Page 1

D

ura

blenD Resin®

M

a

d

e

w

i

t

h

P

r

i

d

e

i

n

t

h

e

U

S

A

DuraResin Blend®

Water Softener

Models:

SA-HB-40-DB-CERT

SA-HB-48-DB-CERT

Page 2

Hamilton Beach Owner’s Manual | 3

MODEL: SA-HB-40-DB-CERT Water Softener

Operating Temperature: 34o–120oF

Operating Pressure: 20–60 psi (#5 injector); 61-120 psi (#4 injector)

Voltage: 110V 60 cycles

Rated Service Flow: 15.2 GPM @ 15 psi

Rated Softening Capacity: 14.2 @ 3.0 (#5 injector)

(Kilograins / Pounds of Salt) 24 @ 7.5, 37.0 @ 15 (#4 injector)

Max Flow Rate to Drain: 4.0 GPM

Amount of High Capacity Resin: 1.25 ft

3

Rated Efficiency: 4,720 grains @ 3.0 lbs

**Observe all state and local plumbing codes.

**This softener conforms to NSF/ANSI 44 for the specifically claimed

performance.

**The efficiency of the softener is valid only at the stated salt

dosage.

Manufactured By:

R&M Manufacturing

28 South 1550 West

Lindon UT 84042-1617

(801) 785-5557

pn: LBL-HB-40-CERT

CAUTION: Do NOT use with water that

is microbiologically unsafe or of unknown

quality without adequate disinfection

before or after the system.

pn: LBL-HB-48-CERT

MODEL: SA-HB-48-CERT Water Softener

Operating Temperature: 34o–120oF

Operating Pressure: 20–60 psi (#5 injector); 61-120 psi (#4 injector)

Voltage: 110V 60 cycles

Rated Service Flow: 18 GPM @ 35 psi inlet

Rated Softening Capacity: 15.1 @ 3.6 (#5 injector)

(Kilograins / Pounds of Salt) 26.0 @ 9.0, 39.7 @ 18 (#4 injector)

Max Flow Rate to Drain: 3.5 GPM

Amount of High Capacity Resin: 1.5 ft

3

Rated Efficiency: 4,210 grains @ 3.6 lbs

**Observe all state and local plumbing codes.

**This softener conforms to NSF/ANSI 44 for the specifically claimed

performance.

**The efficiency of the softener is valid only at the stated salt dosage.

Manufactured By:

R&M Manufacturing

28 South 1550 West

Lindon UT 84042-1617

(801) 785-5557

CAUTION: Do NOT use with water that

is microbiologically unsafe or of unknown

quality without adequate disinfection

before or after the system.

2 | Hamilton Beach Owner’s Manual

See pages 8 through 11 for:

• pre-installation checklist

• installation instructions

• start-up directions

Page 3

Table of Contents

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Equipment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Job Specifications Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sizing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Water Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Homeowner Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Manual Bypass Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Pre-Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Detailed Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Start-Up Rinsing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Battery Backup Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Programming the Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Level I Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Level I Programming Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Level II Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Level II Programming Parameters . . . . . . . . . . . . . . . . . . . . . . . . . .15

Level I and II Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

System Capacity Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Flow Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Control Valve Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Systems Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Hamilton Beach Owner’s Manual | 3

Page 4

Hamilton Beach Owner’s Manual | 5

Introduction / Equipment Specification

Introduction

Your Hamilton Beach owner’s manual is designed to

assist owners and installers with the installation, operation,

and maintenance of your new water-conditioning system. The

simplified photo format is designed to assist all aspects of

operation.

In the event service or plumbing changes are required, contact

your local authorized Hamilton Beach dealer. If further

assistance is required, call 800.685.8440.

Equipment Specifications

Working Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 psi to 120 psi

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102 to 132 vac, 60 Hz

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 mA

Transformer . . . . . . . . . . . . . . . . . . . . . Wall Mount (indoor use only)

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . 34o F to 120o F

Humidity . . . . . . . . . . . . . . . . . . .10% to 100%, Condensing Allowed

Service Connections . . . . . . . . . . .3/4”, 1”, 11/4” Copper Tube Adapter

Brine Line Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8” Tubing

Drain Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2” NPT Male

Water Flow . . . . . . . . . . . . . . . . Accurate over range of .5 to 23 gpm

4 | Hamilton Beach Owner’s Manual

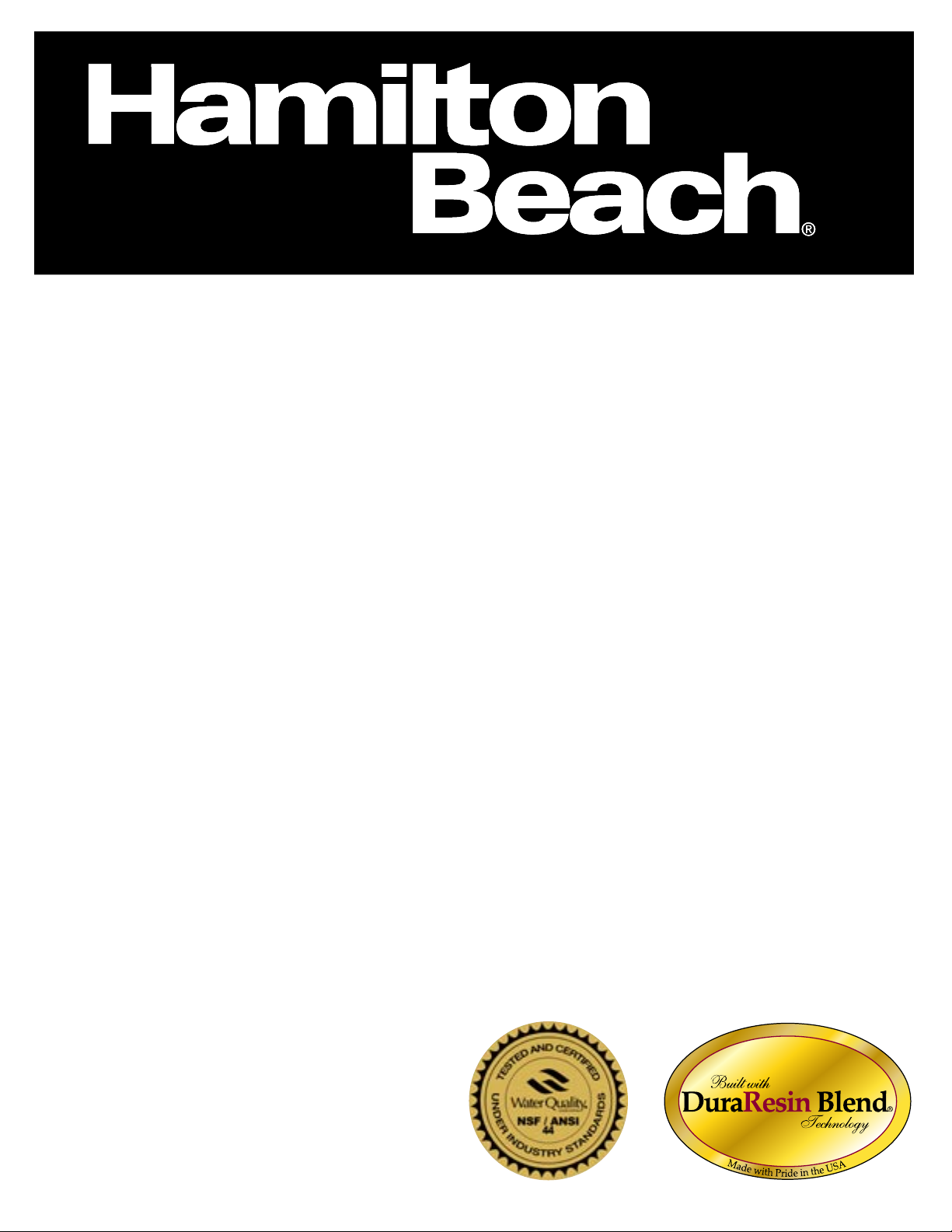

Figure 1: Control valve interface.

System Specifications

SA-HB-40-DB-CERT SA-HB-48-DB-CERT

Resin Tank Size 10x44” 12x48”

Resin Volume 1.25 ft

Refill Controller 0.35 gpm 0.35 gpm

Backwash Controller 2.8 gpm 2.8 gpm

Salt Tank Size 15x40” 15x40”

Capacity 450 lbs 450 lbs

Operation

Temperature

Flow Rate 15.2 gpm 18.0 gpm

Pressure Drop 15.0 psi 15.0 psi

Max Flow to Drain 4.0 gpm 3.5 gpm

Table 1: System specifications

Min 34

Max 120

3

o

o

1.50 ft

34

120

3

o

o

Page 5

Job Specification Sheet

Homeowner._________________________________________________

Dealer._______________________________________________________

Date of Installation.__________________

Installers Name. ____________________

Model #._____________________Serial #._________________________

Water Characteristics

__________Hardness as CaCo3 (check one____gpg or____ Mg/L)

__________Iron (ppm)

________Water pressure (psi)

Job Specification Sheet / Sizing Information

__________ PH

___Yes ___ No Pressure regulator.

__________Other ____________ , __________ Other ___________.

__________Other ____________, __________Other ___________.

Sizing Information

All Water is treated except:___Front hose bib __Rear hose bib ___Kitchen

___Toilets ____Other___________________________________________.

Sizing formula: On the average, a person uses 70 gallons of water per day

(20 gallons hot water, and 50 gallons cold water.

Example:

Daily usage: 70 gallons per person

Family size: x 6 persons

Total family daily usage: 420 gallons

Hardness: x 20 grains per gallon

Total removal per day: 8,400 grains

Actual Usage

Daily usage: 70 gallons per person

Family size: x _________ persons

Total family daily usage: _________ gallons

Hardness: x _________ grains per gallon

Total removal per day: _________ grains

Hamilton Beach Owner’s Manual | 5

Page 6

Hamilton Beach Owner’s Manual | 7

Water Conditioning / Homeowner Maintenance

Water Conditioning Homeowner Maintenance

Glossary of Terms

Hardness is comprised of dissolved calcium and magnesium.

As a general rule water is considered to be extremely hard

when over 10 gpg of hardness, hard when 6-10 gpg, mildly

hard when 3-6 gpg, slightly hard when 1-2 gpg and soft when

0 gpg.

Hard

Soft Water

0–1 gpg

1.0–3.5 gpg

Moderately Hard

Measurements

3.5–7.0 gpg

: Your Hamilton Beach water system registers

hardness in grains per gallon (gpg). Most water analysis reports

register hardness in milligrams per liter (Mg/L) or parts per

million (ppm). To convert either Mg/L or ppm to gpg, divide

the indicated amount by 17.1.

Example: Water report indicates total hardness of

350 Mg/L, divide this number by 17.1 to get the

gpg, which would be 20.4 gpg.

Ion Exchange

: Your water conditioning system utilizes ionexchange media, also referred to as resin, to effectively remove

hardness ions from the water and replace them with sodium

ions. Exhausted resin beads are rinsed with a salt solution

called “brine.” This causes the resin to exchange hardness ions

for the sodium ions, returning the resin to its sodium state.

Very Hard

7.0–10.5 gpg

10.5+ gpg

Extremely Hard

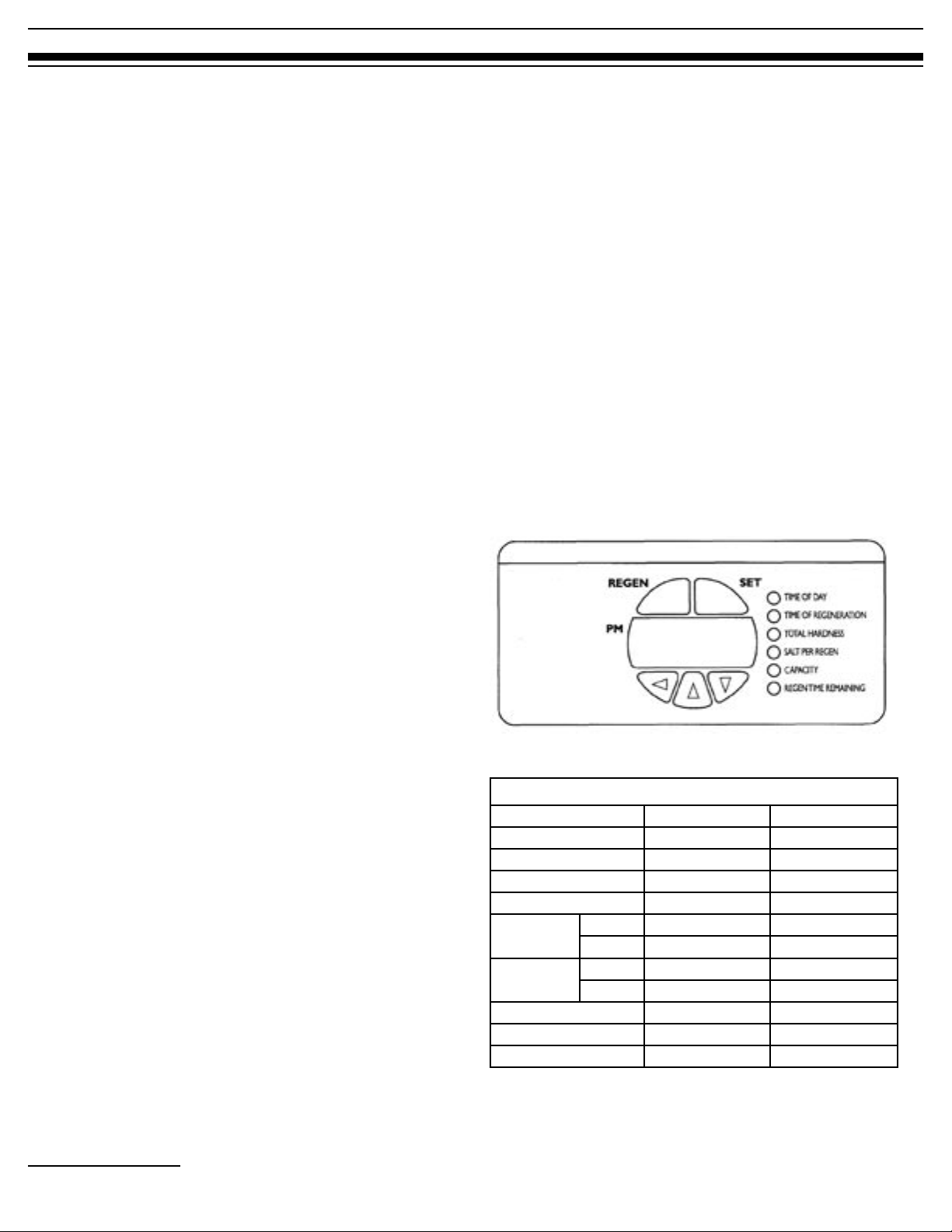

Manual Regeneration

Occasionally you may find it necessary to initiate a manual

regeneration. This is done by pressing the [REGEN] button on

the front of the display. (See Figure 2.) When you press the

[REGEN] button, the control performs a full regeneration of

the water conditioner immediately.

In the event the system is allowed to run out of salt, it will be

necessary to run “Back to Back” regenerations. This can be

done easily by pressing the [REGEN] button one time, waiting

at least one minute and pressing the [REGEN] button again.

------------------------------------------------------------------------------------Note: The second regeneration will begin immediately after the

first is completed.

-------------------------------------------------------------------------------------

“Back to Back” regenerations are necessary if full exhaustion

occurs due to low regenerate levels or system malfunction.

The system works on a highly efficient proportionate-brining

method. When the system is not aware of the lack of proper

regenerate(salt) a larger portion of the resin bed becomes

exhausted.

[REGEN] Button

Proportionate Brining

: Your Hamilton Beach System utilizes

an advanced microprocessor to control the amount of

regenerant proportionate to the amount of exhausted resin.

It uses enough salt to bring the system back to 100% capacity.

The microprocessor also incorporates a variable-reserve feature

to enable the system to adjust to patterns of usage, thus

maintaining high efficiency.

6 | Hamilton Beach Owner’s Manual

Figure 2: Control valve interface: regeneration button (REGEN).

Page 7

Homeowner Maintenance (Continued)

Calendar Day Override Feature

Hamilton Beach systems have an optional calendar day

override feature. The systems come pre-programmed with

this feature turned off. To activate this feature, see Level II

Programming instructions. This feature overrides the registered water volume and initiates a regeneration based on the

days selected even if there has been 0 water usage registered.

This feature is sometimes used if long absences from the home

occur. This ensures a freshly regenerated bed of resin and

minimizes the chance of resin fouling.

Regeneration:

Salt is used to regenerate the system. Salt pellets are generally cleaner

than extra-course rock salt. DO NOT use salt blocks as they may contain

vitamins or other undesirable additives. Add salt to the brine tank when it

drops to within 12 inches of the bottom.

Dry Brine Tank:

Hamilton Beach Systems use a dry brine tank. Since the system

determines the amount of solution necessary to regenerate

the exhausted resin, water is sent to the brine tank as part of

the regeneration sequence in an amount proportionate to the

exhausted resin that needs to be regenerated.

Note: While it is a dry brine tank, you will see approximately 1” of water

in the bottom of the tank during normal service. This amount of water is

necessary for the proper function of the brine air-check assembly. If water

amount exceeds this level while in normal service position, refer to the

troubleshooting guide; or contact your local authorized Hamilton Beach

dealer or qualified plumbing professional

Disinfection of Water Conditioners:

The construction materials of the water conditioning system

do not contaminate the water supply. However, we

recommend that the conditioner be disinfected after

installation. Periodic disinfection is recommended for all

conditioners. Use the following method of disinfection to

clean your system:

• Sodium Hypochlorite 5.25%: Sodium Hypochlorite

solutions can be used with polystyrene resin, synthetic

gel zeolite, greensand, and bentonites and are available

under trade names such as Clorox*. Adjust the dosage

if stronger commercial solutions are used.

The recommended dosage for a 5.25% depends on

your system size. Use the following amount depending

on your system model:

Model: SA-HB-40-DB-CERT . . . . . 1.5 Fluid ounces

SA-HB-48-DB-CERT . . . . . 1.8 Fluid ounces

Add the sodium hypochlorite solution to the brine well of the

brine tank. Make sure that the brine tank has water in it so the

solution is carried into the conditioner. Proceed with manual

regeneration. Refer to the Manual Regeneration section on

page 6.

* Clorox is a trademark of the Clorox Co.

Battery Backup Feature:

Brine Tank Cleaning:

Insoluble materials gradually build up in the salt tank

depending on the levels found in the salt. As a general rule,

inspect the brine tank once a year when the salt level is low.

To clean the tank, disconnect the brine-line connection, rinse

out any insoluble build-up, reconnect the brine-line, and add

one inch of fresh water. Then totally refill the tank with salt.

Setting Time Clock:

Your clock should indicate the current time of day, provided

the clock is set correctly. The system will clean at the specified

time of regeneration.

Your Hamilton Beach system has a battery backup feature. (See

Figure 3.) During a power outage the display will be blank but

the microprocessor will continue registering water flow. The

system will not initiate regeneration during a power outage;

instead it will wait until full power returns.

It is recommended the battery be replaced once a year or after

any extended power outage. The battery is a standard 9-volt.

Detailed instructions can be found in the programming section

on page 12 of this manual.

Figure 3: Battery installation for

battery backup feature.

Hamilton Beach Owner’s Manual | 7

Page 8

Hamilton Beach Owner’s Manual | 9

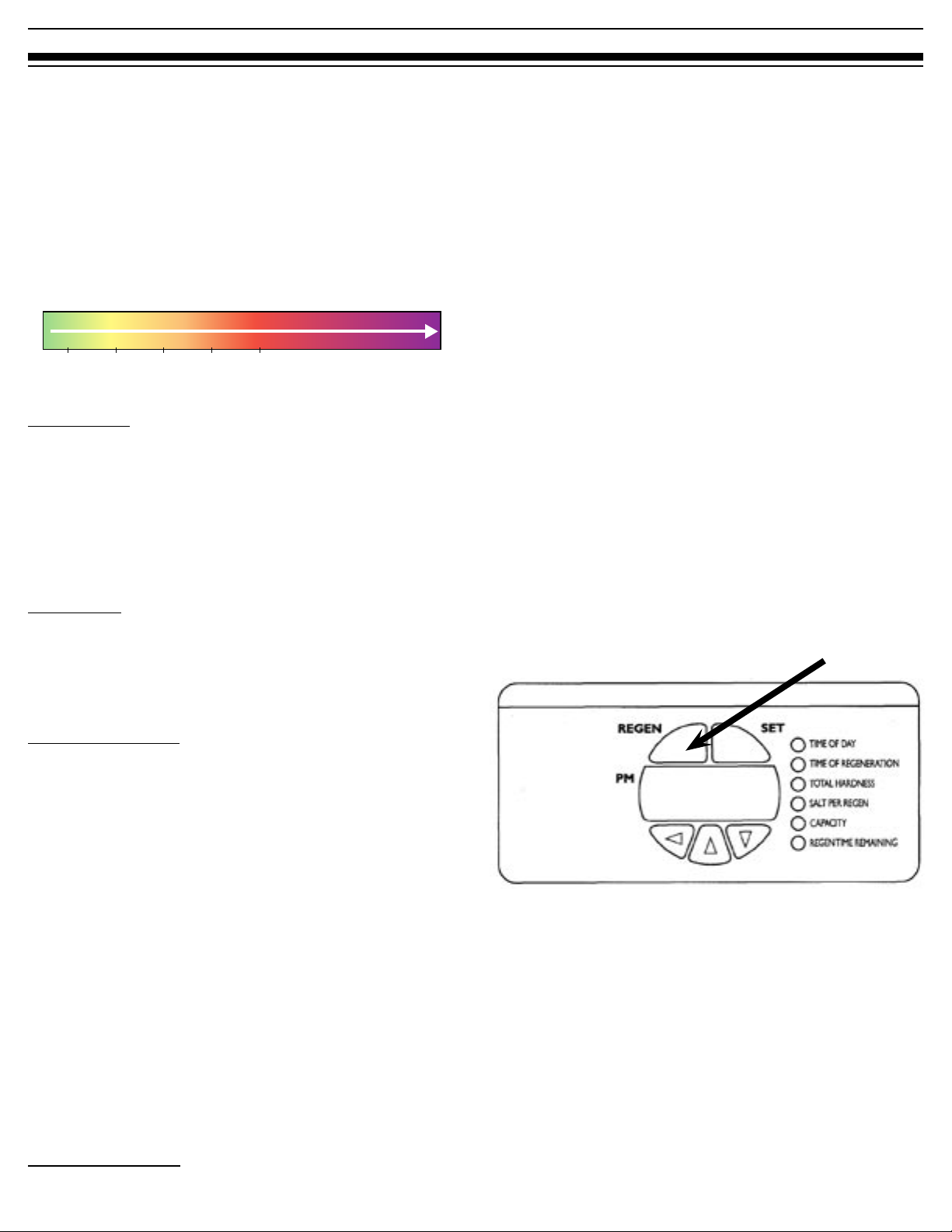

Manual Bypass Valve / Pre-Installation Check List

Manual Bypass Valve (Optional)

Your Hamilton Beach system is equipped with a manual

bypass valve. (See Figure 4.) This valve is to be used if you

want to stop the flow of water through the equipment but still

allow untreated water into your home.

Figure 4: Bypass valve.

For example, a bypass valve may be used if a leak occurs in

the system or when the homeowner(s) will be gone from the

home for an extended period of time.

------------------------------------------------------------------------------------Note:

It is recommended that the bypass valve knobs be engaged and

disengaged (turned in and out of service) once a year to ensure

that the O-rings are functioning. This allows the bypass valve

to turn more freely if it becomes necessary.

-------------------------------------------------------------------------------------

Do not use soft vinyl tubing, 3/8” or smaller

tubing. Do not expose tubing to freezing.

When barb drain fittings are used, always use a

hose clamp to secure the tubing to the fitting. Do

not connect the drain line to the overflow line on

the salt storage container. Installation of the drain

line should be in accordance with all state and

local plumbing codes.

o Installation Site: When choosing the proper

locations for the equipment, consider the

following factors:

• Proximity to drain.

• Proximity to electrical outlet.

• Access to plumbing; it is recommended

that when possible both hot and cold water

be treated with the exception of outside

taps. Kitchen cold is optional. Additional

equipment may work better with treated

water. Consult your dealer for details and

the best option for the application. (See

Figure 5.)

o Unpacking System: After removing the system

from the box, inspect the system for any

concealed damage that may have occurred

in shipping. If damage occurred, contact your

dealer for details. Do not install if the system has

sustained damage.

Pre-Installation Check List

The following items should be checked and verified prior to

the installation of the equipment. Under certain circumstances,

as indicated, additional procedures or pieces of equipment

may be recommended.

o Water Pressure Verification: A minimum

water pressure of 20 psi is required for normal

operation. Maximum water pressure is 120 psi.

o Electrical Requirements: The system includes a

12-volt transformer to be plugged into a standard

110 volt 60 Hz current. If additional cord length is

required, a 15 foot extension is available.

(AVP-1000907, see pg. 11)

o Drain-Line Connection: Choose a location close

to a drain to put your brine tank. Avoid overhead

runs in excess of 25 feet. Drain line must be a

minimum of ” inside diameter.

8 | Hamilton Beach Owner’s Manual

Whole-home media

filtration system

Water conditioner

Figure 5: Water-using appliances and fixtures in reference to

water-conditioner system installation site.

Page 9

Detailed Installation Instructions

Detailed Installation

Instructions

General Installation Warnings

The following general warnings should be observed when

installation and/or general service maintenance is performed.

• Plumbing connections should be done in

accordance with state and local plumbing codes.

• Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

• Drain lines should be ” minimum for drain line

flows up to 7 gpm. Flows above 7 gpm or runs in

excess of 20 feet require ” drain line.

WARNING: Never connect drain line directly into a drain, sewer line or

trap. Plumbing code requires installation to allow an air gap* between the

drain line and the wastewater to prevent the possibility of sewage backsiphoning into the conditioner. (See Figure 6.) Sewage backup can have

harmful health effects.

• A Brine Tank over-flow line of ” ID 5/8” OD is

recommended for the brine tank. This line should

run from the barb fitting on the side of the tank to

an unobstructed drain. (See Figure 7.)

• Each system comes standard with a high-pressure

injector.* It may be necessary to change the

injector (see Figure 8) to match your incoming

water pressure. (See Table 2 for injector sizes.)

*Standard Injector (High Pressure)

Brine tank

Overflow fitting

installed

Connect 1/2” (1.3 cm) ID tubing

or hose and run to drain.

Figure 6: Correct air-gap installation.

* Plumbing code air gap is one inch above the flood plane.

• All electrical connections must be connected

according to local codes. The electrical source

must be uninterrupted. Install grounding strap on

metal pipes.

• Do not use pipe dope or other types of liquid

sealants on any threads. Teflon tape must be used

on the drain line ” threads and also on the 3/8”

brine-line connections.

Note: Factory has teflon taped these fittings.

• Use caution if soldering inlet, outlet, or drain lines.

Excess heat will damage the control valve and/or

bypass valve.

Figure 7: Brine tank tubing connection with overflow fitting.

Injector

Injector cap

Injector

Figure 8: Injector screen and cap installation.

Injector Selection

Water Pressure Injector Part Number

20–60 psi

(138–414 bar)

61–120 psi

(420–827 bar)

Table 2: Injector selection based on water pressure.

AVP-1032980 (#5 Injector)

AVP-1032977 (#4 Injector)

Hamilton Beach Owner’s Manual | 9

Page 10

Hamilton Beach Owner’s Manual | 11

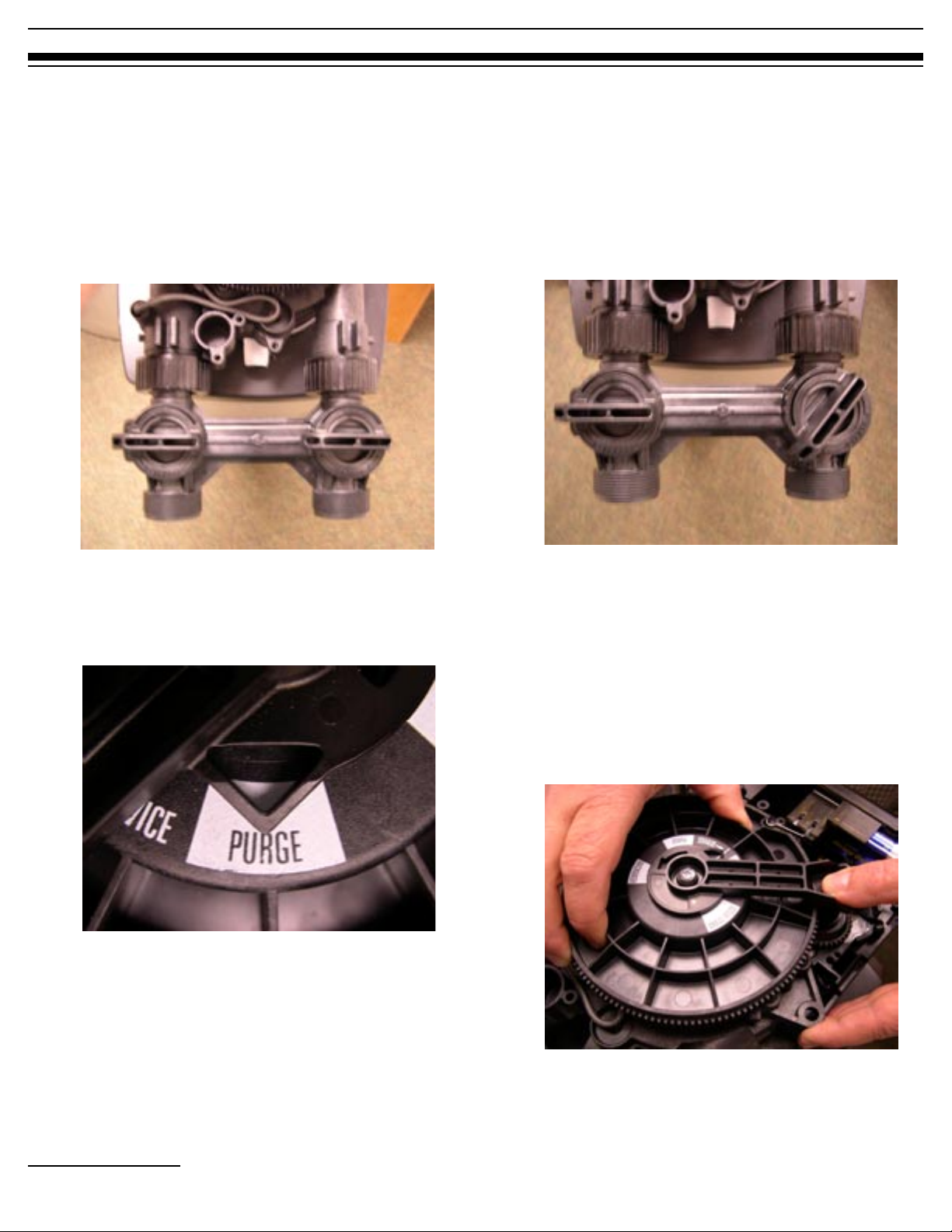

Start-up Rinsing Procedure

Start-Up Rinsing Procedure

(Bypass valve is optional)

1. With the plumbing, drain line, and overflow

connections completed, slowly open the water

supply allowing the lines to pressurize.

Note: The optional bypass should still be in bypass mode as

shown in Figure 9.

Once the air clears and water begins to run to the

drain, open the inlet valve (only) to the full open

position and allow the water to run to the drain in

purge for a minimum of 20 minutes. (See Figure

11.)

Outlet

Inlet

Figure 9

2. With the control valve unplugged, manually

advance the control valve by depressing the drive

gear and rotating the main system gear to the

purge position. (See Figure 10.)

Figure 10

Outlet

Inlet

Figure 11

4. After the 20-minute purge cycle, manually

advance the main gear to the backwash cycle and

allow to run for a minimum of 10 minutes. (See

Figure 12.)

Note: when advancing the main gear manually while under

water pressure it is normal for the gear to encounter resistance

as the valve chambers depressurize. If resistance occurs,

pause five seconds to allow the valve to depressurize before

advancing to the next step.

3. Slowly open the inlet valve (only) on the bypass

valve allowing the system to pressurize. It is

normal to hear air blowing to the drain during this

procedure.

10 | Hamilton Beach Owner’s Manual

Figure 12

Page 11

Start Up Rinsing Procedure (con’t)

5. After the ten-minute backwash cycle, manually

advance the control valve to the brine refill

position for ten minutes allowing water to flow

into the brine storage tank. (See Figure 13.)

Figure 13

Once water begins to flow into the tank fill the

brine tank with a minimum of 100 lbs of salt

pellets.

6. After the ten-minute refill time, manually advance

the control valve to the service position. (See

Figure 14.)

7. Plug in the control valve. (See Figure 15.)

Figure 15

8. If it is necessary to extend the length of the

transformer cord, an optional 15 foot (4.6-m)

extension cord is available, (See Figure 16), or the

cord may be spliced as follows:

a. Strip insulation from wire 5/16 inch (7.87 mm)

from wire end.

b. Insert stripped wire into barrel of connector

and crimp. For best results, crimp twice per

wire as shown in Figure 17 .

Neither splice connections nor extension wire

are supplied. They are available at hardware or

electrical stores.

Figure 14

Figure 16

(AVP-1000907)

Figure 17

Hamilton Beach Owner’s Manual | 11

Page 12

Hamilton Beach Owner’s Manual | 13

Battery Backup/ Programming the Control Valve

Battery Backup Feature

Your Hamilton Beach softening system has a battery backup

feature that allows the control to continue monitoring water

flow and maintain the proper time of day during short power

outages. The control uses a standard 9-volt battery (not

supplied).

During a power outage, the display will be turned off and the

motor will not run, but the control will continue to monitor

water flow. If power is out and a regeneration is needed, the

regeneration will be delayed until power is restored. If power

is lost during the regeneration, the control will resume the

regeneration when power is restored.

While batteries may last for over a year, the factory recommends

replacing the battery every year. During an interruption in

power supply, a typical new 9-volt alkaline battery provides

approximately two days of power for the control. Older

batteries and those exposed to temperature over 750 F (23.9O C)

provide power for shorter periods of time.

The control can be operated without a battery, but the control

will not measure water usage or time while the power is off.

The control will save all important operating information and

programming data during a power outage. No reprogramming

is necessary.

Programming the Control

Valve

You are now ready to continue programming the control.

Programming can be done in both Level I and Level II.

Accompanying tables are included for selecting the correct

settings for each level .

Note: The system has been pre-programmed with default settings based

on model number and ultra-high efficiency settings at a water hardness of

15 grains per gallon. While the system may operate with these settings,

the following Level I & II settings may need to be changed to meet the

actual operating conditions and achieve maximum system capacity and salt

efficiency.

Figure 18

Note: It is recommended that the battery be replaced every year or after

any extended power outage.

To install a battery:

1. Remove the control valve cover.

2. The battery pocket is located in the upper left

corner of the control as shown in Figure 18.

3. Insert the battery, matching up negative and

positive posts.

12 | Hamilton Beach Owner’s Manual

Page 13

Programming Guide

Level I Programming

Parameters

P1 Time of day

P2 Time of regeneration

P3 Water hardness (grains per gallon—gpg)

P4 Salt usage per regeneration (lbs)

P5 System capacity (Kg)

Table 3: Level I programming parameters overview.

Default settings for models:

SA-HB-40-DB-CERT (40DB)

SA-HB-48-DB-CERT (48DB)

(Ultra-high efficiency settings)

Setting Description 40DB 48DB

P1 Time of day Set to current time of day

P2 Time of regeneration 2 a.m. 2 a.m.

P3 Water hardness Set in field Set in field

P4* Salt usage 3.0 lbs 3.6 lbs

P5 System capacity 14.1 Kg 15.2 Kg

Table 4: Level I programming default settings.

Level I Programming

Parameters

P1

Time of Day AM or PM

Ranges: 1:00 to 12:59 or 00:00 to 23:59

Minimum Increments: 1 Min.

Units of Measure: Hours & Minutes

Range: Depends on the value selected for P13

P2

Time of Regeneration

Ranges: 1:00 to 12:59 a.m. or p.m, 00:00 to 23:59

Minimum Increments: 1 Min.

Units of Measure: Hours & Minutes

Range: Depends on the value selected for P13

P3

Water Hardness Setting

Range: 3 to 250 (grains per gallon) gpg / 30 to 2500

(milligrams per liter) Mg/L

* Default settings are representative of ultra-high efficiency.

Level I Settings are identified as those that have an LED

indicator on the front panel. The green indicator illuminates

next to the name of the active control setting. (See Figure 19.)

Pressing the down arrow [$ ] button displays the Level I settings

in order. By continuing to press the down arrow [$] button, the

settings start over beginning with the time of day. Pressing the

up arrow [ # ] button displays the settings in reverse order.

Figure 19: Control valve interface.

Minimum Increments: 1 for (gpg), 10 for (Mg/L)

Units of Measure: Grains per gallon (gpg) / Milligram

per liter (Mg/L)

Range: Unit of measure depends on the value selected

for P12. Test water hardness (compensated hardness)

and enter that value.

P4

Salt Amount (maximum)

Ranges: 0.5 to 99.5 (pounds) or 0.1 to 25.5

(kilograms)

Minimum Increments: 0.5 (pounds) or 0.1

(kilograms)

Units of Measure: Pounds or Kilograms

Range: Unit of measure and default depends on value

selected for P12.

P5

System Capacity

Ranges: 0.1 to 140 Kgr or 0.01 to 14.0 Kgr

Minimum Increments: 0.1 Kgr or 0.01 Kgr

Units of Measure: Kgr or Kilograms

Range: Depends on value selected for P12

Hamilton Beach Owner’s Manual | 13

Page 14

Hamilton Beach Owner’s Manual | 15

Programming Guide

Changing the Settings

To change the settings press the [SET] button on the far right.

The digit of the display starts flashing. If you want to change

this number, press the up arrow [# ] button to increase the

number or the down arrow [ $ ] button to decrease the number.

To skip the number without changing, press the left arrow [! ]

button. When you reach the far left digit, pressing the left arrow

[! ] button will return you to the far right digit.

Note: If you press and hold either the up or down arrow [ # ] [ $ ] button for

more than 1 second, the flashing number will increase or decrease at ten

counts per second.

When the number is correct, press the left arrow [ ! ] button.

The far right digit stops flashing and the next digit to the left

starts flashing.

You can only change the flashing number. Continue changing

numbers until you reach the desired setting. Press the [SET]

button. The numbers stop flashing and the control accepts the

new setting. After approximately 30 seconds, the control starts

alternating the display between Time of Day and Capacity.

Note: If the new setting is not accepted because it was outside the

allowable range, the old value will be displayed. Refer to the table guides

for the correct settings. (Default settings can be found on Table 6, on page

15.)

Time of Day

Press the [SET] button. The display will show the Time of Day

with the minutes digit blinking. If you want to change this

number, press the up arrow [#] button to increase the number

or the down arrow [$ ] button to decrease the number.

To skip the number without changing, press the left arrow [! ]

button. The first number stops flashing and the next number

starts flashing. You can only change the flashing number. When

you have reached the far left digit, pressing the left arrow [!]

button returns you to the far right digit. Continue changing

numbers until you reach the desired setting. Press the [SET]

button again to enter the value.

Time of Regeneration

The next value displayed is the Time of Regeneration, which is

similar to Time of Day programming. It has a default setting

of 2:00 a.m. If 2:00 a.m. is acceptable, press the down arrow

button [ $ ] .

If this is not acceptable, press the [SET] button and change the

numbers. Press the [SET] button again to enter the value.

Water Hardness

The next setting displayed is the Water Hardness in grains per

gallon(gpg). It is recommended that a water test be performed

at the time of installation. This Hamilton Beach is designed to

run on one water source. If multiple water sources are used, it

will be necessary to change the water hardness settings to match

the current water source.

The default setting is 15 grains per gallon of water hardness.

If this is not accurate, press the [SET] button and enter a new

value. U.S. settings allow any value between 3 and 250 grains

per gallon. Metric settings allow any value between 30 and 2500

milligrams per liter. Press the [SET] button again to enter the

new value.

Salt Amount

Capacity is the next value displayed and is expressed in

Kilograins (Kgr).

The pre-set default values for each model are listed in Table 5.

To change these values, press the [SET] button and enter a new

value. Any value between 0.1 and 14.0 Kilograins is allowed.

Note: If the calculation for the system capacity exceeds 9999 gallons (99.99

cubic meters) (P5, Capacity, divided by P3, Hardness), the control will

display 9999 for capacity until the water usage has dropped the remaining

capacity below that number. When water is flowing through the system, the

colon in the Time of Day display will blink.

Salt Settings (Ultra-High Efficiency Settings)

Model Capacity Default Salt Default

SA-HB-40-DB-CERT 14.1 Kgr 3.0 lbs

SA-HB-48-DB-CERT 15.2 Kgr 3.6 lbs

Table 5: Salt settings to obtain ultra-high efficiency.

You have now finished Level I programming. The display will

alternate between the Time of Day and Capacity if no keys are

pressed for 30 seconds. The Capacity value displayed is the

volume remaining in gallons (cubic meters for metric) before a

regeneration is needed.

14 | Hamilton Beach Owner’s Manual

Page 15

Level II Programming

The Level II programming has been programmed by the

manufacturer to the settings in Table 6. The changing of preset

values can be done at this time. Refer to Level II programming

parameters in Table 6 for options.

Note: It is not recommended that homeowners change these values

without checking with local water-treatment professional for details.

Incorrect programming can cause system malfunction and the possible

need for a field service call to reprogram the system. System programming

is not covered under warranty.

To access Level II programming, simultaneously hold down the

up [ # ] and down [$ ] arrows. This will allow you to enter Level

II settings P6 through P19. (See Table 6.)

Level II Programming

Programming Guide

Parameters

Level II Programming Parameters

Parameter Description Range Minimum

P6 Refill controller 1–99 1 gpm .35 gpm, both models

P7 Brine draw value 1–99 1 Minutes 15, both models

P8 Not used n/a n/a n/a n/a

P9 Backwash time 3–30 1 Minutes Skip this parameter to accept the default or enter a value

P10 Slow rinse time 8–125 1 Minutes SA-HB-40-DB-CERT = 67

P11 Fast rinse time 2–19 1 Minutes Skip this parameter to accept the default or enter a value

P12 Units of measure 0–1 1 0 = U.S.

P13 Clock mode 0–1 1 0 = 12-hour clock

P14 Calendar override 0–30 1 days 0 = no calendar override

P15 Reserve type 0–3 1 0 = variable reserve

P16 Fixed reserve capacity

or initial average

value

P17 Operation type 0–1 1 0 = Not used

P18 Salt / capacity change

lock out

P19 Factory defaults DO NOT

Table 6: Level II programming parameters.

0–70 1 percent of

0–1 1 0 = none

CHANGE

Increments

1 Loads in factory default values. DO NOT CHANGE THIS

Units of

Measure

capacity

Notes

SA-HB-48-DB-CERT = 80

1 = Metric

Skip this parameter to accept the default (U.S.)

1 = 24-hour clock

Skip this parameter to accept the default (12-hour)

Skip this parameter to accept the default (no override)

Description depends on the value entered for P15 (Reserve

type). Skip this parameter to accept the default.

1 = 5-cycle counter current

1 = salt / capacity change locked out

Skip this parameter to accept the default (no lock out)

PARAMETER.

Hamilton Beach Owner’s Manual | 15

Page 16

Hamilton Beach Owner’s Manual | 17

Programming Guide

Level I and II Default Settings

The following table represents preset values programmed into the systems at the factory for both levels I

and II for the model shown. (See Table 7.)

Level I Parameters

Name Description SA-HB-40-DB-CERT SA-HB-48-DB-CERT

P1 Time of day Set in field Set in field

P2 Time of regeneration 2:00 a.m. 2:00 a.m.

P3 Hardness Set in field Set in field

P4 Salt amount 3.0 lbs 4.0 lbs

P5 Capacity 14.1 Kgr @ 3.0 lbs of salt 15.2 Kgr @ 3.6 lbs of salt

Level II Parameters

P6 Refill controller 0.35 gpm 0.35 gpm

P7 Brine draw value 3.0 lbs @ 7 min w/ 5 bump injector

P8 Not used n/a n/a

P9 Backwash time 3.9 min 3.9 min

P10 Slow rinse time 75.5 min @ 3.0 lbs with 5 bump injector

P11 Fast rinse time 3.5 min 3.5 min

P12 Units of measure 0 0

P13 Clock mode 0 0

P14 Calendar override 0 0

P15 Reserve type 0 0

P16 Fixed reserve capacity

or initial average value

P17 Operation type 1 1

P18 Salt / capacity change

lock out

P19 Factory defaults 9 9

7.5 lbs @ 26 min w/ 4 bump injector

15.0 lbs @ 51 min w/ 4 bump injector

62.0 min @ 7.5 lbs with 4 bump injector

57.0 min @ 15.0 lbs with 4 bump injector

n/a n/a

0 0

Table 7: Level I and II programming default settings.

4.0 lbs @ 9 min w/ 5 bump injector

9.0 lbs @ 31 min w/ 4 bump injector

18.0 lbs @ 61 min w/ 4 bump injector

75.5 min @ 3.0 lbs with 5 bump injector

62.0 min @ 7.5 lbs with 4 bump injector

57.0 min @ 15.0 lbs with 4 bump injector

16 | Hamilton Beach Owner’s Manual

Page 17

System Capacity Inputs

System Capacity Inputs

Salt Settings and Capacity (Kgr)

Lbs of Salt SA-HB-40-DB-CERT SA-HB-48-DB-CERT

3.0 14.1

3.6 15.5 15.2

4.0 16.5 15.5

5.0 19.0 18.0

6.0 22.0 21.0

7.0 24.0 23.5

7.5 24.4

8.0 25.6 25.0

9.0 27.9 26.1

10.0 30.0 30.0

11.0 31.9 31.5

12.0 33.6 33.0

13.0 35.1 34.0

14.0 36.4 35.2

15.0 37.1

16.0 38.4 37.0

17.0 39.1 38.0

18.0 39.6 39.8

19.0 39.9 41.0

20.0 40.0 41.5

21.0 n/a 42.0

22.0 n/a 43.0

23.0 n/a 44.0

24.0 n/a 45.2

25.0 n/a 45.9

26.0 n/a 46.5

27.0 n/a 47.2

28.0 n/a 48.0

Table 8: System capacity by pounds of salt.

40

40

40

n/a

24.3

36.0

SA-HB-40-DB-CERT

30

48

25

20

15

10

Salt Setting (lbs)

5

48

0

0 10 20 30 40 50

Capacity (Kgr)

Figure 19

SA-HB-48-DB-CERT

30

25

48

20

15

10

Salt Setting (lbs)

5

0

0 10 20 30 40 50

Capacity (Kgr)

Figure 20

40

SA-HB-40-DB-CERT certified capacity at salt setting

48

SA-HB-48-DB-CERT certified capacity at salt setting

Note: The 3.0 lbs salt setting (40 DB model) and the 3.6 lbs salt setting (48

DB model) are certified using the 5 bump injector. The 7.5 lbs (40 DB), 15

lbs (40 DB), 9 lbs (48 DB), and 18 lbs (48 DB) are certified using the 4 bump

injector.

Hamilton Beach Owner’s Manual | 17

Page 18

Hamilton Beach Owner’s Manual | 19

Flow Diagrams

Flow Diagrams

Figure 20 Figure 21

18 | Hamilton Beach Owner’s Manual

Figure 22

Figure 23

Page 19

Flow Diagrams

Figure 24

Figure 25

Figure 26

Hamilton Beach Owner’s Manual | 19

Page 20

Hamilton Beach Owner’s Manual | 21

Control Valve Diagram

Control Valve Diagram

20 | Hamilton Beach Owner’s Manual

Page 21

Control Valve Parts

Code Part Number Description Qty

1 AVP-1034448 Valve Body Assembly 1

2 AVP-1034347

AVP-1034346

3 AVP-1034424 Control Assembly, 1000i 1

4 AVP-1034362

AVP-1034363

5 AVP-1032881 Bracket 1

6 AVP-1005001 Screw, 10-32 x 1/2 inch 1

7 AVP-1033670 Turbine Group 1

8 AVP-1034340 10-inch Brine/backwash Control 1

9 AVP-1032988 Injector Screen Assembly 1

10 AVP-1032977

AVP-1032980

11 AVP-1032985 Injector Cap Assembly 1

12 AVP-1010140 O-Ring, 1 x 1-1/4 x 1/8 inch 1

13 AVP-1010129 O-Ring, 1-5/16 x 1-1/2 x 3/32” 1

14 AVP-1010429 O-Ring, 3-1/8 ID, 3/16 inch 1

15 AVP-1009056 Cap plug, Black, 1/2 inch 1

16 AVP-1040717 Valve Disc Kit 1

17 AVP-1001580 Valve Disc Spring 11

18 AVP-1034360 Top Plate Assembly with Springs 1

19 AVP-1032416 Air Check Kit 1

20 AVP-1032250 Drive Gear 1

21 AVP-1006002 Screw, 8-18 x 1-1/2 inch 2

22 AVP-1031118 Spring 1

23 AVP-1006093 Top Plate Screw 17

24 AVP-1033998 Black Cover 1

25 Not Used — —

26 AVP-1000811 Transformer, 120V 1

27 AVP-1000906 Micro Switch 1

Motor Drive Assembly, 60 Hz

Motor Drive Assembly, 50 Hz

Cam Gear, 1100 English

Cam Gear, 1100 Symbols

Injector Assembly, 4 Bumps

Injector Assembly, 5 Bumps

1

1

1

Hamilton Beach Owner’s Manual | 21

Page 22

Hamilton Beach Owner’s Manual | 23

Systems Diagram

Systems Diagram

14

Systems Parts

SA-HB-40-DB-CERT

Code Part Number Description Qty

1 AUV-1050643 Hamilton Beach Valve 1

2 MTK-SP-1044 10x44 Mineral Tank 1

3 DST-1080 Hamilton Beach Distributor, 10x44 1

4 MP-TECH 40DB Resin Media, 1.25 cf 1

5 JKT-1325 Mineral Tank Jacket 1

6 TB-1085 Brine Line, 3/8”(per foot) 5

7 BTC-1214 Brine Tank w/ Lid, Hamilton Beach 1

8 BTC-1093 Brine Well 1

9 BTC-1054 Hamilton Beach Float Assembly 1

10 BTC-1000 Overflow Assembly 1

11 BTC-1303 Brine Well Cap 2

12

BP-A-1001606

BP-A-1001670

BP-A-1041210

BP-A-1001613

BP-A-1001614

13 BP-A-1040930 Hamilton Beach Bypass 1

14 BTC-1423 Brine Tank Lid 1

Bypass Tail Kit

3/4” Copper Tail Kit

1” Copper Tail Kit

1 1/4” Copper Tail Kit

3/4” CPVC Tail Kit

1” CPVC Tail Kit

1

13

12

SA-HB-48-DB-CERT

Code Part Number Description Qty

1 AUV-1050643 Hamilton Beach Valve 1

2 MTK-SP-1248 12x48 Mineral Tank 1

3 DST-1085 Hamilton Beach Distributor, 12x48 1

4 MP-TECH 48DB Resin Media, 1.5 cf 1

5 JKT-1325 Mineral Tank Jacket 1

6 TB-1085 Brine Line, 3/8”(per foot) 5

7 BTC-1214 Brine Tank w/ Lid, Hamilton Beach 1

8 BTC-1093 Brine Well 1

9 BTC-1054 Hamilton Beach Float Assembly 1

10 BTC-1000 Overflow Assembly 1

11 BTC-1303 Brine Well Cap 2

12

BP-A-1001606

BP-A-1001670

BP-A-1041210

BP-A-1001613

BP-A-1001614

13 BP-A-1040930 Hamilton Beach Bypass 1

14 BTC-1423 Brine Tank Lid 1

Bypass Tail Kit

3/4” Copper Tail Kit

1” Copper Tail Kit

1 1/4” Copper Tail Kit

3/4” CPVC Tail Kit

1” CPVC Tail Kit

1

22 | Hamilton Beach Owner’s Manual

Page 23

Troubleshooting

Troubleshooting

Manual Indexing for Each Regeneration

The control valve may be manually indexed to each

regeneration position as follows:

1. Remove the control valve cover.

2. Press down on the top of the drive gear to

disengage the cam gear. (See Figure 9 on page

10.)

3. With the cam gear disengaged, rotate the cam

gear counterclockwise to the various positions,

using the same steps as the Start-up Rinse

procedure (see page 10).

The control valve may also be operated in a fast mode for

testing the control. To activate the fast mode, follow steps 1

and 2 outlined above to disengage the cam gear. When the

cam gear is disengaged, it should be advanced slightly in a

counterclockwise direction.

The switch will then activate the motor to cause the cam gear

to advance through all the cycles in about 30 minutes. The

control will not recognize a fast mode as a regeneration. Manual

regenerations can be initiated only by pressing the manual

regeneration switch on the face of the control.

Errors

The Hamilton Beach System continuously monitors itself and

displays an error message if it detects something wrong.

When an error is detected, the display shows the letters “Err”

with a number from 1 to 4. The table below lists Err numbers,

a description of each error, the cause of the error, and the

solutions. (See Table 9.)

To clear the error from the display, press any button on the

control. If the error still exists, the control will display the error

message again after 30 seconds.

For additional troubleshooting information, see the

troubleshooting guide (Table 10), which may help determine

the problem and potentially solve the problem. If consulting

the troubleshooting guide fails to resolve the problem, contact

your authorized Hamilton Beach dealer or qualified plumbing

professional. If further assistance is required, call 800.685.8440.

Hamilton Beach Error Detection Codes

Code Description Cause Solution

Err 1 Electronics failure Control settings need reprogramming Press any key to load default values. Refer to

Err 2 Improper start of regeneration (limit

switch open when it should be

closed)

Err 3 Improper finish of regeneration (limit

switch closed when it should be

open)

Err 4 Improper control settings (one or

more settings out of the allowable

range)

Table 9: Error-detection codes.

Valve cam gear has been manually rotated during

a regeneration

Valve cam gear has been manually rotated out of

“service” position

Faulty motor Replace motor assembly

Faulty motor drive Replace motor assembly

Faulty switch Replace switch

Valve cam gear has been manually rotated out of

“service” position

Faulty motor Replace motor assembly

Faulty motor drive Replace motor assembly

Faulty switch Replace switch

One or more settings is out of the allowable

range

“Programming the Hamilton Beach 1100 Control”

Press any key to clear the alarm (Alarm automatically

clears at “TIME OF REGEN”)

The control will turn the motor on and drive the cam

gear to the proper location

The control will turn the motor on and drive the cam

gear to the proper location

Hardness: Adjust range (3–250)

Capacity: Adjust range (0.1–140.0)

Refill control: Adjust range (see table 4)

Brine draw value: Adjust range (see table 4)

Hamilton Beach Owner’s Manual | 23

Page 24

Hamilton Beach Owner’s Manual | 25

Troubleshooting

Troubleshooting Procedures

Problem Description Possible Cause Solution

• Capacity display stays at “9999” even though

there is water usage

• Control does not respond to [REGEN] button Button is not active in the programming mode Refer to the regeneration section

• Control does not display time of day Transformer is unplugged Connect power

• Control does not display correct time of day Outlet operated by a switch Use an outlet not controlled by a switch

• No water flow display when water is flowing

(colon doesn’t blink)

• Control display is frozen at REGEN TIME

REMAINING

• Control regenerates at the wrong time of day Power outages Reset time of day to correct time of day and

• Cam gear stalled in regeneration cycle Motor not operating Replace motor assembly

• Continuous regeneration. Cam gear does not

stop at the end of regeneration

• Control does not regenerate automatically or

when [REGEN] button is depressed

Table 10: Troubleshooting procedures for most common problems.

Total system capacity was calculated to be a

value greater than 9999

No electric power at outlet Repair outlet or use a working outlet

Defective transformer Replace transformer

Defective circuit board Replace control

Power outage Reset time of day and replace battery

Bypass valve in “ bypass” position Shift bypass valve into “service” position

Meter probe disconnected or not fully

connected to meter housing

Restricted meter turbine rotation due to foreign

material in meter

Defective meter probe Replace control

Defective circuit board Replace control

Back to back regenerations were requested Refer to manual regeneration section

Time of day set incorrectly Reset time of day to correct time of day

Time of regeneration set incorrectly Reset time of regeneration

Motor runs backwards Replace motor assembly

No electric power at outlet Repair outlet or use a working outlet

Incorrect voltage or frequency (Hz) Replace timer and/or transformer with one of

Broken gear Replace gear

Defective switch Replace switch

Binding of cam gear Remove foreign object obstruction from valve discs

Water pressure greater than 125 psi during

regeneration

Defective circuit board Replace control

Defective switch Replace switch

Transformer unplugged Connect power

No electric power at outlet Repair outlet or use working outlet

Defective motor Replace motor assembly

Defective switch Replace switch

As the water usage continues, the remaining

capacity will drop below 9999—then other values

will be shown

Fully insert probe into meter housing

Remove meter housing, free up turbine and flush

with clean water. Turbine should spin freely. If not,

refer to the water meter maintenance section

replace battery

correct voltage and frequency

or cam gear

Install pressure regulator to reduce pressure

24 | Hamilton Beach Owner’s Manual

Page 25

Troubleshooting

Problem Description Possible Cause Solution

• Control does not regenerate automatically

but does regenerate when [REGEN] button is

depressed

• Run out of soft water between regenerations Improper regeneration Repeat regeneration making certain correct salt

• Control does not draw brine Low water pressure Increase water pressure (20 psi at conditioner)

• Brine tank overflow Brine valve disc 1 held open Manually operate cam gear to flush out foreign

• Intermittent or irregular brine draw Low water pressure Increase water pressure (20 psi at conditioner)

• No conditioned water after regeneration Unit did not regenerate Check for power

Table 10:(Contiuned) Troubleshooting procedures for most common

If water flow display is not operative, refer to

item 5 (“No water flow display when water is

flowing”) in this table

Incorrect hardness and capacity settings Set new control values—Refer to programming

Defective circuit board Replace control

Fouled resin bed Use resin cleaner

Incorrect salt setting Set salt setting to proper level—refer to the

Incorrect hardness or capacity settings Set to correct values—refer to the programming

Water hardness has increased Set to new value—refer to the programming

Restricted meter turbine rotation due to foreign

material in meter housing

Water usage below 1/5 gallon per minute Repair leaky plumbing and/or fixtures

Brine draw value from table 4 is incorrect Set correct brine draw value

Incorrect salt type, or use of grid plate (salt shelf) Do not use block salt or grid plate (salt shelf) in

Restricted drain line Remove obstruction

Injector or injector screen is plugged Clean injector and screen—refer to the “Cleaning

Injector defective Replace injector and cap

Valve disc 3 and/or 5 not closed Manually operate cam gear to flush out foreign

Air check valve prematurely closed Briefly put control into brine refill status. Refer

Valve disc 2 not closed during brine draw,

causing brine refill

Air leak in brine line to air check Check all connections in brine line for leaks

Salt setting too high Set in new values—refer to programming section

Defective injector Replace both injector and injector cap

No salt in brine tank Add salt to brine tank

Plugged injector Remove injector and flush it and injector screen

Air check valve closed prematurely Put control momentarily into REFILL to free air

Incorrect salt type or use of grid plate (salt shelf)

in brine tank

Refer to item 5 (“No water flow display when

water is flowing”) in this table

section

dosage is used

programming section

section

section

Remove meter housing, free up turbine, and flush

with clean water. Turbine should spin freely—if not

replace meter

brine tank

the Injector / Injector Screen” section

matter holding disc open. Replace if needed

to the “Manual Regeneration” section. Repair air

check valve if needed

matter holding disc open

Manually operate cam gear to flush out foreign

matter holding disc open

check—replace or repair air check as needed

Do not use block salt or grid plate (salt shelf) in

brine tank

Hamilton Beach Owner’s Manual | 25

Page 26

Hamilton Beach Owner’s Manual | 27

Troubleshooting

Problem Description Possible Cause Solution

• Control backwashes at excessively low or high

rate

• Flowing or dripping water at drain line or brine

line after regeneration

• Hard water leakage during service Improper regeneration Repeat regeneration making sure the correct salt

Table 10:(Continued) Troubleshooting procedures for most common problems.

Incorrect backwash controller Replace with correct size controller

Foreign matter affecting controller operation Remove and clean controller

Drain valve (2 or 6) or brine valve (1) held open

by foreign matter

Weak valve stem return spring on top plate Replace spring

Resin in valve Clean valve and backwash control

Leaking bypass valve Replace O-ring

O-ring around riser tube damaged Replace O-ring

Incorrect salt type or use of grid plate (salt shelf)

in brine tank

Manually operate cam gear to flush out foreign

matter holding disc open

dosage is used

Do not use block salt or grid plate (salt shelf) in

brine tank

26 | Hamilton Beach Owner’s Manual

Page 27

Notes

Hamilton Beach Owner’s Manual | 27

Page 28

Hamilton Beach Owner’s Manual | 29

Notes

28 | Hamilton Beach Owner’s Manual

Page 29

Notes

Hamilton Beach Owner’s Manual | 29

Page 30

Hamilton Beach Owner’s Manual | 31

Notes

30 | Hamilton Beach Owner’s Manual

Page 31

Notes

Hamilton Beach Owner’s Manual | 31

Page 32

Logo:

Black

Logo Usage

© 2005 R&M Water Group. Water Technologies, Inc.. and R&M Water

Group are branded trademarks of Water Technologies, Inc. All rights

reserved.

Material produced by Water Technologies, Inc. and authorized by

Hamilton Beach.

VERSION: 25 May 2005 | PN: L-R-HAMILTONBEACH-OM-CERT

Loading...

Loading...