Page 1

DIGITAL Multimeter

HMC8012

User Manual

Benutzerhandbuch / User ManualBenutzerhandbuch / User Manual

Benutzerhandbuch / User Manual

Page 2

35

HMC8012 Brief Introduction

3 HMC8012 Brief

Introduction

The following chapter is an introduction to the most important HMC8012 multimeter features and settings allowing

you to use the measurement instrument promptly. A more

detailed description of basic operating steps is given in the

manual.

3.1 Setting Parameters

Each function and operating mode of the multimeter can

be selected with the keys on the front panel of the instrument. Use the respective function keys to select basic functions such as voltage, current or resistance measurement.

Advanced functions are managed by use of soft menu keys

to the right of the display. Pressing the SHIFT key activates

the numeric keypad.

3.2 Measuring a Direct/Alternating Voltage

An example for a basic measurement that can be performed with a multimeter is the measurement of a DC

voltage, for instance. The following measurement example

shows the individual steps to perform this measurement

effectively with the HMC8012. A DC power supply unit,

e.g. the HMP2030, is used.

To measure a DC voltage, you can connect a power supply

unit to the HMC8012 multimeter via silicon test leads, for

instance. Use the COM and V connectors on the bottom

right. Once the DC V key on the front panel of the instrument is used, the DC voltage value will be shown on the

multimeter display.

The measurement of alternating voltage applies the same

principle. In contrast to the DC voltage measurement, the

AC voltage measurement requires the use of the AC V key.

Please note that for an AC measurement, RMS values will

be shown on the display.

3.3 Automatic / Manual Selection of the Measurement Range

You can use the soft menu keys Range Up or Range Down

to switch the measurement range. Pressing Range Down

will switch to the next lower measurement range, pressing

Range Up will switch to the next higher measurement

range. The automatic selection of the measurement range

(Auto Range) is deactivated.

If the function Auto Range is activated, the measurement

instrument automatically selects the optimal measurement

range. If the selected measurement value is too great while

the manual selection of the measurement range is activated, the message OVER RANGE appears on the display.

3.4 Displaying Several Measurement Values

If you would like to view a second measurement value on

the display, select the soft menu 2nd Function and select

a second measurement value via knob. In the current example, the second measurement value could be AC V. The

second measurement value (2nd) will be displayed in blue

above the display of the main measurement value (Main). If

you select the option None via knob, the second measurement value will be deactivated.

3.5 Resistance Measurement with Zero Point

For the resistance measurement, connect measurement

cables with clamps to the respective connectors on the

front panel of the instrument. A two-wire measurement

only requires the COM and V connectors. A four-wire

measurement also requires the LO/HI connectors (SENSE).

After connecting the cables and connecting with a resistance, press the Ω key. The resistance value will show on

the display. During a resistance measurement, the cable

resistance (cable offset) requires particular attention. Especially for small resistances which may be close to the cable

offset it is recommended to zero the measurement section.

A zero measurement is also called a relative measurement,

i.e. each measurement value indicates the difference between a saved zero value and the input signal.

In this case it is necessary to short circuit the measurement

cables and then press the NULL key. This triggers the offset

correction of the entire measurement section. This value

will be shown on the display below the main measurement

value. The line resistance of the measurement cable, contact resistances and thermoelectric voltages between different metals have been intentionally eliminated by this offset

correction. The compensation values will not be stored

after the HMC8012 has been switched off and have to be

redetermined.

3.6 Statistic / Measuring Limits

In addition to the basic functions of the multimeter, mathematical functions are also available. These can be accessed by pressing the MEAS key on the front panel of the

instrument.

The soft menu Stats allows the user to activate individual

statistic functions (Min/Max, Mean, StdDev, Pk to Pk,

Count). Use the soft menu key STATS to activate (On) or

deactivate (Off) statistic values. The statistic functions will

be displayed below the main measurement value. You can

use the soft menu key #MEAS. to determine how many

measurement values are to be included in the statistic. You

can select the number of measurement values via knob

or via numeric keypad. If #MEAS is set to „0“, the statistic

will be performed on all measurement values. If #MEAS is

set to „7“, for instance, the statistic will be performed on 7

measurement values. The soft menu key Reset resets the

statistic.

Page 3

36

HMC8012 Brief Introduction

4 Setting Parame-

ters

Each function and operating mode of the multimeter

can be selected with the keys on the front panel of the

instrument. Use the respective function key to select the

measurement function. An active measurement function is

highlighted by an illuminated white LED. Subsequent settings refer to the selected measurement function.

4.1 Soft Menu Keys

The soft menu keys on the upper right of the screen allow

you to use the shown menu eld in the display. Use the

numeric keypad or the knob to set the respective selec-

ted parameter. If a menu eld has been selected via soft

menu keys, this function will be marked in yellow and will

be activated to set the parameter and function. If a spe-

cic setting makes an instrument setting unavailable, the

respective soft menu key will be deactivated and the label

will be displayed in gray.

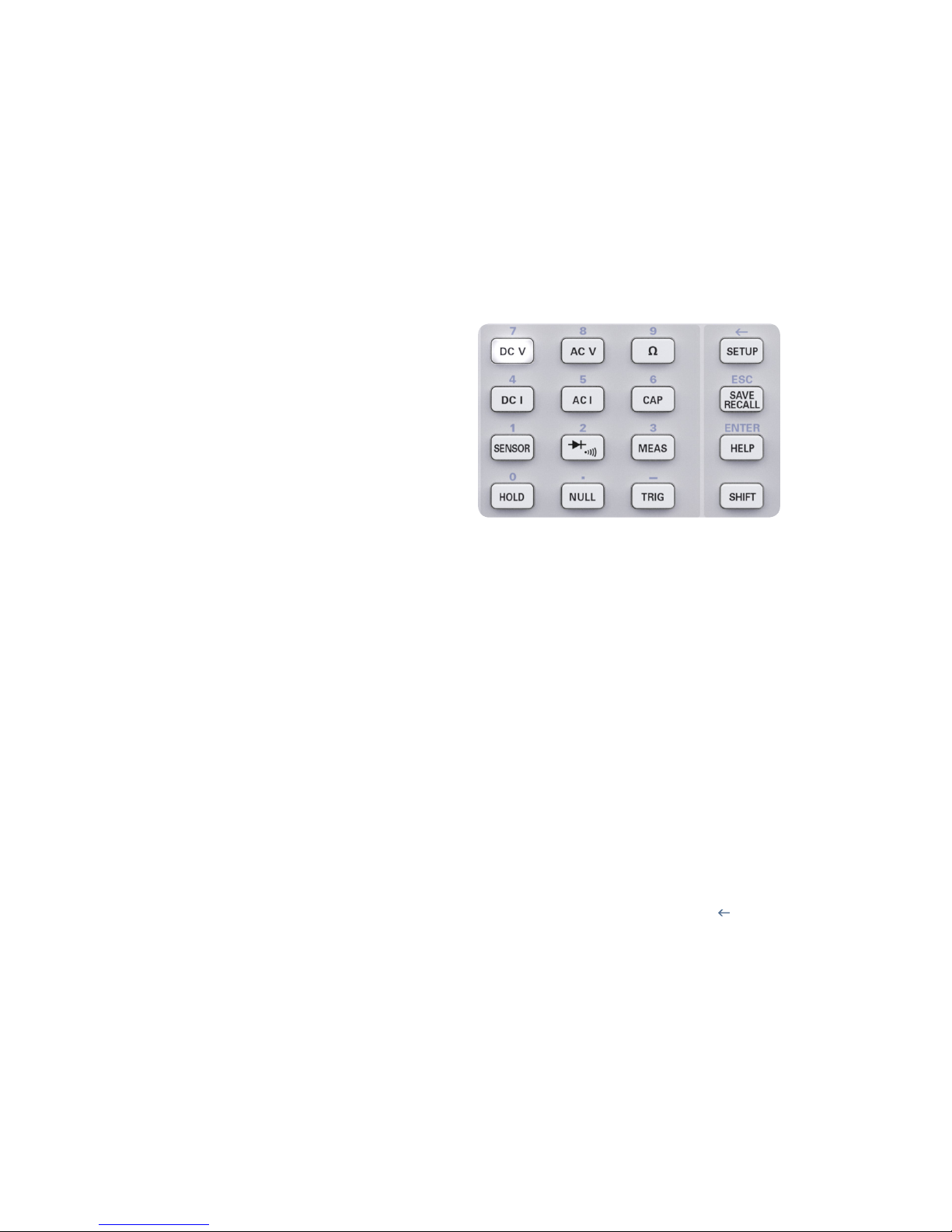

4.2 Numeric Keypad

The easiest way to enter a value precisely and promptly is

to use the numeric keypad. Pressing the SHIFT key activates the numeric keypad. When entering a numeric value

via keypad, you can accept the entry by pressing a soft

menu key with the corresponding unit. Before conrming

the parameter unit, you can delete any value that has been

entered incorrectly by pressing the key

(SHIFT + SETUP

key). The ESC key allows you to cancel the operation to enter parameters. This will close the editing window.

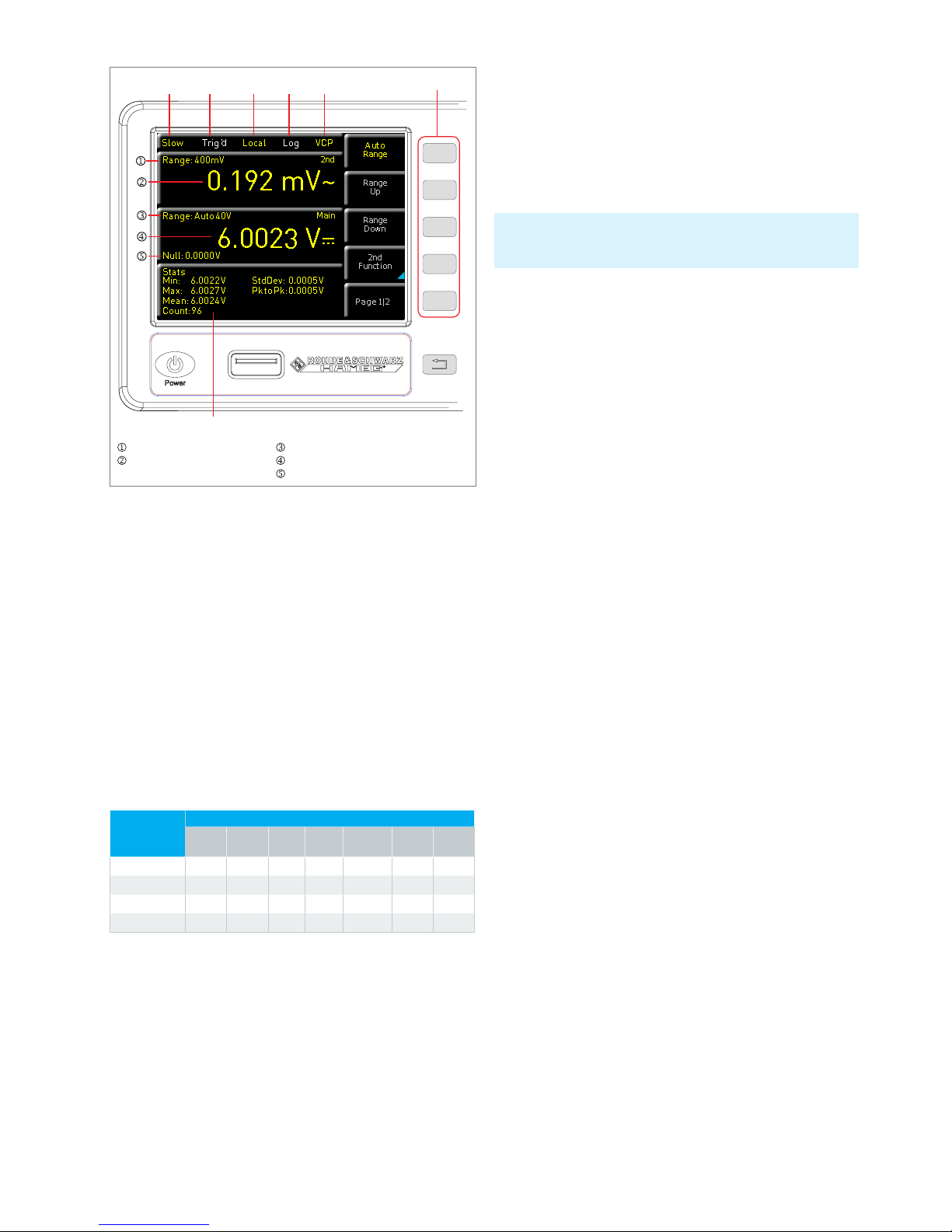

4.3 Display of Measurement Values

The HMC8012 multimeter includes a brilliant TFT color

display with 5-3/4 digits. The display can show up to 3

measurement values simultaneously. The display of the

third measurement value is intended for the display of

mathematical functions, such as statistic or limit display.

The signal displays indicate the measurement units and the

operating environment of the multimeter. Figure 4.2 shows

an overview of the screen layout.

Fig. 4.1: Numeric keypad and editing keys

The soft menu Limit allows you to select the High Limit

and Low Limit for a measurement. Based on these limits,

a test can be evaluated as passed or not passed. The

limits can be activated (On) or deactivated (Off) via soft

menu key LIMITS. The limits will be displayed below the

main measurement value. If a value is exceeded or falls

below the set limit during a test, it will be reected by the

color display of the measurement value. A measurement

value that exceeds or falls below a limit is marked in red;

a measurement value within a limit is marked in green. In

addition, you can activate (On) or deactivate (Off) an error

tone (soft menu key Beeper) which will sound when the

value exceeds or falls below the set limits.

3.7 Storing Data

The HMC8012 multimeter can store two different types of

data:

❙ Instrument settings

❙ Screen displays

Out of these data types, screen displays can only be stored

on a USB stick. Instrument settings can be stored on a

USB stick or internally in the instrument to non-volatile

storage media.

Press the key SAVE/RECALL to open the store and load

menu. The soft menu Device Settings allows you to load

or store instrument settings. Select the submenu Save to

store the current instrument settings. Select the storage

location and the le name, then press the soft menu key

Save to save the current instrument settings. This le may

be reloaded at a later time.

The menu item Default Settings in the main menu also allows you to load the factory default settings.

Page 4

37

Setting Parameters

4.4 Displaying Several Measurement Values

The HMC8012 offers the option (depending on the selected

measurement function) to simultaneously show multiple

measurement values on the display. The main measurement value is labeled as „Main“. A second measurement

value can be activated via soft menu key 2nd Function

(depending on the measurement function). If you press the

soft menu key 2nd Function, you can use the soft menu

key SELECT and the knob to select a second measurement

value. The second measurement value (2nd) will be displayed in blue above the display of the main measurement

value (Main). If you select the option None via knob, the

second measurement value will be deactivated.

4.5 Automatic / Manual Selection of the Measurement Range

Depending on the selected measurement value, you can

change the measurement range via soft menu keys Range

Up or Range Down. Pressing Range Down will switch to

the next lower measurement range, pressing Range Up

will switch to the next higher measurement range. This will

deactivate the automatic selection of the measurement

range (Auto Range).

Main (main

measurement value)

2nd (secondary measurement value)

DC V AC V DC I AC I Fre-

quency

dB dBm

DC V

− ● ● − − ● ●

AC V

● − − − ● ● ●

DC I

● − − ● − ● ●

AC I

− − ● − ● ● ●

Tab. 4.1: Displaying Several Measurement Values

If the function Auto Range is activated, the measurement

instrument automatically selects the optimal measurement

range. Activating the automatic mode enables you to

switch to a higher measurement range when 90% of the

respective range end value have been reached. Operation

will switch to the lower range if the value falls below 10%

of the range end value.

If the set measurement value is too large (whether the measurement range is selected manually or automatically), the display

shows the message OVER RANGE.

Description of the Operating Elements

soft menu keys

Display for math. function (e.g.: statistic)

Range (2nd)

Second measurement value

(2nd Function)

Range (Main)

Main measurement value

Zero measurement (Null)

ADC

Rate Trigger

Local/

Remote

Log-

ging

Inter-

face

Fig. 4.2: Screen layout

Page 5

38

Instrument Functions

5 Instrument

Functions

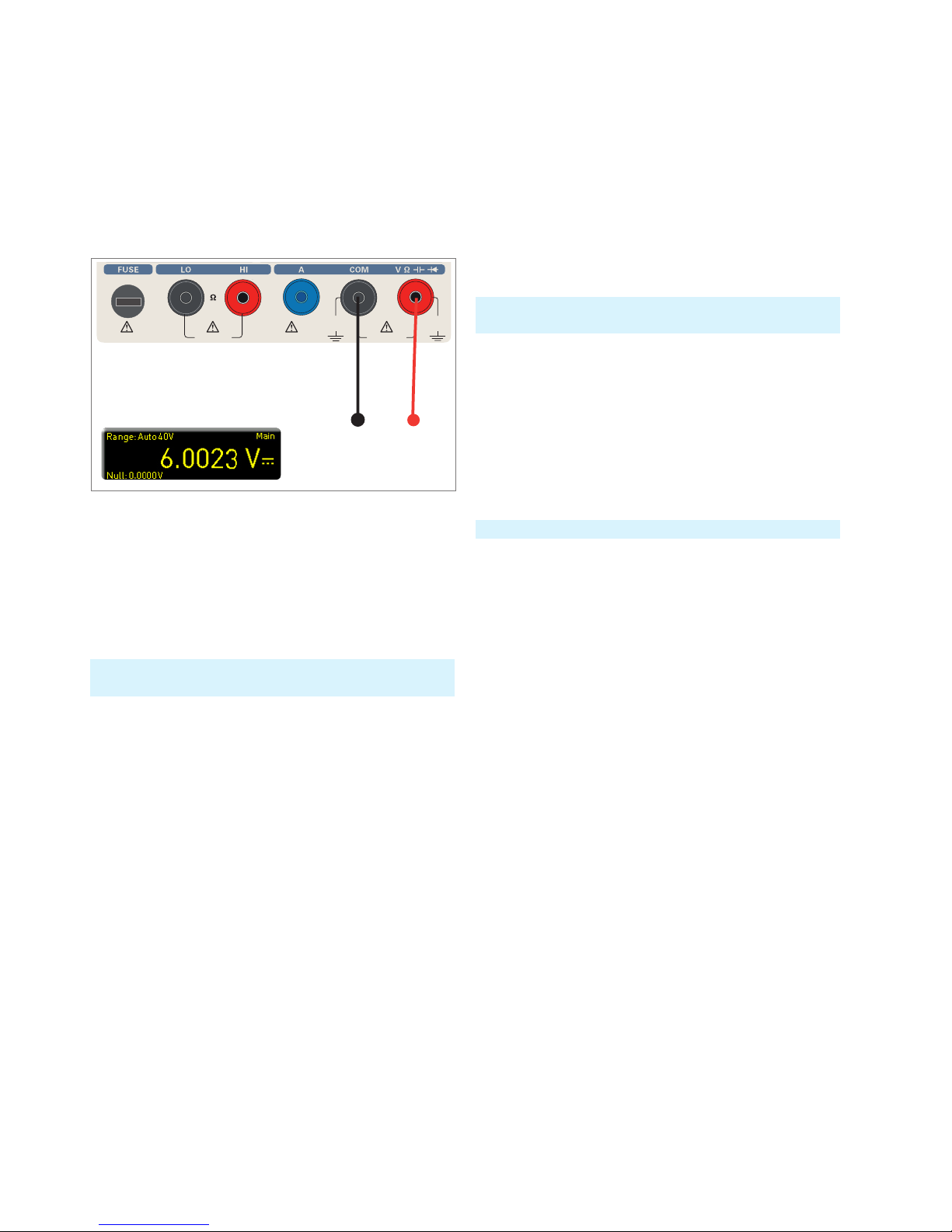

5.1 Measuring a DC / AC Voltage

A basic measurement that can be performed with a multimeter is the measurement of a DC or an AC voltage.

To measure a DC or AC voltage, you can connect a voltage

source to the HMC8012 multimeter via silicon test leads,

for instance. Use the COM and V connectors on the bottom right. Once the DC V / AC V key on the front panel of

the instrument is used, the DC or AC voltage value will be

shown on the multimeter display.

In addition, it is possible to show a second function (2nd)

on the display. The soft menu key 2nd Function and the

knob allow you to select AC V, DC I, dB or dBm. The selected function is shown above the main measurement

value display. The menu display changes depending on the

selected second function. The soft menu key Remove 2nd

allows you to hide the second function from the display.

You can select the option Slow, Medium or Fast via soft

menu key AC Filter and knob. This applies to a low pass

lter. A lower setting (Slow) ensures more stable measurement values. However, the measurement is slow and signal

elements of higher frequency will be attenuated. Depending on the input frequency, this function will smoothen

the displayed value. The setting Medium is saved as default

value. Select the setting Slow for an input frequency of

<50kHz, and select Fast for a setting of >1kHz.

To compensate for the line resistance of measurement

cables, it is necessary to short circuit the measurement

cables and press the NULL key. This triggers the offset

correction of the entire measurement section. This value

will be shown next to the soft menu key NULL and on

the display below the main measurement value. The line

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

- +

voltage source

(AC/DC)

Fig. 5.1: Measuring a DC or AC voltage

Please note that for an AC measurement, RMS values will be

shown on the display.

resistance of the measurement cable, contact resistances

and thermoelectric voltages between different metals have

been intentionally eliminated by this offset correction. The

compensation values will not be stored after the HMC8012

has been switched off and have to be redetermined. In

addition, you may also enter the NULL value numerically or

via knob.

The soft menu key ADC Rate and the knob allow you to

set the display refresh rate to Slow (5 measurements per

second), MEDIUM (10 measurements per second) or FAST

(200 measurements per second).

The function Auto Zero on page 2|2 of the DC V main

menu may be activated (ON) or deactivated (OFF). If this

function is activated, the instrument automatically compensates for the connected measurement cables and deducts

this offset from the measurement result (automatic zero

measurement).

The input impedance can be set via soft menu key Input

Imp. to 10 MOhm or >10 GOhm.

If the second function (2nd Function) is activated (dB or

dBm), you have the option to dene a reference value. For

the function dB, the reference value is the voltage (Ref.

Value). You can set the reference value numerically or via

knob. If a reference value is dened, you can reset the previously selected reference value via soft menu key Null.

For the function dBm, the reference value is 1mW and is

often used for RF signal measurements. If the dBm function is activated, the multimeter performs a measurement

and calculates the power supplied to a comparator resistance. The reference value (Ref. Value) in this case is 50,

75 or 600 Ω. In addition, you can set a user-dened value

(User) either numerically or via knob.

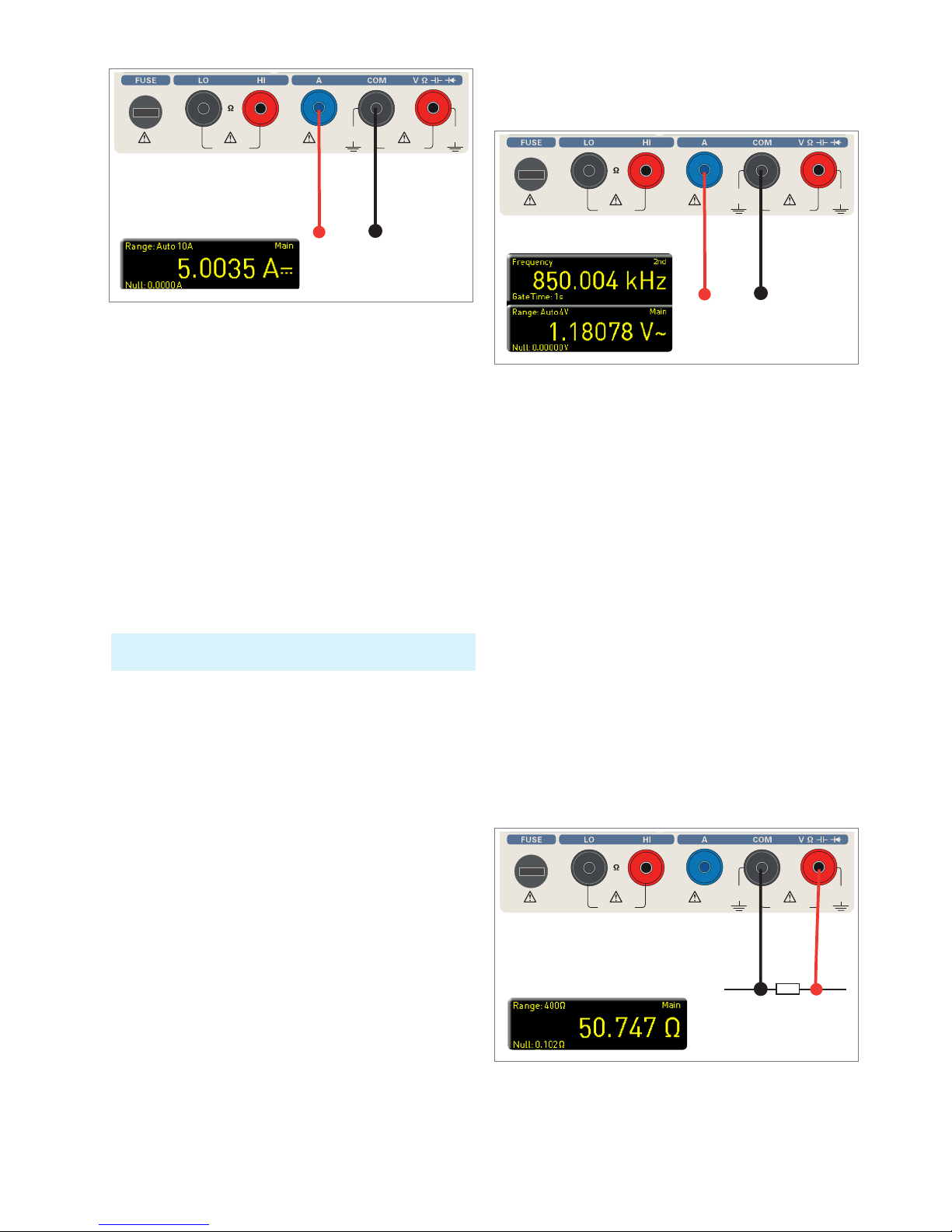

5.2 Measuring a DC / AC Current

To measure a DC or AC current, you can connect a power

supply unit to the HMC8012 multimeter via silicon test

leads, for instance. Use the COM and A connectors on

the bottom. Once the DC I / AC I key on the front panel of

the instrument is used, the DC or AC current value will be

shown on the multimeter display.

In addition, it is possible to show a second function (2nd)

on the display. The soft menu key 2nd Function and the

knob allow you to select AC I, DC V, dB or dBm. The selected function is shown above the main measurement

value display. The menu display changes depending on the

selected second function. The soft menu key Remove 2nd

allows you to hide the second function from the display.

To compensate for the line resistance of measurement

cables, it is necessary to short circuit the measurement

cables and press the NULL key. This triggers the offset

The maximum accuracy in measurements is achieved when using

the setting Slow (ADC Rate).

The impedance setting is dependent on the measurement range

Page 6

39

Instrument Functions

correction of the entire measurement section. This value

will be shown next to the soft menu key NULL and on

the display below the main measurement value. The line

resistance of the measurement cable, contact resistances

and thermoelectric voltages between different metals have

been intentionally eliminated by this offset correction. The

compensation values will not be stored after the HMC8012

has been switched off and have to be redetermined. In

addition, you may also enter the NULL value numerically or

via knob.

The soft menu key ADC Rate and the knob allow you to set

the display refresh rate to Slow (5 measurements per second), Medium (10 measurements per second) or Fast (200

measurements per second).

You can select the option Slow, Medium or Fast via soft

menu key AC Filter (main function AC I) and knob. This

applies to a low pass lter. A lower setting (Slow) ensures

more stable measurement values. However, the measurement is slow and signal elements of higher frequency will

be attenuated. Depending on the input frequency, this

function will smoothen the displayed value. The setting

Medium is saved as default value. Select the setting Slow

for an input frequency of

<50 kHz, and select Fast for a set-

ting of

>1 kHz.

If the second function (2nd Function) is activated (dB or

dBm), you have the option to dene a reference value. For

the function dB, the reference value is the current (Ref.

Value). You can set the reference value numerically or via

knob. If a reference value is dened, you can reset the previously selected reference value via soft menu key „Null.

For the function dBm, the reference value is 1mW and is

often used for RF signal measurements. If the dBm function is activated, the multimeter performs a measurement

and calculates the power supplied to a comparator resistance. The reference value (Ref. Value) in this case is 50,

75 or 600 Ω. In addition, you can set a user-dened value

(User) either numerically or via knob.

The maximum accuracy in measurements is achieved when using

the setting „Slow (ADC Rate).

5.3 Measuring Frequency

The frequency display can be added in the main function

AC V and AC I as the second measurement function (2nd).

The measurement time can be set via soft menu key Gate

Time. The measurement time can vary between 10ms,

100 ms and 1s and is shown below the frequency information on the display. The display refresh rate is dependent

on the selected ADC rate in the AC V or AC I mode. For

the setting SLOW, the measurement rate of the frequency

measurement is 1 measurement per second, for MEDIUM

it is 10 measurements per second and for FAST it is 100

measurements per second.

5.4 Measuring Resistance

For the resistance measurement, connect measurement

cables with clamps to the respective connectors on the

front panel of the instrument. A two-wire measurement

only requires the COM and V connectors. A four-wire

measurement also requires the LO/HI connectors (SENSE).

After connecting the cables and connecting with a resistance, press the Ω key. The resistance value will show on

the display. During a resistance measurement, the cable

resistance (cable offset) requires particular attention. Especially for small resistances which may be close to the cable

offset it is recommended to zero the measurement section.

A zero measurement is also called a relative measurement,

i.e. each measurement value indicates the difference between a saved zero value and the input signal.

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

+ -

frequency source

Fig. 5.3: Measuring frequency

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

Fig. 5.4: Measuring resistance (2-wire)

- +

resistance 2-wire

(Ω)

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

+ -

current source

(AC/DC)

Fig. 5.2: Measuring a DC or AC current

Page 7

40

Instrument Functions

In this case it is necessary to short circuit the measurement

cables and then press the NULL key. This triggers the offset

correction of the entire measurement section. This value

will be shown on the display below the main measurement

value. The line resistance of the measurement cable, contact resistances and thermoelectric voltages between different metals have been intentionally eliminated by this offset

correction. The compensation values will not be stored

after the HMC8012 has been switched off and have to be

redetermined. In addition, you may also enter the NULL

value numerically or via knob.

On page 2|2 of the Ω main menu, you can use the soft

menu key Mode to distinguish between 2-wire operation

(2w) and 4-wire operation (4w - (4w - connect SENSE

cables).

The soft menu key ADC Rate and the knob allow you to

set the display refresh rate for the 2-wire operation (2w) to

Slow (5 measurements per second), Medium (10 measurements per second) or „Fast (50 measurements per second).

For the 4-wire operation (4w), you can set the display refresh rate to Slow (5 measurements per second), Medium

(10 measurements per second) or Fast (25 measurements

per second).

5.5 Measuring a Capacity

To measure a capacity, you can connect a capacitor with

the HMC8012 multimeter via silicon measurement cables

and clamp-type test probes, for instance. Use the COM

and V connectors on the bottom. Once the CAP key on the

front panel of the instrument is used, the capacity value

will be shown on the multimeter display.

To compensate for the line resistance of measurement

cables, it is necessary to short circuit the measurement

cables and press the NULL key. This triggers the offset

correction of the entire measurement section. This value

will be shown next to the soft menu key NULL and on

the display below the main measurement value. The line

resistance of the measurement cable, contact resistances

The maximum accuracy in measurements is achieved when using

the setting „Slow (ADC Rate).

and thermoelectric voltages between different metals have

been intentionally eliminated by this offset correction. The

compensation values will not be stored after the HMC8012

has been switched off and have to be redetermined. In

addition, you may also enter the NULL value numerically or

via knob.

5.6 Measuring Sensors (PT100 / PT500 / PT1000)

Sensor measurements can be performed with various temperature probes. The temperature probes HZ812 (2w) or

HZ887 (4w) are available as optional accessories. Depending on the type used, you can select „2w“ or „4w“ with

the respective soft menu key. The soft menu key PT Type

allows you to select PT100, PT500 or PT1000 as probe

type. The measurement value may be displayed in °C, K or

°F (Unit).

To perform precise measurements, it is necessary to compensate for the measurement section with the NULL function, especially for the two-wire measurement. PT sensors

include a lead resistance which is typically indicated on

the data sheet. For an optimally adjusted measurement

section, it is necessary to know the exact lead resistance.

The measurement rate in this case is 10 measurements per

second.

5.7 Continuity / Diode Testing

Pressing the key

opens the main menu for the diode

and continuity testing If the soft menu key is marked in

Fig. 5.7: 2-wire sensor measurement (temperature)

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

- +

temperature (2-wire)

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

Fig. 5.5: Measuring resistance (4-wire)

- +

resistance 4-wire

(Ω)

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

Fig. 5.6: Measuring the capacity

- +

capacity

Page 8

41

Instrument Functions

yellow, the respective function „Diode or Continuity is

activated.

For both functions, you can dene / set a so-called thres-

hold via soft menu key „Threshold. In addition, the soft

menu key Beep allows you to activate (On) or deactivate

(Off) an acoustic signal to be used in case of a threshold

violation. For the diode testing, the measurement rate is 10

measurements and for the continuity testing 200 measurements per second.

5.8 Measuring with HOLD Function

The HOLD function allows you to maintain the current

measurement results on the display. If you press the HOLD

key (white LED is illuminated), the measurement result(s)

will be frozen on the display. Press the HOLD key again

(LED is off) to deactivate the function.

5.9 Trigger Function

Pressing and holding the TRIG key or pressing the SETUP

key (submenu TRIGGER) opens the trigger menu. The

soft menu key Mode and the knob allow you to select the

respective trigger mode. There are three different options

to trigger a measurement:

Manual:

If the trigger mode „Manual“ is selected, press the key

TRIG to start recording measurement values. The TRIG key

blinks while measurement values are captured. Press the

TRIG key again to stop the capture of measurement values.

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

Fig. 5.9: Diode testing

- +

Diode

The TRIG key will stop blinking. The label „Armed“ indicates that the instrument is waiting for a trigger (waiting for

the TRIG key to be pressed again) and is consequently not

triggering at the moment.

Single:

In the trigger mode Single, the soft menu key „Interval“

and the knob allow you to select a measurement interval.

The measurement interval describes the time between the

recorded measurements. For instance, if the function Interval is set to 2, all 2s will be included in the measurements.

In addition, the soft menu key Count and the knob enable

you to set the number of measurement values to be captured. Pressing the TRIG key starts the capture of measurement values. For instance, if you set an Interval of 2s and a

Count of 5, 5 measurement values will be captured in intervals of 2s. During the capture of the measurement values,

the LED for the TRIG key is blinking and the label „Trig“ is

displayed on the upper right of the screen. Alternatively, the

label „Armed“ indicates that the instrument is waiting for a

trigger (e.g. waiting for the TRIG key to be pressed again)

and is consequently not triggering at the moment.

Auto (Default Setting):

In the trigger mode Auto, the instrument does not wait for

a specic event. Instead, it performs permanent measurements. The number of measurements is dependent on the

selected ADC rate. In addition, you may dene a threshold.

The measurement value display changes depending on

the selected treshold settings. If the function Continue is

activated, the display runs continuously. For the function

Above/Below Threshold a measurement value is not captured until the current value falls below or exceeds the set

treshold. If the instrument triggers permanently, the label

„Trig“ will be displayed on the upper right of the screen.

Fig. 5.10: Trigger menu Auto

Depending on which settings for the time interval and the number

of measurement values to be captured have been conrmed in the

trigger menu, these settings will be synchronized with the logging

menu (see chapter 6: Mathematical Functions).

ESC

ENTER

89

456

123

0

.

--

7

SETUP

SAVE

RECALL

HELP

SHIFT

DC V AC V

CAP

MEAS

AC I

DC I

SENSOR

HOLD

TRIGNULL

max.

600 V

pk

F10H250V

max.

10 A

CAT II

600 V

max. 200 V

pk

max. 1000 V

pk

max.

1000 V

pk

Fused

SENSE

4 W

Fig. 5.8: 4-wire sensor measurement (temperature)

- +

temperature (2-wire)

Page 9

42

Mathematical Functions

6 Mathematical

Functions

In addition to the basic functions of the multimeter,

mathematical functions are also available.

These can be accessed by pressing the MEAS

key on the front panel of the instrument.

Tab. 6.1 describes which mathematical functions can be

used with which measurement functions.

6.1 Statistic

The soft menu Stats allows the user to activate the statistic

functions (Min/Max, Mean, StdDev, Pk to Pk, Count). Use

the soft menu key STATS to activate (On) or deactivate

(Off) statistic values. The statistic functions will be displayed below the main measurement value (Main). You can

use the soft menu key #MEAS. to determine how many

measurement values are to be included in the statistic. You

can select the number of measurement values via knob

or via numeric keypad (SHIFT key). The statistic may be

performed on a maximum of 50,000 measurement values.

If #MEAS is set to „0“, the statistic will be performed on all

measurement values. If #MEAS is set to „7“, for instance,

the statistic will be performed on 7 measurement values.

The soft menu key RESET resets the statistic. Additionally,

the soft menu AUTO REST is available. If the Auto Reset

function is activated (ON), the statistic measurement points

(Count) will be not reset in Auto Range mode.

6.2 Measuring Limits (Limits)

The soft menu LIMIT allows you to select the HIGH LIMIT

and LOW LIMIT for a measurement. Based on these li-

If the instrument shows OVER RANGE on the display, the statistic

measurement values can be not captured. This values will be displayed as INVALID COUNT in red.

mits, a test can be evaluated as passed or not passed. The

limits can be activated (ON) or deactivated (OFF) via soft

menu key LIMITS. The limits will be displayed below the

main measurement value (Main). If a value falls below or

exceeds the limits during a test, it will be reected by the

color display of the measurement value. If the limits are observed, the measurement value is displayed in green. If the

value falls below or exceeds the set limits, the limit value

will be displayed in red. In addition, you can activate (ON)

or deactivate (OFF) an error tone (soft menu key BEEPER)

which will sound when the value exceeds or falls below the

set limits.

6.3 Recording Data (Logging)

The soft menu LOGGING allows you to start the capture

of measurement values and to select various settings. Use

the soft menu key LOGGING to activate (ON) or deactivate

(Off) the capture and the storage of measurement values.

Use the soft menu Storage to select the storage location

(Internal/USB stick), the le name (File Name) and the le

format (CSV/TXT). The soft menu key Interval and the knob

allow you to select a measurement interval. The measurement interval describes the time between the recorded

measurements. For instance, if the function Interval is set

to 2, all 2s will be included in the measurements.

The soft menu MODE offers three different logging modes.

Select the function U if you intend to perform an innite

data capture. The limiting factor in this context is the size

of the internal storage (maximum of 50,000 measurement

points) or of the connected USB stick. If the function N is

activated, the soft menu key Count and the knob enable

you to set the number of measurement values to be captured. For instance, if you set an interval of 2 s and a count of

5, 5 measurement values will be captured in intervals of 2 s.

If the function T is activated, the soft menu key TIME and

the knob enable you to set the duration of the capture of

the measurement values.

Depending on which settings for the time interval and the number

of measurement values to be captured have been conrmed in the

logging menu, these settings will be synchronized with the trigger

menu (see chapter 5: Instrument Functions).

Fig. 6.1: Logging menu setting

Measurement

function

Mathematic

functions

Stats Limits HOLD NULL

DC V

● ● ● ●

AC V

● ● ● ●

DC I

● ● ● ●

AC I

● ● ● ●

Ω

● ● ● ●

CAP

● ● ● ●

SENSOR

● − ● ●

− − − −

Tab. 6.1: Measurement functions with possible math options

Page 10

43

Documentation, Storage and Recall

Date Format Example for a Logging File

# HAMEG Device under test HM -Log-File ;

# Date: 2013-05-27 ;

# Start Time:, 14:27:07;

# Stop Time:, 14:27:11 ;

# Settings: ;

# ADC Rate : Slow;

# AC Filter : ------;

# Input Imp. : 10M;

;

;

;

DCV[V],ACV[V],Flag;

15.005159, 0.000186 ;

15.005088, 0.000195 ;

15.004896, 0.000200

;

6.4 Power Display (Power)

The soft menu key Power activates the power display. The

function Power is only available if the measurement of DC /

AC current is activated. For instance, if you select the function DC V as the main measurement value (Main) and DC

I as secondary measurement value (2nd Function) (or vice

versa), the power will be shown in the lower display section

after conrming your selection via soft menu key Power.

If the power display is activated, the soft menu key Power

is marked in yellow. To deactivate the power display, press

the soft menu key Power again.

6.5 Measuring AC+DC (True RMS)

You can show the true RMS value (True RMS) below the

main measurement value (Main) on the display via soft

menu key AC+DC. This function is only available if the

measurement of AC voltage or AC current is activated.

Otherwise, the function is grayed out.

7 Documentation,

Storage and

Recall

The multimeter HMC8012 enables users to store all screenshots and user settings. Instrument settings may be saved

internally. This data can also be stored on a connected USB

stick. Screenshots may only be stored on a USB stick. You

can access the main menu to store and load functions by

pressing the SAVE/RECALL key.

7.1 Instrument Settings

Use the soft menu Device Settings to save current instrument settings and to load previously saved settings.

Press the soft menu key Save to open the „Save“ menu.

You can use the soft menu key Storage to select a possible

location (Internal or Front) where you would like to save

the instrument settings. Selecting the respective storage

location and conrming the selection via soft menu key Accept opens the le system manager. The FILE NAME can

be changed or adjusted to the corresponding setting (SET

is the default label). You can use the soft menu key Com-

ment to enter a comment which will be displayed in the le

manager footer once a le has been selected. Instrument

settings are saved in the HDS format (binary). The format

may not be changed. The option Save allows you to store

the settings.

To reload stored preference les, press the respective soft

menu key to open the soft menu Load. This open the le

manager where you can use the knob to select the respec-

tive le.

Fig. 7.1: Menu for storing instrument settings

Instrument settings from a previous rmware version cannot be

loaded with a new rmware version.

Page 11

44

Documentation, Storage and Recall

Once the storage location and the respective settings le

has been selected, you can load the le by pressing the

soft menu key Load. To remove les that are no longer

required you can use the knob to select the respective settings le and remove it by pressing the soft menu key Remove File. If a USB stick is connected, you can also change

or delete directories.

The menu item Default Settings also allows you to load the

factory default settings.

7.2 Screenshot

The most important format to store information for documentation purposes is the screenshot. A screenshot is an

image le which shows the current screen content at the

time that storage takes place.

Screenshots may only be stored to a USB stick. If a USB

stick is connected, you can also change, create or delete

directories. Press Accept to conrm the location of the

target directory.

The FILE NAME can be changed or adjusted to the corresponding setting (SCR is the default label).

The le format of a graphics le determines the color depth

and the type of compression. The quality of the various

formats is identical for the multimeter graphics. You can

choose from the following le formats in the soft menu

Format:

❙ BMP = Windows Bitmap Format

❙ PNG = Portable Network Graphic

Use the soft menu key Color Mode and the knob to select

between Grayscale, Color and Inverted.

If Grayscale is selected, the colors are converted to gray

scales when the data is stored, if Color is selected, the data

is stored as it displays in the screen, and if Inverted

is activated, data will be stored in color with a white

back-ground.

If you press the key Save, the current screen will be saved

immediately to the selected storage location with the selected name and format.

Fig. 7.2: Screenshot menu

The soft menu key Print allows you to print a screenshot

immediately to a connected printer (e.g. PCL or PCLX as

„printer language“). If a printer is detected, the soft menu

key Print will no longer be grayed out. The free software

HMScreenshot (software module of the HMExplorer software) enables the transfer of screenshots in bitmap or PNG

format from the HMC8012 via interface to a connected PC

where the screenshots may then be saved or printed. For

additional information on the software, refer to the internal

HMExplorer help at www.hameg.com.

Pressing and holding the HELP key allows you to save a screenshot to a connected USB stick.

Page 12

45

General Instrument Settings

8 General Instru-

ment Settings

Important general settings, such as basic settings or interface settings may be selected via SETUP key. Press the

key to move up one level.

8.1 Update (Instrument Firmware / Help)

Firmware and help (if available) are packed in one ZIP le.

Depending on the required extent of the update, the ZIP le

might include either all updates or simply the instrument

rmware, for instance. After downloading the ZIP le, un-

pack the data to the base directory of a USB stick. Then

connect the USB stick with the USB port of the multimeter

and press the SETUP key. Press the soft menu key Update

to access the update menu. Selecting this menu item

opens a window displaying version number, date and build

information of the currently installed rmware.

Pressing the soft menu key Firmware to update the instru-

ment rmware will result in a search for the corresponding

le on the USB stick. The information for the new rmware

to be installed will then be displayed on the stick below the

row labeled NEW:. The version number will be displayed

in red in case the existing rmware on the instrument is

identical to the latest version; otherwise the version number will be shown in green. Only if this is the case, press

the soft menu Execute to start the update. To update the

help, select the menu item Help in the update menu. The

information window will now display all installed languages, the date and relevant information about the languages

available on the stick. The soft menu allows you to add,

remove or update languages. Please note the date format

(YYYY-MM-DD) in compliance with multilingual help ISO

8601 standards.

8.2 Interface Setting

The soft menu Interface enables you to select the settings

for:

❙ VCP (Virtual COM Port)

❙ USB

Fig. 8.1: Firmware update menu

❙ Ethernet (IP address, sub-net mask etc.) and

❙ IEEE-488 GPIB interface (GPIB address)

Select the respective interface for the communication via

respective soft menu key. Set the required interface parameters via soft menu item Parameter. Please refer to chapter 9 „Remote Control via Interfaces“ for more information

about the used interfaces.

8.3 Trigger Settings

See chapter „Instrument Functions“ for a description of the

trigger menu.

8.4 Default Settings

The soft menu key „Default Settings“ allows you to load

the factory default settings.

8.5 General Settings (Misc)

Device Infos

This soft menu key allows you to retrieve instrument information such as serial number, software version etc.

Fig. 8.2: Device Infos

Date & Time

The soft menu key Date&Time allows you to set the time

and date and add a date and time stamp to printouts and

saved data records. The user can reset the date and time.

Date and time can be set via knob. The respective soft

menu item is activated when it is marked in yellow. Press

Save to accept the date and time parameters.

SOUND

The HMC8012 offers the option to issue a signal in the

event of an error (or simply as a control measure). This

signal can be activated (On) or deactivated (Off) via soft

menu key Error Beep or Control Beep.

Display

The soft menu Display and the soft menu key Backlight

allows you to set the screen intensity via knob from 10% to

100%.

Key Brightness

The soft menu key „Key Bright“ allows you to set the key

brightness via knob from 0% to 100%.

Page 13

46

General Instrument Settings

9 Remote Control

via Interfaces

As a standard feature, the HMC8012 is equipped with a

built-in interface card which includes an Ethernet and a

USB connection.

9.2 USB

In addition to a LAN interface, the HMC8012 includes a

USB device port. For this interface, the user can select

if the instrument is accessed via virtual COM port (VCP)

or via USB TMC class. The traditional version of the VCP

allows the user to communicate with the HMC using any

terminal program via SCPI commands once the corresponding Windows drivers have been installed. These commands are generally compatible with the Agilent multimeters 34401A and 34410A. In addition, you may use the free

HAMEG software „HMExplorer“. This Windows application

offers HMC8012 instruments a terminal function, the option to create screenshots and to sort the measured data

storage.

A modern alternative to the virtual COM port (VCP) is the

control via USB TMC class. TMC stands for „Test & Measurement Class“ which indicates that the connected

measurement instrument can be recognized without

special Windows drivers if VISA drivers are installed and

that it can be used directly in corresponding environments.

The GPIB interface serves as model to the structure of the

TMC design. A major benet of the USB TMC class is that

by sampling specic registers the user can determine if

commands have been terminated and if they have been

processed correctly. However, the communication via VCP

requires analysis and polling mechanisms within the controlling software which may signicantly strain the interface

of the measurement instruments. The TMC status registers

solve this problem with the USB TMC in the same manner

as is the case with the GPIB interface for the hardware,

namely via corresponding control lines.

9.1 Ethernet

In addition to the USB interface, the interface card includes

an Ethernet interface. Select Ethernet as interface and

press the soft menu key Parameter to then determine the

settings for the necessary parameters directly within the

To enable communication, the selected interface and the respective settings in the instrument must be identical to the selections

for the PC.

All currently available USB drivers have been fully tested and

released for Windows XP™, Windows VISTA™ and Windows 7™

(32 + 64 bit).

Device Name

In this menu, you can select an instrument name. Pressing

the soft menu key DEVICE NAME opens a keypad. Use the

knob to select the letters. You can conrm each letter via

ENTER key (SHIFT). Press the soft menu key ACCEPT to

conrm the entered instrument name.

Page 14

47

Remote Control via Interfaces

multimeter. You can specify all parameters and assign a

xed IP address. You can also assign a dynamic IP address

with the activated DHCP function. Please contact your IT

management to congure the settings properly.

If the device has an IP address, it can be accessed via

web browser at this IP since the Ethernet interface includes an integrated web server. Enter the IP address in the

browser‘s address bar (http://xxx.xxx.xxx.xxx). This will

open a window including the instrument type and the serial

number.

9.3 IEEE 488.2 / GPIB

In addition to the GPIB functions which are available via

USB TMC class, the HMC8012 is optionally available with

an integrated GPIB interface. This solution is particularly

attractive for customers who already have an existing GPIB

environment. With minimum efforts, an old instrument can

be replaced by a HMC8012 model.

If DHCP is used and the system cannot assign an IP address to the

HMC8012 (for instance, if no Ethernet cable is connected or the

network does not support DHCP), it may take up to three minutes

until a timeout allows the interface to be congured again.

Fig. 9.2: Web server

Congure the settings in the HMC8012 for all necessary

parameters after you select IEEE488 as interface and press

the soft menu key Parameter.

The optional IEEE 488 interface (GPIB) can only be factory-tted

as it is necessary for this purpose to open the instrument and

break the guarantee seal.

Fig. 9.1: Ethernet-Settings

Page 15

48

Specications

Digital Multimeter HMC8012

All data valid at 23°C ±5K after 90 minutes warm-up and with 5 3/4 digits.

DC Specifications DC Accuracy in ± (% of reading + % of range):

Function Range

1)

Test Current

Voltage drop

Input Impedance 1 Year 23 °C ± 5 K Temp. Coefficient

0-18 °C, 28-55 °C

DC Voltage 400.000 mV

4.00000 V

40.0000 V

400.000 V

1000.00 V

10 MΩ/>10 GΩ

10 MΩ/>10 GΩ

10 MΩ

10 MΩ

10 MΩ

0.015+0.002

0.015+0.002

0.020+0.002

0.020+0.002

0.025+0.002

0.0010+0.0005

0.0008+0.0003

0.0010+0.0005

0.0015+0.0005

0.0015+0.0005

Resistance

(2/4-wire)

2)

400.000 Ω

4.00000 kΩ

40.0000 kΩ

400.000 kΩ

4.00000 MΩ

40.0000 MΩ

250.000 MΩ

1 mA

1 mA

100 µA

10 µA

1 µA

100 nA

460 nA || 10 MΩ (parallel)

0.050+0.005

0.015+0.002

0.015+0.002

0.030+0.003

0.060+0.005

0,250+0.003

2.000+0.010

0.0020+0.0005

0.0020+0.0002

0.0020+0.0002

0.0020+0.0002

0.0020+0.0002

0.0080+0.0005

0,200+0.0005

DC Current

4)

20.0000 mA

200.000 mA

2.00000 A

10.0000 A

3)

<0,30 V

<0,27 V

<0,2 V

<0,60 V

0.05+0.010

0.05+0.010

0,25+0.070

0,25+0.070

0.008+0.0010

0.008+0.0010

0.012+0.0015

0.010+0.0010

Continuity 4000 Ω 1 mA 0.05+0.010 0.005+0.0005

Diode Test 5 V 1 mA 0.05+0.010 0.005+0.0005

Notes: 1) 240.000 / 480.000 counts exept in 1000 V and 10 A range

2) Specifications are for 4-wire measurement; 2-wire measurement using NULL function.

3) Maximum current load at >5 A is 30 seconds, followed by a pause of >30 seconds

4) At 250 V maximum

AC Specifications AC Accuracy in ± (% of reading + % of range):

Function Range

1)

Frequency 1 Year 23 °C ± 5 K Temp. Coefficient 0-18 °C, 28-55 °C

AC Voltage

2)

400.000 mV

4.00000 V

40.0000 V

400.000 V

750.00 V

6)

10 Hz–20 Hz

20 Hz–45 Hz

45 Hz–20 kHz

20 kHz–50 kHz

50 kHz–100 kHz

3.0+0.05

1.5+0.05

0.3+0.05

1.0+0.05

3.0+0.05

0.01+0.01

0.01+0.01

0.01+0.01

0.02+0.01

0.05+0.01

AC Current

5)

20.0000 mA

200.000 mA

2.00000 A

10.0000 A

4)

20 Hz–40 Hz

40 Hz–1 kHz

1 kHz–5 kHz

5 kHz–10 kHz

3)

1.5+0.05

0.5+0.05

1.5+0.05

2.5+0.05

0.01+0.01

0.01+0.01

0.01+0.01

0.01+0.01

Notes: 1) 240.000 / 480.000 counts exept in 750 V and 10 A range

2) Specifications are for sinusoidal curves. Input impedance is 1 MΩ parallel <100 pF

3) Except 10 A range

4) Maximum current load at >5 A is 30 seconds, followed by a pause of >30 seconds

5) At 250 V maximum

6) For ACV measurements and frequencies above 50 kHz the user is required to choose an appropriate measurement range

Frequency Counter Specifications Frequency Accuracy in ± (% of reading):

Function Range

1)

Frequency 1 Year 23 °C ± 5 K Temp. Coefficient 0-18 °C, 28-55 °C

AC Voltage

2)

all ranges 5 Hz–700 kHz 0.01 0.005

AC Current

2)

20 mA, 200 mA

2 A, 10 A

5 Hz–10 kHz

5 Hz–5 kHz

0.01

0.01

0.005

0.005

Anmerkungen: 1) Display of frequency available as 2nd measurent for main functions ACV and ACI

2) Input sensitivity: >7,5 % of full scale (5 Hz-400 kHz) resp. >20 % (400-700 kHz)

Frequency Counter Resolution

Setting Measurement time Display range Resolution

Slow 1 s 999,999 kHz 1 Hz

Medium 100 ms 999,99 kHz 10 Hz

Fast 10 ms 999,9 kHz 100 Hz

Capacitance Specifications Capacitance Accuracy in ± (% of reading + % of range):

Function Range 1 Year 23 °C ± 5 K Temp. Coefficient 0-18 °C, 28-55 °C

Capacitance 5.000 nF

50.00 nF

500.0 nF

5.000 µF

50.00 µF

500.0 µF

2.0+2,5

1.0+2.0

1.0+0,5

1.0+0,5

1.0+0,5

2.0+1.0

0.02+0.002

0.02+0.002

0.02+0.002

0.02+0.002

0.02+0.002

0.02+0.002

10 Specications

Page 16

49

Specications

All data valid at 23°C ±5K after 90 minutes warm-up and with 5 3/4 digits

Reading Rates

Function Setting Resolution Display Reading

Rates

(per sec.)

AC Voltage Slow 5 3/4 400.000 5

Medium 4 3/4 40.000 10

Fast 4 3/4 40.000 200

DC Voltage Slow 5 3/4 400.000 5

Medium 4 3/4 40.000 10

Fast 4 3/4 40.000 200

AC Current Slow 5 3/4 200.000 5

Medium 4 3/4 20.000 10

Fast 4 3/4 20.000 200

DC Current Slow 5 3/4 200.000 5

Medium 4 3/4 20.000 10

Fast 4 3/4 20.000 200

Resistance Slow 5 3/4 400.000 5

(2-wire) Medium 4 3/4 40.000 10

Fast 4 3/4 40.000 50

Resistance Slow 5 3/4 400.000 5

(4-wire) Medium 4 3/4 40.000 10

Fast 4 3/4 40.000 25

Frequency Slow 6 999,999 1

Medium 5 99,999 10

Fast 4 9,999 100

Diode 4 3/4 40.000 10

Continuity 4 3/4 40.000 200

Temperature 4 999,9 10

Additional Specications

DC voltage

Measuring Method Sigma Delta analog/digital converter

Input Resistance

>10 G Ω (selectable for ranges 400 mV / 4 V

10 MΩ (on all ranges)

CMRR 120 dB for VCM <500 V, 1 kΩ unbalance in the

LO-line and 5 measurements/second

SMRR

>60 dB for 50 or 60 Hz ±0,1% and 5

measurements/second

Input current 60 pA at 25 °C

Overload protection 1000 V for all ranges

AC voltage

Measuring Method AC coupled True RMS measurement

Input Resistance 1 MΩ parallel <100 pF (on all ranges)

Crest Faktor Max. 10 (0,5% additional measurement

uncertainty)

CMRR

>60 dB 1 kΩ in the LO -line and frequency

<60 Hz

Overload protection 750 V

rms

(for all ranges)

AC current / DC current

Shunt Resistance 13,75 Ω at 20 mA; 1,25 Ω at 200 mA; 25 mΩ bei

2 A, 10 A

Overload protection Fuse: F10H250V on the front panel

Resistance

Measuring Method 2-wire and 4-wire

Overload protection 1000 V for all ranges

Continuity

Measuring Method 1 mA constant current

Threshold value Adjustable in 1Ω steps

Response Time 200 measurements/second

Overload protection 1000 V

Diode Test

Measuring Method 1 mA constant current

Threshold value Adjustable in 10 mV steps

Response Time 10 measurements/second

Overload protection 1000 V

Temperature

Measuring Method Resistance measurement with platinum

sensor

Sensor types PT100, PT500, PT1000

Connection 2-wire, 4-wire

Overload protection 1000 V

Math Functions

Statistics Min/Max/Average/Standard deviation

Relative measurement NULL key, offset via keyboard

Logarithmic functions dB Reference level via keyboard or NULL key

dBm Reference impedance 50/75/600Ω or

freely selectable

Accessories supplied:

Line cord, printed operating manual, HZ15 Silicon test

lead with safety connector and test probe, 1m (black +

red), Software-CD

Recommended accessories:

HZ812 PT100 Temperature probe 2-wire

HZ887 PT100 Temperature probe 4-wire

HZC95 19“ rackmount kit 2RU for HMC series

General Specications

Power supply: 115 V / 230 V ±10%, adjustable voltage selector

on rear panel; Frequency 50Hz / 60Hz

Power consumption: 25 W max., 12 W typ.

Ambient temperature: 0 …+55 °C (operating); –40 …+70 °C (storage)

EMC compliance: DIN EN 61326-1, DIN EN 55011

Safety compliance: DIN EN 61010-1, CAN/CSA-C22.2 No.

61010-1-12

Measuring Category: CAT II, 600 V; CAT I, 1000 V

DC

, 750 VAC

RMS

Dimensions: 222 x 88 x 280 mm

Weight: approx. 2,7 kg

Warm-up time: 90 minutes

Data logging

Number of measuring

counts

Internal: 50.000;

external: defined by USB stick capacity.

Rate Log Min.: 5 ms typ. (in accordance to measuring

function and resolution); Max: 3.600 s

Duration Log Internal: 250 s...50.000 h;

External: defined by USB stick capacity

Log Daten Main, 2nd, Time-Stamp

Interfaces USB 2.0 (TMC and CDC/VCP), Ethernet

10/100 (LXI in Preparation), IEEE-488/GPIB

optional

Programming SCPI, compatible with Agilent 34401A and

34410A

Page 17

50

Appendix

11 Appendix

11.1 List of Figures

Fig. 1.1: Operating positions ......................30

Fig. 1.2: Rear panel of the HMC with voltage selector and

connectors ............................32

Fig. 1.3: Connectors on the front panel of the

instrument .............................32

Fig. 1.4: Product labeling in accordance with

EN 50419 ..............................33

Fig. 2.1: Front panel of the HMC 8012 ..............34

Fig. 2.2: Rear panel of the HMC 8012 ..............34

Fig. 4.1: Numeric keypad and editing keys ..........36

Fig. 4.2: Screen layout ..........................37

Tab. 4.1: Displaying Several Measurement Values .....37

Fig. 5.1: Measuring a DC or AC voltage .............38

Fig. 5.2: Measuring a DC or AC current .............39

Fig. 5.3: Measuring frequency ....................39

Fig. 5.4: Measuring resistance (2-wire) .............39

Fig. 5.5: Measuring resistance (4-wire) .............40

Fig. 5.6: Measuring the capacity ..................40

Fig. 5.7: 2-wire sensor measurement (temperature) ...40

Fig. 5.8: 4-wire sensor measurement (temperature) ...41

Fig. 5.9: Diode testing ...........................41

Fig. 5.10: Trigger menu Auto ......................41

Fig. 6.1: Logging menu setting ....................42

Fig. 7.1: Menu for storing instrument settings ........43

Fig. 7.2: Screenshot menu .......................44

Fig. 8.1: Firmware update menu ..................45

Fig. 8.2: Device Infos ............................45

Fig. 9.1: Ethernet-Settings .......................47

Fig. 9.2: Web server ............................47

11.2 Glossary

A

accuracy in measurements: 38, 39, 40

AC Filter: 38, 39, 43

AC voltage: 34, 35, 38, 43

ADC rate: 39, 41, 43

Alternating Voltage: 35

Auto Range: 35

B

Bitmap: 44

C

cable offset: 35, 39

capacity: 34, 40

continuity testing: 40, 41

D

DC voltage: 30, 34, 35

Diode Testing: 40

E

Ethernet: 46

F

le format: 42, 44

Firmware: 45

four-wire measurement: 35, 39

Frequency: 32, 39

frequency display: 39

G

GPIB: 47

GPIB address: 45

GPIB interface: 45

I

input frequency: 38, 39

instrument information: 45

instrument settings: 34, 36, 43

interface: 34, 44, 45, 46, 47

K

keypad: 34, 35, 36, 42, 46

knob: 34, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46

L

limits: 32, 35, 36, 42

Logging: 42, 43

logging menu: 41, 42

M

main measurement value: 35, 36, 37, 38, 39, 40, 42, 43

Maintenance: 31

measurement categories: 32

measurement interval: 41, 42

measurement rate: 39, 40, 41

measurement time: 39

Measuring category: 32

O

OVER RANGE: 35, 37, 42

P

power display: 43

Product Disposal: 33

R

reference value: 38, 39

repair: 31

resistance: 31, 34, 35, 38, 39, 40

resistance measurement: 31, 35, 39

RMS: 35, 38, 43

RMS values: 35, 38

S

Safety: 30

safety class: 32

screen displays: 36

second measurement value: 35, 37

statistic: 34, 35, 36, 42

statistic functions: 35, 42

store: 36, 43, 44

Page 18

51

Appendix

T

treshold settings: 41

trigger mode: 41

two-wire measurement: 35, 39, 40

U

USB: 34, 36, 42, 43, 44, 45, 46, 47

USB stick: 36, 42, 43, 44, 45

V

VCP: 45, 46

Virtual COM Port: 45

voltage value: 35, 38

W

Warranty: 31

Z

zero measurement: 35, 38, 39

Zero Point: 35

zero value: 35, 39

Page 19

value-instruments.com

R&S® ist ein eingetragenes Warenzeichen

der Rohde & Schwarz GmbH & Co. KG

HAMEG Instruments® ist ein eingetragenes Warenzeichen

der HAMEG Instruments GmbH

Markennamen sind Warenzeichen der Eigentümer

05 / 2014 | © HAMEG Instruments GmbH | 48-8012-C000

In Deutschland gedruckt | Änderungen vorbehalten

www.hameg.com

HAMEG Instruments GmbH

Industriestr. 6 | 63533 Mainhausen | Germany | Tel +49 (0) 6182 8000

Loading...

Loading...