CHECK VALVES

General purpose xed cracking pressure

check valve (MAWP 3000 psig)

Adjustable cracking pressure check valve (MAWP 3000 psig)

H-400 SERIES

VALVES & ACTUATORS

GENERAL PURPOSE FIXED CRACKING PRESSURE CHECK VALVE H-400 SERIES

FEATURES

n

316 St.St. and Brass construction

n

Moderate Pressure Characteristics up to 3000 psi (206 bar)

n

Compact Design

n

Variable xed cracking-pressure springs

n

HAM-LET LET-LOK®, Male & Female NPT, and HTC®

Face-Seal Bead Ends.

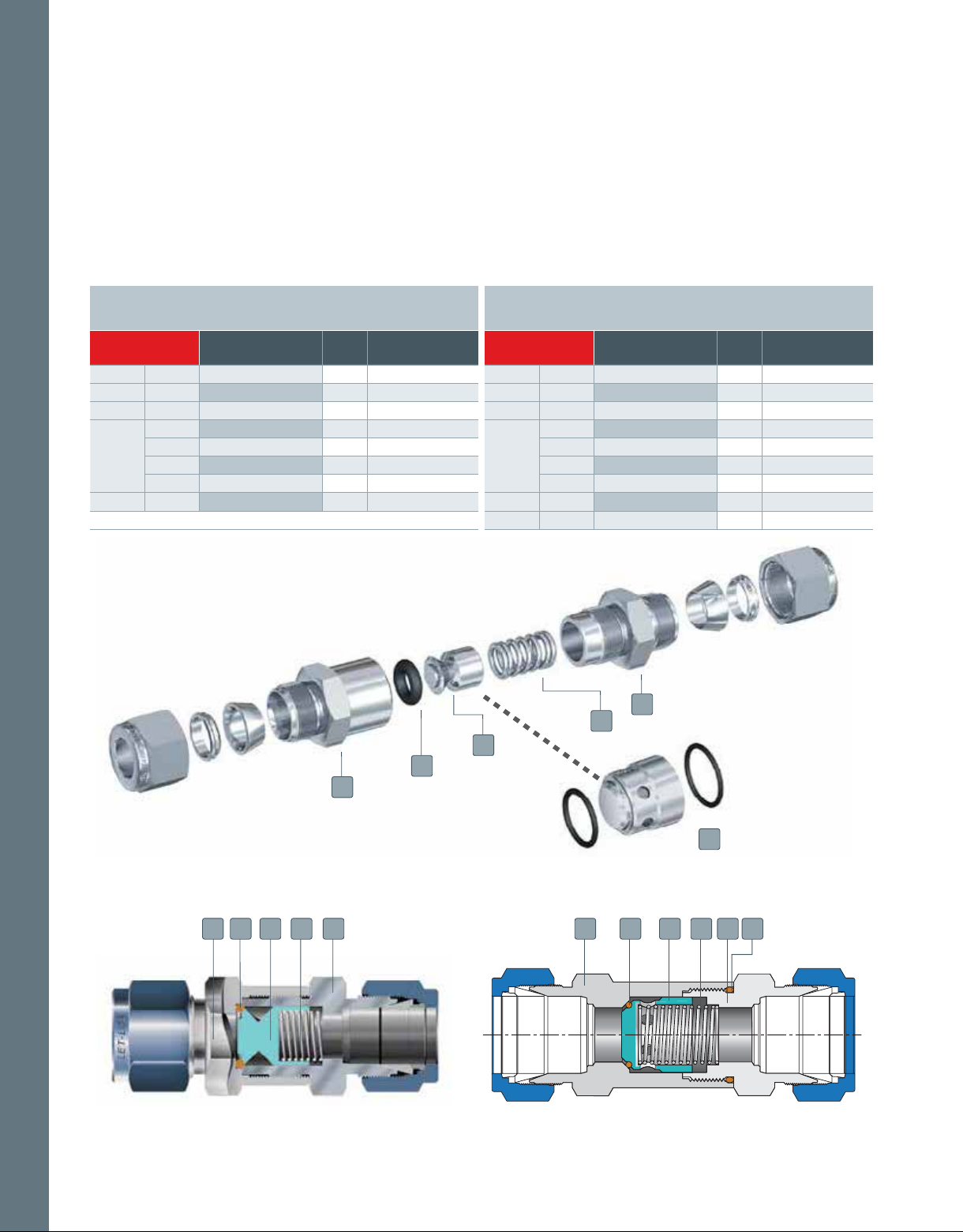

MATERIALS OF CONSTRUCTION

for sizes 1/8"-1/2"

Item No. Components Qty.

1

2

3

4

5

Body 1 St.St. 316

O-ring

Poppet 1 St.St. 316

Spring 1/3 psi

A

Spring 3 psi 1 St.St. 302

B

Spring 10 psi

C

Spring 25 psi 1 St.St. 302

D

End

Valve Body

Material

1 Fluorocarbon FKM

1 St.St. 302

1 St.St. 302

1 St.St. 316

GENERAL

The H-400 Series is a compact design for instrumentation panels

and systems, which provides an accurate operating point. H-400

valves are normally closed. When differential pressure between

the inlet and outlet is higher than the set pressure of the spring,

the loaded poppet will move backwards and will enable a free

passage of flow through the valve.

For vacuum applications please select H-400HP series.

MATERIALS OF CONSTRUCTION

for sizes 3/4"-1"

Item No. Components Qty.

1

2

3B

4

5

6

Body 1 St.St. 316

O-ring

Poppet 1 St.St. 316

Spring 1/3 psi

A

Spring 3 psi 1 St.St. 302

B

Spring 10 psi

C

Spring 25 psi 1 St.St. 302

D

End

Upper O-ring 1 Fluorocarbon FKM

Valve Body

Material

1 Fluorocarbon FKM

1 St.St. 302

1 St.St. 302

1 St.St. 316

VALVES & ACTUATORS

Sizes 1/8"-1/2"

1 1 2 3 54

1

Body

2

O-ring

3

Poppet

O-ring

Sizes 3/4"-1"

4

Spring

5

End

3B

Poppet

(3/4 -

1''

Upper O-ring

)

62 3 4 5

CHECK VALVES H400- SERIES

260

STANDARD CONFIGURATION DIMENSIONS

Valve Type

Inlet Outlet

H-400 1/8'' LET-LOK

H-400 1/4'' LET-LOK

H-400 6 MM LET-LOK

H-400 3/8'' LET-LOK

H-400 8 MM LET-LOK

H-400 10 MM LET-LOK

H-400 1/2'' LET-LOK

H-400 12 MM LET-LOK

H-400 3/4'' LET-LOK

H-400 1'' LET-LOK

Connection / Size

®

®

®

®

®

®

®

®

®

®

1/8'' LET-LOK

1/4'' LET-LOK

®

®

6 MM LET-LOK

3/8'' LET-LOK

®

8 MM LET-LOK

10MM LET-LOK

1/2'' LET-LOK

®

12 MM LET-LOK

3/4'' LET-LOK

1'' LET-LOK

®

®

Cv

0.1 56.0 2.20 25.3 1.00 15.88 5/8 11.11 7/16

0.47 60.5 2.38 25.0 0.98 15.88 5/8 14.28 9/16

®

0.47 60.5 2.38 25.0 0.98 15.88 5/8 14.00

1.47 63.5 2.50 24.9 0.98 17.46 11/16 17.46 11/16

®

®

1.47 63.3 2.49 24.9 0.98 17.5 11/16 16.00

1.68 64.0 2.52 24.9 0.98 17.46 11/16 19.00

1.68 77.0 3.03 32.6 1.28 23.8 15/16 22.23 7/8

®

1.68 77.0 3.03 32.8 1.28 23.8 15/16 22.00

4.48 88.5 3.48 44.4 1.75 28.6 1-1/8 28.60 1-1/8

4.48 120 4.72 67.2 2.65 34.9 1-3/8 38.10 1-1/2

A B C D

mm in mm in mm in mm in

H-410 1/8'' Female NPT 1/8'' Female NPT 0.1 44.0 1.73 25.4 1.00 15.88 5/8

H-410 1/4'' Female NPT 1/4'' Female NPT 0.47 52.5 2.07 28.0 1.10 19.05 3/4

H-410 3/8'' Female NPT 3/8'' Female NPT 1.47 51.5 2.03 34.1 1.34 22.23 7/8

H-410 1/2'' Female NPT 1/2'' Female NPT 1.68 76.5 3.01 43.4 1.71 28.6 1-1/8

H-410 3/4'' Female NPT 3/4'' Female NPT 4.48 86.0 3.39 56.0 2.20 34.9 1-3/8

H-410 1'' Female NPT 1'' Female NPT 4.48 107 4.21 73.0 2.87 41.28 1-5/8

H-480 1/8'' Male NPT 1/8'' Male NPT 0.1 44.3 1.74 24.9 0.98 15.88 5/8

H-480 1/4'' Male NPT 1/4'' Male NPT 0.47 55.9 2.20 25.0 0.98 19.05 3/4

H-480 3/8'' Male NPT 3/8'' Male NPT 1.47 53.1 2.09 24.9 0.98 17.46 11/16

H-480 1/2'' Male NPT 1/2'' Male NPT 1.68 70.4 2.77 32.6 1.28 23.8 15/16

H-480 1/4'' Male Face Seal 1/4'' Male Face Seal 0.47 56.4 2.22 24.9 0.98 15.88 5/8

H-480 1/2"Male Face Seal 1/2'' Male Face Seal 1.68 68.2 2.69 32.6 1.28 23.8 15/16

H-485 1/8''Male NPT 1/8'' Female NPT 0.1 44.3 1.74 25.4 1.0 15.88 5/8

H-485 1/4''Male NPT 1/4'' Female NPT 0.47 53.7 2.11 27.3 1.07 19.05 3/4

Dimensions are for reference only, and are subject to change.

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

261

GENERAL PURPOSE FIXED CRACKING PRESSURE CHECK VALVE H-400 SERIES

CRACKING PRESSURE

The differential pressure between the inlet and outlet,

at which an initial ow is passing through the valve.

RESEAL PRESSURE

The differential pressure between the outlet and inlet,

at which no ow is passing through the valve.

O-RINGS*

O-ring Material

Buna N -10 to 250 (-23 to 121)

EPDM -50 to 300 (-45 to 148)

Fluorocarbon FKM -10 to 375 (-23 to 190)

Peruor -15 to 500 (-26 to 260)

Polychloroprene (CR) -40 to 250 (-40 to 121)

*Different materials are available for special applications.

CRACKING AND RESEAL PRESSURE

Nominal

Cracking

Pressure

psi (bar) psi (bar) psi (bar)

1/3 (0.02) Up to 3 (0.2) Up to 6 (0.40) back pressure

1 (0.06) Up to 4 (0.27) Up to 6 (0.41) back pressure

5 (0.34) 3 to 9 (0.20 to 0.62) Up to 2 (0.13) back pressure

10 (0.68) 7 to 15 (0.48 to 1.0) 3 (0.2) or more inlet pressure

25 (1.7) 20 to 30 (1.3 to 2.0) 17 (1.1) or more inlet pressure

Temperature Rating

°F (°C)

BACK PRESSURE

Maximum allowable back pressure is rated to 1000 psi (69 bar) for 1/4,

200 psi (14 bar) for 3/8 to 1". For higher back pressure please select valve

from the H-400HP Series.

Cracking Pressure

Range

MAWP PRESSURE AT 21°C (70°F)

SIZE BRASS psi (bar) AISI 316 psi (bar)

1/8 ,1/4,

3/8, 1/2, 5/8, 6mm,

8mm,10mm,12mm

3/4, 1", 16mm,

20mm, 22 mm

3000 (207) 3000 (207)

1500 (103) 2000 (138)

Reseal Pressure

VALVES & ACTUATORS

PRESSURE - TEMPERATURE RATING FOR STANDARD CONFIGURATIONS

1/8 TO 1/2 INCH, 3MM TO 12 MM

Material 316St.St. Brass

Temperature F° (C°) Working Pressure, psi (bar)

-10 (-23) to 100 (37) 3000 (206) 3000 (206)

200 (93) 2575 (177) 2600 (179)

250 (121) 2450 (168) 2405 (165)

300 (148) 2325 (160) 375 (190) 2185 (150) -

Note: Ratings based on Fluorocarbon FKM O-ring.

CHECK VALVES H400- SERIES

262

3/4 TO 1 INCH, 18MM TO 25MM

Material 316St.St. Brass

Temperature F° (C°) Working Pressure, psi (bar)

-10 (-23) to 100 (37) 2000 (137) 1500 (103)

200 (93) 1715 (118) 1300 (89.5)

250 (121) 1630 (112) 1200 (82.6)

300 (148) 1545 (106) 375 (190) 1450 (99.9) -

CLEANING & PACKAGING

Every H-400 series Check valve is cleaned in accordance with

Standard Cleaning and Packaging (procedure 8184). Oxygen

Clean & Lubricant Free Cleaning and packaging, in accordance

with Special Cleaning and Packaging (procedure 8185), is

available as an option.

H-400 SERIES ORDERING INFORMATION

TESTING

The H-400 valve designs have been tested for Proof and Burst.

Every H-400 valve is factory tested for proper assembly, by

leakage detection at 1000 psig (68 bar) for 10 seconds.

Every H-400 valve is factory tested for functionality at the

relevant cracking pressure, 5 cycles each.

H-4

Valve Series

Valve Type

- LET-LOK® End

00

- Female End

10

- Female to Male End

15

- Male End

80

- Male to Female End

85

- Female to LET-LOK® End

90

- Male to LET-LOK® End

95

SPARE KITS

00

-

Material

- St.St. 316

SS

- Brass

B

End Connection

- LET-LOK® Tube Fitting

L

- NPT

N

- ISO Parallel

G

- ISO Tapered

R

- Face Seal Male Connector

GL

- ONE-LOK® Tube Fitting

HL

Other end connections are

available upon request.

- - - -

LSS 1/4 1/3

End Connection

Size

1/4 6 MM

3/8 8 MM

1/2 10 MM

3/4 12 MM

1 25 MM

Cracking Pressure

1/3 PSI

1 PSI

3 PSI

5

PSI

10

PSI

25

PSI

50

PSI

O-ring Material

BLANK

BU

EP

NE

KZ

PT*

VI - Fluorocarbon FKM is a standard

*PTFE seals are available up to 1/2"

valves only and require relatively

high back pressure to seal leaktight.

Treatment

BLANK - Standard Cleaning &

OC - Oxygen Clean

LF - Lubricant Free

OPTIONAL

- Fluorocarbon FKM

- Buna N

- EPDM

- Polychloroprene (CR)

- Peruor

- PTFE

Passivation

Series End Size Spring Kit* O-Ring Kit**

H-410 Female Ends

®

H-490 Female to Let-Lok

H-485 Male to Female

H-415 Female to Male

®

H-400 Let-Lok

H-480 Male Ends

H-495 Male to Let-Lok

Spring Kit includes Spring and lable

*

O-ring Kit includes O-ring and lable

**

1/8

1/4 , 3/8

1/2

3/4

1

1/8

¼,3/8

1/2

3/4

1/8, 1/4, 6mm

3/8 ,8mm, 10mm

1/2, 12mm

3/4

1

Z-400-SPK-1/4-X PSI

Z-400-SPK-3/8-X PSI

Z-410-SPK-1/2-X PSI

Z-410-SPK-3/4-X PSI

Z-410-SPK-1"-X PSI

Z-400-SPK-1/4-X PSI

Z-400-SPK-3/8-X PSI

Z-410-SPK-1/2-X PSI

Z-410-SPK-3/4-X PSI

Z-400-SPK-1/4-X PSI

Z-400-SPK-3/8-X PSI

Z-400-SPK-1/2-X PSI

Z-400-SPK-3/4-X PSI

Z-410-SPK-3/4-X PSI

X

Z-400-SK-1/4-

Z-400-SK-3/8Z-410-SK-1/2Z-410-SK-3/4-

Z-410-SK-1"Z-400-SK-1/4Z-400-SK-3/8Z-410-SK-1/2Z-410-SK-3/4Z-400-SK-1/4Z-400-SK-3/8Z-400-SK-1/2Z-400-SK-3/4Z-410-SK-3/4-

=spring type per "How To Order"

=O-Ring material per "How To Order"

HAM-LET Check Valves should never be used as safety relief devices. These valves are not designed for pressure release.

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

263

HIGH PERFORMANCE FIXED CRACKING PRESSURE CHECK VALVE

H-400HP SERIES

FEATURES

n

316 St.St. construction

n

High Pressure Characteristics up to 6000 psi (413 bar)

n

Small Size

n

Variable Fixed Cracking Pressure

n

HAM-LET LET-LOK®, Male & Female NPT, and HTC

Face Seal Bead Ends

n

Suitable for vacuum applications

n

ECE R110 approved for the CNG/NGV as an option

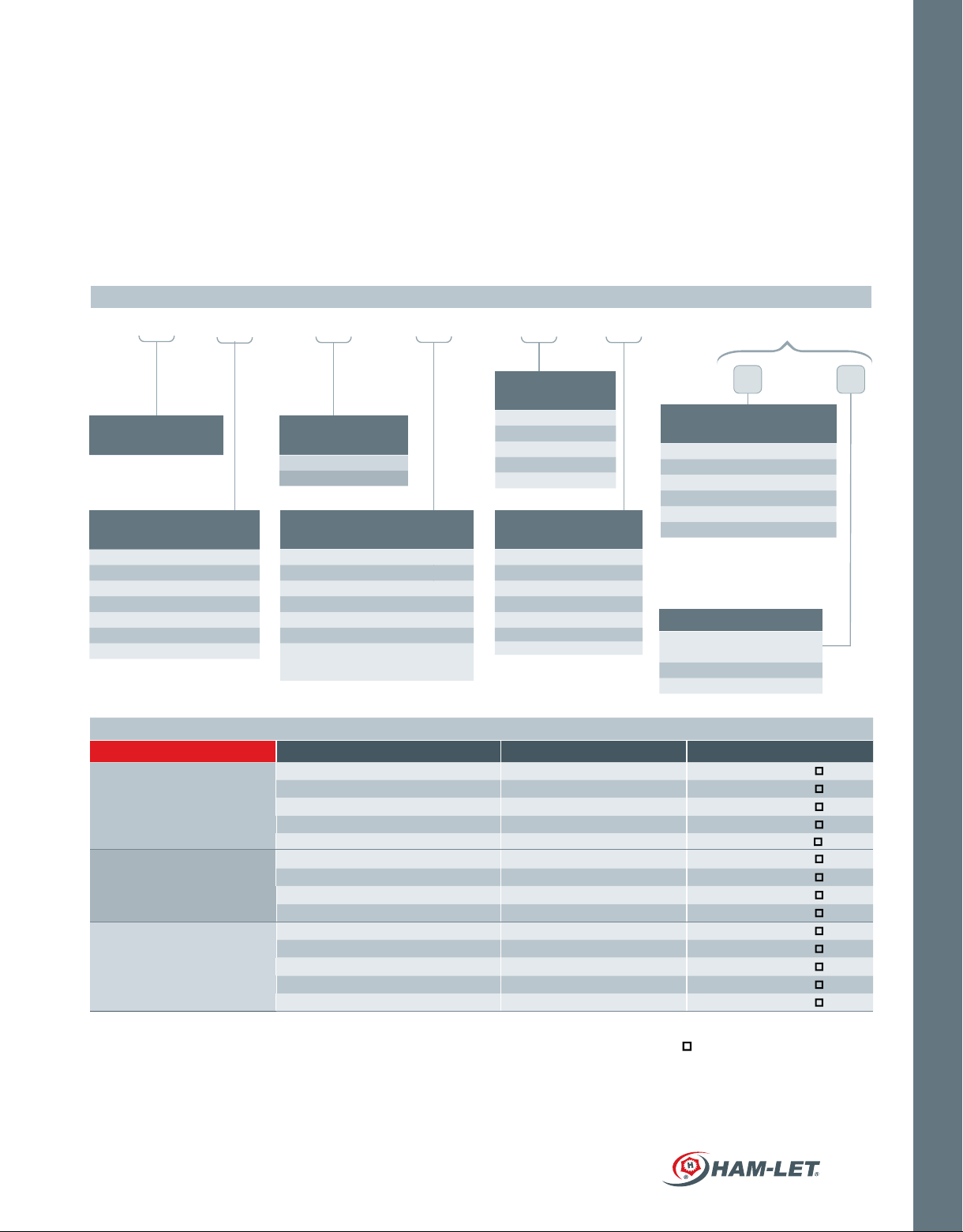

MATERIALS OF CONSTRUCTION

No. Components Qty. Standard CNG*

Body 1 St.St. ASTM A-276 St.St. ASTM A-276

1

Bonded Poppet

2

Pusher 1 St.St. ASTM A-276 St.St. ASTM A-276

3

Spring

4

O-ring 1 Fluorocarbon FKM

5

Back Up

6

End 1 St.St. ASTM A-276 St.St. ASTM A-276

7

*CNG: MAWP 3770 psi (260 bar) Temprature range: -40°C (-40°F) - 120°C (248°F)

Pressure estimates may be limited by the end connections

(See Table of dimensions on the next page).

Fluorocarbon FKM

1

1 St.St. 304 St.St. 304

1 Fluorocarbon FKM Fluorocarbon FKM

Bonded on

316 St.St.

Low temprature

Fluorocarbon FKM Bonded

on 316 St.St.

Low temprature

Fluorocarbon FKM

5

GENERAL

The H-400HP Series is a compact, robust and heavy duty design

for high-pressure (up to 6000 psi) instrumentation panels and

systems, which provides an accurate operating point. H-400HP

valves are normally closed. When the differential pressure between

the inlet and the outlet is higher than the set pressure of the spring,

the loaded poppet will move backwards and provide a free

passage of ow through the valve.

H-400HP CNG is specially designed for the CNG/NGV

PRESSURE TEMPERATURE RATING*

Material Size

Temperature F° (C°) Working Pressure, psi (bar)

-10 (-23) to 100 (37) 6000 (413) 5000 (344)

200 (93)

250 (121) 4910 (338) 4080 (281)

300 (148)

400 (204) 4280 (295) 3560 (245)

1/8, 1/4, 3/8, 1/2'',

6,8,10,12mm

5160 (355) 4290 (296)

4660 (321) 3875 (267)

6

316SS

22&25mm , 3/4&1''

VALVES & ACTUATORS

CRACKING AND RESEAL PRESSURE

Nominal

Cracking

Pressure

psi (bar) psi (bar) psi (bar)

1/3 (0.02) Up to 3 (0.2) Up to 6 (0.40) back pressure

1 (0.06)

5 (0.34) 3 to 9 (0.20 to 0.62) Up to 2 (0.13) back pressure

10 (0.68)

25 (1.7) 20 to 30 (1.3 to 2.0) 17 (1.1) or more inlet pressure

Cracking Pressure

Range

Up to 4 (0.27) Up to 4 (0.27) back pressure

7 to 15 (0.48 to 1.0) 3 (0.2) or more inlet pressure

Reseal Pressure

CRACKING PRESSURE

The differential pressure between the inlet and outlet, at which

an initial ow is passing through the valve.

7

4

3

2

1

TECHNICAL DATA

Connection

Sizes

1/8, 1/4, 6mm 0.67 1/3, 1, 5, 10 & 25

3/8, 1/2, 8-12 mm

3/4, 1, 22mm, 25mm

Max. Flow

Coefcient

(Cv)

1.80 (0.02, 0.06, 0.34,

4.7 0.68, and 7.1) 5000 (344)

Nominal

Cracking

Pressure

psi (bar)

RESEAL PRESSURE

The differential pressure between the outlet and inlet, at

which no ow is passing through the valve.

Back Pressure

at 70°F (20°C)

psi (bar)

6000 (413)

CHECK VALVES H400- SERIES

264

CLEANING & PACKAGING

Every H-400HP series Check valve is cleaned in accordance

with Standard Cleaning and Packaging (procedure 8184).

Oxygen Clean & Lubricant Free Cleaning and packaging, in

accordance with Special Cleaning and Packaging (procedure

8185), is available as an option.

STANDARD CONFIGURATION DIMENSIONS

Valve Type Inlet Outlet

H-400HP

H-410HP

H-480HP

1/8" LET-LOK

1/4" LET-LOK

3/8" LET-LOK

1/2" LET-LOK

3/4" LET-LOK

1" LET-LOK

6MM LET-LOK

8MM LET-LOK

12MM LET-LOK

22MM LET-LOK

25MM LET-LOK

®

®

®

®

®

®

®

®

®

®

®

®

1/4" Female NPT/BSPT 1/4" Female NPT/BSPT 6000 (413) 54.1 2.13 11/16

3/8" Female NPT/BSPT 3/8" Female NPT/BSPT

1/2" Female NPT/BSPT 1/2" Female NPT/BSPT 4600 (316) 83.6 3.03 1

3/4" Female NPT/BSPT 3/4" Female NPT/BSPT

1" Female NPT/BSPT 1" Female NPT/BSPT 4100 (282) 97.3 3.83

1/4" Female BSPP 1/4" Female BSPP

1/2" Female BSPP 1/2" Female BSPP 4600 (316) 83.5 3.29 1

3/4" Female BSPP 3/4" Female BSPP

1" Female BSPP 1" Female BSPP 4100 (282) 97.4 3.83

1/2" Female SAE/MS 1/2" Female SAE/MS

1/8" Male NPT/BSPT 1/8" Male NPT/BSPT

1/4" Male NPT/BSPT 1/4" Male NPT/BSPT

3/8" Male NPT/BSPT 3/8" Male NPT/BSPT

1/2" Male NPT/BSPT 1/2" Male NPT/BSPT 6000 (413) 69.2 2.72

3/4" Male NPT/BSPT 3/4" Male NPT/BSPT

1" Male NPT/BSPT 1" Male NPT/BSPT 93.3 3.67

1/4" Male BSPP 1/4" Male BSPP

1/2" Male BSPP 1/2" Male BSPP 69.2 2.72 1

3/4" Male BSPP 3/4" Male BSPP

1" Male BSPP 1" Male BSPP 93.3 3.67

1/2" Male SAE/MS 1/2" Male SAE/MS

1/4" Male HO Fitting 1/4" Male HO Fitting

1/2" Male HO Fitting 1/2" Male HO Fitting 59.8 2.35 1

3/4" Male HO Fitting 3/4" Male HO Fitting

1" Male HO Fitting 1" Male HO Fitting 73.6 2.90

1/4" Male Face Seal 1/4" Male Face Seal

1/2" Male Face Seal 1/2" Male Face Seal 3500 (241) 69.2 2.72 1

3/4" Male Face Seal 3/4" Male Face Seal

1/8" LET-LOK

1/4" LET-LOK

3/8" LET-LOK

1/2" LET-LOK

3/4" LET-LOK

1" LET-LOK

®

6MM LET-LOK

8MM LET-LOK

10MM LET-LOK

12MM LET-LOK

22MM LET-LOK

25MM LET-LOK

Pressure Ratings at

100F° / 37C° psig (bar)

®

®

®

®

®

®

®

®

®

®

®

6000 (413)

5000 (344) 89.5 3.52

4700 (323) 98.5 3.88

6000 (413)

5000 (344) 88.5 3.48

4700 (323) 98.5 3.88

Dimensions

A B

mm in in

57.8 2.28

61.8 2.43

70.0 2.76

75.3 2.96

61.8 2.43 11/16

68.5 2.70

71.1 2.80

75.3 2.96

11/16

1

5

1

110MM LET-LOK

5

1

/8

/8

5000 (344) 64.8 2.55 1

4300 (296) 90.1 3.23

5

/8

1

6000 (413) 58.0 2.28 11/16

4300 (296) 90.1 3.55

5

1

/8

4600 (316) 69.5 2.74 1

6000 (413) 45.6 1.80

6000 (413)

5000 (344)

6000 (413)

5000 (344)

55.0 2.17

60.0 2.36

83.5 3.29

55.0 2.17 3/4

85.2 3.35

11/16

1

5

1

5

1

VALVES & ACTUATORS

/8

/8

63.0 2.48 1

6000 (413)

5000 (344)

50.4 1.98 11/16

73.6 2.90

5

1

/8

6000 (413) 58.0 2.28 11/16

3000 (206) 96.1 3.78 1

5

/8

Dimensions are for reference only and are subject to change.

HAM-LET ADVANCED CONTROL TECHNOLOGY

265

HIGH PERFORMANCE FIXED CRACKING PRESSURE CHECK VALVE

H-400HP SERIES

O-RINGS

Different materials are available for special applications.

O-ring Material

Temperature Rating

°F (°C)

Buna N -10 to 250 (-23 to 121)

EPDM -50 to 300 (-45 to 148)

Fluorocarbon FKM -10 to 400 (-23 to 204)

Polychloroprene (CR) -40 to 250 (-40 to 121)

H-400HP SERIES ORDERING INFORMATION

H-4

Valve Series

00HP

- -

Material

- St.St.316

SS

TESTING

The H-400HP valve designs have been tested for Proof and Burst.

Every H-400HP valve is factory tested for proper assembly, by

leakage detection at 1000 psig (68 bar) for 10 seconds.

Every H-400HP valve is factory tested for functionality at the

relevant cracking pressure, 5 cycles each.

-

LSS 1/4 1/3

End Connection

Size

1/8 6 MM

1/4 8 MM

3/8 10 MM

1/2

3/4 22 MM

1 25 MM

-

OPTIONAL

Approval

BLANK

-

Standard

CNG

-

ECE R110

Treatment

BLANK - Standard Cleaning &

OC - Oxygen Clean

LF - Lubricant Free

Passivation

VALVES & ACTUATORS

Valve Type

- LET-LOK® End

00HP

- Female End

10HP

- Female to Male End

15HP

- Male End

80HP

- Male to Female End

85HP

- Female to LET-LOK® End

90HP

- Male to LET-LOK® End

95HP

Note: Check valves are designed and suitable for direct ow control only. These valves are not meant for pressure release.

CHECK VALVES H400- SERIES

266

End Connection Type

- LET-LOK® Tube Fitting

L

- NPT

N

- ISO Tapered

R

- Metal Face Seal Male

GL

- O-ring Face Seal Male

HO

HL

OB

- ONE-LOK

- SAE/MS

®

Cracking Pressure

1/3 PSI

1 PSI

3 PSI

5 PSI

10 PSI

25 PSI

Seal Material

BLANK

BU

EP

NE

Fluorocarbon FKM Seals are standard.

-

- Buna N

- EPDM

- Polychloroprene (CR)

ORDERING INFORMATION SPARE-PARTS KIT / REPAIR KIT

SEAL KIT

The kit includes O-ring , Back-up & Bonded Poppet and Label.

Z - 400HP - SK - 1/4 - VI

Seal

Material

VI

- Fluorocarbon FKM

BU

- Buna N

NE

- Polychloroprene (CR)

EP

- EPDM

SPRING KIT

Body Designator

per End Connection

For 1/8, 1/4, 6MM

1/4

For 3/8, 1/2, 10MM, 12MM

1/2

For 3/4, 1", 25MM

3/4

The kit includes Spring & Label.

Z - 400HP - SPK - 1/4 - 1/3

Body Designator

per End Connection

For 1/8, 1/4, 6MM

1/4

For 3/8, 1/2, 10MM, 12MM

1/2

For 3/4, 1", 25MM

3/4

Cracking Pressure

1/3 PSI

1 PSI

3 PSI

5 PSI

10 PSI

25 PSI

VALVES & ACTUATORS

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance.

Application details, material compatibility and product ratings should all be considered for each selected

product. Improper selection, installation or use of products can cause property damage or personal injury.

HAM-LET Check Valves should never be used as safety relief devices.

HAM-LET ADVANCED CONTROL TECHNOLOGY

267

COMPACT ONE PIECE FIXED CRACKING PRESSURE CHECK VALVE

GENERAL

The H-400OP Series is a compact one-piece design for moderate

pressure (up to 3000 psi) instrumentation panels and systems,

which provides a xed operating point. H-400OP valves are

normally closed. When the differential pressure between the inlet

and the outlet is higher than the set pressure of the spring, the

loaded poppet will move backwards and provide a free passage

for ow through the valve.

For vacuum applications, please select the H-400HP series.

MATERIALS OF CONSTRUCTION

Item

Components

No.

1 Lock Screw 1 St.St. 304 Brass ASTM B-16

O-ring Holder

2

3 O-ring 1 Fluorocarbon FKM

Poppet

4

5 Spring 1 St.St. 302

Body

6

Qty.

1 St.St. ASTM A-276

1

St.St. ASTM A-276

1

Valve Body Material

316 St.St. Brass

St.St. ASTM A-276

Brass ASTM B-16

H-400OP SERIES

Ordering

Information

VALVES & ACTUATORS

3

2

1

O-RINGS

Different materials are available for special applications.

O-ring Material

Buna N -10 to 250 (-23 to 121)

Ethylene Propylene (EPDM) -50 to 300 (-45 to 148)

Fluorocarbon FKM -10 to 375 (-23 to 190)

Peruor -15 to 500 (-26 to 260)

Polychloroprene (CR) -40 to 250 (-40 to 121)

Temperature Rating

°F (°C)

5

4

TECHNICAL DATA

Connection

Sizes

1/4 0.35 1/3, 1,10 & 25

1/2 1.20 (0.02, 0.06, 0.68, and 7.1)

Max. Flow

Coefcient

(Cv)

Nominal Cracking

Pressure

psi (bar)

6

Back Pressure

at 70°F (20°C)

psi (bar)

3000 (207)

CHECK VALVES H400- SERIES

268

CLEANING & PACKAGING

Every H-400OP series Check valve is cleaned in accordance with

Standard Cleaning and Packaging (procedure 8184). Oxygen

Clean & Lubricant Free Cleaning and packaging, in accordance

with Special Cleaning and Packaging (procedure 8185), is

available as an option.

STANDARD CONFIGURATION DIMENSIONS

End Connection

Inlet / Outlet

Female NPT

Male NPT

Female / Male NPT

Male /

Female NPT

Female BSPT

Male BSPT 1/2 41.0 1.61 9/16

Dimensions are for reference only and are subject to change.

Size

1/4 61.0 2.4 3/4

1/2 94.0 3.7 1

1/4 41.0 1.61 9/16

1/2 58.0 2.28 7/8

1/4 58.0 2.28 3/4

1/4 44.5 1.75 3/4

1/2 72.0 2.83 1

1/4 61.0 2.54 3/4

Dimensions

A B

mm in in

1

/16

1

/16

TESTING

The H-400OP valve designs have been tested for Proof and Burst.

Every H-400OP valve is factory tested for proper assembly, by

leakage detection at 100 psig (6.8bar) for 10 seconds.

Every H-400OP valve is factory tested for functionality at the

relevant cracking pressure, 5 cycles each.

PRESSURE TEMPERATURE RATING

Material

Temperature F° (C°) Working Pressure, psi (bar)

-10 (-23) to 100 (37) 3000 (206) 3000 (206)

200 (93) 2575 (177) 2600 (179)

250 (121) 2450 (168) 2405 (165)

300 (148) 2325 (160) 375 (190) 2185 (150) -

CRACKING AND RESEAL PRESSURE

Nominal

Cracking

Pressure

psi (bar) psi (bar) psi (bar)

1/3 (0.02) Up to 3 (0.02) 6 to 20 (0.41 to 1.3) back pressure

1 (0.06) Up to 4 (0.27) 5 to 20 (0.34 to 1.3) back pressure

10 (0.68) 7 to 13 (0.48 to 0.89) 3 to 10 (0.2 to 0.68) back pressure

25 (1.7) 21 to 29 (1.4 to 1.9) 5 (0.34) or more inlet pressure

Cracking

Pressure

Range

316 St.St. Brass

Reseal Pressure

CRACKING PRESSURE

The differential pressure between the inlet and outlet, at which

an initial ow is passing through the valve.

RESEAL PRESSURE

The differential pressure between the outlet and inlet, at which

no ow is passing through the valve.

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

269

COMPACT ONE PIECE FIXED CRACKING PRESSURE CHECK VALVE

H-400OP SERIES ORDERING INFORMATION

H-400OP SERIES

OPTIONAL

VALVES & ACTUATORS

H-4

Valve Series

Valve Type

- Female End

10

- Male End

80

- Male to Female

85

00OP

-

Material

- St.St.316

SS

- Brass

B

End Connection

- NPT

N

- ISO Tapered

R

-

NSS 1/4 1/3

-

End Connection Size

Cracking Pressure

1/3 PSI

1 PSI

5 PSI

10 PSI

25 PSI

-

1/4

1/2

Seal Material

BLANK

BU

EP

NE

KZ

Note: Check valves are designed and suitable for direct ow control only. These valves are not meant

for pressure release.

ORDERING INFORMATION SPARE KITS

SEAL KIT SPRING KIT

The kit includes O-Ring and label

Z - 400OP - SK - 1/4 - VI

The kit includes Spring & label

Z - 400OP - SPK - 1/4 - 1/3

Passivation

Seals are standard

-

-

Treatment

BLANK - Standard Cleaning &

OC - Oxygen Clean

LF - Lubricant Free

Fluorocarbon FKM

-

- Buna N

- EPDM

- Polychloroprene (CR)

- Peruor

Body Designator

per End Connection

1/4

1/2

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance.

Application details, material compatibility and product ratings should all be considered for each selected

product. Improper selection, installation or use of products can cause property damage or personal injury.

Seal Material

- Fluorocarbon FKM

VI

- Buna N

BU

- EPDM

EP

- Polychloroprene (CR)

NE

- Peruor

KZ

*Dimensions are for reference only, and are subject to change

CHECK VALVES H400- SERIES

270

Body Designator

per End Connection

1/4

1/2

Cracking Pressure

1/3 PSI

1 PSI

5

PSI

10 PSI

25 PSI

Springs for other cracking

pressures are available upon

request.

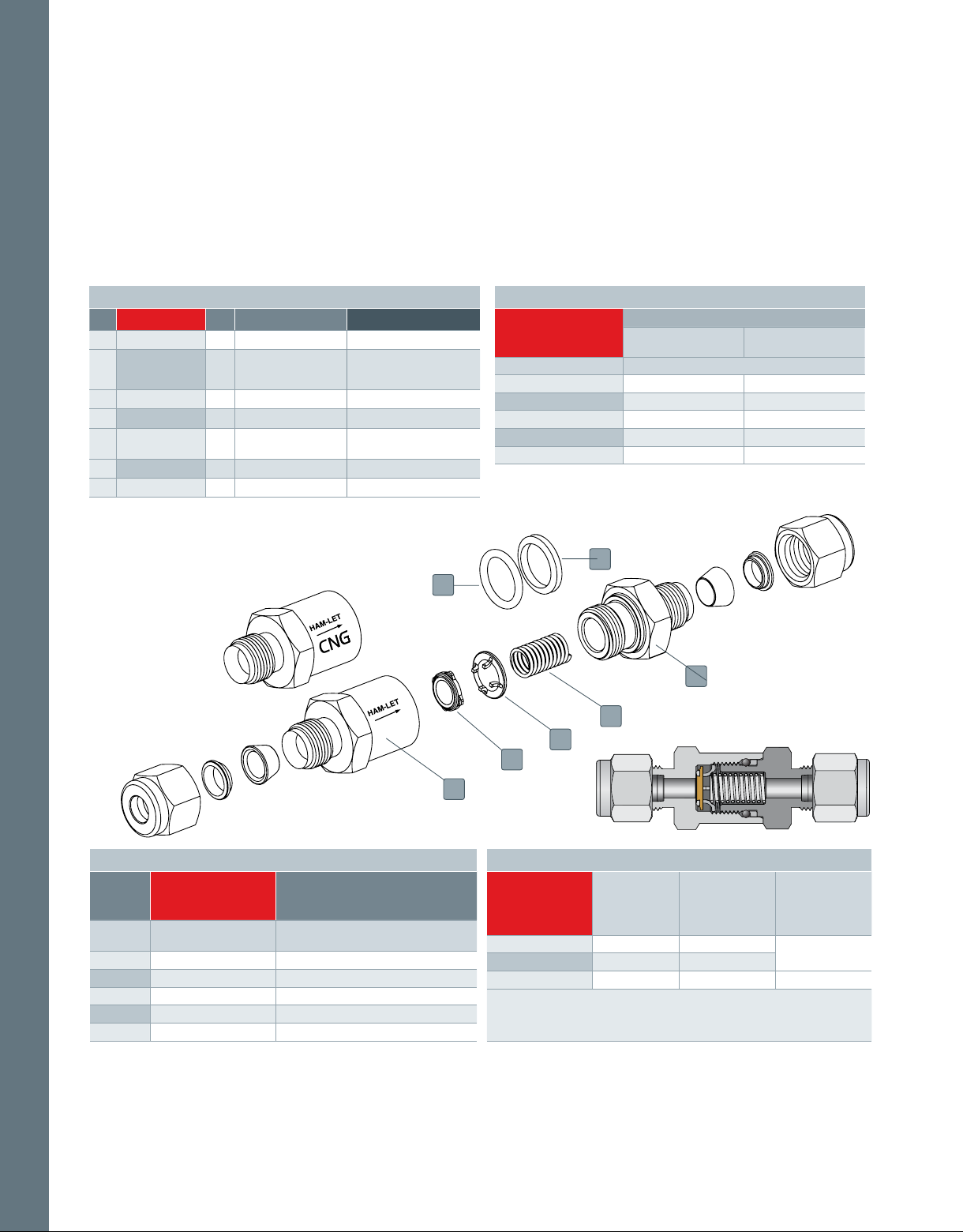

ONE PIECE ADJUSTABLE CRACKING PRESSURE CHECK VALVE

H-400OPA SERIES

FEATURES

n

One-piece Body

n

316 St.St. or Brass Construction

n

Variable Adjustable Cracking Pressure Ranges

n

Pressure Characteristics: up to 3000 psi

n

HAM-LET Male & Female NPT, Male BSPT

MATERIALS OF CONSTRUCTION

Item No. Components Qty.

Inlet Lock Screw 1 St.St. 304

1

O-ring Holder

2

O-ring 1 Fluorocarbon FKM

3

Poppet

4

Body 1

5

Spring

6

Adjusting Screw 1 St.St. 304

7

Lock Screw

8

1

1

1 St.St. 302

1 St.St. 304

316 St.St. Brass

St.St. ASTM

St.St. ASTM A-276

GENERAL

The H-400OPA Series is a compact one-piece design for moderate-pressure up

to 3000 psi (206 bar) instrumentation panels and systems, which provides an

accurate and adjustable operating point. H-400OPA valves are normally closed.

When the differential pressure between the inlet and the outlet is higher than the

set pressure of the spring, the loaded poppet will move backwards and provide a

free passage for ow through the valve.

For vacuum applications, please select the H-400HP series.

Valve Body Material

Brass ASTM B-16

A-276 Brass ASTM B-16

St.St. ASTM A-276

Brass ASTM B-16

4

22

2

1

PRESSURE TEMPERATURE RATING

Material Size 316St.St. Brass

Temperature F° (C°) Working Pressure, psig (bar)

-10 (-23) to 100 (37) 3000 (206) 3000 (206)

200 (93) 2575 (177) 2600 (179)

250 (121) 2450 (168) 2405 (165)

300 (148) 2325 (160) 375 (190) 2185 (150) -

6

5

O-RINGS

Different materials are available for special applications.

O-ring Material

Buna N -10 to 250 (-23 to 121)

EPDM -50 to 300 (-45 to 148)

Fluorocarbon FKM -10 to 375 (-23 to 190)

Peruor -15 to 500 (-26 to 260)

Polychloroprene (CR) -40 to 250 (-40 to 121)

Temperature Rating

°F (°C)

8

7

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

271

ONE PIECE ADJUSTABLE CRACKING PRESSURE CHECK VALVE

H-400OPA SERIES

CLEANING & PACKAGING

HAM-LET H-400OPA valves are treated with HAM-LET Passivation,

Cleaning and Packaging (Procedure 8075).

HAM-LET H-400OPA valves with face-seal end connections are

treated with HAM-LET Oxygen Cleaning and Packaging (Procedure

8055). Oxygen Cleaning and Packaging for other end connections

are available as an option.

STANDARD CONFIGURATION DIMENSIONS

End Connection

Female NPT 1/4 75.5 2.97 3/4

Male NPT

Male BSPT

Dimensions are for reference only and are subject to change.

TECHNICAL DATA

End Connection Size

1/4 0.35

1/2 1.20

Size

Inlet / Outlet

1/4 41 1.61 9/16

1/2 65 2.55 7/8

1/4 41 1.61 9/16

1/2 65 2.55 7/8

Max. FlowCoefcient

( Cv )

Dimensions

A B

mm in in

Nominal Cracking Pressure

3 to 50 (0.2 to 3.4)

50 to 150 (3.4 to 10.3)

150 to 350 (10.3 to 24.1)

350 to 600 (24.1 to 41.3)

CLEANING & PACKAGING

Every H-400OPA series Check valve is cleaned in accordance with

Standard Cleaning and Packaging (procedure 8184). Oxygen

Clean & Lubricant Free Cleaning and packaging, in accordance

with Special Cleaning and Packaging (procedure 8185), is

available as an option.

A

B

psi (bar)

Back Pressure at 70°F (20°C)

psi (bar)

3000 (207)

VALVES & ACTUATORS

CRACKING AND RESEAL PRESSURE

Cracking Pressure (Bar)

0 4 8 12 16 20 24 28 32 36 40

650

600

550

500

450

400

350

300

250

200

150

100

Reseal Pressure (psi)

50

0

-50

0 50 100 150 200 250 300 350 400 450 500 550 600

Cracking Pressure (psi)

40

36

32

28

24

20

16

12

Reseal Pressure (Bar)

8

4

0

CHECK VALVES H400- SERIES

272

H-400OPA SERIES ORDERING INFORMATION

OPTIONAL

H-4

Valve Series End Connection Size

Valve Type

- Female End

10

- Male End

80

10OPA

- - - --

Material

- St.St. 316

SS

- Brass

B

End Connection

- NPT

N

- ISO Tapered

R

NSS 1/4 3

1/4

1/2

Cracking Pressure

Designator Values (psi)

3 3-50

50 50-150

150 150-350

350 350-600

C* 3-600

Note: Check valves are designed and suitable for direct ow

control only. These valves are not meant for pressure release.

ORDERING INFORMATION SPARE KITS

SEAL KIT SPRING KIT

The kit includes O-Ring & label

Z - 400OPA - SK - 1/4 - VI

*Factory Calibration

Designator

3-600 Psi

Example: H-480OPA-SS-N-1/4-C100

Will be Calibrated to 100 Psi

The kit includes Spring & label.

Z - 400OPA - SPK - 1/4 - 3

--

Treatment

BLANK - Standard Cleaning &

OC - Oxygen Clean

LF - Lubricant Free

O-ring Material

BLANK

BU

EP

NE

KZ

Passivation

- Fluorocarbon FKM

Seals are standard

- Buna N

- EPDM

- Polychloroprene (CR)

- Peruor

VALVES & ACTUATORS

Body Designator

per End Connection

1/4

1/2

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance.

Application details, material compatibility and product ratings should all be considered for each selected

product. Improper selection, installation or use of products can cause property damage or personal injury.

Seal

Material

VI

- Fluorocarbon FKM

BU

- Buna N

NE

- Polychloroprene (CR)

KZ

- Peruor

EP

- EPDM

Body Designator

per End Connection

HAM-LET ADVANCED CONTROL TECHNOLOGY

1/4

1/2

Cracking Pressure

Designator Values (psi)

3 3-50

50 50-150

150 150-350

350 350-600

273

ADJUSTABLE CRACKING PRESSURE CHECK VALVE

H-400A SERIES

FEATURES

n

316 St.St. or Brass Construction

n

Variable Adjustable Cracking Pressure Ranges

n

Pressure Characteristics: up to 3000 psi

n

HAM-LET LET-LOK® Fittings, Male NPT,

and HTC® Face Seal Bead

MATERIALS OF CONSTRUCTION

Item

No.

10

Components Qty.

Gasket 1 316 St.St. Silver plated Al-6061 Silver plated

1

O-ring Holder

2

O-ring 1 Fluorocarbon FKM

3

Poppet

4

Body 1 St.St. ASTM A-276 Brass ASTM B-16

5

Spring

6

Adjusting Screw 1 St.St. 304

7

Lock Screw

8

Gasket 1 316 St.St. Silver plated Al-6061 Silver plated

9

End

1 St.St. ASTM A-276 Brass ASTM B-16

1 St.St. ASTM A-276

1 St.St. 302

1 St.St. 304

2 St.St. ASTM A-276 Brass ASTM B-16

316 St.St. Brass

GENERAL

The H-400A Series is a compact design for moderate-pressure (up to 3000 psi)

instrumentation panels and systems, which provides an accurate and adjustable

operating point. H-400A valves are normally closed. When the differential

pressure between the inlet and the outlet is higher than the set pressure of the

spring, the loaded poppet will move backwards and provide a free passage for

ow through the valve.

Valve Body Material

PRESSURE - TEMPERATURE RATING

FOR STANDARD CONFIGURATIONS

Material Size 316St.St. Brass

Temperature F° (C°) Working Pressure, psi (bar)

-10 (-23) to 100 (37) 3000 (206) 3000 (206)

200 (93) 2575 (177) 2600 (179)

250 (121) 2450 (168) 2405 (165)

300 (148) 2325 (160) 375 (190) 2185 (150) -

10

VALVES & ACTUATORS

9

8

7

6

5

4

3

2

1

Adjustment and Locking

Mechanism - facilitates

adjustment and locking at the

required cracking pressure by

spring loading

CHECK VALVES H400- SERIES

274

CLEANING & PACKAGING

Every H-400OA series Check valve is cleaned in accordance with

Standard Cleaning and Packaging (procedure 8184). Oxygen

Clean & Lubricant Free Cleaning and packaging, in accordance

with Special Cleaning and Packaging (procedure 8185), is

available as an option.

DIMENSIONS

Intlet Outlet

1

/4 Let-Lok

6MM Let-Lok

8MM Let-Lok

® 1

®

®

/4 Let-Lok

6MM Let-Lok

8MM Let-Lok

1/4 Male NPT 1/4 Let-Lok

®

®

®

®

A BC

mm in Hex Hex

82.5 3.25 9/16 5/8

82.5 3.25 14MM 5/8

84.4 3.32 16MM 5/8

79.3 3.12 9/16 5/8

1/4 Male Face Seal 1/4 Male Face Seal 78.4 3.09 - 5/8

1/4 Male NPT 1/4 Male NPT 75.7 2.98 - 5/8

Dimensions are for reference only and are subject to change.

TECHNICAL DATA

Connection

Size

Max. Flow

Coefcient

(Cv)

Nominal Cracking

Pressure

psi (bar)

Back Pressure

at 70°F (20°C)

psi (bar)

3 to 50 (0.2 to 3.4)

1/4, 6mm, 8mm 0.37

50 to 150 (3.4 to 10.3)

150 to 350 (10.3 to 24.1)

3000 (413)

350 to 600 (24.1 to 41.3)

CRACKING AND RESEAL PRESSURE

Cracking Pressure (Bar)

0 4 8 12 16 20 24 28 32 36 40

650

600

550

500

450

400

350

300

250

200

150

100

Reseal Pressure (psi)

50

0

-50

0 50 100 150 200 250 300 350 400 450 500 550 600

Cracking Pressure (psi)

A

(HEX)

C

B

(HEX)

O-RINGS

Different materials are available for special applications.

O-ring Material

Temperature Rating

°F (°C)

Buna N -10 to 250 (-23 to 121)

EPDM -50 to 300 (-45 to 148)

Fluorocarbon FKM -10 to 375 (-23 to 190)

Peruor -15 to 500 (-26 to 260)

Polychloroprene (CR) -40 to 250 (-40 to 121)

40

36

32

28

24

20

16

12

8

Reseal Pressure (Bar)

4

0

VALVES & ACTUATORS

HAM-LET ADVANCED CONTROL TECHNOLOGY

275

ADJUSTABLE CRACKING PRESSURE CHECK VALVE

TESTING

The H-400A valve designs have been tested for Proof and Burst.

Every H-400A valve is factory tested for proper assembly by leak

detection at 1000 psig (68 bar) for 10 seconds.

Every H-400A valve is factory tested for functionality at the relevant

cracking pressure, 5 cycles each.

H-400A SERIES ORDERING INFORMATION

H-400A SERIES

OPTIONAL

VALVES & ACTUATORS

H-4

Valve Series End Connection Size

Valve Type

- LET-LOK® End

00A

- Male End

80A

For other valve types please

consult HAM-LET.

Note: Check valves are designed and suitable for direct ow

control only. These valves are not meant for pressure release.

00A

ORDERING INFORMATION SPARE KITS

SEAL KIT

The kit includes O-ring & Label .

Z - 400A - SK - 1/4 - VI

-

Material

- St.St.316

SS

- Brass

B

End Connection

- LET-LOK® Tube Fitting

L

- NPT

N

- ISO Tapered

R

- Face Seal Male Connector

GL

- ONE-LOK

HL

Other end connections are

available upon request.

®

- - -

LSS 1/4 50

1/4

6 MM

8 MM

Cracking Pressure

Designator Values (psi)

3 3-50

50 50-150

150 150-350

350 350-600

C* 3-600

*Factory Calibration

Designator

3-600 Psi

Example: H-400A-SS-L-1/4-C60

Will be Calibrated to 60 Psi

SPRING KIT

The kit includes Spring & Label.

Z - 400A - SPK - 1/4 - 3

-

Treatment

BLANK - Standard Cleaning &

OC - Oxygen Clean

LF - Lubricant Free

O-ring Material

BLANK

BU

EP

NE

KZ

--

Passivation

- Fluorocarbon FKM

Seals are standard

- Buna N

- EPDM

- Polychloroprene (CR)

- Peruor

Body Designator

per End Connection

For all dimensions

1/4

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance.

Application details, material compatibility and product ratings should all be considered for each selected

product. Improper selection, installation or use of products can cause property damage or personal injury.

Seal Material

- Fluorocarbon FKM

VI

- EPDM

EP

- Polychloroprene (CR)

NE

- Peruor

KZ

- Buna N

BU

Body Designator

per End Connection

For all dimensions

1/4

HAM-LET Check Valves should never be used as safety relief devices.

CHECK VALVES H400- SERIES

276

Cracking Pressure

Designator Values (psi)

3 3-50

50 50-150

150 150-350

350 350-600

H-400,

Rev 08, January 2014

Loading...

Loading...