SCREWED BONNET

NEEDLE VALVES

H-99 SERIES

VALVES & ACTUATORS

FEATURES

n

Blowout-Proof Stem

n

MAWP* up to 10,000 psi (690 bar)

n

MAWT* up to 648°C (1200°F)

n

End connection size range: 1/4" to 1" or 6mm to 25mm

n

Flow Coefcient (Cv) 0 to1.5

n

Variety of stem types

n

Packing bolt for easy panel mounting, no packing

disassembling is required

* Maximum Allowed Working Pressure, Maximum Allowed Working Temperature.

GENERAL

The H-99 Series offers a general-service valve of rugged design and

construction. It is available in stainless steel to suit a wide range of

services.

Capable of withstanding high pressures (10,000 psig max) and high

temperatures.

This valve is typically used in a severe environments, high pressure

sampling systems, high pressure shut-down systems and test stands.

MATERIALS OF CONSTRUCTION

No. Components Qty Material

1

Set Screw 1 St.St. 18-8

2

Handle 1

3

Upper Bonnet 1

4

Lock Nut 1

5

Panel Nut 1

6

Stem Washer 2

7

Packing 1 PTFE / PEEK / Grafoil

8

Bonnet 1

9

Stem

10

Safety Pin

11

Gasket 1

12

Body* 1

*For weld ends valves, body is made of low carbon stainless steel

St.St.316 ASTM A-276 / A-479

St.St.316 ASTM A-276 / A-479

St.St.316 ASTM A-276 / A-479

St.St.316 ASTM A-276 / A-479

St.St.316 ASTM A-276 / A-479

St.St.316 ASTM A-276 / A-479

St.St.316 ASTM A-276 / A-479

1

St.St. 304

1

St.St.316

St.St.316 ASTM A-479

®

Stem Seals below stem

threads:

PTFE / PEEK / Grafoil

seals are available

®

Packing bolt enables easy

mounting with the packing

remaining untouched

2

1

3

4

5

7

6

8

VALVES & ACTUATORS

Safety stop pin –

prevents the bonnet

from detaching

the body due to

vibration

Stem diffusion surface

hardening provides the best

galling resistance and protection

from wear and corrosion.

Grafoil - TM GrafTech International Holdings, Inc.

SCREWED-BONNET NEEDLE VALVES H-99 SERIES

228

9

10

11

12

E

D Open

C

B

A

C

Table 1

STANDARD CONFIGURATION DIMENSIONS

End Body Orice A B C D E F G H

Size

Connection Size

Let-Lok

Inch

1/4"

®

3/8"

1/2"

3/4"

Let-Lok

Metric

8mm

10mm

6mm

®

12mm

mm in mm in mm in mm in mm in mm in mm in mm in mm in

72.7 2.9 36.4 1.4

S

6.35 0.25

72.7 2.9 36.4 1.4

25.0 1.0 78.9 3.1 65.0 2.6

78.3 3.1 39.2 1.5

M 6.35 0.25 85.3 3.4 42.7 1.7 30.0 1.2 81.4 3.2 80.0 3.2

72.8 2.9 36.4 1.4

S 6.35 0.25

73.0 2.9 36.5 1.4

73.2 2.9 36.6 1.4

25.0 1.0 78.9 3.1 65.0 2.6

78.2 3.1 39.1 1.5

1/8"

1/4"

S

Female

Thread

(NPT/ISO)

3/8"

1/2"

3/4"

1"

1/4"

Tube

Socket Weld

Inch

3/8"

1/2"

3/4"

1"

6mm

Tube

Socket Weld

Metric

8mm

10mm

12mm

25mm

1/8"

1/4"

Pipe

Socket Weld

3/8"

1/2"

3/4"

1"

1/4"

Tube

Butt Weld

Inch

3/8"

1/2"

3/4"

1"

6mm

Tube

Butt Weld

Metric

8mm

10mm

12mm

25mm

1/8"

1/4"

Pipe (S40)

Butt Weld

3/8"

1/2"

3/4"

1"

Male Thread

to

Female Thread

(NPT/ISO)

Body Dimensions: S - 25mm / M - 30mm / L - 35mm / XL - 45mm.

Dimensions are for reference only, and are subject to change. Face to face dimensions for LET-LOK® end connections (dimensions A and B) are nger tight.

1/4"

3/8"

1/2"

3/4"

1"

6.35 0.25 58.0 2.3 29.0 1.1 25.0 1.0 78.9 3.1 65.0 2.6

M

6.35 0.25

L 9.50 0.375

XL

9.50 0.375 80.0 3.1 40.0 1.6 45.0 1.8 99.6 3.9 80.0 3.2

2.6 32.5 1.3 30.0 1.2 81.4 3.2 80.0 3.2

65.0

70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2

6.4 0.25 6.5 0.26

6.35 0.25 58.0 2.3 29.0 1.1 25.0 1.0 78.9 3.1 65.0 2.6

S

9.7 0.38 9.7 0.38

12.7 0.50 12.9 0.51

M

L

6.35 0.25

9.50 0.375

65.0 2.6 32.5 1.3 30.0 1.2 81.4 3.2 80.0 3.2 14.2 0.56 19.2 0.76

70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2 19.2 0.76 25.6 1.01

6.0 0.24 6.2 0.24

S 6.35 0.25 58.0 2.3 29.0 1.1 25.0 1.0 78.9 3.1 60.0 2.6

7.9 0.31 8.2 0.32

12.7 0.50 10.2 0.40

12.7 0.50 12.2 0.48

L 9.50 0.375 70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2 19.2 0.76 25.2 0.99

9.0 0.35 10.8 0.43

S 6.35 0.25 58.0 2.3

29.0 1.1 25.0 1.0 78.9 3.1 60.0 2.6

14.0 0.55 14.0 0.55

14.0 0.55 17.5 0.69

M

6.35 0.25

L

9.50 0.375

XL

9.50 0.375 80.0 3.1 40.0 1.6 45.0 1.8 99.6 3.9 80.0 3.2 20.0 0.79 34.5 1.36

65.0 2.6 32.5 1.3 30.0 1.2 81.4 3.2 80.0 3.2 16.5 0.65 22.0 0.87

70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2 18.0 0.71 27.5 1.08

6.4 0.25 3.1 0.12 6.4 0.25

6.35 0.25 58.0 2.3 29.0 1.1 25.0 1.0 78.9 3.1 60.0 2.6

S

6.0 0.24 6.2 0.24 9.5 0.37

6.0 0.24 8.5 0.33 12.7 0.50

M

L

6.35 0.25

9.50 0.375

65.0 2.6 32.5 1.3 30.0 1.2 81.4 3.2 80.0 3.2 8.0 0.31 13.5 0.53 19.1 0.75

70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2 10.0 0.39 19.3 0.76 25.4 1.00

6.0 0.24 3.1 0.12 6.0 0.24

S 6.35 0.25 58.0 2.3 29.0 1.1 25.0 1.0 78.9 3.1 60.0 2.6

7.9 0.31 4.8 0.19 8.0 0.31

6.0 0.24 6.7 0.26 10.0 0.39

6.0 0.24 7.8 0.31 12.0 0.47

L

9.50 0.375 70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2 10.0 0.39 18.9 0.74 25.0 0.98

7.1 0.28 10.5 0.41

S 6.35 0.25 58.0 2.3 29.0 1.1 25.0 1.0 78.9 3.1 60.0 2.6

6.0 0.24

9.2 0.36 13.7 0.54

12.5 0.49 17.1 0.67

M

L

6.35 0.25

9.50 0.375

65.0 2.6 32.5 1.3 30.0 1.2 81.4 3.2 80.0 3.2 8.0 0.31 15.8 0.62 21.3 0.84

70.0 2.8 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2 10.0 0.39 21.0 0.83 26.7 1.05

XL 9.50 0.375 80.0 3.1 40.0 1.6 45.0 1.8 99.6 3.9 80.0 3.2 12.0 0.47 26.6 1.04 33.4 1.31

S 6.35 0.25 60.0 2.4 29.0 1.1 25.0 1.0 78.9 3.1 60.0 2.6

M

L

6.35 0.25

9.50 0.375

70.0 2.8 32.5 1.3 30.0 1.2 81.4 3.2 80.0 3.2

75.0 3.0 35.0 1.4 35.0 1.4 92.5 3.6 80.0 3.2

XL 9.50 0.375 85.0 3.3 40.0 1.6 45.0 1.8 99.6 3.9 80.0 3.2

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

229

HIGH PERFORMANCE NEEDLE VALVE

FOR EASY MOUNTING

H-99 SERIES

Max Panel

Thickness

Panel Hole

MOUNTING CONFIGURATION DIMENSIONS

End Body Panel Hole Max Panel Thickness

mm in mm in

Connection Size

Let-Lok

Inch

1/4"

®

3/8"

1/2"

3/4"

6mm

®

Let-Lok

Metric

8mm

10mm

Size

S 22.0 0.87

M 25.0 0.98

S 22.0 0.87 6.35 0.25

6.35 0.25

6.35 0.25

12mm

1/8"

Female

Thread

(NPT/ISO)

1/4"

3/8"

1/2" M

3/4" L

1"

S 22.0 0.87 6.35 0.25

25.0 0.98

XL 27.0 1.06

6.35 0.25

6.35 0.25

1/4"

Tube

Socket Weld

Inch

3/8"

1/2"

3/4" M

1" L

S 22.0 0.87 6.35 0.25

25.0 0.98

6.35 0.25

6mm

Tube

Socket Weld

Metric

Body Dimensions: S - 25mm / M - 30mm / L - 35mm / XL - 45mm.

8mm

10mm

12mm

25mm

S 22.0 0.87 6.35 0.25

L 25.0 0.98 6.35 0.25

MOUNTING CONFIGURATION DIMENSIONS

End Body Panel Hole Max Panel Thickness

mm in mm in

Connection Size

Size

1/8"

Pipe

Socket Weld

1/4"

3/8"

1/2" M

3/4" L

1"

S 22.0 0.87

25.0 0.98

XL 27.0 1.06

1/4"

Tube

Butt Weld

Inch

3/8"

1/2"

3/4" M

1" L

S 22.0 0.87

25.0 0.98

6mm

Tube

Butt Weld

Metric

8mm

10mm

12mm

25mm

S 22.0 0.87 6.35 0.25

L 25.0 0.98

1/8"

Pipe (S40)

Butt Weld

Male Thread

to

Female Thread

(NPT/ISO)

1/4"

3/8"

1/2" M

3/4" L

1"

1/4"

3/8"

1/2" M

3/4" L

1"

S 22.0 0.87 6.35 0.25

25.0 0.98

XL 27.0 1.06

S 22.0 0.87 6.35 0.25

25.0 0.98

XL 27.0 1.06

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

6.35 0.25

VALVES & ACTUATORS

EASY MOUNTING PROCEDURE

1.

Disassemble the handle, using an

appropriate hex key. Take off the

panel nut.

SCREWED-BONNET NEEDLE VALVES H-99 SERIES

230

2.

Insert the valve into the panel hole

and reassemble the panel nut.

Firmly tighten the nut.

3.

Reassemble the handle.

Firmly tighten the hex screw.

CLEANING & PACKAGING

Every H-99 series needle valve is cleaned

in accordance with Standard Cleaning and

Packaging (procedure 8184). Oxygen Clean

& Lubricant Free Cleaning and packaging,

in accordance with Special Cleaning and

Packaging (procedure 8185), is available as an

option.

Lubricant free cleaned valves have

signicantly higher actuation torque.

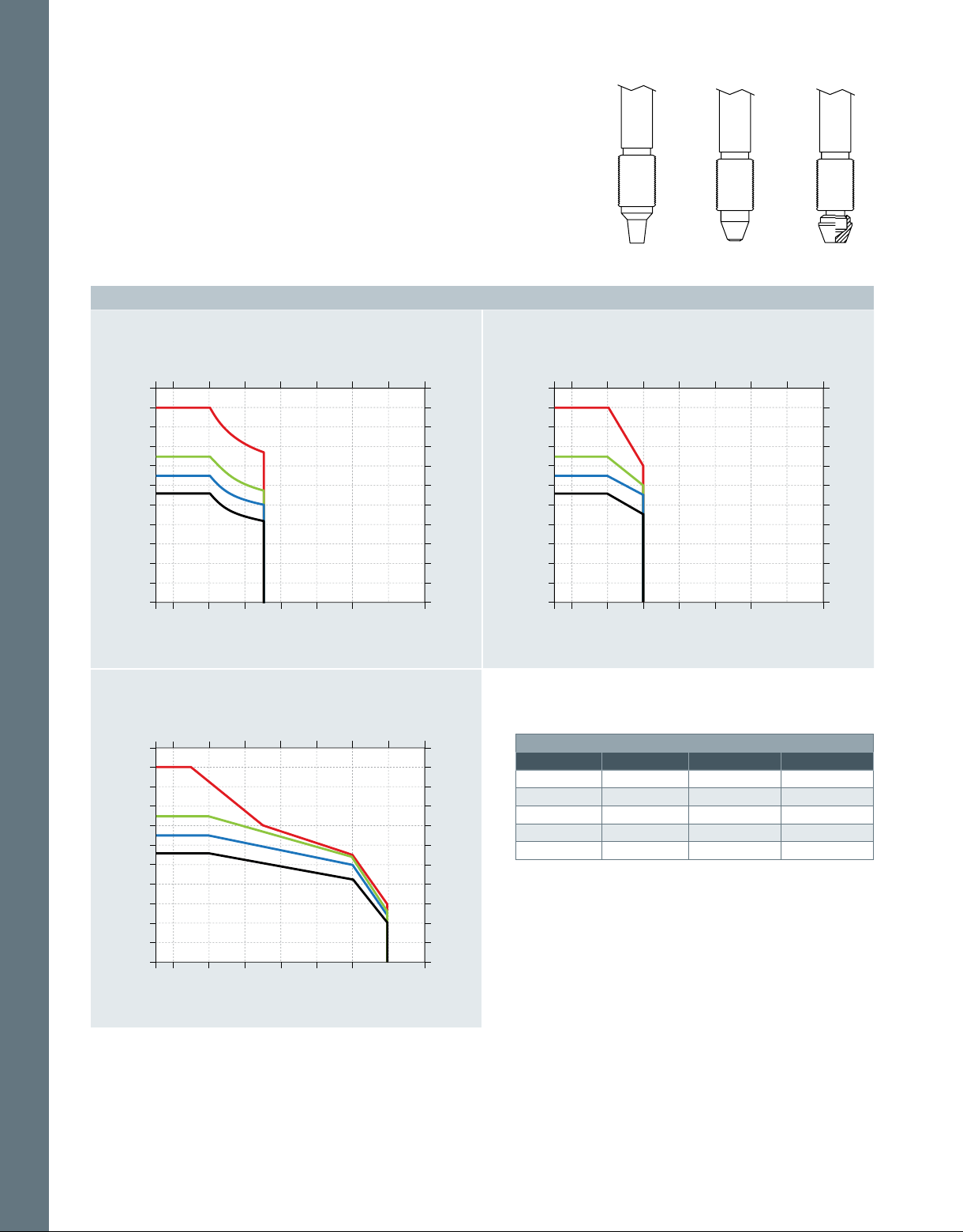

FLOW DATA AT 100°F (37°C)

V-STEM / NR-STEM R-STEM

1.60

1.40

1.20

1.00

0.80

0.60

0.40

Flow Coefficient (Cv)

XL Body size

L Body size

M Body size

S Body size

TESTING

The H-99 Series Needle Valve design have

been tested for Proof and Burst.

Every H-99 Needle Valve is factory tested with

Nitrogen at 1000 psi (69 bar).

The maximum allowable leakage across the

seat is 0.1 std cc/min.

1.60

1.40

1.20

1.00

0.80

0.60

0.40

Flow Coefficient (Cv)

PACKING ADJUSTMENT

Due to the varied service applications of the

valve, packing adjustment may be occasionally

necessary.

Valve Packing is factory preadjusted to 1000

psig service.

Initial packing adjustment is recommended

after installation and prior to start-up.

XL Body size

L Body size

M Body size

S Body size

0.20

0

0

1 2 3

4

5

0.20

0

Handle Turns

PRESSURE TEMPERATURE RATING THREADED & WELD CONNECTION

Temp. (°C)

-40

0 93

11000

10000

9000

8000

7000

6000

5000

4000

Pressure (psig)

3000

2000

1000

0

-40

204 316 427 538 648 760

PTFE

PEEK

GRAFOIL

®

400 600 800 1000 1200 1400

20032

758

690

620

552

482

414

345

276

207

138

69

Temp. (°F)

0

1 2 3

Handle Turns

MAX. PRESSURE RATING

AT 70°F (21°C)

Body Raw Material

St.St.316 ASTM A-479 10000 690

MAX. ALLOWED WORKING

TEMPERATURE

Packing Material

Pressure (bar)

PTFE 204 400

PEEK 260 500

®

GRAFOIL

The max. allowable pressure of welded connected

valve is limited to the max. allowed working

pressure of the tube.

Pressure

psi bar

Max. Temperature

°C °F

648 1200

4

5

VALVES & ACTUATORS

Note

: For lower temprature applications please contact your local representive.

Grafoil - TM GrafTech International Holdings, Inc.

HAM-LET ADVANCED CONTROL TECHNOLOGY

231

ALTERNATIVE STEMS

HAM-LET Needle Valves are available with a choice of

stem-tip options to allow greater exibility.

V-

Stem:

liquids and gas service.

RNR-

valve life and prevent stem rotation inside the body tip, a suitable selection for

gaseous high pressure applications.

PRESSURE TEMPERATURE RATING LET-LOK CONNECTION

Standard stem tip used for the on/off operation in general-purpose

Regulating:

Non-Rotating:

Used where some degree of ow control is required.

Typically used in high-cycle applications to extend

Regulating

Stem

V-Stem Non-Rotating

Stem

VALVES & ACTUATORS

0-40

11000

10000

9000

8000

7000

6000

5000

4000

Pressure (psig)

3000

2000

1000

0

-40

32

-40

0 93

11000

1/4”, 6mm

10000

9000

8mm, 10mm

8000

7000

3/8”,1/2”, 12mm

6000

3/4”

5000

4000

Pressure (psig)

3000

2000

1000

0

-40

PEEK PACKING

Temp. (°C)

204 316 427 538 648 760

93

1/4”, 6mm

8mm, 10mm

3/8”,1/2”, 12mmm

3/4”

400 600 800 1000 1200 1400

200

Temp. (°F)

GRAFOIL® PACKING

Temp. (°C)

204 316 427 538 648 760

400 600 800 1000 1200 1400

20032

Temp. (°F)

758

690

620

552

482

414

345

276

Pressure (bar)

207

138

69

758

690

620

552

482

414

345

276

Pressure (bar)

207

138

69

PTFE PACKING

Temp. (°C)

-40

0

11000

10000

9000

8000

7000

6000

5000

4000

Pressure (psig)

3000

2000

1000

0

-40

204 316 427 538 648 760

93

1/4”, 6mm

8mm, 10mm

3/8”,1/2”, 12mmm

3/4”

400 600 800 1000 1200 1400

20032

758

690

620

552

482

414

345

276

207

138

69

Temp. (°F)

MAX. PRESSURE RATING

AT 70°F (21°C)

Pressure per LET-LOK® Size

in Pressure mm Pressure

1/4 10000 psi 6 10000 psi

3/8 6500 psi 8 7500 psi

1/2 6500 psi 10 7500 psi

3/4 5650 psi 12 6500 psi

1" 4000 psi 25 4700 psi

Note: The maximum allowed working pressure that is marked on

the valve may be limited according to the pressure limitations that are

recommended by the tubing /piping standards (Reference: Let-Lok tube

fittings General Information).

Pressure (bar)

Note

:

Valves with Let-Lok ends are always made of bar stock body.

For lower temprature applications please contact your local representive.

Grafoil - TM GrafTech International Holdings, Inc.

SCREWED-BONNET NEEDLE VALVES H-99 SERIES

232

H-99 SERIES ORDERING INFORMATION

OPTIONAL

H-99

- - - -

L L V00 1/2SS

Valve Series

Body

Valve Type

Designator

S

M

L

XL

- Small

- Medium

- Large

- Extra Large

LET-LOK® End

00 -

Female End

10 -

Female to Male End

15 -

Male End

80 -

Male to Female End

85 -

SEAL KIT

Included: Packing & Label

Z - 99 - M - SK - P T

Body's size

Small (25mm)

S

Medium (30mm)

M

Large

L

Extra Large (45mm)

XL

(35mm)

Packing

PT

- PTFE

PK

- PEEK

G

- Grafoil

Material

St.St. 316

®

End Connection

Type

LET-LOK®

L -

Threaded NPT

N -

ISO Taper

R -

ISO Parallel

G -

Tube Butt-Weld

TBW -

Tube Socket-Weld

TSW -

Pipe Butt-Weld

PBW -

(Schedule 40)

Pipe Socket Weld

PSW -

HANDLE KIT

Stem

V Stem

V -

Regulating Stem

R -

Non Rotating

NR -

Z - 99 SS

-

-

-

Size

1/4 6

3/8 8

1/2 10

3/4 12

1” 25

MM

MM

MM

MM

MM

Treatment

BLANK - Standard Cleaning &

Passivation

OC - Oxygen Clean

LF - Lubricant Free

- -

HK 65mm

SIZE

For S body size

65mm

80mm

For M body size

For L / XL body size

90mm

Packing

Blank

- PTFE

PK

- PEEK

G

- Grafoil

-

®

VALVES & ACTUATORS

Grafoil - TM GrafTech International Holdings, Inc.

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance.

Application details, material compatibility and product ratings should all be considered for each selected

product. Improper selection, installation or use of products can cause property damage or personal injury.

H-99S, Rev.00, February 2015

HAM-LET ADVANCED CONTROL TECHNOLOGY

233

Loading...

Loading...