Page 1

4¾-Digit Multimeter

HM8012

Service-Manual

Page 2

General information regarding the CE marking

Hersteller HAMEG Instruments GmbH KONFORMITÄTSERKLÄRUNG

Manufacturer Industriestraße 6 DECLARATION OF CONFORMITY

Fabricant D-63533 Mainhausen DECLARATION DE CONFORMITE

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produkt

The HAMEG Instruments GmbH herewith declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

Bezeichnung / Product name / Designation:

Multimeter / Multimeter /

Multimètre

Typ / Type / Type: HM8012

mit / with / avec: –

Optionen / Options / Options: –

mit den folgenden Bestimmungen / with applicable regulations / avec les directives

suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied / Normes

harmonisées utilisées

Sicherheit / Safety / Sécurité

EN 61010-1:2001 (IEC 61010-1:2001)

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique

EN 61326-1/A1 Störaussendung / Radiation / Emission:

Tabelle / table / tableau 4; Klasse / Class / Classe B.

Störfestigkeit / Immunity / Imunitee: Tabelle / table / tableau A1.

EN 61000-3-2/A14 Oberschwingungsströme / Harmonic current emissions / Émissions

de courant harmonique: Klasse / Class / Classe D.

EN 61000-3-3 Spannungsschwankungen u. Flicker / Voltage fl uctuations and fl icker /

Fluctuations de tension et du fl icker.

Datum /Date /Date

22.07.2004

Unterschrift / Signature /Signatur

G. Hübenett

Produktmanager

General information regarding the CE marking

HAMEG instruments fulfi ll the regulations of the EMC directive. The

conformity test made by HAMEG is based on the actual generic- and

product standards. In cases where different limit values are applicable,

HAMEG applies the severer standard. For emission the limits for

residential, commercial and light industry are applied. Regarding the

immunity (susceptibility) the limits for industrial environment have

been used.

The measuring- and data lines of the instrument have much infl uence

on emmission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may

be different. For measurement operation the following hints and

conditions regarding emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and

external devices, (computer, printer etc.) suffi ciently screened cables

must be used. Without a special instruction in the manual for a reduced

cable length, the maximum cable length of a dataline must be less than

3 meters and not be used outside buildings. If an interface has several

connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cables HZ72S and HZ72L from HAMEG

are suitable.

3. Infl uence on measuring instruments.

Under the presence of strong high frequency electric or magnetic fi elds,

even with careful setup of the measuring equipment an infl uence of

such signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifi cations may result from such conditions in individual cases.

HAMEG Instruments GmbH

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the

manual for a shorter length, signal lines must be less than 3 meters

and not be used outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

2

Subject to change without notice

Page 3

Content

Declaration of Conformity 2

General information regarding the CE-marking 2

4¾ Digit Programmable Multimeter HM8012 4

Specifi cations 5

Control elements 6

Function test 7

Calibration 8

Circuit and layout diagrams 9

Subject to change without notice

3

Page 4

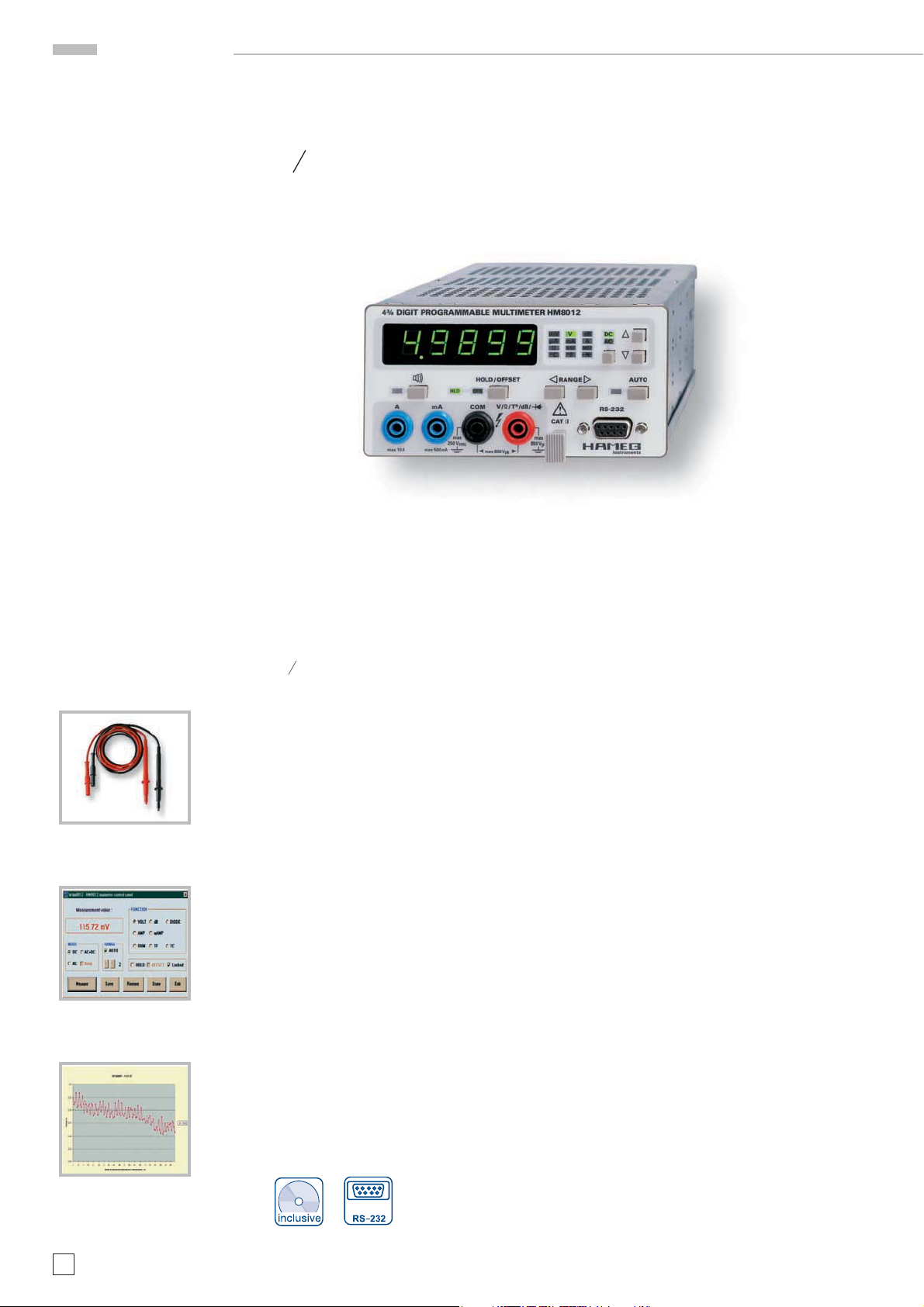

HM8012

4 -digit display with 50,000 counts, basic accuracy 0.05%

Automatic and manual range selection

Max. resolution 10 μV, 0.01 dBm, 10 nA, 10 mΩ, 0.1 °C/°F

Offset function / relative value measurement in basic

measurement functions

Input impedance ›1 GΩ (0.5 V and 5 V DC range)

RS-232 interface

PC software for control and data logging

Mainframe HM8001-2 required for operation

3

4

4 -Digit Programmable Multimeter

HM8012

3

4

WDM8012 Software

(included)

HZ15 (included)

WDM8012 Software

(included)

4

Subject to change without notice

Page 5

Specifications

4 -Digit programmable Multimeter HM8012

Valid at 23 °C after a 30 minute warm-up period

DC voltage

Measurement ranges: 500mV, 5V, 50 V, 500V, 600 V

Resolution: 10 μV, 100μV, 1m V, 10mV, 100m V

Accuracy:

5 V, 500 V, 600V: ±(0.05 % of reading +0.002 % of full scale)

500 mV, 50 V: ±(0.05% of reading + 0.004 % of full scale)

Overload protection:

V/Ω/T°/dB/ to COM and to chassis:

850 V

p

at max. 60 Hz or 600 V

DC

COM against chassis: 250 V

rms

at max. 60 Hz or 250 V

DC

Input resistance:

50 V, 500 V, 600V: 10 MΩ II 90 pF

500 mV, 5 V: › 1GΩ II 90 pF

Input current: 10 A

CMRR1): ≥ 100 dB (50 /60Hz ± 0.5 %)

SMRR2): ≥ 60 dB (50/60 Hz ± 0.5%)

dB Mode

Accuracy: ±(0.02 dB+2 digits) (display › -38.7 dBm)

Resolution: 0.01 dB above 18 % of rating

DC current

Measurement ranges: 500μA, 5 mA, 50 mA, 500mA, 10 A

Resolution: 10 nA, 100nA, 1 μA, 10μA, 1 mA

Accuracy:

0.5-500 mA: ±(0.2 % of reading + 0.004 % of full scale)

10 A: ±(0.3 % of reading + 0.004 % of full scale)

Voltage drop:

10 A range: 0.2 V max.

500 mA range: 2.5 V max.

other ranges: 0.7 V max.

AC voltage

Measurement ranges: 500mV, 5 V, 50 V, 500V, 600 V

Resolution: 10 μV, 100 mV, 1mV, 10 mV, 100mV

Accuracy 0.5-50 V:

40 Hz-5 kHz: ± (0.4 % of reading + 0.07 % of full scale)

20 Hz-20 kHz: ± (1 % of reading + 0.07 % of full scale)

Accuracy 500 V and 600 V:

40 Hz-1 kHz: ± (0.4 % of reading + 0.07 % of full scale)

20 Hz-1 kHz: ± (1 % of reading + 0.07 % of full scale)

Overload protection:

V/Ω/T°/dB/ to COM and to chassis:

850 Vpat max. 60 Hz or 600 V

DC

COM against chassis: 250 V

rms

at max. 60 Hz or 250 V

DC

Input impedance

AC mode: 1 MΩ II 90pF

AC + DC mode: 10 MΩ II 90 pF

Bandwidth at –3 dB: 80 kHz typical

dB mode: 20 Hz - 20 kHz

Accuracy

–23.8 dBm to 59.8 dBm: ±0.2 dBm

Resolution: 0.01 dB above 9 mV

CMRR1): ≥ 60 dB (50/60 Hz ± 0.5%)

Crest factor: 7 max.

3

4

AC current

Measurement ranges: 500μA, 5 mA, 50 mA, 500mA, 10 A

Resolution: 10 nA, 100nA, 1 μA, 10μA, 1 mA

Accuracy:

0.5 - 500 mA: ±(0.7 % of reading + 0.07 % of f.s.)40 Hz - 5 kHz

10 A: ±(1 % of reading + 0.07 % of full scale)

AC + DC measurements

As shown for AC + 25 digits

Resistance

Measurement ranges: 500Ω, 5 kΩ, 50 kΩ, 500kΩ, 5 MΩ, 50 MΩ

Resolution: 10 mΩ, 100 mΩ, 1Ω, 10 Ω, 100Ω, 1 kΩ

Accuracy:

500 Ω to 500 kΩ: ±(0.05% of reading + 0.004% of f.s.+50 mΩ)

5 MΩ to 50 MΩ: ±(0.3% of reading + 0.004 % of full scale)

Input protection max. 300V

rms

Measurement current: 500 Ω-5kΩ range: 1 mA

50 kΩ range: 100 μA

500 kΩ range: 10 μA

5-50 MΩ range: 100 nA

Measurement voltage: 10V typical for open inputs, depending on the

value of resistance to be measured. Negative polarity of measurement

voltage is across common terminal.

Temperature

2-wire resistance measurement with linearization for PT100 sensors as

per standard EN60751

Range: –200° C to +500° C

Resolution: 0.1° C

Measurement current: approx. 1mA

Display: in ° C, ° F

Accuracy: ± 0.1°C from – 200° C to + 200° C

± 0.2° C from 200° C to 500° C

(exception: sensor tolerance)

Temperature coefficient: (reference 23°C)

V = 500 mV, 50 V 30 ppm/° C

600 V range 80 ppm/° C

other ranges 20 ppm/° C

V ~ 600 V range 80 ppm /° C

other ranges 50 ppm/° C

mA all ranges 200 ppm/° C

mA~all ranges 300 ppm/° C

Ω 5MΩ, 50 MΩ ranges 200 ppm/° C

other ranges 50 ppm/° C

Miscellaneous

Power supply (from mainframe):

+ 5 V 300 mA

~26 V 140 mA

Operating temperature: + 10°C to + 40° C

Max. relative humidity: 80 % (without condensation)

Dimensions ( W x H x D) (without 22-pole flat plug):

135 x 68 x 228 mm

Weight: approx. 0.5kg

1)

Common mode rejection ratio

2)

Serial mode rejection ratio

Accessories supplied: Operator’s Manual, HZ15 PVC test leads, HM8012: +

Software CD and interface cable

Optional accessories: HZ10 Silicone test leads, HZ812 PT100 Temperature Sensor

HM8012E/140705/ce · Subject to alterations · © HAMEG Instruments GmbH · ® Registered Trademark · DQS-certified in accordance with DIN EN ISO 9001:2000, Reg.-No.: DE-071040 QM

HAMEG Instruments GmbH · Industriestr. 6 · D-63533 Mainhausen · Tel +49 (0)6182 800 0 · Fax +49 (0)6182 800 100 · www.hameg.com · info@hameg.com

A Rohde & Schwarz Company

www.hameg.com

Subject to change without notice

5

Page 6

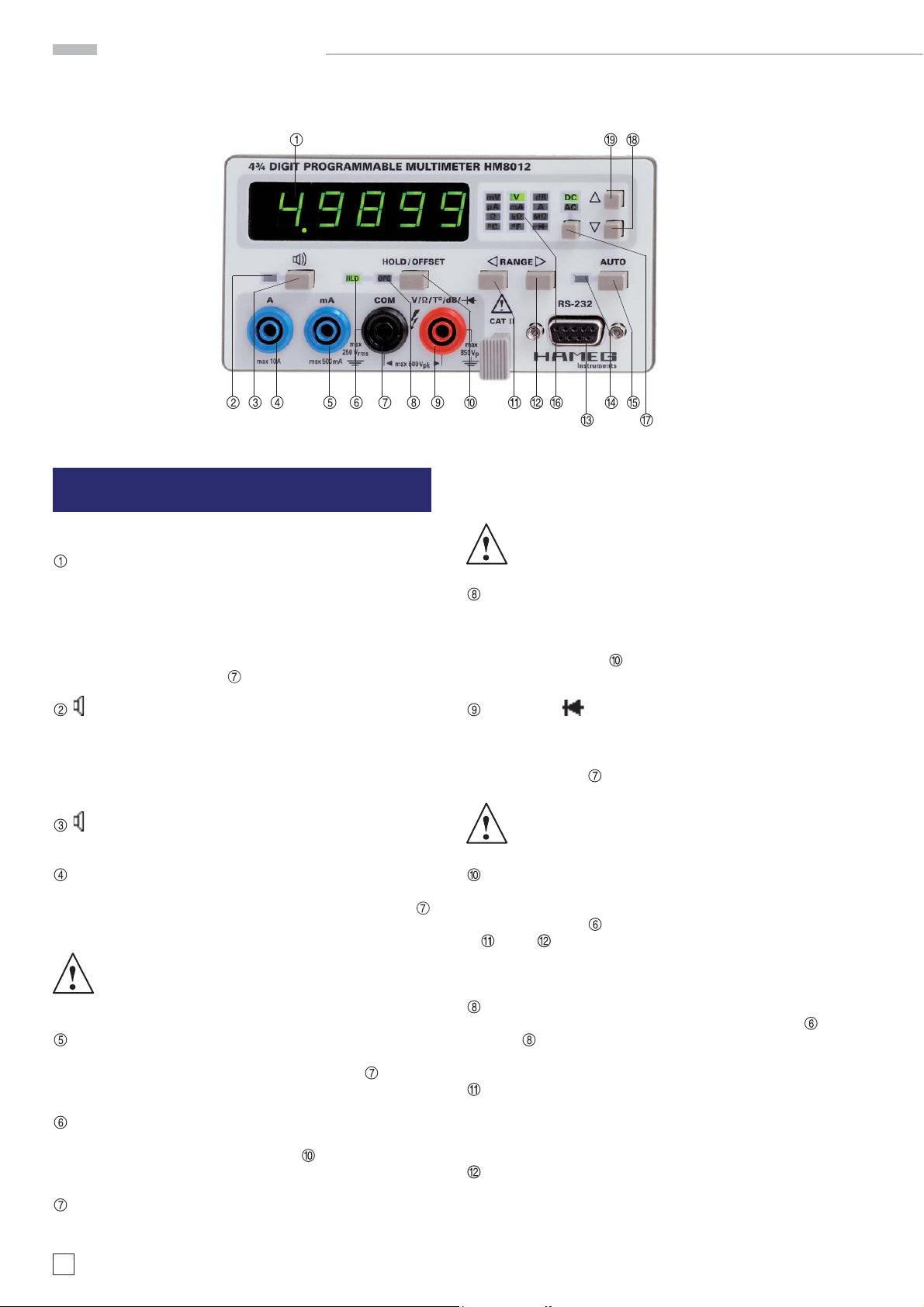

Control Elements

Control Elements

DISPLAY (7-segment LED + LED)

The digital display shows the measurement value with 4¾ digit

resolution, in which the largest fi gure is used up to “5”. It will

also display various warning messages. The measurement

value will be displayed with decimal points and polarity sign.

For DC measurement, a minus sign will appear in front of the

fi gures when the positive polarity of the measured value is

connected to the COM input

(LED)

Indicator denoting validation of the audible continuity test signal. When used as an ohmmeter, the audible signal triggers

when the measured resistance value is less than 0.1% of the

range or 50 counts. For other functions, the indicator is hidden.

BEEP (pushbutton)

Pushbutton for activating the audible signal.

A (safety terminal for 4 mm banana plugs)

Connection (high potential) for DC and AC current measurements in the 10 A range in conjunction with the COM input

(low potential).

Current in excess of 10 A (max. 20 A) must not be

applied for a period exceeding 30 s, otherwise the

internal measurement resistor thermal device will

blow.

mA (safety terminal for 4 mm banana plugs)

Connection (high potential) for DC and AC current measurements up to 500 mA in conjunction with COM input

tential). The input is fuse-protected.

HOLD (LED)

Indicator denoting that the displayed value has been frozen.

The function can be activated using key

pressing the HOLD/OFFSET key.

COM (safety terminal for 4 mm bana plugs)

The COM terminal (low potential) is the common connector for

.

(low po-

. Deactivation is by

all the measurement functions to which the potential close to

the ground of the measured quantity will be applied.

For safety reasons, the voltage across this ter-

minal compared to the case (guard wire, ground)

shall be 250 V at most.

OFFSET (LED)

Indicator denoting that the displayed value is a relative measurement. The displayed value corresponds to the input value

less the value present on the display during initial action on

the HOLD/OFFSET key

. Activate this function by means of a

second press on the HOLD/OFFSET key.

V/Ω/T°/dB/

(safety terminal for 4 mm banana plugs)

Connection (high potential) for measurements of voltages,

resistances, temperatures and diode junctions in conjunction

with the COM input

(safety terminal).

For safety reasons, the voltage across this ter-

minal compared to the case (guard wire, ground)

shall be 600 V

at most.

DC

HOLD/OFFSET (pushbutton)

Pushbutton for validating the HOLD or OFFSET functions. Pressing the key the fi rst time will freeze the front panel display.

The HOLD indicator

and keys are inoperative.

then lights up. The AUTO, AC-DC, BEEP,

A second press gives access to the relative mode. The value

mem or ized b y the HOLD func ti on is then su btr acted f ro m each

measurement before being displayed. The OFFSET indicator

lights up.

A third press will freeze the relative value. The HOLD

OFFSET

indicators light up. A fourth press will delete the

HOLD and OFFSET mode.

(pushbutton)

Pushbutton for changing to a lower range. On each press, the

new range is displayed fl eetingly on the display in code form

(L1 for lowest range, L2 for second range, etc.).

(pushbutton)

Pushb ut ton fo r changin g to a higher r an ge. Each t ime presse d,

the new range will be displayed fl eetingly on the d ispl ay i n code

form (L1 for lowest range, L2 for second range, etc.).

and

6

Subject to change without notice

Page 7

Function Test

RS-232 (DB9)

Female DB9 connector intended for serial communication.

AUTO (LED)

Indicator signalling that the multimeter is in AUTOMATIC mode.

In this mode, action on keys

and is inoperative.

AUTO (pushbutton)

Pushbutton for switching the AUTO range selection to the MANUAL range selection and vice versa.

In MANUAL mode, the choice of range is left to user initiative

using the keys

and .

Unit display zone (LED)

This zone contains a display of the measurement units. It also identifi es the function selected by pressing the

or

key.

AC-DC (pushbutton)

This key is used for selecting the measurement mode (DC, rms

AC or rms AC + DC).

Indicators below indicate the measurement mode:

DC: measurement of DC voltages

AC: measurement of RMS AC voltages

DC + AC: measurement of RMS AC+DC voltages.

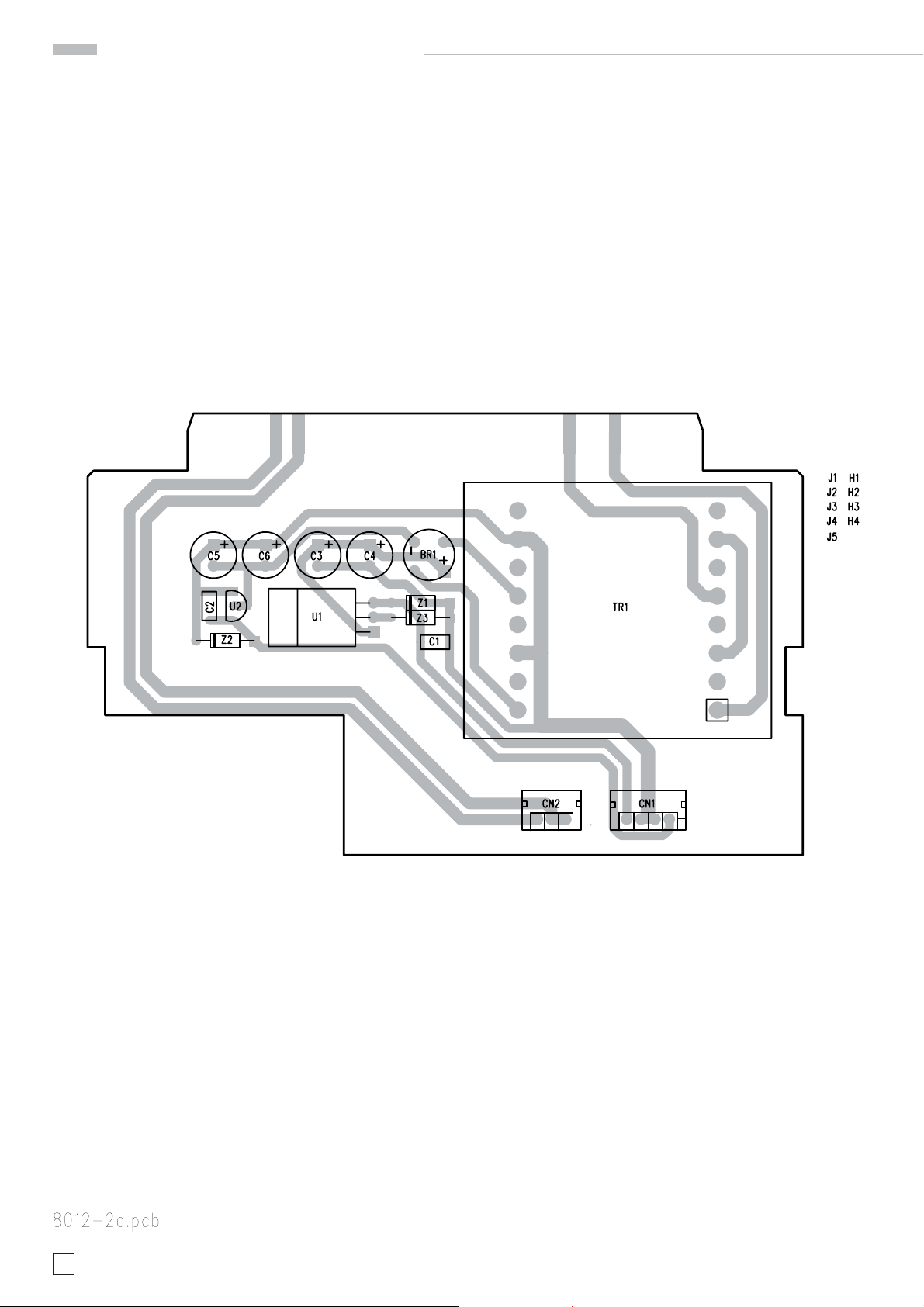

(pushbutton)

Pushbutton for selecting the next function.

a) DC voltage ranges

No. Range Reference Display limits

(+23 °C)

1 500 mV 250 mV 249.85 - 250.15

2 5 V 2.5 V 2.4986 - 2.5014

3 50 V 25. V 24.985 - 25.015

4 500 V 250 V 249.86 - 250.14

5 600 V 550.00 V 549.7 - 550.3

b) AC voltage ranges

No. Range Reference Display limits

(+23 °C)

1 500 mV 250 mV (1) 248.65 - 251.35

(2) 247.15 - 252.85

2 5 V 2.5 V (1) 2.4865 - 2.5135

(2) 2,4715 - 2.5285

3 50 V 25 V (1) 24.865 - 25.135

(2) 24.715 - 25.285

4 500 V 250 V (3) 248.65 - 251.35

(4) 247.15 - 252.85

5 600 V 550 V (3) 547.3 - 552.6

(4) 544.0 - 555.9

(1) = 40 Hz to 5 kHz

(2) = 20 Hz to 20 kHz

(3) = 40 Hz to 1 kHz

(4) = 20 Hz to 1 kHz.

(pushbutton)

Pushbutton for selecting the previous function. On startup,

the unit switches automatically to the DC voltmeter, MANUAL

mode function and 600 voltrange.

Function Test

This test should help to verify, at certain intervals, the functions of HM8012 without any great expenditure in measurement

instruments. To achieve thermal balance, the module and the

basic instrument, in its case, must be energized for at least 60

minutes before the test begins.

Measurement equipment used

Calibrator AC/DC for instance Fluke 5101B / Fluke 5700A /

Rotek 600

Resistors of 5 k

J by Vishay

Resistors 500 k

Vishay.

Test procedure

If one of the indicated calibrators is available or if precision calibrators are appropriate, all the HM8012 measurements ranges

can be checked using the following tables which indicate the

limi t v alues. Re ca libr atio n, ho wever, s ho uld o nly be p er fo rm ed

if the appropriate precision calibrator is available.

, 50 k , 500 k 0.01% for instance model S102

, 5 M 0.02%, for instance models CNS020 by

c) DC current ranges

No.

Range Reference Display limits

(+23 °C)

1 500 μA 250.00 μA 249.48 - 250.52

2 5 mA 2.5000 mA 2.4948 - 2.5052

3 50 mA 25.000 mA 24.948 - 25.052

4 500 mA 250.00 mA 249.48 - 250.52

5 10 A 1.800 A 1.794 - 1.806

d) AC current ranges (f = 400 Hz)

No.

Range Reference Display limits

(+23 °C)

1 500 μA 250.00 μA 247.9 - 252.1

2 5 mA 2.5000 mA 2.479 - 2.521

3 50 mA 25.000 mA 24.79 - 25.21

4 500 mA 250.00 mA 247.9 - 252.1

5 10 A 1.800 A 1.775 - 1.825

e) Resistor ranges

No.

Range Reference Display limits

(+23 °C)

1 500 200.00 199.83 - 200.17

2 5 k 2.0000 k 1.9989 - 2.0011

3 50 k 20.000 k 19.989 - 20.011

4 500 k 200.00 k 199.89 - 200.11

5 5 M 2.0000 M 1.9939 - 2.0061

6 50 M 20.000 M 19.393 - 20.061

Before any change of ranges, ensure that the signal at HM8012

does not represent an unacceptable load of the object under

examination. For the link between the calibrator and HM8012,

shielded cables must be used to prevent any unwanted infl u-

ence caused by the measurement signal.

Subject to change without notice

7

Page 8

Calibration

Calibration

Calibration of the HM8012 digital multimeter is performed

mainly by software. In order to enter the calibration menu keep

both pushbuttons AUTO

message CAL is displayed. After the release of both pushbuttons the fi rst calibr ation step will be indicated. First the unit will

be shown then the value of the calibration voltage etc. which

has to be applied to the instrument. In this mode the following

pushbuttons will function as given:

Pushbutton Action

AUTO

BEEP

AC+DC

Corrected value of the range selected if the

LED

ding step will be displayed.

Displays not yet calibrated values. The LED

will be on, the value can be changed by pushbutton

Change to the following calibration step.

Change to the preceding calibration step.

Saving the calibrated values.

and BEEP depressed until the-

is on, otherwise the input of the prece-

.

Calibration of frequency compensation

While observing the necessary safet y precautions open the instrument. Select the 50 V AC range. Apply 25 V AC 15 kHz. Adjust

the capacitor CV1 until the display reads 25,000 ±5 digits.

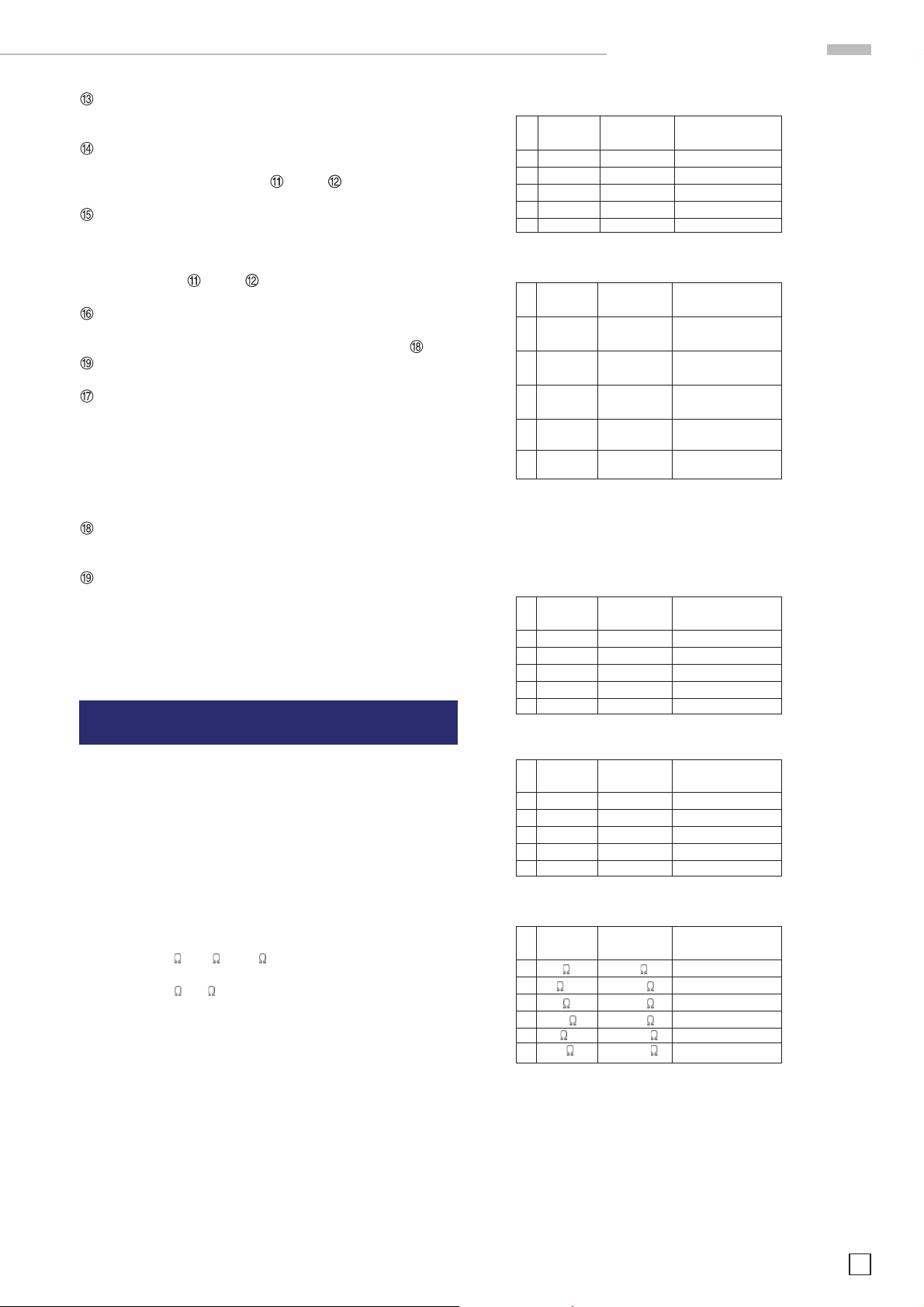

Listing of calibration steps

Calibration procedure

1. Apply the calibration value specifi ed.

2. Press BEEP

displayed. The LED

3. Press AUTO

value should be displayed.

4. Press

play the actual calibration information without moving to

another step.)

Please note:

In order to guarantee a fully calibrated instrument be sure to

perform a complete calibration cycle.

Hints:

– Pressing the AUTO

pushbutton will display the value resulting from the preceding calibration; in case it is correct no calibration will

be necessary. Pressing AUTO

strument to the menu. Pressing either or the next or

the last calibration step will be accessed.

– For precise resistance calibration it is necessary to connect

the calibration resistors as closely to the input terminals

as possible.

– Pressing the AC/DC

values.

. The former not yet corrected value will be

will be on.

to perform the calibration, the corrected

in order to proceed. (Pressing will dis-

pushbutton without the BEEP

again will return the in-

pushbutton will store the calibrated

(*) Wait for complete stabilization of the display.

8

Subject to change without notice

Page 9

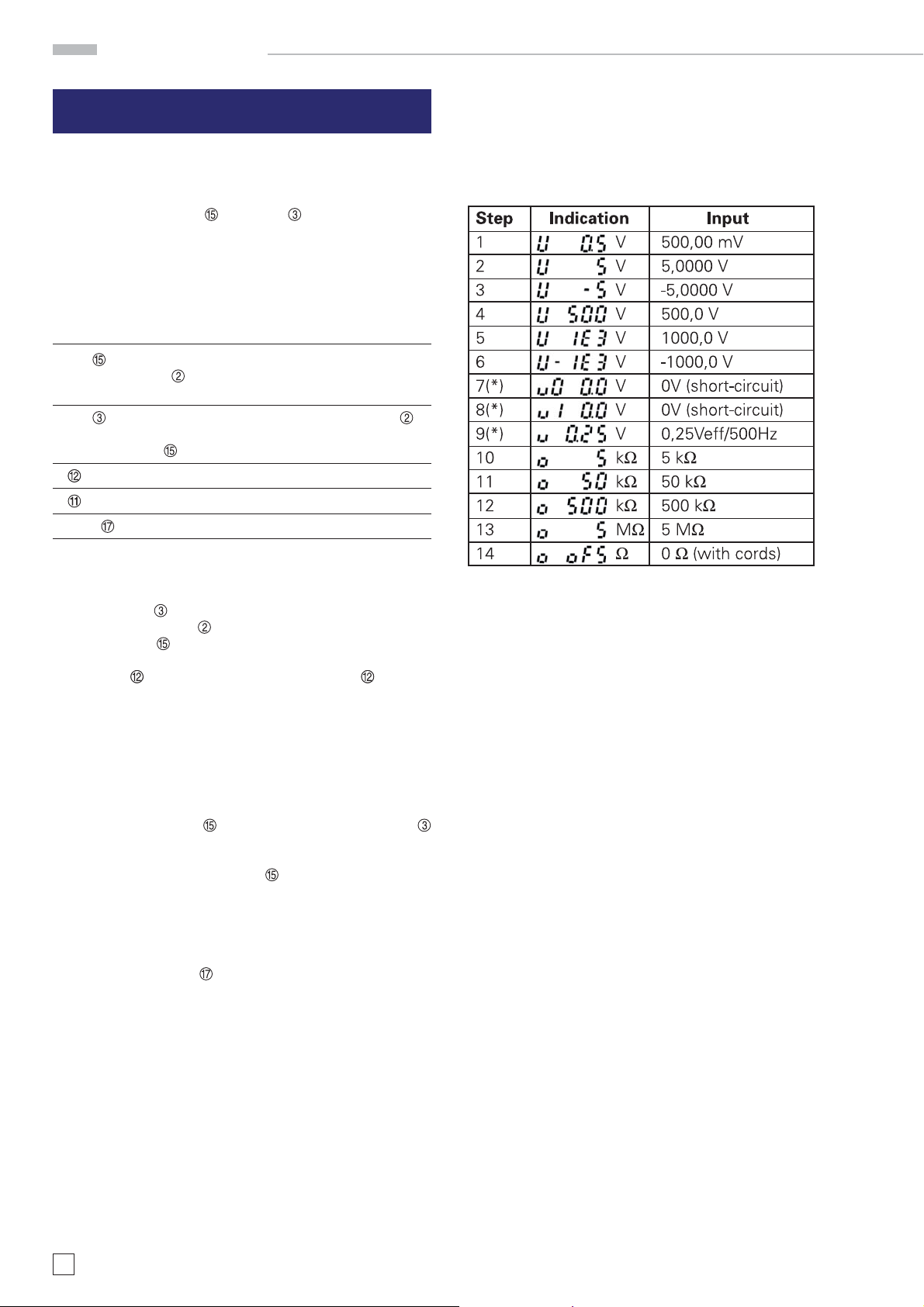

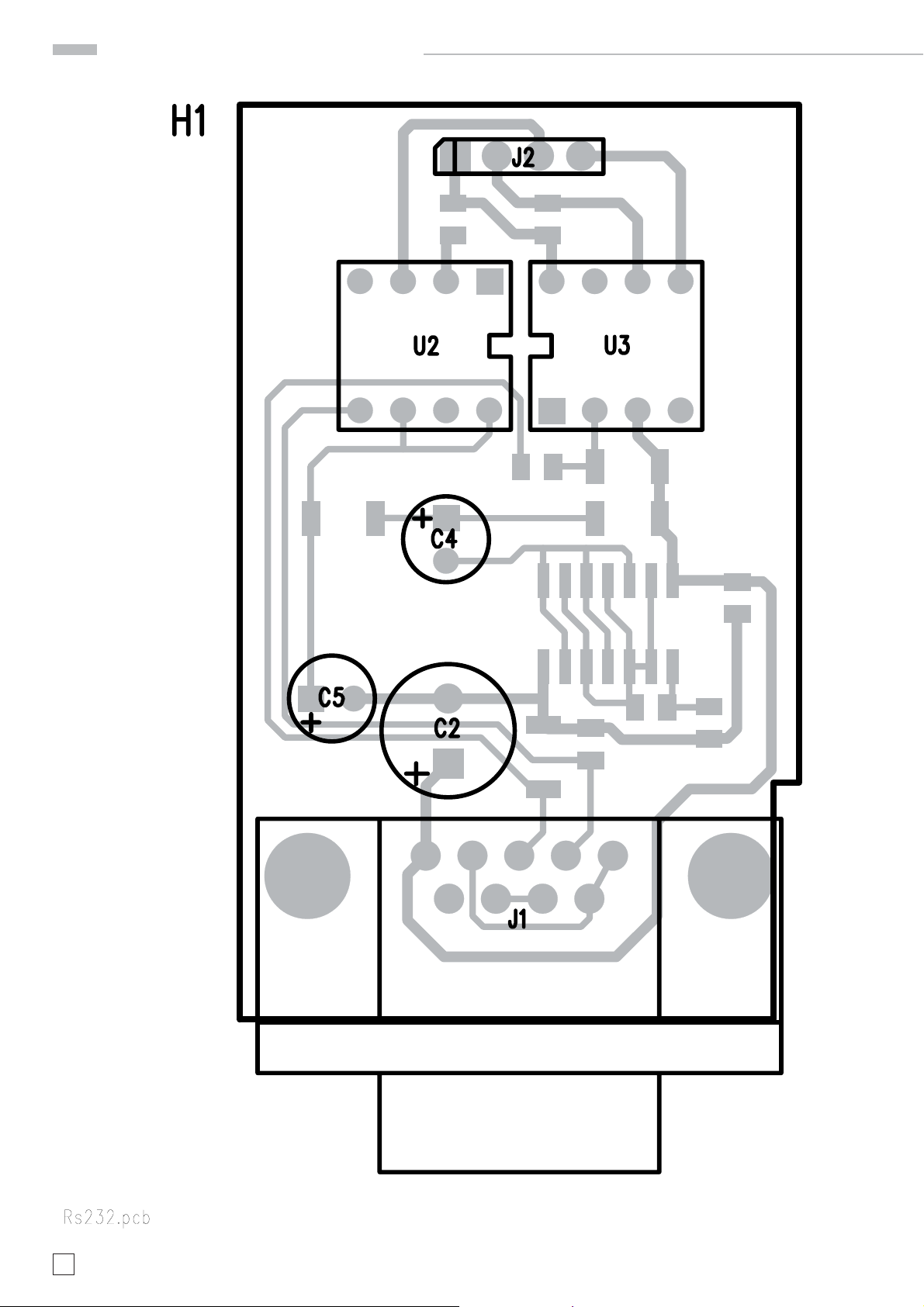

Circuit and layout diagrams

Subject to change without notice

9

Page 10

Circuit and layout diagrams

10

Subject to change without notice

Page 11

Circuit and layout diagrams

Subject to change without notice

11

Page 12

Circuit and layout diagrams

12

Subject to change without notice

Page 13

Circuit and layout diagrams

Subject to change without notice

13

Page 14

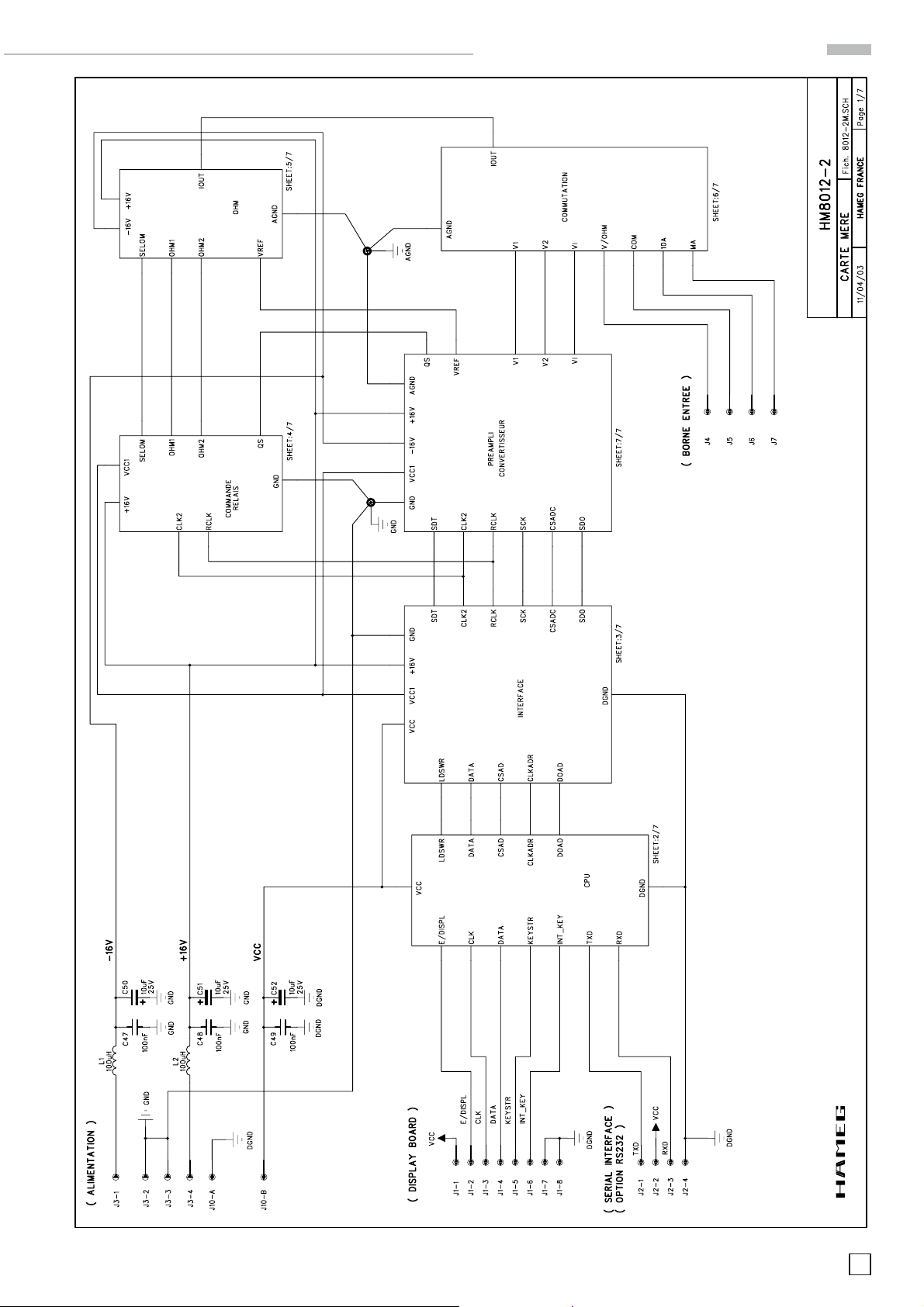

Circuit and layout diagrams

14

Subject to change without notice

Page 15

Circuit and layout diagrams

Subject to change without notice

15

Page 16

Circuit and layout diagrams

16

Subject to change without notice

Page 17

Circuit and layout diagrams

Subject to change without notice

17

Page 18

Circuit and layout diagrams

18

Subject to change without notice

Page 19

Circuit and layout diagrams

Subject to change without notice

19

Page 20

Circuit and layout diagrams

20

Subject to change without notice

Page 21

Circuit and layout diagrams

Subject to change without notice

21

Page 22

Circuit and layout diagrams

22

Subject to change without notice

Page 23

Circuit and layout diagrams

Subject to change without notice

23

Page 24

Circuit and layout diagrams

24

Subject to change without notice

Page 25

Circuit and layout diagrams

Subject to change without notice

25

Page 26

Notes

26

Subject to change without notice

Page 27

Notes

Subject to change without notice

27

Page 28

Oscilloscopes

Spectrum Analyzer

Power Supplies

Modular System

8000 Series

Programmable Instruments

8100 Series

authorized dealer

4S-8012- 00E0

www.hameg.de

Subject to change without notice

4S-8012-00E0 / 02-11-2005-gw HAMEG Instruments GmbH

© HAMEG Instruments GmbH Industriestraße 6

A Rohde & Schwarz Company D-63533 Mainhausen

® registered trademark Tel +49 (0) 61 82 800-0

DQS-Certifi cation: DIN EN ISO 9001:2000 Fax +49 (0) 61 82 800-100

Reg.-Nr.: 071040 QM sales@hameg.de

Loading...

Loading...