Page 1

THREE-PIECE BALL VALVES

H-500 SERIES

VALVES & ACTUATORS

Page 2

H-500 FEATURES

3-piece heavy-duty ball valves with:

Certied for ISO 15848-1:2006(E)

Precision Investment cast body in CF8M stainless steel

Precision Investment cast end caps in CF3M stainless steel

Blow-out proof stem with Belleville washer design for long life stem sealing

Manual Operation with integral locking device

Flow coefcient (Cv) from 1.2 to 24.0

MAWP 3000 psig (206 Barg), 2000 psig (137 Barg) for “-FP” option

MAWT 450°F (232°C)

H-500S seat material is Modied PTFE as standard

GENERAL

The H-500 Series is a moderate-pressure instrumentation

Ball Valve for general service and instrumentation panels.

The valves offer large ports for high ow, tight shutoff, long-life

service and low operating torque.

The H-500 Series can be used for bi-directional ow, is rated to

max. 3000 psig (204 Bar) and performs as on/off service.

1

VALVES & ACTUATORS

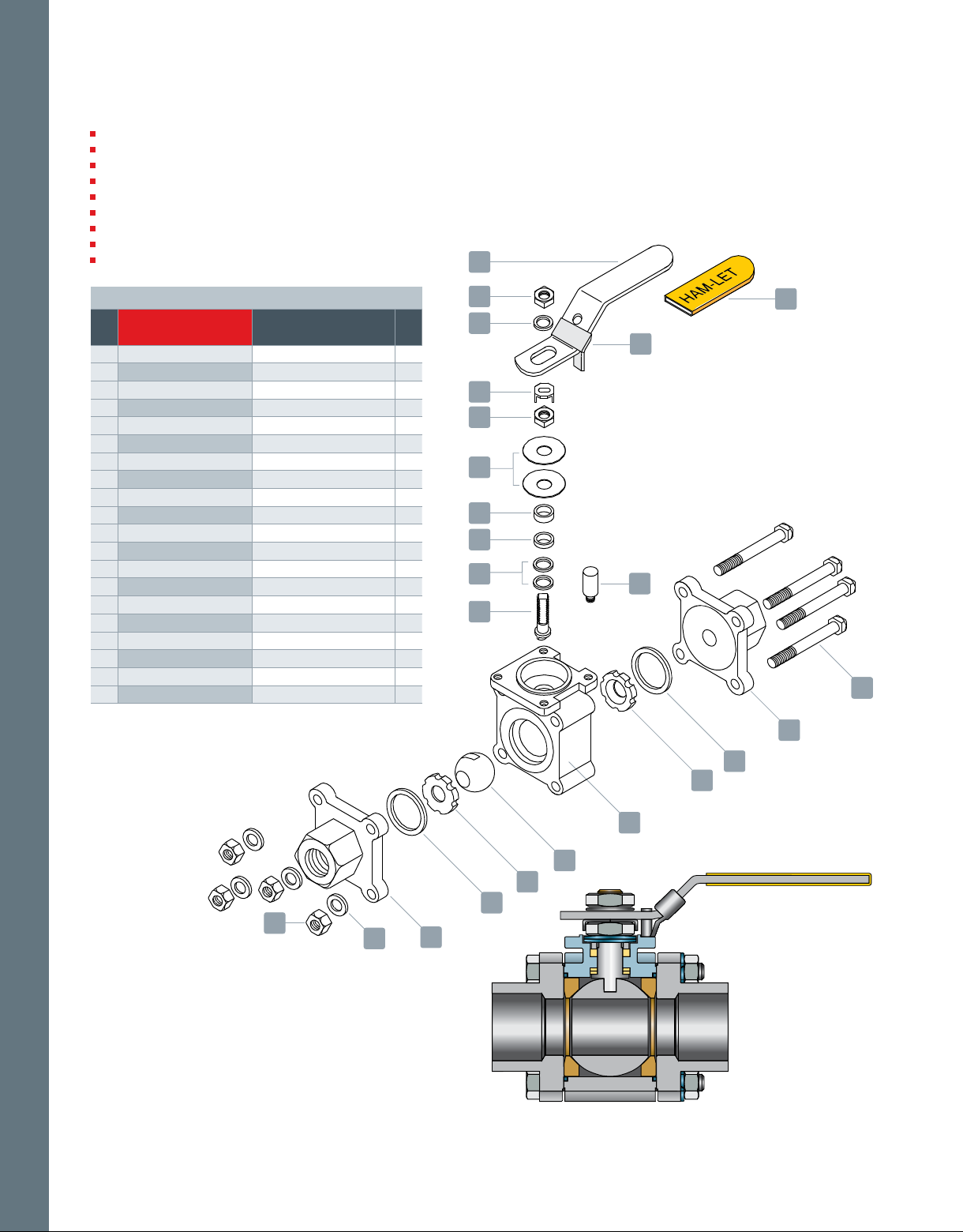

MATERIALS OF CONSTRUCTION

No. Components Material Qty

1 Handle St.St. 304

2 Stem Nut St.St. 304

3 Stem Washer St.St. 316

4 Lock Saddle St.St. 304

5 Belleville Washer

6 Gland St.St. 304

7 Stem Packing MG1241 / PTFE

8 Stem Seal MG1241

9 Stem St.St. 316

10 Locking Device St.St. 316

11 Handle Sleeve Vinyl

12 Stop Pin St.St. 304

13 Tightening Bolt

14 End Cap ASTM A351 Gr. CF3M

15 Joint Gasket PTFE

16 Seat PTFE

17 Body ASTM A351 Gr. CF8M

18 Ball St.St. 316

19 Washer St.St. 316

20 Bolt Nut St.St. 316

St.St. 304

St.St. 304

1

2

1

1

2

1

1

2

1

1

1

1

4

2

2

2

1

1

4

4

Note: If seat material other than PTFE is selected, Joint Gasket

and Stem Packing are changed accordingly.

2

11

3

10

4

2

5

6

7

8

12

9

12

13

14

15

16

17

20

19

THREE-PIECE BALL VALVES H-500 SERIES

210

18

16

15

14

Page 3

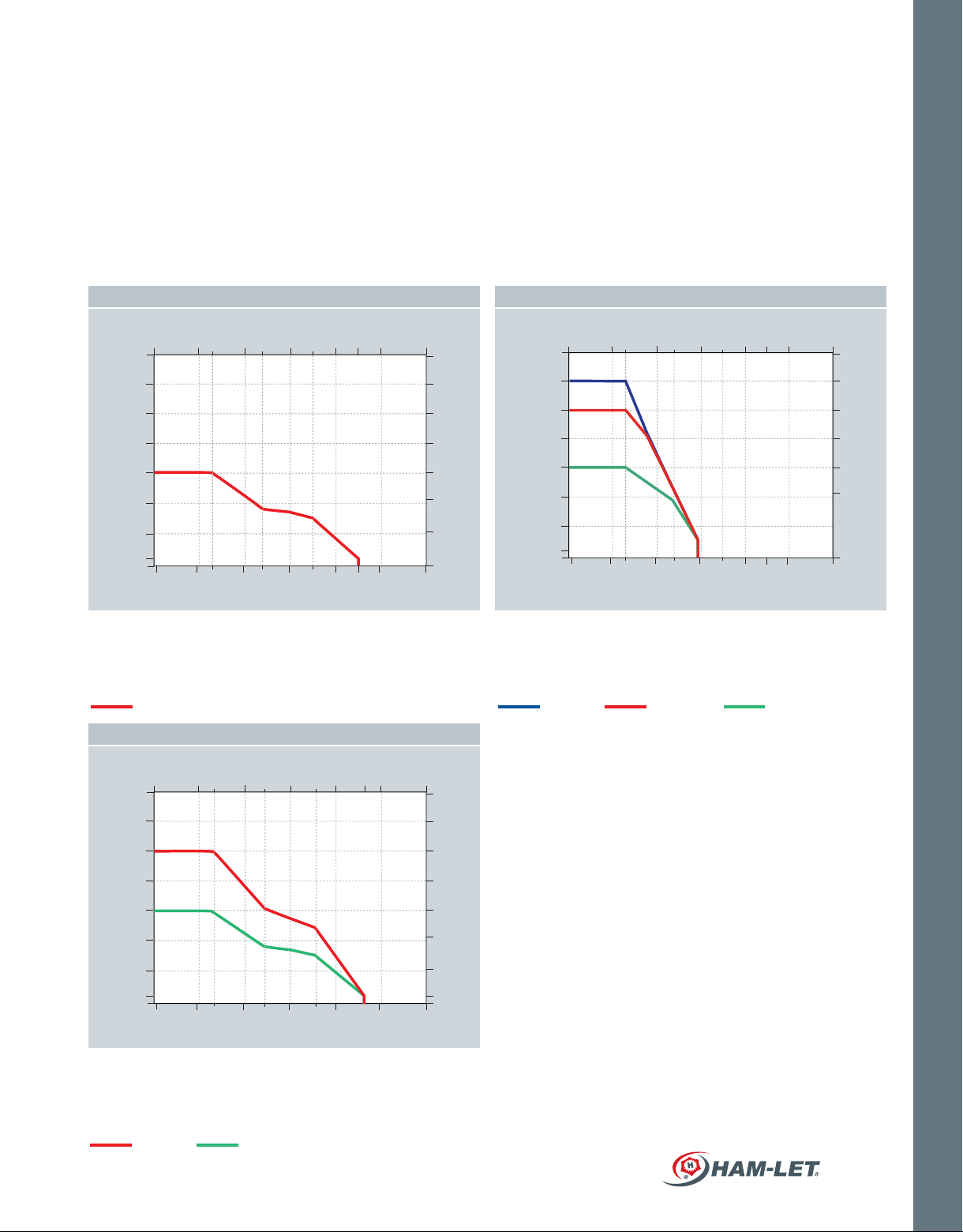

PRESSURE TEMPERATURE RATING

VIRGIN PTFE SEAT UHMWPE SEAT

Temp (°C) Temp (°C)

3500

3000

2500

2000

1500

Inlet Pressure (Psig)

1000

500

100

-28

0

-19

7222 122 172 186 222

93

148

298

98

37

199

160 250 340 43036770

240

207

172

137

103

70

35

6.9

Temp (°F) Temp (°F)

PTFE (Virgin PTFE) Color - White

PTFE is a good all around, general-purpose seat material. PTFE has

outstanding resistance to chemical attacks by a broad range of organic

chemicals, inorganic chemicals and solvents, and is generally considered

chemically inert. PTFE is a self lubricating polymer with a very low coefcient

of friction, which makes an excellent seat material

For all sizes

MODIFIED PTFE SEATS

Temp (°C)

-28

3500

3000

37

72 122 172 22220422

93

148

240

207

Inlet Pressure (bar)

UHMWPE Ultra-high-molecular-weight polyethylene

UHMWPE is a very tough material, highly resistant to corrosive chemicals

and suitable for low-radiation service. UHMWPE is self-lubricating, highly

resistant to abrasion, has an extremely low moisture absorption and a very

low coefcient of friction. UHMWPE meets the requirements for the tobacco

industry.

Inlet Pressure (Psig)

3500

3000

2500

2000

1500

1000

500

100

0

Up to 1/2”

-28

-19

7222 122 172 186 222

93

37

199

98

160 250 340 43036770

148

298

3/4” to 1” 1-1/4” to 2”

240

207

172

137

103

70

35

6.9

Inlet Pressure (bar)

VALVES & ACTUATORS

2500

2000

1500

1000

Inlet Pressure (Psig)

500

100 6.9

0

-19

98

199

160 250 340 43040070

298

172

137

103

70

35

Temp (°F)

MODIFIED PTFE - (PFA and PTFE composite) Color - Bright White

MODIFIED PTFE is an excellent seat material for purity applications and has

very low residual material during operation. It has a lower deformation ratio

than PTFE, but a higher pressure and temperature rating than PTFE. Chemical

resistance is equal to PTFE material.

1/4” to 1”

1-1/4” to 2”

HAM-LET ADVANCED CONTROL TECHNOLOGY

Inlet Pressure (bar)

211

Page 4

PACKING ADJUSTMENT

Due to the varied service applications of the

valve, packing adjustment may occasionally

be necessary. Packing is factory adjusted to

1000 psig service. Initial packing adjustment

is recommended after installation and prior

to start-up. Please nd more information on

H-500 under Installation Instructions.

HAM-LET Ball Valves are designed for

operation in the fully closed or fully open

position.

TESTING

The H-500 design has been tested for Burst

and Proof. Standard testing for each H-500

valve includes testing with nitrogen at 80

&1000 psig. Each valve is tested for leakage

through the shell, packing and ball seats. The

maximum allowable leakage across the ball

seats is 0.1 std cc/min.

CLEANING & PACKAGING

Every H-500 series ball valve is cleaned in

accordance with Standard Cleaning and

Packaging (procedure 8184). Oxygen Clean

& Lubricant Free Cleaning and packaging,

in accordance with Special Cleaning and

Packaging (procedure 8185), is available as an

option.

Lubricant free cleaned valves have

signicantly higher actuation torque.

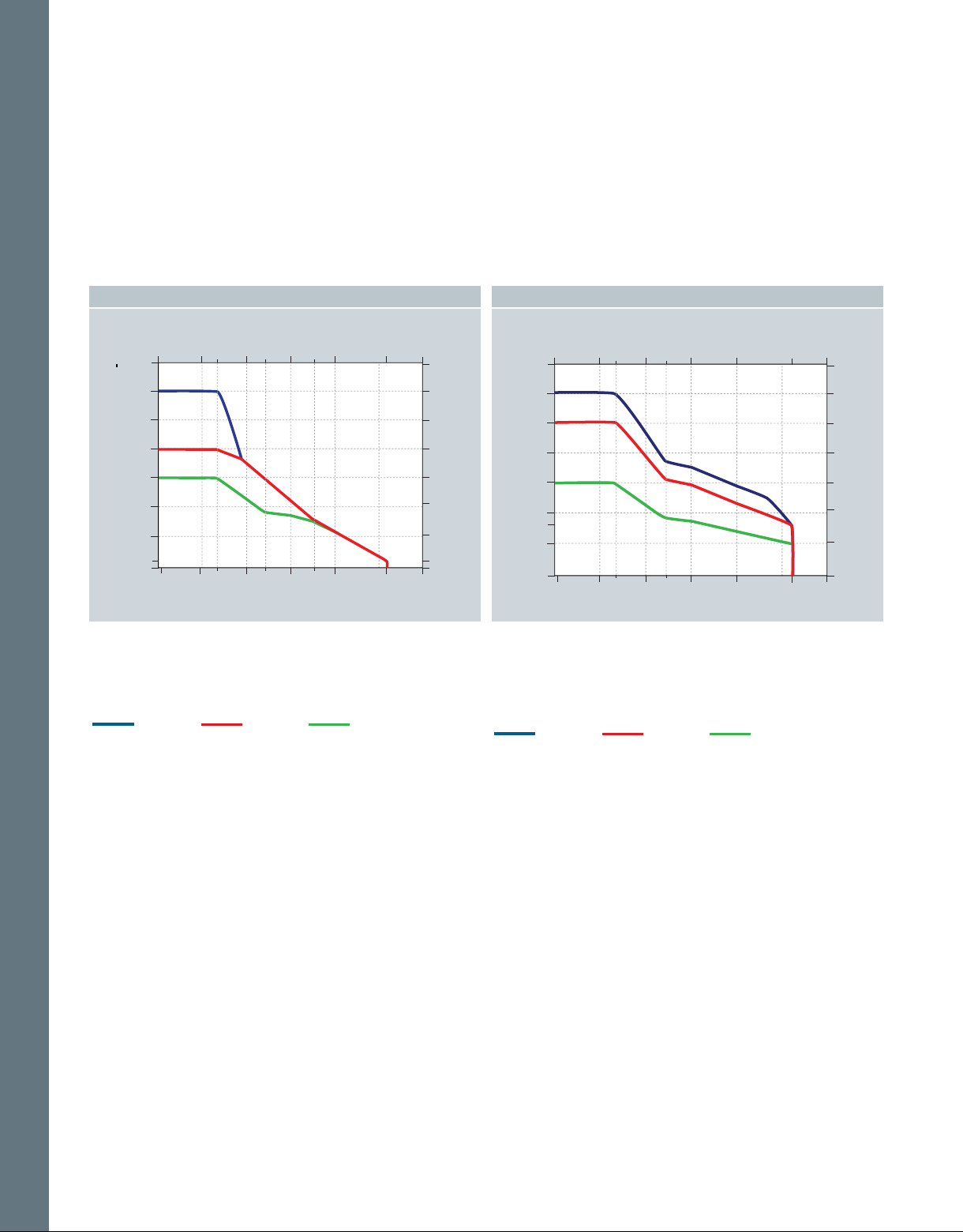

ST. ST. POWDER 50% FILLED PTFE SEATS

Temp (°C)

3500

3000

2500

2000

1500

1000

Inlet Pressure (Psig)

500

100

-28

0

-19

72 122 172 23222

93

3737

199

98

160 250 340 45070

148

298

240

207

172

137

103

70

35

6.9

Temp (°F)

St. St. Powder Filled PTFE Color - Gray

Excellent seat material for general applications to prevent over

expansion and seat extrusion.

It has a lower deformation ratio than PTFE, but a higher pressure and

temperature rating. Chemical resistance is equal to PTFE material.

3/4” to 1”Up to 1/2”

1-1/4” to 2”

PEEK SEATS

Temp (°C)

Inlet Pressure (bar)

3500

3000

2500

2000

1500

1000

Inlet Pressure (Psig)

800

500

-28

0

-19

98

3737

72 122 172 23222

93

199

160 250 340 45070

Temp (°F)

PEEK (Poly Ether Ether Keton) Color - Offwhite

Excellent seat material for high-pressure and high-temperature

applications. Excellent chemical resistance.

Can be used countinuously to 450°F (232°C) and in hot water or steam

without permanent loss in physical properties.

High strength for hostile environment and high pressure.

3/4” to 1”Up to 1/2” 1-1/4” to 2”

240

207

172

137

103

70

35

6.9

Inlet Pressure (bar)

VALVES & ACTUATORS

THREE-PIECE BALL VALVES H-500 SERIES

212

Page 5

H-500 LET-LOK® STANDARD CONFIGURATION DIMENSIONS

SERIES

H-500S

H-500

End Connection

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

6

10

12 1/2” 10.3 0.40 7.6 11.0 0.43 92.3 3.63 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 22.2 0.87 121.5 4.78

20 3/4” 13.0 0.51 13.6 14.1 0.56 92.7 3.65 24.6 0.97 50.8 2.00 44.0 1.73 60.0 2.36 28.6 1.13 121.5 4.78 38.2 1.50

25 1” 20.0 0.79 36.0 20.0 0.79 124.4 4.90 31.8 1.25 60.0 2.36 56.7 2.23 74.5 2.93 38.1 1.50 151 5.94 44.0 1.73

Orice Cv Ball ID A B F C D H J G

4.8 0.19 1.2 4.8 0.19 80.5 3.17 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 14.3 0.56 61.0 2.40

1/4’’

7.1 0.28 3.7 7.1 0.28 80.5 3.17 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 17.5 0.69 61.0 2.40

3/8”

25.5 1.00

25.5 1.00

32.0 1.26

H-510 FEMALE NPT / BSPT STANDARD CONFIGURATION DIMENSIONS

SERIES

H-510S

H-510

Dimensions are for reference only, and are subject to change without notice.

End

Connection

1/4’’

3/8”

1/2” 11.0 0.43 10 11.0 0.43 70.0 2.76 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 27.0 1.06 121.5 4.78

3/4” 14.1 0.56 12.0 14.1 0.56 74.0 2.91 24.6 0.97 50.8 2.00 44.0 1.73 60.0 2.36 33.0 1.30 121.5 4.78 38.2 1.50

1” 20.0 0.79 36.0 20.0 0.79 99.0 3.90 31.8 1.25 60.0 2.36 56.7 2.23 74.5 2.93 42.0 1.65 151 5.94 44.0 1.73

Orice Cv Ball ID A B F C D H J G

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

7.1 0.28 1.2 7.1 0.28 54.9 2.16 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 19.0 0.75 61.0 2.40

11.0 0.43 10 11.0 0.43 70.0 2.76 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 27.0 1.06 121.5 4.78 32.0 1.26

HAM-LET ADVANCED CONTROL TECHNOLOGY

VALVES & ACTUATORS

25.5 1.00

32.0 1.26

213

Page 6

ID

M

H-510 TUBE SOCKET WELD STANDARD CONFIGURATION DIMENSIONS

SERIES

H-510S

H-510

End

Connection

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

10

12 1/2”

20 3/4”

25 1”

Orice Cv Ball ID A B F C D OD J G ID M

4.8 0.19 1.2 4.8 0.19 54.9 2.16 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 19.0 0.75 61.0 2.40

6

1/4’’

7.1 0.28 3.7 7.1 0.28 54.9 2.16 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 19.0 0.75 61.0 2.40

3/8”

10.3 0.40 7.5 11.0 0.43 70.0 2.76 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 20.5 0.81 121.5 4.78

14.1 0.56 12.0 14.1 0.56 74.0 2.91 24.6 0.97 50.8 2.00 44.0 1.73 60.0 2.362 27.0 1.06 121.5 4.78 38.2 1.50 19.2 0.76 14.2 0.56

22.35 0.88 38.0 22.35 0.88 99.0 3.90 31.8 1.25 60.0 2.36 56.7 2.23 74.5 2.93 34.0 1.34 151.0 5.94 44.0 1.73 25.55 1.08 19.2 0.76

25.5 1.00 4.80 0.19 7.10 0.28

25.5 1.00 7.10 0.28 7.90 0.31

32.0 1.26 12.85 0.51 12.7 0.50

VALVES & ACTUATORS

H-510 PIPE SOCKET WELD STANDARD CONFIGURATION DIMENSIONS

SERIES

H-510

Dimensions are for reference only, and are subject to change without notice.

214

End

Connection

1/4’’

3/8”

1/2”

3/4”

Orice Cv Ball ID A B F C D H J G ID M

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

11.0 0.43 10 11.0 0.43 70.0 2.76 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 27.0 1.06 121.5 4.78

11.0 0.43 10 11.0 0.43 70.0 2.76 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 27.0 1.06 121.5 4.78 32.0 1.26 17.5 0.69 11.0 0.43

11.0 0.43 10 11.0 0.43 70.0 2.76 20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 27.0 1.06 121.5 4.78

14.1 0.56 12.0 14.1 0.56 74.0 2.91 24.6 0.97 50.8 2.00 44.0 1.73 60.0 2.36 33.0 1.30 121.5 4.78 38.2 1.50 27.4 1.08 14.3 0.56

1”

20.0 0.79 36.0 20.0 0.79 99.0 3.90 31.8 1.25 60.0 2.36 56.7 2.23 74.5 2.93 42.0 1.65 151 5.94 44.0 1.73 34.2 1.35 15.9 0.63

THREE-PIECE BALL VALVES H-500 SERIES

32.0 1.26 14.1 0.56 9.70 0.38

32.0 1.26 22.2 0.87 9.50 0.37

Page 7

J

ID

C

F

OD

G

B

A

H-580 PIPE BUTTWELD STANDARD CONFIGURATION DIMENSIONS

SERIES

H-580S

H-580

End

Connection

1/4’’

3/8”

1/2”

3/4”

1”

Orice Cv Ball ID A B F C D OD ID J G

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

7.1 0.28 3.7 7.1 0.28 52.8 2.08 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 13.7 0.54 9.20 0.36 61.0 2.40

7.1 0.28 3.7 7.1 0.28 52.8 2.08 15.1 0.59 38.5 1.52 33.2 1.31 48.0 1.89 17.1 0.67 10.7 0.42 61.0 2.40

11 0.43 10

14.1 0.56 12

20 0.79 36

11.0 0.43

14.1 0.56

20.0 0.79

71.6 2.82

72.0 2.83

97.0 3.82

20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22

24.6 0.97 50.8 2.00 44.0 1.73 60.0 2.36

31.8 1.25 60.0 2.36 56.7 2.23 74.5 2.93

D

25.5 1.00

25.5 1.00

121.5

21.3 0.84 15.8 0.62

27.1 1.07 21.0 0.83

33.4 1.32 26.6 1.05

4.78

32.0 1.26

121.5

4.78 38.2 1.50

151 5.94 44.0 1.73

ID

H-580 EXTENDED AND SHORT TUBE BUTTWELD STANDARD CONFIGURATION DIMENSIONS

SERIES

H-580

Dimensions are for reference only, and are subject to change without notice.

End

Connection

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

6

10

12 1/2” 9.4 0.37 7 9.4 0.37 140 5.5 64.6 2.54

20 3/4” 15.75 0.62 18 15.8 0.87 150 5.9 - -

25 1” 22.1 0.87 38 22.35 0.88 161.2 6.35 - -

Orice Cv Ball ID A

4.4 0.17 1 9.4 0.37 - - 71.5 2.81

1/4’’

7.7 0.3 3.8 9.4 0.37 - - 71.5 2.81

3/8”

extendedAshort

B F C D OD J G ID

20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 6.4 0.25

20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 9.57 0.38

20.6 0.81 44.4 1.75 40.5 1.59 56.5 2.22 12.7 0.5

24.6 0.97 50.8 2.00 44.0 1.73 60.0 2.36

31.8 1.25 60.0 2.36 56.7 2.23 74.5 2.93 25.4 1

19.05

0.75

121.5

4.78

32.0 1.26 4.40 0.17

121.5

4.78 32.0 1.26 7.70 0.30

121.5

4.78

32.0 1.26 9.40 0.37

121.5

4.78 38.2 1.50

151

5.94 44.0 1.73 22.1 0.87

15.75

VALVES & ACTUATORS

0.62

HAM-LET ADVANCED CONTROL TECHNOLOGY

215

Page 8

H-500 OVAL HANDLE

End Connection N L M

mm inch mm inch mm inch

1/4'', 3/8”, 1/2”

6mm, 10mm, 12mm

3/4”

20mm

1”

25mm

40.5 1.6 105.0 4.13 66 2.6

44 1.73 105.0 4.13 70 2.75

56.7 2.23 105.0 4.13 88.7 3.49

L

L

M

N

VALVES & ACTUATORS

H-500 GRIP HANDLE (OVAL)

End Connection L M N P Q

mm inch mm inch mm inch mm inch mm inch

1/4'', 3/8”, 1/2”

6mm, 10mm, 12mm

3/4”

20mm

Dimensions are for reference only, and are subject to change without notice.

104 4.09 94.5 3.72 40.5 1.59 27.5 1.08 49.5 1.95

104 4.09 98 3.86 44 1.73 30.5 1.2 56 2.2

M

N

P

Q

THREE-PIECE BALL VALVES H-500 SERIES

216

Page 9

H-500 - PNEUMATIC ACTUATED VALVES

FEATURES

90° Actuation for 2-way valves

Actuators comply with industry standards for interface with

ISO 5211, NAMUR and VDI/VDE 3845

Actuated valves are available factory assembled or seperately, actuator

and mounting kits

Limit switches, proximity sensors, position indicators, solenoid valves and

other accessories are available upon request

Standard Temperature range: -32°C to 90°C (-25.6°F to 194°F)

Optional: High Temperature, Low Temperature

MATERIAL OF CONSTRUCTION

No. Part Qty Material

1 Actuator 1 AL 356-T5

2 Coupling 1 St.St.316

3 Bracket 1 St.St.304

4 Washer Flat 4 St.St.304

5 Washer Spring 8 St.St.304

6 Screw 8 St.St.304

7 H500 1 St.St.316

GENERAL

Four standard actuator sizes are available upon request:

Mini (designator “A1”), Small (designator “A2”), Medium

(designator “A3”), and Large (designator “A4”).

Improved operational speed enables better valve opening and closing control.

ATEX certication of Valves-Actuators’ assemblies are

available on request at the time

of order quotation.

1

4

5

2

6

3

5

6

VALVES & ACTUATORS

7

HAM-LET ADVANCED CONTROL TECHNOLOGY

217

Page 10

VALVES & ACTUATORS

ACTUATED H-500 SERIES

The selection of Valve-Actuator assemblies provided herein is based on:

Valve maximum allowable working pressure

Ambient temperature (50 to 100°F / 10 to 37°C)

Actuator ts to valve based on operating pressure of 6 bar, in accordance with table A.

To order H-500 ball valve factory assembled with an actuator, the actuator designator

shall be added to the valve part number/description per the below table.

Example:

H-500-SS-L-3/4-T with standard Double Acting Aluminum Actuator

H-500-SS-L-3/4-T-A2

To order an actuator and mounting kit for eld assembly:

Double Acting Actuator ordering number: Z-A2

Corresponding mounting kit: Z-500-MK-3/4 -F03-F04-A2

Lubricant free Valves:

For Spring Return Actuator - select one size bigger then offered in the table below.

Example: If the offered actuator in the table is A2C, select A3C

For Double Acting Actuator - please contact your local representative

Table A: Ordering information for Actuated Valves

Series Ends Size Seats Minimum

H-500S

H-500

1/4”, 3/8”

(6 mm, 10 mm)

1/4”-1/2”

(6 mm-12 mm)

3/4”

(20 mm)

1”

(25 mm)

Modied

PTFE

PTFE

Modied

PTFE

St.St. PTFE 5 (72.5) A2O A2C A2 Z-A2S Z-A2

PEEK 5 (72.5) A4O A4C A3 Z-A4S Z-A3

PTFE

Modied

PTFE

St.St. PTFE 5 (72.5) A3O A3C A2 Z-A3S Z-A2

PEEK 5 (72.5) A4O A4C A4 Z-A4S Z-A4

PTFE

Modied

PTFE

St.St. PTFE

PEEK 5 (72.5) A5O A5C A4 Z-A5S Z-A4

Actuator

Operating

Pressure

Bar (Psi)

5 (72.5) A1O A1C A1 Z-A1S Z-A1

5 (72.5) A2O A2C A1 Z-A2S Z-A1

5 (72.5) A2O A2C A2 Z-A2S Z-A2

5 (72.5) A4O A4C A3 Z-A4S Z-A3

Actuator Designators

(Factory Assembled)

Spring Return

NO NC

Double

Acting

Actuator Ordering

Code

Spring

Return

Double

Acting

Mounting Kit

Ordering Info

Z-500-MK-1/4”-F03-F04-A1

SR: Z-500-MK-1/2”-F03-F04-A2

DA: Z-500-MK-1/2”-F03-F04-A1

Z-500-MK-1/2”-F03-F04-A2

SR: Z-500-MK-1/2”-F05-F07-A4

DA: Z-500-MK-1/2”-F04-F05-A3

Z-500-MK-3/4”-F03-F04-A2

SR: Z-500-MK-3/4”-F04-F05-A3

DA: Z-500-MK-3/4”-F03-F04-A2

Z-500-MK-3/4”-F05-F07-A4

SR: Z-500-MK-1”-F05-F07-A4

DA: Z-500-MK-1”-F04-F05-A3

SR: Z-500-MK-1”-F05 F07-A5

DA: Z-500-MK-1”-F05-F07-A4

Note: For dimensions of Actuators assembled on the H-500 series, please

refer to the HPA section.

THREE-PIECE BALL VALVES H-500 SERIES

218

Page 11

H-500 SERIES ORDERING INFORMATION

OPTIONAL

H-5

Valve Series

Valve Type

00 - LET-LOK® ends

10 - Female ends

80 - Male ends

85 - Male to Female ends

90 - Female to LET-LOK® ends

95 - Male to LET-LOK® ends

Valve Body Size

Blank - Standard

S - Small

Structure Material

SS - St.St.316

End Cups - ASTM A351 Gr. CF3M

Body - ASTM A351 Gr. CF8M

End Connection Type

L LET-LOK®

HL ONE-LOK®

N NPT

R ISO Tapered

TSW Tube socket weld

TBW Tube buttweld

XTBW Extended Tube buttweld

PSW Pipe socket weld

PBW Pipe buttweld sch 40

1

-

/4”,

- -00 S SS L 1/4

End Connection

Size

1/4 6 MM

3/8 10 MM

1/2 12 MM

3/4 20 MM

1” 25 MM

1

1

/4” -FP* 32 MM

1

1

/2” -FP* 38 MM

2” -FP* 50 MM

Full bore for 1

*

11/2”, 2” as standard with

threaded ends only

-

Handle

BLANK Lever Handle

OH Oval Handle

GH Grip Handle

* All handles are with

locking device as standard

Seat Material

BLANK PTFE

T - Modied PTFE*

E - St.St. Filled PTFE

PK- PEEK

U - UHMWPE

*Standard for H-500S

Actuator Type

Select Per

Table A

*See Notes below

Aluminum

Actuator*

Treatment

BLANK - Standard Cleaning &

Passivation

OC - Oxygen Clean

LF - Lubricant Free

For Actuated Valves

If special cleaning is required, LF / OC will be added in the end,

and will refer to the Valve only.

For example: H - 500- SS - L- 3/4 - T - A2 - OC

For ordering information of actuators for high temperature please

refer to HAM-LET Pneumatic Actuator Catalog

For double mounting actuators, please contact your local representative

For Actuators Accessories (Limit Switch, Solenoid Valve),

please refer to HAM-LET Pneumatic Actuator Catalog

For Stainless Steel Actuator or Electric Actuator please contact your

local representative

VALVES & ACTUATORS

ORDERING INFORMATION FOR HANDLE KITSORDERING INFORMATION FOR SEAL KITS

The kit includes gaskets, seats, stem packing and stem seal.

Z - 500

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special application requirements, ensuring their safe and trouble-free installation,

operation, and maintenance. Application details, material compatibility and product ratings should all be considered for each selected product. Improper selection, installation

or use of products can cause property damage or personal injury.

-

SK

- - 1/4

Body Designator per

End Connections

For 1/4, 1/2, 3/8, 6MM,

1/2

10MM, 12MM

For 3/4, 20MM

3/4

For 1”, 25MM

1”

P

Seal

Material

P - PTFE

T -

Modied PTFE

E - St.St. Filled PTFE

PK- PEEK

U - UHMWPE

Z - 500

-

Body Designator per

End Connections

1/2

3/4

1”

HK

For 1/4, 1/2, 3/8, 6MM,

10MM, 12MM

For 3/4, 20MM

For 1”, 25MM

1/4 LH

-

-

Handle

LH Lever Handle

OH Oval Handle

GH Grip Handle

* all Handles are with

locking device standard

H-500, Rev.11, January 2015

HAM-LET ADVANCED CONTROL TECHNOLOGY

219

Loading...

Loading...