Page 1

Table of contents

Technical Data

Accessories .....................

Operating Instructions

General Information

Use of tilt handle

Safety.

Operating conditions

Warranty

Maintenance

Mains/Line voltage change

Type of Signal

Amplitude Measurements

Time Measurements

Connection of Test Signal

Operating

First Time Operation

Trace Rotation TR

DC Balance Adjustment

Use and Compensation of Probes

Operating Modes of the Y Amplifier

X-Y Operation

X-Y Phase Measurements

Dual Trace Phase Difference Measurements

Measurement of an amplitude modulation

Triggering and

Triggering of video signals

Function of variable HOLD OFF control

Sweep Delay /After Delay Triggeringe

Delay Mode Indication

Component Tester

Miscellaneous

Test Patterns

Short Instruction

Front Panel Elements

Folder with Front View

Test Instructions

General

Cathode-Ray Tube: Brightness, Focus,

Astigmatismus Check

Symmetry and Drift of

Calibration of the Vertical Amplifier

Transmission Performance of the Vertical Amplifier

............................T2

Operating Modes: CH I/II-TRIG.

Triggering Checks

Timebase

SweepDelay

Component Tester

Trace Alignment

Miscellaneous

....................

.................

......................

.....................

...................

...................

.....................

.................

...................

Timebase

................

..................

...................

.......................

Linearity, Raster Distortions . T 1

CHOP., INV. l/II and XY-Betrieb . T 2

.................

......................

....................

.................

..................

...................

...............

................

............

............

...............

............

...............

.............

............

.............

............

..............

..............

...............

thevertical

........

.......

......

......

Amplifier

.........

l/II,

DUAL, ADD,

....

. .

....

M 10

P

1

Z 1

M 1

M 1

M 1

M 2

M 2

M 2

M 2

M 3

M 3

M 4

M 5

M 6

M 7

M 7

M 7

M 8

M 9

Ml 0

Ml 0

Ml 1

Ml 1

Ml 2

Ml3

Ml 3

Ml 5

Ml 5

Ml 7

Ml 8

K 1.

K

2

T 1

T 1

T 1

T 1

T 3

T 3

T 4

T 4

T 4

T 4

Oscilloscope

HM 604

Service Instructions

General .......................S 1

Instrument Case Removal ............. S 1

Operating Voltages ................. S 1

Minimum Brightness ................ S 1

Astigmatismus control ............... S 1

Trouble Shooting the Instrument ..........S 2

Replacement of Components and Parts ......S 2

Replacement of the Power Transformer ......S 2

Adjustments ....................S 3

Circuit Diagrams

Block Diagram

Wiring Diagram

Identification of Components

Y Input, Attenuator, Preamplifier CH.

Y intermediate Amplifiers, Trigger Pre-Amplifiers,

Component Tester

Y Final Amplifier

Post Trigger, Field Selector

Timebase (analog)

Timebase

Tim,ebase Generator

X Final Amplifier, Calibrator

CRT and HV circuit

Power Supply

Component Locations

XY Board

TB Board

PTFS Board

TBG, CAL, YF Boards

CO, EY, Z Boards

...................

...................

..................

(digital)

..................

....................

......................

......................

.....................

..................

................

.............

.................

................

.............

.................

................

............

l/II

......

D 1

D 2

D 3

D 4

D 5

D 6

D 7

D 8

D 9

DlO

Dl

D12

D13

D14

D15

D16

D17

D18

1

Subject to change without notice

9.88. 604

Page 2

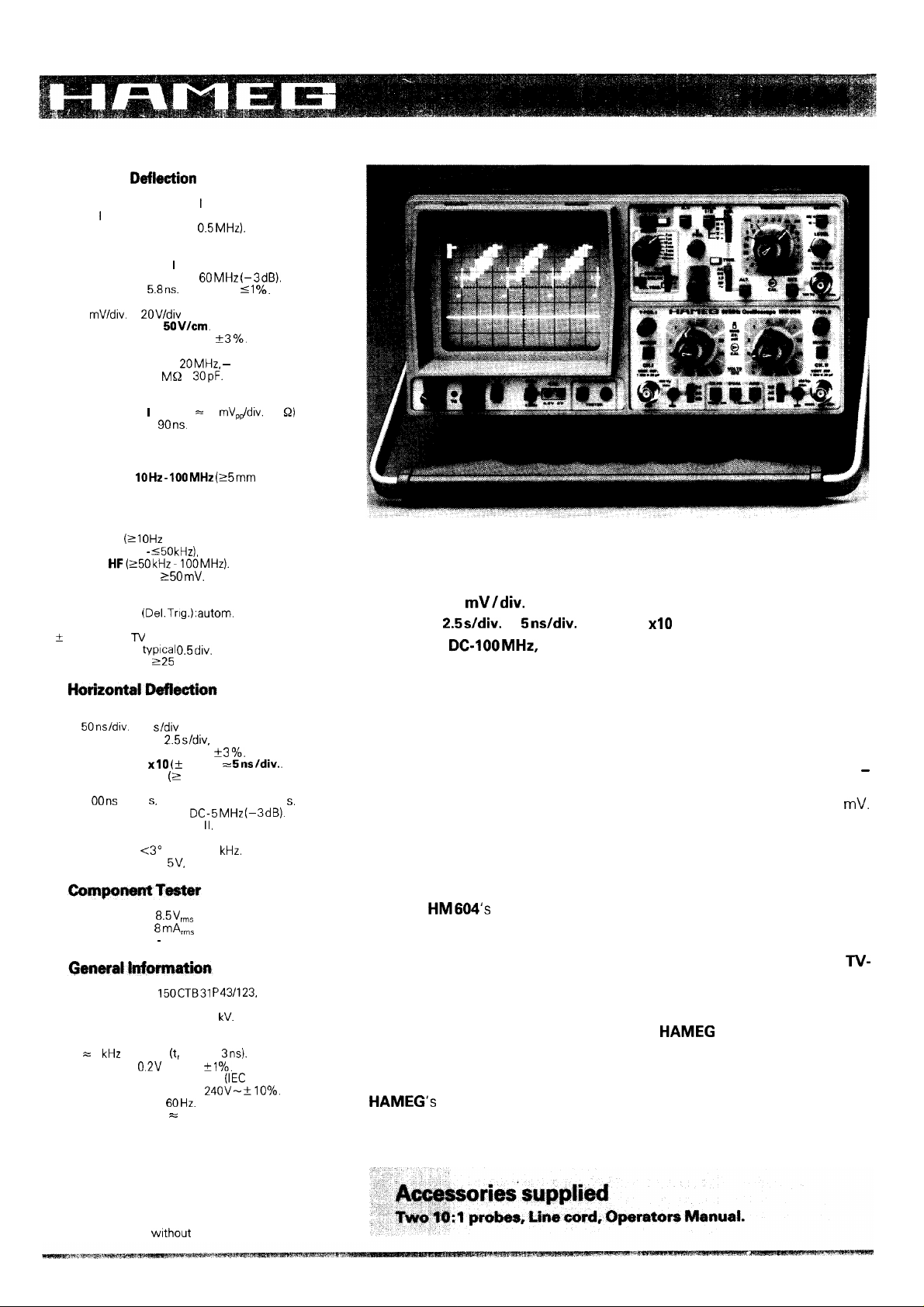

Specification

Vertical

Operating modes: Channel I or Ch. II separate,

Channel I and II: alternate or chopped.

(Chopper frequency approx.

Sum or difference of Ch. I and Ch. II,

(with invert buttons for both Channels).

XY-Mode: via Channel I and Channel II.

Frequency range: 2x DC to 6OMHz (- 3dB).

Risetime: approx. 5.8ns. Overshoot: II %.

Deflection coefficients: 12 calibrated steps

from 5 mV/div. to

variable 2.5: 1 to min.

Accuracy in calibrated position:

Y-Magnification x5 (calibrated) to 1 mV/div.

(Frequency range DC to

input impedance: 1 MQ II

Input coupling: DC-AC-GD (Ground)

Input voltage: max. 400V (DC + peak AC).

Y-output from CH I or CH II, = 50

Delay Line: approx. 90ns.

Mhtion

ZOV/div

50V/cm.

0.5MHz).

in l-Z-5 sequence,

+3%.

20MHz. -

3OpF.

3dB.

mV,Jdiv.

(50

Trigger System

With automatic

normal with level control from DC- 100 MHz.

LED indication for trigger action.

Slope: positive or negative.

Sources: Ch. I, Ch. II, line, external.

Coupling: AC (21

Threshold: external

Active TV-Sync-Separator for line and frame.

Slope positive or negative.

2nd. Triggering

trolled (independent from slope direction).

+ selection for TV mode.

Threshold: 1 div; typlcal

Trigger bandwidth:

lOHz-IOOMHz (P5mm

OHz

LF

HF(?50kHzmlOOMHz).

to approx. 20 MHz), DC

(DC -

550 kHz),

r50mV.

(Del. Trig.):

0.5div.

225

Hz to 60 MHz.

autom. or slope con-

height)

52)

60 MHz Universal Oscilloscope

2 Channels, 1

Timebase: 2.5s/div. to 5ns/div. including

Triggering:

mV/div.

DC-lOOMHz,

Sensitivity, Delay Line, Component Tester

x10

Magnifier&Sweep Delay

TV Sync Separator, After-Delay Trigger

Time coefficients: 23 calibrated steps

from

50ns/div.

variable 2.5: 1 to min.

accuracy in calibrated position:

with X-Magnifier

Hold-Off time: variable (2 5 : 1).

Delay: 7 decade steps

from 1 OOns

Bandwidth X-Amplifier:

Input X-Amplifier via Channel

sensitivity see Ch. II specification.

X-Y phase shift:

Ramp output: approx 5V. positive going

Test voltage: max.

Test current: max.

Test frequency: 50 - 60 Hz (line frequency).

Cathode-ray tube:

rectangular screen, internal graticule 8x10 cm.

Total acceleration voltage: 12

Trace rotation: adjustable on front panel.

Calibrator: square-wave generator switchable

from

Output voltage: 0.2V and 2V fl

Protective system Safety Class I

Linevoltage: 110. 125, 220,

Line frequency: 50 to 60Hz.

Power consumption: = 40 Watt.

Weight: approx. 8kg. Colour: techno-brown.

Cabinet: W 285, H 145, D 380mm.

Lockable tilt handle.

to 1

s/div

in l-2-5 sequence,

2.5s/div,

x10 (k

to 0.1 s, variable approx 10 : 1 to 1 s.

<3”

below 120

8.5V,,,

8mA,,,

150CTB31

=

1

kHz

to 1 MHz

+3%.

5%) to =

DC-5MHz (-3dB).

II,

(open circuit).

(shorted).

P43l123,

(t,

approx. 3ns).

24OV- *IO%.

5nsIdiv..

kHz.

kV.

%.

(IEC

348).

With its variety of operating and trigger modes, the HM604 is a new in-

novative general purpose oscilloscope satisfying a wide range of exacting re-

quirements in laboratory, production, and service. The dual-channel measure-

ment amplifier ensures highly faithful waveform transfer characteristics,

which can be readily checked on the built-in fast-risetime 1 MHz Calibrator

from probe tip to CRT screen! Using Y-axis magnification, the instrument’s

high sensitivity enables stable displays of very small signals as low as 0.5

mV.

An analog output is provided for connecting multimeters or counters. Another

important feature is the internal delay line for observations of the leading edge

of a signal. As in dual-time base oscilloscopes, the HM604 features a calibrated sweep delay mode, allowing smallest waveform sections to be expanded

up to 1000 times.

The

HM604’s

most outstanding feature, however, is the unique, newly

developed automatic After-Delay Trigger mode to ensure extremely stable

displays and jitter-free measurements of asynchronous signal sections and

bursts or pulse trains, independent of amplitude fluctuations. An active

TV-

Sync-Separator further enhances trigger quality of video frame and line signals. In the alternate trigger mode, two signals of different frequencies can be

compared.

With this state-of-the-art oscilloscope, HAMEG again sets a new price/

performance standard which is not likely to be met by others in this category.

Users will be particularly impressed by the instrument’s outstanding versatility

and ease of operation. These features are possible in the HM604 due to

HAMEG’s

meticulous attention to detail and many decades of successful

design experience.

-

Subject to change

without

notice

Page 3

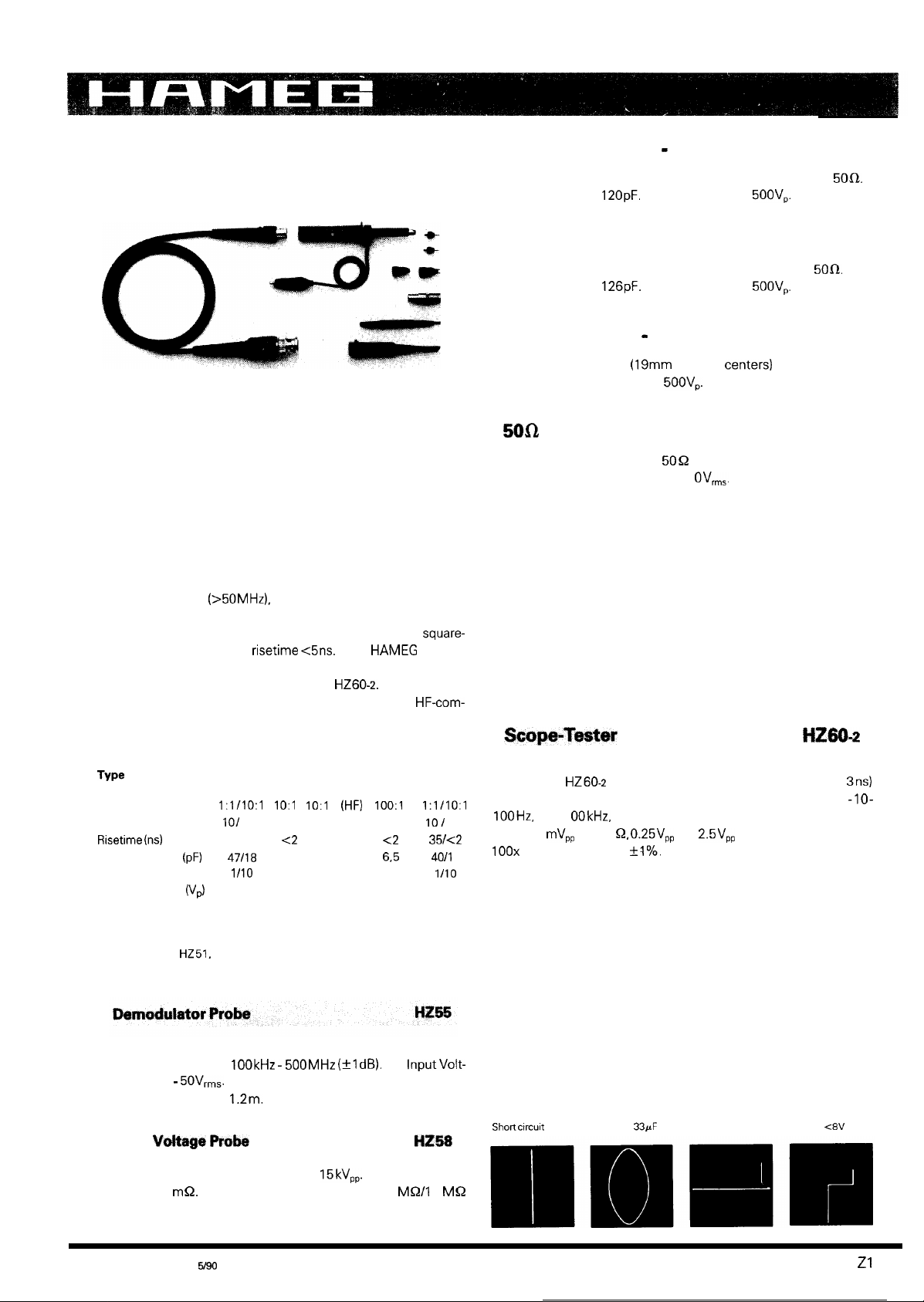

Test

Cable Banana - BNC

Coaxial test cable; length 1.15 m, characteristic impedance 5Ofi.

Cable capacitance

12OpF.

Input voltage max.

5OOV,.

HZ32

Modular Probes

The clear advantage over ordinary probes are field replaceable

parts and the HF-compensation feature on the 10: 1 attenuator pro-

bes For the first time, probes in this price range allow adjustments

of their HF-characteristics to match individually the input impedance of each scope. This is particularly important for scopes with

higher bandwidths (>SOMHz), as otherwise strong overshoot or

rounding may occur, when measuring fast-rising square waves.

An exact HF-compensation, however, is only possible with square-

wave generators having a

already feature such a calibration generator. For other oscillo-

scopes, it is available as accessory item

following Modular Probes are available (HZ36 without HF-com-

pensation):

risetime <5ns.

Most

HZ60-2.

HAMEG

scopes

At present the

Test Cable BNC-BNC

Coaxial test cable; length 1 m, characteristic impedance

Cable capacitance 126pF. Input voltage max.

5OOV,.

Adapter Banana - BNC

Two 4mm binding posts

male plug. input voltage max.

5Ofz

Through-Termination

For terminating systems with

Maximum load 2 W. Max. voltage 1

(19mm

between

5OOV,.

5OS2

centers)

characteristic impedance.

OV,,,.

HZ34

500.

HZ20

to standard BNC

HZ22

Carrying Cases

For HM 103

For HM203, HM204. HM205, HM208, HM408. HM604,

HM605 and HM 1005

Viewing Hood

For HM203, HM204, HM205, HM208, HM408, HM604, HM605

and HM 1005

Scope-T-tar

HZ95

HZ96

HZ47

HZtiOa

Type

Attenuation Ratio

Bandwidth min. (MHz)

Risetime

(ns)

Inp. Capacitance

Inp. Resistance (MR)

Inp. Voltage max.

Cable Length (m)

Spare Cable for HZ36

Spare Cable for HZ51, HZ54

Sparepart Kit (2 sprung

Special probe for AM-demodulation and wobbulator measure-

ments. HF-Bandwidth

age 250mV -

peak AC. Cable length 1.2m.

High

For measurement of voltages up to

approx. 500 mQ. Recommended load resistance1

(switchable). Attenuation ratio 1000 : 1. Bandwidth 1 MHz. Cable

length 1.5 m. BNC connector.

5OV,,,.

Vdtaget

HZ36

selectable

l:l/lO:l 1O:l

IO/

3513.5

(pF)

47/18

(V,)

hooks, 2 screw tips, 1 ground cable)

I’mbe

HZ51 HZ52 HZ53

IO:1

100

150

<2

16

l/10

600 600

1.5 1.2

IOOkHz

DC isolation Voltage 200V DC including

10

-5OOMHz

(HF) 1OO:l

250

tl.4

16

10 100

600 1200

1.5 1.5

(+ldB).

150

<2

65

AC

HZ54

selectable

1:1/10:1

IO/

150

35/<2

40/I

l/10

600

1.2

HZ39

HZ57

HZ46

InputVolt-

Hz58

15kV,,.

Input resistance

Ma/l

0

MQ

For Checking the Y amplifier, timebase, and compensation of all

probes, the

square-wave generator with switchable frequencies of DC, 1

IOOHz,

nals of 25

100x probes); accuracy +q %. Battery-powered.

8

I-IO-I

mV,,

HZ6O-2

is a crystal-controlled, fast rising (typ. 3ns)

OOkHz,

and 1 MHz. Three BNC outputs provide sig-

into 50 M,

0.25V,,

and

2.5V,,

(open circuit for 1 Ox and

Component-Tester

Indispensable for trouble-shooting in electronic circuits. Single

component and in-circuit tests are both possible. The HZ65 operates with all scopes, which can be switched to X-Y operation (ext.

horizontal deflection). Non-destructive tests can be carried out on

almost all semiconductors, resistors, capacitors, and coils. Two

sockets provide for quick testing of the 3 junction areas in any small

power transistor. Other components are connected by using 2

banana jacks. Test leads supplied.

Examples of Test Displays:

ShortcircuIt

Capacitor

33~F

Junction E-C Z-Diode

-lO-

HZ65

t8V

Printed in West Germany 5/90

Zl

Page 4

Operating Instructions

General Information

This oscilloscope is easy to operate. The logical arrange-

ment of the controls allows anyone to become familiar with

the operation of the instrument after a short time, however,

experienced users are also advised to read through these

instructions so that all functions are understood.

Immediately after unpacking, the instrument should be

checked for mechanical damage and loose parts in the interior. If there is transport damage, the supplier must be informed immediately. The instrument must then not be put

into operation.

Check that the instrument is set to the correct mains/line

voltage. If not, refer to instructions on page M2.

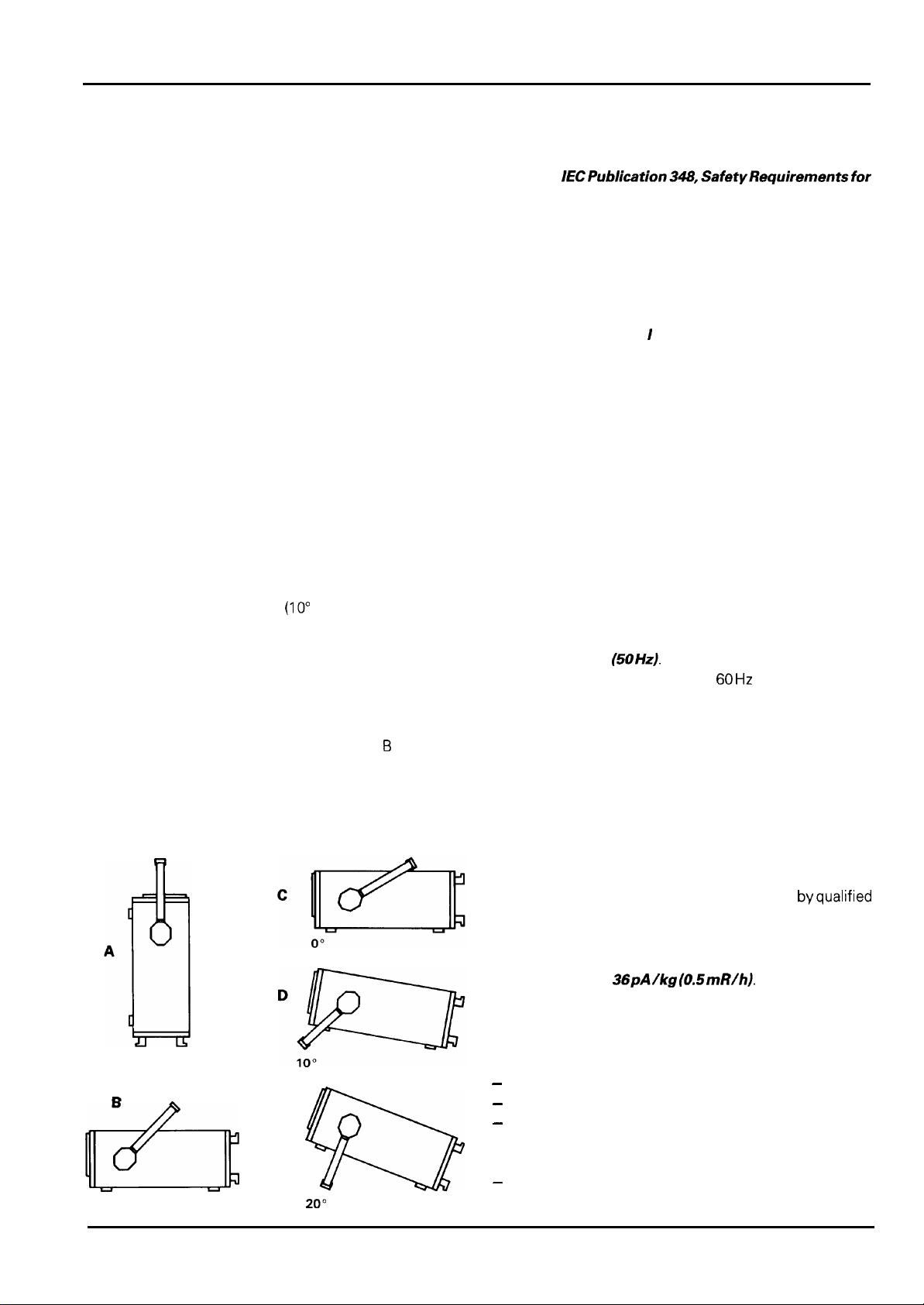

Use of tilt handle

To view the screen from the best angle, there are three dif-

ferent positions (C, D, E) for setting up the instrument. If the

instrument is set down on the floor after being carried, the

handle remains automatically in the upright carrying posi-

tion (A).

In order to place the instrument onto a horizontal surface,

the handle should be turned to the upper side of the oscilloscope (C). For the D position

should be turned in the opposite direction out of the carry

ing position until it locks in place automatically underneath

the instrument. For the E position (20” inclination), the

handle should be pulled to release it from the D position and

swing backwards until it locks once more.

The handle may also be set to a position for horizontal carry-

ing by turning it to the upper side to lock in the B position. At

the same time, the instrument must be moved upwards,

because otherwise the handle will jump back.

B

6

(IO’

inclination), the handle

E

cict

20”

Safety

This instrument has been designed and tested in accordance with

Electronic Measuring Apparatus, and has left the factory

in a safe condition. The present instruction manual contains

important information and warnings which have to be followed by the user to ensure safe operation and to retain the

oscilloscope in safe condition. The case, chassis and all

measuring terminals are connected to the protective earth

contact of the appliance inlet. The instrument operates according to Safety C/ass I (three-conductor power cord with

protective earthing conductor and a plug with earthing contact). The mains/line plug shall only be inserted in a socket

outlet provided with a protective earth contact. The protective action must not be negated by the use of an extension

cord without a protective conductor.

Warning! Any interruption of the protective conductor

inside or outside the instrument or disconnection of the

protective earth terminal is likely to make the instru-

ment dangerous. Intentional interruption of the protec-

tive earth connection is prohibited. The mains/line plug

should be inserted before connections are made to

measuring circuits.

The grounded accessible metal parts (case, sockets, jacks)

and the mains/line supply contacts (line, neutral) of the in-

strument have been tested against insulation breakdown

with 2000 Vr.m.s.

Under certain conditions, 50 Hz or 60Hz hum voltages can

occur in the measuring circuit due to the interconnection

with other mains/line powered equipment or instruments.

This can be avoided by using an isolation transformer

(Safety Class II) between the mains/line outlet and the

power plug of the instrument. When displaying waveforms

where the “low-level” side of the signal is at a high potential, even with the use of a protective isolation transformer,

it should be noted that this potential is connected to the os-

cilloscope’s case and other accessible metal parts. High

voltages are dangerous. In this case, special safety precau-

tions are to be taken, which must be supervised

personnel if the voltage is higher than 42V.

Most cathode-ray tubes develop X-rays. However, the

dose equivalent rate falls far below the maximum per-

missible value of

Whenever it is likely that protection has been impaired, the

instrument shall be made inoperative and be secured

against any unintended operation. The protection is Ii kely to

be impaired if, for example, the instrument

-

shows visible damage,

-

fails to perform the intended measurements,

-

has been subjected to prolonged storage under un-

favourable conditions (e.g. in the open or in moist envi-

ronments),

-

has been subject to severe transport stress (e.g. in poor

packaging).

IECPublication346,SafetyRequirementsfor

(5OHz).

by qualified

36pA/kg (0.5mRlh).

Subject to change without notice

Ml

Page 5

Operating conditions

Maintenance

The instrument has been designed for indoor use.

The permissible ambient temperature range during operation is + 15°C

. . .

+3O”C. It may occasionally be subjected to

temperatures between + 10°C and - 10°C without degrad-

ing its safety. The permissible ambient temperature range

for storage or transportation is -40°C .

+70X.

The maximum operating altitude is up to 2200m (non-

operating 15000m). The maximum relative humidity is up

to 80%.

If condensed water exists in the instrument it should be

acclimatized

before switching on. In some cases (e.g.

extremely cold oscilloscope) two hours should be allowed

before the instrument is put into operation. The instrument

should be kept in a clean and dry room and must not be

operated in explosive, corrosive, dusty, or moist environ-

ments The oscilloscope can be operated in any position,

but the convection cooling must not be impaired. The

wen-

tilation holes may not be covered. For continuous operation the instrument should be used in the horizontal position, preferably tilted upwards, resting on the tilt handle.

The specifications stating tolerances are only valid if

the instrument has warmed up for 30 minutes at an

ambient temperature between

+15C”

and +3OC9 Values not stating tolerances are typical for an average

instrument.

Warranty

Each instrument runs through a quality test with 10 hour

burn-in before leaving the production. Practically every early

failure is detected in intermittent operation by this method.

However, it is possible that a component fails only after a

lengthy operating period. Therefore a functional guaran-

tee of 2 years is given for all units. The condition for this is

that no modifications have been made in the instrument. In

the case of shipments by post, rail or carrier it is recom-

mended that the original packing is carefully preserved.

Transport damages and damage due to gross negligence

are not covered by the guarantee.

In the case of a complaint, a label should be attached to the

housing of the instrument which describes briefly the faults

observed. If at the same time the name and telephone

number (dialing code and telephone or direct number or

department designation) is stated for possible queries, this

helps towards speeding up the processing of guarantee

claims.

Various important properties of the oscilloscope should be

carefully checked at certain intervals. Only in this way is it

largely certain that all signals are displayed with the accuracy on which the technical data are based. The test

methods described in the test plan of this manual can be

performed without great expenditure on measuring instruments. However, purchase of the new HAMEG scope tester HZ 60, which despite its low price is highly suitable for

tasks of this type, is very much recommended.

The exterior of the oscilloscope should be cleaned regularly

with a dusting brush. Dirt which is difficult to remove on the

casing and handle, the plastic and aluminium parts, can be

removed with a moistened cloth (99% water +I % mild

detergent). Spirit or washing benzine (petroleum ether) can

be used to remove greasy dirt. The screen may be cleaned

with water or washing benzine (but not with spirit (alcohol)

or solvents), it must then be wiped with a dry clean lint-free

cloth. Under no circumstances may the cleaning fluid get

into the instrument. The use of other cleaning agents can

attack the plastic and paint surfaces.

Switching over the mains/line voltage

The instrument is set for 220V (240V U.K.) line voltage on

delivery. It can be switched over to other voltages at the

fuse holder combined with the 3-pole appliance inlet at the

rear of the instrument. Firstly the fuse holder printed with

the voltage values is removed using a small screw driver

and - if required - provided with another fuse. Refer to the

table below for the prescribed value of the fuse. Then

replace the fuse holder so that the impressed white triangle

points to the desired voltage. Here pay attention that the

cover plate is also correctly engaged. The use of repaired

fuses or short circuiting the fuse holder is not allowed. Damage arising because of this is not covered by the guarantee.

Fuse type: Size 5 x 20 mm; 250 V-, C;

IEC 127, Sheet III; DIN 41 662 (possibly DIN

sheet 3).

Cutoff: time lag

Line voltage

llOV-flO%

125V- &IO%

22ov- &IO%

24OV- &IO%

(T).

Fuse rating

TO.63 A

TO.63 A

T0.315A

T0.315A

.41

571

M2

Subject to change

wlthout

notice

Page 6

Type of Signal

All types of signals with a frequency spectrum below

60 MHz can be displayed on the HM 604. The display of sim-

ple electrical processes such as sinusoidal RF and AF signals or ripple poses no problems. However, when square or

pulse-shaped signals are displayed it must be remembered

that their harmonic content must also be transmitted. In

this case, the bandwidth of the vertical amplifier must be

considerably higher than the repetition frequency of the sig-

nal. In view of this, accurate evaluation of such signals with

the HM 604 is only possible up to a maximum repetition rate

of

6MHz.

Operating problems can sometimes occur when

composite signals are to be displayed, especially if they do

not contain any suitable level components and repetition

frequency which can be used for triggering. This occurs, for

example, with burst signals. To obtain a stably triggered display in these cases, it may be necessary to use Normal Triggering, HOLD OFF time control, and/or

control.

TIME/DIV.

variable

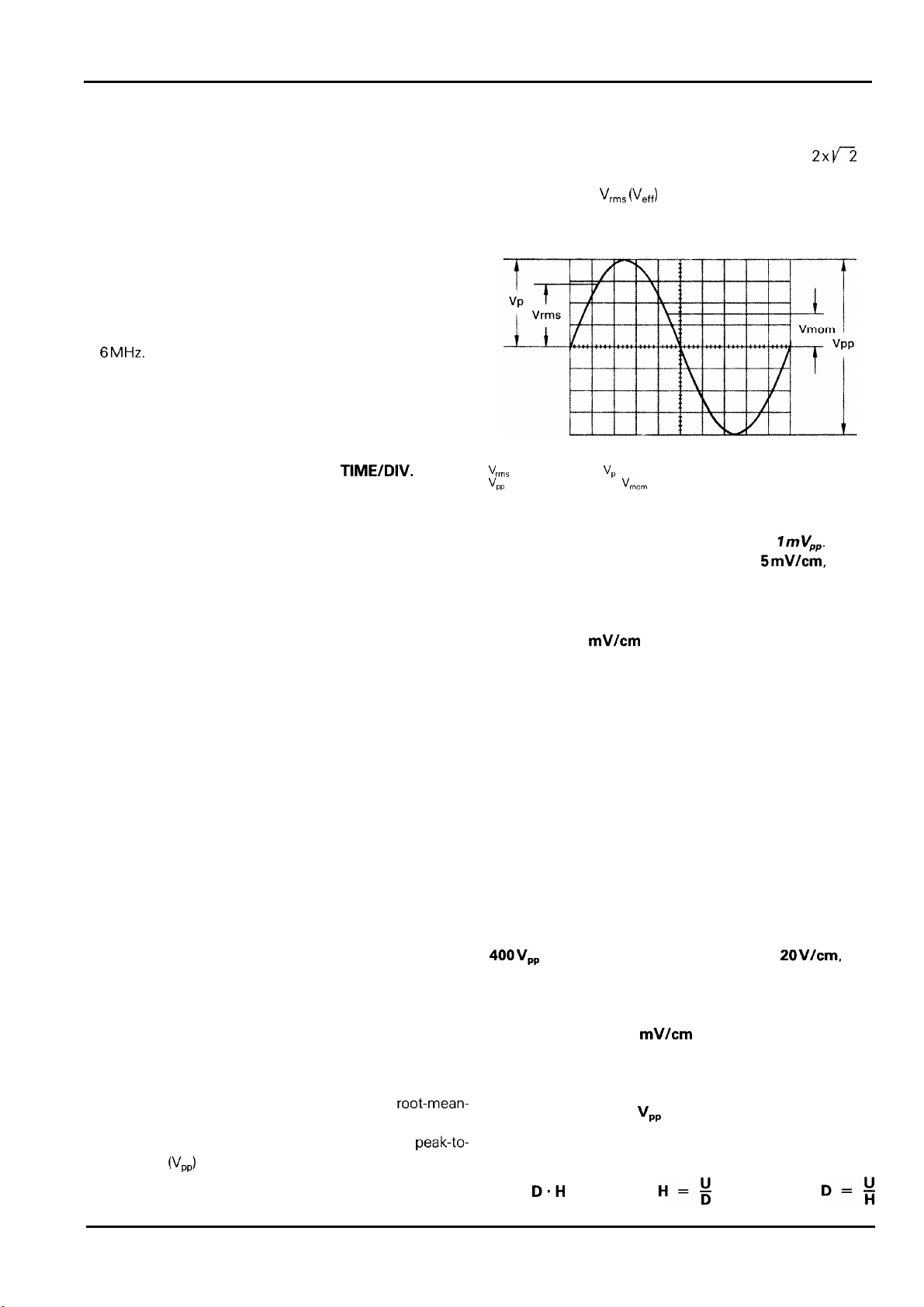

If a sinusoidal waveform, displayed on the oscilloscope screen, is to be converted into an effective (rms) value, the resulting peak-to-peak value must be divided by

2x-

=

2.83. Conversely, it should be observed that sinusoidal voltages indicated in

V,,,

(V,,,)

have 2.83 times the potential difference in V,,. The relationship between the different voltage magnitudes can be seen from the following figure.

Voltage values of a sine curve

v

= effective value;

rms

V,,

= peak-to-peak value;

V,

= simple peak or crest value;

V,,,

= momentary value.

Video signals are easily triggerable by the aid of the active

TV sync separator (TV SEP. switch).

For optional operation as a DC or AC voltage amplifier, each

channel is provided with a DC-AC coupling switch. The DC

position should only be used with an attenuator probe or at

very low frequencies or if the determination of DC voltage

content of the signal is absolutely necessary.

However, when investigating very low-frequency pulses,

misleading ramp-offs may occur with AC coupling. In this

case, DC operation is to be preferred if the signal voltage is

not superimposed on a too high DC voltage level. Otherwise, a capacitor of adequate capacitance must be con-

nected before the input of the vertical amplifier (switched to

DC coupling). It should be remembered that this capacitor

must have a sufficiently high breakdown voltage. DC opera-

tion is also recommended for the display of logic and pulse

signals, particularly if their pulse duty factor changes perma-

nently during operation. Otherwise, the display will move

up and down with any change. DC voltages can only be

measured in the DC position.

Amplitude Measurements

The minimum signal voltage required at the vertical amplifier

input for a display of 1 cm is approximately

achieved with the attenuator control set at

7mV,,.

5mV/cm,

This is

its var-

iable control in the fully clockwise position and pulled

out. However, smaller signals than this may also be dis-

played. The deflection coefficients on the input attenuators

are indicated in

mV/cm

or V/cm (peak-to-peak value).

The magnitude of the applied voltage is ascertained by

multiplying the selected deflection coefficient by the

vertical display height in cm.

If an attenuator probe x 70 is used, a further multiplication by a factor of 70 is required to ascertain the correct

voltage value.

For exact amplitude measurements the variable con-

trol on the attenuator switch must be set to its calibra-

ted detent CAL. When turning the variable control ccw

the sensitivity will be decreased by a factor of 2.5.

Therefore every intermediate value is possible within

the 7-2-5 sequence.

With direct connection to the vertical input, signals up to

4OOV,, may be displayed (attenuator set to

ZOV/cm,

variable control ccw).

When pulling the variable control knob (MAG x5), the sen-

sitivity is increased by a factor of 5. Hence follows a min. deflection coefficient of 1

mV/cm

(reduced bandwidth).

In general electrical engineering, alternating voltage data

normally refers to effective values (rms = root-mean-

square value). However, for signal magnitudes and voltage

designations in oscilloscope measurements, the peak-to-

peakvoltage (V,,) value is applied. The latter corresponds to

the real potential difference between the most positive and

most negative points of a signal waveform.

Subject to change without notice

With the designations

H = display height in cm,

= signal voltage in

U

V,,

at the vertical input,

D = deflection coefficient in V/cm at attenuator switch,

the required quantity can be calculated from the two given

quantities:

=

D-H

U

H=;

D+

M3 604

Page 7

However, these three values are not freely selectable. They

have to be within the following limits (trigger threshold, ac-

curacy of reading):

H between 0.5 and

U between 1

D between

5mV/cm

D between 1 mV/cm and

(with

pulled MAG x5 knob). As a rule, all signals to be displayed are periodically repeat-

mV,,

and 16OV,,,

8cm,

if possible 3.2 to

and

20V/cm

4V/cm

8cm,

in l-2-5 sequence.

in l-2-5 sequence

Examples:

Set deflection coefficient D = 50 mV/cm 2 0.05 V/cm,

observed display height H = 4.6 cm,

required voltage U =

Input voltage U =

5V,,,

0.05.4.6

= 0.23 V,,.

set deflection coefficient D = 1 V/cm,

required display height H = 5: 1 = 5cm

Signal voltage U =

22OV,,;2.fl=

622

V,,

(voltage > 16OV,,, with probe X 10 : U = 62.2 V,,),

desired display height H = min.

3.2cm,

max.

8cm.

max. deflection coefficient D = 62.2 : 3.2 = 19.4V/cm,

min. deflection coefficient D = 62.2 : 8 = 7.8V/cm,

adjusted deflection coefficient D =

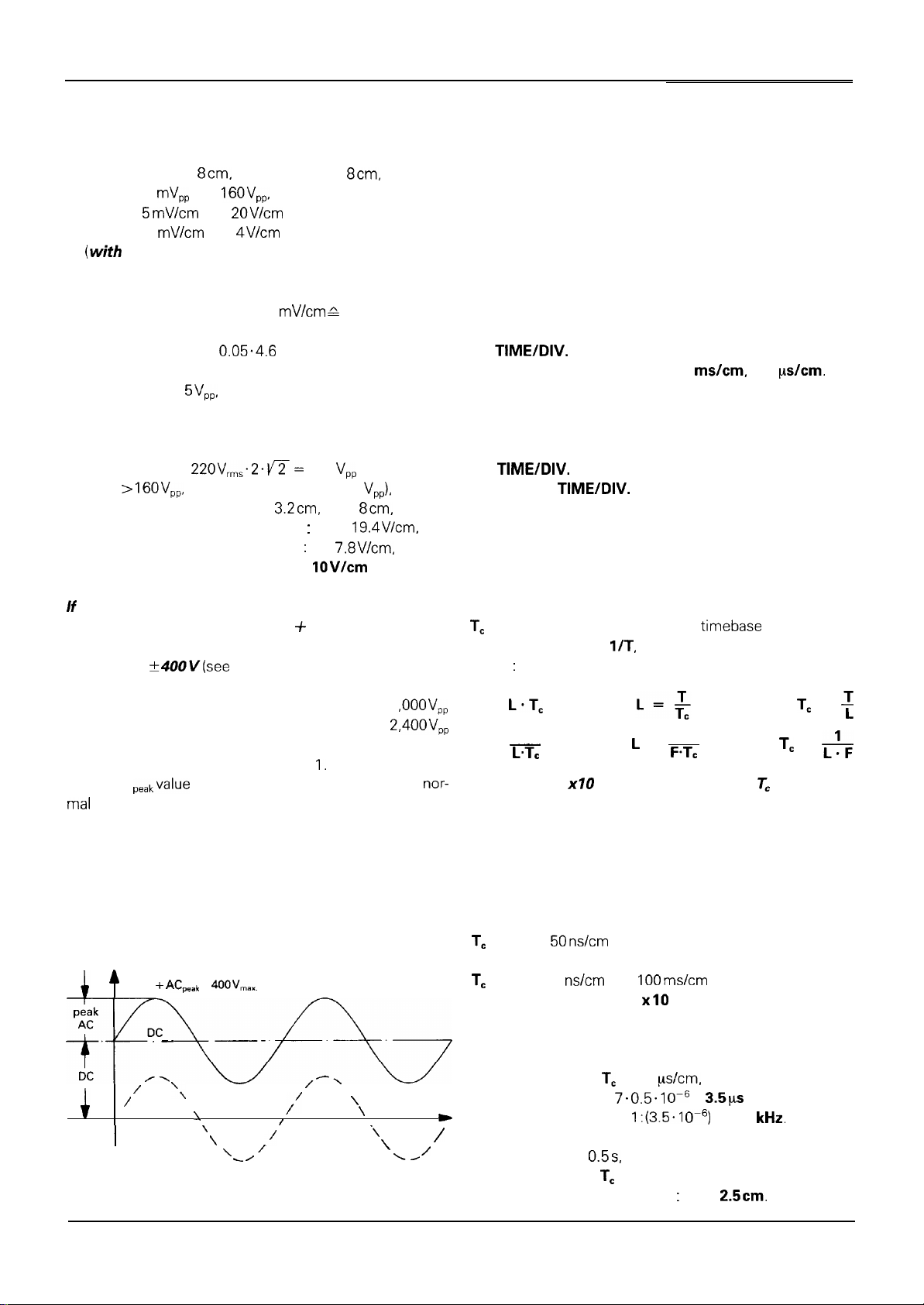

If

the applied signal is superimposed on a DC (direct

lOV/cm

voltage) level the total value (DC + peak value of the alternating voltage) of the signal across the Y-input must

not exceed

*4OOV(see

figure). This same limit applies to

normal x 10 attenuator probes, the attenuation ratio of

which allows signal voltages up to approximately 1

to be evaluated. Voltages of up to approximately

,OOOV,,

2,4OOV,,

may be measured by using the HZ53 high voltage probe

which has an attenuation ratio of 100: 1. It should be noted

that its AC

peakvalue

is derated at higher frequencies. If a

normal x 10 probe is used to measure high voltages there is the

risk that the compensation trimmer bridging the attenuator

series resistor will break down causing damage to the input

of the oscilloscope. However, if for example only the residual ripple of a high voltage is to be displayed on the oscil-

loscope, a normal x 10 probe is sufficient. In this case, an appropriate high voltage capacitor (approx. 22-68nF) must be

connected in series with the input tip of the probe.

Voltage

’

DC +

AC,,,k

=

I

peak

F@u

AC

DC

DC

.-

/\

/

/

I

Total value of input voltage ’ -

The dotted line shows a voltage alternating at zero volt level. When superim-

posed a DC level, the addition of the positive peak and the DC voltage results

in the max. voltage (DC + AC,,,,).

4OOV,,,.

-.

-1

/

‘\

AC

\

\.

\

1

1’

/

!

/

’

\

\

Time

\

\

‘\

\

\

/

\,

It is very important that the oscilloscope input coupling is

set to DC, if an attenuator probe is used for voltages higher

than 400V (see page M6: Connection of Test Signal).

Time Measurements

ing processes and can also be designated as periods. The

number of periods per second is the recurrence frequency

or repetition rate. One or more signal periods or even part of

a period may be shown as a function of the adjustment of

the

TIMEIDIV.

DIV. switch are indicated in s/cm,

cordingly, the dial is subdivided into three sectors. The duration of a signal period or a portion of the waveform is

ascertained by multiplying the relevant time (horizon-

tal distance in cm) by the time coefficient selected on

the

TIME/DIV.

knob on the

detent CAL. for accurate measurement (arrow horizontal

and pointing to the right).

With the designations

L

= displayed wave length in cm of one period,

T = time in seconds for one period,

F

= recurrence frequency in Hz of the signal,

T,

= time coefficient in s/cm on

and the relation F =

stated

:

T =

L.T,

F

-

=

L.Tc

With X-MAG.

be divided by 10.

However, these four values are not freely selectable. They

have to be within the following’limits:

L

between 0.2 and 1 Ocm, if possible 4 to 1 Ocm,

T between 5 ns and 1 OS,

F

between 0.1 Hz and 60 MHz,

T,

between

(with X MAG. x 10

T,

between 5 ns/cm and

(with pushed X MAG.

Examples:

Displayed wavelength L = 7 cm,

set time coefficient T, = 0.5 ps/cm,

required period T =

c

required rec. freq. F = 1:(3.5.1

/

Signal period T =

set time coefficient T, = 0.2 s/cm,

required wavelength L = 0.5 : 0.2 =

switch. The time coefficients on the TIME/

ms/cm,

and ps/cm. Ac-

switch. The time variable control (small

TIME/DIV.

switch) must be in its calibrated

timebase

l/T,

the following equations can be

1

L

xl0

button depressed the T, value must

50ns/cm

and 1 s/cm in l-2-5 sequence

=

1

F.Tc

in out position), and

lOOms/cm

x10

7.0.5.1

in l-2-5 sequence

button).

O-” =

3.5~s

OP6)

= 286

0.5s,

2.5cm.

switch

kHz.

T,

T,

=

=

;

&

.

M4 604

Subject to change without notice

Page 8

Displayed ripple wavelength L = 1 cm,

set time coefficient T, = 10 ms/cm,

required ripple freq. F = 1 : (1 .10.10-3) = 100Hz.

If magnification is used, this product must be divided by 10.

The

fall

time of a pulse can also be measured by using this

method.

TV-line frequency F = 15 625 Hz,

set time coefficient T, = 10 @cm,

required wavelength L = 1: (15 625.1

Sine wavelength L = min.

Frequency F = 1

max. time coefficient T, = 1 :

min. time coefficient T, = 1

set time coefficient T, = 0.2

required wavelength L = 1: (1

Displayed wavelength L =

set time coefficient T, = 0.5

pressed MAG X 10 button: T, = 0.05

required rec. freq. F = 1: (0.8.0.05.1

required period T = 1: (25.1

If the time is relatively short as compared with the complete

signal period, an expanded time scale should always be

applied (X MAG

tained time values have to be divided by

intervals at optional points of the signal can be measured

more exactly with the aid of the sweep delay. With it, the

display and measurement of time intervals, which are smal-

ler than 1 % of the full signal period, are possible. The smallest measurable time interval is, on the whole, dependent on

the obtainable brightness of the CRT. The limit is an expansion of approximately 1000 times. Using a Viewing Hood

HZ47, more expansion is possible, provided that the time

coefficient set on the

S@cm

basic period. Otherwise, the fastest sweep speed deter-

mines the greatest possible expansion.

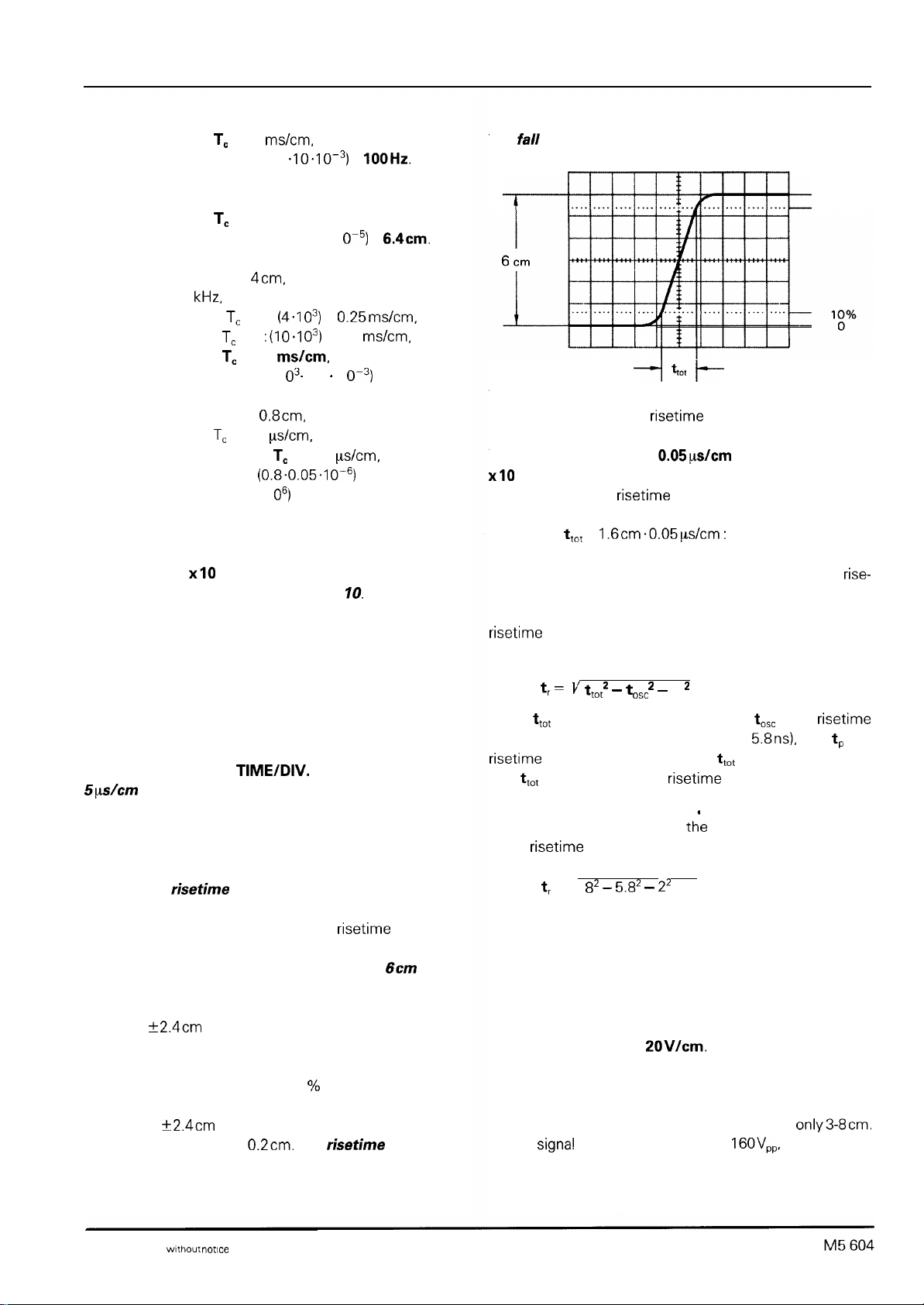

When investigating pulse or square waveforms, the critical

feature is the

transients, ramp-offs, and bandwidth limits do not unduly

influence the measuring accuracy, the

measured between 10% and 90% of the vertical pulse

height. For peak-to-peak signal amplitude of

which are symmetrically adjusted to the horizontal center

line, the internal graticule of the CRT has two horizontal dotted lines

tenuator switch with its variable control together with the

Y-POS. control so that the pulse height is precisely aligned

with the 0 and 100 % lines. The 10 % and 90 % points of the

signal will now coincide with the two lines, which have a

distance of

additional subdivision of

the product of the horizontal distance in cm between

these two coincidence points and the time coefficient

setting.

(and using the X MAG x 10 facility) for the signal’s

risetime

&2.4cm

f2.4cm

kHz,

x10

from the center line. Adjust the Y at-

4cm,

max. 1 Ocm,

(4.1 03)

:(I O-1 03)

ms/cm,

03-

0.8cm,

ys/cm,

06)

= 40 ns.

button pushed). In this case, the ascer-

TIME/DIV.

of the voltage step. To ensure that

from the horizontal center line and an

0.2cm.

The

0p5)

=

6.4cm.

=

0.25ms/cm,

= 0.1

m&m,

0.2 - 1

0p3)

= 5cm.

@cm,

Ov6)

= 25 MHz,

70.

Very small time

switch is greater than

risetime

risetime

is generally

6cm

height,

is given by

100%

90%

-I

qot t-

The above figure shows correct positioning of the oscilloscope trace for accurate

With a time coefficient of O.O5ys/cm and pushed X MAG

x10

button the example shown in the above figure results

in a measured total

ttor

=

1.6cm.O.O5@cm:

When very fast risetimes are being measured, the rise-

times of the oscilloscope amplifier and the attenuator probe

have to be deducted from the measured time value. The

risetime

formula.

In this

of the oscilloscope amplifier (approx. 5.8ns), and t, the

risetime

then t,,, can be taken as the

lation is unnecessary.

Calculation of the example in

signal

of the signal can be calculated using the following

t,

=

v

ttot2 - t

ttot

is the total measured risetime,

of the probe (e.g. = 2 ns). If

risetime

t,

= V 8* -

risetime

risetime

2 -

osc

5.8* - 2*

measurement.

of

10 = 8ns

t

2

P

to,,

is the

ttot

is greater than 42 ns,

risetime

= 5.1 ns

of the pulse, and calcu-

tie

figure above results in a

risetime

Connection of Test Signal

Caution: When connecting unknown signals to the oscillo-

scope input, always use automatic triggering and set the

DC-AC input coupling switch to AC. The attenuator switch

should initially be set to POV/cm.

Sometimes the trace will disappear after an input signal has

been applied. The attenuator switch must then be turned

back to the left, until thevertical signal height is

With a

probe must be inserted before the oscilloscope’s vertical

input. If, after applying the signal, the trace is nearly

blanked, the period of the signal is probably substantially

signa!

amplitude greater than 16OV,,, an attenuator

only3-8cm.

Subject to change

wlthout

notlce

Page 9

longer than the set value on the

should be turned to the left to an adequately greater time

coefficient.

The signal to be displayed should be fed to the vertical input

of the oscilloscope by means of a shielded test cable, e.g.

the HZ32 or HZ34, or by a x 10 or x 100 attenuator probe.

The use of these shielded cables with high impedance cir-

cuits is only recommended for relatively low frequencies

(up to approx. 50kHz). For higher frequencies, and when

the signal source is of low impedance, a cable of matched

characteristic impedance (usually

In addition, and especially when investigating square or

pulse waveforms, a resistor equivalent to the characteristic

impedance of the cable must also be connected to the cable

directly at the input of the oscilloscope. When using a 509

cable, such as the HZ34, a

HZ22 is available from HAMEG. When investigating square

or pulse waveforms with fast risetimes, transient

phenomena on both the edge and top of the signal may become visible if the correct termination is not used. It must

be remembered that the

dissipate a maximum of 2 watts. This power consumption

is reached with 1

If a x 10 or x 100 attenuator probe is used, no termination is

necessary. In this case, the connecting cable is matched di-

rectly to the high impedance input of the oscilloscope.

When using attenuator probes even high internal imped-

ance sources are only slightly loaded by approximately

10 MQ I I 16 pF or 100 MQ I I7 pF respectively. Therefore,

when the voltage loss due to the attenuation of the probe

can be compensated by a higher sensitivity setting on the

HM 604, the probe should always be used. Also it should be

remembered that the series impedance of the probe provides a certain amount of protection for the input of the os-

cilloscope amplifier. It should be noted that all attenuator

probes must be compensated in conjunction with the oscil-

loscope (see: Probe Adjustment, page M8).

If a x IO or x 100 attenuator probe is used at voltages

higher than 400 V, the DC input coupling must always

be set. With AC coupling, the attenuation is frequency-de-

pendent, the pulses displayed can exhibit ramp-off, DC-volt-

age contents are suppressed - but loads the respective

input coupling capacitor of the oscilloscope. The electric

strength of which is maximum 400V (DC + peak AC). For

the suppression of unwanted DC voltages, a capacitor of

adequate capacitance and electric strength may be con-

nected before the input tip of the probe (e.g. for ripple

measurements).

It is important to remember that when low voltage signals

are being investigated the position of the ground point on

the test circuit can be critical. This ground point should always be located as close as possible to the measuring

point. If this is not done, serious signal deformation may

OV,,,

50R

5OQ

through-termination will only

or with

TIMEIDIV.

5OQ)

is recommended.

through-termination type

28V,,

sine signal.

switch. It

result from any spurious currents through the ground leads

or test chassis parts. This comment also applies to the

ground leads on attenuator probes which ideally should be

as short and as thick as possible. For connection of a probe

to a BNC socket, a BNC-adapter should be used. It forms

often a part of the probe accessory. Grounding and matching problems are then eliminated.

Hum or interference voltage appearing in the measuring circuit (especially with a small deflection coefficient) is possibly caused by multiple grounding, because equalizing currents can flow in the shielding of the measuring cables (voltage drop between non-fused earthed conductors of other

line powered devices, which are connected to the oscilloscope or test object, e.g. signal generators with anti-interference capacitors).

Operating

For a better understanding of these Operating Instructions

the front panel picture at the end of these instructions can

be unfolded for reference alongside the text.

The front panel is subdivided into three sections according

to the various functions. The INTENS., FOCUS and TR

(trace rotation) controls are arranged on the left directly

below the screen of the cathode-ray tube (CRT). Continuing

towards the right are the horizontal magnification button (X

MAG. x10), the switch for calibrator frequency selection

(1

kHz/l

MHz) and calibrator output sockets

(CAL.). The COMPONENT TESTER pushbutton and its

measuring socket are located on the right side.

The X-Section, located on the upper right, next to the screen,

contains the red POWER pushbutton and indicating LED, all

controls for

zontal trace position (X-POS.), sweep delay (DELAY), TV

separator (TV SEP.) together with the field select button

(FIELD

doff adjustment (HOLD OFF).

The lower Y-Section contains the controls for the vertical

deflection system. On the right and left in this section are located: vertical input connector, DC-AC-GD input coupling

slide switch, Y-POS. control, INVERT pushbutton, attenuator switch with variable control, and ground jack. All

these controls and connectors exist in duplicate for each of

the Channels I and II. Three pushbuttons for selecting the

operating mode are arranged below the attenuator

switches: CH

These are explained later.

The instrument is so designed that even incorrect operation

will not cause serious damage. The pushbuttons control

only minor functions, and it is recommended that before

commencement of operation all pushbuttons are in the

“out” position. After this the pushbuttons can be operated

depending upon the mode of operation required.

timebase

l/II),

the XYmode button (XV), and the knob for

l/II

(TIME/DIV.),

triggering (TRIG.), hori-

-TRIG l/II, DUAL and ADD.

0.2V/2V

hol-

M6 604

Subject to change without notice

Page 10

The HM 604 accepts all signals from DC (direct voltage) up

to a frequency of at least

voltages the upper frequency limit will be

ever, in this higher frequency range the vertical display

height on the screen is limited to approx. 6cm. The time resolution poses no problem. For example, with 100 MHz and

the fastest adjustable sweep rate (5ns/cm), one cycle will

be displayed every 2cm. The tolerance on indicated values

amounts to

be measured can therefore be determined relatively accu-

rately. However, from approximately 25 MHz upwards the

measuring error will increase as a result of loss of gain. At

40MHz

11 % should be added to the measured voltage at this frequency. As the bandwidth of the amplifiers differ (normally

between 65 and 70 MHz), the measured values in the upper

limit range cannot be defined exactly. Additionally, as al-

ready mentioned, for frequencies above

dynamic range of the display height steadily decreases. The

vertical amplifier is designed so that the transmission performance is not affected by its own overshoot.

f3%

in both deflection directions. All values to

this reduction is about 10%. Thus, approximately

60MHz (-3dB).

For

80MHz.

60MHz

sinewave

How-

the

First Time Operation

Check that the instrument is set to the correct mains/

line voltage. (Refer to page

Before applying power to the oscilloscope it is recom-

mended that the following simple procedures are performed:

-

Check that all pushbuttons are in the out position, i.e. released.

-

Rotate the three variable controls with arrows to their

calibrated detent.

-

Set the variable controls with marker lines to their mid-

range position (marker lines pointing vertically).

-

The LEVEL control knob should be on its left stop (AT).

-

The three lever switches in the X-Section should be set

to their uppermost position.

-

Both input coupling slide switches for CH.1 and

the Y-Section should be set to the GD position.

Switch on the oscilloscope by depressing the red POWER

pushbutton. An LED will illuminate to indicate working

order. The trace, displaying one baseline, should be visible

after a short warm-up period of 10 seconds. Adjust

and X-POS. controls to center the baseline. Adjust

TENS. (intensity) and FOCUS controls for medium bright-

ness and optimum sharpness of the trace. The oscilloscope

is now ready for use.

If only a spot appears (CAUTION! CRT phosphor can be

damaged.), reduce the intensity immediately and check

that the X-Y pushbutton is in the released (out) position. If

the trace is not visible, check the correct positions of all

knobs and switches (particularly LEVEL knob in AT position

and DELAY MODE lever switch to OFF).

M2).

CH.11

Y-P0S.I

IN-

in

To obtain the maximum life from the cathode-ray tube, the

minimum intensity setting necessary for the measurement

in hand and the ambient light conditions should be used.

Particular care is required when a single spot is displayed, as a very high intensity setting may cause damage

to the fluorescent screen of the CRT. Switching the oscilloscope off and on at short intervals stresses the cathode of

the CRT and should therefore be avoided.

Trace Rotation TR

In spite of Mumetal-shielding of the CRT, effects of the

earth’s magnetic field on the horizontal trace position

cannot be completely avoided. This is dependent upon

the orientation of the oscilloscope on the place of work.

A centred trace may not align exactly with the horizon-

tal center line of the graticule. A few degrees of misalignment can be corrected by a potentiometer acessi-

ble through an opening on the front panel marked

TR.

DC Balance Adjustment

The vertical preamplifiers for

matched dual

After long periods of use the FET characteristics may

change which can alter the DC balance of the vertical

amplifier. A quick check of DC Balance can be made on each

channel by pulling the fine amplitude control MAG x5 and

pushing it back. If the trace moves from the vertical position

(up or down) more than 1 mm, the DC Balance will require

readjustment. This check should be made after a 20-minute

warm-up period.

FETs

connected as input source followers.

Adjustment procedure

The following instructions should be performed to obtain

the correct DC balance adjustment of both channels.

-

Remove all input cables and adjust oscilloscope controls

to display the baseline.

-

Center the baseline using Y-POS. and X-POS. controls.

-

Set attenuator switches to

switches to GD.

-

Release all pushbuttons in the Y-Section.

-

Place the oscilloscope so that it rests

right position) and locate DC balance adjustment potentiometer access holes - marked

CH.11 -

which are found underneath the instrument.

-

Insert a screwdriver (blade approx.

20 mm) in

is located behind the hole.

-

Pull and push the

just balance pot so that the baseline no longer moves up

or down. When the trace remains steady, correction of

CH.1

-

Depress CH I/II-TRIG.

procedure for

CH.1

hole. A plastic guide with slotted bottom

is completed.

CH.II.

CH.1

variable control MAG x5 and ad-

CH.1

and

CH.11

contain

5mV/cm

l/II

button. Repeat adjustment

and input coupling

firmlyon

CH.1

its back (up-

DC-BALANCE

3mm,

length min.

Subject to change without notice

M7 604

Page 11

Use and Compensation of Probes

To

display an undistorted waveform on an oscilloscope, the

probe must be matched to the individual input impedance

of the vertical amplifier.

small insulated non-metallic screwdriver or trimming tool,

the trimmer has to be adjusted slowly until the tops of the

squarewave signal are exactly parallel to the horizontal

graticule lines. (See Fig. above for 1

amplitude shown should be 4cm + 1.2 mm (= 3 %), During

this adjustment, the signal edges will remain invisible.

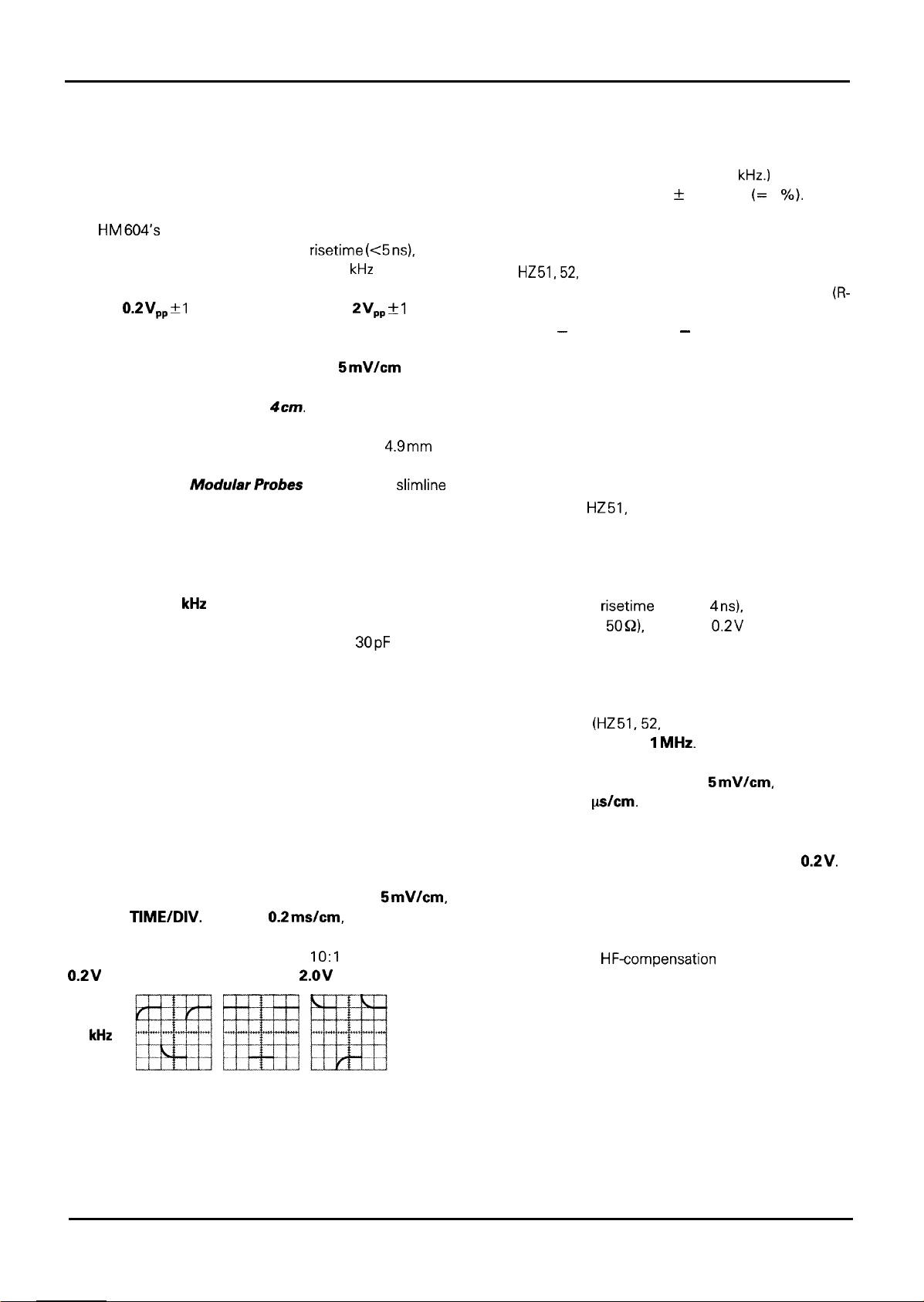

The HM604’s built-in calibration generator provides a

squarewave signal with a very low

switch-selectable frequencies of approx.

at two output sockets below the CRT screen. One output

provides

0.2V,, *I

% for 10: 1 probes, and

present at the other, for 100: 1 probes.

risetime

1 kHz and 1

(<5ns), and

MHz

2V,,

+I % are

Adjustment at 1 MHz

Probes

They incorporate resonance deemphasizing networks

trimmer in conjunction with inductances and capacitors)

which permit - for the first time - probe compensation in

the range of the upper frequency limit of the vertical oscillo-

When the attenuator switches are set to 5mV/cm vertical

deflection coefficient, these calibration voltages correspond to a screen amplitude of

The output sockets have an internal diameter of

accommodate the internationally accepted shielding tube

diameter of modern

Modular

4cm.

Probes and F-series

4.9mm

slimline

probes. Only this type of construction ensures the

extremely short ground connections which are essential for

an undistorted waveform reproduction of non-sinusoidal

scope amplifier. Only this compensative adjustment

ensures optimum utilisation of the full bandwidth, together

with constant group delay at the high frequency end,

thereby reducing characteristic transient-distortion near the

to

leading signal edge (e.g. overshoot, rounding, ringing, holes

or bumps) to an absolute minimum.

Using the probes HZ51, 52, and 54, the full bandwidth of

the HM 604 can be utilized without risk of unwanted waveform distortion.

high frequency signals.

Prerequisite for this HF-adjustment is a squarewave

Adjustment at 1

The C-trimmer adjustment compensates the capacitive

loading on the oscilloscope input (approx.

HM604). By this adjustment, the capacitive division

assumes the same division ratio as the ohmic voltage

kHz

3OpF

with the

generator with fast

impedance (approx.

quency of approx. 1 MHz. The calibrator output of the

HM604 meets these requirements when the pushbutton

1 MHz is depressed.

divider to ensure an equal division ratio for high and low frequencies, as for DC. (For

set to 1: 1, this adjustment is neither required nor possible).

A baseline exactly parallel to the horizontal graticule lines is

a major condition for accurate probe adjustments. (See also

‘Trace Rotation

TR’,

Connect the probes (Types HZ51, 52, 53,

CH.1 input. All pushbuttons should be released (in the ‘out’

position), and all push-pull knobs pushed ‘in’. Set the input

coupling switch to DC, the attenuator switch to 5mV/cm,

and the

controls to CAL. position. Plug the probe tip into the appropriate calibrator output socket, i.e. IO:1 probes into the

0.2V

1

TIME/DIV.

socket, 100: 1 probes into the 2.OV socket.

kHz

incorrect correct

Approximately 2 complete waveform periods are displayed

on the CRT screen. Now the compensation trimmer has to

be adjusted. Normally, this trimmer is located in the probe

1: 1

page M7.)

switch to

probes or switchable probes

54,

or HZ37) to

0.2ms/cm,

and all variable

incorrect

Connect the probe

the calibrator pushbutton

should be released (‘out’ position). Set the input coupling

switch to DC, attenuator switch to

DIV. switch to 0.1

position.

Insert the probe tip into the output socket marked

waveform will be displayed on the CRT screen, with leading

and trailing edges clearly visible. For the HF-adjustment

now to be performed, it will be necessary to observe the ris-

ing edge as well as the upper left corner of the pulse top. To

gain access to the HF-compensation trimmer, the plastic

cover of the probe connecting box has to be slid off after

unscrewing the probe cable. The connecting boxes of the

HZ51 and HZ54 contain one R-trimmer screw, each, while

that of the HZ52 provides three. These R-trimmers have to

be adjusted in

top is as straight as possible. Overshoot or excessive round-

ing are unacceptable. This is relatively easy on the HZ51

and HZ54, but slightly more difficult on the HZ52. The rising

edge should be as steep as possible, with the pulse top

remaining as straight and horizontal as possible.

head. On the 100: 1 probe HZ53, however, it is located in

the connecting box at the other end of the cable. Using a

On the HZ52, each of the three trimmers has a clearly

kHz.)

The signal

HZ51,52,

and 54 will also allow for HF-adjustments.

risetime

(HZ51,52,

l&cm.

(typical 4ns). and low output

5OQ).

providing

or 54) to CH.1 input. Depress

1MHz.

Set all variable controls to CAL.

0.2V

and 2V at a fre-

All other pushbuttons

5mV/cm,

and TIME/

such a manner that the beginning of the pulse

0.2V.

(R-

A

M8 604

Subject to change without notice

Page 12

defined area of influence on the waveform shape (see Fig.),

offering the added advantage of being able to ‘straighten

out’ waveform aberrations near the leading edge.

The adjustment sequence must be followed in the order

described, i.e. first at 1

frequencies should not be used for timebase calibrations.

The pulse duty cycle deviates from 1 : 1 ratio.

Adjustment points of the probes

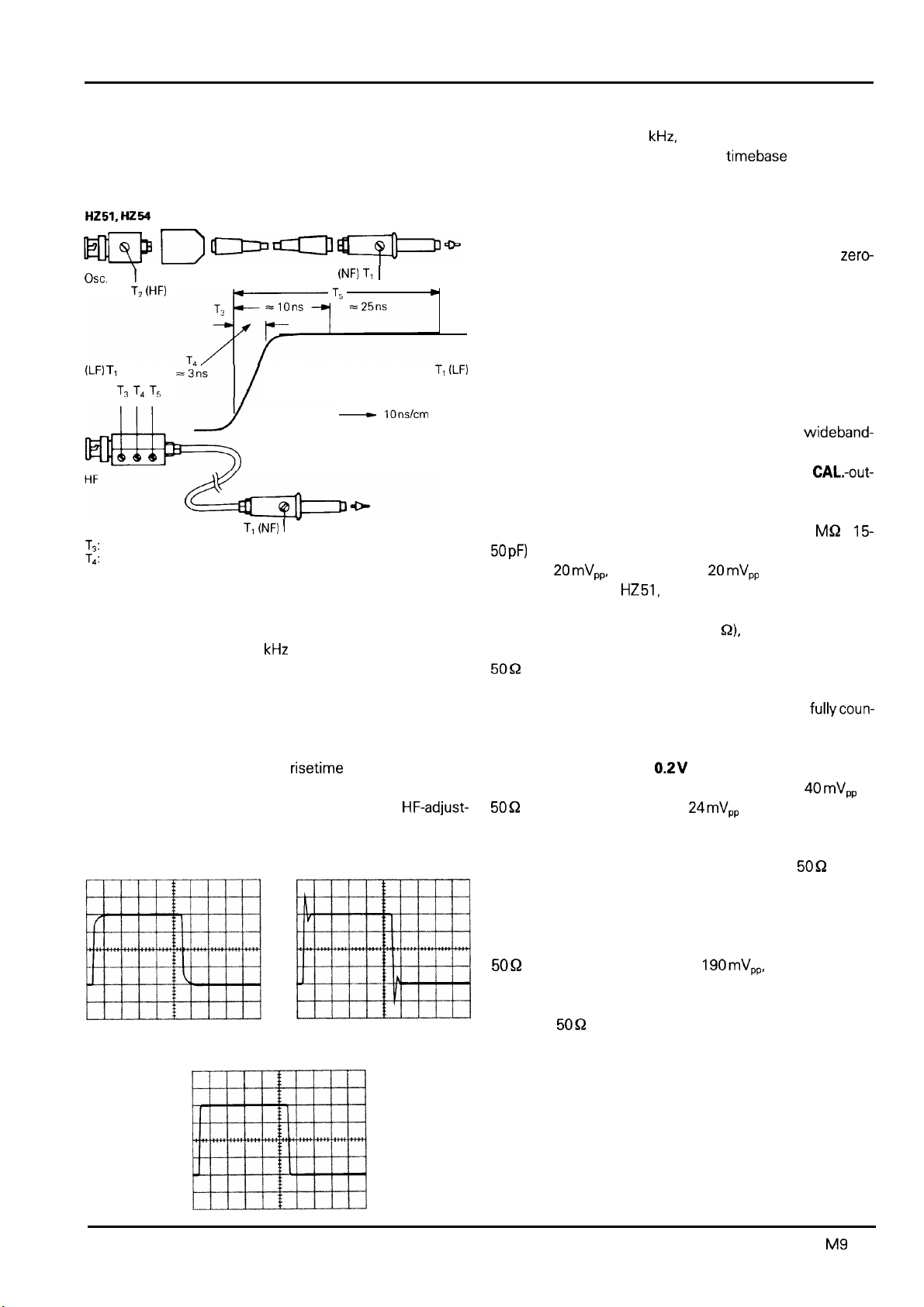

HZ51, HZ54

Prerequisites for precise and easy probe adjustments, as

well as checks of deflection coefficients, are straight horizontal pulse tops, calibrated pulse amplitude, and

osc.

I

Tz (I+)

1

CAL.

potential at the pulse base. Frequency and duty cycle are

relatively uncritical.

(NF) T,

response,

generator outputs are of particular importance.

kHz,

then at 1 MHz. The calibrator

zero-

For interpretations of transient

fast pulse risetimes and low-impedance

(I-F) T,

T3 T, T,

T,_:

alters the middle frequencies

Ti: alters the leading edge

T,: alters the lower frequencies

T,

(NF) 1

-

IOnskm

-

HZ52

T, (LF)

After completion of the HF-adjustment, the signal

amplitude displayed on the CRT screen should have the

same value as during the 1

kHz

adjustment.

Probes other than those mentioned above, normally have a

larger tip diameter and may not fit into the calibrator outputs Whilst it is not difficult for an experienced operator to

build a suitable adapter, it should be pointed out that most

of these probes have a slower risetime with the effect that

the total bandwidth of scope together with probe may fall

far below that of the HM604. Furthermore, the

HF-adjust-

ment feature is nearly always missing so that waveform distortion can not be entirely excluded.

Providing these essential features, as well as switch-select-

able output-frequencies, the calibrator of the HM 604 can,

under certain conditions, replace expensive squarewave

generators when testing or compensating

wideband-

attenuators or -amplifiers. In such a case, the input of an

appropriate circuit will be connected to one of the

CAL.-out-

puts via a suitable probe.

The voltage provided at a high-impedance input (I

5OpF)

will correspond to the division ratio of the probe used

(10:

1 =

20mV,,,

Suitable probes are

For low-impedance inputs (e.g. 50

100:

HZ51,

1 =

also

20mV,,

52, 53, and 54.

Q),

from 2V output).

a 1: 1 probe can be

MSJ

II

15-

employed which, however, must be fully terminated with a

5052

through-termination. Suitable probe types are HZ50

and HZ54. The latter must be switched to the 1: 1 position,

and the HF-trimmer in the connecting box turned fullycoun-

terclockwise.

When connected to the

0.2V

CAL. socket, and using the

HZ50, this arrangement will provide approx. 40mV,, at

50Q circuit input, and approx.

24mV,,

if the HZ54 is used.

The voltages given here will have larger tolerances than 1 %

since operation of a 1: 1 probe together with a

5OQ

load is

very uncommon.

incorrect

Adjustment

1 MHz

Subject to change without notice

correct

incorrect

Using the 2V CAL. socket under similar conditions is only

possible with the HZ54 probe. The potential obtained at the

5OQ

input will then be approx.

190mV,,,

but with almost

twice the risetime. Accurate readings of the available input

voltage can be shown directly on the HM604 when con-

necting a

5OQ

through-termination between the BNC plug

of the probe and the input of the oscilloscope.

Operating Modes of the Y Amplifier

The required operating modes are selected on three

pushbuttons located in the Y-Section. For Mono operation

all pushbuttons should be in the out position, the instrument is then operating on Channel/only.

M9

604

Page 13

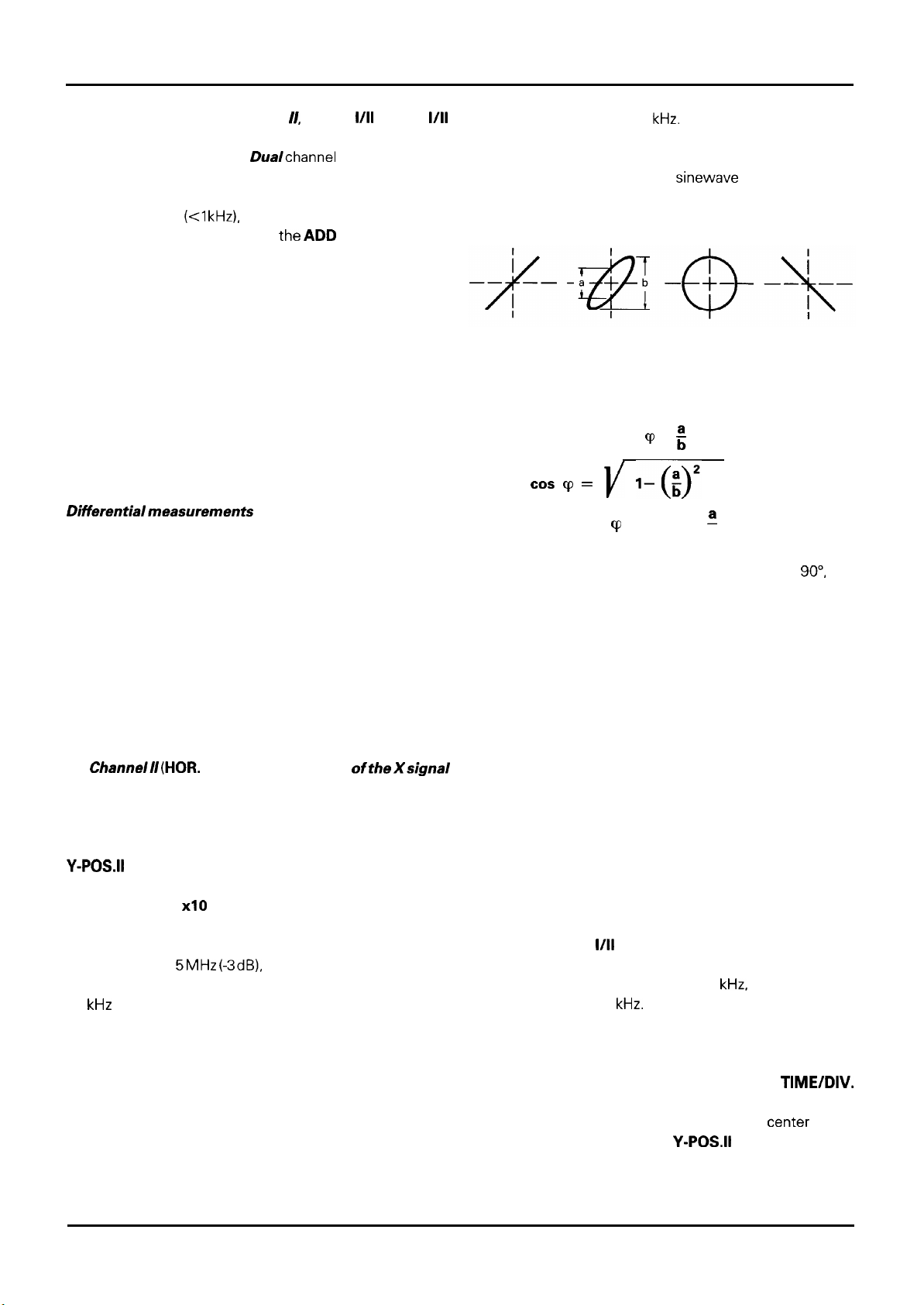

For Mono operation with Channel

pushbutton has to be pressed. When the DUAL button is

depressed, the HM604 is in

mode, the channels are displayed consecutively (alternate

mode). This mode is not suitable for the display of very low

frequency signals

or jump. Under these conditions,

depressed additionally selecting chopped mode. In this

position, both channels then share the trace during each

sweep period. For the display of high frequency signals, the

type of channel switching selected is less important.

To select the add mode only the ADD button should be

depressed. The signals on both channels are then added

together. If in this mode one channel is inverted (pushbutton INVERT depressed), then the difference between the

two channels is displayed. For both of these operating

modes, the vertical position of the trace depends on the setting of the Y-POS. controls of both channels.

(<l kHz),

as the tracewill appear to flicker

II,

the CH

Dualchannel

the ADD

l/II

-TRIG.

operation. In this

button should be

l/II

nal frequencies up to 120

quency the inherent phase difference between the vertical

and horizontal system makes accurate measurements difficult. In this mode, one of the

horizontal deflection (X) while the other signal provides the

vertical deflection (Y).

0”

The phase angle between the two signals can be deter-

mined from the Lissajous pattern as follows:

cos

cp

35”

=

1/ I-@

kHz.

sin cp =

However, above this fre-

sinewave

signals provides

90” 180”

E

Differentialmeasurements

urement of the voltage drop across floating components

(both ends above ground). Two identical probes should be

used for both vertical inputs. Using a separate ground connection and notconnecting the probe or cable shields to the

circuit under test avoid ground loops (hum, common-mode

disturbances).

X-Y Operation

For X-Yoperation, the pushbutton in the X-Section marked

X-Y must be depressed. The X signal is then derived from

the

Channe///(HOR.

during X-Y operation is determined by the setting of

the Channel II input attenuator and variable control.

This means that the sensitivity ranges and input impedances are identical for both the X and Y axes. However, the

Y-POS.II

is taken over by the X-POS. control. It is important to note

that the X MAG.

the sweep, should not be operated in the X-Y mode. It

should also be noted that the bandwidth of the X amplifier

is approximately

phase difference between both axes is noticeable from

50

The Y-Input signal may be inverted by using the INVERT

(channel I) facility.

control is disconnected in this mode. Its function

kHz

upwards.

INP.). The calibration

x10

facility, normally used for expanding

5MHz

X-Y Phase Measurements

The X-Y phase measurement method can be used to meas-

ure the phase difference between two signals of the same ence signal occupies exactly 10 divisions (see next figure).

frequency. This provides a method of measurement for sig-

techniques allow direct meas-

ofthexsignal

(-3dB), and therefore an increase in

= arc sin

%J

This simple formula works for angles less than

independent from both deflection amplitudes on the

screen.

Caution!

If a single spot appears (both deflection voltages are missing)

reduce the intensity immediately, as a high intensity setting

may cause damage to the fluorescent screen of the CRT.

f

b

90”,

it is

Dual-Trace Phase Difference Measurements

Phase comparison between two signals of the same fre-

quency can be made using the dual-trace feature (DUAL

button depressed). This method of phase difference meas-

urement can be used up to the frequency limit of the vertical

system. To make the comparison, use the following procedure:

Set the Input Coupling switches to the same position, and

the CH. I/II-TRIG.

reference signal (Phase 0”) is connected. Select ALT. chan-

nel switching for frequencies above 1

frequencies below 1

time delay to connect the signals to the input connectors.

Set the Input Attenuator switches and the CH I and CH II var-

iable controls so that the displays are approximately equal

and about five divisions in amplitude. Set the TIME/DIV.

switch to a sweep rate which displays about one cycle of

the waveform. Move the waveforms to the

graticule with the Y-P0S.I and

Turn the Variable Time Control until one cycle of the refer-

Each division represents 36” of the cycle.

l/II

pushbutton to the channel where the

kHz,

and CHOP. for

kHz.

Use probes which have equal

center

Y-POS.II

controls.

of the

Ml0 604

Subject to change without notice

Page 14

Figure 2

Amplitude modulated oscillation: F = 1 MHz; f = 1 kHz;

m = 50 %

; UT =

28.3

mVrms.

Dual-Trace Phase Difference Measurements

T =

Horizontal distance

t

= Horizontal distance of zero-crossing points (cm).

foroneperiod(cm).

Assume a horizontal difference of 3 divisions (t = 3cm) and

a period of

10

divisions (T = 1 Ocm), the phase difference

91

can be calculated using the following formula:

=

108”

l.885rad

or

arcg,

-2~t =$ a2~~

=f

respectively.

Measurement of an amplitude modulation

The momentary amplitude u at time t of a HF-carrier voltage, which is amplitude modulated without distortion by a

sinusoidal AF voltage, is in accordance with the equation

u

=

U,.

sinQt

+

0,5m

. UT - cos(S&w)t -

where

= unmodulated carrier amplitude

U,

S2= 2~rF

0

=2nf

= angular carrier frequency

= modulation angular frequency

m= modulation factor (S 1 P 100

The lower side frequency F-fand the upper side frequency

F+f

arise because of the modulation apart from the carrier

frequency

F.

T

0,5m *

Figure 1

Amplitude and frequency spectrum for AM display (m = 50%)

UT

4

I

F-f F F+f

The display of the amplitude-modulated

evaluated with the oscilloscope provided the frequency

spectrum is inside the oscilloscope bandwidth. The time

base is set so that several cycles of the modulation frequency are visible. Strictly speaking, triggering should be external with modulation frequency (from the AF generator or a

demodulator). However, internal triggering is frequently possible with normal triggering using a suitable LEVEL setting

and possibly also using the time variable adjustment.

0,5m

- UT -

cos(l(r+o)t

%).

UT

0,5m

-

UT

4

HF

oscillation can be

Oscilloscope setting for a signal according to figure 2:

Depress no buttons.

TIM

E/DIV. :

0.2

Triggering: NORMAL with LEVEL-setting; internal (or

Y:

ms/div.

CH. I; 20mV/div; AC.

external) triggering.

If the two values

ulation factor is calculated from

a-

m =

a+b

aand

b

resp. m =

bare read from the screen, the mod-

a*.

100

[%J

where a = UT (l+m) and b = UT (l-m).

The variable controls for amplitude and time can be set arbitrarily in the modulation factor measurement. Their position does not influence the result.

Triggering and Timebase

With the LEVEL knob in locked position (turned ccw to AT

position = automatic triggering), a baseline is displayed con-

tinuously even when no signal is present. In this position it is

possible to obtain stable displays of virtually all uncomplicated, periodically repeating signals above 30 Hz. Adjustments of the

With normal triggering (LEVEL knob not in AT position) and

LEVEL adjustment, triggering of time/div. deflection can be

set in any point of a given signal. The triggering range which

can be set with the LEVEL control depends greatly on the

amplitude of the displayed signal. If it is less than 1 div, then

the range is quite small and performance of settings requires a delicate touch.

If the

LEVEL

ble.

In order to obtain a satisfactory stable display, the

must be triggered synchronously with the test signal. The

trigger signal can be derived from the test signal itself,

when internal triggering is selected, or from a frequency related signal applied to the external trigger input.

timebase

then are limited to

timebase

setting.

control is incorrectly set, no trace will be visi-

timebase

Subject to change without notice

Ml1 604

Page 15

Triggering can be selected on either the rising or falling edge

of the trigger signal depending on whether the SLOPE +/pushbutton (next to

out position, triggering from the positive-going edge is

selected. The correct slope setting is important in obtaining

a display when only a portion of a cycle is being displayed.

With internal

the Y amplifier, the trigger signal is derived from the respective channel in use. In the Dualchannelmode, the internal

trigger signal may be selected from either Channel I or

Channel//using the

sition, the trigger signal is derived from Channel I. However,

it is always preferable to trigger from the less complicated

signal.

With

internalalternate

X-Section depressed) in the DUAL channel alternate mode

of the Y amplifier, the trigger voltage is derived alternately

from Channel I and Channel

ticularly useful when two asynchronous signs/s are being

investigated. Normal triggering should be preferable in this

mode. The display of one signal only is not possible on the

alternate trigger mode.

For

exfernaltriggering,

tion must be depressed. The sync. signal

must then be fed to the TRIG. INP. input socket.

Coupling mode and frequency range of the trigger signal

are selected with the TRIG. lever switch in the X-Section for

internal and external triggering, provided that the TV SEP.

switch is in off position. The HM 604 has 4 coupling modes:

AC, DC, LF, HF. The AC coupling mode is mainly used. DC

trigger coupling is only recommended, when very low fre-

quency signals are being investigated and triggering at a

particular value is necessary, or when pulses, which significantly change in duty cycle during observation time,

have to be displayed. If DC coupling is selected, it is advisable to use the normal triggering mode. In the HF coupling

mode, a high pass filter is switched into the trigger

amplifier. This filter cuts off the DC content of the trigger

signal and the lower frequency range.

LEVEL)is

triggering

in the out or in position. In the

in the Mono channel mode on

CHMI-TRIG.I/II

triggering (ALT pushbutton in the

the EXT. pushbutton in the X-Sec-

button; in the out po-

II.

This trigger mode is par-

(0.05V,,-0.5VJ

frequency component in complex waveforms. Therefore it

is especially suited for the measurement of small ripple volt-

ages from power supply rectifiers or of magnetic or static

leakage

In some countries, the standard power plug has symmetri-

cally arranged plugs (interchanging of Line and Neutral is

possible). In such cases, the SLOPE

indicate the wrong polarity compared with the display (triggering with falling edge instead of rising edge). For correction, the power plug of the instrument has to be turned.

fields~in

a circuit.

+/-

pushbutton may

Triggering of video signals

The built-in active TV-Sync-Separator separates the sync

pulses from the video signal, permitting the display of distorted video signals either in line (H = horizontal) or in frame

(V = vertical) trigger mode. The TV lever switch has five po-

sitions: the OFF position is for normal operation.

The TV: H+ and H- positions (horizontal= line) and the

TV: V+ and V- (vertical

video triggering. In these four positions the TRIG. coupling

switch and the LEVEL control (in NORM. trigger mode) are

inoperative. In the TV: V+ and V- positions (frame trigger-

ing), a low-pass filter or integrating network is connected

into circuit, which forms a trigger pulse sequence with

frame frequency from thevertical sync pulses (incl. pre-and

postequalizing pulses).

When in V mode, it is possible to select field I or II by releas-

ing or depressing FIELD

For correct video triggering, the + and - positions at V and

H must be selected corresponding to the video input signal.

If the sync pulses are placed above the picture content, H+

or V+ should be in use. For sync pulses below the picture

content of the input signal, correct triggering, without any

influence from changing picture contents, will be possible

only in V- or H-setting. The INVERT pushbutton only

changes the display on the CRT, not the input signal.

=frame)

l/II

pushbutton.

positions are used for

In the LF coupling mode, a low-pass

the trigger amplifier. This filter cuts off any amplifier noise

and the frequency range of the trigger signal above 50

For the purpose of line triggering (TRIG. lever switch in the

X-Section) to N, a (divided) secondary voltage of the power

transformer is used as a trigger signal. This trigger mode is

independent of the signal amplitude or display height and al-

lows a display below the (internal) trigger threshold. Line

triggering is recommended for all signals which are time-re-

lated (multiple or submultiple) to the mains/line frequency

or when it is desirable to provide a stable display of a line-

Ml2 604

filter

is switched into

kHz.

In TV: H trigger mode, the trigger point lies on the starting

edge of a sync pulse if SLOPE button is in + position. As