

top

slugs

of

Tl

Pushing

the

turns

slightly

closer

together

increas-

and

T2

for

maximum

Meter

Reading.

es

the

inductance.

The

OSC

coil

slug

for

this

hand

e.

Turn

the

SELECTIVITY

control

clockwise

to

a

is

at

the

underside

of

the

chassis.

position

helow

the

oscillating

point.

With

its

col-

c.

Connect

the

unmodulated,

signal

generator

out-

lar

set-screw

loosened

to

permit

the

frequency

put

cahle

to

the

antenna

and

ground

terminals

of

shaft

to

turn

without

hindrance

hy

the

stop,

ad-

the

receiver,

with

the A terminal

adjacent

to

the

just

the

FREQ.

control

to

ohtain a maximum

G

terminal

jumped

together.

Leave

the

vacuum-

meter

indication.

The

input

signal

must

he

ad-

tuhe

voltmeter

connected

as

for

IF

alignment.

justed

to a value

just

sufficient

to

ohtain a good

d.

Set

the

controls

the

same

as

for

IF

alignment,

meter

swing.

This

adjustment

is

the

center

fre-

"c."

ahove.

Adjust

the

SENSITIVITY

control

as

quency

of

the

pass

hand.

While

the

meter

is

at

required

to

ohtain

a sufficient

voltmeter

reading

maximum,

turn

the

collar

so

that

the

long

set

and

to

prevent

overloading.

Set

the

CAL

SET

con·

screw

is

in a position

180

degrees

directly

oppo-

trol

to

the

vertical

marker.

site

the

stop

lug.

Holding

it

in

this

position,

e.

The

oscillator

adjustment

is

made

first.

The

RF

tighten

the

set

screw,

making

sure

that

the

shaft

is

adjusted

next

to

ohtain

maximum

amplitude.

has

not

turned

hy

checking

the

zero

setting.

The

antenna

slugs

are

adjusted

last. A certain

f.

Turn

the

FUNCTION

switch

to

CW-SSB

and

amount

of

interaction

will

occur

hetween

the

os·

with

the

CW

PITCH

control

stop

collar

loosened,

cillator

and

RF

adjustments,

particularly

on

the

adjust

the

CW

PITCH

control

for

zero

heat.

higher

frequency

hands.

Final

adjustment

should

Turn

the

collar

so

that

the

long

set

screw

is

in

a

he

accomplished

hy

comhined

or

alternate

ad-

position

180

degrees

from

the

stop

lug.

Holding

justment

of

the

oscillator

and

RF

for

maximum

it

in

this

position,

tighten

the

set

screws,

making

amplitude.

sure

that

the

shaft

has

not

turned

from

the

zero

Note

heat

position.

The

trimmer

adjustments,

if

required,

should

g.

Turn

the

FUNCTION

switch

to

REC

and

the

he

the

final

adjustments

for

each

hand.

other

controls

as

shown

under

"c."

Set

the

TUN-

r.

Note

that

the

oscillator

frequency

in

the

HQ-

ING

RANGE

switch

to

7.0 - 7.3 MCS.

Set

the

un-

BOA

is

on

the

high

side

of

the

signal

frequency,

modulated

signal

generator

frequency

to

3035

except

on

the 6 meter

hand,

50-54 mcs,

where

it

KCS.

Using a non-metallic

alignment

tool,

such

is

on

the

low

side

of

the

signal.

Therefore,

it

is

as

General

Cement

Co.

No.

8282,

or

equal,

ad-

necessary

to

make

sure

that

the

oscillator

fre-

just

the

hottom

cores

of

the

transformers

Tl

and

quency

is

not

adjusted

helow

the

signal

frequency

T2

for

maximum

meter

reading.

During

this

a-

which

would

he

an

image

response

of

the

signal

lignment,

adjust

the

generator

output

and

the

on

all

hands

except

50-54

mcs

where

the

reverse

SENSITIVITY

control

to

prevent

overloading.

is

true.

h.

With

the

MAN -AVC

switch

on

AVC,

the

SEN-

g.

It

will

he

necessary

to

repeat

low

and

high

end

SITIVITY

control

at

maximum,

with

grid,

pin

1,

alignment

adjustments

of

each

hand

since

the

of

the

VI

amplifier

tuhe

grounded,

and

with

no

adjustments

are

interdependent.

The

process

signal

input,

adjust

the

METER

ZERO

ADJUST.

should

he

repeated

until

maximum

amplitude

is

potentiometer

at

the

rear

of

the

chassis

for

a

ohtained

at

hoth

alignment

frequencies

of

each

reading

of

zero

on

the

"S"

meter.

hand.

RF

ALIGNMENT

h.

On

the

6-meter

hand, a shift

in

oscillator

fre-

Note

quency

occurs

upon

replacing

the

receiver

in

the

Use a

non-metallic

alignment

tool

such

as

cahinet,

with

the

result

that

the

dial

reads

ap-

General

Cement

Co.

No.

8282,

or

equal.

proximately

50

KCS,

or

one

division

low.

This

a.

The

slugs

and

trimmers,

having heen

factory

ad-

condition

may

he

corrected

as

follows:

justed,

should

require a minimum

amount

of

(1)

After