Hamilton Sundstrand Company ACT2000 User Manual

User Manual

ACT2000 All-Electric Actuator

SD-6008 Rev. 6

October 2008

PRECISION ENGINE CONTROLS CORPORATION

This manual provides installation, maintenance, and operating instructions for the ACT2000

All-Electric Actuator.

Every attempt has been made to provide sufficient information in this manual for the

proper operation and preventive maintenance of the actuator. Read this manual in its

entirety to fully understand the system.

Operating the ACT2000 All-Electric Actuator in accordance with instructions herein ensures

long term and reliable operation.

If you need additional information, please contact:

Precision Engine Controls Corporation

11661 Sorrento Valley Road

San Diego, California 92121

(858) 792-3217 • (800) 200-4404

Fax: (858) 792-3200

E-mail: peccntl@precisioneng.com

© 2006 PRECISION ENGINE CONTROLS CORPORATION. ALL RIGHTS RESERVED

TABLE OF CONTENTS

Purpose of This Guide ................................................................................................................................... iii

Product Identification...................................................................................................................................... iii

What the User Should Know ......................................................................................................................... iv

Related Publications....................................................................................................................................... iv

1 INSTALLING THE ACT2000 ..................................................................................................................... 1

1.1 Before Beginning..................................................................................................................................... 1

1.2 General Specification Summary............................................................................................................. 3

1.3 Mechanical Installation............................................................................................................................ 4

1.4 Electrical Connections............................................................................................................................. 11

2 UNDERSTANDING THE ACT2000 .......................................................................................................... 21

2.1 System Description ................................................................................................................................. 21

2.2 Electrical Description............................................................................................................................... 21

2.3 Mechanical Description........................................................................................................................... 25

2.4 Identification Plate ................................................................................................................................... 30

3 OPERATING THE ACT2000 ..................................................................................................................... 33

3.1 Powering Up ............................................................................................................................................ 33

3.2 Finding Home Position............................................................................................................................ 33

3.3 Holding Motor Current State................................................................................................................... 34

3.4 Moving to Stop Position .......................................................................................................................... 34

3.5 Controlling Motion ................................................................................................................................... 36

3.6 Resetting the Actuator............................................................................................................................. 39

3.7 Monitoring System Health....................................................................................................................... 39

3.8 Changing Set-Up Parameters ................................................................................................................ 44

4 MAINTAINING THE ACT2000................................................................................................................... 47

4.1 Refurbishment ......................................................................................................................................... 47

5 TROUBLESHOOTING............................................................................................................................... 49

5.1 FAULT File............................................................................................................................................... 52

APPENDIX A: DECOMMISSIONING & DISPOSAL ...................................................................................... 55

APPENDIX B: GLOSSARY ............................................................................................................................. 57

PREFACE i

LIST OF FIGURES

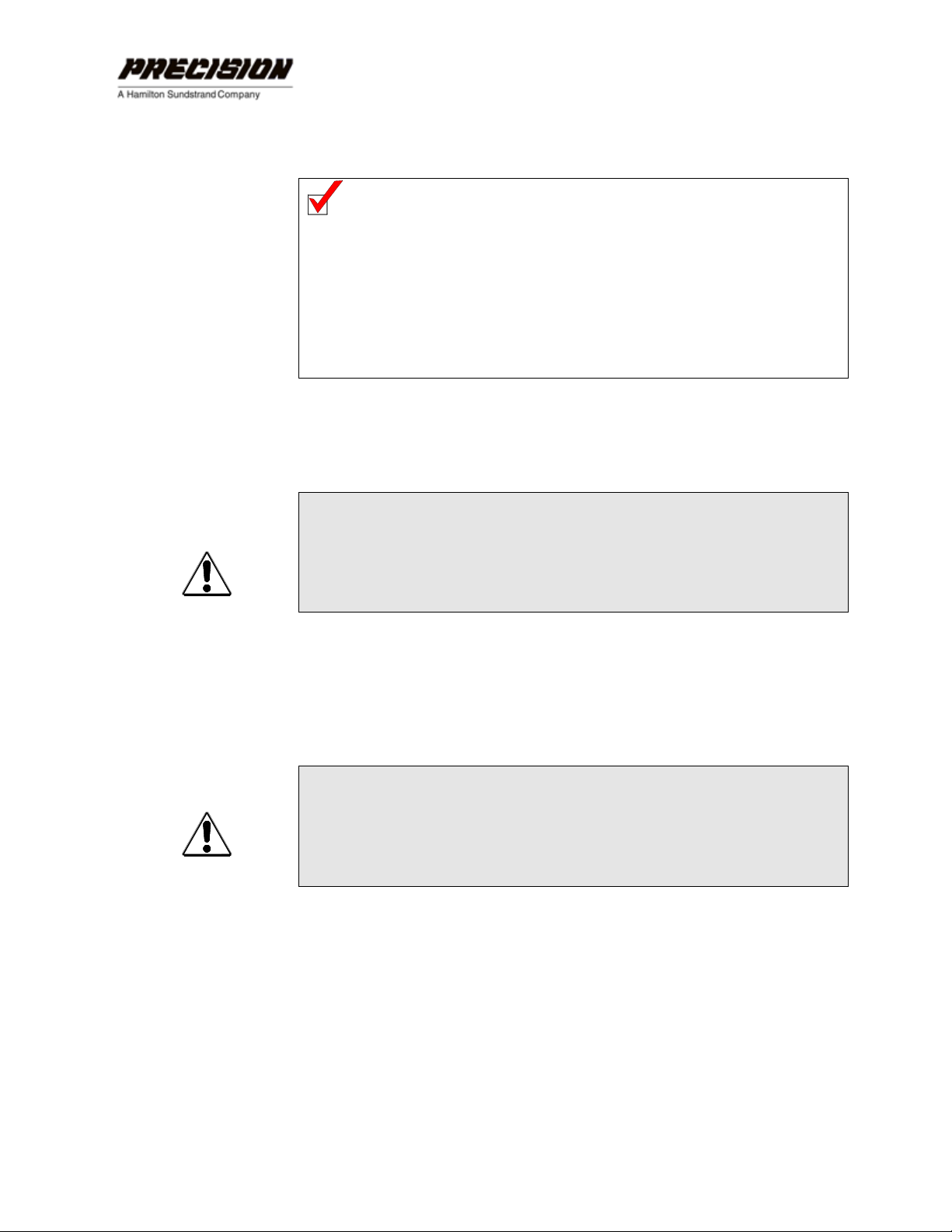

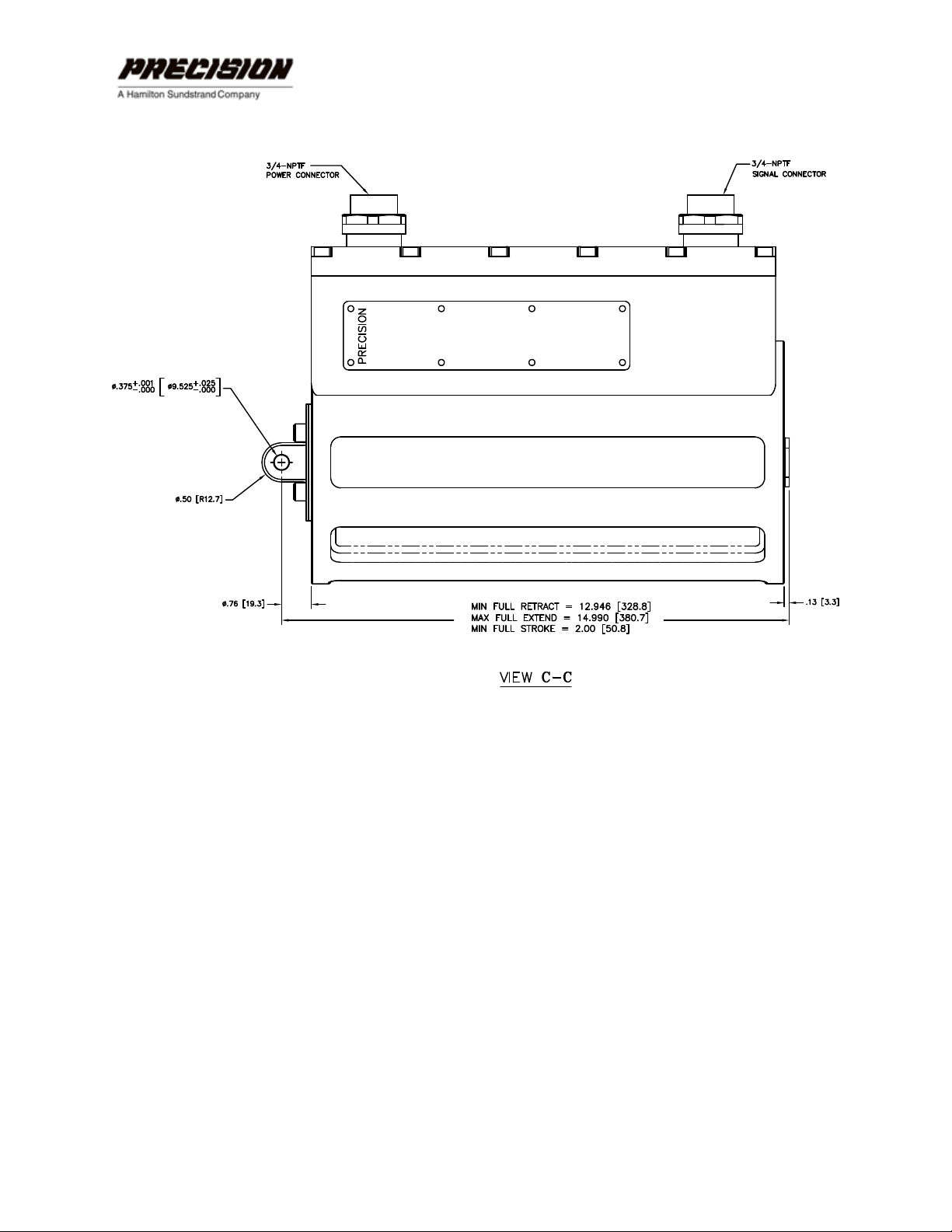

Figure 1-1. ACT2000-590P Dimensions .............................................................................7

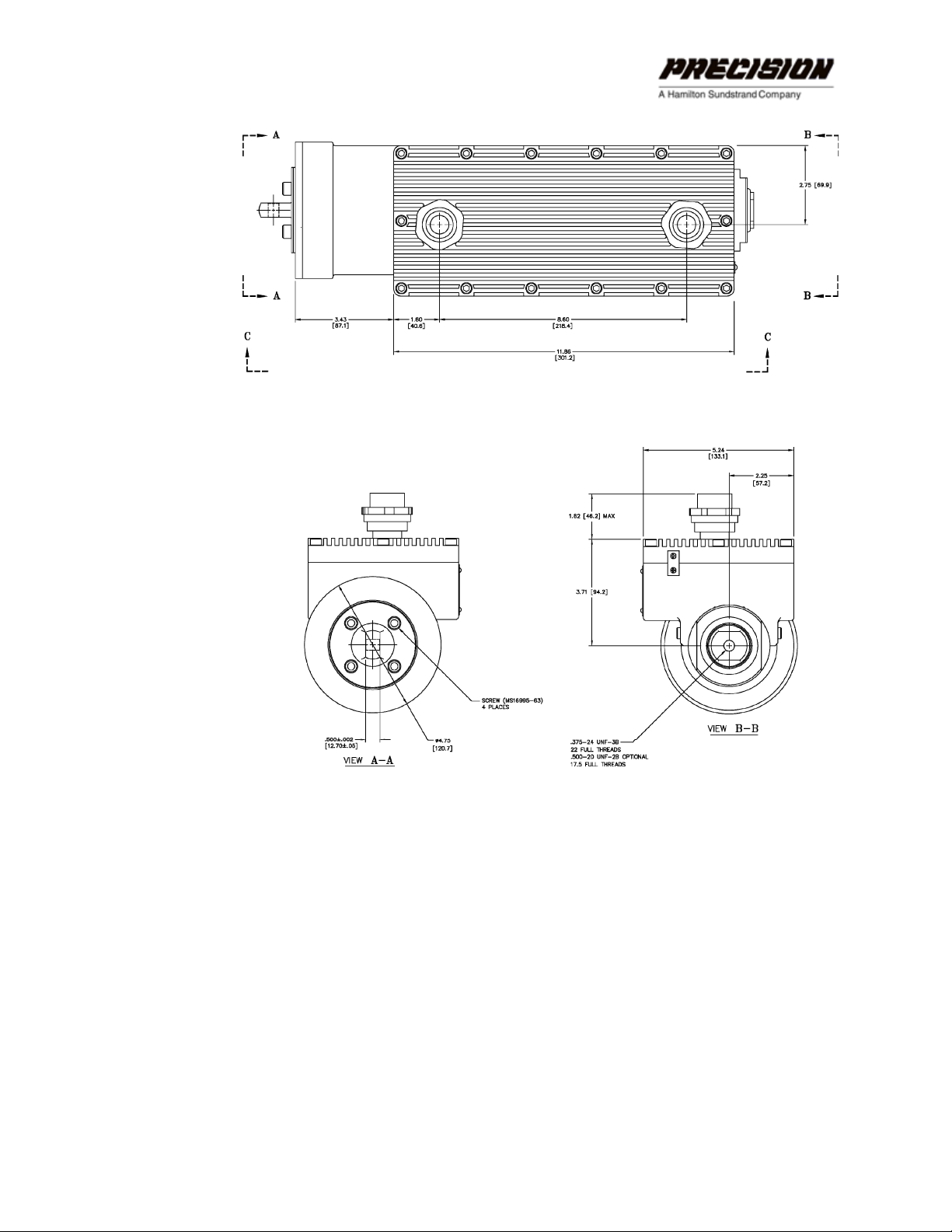

Figure 1-2. ACT2000-200F Dimensions ............................................................................. 8

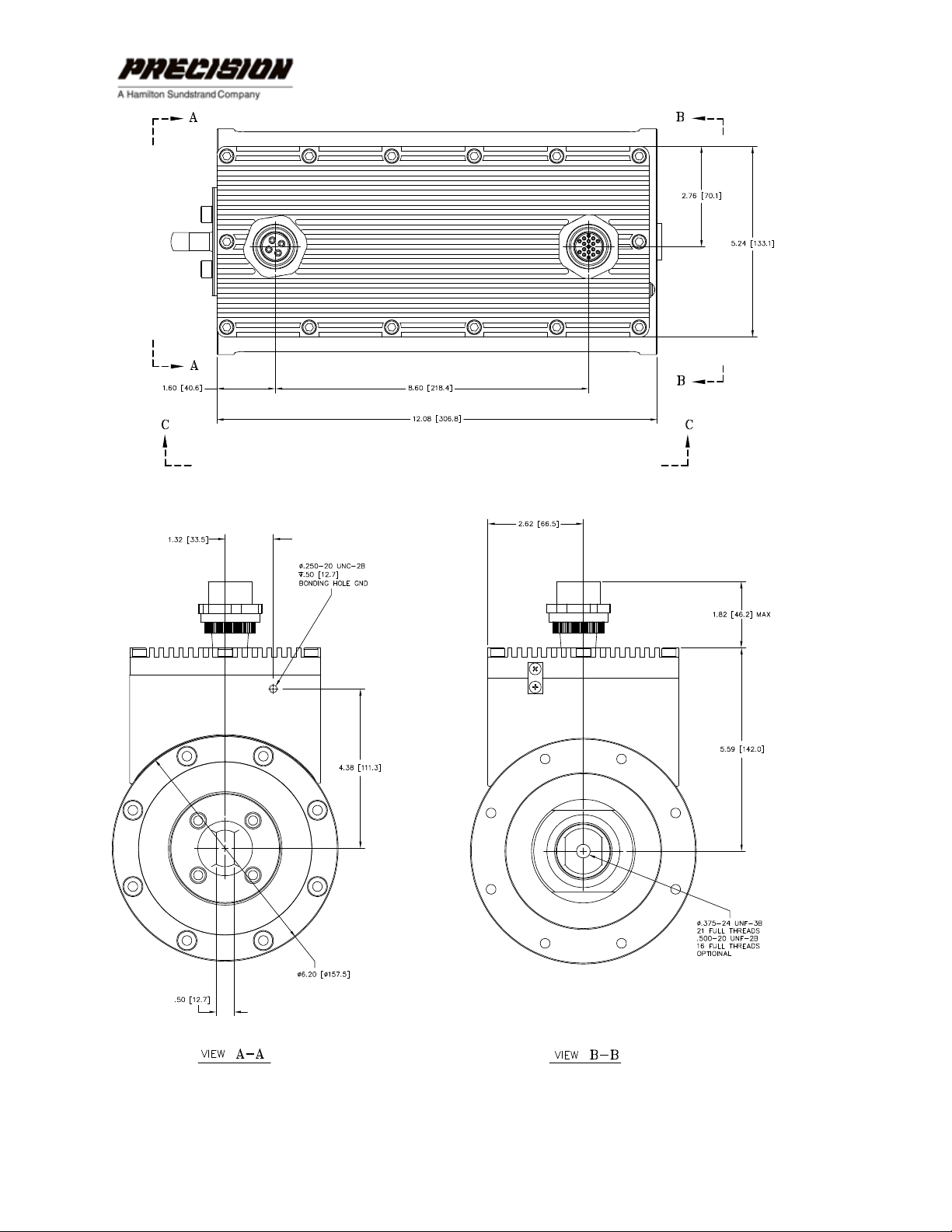

Figure 1-3. ACT2000-590P Pin-Mounting Provisions ........................................................ 9

Figure 1-4. ACT2000-200F Flange-Mounting Provisions.................................................10

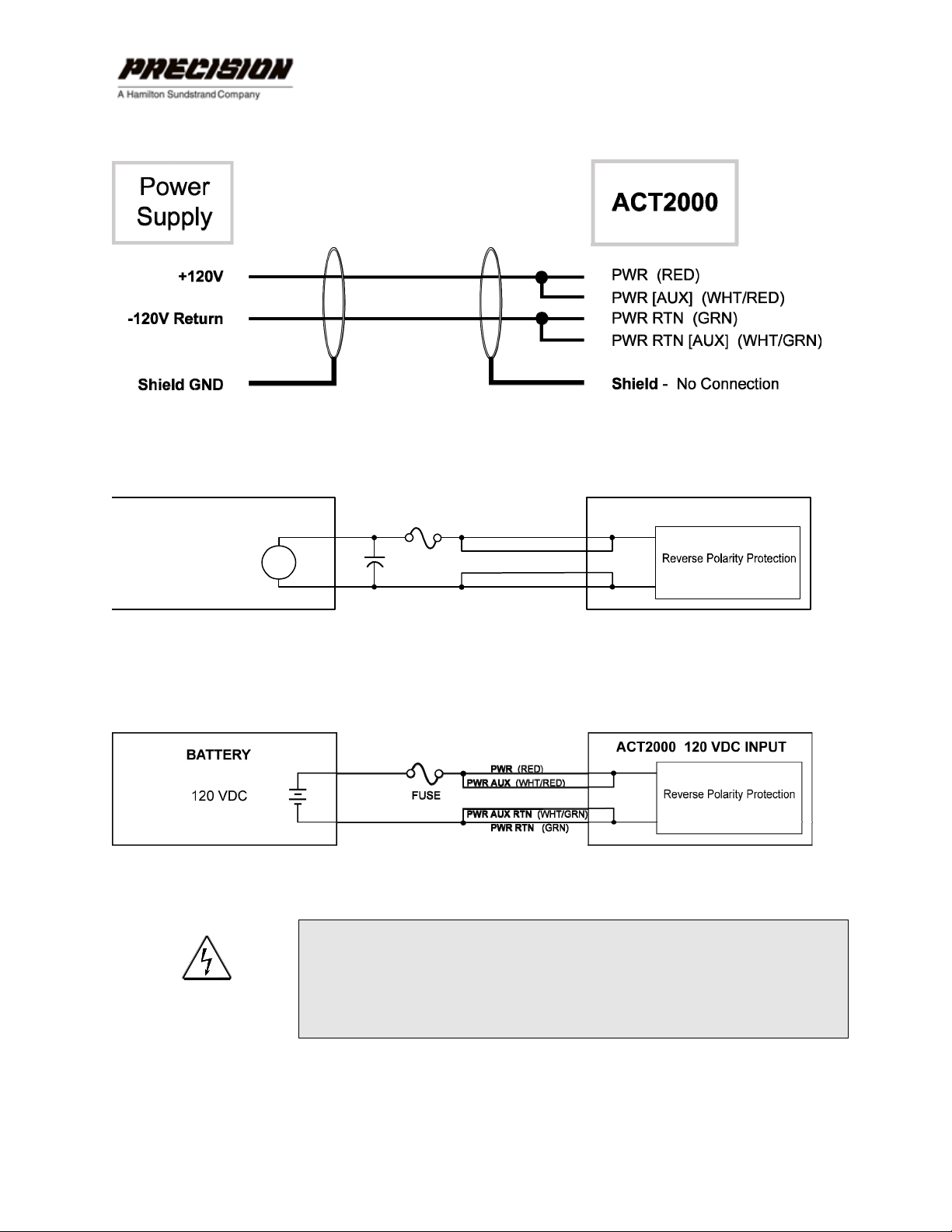

Figure 1-5: ACT2000 System Power Wiring Diagram......................................................12

Figure 1-6. Typical Power Connection With Power Supply..............................................12

Figure 1-7. Typical Power Connection With Battery.........................................................12

Figure 1-8: ACT2000 System Signal Wiring Diagram ...................................................... 16

Figure 1-9. Typical Analog Input Connection....................................................................17

Figure 1-10. Typical Analog Output Connection ...............................................................17

Figure 1-11. Typical Discrete Input Command Connection .............................................17

Figure 1-12. Typical Discrete Output Alarm Connection ..................................................18

Figure 1-13. Typical RS232 Serial Interface Connection .................................................18

Figure 2-1. ACT2000 Electronics System Block Diagram................................................23

Figure 2-2. ACT2000-590P Cut-Away View .....................................................................28

Figure 2-3 ACT2000-200F Cut-Away View...................................................................... 29

Figure 2-4. Typical Identification Plate............................................................................... 30

Figure 2-5. Typical Refurbishment Plate ........................................................................... 31

Figure 3-1. ACT2000 Basic Operation Flow Chart...........................................................35

Figure 3-2. Actuator Position vs. DEMAND, Home as Mech. Stop in Actuator ..............37

Figure 3-3. Dead Band of Actuator, Position vs. DEMAND Curve ..................................38

Figure 3-4. Actuator Position vs. DEMAND, Home as Mech. Stop in User’s System ... 38

LIST OF TABLES

Table 1-1. Wire List for ACT2000 Power Harness............................................................11

Table 1-2. Power Supply Requirements............................................................................13

Table 1-3. Wire Size for ACT2000 Power Harness.......................................................... 14

Table 1-4. Wire List for ACT2000 System Signal Harness ..............................................15

Table 1-5. Computer COM Port Pin Outs .........................................................................18

Table 1-6. Wire Size for ACT2000 Signal Harness ..........................................................20

Table 3-1. Default Configuration For FAULT Alarm ..................................................41

Table 3-2. Default Configuration For OVERTEMP Alarm .........................................41

Table 3-3. Fault Configuration For FAULT Alarm ...........................................42

Table 3-4. Fault Configuration For OVERTEMP Alarm ..................................43

Table 3-5. Typical ACT2000 Setup Parameters With Default Values............................. 45

Table 5-1. Initial Installation Troubleshooting Chart.......................................................... 50

Table 5-2. ACT2000 In-Service Troubleshooting Chart ...................................................51

Table 5-3. ACT2000 Electrical Continuity Troubleshooting Chart ...................................51

ii ACT2000 USER GUIDE

Purpose of This Guide

This publication is designed to help the user install, operate, maintain and

troubleshoot the ACT2000 All-Electric Actuator.

Product Identification

Most of the information in this manual is applicable to all generations of

the product. Where unique information applies to a specific generation,

one of the following symbols will be shown to indicate as such:

Fourth generation (isolated RS-232)

Actuator P/Ns: 50026XX-XXX or:

Any Remanufactured Part with Config 116 and above

Configuration: 116 and above

Firmware version: 3.00 and above

Third generation (isolated RS-232)

Actuator P/Ns: 50026XX-XXX or:

Any Remanufactured Part with Config 109 and DP 1028

Any Remanufactured Part with Config 110 and above

Configuration: 110 and above

Firmware version: 2.02 and above

Second generation (non-isolated RS-232)

Actuator P/Ns: 50026XX-XXX

Configuration: Between 105 and 108

Firmware versions: 2.0, 2.1

First generation (non-isolated RS-232)

Actuator P/Ns: 50023XX-XXX

Configuration: earlier than 105

Firmware versions: 1.00, 1.01

PREFACE iii

What the User Should Know

To install, operate, and troubleshoot the ACT2000, it is necessary for the

user to have a fundamental understanding of:

• Electronics concepts, such as voltage, current, and switches

• Mechanical motion control concepts, such as inertia, torque,

velocity, distance, force

Related Publications

• ActWiz Software Operations Manual (p/n SD-6010)

iv ACT2000 USER GUIDE

1 INSTALLING THE ACT2000

1.1 Before Beginning

Inspection

The ACT2000 should be inspected immediately after unpacking. Check

for dings or dents or any other obvious signs of damage. Remove the

protective caps from the connectors and check for any bent pins or

damage to the threads of the connectors. Examine the wires of the signal

and power harnesses for any signs of damage to the wire insulation.

In the event that any damage is detected, contact PECC for instructions

about how to proceed.

Note: Retain the actuator’s original shipping container. In the

event of future transportation requirements, this container

will minimize any damage during shipment.

Recommended Installation Process

Users must determine if it is best to couple the ACT2000 to the load

before or after the installation has been tested.

• Review the general specifications

• Mechanically connect the clevis of the ACT2000

• Mechanically connect the flange (ACT-2000-200F only)

• Mechanically connect the extension rod of the ACT2000

• Connect Case Ground of the ACT2000 to System Ground

• Connect the 4-wire Power Harness of the ACT2000 to the user’s

power supply or battery

• Connect the 17-wire Signal Harness of the ACT2000 to the user’s

controller

• Test the installation

INSTALLING THE ACT2000 1

Electrical Noise Guidelines

PECC has taken the following measures to reduce electrical noise with

the ACT2000:

• High-voltage wires are routed separately from low-level signals

through the use of separate power and signal harnesses.

An additional measure to reduce electrical noise is to:

• Ensure that the ACT2000 is properly grounded, as per

Section 1.4 of this manual.

Environmental Considerations

The ACT2000 operates satisfactorily with ambient air temperature of

-40 °C (-40 °F) to +93 °C (+200 °F), and is designed as an explosion-

proof assembly. The ACT2000 enclosure is Canadian Standards

Association (CSA) Type 3, European IP65.

CAUTION

Solvent/water may enter the electronics area during a high-pressure

wash, which can cause decreased performance or failure of the unit.

2 ACT2000 USER GUIDE

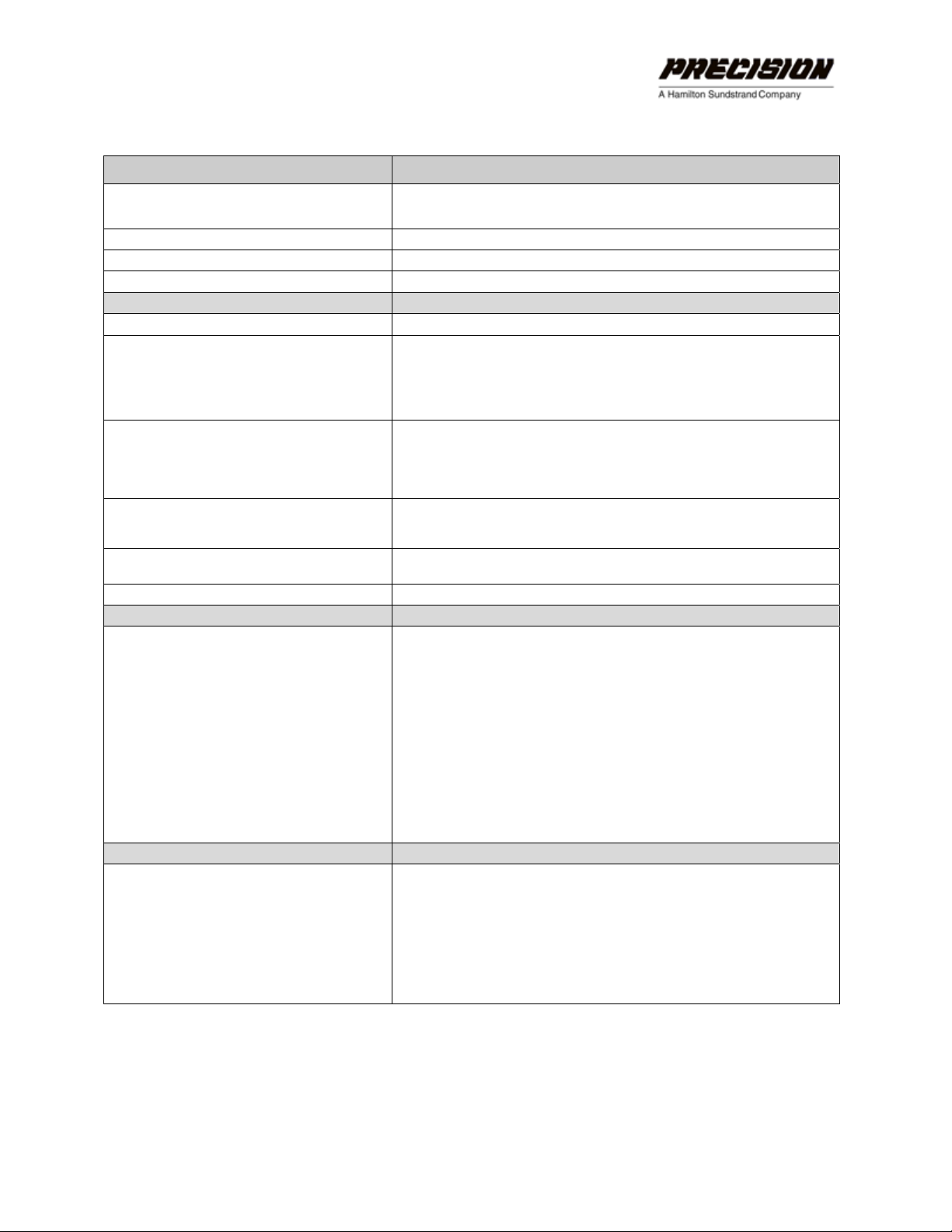

1.2 General Specification Summary

PARAMETER VALUE

Power Input

Voltage Range 80-160 VDC; 120 VDC nominal

Maximum Current 20 A

Typical Transient Current +20A < 60ms; +10A < 600ms; -5A < 100ms

Typical Continuous Current < 1A

Inputs and Outputs

Discrete Inputs

RUN and RESET commands

Discrete Outputs

FAULT & OVERTEMP alarms

Analog Input

DEMAND command signal

Analog Outputs

POSITION & MTR CURRENT feedback

Maximum Common Mode Voltage ±200 VDC User I/O to 120 VDC Return (less serial interface)

Performance All performance values are based on use with ACT2000 in default

Maximum Velocity 10 in/sec

Maximum Continuous Force 500 lbf (100% Duty Cycle)

Maximum Peak Force 1000 lbf (100% Duty Cycle)

Maximum Stroke 5.9 in (ACT2000-590P, configuration dependent)

Accuracy

Mean Time Before Unscheduled Removal 30,000 Hours

Life Cycles 32,000 Minimum

ON Voltage:

12 – 32 VDC,

+24 VDC nominal @ 6.5 mA

OFF Voltage:

OFF Voltage:

Effective ON Resistance

@ ≥ 1.5 VDC:

Current: 4 to 20 mA; 25 mA Maximum

Voltage: 5 VDC Maximum

Internal Impedance: 200 Ώ

Current: 4 to 20 mA

External Load Resistance: 300 Ώ, Maximum

configuration. Any changes to ACT2000 firmware settings to change stroke

profile will alter performance values.

2.0 in (ACT2000-200F, configuration dependent)

± 1% Full Stroke

1.0 VDC, maximum

32 VDC maximum @ 150 µA typical

1.1 kΏ, nominal

Environmental

Temperature, Operating Ambient:

Temperature, Storage

-40° C (-40° F) to +93° C (+200° F)

-40° C (-40° F) to +125° C (+257° F)

Environmental Rating Rated to CSA Type 3 and European IP65

Sealed against dust, protected against water

EMC Meets EN 50081-2 and EN50082-2 for DC powered industrial equipment

Vibration Meets Mil-Std-810E, Category 4 (5 – 2000 Hz)

INSTALLING THE ACT2000 3

Certifications

North American Certifications CSA Class I, Div 1, Group B, C, D; T4

European Directive Compliance (CE Mark)

EEx d, IIB+H

94/9/EC Potentially Explosive Atmospheres (ATEX) 08 ATEX 6108 X

(replaces 02ATEX6050X)

98/37/EC Machinery Directive

89/336/EEC Electromagnetic Compatibility Directive (EMC)

Materials

Housing 6061-T6 Anodized Aluminum

Conduit Union Zinc Plated Steel

Extension Rod 17-4 PH CRES

Clevis 17-4 PH CRES

Seals Nitrile, RTV and Teflon

Rod End Bearings Aluminum Bronze

Connectors Aluminum

Dimensions 5.2 in x 6.5 in x 16.7 in (ACT2000-590P)

6.0 in x 10.0 in x 12.9 in (ACT2000-200F)

Weight 35 lbs (ACT2000-590P)

50 lbs (ACT2000-200F)

; T4

2

1.3 Mechanical Installation

This section describes proper ACT2000 installation. Ensure compliance

with the factory recommendations.

Dimensions

The ACT2000 can be mounted with any directional orientation, whether

horizontal, vertical, or at an angle. Figures 1-1 and 1-3 show external

dimensions and mounting provisions for the pin-mount version of the

ACT2000. Figures 1-2 and 1-4 show external dimensions and mounting

provisions for the flange-mount version. Ensure that additional swing

clearance is factored into mounting calculations, as required.

Lifting Hazard – Do not attempt to hand-lift the actuator. Use

appropriate lifting equipment.

WARNING

4 ACT2000 USER GUIDE

Connecting the Clevis

The ACT2000 features a clevis for securing the motor end of the actuator.

A high-strength shoulder bolt (0.375” diameter) is recommended to fasten

the actuator to a user-provided mount bracket.

The clevis can be rotated to any orientation to support installation. Loosen

the four retaining screws and rotate to the desired angle. The screw

pattern can be indexed ± 45 degrees to provide additional adjustment.

When adjustments are complete, torque the four retaining screws to

117-138 in-lbs.

WARNING

Explosion Hazard – Do not remove the clevis. Removing the clevis

violates the warranty.

Care should also be taken when rotating the clevis or indexing the

screw pattern to avoid scratching the flame path or introducing

particulates to the assembly.

Connecting the Flange (ACT2000-200F only)

The ACT2000-200F can be flange mounted to a valve or other device.

The ACT2000-200F features eight (8) unthreaded through-holes situated

along the length of the actuator chassis. Use ¼ - 20 x ⅞” bolts to pass

through both the actuator chassis and the valve flange to secure the

ACT2000-200F in place.

Connecting the Extension Rod

The extension rod has a 0.375-24 UNF-3B female thread for connecting

user-supplied end attachments with a 0.375-24 UNF-3A male thread. A

spherical rod-end bearing attachment that will minimize any non-axial

forces on the extension rod as it extends and retracts is preferred.

INSTALLING THE ACT2000 5

Note: It is important that user-supplied end attachments and

connecting hardware align properly with the axis of the

extension rod. Any misalignment will result in a side load on

the extension rod (force applied perpendicular to the axis of

extension rod) as it extends and retracts. Such a side load

will reduce the efficiency of the ACT2000, requiring more

electrical current to achieve a given amount of force or

torque. A side load will also increase the mechanical stress

and friction, increasing the rate of wear on the ACT2000.

The extension rod has wrench flats to counteract mounting hardware

installation torque.

WARNING

Property Damage Hazard – Always use the extension rod wrench

flats when installing mounting hardware. Failure to use the wrench

flats may damage or break the internal anti-rotation guide.

When no power is applied to the ACT2000, its extension rod can be

moved manually, if necessary. Approximately 60 to 100 lbf is required to

extend or retract the extension rod. A rod guide is provided internally to

prevent extension rod rotation.

WARNING

Property Damage Hazard – Do not attempt to rotate the extension

rod. This may damage the internal anti-rotation guide and void the

warranty.

6 ACT2000 USER GUIDE

Figure 1-1. ACT2000-590P Dimensions

INSTALLING THE ACT2000 7

Figure 1-2. ACT2000-200F Dimensions

8 ACT2000 USER GUIDE

Figure 1-3. ACT2000-590P Pin-Mounting Provisions

INSTALLING THE ACT2000 9

Figure 1-4. ACT2000-200F Flange-Mounting Provisions

10 ACT2000 USER GUIDE

1.4 Electrical Connections

The ACT2000 is suitable for use in hazardous locations. See the General

Specification Summary in Section 1.2 for certifications. Ensure compliance

with the factory recommendations, and that wiring is in accordance with

local requirements.

WARNING:

94/9/EC (ATEX) Compliance – Special Conditions for Safe Use:

Two special factory-sealed unions are mounted on the equipment to

ensure the electrical connection to the network and to provide the

feedback signal to the user.

The installation of these devices and the final connections to the

conduit shall comply with the requirements of the European

standards.

Ground Connection

The case of the ACT2000 features a threaded hole (0.250-20 UNC-2B

female thread) that is dedicated for the ground connection. This hole has

been left unpainted and uncoated to ensure a good electrical contact. On

the pin-mounted version (ACT2000-590P), this threaded hole is located

on the underside of the unit below the identification plate (see Figure 1-3).

On the flange-mounted version (ACT2000-200F), this threaded hole is

located on the clevis end of the unit (see Figure 1-2). Use a screw with a

0.250-20 UNC-2A thread to connect the case of the ACT2000 to the

same ground plane as the user’s controller.

Power Connections

The ACT2000 operates on a 120VDC (nominal), user-provided input

voltage, which is supplied to the unit through the integral four-wire power

harness. The length of the power harness is 90 inches. See Table 1-1 for

the wire list for the ACT2000 power harness. See Figure 1-5 for the

ACT2000 system power wiring diagram. See Figure 1-6 for a typical

power connection with a power supply. See Figure 1-7 for a typical power

connection with a battery.

WIRE COLOR FUNCTION AWG

RED Power 14

WHITE/RED Power (AUX) 14

GREEN Power Return 14

WHITE/GREEN Power Return (AUX) 14

Table 1-1. Wire List for ACT2000 Power Harness

INSTALLING THE ACT2000 11

Figure 1-5: ACT2000 System Power Wiring Diagram

POWER SUPPLY

120 VDC

ACT2000 120 VDC INPUT

PWR (RED)

+

_

50,000 µF

FUSE

PWR AUX (WHT/RED)

PWR AUX RTN (WHT/ GRN)

PWR RTN (GRN)

Figure 1-6. Typical Power Connection With Power Supply

Figure 1-7. Typical Power Connection With Battery

WARNING - Shock Hazard

Connect both the 120 VDC power and auxiliary wires. If only the

primary power wires are connected, the 120 VDC auxiliary power

wires are electrically live and must be insulated on the ends.

12 ACT2000 USER GUIDE

Note: A battery system is recommended for highest reliability.

Note: If a 120 VDC power supply is used rather than a battery,

ensure an output capacitance of at least 50,000 µF, which

can both sink and source electric current. See Power

Supply Requirements (Table 1-2).

Note: Use a separate conduit for the power wiring. This prevents

noise pickup and transmission from ancillary equipment,

which could cause instability in the actuator.

Power Supply Requirements

Table 1-2 below lists the power supply requirements for the ACT2000.

PARAMETER VALUE

Voltage

Nominal

Range

Max. Ripple

Current

Maximum

Continuous , Typical

Transient, Typical

*Output Capacitance

120 VDC

80 – 160 VDC

4 VAC RMS or 12 VAC p-p

20 Amps

<1 Amp

+20 A <60 ms

+10 A <600 ms

-5 A <100 ms

50,000 µF (typical)

Table 1-2. Power Supply Requirements

*The output capacitance applies for non-battery power systems and assumes full-stroke step

changes in actuator position at rated load. This value is typical. The actual value required is

dependent on the user’s specific DC power system design, including:

• Power sources used in the DC power system (their output impedance, transient response,

rating, diode decoupling [if any], topology, etc.)

• All electrical loads and components connected to each respective power bus branch

• Switching relationships of these electrical loads and components to each other (for example,

does a large motor and actuator turn off at about the same time, etc.)

• Bus branch conductor length and arrangement (flat bus bars, round cables, twisted, etc.)

INSTALLING THE ACT2000 13

Therefore, it is not possible to correctly state a single capacitance value that should be placed on

the bus. It may require no added bus capacitance or hundreds of thousands of microfarads of

capacitance. A typical output capacitance value used for non-battery power systems is 50,000uF,

but the actual value depends on the specific power system as discussed above.

It is best to test the power system for adequate capacitance by executing full-stroke step changes

with the actuator at the same time as all other devices on the bus are switched and measuring the

bus voltage at the actuator power input point to verify that it does not dip below the minimum or

exceed the maximum bus voltage specifications. This test should be performed at both the

minimum and maximum expected operating voltages

Also, the output capacitance should be carefully positioned so that it is never disconnected from

the ACT2000 power input during any contact or switching operations.

Recommended Wiring for System Power

The recommended wire for connecting to system power is a twoconductor shielded cable containing twisted-pair wires with individual

shields. Use a wire size large enough to accommodate the installation

and provide a maximum one (1) ohm loop resistance. See Table 1-3

(below) for recommended wire sizes.

DISTANCE TO

USER POWER

≤ 500 ft. AWG 10, stranded

> 500 ft. Consult Factory

RECOMMENDED WIRE SIZE

(Minimum)

Table 1-3. Wire Size for ACT2000 Power Harness

WARNING

Explosion Hazard – Do not connect or disconnect while circuit is

live. For US Group B hazardous locations, an explosion proof seal

must be placed within 18 inches.

CAUTION

Disconnect all ACT2000 connections prior to welding.

14 ACT2000 USER GUIDE

Loading...

Loading...