TOGGLE VALVES

H-1200 SERIES

VALVES & ACTUATORS

FEATURES

n

Compact rugged design

n

Stainless Steel and Brass Construction

n

Panel mountable

n

Quick On/Off service

n

Straight and angle patterns available

n

Sizes: 1/8" & 1/4"

n

LET-LOK

n

MAWP 300 psig (20 Bar) at 20°C (70°F)

n

Temperature rating: -20°F to 200°F (-28°C to 93°C)

n

Flow coefcient (Cv) 0.11 to 0.2

n

Colored Nylon Handles

MATERIALS OF CONSTRUCTION

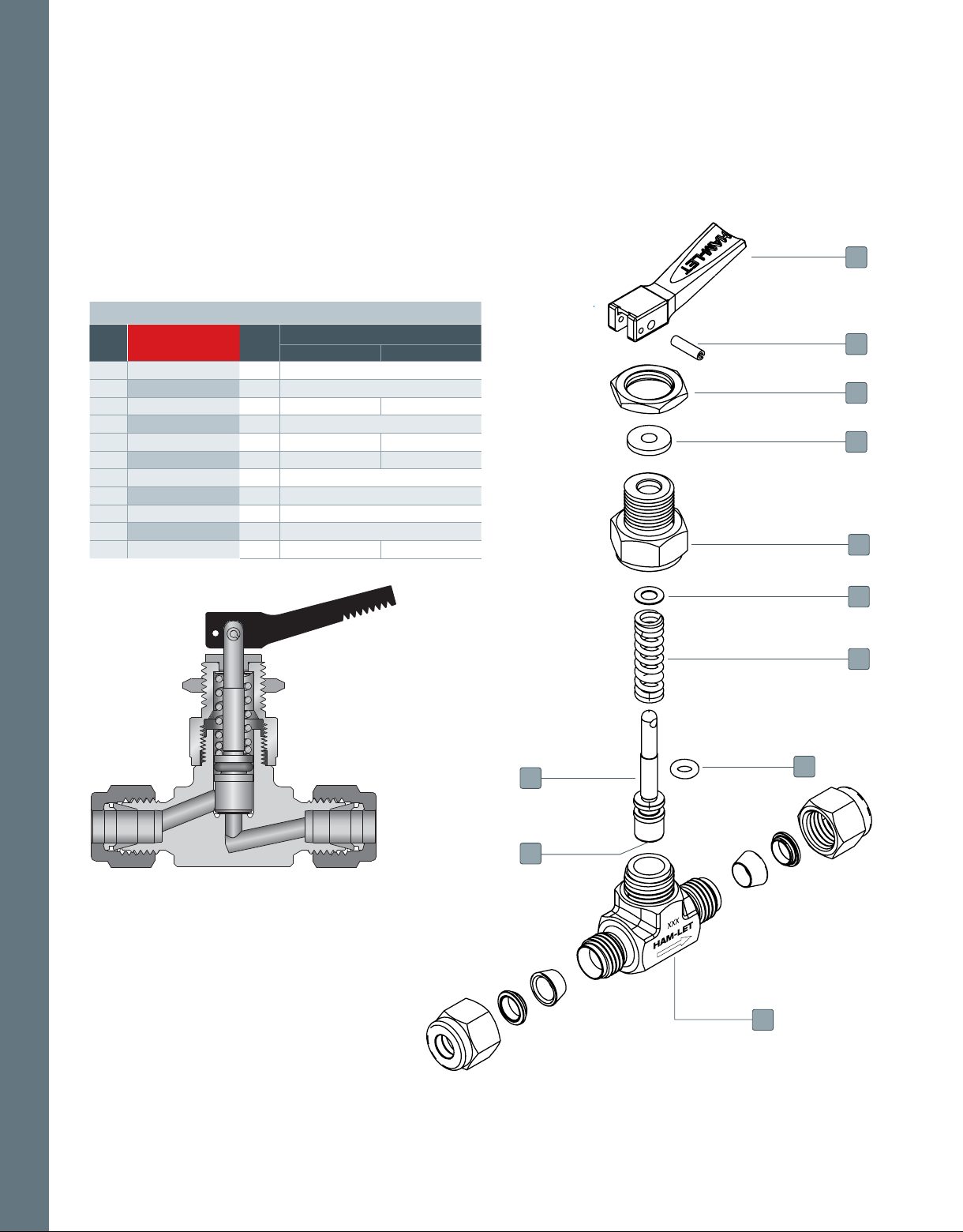

Item Components Qty.

1 Handle 1 Nylon

2

3 Panel Nut 1

4

5 Packing Nut 1

6

7 Spring 1 302SS / A313

8

9 Stem 1 St.St. ASTM A-276

10

11 Body 1

, male and female NPT ends

Roll Pin

Washer

Thrust Washer

O-ring

Stem Seat

316 St.St. Brass

1 St.St. 420 SS

St.St. ASTM A-276

1 Nylon

St.St. ASTM A-276

1 N/A Nylon

1 Fluorocarbon FKM

1 PTFE

St.St. ASTM A-182

GENERAL

The H-1200 Series standard toggle valve is a compact design for normally closed

and quick on/off service. Moving the handle 90 degrees upwards opens the valve

to full flow and stops it firmly in the open position. Shifting the handle position

downwards shuts off the valve by spring return. The PTFE soft seat at the tip of

the stem provides a positive repetitive seal.

Valve Body Material

Brass ASTM B-16

Brass ASTM B-16

Brass ASTM B-283

1

2

3

4

5

VALVES & ACTUATORS

9

10

6

7

8

11

TOGGLE VALVES H-1200 SERIES

242

TESTING

All H-1200 Series designs have been tested and approved for Burst

and Proof. All valves are factory tested with Nitrogen pressure at 300

psig (20.7 bar) for shell, stem and across-the-seat leak detection.

Each valve is tested for leak tight performance.

CLEANING & PACKAGING

Every H-1200 series needle valve is cleaned in accordance with Standard Cleaning and Packaging (procedure 8184). Oxygen Clean & Lubricant Free Cleaning and packaging, in accordance with Special

Cleaning and Packaging (procedure 8185), is available as an option.

STANDARD CONFIGURATION DIMENSIONS

End connection

Type Size

Female NPT

Male NPT

Male NPT

®

Let-Lok

®

Let-Lok

1/8

1/8

1/4

1/8

1/4

Male to Let-Lok®1/4

Dimensions are for reference only, and are subject to change without notice.

H-1200 SERIES ORDERING INFORMATION

Orice A B B1 C D E G H (Open)

Cv

mm in mm in mm in mm in mm in mm in mm in mm in mm in

0.20 3.28 0.13 41.2 1.66 20.6 0.81 20.6 0.81 N/A N/A

0.11 2.50 0.10 43.7 1.72 21.8 0.86 21.9 0.86 29.7 1.17

0.20 3.28 0.13 49.8 1.96 24.9 0.98 24.9 0.98 32.8 1.29

0.11 2.30 0.09 49.8 1.96 24.9 0.98 24.9 0.98 32.8 1.29

0.20 3.28 0.13 57.4 2.26 28.7 1.13 28.7 1.13 36.5 1.44

0.20 3.28 0.13 53.6 2.11 24.9 0.98 28.7 1.13 32.8 1.29

21.8 0.85 7.95 0.31 13.5 0.53 65.5 2.57

OPTIONAL

H - 12 1/8 A

Valve

Series

Valve Type

-

LET-LOK® Ends

00

80

- Male NPT Ends

95

- Male to LET-LOK® Ends

SEAL KIT

Z - 1200

Body Designator

per End Connection

1/4 for all ends connections

-

SK

- - - - -

Body

Material

- 316 SS

SS

- Brass

B

End

Connection

- LET-LOK

L

- NPT

N

-

O-ring

Material

VI

BU

EP

NE

KZ

-

1/4

- Fluorocarbon FKM

- Buna N

- EPDM

- Polychloroprene (CR)

- Peruor

NSS00

Size

Designator

3 mm 1/8

6 mm 1/4

Pattern

Designator

®

BLANK -

A

- Angle

Straight

VI

-

Handle Type

Black Nylon Handle

BLANK

Red Nylon Handle

RH

Blue Nylon Handle

BH

Yellow Nylon Handle

YH

Green Nylon Handle

GH

Orange Nylon Handle

OH

HANDLE KIT

Z - 1200

Body Designator

per End Connection

1/4 for all ends connections

O-ring

Material

- Buna N

BU

- EPDM

EP

NE

- Polychloroprene (CR)

- Peruor

KZ

Fluorocarbon FKM O-ring is standard

Treatment

BLANK - Standard Cleaning &

OC - Oxygen Clean

LF - Lubricant Free

-

HK

-

1/4

Handle Type

S Black Nylon Handle

R Red Nylon Handle

B Blue Nylon Handle

Y Yellow Nylon Handle

G Green Nylon Handle

O Orange Nylon Handle

Passivation

-

S

-

VALVES & ACTUATORS

Warning!

The system designer and user have the sole responsibility for selecting products suitable for their special

application requirements, ensuring their safe and trouble-free installation, operation, and maintenance.

Application details, material compatibility and product ratings should all be considered for each selected

product. Improper selection, installation or use of products can cause property damage or personal injury.

HAM-LET ADVANCED CONTROL TECHNOLOGY

H-1200, Rev.10, January 2015

243

Loading...

Loading...