Page 1

Page 2

Oscilloscope data sheet with technical details . .... 4

Operating Instructions

General Information ................................................. 5

Symbols ................................................................... 5

Use of tilt handle .....................................................5

Safety ....................................................................... 5

Operating conditions ............................................... 5

EMC .........................................................................6

Warranty .................................................................. 6

Maintenance ............................................................ 6

Protective Switch-Off .............................................. 6

Power supply ........................................................... 6

Type of signal voltage..............................................7

Amplitude Measurements ....................................... 7

Total value of input voltage .....................................8

Time Measurements ............................................... 8

Connection of Test Signal........................................9

First Time Operation..............................................1 0

Trace Rotation TR ..................................................10

Probe compensation and use ...............................11

Adjustment at 1kHz ...............................................11

Adjustment at 1MHz ............................................. 11

Operating modes of the vertical

amplifiers in Yt mode. ...........................................12

X-Y Operation .........................................................1 2

Phase comparison with Lissajous figures ............ 1 3

Phase difference measurement

in DUAL mode .......................................................13

Measurement of an............................................... 13

amplitude modulation ............................................1 3

Triggering and time base ....................................... 14

Automatic Peak-Triggering .................................... 14

Normal Triggering ..................................................15

Slope ...................................................................... 1 5

Trigger coupling ...................................................... 15

Line triggering (~) .................................................. 16

Alternate triggering................................................ 16

External triggering ................................................. 1 6

Trigger indicator ..................................................... 16

Holdoff-time adjustment ....................................... 16

Delay / After Delay Triggering ...............................17

AUTO SET ..............................................................18

SAVE/RECALL........................................................19

Component Tester ................................................. 1 9

Using the Component Tester ................................ 19

Test Procedure ....................................................... 19

Test Pattern Displays............................................. 19

Testing Resistors ................................................... 20

Testing Capacitors and Inductors..........................20

Testing Semiconductors ........................................2 0

Testing Diodes ....................................................... 20

St.1196-Hüb/Ros

Testing Transistors ................................................. 2 0

In-Circuit Tests ....................................................... 20

Table of contents

Oscilloscope

HM604-3

Test Instructions

General ...................................................................23

Astigmatism Check ............................................... 2 3

Symmetry and Drift of the Vertical Amplifier ....... 23

Calibration of the Vertical Amplifier ....................... 23

Transmission Performance of the

Vertical Amplifier.................................................... 2 3

Triggering Checks .................................................. 24

Timebase................................................................ 2 4

Holdoff time ...........................................................25

Component Tester ................................................. 2 5

Trace Alignment .....................................................25

Service Instructions

General ................................................................... 25

Instrument Case Removal .....................................25

Operating Voltages ................................................ 26

Maximum and Minimum Brightness .................... 26

Astigmatism control .............................................. 26

Trigger Threshold ................................................... 26

Trouble-Shooting the Instrument .......................... 26

Adjustments ........................................................... 26

RS232 Interface - Remote Control .......................27

Baud-Rate Setting ..................................................27

Data Communication ............................................. 27

Command definition .............................................. 27

Command Chart: ................................................... 27

Instrument Data Field with Single Commands ....28

Short instruction for HM304 ................................. 29

Switching on and initial setting ............................. 2 9

Vertical amplifier mode.......................................... 29

Triggering mode .....................................................29

Measurements ...................................................... 2 9

Component tester mode.......................................29

Front Panel Elements HM604-

(Brief Description - Front View) ............................. 30

3

Subject to change without notice

Printed in Germany

1

Page 3

General information regarding the CE marking

HAMEG instruments fulfill the regulations of the EMC directive. The conformity test made by

HAMEG is based on the actual generic- and product standards. In cases where different limit

values are applicable, HAMEG applies the severer standard. For emission the limits for residential,

commercial and light industry are applied. Regarding the immunity (susceptibility) the limits for

industrial environment have been used.

The measuring- and data lines of the instrument have much influence on emmission and immunity

and therefore on meeting the acceptance limits. For different applications the lines and/or cables

used may be different. For measurement operation the following hints and conditions regarding

emission and immunity should be observed:

1. Data cables

For the connection between instruments resp. their interfaces and external devices, (computer,

printer etc.) sufficiently screened cables must be used. Without a special instruction in the manual

for a reduced cable length, the maximum cable length of a dataline must be less than 3 meters

long. If an interface has several connectors only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus purposes the double screened

cables HZ72S and HZ72L from HAMEG are suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and instrument should be as

short as possible. Without instruction in the manual for a shorter length, signal lines must be less

than 3 meters long.

Signal lines must screened (coaxial cable - RG58/U). A proper ground connection is required. In

combination with signal generators double screened cables (RG223/U, RG214/U) must be used.

3. Influence on measuring instruments.

Under the presence of strong high frequency electric or magnetic fields, even with careful setup of

the measuring equipment an influence of such signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small deviations of the measuring

value (reading) exceeding the instruments specifications may result from such conditions in individual

cases.

December 1995

HAMEG GmbH

Page 4

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE

Name und Adresse des Herstellers HAMEG GmbH

Manufacturer´s name and address Kelsterbacherstraße 15-19

Nom et adresse du fabricant D - 60528 Frankfurt

HAMEG S.a.r.l.

5, av de la République

F - 94800 Villejuif

Die HAMEG GmbH / HAMEG S.a.r.l bescheinigt die Konformität für das Produkt

The HAMEG GmbH / HAMEG S.a.r.l herewith declares conformity of the product

HAMEG GmbH / HAMEG S.a.r.l déclare la conformite du produit

®

Instruments

Bezeichnung / Product name / Designation:

Typ / Type / Type:

mit / with / avec:

Optionen / Options / Options:

mit den folgenden Bestimmungen / with applicable regulations / avec les directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied / Normes harmonisées utilisées

Sicherheit / Safety / Sécurité

EN 61010-1: 1993 / IEC (CEI) 1010-1: 1990 A 1: 1992 / VDE 0411: 1994

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility / Compatibilité électromagnétique

Oszilloskop/Oscilloscope/Oscilloscope

HM604-3

-

-

EN 50082-2: 1995 / VDE 0839 T82-2

ENV 50140: 1993 / IEC (CEI) 1004-4-3: 1995 / VDE 0847 T3

ENV 50141: 1993 / IEC (CEI) 1000-4-6 / VDE 0843 / 6

EN 61000-4-2: 1995 / IEC (CEI) 1000-4-2: 1995 / VDE 0847 T4-2: Prüfschärfe / Level / Niveau = 2

EN 61000-4-4: 1995 / IEC (CEI) 1000-4-4: 1995 / VDE 0847 T4-4: Prüfschärfe / Level / Niveau = 3

EN 50081-1: 1992 / EN 55011: 1991 / CISPR11: 1991 / VDE0875 T11: 1992

Gruppe / group / groupe = 1, Klasse / Class / Classe = B

Datum /Date /Date Unterschrift / Signature /Signatur

14.12.1995

Dr. J. Herzog

Technical Manager

Directeur Technique

Page 5

Specifications

Vertical Deflection

Operating modes: Channel I or II separate,

Channel I and II: alternate or chopped.

(0.5MHz chopper frequency, approx.)

Sum or difference with Ch. I and Ch. II

(both channels invertable).

XY-Mode: via channel I and channel II

Frequency range: 2xDC to 60MHz (-3dB)

Risetime: <5.9ns. Overshoot max. 1%.

Deflection coefficients: 14 calibrated steps

from 1mV/div. to 20V/div. (1-2-5 sequence)

with variable 2.5:1 up to 50V/div.

Accuracy in calibrated position:

1mV/div. to 2mV/div.: ±5% (0 to 10MHz (-3dB))

5mV/div. to 20V/div.: ±3%

Input impedance: 1MΩ II 20pF.

Input coupling: DC-AC-GD (ground).

Input voltage: max. 400V (DC + peak AC).

Delay line: approx. 90ns

Triggering

OSCILLOSCOPES

Automatic:

Normal with level control: DC-100MHz (≤0.5div.)

Slope: positive or negative,

ALT. Triggering; LED indicator for trigger action

Sources: Channel I or II, CH. I alternating CH II,

Coupling: AC (10Hz to 100MHz), DC (0

Active TV-Sync-Separator (pos. and neg.)

External: ≥0.3Vpp from DC to 60MHz

2nd triggering (Del. Trig.): normal with level

(peak to peak) <20Hz-100MHz (≤ 0.5div.)

line and external

HF (1.5kHz to100MHz), LF (0 to 1.5kHz)

control DC to 100 MHz

to

100MHz),

Horizontal Deflection

Time coefficients: 22 calibrated steps

from 0.5s/div. to 50ns/div. in 1-2-5 sequence

Accuracy in calibrated position: ±3%.

variable 2.5:1 up to 1.25s/div.,

with X-Mag. x10: 5ns/div. ±5%

Holdoff time: variable to approx. 10:1

Delay: 50ms - 100ns, variable 6:1 up to 300ms

Bandwidth X-amplifier: 0-3MHz (-3dB).

Input X-Amplifier via Channel II,

(sensitivity see Channel II specification)

X-Y phase shift: <3° below 120kHz.

Operation / Control

Auto Set (automatic parameter selection)

Manual (Front Panel switches)

Memory for 6 user-defined parameter settings

Remote control with built-in RS-232 interface

Component Tester

Test voltage: approx. 8.5V

Test current: approx. 7mA

Test frequency: approx. 50Hz

Test connection: 2 banana jacks 4mmØ

One test lead is grounded (Safety Earth)

(open circuit).

rms

(shorted).

rms

General Information

CRT: D14-372GH, rectangular screen (8x10div.)

internal graticule

Acceleration voltage: approx 14kV

Trace rotation: adjustable on front panel

Calibrator: square-wave generator (tr <4ns)

≈1kHz/1MHz; Output: 0.2V ±1% and 2V

Line voltage: 100-240V AC ±10%, 50/60Hz

Power consumption: approx. 40 Watt at 50Hz.

Min./Max. ambient temperature: -10°C...+40°C

Protective system: Safety class I (IEC1010-1)

Weight: approx. 5.6kg (12.4lbs), color:

Cabinet: W 285, H 125, D 380 mm

Lockable tilt handle

Subject to change without notice. 10/95

techno-brown

(11.1x4.9x14.8 inches)

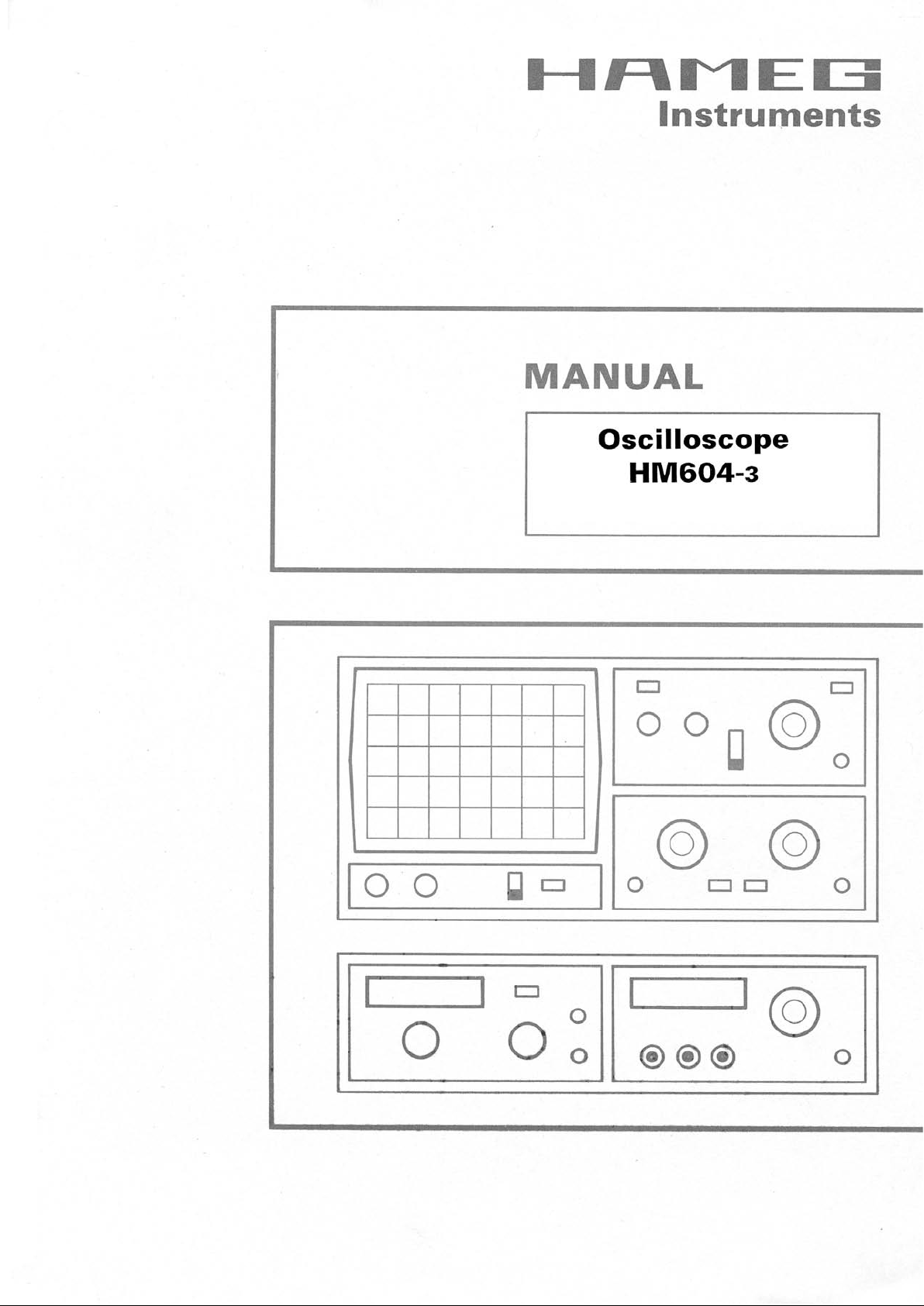

60MHz Multi-Function Oscilloscope HM 604

-3

with Auto-Set, Save and Recall (6 Setup Memories)

Remote control via built-in RS-232 Interface

Vertical: 2 Channels, 1 mV/div. - 20 V/div., Comp.-Tester, 1MHz Calibrator

Time Base: 0.5 s/div. to 5 ns/div.; Trigger-after-delay; Alternate Trigger

Triggering: DC to 100 MHz; Automatic Peak to Peak; TV-Sync-Separator

The HM604-3 is HAMEG‘s 60 MHz microprocessor controlled analog oscil-

loscope. The internal microprocessor has the capability of automatically

configuring the oscilloscope parameters, when used in the "Auto Set"

mode, so as to present a display of three cycles of the input signal, with all

of the proper control settings automatically configured: a single trace will

be displayed with 4 to 6 divisions amplitude, while each signal will be 3 to 4

divisions high in dual trace mode. At a touch of the controls, the user can

over-ride the automatic settings. Manual control is simple with easy to see

indicators denoting uncalibrated operation by blinking. Switch/parameter

settings are easily visible as bright LED scale value indications.

One powerful feature is the ability to store user-defined test scenarios, that

can be called up on demand for repeated measurement tasks. A total of

6 setups can be saved and recalled as many times as required. Additional

setup information is possible via the RS-232 port, which can be controlled

from the serial port of a PC.

Although the instrument‘s vertical bandwidth is specified as 60 MHz, signals

to 100 MHz can be displayed and triggered. Signal expansion up to a factor

of 1,000 times can be obtained in the "Delay" and "Trigger after Delay"

modes. A switching mode power supply minimises power and results in a

lightweight unit weighing only 12.4 pounds (5.6kg).

The scope is ideal for fast troubleshooting. The Auto Set feature permits the

rapid inspection of test points, without the need to constantly adjust the

scope for each new test mode. The ability to Save/Recall facilitates the use

of this unit for final inspections, where multiple, repeated scope settings are

required. These capabilities result in labor saving operations which translate

to more efficiency and cost savings to the customer.

Accessories supplied: Line Cord, Operators Manual, 2 Probes 10:1

4

Subject to change without notice

Page 6

General Information

This oscilloscope is easy to operate. The logical arrangement

of the controls allows anyone to quickly become familiar with

the operation of the instrument, however, experienced users

are also advised to read through these instructions so that all

functions are understood.

Immediately after unpacking, the instrument should be

checked for mechanical damage and loose parts in the interior.

If there is transport damage, the supplier must be informed

immediately. The instrument must then not be put into

operation.

Symbols

ATTENTION - refer to manual

Danger - High voltage

contains important information and warnings which have to

be followed by the user to ensure safe operation and to retain

the oscilloscope in a safe condition.

The case, chassis and all measuring terminals are

connected to the protective earth contact of the

appliance inlet. The instrument operates according to

Safety Class I (three-conductor power cord with

protective earthing conductor and a plug with earthing

contact).

The mains/line plug shall only be inserted in a socket outlet

provided with a protective earth contact. The protective action

must not be negated by the use of an extension cord without

a protective conductor.

The mains/line plug should be inserted before

connections are made to measuring circuits.

Protective ground (earth) terminal

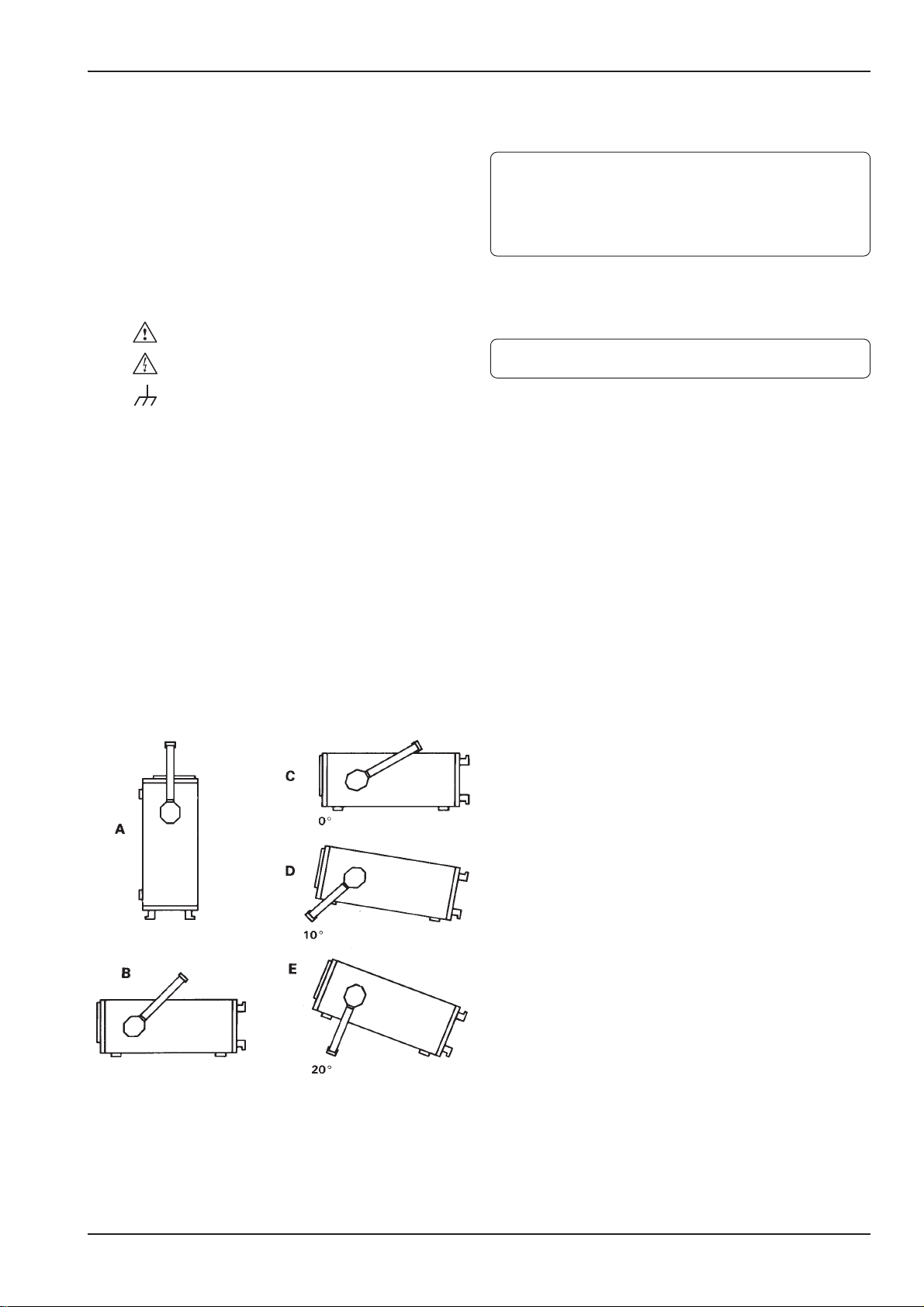

Use of tilt handle

To view the screen from the best angle, there are three different positions (C, D, E) for setting up the instrument. If the

instrument is set down on the floor after being carried, the

handle automatically remains in the upright carrying position

(A).

In order to place the instrument onto a horizontal surface,

the handle should be turned to the upper side of the

oscilloscope (C). For the D position (10° inclination), the handle

should be turned to the opposite direction of the carrying

position until it locks in place automatically underneath the

instrument. For the E position (20° inclination), the handle

should be pulled to release it from the D position and swing

backwards until it locks once more.

The handle may also be set to a position for horizontal carrying

by turning it to the upper side to lock in the B position. At the

same time, the instrument must be lifted, because otherwise

the handle will jump back.

The grounded accessible metal parts (case, sockets, jacks)

and the mains/line supply contacts (line/live, neutral) of the

instrument have been tested against insulation breakdown

with 2200V DC.

Under certain conditions, 50Hz or 60Hz hum voltages can

occur in the measuring circuit due to the interconnection with

other mains/line powered equipment or instruments. This

can be avoided by using an isolation transformer (Safety Class

II) between the mains/line outlet and the power plug of the

device being investigated.

Most cathode-ray tubes develop X-rays. However, the dose

equivalent rate falls far below the maximum permissible

value of 36pA/kg (0.5mR/h).

Whenever it is likely that protection has been impaired, the

instrument shall be made inoperative and be secured against

any unintended operation. The protection is likely to be

impaired if, for example, the instrument

• shows visible damage,

• fails to perform the intended measurements,

• has been subjected to prolonged storage under

unfavourable conditions (e.g. in the open or in moist

environments),

Safety

This instrument has been designed and tested in accordance

with IEC Publication 1010-1 (overvoltage category II, pollution

degree 2), Safety requirements for electrical equipment for

measurement, control, and laboratory use. The CENELEC

regulations EN 61010-1 correspond to this standard. It has

left the factory in a safe condition. This instruction manual

Subject to change without notice

• has been subject to severe transport stress (e.g. in poor

packaging).

Operating conditions

The instrument has been designed for indoor use. The

permissible ambient temperature range during operation is

+10°C (+50°F) ... +40°C (+104°F). It may occasionally be

subjected to temperatures between +10°C (+50°F) and 10°C (+14°F) without degrading its safety. The permissible

ambient temperature range for storage or transportation is

-40°C (-40°F) ... +70°C (+158°F).

The maximum operating altitude is up to 2200m (nonoperating 15000m). The maximum relative humidity is up

to 80%.

If condensed water exists in the instrument it should be

acclimatized before switching on. In some cases (e.g.

extremely cold oscilloscope) two hours should be allowed

before the instrument is put into operation. The instrument

should be kept in a clean and dry room and must not be

operated in explosive, corrosive, dusty, or moist

environments. The oscilloscope can be operated in any

position, but the convection cooling must not be impaired.

The ventilation holes may not be covered. For continuous

5

Page 7

operation the instrument should be used in the horizontal

position, preferably tilted upwards, resting on the tilt handle.

The specifications stating tolerances are only valid if

the instrument has warmed up for 30minutes at an

ambient temperature between +15°C (+59°F) and +30°C

(+86°F). Values without tolerances are typical for an

average instrument.

removed with a moistened cloth (99% water +1% mild

detergent). Spirit or washing benzine (petroleum ether) can

be used to remove greasy dirt. The screen may be cleaned

with water or washing benzine (but not with spirit (alcohol)

or solvents), it must then be wiped with a dry clean lint-free

cloth. Under no circumstances may the cleaning fluid get

into the instrument. The use of other cleaning agents can

attack the plastic and paint surfaces.

Protective Switch-Off

EMC

This instrument conforms to the European standards

regarding the electromagnetic compatibility. The applied

standards are: Generic immunity standard EN50082-2:1995

(for industrial environment) Generic emission standard

EN50081-1:1992 ( for residential, commercial und light

industry environment).

This means that the instrument has been tested to the highest

standards.

Please note that under the influence of strong

electromagnetic fields, such signals may be superimposed

on the measured signals. Under certain conditions this is

unavoidable due to the instrument‘s high input sensitivity,

high input impedance and bandwidth. Shielded measuring

cables, shielding and earthing of the device under test may

reduce or eliminate those effect‘s.

Warranty

HAMEG warrants to its Customers that the products it

manufactures and sells will be free from defects in materials

and workmaship for a period of 2 years. This warranty shall

not apply to any defect, failure or damage caused by improper

use or inadequate maintenance and care. HAMEG shall not

obliged to provide service under this warranty to repair

damage resulting from attempts by personnel other than

HAMEG represantatives to install, repair, service or modify

these products.

In order to obtain service under this warranty, Customers

must contact and notify the distributor who has sold the

product.

Each instrument is subjected to a quality test with 10 hour

burn-in before leaving the production. Practically all early

failures are detected by this method. In the case of shipments

by post, rail or carrier it is recommended that the original

packing is carefully preserved. Transport damages and

damage due to gross negligence are not covered by the

guarantee.

In the case of a complaint, a label should be attached to the

housing of the instrument which describes briefly the faults

observed. If at the same time the name and telephone

number (dialing code and telephone or direct number or

department designation) is stated for possible queries, this

helps towards speeding up the processing of guarantee

claims.

This instrument is equipped with a switch mode power supply.

It has both overvoltage and overload protection, which will

cause the switch mode supply to limit power consumption

to a minimum.

In this case a ticking noise may be heard.

Power supply

The oscilloscope operates on mains/line voltages between

100VAC and 240VAC. No means of switching to different

input voltages has therefore been provided.

The power input fuses are externally accessible. The

fuseholder is located above the 3-pole power connector.

The power input fuses are externally accessible, if the rubber

conector is removed. The fuseholder can be released by

pressing its plastic retainers with the aid of a small

screwdriver. The retainers are located on the right and left

side of the holder and must be pressed towards the center.

The fuse(s) can then be replaced and pressed in until locked

on both sides.

Use of patched fuses or short-circuiting of the fuseholder is

not permissible; HAMEG assumes no liability whatsoever for

any damage caused as a result, and all warranty claims

become null and void.

Fuse type:

Size 5x20mm; 0.8A, 250V AC fuse;

must meet IEC specification 127,

Sheet III (or DIN 41 662

or DIN 41 571, sheet 3).

Time characteristic: time-lag (T).

Attention!

There is a fuse located inside the instrument within

the switch mode power supply:

Size 5x20mm; 0.5A, 250V AC fuse;

must meet IEC specification 127,

Sheet III (or DIN 41 662

or DIN 41 571, sheet 3).

Time characteristic: fast (F).

This fuse must not be replaced by the operator!

Maintenance

Various important properties of the oscilloscope should be

carefully checked at certain intervals. Only in this way is it

largely certain that all signals are displayed with the accuracy

on which the technical data are based. The test methods

described in the test plan of this manual can be performed

without great expenditure on measuring instruments.

However, purchase of the HAMEG scope tester HZ 60,

which despite its low price is highly suitable for tasks of this

type, is very much recommended.

The exterior of the oscilloscope should be cleaned regularly

with a dusting brush. Dirt which is difficult to remove on the

casing and handle, the plastic and aluminium parts, can be

6

Subject to change without notice

Page 8

Type of signal voltage

With the HM604-3, most repetitive signals in the frequency

range up to at least 60MHz (-3dB) can be examined.

Sinewave signals of 100MHz are displayed with a height of

approx. 50% (-6dB). However when examining square or

pulse type waveforms, attention must be paid to the harmonic

content of such signals. The repetition frequency (fundamental frequency) of the signal must therefore be significantly

smaller than the upper limit frequency of the vertical amplifier.

Displaying composite signals can be difficult, especially if they

contain no repetitive higher amplitude content which can be

used for triggering. This is the case with bursts, for instance.

To obtain a well-triggered display in this case, the assistance

of the variable holdoff and/or delay function may be required.

Television video signals are relatively easy to trigger using

the built-in TV-Sync-Separator (TV).

For optional operation as a DC or AC voltage amplifier, the

vertical amplifier input is provided with a DC/AC switch. The

DC position should only be used with a series-connected

attenuator probe or at very low frequencies or if the

measurement of the DC voltage content of the signal is

absolutely necessary.

The minimum signal voltage which must be applied to the Y

input for a trace of 1div. height is 1mVpp when the 1mV LED

is lit and the vernier is set to CAL by turning the fine

adjustment knob within the VOLTS/DIV. section fully

clockwise. However, smaller signals than this may also be

displayed. The deflection coefficients on the input attenuators

are indicated in mV/div. or V/div. (peak-to-peak value).

The magnitude of the applied voltage is ascertained by

multiplying the selected deflection coefficient by the vertical

display height in div. If an attenuator probe x10 is used, a

further multiplication by a factor of 10 is required to ascertain

the correct voltage value.

For exact amplitude measurements, the variable control

( VAR. 2.5:1) must be set to its calibrated detent CAL

position. When turning the variable control ccw, the

deflection coefficient LED will start to blink and the sensitivity

will be reduced until a maximum factor of 2.5 is reached.

Therefore any intermediate value is possible within the 1-2-5

sequence.

With direct connection to the vertical input, signals

up to 400Vpp may be displayed (attenuator set to 20V/

div., variable control to left stop).

With the designations

When displaying very low frequency pulses, the flat tops may

be sloping with AC coupling of the vertical amplifier (AC limit

frequency approx. 1.6 Hz for 3dB). In this case, DC operation

is preferred, provided the signal voltage is not superimposed

on a too high DC level. Otherwise a capacitor of adequate

capacitance must be connected to the input of the vertical

amplifier with DC coupling. This capacitor must have a

sufficiently high breakdown voltage rating. DC coupling is

also recommended for the display of logic and pulse signals,

especially if the pulse duty factor changes constantly.

Otherwise the display will move upwards or downwards at

each change. Pure direct voltages can only be measured with

DC-coupling.

Amplitude Measurements

In general electrical engineering, alternating voltage data

normally refers to effective values (rms = root-mean-square

value). However, for signal magnitudes and voltage

designations in oscilloscope measurements, the peak-to-peak

voltage (Vpp) value is applied. The latter corresponds to the

real potential difference between the most positive and most

negative points of a signal waveform.

If a sinusoidal waveform, displayed on the oscilloscope

screen, is to be converted into an effective (rms) value, the

resulting peak-to-peak value must be divided by 2x√2 = 2.83.

Conversely, it should be observed that sinusoidal voltages

indicated in Vrms (Veff) have 2.83 times the potential

difference in Vpp. The relationship between the different

voltage magnitudes can be seen from the following figure.

H = display height in div.,

U= signal voltage in Vpp at the vertical input,

D = deflection coefficient in V/div. at attenuator switch,

the required value can be calculated from the two given

quantities:

⋅

However, these three values are not freely selectable. They

have to be within the following limits (trigger threshold,

accuracy of reading):

H between 0.5 and 8div., if possible 3.2 to 8div.,

U between 1mVpp and 160Vpp,

D between 1mV/div. and 20V/div. in 1-2-5 sequence.

Examples:

Set deflection coefficient D = 50mV/div. 0.05V/div.,

observed display height H = 4.6div.,

required voltage U = 0.05x4.6 = 0.23Vpp.

Input voltage U = 5Vpp,

set deflection coefficient D = 1V/div.,

required display height H = 5:1 = 5div.

Signal voltage U = 230Vrmsx2√2 = 651Vpp

(voltage > 160Vpp, with probe 10:1: U = 65.1Vpp),

desired display height H = min. 3.2div., max. 8div.,

max. deflection coefficient D = 65.1:3.2 = 20.3V/div.,

min. deflection coefficient D = 65.1:8 = 8.1V/div.,

adjusted deflection coefficient D = 10V/div.

Voltage values of a sine curve

Vrms = effective value; Vp = simple peak or crest value;

Vpp = peak-to-peak value; Vmom = momentary value.

Subject to change without notice

The input voltage must not exceed 400V, independent

from the polarity.

If an AC voltage which is superimposed on a DC voltage is

applied, the maximum peak value of both voltages must not

exceed + or -400V. So for AC voltages with a mean value of

zero volt the maximum peak to peak value is 800Vpp.

If attenuator probes with higher limits are used, the

probes limits are valid only if the oscilloscope is set to

7

Page 9

DC input coupling. If DC voltages are applied under AC input

coupling conditions the oscilloscope maximum input voltage

value remains 400V. The attenuator consists of a resistor in

the probe and the 1MΩ input resistor of the oscilloscope,

which are disabled by the AC input coupling capacity when

AC coupling is selected. This also applies to DC voltages with

superimposed AC voltages. It also must be noted that due

to the capacitive resistance of the AC input coupling capacitor,

the attenuation ratio depends on the signal frequency. For

sinewave signals with frequencies higher than 40Hz this

influence is negligible.

In the GD (ground coupling) setting, the signal path is

interrupted directly beyond the input. This causes the

attenuator to be disabled again, but now for both DC and AC

voltages.

With the above listed exceptions HAMEG 10:1 probes can

be used for DC measurements up to 600V or AC voltages

(with a mean value of zero volt) of 1200Vpp. The 100:1 probe HZ53 allows for 1200V DC or 2400Vpp for AC.

It should be noted that its ACpeak value is derated at higher

frequencies. If a normal x10 probe is used to measure high

voltages there is the risk that the compensation trimmer

bridging the attenuator series resistor will break down causing

damage to the input of the oscilloscope. However, if for

example only the residual ripple of a high voltage is to be

displayed on the oscilloscope, a normal x10 probe is sufficient.

In this case, an appropriate high voltage capacitor (approx.

22-68nF) must be connected in series with the input tip of

the probe.

Total value of input voltage

The duration of a signal period or a part of it is

determined by multiplying the relevant time (horizontal distance in div.) by the time coefficient indicated

on the TIME/DIV. LED scales.

The variable time control (identified with an arrow

knob cap) must be in its calibrated position CAL. (arrow

pointing horizontally to the right). For exact time

measurements, the variable control ( VAR. 2.5:1) must

be set to its calibrated detent CAL position. When

turning the variable control ccw, the time coefficient

indicator LED starts blinking and the timebase speed

will be reduced until a maximum factor of 2.5 is

reached. Therefore any intermediate value is possible

within the 1-2-5 sequence.

With the designations

L = displayed wave length in div. of one period,

T = time in seconds for one period,

F = recurrence frequency in Hz of the signal,

Tc = time coefficient in s/div. on timebase switch and

the relation F = 1/T, the following equations can be stated:

= ⋅

=

=

=

⋅

⋅

=

=

⋅

With active X-MAG (x10) indicated by the x10 LED lit, the Tc

value must be divided by 10.

However, these four values are not freely selectable. They

have to be within the following limits:

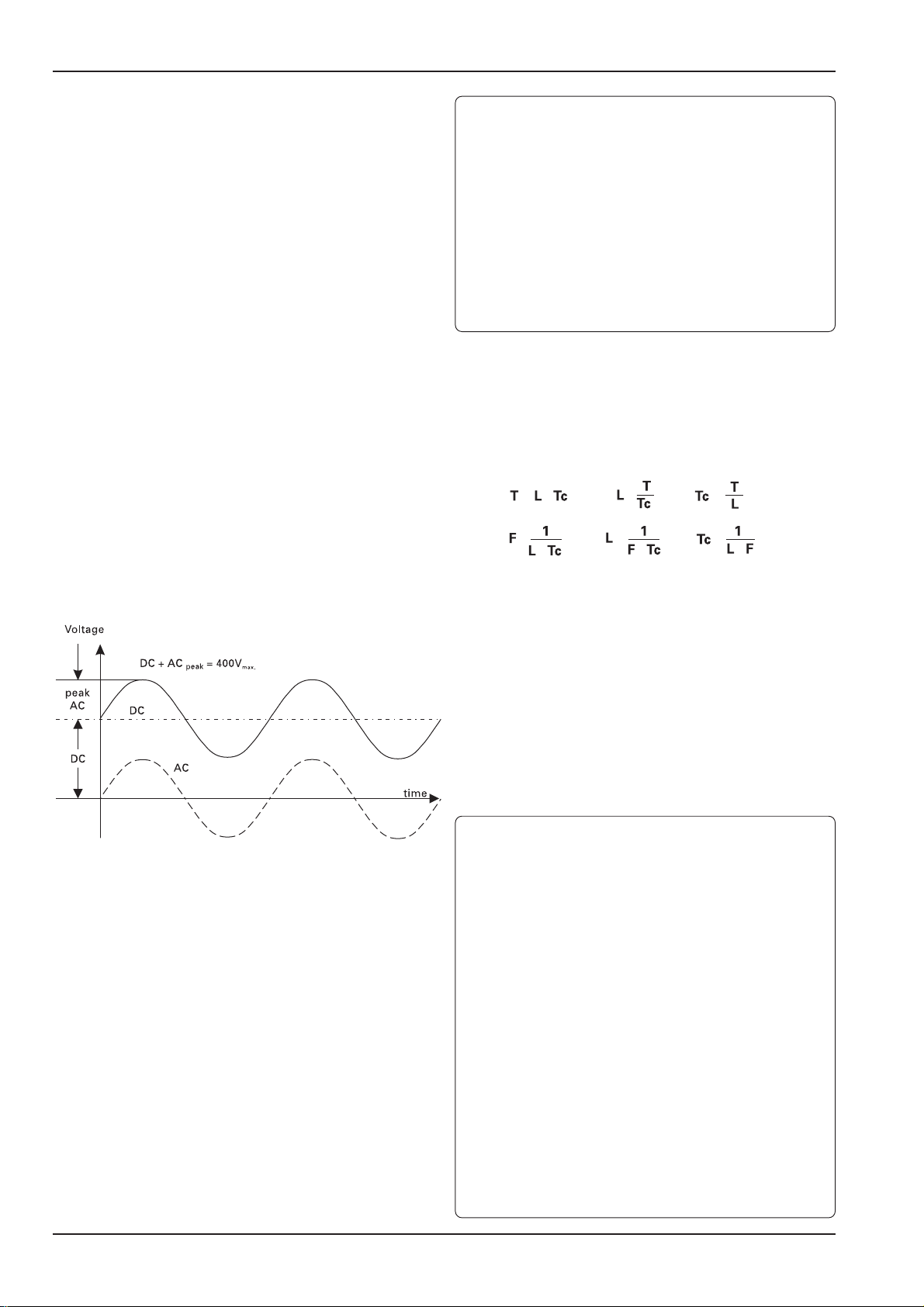

The dotted line shows a voltage alternating at zero volt level.

If superimposed on a DC voltage, the addition of the positive

peak and the DC voltage results in the max. voltage (DC +

ACpeak).

With Y-POS. control (input coupling to GD) it is possible to

use a horizontal graticule line as reference line for ground

potential before the measurement. It can lie below or above

the horizontal central line according to whether positive and/

or negative deviations from the ground potential are to be

measured.

Time Measurements

As a rule, most signals to be displayed are periodically

repeating processes, also called periods. The number of

periods per second is the repetition frequency. Depending

on the time base setting indicated by one of the TIME/DIV.

LED‘s, one or several signal periods or only a part of a period

can be displayed. The time coefficients are stated in s/div.

when the red sec-LED and the 0.5 or 0.2 LED (ms/div scale)

are lit. The ms/div. or µs/div. time coefficients are indicated

by one of the LED‘s on the ms or µs scale.

L between 0.2 and 10div., if possible 4 to 10div.,

T between 0.01µs and 5s,

F between 0.5Hz and 35MHz,

Tc between 0.05µs/div. and 0.5s/div. in 1-2-5 sequence

(with X-MAG. (x10) inactive), and

Tc between 5ns/div. and 20ms/div. in 1-2-5 sequence

(with X-MAG. (x10) active).

Examples:

Displayed wavelength L = 7div.,

set time coefficient Tc = 0.1µs/div.,

required period T = 7x0.1x10

required rec. freq. F = 1:(0.7x10

-6

= 0.7µs

-6

) = 1.428MHz.

Signal period T = 1s,

set time coefficient Tc = 0.2s/div.,

required wavelength L = 1:0.2 = 5div..

Displayed ripple wavelength L = 1div.,

set time coefficient Tc = 10ms/div.,

required ripple freq. F = 1:(1x10x10

-3

) = 100Hz.

TV-line frequency F = 15625Hz,

set time coefficient Tc = 10µs/div.,

required wavelength L = 1:(15 625x10-5) = 6.4div..

Sine wavelength L = min. 4div., max. 10div.,

Frequency F = 1kHz,

max. time coefficient Tc = 1:(4x10

3

) = 0.25ms/div.,

min. time coefficient Tc = 1:(10x103) = 0.1ms/div.,

set time coefficient Tc = 0.2ms/div.,

required wavelength L = 1:(10

3

x0.2x10-3) = 5div.

8

Subject to change without notice

Page 10

Displayed wavelength L = 0.8div.,

set time coefficient Tc = 0.5µs/div.,

pressed X-MAG. (x10) button: Tc = 0.05µs/div.,

required rec. freq. F = 1:(0.8x0.05x10

required period T = 1:(25x10

6

) = 40ns.

-6

) = 25MHz,

If the time is relatively short as compared with the complete

signal period, an expanded time scale should always be

applied (X-MAG. (x10) active). In this case, the ascertained

time values have to be divided by 10. The time interval of

interest can be shifted to the screen center using the X-POS.

control.

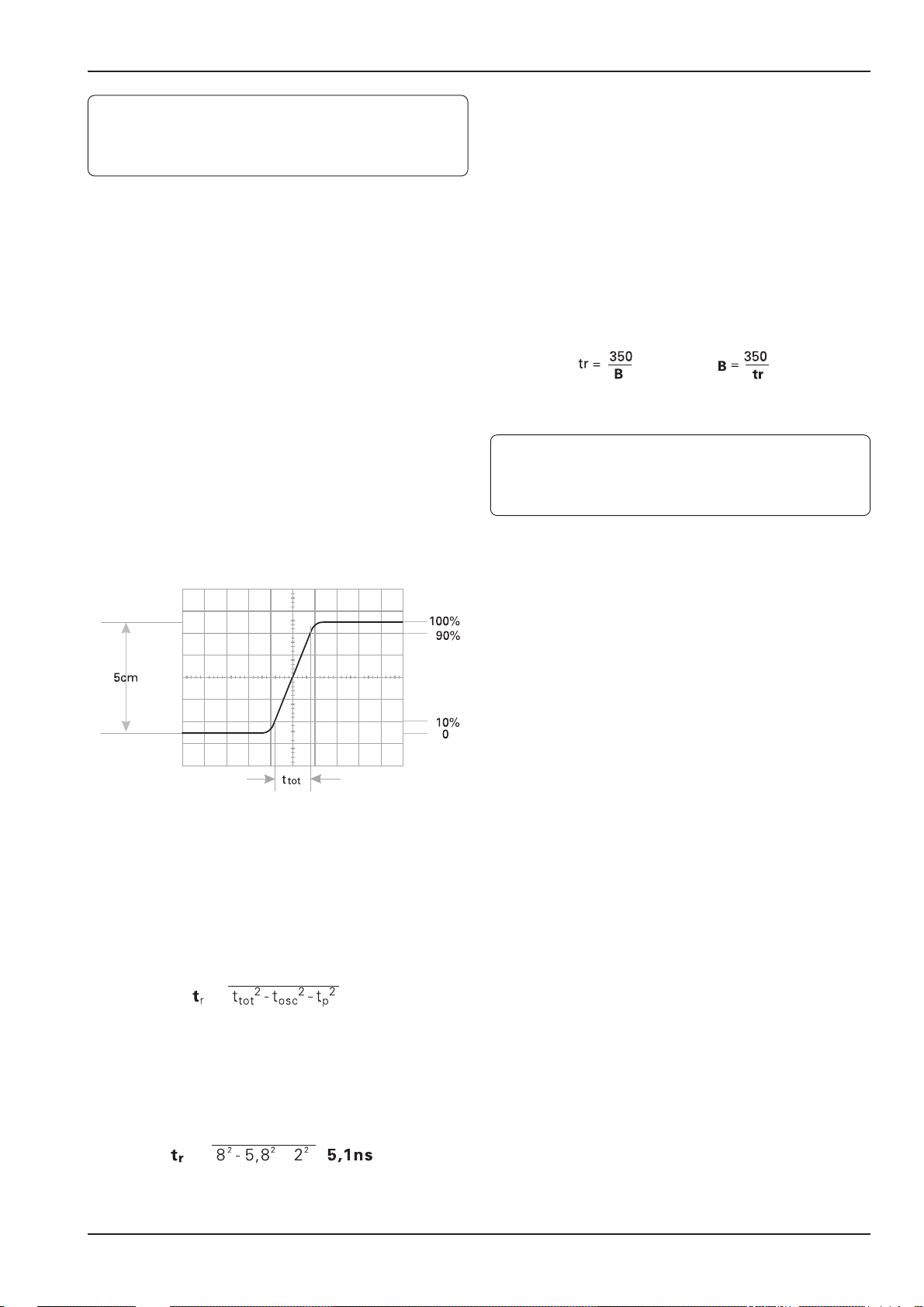

When investigating pulse or square waveforms, the critical

feature is the risetime of the voltage step. To ensure that

transients, ramp-offs, and bandwidth limits do not unduly

influence the measuring accuracy, the risetime is generally

measured between 10% and 90% of the vertical pulse height.

For measurement, adjust the Y deflection coefficient with

its variable control together with the Y-POS. control so that

the pulse height is precisely aligned with the 0% and 100%

lines of the internal graticule. The 10% and 90% points of

the signal will now coincide with the 10% and 90% graticule

lines. The risetime is given by the product of the horizontal

distance in div. between these two coincident points and the

time coefficient setting. If X x10 magnification is used, this

product must be divided by 10. The fall time of a pulse can

also be measured by using this method.

The following figure shows correct positioning of the

oscilloscope trace for accurate risetime measurement.

... .... .... .... .... .... .... .... .... ....

.

... .... .... .... .... .... .... .... .... ....

particularly simple in this way. In principle it is possible to

measure in any display position and at any signal amplitude.

It is only important that the full height of the signal edge of

interest is visible in its full length at not too great steepness

and that the horizontal distance at 10% and 90% of the

amplitude is measured. If the edge shows rounding or

overshooting, the 100% should not be related to the peak

values but to the mean pulse heights. Breaks or peaks

(glitches) next to the edge are also not taken into account.

With very severe transient distortions, the rise and fall time

measurement has little meaning. For amplifiers with

approximately constant group delay (therefore good pulse

transmission performance) the following numerical

relationship between rise time tr (in ns) and bandwidth B

(in MHz) applies:

Connection of Test Signal

Caution: When connecting unknown signals to the

oscilloscope input, always use automatic triggering

and set the DC-AC input coupling switch to AC (DC

not lit). The attenuator should initially be set to 20V/

div.

Sometimes the trace will disappear after an input signal has

been applied. The attenuator must be switched to a higher

deflection coefficient by pressing the left (<) arrow pushbutton

in the VOLTS/DIV. section constantly or step by step, until

the vertical signal height is only 3-8div. With a signal amplitude

greater than 160Vpp, an attenuator probe must be inserted

before the vertical input. If, after applying the signal, the trace

is nearly blanked, the period of the signal is probably

substantially longer than the set value on the TIME/DIV. scale.

It should be switched to an adequately larger time coefficient

by pressing the left (<) arrow pushbutton in the TIME/DIV

section by pressing it constantly or step by step. In most

cases the easiest way to adapt the instruments settings to

the input signal is to depress the AUTO SET pushbutton for

automatic instrument settings.

With a time coefficient of 0.05µs/div. and X x10 magnification,

the example shown in the above figure results in a total

measured risetime of

= 1.6div x 0.05µs/div. : 10 = 8ns

t

tot

When very fast risetimes are being measured, the risetimes

of the oscilloscope amplifier and of the attenuator probe has

to be deducted from the measured time value. The risetime

of the signal can be calculated using the following formula.

=√

In this t

of the oscilloscope amplifier (approx. 12ns), and t

of the probe (e.g. = 2ns). If t

can be taken as the risetime of the pulse, and calculation is

is the total measured risetime, t

tot

is greater than 100ns, then t

tot

unnecessary.

Calculation of the example in the figure above results in a

signal risetime

is the risetime

osc

the risetime

p

=√ − =

The measurement of the rise or fall time is not limited to the

trace dimensions shown in the above diagram. It is only

The signal to be displayed can be connected directly to the Y input of the oscilloscope with a shielded test cable such as

HZ32 or HZ34, or reduced through a x10 or x100 attenuator

probe. The use of test cables with high impedance circuits is

only recommended for relatively low frequencies (up to

approx. 50kHz). For higher frequencies, the signal source

must be of low impedance, i.e. matched to the characteristic

resistance of the cable (as a rule 50Ω). Especially when

transmitting square and pulse signals, a resistor equal to the

characteristic impedance of the cable must also be connected

across the cable directly at the Y-input of the oscilloscope.

When using a 50Ω cable such as the HZ34, a 50Ω through

termination type HZ22 is available from HAMEG. When

transmitting square signals with short rise times, transient

phenomena on the edges and top of the signal may become

visible if the correct termination is not used. A terminating

resistance is sometimes recommended with sine signals as

well. Certain amplifiers, generators or their attenuators

tot

maintain the nominal output voltage independent of frequency

only if their connection cable is terminated with the prescribed

resistance. Here it must be noted that the terminating resistor

HZ22 will only dissipate a maximum of 2Watts. This power

is reached with 10Vrms or at 28.3Vpp with sine signal.

If a x10 or x100 attenuator probe is used, no termination is

necessary. In this case, the connecting cable is matched

directly to the high impedance input of the oscilloscope. When

using attenuators probes, even high internal impedance

Subject to change without notice

9

Page 11

sources are only slightly loaded (approx. 10MΩ II 16pF or

100MΩ II 9pF with HZ53). Therefore, if the voltage loss due

to the attenuation of the probe can be compensated by a higher

amplitude setting, the probe should always be used. The series

impedance of the probe provides a certain amount of protection

for the input of the vertical amplifier. Because of their separate manufacture, all attenuator probes are only partially

compensated, therefore accurate compensation must be

performed on the oscilloscope (see Probe compensation ).

Standard attenuator probes on the oscilloscope normally

reduce its bandwidth and increase the rise time. In all cases

where the oscilloscope bandwidth must be fully utilized (e.g.

for pulses with steep edges) we strongly advise using the

probes HZ51 (x10) HZ52 (x10 HF) and HZ54 (x1 and x10).

This can save the purchase of an oscilloscope with larger

bandwidth.

The probes mentioned have a HF-calibration in addition to

low frequency calibration adjustment. Thus a group delay

correction to the upper limit frequency of the oscilloscope is

possible with the aid of an 1MHz calibrator, e.g. HZ60.

where a trace appears on the screen if the INTENS. knob is

in center position, all LED‘s should remain unlit. The trace,

displaying one baseline or the shorter COMP TESTER

baseline, should be visible after a short warm-up period of

approx. 10 seconds. If the COMP TESTER mode is active,

depress the COMP TESTER pushbutton once to switch to

XY or Yt mode. In XY mode the XY LED in the TIME/DIV

section is lit, in this case depress the XY pushbutton once to

switch over to Yt mode. Adjust Y-POS.I and X-POS. controls

to center the baseline. Adjust INTENS. (intensity) and FOCUS

controls for medium brightness and optimum sharpness of

the trace. The oscilloscope is now ready for use.

• Rotate the variable controls with arrows, i.e. TIME/DIV.

variable control, CH.I and CH.II attenuator variable

controls, and HOLD OFF control to their calibrated detent.

• Set all controls with marker lines to their midrange position

(marker lines pointing vertically).

••

• Depress the upper NORM. pushbutton until the AC

••

symbol on the trigger coupling scale is lit.

• Both GD input coupling pushbutton switches for CH.I and

CH.II in the Y-field should be set to the GD position (GD lit).

In fact the bandwidth and rise time of the oscilloscope are

not noticably changed with these probe types and the

waveform reproduction fidelity can even be improved because

the probe can be matched to the oscilloscopes individual pulse

response.

If a x10 or x100 attenuator probe is used, DC input

coupling must always be used at voltages above 400V .

With AC coupling of low frequency signals, the

attenuation is no longer independent of frequency,

pulses can show pulse tilts. Direct voltages are

suppressed but load the oscilloscope input coupling

capacitor concerned. Its voltage rating is max. 400 V

(DC + peak AC). DC input coupling is therefore of quite

special importance with a x100 attenuation probe

which usually has a voltage rating of max. 1200 V (DC

+ peak AC). A capacitor of corresponding capacitance

and voltage rating may be connected in series with

the attenuator probe input for blocking DC voltage (e.g.

for hum voltage measurement).

With all attenuator probes, the maximum AC input voltage

must be derated with frequency usually above 20kHz.

Therefore the derating curve of the attenuator probe type

concerned must be taken into account.

The selection of the ground point on the test object is

important when displaying small signal voltages. It should

always be as close as possible to the measuring point. If this

is not done, serious signal distortion may result from spurious

currents through the ground leads or chassis parts. The

ground leads on attenuator probes are also particularly critical.

They should be as short and thick as possible. When the

attenuator probe is connected to a BNC-socket, a BNCadapter, should be used. In this way ground and matching

problems are eliminated. Hum or interference appearing in

the measuring circuit (especially when a small deflection

coefficient is used) is possibly caused by multiple grounding

because equalizing currents can flow in the shielding of the

test cables (voltage drop between the protective conductor

connections, caused by external equipment connected to the

mains/line, e.g. signal generators with interference protection

capacitors).

If only a spot appears (CAUTION! CRT phosphor can be

damaged), reduce the intensity immediately and check that

the XY mode is not selected (XY LED dark). If the trace is

not visible, check the correct positions of all knobs and modes

(particularly NM LED - normal triggering - LED on).

To obtain the maximum life from the cathode-ray tube, the

minimum intensity setting necessary for the measurement

in hand and the ambient light conditions should be used.

Particular care is required when a single spot is displayed, as

a very high intensity setting may cause damage to the

fluorescent screen of the CRT. Switching the oscilloscope

off and on at short intervals stresses the cathode of the CRT

and should therefore be avoided.

The instrument is so designed that even incorrect operation

will not cause serious damage.

The HM604-3 accepts all signals from DC (direct voltage) up

to a frequency of at least 60MHz (-3dB). For sinewave

voltages the upper frequency limit will be 100MHz (-6dB).

However, in this higher frequency range the vertical display

height on the screen is limited to approx. 4-5div. The time

resolution poses no problem. For example, with 100MHz and

the fastest adjustable sweep rate (5ns/div.), one cycle will

be displayed every 2div. The tolerance on indicated values

amounts to ±3% in both deflection directions. All values to

be measured can therefore be determined relatively

accurately.

However, from approximately 10MHz upwards the measuring

error will increase as a result of loss of gain. At 18MHz this

reduction is about 10%. Thus, approximately 11% should be

added to the measured voltage at this frequency. As the

bandwidth of the amplifiers may differ slightly (normally

between 60 and 78MHz), the measured values in the upper

frequency range cannot be defined exactly. Additionally, as

already mentioned, for frequencies above 60MHz the dynamic

range of the display height steadily decreases. The vertical

amplifier is designed so that the transmission performance

is not affected by its own overshoot.

First Time Operation

Switch on the oscilloscope by depressing the red POWER

pushbutton. The instrument will revert to its last used

operating mode. Except in the case of COMP. TESTER mode,

10

Trace Rotation TR

In spite of Mumetal-shielding of the CRT , effects of the earths

magnetic field on the horizontal trace position cannot be

completely avoided. This is dependent upon the orientation

Subject to change without notice

Page 12

of the oscilloscope on the place of work. A centred trace

may not align exactly with the horizontal center line of the

graticule. A few degrees of misalignment can be corrected

by a potentiometer accessible through an opening on the

front panel marked TR.

Probe compensation and use

trimmer can be found in the probe information sheet. Adjust

the trimmer with the insulated screw driver provided, until

the tops of the square wave signal are exactly parallel to the

horizontal graticule lines (see 1kHz diagram). The signal height

should then be 4div. ± 0.16div. (= 4 % (oscilloscope 3% and

probe 1%). During this adjustment, the signal edges will

remain invisible.

To display an undistorted waveform on an oscilloscope, the

probe must be matched to the individual input impedance of

the vertical amplifier.

For this purpose a square wave signal with a very fast rise

time and minimum overshoot should be used, as the

sinusoidal contents cover a wide frequency range. The

frequency accuracy and the pulse duty factor are not of such

importance.

The built-in calibration generator provides a square wave signal

with a very fast risetime (<4ns), and switch-selectable

frequencies of approx. 1kHz and 1MHz from two output

sockets below the CRT screen.

As the squarewave signals are used for probe compensation

adjustments, neither the frequency accuracy nor the pulse

duty factor are of importance and therefore not specified.

One output provides 0.2Vpp ±1% (tr <4ns) for 10:1 probes,

and the other 2Vpp for 100:1 probes. When the Y deflection

coefficients are set to 5mV/div., these calibration voltages

correspond to a screen amplitude of 4div.

The output sockets have an internal diameter of 4.9mm to

accommodate the internationally accepted shielding tube

diameter of modern Probes and F-series slimline probes. Only

this type of construction ensures the extremly short ground

connections which are essential for an undistorted waveform

reproduction of non-sinusoidal high frequency signals.

Adjustment at 1kHz

The C-trimmer adjustment (low frequency) compensates the

capacitive loading on the oscilloscope input (approx. 20pF

for the HM604-3). By this adjustment, the capacitive division

assumes the same ratio as the ohmic voltage divider to ensure

the same division ratio for high and low frequencies, as for

DC. (For 1:1 probes or switchable probes set to 1:1, this

adjustment is neither required nor possible). A baseline parallel to the horizontal graticule lines is essential for accurate

probe adjustments. (See also

Connect the probes (Types HZ51, 52, 53, 54, or HZ36) to the

CH.I input. One deflection coefficient in the VOLTS/DIV

section of channel I must lit. If this is not the case depress

the CHI pushbutton once and switch off channel II by

depressing the CHII pushbutton once. Set input coupling CH

I to DC (LED illuminates) and check that GD is switched off.

The CHI deflection coefficient must be 5mV/div., and TIME/

DIV. should be set to 0.2ms/div., and all variable controls to

CAL. position. Plug the the probe tip into the appropriate

calibrator output socket, i.e. 10:1 probes into the 0.2V socket,

100:1 probes into the 2V socket.

incorrect correct incorrect

Approximately 2 complete waveform periods are displayed

on the CRT screen. The compensation trimmer should be

adjusted. The location of the low frequency compensation

„Trace rotation TR“

).

Adjustment at 1MHz

Probes HZ51, 52 and 54 can also be HF-compensated. They

incorporate resonance de-emphasing networks (R-trimmer

in conjunction with inductances and capacitors) which permit probe compensation in the range of the upper frequency

limit of the vertical oscilloscope amplifier. Only this

compensative adjustment ensures optimum utilisation of the

full bandwidth, together with constant group delay at the

high frequency end, thereby reducing characteristic transient

distortion near the leading edge (e.g. overshoot, rounding,

ringing, holes or bumps) to an absolute minimum.

Using the probes HZ51, 52 and 54, the full bandwidth of the

HM604-3 can be utilized without risk of unwanted waveform

distortion.

Prerequisite for this HF compensation is a square wave

generator with fast risetime (typically 4ns), and low output

impedance (approx. 50Ω), providing 0.2V and 2V at a

frequency of approx. 1MHz. The calibrator output of the

HM604-3 meets these requirements when the CAL.

pushbutton is depressed.

Connect the probe to CH.I input. Depress the CAL.

pushbutton for 1MHz. Operate the oscilloscope as described

under 1kHz but select for 0.2µs/div TIME/DIV. setting.

Insert the probe tip into the output socket marked 0.2V. A

waveform will be displayed on the CRT screen, with leading

and trailing edges clearly visible. For the HF-adjustment now

to be performed, it will be necessary to observe the rising

edge as well as the upper left corner of the pulse top. The

location of the high frequency compensation trimmer(s) can

also be found in the probe information sheet. These Rtrimmer(s) have to be adjusted such that the beginning of

the pulse is as straight as possible. Overshoot or excessive

rounding are unacceptable. The adjustment is relatively easy

if only one adjusting point is present. In case of several

adjusting points the adjustment is slightly more difficult, but

causes a better result. The rising edge should be as steep as

possible, with a pulse top remaining as straight and horizontal as possible.

incorrect correct incorrect

After completion of the HF-adjustment, the signal amplitude

displayed on the CRT screen should have the same value as

during the 1kHz adjustment.

Probes other than those mentioned above, normally have a

larger tip diameter and may not fit into the calibrator outputs.

Whilst it is not difficult for an experienced operator to build a

suitable adapter, it should be pointed out that most of these

probes have a slower risetime with the effect that the total

bandwidth of scope together with probe may fall far below

that of the HM604-3. Furthermore, the HF-adjustment feature

is nearly always missing so that waveform distortion can not

be entirely excluded.

Subject to change without notice

11

Page 13

The adjustment sequence must be followed in the order

described, i.e. first at 1kHz, then at 1MHz. The calibrator

frequencies should not be used for timebase calibration. The

pulse duty cycle deviates from 1:1 ratio.

Prerequisites for precise and easy probe adjustments, as well

as checks of deflection coefficients, are straight horizontal

pulse tops, calibrated pulse amplitude, and zero-potential at

the pulse base. Frequency and duty cycle are relatively

uncritical. For interpretation of transient response, fast pulse

risetimes and low-impedance generator outputs are of

particular importance.

Providing these essential features, as well as switchselectable output-frequencies, the calibrator of the HM6043 can, under certain conditions, replace expensive

squarewave generators when testing or compensating

wideband-attenuators or -amplifiers. In such a case, the input

of an appropriate circuit will be connected to one of the CAL.-

outputs via a suitable probe.

The voltage provided at a high-impedance input (1MΩ II 1530pF) will correspond to the division ratio of the probe used

(10:1 = 20mVpp, 100:1 = also 20mVpp from 2V output).

Suitable probes are HZ51, 52, 53, and 54.

Operating modes of the vertical

amplifiers in Yt mode.

The vertical amplifier is set to the desired operating mode by

using the 2 pushbuttons CH I and CH II (for CH I, CH II,

DUAL and ADD mode) in the Y field of the front panel. The

different modes are indicated by LED‘s in the channel I and

channel II VOLTS/DIV sections and the ADD LED in ADD

mode.

If only CH II is active to switch to CH I mode, first press the

CH I pushbutton to switch on channel I. Now the oscilloscope

is in DUAL mode where LED‘s in both VOLTS/DIV sectors

are lit. Then the CH II pushbutton must be depressed once

to switch off channel II. It is not possible to operate the

oscilloscope with both channels switched off. That is why

the required channel must first be switched on and then the

unwanted channel must be switched off.

To switch from CH I to CH II mode, first switch on CH II and

then switch off CH I. If internal triggering is selected (EXT

LED near the TRIG. INP. socket extinguished), the trigger

source indicator LED‘s (TR I and TR II) will be switched over

simultaneously.

DUAL mode is selected if a LED is lit in each VOLTS/DIV

sectors. As mentioned before, one channel is always present

and so the other channel must be switched on for DUAL

mode operation.

In DUAL mode both channels are working. Two signals can

be displayed together in alternate or chopped mode. The

alternate mode is not suitable for displaying very slow-running

processes. The display then flickers or appears to jump.

Therefore the instrument automatically switches over from

alternate to chopped mode if TIME/DIV settings from 0.5ms/

div to 0.5s/div are used. If in chopped DUAL mode, both

channels are switched over constantly at a high frequency

within a sweep period. Low frequency signals below 1kHz,

or with periods longer than 1ms are then displayed without

flicker. Conversely in DUAL alternate mode, the displayed

channel switches over from channell I to channel II and vice

versa after each sweep period.

In DUAL mode the internal trigger source can be switched

over from channel I to channel II and vice versa if the TRIG.

pushbutton is depressed for a short time. Depressing the

TRIG. pushbutton in DUAL mode for a longer time switches

over to alternate triggering and consequently both TR I and

TR II LED‘s are lit. As alternate triggering is not possible in

combination with DUAL chopped mode, the instrument

automatically switches over to the alternate mode if DUAL

chopped mode was active before. Alternate triggering can

be switched off by depressing the TRIG. pushbutton for a

short time. Then just one TR LED is lit.

DUAL chopped mode is also automatically switched off when

TV-F (television frame triggering) is selected to avoid

interference.

In combination with delay and triggered delay mode, DUAL

chopped mode can also be switched to DUAL alternate mode

by simultaniously depressing both pushbuttons marked with

< and > arrows in the TIME/DIV sector. Any change in the

delay mode time base setting reverts to the DUAL chopped

mode.

ADD mode is selected by simultaneously depressing both

CH I and CH II pushbuttons which causes the ADD LED

between both pushbuttons to light.

In ADD mode the signals of both channels are algebraically

added (±I ±II) and displayed as one signal. Whether the

resulting display shows the sum or difference is dependent

on the phase relationship or the polarity of the signals and on

the invert function indicated by the INV LED‘s for each

channel. To quit the ADD mode, depress the pushbutton for

the required channel or depress both CH I and CH II

pushbuttons for a short time to switch back to DUAL mode.

As alternate triggering is not available in ADD mode, the

instrument switches over from ADD mode to alternate DUAL

mode if the TRIG pushbutton is depressed for a longer time.

In ADD mode the following combinations are possible for

In-phase input voltages:

• Both INV (invert) function CH.I and

INV (invert) function CH.II active

• released or depressed = sum.

• Only one INV (invert) function active = difference.

Antiphase input voltages:

• Both INV (invert) function active

or inactive = difference.

• INV (invert) function CH.I or INV

(invert) function CH.II active = sum.

In the ADD mode the vertical display position is dependent

upon the Y-POS. setting of both channels. The same Y

deflection coefficient is normally used for both channels with

algebraic addition.

Please note that the Y-POS. settings are also added

but are not affected by the INV setting.

Differential measurement techniques allow direct

measurement of the voltage drop across floating components

(both ends above ground). Two identical probes should be

used for both vertical inputs. In order to avoid ground loops,

use a separate ground connection and do not use the probe

ground leads or cable shields.

X-Y Operation

For X-Y operation, the pushbutton in the X field marked XY

must be depressed. Then the XY LED in the TIME/DIV sector

is lit and the time coefficient indication is switched off. The X

signal is then derived from the INPUT CH II (X). The

calibration of the X signal during X-Y operation is determined

by the setting of the Channel II Y deflection coefficient and

variable control.

This means that the sensitivity ranges and input impedances

12

Subject to change without notice

Page 14

are identical for both the X and Y axes. However , the Y-POS.II

control is disconnected in this mode. Its function is taken

over by the X-POS. control. It is important to note that the

X-MAG. (x10) facility, normally used for expanding the

sweep, is inoperative in the X-Y mode. It should also be noted

that the bandwidth of the X amplifier is ≤ 2.5MHz (-3dB), and

therefore an increase in phase difference between both axes

is noticeable from 50kHz upwards.

The inversion of the X-input signal using the INV CH.II button

is not possible.

Lissajous figures can be displayed in the X-Y mode for certain

measuring tasks:

• Comparing two signals of different frequency or bringing

one frequency up to the frequency of the other signal.

This also applies for whole number multiples or fractions

of the one signal frequency.

• Phase comparison between two signals of the same

frequency.

Phase comparison with Lissajous figures

The following diagrams show two sine signals of the same

frequency and amplitude with different phase angles.

Should both input voltages be missing or fail in the XY mode, a very bright light dot is displayed on the

screen. This dot can burn into the phosphor at a too

high brightness setting (INTENS. knob) which causes

either a lasting loss of brightness, or in the extreme

case, complete destruction of the phosphor at this

point.

Phase difference measurement

in DUAL mode

A larger phase difference between two input signals of the

same frequency and shape can be measured very simply on

the screen in Dual mode. The time base should be triggered

by the reference signal (phase position 0). The other signal

can then have a leading or lagging phase angle.

For greatest accuracy adjust slightly over one period and

approximately the same height of both signals on the screen.

The variable controls for amplitude and time base and the

TRIG. LEVEL knob can also be used for this adjustment

without influence on the result. Both base lines are set onto

the horizontal graticule center line with the Y-POS. knobs

before the measurement. With sinusoidal signals, observe

the zero (crossover point) transitions; the sine peaks are less

accurate. If a sine signal is noticeably distorted by even

harmonics, or if a DC voltage is present, AC coupling is

recommended for both channels. If it is a question of pulses

of the same shape, read off at steep edges.

It must be noted that the phase difference cannot be

determined if alternate triggering (TR I and TR II lit) is selected.

Calculation of the phase angle or the phase shift between

the X and Y input voltages (after measuring the distances a

and b on the screen) is quite simple with the following

formula, and a pocket calculator with trigonometric functions.

Apart from the reading accuracy, the signal height has no

influence on the result.

ϕ=

ϕ=√

ϕ=

The following must be noted here:

• Because of the periodic nature of the trigonometric

functions, the calculation should be limited to angles ≤90°

However here is the advantage of the method.

• Do not use a too high test frequency. The phase shift of

the two oscilloscope amplifiers of the HM604-3 in the XY mode can exceed an angle of 3° above 120kHz.

• It cannot be seen as a matter of course from the screen

display if the test voltage leads or lags the reference

voltage. A CR network before the test voltage input of

the oscilloscope can help here. The 1 MΩ input resistance

can equally serve as R here, so that only a suitable

capacitor C needs to be connected in series. If the

aperture width of the ellipse is increased (compared with

C short-circuited), then the test voltage leads the

reference voltage and vice versa. This applies only in the

region up to 90° phase shift. Therefore C should be

sufficiently large and produce only a relatively small just

observable phase shift.

Phase difference measurement in DUAL mode

t = horizontal spacing of the zero transitions in div.

T = horizontal spacing for one period in div.

In the example illustrated, t = 3div. and T = 10div. The phase

difference in degrees is calculated from

ϕ

ϕ π π

Relatively small phase angles at not too high frequencies can

be measured more accurately in the X-Y mode with Lissajous

figures.

Measurement of an

amplitude modulation

The momentary amplitude u at time t of a HF-carrier voltage,

which is amplitude modulated without distortion by a

sinusoidal AF voltage, is in accordance with the equation

Subject to change without notice

13

Page 15

Ω Ω ω Ω ω

where

= unmodulated carrier amplitude

U

T

ΩΩ

Ω = 2πF = angular carrier frequency

ΩΩ

ωω

ω = 2πf = modulation angular frequency

ωω

m = modulation factor (i.a. œ 1 100%).

The lower side frequency F-f and the upper side frequency

F+f arise because of the modulation apart from the carrier

frequency F.

Amplitude and frequency spectrum for AM display (m = 50%)

The display of the amplitude-modulated HF oscillation can be

evaluated with the oscilloscope provided the frequency

spectrum is inside the oscilloscope bandwidth. The time base

is set so that several cycles of the modulation frequency are

visible. Strictly speaking, triggering should be external with

modulation frequency (from the AF generator or a

demodulator). However, internal triggering is frequently

possible with normal triggering (NM LED lit) button

depressed) using a suitable TRIG. LEVEL setting and possibly

also using the time variable adjustment.

Oscilloscope setting for a signal according to figure 2:

• Y: CH. I; 20mV/div.; AC.

• TIME/DIV.: 0.2ms/div.

• Triggering: Normal (NM LED lit); with LEVEL-setting;

internal (or external) triggering.

Figure 2

Amplitude modulated oscillaton: F = 1 MHz; f = 1 kHz;

m = 50 %; UT = 28.3 mVrms.

If the two values a and b are read from the screen, the

modulation factor is calculated from

where a = UT (1+m) and b = UT (1-m).

The variable controls for amplitude and time can be set

arbitrarily in the modulation factor measurement. Their

position does not influence the result.

Triggering and time base

Time related amplitude changes on a measuring signal (AC

voltage) are displayable in Yt-mode. In this mode the signal

voltage deflects the beam in vertical direction while the

timebase generator moves the beam from the left to the

right of the screen (time deflection).

Normally there are periodically repeating waveforms to be

displayed. Therefore the time base must repeat the time

deflection periodically too. To produce a stationary display,

the time base must only be triggered if the signal height and

slope condition coincide with the former time base start

conditions. A DC voltage signal can not be triggered as it is a

constant signal with no slope.

Triggering can be performed by the measuring signal itself

(internal triggering) or by an external supplied but synchronous

voltage (external triggering).

The trigger voltage should have a certain minimum amplitude.

This value is called the trigger threshold. It is measured with

a sine signal. Except when external trigger is used the trigger

threshold can be stated as vertical display height in div.,

through which the time base generator starts, the display is

stable, and the trigger LED (located in the X field above the

trigger coupling scale) lights.

The internal trigger threshold of the HM604-3 is given as ≤

5div. When the trigger voltage is externally supplied, it can

be measured in Vpp at the TRIG. INP. socket. Normally, the

trigger threshold may be exceeded up to a maximum factor

of 20.

The HM604-3 has two trigger modes, which are characterized

in the following.

Automatic Peak-Triggering

The triggerring mode is indicated by the NM LED beside the

NORM pushbuttons on the X field of the front panel.

Automatic triggering is selected if the NM LED is unlit,

otherwise simultaneously depress both NORM pushbuttons

to select automatic triggering. Then the sweep generator

will be running without test signal or external trigger voltage.

A base line will always be displayed even with no signal.

With an applied AC signal the peak value triggering enables

the user to select the voltage point on the trigger signal, by

the adjustment of the TRIG. LEVEL control. The TRIG. LEVEL

control range depends on the peak to peak value of the signal.

This trigger mode is therefore called Automatic Peak (Value)Triggering. Operation of the scope needs only correct

amplitude and timebase settings, for a constantly visible trace.

Automatic mode is recommended for all uncomplicated

measuring tasks. However, automatic triggering is also the

appropriate operation mode for the „entry“ into difficult

measuring problems, e.g. when the test signal is unknown

relating to amplitude, frequency or shape. Presetting of all

parameters is now possible with automatic triggering; the

change to normal triggering can follow thereafter . AUTO SET

therefore sets the instrument to automatic peak-triggering

mode in combination with AC trigger coupling.

The automatic triggering works above 20Hz. The failure of

automatic triggering at frequencies below 20Hz is abrupt.

However, it is not signified by the trigger indicator LED (above

TRIG.) this is still blinking. Break down of triggering is best

recognizable at the left screen edge (the start of the trace in

differing display height).

The automatic peak triggering operates over all variations or

fluctuations of the test signal above 20Hz. However, if the

pulse duty factor of a square-wave signal exceeds a ratio of

100:1, switching over to normal triggering will be necessary.

As the peak value detection makes no sense in combination

with DC signals, it is switched off automatically in DC trigger

14