Hamilton Conducell 4US, Conducell 4US-T150-50, Conducell 4US-G125, Conducell 4US-T150-100 Operating Instructions Manual

Page 1

Conducell™ 4US Sensors

Operating Instructions

Bedienungsanleitung

Page 2

Important note

Reproduction of any part of this manual in any form whatsoever without the express written

consent of Hamilton Bonaduz AG is forbidden. The contents of this manual are subject to

change without notice. Technical changes reserved.

TABLE OF CONTENTS

Table of Contents

1 Liability ................................................................................. 4

2 Intended use ........................................................................ 5

3 Safety ................................................................................... 5

4 Initial operation .................................................................... 5

5 Electrical wiring ................................................................... 6

6 Assembly ............................................................................. 8

7 Diagrams with dimensions ................................................. 9

8 Calibration ......................................................................... 10

9 Measurement......................................................................11

10 Cleaning ..............................................................................11

11 Dispo s a l ..............................................................................11

12 Technical data ................................................................... 12

13 Instructions for use in potentially

explosive atmospheres ..................................................... 13

14 Connection to transmitter ................................................ 14

15 Accessories ....................................................................... 15

All efforts have been made to ensure the accuracy of the contents of this manual. However,

should any errors be detected, Hamilton Bonaduz AG would greatly appreciate being informed

of them. The above notwithstanding, Hamilton Bonaduz AG can assume no responsibility for

any errors in this manual or their consequences.

Copyright © 2019 Hamilton Bonaduz AG, Bonaduz Switzerland. All rights reserved.

™

4US Sensors Operating Instructions

3Conducell

Page 3

INTENDED USE • SAFETY • INITIAL OPERATIONLIABILITY

Operating Instructions

These operating instructions are intended for the Hamilton Conducell 4US sensors.

Ref Description Thread ATEX

1

237700-OP Conducell 4US-G125 G 1

237750 Conducell 4US-T150-50 Triclamp 1.5”

237760 Conducell 4US-T150-100 Triclamp 1.5”

Hamilton Conducell 4US sensors are quality products manufactured with the latest technology.

These instructions should be read, understood and followed by all staff using the device.

Hamilton can assume no responsibility for damage and operational disruptions arising from

failure to observe these instructions.

1 Liability

The Liability of Hamilton Bonaduz AG is detailed in the document «General Terms and Conditions

of Sale and Delivery (GTS)», chapter 12.

Hamilton is expressly not liable for direct or indirect losses arising from use of the sensors. It

must in particular be insured in this conjunction that malfunctions can occur on account of the

inherently limited useful life of sensors contingent upon their relevant applications. The user is

responsible for the calibration, maintenance and regular replacement of the sensors. In the case

of critical sensor applications, Hamilton recommends using back-up measuring points in order

to avoid consequential damages. The user is responsible for taking suitable precautions in the

event of a sensor failure.

⁄4”

2 Intended use

With the Conducell 4US line, Hamilton has developed a family of in-line conductivity sensors

which perform under demanding conditions in biotechnology and the general chemical industry.

During development, special attention was paid to an optimum sanitary design. All materials in

contact with the solution are FDA approved.

The sensors are based on the 4-electrode principle which excludes polarization phenomena

normally observed with 2-electrode sensors. The engineered design guarantees an excellent

linearity over a conductivity range of more than 6 decades.

3 Safety

This sensor is to be used only as intended and is to be kept in a condition that ensures complete safety. The specifications given in the section «Technical Data» as regards temperature,

pressure etc. may under no circumstances be exceeded.

Inappropriate use or misuse can be dangerous.

Assembly and maintenance may only be done by trained personnel.

During assembly, ensure that the positioning is correct and that the O-ring is undamaged.

O-rings are consumable items and must be replaced regularly – at least once a year.

The built-in temperature sensor should only be used for compensation of conductivity, not for

controlling the process temperature.

Conducell 4US sensors are used to determine electrolyte conductivity in solutions. If these

sensors are used in potentially explosive atmospheres, see the section «Instructions for use in

potentially explosive atmospheres».

Every product for shipment or sent back for repair must be decontaminated. If working with

hazardous liquids observe and carry out the maintenance procedures, paying particular attention to cleaning and decontamination. If the product becomes contaminated with biohazardous,

radioactive or chemical material, it should be cleaned.

4 Initial operation

This Conducell 4US sensor has been carefully tested and is ready for use. During unpacking,

please check for any mechanical defects. In case of a complaint please return the Conducell

4US in its original packing to Hamilton and describe the problem.

™

4US Sensors Operating Instructions

5Conducell

Page 4

5 Electrical wiring

ELECTRICAL WIRINGELECTRICAL WIRING

Signal description Cable Conducell 4US

Pt1000 (low end) Grey

Pt1000 (low end) White

Pt1000 (high end) Blue

Current electrode (high end) Pink

Potential electrode (high end) Green

Potential electrode (low end) Brown

Current electrode (low end) Yellow

Not connected on sensor Shield

Not connected Red

Conducell Hamilton Knick Knick Stratos Knick Stratos e

4US H100 Cond Cond 2201 X 2401 Cond 2402 / 2405 Cond

Grey D 7 6 D

White D 7 6 D

Blue E 8 5 E

Pink 1 1 1 1

Green 2 2 2 2

Brown 3 3 3 3

Yellow 4 4 4 4

Shield C 5 5 C

Red - - - Comment Short 4 and 5 Short 4 and 5 Short 4 and 5 Short 4 and 5

Conducell 4US Emerson Yokogawa SIEMENS

5081 C Model SC150, SC202, SIPAN

SC402, SC450 32/32X

Grey 3 11 23

White 4 11 24

Blue 5 12 25

Pink 8 14 26

Green 11 13 29

Brown open 15 27

Yellow open 16 30

Shield 5 63 Shield

Red - - Comment 2-electrode arrangement *

* For Yokogawa SC150, SC202, SC402, SC450 please be aware that the measuring

range must stay within the specified input range of the instrument.

ATTENTION! The linearity of the system is strongly dependent on the instrument to which the sensor is attached. For applicable measuring range refer to

Technical Specifications of the manufacturer of the instrument.

™

4US Sensors Operating Instructions

7Conducell

Page 5

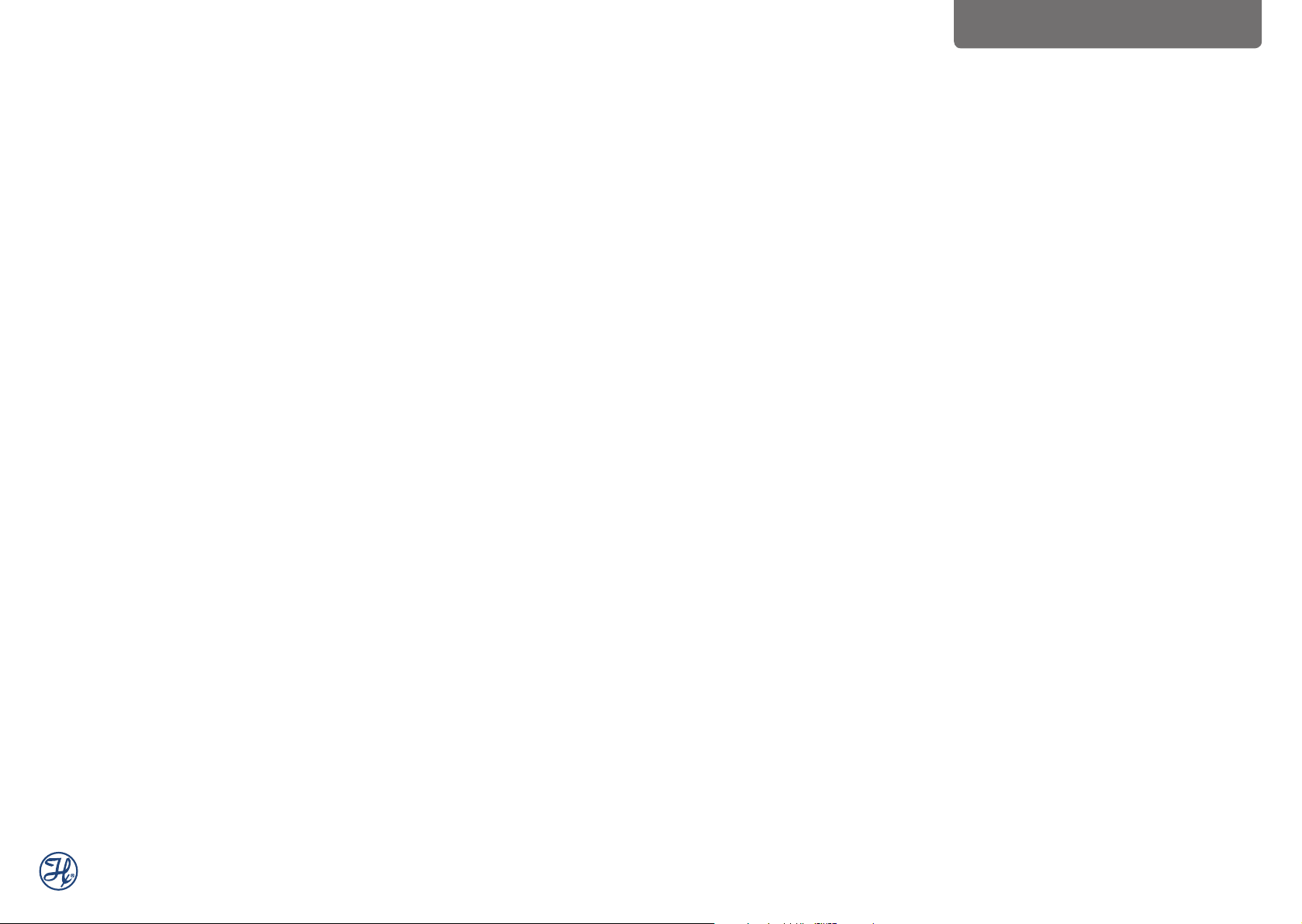

6 Assembly

Please check if the process connection is sufficiently clean. Then fit the Conducell 4US.

Please follow the instructions mentioned below.

Examples:

DIAGRAMS WITH DIMENSIONSASSEMBLY

Ø 60mm

min

ATTENTION! The cell

constant and the linearity

of the sensor can vary

with the fitting situation.

A symmetrical setup is

recommended. Leave an

open space of 60 mm

minimum diameter.

Partitions made of

non-conductive material

should preferably be

used.

ATTENTION!

A symmetrical setup is

recommended in order to

ensure a high degree of

linearity. To achieve high

precision the cell constant should be calibrated

in the final setup. Make

sure that all 4 electrodes

are completely and

continuously immersed in

the measuring sample.

Position marker

If the sensor is dismounted, the position marker helps to remount it in the original position.

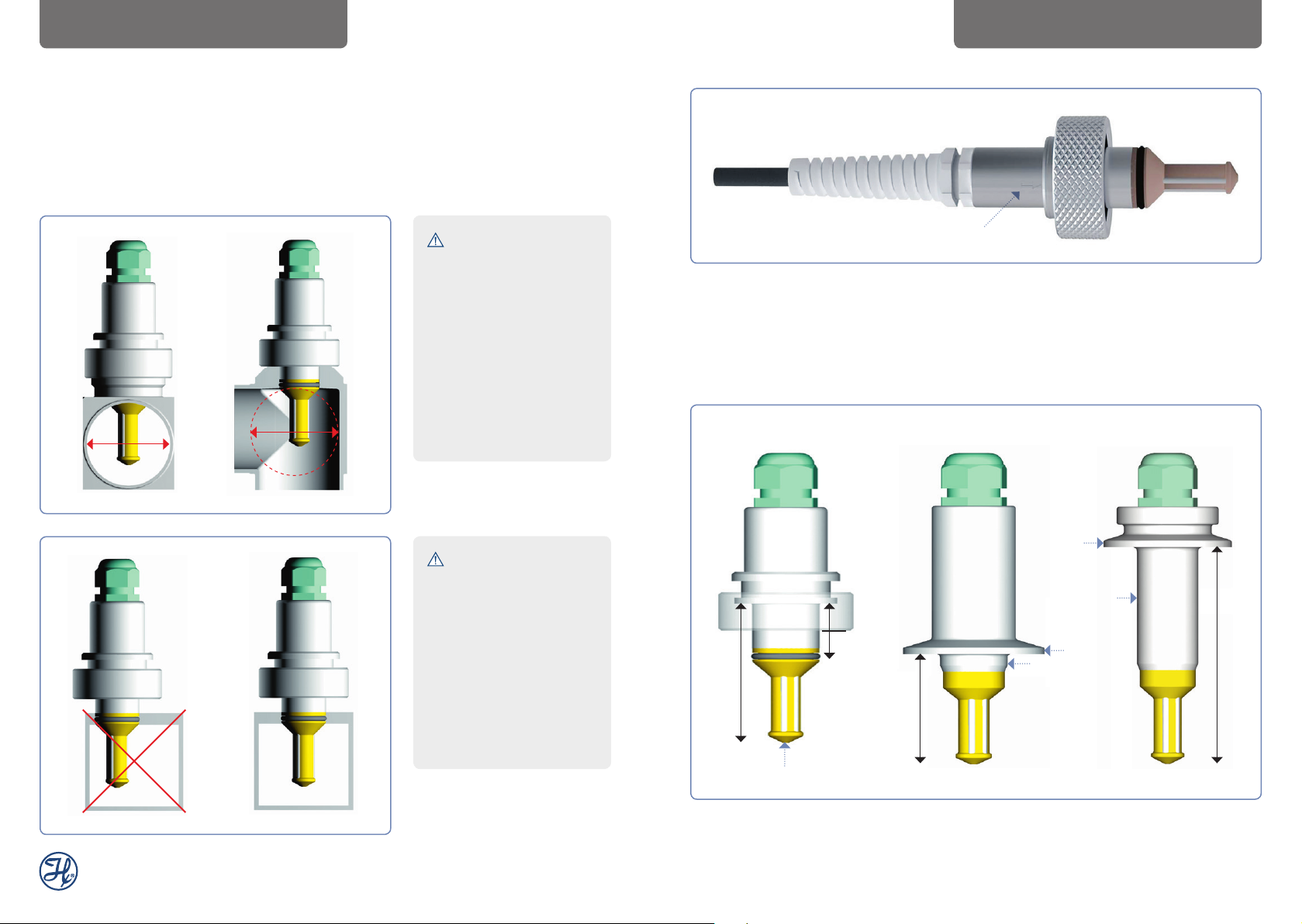

7 Diagrams with dimensions

E = H + 37

Ø 50.5

Ø 24

H*

50

Ø 50.5

Ø 24

97

Ø 13

* H = O-ring position ( 22 mm ≤ OP ≤ 55 mm)

™

4US Sensors Operating Instructions

9Conducell

Page 6

MEASUREMENT • CLEANING • DISPOSALCALIBRATION

8 Calibration

There are two possibilities for calibration:

1) Calibration while sensor is disassembled from process:

• First, rinse the sensor thoroughly with deionized water.

• Use a beaker or container that has an (internal) diameter of at least 30 mm. (Conducell

4US fits perfectly into the Hamilton Conductivity Standards, and can be calibrated directly

in the bottle.)

• Use a solution of known conductivity. Check the temperature table of the conductivity

standard.

• Immerse the lower part of the sensor in the standard. Make sure that the 4 electrodes are

completely immersed. The sensor should be placed in the center of the beaker.

• Leave the sensor for at least 5 minutes for equilibration, before initiating the calibration on the

instrument.

For precise determination of the cell constant, it is recommended that you use an assembly

situation similar or equal to the situation in the process. The cell constant may vary with the

assembly situation.

2) Calibration in the process:

• Insert the sensor in the process.

• Leave conductivity and temperature at least 15 min. for equilibration.

• Take a process sample and perform an external measurement with a reference conductivity

system. The best approach is to perform the measurement at a temperature equal to that

of the process. If this is not possible, you need to know the temperature coefficient of your

sample (similar to temperature table on Hamilton Conductivity Standards bottle).

• Manually adjust the cell constant to read the same conductivity value on the process

instrument.

• You may switch off the temperature compensation of the process and the laboratory instruments to prevent any errors.

9 Measurement

Air/gas bubbles may stick to the sensitive area of the sensor. As a consequence, the measurement value might be wrong. In case of a shutdown of the power supply (230V) the measurement value could be wrong.

10 Cleaning

Conducell 4US can be cleaned with standard cleaning agents. Never use scouring agents

which contain hard particles. Please check the O-rings from time to time. When mounting the

new O-ring take care not to damage the O-ring nut or the O-ring itself. Otherwise the tightness

of seal can no longer be guaranteed.

If working with hazardous liquids observe and carry out the maintenance procedures, paying

particular attention to cleaning and decontamination.

Cleaning, assembly and maintenance should be performed by personnel trained in such work.

Do not use any abrasive tissues or cleaning materials and do not use any cleaning chemicals

other then described above. Before removing the sensor from the measuring setup, always

make sure that the setup is pressure-less and cold and that no process medium can be accidentally spilled. When removing and cleaning the sensor, it is recommended to wear safety

glasses and protective gloves.

11 Disposal

The design of Hamilton sensors minimizes environmental impact. According to the

EU directive 2002/96/EC the Hamilton sensors should be disposed as waste of

electrical and electronic equipment, and not in municipal waste, or it can be sent

back to Hamilton for disposal.

有害物質表,請參閱 www.hamiltoncompany.com

章節過程分析,符合性聲明

™

4US Sensors Operating Instructions

11Conducell

Page 7

TECHNICAL DATA

INSTRUCTIONS FOR USE IN POTENTIALLY

EXPLOSIVE ATMOSPHERES

12 Technical data

Measuring Range 0.1 μS/cm to 500 mS/cm

Linearity (relative) ± 0.5 - 5 %

Cell constant 0.147 cm-1

Process Temperature -20 to 135 °C

Pressure Range 0 to 6 bar

Temperature Sensor Pt1000

Wetted Parts PEEK (FDA approved), Stainless Steel DIN 1.4435,

EPDM (FDA approved)

Surface Quality of Steel Ra < 0.4 μm (N5)

O-ring Material EPDM (FDA approved)

Process Connection G125: G 1-1/4” / T150: Triclamp 1.5”

Electrical Connector 5 m Open End

1) Uncertainty of ± 5 % arise when using only ONE single cell constant for the full range. ± 0.5% accuracy can be

achieved when calibration is performed in a conductivity range close to that of the sample. Remember also that

linearity is strongly influenced by the transmitter used.

2) Individual cell constant measured with Hamilton standard procedure printed on the label. The cell constant is

influenced by the assembly situation.

1)

2)

13 Instructions for use in potentially explosive atmospheres

ATEX / IECEx marking:

Gas: CE 0035

Dust: CE 0035

Manufacturer: Hamilton Bonaduz AG, 7402 Bonaduz, Switzerland

EC type examination report: TÜV 03 ATEX 7005 X

IECEx certificate of conformity: IECEx TUR 14.0001 X

EC type examination report and IECEx certificate of conformity can be downloaded from

www.hamiltoncompany.com.

The conditions described in the ATEX / IECEx certificate must be respected.

ATTENTION! In case a gas atmosphere and a dust atmosphere are or could

be present at the same time, the risk of explosion must be examined carefully

and special precautions may be necessary.

Assembly

1) The operator of equipment in potentially explosive atmospheres is responsible for ensuring

that all components of the system are certified for that area classification and are compatible

with each other.

II 1/2 G Ex ia IIB T4/T5/T6 Ga/Gb

II 1/2 D Ex ia IIIC T x °C Da/Db

Fig. 1: Linearity of the Conducell 4US, connected to a typical

process transmit ter. One single cell constant determined at

1413 μS/cm was used over the full range.

ATTENTION! The linearity of the system is strongly dependent on the

transmitter connected to the sensor.

2) In gas atmospheres, the Ex approval is not dependent on any conditions regarding mounting of the sensor. In dust atmospheres, however, special restrictions may apply when using

armatures made of plastic material.

3) O-rings having a sealing function between Ex-zone 0 and 1 or Ex-zone 20 and 21, respectively,

must be replaced at each dismantling of the sensor.

4) Sensors, transmitter and equipment required are to be set up within one balanced potential

system.

5) When the sensor is assembled, the ATEX / IECEx sticker is to be attached to the cable in an

easily visible place, as near as possible to the sensor itself. This sticker is to indicate that an

ATEX / IECEx approved sensor is in use. The sticker should not be removed at any time.

™

4US Sensors Operating Instructions

13Conducell

Page 8

ACCESSORIESCONNECTION TO TRANSMITTER

14 Connection to transmitter

Conducell 4US is suitable for connection to an intrinsically safe electrical circuit with protection

level ia. The operator of the equipment must ensure that the allowable electrical values for the

sensor all exceed those for the transmitter. None of the values cited for electrical power, voltage

and current may be exceeded in sum (measurement and temperature circuit together). Electric

values for Conducell 4US are as follows:

U = 24 V; I = 173 mA; P: Function of process temperature. The maximum allowable electric

power P of the transmitter (measurement and temperature circuit together) depends on the

desired process temperature.

For gas atmospheres:

Typ e 6 P ≤ 50 mW P ≤ 100 mW P ≤ 150 mW

T4 109°C 91°C 72°C

T5 74°C 56°C 37°C

T6 59°C 41°C 22°C

For dust atmospheres:

Table for the calculation of the maximum surface temperature «x» of the sensor as a function of

the maximum electrical power of the transmitter «P

«x» has to be smaller than the ignition temperatures of dust involved.

» and ambient/process temperatures «Ta».

i

15 Accessories

Conductivity standards

Value at 25°C Accuracy Stability Certified Package Ref

(month) by

1.3 μS/cm 1% 12 DFM Glass bottle 300 mL 238973

5 μS/cm 1% 36 DFM Glass bottle 300 mL 238926

15 μS/cm 1% 36 DFM Glass bottle 300 mL 238927

84 μS/cm 1% 18 DFM 1 Calpack bottle 500 mL 238984

100 μS/cm 1% 36 DFM Glass bottle 300 mL 238934

147 μS/cm 1% 18 DFM 1 Calpack bottle 500 mL 238985

706 uS/cm 2% 36 Hamilton Glass bottle 300 mL 238929

1413 μS/cm 1% 36 DFM Glass bottle 300 mL 238928

1413 μS/cm 1% 18 DFM 1 Calpack bottle 500 mL 238986

12880 μS/cm 1% 18 DFM 1 Calpack bottle 500 mL 238988

100 mS/cm 1% 24 Hamilton Glass bottle 300 mL 238935

Typ e Pi ≤ 50 mW Pi ≤ 100 mW Pi ≤ 15 0 mW

6 x = T

Ta: ambient / process temperature

+ 21°C x = Ta + 39°C x = Ta + 58°C

a

The temperature limit stated on the sensor must always be respected.

™

4US Sensoren Bedienungsanleitung

15Conducell

Page 9

Wichtiger Hinweis

Die Reproduktion irgendeines Teils dieses Handbuchs in jeder beliebigen Form ist ohne die ausdrückliche schriftliche Zustimmung der Hamilton Bonaduz AG untersagt. Der Inhalt dieses Handbuchs kann ohne vorherige Ankündigung geändert werden. Technische Änderungen vorbehalten.

INHALTSVERZEICHNIS

Inhaltsverzeichnis

1 Haftung .............................................................................. 18

2 Bestimmungsgemässe Verwendung ............................... 19

3 Sicherheitshinweise .......................................................... 19

4 Inbetriebnahme ................................................................. 20

5 Elektrische Anschlüsse .................................................... 20

6 Einbau des Leitfähigkeitssensors .................................... 22

7 Masszeichnungen ............................................................. 23

8 Kalibration .......................................................................... 24

9 Messung ............................................................................ 25

10 Reinigung ........................................................................... 25

11 Entsorgung ........................................................................ 25

12 Technische Daten .............................................................. 26

13 Hinweise für den Einsatz in

explosionsgefährdeten Bereichen ................................... 27

14 Anschluss an Transmitter ................................................. 28

15 Zubehör .............................................................................. 29

Es wurde grösstmögliche Sorgfalt auf die Richtigkeit der Informationen in diesem Handbuch

verwendet. Sollten dennoch Fehler entdeckt werden, würde sich die Hamilton Bonaduz AG

freuen, darüber informiert zu werden. Ungeachtet dessen kann die Hamilton Bonaduz AG keine

Haftung für etwaige Fehler in diesem Handbuch oder deren Folgen übernehmen.

Copyright © 2019 Hamilton Bonaduz AG, Bonaduz Schweiz. Alle Rechte vorbehalten.

™

4US Sensoren Bedienungsanleitung

17Conducell

Page 10

HAFTUNG

BESTIMMUNGSGEMÄSSE VERWENDUNG

SICHERHEITSHINWEISE

Bedienungsanleitung

Diese Bedienungsanleitung bezieht sich auf die Hamilton Conducell 4US Sensoren.

Ref Beschreibung Anschluss ATEX

1

237700-OP Conducell 4US-G125 G 1

237750 Conducell 4US-T150-50 Triclamp 1.5”

237760 Conducell 4US-T150-100 Triclamp 1.5”

Hamilton Leitfähigkeitssensoren sind nach neuesten Erkenntnissen hergestellte Qualitätsprodukte.

Diese Betriebsanleitung muss vom zuständigen Personal gelesen, verstanden und beachtet

werden. Für Schäden und Betriebsstörungen, die sich aus Nichtbeachten der Betriebsanleitung

ergeben, übernimmt die Firma Hamilton keine Haftung.

1 Haftung

Die Haftung der Hamilton Bonaduz AG wird in Kapitel 12 der «Allgemeine Verkaufs- und Lieferbedigungen (AVB)» geregelt.

Hamilton haftet insbesondere nicht für direkte oder indirekte Schäden, die sich aus der Nutzung

der Sensoren ergeben. Insbesondere ist hier zu beachten, dass Fehlfunktionen durch die naturgemäss applikativ beschränkte Lebensdauer von Sensoren auftreten können. Der Benutzer ist

für Kalibration, Wartung und den rechtzeitigen Austausch der Sensoren verantwortlich. Bei kritischen Anwendungen der Sensoren empfiehlt Hamilton redundante Messstellen, um Folgeschäden zu vermeiden. Die Einrichtung geeigneter Absicherungen für den Fall eines Sensorausfalles

obliegt dem Anwender.

⁄4”

2 Bestimmungsgemässe Verwendung

Mit der Conducell 4US Linie hat Hamilton in-line Leitfähigkeitssensoren entwickelt, welche den

strengen Anforderungen in der Biotechnologie und in der chemischen Industrie gewachsen

sind. Sie werden für die Bestimmung der elektrolytischen Leitfähigkeit in Lösungen verwendet.

Spezielle Aufmerksamkeit während der Entwicklung hat das hygienische Design erhalten. Alle

Materialien, welche in Kontakt mit der Messlösung kommen sind FDA geprüft.

Die Sensoren sind auf dem 4-Pol Prinzip aufgebaut, welches Polarisierungsphänomene, wie sie

bei einer 2-Pol Zelle auftauchen, ausschliesst. Dieses Prinzip garantiert eine exzellente Linearität

über den ganzen Linearitätsbereich von 6 Dekaden!

3 Sicherheitshinweise

Dieser Sensor ist nur zu benutzen für die bestimmungsgemässe Verwendung und in sicherheitstechnisch einwandfreiem Zustand. Die Spezifikationen bezüglich Druck und Temperatur müssen eingehalten werden (Siehe technische Informationen). Bei Fehlbedienung oder

Missbrauch drohen Gefahren. Montage und Wartung dürfen nur durch geschultes Personal

vorgenommen werden.

Beim Einbau muss auf die korrekte Position und auf einwandfreien Zustand des O-Rings

geachtet werden. O-Ringe sind Verschleissteile, die regelmässig gewechselt werden müssen,

spätestens nach einem Jahr.

Der integrierte Temperaturfühler soll nur für die Kompensation der Leitfähigkeit verwendet

werden und nicht für die Steuerung der Prozesstemperatur.

Die Conducell 4US Sensoren werden eingesetzt zur Bestimmung der elektrolytischen Leitfähigkeit in Lösungen. Werden die Sensoren in explosionsgefährdeten Zonen eingesetzt, so

müssen die Hinweise im Kapitel «Hinweise für den Einsatz in explosionsgefährdeten Bereichen» beachtet werden.

Jedes Produkt das verschickt oder zurück zur Reparatur geschickt wird muss dekontaminiert

werden. Wird mit gefährlichen Flüssigkeiten gearbeitet, muss bei Wartungsarbeiten speziell

auf die Reinigung und Dekontaminierung geachtet werden. Wenn das Produkt mit biologisch

gefährlichen-, radioaktiven- oder chemischen Substanzen kontaminiert, dann muss es gereinigt

werden.

™

4US Sensoren Bedienungsanleitung

19Conducell

Page 11

INBETRIEBNAHME

ELEKTRISCHE ANSCHLÜSSE

ELEKTRISCHE ANSCHLÜSSE

4 Inbetriebnahme

Überprüfen Sie den Sensor beim Auspacken auf eventuelle Schäden. Beanstandete Sensoren

sind Hamilton in der Originalverpackung einzusenden.

5 Elektrische Anschlüsse

Signalbeschreibung Kabel Conducell 4US

Pt1000 (negativ) Grau

Pt1000 (negativ) Weiss

Pt1000 (positiv) Blau

Stromführende Elektrode (positiv) Rosa

Spannungsabgriff (positiv) Grün

Spannungsabgriff (negativ) Braun

Stromführende Elektrode (negativ) Gelb

Nicht angeschlossen am Sensor Schirm

Nicht angeschlossen Rot

Conducell 4US Emerson Yokogawa SIEMENS

5081 C Model SC150, SC202, SIPAN

SC402, SC450 32/32X

Grau 3 11 23

Weiss 4 11 24

Blau 5 12 25

Rosa 8 14 26

Grün 11 13 29

Braun offen 15 27

Gelb offen 16 30

Schirm 5 63 Schirm

Rot - - Kommentar 2-Elektroden Anordnung *

* Bitte be achten Sie für Yokogawa SC150, SC202, SC402, SC450 dass der Messbereich

der Eingangsspezifikation des Gerätes entspricht.

ACHTUNG! Die Linearität des Systems hängt stark vom Instrument ab, an

welches der Sensor angeschlossen ist. Beachten Sie die technischen Spezifikationen des Instrumentenherstellers für den geeigneten Messbereich.

Conducell Hamilton Knick Knick Stratos Knick Stratos e

4US H100 Cond Cond 2201 X 2401 Cond 2402 / 2405 Cond

Grau D 7 6 D

Weiss D 7 6 D

Blau E 8 5 E

Rosa 1 1 1 1

Grün 2 2 2 2

Braun 3 3 3 3

Gelb 4 4 4 4

Schirm C 5 5 C

Rot - - - Kommentar 4 + 5 brücken 4 + 5 brücken 4 + 5 brücken 4 + 5 brücken

™

4US Sensoren Bedienungsanleitung

21Conducell

Page 12

6 Einbau des Leitfähigkeitssensors

Bitte kontrollieren Sie, dass die Prozessverbindung sauber ist. Montieren der Conducell 4US

und befestigen. Bitte beachten Sie die untenstehenden Instruktionen.

Beispiele:

MASSZEICHNUNGENEINBAU DES LEITFÄHIGKEITSSENSORS

Ø 60mm

min

ACHTUNG! Die

Zellenkonstante und die

Linearität kann je nach

Einbausituation variieren.

Ein symmetrischer

Einbau wird empfohlen.

Lassen Sie ein Feld von

mindestens 60 mm

Durchmesser offen.

Verwenden Sie vorzugsweise Wandungen aus

nicht leitfähigem Material.

ACHTUNG!

Um die Linearität zu

gewährleisten wird ein

symmetrischer Einbau

empfohlen. Um eine

hohe Präzision zu

erreichen, sollte die

Zellkonstante im Endaufbau bestimmt werden.

Stellen Sie sicher, dass

alle 4 Elektroden komplett und stetig in der zu

messenden Lösung

eingetaucht sind.

Positionsmarkierung

Die Positionsmarkierung hilft dabei, sicherzustellen, dass ein Sensor immer die gleiche

Einbaulage hat.

7 Masszeichnungen

E = H + 37

Ø 50.5

Ø 24

H*

50

Ø 13

Ø 50.5

Ø 24

97

* H = O-Ring Position ( 22 mm ≤ OP ≤ 55 mm)

™

4US Sensoren Bedienungsanleitung

23Conducell

Page 13

KALIBRATION

MESSUNG • REINIGUNG • ENTSORGUNG

8 Kalibration

Es gibt zwei Möglichkeiten zu kalibrieren:

1) Kalibrierung ausserhalb des Prozesses:

• Zuerst den Sensor gründlich mit deionisiertem Wasser spülen.

• Benützen Sie einen Becher mit einem Minimum Innendurchmesser von 30mm.

(Die Conducell 4US passt in ein Hamilton Leitfähigkeitsstandard und kann direkt in der

Flasche kalibriert werden.)

• Brauchen Sie eine Lösung mit einem bekannten Leitfähigkeitsmesswert. Kontrollieren Sie die

Temperaturtabelle auf dem Leitfähigkeitsstandard.

• Tauchen Sie den unteren Teil des Sensors in die Lösung ein. Stellen Sie sicher, dass

die 4 Elektroden komplett eingetaucht sind. Der Sensor sollte in der Mitte des Bechers

platziert sein.

• Lassen Sie den Sensor für mindestens 5 Minuten in der Messlösung stehen, bis das Gleichgewicht erreicht ist, und starten Sie erst danach die Kalibrierung am Instrument.

Für eine präzise Bestimmung der Zellkonstante, sollte der Sensor in einer gleichen oder ähnlichen

Situation wie im Prozess eingebaut werden. Die Zellkonstante ist von der Einbausituation abhängig.

2) Kalibrierung im Prozess:

9 Messung

Stellen Sie sicher, dass keine Luft- oder Gasblasen an messsensiblen Teilen des Sensors

vorhanden sind. Mögliche Folgen könnten falsche Messwerte sein. Bei einer Abschaltung der

Stromversorgung (230V), könnte der Messwert falsch sein.

10 Reinigung

Die Conducell 4US kann mit den üblichen Reinigungsmitteln gereinigt werden. Scheuermittel

sind ungeeignet. Von Zeit zu Zeit sollten die O-Ringe überprüft werden. Beim Ersatz beschädigter O-Ringe darf die Nut wie auch der neue O-Ring mechanisch nicht verletzt werden, da

sonst die Dichtfunktion nicht mehr gewährleistet ist.

Wird mit gefährlichen Flüssigkeiten gearbeitet, muss bei Wartungsarbeiten speziell auf die Reinigung und Dekontaminierung geachtet werden. Reinigung, Montage und Wartung muss von

trainiertem Personal ausgeführt werden. Verwenden Sie nicht abrasive Tücher oder Reinigungsmaterialien oder andere Reinigungsmittel als diejenigen oben beschrieben. Bevor der Sensor

aus dem Prozess entfernt wird, muss sichergestellt werden, dass der Prozess drucklos und

abgekühlt ist und dass kein Prozessmedium fälschlicherweise verschüttet werden kann.

Wird ein Sensor aus dem Prozess entfernt, muss eine Schutzbrille und Handschuhe getragen

werden.

• Montieren Sie den Sensor im Prozess.

• Lassen Sie den Sensor stabilisieren für mindestens 15 min.

• Nehmen Sie ein Prozessmuster und machen Sie eine externe Referenzmessung. Das beste

Messergebnis erhalten Sie, wenn die Messung bei der gleicher Temperatur durchgeführt wird

wie im Prozess. Sollte das nicht möglich sein, muss der Temperaturkoeffizient der Messlösung

bekannt sein.

• Manuell die Zellkonstante verstellen, damit der gleiche Leitfähigkeitswert am Prozessinstrument abgelesen wird (ähnlich wie auf der Temperaturtabelle auf den Hamilton Leitfähigkeitsstandards).

• Sie können die Temperaturkompensation am Prozess- und Laborinstrument ausschalten, um

Fehler zu vermeiden.

11 Entsorgung

Das Design der Hamilton Sensoren berücksichtigt bestmöglichst die Umweltverträglichkeit. Gemäss der EU Richtlinie 2002/96/EG müssen Hamilton Sensoren einer ge-

trennten Sammlung für Elektro- und Elektronikgeräten zugeführt werden oder können

an Hamilton zur Entsorgung geschickt werden. Sie dürfen nicht dem unsortierten Siedlungsabfall zugeführt werden.

™

4US Sensoren Bedienungsanleitung

25Conducell

Page 14

TECHNISCHE DATEN

EXPLOSIONSGEFÄHRDETEN BEREICHEN

HINWEISE FÜR DEN EINSATZ IN

12 Technische Daten

Messbereich 0.1 μS/cm bis 500 mS/cm

Linearität (relativ) ± 0.5 - 5 %

Zellkonstante 0.147 cm-1

Temperaturbereich -20 bis 135 °C

Druckbereich 0 bis 6 bar

Temperatursensor Pt1000

Medienberührende Materialien PEEK (FDA geprüft), Edelstahl DIN 1.4435,

EPDM (FDA geprüft)

Oberflächenqualität Ra < 0.4 μm (N5)

O-Ring Material EPDM (FDA geprüft)

Prozessanschluss G125: G 1-1/4” / T150: Triclamp 1.5”

Elektrischer Anschluss 5 m offenes Ende

1) Unsicherheiten von ± 5 % entstehen, wenn eine Zellkonstante über den ganzen Bereich verwe ndet wird.

± 0.5% Genauigkeiten können erzielt werden, wenn der Messwert der Kalibrierung nahe am Leitfähigkeits

messwer t des Musters liegt. Beachten Sie, dass die Linearität stark vom verwendeten Instrument abhängig ist.

2) Zellkonstante wird von der Einbausituation bee influsst.

1)

2)

13 Hinweise für den Einsatz in explosionsgefährdeten Bereichen

ATEX / IECEx Kennzeichnung:

Gas: CE 0035

Staub: CE 0035

Hersteller: Hamilton Bonaduz AG, CH-7402 Bonaduz, Switzerland

EG-Baumusterprüfbescheinigung: TÜV 03 ATEX 7005 X

IECEx Certificate of Conformity: IECEx TUR 14.0001 X

EG-Baumusterprüfung und IECEx Certificate of Conformity können über

www.hamiltoncompany.com heruntergeladen werden.

Die in der EG-Baumusterprüfbescheinigung bzw. in der IECEx Certificate of Conformity

beschriebenen Bedingungen sind einzuhalten.

ACHTUNG! Wenn eine explosionsfähige Gasatmosphäre und eine brennbare

Staubatmosphäre zur selben Zeit vorhanden sind oder vorhanden sein dürfen,

sollte das gleichzeitige Vorhandensein berücksichtigt werden und bedarf zusätzlicher Schutzmassnahmen.

Montage

1) Der Betreiber einer Anlage in explosionsgefährdeten Zonen ist dafür verantwortlich, dass alle

Komponenten des Systems für die jeweilige Zoneneinteilung zertifiziert sind und untereinander

kompatibel sind.

II 1/2 G Ex ia IIB T4/T5/T6 Ga/Gb

II 1/2 D Ex ia IIIC T x °C Da/Db

Fig. 1: Linearität einer Conducell 4US, angeschlossen an ein

typisches Prozessmessgerät. Mit einer einzigen Zellkonstante,

welche be i 1413 μS/cm be stimmt wurde, wurde über den

ganzen Bereich gemessen.

ACHTUNG! Die Linearität des Systems ist stark vom verwendeten

Instrument abhängig.

2) Der Einsatz des Sensors in einer Gasatmosphare ist an keine Bedingungen bezüglich des

Einbaus des Sensors gebunden. Bei einer Staubatmosphare hingegen sind Einschränkungen zu beachten bei Verwendung von Armaturen aus Kunststoff.

3) Jene O-Ringe, die eine dichtende Funktion zwischen Ex-Zone 0 und 1 bzw. 20 und 21 übernehmen, müssen bei jedem Ausbau der Elektrode ersetzt werden.

4) Die Sensoren, die Leitungswege und die dazugehörigen Betriebsmittel sind innerhalb eines

einzigen Potentialausgleichsystems zu errichten.

5) Bei der Montage des Sensors muss das beiliegende ATEX / IECEx Kennzeichnungsschild an

gut sichtbarer Stelle am Kabel befestigt werden, möglichst nahe beim Sensor. Dieses Schild

soll darauf hinweisen, dass ein ATEX / IECEx zugelassener Sensor montiert ist. Es darf nicht

entfernt werden.

™

4US Sensoren Bedienungsanleitung

27Conducell

Page 15

ANSCHLUSS AN TRANSMITTER ZUBEHÖR

14 Anschluss an Transmitter

Conducell 4US ist geeignet zum Anschluss an einen eigensicheren Stromkreis mit Schutzniveau ia. Der Betreiber der Anlage muss sicherstellen, dass die zulässigen elektrischen Werte

des Sensors grösser sind als die maximalen Werte des Transmitters. Keiner der angegebenen

Werte für Spannung, Strom und Leistung darf in Summe (Mess- und Temperaturstromkreis

zusammen) überschritten werden. Die elektrischen Werte für die Conducell 4US sind wie folgt:

U = 24 V; I = 173 mA; P: Funktion der Prozesstemperatur. Die maximal zulässige elektrische

Leistung P des Transmitters (Mess- und Temperaturstromkreis zusammen) ist abhängig von der

gewünschten Prozesstemperatur.

Für Gasatmosphäre:

Typ 6 P ≤ 50 mW P ≤ 100 mW P ≤ 150 mW

T4 109°C 91°C 72°C

T5 74°C 56°C 37°C

T6 59°C 41°C 22°C

Für Staubatmosphäre:

Tabelle zur Ermittlung der maximalen Oberflächentemperatur «x» des Sensors in Abhängigkeit

der Leistung des Transmitters «P

Zündtemperatur des Staubes in der entsprechenden Applikation.

» und der Prozesstemperatur «Ta». «x» muss kleiner sein als die

i

15 Zubehör

Leitfähigkeitsstandards

Wert bei 25°C Genauig- Stabilität Zertifiziert Verpackungseinheit Ref

keit (Monate) vom

1.3 μS/cm 1% 12 DFM Glasflasche 300 mL 238973

5 μS/cm 1% 36 DFM Glasflasche 300 mL 238926

15 μS/cm 1% 36 DFM Glasflasche 300 mL 238927

84 μS/cm 1% 18 DFM 1 Calpack Flasche 500 mL 238984

100 μS/cm 1% 36 DFM Glasflasche 300 mL 238934

147 μS/cm 1% 18 DFM 1 Calpack Flasche 500 mL 238985

706 uS/cm 2% 36 Hamilton Glasflasche 300 mL 238929

1413 μS/cm 1% 36 DFM Glasflasche 300 mL 238928

1413 μS/cm 1% 18 DFM 1 Calpack Flasche 500 mL 238986

12880 μS/cm 1% 18 DFM 1 Calpack Flasche 500 mL 238988

100 mS/cm 1% 24 Hamilton Glasflasche 300 mL 238935

Typ Pi ≤ 50 mW Pi ≤ 100 mW Pi ≤ 15 0 mW

6 x = T

Ta: Umgebungs- / Prozesstemperatur

+ 21°C x = Ta + 39°C x = Ta + 58°C

a

Die auf dem Sensor definierte Temperaturlimite muss in jedem Fall eingehalten werden.

™

4US Sensoren Bedienungsanleitung

29Conducell

Page 16

NOTES NOTIZEN

™

4US Sensoren Bedienungsanleitung

31Conducell

Page 17

© 2019 Hamilton Bonaduz AG. All rights reserved.

610916/06 — 03/2019

Web: www.hamiltoncompany.com

Hamilton Americas & Pacific Rim

4970 Energy Way

Reno, Nevada 89502 USA

Tel: +1-775-858-3000

Fax: +1-775-856-7259

sales@hamiltoncompany.com

Hamilton Europe, Asia & Africa

Via Crusch 8

CH-7402 Bonaduz, Switzerland

Tel: +41-5 8- 610-10 -10

Fax: +41-58-610-00-10

contact.pa.ch@hamilton.ch

USA: 800-648-5950

Europe: +41-58-610-10-10

To find a representative in your area, please visit hamiltoncompany.com.

This guide may be available in other languages. Visit www.hamiltoncompany.com for more information.

Loading...

Loading...