Hamilton Home Products WGH Installation And Service Manual

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

Inspection on Arrival

1. Inspect unit upon arrival. .

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

For technical assistance and Warranty Administration,

contact Hamilton Home Products at 1.800.879.0123. Do not

return equipment to the home center.

Table of Contents

Inspection on Arrival . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Special Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SI (Metric) Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . .3

Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Combustible Material and Service Clearances . . . . . . . . .3

Unit Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Checking Input Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Service/Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

INSTALLATION AND SERVICE MANUAL

gas-fired unit heaters

model WGH

VHHP6-576.5

Part 5H76253 Rev. E

March, 2004

All models approved for use in California by the CEC, in New

York by the MEA division, and in Massachusetts. Unit heater

is certified for residential and commercial applications.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies to cause

cancer, birth defects or other reproductive

harm. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance

is hazardous.

CAUTION

To prevent premature heat exchanger failure

do not locate ANY gas-fired units in areas

where chlorinated, halogenated or acid

vapors are present in the atmosphere.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

1. Open windows.

2. Do not try to light any appliance.

3. Do not touch any electrical switch; do not

use any phone in your building.

4. Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions. If you can not reach

your gas supplier, call your fire department.

IMPORTANT

The use of this manual is specifically

intended for a qualified installation and

service agency. All installation and service

of these units must be performed by a

qualified installation and service agency.

Hamilton Home Products, Inc.

SPECIAL PRECAUTIONS/TABLE OF CONTENTS

2

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN THIS

MANUAL MUST BE FOLLOWED TO PROVIDE SAFE, EFFICIENT

AND TROUBLE-FREE OPERATION. IN ADDITION, PARTICULAR

CARE MUST BE EXERCISED REGARDING THE SPECIAL

PRECAUTIONS LISTED BELOW. FAILURE TO PROPERLY

ADDRESS THESE CRITICAL AREAS COULD RESULT IN PROPERTY

DAMAGE OR LOSS, PERSONAL INJURY, OR DEATH. THESE

INSTRUCTIONS SUBJECT TO ANY MORE RESTRICTIVE LOCAL OR

NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation which,

if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

DANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

4. Gas pressure to appliance controls must never exceed 14"

W.C. (1/2 psi).

5. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

6. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard to

persons and property.

7. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

8. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacements parts list may be obtained by contacting

the factory. Refer to the rating plate on the appliance for

complete appliance model number, serial number, and

company address. Any substitution of parts or controls not

approved by the factory will be at the owners risk.

9. If you are replacing an existing heater, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA B149.1 or .2 latest edition. Failure to

follow these instructions can result in injury or death.

10. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input, or

5% below the minimum rated input of duel rated units.

11. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than the

rated voltage.

CAUTION

1. Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment,

of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) latest edition. In Canada installation must be in accordance

with CAN/CGA-B149.1 for natural gas units, and

CAN/CGA-B149.2 for propane units.

2. Consult piping, electrical, and venting instructions in this

manual before final installation.

3. Turn off all gas before installing appliance.

4. Do not locate units in tightly sealed rooms or small

compartments (commonly referred to as confined spaces)

without provisions for adequate combustion air and venting.

Combustion air must have access to the confined space

through a minimum of two permanent openings in the

enclosure, at least one near the bottom. They should

provide a free area of one square inch per 10,000 BTU/Hr

input rating of the unit with a minimum of 100 square inches

for each opening, whichever is greater.

5. When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

6. Check the gas inlet pressure at the unit upstream of the

combination gas control. The inlet pressure should be 6-7"

W.C. on natural gas or 12-14" W.C. on propane. If inlet

pressure is too high, install an additional pressure regulator

upstream of the combination gas control.

7. Purging of air from gas supply line should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CAN/CGA-B149 codes.

8. The minimum distance from combustible material is based

on the combustible material surface not exceeding 160°F.

Clearance from the top of the unit may be required to be

greater then the minimum specified if heat damage, other

than fire, may occur to materials above the unit heater at

the temperature described.

9. Do not attempt to reuse any mechanical or electronic

ignition controllers which has been wet. Replace defective

controller.

10. Do not install unit outdoors.

11. Servicing or repairing of this equipment must be performed

by a qualified service agency.

12. Do not install units below 7' measured from the bottom of

the unit to the floor in commercial applications and 5'

measured from the bottom of the unit to the floor in

residential applications.

13. Be sure no obstructions block air intake and discharge of

unit heaters.

14. Allow 18" of clearance at rear (or 6" beyond end of motor at

rear of unit, whichever is greater) and access side to

provide ample air for combustion and proper operation of fan.

15. Installation of units in high humidity or salt water

atmospheres will cause accelerated corrosion resulting in a

reduction of the normal life of the units.

16. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

This manual shut-off valve should be located within 6' of

the heater.

17. In aircraft hangars, keep the bottom of the unit at least 10'

from the highest surface of the wings of engine enclosure

of the highest aircraft housed in the hangars and in

accordance with the requirements of the enforcing authority

and/or NFPA 409-latest edition.

33

SI (METRIC) CONVERSION FACTORS

Table 3.1

GENERAL

In the U.S., the installation of these units must comply with the

“National Fuel Gas Code,” ANSI Z223.1, latest edition (also

known as NFPA 54) and other applicable local building codes.

In Canada, the installation of these units must comply with local

plumbing or waste water codes and other applicable codes and

with the current code CAN/CGA-B149.1 “Installation Code for

Natural Gas Burning Appliances and Equipment” or CAN/CGAB149.2, “Installation Code for Propane Burning Appliances and

Equipment.”

1. All installation and service of these units must be

performed by a qualified installation and service agency

only as defined in ANSI Z223.1, latest edition or in Canada

by a licensed gas fitter.

2. This unit is certified with the controls furnished. For

replacements parts, please order according to the

replacement parts list on serial plate. Always know your

model and serial numbers. The right is reserved to

substitute other authorized controls as replacements.

3. Unit is balanced for correct performance. Do not alter fan

or operate motors at reduced speed.

4. Information on controls is supplied separately.

5. The same burner is used for natural and propane gas.

UNIT LOCATION

Location Recommendations

1. When locating the furnace, consider general space and

heating requirements, availability of gas and electrical

supply, and proximity to vent locations.

2. When locating units, it is important to consider that the

exhaust vent piping must be connected to the outside

atmosphere.

SPECIAL PRECAUTIONS / SI (METRIC) CONVERSION FACTORS / UNIT LOCATION

CAUTION

1. Do not locate units in tightly sealed rooms or small

compartments (commonly referred to as confined spaces)

without provisions for adequate combustion air and

venting. Combustion air must have access to the confined

space through a minimum of two permanent openings in

the enclosure, at least one near the bottom. They should

provide a free area of one square inch per 10,000 BTU/Hr

input rating of the unit with a minimum of 100 square

inches for each opening, whichever is greater.

2. Low profile heaters are designed for use in heating

applications with ambient temperatures between -40°F

and 90° F.

3. Do not install unit outdoors.

4. In commercial garages or other sections of aircraft hangars

such as offices and shops which communicate with areas

used for servicing or storage, keep the bottom of the unit

at least 7' above the floor. In public garages, the unit must

be installed in accordance with the Standard for Parking

Structures NFPA 88A and the Standard for Repair Garages

NFPA 88B. In Canada, installation of unit heater in airplane

hangars must be in accordance with the requirements of the

enforcing authority, and in public garages in accordance with

the current CAN/CGA-B149. codes.

5. In aircraft hangars, keep the bottom of the unit at least 10'

from the highest surface of the wings or engine enclosure

of the highest aircraft housed in the hangars and in

accordance with the requirements of the enforcing authority

and/or NFPA 409-latest edition.

6. Installation of units in high humidity or salt water atmospheres

will cause accelerated corrosion resulting in a reduction of

the normal life of the units.

DANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

To Convert Multiply By To Obtain

"W.C. 0.24 kPa

psig 6.893 kPa

°F (°F-32) x 0.555 °C

inches 25.4 mm

feet 0.305 meters

CFM 0.028 m

3

/min

To Convert Multiply By To Obtain

CFH 1.699 m3/min

Btu/ft

3

0.0374 mJ/m

3

pound 0.453 kg

Btu/hr 0.000293 kW/hr

gallons 3.785 liters

psig 27.7 "W.C.

CAUTION

1. All literature shipped with this unit should be kept for future

use for servicing or service diagnostics. Do not discard

any literature shipped with this unit.

2. Consult piping, electrical, and venting instructions in this

manual before final installation.

3. Do not attach ductwork, air filters, or polytubes to any

propeller unit heater.

CAUTION

18. In commercial garages or other sections of aircraft hangars

such as offices and shops which communicate with areas

used for servicing or storage, keep the bottom of the unit

at least 7' above the floor. In public garages, the unit must

be installed in accordance with the Standard for Parking

Structures NFPA 88A and the Standard for Repair Garages

NFPA 88B. In Canada, installation of unit heater in airplane

hangars must be in accordance with the requirements of

the enforcing authority, and in public garages in

accordance with the current CAN/CGA-B149 codes.

19. Low profile heaters are designed for use in heating

applications with ambient temperatures between -40°F

and 90°F.

20. All literature shipped with this unit should be kept for

future use for servicing or service diagnostics. Do not

discard any literature shipped with this unit.

21. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the rated

voltage.

IMPORTANT

1. To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

2. To prevent premature heat exchanger failure, the input to

the appliance as indicated on the serial plate, must not

exceed the rated input by more then 5%.

IMPORTANT

To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

3. Be sure the structural support at the unit location site is

adequate to support the weight of the unit. For proper

operation the unit must be installed in a level horizontal

position.

4. Do not install units in locations where the flue products can

be drawn into the adjacent building openings such as

windows, fresh air intakes, etc.

5. Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. Units are designed for installation with the

minimum clearances below:

Top and bottom 1" Non-Access Side 1"

Vent Connector 4" Rear 18"

Access Side 18"

6. Do not install units in locations where gas ignition system is

exposed to water spray, rain, or dripping water.

7. Mounting Height (measured from bottom of unit) at which unit

heaters are installed is critical. Refer to mounting height

information and heat throw data on page 16 of this manual.

The maximum mounting height for any unit is that height

above which the unit will not deliver heated air to the floor.

Combustion Air Requirements

The National Fuel Gas Code defines an “unconfined space” as

a space whose volume is greater than 50 cubic feet per 1,000

Btu/Hr input of the installed appliance(s). A confined space is 50

cubic feet or less per 1,000 Btu/Hr input of the installed

appliance(s).

It is not recommended to install these unit heaters into residential

confined spaces. This recommendation is due to the concern

that at some point in time, the combustion air openings provided

by the installer may become blocked or eliminated by the owner,

either intentionally or unintentionally. Despite this commendation,

if these units are installed into a residential confined space, see

National Fuel Gas Code ANSI Z223.1 or CAN/CGA B149.1 or .2

Installation Code, latest edition, for detailed combustion air

provisions. These requirements must be adheard to.

Units installed into confined spaces in industrial/commercial

installations, must be provided with two permanent openings,

one near the top of the confined space and one near the bottom

of the confined space. Each opening should have a free area of

not less than one square inch per 1,000 BTU per hour of the total

input rating of all units in the confined space, freely

communicating with interior areas having, in turn, adequate

infiltration from the outside.

For further details on supplying combustion or to a confined

(tightly sealed) space or unconfined space, see the National Fuel

Gas Code ANSI Z223.1 or CAN/CGA B149.1 or .2 Installation

Code, latest edition.

Turning The Unit 180°

All units are produced at the factory with left-side controls, when

looking at the unit. If the installation requires that the controls be

on the right side, the unit heater can be “turned over”. In addition,

the following instructions must be followed:

• By turning the unit 180° from the way it was received from

the factory, the sides become opposite but the front and

back remain in the same relative position. The bottom panel

now becomes the top panel and vice-versa.

• Remove the access panel, turn it 180°, and re-attach it to

the unit. This is important so that all the information labels

can be read.

• Remove the spring loaded deflector blades, turn them over,

replace, and adjust so they are open and in a position to

direct the heated air down to the floor.

1. Be sure the means of suspension is adequate to support

the weight of the unit (see page 16 for unit weights).

2. For proper operation, the unit must be installed in a level

horizontal position.

3. Clearances to combustibles as previously specified must be

strictly maintained.

4. Mounting bracket installation:

Before lifting the heater for suspension, the mounting

brackets must be installed. Decide if the unit will be

installed as standard; that is with left-side controls when

looking at the front of the unit or with right-side controls.

For standard (left side)remove brackets from shipping

position and remove the (3) screws along the top edge of

both the front and back of unit. Align screw holes on

mounting bracket with holes along front and back top

edges. Secure (1) mounting bracket to front of unit with

retained screws. Secure the other mounting bracket to back

of unit in a similar way.

For right-hand, the mounting brackets are attached in a

similar manner after the unit is turned over.

5a. Suspension by screws/lag bolts:

Secure the mounting brackets to the ceiling joists or truss,

using 1/4" screws with 1/2" washers. These 1" - angle,

mounting brackets are slotted to accommodate joists on 16"

or 24" centerlines.

5b. Suspension by threaded rod:

This heater can also be hung utilizing the same mounting

brackets and threaded rod. Attach the threaded rod to the

unit mounting brackets, securing with a top and bottom nut.

Next, drill holes into a steel channel or angle iron at the

same centerline dimensions as those chosen for the heater

that is being installed. The steel channels or angle iron

pieces need to span and be fastened to appropriate

structural members. Cut the threaded rods to the preferred

length, push them through the holes in the steel channel or

angle iron and secure with washers and lock nuts, lock

washers and nuts, or a double nut arrangement like used on

the unit heater mounting brackets.

5c. Shelf mounted units:

The unit heater can also be installed on a shelf, if so

desired. The mounting brackets will need to be attached to

the heater the same manner as explained earlier, however,

to mount on a shelf the brackets must go on the bottom of

the heater. The brackets must be affixed to the shelf using

similar screws (1/4" screw with 1/2" washer) as overhead

joist or truss mounting. Be sure all clearance to combustible

requirements are met.

4

CAUTION

1. Do not install units below 7' measured from the bottom

of the unit to the floor in commercial applications and 5'

measured from the bottom of the unit to the floor in

residential applications.

2. Be sure no obstructions block air intake and discharge

of unit heaters.

3. The minimum distance from combustible material is

based on the combustible material surface not

exceeding 160°F. Clearance from the top of the unit

may be requited to be greater than the minimum

specified if heat damage, other than fire, may occur to

materials above the unit heater at the temperature

described.

4. Allow 18" clearance at rear (or 6" beyond end of motor

at rear of unit, whichever is greater) and access side to

provide ample air for combustion and proper operation

of fan.

UNIT LOCATION / UNIT MOUNTING

UNIT SUSPENSION

Before you start use the following steps to verify

that the venting system is adequately sized:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA B149.1 or .2 Installation Code-latest

edition and these instructions. Determine that there is no

blockage or restriction, leakage, corrosion and other

deficiencies, which could cause an unsafe condition.

3. In so far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building. Turn on clothes dryers and any

exhaust fans such as range hoods and bathroom exhausts,

so they shall operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so that the

appliance will operate continuously.

5. After it has been determined that each appliance connected

to the venting system properly vents when tested as

outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-burning appliance to

their previous conditions of use.

6. If improper venting is observed during any of the above

tests, the venting system must be corrected.

Note: A vent is the vertical passageway used to convey flue

gases from the unit or the vent connector to the outside

atmosphere. A vent connector is the pipe which connects the

unit to a vent or chimney. Vent connectors serving Category I

appliances shall not be connected into any portion of mechanical

draft systems operating under positive pressure.

Venting Instructions

1. All vertically vented heaters are category I venting.

All horizontally vented heaters are category I or III

depending on venting. For a unit to be classified vertical,

the horizontal run may not exceed 75% of the vertical rise.

2. Using Table 5.1, determine the venting requirements for the

category determined above. A category III heater must

conform to the venting requirements called out in Table 5.1,

which are detailed in the following sections, as well as

additional requirements also detailed in following sections.

3. Vertically vented heaters may be vented with either single

wall or double wall vent pipe. Follow the double wall

manufacturers clearances to combustibles.

4. All heaters come with a factory installed 3" vent adapter for

attaching the vent pipe to the heater. Attach the vent pipe to

the adapter with 3 non-corrosive screws. (Drill pilot holes

through the vent pipe and adapter prior to screwing in place)

5. Do not use any vent pipe smaller than 3". Refer to the

National Fuel Gas Code for the minimum material thickness.

6. A minimum of 12" straight pipe is recommended from the

power exhauster outlet before turns in the vent system.

Suspend horizontal runs at a minimum of 3' intervals.

7. Avoid venting through unheated spaces when possible.

When single wall pipe does pass through an unheated

space, insulate runs greater than 5' to minimize

condensation. Inspect for leakage prior to insulating and

use insulation that is noncombustible with a rating of not

less 350°F. Install a tee fitting at the low point of the vent

system and provide a drip leg with a cleanout cap as

shown in Figures 6.2 and 6.3. The drip leg should be

cleaned annually.

8. Keep single wall vent pipe at least 6" from combustible

material. The minimum distance from combustible material

is based on the combustible material surface not exceeding

160°F. Clearances from the vent pipe (or top of the unit)

may be required to be greater than the minimum clearance

if heat damage (such as material distortion or discoloration)

may occur.

9. When a single wall vent passes through a combustible wall

or floor, a listed thimble must be used. When a type B

double wall vent passes through a combustible wall or floor,

follow the vent pipe manufacturers clearances to

combustibles. Refer to Figure 6.1.

10. This heater is equipped with a power exhaust system.

DO NOT use any additional power exhaust systems or vent

dampers. FAILURE TO FOLLOW THESE INSTRUCTIONS

could result in serious injury or death.

11. All vertically vented heaters are category I and must be

connected to a factory built chimney or vent complying with

a recognized standard, or a masonry (or concrete) lined

chimney with a material acceptable to the authority having

jurisdiction. Venting into an unlined masonry chimney is

not permitted. Refer to the National Fuel Gas Code for

common venting.

12. Secure all vent joints with at least 3 corrosion-resistant

screws. Use an approved vent terminal to reduce down

drafts and moisture in the vent.

13. The vent must terminate no less than 5' above the vent

connector. The top of the vertical stack should extend

above any portion of a building within a horizontal distance

of 2' (see Figure 6.2).

14. The outlet of the vent should extend as shown in Figure

6.3 and Table 6.1 if the following conditions are met:

Vent diameter is less than 12 inches, vent is of double wall

construction and is a listed product, and the vent does not

terminate within 10' of a vertical wall or similar obstruction.

For vents that have a diameter of 12 inches or larger,

constructed of single wall, or terminate within 2' of a vertical

wall or similar obstruction, the vent pipe shall extend at

least 2' higher than any portion of a building within a

horizontal distance of 2' (refer to Figure 6.2).

55

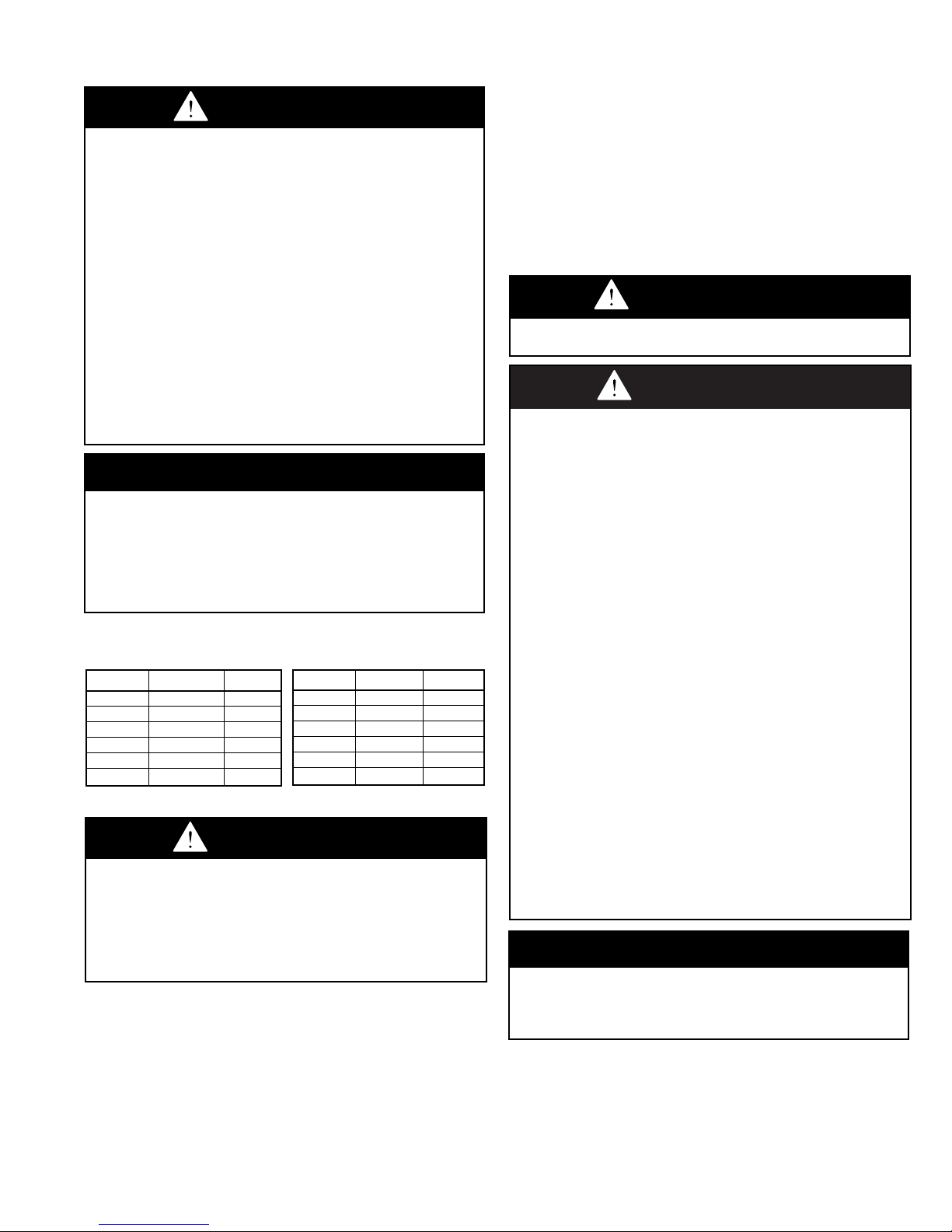

Table 5.1

ANSI Unit Heater Venting Requirements

Venting

Category Description Requirements

I Negative vent pressure Follow standard

Non-condensing venting requirements.

II Negative vent pressure Condensate must

Condensing be drained.

III Positive vent pressure Vent must be gas tight.

Non-condensing

IV Positive vent pressure Vent must be liquid and

Condensing gastight. Condensate

must be drained.

INSTALLATION

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If you are replacing an existing heater, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA B149.1 or .2 latest edition. Failure to

follow these instructions can result in serious injury or death.

CAUTION

Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) - latest

edition. In Canada installation must be in accordance with

CAN/CGA-B149.1 for natural gas units, and CAN/CGA-B149.2

for propane units.

Venting

15. A unit located within an unoccupied attic or concealed

space shall not be vented with single wall vent pipe.

16. Single wall vent pipe must not pass through any attic,

inside wall, concealed space, or floor.

General Instructions For Double Wall (Type B) Terminal Pipe

Installation:

1. How to attach a single wall vent terminal to double wall (type

B) vent pipe:

A. Look for the “flow” arrow on the vent pipe. Attach the

vent terminal to the exhaust end of the double wall

vent pipe.

B. Slide the vent terminal inside the pipe.

C. Drill a hole through the pipe and the vent terminal.

Using 3/4" long sheet metal screws, attach the

cap to the pipe.

2. How to connect a single wall vent system to a double wall

(type B) vent pipe:

A. Slide the single wall pipe inside the inner wall of the

double wall pipe.

B. Drill a hole through both walls of the double wall pipe

and through the single wall pipe. Using 3/4" sheet

metal screws, attach the two pieces of pipe. Do not

over tighten.

C. Repeat Step B drilling and inserting (2) additional

screws, attach the two pieces of pipe. Do not over

tighten.

D. To seal the annular opening, run a large bead of

350°F silastic. The “GAP” between the single and

double wall pipe must be sealed but it is not

necessary to fill the full volume of the annular area.

6

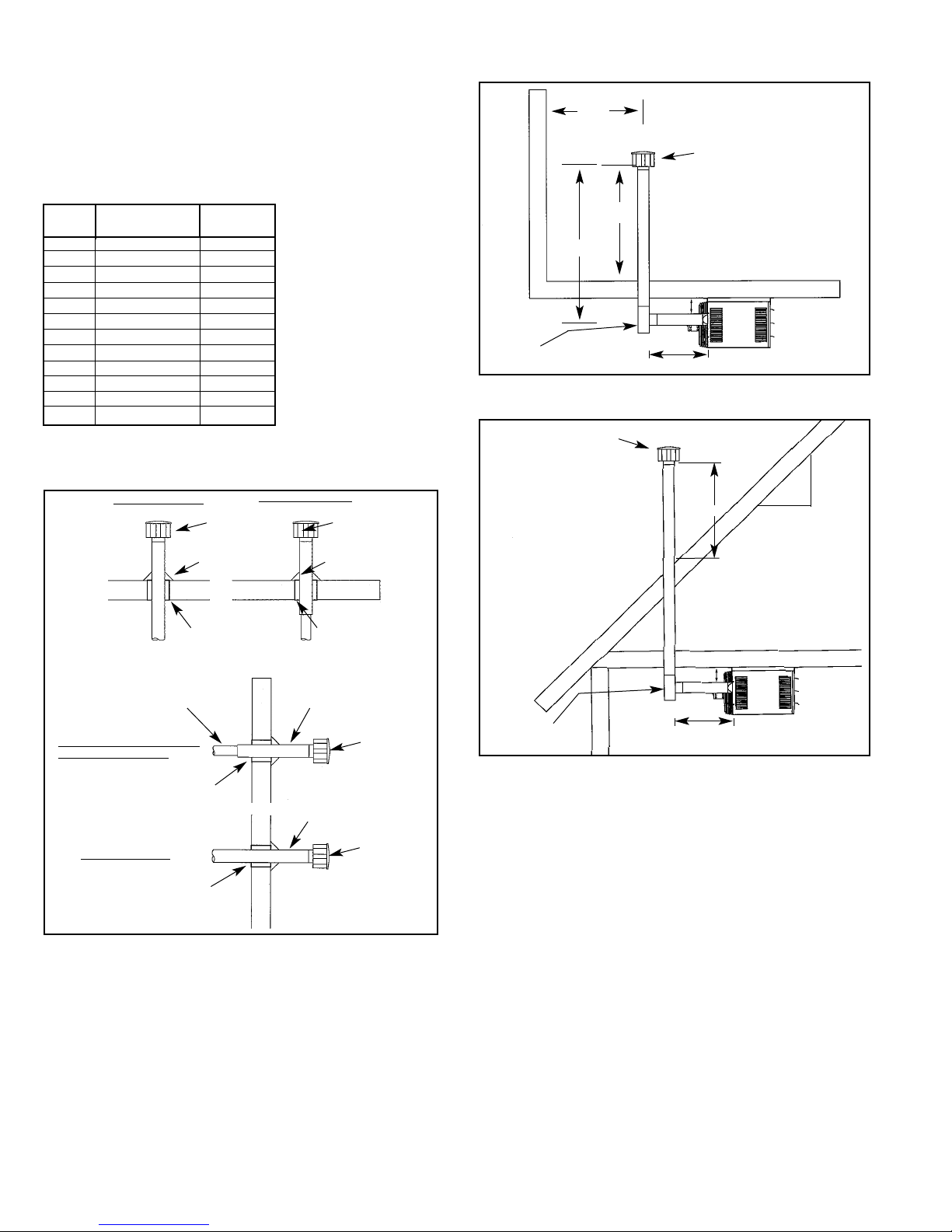

Figure 6.2

Vertical Venting Through Flat Roof

Figure 6.3

Vertical Venting Through Sloped Roof

2' Min

5' Min

Drip Leg

Drip Leg

2' Min

4" Min

12" Min

Downward

Slope

1

/4" towards drip leg.

4" Min

Listed

Terminal

Listed Terminal

12" Min

Downward

Slope

1

/4" towards drip leg.

Figure 6.1

Venting Through Combustible Wall or Roof

Listed

Terminal

Flashing

Listed

Thimble

Listed

Terminal

Flashing

Clearance Specified

by Type B Vent Mfg.

Specified

Terminal

(See No.4,

page 6)

Clearance Specified

by Type B Vent Mfg.

Listed

Thimble

Single Wall Vent Pipe

Double Wall Vent Pipe ➀

Specified

Terminal

(See No.4,

page 6)

Single Wall Vent Pipe Terminating

with Double wall vent pipe. ➁

Single Wall Vent Pipe

INSTALLATION

Rise Roof Pitch Min Height

X (in) H (ft) ➀

0-6 Flat to 6/12 1.00

6-7 6/12 to 7/12 1.25

7-8 7/12 to 8/12 1.50

8-9 8/12 to 9/12 2.00

9-10 9/12 to 10/12 2.50

10-11 10/12 to 11/12 3.25

11-12 11/12 to 12/12 4.00

12-14 12/12 to 14/12 5.00

14-16 14/12 to 16/12 6.00

16-18 16/12 to 18/12 7.00

18-20 18/12 to 20/12 7.50

20-21 20/12 to 21/12 8.00

Table 6.1

Minimum Height from Roof to

Lowest Discharge Opening

➁ See Instructions for attaching single wall pipe to double wall pipe (page 6)

Double

Wall

Single

Wall

Single

Wall

H

X

12

Roof Pitch is

x/12

➀ Size according to expected snow depth.

Additional Requirements For Horizontal Category III

Venting:

1. All heaters that are horizontally vented with 3" vent pipe,

perform as category III appliance. Category III venting has

special venting requirements as follows:

A. All residential, horizontally vented category III heaters

must be vented with an agency certified category III

venting system. Agency certified category III venting

systems are available from your local vent pipe

distributor. Follow the agency certified category III vent

manufacturers instructions for installations.

B. For commercial and industrial horizontally vented

heaters you may use either agency certified category III

venting systems or single wall galvanized or stainless

steel vent pipe. If uncertified single wall vent pipe is

used, all joints must be sealed with metallic tape or

silastic suitable for temperatures up to 400°F. Wrap

tape (2) full turns around the vent pipe.

2. Limit the total equivalent vent pipe length to a minimum of

3' and a maximum of 30', making the vent system as

straight as possible. see Figure 7.3. (The equivalent length

of a 3" elbow is 1').

3. The vent system shall terminate at least 3' above any

forced air inlet (except direct vent units) located within 10',

and at least 4' below, 4' horizontally from, or 1' above any

door, window, or gravity air inlet into any building. The

bottom of the vent terminal shall be located above the snow

line or at least 1’ above grade; whichever is greater. When

located adjacent to public walkways the vent system shall

terminate not less than 7' above grade.

4. All horizontal category III vents must be terminated with a

Gary Steel 1092 or Breidert Type L style vent cap. The vent

cap must be 11" from side of wall. Refer to Figures 7.1-7.3.

5. When condensation may be a problem, the vent system

shall not terminate over public walkways or over an area

where condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of

regulators, relief openings, or other equipment.

6. The venting system must be exclusive to a single unit, and

no other unit is allowed to be vented into it.

7. When vented horizontally, maintain a 1/4" per foot rise

away from the heater. Place a drain tee and clean out near

the unit. See Figure 7.1. Where local authorities have

jurisdiction, a 1/4" per foot downward slope is acceptable.

Use a drain tee with a clean out near the exit of the vent,

see Figure 7.2, or allow the condensate to drip out the end.

See Figure 7.3.

8. When the vent is routed through a combustible wall, use

either an agency approved thimble, or where authorities

have jurisdiction use type B vent for the last section of vent

pipe to maintain clearance to combustibles while passing

through wall. See Figure 7.1.

Additional Requirements For Horizontal Category I

Venting (Residential Only).

1. All heaters installed with category I horizontal vents

must be equipped with a vent transition (3" to 4" or 5"

depending on vent size selected) attached to the

power exhaust adapter located on the unit. All other

portions of the vent system shall consist of 4 or 5inch diameter single wall vent pipe and fittings

depending on vent size selected. All joints of the venting

system must be sealed with metallic tape or silastic

suitable for temperatures up to 400°F. Wrap tape (2) full

turns around the vent pipe joint. One continuous section of

double wall vent pipe may be used with the vent system.

Under no circumstances should two sections of double

wall vent pipe be joined together within one vent system

due to the inability to verify complete seal of inner pipes.

2. The maximum length of the horizontal run of the vent shall

be limited to the length listed in Table 8.1.

77

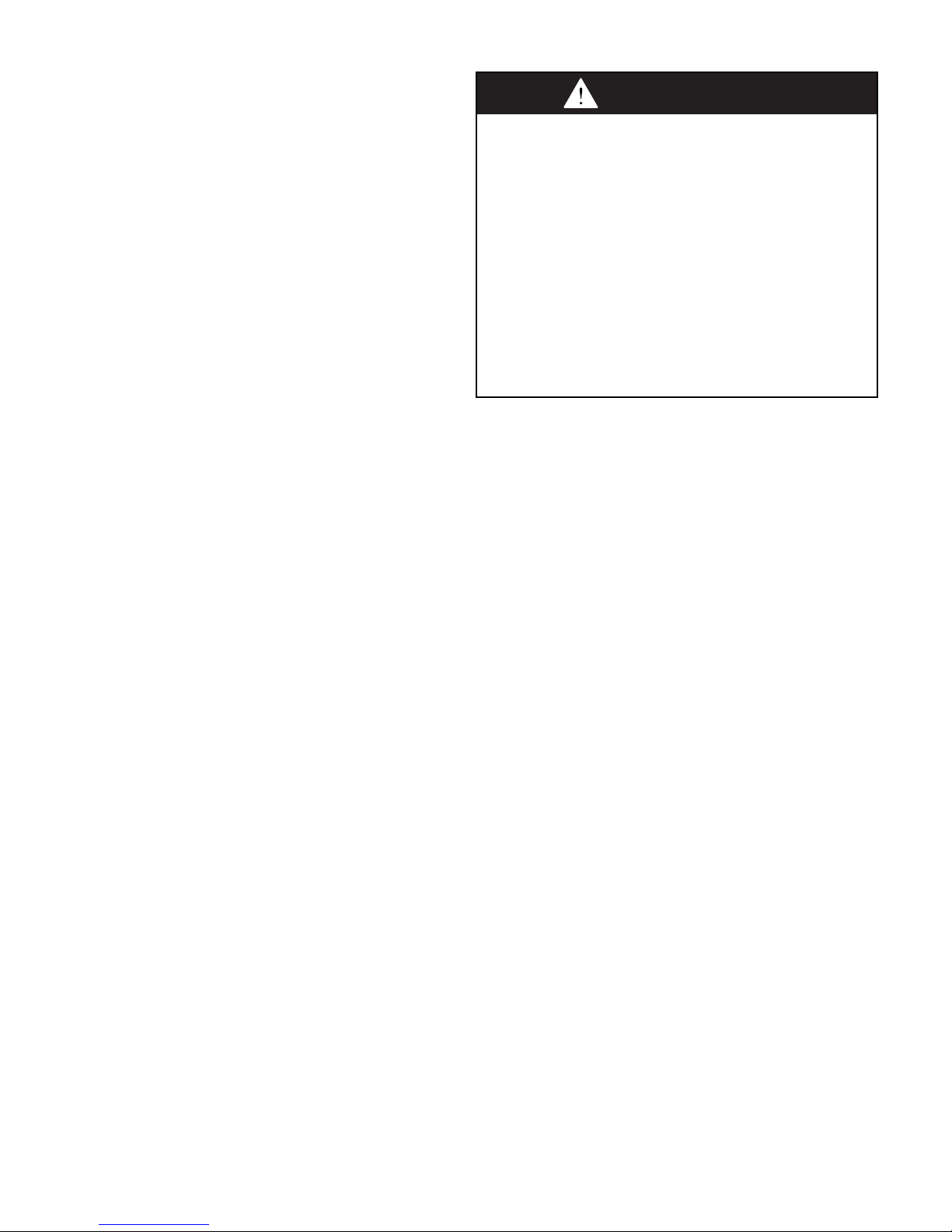

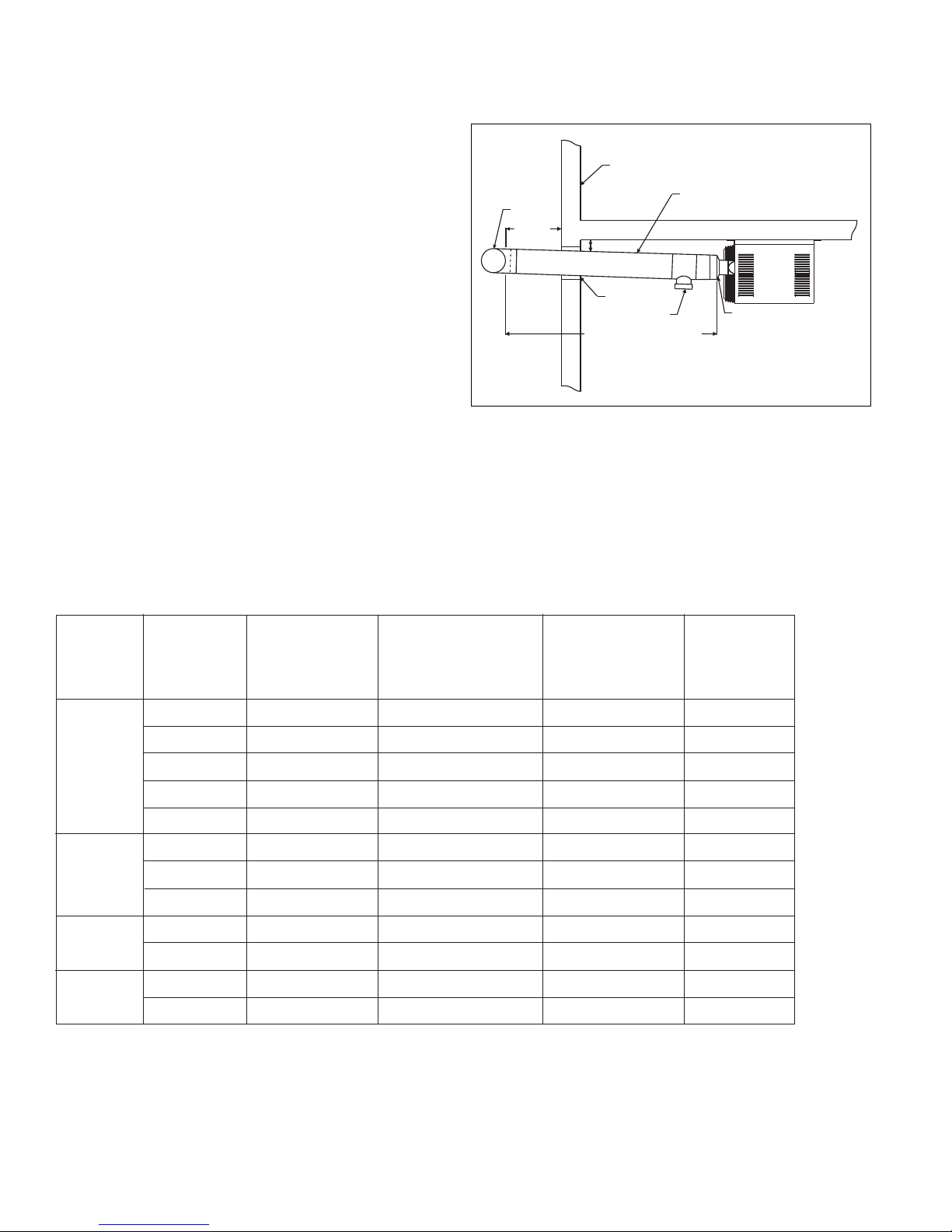

Figure 7.2

Horizontal Category III Venting with Downward

Pitch (with drip leg)

Figure 7.3

Horizontal Category III Venting with Downward

Pitch (Condensate Drips Out End)

1

/4" Slope down towards termination

Listed Thimble

11"

3' Min

Listed Thimble

3' Min

Specified Terminal Cap (See No.4, page 7)

Figure 7.1

Horizontal Category III Venting with Upward Pitch

1

/4" Slope up towards termination

Clean out / drip leg

6" Above snow

grade

Listed Thimble

11"

Specified Terminal (See No.4, page7)

1

/4

" Slope down towards termination

11"

Specified Terminal (See No.4, page 7)

8

3. The vent terminal for a horizontal category I vent may be

either a standard vent TEE, a Gary Steel 1092 or a Breidert

Type L style cap. The maximum number of elbows, slope of

the horizontal section, and minimum vertical rise from

horizontal vent pipe for each configuration is listed in Table

8.1.

A. When using a standard vent TEE, the preferred

orientation of the TEE is for the open ends of the

TEE to be oriented horizontally. In this orientation, the

minimum clearance to combustibles is 6 inches above

the TEE to the eave. If the TEE is oriented vertically,

the minimum clearance to combustibles is 27 inches

above the TEE to the eave. Refer to Figure 9.1. The

vent TEE should incorporate a bird screen made from

corrosion resistant material. The individual strands

of mesh in the bird screen must be located at least

1/4

"

apart.

B. When using a vent cap, the minimum clearance to

combustibles is 6 inches above the cap to the eave.

Refer to Figure 9.1.

4. When vented horizontally, maintain a 1/4

"

per foot rise away

from the heater. Place a drain tee and clean out near the

vent connector. See Figures 8.1 and 9.3. Where local

authorities have jurisdiction, a 1/4

"

per foot downward slope

is acceptable. The Condensate is allowed to drip out of the

end when using a TEE terminal. See Figure 9.2. When

using a vent cap with an extension, a 3/8

"

diameter hole is

drilled in the low point of the vent by the installer exterior to

the space to allow condensation drainage. See Figure 9.4.

Figure 8.1

Horizontal Category I Venting -TEE With Upward Pitch

Table 8.1

Allowable Vent Configurations for Category I Horizontal Venting

Model Vent Maximum No. Minimum Vertical Maximum Vent

Size Terminal Elbows Rise From Horizontal Vent Diameter (in)

Horizontal (in) Length (ft)

(A) (B)

30 Vent TEE 1 0 10 5

Vent Cap 2 ① 4 ② 10 5

Vent TEE 1 0 5 4

Vent Cap 2 ① 12 ② 54

Vent Cap 2 ① 18 ② 10 4

45 Vent TEE 1 0 10 5

Vent Cap 2 ① 12 ② 10 5

Vent Cap 2 ① 18 ② 54

60 Vent TEE 1 0 10 5

Vent Cap 2 ① 15 ② 10 5

75 Vent TEE 1 0 5 5

Vent Cap 2 ① 18 ② 55

①

One of the two allowed elbows is required to create the vent extension shown in figures 9.3 and 9.4.

② The vertical rise gained from an elbow is 4

"

. Therefore, 4"may be subtracted from the length of vertical

pipe needed in the vent extension. If the minimum vertical rise required is 4

"

you do not need to add a

section of vertical pipe to the vent extension.

INSTALLATION

Exterior wall

1/4" Slope up

Vent tee

12" Min

4" Min

Listed thimble

Clean out/Drip leg

Maximum vent length (B)

towards termination

Vent transition

Loading...

Loading...