Page 1

SERVICE MANUAL

SmartServe™ Drink Mixers

MIC2000

BIC2000

– NOTICE –

This Manual is prepared for the use of trained Service T echnicians and should

not be used by those not properly qualifi ed.

This Manual is not intended to be all-encompassing. You should read, in its

entirety , the repair procedure you wish to perform to determine if you have the

necessary tools, instruments, and skills required to perform the procedure.

Procedures for which you do not have the necessary tools, instruments, and

skills should be performed by a trained Service Technician.

Reproduction or other use of this Manual, without the express written consent

of Hamilton Beach, is prohibited.

520008300

www.commercial.hamiltonbeach.com

08/14

Page 2

SmartServe™ Drink Mixers Service Manual

TABLE OF CONTENTS

GENERAL

Safety Information ..................................................................................................................4

Technical Services .................................................................................................................5

Introduction ............................................................................................................................5

Tools and Materials ................................................................................................................6

PREVENTATIVE MAINTENANCE

Preventative Maintenance......................................................................................................7

General Cleaning ..............................................................................................................7

Sanitizing ..........................................................................................................................8

Inspection Checklist ..........................................................................................................8

TROUBLESHOOTING

Component Functions ............................................................................................................9

Control Board Connections ..................................................................................................10

Interface Display Board Connections ...................................................................................14

Power Supply Connections ..................................................................................................15

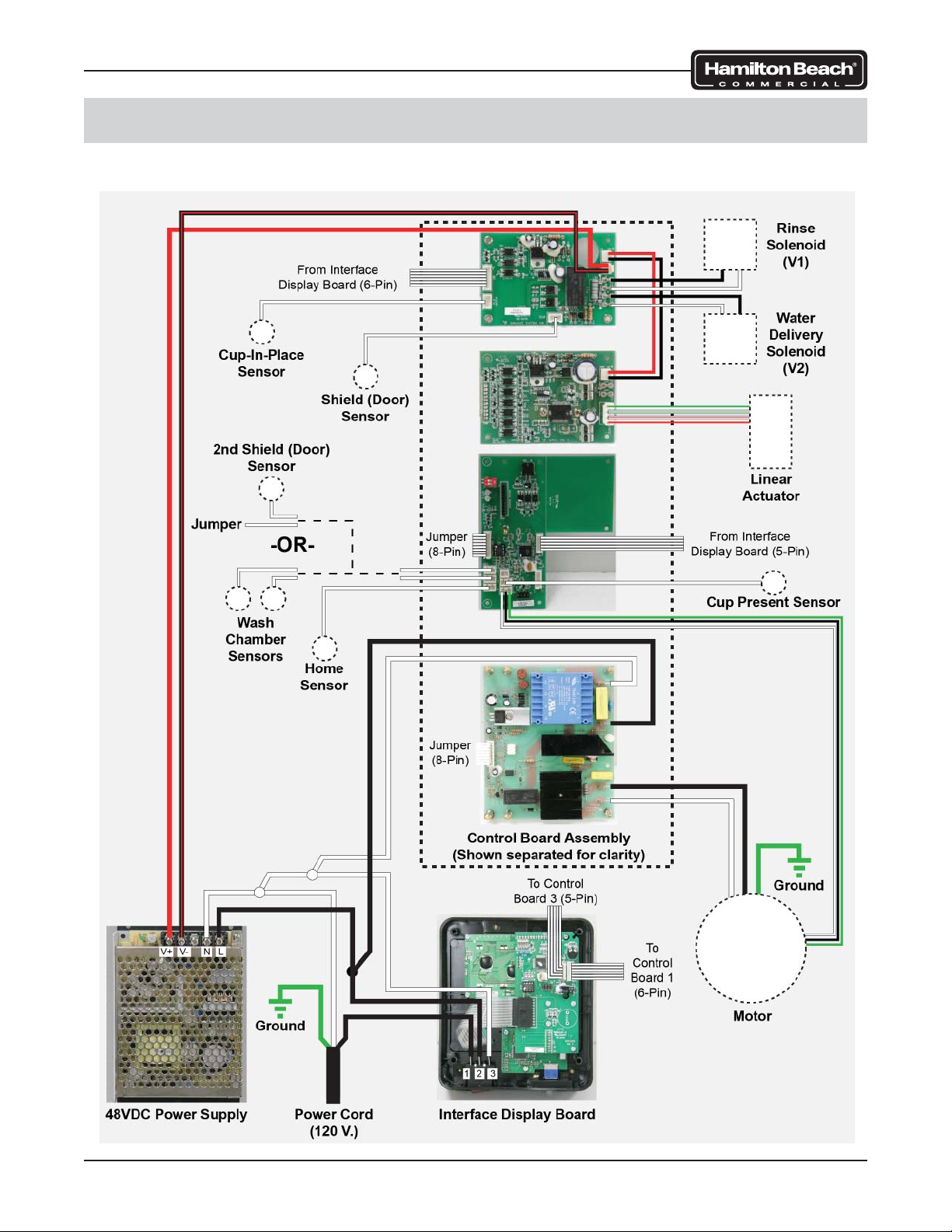

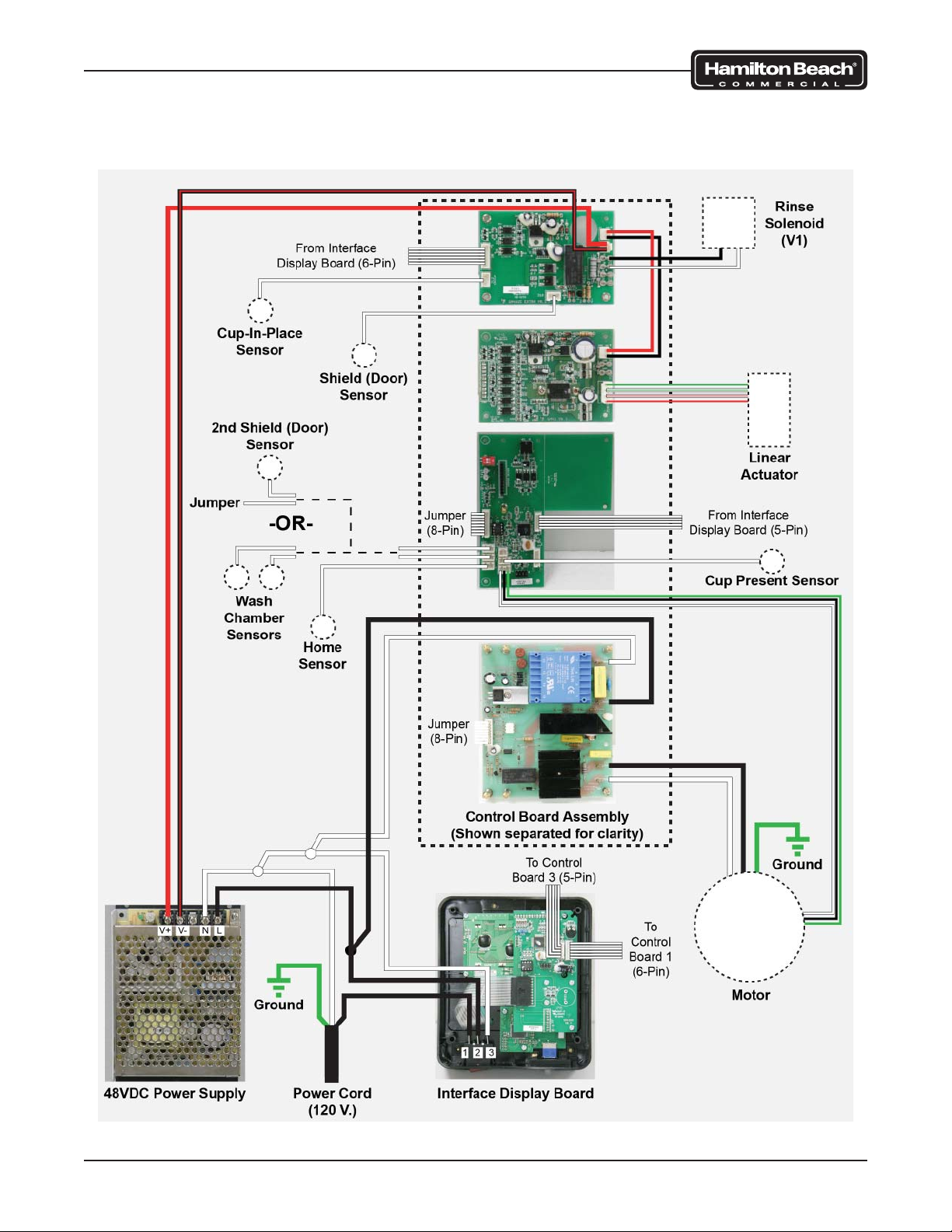

Wiring Diagrams ...................................................................................................................16

MIC2000 .........................................................................................................................16

BIC2000 ..........................................................................................................................17

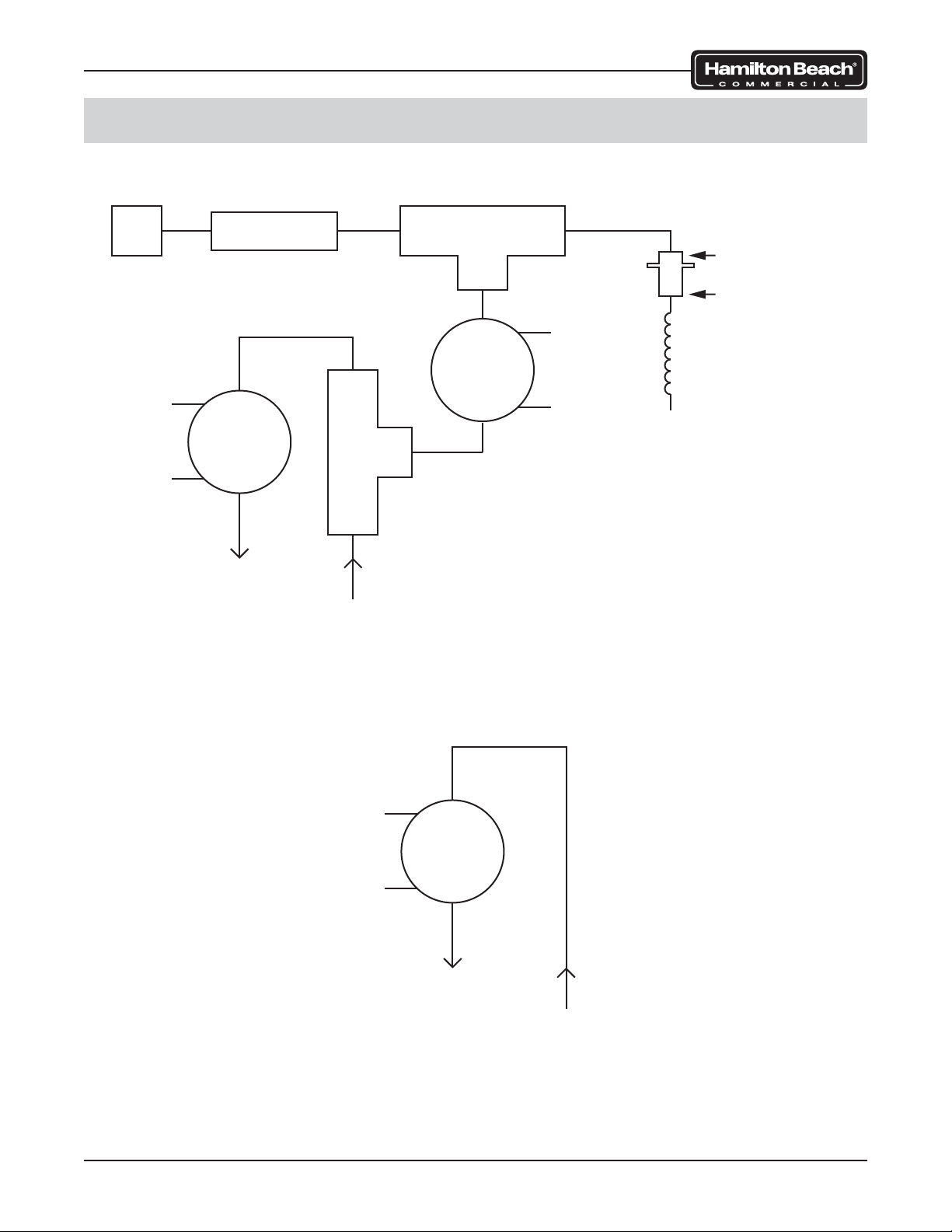

Water and Valve Diagrams...................................................................................................18

MIC2000 .........................................................................................................................18

BIC2000 ..........................................................................................................................18

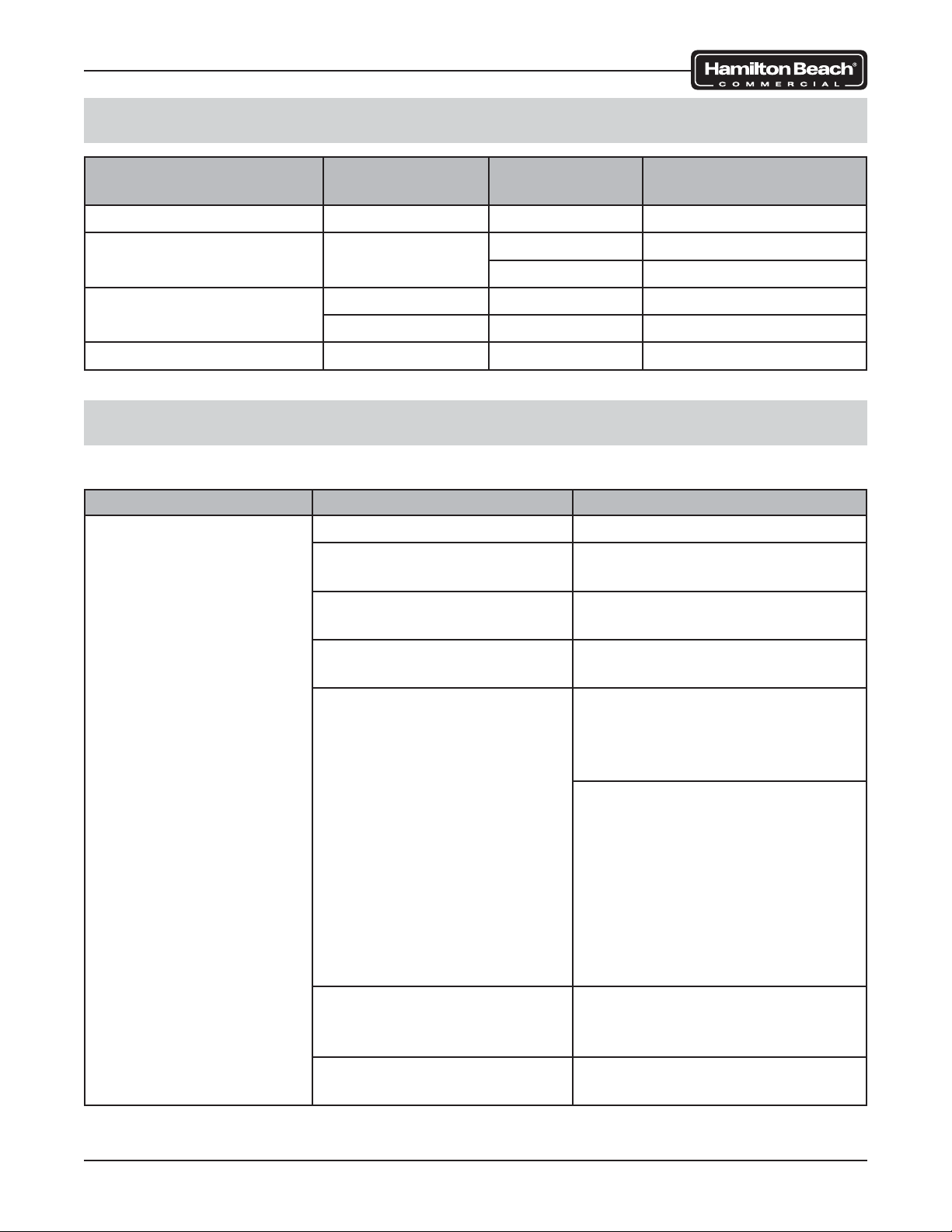

Component Testing ..............................................................................................................19

Troubleshooting Guide .........................................................................................................19

Error Code Troubleshooting .................................................................................................22

REMOV AL AND REPLACEMENT

Safety Shield Assembly........................................................................................................26

Top Cover .............................................................................................................................28

Operator Interface Panel Assembly .....................................................................................30

Breaker Switch .....................................................................................................................32

Interface Display Board ........................................................................................................33

Touch Pad ............................................................................................................................34

Cup Guard & Shield Assembly .............................................................................................35

Motor Assembly....................................................................................................................38

Linear Actuator Assembly.....................................................................................................41

48VDC Power Supply ..........................................................................................................44

Control Board Assembly.......................................................................................................47

Sensor Assembly (Home Position).......................................................................................50

Sensor Assembly (Cup Present) ..........................................................................................52

Cup-In-Place Sensor (Infrared) ............................................................................................55

Shield Door Sensor ..............................................................................................................60

Wash Chamber Assembly ....................................................................................................65

© Hamilton Beach Brands, 2014

Page 2 of 92 520008300 08/14

Page 3

SmartServe™ Drink Mixers Service Manual

Water Solenoid .....................................................................................................................70

Wash Chamber Gasket ........................................................................................................72

Water Manifold (MIC2000 Only) ...........................................................................................74

Cup Shield Gasket ...............................................................................................................75

REPLACEMENT PARTS LIST

SHIELD DOOR ASSEMBLY & PANELS ..............................................................................76

OPERATOR INTERFACE PANEL ASSEMBLY ....................................................................78

CONTROL BOARD ASSEMBL Y AND SENSORS ...............................................................80

LINEAR ACTUATOR, MOTOR, & CUP GUARD (BIC2000) ................................................82

LINEAR ACTUATOR, MOTOR, & CUP GUARD (MIC2000) ................................................84

MOTOR ASSEMBL Y ............................................................................................................86

WASH CHAMBER & WATER LINES (BIC2000) ..................................................................88

WASH CHAMBER & WATER LINES (MIC2000) .................................................................90

Page 3 of 92 520008300 08/14

Page 4

SmartServe™ Drink Mixers Service Manual

SAVE THESE INSTRUCTIONS

REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL AND

TECHNICAL SHEETS BEFORE BEGINNING REPAIRS.

Pride and workmanship go into every product to provide our customers with quality products.

It is possible, however, that during its lifetime, a product may require service. Products should

be serviced only by a qualified service technician who is familiar with the safety procedures

required in the repair and who is equipped with the proper tools, parts, testing instruments, and

the appropriate service manual.

Safety Information

We have provided many important safety messages in this manual and on the appliance.

ALWAYS read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others. All safety messages will

be preceded by the safety alert symbol and the word “DANGER”, “WARNING”, or “CAUTION”.

These words mean:

DANGER

IMMEDIATE HAZARDS THAT WILL RESULT IN SEVERE PERSONAL INJURY OR

DEATH.

WARNING

Hazards or unsafe practices that COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices that COULD result in minor personal injury or product or

property damage.

General

Page 4 of 92 520008300 08/14

Page 5

SmartServe™ Drink Mixers Service Manual

All safety messages will identify the hazard, describe how to reduce the chance of injury, and

describe what can happen if the instructions are not followed.

WARNING

To avoid risk of serious injury or death, repairs should not be attempted by

unauthorized personnel.

CAUTION

Hamilton Beach will not be responsible for any injury or property damage from

improper service procedures. If performing service on your own product, you must

assume responsibility for any personal injury or property damage that may result.

Technical Services

Visit www.commercial.hamiltonbeach.com for technical service information.

To change your program or create a new one, contact your salesperson.

For assistance, copy of an existing program, or replacement parts, call our Technical Services

phone number:

866-285-1087 or 910-693-4277

8 a.m. – 5 p.m. EST Monday – Friday

Introduction

This manual covers the MIC2000 and BIC2000 Drink Mixer. Detailed information about the

operation and cleaning of these machines can be found in the Use & Care Manual. Contact

your salesperson to obtain a copy or visit www.commercial.hamiltonbeach.com.

The operating specifications are as follows:

Model Volts Hertz Phase

MIC2000 120 60 1

BIC2000 120 60 1

MIC2000-CE 230 50/60 1

BIC2000-CE 230 50/60 1

General

Page 5 of 92 520008300 08/14

Page 6

SmartServe™ Drink Mixers Service Manual

Tools and Materials

CAUTION

Do not use power tools to remove hardware. Damage to the hardware or the machine

may occur. Do not lose hardware.

• Standard set of hand tools

• VOM with AC current tester (any quality VOM with a sensitivity of at least 20,000 ohms

per volt can be used)

• Loctite No. 242

• Adhesive remover

General

Page 6 of 92 520008300 08/14

Page 7

SmartServe™ Drink Mixers Service Manual

Preventative Maintenance

To keep the machine operating properly, it is essential that the machine is cleaned regularly.

Whenever service is performed on the machine, a visual inspection of the components should

be performed to ensure optimal operating conditions.

General Cleaning

The shield will need to be cleaned depending on the application and how many cycles are

completed in a given period.

1. Clean SmartServe™ using a cleaning solution of hot water (less than 115°F/46°C) and

a nonsudsing detergent according to the package directions.

2. Turn ON (I) by pressing the power switch under the control panel on the right side.

3. Remove cup holder.

NOTE: MIC models do not require daily cup holder removal.

4. Press MENU and select “LOWER SHIELD.” Press START.

5. Turn power OFF (O).

6. Remove the two thumbscrews from the door assembly and pull off the door assembly.

7. Push the tab on the front of the cup guard assembly while turning the splash shield to

the left. Let splash shield rest in the wash chamber.

8. Lift the cup guard assembly upward approximately 3” to allow room to remove the

splash shield.

CAUTION

Blades are sharp.

9. Wipe the wash chamber, cup lid, and upper part of cup guard assembly with a soft cloth,

bottle brush, or sponge dampened with the cleaning solution.

10. Immerse cup holder, door assembly, and splash shield in cleaning solution and wipe

with a soft cloth or sponge.

NOTE: PARTS ARE NOT DISHWASHER-SAFE.

11. Rinse cup holder, door assembly, and splash shield in clean water; allow to dry.

12. Reassemble the cup holder, splash shield, and door assembly.

13. Turn power ON (I) and allow the machine to return to its HOME position; press the

FLUSH button to flush the water lines.

14. Following the flush cycle, insert a cup filled with cleaning solution and run any preprogrammed cycle. DO NOT OPEN DOOR WHILE CYCLE IS IN PROGRESS!

15. When cycle is finished, open the door, remove the cup, and pour the solution into the

wash chamber. Close the door. The unit will automatically run through a rinse cycle.

16. Follow sanitizing instructions.

Preventative Maintenance

Page 7 of 92 520008300 08/14

Page 8

SmartServe™ Drink Mixers Service Manual

Sanitizing

The SmartServe™ must be sanitized before daily use.

1. Wash SmartServe™ following instructions in “General Cleaning.”

2. Sanitize using 1 Tablespoon (15 mL) of bleach per 1 gallon (3.8 liter) of clean, cool

water (60°F/16°C), mixed according to the instructions on the bleach. (If using a

sanitizing solution other than bleach, test the concentration using commercial test strips.

Concentration levels should be between 100 and 200 parts per million of bleach to

water.)

3. Turn ON (I) by pressing the power switch under the control panel on the right side and

flush system as prompted.

4. Insert a cup filled with sanitizing solution and run any pre-programmed cycle (using the

1–3 and A–C buttons). DO NOT OPEN DOOR WHILE CYCLE IS IN PROGRESS!

5. Allow cycle to finish. Open the door, remove the cup, and pour the solution into the

wash chamber.

6. NOTE: For MIC models, use the sanitizing syringe to inject at least 50 mL of sanitizing

solution into the sanitizing port. Remove syringe and set aside.

7. Remove the two thumbscrews from the door assembly and pull off the door assembly to

allow the equipment to dry overnight. If equipment is needed immediately, press FLUSH

button before programming equipment for a drink.

Inspection Checklist

Whenever service is performed on the machine, review this checklist to ensure the machine

operates efficiently.

Date Inspection Action

Check all water lines and connections for leaks.

Check all drain connections for

leaks.

Visually inspect all wires and wire

harnesses for wear.

Ensure all necessary wire ties are

secure and in place.

Observe the travel of the motor

on the linear actuator. The motor

should move freely without obstruction or resistance.

Repair or replace any items found leaking.

Repair or replace any items found leaking.

Repair or replace any damaged wires.

Replace any missing or broken wire ties.

Clean slide rods and apply a food safe lubricant to the lead screw and reroute any wire

harnesses or water lines that interfere with

operation.

Preventative Maintenance

Page 8 of 92 520008300 08/14

Page 9

SmartServe™ Drink Mixers Service Manual

Component Functions

Motor

Linear Actuator

Power Supply

Control Board

Home Sensor

Cup Present

Sensor

Cup-In-Place

Sensor

Wash Chamber

Sensors

The motor is used to turn the blade assembly. It receives power

through the control board.

The linear actuator is used to lower and raise the motor and cup

guard/shield assembly during use. It receives power and is controlled

by the control board.

The power supply distributes 48VDC power to the control board to

operate the linear actuator motor and the valve(s).

The control board is the brain of the machine. It receives power from

the power supply and provides command logic to operate the machine.

The home sensor determines the highest position of the motor and

cup guard/shield assembly and establishes a starting point for the

linear actuator.

The cup present sensor lets the machine know if the linear actuator

has reached a position where it is acceptable to fl ush, rinse, or blend.

The cup-in-place sensor is an infrared sensor designed to determine

the presence of a cup in the mixing chamber.

The wash chamber sensors are embedded in the wash chamber

assembly. They are designed to sense when the cup guard is in the

wash chamber. These sensors are not present on all models.

Shield Sensor

Interface Display

Board

Touch Pad

Control Panel

Breaker Switch

Water Solenoid

Valve (1)

Water Solenoid

Valve (2)

The shield sensor is located under the wash chamber area. A magnet

in the safety shield assembly interacts with the sensor and requires

that the door be closed in order for the machine to operate. Some

models have two sensors.

The interface display board is located in the interface control panel.

The board receives input from the touch pad and sends the commands to the control board.

The touch pad is on the interface control panel. It is connected to the

interface panel control board with a ribbon style cable.

The breaker switch is located on the interface control panel. It controls power to the power supply and main control board.

This water solenoid controls the fl ow of water to the wash chamber

during RINSE and FLUSH cycles.

This water solenoid controls the fl ow of water to the drink mixing area.

Troubleshooting

Page 9 of 92 520008300 08/14

Page 10

SmartServe™ Drink Mixers Service Manual

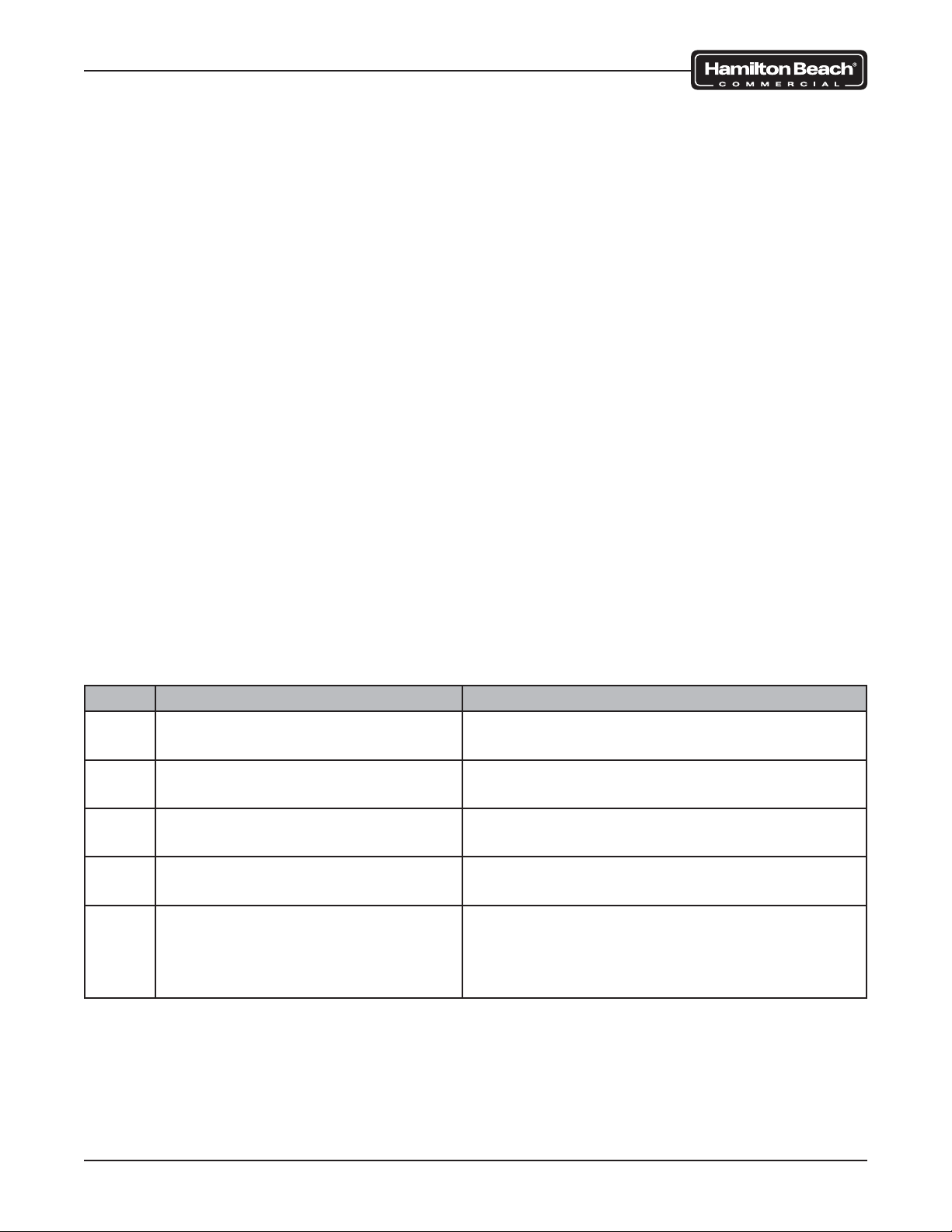

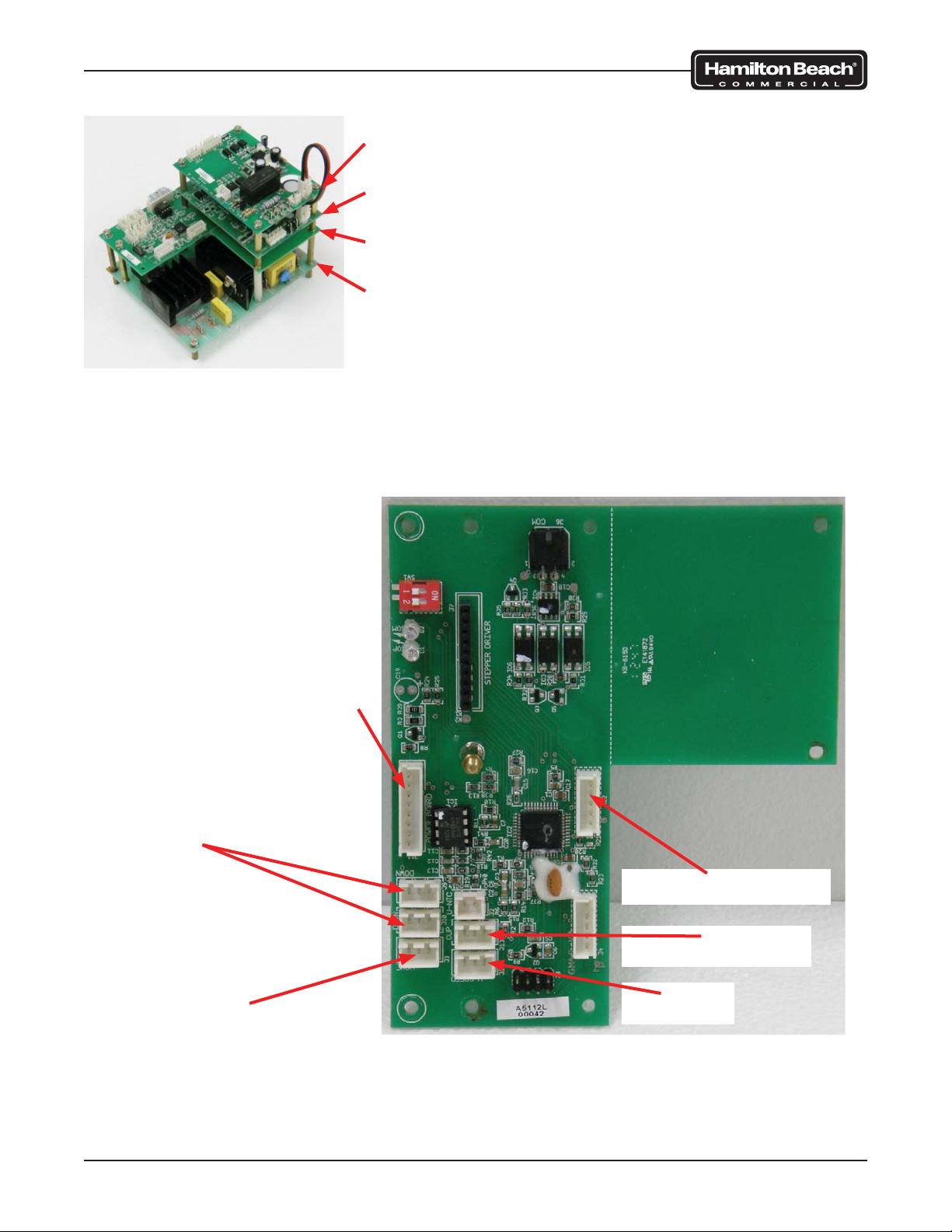

Control Board Connections

Control Board 1 (Solenoid and Sensor)

Control Board 2 (Linear Motor)

Control Board 3 (Command Logic)

Control Board 4 (Motor Power)

Control Board Assembly

To

Interface

Display Board

To

Cup-In Place

Sensor

Jumper

To Board 2

(2-Pin)

From Power

Supply

(V- & V+)

V1 (Black)

To Solenoid

V1 (White)

To Solenoid

V2 (Black)

To Solenoid

V2 (White)

To Solenoid

Troubleshooting

To Shield

(Door)

Sensor

Control Board 1 (Solenoid and Sensor)

Page 10 of 92 520008300 08/14

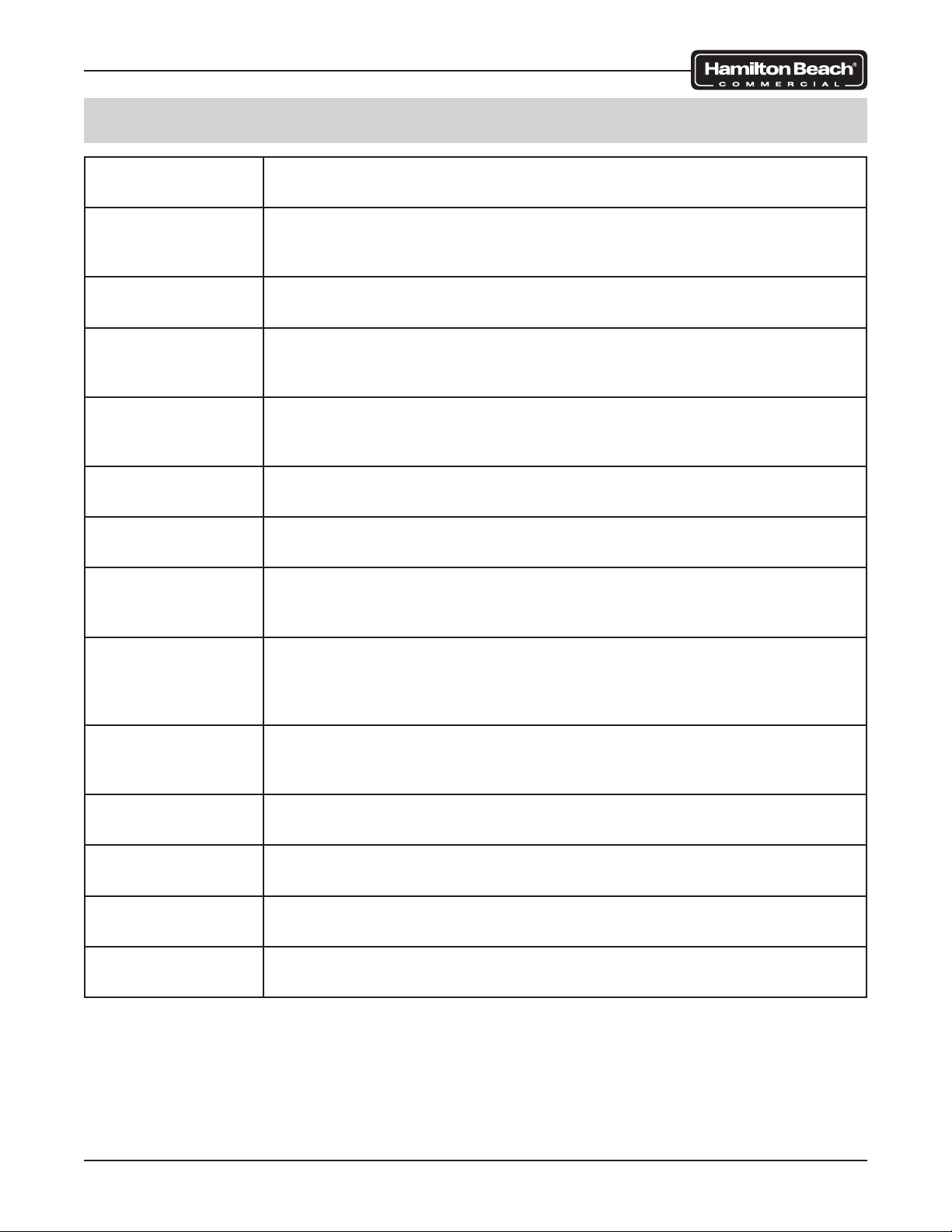

Page 11

SmartServe™ Drink Mixers Service Manual

Control Board 1 (Solenoid and Sensor)

Control Board 2 (Linear Motor)

Control Board 3 (Command Logic)

Control Board 4 (Motor Power)

Control Board Assembly

Control Board 2 (Linear Motor)

Jumper

From Board 1

(2-Pin)

To Linear

Actuator

Motor

Troubleshooting

Page 11 of 92 520008300 08/14

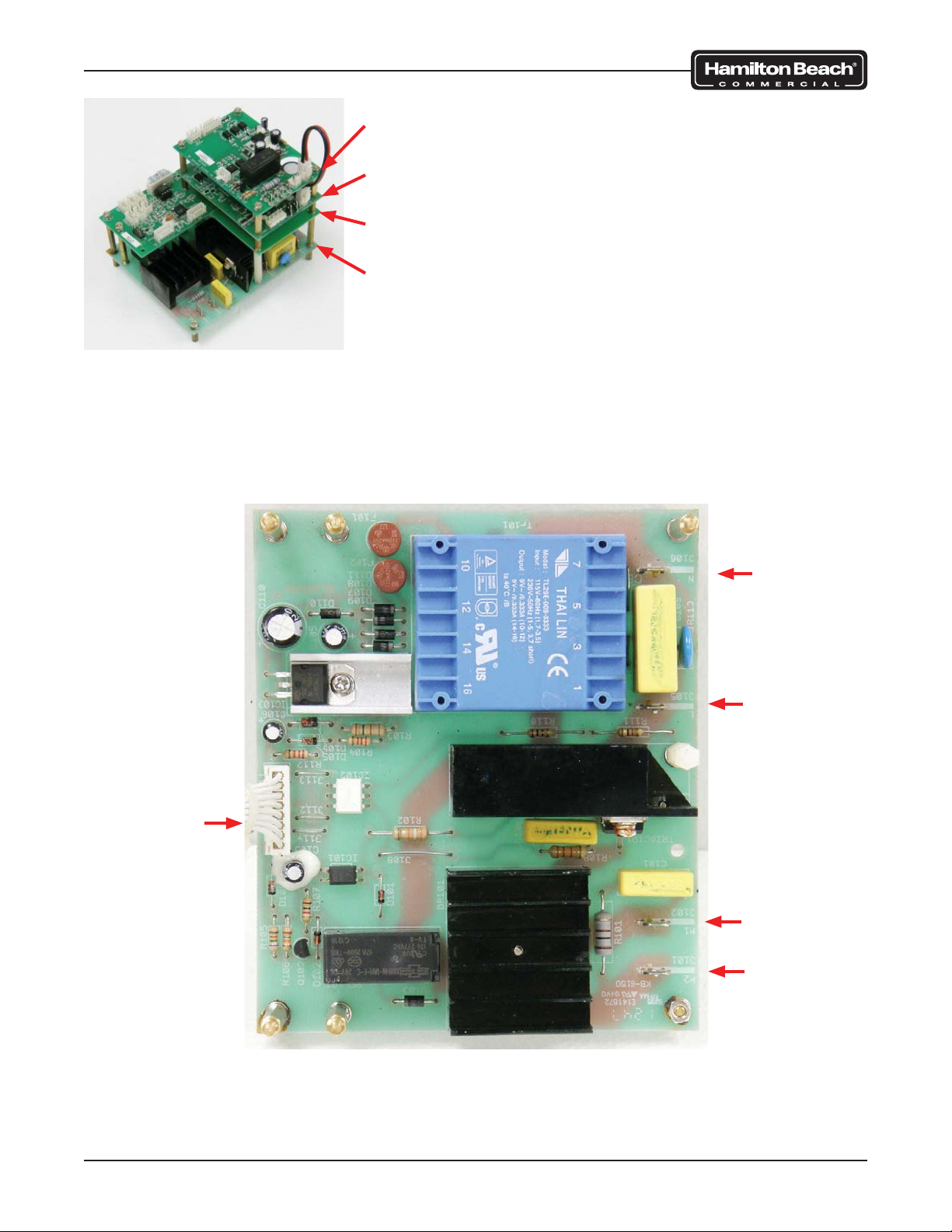

Page 12

SmartServe™ Drink Mixers Service Manual

Control Board 1 (Solenoid and Sensor)

Control Board 2 (Linear Motor)

Control Board 3 (Command Logic)

Control Board 4 (Motor Power)

Control Board Assembly

To Wash

Chamber

Sensor

OR

To second Shield

(Door) Sensor

and Jumper

To

Home

Sensor

Jumper

From Board

4 (8-Pin)

To

Interface Display Board

To

Cup Present Sensor

To

Motor

Control Board 3 (Command Logic)

Troubleshooting

Page 12 of 92 520008300 08/14

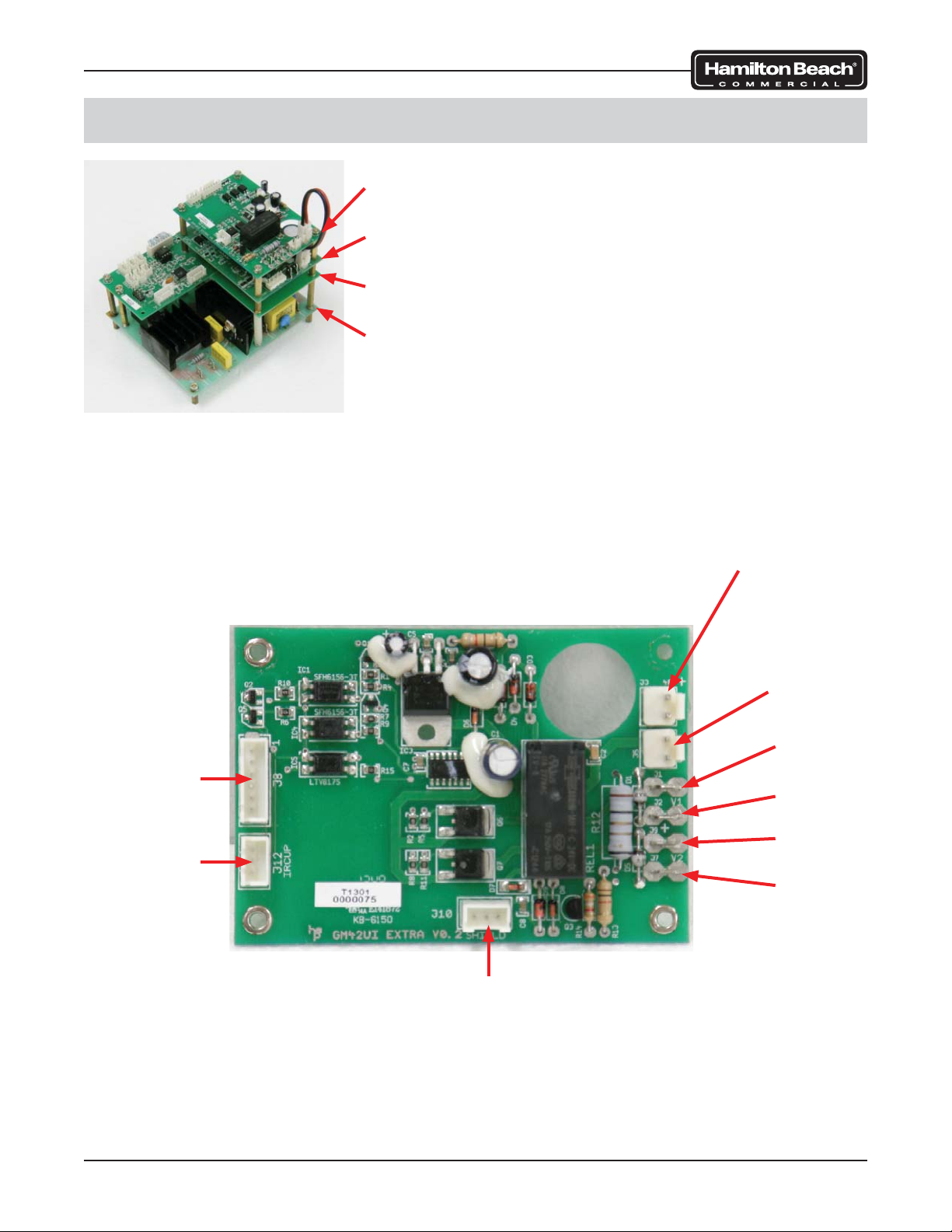

Page 13

SmartServe™ Drink Mixers Service Manual

Control Board 1 (Solenoid and Sensor)

Control Board 2 (Linear Motor)

Control Board 3 (Command Logic)

Control Board 4 (Motor Power)

Control Board Assembly

Jumper

To Board 3

(8-Pin)

N

(White)

L

(Black)

From Main

Breaker

Switch

M1

(Black)

Motor

M2

(White)

Motor

Troubleshooting

Control Board 4 (Motor Power)

Page 13 of 92 520008300 08/14

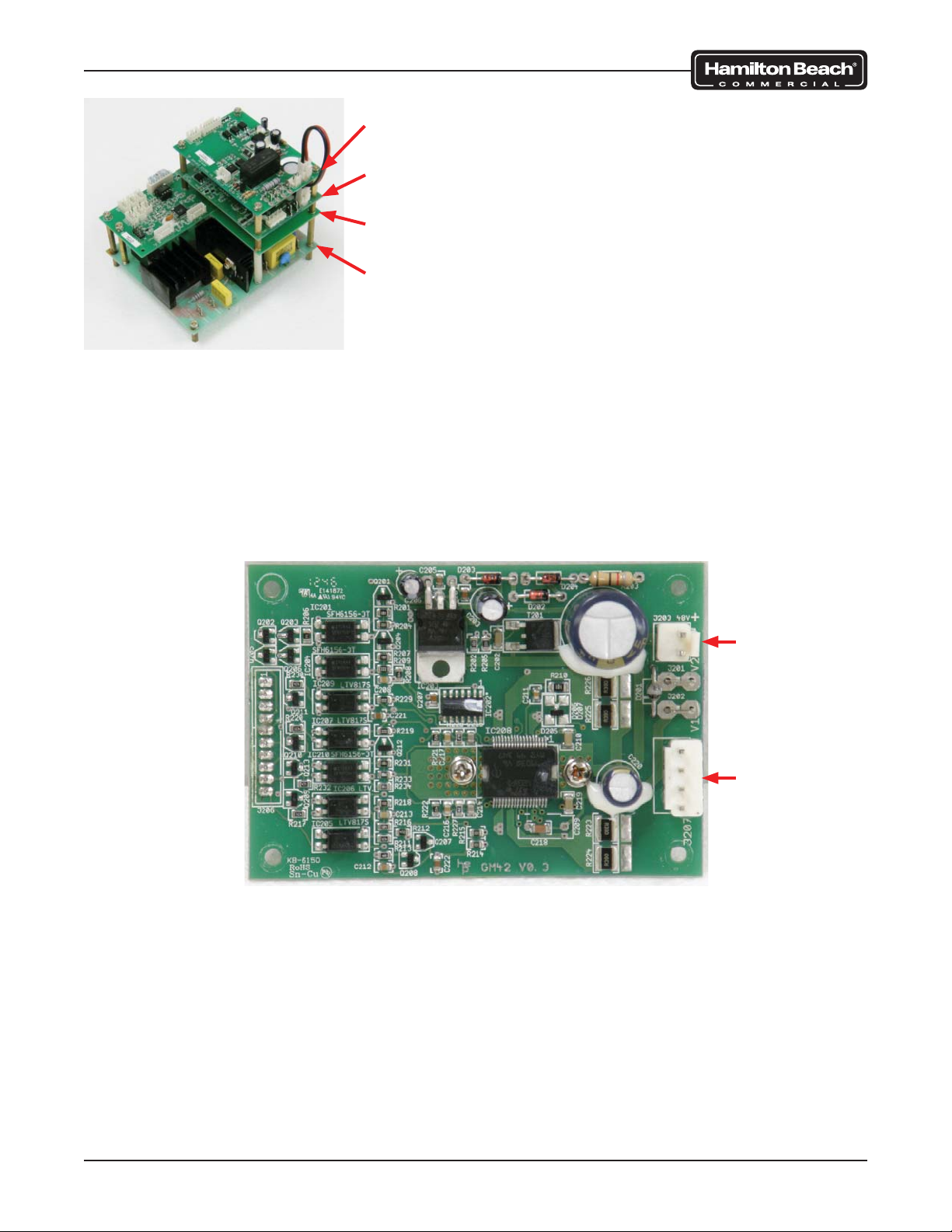

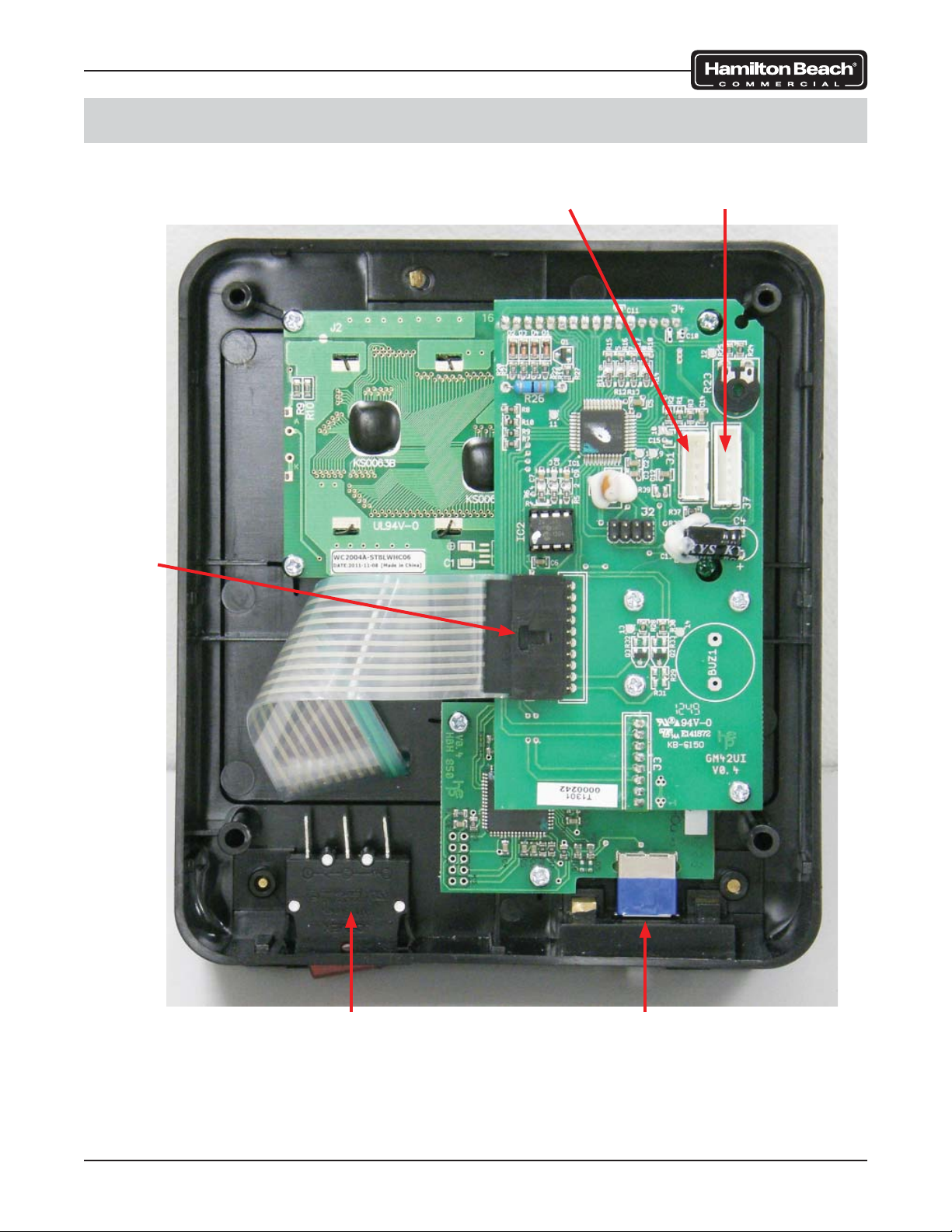

Page 14

SmartServe™ Drink Mixers Service Manual

Interface Display Board Connections

Lock Tab

To Control

Board 3 (5-Pin)

To Control

Board 1 (6-Pin)

Troubleshooting

Breaker

Switch

USB Port

Page 14 of 92 520008300 08/14

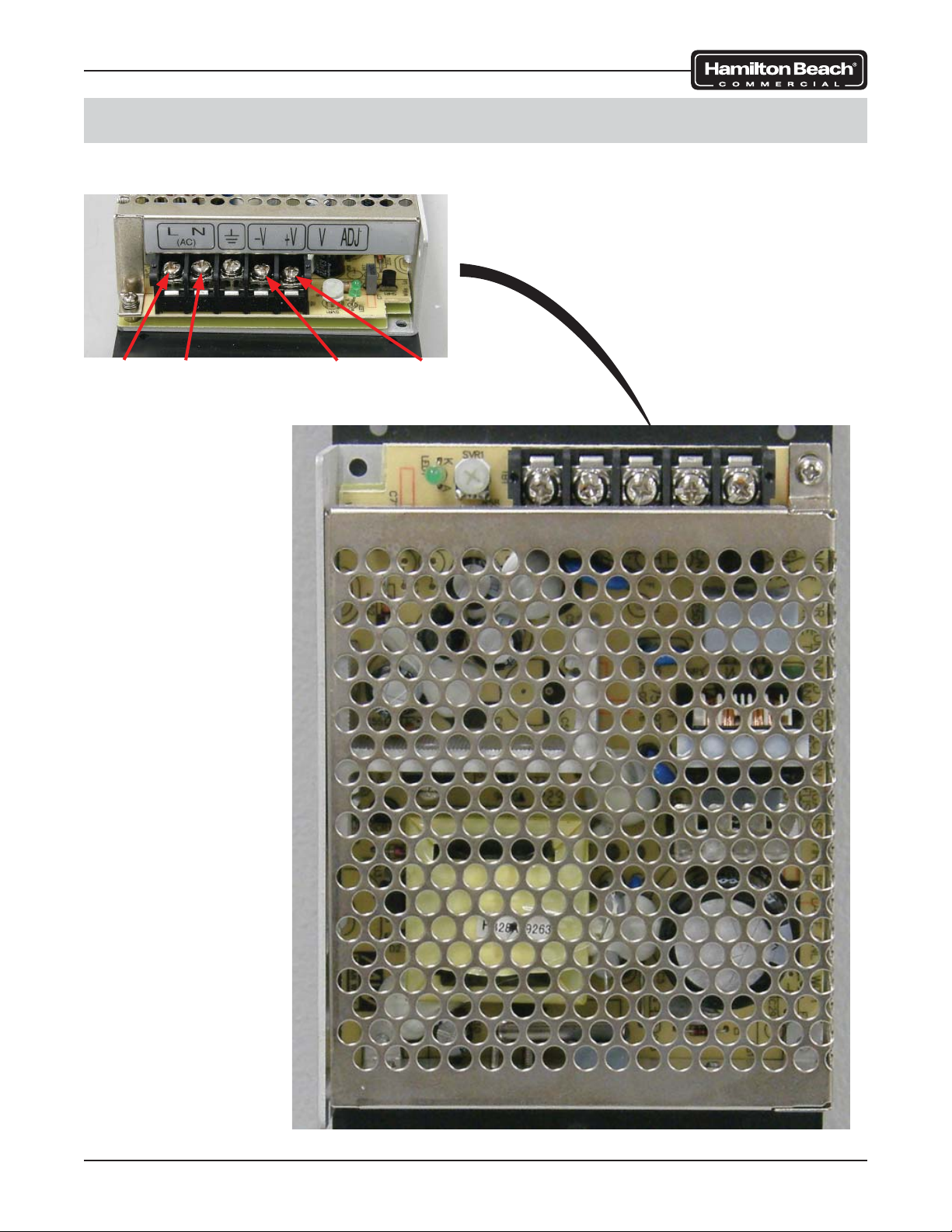

Page 15

SmartServe™ Drink Mixers Service Manual

Power Supply Connections

48 VDC POWER SUPPLY

L

(Black)N(White)

V-

(Black/Red)V+(Red)

Troubleshooting

Page 15 of 92 520008300 08/14

Page 16

SmartServe™ Drink Mixers Service Manual

Wiring Diagrams

MIC2000

Troubleshooting

Page 16 of 92 520008300 08/14

Page 17

SmartServe™ Drink Mixers Service Manual

BIC2000

Troubleshooting

Page 17 of 92 520008300 08/14

Page 18

SmartServe™ Drink Mixers Service Manual

Water and Valve Diagrams

MIC2000

Sanitize

Port

Black 2

White 1

Check Valve

Valve

OUT

To Wash

Chamber

Stem Tee

1/4” OD TUBE

3/16” OD TUBE

4 Black

Valve

3 White

Water

Delivery

to Cup

WATER INLET

BIC2000

Black 2

White 1

Valve

OUT

To Wash

Chamber

WATER INLET

Troubleshooting

Page 18 of 92 520008300 08/14

Page 19

SmartServe™ Drink Mixers Service Manual

Component Testing

COMPONENT OPERATING

VOLTAGE

Motor 85 VDC 4.4 Ω WHT to BLK

Linear Actuator 48 VDC 2.7 Ω RED/WHT to RED

Power Supply 120 VAC N/A L to N

48 VDC N/A V- to V+

Water Solenoid Valve 24 VDC 92 Ω at valve

RESISTANCE

(Approximate)

2.7 Ω GRN/WHT to GRN

TEST

LOCATION

Troubleshooting Guide

If SmartServe™ is not operating properly, identify the problem and use the tables below:

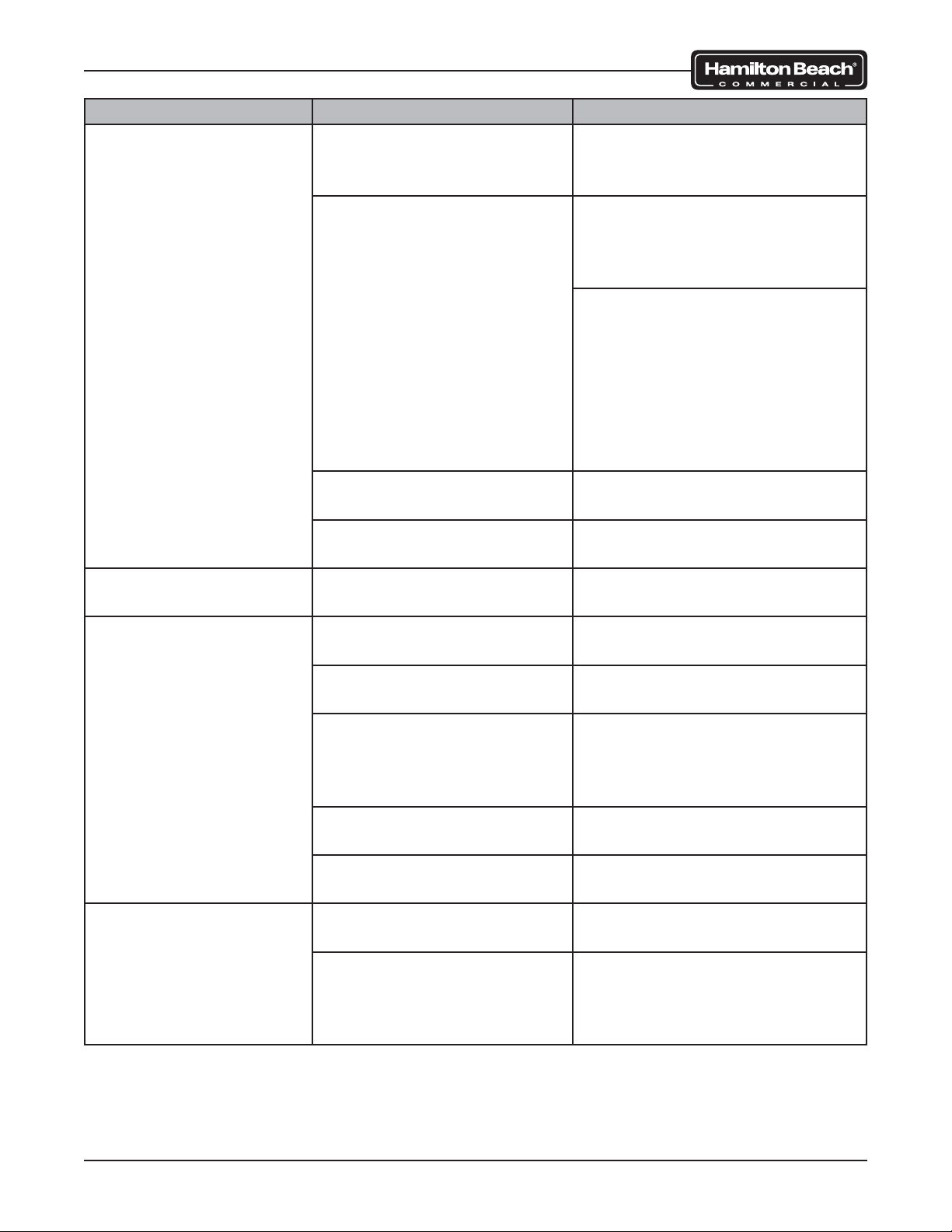

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Product too thick after

blending (MIC Only)

Water is turned off Turn water on.

Not enough water pressure

(less than 45 psi)

Obstruction in water supply

line

Clogged water fi lter (if ap-

plicable)

Improperly calibrated water Use operator interface panel to

Product is too cold or being

stored at incorrect temperature

Water solenoid valve malfunction (stuck closed)

Ensure location has

suffi cient water pressure.

Repair kinks or replace line.

Check in-store water

fi ltration system.

check WATER SCALE percentage. Record reading. Contact

Technical Services.

Check if SmartServe™ is using

factory settings or if customized

settings were implemented via

USB port during installation. If

factory settings are being used,

contact sales

representative to have

SmartServe™ custom-programmed.

Check temperature of freezer

unit. Adjust as necessary.

Test water solenoid valve. Replace as necessary.

Troubleshooting

Page 19 of 92 520008300 08/14

Page 20

SmartServe™ Drink Mixers Service Manual

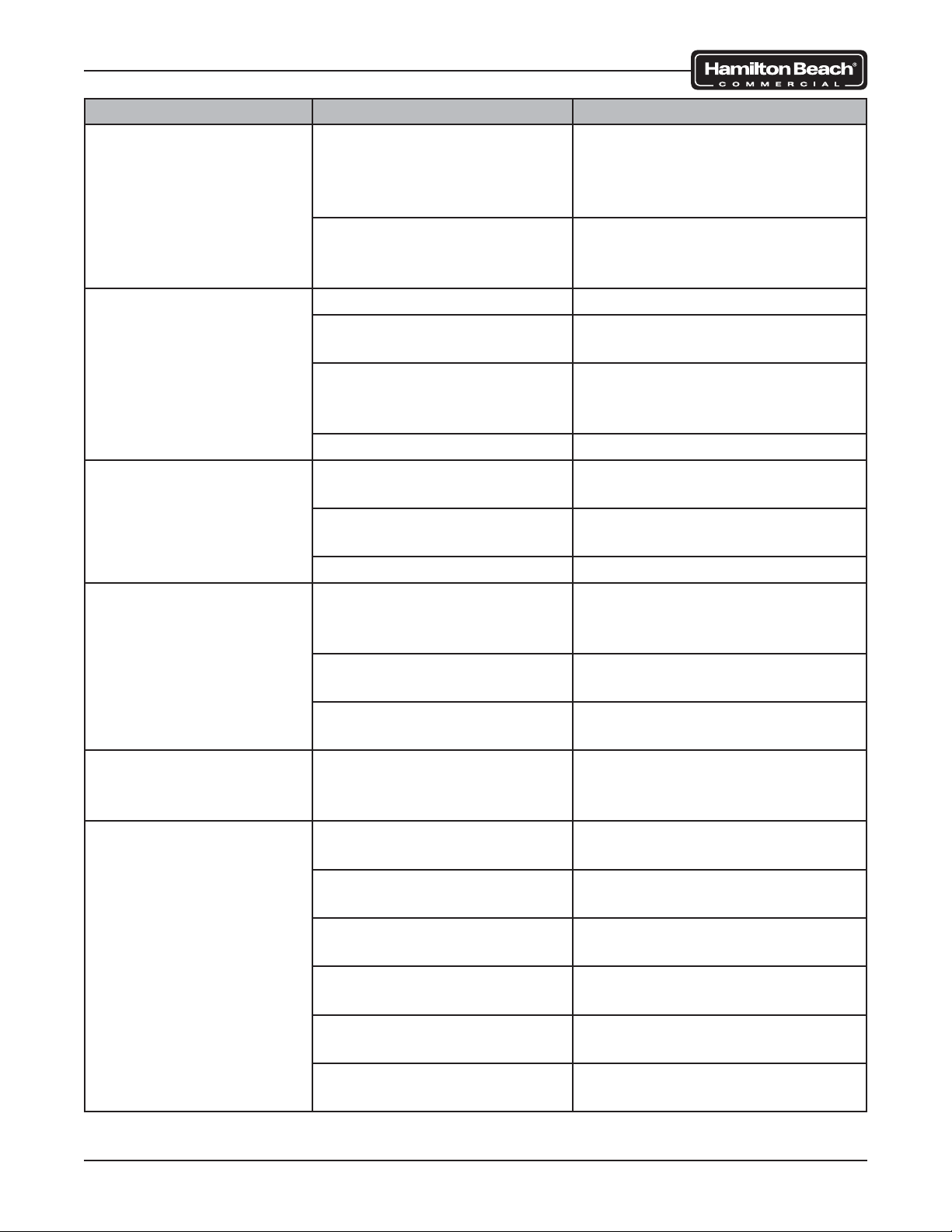

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Product too thin after

blending (MIC Only)

Product is too warm or

being stored at incorrect

temperature

Improperly calibrated water Use operator interface panel to

Hot water is being used for

water supply

Water solenoid valve

malfunction (stuck open)

Cup holder is loose or

Failed cup holder Replace cup holder.

missing

Water leaking from bot-

tom of SmartServe™

Loose or damaged water

lines

Leaking water solenoid

valve

Leaking water delivery

manifold assembly (MIC

only)

Leaking drain line or fi tting Replace drain line(s) and

SmartServe™ isn’t level Ensure SmartServe™ is mount-

Water leaking from top

of SmartServe™ (MIC

only)

Leaking water delivery coil

tube

Leaking water delivery

manifold assembly (MIC

only)

Check temperature of freezer

unit. Adjust as necessary.

check WATER SCALE percentage. Record reading. Contact

Technical Services.

Check if SmartServe™ is using

factory settings or if customized

settings were implemented via

USB port during installation. If

factory settings are being used,

contact sales representative to

have SmartServe™ customprogrammed.

Ensure water supply is connected to cold water.

Test water solenoid valve. Replace as necessary.

Repair or replace water lines.

Replace water solenoid valve.

Replace water delivery manifold

assembly. Check boards for

signs of shorting because the

boards probably got wet.

fi tting(s) as necessary.

ed on a level surface.

Repair loose connection or re-

place water delivery coil tube.

Replace water delivery manifold

assembly. Check boards for

signs of shorting because the

boards probably got wet.

Troubleshooting

Page 20 of 92 520008300 08/14

Page 21

SmartServe™ Drink Mixers Service Manual

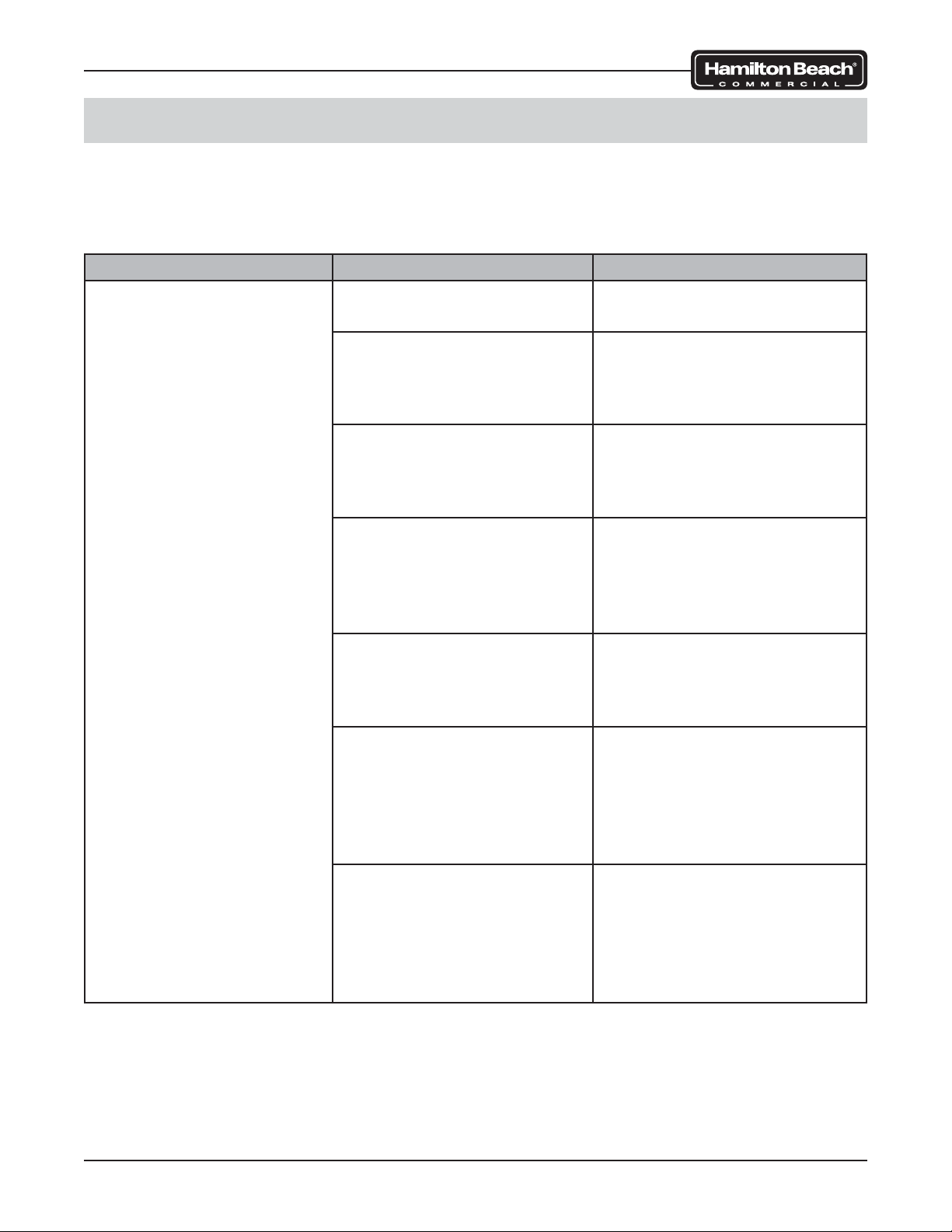

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Clicking noise at start of

blend cycle

Stepper motor lead screw

needs lubrication

Water delivery coil tube

cover getting caught while

moving down (MIC only)

Smell coming from

SmartServe™

Wash cycle wasn’t initiated Run wash cycle.

Sanitize cycle wasn’t initi-

ated

SmartServe™ and sur-

rounding area requires

cleaning

Obstructed drain line Clear drain line.

Buttons on touch pad

do not work

Loose connection at user

interface display

Loose connection at control

board

Failed touch pad Replace touch pad.

Wash chamber fi lling up

Obstructed drain line Clear drain line. Check drain

with water during rinse

and/or fl ush cycles

Too much soap suds in

wash chamber

SmartServe™ isn’t level Ensure SmartServe™ is mount-

Flashing lights inside

Normal operation No corrective action necessary.

SmartServe™ on control board

SmartServe™ not rins-

Auto-rinse disabled Enable auto-rinse using user

ing

Obstruction inside safety

shield

Loose connection on control

board

Not enough water pressure

(less than 45 psi)

SmartServe™ needs to be

rebooted

Rinse valve not operable Diagnose and replace rinse

Apply lubricant to stepper motor lead screw. Linear actuator

slides should only be cleaned,

never lubricated.

Reroute or move coil tube and

cover as necessary.

Run sanitize cycle.

Clean around and under machine.

Check connections at user interface display.

Check connections at control

board.

line to ensure it is pitched and

vented correctly, if applicable.

Use less soap.

ed on a level surface.

interface display.

Ensure there are no obstruc-

tions inside safety shield.

Ensure there are no loose con-

nections on control board.

Ensure location has suffi cient

water pressure.

Power down SmartServe™ and

turn back on.

valve as required.

Troubleshooting

Page 21 of 92 520008300 08/14

Page 22

SmartServe™ Drink Mixers Service Manual

Error Code Troubleshooting

If Operator Interface Panel displays an error code message, press STOP button repeatedly

until error code message clears or power down SmartServe™ and turn back on to reboot. If

error code message remains, use the table below:

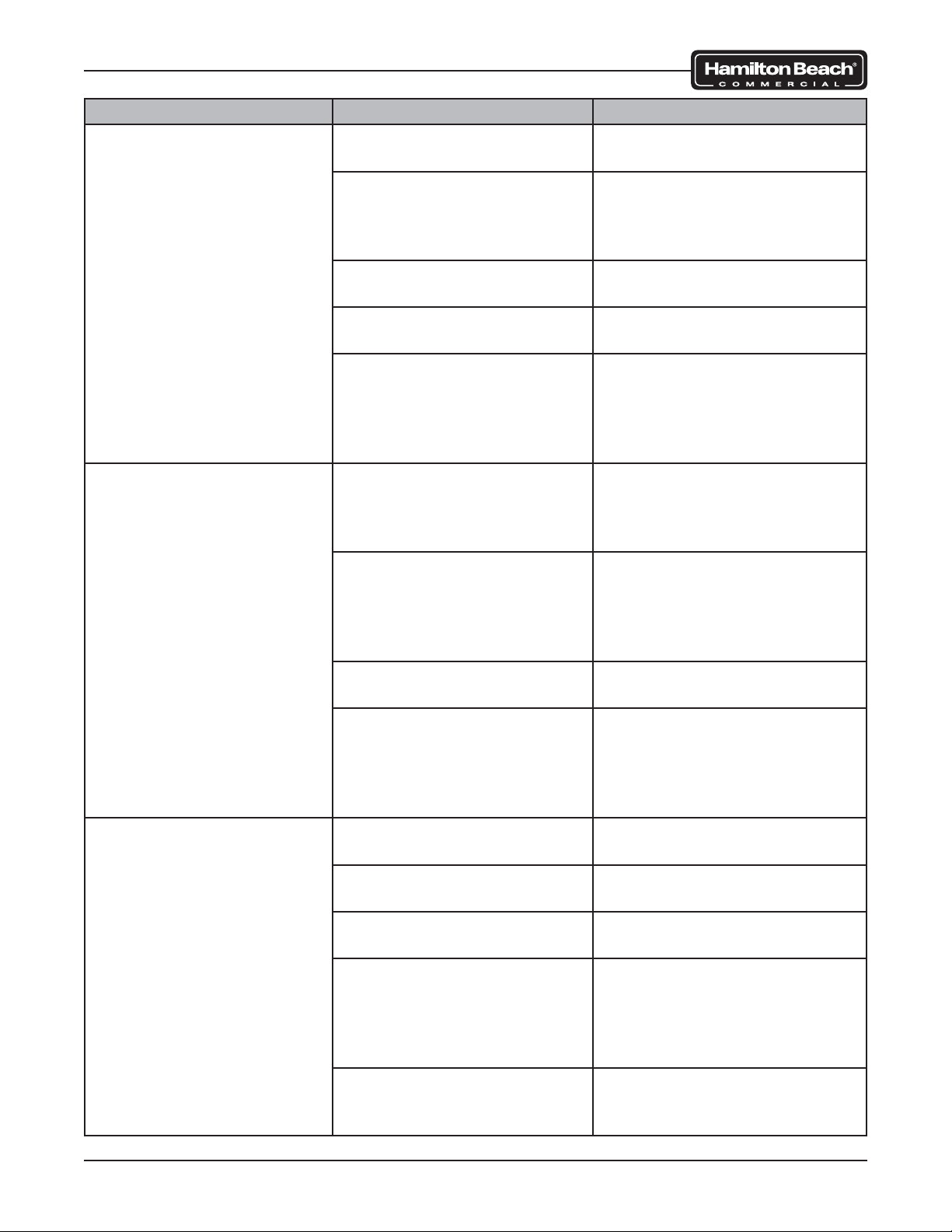

ERROR CODE MESSAGE POSSIBLE CAUSE CORRECTIVE ACTION

U-Interface Error Shake cup not in place Ensure shake cup is placed

inside cup holder properly.

Obstruction in safety shield Ensure there are no obstruc-

tions inside safety shield preventing machine from rinsing

or fl ushing.

Disrupted blend, rinse,

fl ush, wash, or sanitize

cycles.

SmartServe™ needs to be

rebooted

Loose connection or failed

shield sensor

Power supply problem Check power supply connec-

Loose or missing shield

magnet in base of door

Ensure there were no disruptions during blend, rinse,

fl ush, wash, or sanitize cycles.

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Check connection on shield

sensor. Test shield sensor if

connection is good. Repair or

replace as necessary.

tions. Check voltage at power

supply. Check harness between power supply and control board. Repair or replace

as necessary.

Repair or replace door assembly as required.

Troubleshooting

Page 22 of 92 520008300 08/14

Page 23

SmartServe™ Drink Mixers Service Manual

ERROR CODE MESSAGE POSSIBLE CAUSE CORRECTIVE ACTION

Motor Control Error Shake cup not in place Ensure shake cup is placed

inside cup holder properly.

Obstruction in safety shield Ensure there are no obstruc-

tions inside safety shield preventing machine from rinsing

or fl ushing.

Loose connection at user

interface display

Loose connection at control

board

SmartServe™ needs to be

rebooted

Check connections at user

interface display.

Check connections at control

board.

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Motor Control Error

Stepper Motion Error

Loose connection or failed

home sensor

Check connection on home

sensor. Test home sensor if

connection is good. Repair or

replace as necessary.

Loose connection or failed

cup present sensor

Check connection on cup

present sensor. Test cup

present sensor if connection

is good. Repair or replace as

necessary.

Failed control board Test control board. Replace as

necessary.

SmartServe™ needs to be

rebooted

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Motor Control Error

Hall Sensor

Loose connection at control

board

Check connections at control

board.

Failed motor Test motor. Replace as neces-

sary.

Failed control board Test control board. Replace as

necessary.

SmartServe™ needs to be

rebooted

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Program ramp rate confl ict Contact sales to supply or

verify any new custom program.

Troubleshooting

Page 23 of 92 520008300 08/14

Page 24

SmartServe™ Drink Mixers Service Manual

ERROR CODE MESSAGE POSSIBLE CAUSE CORRECTIVE ACTION

Communication Error Shake cup not in place Ensure shake cup is placed

inside cup holder properly.

Disrupted blend, rinse,

fl ush, wash, or sanitize

cycles.

Ensure there were no disruptions during blend, rinse,

fl ush, wash, or sanitize cycles.

Lower cup shield is assembled improperly or not

installed on cup guard housing properly

Loose connection at user

interface display

Loose connection at control

board

Loose connection or failed

wash chamber sensor

Ensure lower cup shield is

assembled correctly and installed on cup guard housing

properly. Magnets go to rear.

Check connections at user

interface display.

Check connections at control

board.

Check connection on wash

chamber sensor. Test wash

chamber sensor if connection

is good. Repair or replace as

necessary.

SmartServe™ needs to be

rebooted

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Shield Obstruction Error Obstruction in safety shield Ensure there are no obstruc-

tions inside safety shield preventing machine from rinsing

or fl ushing.

Shake cup not in place Ensure shake cup is placed

inside cup holder properly.

Lower cup shield is assembled improperly or not

installed on cup guard housing properly

Loose connection at control

board

SmartServe™ needs to be

rebooted

Ensure lower cup shield is

assembled correctly and installed on cup guard housing

properly. Magnets go to rear.

Check connections at control

board.

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Troubleshooting

Page 24 of 92 520008300 08/14

Page 25

SmartServe™ Drink Mixers Service Manual

ERROR CODE MESSAGE POSSIBLE CAUSE CORRECTIVE ACTION

Interlock Error Product is too cold or being

stored at incorrect tempera-

Check temperature of freezer

unit. Adjust as necessary.

ture

Obstruction in safety shield Ensure there are no obstruc-

tions inside safety shield preventing machine from rinsing

or fl ushing.

SmartServe™ needs to be

rebooted

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Replace Cup Cup sensor is disabled Use operator interface panel

to see if cup sensor is enabled. If disabled, set to

enabled.

Loose connection or failed

cup sensor

Check connection on control board. Test cup sensor if

connection is good. Repair or

replace as necessary.

SmartServe™ needs to be

rebooted

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Hamilton Beach

Commercial (screen froze,

touch pad doesn’t work)

SmartServe™ needs to be

rebooted

Press STOP button repeatedly until error code messages clear or power down

SmartServe™ and turn back

on to reboot.

Failed linear actuator Test linear actuator. Replace

as necessary.

Failed motor Test motor. Replace as nec-

essary.

Failed touch pad Test touch pad. Replace as

necessary.

Troubleshooting

Page 25 of 92 520008300 08/14

Page 26

SmartServe™ Drink Mixers Service Manual

Safety Shield Assembly

The safety shield assembly is located on the front of the machine. The assembly includes a

shield door that can be serviced separately. A magnet embedded in the assembly interacts with

the shield sensor. Some models have two door magnets and sensors. The machine will not

operate if the safety shield assembly is not installed and the door is not closed properly.

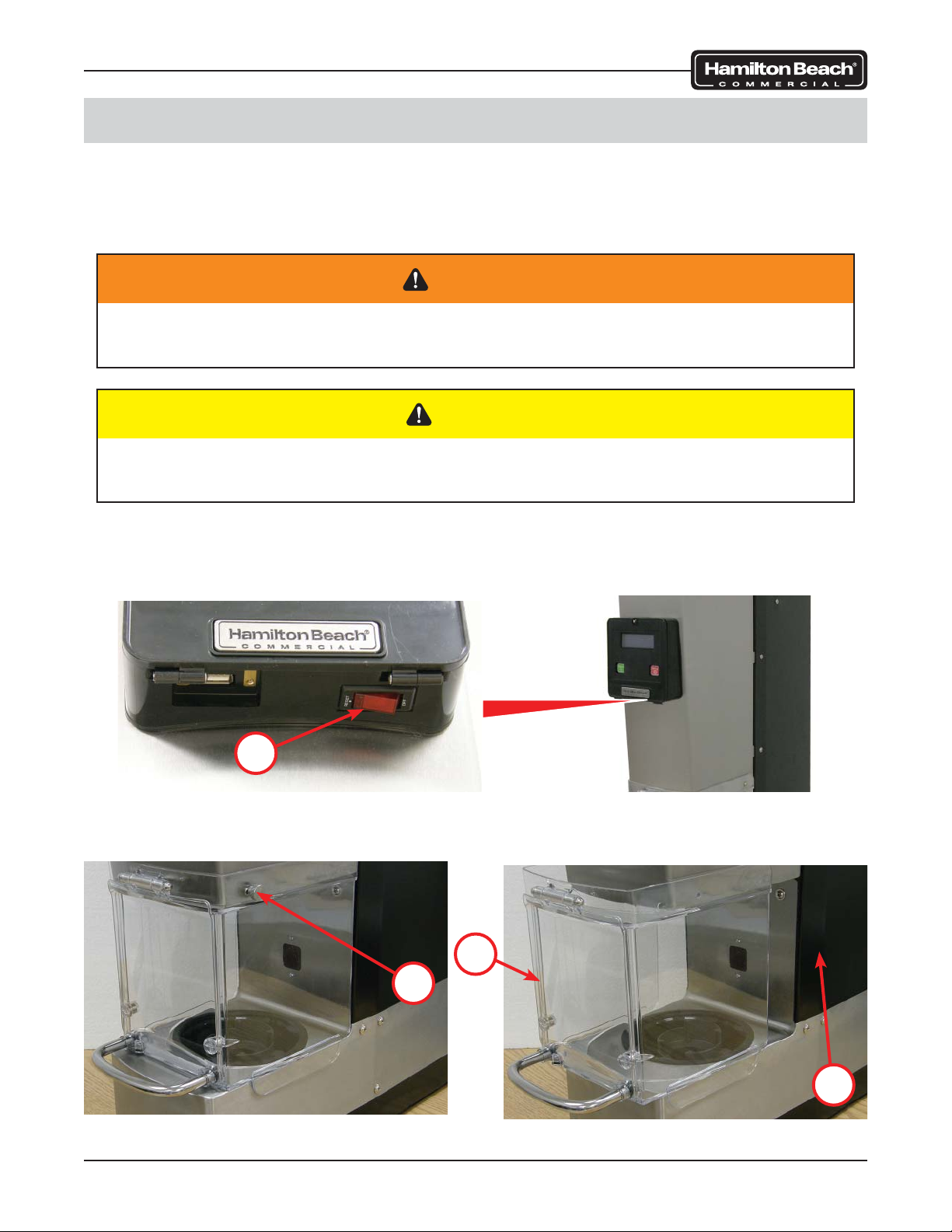

WARNING

To avoid risk of serious injury or death, disconnect power to the machine before

cleaning, servicing, or removing parts.

CAUTION

Do not use power tools to remove hardware. Damage to the hardware or the machine

may occur. Do not lose hardware.

To remove the safety shield assembly:

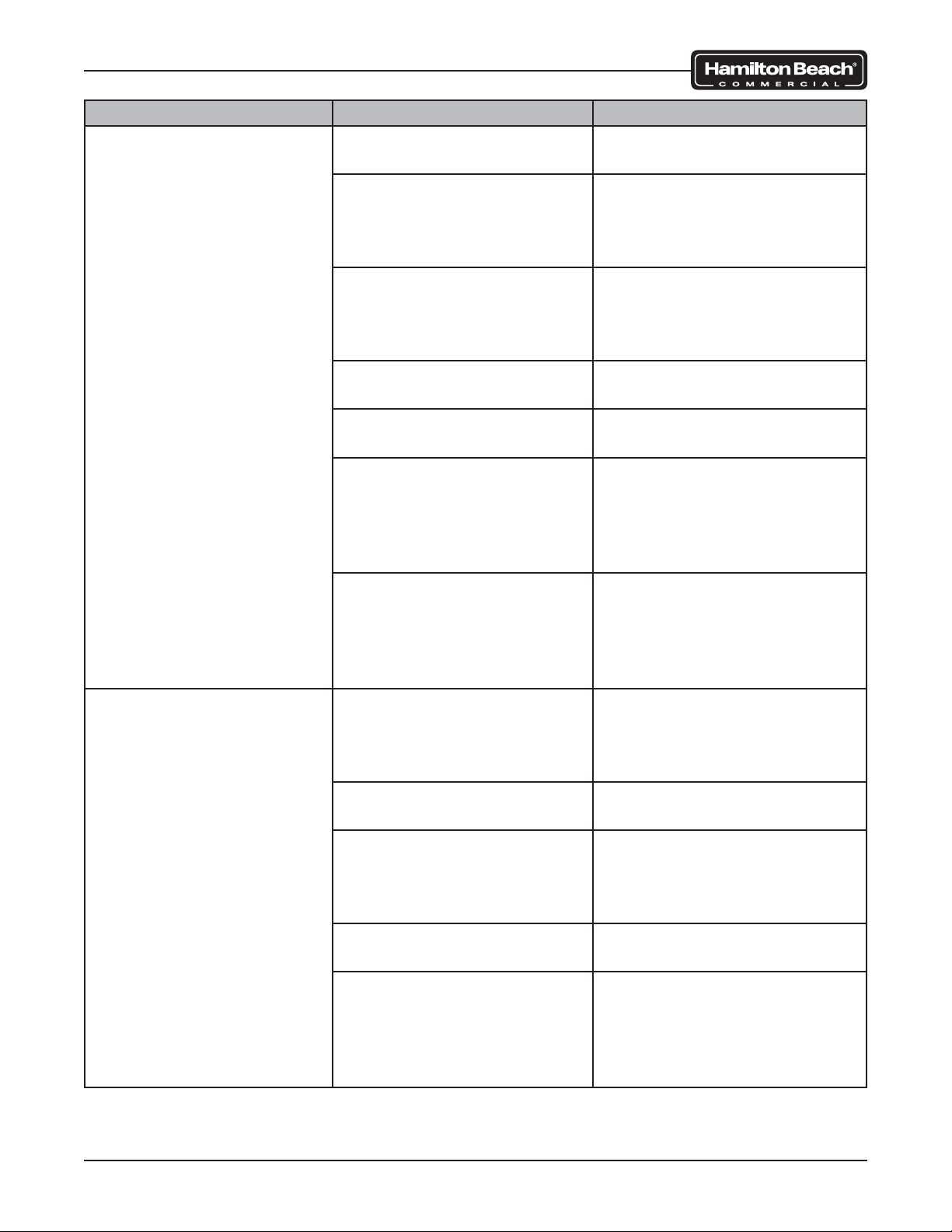

1. Ensure the control panel power switch (1) is in the OFF position and unplug the

machine.

1

2. Remove two thumb screws (2) from the safety shield assembly (3).

3. Slide the safety shield assembly (3) forward to remove from the machine (4).

3

Removal and Replacement

2

4

Page 26 of 92 520008300 08/14

Page 27

SmartServe™ Drink Mixers Service Manual

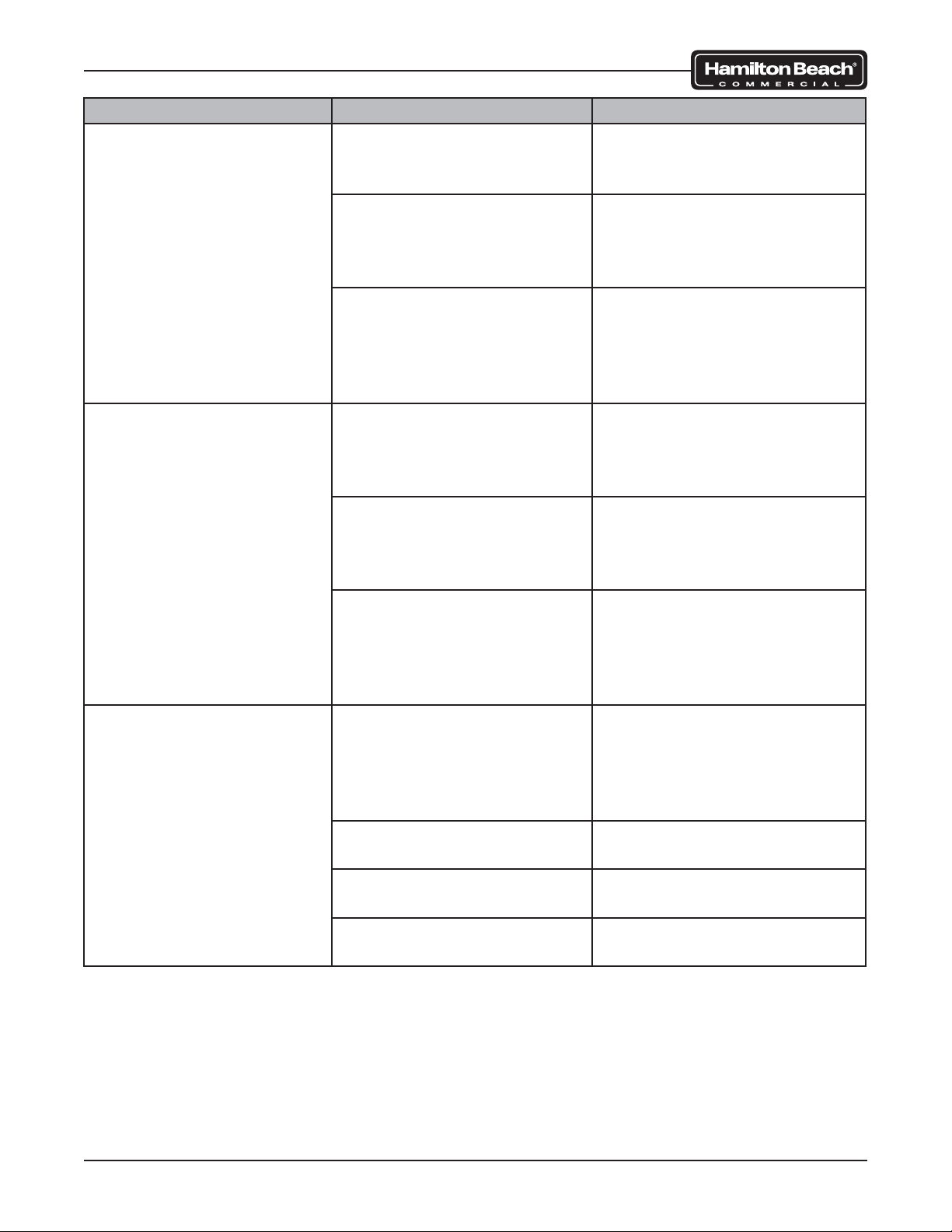

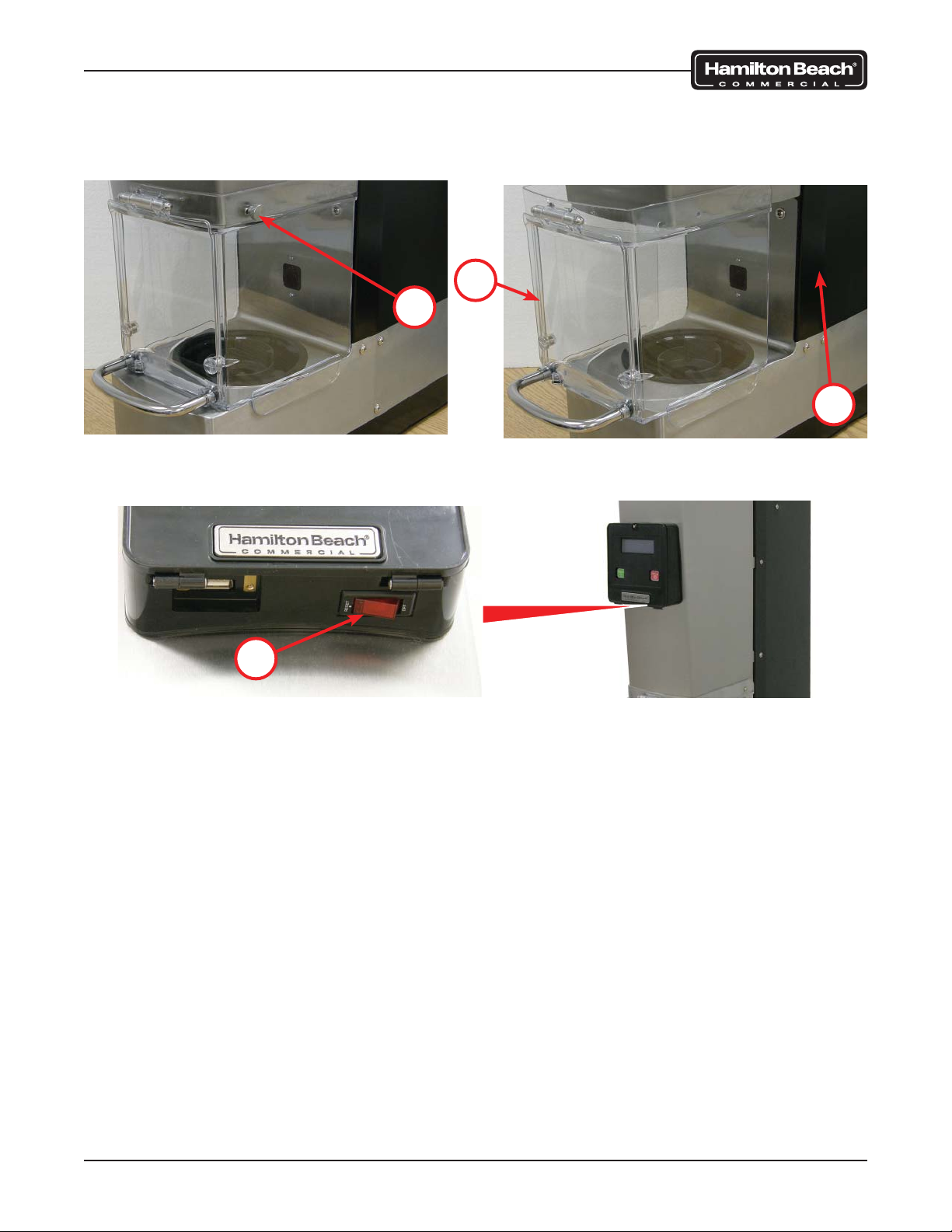

To install the safety shield assembly:

1. Slide the safety shield assembly (3) onto the machine (4).

2. Install a thumb screw (2) on each side of the safety shield assembly (3).

3

2

3. Plug in the power cord to the machine, turn the control panel power switch (1) to the

RESET position, and verify machine operates.

4

1

Removal and Replacement

Page 27 of 92 520008300 08/14

Page 28

SmartServe™ Drink Mixers Service Manual

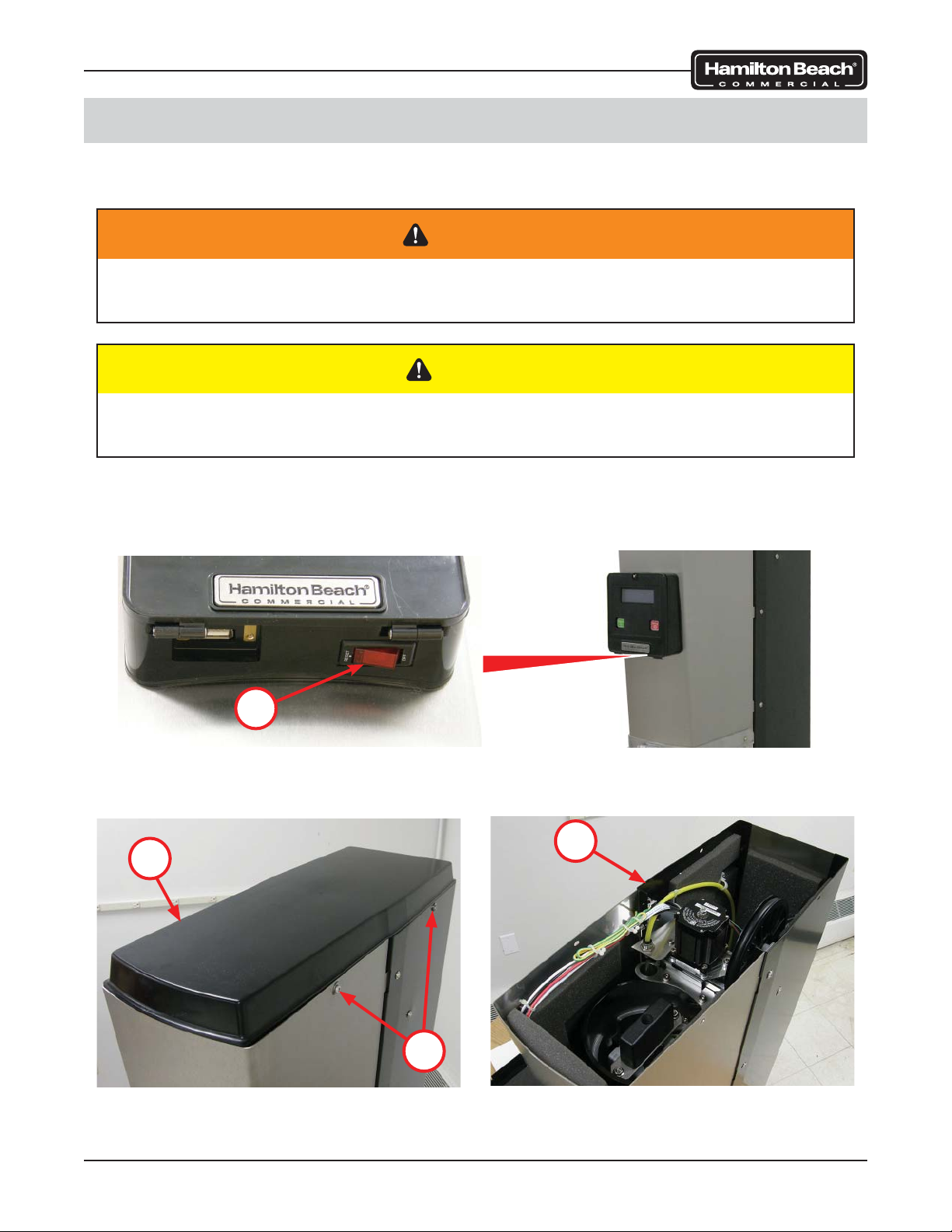

Top Cover

The top cover is located on the top of the machine. Removal of the top cover allows access to

various components of the machine.

WARNING

To avoid risk of serious injury or death, disconnect power to the machine before

cleaning, servicing, or removing parts.

CAUTION

Do not use power tools to remove hardware. Damage to the hardware or the machine

may occur. Do not lose hardware.

To remove the top cover:

1. Ensure the control panel power switch (1) is in the OFF position and unplug the

machine.

1

2. Remove two screws (2) from each side of the machine (3).

3. Lift the top cover (4) from the machine (3).

3

4

Removal and Replacement

2

Page 28 of 92 520008300 08/14

Page 29

SmartServe™ Drink Mixers Service Manual

To install the top cover:

1. Place the top cover (4) onto the machine (3) as shown.

2. Install two screws (2) on each side of the machine (3).

3

4

2

3. Plug in the power cord to the machine, turn the control panel power switch (1) to the

RESET position, and verify machine operates.

1

Removal and Replacement

Page 29 of 92 520008300 08/14

Page 30

SmartServe™ Drink Mixers Service Manual

Operator Interface Panel Assembly

The operator interface panel assembly is located on the front of the machine and is used

to operate the machine. The assembly has a breaker switch, control board, touch pad, and

access door that are serviceable.

WARNING

To avoid risk of serious injury or death, disconnect power to the machine before

cleaning, servicing, or removing parts.

CAUTION

Do not use power tools to remove hardware. Damage to the hardware or the machine

may occur. Do not lose hardware.

To remove the operator interface panel assembly:

1. Ensure the control panel power switch (1) is in the OFF position and unplug the

machine.

2. Lift the metal tab (2) on the panel to lower the access door (3).

2

3

1

Removal and Replacement

Page 30 of 92 520008300 08/14

Page 31

SmartServe™ Drink Mixers Service Manual

3. Remove four screws (4) from the panel (5).

4. Carefully lift the panel (5) from the machine.

5. Mark and disconnect two connectors (6) from the interface control board (7).

6. Mark and disconnect three wires (8) from the breaker switch (9).

5

6

8

4

9

To install the operator interface panel assembly:

1. Ensure the panel gasket (10) is on the machine.

2. Connect three wires (8) to the breaker switch (9).

3. Connect two connectors (6) to the interface control panel (7).

4. Position the panel (5) on the machine and ensure the gasket (10) is seated properly.

5. Install four screws (4) on the panel (5).

6. Close the access door (3).

7

10

7. Plug in the power cord to the machine, turn the control panel power switch (1) to the

RESET position, and verify machine operates.

3

1

Removal and Replacement

Page 31 of 92 520008300 08/14

Page 32

SmartServe™ Drink Mixers Service Manual

Breaker Switch

The breaker switch is located on the operator interface panel and is used to turn the main

power on or off.

To remove the breaker switch:

1. Remove the operator interface panel assembly (1) as outlined in this manual.

2. Depress the tabs (2) on the switch (3) and remove the switch from the operator interface

panel assembly (1).

3

2

1

To install the breaker switch:

1. Push the switch (3) into the operator interface panel assembly (1) until the tabs (2) lock

the switch (3) in place.

2. Install the operator interface panel assembly (1) as outlined in this manual and verify

operation.

Removal and Replacement

Page 32 of 92 520008300 08/14

Page 33

SmartServe™ Drink Mixers Service Manual

Interface Display Board

The interface display board is located on the operator interface panel and is used to display

information to the user and relay input commands to the control board assembly.

To remove the interface display board:

1. Remove the operator interface panel assembly (1) as outlined in this manual.

2. Disconnect the touch pad ribbon cable (2) from the display board (3).

3. Remove eight screws (4) and gently pull upper boards from lower board.

CAUTION

Use care when removing the upper boards from the lower board to avoid damage to

the pins.

4. Remove three screws (5) and lower board from panel.

4

1

3

4

2

To install the interface display board:

1. Separate the display board assembly.

2. Install the lower board with three screws (5) to the operator interface panel

assembly (1).

CAUTION

Use care when installing the upper boards on the lower board to avoid damage to the

pins.

5

3. Gently place the upper boards on the lower board. Ensure the pins line up.

4. Install eight screws (4).

5. Connect the touch pad ribbon cable (2) to the display board (3).

6. Install the operator interface panel assembly (1) as outlined in this manual and verify

operation.

Removal and Replacement

Page 33 of 92 520008300 08/14

Page 34

SmartServe™ Drink Mixers Service Manual

Touch Pad

The touch pad is located on the operator interface panel and is used by the operator to control

the machine.

To remove the touch pad:

1. Remove the operator interface panel assembly (1) as outlined in this manual.

2. Disconnect the touch pad ribbon cable (2) from the display board (3).

3. Using a flat tool, such as a razor, start at the corner and peel the touch pad (4) off the

operator interface panel assembly (1).

4. Pull the ribbon cable (2) through the slot on the operator interface panel assembly (1).

1

4

2 3

To install the touch pad:

1. Clean the surface thoroughly to remove any adhesive residue.

2. Clean the LCD screen to remove any smudges or fingerprints.

3. Insert the ribbon cable (2) through the slot of the operator interface panel assembly (1).

NOTE: The adhesive on the touch pad will adhere to the plastic instantly. It will be very difficult

to reposition the touch pad if not aligned properly. Be careful to avoid air pockets/bubbles. Do

not remove the protective paper all at once.

4. Apply the touch pad (4) starting on the upper left side and slowly roll the protective

paper off the touch pad (4) while applying the touch pad (4) to the panel. Continuously

feed the ribbon cable (2) through the slot.

5. Connect the touch pad ribbon cable (2) to the display board (3).

6. Install the operator interface panel assembly (1) as outlined in this manual and verify

operation.

Removal and Replacement

Page 34 of 92 520008300 08/14

Page 35

SmartServe™ Drink Mixers Service Manual

Cup Guard & Shield Assembly

The cup guard & shield assembly is lowered over the cup during operation and cleaning

cycles. It is mounted on the motor assembly.

To remove the cup guard & shield assembly:

1. Remove the safety shield assembly as outlined in this manual.

2. Remove the top cover as outlined in this manual.

3. Remove the blades using the removal tool (PN 9900167800). The threads are right

hand and it may be necessary to strike the tool with a hammer to loosen the blades.

4. Remove three screws (1) from each side of the machine.

5. Lift the front panel wrap (2) from the machine.

NOTE: Avoid overextending the wire harness attached to the interface panel on the wrap.

NOTE: Cover front panel wrap to avoid scratches/damage from contact with side of machine.

6. Using a large wire tie (3), secure the wrap (2) to the machine using the hole in the top of

the side panel (4).

2

2

1

7. Remove the cup shield (5) by pressing the tab (6) in the cup guard and shield

assembly (7) and turn the cup shield (5) clockwise.

7

3

4

6

ROTATE

Removal and Replacement

5

Page 35 of 92 520008300 08/14

Page 36

SmartServe™ Drink Mixers Service Manual

8. Raise the cup guard and shield assembly (7) and place a support block (8) under the

shield block (9).

9. Remove two flange nuts (10), shield block (9), and cup guard and shield assembly (7)

from the motor assembly (11).

9

8

11

10

7

11

To install the cup guard & shield assembly:

1. Install the cup guard and shield assembly (7) with two flange nuts (10) and shield

block (9) on the motor assembly (11).

NOTE: Take care to align motor shaft with shaft seal so bearing grommet and shaft seal are

not pushed out of place by motor shaft during installation.

2. Install the cup shield (5) on the cup guard and shield assembly (7) until the tab (6) locks

into place.

7

6

5

ROTATE

Removal and Replacement

Page 36 of 92 520008300 08/14

Page 37

SmartServe™ Drink Mixers Service Manual

3. Remove the wire tie (3) holding the wrap (2) to the side panel (4).

4. Position the wrap (2) on the machine and secure the wrap with six screws (1).

NOTE: Ensure the wire harness is positioned in a way to avoid interference with the movement

of the cup guard and shield assembly.

2

2

1

5. Install the blade assembly. It is not necessary to tighten the blades with a tool. The

operation of the machine will tighten the bladed assembly sufficiently.

6. Install the top cover as outlined in this manual.

7. Install the safety shield assembly as outlined in this manual.

8. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

3

4

Removal and Replacement

Page 37 of 92 520008300 08/14

Page 38

SmartServe™ Drink Mixers Service Manual

Motor Assembly

The motor assembly is used to turn the blade assembly. It receives power through the control

board.

To remove the motor assembly:

NOTE: This removal procedure is for the BIC2000. The removal procedure for the MIC2000

is similar and will require the water supply to be disconnected and the system purged before

removing the motor assembly.

1. Remove the blades using the removal tool (PN 9900167800). The threads are right

hand and it may be necessary to strike the tool with a hammer to loosen the blades.

2. Remove the shield assembly as outlined in this manual.

3. Pull up on the motor cord (1) just under the top pulley (2). This will raise the lower pulley

(3). Position a punch or screwdriver through the hole in the upper portion of the festoon

sheet metal (4) and one of the holes in the lower pulley (3). This will hold the spring

force and create slack in the motor cord (1).

4. Remove two clamps (5) from the motor assembly (6).

3

1

5

6

4

2

5. Mark and disconnect six wires (7).

NOTE: On the MIC2000, disconnect the spiral water line from the water delivery manifold

before step 5.

6. Remove two screws (8) and motor assembly (6) from the linear actuator assembly (9).

8

Ground

9

7

MOTOR

CORD

Removal and Replacement

MOTOR

6

Page 38 of 92 520008300 08/14

Page 39

SmartServe™ Drink Mixers Service Manual

7. Remove four screws (10) and harness cover (11) from motor assembly (6).

8. Pull six wires (7) from the motor assembly (6).

10

11

7

10

6

To install the motor assembly:

1. Feed six wires (7) into the motor assembly (6).

2. Secure the wire harness in place with the harness cover (11) and four screws (10).

3. Install the motor assembly (6) on the linear actuator assembly (9) with two screws (8).

4. Connect six wires (7).

MOTOR

CORD

8

Ground

MOTOR

9

7

6

Removal and Replacement

Page 39 of 92 520008300 08/14

Page 40

SmartServe™ Drink Mixers Service Manual

5. Secure the wires (7) with two clamps (5) on the motor assembly (6).

NOTE: On the MIC2000, connect the spiral water line to the water delivery manifold after

step 5.

6. Pull up on the motor cord (1) just under the top pulley (2). This will raise the lower pulley

(3). Remove the punch or screwdriver holding the lower pulley (3) and gently lower the

motor cord (1) into place.

3

1

5

6

4

2

7. Install the shield assembly as outlined in this manual.

8. Install the blade assembly. It is not necessary to tighten the blades with a tool. The

operation of the machine will tighten the bladed assembly sufficiently.

9. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

Removal and Replacement

Page 40 of 92 520008300 08/14

Page 41

SmartServe™ Drink Mixers Service Manual

Linear Actuator Assembly

The linear actuator assembly is used to lower and raise the motor carriage during use.

To remove the linear actuator assembly:

1. Remove the safety shield assembly as outlined in this manual.

2. Remove the top cover as outlined in this manual.

3. Remove three screws (1) from each side of the machine.

4. Lift the front panel wrap (2) from the machine.

NOTE: Avoid overextending the wire harness attached to the interface panel on the wrap.

NOTE: Cover front panel wrap to avoid scratches/damage from contact with side of machine.

5. Using a large wire tie (3), secure the wrap (2) to the machine using the hole in the top of

the side panel (4).

2

2

1

6. Remove six screws (5) and back cover (6) from machine.

NOTE: Remove any wire ties as required.

7. Remove four nuts (7) and lockwashers (8) from control board (9).

8. Position the control board (9) to the left to access and disconnect the linear motor

connector (10).

3

4

7

5

9

6

5

Removal and Replacement

9

8

Page 41 of 92 520008300 08/14

10

Page 42

SmartServe™ Drink Mixers Service Manual

NOTE: On the MIC2000, disconnect the spiral water line from the water delivery manifold

before step 9.

9. Remove two screws (11) and lift motor assembly (12) from the linear motor assembly

(13). Allow the motor assembly to hang by the motor cord.

10. Position the motor mount (14) so that all eight screws (15) are accessible.

11. Remove eight screws (15) and linear motor assembly (13) from machine.

NOTE: Motor shown removed for clarity.

11

13

15

15

14

12

15

15

13

To install the linear actuator assembly:

1. Install the linear motor assembly (13) on the machine with eight screws (15).

2. Place the motor assembly (12) on the linear motor assembly (13) and secure in place

with two screws (11).

Removal and Replacement

Page 42 of 92 520008300 08/14

Page 43

SmartServe™ Drink Mixers Service Manual

NOTE: On the MIC2000, connect the spiral water line to the water delivery manifold after

step 2.

3. Connect the linear motor connector (10) to the control board (9).

4. Position the control board (9) on the standoffs and install lockwashers (8) and nuts (7).

NOTE: Secure any loose wires with wire ties as required.

5. Install six screws (5) and back cover (6) on the machine.

7

5

9

6

5

9

10

8

6. Remove the wire tie (3) holding the wrap (2) to the side panel (4).

7. Position the wrap (2) on the machine and secure the wrap with six screws (1).

NOTE: Ensure the wire harness is positioned in a way to avoid interference with the movement

of the cup guard and shield assembly.

2

2

3

1

8. Install the top cover as outlined in this manual.

9. Install the safety shield assembly as outlined in this manual.

10. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

Removal and Replacement

Page 43 of 92 520008300 08/14

4

Page 44

SmartServe™ Drink Mixers Service Manual

48VDC Power Supply

The 48VDC power supply is located behind the back panel and distributes power to control

board #1 and jumps to control board #2 to supply power for valves and linear actuator motor.

WARNING

To avoid risk of serious injury or death, disconnect power to the machine before

cleaning, servicing, or removing parts.

CAUTION

Do not use power tools to remove hardware. Damage to the hardware or the machine

may occur. Do not lose hardware.

To remove the power supply:

1. Ensure the control panel power switch (1) is in the OFF position and unplug the

machine.

1

2. Remove six screws (2) and back cover (3) from machine.

NOTE: Remove any wire ties as required.

3. Loosen four knobs (4). Do not remove the knobs.

2

Removal and Replacement

4

4

3

2

Page 44 of 92 520008300 08/14

Page 45

SmartServe™ Drink Mixers Service Manual

4. Lift and rotate clockwise the power control assembly (5) until you are able to access the

rear of the power control assembly (5).

5. Mark and disconnect four wires (6) from the power supply (7).

6. Remove four screws (8), washers (9), and power supply (7) from the power control

assembly (5).

V+

(Red)

V-

(Black/Red)

N

(White)

L

(Black)

5

7 8

6

7

9

7. Remove four screws (10) and power supply (7) from the isolation panel (11).

7

11

10

To install the power supply:

1. Install four screws (10) and power supply (7) on the isolation panel (11).

2. Install the power supply (7) on the power control assembly (5) with four washers (9) and

screws (8).

3. Connect four wires (6) to the power supply (7).

Removal and Replacement

Page 45 of 92 520008300 08/14

Page 46

SmartServe™ Drink Mixers Service Manual

4. Carefully position the power control assembly (5) on the four knobs (4).

NOTE: Ensure all connections on the power supply and control board are secure. Replace any

wire ties as required.

5. Hand-tighten the four knobs (4).

6. Install the back cover (3) with six screws (2).

2

4

4

3

2

7. Plug in the power cord to the machine, turn the control panel power switch (1) to the

RESET position, and verify machine operates.

1

Removal and Replacement

Page 46 of 92 520008300 08/14

Page 47

SmartServe™ Drink Mixers Service Manual

Control Board Assembly

The control board assembly is located behind the back panel and controls all functions of the

machine.

WARNING

To avoid risk of serious injury or death, disconnect power to the machine before

cleaning, servicing, or removing parts.

CAUTION

Do not use power tools to remove hardware. Damage to the hardware or the machine

may occur. Do not lose hardware.

To remove the control board assembly:

1. Ensure the control panel power switch (1) is in the OFF position and unplug the

machine.

1

2. Remove six screws (2) and back cover (3) from machine.

NOTE: Remove any wire ties as required.

3. Loosen four knobs (4). Do not remove the knobs.

2

Removal and Replacement

4

4

3

2

Page 47 of 92 520008300 08/14

Page 48

SmartServe™ Drink Mixers Service Manual

4. Remove four nuts (5) and lockwashers (6) from control board (7).

5. Position the control board (7) to the left to access and disconnect the linear motor

connector (8).

6. Position the control board (7) on the standoffs (9) and install lockwashers (6) and

nuts (5).

5

7

7

6

7. Lift and rotate clockwise the power control assembly (10) until you are able to access

the rear of the power control assembly (10).

8. Mark and disconnect all wires (11) and connectors (12) from the control board (7).

9. Remove four screws (13) and control board (7) from the power control assembly (10).

12

11

7

8

9

13

12

12

To install the control board assembly:

1. Install the control board (7) on the power control assembly (10) with four screws (13).

2. Connect all wires (11) and connectors (12) to the correct location on control board (7).

Removal and Replacement

11

Page 48 of 92 520008300 08/14

10

Page 49

SmartServe™ Drink Mixers Service Manual

3. Remove four nuts (5) and lockwashers (6) from control board (7).

4. Position the control board (7) to the left to connect the linear motor connector (8).

5. Position the control board (7) on the standoffs (9) and install lockwashers (6) and

nuts (5).

5

7

7

6

6. Carefully position the power control assembly (10) on the four knobs (4).

NOTE: Ensure all connections on the power supply and control board are secure. Replace any

wire ties as required.

7. Hand-tighten the four knobs (4).

8. Install the back cover (3) with six screws (2).

8

9

2

4

4

3

2

9. Plug in the power cord to the machine, turn the control panel power switch (1) to the

RESET position, and verify machine operates.

1

Removal and Replacement

Page 49 of 92 520008300 08/14

Page 50

SmartServe™ Drink Mixers Service Manual

Sensor Assembly (Home Position)

The sensor assembly (home position) is located on the frame near the top of the machine. The

sensor determines the highest position of the motor and cup guard/shield assembly.

To remove the sensor assembly (home position):

1. Remove the top cover as outlined in this manual.

2. Remove six screws (1) and back cover (2) from machine.

NOTE: Remove any wire ties as required. Note the routing of the sensor wiring being replaced.

3. Disconnect sensor connector (3) from control board (4).

1

4

2

3

1

4. Use a screwdriver to depress the tabs on the side of the sensor assembly (5) and

push the sensor assembly (5) through the hole in the frame (6) and remove the sensor

assembly (5). The black plastic housing is part of the sensor assembly.

6

Removal and Replacement

5

PUSH THROUGH

Page 50 of 92 520008300 08/14

Page 51

SmartServe™ Drink Mixers Service Manual

To install the sensor assembly (home position):

1. Push the sensor assembly (5) into the hole in the frame (6).

6

5

NOTE: Route the wire harness for the sensor to the control board in a way that will avoid any

chance of pinching or fraying of the wires. Replace any wire ties as required.

2. Connect sensor connector (3) to the control board (4).

3. Install the back cover (2) with six screws (1).

4

1

2

3

1

4. Install the top cover as outlined in this manual.

5. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

Removal and Replacement

Page 51 of 92 520008300 08/14

Page 52

SmartServe™ Drink Mixers Service Manual

Sensor Assembly (Cup Present)

The sensor assembly (cup present) is located on the frame near the motor assembly. The

sensor determines the lowest position of the motor and cup guard/shield assembly.

To remove the Sensor Assembly (Cup Present):

1. Remove the safety shield assembly as outlined in this manual.

2. Remove the top cover as outlined in this manual.

3. Remove three screws (1) from each side of the machine.

4. Lift the front panel wrap (2) from the machine.

NOTE: Avoid overextending the wire harness attached to the interface panel on the wrap.

NOTE: Cover front panel wrap to avoid scratches/damage from contact with side of machine.

5. Using a large wire tie (3), secure the wrap (2) to the machine using the hole in the top of

the side panel (4).

2

2

1

6. Remove six screws (5) and back cover (6) from machine.

NOTE: Remove any wire ties as required. Note the routing of the sensor wiring being replaced.

7. Disconnect sensor connector (7) from control board (8).

5

3

4

8

5

Removal and Replacement

6

Page 52 of 92 520008300 08/14

7

Page 53

SmartServe™ Drink Mixers Service Manual

8. Use a screwdriver to depress the tabs on the side of the sensor assembly (9) and push

the sensor assembly (9) through the hole in the frame (10) and remove the sensor

assembly (9). The black plastic housing is part of the sensor assembly.

9

10

To install the sensor assembly (cup present):

1. Push the sensor assembly (9) into the hole in the frame (10).

NOTE: Route the wire harness for the sensor to the control board in a way that will avoid any

chance of pinching or fraying of the wires. Replace any wire ties as required.

2. Connect sensor connector (7) to the control board (8).

3. Install the back cover (6) with six screws (5).

5

6

7

8

5

Removal and Replacement

Page 53 of 92 520008300 08/14

Page 54

SmartServe™ Drink Mixers Service Manual

4. Remove the wire tie (3) holding the wrap (2) to the side panel (4).

5. Position the wrap (2) on the machine and secure the wrap (2) with six screws (1).

NOTE: Ensure the wire harness is positioned in a way to avoid interference with the movement

of the cup guard and shield assembly.

2

2

1

6. Install the top cover as outlined in this manual.

7. Install the safety shield assembly as outlined in this manual.

8. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

3

4

Removal and Replacement

Page 54 of 92 520008300 08/14

Page 55

SmartServe™ Drink Mixers Service Manual

Cup-In-Place Sensor (Infrared)

The cup-in-place sensor is located on the front of the machine in the mixing chamber.

To remove the cup-in-place sensor:

1. Remove the safety shield assembly as outlined in this manual.

2. Remove the top cover as outlined in this manual.

3. Remove three screws (1) from each side of the machine.

4. Lift the front panel wrap (2) from the machine.

NOTE: Avoid overextending the wire harness attached to the interface panel on the wrap.

NOTE: Cover front panel wrap to avoid scratches/damage from contact with side of machine.

5. Using a large wire tie (3), secure the wrap (2) to the machine using the hole in the top of

the side panel (4).

2

2

1

6. Raise the cup guard and shield assembly (5) and place a support block (6) under the

shield block (7).

3

4

7

6

Removal and Replacement

5

Page 55 of 92 520008300 08/14

Page 56

SmartServe™ Drink Mixers Service Manual

7. Remove two screws (8), washer (9), and plastic spacers (10).

8. Remove two screws (11) from the top of the wash chamber cover (12).

9. Remove six screws (13) from each side of the wash chamber cover (12).

10. Remove two screws (14) from the back of the machine.

13

11

12

13

8 9 10

14

11. Remove six screws (15) and back cover (16) from machine.

NOTE: Remove any wire ties as required. Note the routing of the sensor wiring being replaced.

12. Disconnect sensor connector (17) from control board (18).

15

18

16

17

15

Removal and Replacement

Page 56 of 92 520008300 08/14

Page 57

SmartServe™ Drink Mixers Service Manual

13. Grasp both sides of the wash chamber cover (12) and gently pull the ends away from

the machine.

NOTE: Cover back sides of wash chamber cover to avoid scratches/damage to side of

machine.

14. Slide the wash chamber cover (12) forward to access the sensor (19).

15. Remove two screws (20) and sensor (19) from the wash chamber cover (12).

19

20

12

12

To install the cup-in-place sensor:

1. Install the sensor (19) on the wash chamber cover (12) with two screws (20).

2. Slide the wash chamber cover (12) onto the machine and make sure the tab ends wrap

around the back of the machine.

NOTE: Use food grade grease to ease the wash chamber cover back onto machine. Cover

back sides of wash chamber cover to avoid scratches/damage to side of machine.

NOTE: Route the wire harness for the sensor to the control board in a way that will avoid any

chance of pinching or fraying of the wires. Replace any wire ties as required.

3. Connect sensor connector (17) to the control board (18).

4. Install the back cover (16) with six screws (15).

15

16

17

15

Removal and Replacement

Page 57 of 92 520008300 08/14

18

Page 58

SmartServe™ Drink Mixers Service Manual

5. Install two screws (8), washers (9), and plastic spacers (10) on the wash chamber

cover (12).

6. Install two screws (11) on the top of the wash chamber cover (12).

7. Install six screws (13) on each side of the wash chamber cover (12).

8. Install two screws (14) on the back of the machine.

11

13

12

13

8 9 10

14

9. Raise the cup guard and shield assembly (5) and remove the support block (6) from

under the shield block (7).

7

6

5

Removal and Replacement

Page 58 of 92 520008300 08/14

Page 59

SmartServe™ Drink Mixers Service Manual

10. Remove the wire tie (3) holding the wrap (2) to the side panel (4).

11. Position the wrap (2) on the machine and secure the wrap with six screws (1).

NOTE: Ensure the wire harness is positioned in a way to avoid interference with the movement

of the cup guard and shield assembly.

2

2

1

12. Install the top cover as outlined in this manual.

13. Install the safety shield assembly as outlined in this manual.

14. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

3

4

Removal and Replacement

Page 59 of 92 520008300 08/14

Page 60

SmartServe™ Drink Mixers Service Manual

Shield Door Sensor

The shield door sensor is located under the wash chamber area. A magnet in the safety

shield assembly interacts with the sensor and requires that the door be closed in order for the

machine to operate. Some models may have two shield door sensors, one on each side of the

door assembly.

To remove the shield door sensor:

1. Remove the safety shield assembly as outlined in this manual.

2. Remove the top cover as outlined in this manual.

3. Remove three screws (1) from each side of the machine.

4. Lift the front panel wrap (2) from the machine.

NOTE: Avoid overextending the wire harness attached to the interface panel on the wrap.

NOTE: Cover front panel wrap to avoid scratches/damage from contact with side of machine.

5. Using a large wire tie (3), secure the wrap (2) to the machine using the hole in the top of

the side panel (4).

2

2

1

6. Remove the cup shield (5) by pressing the tab (6) in the cup guard and shield

assembly (7) and turn the cup shield (5) clockwise.

7

3

4

6

Removal and Replacement

5

Page 60 of 92 520008300 08/14

Page 61

SmartServe™ Drink Mixers Service Manual

7. Remove two screws (8), washer (9), and plastic spacers (10).

8. Remove two screws (11) from the top of the wash chamber cover (12).

9. Remove six screws (13) from each side of the wash chamber cover (12).

10. Remove two screws (14) from the back of the machine.

13

11

12

13

8 9 10

14

11. Remove six screws (15) and back cover (16) from machine.

NOTE: Remove any wire ties as required. Note the routing of the sensor wiring being replaced.

12. Disconnect sensor connector (17) from control board (18).

NOTE: See wiring diagram for models with two shield door sensors.

15

18

17

16

15

Removal and Replacement

Page 61 of 92 520008300 08/14

Page 62

SmartServe™ Drink Mixers Service Manual

13. Grasp both sides of the wash chamber cover (12) and gently pull the ends away from

the machine.

NOTE: Cover back sides of wash chamber cover to avoid scratches/damage to side of

machine.

14. Slide the wash chamber cover (12) forward and rotate as shown to access the

sensor (19).

15. Remove two screws (20) and sensor (19) from the wash chamber cover (12).

19

20

12

To install the shield sensor:

1. Install the sensor (19) on the wash chamber cover (12) with two screws (20).

2. Slide the wash chamber cover (12) onto the machine and make sure the tab ends wrap

around the back of the machine.

NOTE: Use food grade grease to ease the wash chamber cover back onto machine. Cover

back sides of wash chamber cover to avoid scratches/damage to side of machine.

NOTE: Route the wire harness for the sensor to the control board in a way that will avoid any

chance of pinching or fraying of the wires. Replace any wire ties as required.

3. Connect sensor connector (17) to the control board (18).

NOTE: See wiring diagram for models with two shield door sensors.

4. Install the back cover (16) with six screws (15).

15

12

18

15

Removal and Replacement

17

16

Page 62 of 92 520008300 08/14

Page 63

SmartServe™ Drink Mixers Service Manual

5. Install two screws (8), washer (9), and plastic spacers (10) on the wash chamber

cover (12).

6. Install two screws (11) on the top of the wash chamber cover (12).

7. Install six screws (13) on each side of the wash chamber cover (12).

8. Install two screws (14) on the back of the machine.

11

13

12

13

8 9 10

14

9. Install the cup shield (5) on the cup guard and shield assembly (7) until the tab (6) locks

into place.

7

6

5

Removal and Replacement

Page 63 of 92 520008300 08/14

Page 64

SmartServe™ Drink Mixers Service Manual

10. Remove the wire tie (3) holding the wrap (2) to the side panel (4).

11. Position the wrap (2) on the machine and secure the wrap with six screws (1).

NOTE: Ensure the wire harness is positioned in a way to avoid interference with the movement

of the cup guard and shield assembly.

2

2

1

12. Install the top cover as outlined in this manual.

13. Install the safety shield assembly as outlined in this manual.

14. Plug in the power cord to the machine, turn the control panel power switch to the

RESET position, and verify machine operates.

3

4

Removal and Replacement

Page 64 of 92 520008300 08/14

Page 65

SmartServe™ Drink Mixers Service Manual

Wash Chamber Assembly

The wash chamber assembly is located under the wash chamber cover.

To remove the wash chamber assembly:

1. Shut off water supply, disconnect water line from machine, and purge the system to

remove water from the lines.

2. Remove the safety shield assembly as outlined in this manual.

3. Remove the top cover as outlined in this manual.

4. Remove three screws (1) from each side of the machine.

5. Lift the front panel wrap (2) from the machine.

NOTE: Avoid overextending the wire harness attached to the interface panel on the wrap.

NOTE: Cover front panel wrap to avoid scratches/damage from contact with side of machine.

6. Using a large wire tie (3), secure the wrap (2) to the machine using the hole in the top of

the side panel (4).

2

2

1

7. Remove the cup shield (5) by pressing the tab (6) in the cup guard and shield

assembly (7) and turn the cup shield (5) clockwise.

7

3

4

6

Removal and Replacement

5

Page 65 of 92 520008300 08/14

Page 66

SmartServe™ Drink Mixers Service Manual

8. Remove two screws (8), washer (9), and plastic spacers (10).

9. Remove two screws (11) from the top of the wash chamber cover (12).

10. Remove six screws (13) from each side of the wash chamber cover (12).

11. Remove two screws (14) from the back of the machine.

13

11

12

13

8 9 10

14

12. Remove six screws (15) and back cover (16) from machine.

NOTE: Remove any wire ties as required. Note the routing of the sensor wiring being replaced.

13. Disconnect two sensor connectors (17) from control board (18).

18

15

16

17

15

Removal and Replacement

Page 66 of 92 520008300 08/14

Page 67

SmartServe™ Drink Mixers Service Manual

14. Grasp both sides of the wash chamber cover (12) and gently pull the ends away from

the machine.

NOTE: Cover back sides of wash chamber cover to avoid scratches/damage to side of

machine.

15. Slide the wash chamber cover (12) forward and rotate as shown.

16. Remove four screws (19) from wash chamber assembly (20).

20

19

12

12

17. Disconnect water line (21) from solenoid (22).

18. Remove the wash chamber assembly (20) from the machine and pull the sensor

harness (23) and water line (21) through the frame cavity.

20

22

21

23

21

To install the wash chamber assembly:

1. Feed the sensor harness (23) and water line (21) through the frame cavity and position

the wash chamber assembly (20) on the frame.

2. Connect water line (21) to the solenoid (22).

3. Install the wash chamber assembly (20) with four screws (19).

4. Slide the wash chamber cover (12) onto the machine and make sure the tab ends wrap

around the back of the machine.

NOTE: Use food grade grease to ease the wash chamber cover back onto machine. Cover

back sides of wash chamber cover to avoid scratches/damage to side of machine.

Removal and Replacement

Page 67 of 92 520008300 08/14

Page 68

SmartServe™ Drink Mixers Service Manual

NOTE: Route the wire harness for the sensor to the control board in a way that will avoid any

chance of pinching or fraying of the wires. Replace any wire ties as required.

5. Connect sensor connector (17) to the control board (18).

6. Install the back cover (16) with six screws (15).

15

18

16

17

15

7. Install two screws (8), washer (9), and plastic spacers (10) on the wash chamber

cover (12).

8. Install two screws (11) on the top of the wash chamber cover (12).

9. Install six screws (13) on each side of the wash chamber cover (12).

10. Install two screws (14) on the back of the machine.

14

13

13

11

12

8 9 10

Removal and Replacement

Page 68 of 92 520008300 08/14

Page 69

SmartServe™ Drink Mixers Service Manual

11. Install the cup shield (5) on the cup guard and shield assembly (7) until the tab (6) locks

into place.

7

6

5

12. Remove the wire tie (3) holding the wrap (2) to the side panel (4).

13. Position the wrap (2) on the machine and secure the wrap with six screws (1).

NOTE: Ensure the wire harness is positioned in a way to avoid interference with the movement

of the cup guard and shield assembly.

2

2

1

14. Install the top cover as outlined in this manual.

15. Install the safety shield assembly as outlined in this manual.

16. Reconnect the main water line to the machine.