Page 1

3½-Digit LCR-Meter

HM8018

Service-Manual

Page 2

General information regarding the CE marking

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE

DECLARACIÓN DE CONFORMIDAD

Hersteller / Manufacturer / Fabricant / Fabricante:

HAMEG Instruments GmbH · Industriestraße 6 · D -63533 Mainhausen

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produk t

The HAMEG Instruments GmbH herewith declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

HAMEG Instruments GmbH certifi ca la conformidad para el producto

Bezeichnung: LCR-Meter

Product name: LCR meter

Designation : LCR mètre

Descripción : Medidor de LCR

Typ / Type / Type / Tipo: HM8018

mit / with / avec / con: HM80 01-2

Optionen / Options /

Options / Opciónes: –

mit den folgenden Bestimmungen / with applicable regulations /

avec les directives suivantes / con las siguientes directivas:

EMV Richtlinie 89/ 336/EWG ergänzt durch 91/263 /EWG, 92 /31/EWG

EMC Directive 89/ 336/EEC amended by 91/263/ EWG, 92/ 31/EEC

Directive EMC 89/ 336/CEE amendée par 91/263/EWG, 92/31/ CEE

Directiva EMC 89/ 336/CEE enmendada por 91/263 /CEE, 92 /31/CEE

Niederspannungsrichtlinie 73/23 /EWG ergänzt durch 93/68 /EWG

Low-Voltage Equipment Directive 73/23 /EEC amended by 93 /68/ EEC

Directive des equipements basse tension 73 /23/ CEE amendée par 93/68/CEE

Directiva de equipos de baja tensión 73 /23/ CEE enmendada por 93 /68/ EWG

Angewendete harmonisierte Normen / Harmonized standards applied /

Normes harmonisées utilisées / Normas armonizadas utilizadas:

Sicherheit / Safety / Sécurité / Seguridad:

EN 61010-1: 1993 / IEC (CEI) 1010-1: 1990 A 1: 1992 / VDE 0 411: 1994

Überspannungskategorie / Overvoltage category / Catégorie de surtension /

Categoría de sobretensión: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution / Nivel de

polución: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique / Compatibilidad electromagnética:

EN 61326 -1/A1: Störaussendung / Radiation / Emission: Tabelle / table /

tableau 4; Klasse / Class / Classe / classe B.

Störfestigkeit / Immunity / Imunitee / inmunidad:

Tabelle / table / tableau / tabla A1.

EN 61000-3 -2/A14: Oberschwingungsströme / Harmonic current emissions

/ Émissions de courant harmonique / emisión de corrientes armónicas:

Klasse / Class / Classe / clase D.

EN 61000-3 -3: Spannungsschwankungen u. Flicker / Voltage fl uctuations

and fl icker / Fluctuations de tension et du fl icker / fl uctuaciones de tensión

y fl icker.

Datum / Date / Date / Fecha

22.07.2004 Unterschrift / Signature / Signatur / Signatura

General information regarding the CE marking

HAMEG instruments fulfi ll the regulations of the EMC directive. The

conformity test made by HAMEG is based on the actual generic- and

product standards. In cases where different limit values are applicable,

HAMEG applies the severer standard. For emission the limits for

residential, commercial and light industry are applied. Regarding the

immunity (susceptibility) the limits for industrial environment have

been used.

The measuring- and data lines of the instrument have much infl uence

on emmission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may

be different. For measurement operation the following hints and

conditions regarding emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and

external devices, (computer, printer etc.) suffi ciently screened cables

must be used. Without a special instruction in the manual for a reduced

cable length, the maximum cable length of a dataline must be less than

3 meters and not be used outside buildings. If an interface has several

connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cables HZ72S and HZ72L from HAMEG

are suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the

manual for a shorter length, signal lines must be less than 3 meters

and not be used outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

3. Infl uence on measuring instruments.

Under the presence of strong high frequency electric or magnetic fi elds,

even with careful setup of the measuring equipment an infl uence of

such signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifi cations may result from such conditions in individual cases.

HAMEG Instruments GmbH

G. Hübenett

Product Manager

2

Subject to change without notice

Page 3

Content

Declaration of Conformity 2

General information regarding the CE-marking 2

3½-Digit LCR-Meter HM8018 4

Specifi cations 5

Alignment procedure 6

Circuit and layout diagrams 7

Subject to change without notice

3

Page 4

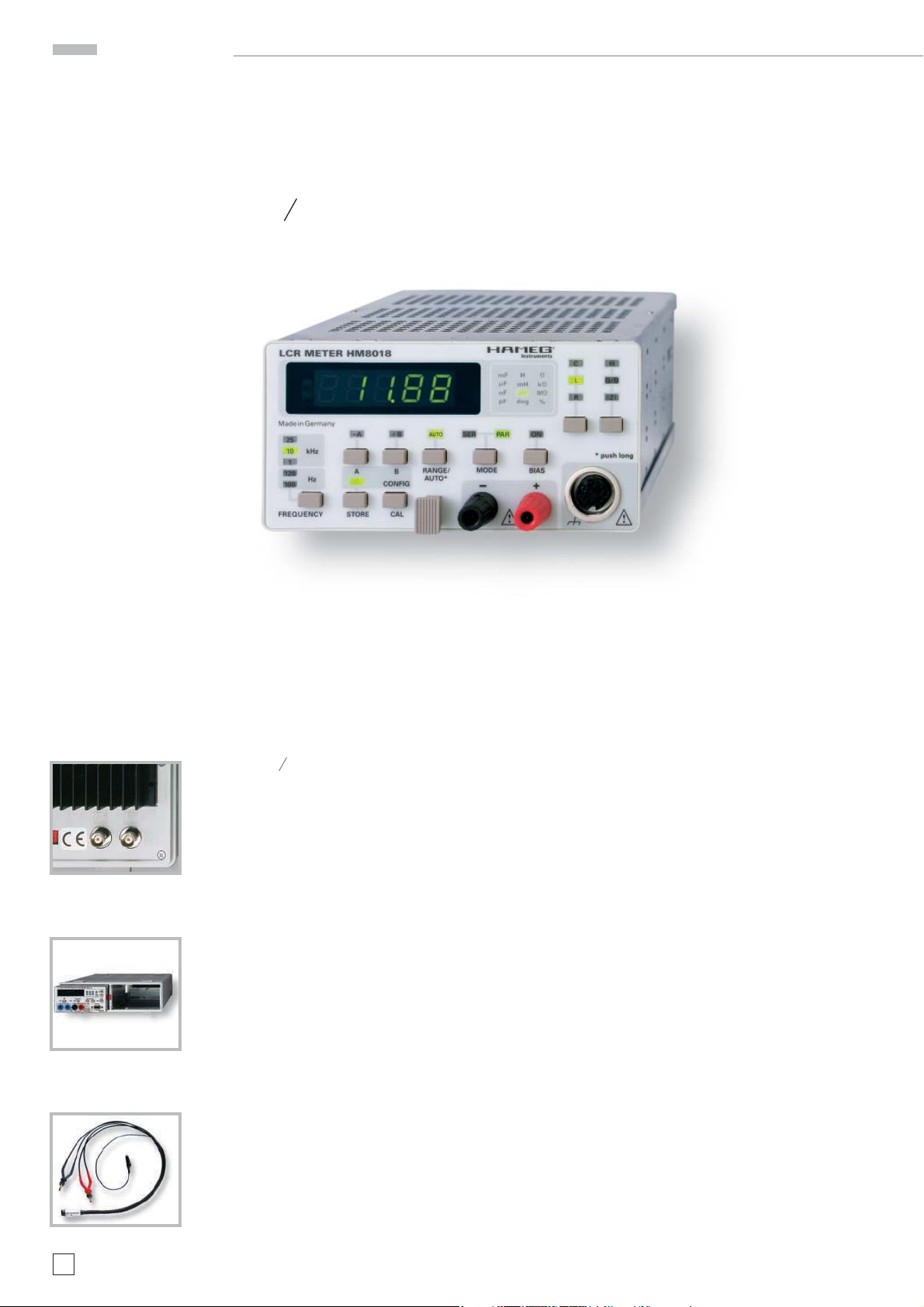

HM8018

Measurement functions: L, C, R

3 -digit display with 2,000 counts, basic accuracy 0.5%

4-wire measurement

Max. resolution: 0.1 pF, 0.1 μH, 10 mΩ, 0.01 μS

Internal bias for electrolytic capacitors selectable

Offset adjustment of cable capacity for the “Kelvin test lead“

AC voltage signal at rear-panel BNC connector proportional

to value shown in the display (with Option HO801 only)

Mainframe HM8001-2 required for operation

Option HZ18 Kelvin test lead

Option HO801

Mainframe HM8001-2

1

2

3 -Digit LC Meter

HM8018

1

2

4

Subject to change without notice

Page 5

Specifications

3 -Digit LC Meter HM8018

Valid at 23 °C after a 30 minute warm-up period

Operating modes

C measurement

L measurement

Series inductance L, Shunt capacitance C

Series resistance R, Parallel conductance G

Measurement ranges

L: 200 μH-200 H (7 ranges)

Rs: 20 Ω-200 kΩ (5 ranges)

C: 200 pF-200 μF (7 ranges)

G: 20 μS-200 mS (5 ranges)

Max. resolution: 0.1 pF

0.1 μH

0.01 Ω

0.01 μS

Measurement frequencies: (sine wave signal)

~160 Hz, 1.6 kHz, 16kHz

(ω = 103, 104,105s-1)

Measurement voltage: max. 1 V

pp

Measurement current: max. 36 mA (eff.)

Power output to device under test:

max. 3.2 mW

Measurement accuracy: ± [0.5 % of reading

+(3 digit s + 0.5pF /0.5 μH /10 mΩ/0.01 μS)]

Measurement error resulting from separation of the real and imaginary part

≤1 % at tanϕ≥1

Display

31/2-digit 7-segment LED display

Sampling rate: 2 measurements per second

Type of measurement: 2- or 4-wire measurement

1

2

Miscellaneous

Inputs are short-circuit-proof and overvoltage protected up to 100 V with a

maximum energy consumption of 10mJ (∧= capacitor 2 μF, charged to

100 V).

Polarization voltage for C measurement: 2V

Zero point correction for display

Compensation of probe capacitance (HZ18)

AC voltage signal at rear-panel BNC connector proportional to value

shown in the display (HM8001 with option HO801)

Power supply +5V/200mA

(from mainframe): -13 V/130 mA

+13V/130 mA

(∑ = 4.5 W)

Operating temperature: + 10° C to +40° C

Max. relative humidity: 80 % (without condensation)

Dimensions (W x H x D) (without 22-pole flat plug):

135 x 68 x 228 mm

Weight: approx. 0.65kg

Accessories supplied: Operator’s Manual

Optional accessories: HZ18 Kelvin test lead

HM8018E/140705/ce · Subject to alterations · © HAMEG Instruments GmbH · ® Registered Trademark · DQS-certified in accordance with DIN EN ISO 9001:2000, Reg.-No.: DE-071040 QM

HAMEG Instruments GmbH · Industriestr. 6 · D-63533 Mainhausen · Tel +49 (0) 6182 800 0 · Fax +49 (0)6182 800 100 · www.hameg.com · info@hameg.com

A Rohde & Schwarz Company

www.hameg.com

Subject to change without notice

5

Page 6

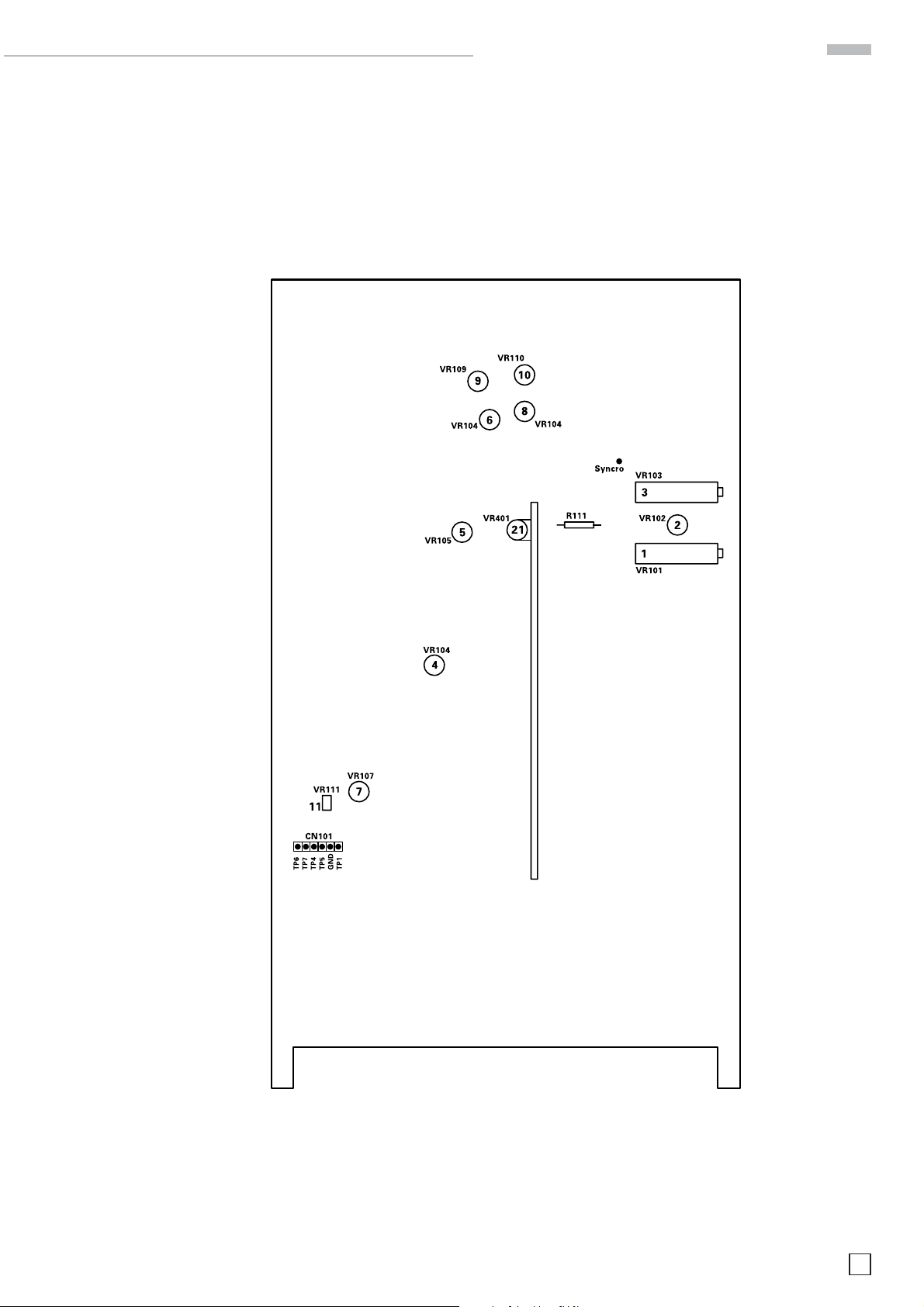

Alignment procedure HM8018

Alignment procedure HM8018

Measuring equipment required:

– Oscilloscope 20 MHz (e.g. HM303)

– Frequency counter (e.g. HM8021)

– Digital Multimeter DMM (e.g. HM8012)

– Load 100 kΩ 0.1%,

– Load 1 kΩ 0.1%

– Capacitor 470 pF (PP or Polysulfon)

– Capacitor with known value between 10...16 nF 0.1%

Presettings:

To start the calibration, fi rst adjust the R-trimmer „Pro-

be comp.“ and „Display Zero“ at the front panel to center

position. Disconnect all cables of the frontpanel HM8018.

1. Test of oscillator frequency:

Connect frequency counter (TI measuring) to testpoint

„Synchro“. Set LC-Meter to range 2 pF, „G“. Adjust period

to 6280 ps ±25 ps with R111.

2. Adjustment of measuring frequency:

Set LC-Meter to the ranges described below. Adjust period

time as following:

2 μF VR103 (3) 6283 μs ±1 μs

200 nF VR102 (2) 628.3 μs ±1 μs

200 pF VR101 (1) 62.83 μs ±1 μs

8. Adjustment of input capacitance:

Connect capacitor 470 pF to banana jacks. Set LC-Meter to

200 pF, „G“. To adjust the input capacitance, it is necessary

to close the module housing (a. and b.).

a) Connect oscilloscope (AC-coupling) to TP5, with modul

cover closed. Pass the cable through holes in the module

cover. Reduce amplitude to minimum by means of VR107

(7).

b) Connect oscilloscope to TP4 [same way as a)]. Remove ca-

pacitor 470 pF. Reduce amplitude to minimum by means of

VR111 (11).

9. Range selection „C“, „L“:

Remove all cables from HM8018. Set LC-Meter to 200 pF,

„C“. Adjust „Display Zero“ (front panel) to 0 ±3 digit on the

display of HM8018.

a) Connect Kelvin probe HZ18 to Kelvin input (5-pin diode jack)

and reduce the reading to 0 ±3 digit via „Probe comp.“ on

front panel.

b) Disconnect HZ18 and connect a known capacitor between

10 nF and 16 nF to the banana jacks. Set LC-Meter range

to 20 nF, „C“. Adjust VR104 (4) for same reading as value of

the capacitor.

3. Adjust offset (PD):

Connect oscilloscope (AC-coupling, max. sensitivity) to TP5

and set LC-Meter to range 200 nF, „G“. Adjust amplitude to

minimum with VR106 (6).

4. Adjust offset (Uref):

Connect DMM (V DC)to TP5. Set LC-Meter to 200 mH. Adjust

VR109 (9) to 0 ±1 mV.

5. Symmetry:

Set LC-Meter to 200nF, „G“. Connect resistance 100 kΩ

to the banana jacks and the oscilloscope (AC, 10 mV/Div.,

0,1 ms/Div.) to TP7. Adjust VR108 (8) for same amplitude.

misaligned aligned

6. Adjust offset (Vin):

Disconnect all cables from the instrument. Set LC-Meter

to range 200 nF. „G“. Connect DMM (VDC) to TP7. Adjust

VR110(10) to 0 ± 1 mV.

7. Range selection und gain:

Connect resistance 1 kΩ to the banana jacks. Set LC-Meter

to 200 mH. Repeat the following steps several times.

a) Set range to „Rs“. Adjust the display of LC-Meter to 1000

±1 Digit by means of VR105 (5).

b) Set range to „G“. Adjust the display of LC-Meter to 1000

±1 Digit by means of VR401 (21).

6

Subject to change without notice

Page 7

Mainboard HM8018

Circuit and layout diagrams

Subject to change without notice

7

Page 8

Circuit and layout diagrams

8

Subject to change without notice

Page 9

Circuit and layout diagrams

Subject to change without notice

9

Page 10

Circuit and layout diagrams

10

Subject to change without notice

Page 11

Circuit and layout diagrams

Subject to change without notice

11

Page 12

Circuit and layout diagrams

12

Subject to change without notice

Page 13

Circuit and layout diagrams

Subject to change without notice

13

Page 14

Circuit and layout diagrams

14

Subject to change without notice

Page 15

Circuit and layout diagrams

Subject to change without notice

15

Page 16

Oscilloscopes

Spectrum Analyzer

Power Supplies

Modular System

8000 Series

Programmable Instruments

8100 Series

authorized dealer

4S-8014-00E0

www.hameg.de

Subject to change without notice

4S-8018-00E0 / 10-01-2006-gw HAMEG Instruments GmbH

© HAMEG Instruments GmbH Industriestraße 6

A Rohde & Schwarz Company D-63533 Mainhausen

® registered trademark Tel +49 (0) 61 82 800-0

DQS-Certifi cation: DIN EN ISO 9001:2000 Fax +49 (0) 61 82 800-100

Reg.-Nr.: 071040 QM sales@hameg.de

Loading...

Loading...