Page 1

Function Generator

HM8030-6

Service-Manual

Page 2

General information regarding the CE marking

Hersteller HAMEG Instruments GmbH KONFORMITÄTSERKLÄRUNG

Manufacturer Industriestraße 6 DECLARATION OF CONFORMITY

Fabricant D-63533 Mainhausen DECLARATION DE CONFORMITE

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produkt

The HAMEG Instruments GmbH herewith declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

Bezeichnung / Product name / Designation:

Funktionsgenerator

Function generator

Générateur de fonctions

Typ / Type / Type: HM8030-6

mit / with / avec: HM8001-2

Optionen / Options / Options:

mit den folgenden Bestimmungen /

with applicable regulations /

avec les directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen /

Harmonized standards applied /

Normes harmonisées utilisées

General information regarding the CE marking

Sicherheit / Safety / Sécurité:

EN 61010-1: 1993 / IEC (CEI) 1010-1: 1990 A 1: 1992 / VDE 0411: 1994

EN 61010-1/A2: 1995 / IEC 1010-1/A2: 1995 / VDE 0411 Teil 1/A1: 1996-05

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility / Compatibilité

électromagnétique

EN 61326-1/A1

Störaussendung / Radiation / Emission: Tabelle / table / tableau 4, Klasse / Class

/ Classe B.

Störfestigkeit / Immunity / Imunitee: Tabelle / table / tableau A1.

EN 61000-3-2/A14

Oberschwingungsströme / Harmonic current emissions / Émissions de courant

harmonique: Klasse / Class / Classe D.

EN 61000-3-3

Spannungsschwankungen u. Flicker / Voltage fl uctuations and fl icker /

Fluctuations de tension et du fl icker.

Datum/Date/Date

22.07.2004

Unterschrift / Signature /Signatur

Manuel Roth

Manager

HAMEG instruments fulfi ll the regulations of the EMC directive. The

conformity test made by HAMEG is based on the actual generic- and

product standards. In cases where different limit values are applicable,

HAMEG applies the severer standard. For emission the limits for

residential, commercial and light industry are applied. Regarding the

immunity (susceptibility) the limits for industrial environment have

been used.

The measuring- and data lines of the instrument have much infl uence

on emmission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may

be different. For measurement operation the following hints and

conditions regarding emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and

external devices, (computer, printer etc.) suffi ciently screened cables

must be used. Without a special instruction in the manual for a reduced

cable length, the maximum cable length of a dataline must be less than

3 meters and not be used outside buildings. If an interface has several

connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cables HZ72S and HZ72L from HAMEG

are suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the

manual for a shorter length, signal lines must be less than 3 meters

and not be used outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

3. Infl uence on measuring instruments.

Under the presence of strong high frequency electric or magnetic fi elds,

even with careful setup of the measuring equipment an infl uence of

such signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifi cations may result from such conditions in individual cases.

HAMEG Instruments GmbH

2

Subject to change without notice

Page 3

Content

Declaration of Conformity 2

General information regarding the CE-marking 2

Function Generator HM8030-6 4

Specifi cations 5

Control elements 6

Adjustment 7

Circuit and layout diagrams 9

Subject to change without notice

3

Page 4

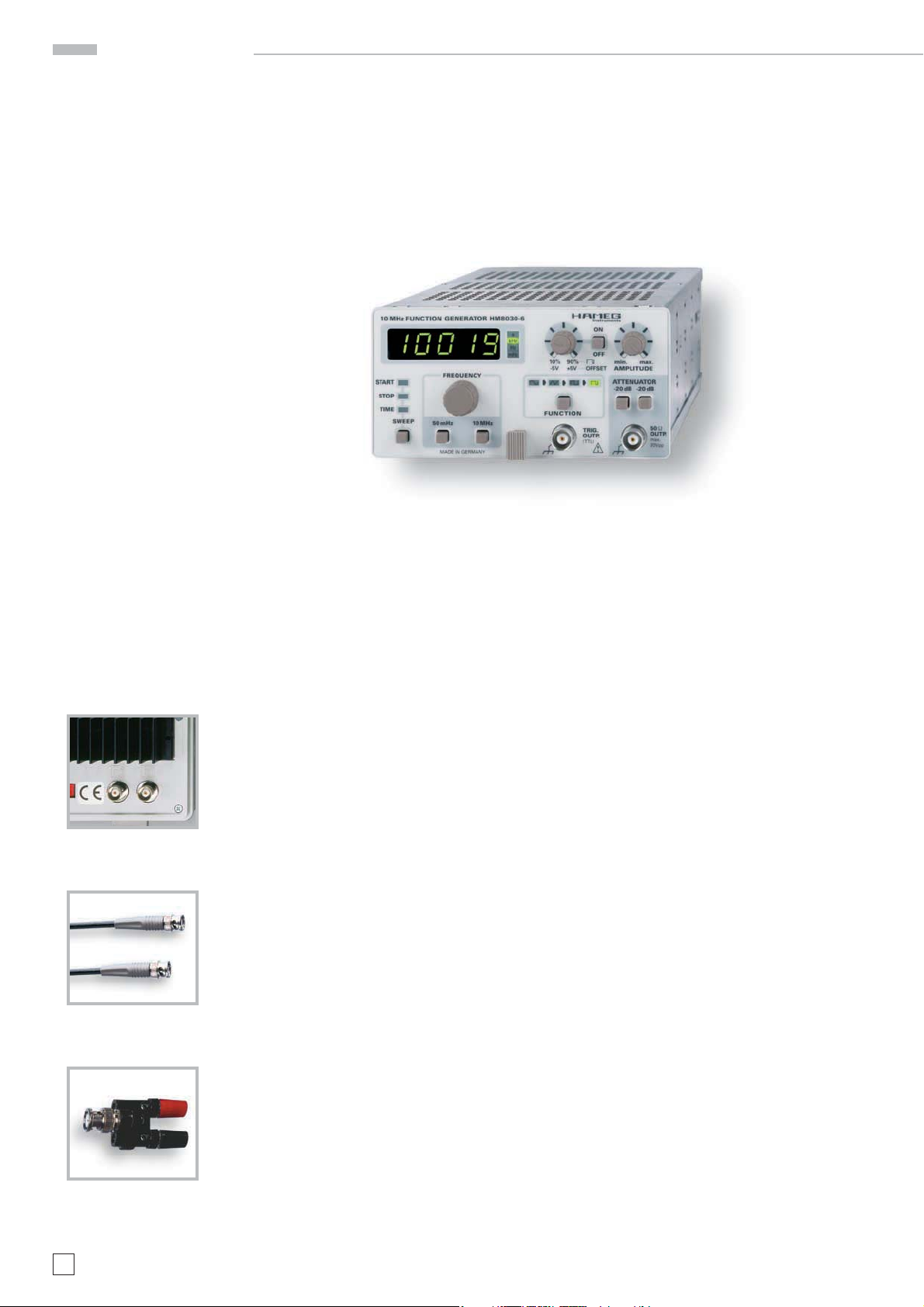

HM8030-6

10 MHz Function Generator

HM8030-6

Frequency range 50 mHz to 10 MHz

High signal purity and amplitude stability

Distortion factor ‹ 0.5 % up to 1 MHz

Output voltage 20 Vpp(10 Vppinto 50 Ω)

Surge- and short-circuit-proof output

Rise and fall time typ. 15 ns

Internal and external sweep

Pulse width adjustment

Highly accurate digital frequency display

Mainframe HM8001-2 required for operation

HZ20 Connector

BNC to 4mm socket

Option HO801

HZ33, HZ34

Test cable BNC/BNC

4

Subject to change without notice

Page 5

Specifications

Accessories supplied: Operator’s Manual

Optional accessories: HZ33/HZ34 BNC Test Cable, HZ22 50Ω feed-through

terminal, HZ10 Silicone test leads

10 MHz Function Generator HM8030-6

Valid at 23 °C after a 30 minute warm-up period

Operating modes

Sine, square, triangle, pulse; free running, internal sweep or external

frequency modulation, with or without DC offset

Frequency ranges

0.05 Hz to 10 MHz in 8 ranges, variable: x 0.09 to x 1.1 (12:1)

Frequency drift: ‹ 0.5 % /hr or 0.8 %/24 hrs. at constant

ambient temperature

Waveform characteristics

Sine wave distortion

0.05 Hz to 1 MHz: max. 0.5 %

1 MHz to 10 MHz: max. 5%

Square wave rise time: typ. 15 ns

Overshoot: ‹ 5 % (for termination into 50 Ω)

Triangle non-linearity: ‹ 1 % (to 100 kHz)

Displays

Frequency: 5-digit, 7-segment LED, each 8 x 5 mm

Accuracy:

up to 5 Hz: ± (1 % + 3 digits)

5 Hz to 10 MHz: ± (5 x 10-5+ 1 digit)

LED indicators for mHz, Hz, kHz and sec

Outputs

Signal output: short-circuit proof,

protected against ext. voltage up to ± 45 VDCmax. (30 sec.)

Impedance: 50 Ω

Output voltage: 10 Vppinto 50 Ω load; 20 V

pp

(open circuit)

Attenuation: max. 60 dB

2 attenuators: each 20 dB ± 0.2 dB

Variable: 0 to 20 dB

Amplitude error: (sine wave/triangle)

0.05 Hz to 0.5 MHz: max. 0.2 dB

0.5 MHz to 10 MHz: max. 0.5 dB

DC offset: variable (on/off, except pulse function)

into 50 Ω load: max. ±2.5 V

in open circuit: max. ±5 V

Trigger output: square wave synchronous to

signal output, approx. +5V/TTL

FM input

(VCF, BNC connector on rear panel of HM8001-2 and option HO801)

Frequency deviation: approx. 1 : 100

Input impedance: 6 kΩ II 25pF

Input voltage: max. ± 30 V

Internal sweep

Sweep speed: 20 ms to 15 s

Sweep range: approx. 1:100

Miscellaneous

Power supply +5V/200mA

(from mainframe): +16V/300mA

-16V/250mA

(∑=9.8 W).

Operating temperature: +10°C to + 40°C

Max. relative humidity: 80 % (without condensation)

Dimensions (W x H x D) (without 22-pole flat plug):

135 x 68 x 228 mm

Weight: approx. 0.80kg

HM8030-6E/140705/ce · Subject to alterations · © HAMEG Instruments GmbH · ® Registered Trademark · DQS-certified in accordance with DIN EN ISO 9001:2000, Reg.-No.: DE-071040 QM

HAMEG Instruments GmbH · Industriestr. 6 · D-63533 Mainhausen · Tel +49 (0) 6182 800 0 · Fax +49 (0)6182 800 100 · www.hameg.com · info@hameg.com

A Rohde & Schwarz Company

www.hameg.com

Subject to change without notice

5

Page 6

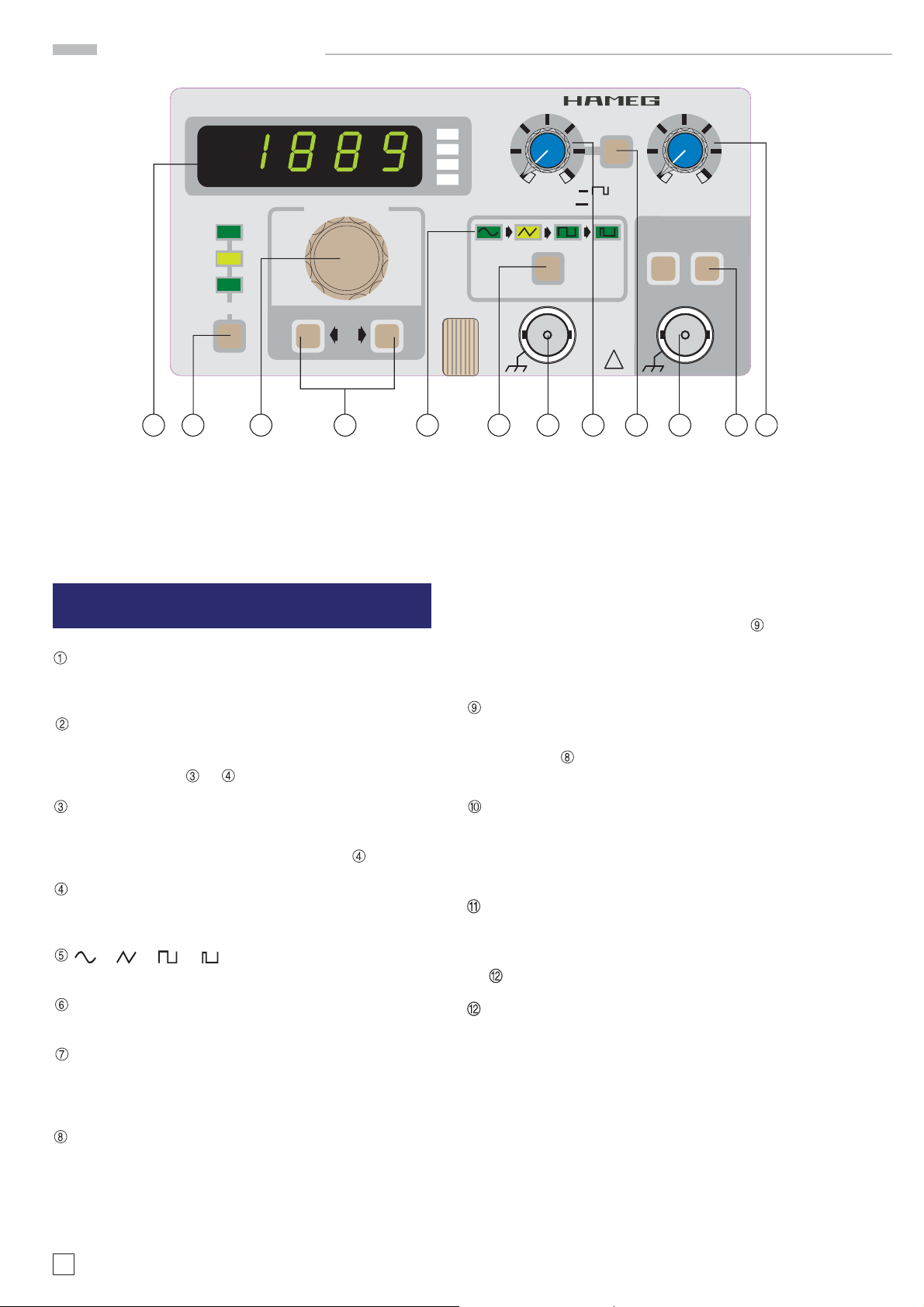

Control elements

10 MHz FUNCTION GENERATOR HM8030-6

FREQUENCY

START

STOP

TIME

SWEEP

50 mHz 10 MHz

MADE IN GERMANY

s

kHz

Hz

mHz

10 % 9 0 %

-5 V + 5 V

FUNCTION

Instruments

OFF

OFFSET

TRIG.

OUTP.

(TTL)

ON

ATTENUATOR

!

min. max.

AMPLITUDE

-20 dB -20 dB

50 Ω

OUTP.

max.

20Vpp

1 2 3 4 5 6 7 8 9 10 11 12

Control elements

DISPLAY (7 segment LED)

5-digit frequency meter. LED indicators for mHz, Hz, kHz

and s

SWEEP (push button) and SWEEP- Indication (LEDs)

Button activates internal sweep generator. The LEDs indi-

cate the function chosen with the SWEEP-Button. Settings

are changed with

FREQUENCY (adjustment knob)

Continuous and linear frequency fi ne ad-justment, with the

setting range from 0.09 to 1.1 (approx 0.045 to 1.1 in 10 MHzrange) overlapping the ranges selected with

FREQUENCY (2 pushbuttons)

Frequency range selection from 50 mHz to 10 MHz in 8 de-

cade steps.

– (LED s)

Indication of selected function.

FUNCTION – (pushbutton)

Mode selection: Triangle, Sine, Square, Pulse and Off.

TRIGGER OUTPUT (BNC connector)

This short-circuit-proof output supplies a square signal in

synchronism with the output signal. It is T TL compatible

and has a duty-factor of approx. 50%.

or .

max. offset voltage is ±5V (o.c.) or ±2.5V respectively when

terminated into 50Ω. The offset voltage is available to all

functions except for pulse and activated by

. In operation

mode OFF (no function activated) it can be used separatey.

In pulse mode the pulse width is set with this control from

10% to 90%.

ON (pushbutton)

Activates the offset function except in pulse mode. If the

ON-button is pushed in pulse mode, pulse width is set with

the control

from 10% to 90%. In OFF-position the fi xed

pulse width amounts to 50%.

50Ω OUTPUT (BNC connector)

Short-circuit proof signal output of the generator. The

output impedance is 50Ω and the max. output amplitude

is 20 V

(o.c.) or 10 Vpp respectively when terminated into

pp

50Ω.

–20dB, –20bB (pushbutton)

Two fi xed attenuators, 20dB each. They can be used se-

parately. When both pushbuttons are activated, a total attenuation of 40dB results. Including the amplitude control

, the max. attenuation amounts to 60dB (factor 1000).

AMPLITUDE (adjustment knob)

Continuous adjustment of the output ampli-tude from 0 to

–20dB terminated into 50Ω.

OFFSET (adjustment knob)

Adjustment of the positive or negative offset voltage. This

DC voltage can be super-imposed on the output signal. The

6

Subject to change without notice

Page 7

Adjustment

Please observe the correct sequence of steps!

Measuring equipment required:

– Digital Multimeter ( HM8012 or similar)

– Frequency counter (HM8021 or similar)

– Distortion meter (HM8027 or similar)

– Oscilloscope (HM1507 or similar)

1) Turning ser vice mode on

a) For a ctivat ing s er vi ce mo de pus h bot h but tons „ 50 mHz“

and „10MHz“ simultaneously and switch on the

HM8030.

b) If the EPROM is empty or if the HM8030 is new, the dis-

pla y w il l sh ow „E “, oth er wis e „F 3 .1“. Pu sh butto n „FUN CTION“.

c) If the display shows „XXX3“ (X = any fi gure, fi gure ‚3’

blinking), turn off the instrument.

2) Switches and controls

These settings must be kept constant during the whole ad-

justment procedure!

a) Open the top cover of the instrument.

b) Set OFFSET control to center position.

c) Button OFFSET deactivated.

d) Set AMPLITUDE control the right stop.

e) Buttons ATTENUATOR deactivated.

f) Push button SWEEP as often as needed to extinguish

the START, STOP and TIME LEDs.

Adjustment

6) OUTPUT Offset

a) Connect HM8012 (measuring range: 500 mV

pass fi lter to OUT.

b) Set HM8030 to triangle function with f = 5250 Hz.

c) Adjust 0 mV ±1 mV with VR111.

7) Distortion

a) Connect HM8027 (20k Frequency Range) to OUT.

b) Set HM8030 to sine function with f = 5250 Hz.

c) Set HM8027 (settings: 100% CAL) with the blue control

to 100, than switch to 10%.

d) Ad just the dis torti on f ac tor to less than 0.3 % by a lte rna-

tely adjusting VR108 and VR109.

e) If this adjustment is not possible, return to step 4) be-

cause the duty cycle was not correctly adjusted.

8) Square 1

a) Connect oscilloscope HM1507 (settings: 1V/div, 100μs/

div) with 50Ω to OUT.

b) Set HM8030 to triangle function with f = 5250 Hz.

c) Adjust VAR on the oscilloscope so that the amplitude of

the signal equals to 6 div.

d) Set HM8030 to square function with f = 5250 Hz.

e) Adjust VR105, VR107 and VR110 so that the amplitude of

the square signal amounts to 6 div.

f) Repeat step e) with f = 52,5 kHz.

9) Square 2

a) Connect oscilloscope HM1507 (settings: 1V/div, 50ns/div)

with a 50Ω load at OUT.

b) Set HM8030 to square function with f = 5250kHz.

c) Adjust VC102 and VC104 so that the amplitude of the

square signal equals to 6 div.

) with low

DC

3) Internal triangle generator

a) Set HM8030 to triangle function with f = 5250 Hz.

b) Connect HM8012 (measuring range: 500 mV

DC

probe (with the low pass fi lter shown) at PT100.

c) Adjust 0 mV ±1 mV with VR103.

d) Connect HM8012 (measuring range: 500 mV

AC

probe (without low pass fi lter) at PT100.

e) Adjust 577,3 mV ±1 mV with VR102.

f) As the settings are interacting, repeat steps b) to e) as

often as is necessary for an optimum result.

4) Duty cycle 1

a) Connect HM8021 (function: pulse) to OUT.

b) Set HM8030 to square function with f = 52,50 kHz.

c) Adjust VR101 so that the positive pulse width is equal to

the negative pulse width.

d) Set HM8030 to square function with f = 4,75 kHz .

e) Adjust VR104 so that the positive pulse width is equal to

the negative pulse width.

f) As the settings are interacting, repeat steps b) to e) as

often as is necessary for an optimum result.

) with a

) with a

10) Triangle

a) Connect oscilloscope HM1507 (settings: 1V/div, 50ns/div)

with a 50Ω load at OUT.

b) Set HM8030 to triangle function with f = 7000 kHz.

c) Adjust VC101 so that the amplitude of the triangle signal

equals to 6 div.

11) Duty cycle of pulse

a) Connect HM8021 (function: pulse) to OUT.

b) Set HM8030 to pulse function with f = 5250 Hz.

c) Adjust VR1 so that the positive pulse width is equal to

the negative pulse width.

5) Duty cycle 2

a) Connect HM8021 (function: pulse) to OUT.

b) Set HM8030 to square function with f = 475 Hz.

c) Adjust VR106 so that the positive pulse width is equal to

the negative pulse width.

Subject to change without notice

7

Page 8

Adjustment

y

)

)

)

h

e

Adjustment HM8030-6

30. November 2004

1) Turning service mode on

a) For activating service mode push both buttons „50mHz“ and „10MHz“ simultaneously and switch on the HM8030.

.

a) If the EPROM is empty or if the HM8030 is new, the display will show „E“, otherwise „F 3.1“. Push button „FUNC-

TION“. If the display shows „XXX3“ (X = any figure, figure ‚3’ blinking), turn off the instrument.

2) Switches and controls - These settings must be kept constant during the whole adjustment!

a) Open the top cover of the instrument.

b) Set OFFSET control to center position.

c) Button OFFSET deactivated.

d) Set AMPLITUDE control to the right stop.

e) Buttons ATTENUATOR deactivated.

f

Push button SWEEP as often as is needed to extinguish the START, STOP and TIME LEDs.

10) Triangle

a) Connect oscilloscope HM1507 (settings: 1V/div,

50ns/div) with a 50 load at OUT.

b) HM8030 - traingle function - f = 7000kHz.

c) Adjust VC101 so that the amplitude of the triangl

signal equals to 6 div.

5) Duty cycle 2

a) Connect HM8021 (function: pulse) to OUT.

b) Set HM8030 to square function with f = 475Hz.

c) Adjust VR106 so that the positive pulse width

is equal to the negative pulse width.

11) Duty cycle of pulse

a) Connect HM8021 (function: pulse) to

OUT.

b) HM8030 - pulse function - f = 5250Hz.

c) Adjust VR1 so that the positive pulse

VR106

width is equal to the negative pulse

width.

4) Duty cycle 1

a) Connect HM8021 (function: pulse) to OUT.

b) HM8030 - square function - f = 52,50kHz.

c) Adjust VR101 the pos. pulse width is equal to neg.

pulse width.

d) HM8030 - square function - f = 4,75kHz .

e) Adjust VR104 so that the positive pulse width is equa

to the negative pulse width.

f

As the settings are interacting, repeat steps b) to e

VR101

VR104

VR103

VC101

PT100

VR102

3) Internal triangle generator

a) HM8030 - triangle function - f = 5250Hz.

b) HM 8012 (500mV

) with a probe (with low-

DC

pass filter) at PT100.

c) Adjust 0mVr 1mV with VR103.

d) Connect HM8012 (500mV

) with a probe

AC

(without lowpass filter) at PT100.

e) Adjust 577,3mVr 1mV with VR102.

f) As settings are interacting, repeat steps b) - e)

as often as is necessar

for an optimum result.

8) Square 1

a) Connect oscilloscope HM1507 (set-

VR1

VR109

tings: 1V/div, 100μs/div) with 50

to OUT.

b) Set HM8030 to triangle function

VR105

VR110

VC104

with f = 5250Hz.

c) Adjust VAR on the oscilloscope so

that the amplitude of the signal

equals to 6 div.

d) Set HM8030 to square function

with f = 5250Hz.

VC102

e) Adjust VR105, VR107 and VR110

so that the amplitude of the square

signal equals to 6 div.

f) Repeat step e) with f = 52,5kHz.

9) Square 2

a) Connect oscilloscope HM1507 (settings: 1V/div, 50ns/div) with a 50

load at OUT.

b) Set HM8030 to square function with f = 5250kHz.

c) Adjust VC102 and VC104 so that the amplitude of the square signal

equals to 6 div.

8

Subject to change without notice

VR106

VR111

VR107

6) OUTPUT Offset

a) Connect HM8012 (500mV

DC

) with

lowpass filter to OUT.

b) HM8030 - triangle function f = 5250Hz.

7) Distortion

a) Connect HM8027 (20k Frequency

Range) to OUT.

b) HM8030 - sine function - f = 5250Hz.

c) Set HM8027 (settings: 100% CAL) wit

the blue control to 100, than switch to

10%.

d) Adjust the distortion factor to less than

0.3% by alternately adjusting VR108

and VR109.

e) If this adjustment is not possible, return

to step 4) because the duty cycle was

not correctly adjusted.

Page 9

Circuit and layout diagrams

Subject to change without notice

9

Page 10

Circuit and layout diagrams

10

Subject to change without notice

Page 11

Circuit and layout diagrams

Subject to change without notice

11

Page 12

Circuit and layout diagrams

12

Subject to change without notice

Page 13

Circuit and layout diagrams

Subject to change without notice

13

Page 14

Circuit and layout diagrams

14

Subject to change without notice

Page 15

Circuit and layout diagrams

Subject to change without notice

15

Page 16

Circuit and layout diagrams

16

Subject to change without notice

Page 17

Circuit and layout diagrams

Subject to change without notice

17

Page 18

Circuit and layout diagrams

18

Subject to change without notice

Page 19

Circuit and layout diagrams

Subject to change without notice

19

Page 20

Oscilloscopes

Spectrum Analyzer

Power Supplies

Modular System

8000 Series

Programmable Instruments

8100 Series

authorized dealer

4S-8030- 06E0

www.hameg.de

Subject to change without notice

4S-8030-06E0 / 07-11-2005-gw HAMEG Instruments GmbH

© HAMEG Instruments GmbH Industriestraße 6

A Rohde & Schwarz Company D-63533 Mainhausen

® registered trademark Tel +49 (0) 61 82 800-0

DQS-Certifi cation: DIN EN ISO 9001:2000 Fax +49 (0) 61 82 800-100

Reg.-Nr.: 071040 QM sales@hameg.de

Loading...

Loading...