ASSEMBLY INSTRUCTIONS

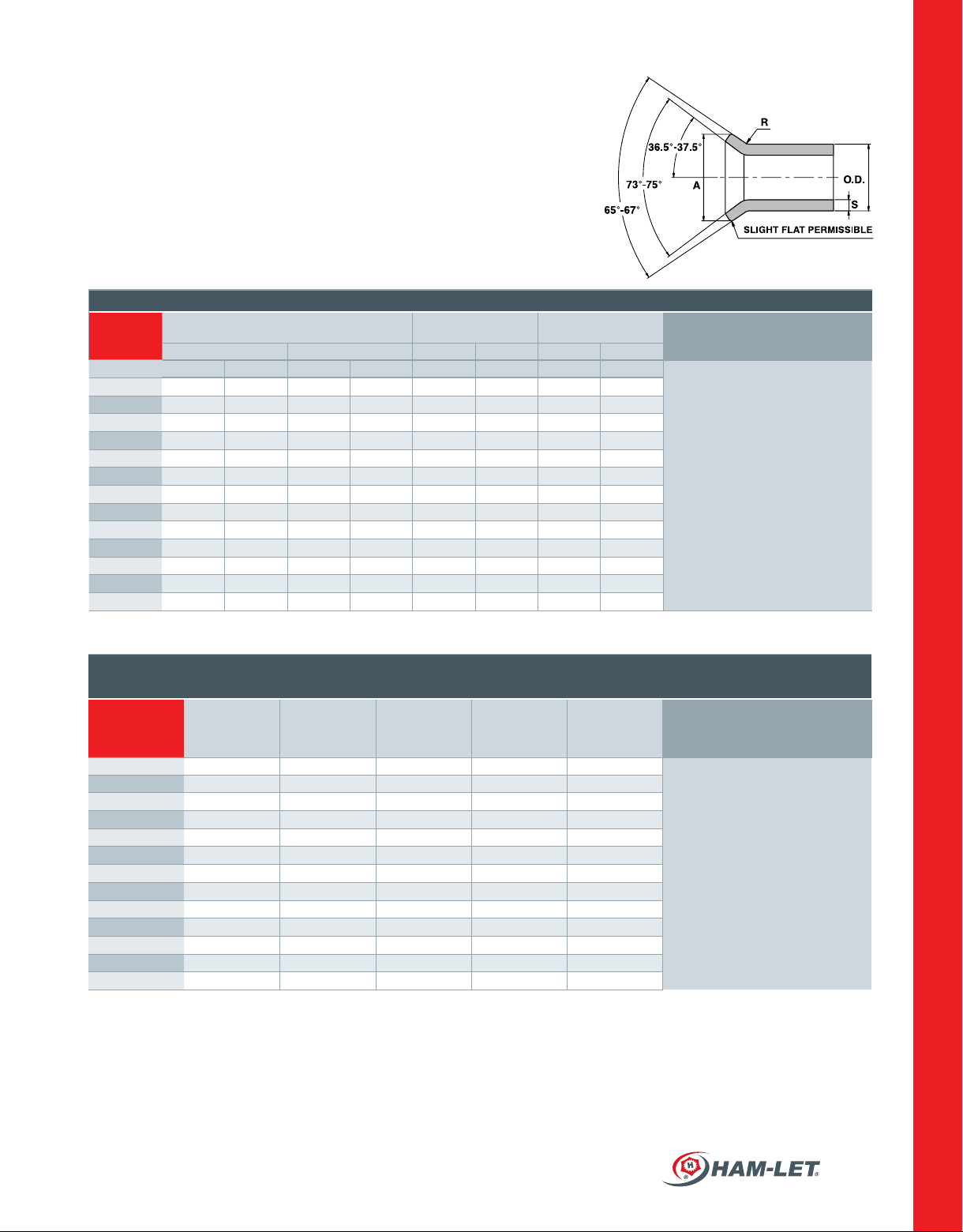

Perform aring according to SAE J533. See Fig. 2.

See Table 1 below for dimensions.

TABLE 1: FLARING

Nominal

Tube O.D

inch mm inch mm inch mm

Max Min Max Min ±0.02 ±0.5 Max Min

1/8

3/16

1/4

5/16

3/8

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

1 1/2

Dimensions are for reference only, and subject to change without notice.

0.20 0.18 5.08 4.58 0.03 0.8 0.035 0.88

0.28 0.26 7.11 6.61 0.03 0.8 0.035 0.88

0.36 0.34 9.14 8.64 0.03 0.8 0.065 1.65

0.43 0.40 10.92 10.16 0.03 0.8 0.065 1.65

0.49 0.46 12.44 11.69 0.04 1.0 0.065 1.65

0.66 0.63 16.76 16.01 0.06 1.5 0.083 2.1

0.79 0.76 20.06 19.31 0.06 1.5 0.095 2.41

0.95 0.92 24.13 23.37 0.08 2.0 0.109 2.76

1.07 1.04 27.17 26.42 0.08 2.0 0.109 2.76

1.20 1.17 30.48 29.72 0.09 2.3 0.12 3.04

1.38 1.35 35.05 34.29 0.09 2.3 0.12 3.04

1.51 1.48 38.35 37.60 0.09 2.3 0.12 3.04

1.73 1.70 43.94 43.18 0.11 2.8 0.12 3.04

A

Single Flare Diameter

R S

Figure 2

DEBURRING PRIOR

TO FLARING

CONNECTORS

To en su re sati sf act or y a re pro duc ti o n,

tu be end de bu r ri ng mi gh t be requ ir ed

prior to aring. It is usually necessary

to break the inside corner smoothly

before single aring. In addition,

some non-ferrous tubing is normally

required to eliminate the cutoff burr,

wh ich mig ht oth erw i se cre ate lea ka g e

pa ths acr oss a sub s ta nti al po rti on of

the are. Smoothly breaking the outside

corner prior to single aring, or both

the outside and inside corners prior

to dou bl e a r in g, is ac cep ta b le for any

tube material to minimize splitting.

TABLE 2: ALLOWABLE WORKING PRESSURE RATINGS

(CAPABLE OF 4’’ TO 1’’ MIN. BURST)

Nom. SAE

Dash Size

Nom. Tube O.D

Inches

37° Flare

Straight Thread

Nom. Pipe

Size

SAE St.Threads

Union and

Bulkhead

2 1/8 5/16" - 24 1/8" 5000 5000

3 3/16 3/8" - 24 1/8" 5000 5000

4 1/4 7/16" - 20 1/8" 5000 5000

5 5/16 1/2" - 20 1/8" 5000 5000

6 3/8 9/16" - 18 1/4" 5000 5000

8 1/2 3/4" - 16 3/8" 4500 4000

10 5/8 7/8" - 14 1/2" 3500 3000

12 3/4 1

14 7/8 1

16 1 1

20 1

24 1

32 2 2

1/4 1 5/8" - 12 1 1/4" 2500 1150

1/2 1 7/8" - 12 1 1/2" 2000 1000

1/16" - 12 3/4" 3500 3000

3/16" - 12 3/4" 3000 2500

5/16" - 12 1" 3000 2000

1/2" - 12 2" 1500 1000

Fittings with

Pipe Threads

NOTE:

As man y fa ct ors in uen ce the pre s su re

at which a system will or will not

perform satisfactorily, values shown

in Table 2 should not be construed

as guaranteed minimum.

HAM-LET ADVANCED CONTROL TECHNOLOGY

125

Loading...

Loading...