Page 1

IEEE-488 (GBIP)

INTERFACE

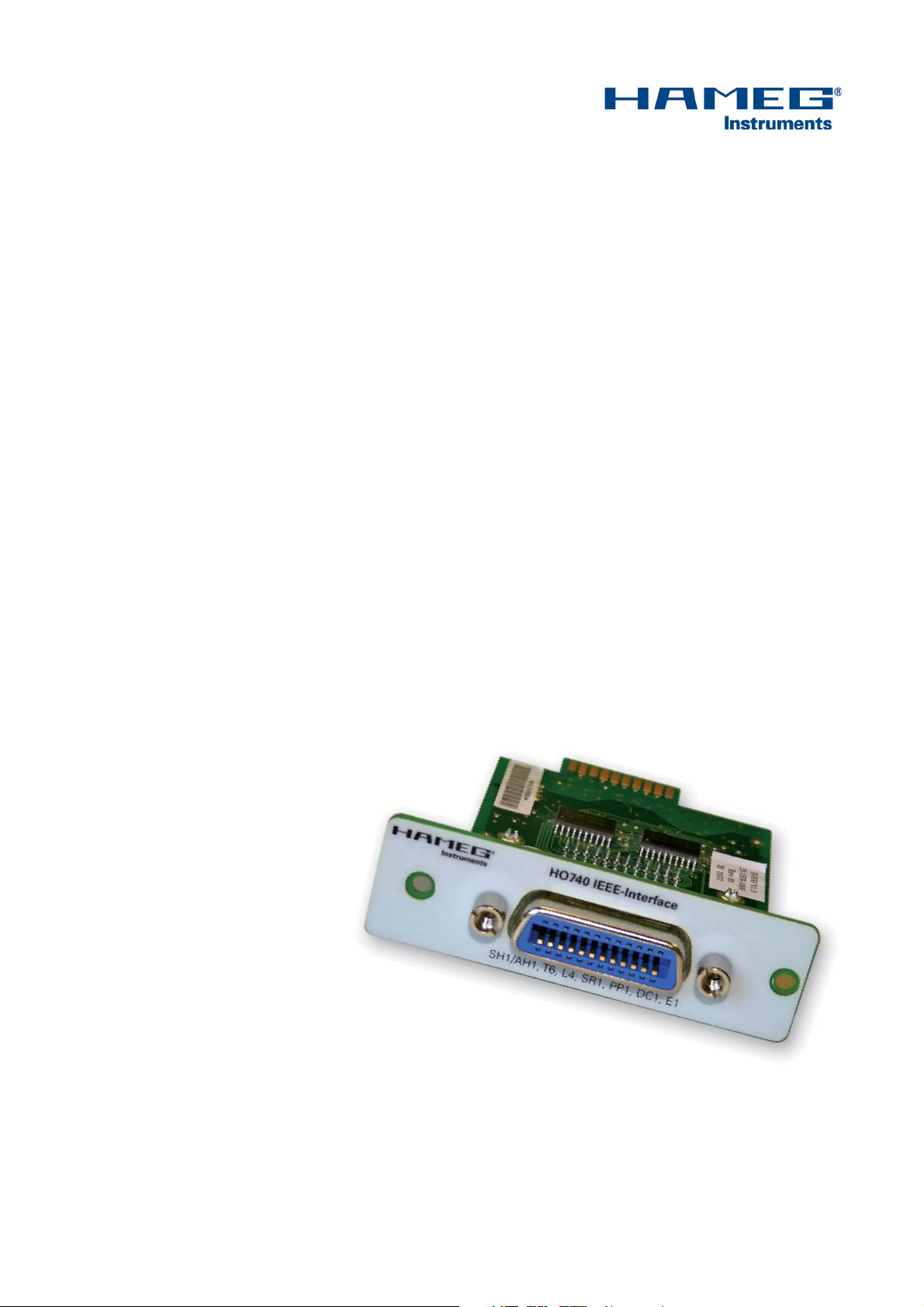

HO740

Fitting Instruction

English

Page 2

General information regarding the CE marking

General information regarding the CE marking

HAMEG instruments fulfi ll the regulations of the EMC directive. The

conformity test made by HAMEG is based on the actual generic- and

product standards. In cases where different limit values are applicable,

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE

DECLARACIÓN DE CONFORMIDAD

Hersteller / Manufacturer / Fabricant / Fabricante:

HAMEG Instruments GmbH · Industriestraße 6 · D -63533 Mainhausen

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produk t

The HAMEG Instruments GmbH herewith declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

HAMEG Instruments GmbH certifi ca la conformidad para el producto

Bezeichnung: IEEE-488 Interface

Product name: IEEE- 488 Interface

Designation: Interface IEEE-488

Descripción: Interfaz IEEE-488

Typ / Type / Type / Tipo: HO740

mit / with / avec / con: HM1008, HM1508, HM1508-2, HM2008

Optionen / Options /

Options / Opciónes: –

mit den folgenden Bestimmungen / with applicable regulations /

avec les directives suivantes / con las siguientes directivas:

EMV Richtlinie 89/ 336/EWG ergänzt durch 91/263 /EWG, 92 /31/EWG

EMC Directive 89/ 336/EEC amended by 91/263/ EWG, 92/ 31/EEC

Directive EMC 89/ 336/CEE amendée par 91/263/EWG, 92/31/ CEE

Directiva EMC 89/ 336/CEE enmendada por 91/263 /CEE, 92 /31/CEE

Niederspannungsrichtlinie 73/23 /EWG ergänzt durch 93/68 /EWG

Low-Voltage Equipment Directive 73/23 /EEC amended by 93 /68/ EEC

Directive des equipements basse tension 73 /23/ CEE amendée par 93/68/CEE

Directiva de equipos de baja tensión 73 /23/ CEE enmendada por 93 /68/ EWG

Angewendete harmonisierte Normen / Harmonized standards applied /

Normes harmonisées utilisées / Normas armonizadas utilizadas:

HAMEG applies the severer standard. For emission the limits for

residential, commercial and light industry are applied. Regarding the

immunity (susceptibility) the limits for industrial environment have

been used.

The measuring- and data lines of the instrument have much infl uence

on emmission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may

be different. For measurement operation the following hints and

conditions regarding emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and

external devices, (computer, printer etc.) suffi ciently screened cables

must be used. Without a special instruction in the manual for a reduced

cable length, the maximum cable length of a dataline must be less than

3 meters and not be used outside buildings. If an interface has several

connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cables HZ73 and HZ72L from HAMEG

are suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the

manual for a shorter length, signal lines must be less than 3 meters

and not be used outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

Sicherheit / Safety / Sécurité / Seguridad:

EN 61010-1: 2001 / IEC (CEI) 1010-1:20 01

Überspannungskategorie / Overvoltage category / Catégorie de surtension /

Categoría de sobretensión: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution / Nivel de

polución: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique / Compatibilidad electromagnética:

EN 61326 -1/A1: Störaussendung / Radiation / Emission: Tabelle / table /

tableau 4; Klasse / Class / Classe / classe B.

Störfestigkeit / Immunity / Imunitee / inmunidad:

Tabelle / table / tableau / tabla A1.

EN 61000-3 -2/A14: Oberschwingungsströme / Harmonic current emissions

/ Émissions de courant harmonique / emisión de corrientes armónicas:

Klasse / Class / Classe / clase D.

EN 61000-3 -3: Spannungsschwankungen u. Flicker / Voltage fl uctuations

and fl icker / Fluctuations de tension et du fl icker / fl uctuaciones de tensión

y fl icker.

Datum / Date / Date / Fecha

26. 04. 2007

Unterschrift / Signature / Signatur / Signatura

3. Infl uence on measuring instruments.

Under the presence of strong high frequency electric or magnetic fi elds,

even with careful setup of the measuring equipment an infl uence of

such signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifi cations may result from such conditions in individual cases.

HAMEG Instruments GmbH

Holger Asmussen

Manager

2

Änderungen vorbehalten

Page 3

Content

Declaration of conformity 2

General information regarding the CE marking 2

2. Safety hints 4

3. Interface Description 4

4. Oscilloscope Firmware 4

5. Interface Fitting Instruction 5

6. Functions and settings 6

7. Appliance 7

Änderungen vorbehalten

3

Page 4

General hints

2. Safety hints

Attention!

Fitting or exchanging of an interface must not be

made unless the oscilloscope is switched off and

not connected to line (mains).

Attention!

During operation the interface opening must be

closed.

Attention!

All interface connections are galvanically isolated

from the scope to avoid so called “hum” loops by

multiple earthing (in this case by the PC).

Measurement at high potentials is prohibited. It

would endanger scope and operator.

If the safety rules are disregarded any damage to HAMEG Instruments GmbH products will void the warranty. Neither will

HAMEG Instruments GmbH take any responsibility for damage

to people or gear of other make.

4. Oscilloscope Firmware

4.1 It is absolutely necessary to check the oscilloscope

fi rmware version before fi tting the Interface HO740. The

fi rmware version already on the scope is displayed after

s w i t c h i n g o n i f “ Q u i c k S t a r t ” i s o f f . T h e “ Q u i c k S t a r t ” f u n c t i o n

can be changed after pressing the SETTINGS pushbutton

and calling “Misc.”.

4.2 If the fi rmware version is 0 5.105-yy.yy y or higher, continue

the inter face fi t ting as des cribed und er item 5 (HO740 Fit ting

Instruc tion). In case fi rmware versions below 05.105-yy.yy y,

HO740 will not be recognised and a fi rmware update is

required as described under item 4.3.

4.3 In case of a fi rmware version below 05.105-yy.yyy, please

download the cur rent fi rmware at www.hameg.com from

the Internet and actualise the oscilloscope. The fi rmware

can be found and download under: Products > Oscilloscopes > (oscilloscope type) > Software/Firmware (below

the oscilloscope picture) > Firmware_HMxxx_Vxxx.zip.

After receiving the current fi rmware and its installation instruction, the fi rmware installation must be done via the present

interface (HO710, HO720 or HO730).

3. Interface Description

HO740 is an IEEE-488.2 (GPIB) Interface enabling the integration

of the oscilloscopes HM1008, HM1508 and HM2008 in automatic

test systems. The interface has an IEEE-488 socket, in which

an IEEE-488 cable can be inserted.

HO740 is a device that receives commands from a controller,

delivers them to the scope and if required transmits signal data

to the controller.

4

Änderungen vorbehalten

Page 5

Fitting Instruction

5. Interface Fitting Instruction

Safety!

The following procedures must only be carried out on condition that the mains (line) power cable is not connected to the

oscilloscope and no connection is made at the measurement

inputs.

Attention!

To avoid damage of the interface during removing

and fi tting by electrostatic discharge, please touch

a metal part of the oscilloscope for potential equalisation between oscilloscope and your body. Abide

this connection during the fi tting/removing!

Only handle the interface by its IEEE-488 socket!!

5.1 Removing of the actually inserted interface.

5.2 Fitting the interface HO740

5.2.1 Insert the interface HO740

in the opening in such a way, that

the PCB will be inserted in the

guidance - visible on both sides – and push it in completely.

5.1.1 Remove both fastening screws

5.1.2 Pull out the interface.

5.2.2 Fit the interface with the previously (item 5.1.1) removed

fastening screws.

Änderungen vorbehalten

5

Page 6

Functions and settings

6. Functions and settings

6.1 Flow control (SH1, AH1)

The fl ow control is for both transmitter and receiver (SH – Source Handshake / AH – Acceptor Handshake) is required for all

further functions incl. the transmission of bus specifi c control

data and therefore supported. Extended fl ow control with the

possibility of a simplifi ed indication is not implemented.

6.2 Transmission and reception of data (T6, L4)

The instrument is able to transmit and receive data if the corresponding function (T – Talker / L – Listener) has been activated

by the control device. For addressing of both functions the same

primary basic address has to be used. Secondary addresses

are not supported.

“Talk Only” and “Listen Only” modes cannot be activated.

6.3 State information (SR1, PP1)

Interface state information can be polled in sequential mode

(Serial Poll) as well as simultaneously from several devices

(PP – Parallel Poll) from the bus. All required interface settings for parallel polling are made by the control device via the

IEEE488-Bus.

6.6 Bus driver (E1)

The IEEE-488 bus data and control lines are controlled by drivers with open collector outputs. As to be seen in IEEE-488.1

standard, this enables a data rate of up to 250000 Bytes per

second.

6.7 Addressing of IEEE-488 devices

The IEEE-488 standard specifi es the address structure for

transmitter and receiver functions of a device. It allows you to

assign separate addresses for different device functions such

as transmission and receiving functions or for several different

transmission and receiving functions as appropriate.

These addresses can consist of a primary and a secondary part.

Both have a variable part (5 bit) for the real address and a fi xed

group allocation (2 bit). The 8th bit is not used.

Thus instrument addresses in the range from 0 to 30 (00h to

1Eh) are available. The address 31 (1Fh) has a special function.

It is used to deactivate the function of an addressed group on

the bus (UNL – Unlisten / UNT – Untalk).

The following address groups are specifi ed:

Primary addresses for receiver function (coding: 20h)

Primary addresses for transmitter function (coding: 40h)

Secondary addresses (coding: 60h).

E.g. the complete primary address of the receiver function of a

device with the basic address 8 will be 40 (28h).

If the confi guration of the device enable register is applicable

(note SCPI programming commands) the interface indicates the

control device internal state changes (SR – Service Request).

This avoids waiting time for the instrument’s reply or the recurrent query for the instrument state. The required device settings

must be made each time the device is switched on.

6.4 Communication initialisation (DC1)

Bus specific control commands “DCL” (Device Clear) and

„SDC“ (Selected Device Clear) will be processed by the internal

management, independent of other SCPI commands still to be

processed (DC – Device Clear). Within the instrument the SCPI

command processing will be newly initiated, the execution of

current commands will be interrupted, and the data buffer will

be deleted. The fl ow control cannot indicate the acceptance for

new data transmission until these data have been completely

processed.

6.5 Not supported functions (RL0, DT0, C0, CF0)

The following functions are not supported:

Switch over between local and remote with the opportunity to

lock local controls (RL – Remote Local)

External start of the instruments basic functions (DT – Device

Trigger)

Bus controller operation (C – Controller)

Considering the control device IEEE-488 bus cable length (CF

– Confi guration)

6.8 Selection of Primary Address

The selection of an address is only possible if, as described

under item 4 (Oscilloscope Firmware) a fi rmware version

05.105-yy.yyy or higher is present in the scope and the interface

HO740 is fi tted.

Pressing the SETTINGS pushbutton calls the “Settings” menu.

The function key “Interface” opens the submenu “Settings

Interface” causing “IEEE-488” and highlight “Address x” to be

displayed. The address (x) can be changed between 0 and 30 by

turning the INTENS knob. Please note that the selected address

must not used by any other instrument on the bus.

Local controls can be locked by SCPI commands (note SCPI

programming commands).

6

Änderungen vorbehalten

Page 7

7. Appliance

The SCPI programming commands list will be provided in the

Internet under www.hameg.com: Service&Support > Downloads > Software/Firmware: Software Commands for Oscilloscopes HM1008, HM1508 and HM2008.

Mainhausen, Germany

May 2007

Appliance

Änderungen vorbehalten

7

Page 8

Oscilloscopes

Spectrum Analyzer

Power Supplies

Modular System

8000 Series

Programmable Instruments

8100 Series

authorized dealer

www.hameg.com

Subject to change without notice

21-05-2007-gw HAMEG Instruments GmbH

© HAMEG Instruments GmbH Industriestraße 6

A Rohde & Schwarz Company D-63533 Mainhausen

® registered trademark Tel +49 (0) 61 82 800-0

DQS-Certifi cation: DIN EN ISO 9001:2000 Fax +49 (0) 61 82 800-100

Reg.-Nr.: 071040 QM sales@hameg.de

Loading...

Loading...