Hamilton 9505936 Maintenance Manual

Hamilton

Installation

Operation

and

Maintenance

Manual

sink

Unit

No.

9505936

Sink

NSN:

Unit

Number:

9505996

6545-01-163-1899

Hamilton

1316

Two

Code

18th

Rivers,

Number:

Industries,

Inc.

Street

WI

54241

26954

Form

Issue

Revision:

Number:

Date:

PL-410-3

October

4

1,

1992

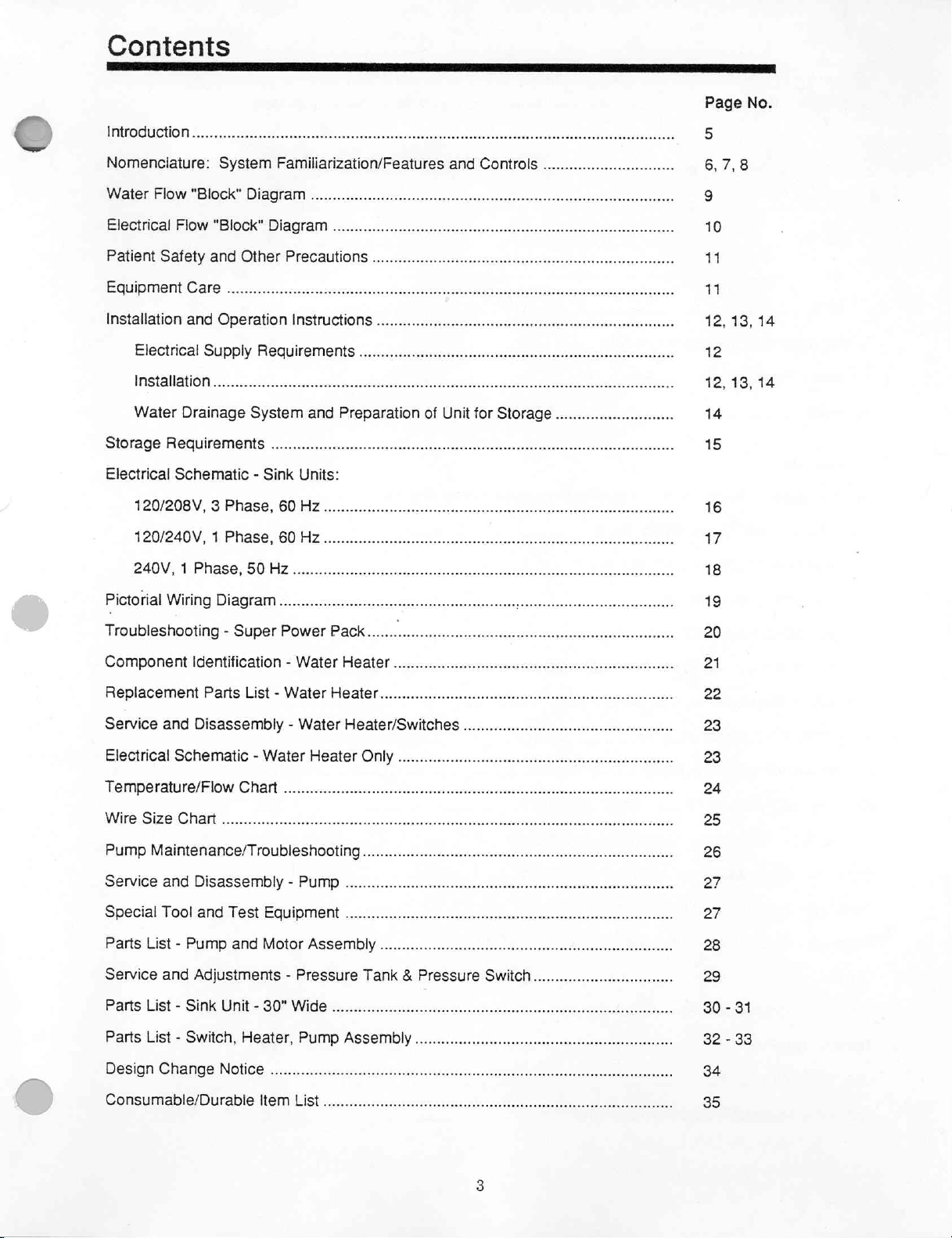

Contents

Introduction

Nomenclature:

Water

Patient:

Equipment

Installation

Flow

Electrical

Flow

Safety

Electrical

"Block"

Care

and

Supply

Πο

Water

Storage

Electrical

120/208V, 3 Phase,

120/240V, 1 Phase,

240V; 1 Phase.50

Pictorial

Drainage

Requirements

Schematic - Sink

WiringDiagram...........................

System

Diagram

"Block"

Diagram

and'Other

Operation

Requirements

System

Familiarization/Features

............

and

Controls

..............................

nen

renerne

rn

rn

ee

Precautions

Instructions...

sise

ο

ο ο ο

and

Preparation

of

линии

ο

Unit

for

Storage

...........................

mers

seeren

dere

νο

vsere

11

12,

12

12,

14

15

13,

13,

14

14

Units:

60

Hz...

60 月 Ze

ssascsscsccpsczsnssciacitisssssecdsecerenenencnenseenensseraecngenenrsenneenenntenneess

een

有

16

17

18

19

Troubleshooting - Super

Componentidentification-WaterHeater.................................................

Replacement

Service

Electrical

Temperature/Flow

MO

Parts

and

Disassembiy

Schematic - Water

AAA

PümpMaiménance/TrOUDISSROO

Service

Special

Parts

Service

Parts'List = Sink

Parts

Design

and

Disassembly - Pump

Tool

and

ТезЕ

List - Pump

and

and

Adjustments - Pressure

Unit

List - Switch,

Change

Notice

Power

List - Water

-WaterHeater/Switches.............................................

Chart

idee

Едшриейи

Motor

=-30"

Wide

Heater,

PUMP

лесопарка

Pack.......

Heater

Heater

ra

i

Only

NY...

.....................

Assembly

Tank & Pressure

ο

ASSEMDIY

ου

.................

линии

Switch

ーー

oeeeee

eee

ce

cn

NE

иена,

ne

ene

eee

ne

nene

................................

iran

ii

20

21

22

23

23

24

25

26

27

27

28

29

30 - 31

32 - 33

34

Consumable/Durable

Item

List...

LE

blender

35

Contents

ER

Short

Form

Provisioning

E

Parts

List

O

B

E

EEN

Page

No.

1

Kit

"Ba"...

КИ

"С"

Quality

Receiver's

PDG

Assurance

人

ee

e

Inspection

Responsibility

Checklist

....

eeoeeeee

ee

Pete o tet

eee

né

a

36

37

38,

40.

42,

44,

46,

Illustrations

Nomenclature:

WaterFlow"Block"DiagramIllus.No.2...............................................

Electrical

Electrical

120/208V,3

Flow

System

"Block"

Familiarization/Features

Diagram

Schematic - Sink

Phase,

60

Illus.

Units:

Hz

Illus.

and

Controls

No. 3 5

ölen

No. 4 аишиашиниы

Illus.

No. 1 ............

a

Bose

8

g

10

16

39

41

43

45

47,

48

120/240V, 1 Phase,

240V, 1 Phase,

Pictorial

Component

Wiring

Identification - Water

Replacement

Electric

Parts

Parts

Parts

Schematic - WaterheaterOnly

List - Pump

List - Sink

List - Switch,

Diagram

Parts

and

Unit - 30"

60

Hz:

50

Hz

IIIus.

Illus.

List - Water

Motor

Assembly

Wide

Heater,

Pump

INSLNOS

No.

No.

7

Heater

Heater

Illus.

Assembly

ito

6...

Illus.No.8.............................................

nene

eee

nenene

Illus.No.9................................................

Illus.No.10.........................................

Illus.No.11...........................................

NO.

12

Illus.

No.

18...

rant

rrrernnne

Charts

Troubleshooting-SuperPowerPack-ChartNo.1..................................

Temperature/Flow

Chart

NO 2 せろ

We

Pump

Maintenance/Troubleshooting-ChartNo.4.............................................

17

18

19

21

22

23

28

31

32

20

24

25

26

introduction

Scrub

sink

unit

for a field

dispenser,

provide

cold

electrical

surgical

Sink

facilities

opment

control

The

which

pounds.

handle

The

pump

adjustable

water,

hot

inlet

soap.

unit

provides

within

of

x-rays.

handles

cabinet

extends

Four

are

used

actuator

to

water

and

cord.

pressurized

the

mdeical

The

on

water

provides

20"

above

carrying

to

secure

for

the

hospital

supply

cold

water

temperature.

faucet

Additional

facility.

unit

also

mixing

an

overall

the

sink

handles,

work

soap

dispenser

consists

pressure,

Unattached

handles,

items

required

cold

and

Provides

provides

faucet

unit

size

top

backsplash.

two

recessed

counters

is

foot

of a cabinet

pressure

waste

hose

but

heated

water

tempered

surgical

and

foot

of

30-1/8"

in

950S927

operated;

with

tank

items

furnished

assembly,

not

supplied

for

use

water

scrub

facilities

operated

wide x 24"

Cabinet

each

side,

or

950S928

the

dispensing

removeable

to

provide

water

are

in

field

for

cleansing

with

soap

dispenser.

deep x 40"

average

and

four

to

casters, a stainless

uniform

are

external

medical

necessary

weight

support

the

nozzle

mixing

supply

water

of

high,

unit.

flow

faucet

hose

facilities.

equipment

sterile

excluding

is

260

bars,

is

on

rate

and a water

with

and

filler

supply,

Provides

and

controls,

pounds

one

recessed

the

unit's

steel

sink,

heater

gooseneck

assembly,

electrical

for

supply

sanitary

assistance

such

as wrist

the

faucet

with a maximum

top.

gooseneck,

above

soap

to

hot

and

and

waste

in

devel-

each

and

of

265

Water

tank

limit,

pressure

The

KW

is

The

supply

to a preset

approximately

limits

water

heater

at

230V

50/60

adjustable

water

using a rheostat

heater

pump

Phase, 2 Wire.

Recommended

(capable

Shipping,

All

personnel

common

better

Heavier

product.

of

furniture

are

carriers.

utilization

items

Our

measuring

Handling

products

loaders

is

powered

upper

limit,

30

psi

are

adjustable.

is

an

in-line

Hz.

and

will

operate

test

equipment

150

have

instructed

The

of

are

exception

the

truckload

floor

to

loaded

are

by a 1/3

approximately

minimum,

heater

will

operate

in a solid

on

the

is

as

degree

and

directional

follow

F).

Storage:

the

to

the

space.

with

lighter

instructed

not

h.p.

(minimum)

60

psi

the

pump

will

which

functions

at

208V,

state

sircuit.

following

follows:

arrows

power

Volt

which

directional

directional

items

to

load

heavy

110/220V

maximum.

automatically

only

when

50/60

Hz,

with

Maximum

supplies:

Ohm

Meter,

indicate

arrows

loaded

when

arrows

on

items

is

allowed

top.

on

50/60

When

the

repressurize

water

wattage

water

temperature

120/208V,

Continuity

how

the

product

loading

when

Heavy

lighter

Hz.

tank

is

flowing

reduced

60

Tester

truck

“Topping”

items

weight

motor, and

pressure

the

tank.

through

accordingly.

is

pressurizes

is

reduced

The

the

150°

F.

upper

heater.

Water

Hz, 1 Phase, 3 Wire;

and

Immersible

is

to

be

loads,

can

be

loaded.

containers

freight

double

Hamilton

or

with

decked

items.

the

pressure

to a preset

and

lower

It

is

rated

temperature

240V,

50

Thermometer

loading

assisting

lighter

on

the

"LIL"

cartons

same

lower

at

Hz,

for

4

1

All

truckloads

The

above

Recommended

Warranty:

All

product

of

one

(1)

year

repair

or

replace,

warranty

made

excludes

by

others.

must

be

secured

instructions

should

Storage

purchased

from

at

any

on

date

its

expense,

damage

at

also

Climate

this

contract

of

acceptance

the

rear

apply

Limits

Are:

are

by

including

or

malfunction

and

pictures

to

storage.

Never

Temperature: 0 Degree

Humidity:

warranted

the

transportation

to

government.

due

to

are

taken

place

be

free

of

During

and

labor,

accident,

as a permanent

heavier

items

Fahrenheit — +130

5%

Min.

Humidity — 95%

defect

alteration,

the

any

in

material

warranty

part

abuse,

record.

on

lighter

period

or

product

negligence,

ones.

and

workmanship

Hamilton

found

Degree

Max.

to

be

misuse,

Fahrenheit

Humidity

for a period

Industries

defective.

or

repairs

will

This

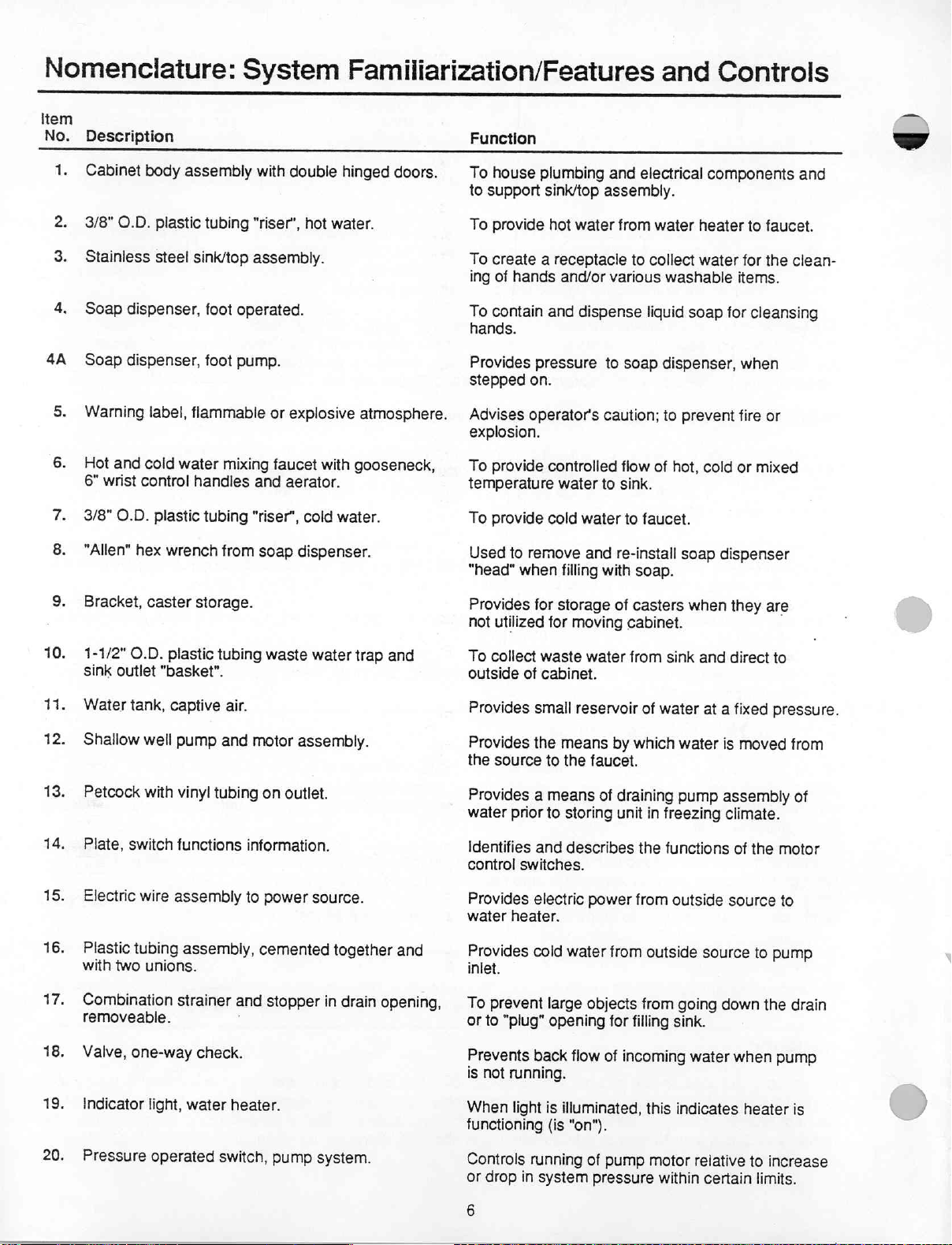

Nomenclature:

Item

No.

Description

1.

Cabinet

2.

3/8"

3.

Stainless

4.

Soap

4A

Soap

5.

Warning

6.

Hot

6"

7.

3/8"

body

O.D.

dispenser,

dispenser,

and

cold

wrist

control

O.D.

assembly

plastic

steel

sink/top

label,

flammable

water

handles

plastic

System

tubing

foot

operated.

foot

pump.

mixing

tubing

with

double

"riser",

hot

assembly.

or

explosive

faucet

and

aerator.

"riser",

cold

Familiarization/Features

Function

hinged

water.

with

water.

doors.

atmosphere.

gooseneck,

To

house

to

support

To

provide

To

create

ing

of

hands

To

contain

hands.

Provides

stepped

Advises

pressure

on.

operator's

explosion.

To

provide

temperature

To

provide

plumbing

sink/top

hot

a

receptacle

assembly.

water

and/or

and

dispense

to

caution;

controlled

water

to

cold

water

and

from

various

and

electrical

water

to

collect

washable

liquid

soap

dispenser,

to

flow

of

sink.

to

faucet.

Controls

components

heater

water

soap

for

prevent

hot,

cold

to

faucet.

for

the

items.

cleansing

when

fire

or

or

mixed

and

clean-

8.

“Allen”

9.

Bracket,

10.

1-1/2"

sink

11.

Water

12.

Shallow

13.

Petcock

14.

Plate,

15.

Electric

16.

Plastic

with

17.

Combination

removeable.

hex

caster

O.D.

outlet

tank,

well

with

switch

wire

tubing

two

unions.

wrench

plastic

from

storage.

tubing

"basket".

captive

pump

vinyl

air.

and

tubing

functions

assembly

assembly,

strainer

soap

dispenser.

waste

water

motor

assembly.

on

outlet.

information.

to

power

source.

cemented

and

stopper

trap

together

in

drain

and

and

opening,

Used

“head"

Provides

not

utilized

To

collect

outside

Provides

Provides

the

source

Provides

water prior

Identifies

control

Provides

water

Provides

inlet.

©

To

prevent

or

to

to

remove

when

for

for

waste

of

cabinet.

small

the

to

a

means

to

and

switches.

electric

heater.

cold

large

"plug"

opening

and

filling

with

storage

of

moving

water

reservoir

means

the

by

faucet.

of

storing

describes

power

water

from

objects

for

re-install

soap

soap.

casters

cabinet.

from

sink

of

water

which

water

draining

unit

pump

in

freezing

the

functions

from

outside

outside

from

going

filling

sink.

when

and

at

source

dispenser

they

are

direct

to

a

fixed

pressure.

is

moved

assembly

climate.

of

the

source

to

pump

down

the

from

of

motor

to

drain

18.

19.

20.

Valve,

one-way

Indicator

Pressure

check.

light,

water

operated

heater.

switch,

pump

system.

Prevents

is

not

When

functioning

Controls

or

drop

back

running.

light

is

(is

running

in

system

6

flow

of

incoming

illuminated,

this

"on").

of

pump

motor

pressure

water

indicates

relative

within

certain

when

heater

to

limits.

pump

is

increase

Item

No.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

Description

Valve,

Rheostat,

Cord

3/8"

Cord

Plastic

Pressure

Cord

Plastic

Switch,

cold

set,

3-wire

O.D.

set,

valve

gauge, 0 to

set,

3-wire

valve,

DPST

heater

plastic

6-wire

water

with

3/4"

on/on

flow

control.

temperature

electric.

tubing.

electric.

3/8"

O.D.

100

Ibs.

electric.

ball

type.

electrical.

Én

control.

plastic

outlet

tube. | Provides

Function

Controls

“temperature

Provides

To

cold

adjustment

provide

source.

To

provide

Provides

power

to

Indicates

Provides

motor

Provides

Provides

outside

source.

storing

on/off

electrical

for

means

unit

water

electric

convenient

means

water

rise"

electric

cold

water

remote

of

in

freezing

system

power

switch.

of

source.

flow

to

control).

to

control

power

to

from

switching

draining

climate.

pressure.

from

means

matching

water

heater

pressure

flow

control

of

motor

hot

water

pressure

for

priming

pump

heater

output

switch

system

motor

(alternate

temperature.

from

valve

to

windings

of

switch

pump

windings

to

with

outside

water

to

match

water

pump

water.

to

heater.

prior

31.

32.

33.

34.

:

35.

36.

37.

38.

39.

40.

41.

42.

Switch,

Water

Manual,

Skid

Caster,

heater,

(2)

swivel

Socket,

Handle,

Bar,

fixed

Label,

electrical

Fitting,

guick-connect

Electric

Wrench,

DPST

on/off

flow-thru

in

pocket

plastic.

(4)

caster.

drop

type

support.

inlet,

4-wire

water

heater,

electrical.

on

door.

with

4"

lift

(90°

supply

water

twist-lock

internal

instantaneous.

diameter

wheel.

upswing).

requirements.

inlet.

grounding.

hex

fittings.

Provides

Provides

Provides

Allows

bottom

ease

from

Provides

Locates

Provides

To

be

used

ets.

(9505927,

Lists

the

nected

to

Provides

source

to

Provides

source

Use

tubes

to

to

prevent

when

on/off

control

heated

water

installation/operating

in

sliding

of

to

unit

pump

mixing

on

floor.

ease

of

movement

and

retains

means

for

hanging

by

9505928

electric

the

power

cabinet.

convenient

caster.

which

method

when

(Casters

cabinet

desk

or

9505929)

source

for

cabinet.

convenient

method

for

cabinet.

rotation

servicing

of

tank

external

motor

only.

faucet.

instructions,

floor

and

isolates

high

mobility

are

can

be

shelf

or

shelf

systems

that

connecting

connecting

connected

connections.

parts

lists,

cabinet

is

required.

removeable).

lifted

and

carried.

hanging

may

Water

electric

brack

be

con-

suppiy

supply

inlet & outlet

etc.

water

’

Accessories:

47.

Cord

connector.

48.

Hose,

49.

Hose

water

Umbilical

set,

4-wire

See

waste

and

filter

supply.

(Not

with

Page

outlet.

See

assembly,

See

Page

Illustrated)

plug

and

21.

Page

quick-connect

21.

twist-lock

21.

Use

to

Connects

facility.

Use

to

--ᾱ

provide

cabinet

connect

electric

waste

outside

power

outlet

water

from

source

to

external

source

to

cabinet

to

cabinet.

waste

dispersal

piping.

M

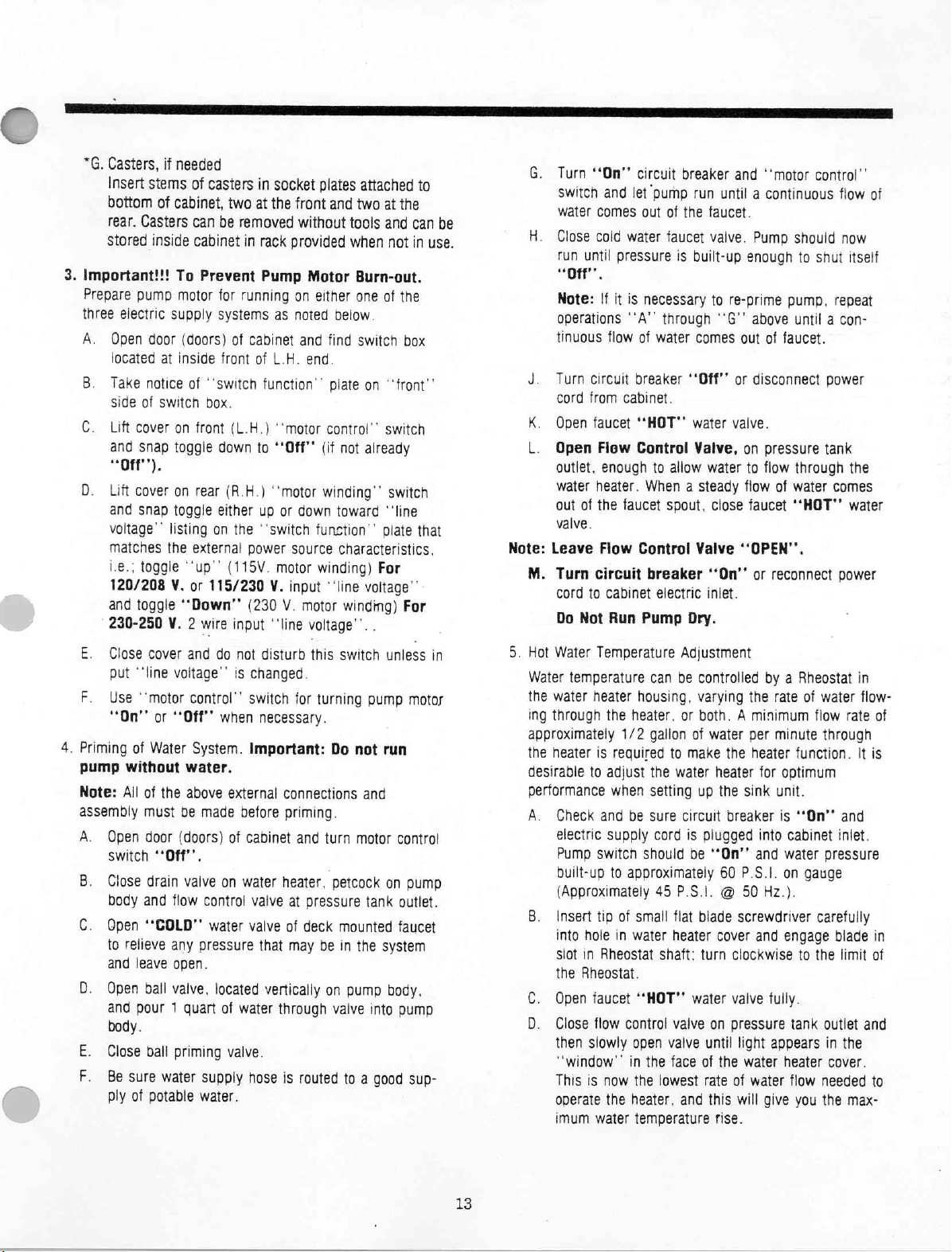

Illus.

No.

1

Aa

E

ГИ

一

=

VR

nA

?

System

|

mai

350

|

125

=

| | 二 | 一

|

LA

\

TAN.

|

|

—

I

|

|

i

Familiarization/Features

|

and

©

/

©

Controls

30

12

Illustration

®

®

(Doors

FRONT

30

Not

00

VIEW

Shown)

=

/

tor

Inlets

Closure

Water

and

Plugs

Electric

CHE

し

NOTE:

Routing

shown

on

contusion

Electrical

120/208 V 3

120/230 V 1

240 V 1

Pictorial

See

Wiring

PH

Wiring

page

this

PH

PH

50

10

SECTION

drawing

Hz - See

of

Schematics,

60 Hz - See

60

Diagram

A-A

Electrical

Hz - See

in

page

with

Wiring

order

is

not

to

avoid

page

7

page

8

9

Instructions

more

END

VIEW

REAR

VIEW

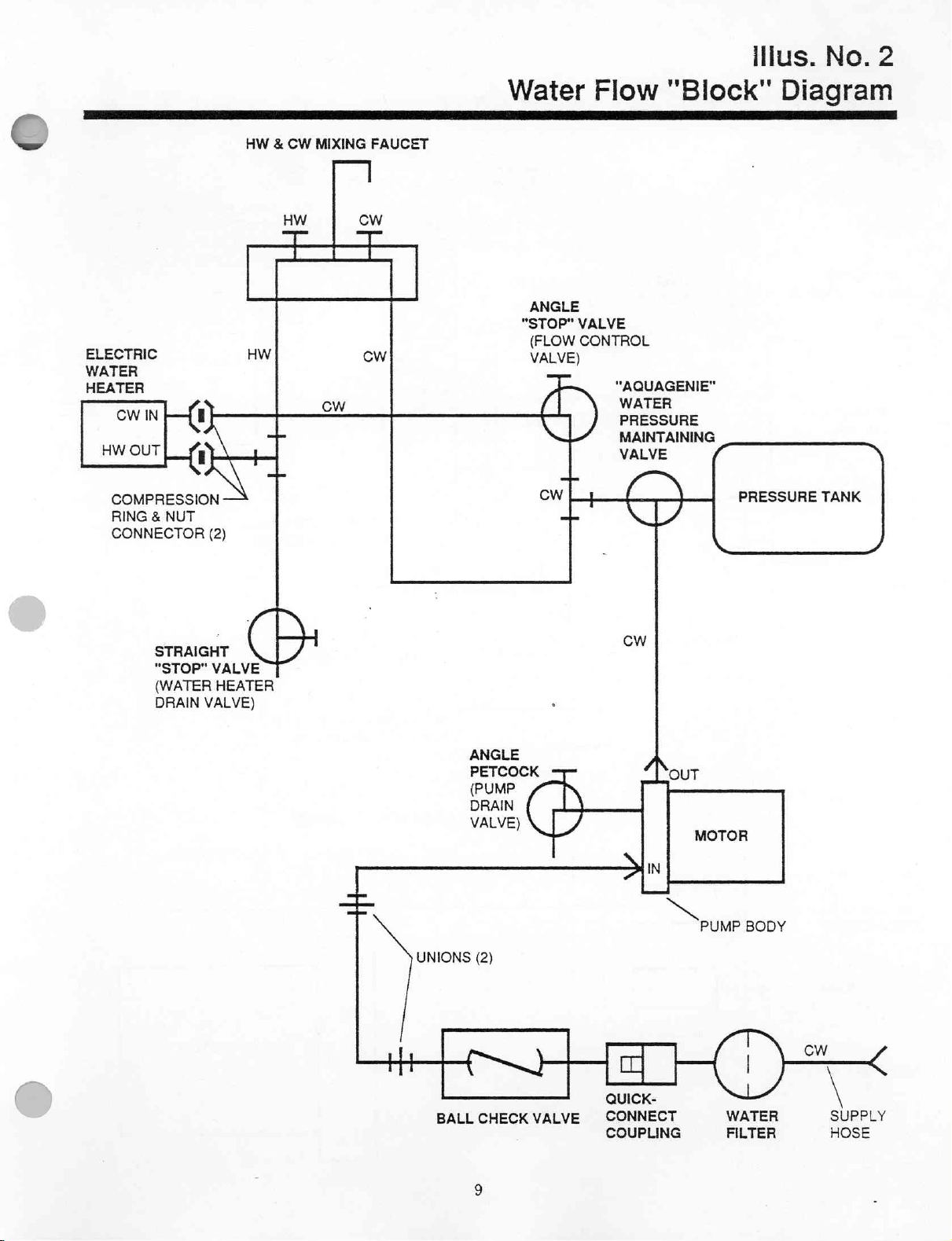

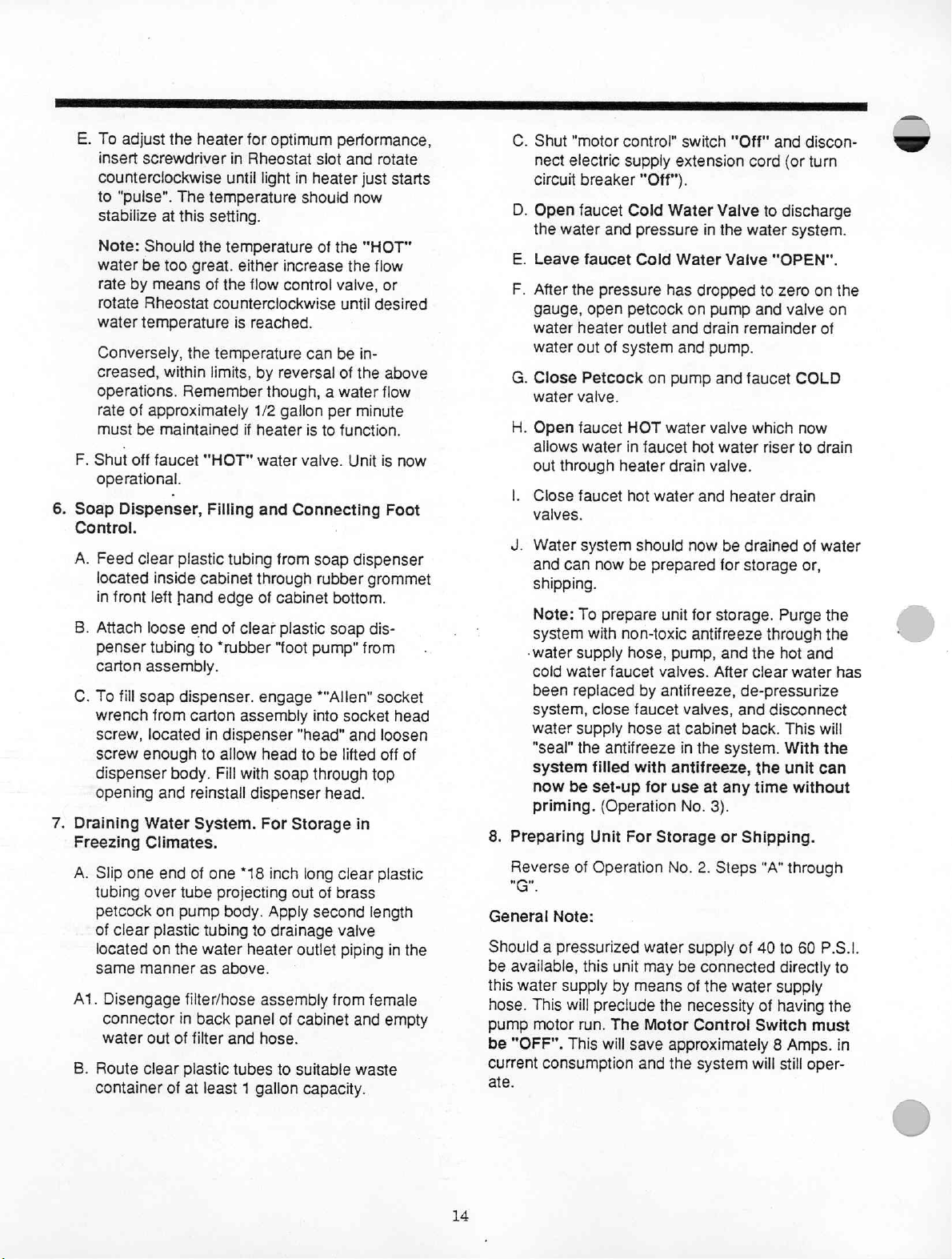

Illus.

No.

2

ELECTRIC

WATER

HEATER

CW

O

COMPRESSION

RING 8 NUT

CONNECTOR

IN

а

N

(2)

HW & CW

HW

二

HW

+

MIXING

一

CW

FAUCET

cw

==

cw

Water

ANGLE

"STOP"

(FLOW

VALVE)

U

cw

4

Flow

VALVE

CONTROL

"AQUAGENIE"

WATER

PRESSURE

MAINTAINING

VALVE

ÓN

NÜ

"Block"

PRESSURE

Diagram

TANK

STRAIGHT

"STOP"

(WATER

DRAIN

(|

VALVE

HEATER

VALVE)

-

|

UNIONS

li

TTT

OR]

BALL

ANGLE

PETCOCK

(РУМР

DRAIN

VALVE)

(2)

CHECK

、

L

VALVE

CW

Лол

Sin

m

QUICK-

CONNECT

COUPLING

MOTOR

PUMP

ST

y

WATER

FILTER

BODY

CW

SUPPLY

HOSE

/

>

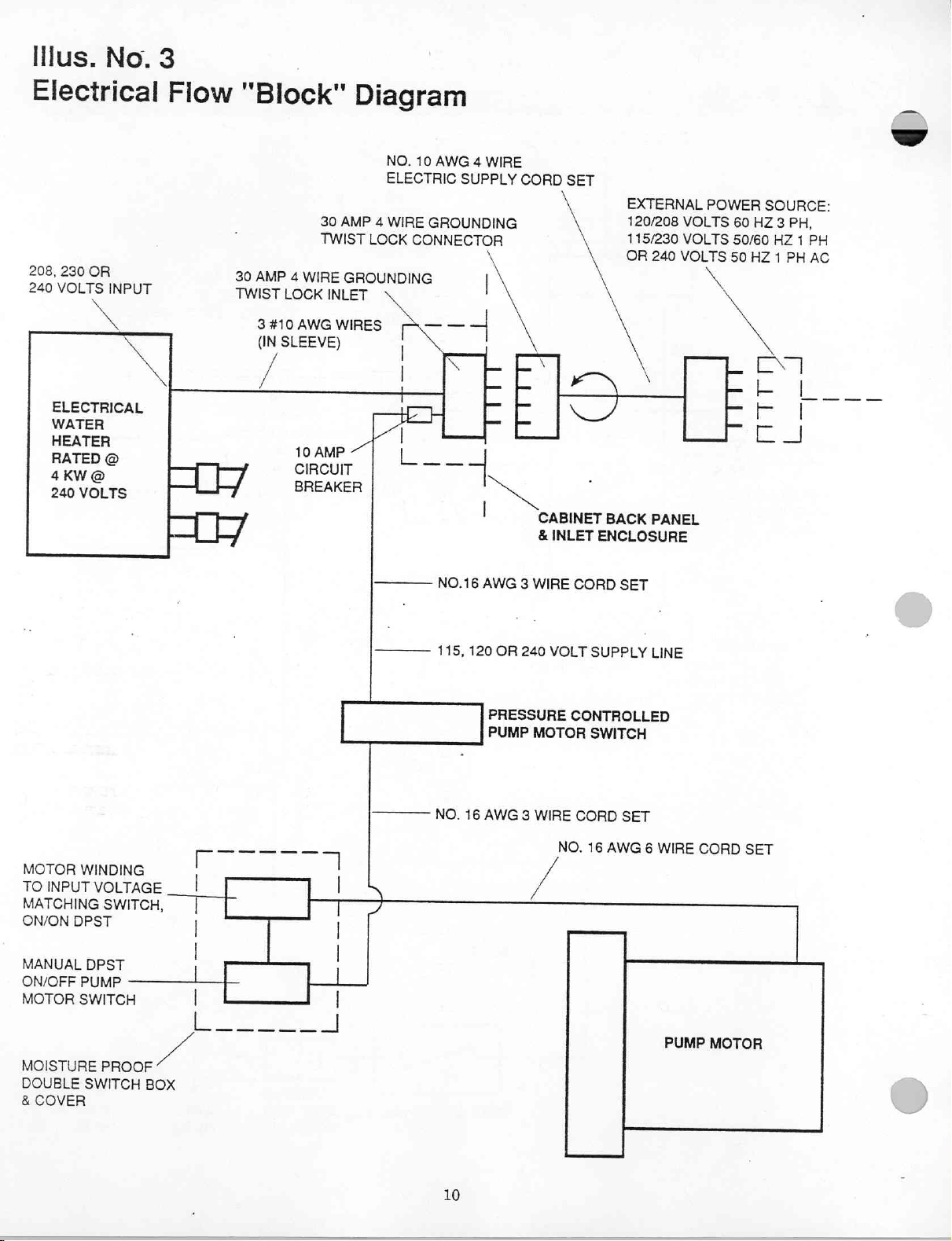

Illus.

No.

3

Electrical

208,

230

OR

240

VOLTS

INPUT

κ

X

ELECTRICAL

WATER

HEATER

re

240

VOLTS

Fiow

"Block"

30

TWIST

30

AMP

4

WIRE

TWIST

LOCK

3410

AWG

(IN

SLEEVE)

/

10

AMP

cIRcur | 上

RES

Diagram

NO.

ELECTRIC

AMP

4

WIRE

LOCK

GROUNDING

INLET

WIRES

S

|

TL

|

10

AWG 4 WIRE

SUPPLY

GROUNDING

CONNECTOR

|

|>

===

一 一 一

|

CORD

rE

TE

SET

ビバ

A

CABINET

&

INLET

BACK

ENCLOSURE

EXTERNAL

120/208

115/230

OR

VOLTS

VOLTS

240

VOLTS

PANEL

POWER

60

50/60

50

№

Lon

PE

Cr

SOURCE:

HZ

3

PH,

HZ

1

HZ 1 PH

L___

|

EJ

PH

AC

MOTOR

TO

MATCHING

ON/ON

MANUAL

ON/OFF

MOTOR

MOISTURE

DOUBLE

&

WINDING

INPUT

DPST

DPST

PUMP

SWITCH

SWITCH

COVER

VOLTAGE.

SWITCH,

PROOF

ノー

BOX

Mera

iel.

Г

|

Γ

|

|

| |

|

|

Yİ

a

一

ー

一

一

一

No.16AwG

—

LS

「

7

|

|

|

115,

No.

3

120

OR

240

PRESSURE

PUMP

16

AWG

3

WIRE

CORD

VOLT

SUPPLY

CONTROLLED

MOTOR

WIRE

SWITCH

CORD

NO.

16

SET

SET

AWG

LINE

6

WIRE

PUMP

CORD

MOTOR

SET

10

S

VERTE

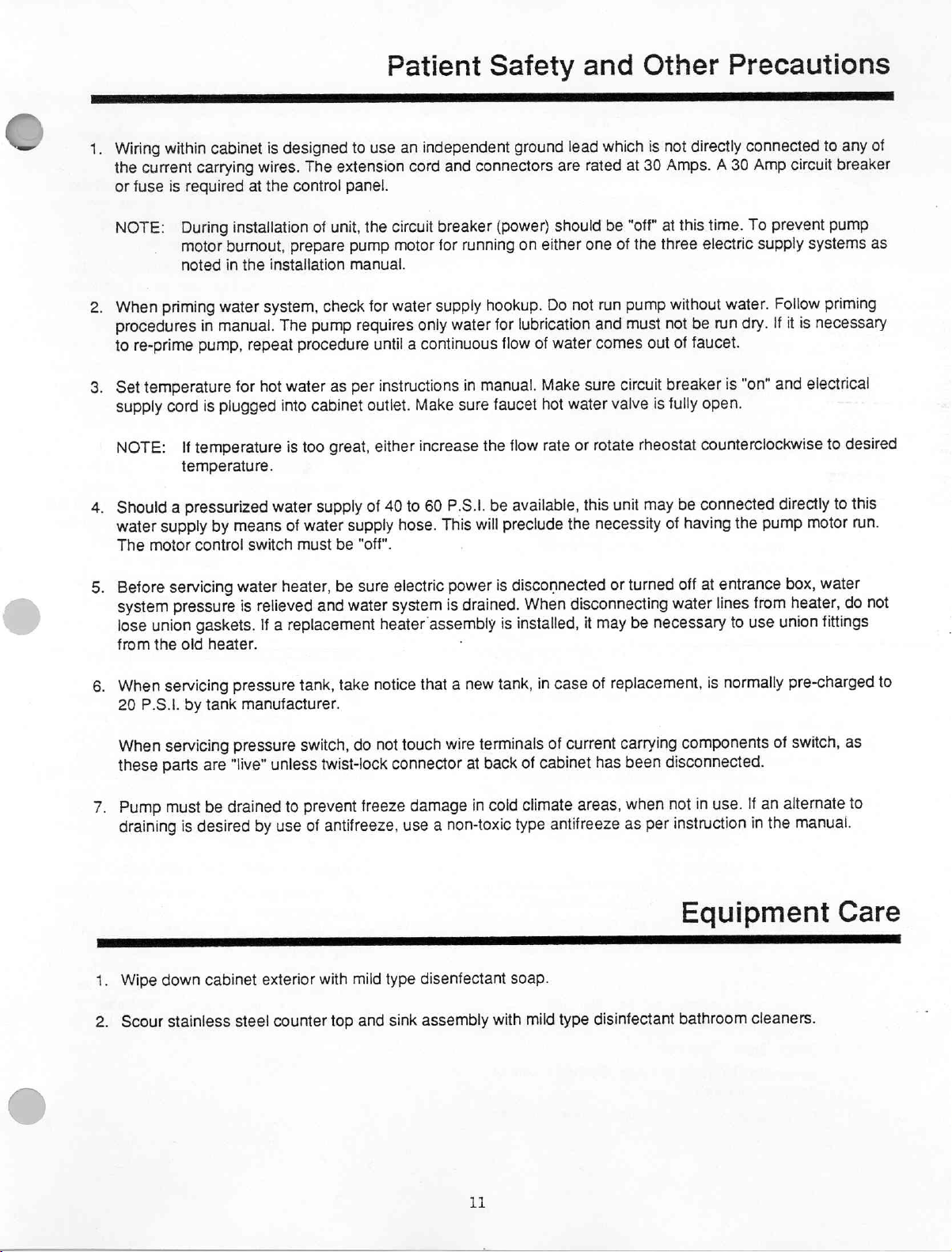

1.

Wiring

current

the

or

fuse

within

carrying

is

required

P

SS

cabinet

at

designed

is

wires.

the

control

The

Patient

use

to

extension

panel.

independent

an

and

cord

Safety

ground

connectors

lead

are

and

which

at

rated

Other

V E

directly

not

is

30

Amps.

A

Precautions

SO

E

T

connected

Amp

30

to

circuit

of

any

breaker

NOTE:

When

2.

procedures

to

Set

3.

supply

NOTE:

Should

4.

water

The

Before

5.

system

lose

from

When

6.

20

During

motor

noted

priming

in

re-prime

pump,

temperature

is

cord

temperature

If

temperature.

pressurized

a

supply

control

motor

servicing

pressure

gaskets.

union

old

the

servicing

P.S.!.

by

installation

burnout,

the

in

system,

water

manual.

repeat

hot

for

plugged

means

by

switch

water

relieved

is

If

heater.

pressure

tank

manufacturer.

unit,

of

prepare

installation

check

pump

The

procedure

as

water

cabinet

into

great,

too

is

supply

water

supply

water

of

be

must

and

tank,

be

water

take

heater,

replacement

a

circuit

the

motor

pump

manual.

water

for

requires

until

a

instructions

per

outlet.

either

to

40

of

hose.

"off".

electric

sure

system

heater

notice

breaker

running

for

supply

water

only

continuous

in

sure

Make

increase

P.S.I.

60

will

This

power

drained.

is

assembly

'

new

a

that

(power)

on

hookup.

lubrication

for

flow

of

manual.

faucet

flow

the

available,

be

preclude

disconnected

is

When

installed,

is

in

tank,

should

one

either

run

not

Do

and

water

comes

sure

Make

water

hot

rotate

or

rate

this

necessity

the

disconnecting

may

it

of

case

this

at

"off"

be

three

the

of

without

pump

not

must

out

of

breaker

circuit

fully

is

valve

rheostat

be

may

unit

of

turned

or

be

replacement,

off

water

necessary

prevent

To

time.

water.

run

is

supply

dry.

"on"

Follow

If

and

electric

be

faucet.

open.

counterclockwise

connected

pump

having

the

entrance

at

lines

to

normally

is

from

use

pump

systems

priming

necessary

is

it

electrical

to

directly

box,

union

to

motor

water

heater,

fittings

pre-charged

as

desired

this

run.

not

do

to

7.

ESS

II

1.

2.

servicing

When

parts

these

must

Pump

draining

Wipe

down

stainless

Scour

are

be

desired

is

TENTA

cabinet

pressure

unless

"live"

drained

use

by

exterior

counter

steel

switch,

twist-lock

prevent

to

antifreeze,

of

with

Re

top

not

do

freeze

mild

and

touch

connector

damage

a

use

type

disenfectant

assembly

sink

terminals

wire

back

at

cold

in

non-toxic

soap.

with

of

cabinet

of

climate

antifreeze

type

mild

current

has

areas,

disinfectant

type

carrying

disconnected.

been

not

when

instruction

per

as

switch,

If

in

an

the

of

alternate

manual.

components

use.

in

Equipment

IO

bathroom

cleaners.

as

to

Care

AB

Installation

and

Operation

A

SR

NS

SESS

da

>

Electric

208

208

(equipment)

230

Volt

ment)

240

an

Note:

independent

connected

The

30

panel.

Installation

1.

2.

Supply

60

Volt,

Outputs;

Volt

50/60

Volt,

Outputs;

ground

50

Volt.

independant

The

extension

circuit

Amp.

Remove

respective

External

from

carton

“A.

Faucet

install

“C"

with

Gooseneck

*B.

Moisten

and

down,

swiveled

Basket

*C.

“Drop”

Filter/Hose

"Di

Engage

in

potabie

end

Drain

“E.

Slide

located

hose

Electric

*F.

Important!!!

“OFF”

Engage

Requirements:

Phase,

3

Hz,

this

ground

wiring,

to

wire.

Hz.

shall

this

wire.

Phase

1

Hz.

(equipment)

within

(equipment)

any

of

the

and

cord

breaker

hardware

cartons.

connections

assemblies.

Handles

handle

on

R.H.

head

flat

''0''

insert

into

ciockwise.

by

hand.

Strainer

10

sink

Assembly

male

back

panel

water

of

hose

at

Assembly

Hose

end

one

back

in

suitable

to

Supply

at

this

female

with

‘’Y'',

wire

4

be

shall

with

Phase.

1

plus

wire

3

be

output:

the

ground

current

this

ground

cabinet.

lead

carrying

connectors

is

fuse

or

and

umbilical

Note:

unit:

to

L.H.

on

‘'H'’

stem

in

the

desired

screws

ring

connector

of

supply.

found

base

on

opening

until

outlet

opening.

cabinet.

Connect,

water

supply.

corrugated

of

of

panel

waste

Extension

Circuit

time.

connector

in

faucet

tight.

in

Route

cabinet.

receptacle

Cord

Breaker

of

120

both

independent

plus

120

both

independent

be

shall

wire.

designed

is

is

which

wires.

rated

are

required

accessories

faucet

in

of

female.

electric

at

indicates

*

stem

positions.

of

top

gooseneck

body.

Gooseneck

connector

hose

or

submerge.

on

hose

Route

area.

or

Set

(Power)

supply

Volt

Volt

wire

2

not

30

at

the

from

and

valve

with

Turn

can

to

nearby

trap

free

and

230

and

(equip-

plus

use

to

directly

Amps.

control

items

handle

Secure

stems.

water

base

be

located

free

outlet

of

end

should

into

cord

an

A

be

male

electrical

and

twist

free

end

nected

to

Should

the

existing

plug

installed

directly

Connections

plug.

Other

electric

Connections

inlet

clockwise

of

cord

into a matching

the

available

plug

and

receptacle

plug

or

the

to a convenient

below

styles

schematics

combination

to

Supply:

(equipment)

line;

the

“Common”

supply

=

208

supply:

blade

supply

wire)

parallel

¡.e.:

blade

along

(red

“X”

‘‘Round’’,

blade

brass,

The

‘‘W'’,

straight

brass,

line,

i.e.:

Volts

Volts.

to

domestic

round.

blade

ground;

(black

line;

The

to

the

opposite

120

Volts

Volts

across

to

foreign 2 wire

round,

blade

ground;

(black

line

and

the

the

with

to

wire)

i.8.:

line,

“Y'*

and

GR".

dent

straight

ply

to

parallel

Volt

Vy" = 120

Connections

Volts

“GR”.

(equipment)

brass,

Volt

(white

"X"

line,

220-240

Connections

“GR”.

(equipment)

brass,

supply

wire)

blade

supply

and

located

to

lock

power

shall

be

supply

power

apply

to

shall

be

on

page

(green

blade

ground:

(black

silver

supply

blade

Voltage

and

voltage

combination

(green

The

wire)

‘‘W’’,

‘‘common"’

side

across

''X"'

(green

the

‘‘Y'’,

wire)

‘'W'',

‘‘X'’,

‘‘common’’

Voltage

across

230-250

=

in

back

panel

in

place.

receptacle

source.

be

incompatible,

removed

wired

and a suitable

cord

can

control

NEMA

14-30P

in

7, 8 or

accordance

120 and

wire)

‘‘Y'’,

The

to

wire)

angle,

blade

line;

and

the

(red

wire)

across

across

wire)

to

‘'Y'’,

adjacent

to

one

side

silver

angle,

supply

of

220-240

**W''

and

and

YY”.

240

Volts

wire)

to

adjacent

to

‘‘Hot'’

side

silver

angle,

parallel

straight

side

“W'

Volts.

of

cabinet

Insert

plug

con-

then,

be

connected

panel.

style

9.

Volt

208

indepen-

to

adjacent

Volt

208

a

(white

wire)

X,

to a 208

‘'W''

and

"X" 8 У”

120

and

240

independent

straight

of

220-240

blade

line;

and

Volt

supply

‘‘Y'',

and

supply:

independent

straight

of

240

blade

(white

brass,

Volt

240

of

“Y”

and

on

with

sup-

;

the

Volt

12

*G.

Casters,

Insert

bottom

rear.

Casters

stored

.

Important!!!

Prepare

three

A.

pump

electric

Open

located

Take

side

of

Lift

cover

and

snap

ΜΗ’).

Lift

cover

and

snap

voltage''

matches

i.e.;

toggle

120/208

and

toggle

230-250

if

needed

stems

of

cabinet,

inside

To

motor

supply

door

(doors)

at

inside

notice

switch

on

toggle

on

toggle

listing

the

V.

**Down””

V. 2 wire

of

casters

two

can

be

cabinet

Prevent

for

systems

front

of

“switch

box.

front

(L.H.)

down

rear

(R.H.)

either

on

external

‘‘up'’

(115V.

or

115/230

in

socket

at

the

front

removed

in

running

of

cabinet

the

power

without

rack

provided

Pump

on

as

noted

and

of

L.H.

function"

‘‘motor

to

‘‘Off’’

‘‘motor

up

or

down

‘‘switch

source

motor

V.

input

(230

V.

motor

input “line

plates

attached

and

two

at

tools

and

when

Motor

Burn-out.

either

one

of

below.

find

switch

end.

plate

on

“front”

control‘

(if

winding’

toward

function’’

winding)

“line

switch

not

already

“line

plate

characteristics,

For

voltage

winding)

voltage”...

to

the

can

not

in

the

box

switch

that

For

be

use.

G.

H.

J.

К.

Note:

M.

Turn

“On”

switch

and

water

comes

Close

cold

run

until

pressure

off”,

Note:

If it

operations

tinuous

Turn

cord

Open

Open

outlet,

water

out

valve.

Leave

Turn

cord

Do

flow

circuit

from

faucet

Fiew

enough

heater.

of

the

faucet spout,

Flow

circuit

to

cabinet

Not

Run

circuit

breaker

let

pump

run

out

of

the

water

faucet

is

built-up

is

necessary

'*A”'

through

of

water

comes

breaker

cabinet.

‘*HOT"'

Control

to

‘‘Off’’

water

Valve,

allow

When a steady

Control

Pump

Valve

breaker

electric

Dry.

and

‘‘motor

until a continuous

faucet.

valve.

Pump

should

to

re-prime

'*G''

out

or

enough

to

pump,

above

until a con-

of

faucet.

disconnect

valve.

on

pressure

water

to

flow

through

flow

of

water

close

faucet

‘‘HOT’’

“OPEN”.

‘‘On’’

or

reconnect

inlet.

control"

flow

of

now

shut

itself

repeat

power

tank

the

comes

water

power

Close

put

Use

“Dn”

.

Priming

pump

Note:

assembly

A

Open

switch

Close

body

Öpen

to

and

Open

and

body.

Close

Be

ply

cover

and

“line

voltage"

“motor

or

“Off”

of

Water

without

All

of

the

must

door

water.

above

be

(doors)

‘‘Off’’.

drain

valve

and

flow

“GOLD”

relieve

any

leave

open.

ball

valve,

pour 1 quart

ball

priming

sure

water

of

potable

do

not

is

control"

when

System.

external

made

before

of

on

water

control

water

pressure

located

of

water

valve.

supply

water.

disturb

changed.

switch

for

necessary.

Important:

connections

priming.

cabinet

and

heater,

valve

at

valve

of

that

may

vertically

through

hose

is

pressure

deck

routed

this

switch

turning

Do

turn

petcock

mounted

be

in

on

pump

valve

to a good

pump

not

run

and

motor

tank

the

system

into

unless

motor

control

on

pump

outlet.

faucet

body,

pump

sup-

in

5.

Hot

Water

Water

temperature

the

water

ing

through

approximately

the

heater

desirable

performance

A.

Check

electric

Pump

built-up

(Approximately

B.

Insert

into

slot

the

Open

Close

then

“window”

This

operate

imum

Temperature

heater

housing,

the

heater,

1/2

is

required

to

adjust

when

and

be

supply

switch

should

to

approximately

tip

of

small

hole

in

water

in

Rheostat

Rheostat.

faucet

‘‘HOT’’

flow

control

slowly

open

in

the

is

now

the

the

heater,

water

temperature

Adjustment

can

be

or

gallon

of

to

make

the

water

setting

sure

circuit

cord

is

be

45

P.S.1. @ 50

flat

heater

shaft:

water

valve

valve

face

lowest

and

controlled

varying

both. A minimum

water

heater

up the

plugged

**On””

blade

cover

turn

on

until

of

rate

this

by a Rheostat

the

per

the

heater

for

sink

breaker

into

and

60

P.S.!.

Hz.).

screwdriver

and

clockwise

vaive

fully.

pressure

light

appears

the

water

of

water

will

give

rate

minute

optimum

unit.

is

cabinet

water

on

engage

tank

heater

flow

rise.

of

water

flow

rate

through

function.

‘‘On’’

and

inlet.

pressure

gauge

carefully

blade

to

the

limit

outlet

in

the

cover.

needed

you

the

max-

in

flow-

of

It

is

in

of

and

to

FRS

E.

F.

6.

Soap

Control.

A.

B.

C.

7.

Draining

Freezing

A.

A1.

B.

RER

To

adjust

insert

screwdriver

the

CP

heater

counterclockwise

to

“pulse”.

stabilize

Note:

water

rate

rotate

water

Conversely,

creased,

operations.

rate

must

Shut

operational.

Dispenser,

Feed

located

in

front

Attach

penser

carton

To

fill

wrench

screw,

screw

dispenser

opening

The

at

this

Should

be

by

too

means

the

great.

Rheostat

temperature

the

within

Remember

of

approximately

be

maintained

off

faucet

clear

plastic

inside

cabinet

left

hand

loose

end

tubing

to

assembly.

soap

dispenser.

from

carton

located

enough

Water

body.

and

reinstall

to

System.

of

"HOT"

Filling

in

Climates.

Slip

one

end

of

tubing

petcock

of

located

same

container

over

on

clear

plastic

on

manner

Disengage

connector

water

out

Route

clear

tube

pump

tubing

the

water

as

filter/hose

in

back

of

filter

plastic

of at

least 1 gallon

RP

for

in

Rheostat

until

temperature

RS

optimum

light

in

should

siot

heater

setting.

temperature

either

the

flow

of

increase

control

counterclockwise

is

reached.

temperature

limits,

by

can

reversal

though, a water

1/2

gallon

if

heater

water

tubing

through

edge

of

of

clear

*rubber

assembly

dispenser

allow

Fill

with

dispenser

one

*18

projecting

body.

to

heater

and

Connecting

from

cabinet

plastic

"foot

engage

"head"

head

soap

For

Storage

inch

out

Apply

drainage

outlet

is

to

valve.

soap

rubber

pump"

*"Allen"

into

to

be

through

head.

long

of

second

above.

assembly

panel

of

cabinet

and

hose.

tubes

to

suitable

capacity.

PN

performance,

and

rotate

just

starts

now

the

"HOT"

the

flow

valve,

or

until

desired

be

in-

of

the

above

flow

per

minute

function.

Unit

is

now

Foot

dispenser

grommet

bottom.

soap

dis-

from

socket

socket

lifted

and

head

loosen

off

of

top

in

clear

plastic

brass

length

valve

piping

in

the

from

female

and

empty

waste

A

C.

Shut

nect

circuit

D.

Open

the

E.

Leave

F.

After

gauge,

water

water

G.

Close

water

H.

Open

allows

out

1.

Close

"motor

electric

water

the

through

control"

supply

breaker

faucet

and

faucet

pressure

open

heater

out

of

system

Petcock

valve.

faucet

water

heater

faucet

valves.

J.

8.

Preparing

Reverse

Water

system

-water

cold

been

system,

water

"seal"

system

now

priming.

system

and can

shipping.

Note:

To

with

supply

water

replaced

close

supply

the

filled

be

set-up

Unit

of

Operation

now

prepare

non-toxic

faucet

antifreeze

(Operation

"G"

General

Should a pressurized

be

this

hose.

pump

be

current

Note:

available,

water

This

motor

"OFF".

this

supply

will

run.

This

consumption

unit

by

preciude

The

will

ate.

K

switch

extension

"Off"

"Off").

Cold

Water

pressure

Cold

has

petcock

outlet

on

HOT

water

in

faucet

hot

water

should

be

prepared

unit

hose,

valves.

by

antifreeze,

faucet

hose

at

with

for

For

Storage

No.

water

may

means

the

Motor

save

approximately 8 Amps.

and

the

Valve

in

the

Water

and

pump

drain

pump,

Valve

dropped

on

pump

drain

and

pump.

and

valve

hot

water

valve.

and

heater

now

be

for

for

storage.

antifreeze

and

After

valves,

cabinet

in

the

system.

and

antifreeze,

use

at

any

No.

3).

or

2.

Steps

supply

be

connected

of

the

water

necessity

Control

system

O

and

discon-

cord

(or

turn

to

discharge

water

system.

"OPEN".

to

zero

on

the

and

valve

on

remainder

faucet

which

riser

drained

storage

through

the

clear

COLD

now

to

drain

of

or,

Purge

hot

and

water

of

drain

water

the

the

has

de-pressurize

disconnect

back.

This

will

With

the

the

unit

can

time

without

Shipping.

"A"

through

of

40

to

60

P.S.I.

directly

to

supply

of

having

Switch

the

must

in

will

still

oper-

~

14

Storage

Requirements

Recommended

Temperature

Humidity

Limits:

Periodic

1.

WATER

2.

WATER

3.

WASTE

4.

SOFT-FLO

GOOSENECK

5.

WATER

6.

INTERIOR

7.

SINK

BOWL/TOP

Long

(Store

Term

within a sheltered

Storage

Limits: 0 Degree

Minimum

Maximum

Maintenance

FILTER

SUPPLY

OUTLET

LEAKS

OF

HOSE

HOSE

NOZZLE

CABINET

Storage

ON

and

area

Climate

Fahrenheit — +130

Schedule:

FAUCET

Maintenance

at

moderate

Limits

Humidity-5%

Humidity-95%

(While

AND

humidity

Degree

unit

is

in

use)

Inspect

and

clean

restricted.

Deterioration

repair

as

necessary.

Deterioration

repair

as

necessary.

Remove

and

restricted.

Check

components

Clean

Clean

daily:

tighten

as

weekly.

as

deemed

Schedule:

and

temperature

Fahrenheit

monthly

and/or

and/or

clean

damage.

damage.

monthly

joint

received.

necessary

levels)

or

sooner,

Monthly

Monthly

or

sooner

fittings

and/or

to

maintain

should

water

flow

be

inspection - replace

inspection - replace

should

water

replace

sanitary

flow

defective

conditions.

or

or

be

1.

WATER

2.

WASTE

3.

ELECTRICAL

4.

CASTER

5.

ELECTRICAL

SUPPLY

OUTLET

WHEELS

CONNECTOR

6.

INTERNAL

WATER

7.

MISSING

8.

PUMP

9.

MOTOR

10.

CABINET - DAMAGE

PIPING

PARTS

MOTOR

BEARINGS

HOSE

HOSE

UMBILICAL

INLET

AND

ELECTRICAL

AND/OR

SHAFT

ASSEMBLY

(EXTENSION

WATER

CORDS

ACCESSORIES

OR

RUSTING

QUICK

AND

Deterioration and/or

repair

as

required.

Deterioration

repair

as

Deterioration

repair

CORD)

Free

wheeling.

Corrosion

repair

as

Deterioration

defective

Resupply

Accessory

Rotate

Yearly

Permanently

years

of

Yearly

rust

and

and/or

required.

and/or

as

required.

Yearly

and/or

obstructions. Yearly

required.

and/or

components.

as

necessary.

List.

Yearly

manually

to

inspection.

lubricated - inspect

storage.

Replace

inspection - Repair

"Touch

Up

damage.

damage.

damage.

inspection.

damage.

See

inspection.

prevent

bearings

minor

Paint".

Yearly

Yearly

Yearly

Yearly

pages

seizure

for

damage

inspection - replace

inspection - replace

inspection - replace

Lightly

oil

or

inspection.

inspection.

20,21,22

at

bearings

"DRY"

or

bearings,

motor.

and/or

grease

Replace

Replace

and

or

remove

23

pump

for

after

or

or

or

bearings.

or

Parts/

seal.

5

15