Page 1

350 MHz

Digital Oscilloscope

with FFT and mixed-signal (option)

HMO3522/3524

Manual

English

Page 2

General information regarding the CE marking

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE

Hersteller HAMEG Instruments GmbH

Manufacturer Industriestraße 6

Fabricant D-63533 Mainhausen

General information regarding the CE marking

HAMEG instruments fulfi ll the re gulations of t he EMC direc tive. The conf ormity

te st ma de b y H AM EG i s b as ed o n t he a ct ua l g ene ri c- and pr od uc t st an da rd s. In

cases where different limit values are applicable, HAMEG applies the severer

stan dard. For emis sion the limit s for reside ntial, commer cial and light i ndustry

are applied. Regarding the immunity (susceptibility) the limits for industrial

environment have been used.

The measuring- and data lines of the instrument have much infl uence on

emission and immunity and therefore on meeting the acceptance limits.

For different applications the lines and/or cables used may be different. For

measurement operation the following hints an d conditions r egarding emi ssion

and immunity should be observed:

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produkt

The HAMEG Instruments GmbH declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

Bezeichnung: Oszilloskop

Product name: Oscilloscope

Designation: Oscilloscope

Typ / Type / Type: HMO3524

mit / with / avec: HO720

Optionen / Options / Options: HO730, HO740

mit den folgenden Bestimmungen / with applicable regulations / avec les

directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par

93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied

Normes harmonisées utilisées:

Sicherheit / Safety / Sécurité:

EN 61010-1:2001 (IEC 61010-1:2001)

1. Data cables

For the connection between instrument interfaces and external devices,

(computer, printer etc.) suffi ciently screened cables must be used. Without

a special instruction in the manual for a reduced cable length, the maximum

cable length of a dataline must be less than 3 meters and not be used outside

buildi ngs. If an inter face has se veral conne ctors only on e connector mu st have

a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cable HZ72 from HAMEG is suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the manual

for a shorter length, signal lines must be less than 3 meters and not be used

outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double screened

cables (RG223/U, RG214/U) must be used.

3. Infl uence on measuring instruments

Under the presence of strong high frequency electric or magnetic fi elds, even

with careful setup of the measuring equipment, infl uence of such signals is

unavoidable.

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifi cations may result from such conditions in individual cases.

Messkategorie / Measuring category / Catégorie de mesure: I

Überspannungskategorie / Overvoltage category /

Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique

EN 61326-1/A1 Störaussendung / Radiation / Emission:

Tabelle / table / tableau 4; Klasse / Class / Classe B.

Störfestigkeit / Immunity / Imunitée: Tabelle / table / tableau A1.

EN 61000-3-2/A14 Oberschwingungsströme / Harmonic current emissions

Émissions de courant harmonique: Klasse / Class / Classe D.

EN 61000-3-3 Spannungsschwankungen u. Flicker / Voltage fl uctuations

and fl icker / Fluctuations de tension et du fl icker.

Datum / Date / Date

01. 03. 2009

Unterschrift / Signature / Signatur

Holger Asmussen

Manager

4. RF immunity of oscilloscopes.

4.1 Electromagnetic RF fi eld

The infl uence of electric and magnetic RF fi elds may become visible (e.g. RF

superimposed), if the fi eld intensity is high. In most cases the coupling into

the oscilloscope takes place via the device under test, mains/line supply, test

leads, control cables and/or radiation. The device under test as well as the

oscilloscope may be effected by such fi elds.

Although the interior of the oscilloscope is screened by the cabinet, direct

radiation can occur via the CRT gap. As the bandwidth of each amplifi er stage

is higher than the total –3dB bandwidth of the oscilloscope, the infl uence of RF

fi elds of even higher frequencies may be noticeable.

4.2 Electrical fast transients / electrostatic discharge

Electrical fast transient signals (burst) may be coupled into the oscilloscope

directly via the mains/line supply, or indirectly via test leads and/or control

cables. Due to the high trigger and input sensitivity of the oscilloscopes, such

normally high signals may effect the trigger unit and/or may become visible

on the TF T, which is unavoidable. These effects can also be caused by direct

or indirect electrostatic discharge.

HAMEG Instruments GmbH

2

Subject to change without notice

Page 3

Contents

General information regarding the CE marking 2

350 MHz Digital Oscilloscope HMO3522 / HMO3524 4

Specifi cations 5

1 Installation and safety instructions 6

1.1. Setting up the instrument 6

1.2. Safety 6

1.3. Correct operation 6

1.4. Ambient conditions 6

1.5. Warranty and repair 6

1.6. Maintenance 7

1.7. CAT I 7

1.8. Mains voltage 7

2 Familiarize yourself with your new HAMEG

Digital Storage Oscilloscope 8

2.1. Front view 8

2.2. Control panel 8

2.3. Screen 9

2.4. Rear view 9

2.5. Options 9

2.6. General concept of instrument operation 9

2.7. Basic setting and integrated help 10

2.8. Firmware- and help updates 11

3 A quick introduction 12

3.1. Setting up and turning the instrument on 12

3.2. Connection of a probe and signal capture 12

3.3. Display of signal details 12

3.4. Cursor measurements 13

3.5. Automatic measurements 13

3.6. Mathematical functions 14

3.7. Storing data 14

7 Display of signals 20

7.1. Display settings 20

7.2. Use of the virtual screen area 20

7.3. Signal intensity and persistence functions 21

7.4. XY display 21

8 Measurements 22

8.1. Cursor measurements 22

8.2. Auto measurements 23

8.3. Quickview measurements 24

9 Analysis 24

9.1. Quick mathematics 24

9.2. Formula editor 25

9.3. Frequency analysis (FFT) 26

10 Documentation, storing and recalling 27

10.1. Instrument settings 27

10.2. References 28

10.3. Curves 28

10.4. Screen shots 29

10.5. Sets of formulas 29

10.6. Defi nition of the FILE/PRINT key 29

11 Mixed Signal Operation (optional) 30

11.1. Logic trigger 30

11.2. Display functions of the logic channels 30

11.3. Cursor measurements for the logic channels 31

12 Appendix 32

4 Vertical system 15

4.1. Coupling 15

4.2. Sensitivity, Y-Positioning, and Offset 16

4.3. Bandwidth Limit and Signal Inversion 16

4.4. Probe attenuation selection 16

5 Horizontal System (Time Base) 17

5.1. Capturing modes RUN and STOP 17

5.2. Time base adjustments 17

5.3. Capture modes 17

5.4. ZOOM function 17

6 Trigger System 18

6.1. Trigger modes Auto, Normal, Single 18

6.2. Trigger sources 19

6.3. Slope trigger 19

6.4. Pulse trigger 19

6.5. Video trigger 20

Subject to change without notice

3

Page 4

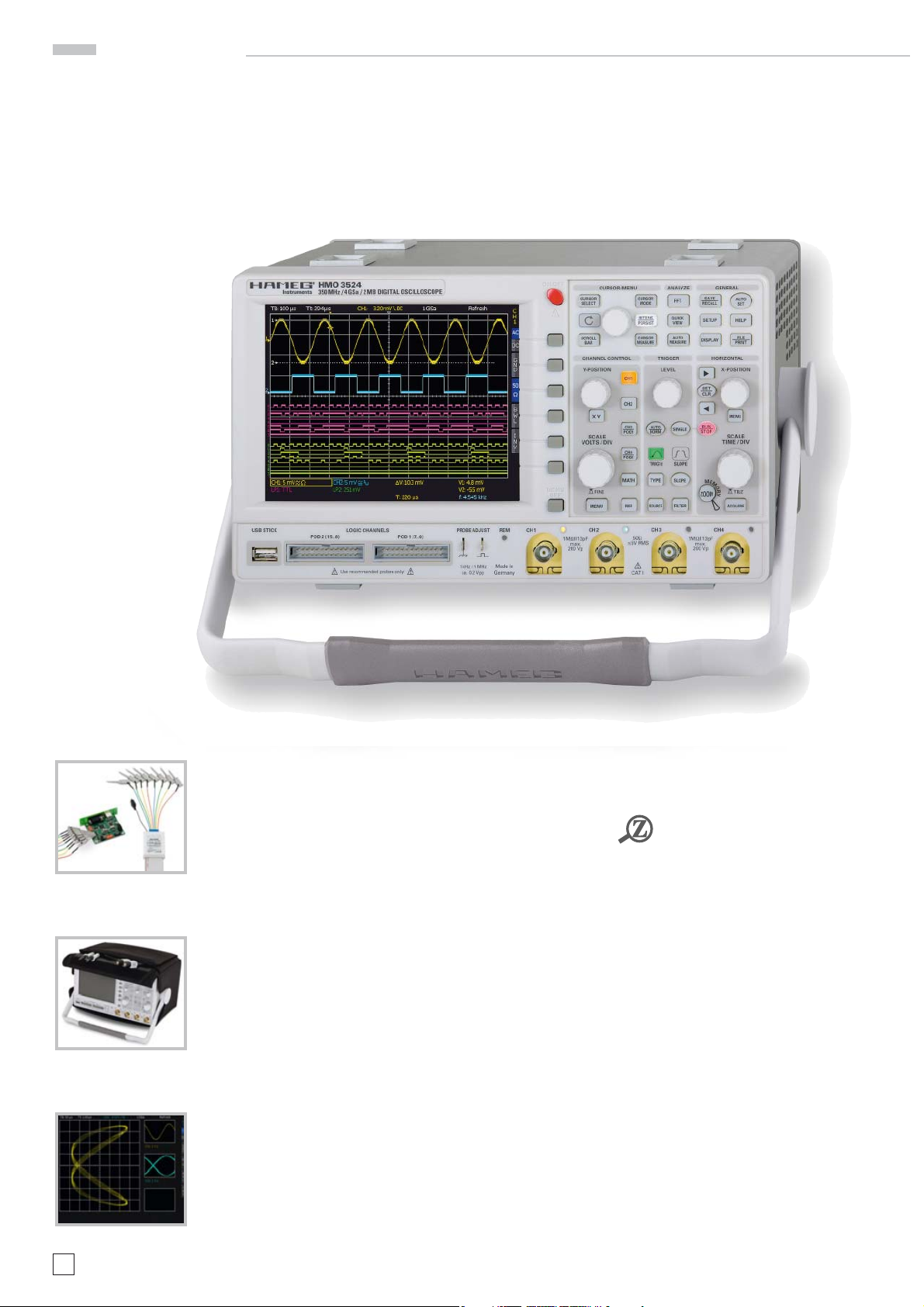

HMO3524

4GSa /s Real time, 50GSa /s Random sampling,

low noise flash A/ D converter (reference class)

2MPts memory per channel, memory oom up to 100,000:1

MSO (Mixed Signal Opt. HO3508) with 8 /16 logic channels

Vertical sensitivity 1mV...5V/div. (into 1MΩ/50Ω)

Offset control ±0,2...±20V

12div. x-axis display range

Trigger modes: slope, video, pulsewidth, logic,

delayed, event

FFT for spectral analysis

6 digit counter, Autoset, automeasurement, formula editor

6.5” TFT VGA display, DVI output

3 x USB for mass storage, printer and remote ctrl.

optional IEEE-488 or Ethernet/USB

350MHz 2/4 Channel Digital Oscilloscope

HMO3522/HMO3524

HMO3524

NEW

The operating mode XYZ

Carrying Case HZ99

8 Channel

logic probe HO3508

4

Subject to change without notice

Page 5

350 MHz 2 [4] Channel Digital Oscilloscope

HMO3522 [HMO3524]

All data valid at 23 °C after 30 minute warm-up

Display

Display: 6,5” VGA Color TFT

Resolution: 640 x480 Pixel

Backlight: LED 400cd/m

2

Display area for curves:

without menu 400 x 600 Pixel (8x 12 div.)

with menu 400 x 500 Pixel (8x 10 div.)

Color depth: 256 colors

Intensity steps per channel: 0…31

Vertical System

Channels:

DSO mode CH1, CH2 [CH1...CH4]

MSO mode CH1, CH2 LCH 0...15 (logic channels)

with 2 x Option HO3508

Auxiliary input: Frontside [Rear side]

Function Ext. Trigger

Impedance 1MΩ || 13pF ± 2pF

Coupling DC, AC

Max. input voltage 100V (DC + peak AC)

XYZ-mode: All analog channels on individual choise

Invert: CH 1, CH 2 [CH1...CH4]

Y-bandwidth (-3dB): 350MHz (5 mV...5V)/ div.

100MHz (1mV, 2mV) / div.

Lower AC bandwidth: 2Hz

Bandwidth limiter

(switchable): approx. 20MHz

Rise time (calculated): ‹ 1ns

DC gain accuracy 2%

Input sensitivity: 12 calibrated steps

CH1, CH2 [CH1...CH4] 1mV/div.…5V/div. (1-2-5 Sequence)

Variable Between calibrated steps

Inputs CH1, CH2 [CH1…CH4]:

Impedance 1MΩ II 13pF ± 2pF (50Ω switchable)

Coupling DC, AC, GND

Max. input voltage 200V (DC + peak AC), 50Ω ‹ 5V

rms

Measuring circuits: Measuring Category I (CAT I)

Position range ± 10Divs

Offset control:

1mV, 2mV ±0,2V

5mV…50mV ±1V

100mV…5V ±20V

Logic channels With Option HO3508

Select. switching thresholds TTL, CMOS, ECL, 2 x User -2V…+8V

Impedance 100kΩ || ‹ 4pF

Coupling DC

Max. input voltage 40V (DC + peak AC)

Triggering

Analog channels:

Automatic: Linking of peakdetection and triggerlevel

Min. signal height 0.8 div; 0.5div typ.

Frequency range 5Hz…400MHz

Level control range From peak- to peak+

Normal (without peak):

Min. signal height 0.8 div; 0.5div typ.

Frequency range 0…400MHz

Level control range –10div....+10div.

Operating modes: Slope / Video/Logic/ Pulse

Slope: Rising, falling, both

Sources: CH1, CH2, Line, Ext., LCH0…15

[CH1...CH4, Line, Ext., LCH0…15]

Coupling: AC: 5Hz...400MHz

DC: 0...400MHz

HF: 30kHz...400MHz

LF: 0...5kHz

Noise rejection: 100MHz LPF switchable

Video: Pos. / neg. sync. impulse

Standards 525 Line / 60Hz systems

625 Line/50Hz systems

Fields Field 1, field 2, both

Line All, selectable line number

Source CH1, CH2, Ext. [CH1...CH4]

Logic: AND, OR, TRUE, FALSE

Source LCH0…15

State LCH0…15 X, H, L

Indicator for trigger action: LED

Ext. Trigger via: Auxiliary input [Aux. input at rear side]

0,3V…10V

ss

2nd Trigger:

Slope Rising, falling, both

Accessories supplied: Line cord, Operating manual, 2 [4] Probes, 10:1 with

attenuation ID (HZ350), Dual-Interface USB/RS-232 (HO720), CD

Optional accessories:

HO730 Dual-Interface Ethernet/USB

HO740 Interface IEEE-488 (GPIB) galvanically isolated

HZ46 4RU 19'' Rackmount Kit

HZ355 Slimline Probe 10:1 with automatically identification

HO3508 8 Channel Logic Probe

Min. signal height 0.8 div; 0.5div typ.

Frequency range 0…400MHz

Level control range –10div....+10div.

Operating modes:

after time 20ns…0.1s

after incidence 1…2

16

Horizontal System

Domain representation: Time, Frequency (FFT), Voltage (XY)

Representation Time Base: Main-window, main- and zoom-window

Memory Zoom: Up to 100.000:1

Accuracy: 15ppm

Time Base:

Refresh operating modes 1ns / div.…20ms / div.

Roll operating modes 50ms / div.…50s / div.

Digital Storage

Sampling rate (real time): 2x2GSa/s, 1x4GSa/s

[4 x 2GSa/s, 2 x 4GSa/s]

Logic channels: 16 x 1GSa/s

Sampling rate (random): 50GSa/s (n / a to logic channels)

Memory: 2 x 2MPts [4 x2MPts]

Operation modes: Refresh, Average, Envelope, Peak-Detect

Roll: free run/ triggered, Smooth

Resolution (vertical) 8Bit

Resolution (horizontal)

Yt Mode (50 Pts./div.)

XY Mode 8Bit

Interpolation: Sinx / x (CH1...CH4), Pulse (LCH0...15)

Persistence: Off, 50 ms...∞

Delay pretrigger: 0...2 Million x (1/samplerate)

posttrigger: 0...8 Million x (1/samplerate)

Display refresh rate: Up to 2500 waveforms/ s

Display: Dots, vectors (interpolation), ‘persistence’

Reference memories: typ. 10 Traces

Operation / Measuring / Interfaces

Operation: Menu-driven (multilingual), Autoset,

help functions (multilingual)

Save / Recall memories: typ. 10 complete instrument parameter

settings

Frequency counter:

0.5Hz...350MHz 6 Digit resolution

Accuracy 15ppm

Auto measurements: Frequency, Period, pulse count, UDC, Upp,

Up+, Up-, U

RMS

, U

Avg

, t

Rise

, t

Fall

Cursor measurements: ΔV, Δt, 1/Δt (f), V to Gnd, Vtrelated to Trigger

point, ratio X and Y, pulse count, peak to

peak, peak+, peak-

Interface: Dual-Schnittstelle USB/RS-232 (HO720)

USB-Stick (frontside)

USB-Printer (rear side) with SW V2.0

DVI for ext. monitor

Optional: IEEE-488, Ethernet/USB

Mathematic functions

Number of formula sets: typ. 10 formula sets with up to 5 formulas each

Sources: All channels and math. memories

Targets: Math. memories

Functions: ADD, SUB, 1/X, ABS, MUL, DIV, SQ,

POS, NEG, INV

Display: Up to 4 math. memories

General Information

Probe ADJ Output: 1kHz/1MHz square wave signal ~0.2V

pp

(ta ‹ 4ns)

Internal RTC (Realtime clock): Date and time for stored data

Line voltage: 105...253V, 50/60Hz, CAT II

Power consumption: Max. 70Watt at 230V, 50Hz

Protective system: Safety class I (EN61010-1)

Operating temperature: +5°C...+40°C

Storage temperature: -20 °C...+70°C

Rel. humidity: 5%...80% (non condensing)

Dimensions (W x H x D): 285x175x220mm

Weight: 3.6kg

Technische Daten

Dual-Interface USB/RS-232 (HO720)

Subject to change without notice

5

Page 6

Installation and safety instructions

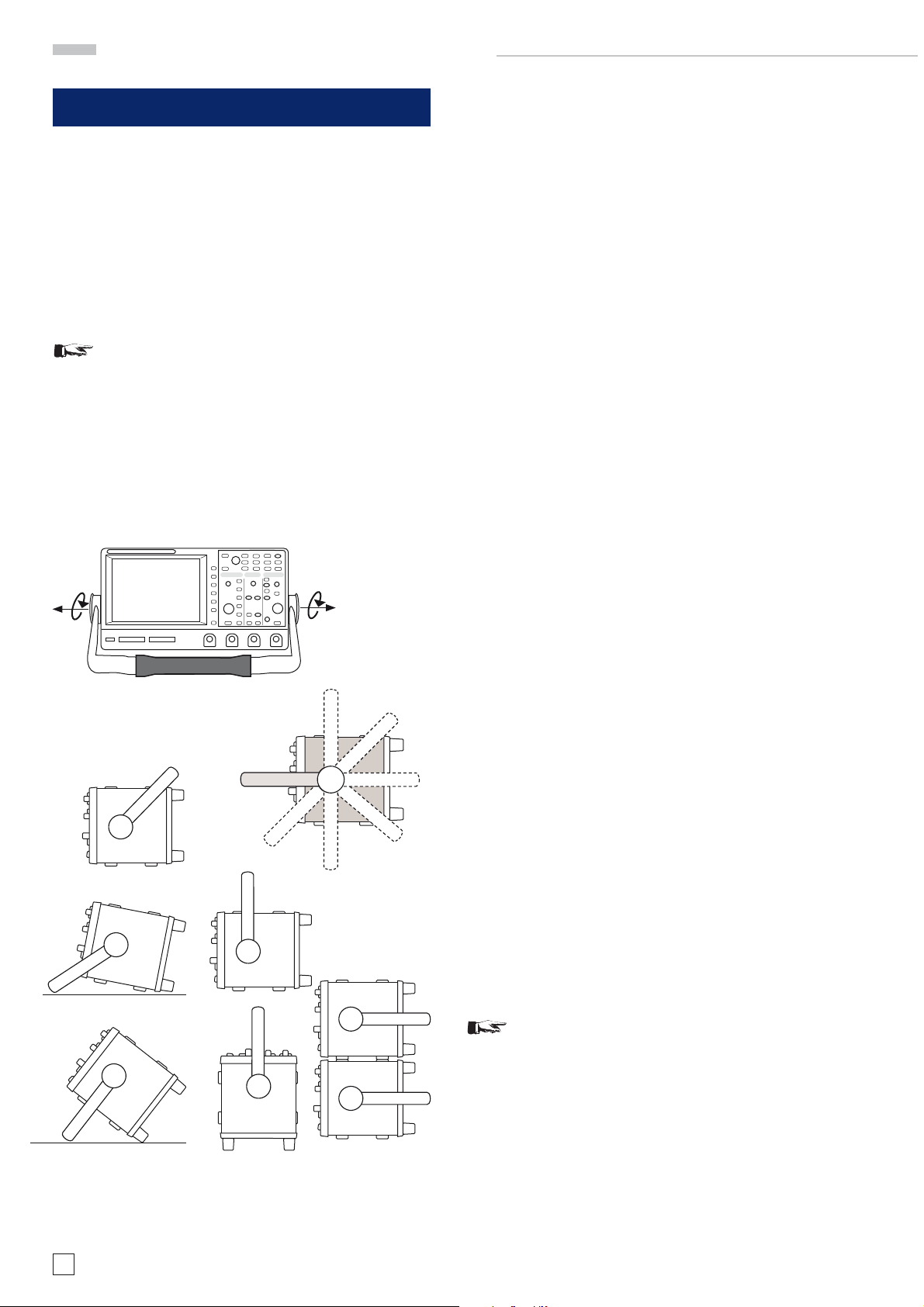

1 Installation and safety instructions

1.1. Setting up the instrument

As can be seen from the fi gures, the handle can be set into

different positions:

A and B = carrying

C = horizontal operating

D and E = operating at different angles

F = handle removal

G = operating using the feet‘s, batch use and for shipping in

original packaging

Attention!

When changing the handle position, the instrument

must be placed so that it cannot fall (e.g. placed on

a table). Then the handle locking knobs must be

simultaneously pulled outwards and rotated to the

required position. Without pulling the locking knobs

they will latch in into the next locking position.

Removal/fi tting of the handle: The handle can be removed in

position F, pulling the side parts outside the housing. Adding

the handle works vice versa.

1.2. Safety

The instrument fulfi ls the VDE 0411 part 1 regulations for

electrical measuring, control and laboratory instruments and

was manufactured and tested accordingly. It left the factory in

perfect safe condition. Hence it also corresponds to European

Standard EN 61010-1 and International Standard IEC 1010-1.

In order to maintain this condition and to ensure safe operation the user is required to observe the warnings and other

directions for use in this manual. Housing, chassis as well as

all measuring terminals are connected to safety ground of the

mains. All accessible metal parts were tested against the mains

with 2200 V

oscilloscope may only be operated from mains outlets with a

safety ground connector. The mains plug has to be installed

prior to connecting any signals. It is prohibited to separate the

safety ground connection. If suspected that safe operation may

not be guaranteed do not use the instrument any more and lock

it away in a secure place.

Safe operation may be endangered if any of the following was

noticed:

– in case of visible damage.

– in case loose parts were noticed

– if it does not function any more.

– after prolonged storage under unfavourable conditions (e.g.

like in the open or in moist atmosphere).

– after any improper transport (e.g. insuffi cient packing not

conforming to the minimum standards of post, rail or transport fi rm)

. The instrument conforms to safety class I. The

DC

Removing the handle (Pos. F)

A

C

D

D

B

A

1.3. Correct operation

Please note: This instrument is only destined for use by personnel well instructed and familiar with the dangers of electrical

measurements. For safety reasons the oscilloscope may only

be operated from mains outlets with safety ground connector.

It is prohibited to separate the safety ground connection. The

B

C

G

F

E

G

plug must be inserted prior to connecting any signals.

The oscilloscope is destined for operation in industrial, business,

manufacturing, and domestic sites.

1.4. Ambient conditions

Operating ambient temperature: +5 °C to +40 °C. During transport or storage the temperature may be –20 °C to +70°C. Please

note that after exposure to such temperatures or in case of

condensation, proper time must be allowed until the instrument

has reached the permissible temperature, and until the condensation has evaporated before it may be turned on! Ordinarily

this will be the case after 2 hours. The oscilloscope is destined

for use in clean and dry environments. Do not operate in dusty

or chemically aggressive atmosphere or if there is danger of

explosion. The any operating position may be used, however,

suffi cient ventilation must be ensured. Prolonged operation

requires the horizontal or inclined position.

Do not obstruct the ventilation holes!

Specifi cations are valid after a 30 minute warm-up period at 23

degr. C (tolerance ±2 degr. C). Specifi cations without tolerances

are average values.

E

Positions of the instrument

6

Subject to change without notice

1.5. Warranty and repair

HAMEG instruments are subjected to a strict quality control.

Carrying positionsOperating positions

Stacking positions

Prior to leaving the factory, each instrument is burnt in for 10

hours. By intermittent operation during this period almost all

defects are detected. Following the burn in, each instrument is

tested for function and quality, the specifi cations are checked

Page 7

Installation and safety instructions

in all operating modes; the test gear is calibrated to national

standards.

The warranty standards applicable are those of the country

in which the instrument was sold. Reclamations should be

directed to the dealer.

Only valid in EU countries

In order to speed claims, customers in EU countries may also

contact HAMEG directly. Also, after the warranty expired, the

HAMEG service will be at your disposal for any repairs.

Return material authorization (RMA):

Prior to returning an instrument to HAMEG, ask for a RMA

number either by internet (http://www.hameg.com) or fax (+49

(0) 6182 800 501). If you do not have an original shipping carton,

you may obtain one by calling the HAMEG service dept (+49 (0)

6182 800 500) or by sending an email to service@hameg.com.

1.6. Maintenance

Clean the outer case using a dust brush at regular intervals.

Dirt can be removed from housing, handle, all metal and plastic

parts using a cloth moistened with water and 1 % detergent.

Greasy dirt may be removed with benzene (petroleum ether) or

alcohol. Thereafter wipe the surfaces with a dry cloth. Plastic

parts should be treated with a suitable antistatic solution. No

fl uid may enter the instrument. Do not use other cleansing

agents as they may adversely affect the plastic or lacquered

surfaces.

The holder with the new fuse can then be pushed back in place

against the spring. It is prohibited to ”repair“ blown fuses or to

bridge the fuse. Any damages incurred by such measures will

void the warranty.

Type of fuse:

Size 5 x 20 mm; 250V~, C; IEC 127, Bl. III; DIN 41 662 (or DIN 41

571, Bl. 3). Cut off: slow blow (T) 2A.

Fuse Mains input connector Interface

1.7. CAT I

This oscilloscope is destined for measurements in circuits not

connected to the mains or only indirectly. Direct measurements,

i.e. with a galvanic connection to circuits corresponding to the

categories II, III, or IV are prohibited! The measuring circuits

are considered not connected to the mains if a suitable isolation

transformer fulfi lling safety class II is used. Measurements

on the mains are also possible if suitable probes like current

probes are used which fulfi ll the safety class II. The measurement category of such probes must be checked and observed.

The measurement categories were derived corresponding to

the distance from the power station and the transients hence to

be expected. Transients are short, very fast voltage or current

excursions which may be periodic or not.

Measurement CAT IV: Measurements close to the power station,

e.g. on electricity meters

Measurement CAT III: Measurements in the interior of buildings

(power distribution installations, mains outlets, motors which

are permanently installed).

Measurement CAT II: Measurements in circuits directly connected to the mains (household appliances, power tools etc).

Measurement CAT I: Electronic instruments and circuits which

contain circuit breakers or fuses.

Type of fuse

1.8. Mains voltage

The instrument has a wide range power supply from 105 to

253 V, 50 or 60 Hz ±10%. There is hence no line voltage selector.

The line fuse is accessible on the rear panel and part of the line

input connector. Prior to exchanging a fuse, the line cord must

be pulled out. Exchange is only allowed if the fuse holder is

undamaged. It can be taken out using a screwdriver put into the

slot. The fuse can be pushed out of its holder and exchanged.

Subject to change without notice

7

Page 8

Introduction

SCALE

VOLTS / DIV

Y-POSITION

CHANNEL CONTROL

FINE

6

2

-

K

3

0

4

-

1

1

5

0

-

1

.

0

MENU

CH1

CH2

CH3

POD1

MATH

REF

X Y

CH4

POD2

CURSOR/MENU ANALYZE GENERAL

CURSOR

SELECT

CURSOR

MODE

AUTO

MEASURE

SCROLL

BAR

CURSOR

MEASURE

FFT

QUICK

VIEW

DISPLAY

AUTO

SET

SETUP HELP

SAVE

RECALL

INTENS

PERSIST

FILE

PRINT

USB STICK

HMO 3524

HMO 3524

350 MH z / 4 GSa / 2 MB DIGI TAL OSCIL LOSCOP E

350 MH z / 4 GSa / 2 MB DIGI TAL OSCIL LOSCOP E

POD 2 (15..8) POD 1 (7..0)

LOGIC CHANNELS REM CH 1

Use recommended probes only!

!!

54

PROBE ADJUST

1 kHz / 1 MHz

ca. 0.2 Vpp

Made in

Germany

1

2

CURSOR/MENU ANALYZE GENERAL

CURSOR

SELECT

SCROLL

BAR

CHANNEL CONTROL HORIZONTALTRIGGER

X Y

SCALE

VOLTS / DIV

K

3

-

0

2

4

6

-

1

1

5

0

-

1

.

0

MENU

CH 2 CH 3 CH 4

1MΩ II 13pF

max.

200 Vp

CH1

CH2

CH3

POD1

CH4

POD2

MATH

REF

≤5V RMS

A

CURSOR

INTENS

PERSIST

CURSOR

MEASURE

50Ω

!

CAT I

MODE

FFT

QUICK

VIEW

AUTO

MEASURE

LEVELY-POSITION X-POSITION

AUTO

SINGLE

NORM

TRIG’d SLOPE

SLOPE

TYPE

SOURCE

FILTER

RECALL

SETUP HELP

DISPLAY

SET

CLR

RUN

STOP

M

1MΩ II 13pF

max.

200 Vp

SAVE

E

M

SCALE

TIME / DIV

O

R

Y

ACQUIRE

MENU

TB/ZFINE

AUTO

SET

FILE

PRINT

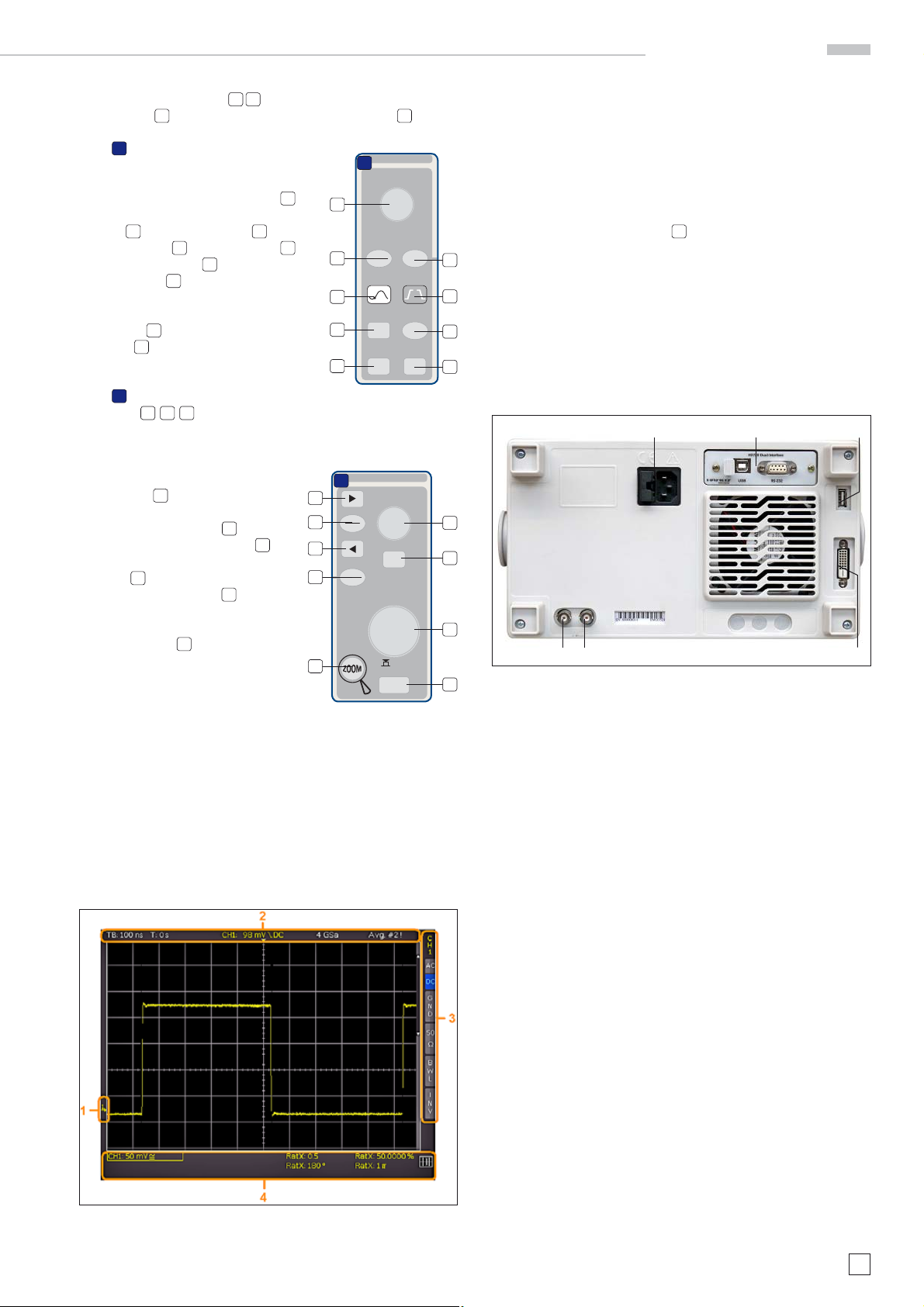

Fig. 2.1: Frontview of the HMO3524

2 Familiarize yourself with your new HAMEG

Digital Storage Oscilloscope

2.1. Front view

The following controls and inputs/outputs are located on the

front: Power switch

connectors of the analog inputs

50

output

51 52

LED

, the connectors for the optional logic probes HO3508

, a USB port for USB sticks 53 , the TFT screen 54 and the

49

for showing activity on the remote interface.

1

, the control panel 2, A,B,C,D, the BNC

45

to 48, the probe adjustment

Please note, the connectors for the active logic

probes HO3508

51 52

are solely for theses probes.

Connecting anything else could destroy the inputs!

2.2. Control panel

The controls on the front panel allow direct access to the most

important functions; all extended functions are available via the

menu structure by using the grey soft keys. The power switch

1

is clearly set apart by its red colour. The most important

controls are backlighted by coloured LEDs in order to immediately indicate the actual settings. The panel is subdivided in

these four areas:

9

10

6

8

7

12 13

11 14

A

3

5

A

Area

Fig. 2.2:

Area A of the

control panel.

8

Subject to change without notice

4

49

48 47 46 4550515253

B C D

This area encompasses these three portions: CURSOR/MENU

– ANALYZE – GENERAL.

In the portion CURSOR/MENU you fi nd the cursor functions

6 8

, the general cursor select and adjustment knob 4, the

Intensity/Persistence key

7

, and the key for the selection of

virtual screen.

The portion ANALYZE allows direct selection of FFT

the Quick-view mode

10

(all important parameters of the ac-

tual signal display), and the „Automeasure“ function

9

displays,

11

for the

automatic measurement of parameters.

The portion headed GENERAL comprises the following keys:

SAVE/RECALL

12

for saving and recalling instrument settings,

reference signals, signals, screen displays, and sets of formulae, HELP

settings, AUTOSET

settings (e.g. the language), FILE/PRINT

B

Area

In the portion CHANNEL CONTROL

you fi nd all controls of the analog

channels such as the position control knob

19

key

15

16

, the vertical gain adjustment

20

knob

tions key

22

to 25, (the two-channel version

HMO3522 has only

also serve as the selection keys for

17

Fig. 2.3: Area B of the

control panel.

16

, DISPLAY 14 for access to the general display

15

, SETUP 13 for access to the general

:

18

, the XY mode select

, the extended menu func-

21

, the channel select keys

22 23

) which

17

.

B

22

18

23

19

24

25

20

26

21

27

Page 9

Introduction

LEVEL

TRIGGER

TRIG’d SLOPE

AUTO

NORM

TYPE

SOURCE

FILTER

SLOPE

SINGLE

SCALE

TIME / DIV

X-POSITION

HORIZONTAL

TB/Z

M

E

M

O

R

Y

MENU

ACQUIRE

RUN

STOP

SET

CLR

the optional logic probes 24 25. There are also the mathematics

26

function key

C

Area

This area TRIGGER of the control

and the reference signal settings key 27.

:

C

panel offers all functions for the

adjustment of the trigger level

, the selection of auto or normal

trigger

trigger source

29

, the trigger type 31, the

32

, single sweep

, the trigger slope 34, the trigger

signal fi lters

36

. In addition, the-

re are status indicators showing

28

33

28

29

30

33

34

whether a signal fulfi lls the trigger

conditions

selected

Area

The keys

30

and which slope was

34

.

D

:

37 38 39

on this control

panel area HORIZONTAL allow to

31

32

Fig. 2.4: Area C of the

control panel

35

36

shift the trigger position horizontally, either step-by-step or using the

smaller one of the knobs. The backlighted key

39

controls the run or

stop modes; the key will light up red

in stop mode. The key

the zoom function, the key

40

activates

44

the

selection of the acquisition modes,

the key

base menus. The knob

42

the access to the time

43

allows to

D

37

38

37

39

41

42

adjust the time base speed.

To the left of the control panel there

are the soft keys

2

which control the

menu functions.

2.3. Screen

The HMO is equipped with a 6.5“

(16.5 cm) LED backlighted colour

40

Fig. 2.5: Area D

of the control panel

43

44

TFT display with VGA resolution (640

x 480 pixels). In normal mode (no menus shown) there are 12

divisions in X direction. If menus are shown, this will be reduced to 10 divisions. On the left of the screen area little arrows

[1] indicate the reference potentials of the channels. The line

above the graticule contains status and settings information

such as the time base speed, the trigger delay and other trigger

conditions, the actual sampling rate, and the acquisition mode

[2]. On the right of the graticule a short menu is shown which

contains the most important settings of the channel actually

being displayed; these may be selected using the soft keys [3].

Below the graticule, measurement results of parameters and

cursors, the settings of the activated vertical channels, of the

reference signal, and of the mathematically derived curves [4]

are shown. Within the graticule, the signals of the selected channels are displayed. Normally, 8 vertical divisions are shown; it

can be virtually extended to 20 divisions which can be displayed

using the SCROLL BAR knob

5

.

2.4. Rear view

On the rear panel there are the mains connector [1], the receptacle for the interface modules [2] (USB / RS-232, Ethernet,

IEEE-488), the standard DVI connector [3] for the connection

of external monitors and projectors, the BNC connector for

the Y output [4] (of the channel selected for triggering) and the

external trigger input [5]. With the two-channel models this

connector is located on the front panel.

[1] [2] [2]

[5] [4] [3]

Fig. 2.7: Rear panel of the HMO3524

2.5. Options

The HMO352x series instruments offer some options which

allow you to extend the areas of application considerably. The

following interface modules are available and may be installed

by the customer in the rear receptacle:

– HO740 (IEEE-4888, GPIB, galvanically isolated)

– HO730 (combination of Ethernet and USB with integrated

web server)

All HMO 352x series instruments are prepared for mixedsignal operation and have the appropriate connectors on the

front panel. Each of these connectors can be connected to an

8-channel logic probe HO3508, hence a maximum of 16 logic

channels is possible. More available options are the passive

500MHz slimline10:1 probes HZ355, the 19inch rack kit HZ46

and the carrying bag HZ99.

Fig. 2.6: Screen

2.6. General concept of instrument operation

HAMEG oscilloscopes are renowned for easy operation, based

on a few basic principles which repeat with the diverse settings

and functions.

– Such keys which do not open a soft menu (e.g. Quickview)

switch a function on, pushing the key again will switch the

function off.

– Such keys which call a specifi c function (e.g. FFT) which

in turn can call or require more settings will activate the

function upon the fi rst touch. Pushing the key a second time

will call the soft menu (sub menu) for the settings. Pushing

the key a third time will deactivate the function.

Subject to change without notice

9

Page 10

Introduction

– Such keys which open a soft menu upon the fi rst touch will

close it upon pushing a second time.

– The universal knob is used in the diverse menus either for

selecting numbers or submenus.

– The key MENU OFF below the soft menu keys closes the

present menu or it switches to the next higher level.

– If a channel is deactivated, pushing the respective channel

key will switch it on. If a channel was already activated

earlier, selecting another channel will change operation

to the channel whose key was pushed (its LED lights up). If

a channel is already selected, pushing its lighted key will

deactivate the channel and select the next channel according

to this sequence: CH1 > CH2 > CH3 > CH4.

– If cursor measurements are activated, the „CURSOR SE-

LECT“ key will select the cursor which can be moved with

the universal knob. In all menus for alpha-numeric inputs

and at the fi lemanager the knob is used to select or confi rm

entries.

The following describes some frequently used navigation elements in the soft menus.

In the Fig. 2.8 there are two basic soft menu elements for choosing

something are shown. To select from the fi rst three you just need

to press the soft key beside and the element is active (shown as

blue color). A second kind of selecting is shown on the lower two

menu entries. Pressing the respective soft key toggles between

the two choices, again the active selection is marked blue.

The menus are used as shown in Fig. 2.9 if they concern functions which have either to be switched on or where values have

to set. The choice is between OFF and the value presented. The

round arrow in the right corner of the menu window points to

the universal knob which is to be used for selecting the value. If

there is a lower menu level, this will be indicated by a small triangle in the right lower corner of the respective menu point.

If there are further pages on the same level, the lowest menu

point will be used for navigation. It shows the number of menu

pages on this level as well as the activated number of pages.

Pushing the respective soft menu key will advance by one page,

after the last page the fi rst one will follow.

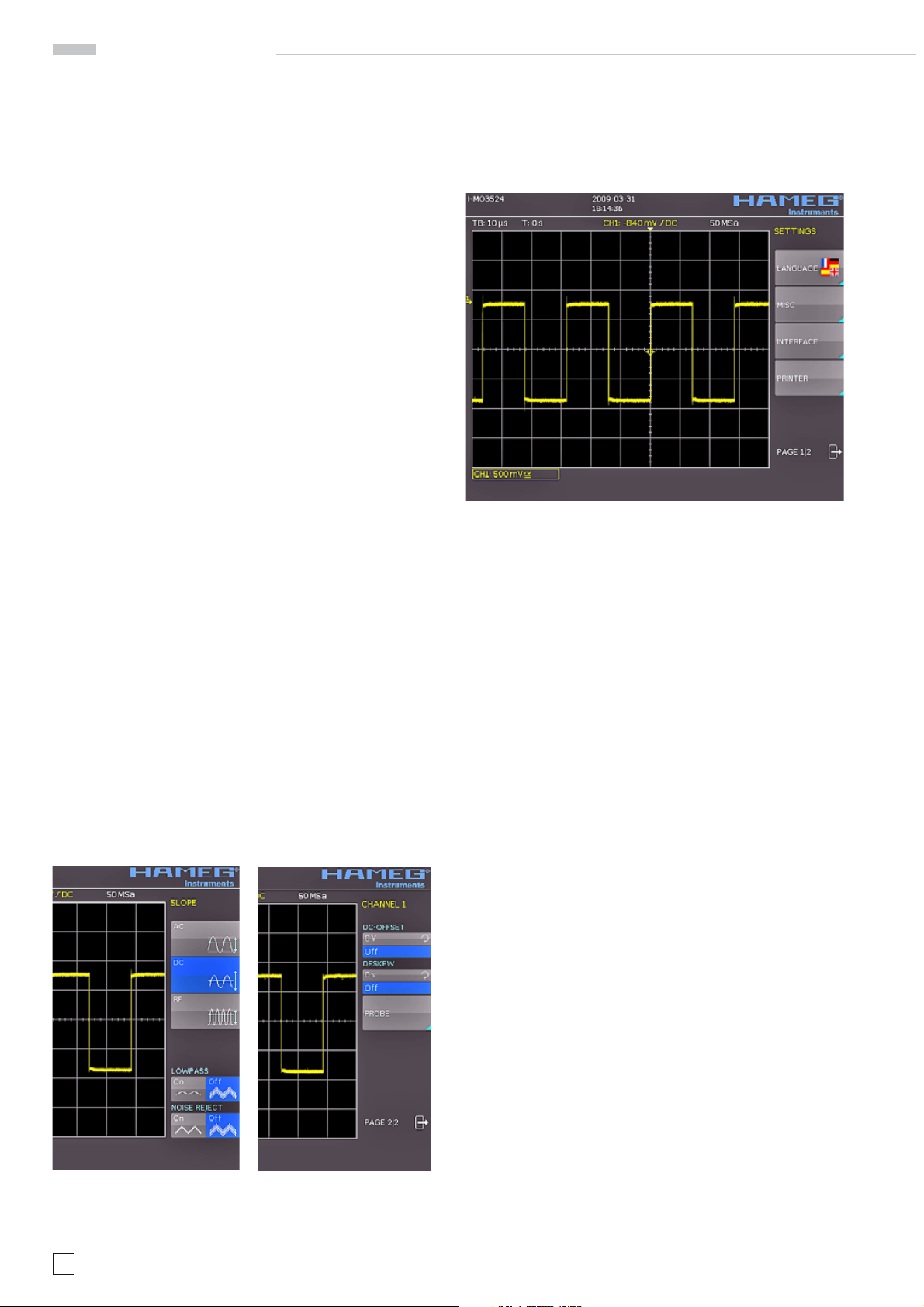

2.7. Basic setting and integrated help

Basic settings like language for user interface and help, miscellaneous settings and interface settings can be set using

the menu which opens after pressing the SETUP key in the

GENERAL area of the control panel

Fig. 2.10: Menu for basic settings

On the fi rst page you can set the user interface and help language by pressing the soft key LANGUAGE and select German or

English. (Complete support for French and Spanish for the help

function will be implemented latest in fi rmware 2.0.)

The soft key beside MISC opens a menu with the following

selections:

– MENU OFF (choose manual or automatic with time limit of

4s up to 30 s for closing soft menus)

– TIME REFERENCE (position for reference of the trigger time,

choose from -5/DIV up to +5/DIV, 0/DIV is in the middle of

the screen and set as standard)

– DATE & TIME (opens menu to set date and time)

– SOUND (opens menu to set any combination of beep for

control, error and/or trigger)

– DEVICE NAME (menu to set a name for the HMO352x, ma-

ximum of 19 characters are allowed, the name will appear

in Screenshot‘s)

– DEVICE INFOS (opens a window with detailed information

about hardware and software of your HMO352x)

Fig. 2.8: Selection of basic soft

menu elements

10

Subject to change without notice

Fig. 2.9: Basic soft menu

elements for settings and

navigation

The next menu entry INTERFACE lets you select the interface

you are using (USB and RS-232 are standard) and possible

settings for that interface.

The last menu entry PRINTER shows all settings for postscript

printer; beginning with fi rmware 2.0 there will be also support

for other compatible printer.

At the second page of the basic menu you fi nd the menu for

fi rmware and help update, which is explained in detail in the

next chapter. The last menu item is the PROBE ADJUST.

Pressing the soft key leads you to the menu where you can set

whether the probe adjust output generates a rectangular signal

with 1 kHz or 1 MHz frequency. There is a setting AUTOMATIC

which means, that for timebase settings up to and including

50 μs/DIV the probe adjust output is 1 MHz, from 100 μs/DIV on

it is switched to 1 kHz.

The integrated help function can be activated by pressing the

key HELP in the GENERAL area of the control panel. A window

will open and the text inside is dynamically updated depending

Page 11

Introduction

on the key (including softmenu key’s) you are pushing or the

knob you are turning. If you do not need the help anymore, you

can switch off the help window by pushing the “HELP” key. The

backlight of the key and the text window will be switched off.

2.8. Firmware- and help updates

The HMO352x series is being improved continuously. You are

invited to download the most recent fi rmware under www.

hameg.com/hmo3524. Firmware and help are packed into one

ZIP data packet. After downloading the ZIP data unpack it into

an USB stick’s basic directory. Thereupon insert the stick into

the USB port of the oscilloscope and push the key SETUP in the

GENERAL area of the front panel. Choose page 2 in the menu,

if this has not been opened already. Here you shall fi nd the

menu item UPDATE. After selecting this menu item a window

will open which displays the actual fi rmware version indicating

the version number, the date and build information.

If you intend to update the help function or add a help language

choose HELP in the updating menu.

The information window will now display the languages installed, the date, and the information about the languages available

on the stick. With the soft menu, languages may be added,

removed or updated. Please note the format of the date:YYYYMM-DD according to the multi language norm of ISO 8601.

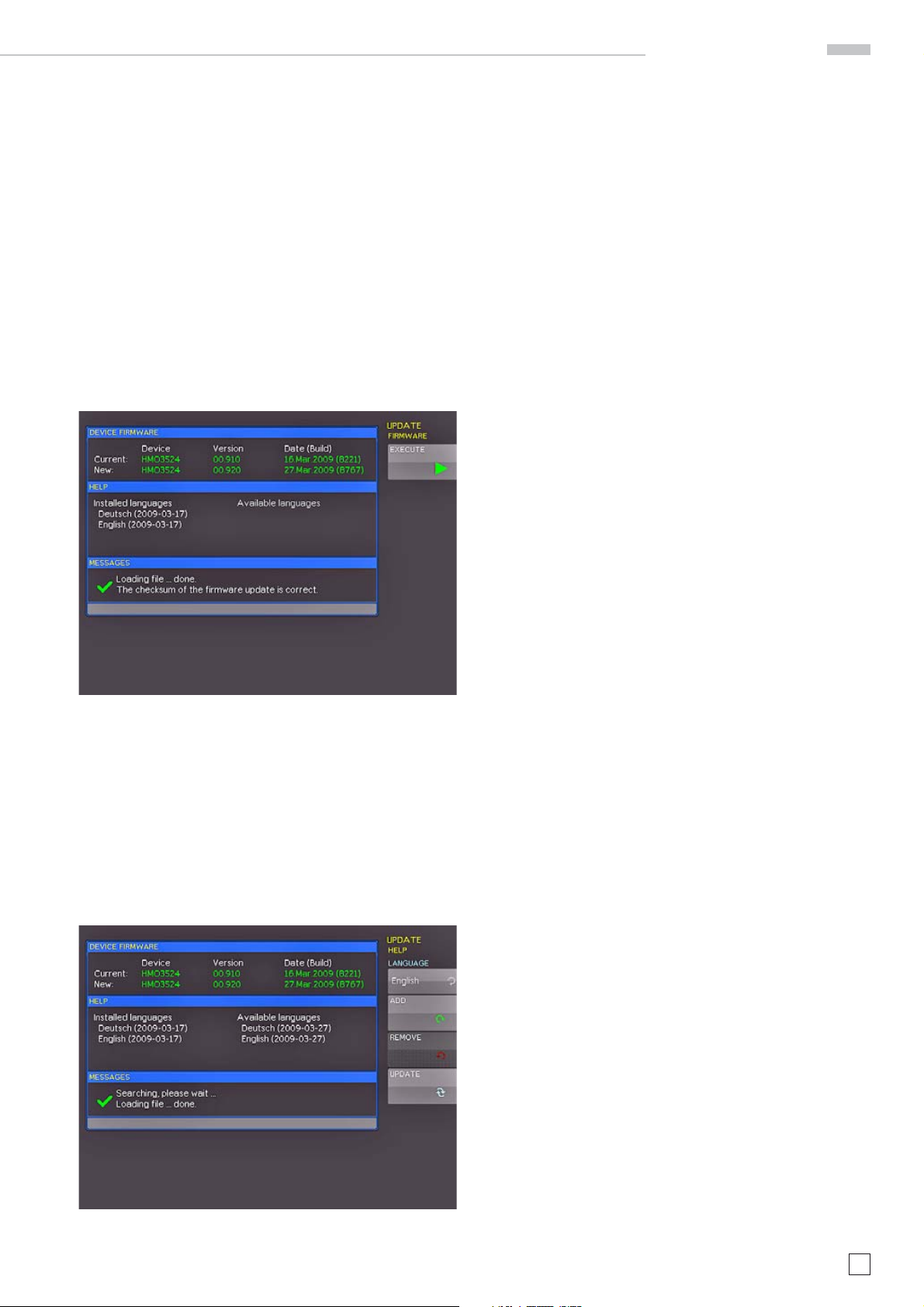

Fig: 2.11: Updating menu and information window

Now choose which to update: the fi rmware or the help function.

If both are to be updated it is recommended to fi rst update the

fi rmware. After you selected fi rmware updating by pushing

the appropriate key the respective date will be searched on

the stick, the information of the fi rmware to be updated from

the stick will be displayed below the line NEW. In case the new

fi rmware should be identical to the existing one, the number

of the version will be shown in red, otherwise it will be shown

in green; only then should you activate the updating by pushing

the soft key EXECUTE.

Fig. 2.12: Menu and information display of the help updating

Subject to change without notice

11

Page 12

A quick introduction

CURSOR/MENU ANALYZE GENERAL

CURSOR

SELECT

CURSOR

MODE

AUTO

MEASURE

SCROLL

BAR

CURSOR

MEASURE

FFT

QUICK

VIEW

DISPLAY

AUTO

SET

SETUP HELP

SAVE

RECALL

INTENS

PERSIST

FILE

PRINT

SCALE

TIME / DIV

X-POSITION

HORIZONTAL

TB/Z

M

E

M

O

R

Y

MENU

ACQUIRE

RUN

STOP

SET

CLR

3 A quick introduction

The following chapter is intended to introduce you to the most

important functions and settings of your new HAMEG HMO352x

oscilloscope in order to allow you to use the instrument immediately. The internal calibrator signal output is used as the

signal source, so you will not need any additional instruments

for the fi rst steps.

3.1. Setting up and turning the instrument on

Position the handle so the display will be inclined slightly upwards. (See chapter 1.2 for positioning of the handle.) Plug the

power cord into the rear panel connector. The instrument will

be turned on by pushing the red key On/Off

After a few seconds the display appears, and the oscilloscope

is ready for measurements. Now press the key AUTOSET

for at least 3 seconds.

9

10

3

4

A

7

6

12 13

1

on the front panel.

15

16

15

On the right hand side of the screen you will see a short menu of

channel 1, the soft keys allow you to select frequently used settings.

Press the top soft key once to change the input coupling to DC.

The actual settings are marked by underlying blue

fi elds, repeated pressing of the keys will alternate

between the settings.

Fig. 3.3: Screen display after changing to DC coupling

5

8

11 14

17

Fig. 3.1: Control panel HMO352x

3.2. Connection of a probe and signal capture

Take one of the probes HZ350 delivered with the instrument,

the ground cable and the probe tip.

The passive probes should be calibrated before

fi rst use. Please follow the instruction of the probe

manual. Please use the shortest ground connection

possible to the PROBE ADJUST output.

Connect the ground cable to the probe and the tip to the top of

the probe. Now connect the compensation box BNC connector

to the input connector of channel 1 and secure it by turning it

CW until it latches. Connect the ground cable to the left output

jack and hold the tip to the right jack of PROBE ADJUST. The

following display should be visible.

Fig. 3.2: Screen display after connection of the probe

12

Subject to change without notice

Now press the AUTOSET key 15 once shortly, after a few seconds

the oscilloscope will have automatically selected appropriate

vertical, horizontal time base and trigger settings. You will see

now a square wave signal.

Fig. 3.4: Screen display after Autosetup

3.3. Display of signal de-

tails

With the knob 43 you can change

the displayed time window: turning

it CCW will slow the time base. The

memory depth of 2 MB per channel

allows you to capture wide time windows with high resolution. Continue

to turn the knob CCW until you read

„TB:5ms“ in the top left corner. Now

press the ZOOM key

Fig. 3.5: Area of the control panel

containing the ZOOM knob

40

.

D

37

38

37

41

42

39

43

40

44

Page 13

A quick introduction

You see now a two-window display: the display will show in

the top area the complete captured signal, below an enlarged

portion. Use the time base knob to select the zoom factor and

the small knob for horizontal positioning.

Fig. 3.6: ZOOM function

By pressing the ZOOM key 40 again the zoom mode be will be

deactivated.

cursors will be switched off by pressing the CURSOR/MEASURE

key and the associated CURSORS OFF soft key.

3.5. Automatic measurements

In addition to cursor measurements the most important signal

parameters can be displayed. Your HAMEG oscilloscope offers

these possibilities:

– the defi nition of the display of 2 parameters which may come

from different sources

– a quick view of all important parameters of one source using

the QUICK VIEW function.

Please change the time base now to 100 μs/div. and press the

10

QUICK VIEW key.

.

3.4. Cursor measurements

After displaying the signal and its details we now proceed to

measuring it using the cursor functions. Press again shortly

AUTOSET

the cursor menu will open up, and you can select the kind of

cursor. Press the top soft key in order to open the appropriate

menu. Use the knob in the CURSOR/MENU area for the selection by turning it CCW until the V-marker is underlined, press

the CURSOR SELECT key or wait for some seconds in order

to accept the selection. Now two cursors will be displayed

along with the signal, and the measurement results in the

right bottom area of the screen. Select the active cursor with

the SELECT key

15

and then the CURSOR/MEASURE key 8. Now

3

and position it with the knob.

Fig. 3.8: Quick View parameter measurement

Here you see the most important parameters of a signal displayed:

– positive and negative – rise and fall times

peak voltages – mean voltage

In the right bottom corner of the screen 4 more parameters

are shown:

– rms value – peak-to-peak voltage

– frequency – period

Thus by simply pressing a key you see 9 parameters at a glance

which characterize the signal. This function applies always to

the acutal active channel.

You may also display two parameters of two different signals. In

order to achieve this deactivate the QUICK VIEW function by pressing the key again, then activate channel 2 by pressing the CH2 key.

Open the following menu by pressing AUTOMEASURE

11

:

Fig. 3.7: Cursor measurements

The cursor measurement results will be displayed in the left

bottom corner of the screen. In this case the „V cursor“ has selected the voltages at the two cursor positions, their difference,

and the time difference between the positions will be shown. The

Fig. 3.9:

AutoMeasure

Subject to change without notice

menu

13

Page 14

A quick introduction

The two parameters are displayed in the right bottom corner of

the screen. You may defi ne the parameter measurement using

this menu. After switching on MEASURE 1 and MEASURE 2 with

the appropriate softkey’s the parameter measurements are

displayed in the right bottom corner of the screen. If you press

the softkey beside TYPE you can choose the parameter you want

from the list using the general knob. This procedure is used in

all menus where choices are available. Please press the key

TYPE and choose risetime.

Fig. 3.12: Formula editor

In order to change the settings use the soft keys and the universal

knob . Here you can program and store the formulae most used.

As mentioned earlier these formulae can be quickly switched on

and off by pessing the MATH key

26

and using the appropriate

short soft menue.

Fig. 3.10: Selection of parameters

Now use soft key next to Source 2 in order to select this menu item

and thus channel 2. Now the rise time of channel 1 and the mean

value of channel 2 are shown. After the menu has been closed,

the parameters can be identifi ed by the colours of the respective

channels, (here yellow for channel 1 and blue for channel 2.)

3.7. Storing data

Your HMO352x can store 5 different kinds of data:

– Instrument settings

– Reference signals

– Signals

– Screen displays

– Sets of formulae.

Signals and screen displays can only be stored on USB sticks.

All other data can be stored either on a USB stick or in the

instrument’s non-volatile memories. In order to store data you

have to defi ne the kind of data and the destination. First attach

a USB stick to the front panel connector. Press SAVE/RECALL

12

in order to call the respective menu.

Fig. 3.11: Measuring the parameters of two sources

3.6. Mathematical functions

In addition to cursor and parameter measurements your HMO

can also apply mathematical functions to the signals. By pressing the MATH key a short menu will open which allows you to

select one or two predefi ned mathematical functions. A quick

setting of mathematical functions is possible by selecting the

menu item at the bottom. This mode allows you to select the

addition or subtraction of two activated sources. The formula

editor allows to predefi ne 5 possible mathematical functions,

it is called by pressing the MATH key (which lights up red) and

the MENU key

14

Subject to change without notice

21

.

Fig. 3.13: Save/Recall menu

Select the kind of data by pressing the respective soft key (in

this example SCREENSHOTS) in order to access the settings

menu.

Page 15

SCALE

VOLTS / DIV

Y-POSITION

CHANNEL CONTROL

FINE

6

2

-

K

3

0

4

-

1

1

5

0

-

1

.

0

MENU

CH1

CH2

CH3

POD1

MATH

REF

X Y

CH4

POD2

Vertical system

4 Vertical system

Fig. 3.14: Menu SCREENSHOTS

Please verify that the USB connector into which you plugged the

USB stick (front or rear) is written in the top soft menue (You

can change the destination by opening the respective menu if

you press the softkey next to STORAGE). You can now save a

Screenshot if you press the softkey next to SAVE using the predefi ned name written in the menu below FILE NAME. You may

name the destination memory with up to 8 characters; in order

to do this select the menu item FILE NAME and defi ne the name

by using the universal knob and the CURSOR SELECT key.

For the vertical settings there are

the knobs for the vertical position

and the sensitivity, an always visible short menu and an extended

menu.

B

22

18

23

19

24

25

20

26

Fig. 4.1: Front panel area with

vertical system controls

21

27

By pushing the respective key the channel will be selected for

which these controls will be activated, this will be indicated by

the key lighting up in the color of the channel. Additionally, the

channel number on the screen will be framed and displayed

lighter than the channels not activated. The appropriate short

menu is always visible, the extended menu will be shown upon

pushing the key MENU

21

.

Fig. 3.15: Defi ning a fi le name

After the soft key next to Accept was pressed the oscilloscope

will have stored the name and return to the settings menu. Here

you can now store the actual screen display by pressing the

STORE soft key. Alternatively, you can return to a lower menu

level (by pressing the lowest Menu OFF key) and select the

menu item key FILE/PRINT. In the following menu press the soft

menu key next to SCREENSHOTS: this will assign the function

Screen Shot to the key FILE/PRINT with the settings chosen.

This enables you to store a bit map fi le on your USB stick by just

pressing FILE/PRINT

17

at any time and in any menu.

Fig. 4.2: Short menu for the vertical settings

4.1. Coupling

The fi rst item to be selected is the input impedance: 1MΩ or

50 Ω.

Do not connect the 50 Ω inputs to effective voltage

higher than 5 volts!

The 50 Ω input impedance should only be selected if the signal source is 50 Ω, such as a generator with a 50 Ω output

where the termination within the scope is to be used. In all

other cases 1 MΩ is to be selected. Next DC or AC coupling

has to be selected: with DC coupling all components of the

signal will be displayed, with AC coupling the DC content will

be removed, the lower bandwidth is 2 Hz. Up to 250 V

be applied directly to the vertical inputs if 1 MΩ is selected.

Higher voltages can be measured with probes (up to 40 KVp).

For general applications the probes HZ350 (10:1, 10 MΩ II 12 pF,

max. 400 Vp) supplied with the instrument will be used. They

are specifi ed for the 1 MΩ input; the probe factor will be read

from the probe and factored in; they feature a 10 MΩ impedance

at low frequencies.

Subject to change without notice

rms

may

15

Page 16

Vertical system

The passive probes must be adjusted to the inputs

to which they are connected. See the probe manual

for the adjustment procedure. The PROBE ADJUST

output is only usable for 1:1 and 10:1 probes, for

100:1 or 1000:1 probes special external generators with a perfect step response have to be used.

Please use the shortest possible ground connection.

The coupling is selected in the short menu: by just pushing the

appropriate key the coupling is chosen, also the signal may be

inverted. The menu is valid for the activated channel as indicated

by the channel key light up. The channel number will be shown

in the top of the menu. By pushing the respective key of another

channel the menu will transfer to this channel.

4.2. Sensitivity, Y-Positioning, and Offset

The sensitivity of the analog inputs can be selected with the large

knob in the CHANNEL CONTROL section of the front panel in

1-2-5 steps from 1 mV/div to 5 V/div independent of the 50 Ω or

1 MΩ selection. The knob is associated with the channel selected

by pushing the respective key. The sensitivity can be changed

to continuous control by pushing the knob once. The smaller

one of the knobs is used for vertical positioning.

By pushing the MENU key the extended menu is called. On page

2 of this menu a DC offset can be added to the signal. In order

to switch this offset in the respective soft key must be pushed.

The settings window will be backlit in blue, and the activity

indicator next to the general knob will light up; the offset can

now be adjusted with the knob. The offset voltage will be added

to the signal at the vertical amplifi er input offsetting it by that

amount from the zero position. The possible amount of offset

depends on the Volts/div setting chosen. The offset function

being activated will be indicated by two channel markers on

the left of the display, also visible if the menu was closed. One

marker indicates the position, the other the offset (refer to Fig.

4.3). The offset is individually adjustable for each channel.

higher frequency interference. The fi lter is activated in the

short menu by pushing the respective soft key; the information

fi eld will be backlit in blue, BW will be displayed in the channel

information window.

Signal inversion is available in the short and the extended menus. If it is activated the information fi eld will be backlit in blue,

and there will be a bar above the channel number.

4.4. Probe attenuation selection

The HZ350 probes supplied with the instrument will be recognized by the instrument which automatically selects the

appropriate factor. If any other probe without automatic recognition of the attenuation ratio or just a cable is connected to the

instrument, the attenuation factor can be set manually in the

extended menu. This is possible for x 1, x 10, x 100 x 1000 or as

defi ned by the user from x 0.001 to x 1000.

Each analog channel may also be shifted in time by ±15 ns. This

adjustment is selected in the same menu and according to the

same method as the DC offset; it is used for compensating for

the different signal delays of voltage and current probes and

different cable lengths.

4.3. Bandwidth Limit and Signal Inversion

An analog 20 MHz low pass can be inserted in the signal path

in either the short or extended menu. This will eliminate all

Fig. 4.3: Vertical offset in the extended menu

16

Subject to change without notice

Page 17

Horizontal System (Time Base)

SCALE

TIME / DIV

X-POSITION

HORIZONTAL

TB/Z

M

E

M

O

R

Y

MENU

ACQUIRE

RUN

STOP

SET

CLR

5 Horizontal System (Time Base)

As well as time base settings, the

horizontal system comprises the

selection of the trigger position, the

zoom functions and the available

modes of signal capture. The knobs

are used for the adjustment of the

time base speed and the trigger position. The signal capture modes are

selected in the respective menus.

There is a key provided for activating

the zoom function.

Fig. 5.1: Control panel of the

horizontal system

D

37

38

37

39

40

41

42

43

44

5.1. Capturing modes RUN and STOP

The capturing modes can be selected with the key RUN/STOP.

In RUN mode signals will be continuously captured; depending

on the trigger conditions selected, and displayed, erasing the

previously captured ones. If it is desired to store and further

analyze a signal and to prevent it being overwritten, capture

must be stopped by pushing the RUN/STOP key. While in STOP

mode capture is disabled and the key will light up red.

5.2. Time base adjustments

The large knob in the HORIZONTAL section of the control panel

is used for the selection of the time base speed. The time base

speed is displayed in the upper left hand corner above the

graticule. (e.g. „TB:500 ns“) To the right there is the display of

the trigger time position with respect to the normal position.

The normal trigger position is in the center of the graticule

such that 50 % of the signal display is before and 50 % is after

this trigger position. The X POSITION knob allows continuous

adjustment of the X position. The available maximum values

depend on the time base setting. By pushing the key SET/CLR

the value will be reset to its reference position. The arrow keys

37 allow you to change the X position by a fi xed amount of

5 divisions in the respective direction. The key MENU opens

a menu which allows you to set the X position to its minimum

and maximum positions by just a key touch. In addition, there

is a submenu NUMER.INPUT which allows entr y of an arbitrary

X position.

– Average:

Functions only with repetitive signals. The universal knob in

the CURSOR/MENU section of the front panel is used to set

the number of signal periods for averaging, this is possible

in powers of 2 from 2 to 256. Please note: Averaging reduces

the bandwidth.

– Smoothing:

In this mode continuous averaging is used which allows in-

crease of the vertical resolution at the expense of bandwidth

reduction.

The second menu page is accessed by pushing the soft key

next to the menu „Page 1/2“, here, extended functions are

available:

– RANDOM SAMPL:

For very fast signals displayed with the fastest sweep speeds

it can be advantageous to switch the instrument to Random

Sampling mode; in this mode very many signal periods are

used to generate a high resolution picture, provided the

signal does not change its shape. This is equivalent to a

sampling rate of approx. 50 GSa/s. The oscilloscope will

not automatically enter this mode, however, it is possible to

select automatic switching to Random sampling >20 ns/div..

The mode can be disabled by pushing the soft key.

– PEAK VALUE:

At very slow sweep speeds fast signal details will not be

visible. By selecting this mode peaks will be detected. This

function can be switched on or off in the menu, it is also

possible to select automatic switching in.

All the preceding functions are normally off. The lowest item in

the soft menu allows you to select the preferred signal capturing

repetition rate, there are 3 options:

– MAX. REP RATE:

In this mode an optimum combination of sampling rate and

memory length used will be selected automatically such that

the signal capturing rate will be maximized.

– MAX. SAMPL. RATE:

In this mode the maximum possible sampling rate will be

used.

– AUTOMATIC:

This mode is the standard mode: the instrument always

selects the optimum combination of capturing and sampling

rates (full memory length used).

5.3. Capture modes

The capture modes are selected by pushing the key ACQUIRE,

this opens a display menu which offers the 5 basic modes of

capture:

– Normal:

In this mode the signals are captured and displayed.

– Roll:

This is a mode especially useful for very slow signals: the

signal „rolls“ slowly untriggered from right to left over the

screen (signals must be slower than 200 kHz).

– Envelope:

In this mode the signal will be displayed as in NORMAL,

but its minimum and maximum excursions will also be

displayed such that, with time, an envelope of the signal

will be displayed.

5.4. ZOOM function

The HMO352x oscilloscope features a memory depth of 2 MB

per channel, this allows you to record long complex signals

which can be analyzed in detail with the ZOOM function. Push

the ZOOM key to activate this function. The screen will be partitioned into two graticule areas: the top one displays the whole

time base window; the lower one displays the zoomed portion of

it. The zoomed portion will be indicated in the upper display by

two blue cursors. With multi channel displays all channels will

be zoomed by the same factor and on the same portion.

In Fig. 5.2 a signal was recorded for 12 ms, the zoom window

is shown with a time scale of 100 μs/div. The time base speed

display in the left upper corner is shown with a grey background,

the zoom time base display is shown in white. This means that

the large knob in the horizontal menu is now available for changing the zoom factor. This knob also features a push contact; if

Subject to change without notice

17

Page 18

Horizontal System (Time Base)

LEVEL

TRIGGER

TRIG’d SLOPE

AUTO

NORM

TYPE

SOURCE

FILTER

SLOPE

SINGLE

the knob is pushed, the time base display will change to white,

and the zoom time base display to grey: now the knob is available

for changing the time base setting. This allows you to change

time base settings without leaving the zoom mode. The position

of the zoomed portion can be moved with the small knob in the

horizontal section of the front panel over the whole captured

signal. If pushing the large knob as described above would infl uence the time base setting and not the zoom factor, the small

knob regains the function of shifting the trigger position so the

relationship of pre to post trigger record can be changed.

6 Trigger System

The trigger system of the HMO is

easy to handle by just observing

the HAMEG concept of instrument

operation.

Fig. 6.1: Front panel control area of

the trigger system

There are 4 keys destined for frequently used functions:

– TYPE: selects the type of trigger: SLOPE, PULSE, LOGIC,

VIDEO and the B-TRIGGER.

– SLOPE: selects the slope polarity.

– SOURCE: opens the menu for the selection of the trigger

source.

C

28

29

30

31

32

33

34

35

36

Fig. 5.2: ZOOM function

– FILTER: opens the menu for the selected trigger type in

order to select the exact trigger conditions.

Additional keys are provided for the selection of the trigger

modes: (AUTO. NORMAL, SINGLE).

6.1. Trigger modes Auto, Normal, Single

The basic trigger modes are directly selectable with the key

AUTO NORM. In AUTO mode the key will not be lit. If the key is

pushed it will light up red indicating NORMAL mode.

The oscilloscope always presents a signal in AUTO mode and

a signal will automatically yield a stable display if it fulfi lls the

trigger conditions.

In NORMAL mode the signal will be displayed if it fulfi lls the

trigger conditions, if it fails to do so the last stable triggered

display will remain on the screen.

If it is desired to record a signal which fulfi lls the trigger con-

18

Subject to change without notice

Fig. 6.2: Coupling modes with slope trigger

Page 19

Trigger System

ditions only once, the key SINGLE must be pushed, it will light

up white. This indicates that the single trigger mode is active,

the RUN/STOP key will blink. The next return of the signal will

cause a single capture, the oscilloscope then goes into the STOP

mode, indicated by the RUN/STOP key lighting up in red.

6.2. Trigger sources

Trigger sources are the 2 (with HMO3522) or 4 (with HMO3524)

analog channels and the external trigger input. If the optional

logic probe HO3508 with 8 or 16 logic channels is connected,

also those up to 16 digital channels can serve as trigger

sources.

6.3. Slope trigger

The simplest and most used trigger type is slope trigger, this

one is also selected in the AUTOSETUP function. Pushing the

AUTOSETUP key will hence change any previously selected

trigger type to slope trigger. For the selection of the trigger

type push the key TYPE in the trigger control section of the front

panel. A menu will open and offer the options. If the type SLOPE

was not selected (blue background) pushing the respective soft

key will change to slope. The SLOPE key is also used to step

through the options rising, falling, or both slopes. In the center

of the status line top center above the graticule the type selected

will be shown. If the key FILTER is pushed, the respective menu

will open and offer the available options.

Here the trigger signal coupling can be selected:

DC: The trigger signal is used with its dc content.

AC: The trigger signal is routed via a 5 Hz high pass fi lter.

HF: The trigger signal is routed via a 15 kHz high pass fi lter.

The trigger level is no longer adjustable. This mode

should only be used with very high frequency signals.

LOW PASS: The trigger signal is routed via a 5 kHz low pass

fi lter.

NOISE RED.: The trigger signal is routed via a 100 MHz low

pass fi lter removing higher frequency interference.

The coupling modes low pass and noise reduction can not be

simultaneously selected, but they can be used with DC or AC

coupling.

The slope trigger can be coupled with a so called „B Trigger“.

This option is available after pushing TYPE. This function allows

you to adjust the trigger such that fi rst condition „A“ must be met

and then another condition „B“ before the trigger will respond

(refer to Fig. 6.3).

E.g. it is possible to defi ne a source (channel) and a level of

120 mV on the rising slope of that signal and for the second

condition a level of 80 mV on the falling slope. Additionally, it is

possible to defi ne whether the B event should occur a time (min.

8 ns) or a number (min. 1) of times after the A event. The level or

time or the number of events can be entered numerically with

the universal knob or in a submenu. In order to do this fi rst select

the setting, then push the soft key next to NUMER. ENTRY. In

the window which will open, you can enter numbers and units

with the combination of universal knob, the CURSOR SELECT

key and the visible softmenu functions.

6.4. Pulse trigger

The pulse trigger allows you to trigger on fi nite pulse widths of

positive or negative pulses, or ranges thereof. Select the pulse

trigger by pushing the key TYPE and the respective soft key

next to PULSE. Further settings are available in the soft menu

after pushing FILTER.

There are 6 options:

ti ≠ t: The pulse width ti is unequal to the reference width t.

ti = t: The pulse width ti is equal to the reference width t.

ti < t: The pulse width ti is smaller than the reference width t.

ti > t: The pulse width ti is greater than the reference width t.

t

<ti<t2: The pulse width ti, is smaller than the reference width

1

t

and greater than the reference width t1.

2

not(t

<ti<t2): The pulse width ti, is greater than the reference

1

width t

and smaller than the reference width t1.

2

First select the desired option and then adjust the desired reference time. If you choose „ti ≠ t“ od „ti = t“, you can select the

reference time after pushing the soft key next to TIME by turning

the universal knob. If you choose the soft menu item DEVIATION

the universal knob is used to defi ne a tolerance interval. If you

chose ti < t or ti > t, you can only defi ne one limit. Both options

with two references (t

spective soft key and turning the universal knob. All these settings

can be combined with positive or negative pulses by selecting

the respective soft menu keys. With positive pulses the width is

defi ned from the rising to the falling slopes, with negative pulses

from the falling to the rising slopes. Triggering will then be on the

second slope of the pulse.

and t2) can be set due to pressing the re-

1

Fig. 6.3: The type B-Trigger

Fig. 6.4: Pulse trigger menu

Subject to change without notice

19

Page 20

Display of signals

6.5. Video trigger

The video trigger allows you to trigger on PAL or NTSC standard

video signals. Select this mode by pushing the key TYPE in the

trigger control section of the front panel. The source is again

selected after pushing the key SOURCE. In the menu which

opens after pushing the key FILTER all further settings may

be performed.

First select the video standard PAL or NTSC by pushing the

respective soft key. As usual the selection will be indicated by

a blue background in the menu. The second setting will apply

to the polarity of the sync pulses. Next either the mode LINE

or FRAME can be selected. If LINE was selected, the precise

number of a desired line can be selected with the universal knob

from the 8th to the 623rd; this will be activated by pushing the

soft key next to the line number. The two other menu items allow

fast selections: LINE MIN sets the trigger line to the minimum

value, ALL LINES will cause triggering on any line. If FRAME

was chosen, the lower menu items will allow to trigger on ALL,

only the ODD or only the EVEN half frames.

7 Display of signals

The following chapter describes the selection and display of signals from various sources and the available display modes.

7.1. Display settings

The HMO352x features a high quality TFT – VGA (640 x 480 pixel

resolution) display with LED backlighting. The basic settings will

become accessible in the menus which will open after pushing

the key DISPLAY in the GENERAL section of the front panel. If

the menu item SCROLL MODE is activated, a rolling bar will

appear to the right of the graticule; a virtual display window of

20 divisions will become available which can be shifted up and

down with the universal knob. A detailed description will follow

in the next chapter.

There are 3 more menu items on the fi rst page:

DOTS ONLY:

The respective soft menu key will toggle between ON and OFF. If

ON is activated, only the captured samples will be shown as dots.

If OFF is activated, interpolated points will be shown as well.

INVERSE LIGHT:

The respective soft menu key will toggle between ON and OFF.

If ON is activated, those display points will be shown darker

which appear most frequently. If OFF is activated, they will be

shown brighter.

Fig. 6.5: Video trigger menu

FALSE COLOURS:

The respective soft menu key will toggle between ON and OFF.

If ON is activated, the color of the display points are shown

from blue over magenta, red and yellow up to white with growing number of appearing points. If OFF is activated, the most

frequently appearing ones will be shown brighter and the rarer

ones darker.

GRATICULE:

If this menu item is selected, the submenu which opens up will

allow you to choose:

LINES:

The graticule is divided into horizontal and vertical divisions.

CENTER CROSS:

There will be just one center vertical line and one center horizontal line; the divisions will be marked by dots.

OFF: The screen will be empty.

INFO WINDOW:

If this menu item is selected, a submenu will open up which

allows change of the transparency of the info windows (e.g.

for showing changes of the offset) from 0 to 100 %. This is done

with the universal knob. The info windows of the POSITION

and the CURVE INTENSITIES may be switched on or off if their

respective menus are chosen.

20

Subject to change without notice

AUX. CURSORS:

Pushing the respective soft menu key will open a submenu

which allows you to switch the auxiliary cursors for the trigger

level, the trigger time and the channel cursors on or off.

7.2. Use of the virtual screen area

The HMO graticule has 8 vertical divisions but there is a virtu-

Page 21

Display of signals

al range of 20 divisions. These may be used by the 16 digital

channels D0 to D15, the math functions and the references.

The analog channels can only use up to ±5 divisions from the

center.

Fig. 7.1: Drawing of the virtual screen area and an example

The picture above explains the function of the virtual screen. The

visible 8 divisions are shown in grey; this is the area available

for analog signals. To the right of the graticule there is a small

bar which indicates the position of the visible 8 divisions within