Ref. 2035481/03.08-en

15202-10

/i

HD 8 VV

HD 10C VV

Applying from factory No. H1700001

Operating instructions

with safety notes

© HAMM AG 2009

The disclosure as well as the duplication of this document, the use and the forwarding of its contents, are forbidden as far as not expressively permitted. Violations will cause indemnities. All rights with respect

to patent, utility sample or design patent registration reserved.

HAMM AG

D-95633 Tirschenreuth/Germany

P .O. Box 1160

Telephone +49-96 31/80-0

Fax +49 96 31/80 120

www.hamm.eu

© HAMM AG 2009 I

/i

Operating instructions

with safety notes

Tandem Roller

HD 8 VV

HD 10C VV

HAMM AG • D-95633 Tirschenreuth/Germany • P. O. Box 1160 • Telephone +49 96 31/80-0 • Fax +49 96 31/80 120

II © HAMM AG 2009

TABLE OF CONTENTS

Table of contents

1 GENERAL 1

1.1 Introduction 1

1.1.1 General 1

1.1.2 Foreword to the operating instructions 2

1.1.3 Special identifications in the text 3

1.2 Use 4

1.2.1 Intended use 4

1.3 Notes 5

1.3.1 Indications on sound and vibration 5

1.3.2 Installation instructions for safe ty device ROPS

anti-rollover bar 6

1.3.3 Safety 7

1.3.4 Fuel 15

1.4 Identification of the roller 16

1.4.1 Type sign, VIN. 16

1.5 Technical data 16

1.5.1 Loading and transport 16

1.5.2 Dimension sheet HD 8 VV 18

1.5.3 Dimension sheet HD 10C VV 19

1.5.4 Technical data HD 8 VV 20

1.5.5 Technical data HD 10C VV 22

2 OPERATION 24

2.1 Control and operation elements 24

2.1.1 General 24

2.1.2 Overview 24

2.1.3 Description of elements 28

2.2 Driving 41

2.2.1 General 41

2.2.2 Precaution measures prior to machine start 43

2.2.3 Start of engine 44

2.2.4 Driving 46

2.2.5 Driving with vibration 46

2.2.6 Stop, switch off engine, leave machine 48

2.2.7 Operation monitoring 49

2.2.8 Towing 50

2.2.9 Water irrigation 52

© HAMM AG 2009 III

TABLE OF CONTENTS

3 MAINTENANCE 54

3.1 Introduction 54

3.1.1 General 54

3.1.2 Notes on spare parts ordering 55

3.1.3 Safety 56

3.1.4 Use of biologic hydraulic oil 57

3.1.5 Refrigerant conditioning 57

3.2 Lubrication indications 58

3.2.1 Viscosity - temperature range 58

3.2.2 Lubricants used in delivery status 59

3.3 Maintenance overview 60

3.3.1 Maintenance plan 60

3.3.2 Required maintenance parts HD 8 VV, HD 10C VV (3W35) 61

3.3.3 Maintenance parts (Service kits) HD 8 VV,

HD 10C VV (3W35) 61

3.3.4 Required maintenance parts HD 8 VV, HD 10C VV (3W35) 62

3.3.5 Maintenance parts (Service kits) HD 8 VV,

HD 10C VV (3W35) 62

3.4 Running-in regulations 63

3.4.1 After 50 operating hours 63

3.5 Operation monitoring 64

3.5.1 Operation monitoring 64

3.5.2 Dry air filter 64

3.6 Maintenance once every 10 operating hours 65

3.6.1 Maintenance points at the engine for engine oil change 65

3.6.2 Check and clean dry air filter 65

3.6.3 Control of oil level in the hydraulic oil tank 66

3.6.4 Control of refrigerant level for engine cooling system 66

3.6.5 Control of parking brake and EMERGENCY STOP

function (NOT-STOP) 67

3.6.6 Clean the water filter for the pressure irrigation system 67

3.6.7 Cleaning the spay nozzles 68

3.7 Maintenance once every 250 operating hours 69

3.7.1 Lubricate articulated frame steering joint 69

3.7.2 Lubrication of steering cylinder rod 69

3.7.3 Control of radiator 70

3.7.4 Control of the scrapers 70

3.8 Maintenance once every 500 operating hours 71

3.8.1 Replacing the filter insert for the hydraulic system 71

3.8.2 Replacing the preliminary fuel filter 71

3.9 Maintenance once every 2000 operating hours,

at least once a year 73

3.9.1 Replacement of hydraulic oil 73

3.9.2 Changing the refrigerant 74

3.9.3 Cleaning the water irrigation system 76

3.9.4 Visual inspection of hydraulic system 76

4TABLES 77

4.1 Diagnostic Code 77

IV © HAMM AG 2009

TABLE OF CONTENTS

© HAMM AG 2009 1

GENERAL

1 GENERAL

1.1 INTRODUCTION

1.1.1 General

You have purchased a HAMM Quality product.

All parts of this machine have been tested and

verified carefully. They correspond to the quality you expect.

This machine has been built according to the

current state-of-the-art and the current safety

regulations. However it is indispensable to

read and to observe the safety notes a s well as

the operating and the maintenance instructions

prior to start-up. Every inappropriate use, or

use not according to the intended use, of the

machine will cause:

• Dangers to life and health of the user or to

third parties

• Impairment of the machine and further

properties of the user

• Dangers to the efficient work of the machine

The operating instructions of the combustion

engine is a part of the overall operating inst ructions. Maintenance and care of the engine

have to be performed according to these operating instructions. Any safety notes have to be

followed.

Even if the regulations for safety, use and

maintenance are followed, residual dangers

will remain. Due to the high operating weight

and to the high distance of gravity centres of

the machine, there is considerable danger of

tilting, in particular during travels in transversal

direction to slopes. The smooth surface of the

drums or the tyres, respectively, decreases lateral stability of wet, uneven ground. Operation

is not admitted on snow and ice. When driving

on hard surfaces, and in particular when driving in transversal direction so slopes, lateral

stability is decreased when the vibration is

switched on (danger of falling).

The high reliability of the machine is preserved

through correct use and careful maintenance.

This includes the use of the obligatory operating resources and the use of original HAMM

spare parts.

This manual will introduce you to the operation

of the machine. You will find the following in it:

• Regulations for your safety

• The introduction of the machine and its

characteristics

• The operation

• The maintenance instruct ions

• Indication on spare parts management

and customer service

Our representations will help you to keep your

roller in perfect operating condition.

Our representations will be at your disposition

with consulting and service even after the warranty period. They will provide our original

HAMM spare parts which do not only correspond to the technical requirements but also

ensure exchangeability and quality.

Our customer service training centre holds

courses for roller drivers.

It will give drivers:

• General safety information

• Information on use and maintenance of

the machine

• Information on the practical use of the roller

• Information of a more rational use with

add-on devices

Furthermore, our specialist sales advisors are

always at your disposition. They will offer you

the optimum product solution for your application. The safety, operation and maintenance

notes included in this manual are intended to

be used by roller drivers and mechanics.

Thus, keep this manual always at hand!

GENERAL

2 © HAMM AG 2009

1.1.2 Foreword to the operating

instructions

These operating instructions shall facilitate the

introduction to the machine and the use of thei r

intended operational possibilities.

The operating instructions includes valuable in formation in order to operate the machine safe ly, appropriately and economically. The observation of the operating instructions will help to

avoid dangers, decrease repair cost and do wntimes, and to increase reliability and lifetime of

the machine.

These operating instructions must be updated

with instructions due to existing national accident prevention and environment protection

regulations.

The operating instructions must always be

present at the place of utilisation of the machine.

The operating instructions of the combustion

engine are a part of the overall operating instructions of the machine. Maintenance and

care of the engine have to be performed according to these operating instructions. Any

safety notes have to be followed.

These operating instructions must be read and

applied by all persons ordered with works with

or on the machine, e.g.

• Operation including care, disposal of operating supply or auxiliary substances

• Servicing (maintenance, inspection, repair) and/or

• Transport.

Apart from these operating instructions and the

binding accident prevention regulations applying in the country of use and at the place of utilisation, also the generally accepted specialist

rules for appropriate and safe work have to be

observed.

© HAMM AG 2009 3

GENERAL

1.1.3 Special identifications in the text

The following symbols or notes are used for

the identification of text which do not apply to

all machine variants:

/i

/i

/i

Positions in figures

The positions in the figures are represented

with letters and numbers. The positions identified with letters in alphabetical order are only

explained in the corresponding text segment,

beginning new for each single figure. The positions identified with numbers correspond to the

numbering of the plates for operating elements, control devices and switches. They are

identical to the numbers of the individual operating and control elements. In the describing

text, these position numbers are in brackets.

Among other things, this ensures that important and additional information can be found

immediately and without difficulties in the descriptions of the elements.

All rights reserved

No part of this publication my be reproduced,

processed, copied and/or published in any way

(imprint, photocopy, microfiche or any other

procedures) without the written consent of

HAMM. This also applies to the corresponding

drawings and schemes.

HAMM reserves the right to change individual

parts at any time without previously informing

the customer. The contents of this publication

can also be changed without prior announcement.

This publication applies to the standard design

of the previously listed machine types. Therefore it is possible that these instruct ions include

descriptions of components not installed in

your machine. HAMM does not accept liability

for possible damages resulting from the application of this publication on machines deviating from the standard design.

Please contact to the customer service of your

supplier for all information about adjustment,

maintenance or repair work not included in this

publication.

Only for machines with CE equipment

Only for machines without CE equipment

Option Special equipm en t

GENERAL

4 © HAMM AG 2009

1.2 USE

1.2.1 Intended use

The machine may only be deployed on surfaces that can support it. It is intended solely for

deployment for compressing loose surfaces,

road foundations, road surfaces and similar

compactible foundations. Any other deployment or a deployment beyond this is not

deemed as intended. The manufacturer/supplier is not liable for any damage resulting from

this. The user will bear the complete risk.

The intended use also includes the observance of the operating instructions as well as

the compliance with the inspection and maintenance requirements set out by the manufacturer.

This machine has been built according to the

state-of-the-art and the generally accepted

safety regulations. However, danger for life

and health of the user or impairment of the machine and of other objects can arise during the

use of the machine.

This machine ma y only be used in technic ally

unobjectionable condition, as well as according

to the intended use, and aware of safet y issues

and possible dangers, always observing the

operating instructions. All safety devices removed for transport purposes (anti-rollover device ROPS, handles, silencers etc.) must be installed to the machine prior to using it. In particular, any troubles which could have effect on

safety must be eliminated immediately.

Arbitrary changes will exclude the manufacturer's liability for any damage resulting from this.

© HAMM AG 2009 5

GENERAL

1.3 NOTES

1.3.1 Indications on sound and

vibration

The subsequently listed sound and vibration

indications correspond to the requirements of

the CE Machinery Directive in the version

2006/42/EG.

The sound emission of the machine was measured according to the CE Sound Emission Directive in the version 2000/14/EG.

Sound indication for driver's seat

The sound pressure level at the place of the

operator, required according to Appendix 1,

section 1.7.4.2 of the CE Machinery Directive,

is:

HD 8 VV....... .. .. ....................... L

pA

= 84 dB(A)

HD 10C VV ............................. L

pA

= 84 dB(A)

Sound emission of the machine

The sound power level of the machine, required according to Appendix 2 of the CE

Sound Emission Directive, is:

HD 8 VV............................... L

WA

= 106 dB(A)

HD 10C VV .......................... L

WA

= 106 dB(A)

Vibration indication

The vibration indications for the whole-body vibration on the driver's seat, requ ir ed accord ing

to Appendix 1, section 3.6.3.1 of the CE Machinery Directive (weighted effective acceleration calculated according to ISO 2631 part 1),

are:

HD 8 VV.... ..........................................0.3 m/s

2

HD 10C VV ..................... ... .................0.3 m/s

2

GENERAL

6 © HAMM AG 2009

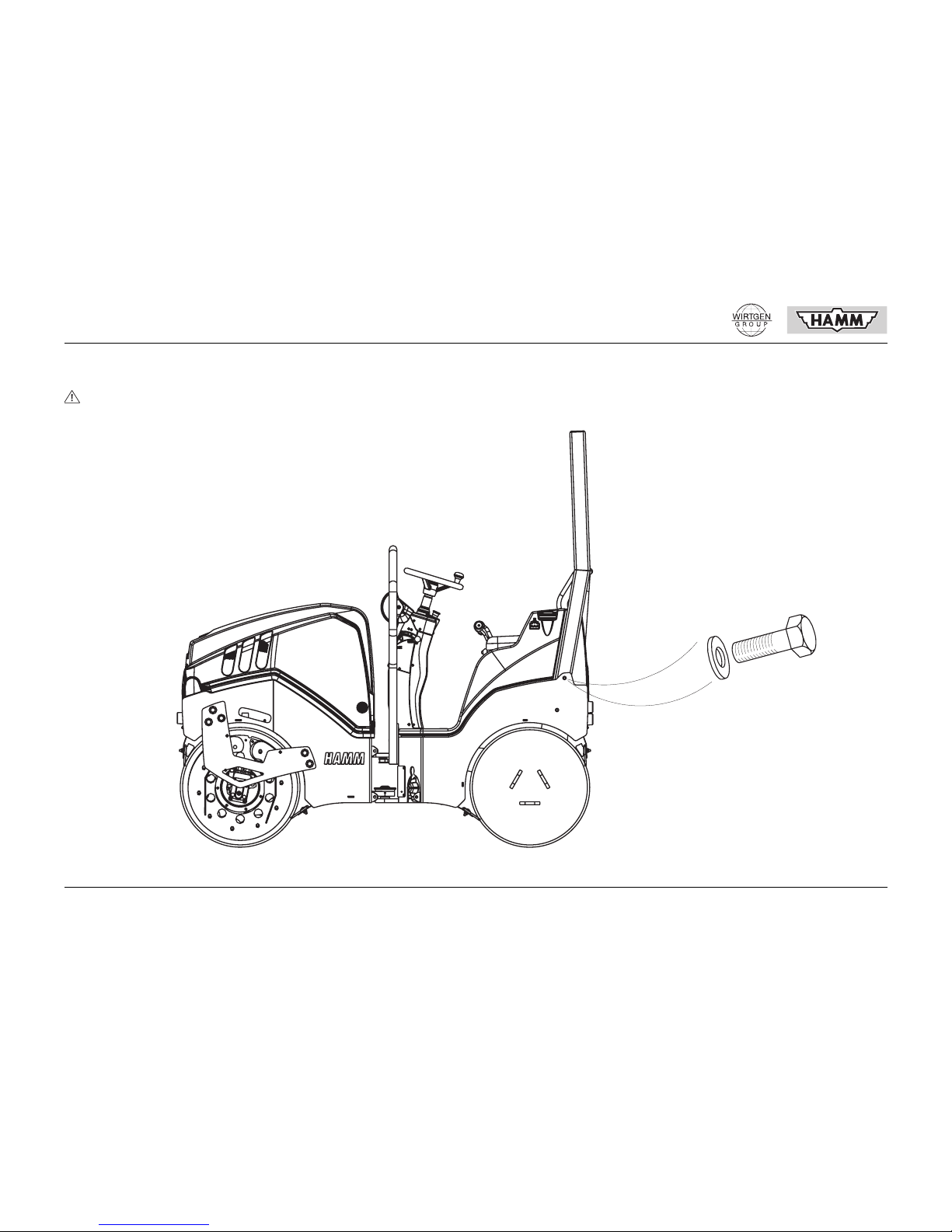

1.3.2 Installation instructions for safety device ROPS anti-rollover bar

The machine may only be operated with installed anti-roll over device!

10081-10

M16x50

Mt 209 Nm

© HAMM AG 2009 7

GENERAL

1.3.3 Safety

The safety notes summary applies to several machine types with different equipment.

Thus, it may be possible that some safety

notes are listed which do not apply to your

machine type.

Warning notes and symbols

The following denominations or symbols are

used in the operation instructions for indications of special importance. Please disclose

these safety instructions also to other users.

Principle; intended use

• This machine has been built according to

the state-of-the-art and the generally accepted safety regulations. However, danger for life and health of the user or impairment of the machine and of other objects

can arise during the use of the machine.

• This machine may only be used in technically unobjectionable condition, as well as

according to the intended use, and aware

of safety issues and possible dangers, always observing the operating instructions.

All safety devices removed for transport

purposes (anti-rollover device ROPS, handles, silencers etc.) must be installed to

the machine prior to using it. In particular,

any troubles which could have effect on

safety must be eliminated immediately.

• Arbitrary changes will exclude the manufacturer's liability for any damage resulting

from this.

• The machine may only be deployed on

surfaces that can support it. It is intended

solely for deployment for compressing

loose surfaces, road foundations, road

surfaces and similar compactable foundations. Any other deployment or a deployment beyond this is not deemed as intended. The manufacturer/supplier is not liable

for any damage resulting from this. The

user will bear the complete risk.

• The intended use also includes the observance of the operating instructions as

well as the compliance with the inspection

and maintenance requirements set out by

the manufacturer.

Immediate danger; possible consequences:

Death or very severe injuries.

Possibly dangerous situation; possible

consequences:

Death or very severe injuries.

Dangerous situation; possible consequences:

Light or insignificant injuries, warning of

property damage.

Possibly detrimental situation; possible

consequences:

The product or things in its surrounding

may be damaged.

Hints on application and useful information.

No information warning against a dangerous or detrimental situation.

GENERAL

8 © HAMM AG 2009

Organisational measures

• The operating instructions must always be

stored readily available at the place of application of the machine (in the tool case or

in the container for this purpose).

• The operating instructions of the combustion engine are a part of the overall operating instructions of the machine.

• The generally applying legal and other

binding accident prevention and environment protection regulations must be observed and instructed supplementary to

the operating instructions.

• Such duties may also concern, e.g., the

handling of hazardous substances or the

disposition/wearing of personal protection

equipment, as well as provisions of traffic

law or occupational health regulations.

• The operating i nst ructi ons mus t be s upple mented by instructions for taking into account factory-related particularities, including supervision and notification duties.

• The personnel ordered to perform activities with this machine must have read

these operating instructions, and in particular the safety section. It is too late to do

this during work. This is particularly true

for staff only working occasionally on the

machine, e.g. for repair and maintenance.

• The safety and danger awareness of the

personnel during work, taking into account

the operating instructions, must be controlled at least from time to time.

• The personnel must not wear open long

hair, loose-fitting clothes, or jewelry, including rings. Danger of injury due to

catching or pulling-in.

• Personal protection equipment must be

used as far as necessary or as required by

regulations.

• All safety and danger indications at the

machine must be observed.

• All safety and danger indications on/at the

machine must be kept complete and legible.

• Any changes, conversions, add-ons to the

machine, which could impair safety, must

not be performed without the approval of

the manufacturer. This also applies to the

installation and the adjustment of safety

devices and valves as well as for welding

on load-bearing parts.

• S pare parts must comply with the technical

requirements determined by the manufacturer. This is always ensured for original

spare parts.

• Hydraulic hoses must be replaced in the

defined or appropriate intervals, even if

safety-relevant defects cannot be detected.

• Any intervals for recurring inspections/

tests defined or indicated in the operating

instructions must be kept.

• A workshop equipment corresponding to

the work is absolutely necessary for performing servicing work.

• The installation of tires requires sufficient

knowledge and appropriate mounting

tools.

• The storage places and the use of fire extinguishers must be announced.

• Fire alarm and fire extinguishing possibilities must be observed.

© HAMM AG 2009 9

GENERAL

Selection and qualification of staff; general

duties

• Any work with or on the mach ine must only

be performed by appropriate and reliable

staff. The minimum legal age must be observed.

• Only trained or instructed staff may be

used.

• The responsibili ty of the st af f for operat ion ,

maintenance and servicing must be clearly

defined.

• It must be ensured that the machine is only operated by staff ordered to do this.

• The responsibility of the machine operator

- also with respect to traffic regulations must be defined; these must allow him or

her to reject unsafe instructions of third

parties.

• Any staff to be trained, instructed, taughtin, or any staff within a general education

measure, may only work on the machine

under the continuous supervision of an experienced person.

• Any work on electrical equipment of the

machine may only be performed by a specialised electrician or by instructed persons under the supervision of a specialised electrician and according to the rules

of electric engineering.

• Any work on suspensions, braking and

steering installations may only be performed by specialised staff trained for this.

• Only staff with specialist knowledge and

experience of hydraulics may work on hydraulic installations.

Safety notes on certain operation phases

Normal operation

• All working modes which are questionable

with respect to safety must not be performed.

• The operator mus t get familiar to the working environment at the place of utilisation

prior to the start of wor k. The work ing envi ronment includes e.g. the obstacles in the

working and traffic area, the load carrying

capacity of the underground and necessary safeguarding of the working site towards public traffic.

• Measures must be taken which only allow

the operation of the machine in a safe and

functional condition. Only operate the machine if all protection devices and safetyrelated devices, e.g. detachable protection

equipment, EMERGENCY STOP devices

(NOT-STOP), sound protection devices,

aspiration devices, are existing and operative.

• The machine must be inspected with respect to visually detectable damages and

defects at least once per shift. Any occurred changes (including changes of the

operational behaviour) must be notified

immediately to the responsible entity/person. If necessary, immediately shut down

and secure the machine.

• In case of malfunctions, the machine must

immediately be shut down and secured.

Have the malfunction eliminated immediately.

• Starting the engine and conducting the

machine may only be performed from the

drivers seat. Do not start the engine by

short-circuiting the electric connections at

the starter, since the machine could immediately start moving. Also, the function of

the starter protection switch must not be

overridden.

• Get familiar with all devices and operating

elements as well as with the functions of

these prior to starting the engine. It is too

late to do this during work.

• The acceleration and braking behaviour of

the machine are influenced by viscous hydraulic oil. For this reason, warm up the

machine during the warming phase with

moderate speed and low load until the hydraulic oil has heated to 20 °C (68 °F).

• Always wear a safety belt during travel.

• Never adjust the driver's seat during travel.

• The vibration function must never be used

in the immediate vicinity of buildings (danger of collapse). Prior to switching on the

vibration function, ensure that any lines

laid in the underground (gas, water, sewage, electricity lines) are not damaged or

destroyed.

• Observe all switching processes and control displays according to the operating instructions.

• Prior to starting the machine ensure that

nobody can be put into danger by the

starting of the machine.

GENERAL

10 © HAMM AG 2009

• Prior to driveaway, check for persons in

the immediate vicinity of the machine.

• Prior to driveaway/start of work, check

whether the brakes, the EMERGENCY

STOP device (NOT-STOP), the steering

system, and the signaling and illumination

installations are operative.

• Check for sufficient vision. Adjust necessary mirrors correctly.

• Prior to driveaway, always check the accident-safe storage of accessories. Lift attached add-on devices off the ground.

• Never leave the driver's stand during travel.

• In emergency situations and when

there is a danger, bring the machine to an

immediate stop by operating the EMERGENCY STOP switch (NOT-STOP).

• Do not use the EMERGENCY STOP

switch (NOT-ST OP) as service brake.

• In emergency situations and when

there is a danger, bring the machine to an

immediate stop by operating the parking

brake!

• Do not use the parking brake as the

service brake.

• When driving on public roads and places,

observe the applying traffic regulations

and bring the machine to an admissible

condition with respect to traffic law, if necessary.

• In case of bad visibility and in darkness always switch on the lights.

• It is forbidden to transpor t passengers.

• Always check for sufficient clearance

when passing underpasses, bridges, tunnels, overhead lines etc.

• Always keep sufficient distance to borders

of excavation pits and batters.

• Do not use any working procedure that

would impair the stability of the machine.

• The driving speed must always correspond to the conditions of the surroundings.

• Do not drive slopes in transversal direction; keep working equipment and loaded

goods always near to the ground, in particular when driving down slopes.

• Avoid driving sudden curves when driving

up or down slopes.

• Always switch to a lower gear before a

slope, never on the slope.

• Before leaving the driver's stand, always

prevent the machine making unintentional

movements (0 position lock engaged,

parking brake applied, engine switched

off).

• If the driver removes from the machine, he

or she must pull out the ignition key and

lock the cabin door and, if applicable, the

cabin doors or the dashboard cover.

• Lower down completely any installed additional devices prior to leaving th e machi ne.

• Never jump from the machine (risk of injury). Use the climbing steps and the grips.

• Disconnect the engine from electrical supply with the battery disconnector.

Special work in the scope of machine

utilisation, servicing work, as well as

troubleshooting during working

procedures; disposal

• Comply with adjustment, maintenanc e and

inspection work and schedules defined in

the operating instructions as well as with

indications on the replacement of parts/

partial equipment. Only specialised staff is

authorised to perform such works.

• Inform operating staff prior to the start of

special work and servicing work. Keep unauthorised persons off the machine during

these works. Denominate a supervisor.

• During all works concerning the operation,

the production adaptation, the conversion

or the adjustment of the machine and its

safety-related devices, as well as inspection, maintenance and repair, observe

processes for switching on and off according to the operating instructions as well as

the notes for servicing work.

• As far as necessary, safeguard the servicing area spaciously.

• Protect the machine against unexpected

starting during maintenance and repair

work.

For this:

• Lock the main command devices and

pull off the key

• Pull off the key from the battery dis-

connector and

• Attach a warning sign to the steering

wheel.

© HAMM AG 2009 11

GENERAL

• Generally, all maintenance and servicing

work may only be performed when the engine is at a standstill.

• Only open the engine hood when the engine is at a standstill.

• Keep away from moving, rotating or revolving parts; do not touch these (danger

of accidents).

• Only perform maintenance and servicing

work if the machine is parked on a level,

stable ground and if it is secured against

rolling away and buckling (danger of bruising).

• Perform maintenance and servicing work

below the lifted driver's stand only when

the lock is latched in. Engine bonnet always fully open (danger of life).

• After maintenance and servicing activities

that require the lifting of the driver's stand,

the driver's stand must be reattached/

screwed to the engine frames. This is the

only way to ensure the roll-ov er protection.

• Individual parts and bigger assemblies

must be attached carefully to lifting equipment and safeguarded in a way that no

danger can emanate from these. Only use

appropriate and technically unobjectionable lifting equipment as well as load-carrying equipment with sufficient loading capacity. Do not rest or work under suspended loads.

• Only order experienced persons with the

fixing of loads and the guidance of crane

operators. The guiding person must be in

visible range of the operator or have a

speaking contact to him or her.

• During installation work above body

height, use safe climbing aids and working

platforms intended for this purpose. Do not

use machine parts as climbing aids. In

case of maintenance work in greater

heights, wear fall protection. Keep all handles, steps, handrails, pedestals, platforms, ladders, free from dirt, snow and

ice.

• Clean all oil, fuel, and care agent residues

from the machine, in particular from connections and screwed connections, prior

to maintenance and repair work (fire hazard). Do not use aggressive cleaning

agents. Use fibre-free cleaning cloth.

• Prior to cleaning the machine with water,

vapour stream (pressure washer) or other

means of cleaning, cover/seal all apertures which must not be penetrated by water/steam/cleaning agent due to safety or

functionality reasons. Electric motors and

distribution cabinets are specially endangered in this respect.

• After cleaning, the covers/seals must be

taken off completely.

• After cleaning, check all fuel lines, engine

oil lines, and hydraulic liquid lines for

leaks, loose connections, chafe marks,

and damage. Eliminate detected defects

immediately.

• Always tighten any screwed connections

loosened during maintenance and servicing work.

• If the removal of safety devices is necessary for rigging, maintenance and repair,

the safety devices have to be re-installed

and checked immediately after the end of

the maintenance and repair work.

• Take care for a safe and environmentfriendly disposal of operating and auxiliary

substances, replaced parts and contaminated cleaning material.

GENERAL

12 © HAMM AG 2009

Notes with respect to special types of

danger

Electrical energy

• Only use original fuses with the correct

power value. Immediately shut down the

machine in case of troubles in the electric

power supply.

• During the start of the machine with battery connection cables, always connect

the positive pole to the positive pole and

the negative pole to the negative pole. Always connect the negative pole last and

disconnect it first.

• Keep sufficient distance between the machine and overhead voltage lines. During

works near electric overhead lines, the

equipment must not come near to the

overhead lines. Danger of life! Inform your self about safety distances to be kept.

• After touching high-voltage lines:

• Do not leave the machine

• Drive the machine out of the danger

area

• Warn surrounding persons not to

come nearer and not to touch the machine

• Have the voltage shut down

• Only leave the machine after it abso-

lutely sure that the touched/damaged

line is de-energised.

• Any work on electrical installations or operating resources may only be performed

by a specialised electrician or by instruct-

ed persons under the supervision of a specialised electrician and according to the

rules of electric engineering.

• During works at the electric installation,

the machine must be de-energised at the

battery disconnector or by disconnecting

the negative pole (earthing strip) at the

battery.

• Do not smoke during maintenance work at

the battery (danger of explosion). Keep

away igniting sparks or open flames.

• Dispose used batteries properly.

• The electrical equipment of a machine

must be inspected/tested regularly. Any

defects, as e.g. loose connections or burnt

cables, must be eliminated immediately.

• Only use tools insulated against voltage.

Gas, dust, vapour, smoke

• Only operate combustion engines and fuel-operated heating systems in sufficiently

ventilated areas. Take care for sufficient

ventilation before starting in closed rooms

(danger of poisoning). Observe t he regulations applying for the respective place of

application.

• The operation of the machine is inadmissible in places where flammable gases or

dusts can occur (e.g. near fuel storage areas, coal storage areas, cereals storage

areas, wood dust or similar).

• Unusual sounds and strong smoke exhaust of the engine during operation can

point to dangers. Find out the cause and

have the damage repaired.

• Welding, torching and grinding work may

only be performed at the machine if this is

expressivley admitted. There may be fire

and explosion hazard.

• Prior to welding, torching and grinding,

clean the machine and its surroundings

from dust and flammable substances and

take care for sufficient ventilation (danger

of explosion).

Hydraulic system, pneumatic system

• Only staff with specialist knowledge and

experience of hydraulics may work on hydraulic installations.

• All lines, hoses and screwed connections

must be checked for leaks and visible

damage (at least once per year). Damaged parts must be replaced immediately.

Further operation is inadmissible. Oil

spurting out can lead to injuries and fire.

• Liquids spurting out under high pressure

(hydraulic oil, fuel) can penetrate the skin.

In case of such injuries consult a doctor

immediately; otherwise, severe infections

may occur.

• Prior to work on hydraulic lines, safeguard

the machine against rolling away (parking

brake, wedges). Lower down add-on devices completely. Only then remove the

pressure from the lines.

• Remove the pressure from system sections to be opened and from pressure lines

(hydraulics, compressed air) according to

the assembly descriptions prior to beginning the repair work.

© HAMM AG 2009 13

GENERAL

• Lay and install hydraulic and compressed

air lines appropriately. Do not confuse connections. The fittings, the length and the

quality of the hose lines must comply with

the requirements.

Noise

• Sound protection devices at the machine

must be in protection position during operation.

Fuel, oils, greases and other chemical

substances

• Only appropriate and clean lubricants may

be used. Otherwise the guarantee becomes void.

• During the handling of oils, greases and

other chemical substances, observe the

safety regulations applying for the respective product.

• Do not heat oil above 160°C (320 °F); otherwise, oil or oil vapours may ignite.

• Prior to fil ling up fuel, switch of f engine and

heating and pull out the ignition key. Do

not fill up fuel in closed rooms. Wipe away

spilled fuel immediately.

• Be extremely careful when handling fuel increased fire hazard. Never fill up fuel

near open flames or igniting sparks. Do

not smoke during filling up!

• Be careful during the handling of brake fluid and battery acid (noxious and caustic).

• Be careful during the handling of hot operation and auxiliary materials (danger of

burning or scalding).

• Release emulsions for tires may only be

mixed from water and release concentrate

according to the indications of the release

agent manufacturer. The environment protection regulations must be observed.

Transport and towing

• Only tow, load and transport according to

the operating instructions.

• Only use appropriate transport means and

lifting hoist with sufficient load capacity.

Take into account the weight and the dimensions (technical data).

• Only use stable loading ramps with sufficient carrying capacity for loading. Take

care not to endanger persons by tilting or

sliding.

• Prior to loading ensure that the vehicle

(e.g. trailer, flat bed etc.) cannot tilt upwards when driving onto the loading area.

• Do not step or rest under suspended loads

(danger of life).

• Do not rest in the danger zone of the machine during the guidance and loading of

the machine (danger of life).

• Use the specified gantries.

• Drive the machine slowly onto or from the

loading area, respectively.

• Safeguard the machine with square timer,

wedges and tensioning ropes against

shifting. Safeguard the attenuation elements of the drum suspension against

overload by means of a support.

• Remove square timbers, wedges and tensioning ropes completely before unloading.

• All safety devices removed for transport

purposes (anti-rollover device ROPS, handles, silencers etc.) must be installed to

the machine prior to using it.

GENERAL

14 © HAMM AG 2009

• During towing, keep the specified transport position, the admissible speed and

the travel path.

ROPS cabin

• The machine frame must not be warped,

bent or cracked in the cabin fixing area

(deformation).

• The reinforcement elements of the ROPS

cabin must not show rust, damage, fissures or open fractures.

• All screwed connections of the reinforcement elements must comply with the given

specifications and must be screwed tightly

to each other (observe tightening torque

values).

• Bolts and nuts must not be damaged, bent

or deformed.

• Additional parts may not be installed to the

reinforcement elements without the manufacturer's approval.

• Any change to the reinforcement elements

which would decrease its strength, is inadmissible.

ROPS anti-rollover bar

• The machine frame must not be warped,

bent or cracked in the ROPS fixing area

(deformation).

• The ROPS must not show rust, damage,

fissures or open fractures.

• All screwed connections must comply with

the given specifications and must be

screwed tightly to each other (observe

tightening torque values).

• Bolts and nuts must not be damaged, bent

or deformed.

• Additional parts may not be installed without the manufacturer's approval.

• Any change which would decrease the

strength of the ROPS is inadmissible.

© HAMM AG 2009 15

GENERAL

1.3.4 Fuel

Only operate the diesel engine with common

diesel fuel with a sulphur content below 0.5 %.

In case of a higher sulphur content, the engine

oil change intervals must be shortened.

Admissible fuel specifications are:

• DIN EN 590

• JIS K 2204 Grade 1 and 2

• ASTM D 975-88: 1-D and 2-D

Marine Diesel Fuel, heating oils etc. may not

be used.

The stated engine oil change intervals require

a diesel fuel with a maximum sulphur content

of 0.5 % and a continuous ambient temperature of a minimum of -10 °C (14 °F).

For diesel fuels with a fuel content between

0.5 % and 1.0 %, or continuous ambient temperatures below -10 °C (14 °F), the engine oil

change intervals must be halved.

If diesel fuels with manufacturer-guaranteed

winter properties are used, additives can be

omitted until the guaranteed temperature is

reached.

In case of low temperatures, fluidity and filterability of the diesel fuel are insufficient (crystallised paraffins).

Therefore, diesel fuels with increased low temperature properties are available in winter

months. Prior to the cold period, ta ke car e t o fil l

up winter diesel fuel.

In order to maintain fluidity and filterability for

summer diesel fuel at low temperatures, a

quantity of engine petroleum, depending on

the external temperature (observe countryspecific regulations), or c ommonly available fuel additives, so-called flow improvers, must be

mixed into the vehicle tank. A dissolving of already crystallised parrafins is impossible.

A maximum of 30 % engine petroleum can be

added:

/i

At extremely low temperatures, add additive also to winter diesel fuel:

/i

The use of flow improvers keeps engine power

constant and allows the use of the vehicle also

for extremely low temperatures.

Observe the manufacturer's indications.

Danger of explosion! Increased fire hazard! Danger of intoxication!

Be careful during the handling of fuel!

Prior to refilling fuel, the diesel engine and

fuel-operated heating systems, if any,

must be shut down.

Do not fill up fuel in closed rooms.

Wipe away spilled fuel immediately. Do not

breathe in vapours.

Fuel is flammable and explosive. Thus,

avoid open flames or igniting sparks during fuel handling, or even near fuel. Do not

smoke! This also applies where the characteristic smell of fuel can be detected. In

case of fuel smells in the machine itself,

the cause must be detected and removed

immediately.

External temperature

(°C / °F)

Summer diesel fuel (%)

Addition

(%)

±0 to -9 (32 to 15.8) 80 20

-10 to -14 (14 to 6.8) 70 30

External temperature

(°C / °F)

Winter diesel

fuel (%)

Addition

(%)

-15 to -25 (5 to - 13) 70 30

GENERAL

16 © HAMM AG 2009

1.4 IDENTIFICATION OF THE

ROLLER

1.4.1 Type sign, VIN.

The unique identification of the roller is given

by the vehicle identification number (VIN). It

can be found on the type sign together with t he

type designation and the weight indications.

The type sign is fixed to the machine frame. It

must neither be changed nor removed.

If the type sign is not legible any longer, or if it

has been lost, a replacement type sign must

be ordered immediately at the HAMM customer service, stating the VIN embossed into the

right front part of the machine frame, and fixed

to the machine.

1.5 TECHNICAL DATA

1.5.1 Loading and transport

When loading rollers onto lorries, trailers or

semitrailers, it is very important to secure the

load properly. The duty for tie-down on street

vehicles arises from StVO § 22, StVO § 23,

HGB § 412 as well as from VDI guideline2700.

Sufficient knowledge about the loading of vehicles as well as about their behaviour under

load are required for loading and transporting

the machine. The machine may only be loaded

by trained loading staff. It must be fixed to the

vehicle in an form-locked or friction-locked and

transport-safe way. The machine must not

change its position of the vehicle duri ng normal

traffic loads. Emergency braking, change manoeuvres and uneven grounds count among

normal traffic loads. If it is impossible to secure

the machine properly onto the vehicle, of if the

loading vehicle shows visible defects which do

not ensure safe transport, loading must not be

performed.

The relevant accident prevention regulations

as well as further generally acknowledged

safety and traffic-related rules must be complied with.

• Weight and dimensions (technical data).

• It is very important to use a loading ramp

when loading the machine onto a lorry.

• If necessary, support the loading area to

the floor in order to prevent the vehicle

(trailer) from tilting upwards when the r oller

is driven onto the loading platform.

• Only use appropriate gantries or planks.

When driving the roller up the loading area, take care that the drums or tires have

appropriate contact.

• Gantries and planks must be free from

grease, dirt, ice etc.

• Drive the machine slowly onto the loading

area with ¾ diesel engine speed.

• On rubber wheel rollers with tyre inflation

system, the tyre pressure must be set to

6 bar (87 psi). The actuation element for

tire filling must set the the centre position

after that.

• Shut down the machine and secure

against unauthorised start (see section

“Stopping, shutting down the engine, leaving the machine”).

• In case of rollers with articulated steering,

the steering blocking must always be activated for transport.

• Secure the drums or tires with wedges

against shifting.

• Lash the machine with appropriate lashing

devices onto the loading area, using only

the marked lashing lugs (see figure).

• In case of crane loading, only fix ropes to

the marked lifting lugs.

Please state the VIN and the type designation of your machine for every spare part

order.

© HAMM AG 2009 17

GENERAL

• Remove wedges and lashing devices

completely before unloading. Unblock

steering system by unblocking the articulated frame steering block.

• All safety devices removed for transport

purposes (anti-rollover device ROPS, handles, silencers etc.) must be installed to

the machine prior to using it.

• Drive the roller slowly and carefully from

the loading area.

Load securing

• Position 2 wedges at each axis, as far to

the outside as possible, flushing with drum

or tyre, and fix them with 3 nails each to

the loading area.

• The lashing devices A and B must be fixed

to the lashing point of the machine and at

the vehicle. The permitted tractive force

must be at least 2000 daN also at the lashing point.

The arrangement of the lashing devices shown

in the figure must be realised on both sides.

10080-10

1 m

A

1 m

B

(39.37")

(39.37")

GENERAL

18 © HAMM AG 2009

1.5.2 Dimension sheet HD 8 VV

10078-10

(26.7" )

(85.7" )

(59.1" )

(24.4"

)

(9.1")

(24.4")

(56.7" )

(57.1" )

(61.4" )

(84.8" )

(31.5")

(33.7")

(2.2")

(90.0" )

(57.3" )

800 56

856

679

1500

230

2155

1440

1450

Ø620

Ø 620

1560

2177

2285

1456

© HAMM AG 2009 19

GENERAL

1.5.3 Dimension sheet HD 10C VV

10079-10

(26.7")

(85.7")

(59.1")

(24.4")

(9.1")

(24.4")

(56.7")

(57.1")

(61.4")

(84.8")

(39.4")

(41.7")

(2.4")

(90.0")

(57.3")

1000

60

1060

679

1500

230

2155

1440

1450

Ø 620

Ø620

1560

2177

2285

1456

20 © HAMM AG 2009

GENERAL

1.5.4 Technical data HD 8 VV

/i

/i

/i

/i

Dimensions and weights

Empty weight 1295 kg (2855 lbs)

Operational weight 1445 kg (3186 lbs)

Front axle load 710 kg (1566 lbs)

Rear axle load 735 kg (1621 lbs)

Vibration front/back

Drum width/working width 800/856 mm (31.5 /33.70")

Turning radius outside/inside 2960/2104 mm (116.54/82.83")

Drum diameter 620 mm (24.41”)

Filling quantities

Fuel tank 30.00 l (7.92 US gal.)

Engine (for oil change) 4.00 l (1.06 US gal.)

Refrigerant 5.50 l (1.45 US gal.)

Oil container for hydraulic installation 26.00 l (6.86 US gal.)

Water container - irrigation for front and rear drum 75.00 l (19.8 US gal.)

Engine

Hatz diesel engine, four-stroke, 3 cylinders, liquid cooled, type 3W35

Power acc. to ISO 14396 15.7 kW/2700 rpm

© HAMM AG 2009 21

GENERAL

/i

/i

/i

Electrical equipment

Operation voltage 12 V

Battery 12 volts/66 Ah

Drive

Hydrostatic drive, continuous, one-lever-operation 4x4

Speed 0-10 km/h (0-6.2 mph)

Gradeability with vibration up to 30 %

Gradeability without vibration up to 40 %

Vibration

Direct hydrostatic drive. Automatic vibration shut-off during reverse and at excessive speed.

Frequency/amplitude max. 62 Hz/0.45 mm (3720VPM/0.02")

Steering

Hydrostatic articulated frame steering.

Service brake

During operation, the machine is braked with the hydrostatic drive. Wear-free braking.

Parking brake

Spring-operated brake acting upon each hydromotor of the drive. Manually and automatically.

EMERGENCY STOP brake (NOT-STOP)

By hydrostatic drive and spring-operated brakes.

Water irrigation

Pressure irrigation, manual operation and automatic interval system.

Special equipment

On request, the machine can be equipped with extensive special equipment.

Changes in design, weight and dimensions reserved.

22 © HAMM AG 2009

GENERAL

1.5.5 Technical data HD 10C VV

/i

/i

/i

/i

Dimensions and weights

Empty weight 1425 kg (3142 lbs)

Operational weight 1575 kg (3473 lbs)

Front axle load 770 kg (1698 lbs)

Rear axle load 805 kg (1775 lbs)

Vibration front/back

Drum width/working width 1000/1060 mm (39/41.73")

Turning radius outside/inside 3060/200 2 mm (120.47/78.82")

Drum diameter 620 mm (24.41”)

Filling quantities

Fuel tank 30.00 l (7.92 US gal.)

Engine (for oil change) 4.00 l (1.06 US gal.)

Refrigerant 5.50 l (1.45 US gal.)

Oil container for hydraulic installation 26.00 l (6.86 US gal.)

Water container - irrigation for front and rear drum 75.00 l (19.8 US gal.)

Engine

Hatz diesel engine, four-stroke, 3 cylinders, liquid cooled, type 3W35

Power acc. to ISO 14396 15.7 kW/2700 rpm

© HAMM AG 2009 23

GENERAL

/i

/i

/i

Electrical equipment

Operation voltage 12 V

Battery 12 volts/66 Ah

Drive

Hydrostatic drive, continuous, one-lever-operation 4x4

Speed 0-10 km/h (0-6.2 mph)

Gradeability with vibration up to 30 %

Gradeability without vibration up to 40 %

Vibration

Direct hydrostatic drive. Automatic vibration shut-off during reverse and at excessive speed.

Frequency/amplitude max. 62 Hz/0.45 mm (3720VPM/0.02")

Steering

Hydrostatic articulated frame steering.

Service brake

During operation, the machine is braked with the hydrostatic drive. Wear-free braking.

Parking brake

Spring-operated brake acting upon each hydromotor of the drive. Manually and automatically.

EMERGENCY STOP brake (NOT-STOP)

By hydrostatic drive and spring-operated brakes.

Water irrigation

Pressure irrigation, manual operation and automatic interval system.

Special equipment

On request, the machine can be equipped with extensive special equipment.

Changes in design, weight and dimensions reserved.

OPERATION

24 © HAMM AG 2009

2 OPERATION

2.1 CONTROL AND

OPERATION ELEMENTS

2.1.1 General

These operating instructions apply to several

types of this series. Therefore it is possi ble that

these instructions include descriptions of operation elements not installed in your machine.

The position numbers refer to the description

of the individual elements in this cha pter. In the

text for operation and maintenance, these position numbers are in brackets.

2.1.2 Overview

302 EMERGENCY STOP switch

(NOT-STOP)

501 Driving lever

503 Multifunctional grip

Vibrator OFF-ON

504 Engine speed

10082-10

302 503

501

504

© HAMM AG 2009 25

OPERATION

302 EMERGENCY STOP switch

(NOT-STOP)

310 Key switch electric system/engine star t

501 Driving lever

503 Multifunctional grip

Vibrator OFF-ON

504 Engine speed

10083-10

302

504 503

501

310

OPERATION

26 © HAMM AG 2009

101 Operation hours counter display

118 Display of diagnostic code

201 Illuminated display for charging current

202 Illuminated display for engine oil pressure

203 Illuminated display for air filter

205 Function not existing

207 Illuminated display for water irrigation

216 Illuminated display for cold start assistance

(option)

219 Illuminated display for working lights (option)

221 Function not existing

222 Illuminated display amplitude vibration

activated

228 Illuminated display for engine temperature

229 Illuminated display for hydraulic system oil

temperature

231 Illuminated display for vibrator preselection

vibration deactivated

232 Illuminated display for irrigation level

233 Illuminated display for headlights (option)

301 Signal horn pushbutton

303 Turning light pushbutton (option)

304 Parking brake pushbutton

305 Warning lights pushbutton (option)

307 Headlights pushbutton (option)

309 Working lights pushbutton (option)

311 Rotating beacon pushbutton (option)

312 Vibration pushbutton

316 Vibrator preselector pushbutton

317 Water irrigation pushbutton

318 Function not existing

319 Vibration mode manual-automatic

pushbutton

373 Irrigation level pushbutton

© HAMM AG 2009 27

OPERATION

520 Seat adjustment weight

521 Seat adjustment forward - backward

522 Seat adjustment backrest

15015-10

520

522

521

OPERATION

28 © HAMM AG 2009

2.1.3 Description of elements

The positions identified with numbers correspond to the numbering of the plates for operating elements, control devices and switches.

They are identical to the numbers of the individual operating and control elements. In the

describing text, these position numbers are in

brackets. Among other things, this ensures that

important and additional information can be

found immediately and without diff icultie s in the

descriptions of the elements.

101 Operation hours counter display

Registers the operating hours of the running

diesel engine. Maintenance work has to be

carried out according to the accumulated operating hours.

118 Display of diagnostic code

During operation, machine malfunctions are

displayed by flashing indicators. A number

code identifies the corresponding malfunction.

After switching on the electric system, an

internal test code is displayed for 2 seconds.

0101-102

1/10h

After switching on the electric system, an

internal test code is displayed for 2 seconds.

See also section 4.1 Diagnostic Code in

the operating instructions.

0118-100

© HAMM AG 2009 29

OPERATION

201 Illuminated display for charging

current

When the electric system is switched on (key

switch (310) in position I) and the engine does

not run, this indicator must be illuminated. Af te r

the start of the engine the illumination must go

out. Lighting up during operation indicates

missing charging current. At the same time an

acoustic signals sounds.

202 Illuminated display for engine oil

pressure

When the electric system is switched on (key

switch (310) in position I) and the engine does

not run, this indicator must flash.

After the start of the engine the illumination

must go out. Flashing during operation indicates insufficient o il p ress ure. At t he same t ime

an acoustic signals sounds. Shut down the engine, determine and eliminate the cause.

A flashing indicator with warm engine and idle

speed is admissible, if the indicat or stop s fla shing when the engine speed increases.

203 Illuminated display for air filter

Flashing during operation indicates a clogged

air filter cartridge. At the same ti me an acoustic

signals sounds.

0201-104 0202-104 0203-104

OPERATION

30 © HAMM AG 2009

207 Illuminated display for water irrigation

The indicator lights up when the water pump

runs during water irrigation.

216 Illuminated display for cold start

assistance (option)

When the electric system is switched on (key

switch (310) in position I), this indicator lights

up. The illumination goes out when the starting

temperature is reached. Start the diesel engine.

219 Illuminated display for working lights

(option)

This indicator lights up when the working lights

are switched on.

0207-103 0216-103 0219-101

© HAMM AG 2009 31

OPERATION

222 Illuminated display amplitude

vibration activated

This indicator lights up when the vibration system is activated.

228 Illuminated display for engine

temperature

Flashing during operation indicates overheating of the diesel engine. At the same time an

acoustic signals sounds. Determine and eliminate the cause for overheating.

229 Illuminated display for hydraulic

system oil temperature

Flashing during operation indicates hydraulic

oil overheating. At the same time an acoustic

signals sounds. Determine and eliminate the

cause for overheating.

0222-101 0228-100 0229-100

OPERATION

32 © HAMM AG 2009

231 Illuminated display for vibrator

preselection vibration deactivated

This illuminated indicator indicates a pre-selected vibrator in case of de-activated vibration.

232 Illuminated display for irrigation level

This indicator lights up when the irrigation system is switched on. It indicates the irrigation

level.

233 Illuminated display for headlights

(option)

This indicator lights up when the lighting is

switched on.

0231-100 0232-100 0233-100

© HAMM AG 2009 33

OPERATION

301 Signal horn pushbutton

The signal horn sound as long as this pushbutton is pressed.

On........................................................PRESS

302 EMERGENCY STOP switch

(NOT-STOP)

When the EMERGENCY STOP switch (NOTSTOP) is pressed, the hydraulic drive is

stopped, the vibration system is shut down, the

diesel engine is shut off, and the hydraulic

brakes are activated (illuminated indicators

(201, 202) active).

On.........................................................DOWN

To disengage the switch knob, turn it clockwise. The illuminated indicators remain active.

Off............................................................... UP

Initial position:

• Latch driving lever (501) in position 0.

• Switch off vibration with pushbutton (312)

(illuminated indicator (222) inactive).

• Release EMERGENCY STOP switch

(NOT-STOP).

• Start the diesel engine.

0301-102

Danger of injuries!

The roller stops immediately without any

delay!

Do not use the service brake!

0302-100

After actuating the EMERGENCY STOP

switch (NOT-STOP), the machine must be

brought to its initial position. If the engine

is started with the EMERGENCY STOP

switch (NOT-STOP) pressed, the engine

will not start for safety reasons.

OPERATION

34 © HAMM AG 2009

303 Turning light pushbutton (option)

The arrows indicate the actuation direction for

the corresponding turning direction of the machine.

When a turning light is switched on, the control

light at the active pushbutton flashes.

On........................................................PRESS

Off ...........................................PRESS AGAIN

304 Parking brake pushbutton

Pressing the pushbutton applies or releases

the parking brake.

Applied................................................. PRESS

(Control light lights up)

Released..................................PRESS AGAIN

(Control light goes out)

305 Warning lights pushbutton (option)

Pressing the pushbutton switches the warning

lights on or off.

On........................................................PRESS

(Control light flashes)

Off .......................................... PRESS AGAIN

(Control light goes out)

0303-106

Use only for stopping and parking the machine. This is not a service brake! Check

operation daily!

0304-102

Check the correct function of the warning

lights prior to starting the engi ne!

0305-104

© HAMM AG 2009 35

OPERATION

307 Headlights pushbutton (option)

When the electric system is switched off (key

switch (310) in position 0) and this pushbutton

is pressed, only the parking lights are switched

on or off.

When the electric system is switched on (key

switch (310) in position I) and this pushbutton

is pressed, the headlights are switched on or

off.

On........................................................PRESS

(Illuminated indicator (233) lights up)

Off ...........................................PRESS AGAIN

(Illuminated indicator (233) goes out)

309 Working lights pushbutton (option)

Pressing the pushbutton switches the working

lights on or off.

On........................................................PRESS

(Illuminated indicator (219) lights up)

Off ...........................................PRESS AGAIN

(Illuminated indicator (219) goes out)

310 Key switch electric system/engine

start

The electrical components are supplied with

power through the key switch, and the Diesel

engine is started and stopped.

Key position 0

Electric system............................... ...........OFF

Diesel engine ...................................... ... STOP

(Key released)

Key position I

Electric system............................... .............ON

Key position II ............... .................. PREHEAT

Key position III ............ .. .. ....... ENGINE START

(Key turns back to position I after starting)

0307-103 0309-100

0310-100

OPERATION

36 © HAMM AG 2009

311 Rotating beacon pushbutton (option)

Pressing the pushbutton switches the rotating

beacon on or off.

On........................................................PRESS

(Control light lights up)

Off ...........................................PRESS AGAIN

(Control light goes out)

312 Vibration pushbutton

Pressing the pushbutton activates or deactivates the vibration system.

Activation .............................................PRESS

(Illuminated indicator (222) lights up)

Deactivation ............................ PRESS AGAIN

(Illuminated indicator (231) lights up)

When the vibration system is activated, the vi-

brator can be switched on or off at the multifunctional grip (503).

When the engine is at a standstill and the

electric system is switched on for a longer

period (key position I), the battery discharges rapidly.

If the engine is started with the EMERGENCY STOP switch (NOT-STOP)

pressed, the engine will not start for safety

reasons. To activate the machine:

• Latch driving lever in position 0.

• Release EMERGENCY STOP switch

(NOT-STOP).

0311-105

Danger of collapse!

Do not switch on the vibration system near

buildings!

0312-106

© HAMM AG 2009 37

OPERATION

316 Vibrator preselector pushbutton

When this pushbutton is pressed, the vibrator

in the front drum, in the rear drum, or in both

drums, is preselected.

This illuminated indicator (symbol withou t oscil lation) indicates a pre-selected vibrator in case

of de-activated vibration. Each actuation of the

pushbutton switches one step ahead in the circulation.

Front vibrator........................................PRESS

Rear vibrator ............................PRESS AGAIN

Double vibrator.........................PRESS AGAIN

If the vibration system is activated with pushbutton (312), the illuminated indicator changes

over to Vibration activated (symbol with oscillation).

317 Water irrigation pushbutton

Pressing the pushbutton switches the water irrigation system on or off. Water consumption is

optimised via a multi-stage automatic interval

system. The irrigation levels can be selected

with pushbuttons (373).

On........................................................PRESS

Off ...........................................PRESS AGAIN

Continuous pressing of the pushbutton will

cause permanent water irrigation. As long as

the pushbutton is pressed, the pump runs in

continuous operation.

Continuous

operation.................PRESS CONTINUOUSLY

319 Vibration mode manual-automatic

pushbutton

The pushbutton sets the operating mode for

the vibration system. The vibrator can be

switched on or off manually or automatically.

Manually...............................................PRESS

(Upper control light lights up)

The vibration can be switched on or off at any

time with the pushbutton on the multifunctional

grip (503).

Automatically........................... PRESS AGAIN

(Lower control light lights up)

0316-105

When the machine is at a standstill, the irrigation system is without function.

0317-104 0319-104

OPERATION

38 © HAMM AG 2009

The switching on and off of the vibr ation i s cou pled to the road speed. When the admissible

road speed with vibration (8 km/h (4.97 mph))

is exceeded, vibration is switched off.

Braking

(below 1.5 km/h (0.93 mph)).....................OFF

Acceleration

(more than 0.5 km/h (0.31 mph)) ...............ON

Driving

(more than 8.0 km/h (4.97 mph))..............OFF

The vibration can be switched on or off at any

time with the pushbutton on the multifunctional

grip.

373 Irrigation level pushbutton

When the water irrigation system is switched

on, water consumption can be selected from

three irrigation levels. An illuminated indicator

indicates the selected level. Each actuation of

the pushbutton causes a level increment.

Increase level....................................PRESS +

Decrease level ...................................PRESS -

501 Driving lever

The driving lever determines the driving direction and speed.

Forward movement ........... .. .......to the FRONT

Backward movement ..................to the BACK

Braking.................................... to the CENTRE

Stopping ................ ........................... CENTRE

The speed is proportionate to the magnitude of

the lever displacement.

Move the lever evenly and uninterruptedly. In

ascending or descending slopes, reduce the

driving speed at the driving lever and increase

engine speed.

The automatic mode must be activated

with the pushbutton at the multifunctional

grip (503) after initial switc h ing on.

0373-100 0501-106

© HAMM AG 2009 39

OPERATION

503 Mult ifunctional grip

Vibration

When the vibration system is activated, the vibrator can be switched on or off at the pushbutton A at any time.

Vibrator on .................. .........................PRESS

Vibrator off ................. .. ... ........PRESS AGAIN

504 Engine speed

The speed of the diesel engine can be regulated between idle speed and maximum speed

using the adjustment lever .

Idle speed .. ...............................................MIN

max. speed ................... .. ... ...................... MAX

520 Seat adjustment weight

In order to absorb impulsive machine movements using the installed attenuation system,

this must be adjusted to the weight of the driver. The pretension of the attenuation system

can be adjusted continuously to a driver's

weight between 50 kg (110 lbs) and

120 kg (265 lbs) by turning the hand wheel to

the left or to the right.

0503-108

A

0504-104

MIN

MAX

0520-104

520

OPERATION

40 © HAMM AG 2009

521 Seat adjustment forward - backward

After lifting the lever, the upper part of the seat

can be shifted in forward or backward direction

in increments of 15 mm (0.59").

522 Seat adjustment backrest

The inclination of the backrest can be adjusted

in forward or backward direction by turning the

handwheel.

0521-103

521

0522-103

522

© HAMM AG 2009 41

OPERATION

2.2 DRIVING

2.2.1 General

What must be done prior to start of work?

• Perform control and maintenance works

(see maintenance section).

• Keep step-on surfaces and driver's stand

free from stumbling hazards, grease, dirt,

ice etc.

• Check the turning lights (303) and warning

lights (305), as well as the signal horn

(301) and the illumination (307).

• Check the parking br ake (304) .

•

• Never drive the machine until the fuel tank

is empty. Check the filling level of the fuel

tank in time. Fill up fuel tank in the

evening; this avoids the precipitation of

condensed water in the empty tank.

Fill up to the lower edge of the f ill i ng spout.

Only use clean fuel!

• Check the filling level of the water t ank. Fill

up to the lower edge of the filling spout.

Use clean water only!

Danger of accidents by operating errors!

Prior to every start-up:

Check the machine for operational and

traffic safety!

Read and observe the operating instructions and the safety notes!

Danger of explosion and increased fire

hazard during fuel handling!

Only fill up fuel when the engine is at a

standstill. Do not smoke during the fillingup process!

Never fill up fuel near open flames or igniting sparks. Do not fill up fuel in closed

rooms!

Notes on filling up fuel, see section “Fuel”.

OPERATION

42 © HAMM AG 2009

Symbols for operating substances

The filling places for operating substances on

the machine are identified with symbols. According to machine type and equipment, the

following symbols are attached to the machine:

A Fuel

B Water irrigation

C Additive irrigation

02460-13

A

B

C

© HAMM AG 2009 43

OPERATION

2.2.2 Precaution measures prior to

machine start

The machine may only be started and driven

by specialist persons authorised to do so.

Danger of accidents and danger of injuries!

The operator must get familiar to the working environment at the place of utilisation

prior to the start of work. The worki ng environment includes e.g. obstacles in the

working and traffic area, the load carrying

capacity of the underground and necessary safeguarding towards public traffic.

Make yourself familiar with all devices and

operating elements of the machine and the

function of these. It is too late to do this

during work.

Ensure that nobody is in front of, under, or

behind the machine. Do not allow anybody

to stay in the danger zone of the machine.

Ensure sufficient sight, adjust necessary

mirrors correctly.

Keep operation and safety signs clean. Illegible or lost signs must be replaced immediately.

After maintenance and repair work requiring a removal of the driver's cabin/ROPS

anti-rollover device, the driver's cabin/

ROPS anti-rollover device must be

screwed again securely to the machine

frame. This is the only way to ensure the

roll-over protection.

After maintenance work, check that all

tools have been removed from the machine and that all protection devices have

been re-attached and are in protection position.

The diesel engine may only be started

from the driver's seat. The engi ne must not

be started by short-circuiting the electric

contacts at the starter.

OPERATION

44 © HAMM AG 2009

2.2.3 Start of engine

Initial position before start ing

Set the operating elements to their initial position prior to the start of the engine.

• Engine speed (504).............................MIN

• Driving lever (501).......................CENTRE

• Vibration (312) ..................................OFF

• Parking brake (304) ...................APPLIED

• EMERGENCY STOP

(NOT-STOP) (302) ...............................UP

Start of engine

• Engine speed (504)...................¼ to MAX

• Key switch (310)...............................0 → I

(Electrical system ON)

When the key switch is turned to position I, all

illuminated indicators light up shortly for function control purposes.

• Key switch........................................I → III

When the engine is running,

• the illuminated indicator for charging current (201)

• the illuminated indicator for engine oil

pressure (202)

must go out.

Danger of intoxication!

Combustion engines and fuel-operated

heating systems may only be operated in

sufficiently ventilated areas. Take care for

sufficient ventilation prior to starting.

Engine starting with maximum engine

speed can lead to engine damage or damage at the hydraulic system.

The starting process may last 20 seconds

as a maximum; otherwise, the starter will

be overheated and destroyed. There must

be pauses between the individual starting

processes in order to allow the starter to

cool down. If the engine doesn't start after

two starting attempts, find out and eliminate the cause. Observe the instruction

manual of the engine.

The engine cannot be started by towing,

because the hydrostatic drive acts as a

brake when the feeding pressure is missing. Drive component damage would be

the consequence.

Only when the driving lever is in centre position, is the start connected to the key

switch via the starter protection device.

This is the only way to start the engine.

15000-10

302 310

504 503

501

© HAMM AG 2009 45

OPERATION

Before driveaway

• The acceleration and braking behaviour of

the machine are influenced by viscous hydraulic oil. In case of low external temperatures, in particular for temperatures below 0 °C (32 °F), wait a few minutes after

starting the engine until driveaway.

Warm up the machine during the warming

phase with moderate speed and low load

until the oil in the hydraulic system has

heated to 20 °C (68 °F).

• If the machine is fro zen to t he gr ound, t ake

care that no clods of earth stick to the

drum, as these could damage the scrapers. Therefore, park the machine on

planks or dry gravel if frost is likely!

Danger of accidents!

Always use safety belt!

Danger of falling!

For machines with driver's cabin, the lower

door parts must always be closed during

driving operation!

Always use safety belt!

Danger of accidents and danger of injuries!

It is forbidden to transport passengers.

Lift attached add-on devices off the

ground.

Prior to driveaway, check for persons in

the immediate vicinity of the machine.

In emergency situations and when there is

a danger, bring the machine to an immediate stop by operating the EMERGENCY

STOP switch (NOT-STOP).

Do not use the EMERGENCY STOP