HIGH PERFORMANCE

BALL VALVES

H-6800 & H-6800 CNG SERIES

VALVES & ACTUATORS

H-6800 FEATURES

Certified for ISO 15848-1:2006(E)

On/off-service ball valve with 2-way pattern

Diverter-service ball valve with 3-way pattern

Stainless Steel and Brass construction

MAWP* 6000 psi (413 bar)

MAWT* 500ºF (260ºC)

Variable end connection types and sizes from 1/16” to 3/4” (3mm to 18mm)

Operation with colored Nylon handles, metal handle, color

anodized aluminum ISLT** (locking device) handles and

pneumatically actuated

* Maximum Allowed Working Pressure, Maximum Allowed Working Temperature.

** ISLT – Integral Safety Lock-out Tag-out Patent pending

MATERIAL OF CONSTRUCTION

No. Part Qty

1

Handle 1 Nylon / Metal / ISLT Nylon / Metal / ISLT

2

Handle Set Screw 1 St.St.304 St.St.304

3

Packing Bolt 1 St.St.316 St.St.316

4

Packing 3 Modified PTFE PCTFE/ PEEK

5

Gland 2 St.St.304 St.St.304

6

Stem 1

7

Ball 1 St.St.316 St.St.316

8

Panel Nut 1 St.St.303 / Brass St.St.303

9

End Cap 2 St.St.316 / Brass St.St.316

10

Body Seal 2 Virgin PTFE PTFE / PEEK

11

Seat 2 Modified PTFE PCTFE / PEEK

12

Body 1

Maximum allowed working pressure

Up to 3000 psig Up to 6000 psig

St.St.316

St.St. ASTM A351 Gr.CF8M

Brass ASTM B-16

St.St.316

St.St. ASTM A-276

GENERAL

The H-6800 Series is a high-performance instrumentation

ball valve for general service and instrumentation panels.

The valves offer a tight shutoff*, long-life service and a low

operating torque. The H-6800 Series is rated to max. 6000psig

and performs on/off or as a diverter service.

*3-Way H-6800 is designed for diverting only and not for shutoff service.

Inlet is from the bottom only. 3-Way H-6800 is designed to be fully

opened to any of the side ports.

2

1

3

VALVES & ACTUATORS

Replaceable Handle

indicates on/off position

1/4 Turn Operation

(for 2-way pattern)

1/2 Turn Operation

(for 3-way pattern)

Straight-through

flow path, minimal

pressure drop

Bi-directional flow

Floating ball provides

tight shut-off

Adjustable packing

Panel mounting

End connections:

LET-LOK

Female & Male,

Face Seal;

others on request

9

®

, Threaded

10

4

5

6

7

8

11

12

11

10

9

HIGH PERFORMANCE BALL VALVES H-6800 SERIES

192

TESTING

application

Metal Handle

The H-6800 design has been tested for Burst and Proof. Standard

testing for each H-6800 valve includes testing with nitrogen at 80

&1000 psig. Each valve is tested for leakage through the shell, packing

and ball seats. The maximum allowable leakage across the ball seats is

0.1 std cc/min.

CLEANING & PACKAGING

Every H-6800 series ball valve is cleaned in accordance with Standard

Cleaning and Packaging (procedure 8184). Oxygen Clean & Lubricant

Free Cleaning and packaging, in accordance with Special Cleaning and

Packaging (procedure 8185), is available as an option.

Lubricant free cleaned valves have significantly higher actuation torque.

PRESSURE TEMPERATURE RATINGS

Temp. (°C)

0 40 90 148 260210-34

6000

5500

5000

4500

4000

3500

3000

2500

Pressure (psig)

2000

1500

1000

500

100

0

Modified PTFE

32 100 200 298 500410-30

PCTFE

(C)

(P)

Temp. (°F)

PEEK

(A)

410

377

343

309

274

240

205

172

137

103

70

34

6.9

Pressure (bar)

PACKING ADJUSTMENT

Due to the varied service applications of the valve, packing adjustment

may be occasionally necessary. Packing is factory adjusted to 1000

psig service. Initial adjustment is recommended after installation

and prior to start-up. Please find more information in the installation

instruction chapter. HAM-LET Ball Valves are designed for operation in

the fully closed or fully open position.

BODY & SEAT MATERIAL COMBINATIONS

Body Material MAWP* MAWT** Seat Material

St.St. ASTM A351

Gr. CF8M

St.St. ASTM A-276 6000psi (413 bar)

St.St. ASTM A-276 6000psi (413 bar)

Brass ASTM B-16 3000psi (206 bar)

For other body and seat combinations, please contact our cutomer service.

* Maximum Allowed Working Pressure.

** Maximum Allowed Working Temperature.

*** Lubricant free cleaned valves with PEEK seats, MAWP is 3000 psi.

3000psi (206bar) 410°F (210°C)

500°F (260°C) PEEK***

298°F (148°C) PCTFE

410°F (210°C)

Modified

PTFE

Modified PTFE

ANGLE AND T-TYPE VALVE

Note: The maximum allowed working pressure that is marked on the valve

may be limited according to the pressure limitations that are recommended

by the tubing /piping standards (Reference: Let-Lok tube fittings General

Information).

SEAT MATERIAL CHARACTERISTICS

MODIFIED PTFE

Excellent seat material for purity applications. Very low residual material

during operation. Lower deformation ratio than PTFE, but higher

pressure and temperature ratings than PTFE. Rated up to 410°F (210°C).

Chemical resistance equal to PTFE material.

PCTFE

Excellent seat material for low temperature applications such as Oxygen

and Nitrogen.

Suitable for low temperature applications down to -40ºC (-40ºF).

PEEK (PolyEtherEtherKeton)

Excellent seat material for high-pressure and high-temperature applications.

Excellent chemical resistance. Can be used continuosly up to 500ºF (260ºC)

and in hot water or steam without permanent loss in physical properties.

High strength for hostile enviroments and high pressure.

Warning: Combination of PEEK seats and hot water can be critical for

valve operating torque.

HAM-LET ADVANCED CONTROL TECHNOLOGY

NOTE: Bottom entry only

MANUAL OPERATION

S - Black Handle*

B - Blue Handle

R - Red Handle

G - Green Handle

*Black nylon handle with brass insert is standard

NOTE:

Y - Yellow

Handle

- Bottom entry only

- Not suitable for shut-off

application

Metal Handle

193

VALVES & ACTUATORS

A

STRAIGHT PORT VALVE

I

C

VALVES & ACTUATORS

J

B

G

Panel Drill

Hole

E

D

H

F

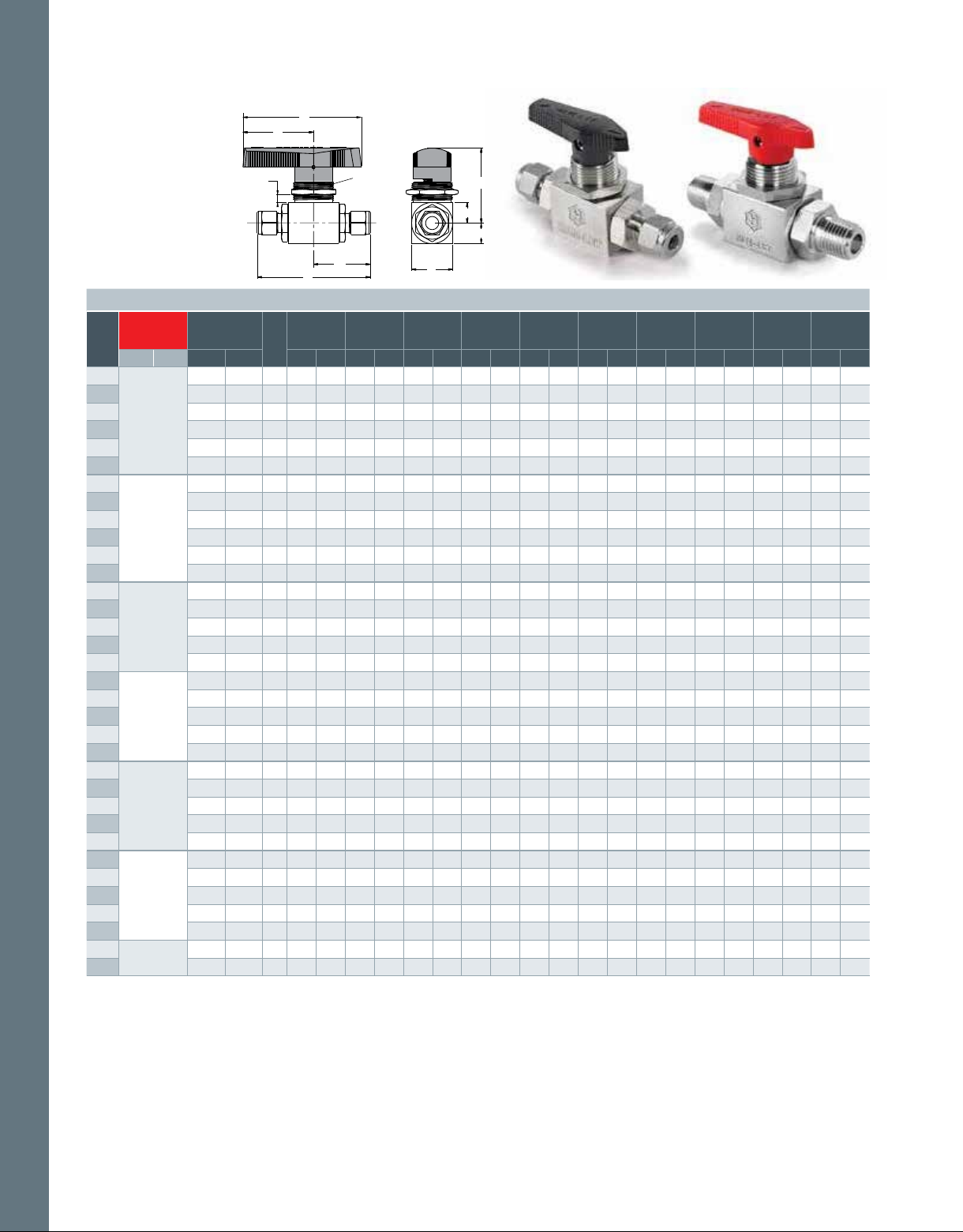

STRAIGHT PORT, STANDARD CONFIGURATION DIMENSIONS

Size

End

Connection

Orifice

Cv A B C D E F G H I* J**

mm inch mm inch mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in

1/16''

1/8''

1/4''

3/8''

1/2''

3/4''

3mm

6mm

8mm

10mm

12mm

18mm

1/8''

1/4''

3/8''

1/2''

3/4''

1/8''

1/4''

3/8''

1/2''

3/4''

1/8''

1/4''

3/8''

1/2''

3/4''

1/8''

1/4''

3/8''

1/2''

3/4''

1/4''

1/2''

Let-Lok

Inch

Let-Lok

Metric

Female

NPT/ BSPT

Female

BSPP

Male

NPT/ BSPT

Male

BSPP

Face Seal

Male

1.3 0.051 0.1 70.2 2.76 35.1 1.38 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

2.4 0.094 0.2 78.6 3.09 39.3 1.55 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 1.5 83.6 3.29 41.8 1.65 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

®

4.8 0.189 1.5 86.3 3.40 43.15 1.70 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 12 102.5 4.04 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

10.3 0.409 6.5 102.5 4.04 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

2.4 0.094 0.2 78.6 3.09 39.3 1.55 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 1.5 83.6 3.29 41.8 1.65 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 1.5 84.8 3.34 42.4 1.67 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

®

4.8 0.189 1.5 86.4 3.40 43.2 1.70 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 12 102.5 4.04 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

10.3 0.409 6.5 102.5 4.04 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

4.8 0.189 1.2 63.6 2.50 31.8 1.25 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 0.9 64.0 2.52 32.0 1.26 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 0.6 69.6 2.74 34.8 1.37 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 6.3 87.4 3.44 43.7 1.72 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

10.3 0.409 6.1 91.0 3.58 45.5 1.79 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

4.8 0.189 1.2 63.6 2.50 31.8 1.25 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 0.9 64.0 2.52 32.0 1.26 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 0.6 69.6 2.74 34.8 1.37 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 6.3 87.4 3.44 43.7 1.72 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

10.3 0.409 6.1 91.0 3.58 45.5 1.79 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

4.8 0.189 1.5 67.6 2.66 33.8 1.33 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 1.2 76.6 3.02 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 0.9 76.6 3.02 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 8.2 92.4 3.64 46.2 1.82 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

10.3 0.409 4.5 94.4 3.71 47.2 1.86 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

4.8 0.189 1.5 65.4 2.57 32.7 1.29 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 1.2 76.6 3.02 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

4.8 0.189 0.9 76.6 3.02 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 8.2 92.4 3.64 46.2 1.82 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

10.3 0.409 4.5 94.4 3.71 47.2 1.86 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

4.5 0.18 2.4 75.0 2.95 37.5 1.47 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 11.1 0.44 50.0 1.96 6.5 0.255

10.3 0.409 12 93.8 3.69 46.9 1.85 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 16.0 0.63 80.0 3.15 6.5 0.255

Face to face dimensions for LET-LOK® end connections (dimensions A and B) are finger tight.

* Refers to standard nylon handle.

** Maximum panel thickness.

Dimensions are for reference only, and are subject to change.

HIGH PERFORMANCE BALL VALVES H-6800 SERIES

194

ANGLE & 3-PORT VALVE

I

C

C

J J

H

ANGLE & 3-PORT, STANDARD CONFIGURATION DIMENSIONS

Size

1/16''

1/8''

1/4''

3/8''

1/2''

3/4''

3mm

6mm

8mm

10mm

12mm

18mm

1/8''

1/4''

3/8''

1/2''

3/4''

1/8''

1/4''

3/8''

1/2''

3/4''

1/8''

1/4''

3/8''

1/2''

3/4''

1/8''

1/4''

3/8''

1/2''

3/4''

1/4''

1/2''

Dimensions are for reference only, and are subject to change without notice.

End

Connection

mm inch mm inch mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in

Orifice

1.3 0.051 0.08 70.2 2.76 46.2 1.82 35.1 1.38 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 37.9 1.49 50.0 1.96 6.5 0.255

2.4 0.094 0.15 78.6 3.09 50.4 1.95 39.3 1.55 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 42.1 1.66 50.0 1.96 6.5 0.255

4.8 0.189 0.90 83.6 3.29 52.9 2.08 41.8 1.65 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 44.6 1.76 50.0 1.96 6.5 0.255

®

Let-Lok

Inch

4.8 0.189 0.60 86.3 3.40 54.25 2.13 43.15 1.70 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 46.0 1.81 50.0 1.96 6.5 0.255

10.3 0.40 4.6 102.5 4.04 67.3 2.65 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 57.5 2.26 80.0 3.15 6.5 0.255

10.3 0.40 3.8 102.5 4.04 67.3 2.65 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 57.5 2.26 80.0 3.15 6.5 0.255

2.4 0.094 0.15 78.6 3.09 52.0 2.05 39.3 1.55 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 42.1 1.66 50.0 1.96 6.5 0.255

4.8 0.189 0.90 83.6 3.29 52.8 2.08 41.8 1.65 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 44.6 1.76 50.0 1.96 6.5 0.255

4.8 0.189 0.80 84.8 3.34 53.5 2.1 42.4 1.67 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 45.2 1.78 50.0 1.96 6.5 0.255

®

Let-Lok

Metric

4.8 0.189 0.60 86.4 3.40 54.3 2.14 43.2 1.70 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 46.0 1.81 50.0 1.96 6.5 0.255

10.3 0.40 4.6 102.5 4.04 67.3 2.65 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 57.5 2.11 80.0 3.15 6.5 0.255

10.3 0.40 2.5 102.5 4.04 67.3 2.65 51.25 2.02 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 57.5 1.19 80.0 3.15 6.5 0.255

4.8 0.189 0.3

Female

NPT/ BSPT

4.8 0.189 0.75

4.8 0.189 0.5

10.3 0.40 3.5

10.3 0.40 2.5

4.8 0.189 0.3

Female

BSPP

4.8 0.189 0.75

4.8 0.189 0.5 69.6 2.74 45.9 1.8 34.8 1.37 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 37.6 1.48 50.0 1.96 6.5 0.255

10.3 0.40 3.5 87.4 3.44 59.7 2.35 43.7 1.72 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 50.0 1.97 80.0 3.15 6.5 0.255

10.3 0.40 2.5 91.0 3.58 61.5 2.42 45.5 1.79 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 50.0 1.97 80.0 3.15 6.5 0.255

4.8 0.189 0.9 67.6 2.66 44.9 1.76 33.8 1.33 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 36.6 1.44 50.0 1.96 6.5 0.255

Male

NPT/ BSPT

4.8 0.189 0.6 76.6 3.02 49.4 1.94 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 41.1 1.62 50.0 1.96 6.5 0.255

4.8 0.189 0.35 76.6 3.02 49.4 1.94 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 41.1 1.62 50.0 1.96 6.5 0.255

10.3 0.40 3.0 92.4 3.64 62.2 2.45 46.2 1.82 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 52.5 2.07 80.0 3.15 6.5 0.255

10.3 0.40 2.0 94.4 3.71 63.2 2.49 47.2 1.86 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 53.5 2.1 80.0 3.15 6.5 0.255

4.8 0.189 0.9 65.4 2.57 43.8 1.72 32.7 1.29 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 36.6 1.44 50.0 1.96 6.5 0.255

Male

BSPP

4.8 0.189 0.6 76.6 3.02 49.4 1.94 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 41.1 1.62 50.0 1.96 6.5 0.255

4.8 0.189 0.35 76.6 3.02 49.4 1.94 38.3 1.51 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 41.1 1.62 50.0 1.96 6.5 0.255

10.3 0.40 3.0 92.4 3.64 62.2 2.45 46.2 1.82 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 52.5 2.07 80.0 3.15 6.5 0.255

10.3 0.40 2.0 94.4 3.71 63.2 2.49 47.2 1.86 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 53.5 2.1 80.0 3.15 6.5 0.255

Face Seal

Male

4.5 0.18 0.9 75.0 2.95 48.6 1.91 37.5 1.47 31.0 1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 40.3 1.58 50.0 1.96 6.5 0.255

10.3 0.40 4.6 93.8 3.69 62.9 2.47 46.9 1.85 50.0 1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 53.2 2.09 80.0 3.15 6.5 0.255

G

Panel Drill

Hole

H

B

K

Cv A K B C D E F G H I* J**

63.6 2.50 42.9 1.7 32.0 1.26 31.0

64.0 2.52 43.1 1.69 31.8 1.25 31.0

69.6 2.74 45.9 1.8 34.8 1.37 31.0

87.4 3.44 59.7 2.35 43.7 1.72 50.0

91.0 3.58 61.5 2.42 45.5 1.79 50.0

63.6 2.50 42.9 1.7 32.0 1.26 31.0

64.0 2.52 43.1 1.69 31.8 1.25 31.0

DIMENSIONS FOR METAL HANDLE

VALVE END CONNECTIONS Handle Designator N L

Up to 3/8 ends M 50 MM 31 MM

Up to 3/8 ends M7 70 MM 45 MM

From 1/2 to 3/4 ends M 110 MM 80 MM

See Ordering Information

G

Panel Drill

Hole

B

A

F

E

D

1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 34.6 1.36 50.0 1.96 6.5 0.255

1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 34.8 1.37 50.0 1.96 6.5 0.255

1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 37.6 1.48 50.0 1.96 6.5 0.255

1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 50.0 1.97 80.0 3.15 6.5 0.255

1.97 16.0 0.63 50.0 1.97 32.0 1.26 20.8 0.82 50.0 1.97 80.0 3.15 6.5 0.255

1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 34.6 1.36 50.0 1.96 6.5 0.255

1.22 11.1 0.44 38.85 1.53 22.2 0.87 19.3 0.76 34.8 1.37 50.0 1.96 6.5 0.255

N

L

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

195

H-6800

FOR THE CNG / NGV

FEATURES

ECE R110, Class 0 approved for the CNG / NGV

MAWP* 3770 psig (260 barg)

Temperature range: -40°C (-40°F) to 120°C (248°F)

Variable LET-LOK® end connection sizes: 1/4”, 3/8”, 6mm, 8mm,10mm

Stainless Steel construction with spring loaded seats

ECE Approved for 20,000 cycles

* Maximum Allowed Working Pressure.

MATERIAL OF CONSTRUCTION

No. Part Qty Material

Handle

1

Panel Nut

2

Packing Bolt

3

Stem washer

4

Stem

5

Stem Upper packing

6

Stem Lower packing

7

Stem O-Ring

8

Packing bolt Gasket

9

Body

10

Ball

11

Seats

12

Seat back up Sealing

13

Seat O-Rings

14

Seat Gasket

15

Seat Spring

16

Body Seal gasket

17

End Cap

18

Nylon

1

St.St.316 ASTM A-276 / A-479

1

St.St.316 ASTM A-276 / A-479

1

PEEK

1

St.St.316 ASTM A-276 / A-479

1

PEEK

1

PTFE

1

Low temperature Fluorocarbon FKM

1

Silver plated St.St.316

1

St.St. ASTM A-479

1

St.St.316 ASTM A-276 / A-479

1

PEEK

2

PTFE

4

Low temperature Fluorocarbon FKM

2

St.St.316 ASTM A-276 / A-479

2

St.St.316 ASTM A-276 / A-479

2

Silver plated St.St.316

2

St.St.316 ASTM A-276 / A-479

2

ORDERING INFORMATION:

H 6800 SS L 3/8 A S S CNG

GENERAL

The H-6800 CNG Series is a high-performance instrumentation manual

ball valve for the CNG / NGV with ECE R110-type approval. The val

ves offer a tight shutoff, long-life service and low operating torque.

The H-6800 CNG Series ball valve is rated to max. 3770 psig and

performs as a manual on/off service.

O-Ring seal provides a Leak Tight

seal, no packing adjustment required.

Reducing the valve operating torque

Blow-out

proof stem

PEEK seats are

1

compatible with a wide

range of chemicals and

for high cycles

VALVES & ACTUATORS

End Connection

Size

3/8

1/4

6MM

8MM

10MM

7

8

9

11

HIGH PERFORMANCE BALL VALVES H-6800 SERIES

196

10

12

Belleville Washers for Low and High

2

operation pressure applications,

Bi-Directional flow and compensates

for wear

3

4

5

6

17

16

15

14

18

13

H-6800 - PNEUMATIC ACTUATED VALVES

FEATURES

90° Actuation for 2-way valves (Straight & Angle)

180° Actuation for T-type valves

Actuators comply with industry standards for interface with

ISO 5211, NAMUR and VDI/VDE 3845

Actuated valves are available factory assembled or seperately, actuator

and mounting kits

Limit switches, proximity sensors, position indicators, Solenoid valves, and

other accessories are available upon request

Standard Temperature range: -32°C to 90°C (-25.6°F to 194°F)

Optional: High Temperature, Low Temperature

MATERIAL OF CONSTRUCTION

No. Part Qty Material

1 Actuator 1 AL 356-T5

2 Coupling 1 St.St.316

3 Bracket 1 St.St.304

4 Washer Flat 4 St.St.304

5 Washer Spring 4 St.St.304

6 Screw 4 St.St.304

7 Panel Nut 2

8 H6800 1 St.St.316 / Brass *

* Body material: St.St. ASTM A-276;

St.St. ASTM A351 Gr. CF8M; Brass ASTM B-16

90° Actuator on 2-way valve

St.St.316

GENERAL

Four standard actuator sizes are available upon request:

Mini (designator “A1”), Small (designator “A2”), Medium

(designator “A3”), Large (designator “A4”) and 180° Actuator

(designator “A2T”).

Improved operational speed enables better valve opening and

closing control.

ATEX certification of Valves-Actuators assemblies are

available on request at the time of order quotation.

180° Actuator on T-type valve

1

1

2

3

2

3

4

VALVES & ACTUATORS

5

6

4

7

5

6

8

7

8

HAM-LET ADVANCED CONTROL TECHNOLOGY

197

ACTUATED H-6800 SERIES

The selection of Valve-Actuator assemblies provided herein is based on:

Valve maximum allowable working pressure

Ambient temperature (50 to 100°F /10 to 37°C)

Actuator fits to valve based on operating pressure of 6 bar, as per table A.

To order H-6800 ball valve factory assembled with an actuator, add the actuator

designator to the valve part number / description per the below table.

Example:

H6800SSL1/4PSS with standard Double Acting Aluminum Actuator

H6800SSL1/4PS-A1

To order an actuator and mounting kit for field assembly:

Double acting Actuator ordering number: Z-A1

Corresponding mounting kit: Z-6800-MK-1/4-F03-F04-A1

Lubricant free Valves:

For Spring Return Actuator - select one size bigger then offered in the table

below. Example: If the offered actuator in the table is A2C, select A3C

For Double Acting Actuator - please contact your local representative

VALVES & ACTUATORS

Table A: Ordering information for Actuated Valves

Series Ends Size Seats Minimum

1/16”-3/8”

(3mm-10mm)

H-6800

(12mm18mm)

1/16”-3/8”

(3mm-10mm)

T-type

H-6800

(12mm-18mm)

1/2”-3/4”

1/2”-3/4”

Modified PTFE

Modified PCTFE

PEEK 5 (72.5) A2O A2C Z-A2S Z-6800-MK-1/4”-F03-F04-A2

Modified PTFE 5 (72.5) A1O A1C A1 Z-A1S Z-A1 Z-6800-MK-1/2”-F03-F04-A1

PCTFE 5 (72.5) A2O A2C

PEEK 5 (72.5) A3O A3C

Modified PTFE

Modified PCTFE

Modified PCTFE

Actuator

Operating

Pressure

Bar (Psi)

5 (72.5) A1O A1C

5 (72.5) A2TS A2TS

Actuator Designators

(Factory assembled)

Spring Return

NO NC

Note: For dimensions of Actuators assembled on the H-6800

series, please refer to the HPA section.

Double

Acting

A1

A2

A2T

Actuator Ordering

Code

Spring

Return

Z-A1S

Z-A2S

NC: Z-A3S

NO: Z-A3O

Z-A2TS

Double

Acting

Z-A1

Z-A2

Z-A2T

Mounting Kit

Ordering Info

Z-6800-MK-1/4”-F03-F04-A1

Z-6800-MK-1/2”-F03-F04-A2

Z-6800-MK-1/2”-F03-F04-A3

Z-6800-MK- 1/4”-F03-F04A2

Z-6800-MK-1/2”-F03-F04-A2

HIGH PERFORMANCE BALL VALVES H-6800 SERIES

198

H-6800 SERIES ORDERING INFORMATION

OPTIONAL

H 68

Valves Series

Valve Type

LET-LOK® End Connection

00 -

Female End Connection

10 -

Male End Connection

80

Male to Female End Connection

85 -

Female to LET-LOK® End Connection

90

Male to LET-LOK® End Connection

95 -

Body and Ends

Material*

SS

- St.St. 316

B

- Brass

*For other materials, please

consult HAM-LET

End Connection

L

- LET-LOK® End

N

- Threaded NPT

G

- ISO parallel

R

- ISO Tapered

GL

- Metal Gasket Face seal

HL

- One-Lok Tube Fittings

NL

- NPT to LET-LOK®

LN

- LET-LOK® to NPT

Other end connections are

available upon request.

For Actuated Valves

If special cleaning is required, LF / OC will be added in the end

and be applicable for the Valve only.

Example: H6800SSL1/4PS - A1 - OC

For ordering infomation of actuators for high temprature please

refer to HAM-LET Pneumatic Actuator Catalog

For double mounting actuators, please contact your local representative

For actuators accessories (Limit Switch, Solenoid Valve)

please refer to HAM-LET Pneumatic Actuator Catalog.

For Stainless Steel Actuator or Electric Actuator please contact your

local representative

00 L C1/4SS S

Seat

Material

P

Modified PTFE

C

PCTFE

A

PEEK

Handle

BLANK

S

R

End

Connection

Size

1/16 3 MM

1/8 6 MM

1/4 8 MM

3/8 10 MM

1/2 12 MM

3/4 18 MM

B

Y

G

M

M7

ISLTS

ISLTB

ISLTR

ISLTY

ISLTG

*Extended Metal Handle for valves up to 3/8”.

Recommended for PCTFE and PEEK valves.

S

Valve Pattern

Type

S

Straight Port Valve

A

Angle Port Valve

T

3-Port Valve

For Actuated valves

Black Nylon Handle

Red Nylon Handle

Blue Nylon Handle

Yellow Nylon Handle

Green Nylon Handle

Metal (St.St.) Handle

Metal (St.St.) Handle 70mm

length*

ISLT Black

ISLT Blue

ISLT Red

ISLT Yellow

ISLT Green

-

Actuator Type

Select Per

Table A

*See Notes below

Treatment

BLANK

OC

LF

SI

Approval

BLANK

-

Standard

CNG

-

ECE R110

Aluminum

Actuator*

- Standard Cleaning &

Passivation

- Oxygen Clean

- Lubricant Free

- Silicon Coating

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

199

ORDERING INFORMATION FOR SPARE KITS

SEAL KIT

Seal Kit includes seats, stem packings, body seals and lable.

Z - 6800 - SK - 1/4 - A - 2 WAY

VALVES & ACTUATORS

Kit Type

Seal Kit

SK

NOTE:

For Seal kits for “Old Design” valves, please contact a HAM-LET representative.

Body Designator per

End Connection

1/16 to 3/8

1/4

3MM to 10MM

1/2 to 3/4

1/2

12MM to18MM

Seat

Material

Modified PTFE

P

PCTFE

C

PEEK

A

HANDLE KIT

Handle kit includes handle and set screw. To order a spare-parts kit, use the following format:

Z - 6800 - HK - 1/4 - S

Kit Type

HK

Handle Kit

Body Designator per

End Connection

1/16 to 3/8

1/4

3MM to 10MM

1/2 to 3/4

1/2

12MM to18MM

Handle Type

S

Black Nylon Handle

R

Red Nylon Handle

B

Blue Nylon Handle

Y

Yellow Nylon Handle

G

Green Nylon Handle

M

Metal (St.St.) Handle

M7

Metal St.St Handle 70 mm*

ISLTS

ISLT Black

ISLTB

ISLT Blue

ISLTR

ISLT Red

ISLTY

ISLT Yellow

ISLTG

ISLT Green

*Extended Metal Handle for valves

up to 3/8”. Recommended for

PCTFE and PEEK valves.

** Does not fit the standard valve.

Valve Pattern

2 Way

3 Way

**

**

**

**

**

For straight and angle Valves

For T Port Valves

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance. Application details, material compatibility and product ratings should all be considered for each selected product.

Improper selection, installation or use of products can cause property damage or personal injury.

H-6800, Rev.12, January 2015

HIGH PERFORMANCE BALL VALVES H-6800 SERIES

200

Loading...

Loading...