Follow the safety precautions in Chapter 1 in order to avoid personal injury and

reading this manual, store it in a location where you can refer to it at any time.

ORCA-Flash4.0 V3

Digital CMOS Camera

C13440-20CU / C13440-20CU01

Instruction manual

Thank you for your purchase

•

damage to property when using this system. The manual describes the correct

handling method of t he sy ste m and pr ov i des i nstructions that should be followed

to avoid accidents. Read this manual carefully before using this system. After

Ver.1.3

April 2017

HAMAMATSU PHOTONICS K.K.

A3410301-03

~ Blank page ~

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Improper handling of the camera without observing these warnings could

lead to serious injury to the user and even death.

Improper handling of the camera without observing these cautions could lead

to personal injury to the user or damage to propert y.

is forbidden. Read and follow the instructions

Note

This symbol indicates a note to help you get the best performance from the camera. Read

these notes might impair the performance of the camera.

1. SAFETY PRECAUTIONS

1-1 SYMBOLS

The symbols shown belo w ar e used f or t his camera.

Direct current

Alternating current

1-2 CLASSIFICATION OF WARNINGS

We have classified the war ning s symbols that appear in this ins t r uct ion manual and on the camera

as follows for your convenience. Make sure that you fully understand them and follow the

instructions they contain.

This symbol indicates a cautionary item that should be followed when handling the

camera. Read the contents carefully to ensure correct and safe use.

This symbol indicates an action that

carefully.

This symbol indicates a compulsory action or instruction. Read and follow the instructions

carefully.

the contents of the note carefully to ensure correct and safe use. Failure to observe one of

3

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Power supply

voltage can damage the camera and lead to fire or electric shock.

Cables

damage the cables and lead to fire or electric shock.

Do not attempt to dismantle or modify the camera

manual.

Do not allow foreign objects

These can damage the camera and lead to fire or electric shock.

In the event of an anomaly

your local distributor. Do not attempt to repair the camera yourself.

Use the camera with th e indicated voltage on the rating sticker. Using a different

Do not to place heavy objects on cables or bend them exce ssively. Doing so ca n

Power supply cord

Use the accessory power supply cord when using this camera.

AC adapter

Use the accessory AC adapter when this using this camera.

Do not touch the plug with wet hands. Doing so can lead to electric shock.

Doing so can also lead to damage and even injury, as some internal components

become very hot or high voltage. Do not touch parts that are not indicated in this

Such as combustible substances, metal objects or water to get inside the camera.

such as the image suddenly disappearing or the occurrence of a strange noise, a

strange smell or smoke coming from the system, immediately turn off the power

switch and unplug the power supply cord and contact a Hamamatsu subsidi ary or

4

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

AC adapter

from the outlet to avoid causing elec tric shock or fire.

Connecting and disconnecting cables

disconnecting cables.

Mounting the camera

surface of the base plate. Screwing it in further can impair normal operation.

Lenses (C13440-20CU)

can have a thread of 7 mm or more.)

Shipping precautions

packaging material or something similar.

Strong impact

damage the camera.

Operating environment

This camera is designed and tested for use in an industrial environment. If this

This camera must not be used in residential areas.

Disposal

disposing of the camera, take appropriate measures in compliance with

applicable regulations regarding waste disposal and correctly dispose of it

province to ensure the camera is disposed of legally and correctly.

When unplugging the power supply cord, do not pull on the cord. Remove the plug

When unplugging the power supply cord, do not pull on the cord, but remove the

plug from the camera to avoid breakdown of the AC adapter

Always turn off the power supply of the peripheral device before connecting and

When mounting the camera to a tripod or other fix ture , use the optional base plate.

Be careful that the mounting screw does not enter more than 8 mm from the

or the camera.

Be careful not to screw the lens more than 7 mm into the C-mount of the camera.

Doing so can scratch the protective glass. (Some wide-angle lenses in particul ar

When transporting the camera by truck, ship, airplane, etc., wrap it securely in

Do not subject the camera to strong shocks (such as dropping it). Doing so can

camera is used in residential areas, EMI (electro-magnetic interference) may occur.

When

yourself, or entru st disposal to a lic ensed industrial w aste disposal comp any.In

any case, be sure to comply with the regulations in your country, state, region or

5

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Using water cooling

water hoses.

Cooling water

Hamamatsu subsidiary or your local distributor.

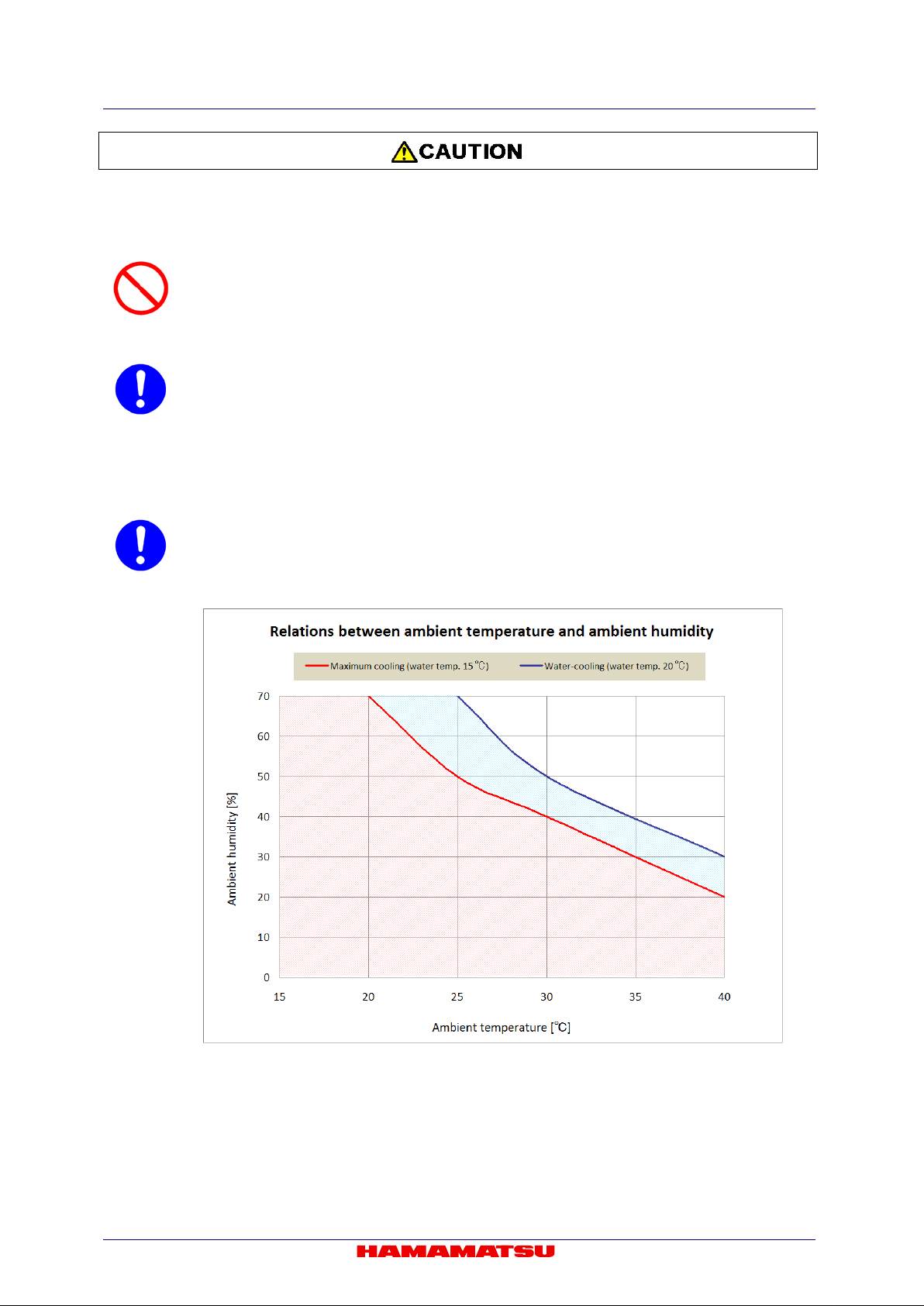

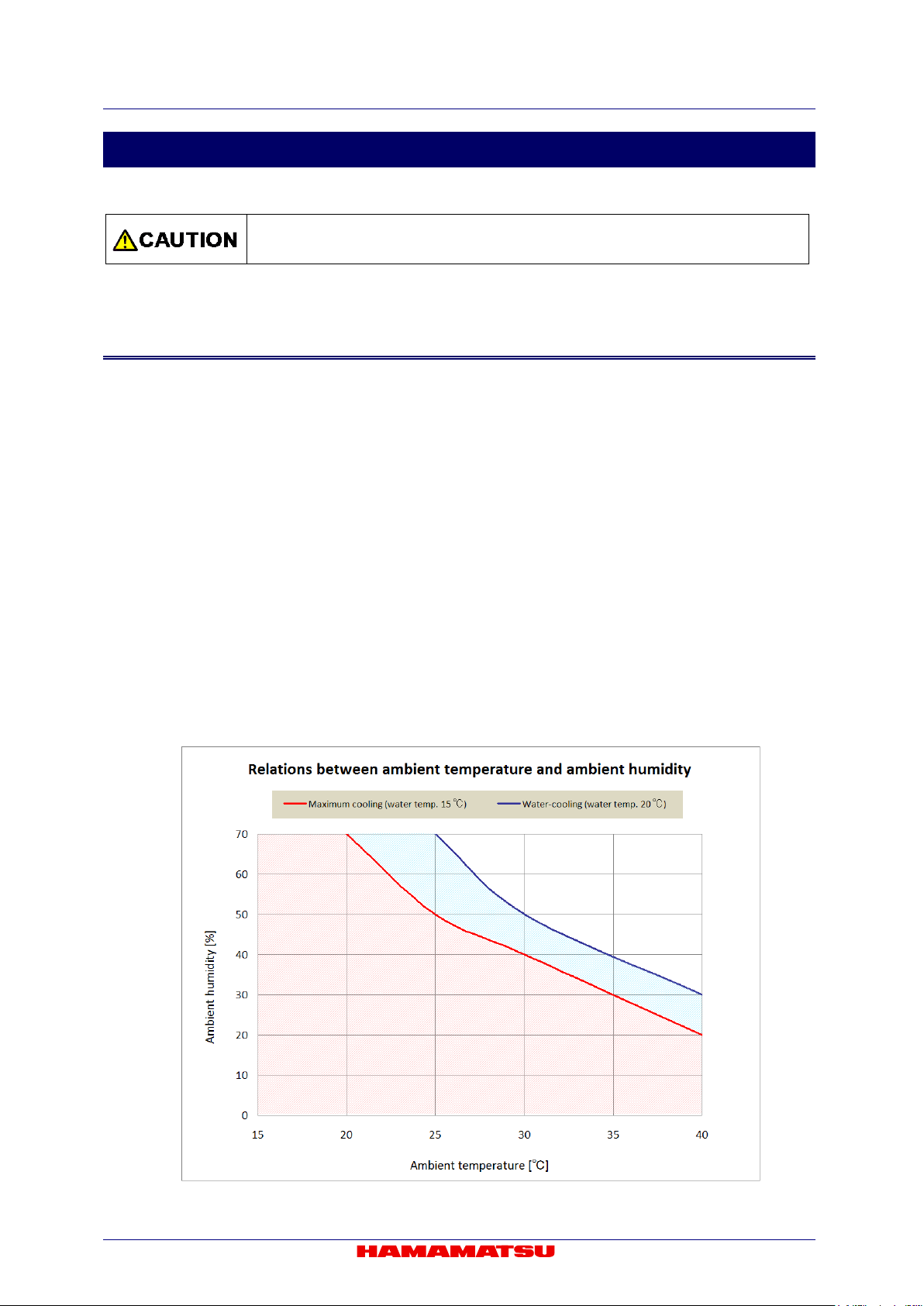

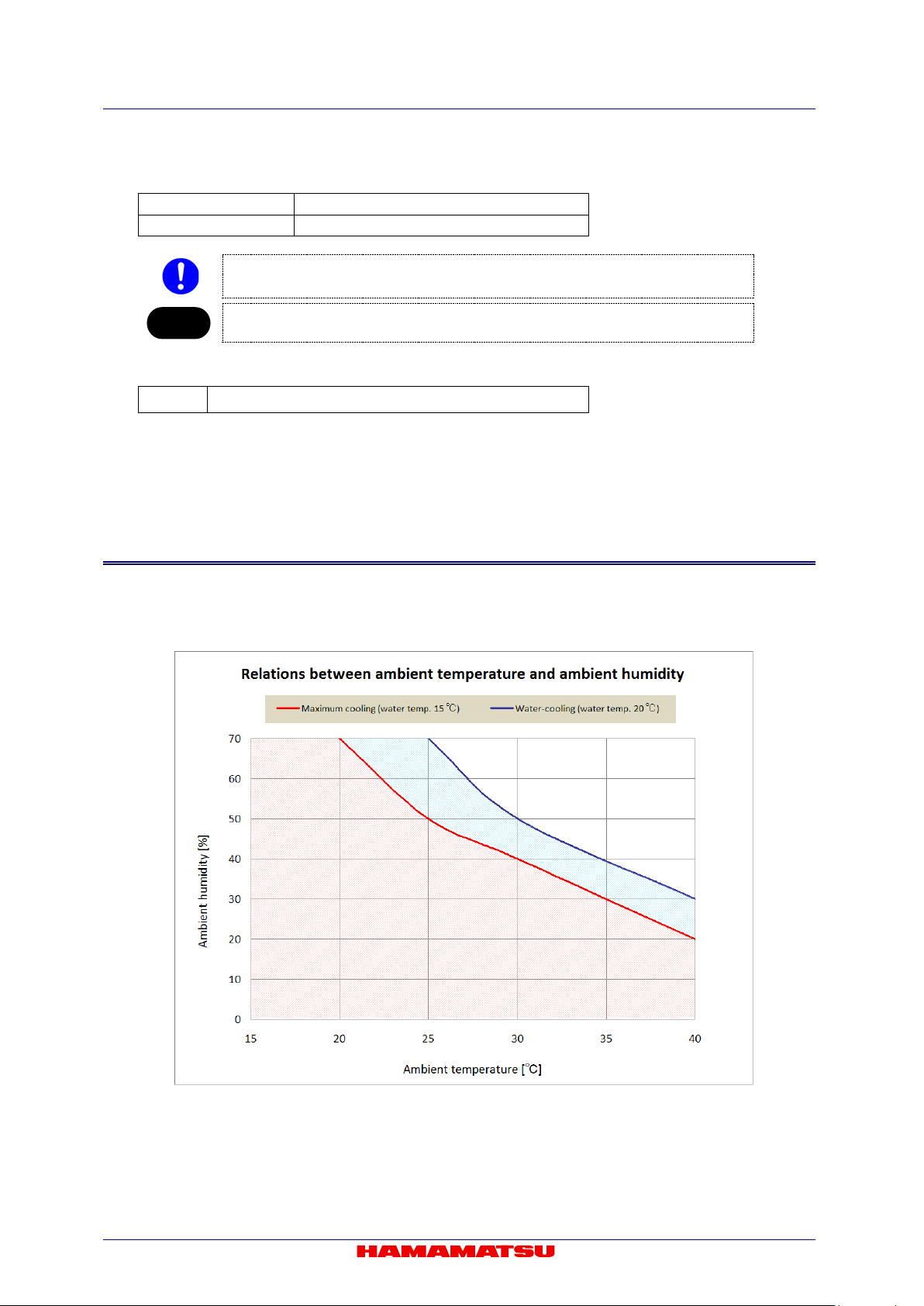

Condensation

condensation will not take place referring to the following graph.

Be careful water does not splash on the camera. Cut off the power supply of the

circulating water cooler and the camera when you remove and install the cooling

It is recommended to use soft water (except pure water) for cooling water. Follow

instruction manual which is attached to your circulating water cooler for an

appropriate temperature range of cooling water. If you plan on using water other

than soft water as recommended for example antifreeze etc, please refer to

description of cooling water which is written in 12. “MAINTENANCE

” o r contact a

At the Water-cooling, if ambient temperature and ambient humidity become high,

condensation will t ake place eas ily. Use the camera un der the env ironment w here

6

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Camera: C13440-20CU or C13440-20CU01

1

AC adapter

1

Power supply cord for AC adapter

1

Lens mount cap (attached to the camera)

1

C13440-20CU Before Use (Booklet)

1

C13440-20CU Instruction manual (CD-ROM)

1

QC sheet

1

[Option]

Cooling water hose (2 hoses)

A10788-04

SMA-BNC cable

A12106-05

SMA-SMA cable

A12107-05

Camera Link interface board

M9982-29

Camera Link interface cable

A14038-04

USB 3.0 interface board

M9982-25

USB 3.0 interface cable

A12467-03

Adjustable pole for C11440-22CU

A11185-01

Fixing bracket for C11440-22CU cable

A13261-01

Note

Note

2. CHECK THE CONTE NT S OF PACKAGE

When opening the package, check that t he f ol low i ng items are included before us e.

If the contents are incorrect, insufficient or damaged in any way, contact a Hamamatsu subsidiary

or your local distributor before at tempting to operate the cam er a.

• Handle the circulating water cooler and the cooling water according to the instruction manual

of the circulating water cooler.

• The cable listed in option is highly recommended for use with the camera. The camera

system may not confirm to CE marking regulation if other type of cable is used with.

• If you use the above options, please refer to the each installation manual.

7

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Places where the temperature is not the operating temperature indicat ed in the spe cifi cat ion s

• Places where there is a lot of dust

How to place the camera (when the camera is placed on a table)

other material, or in any way allow the camera’s ventilation ports to become

closed environment, ensure

up when setting up the camera.

3. INSTALLATION

Avoid using or storing this camera in the following places

•

• Places where the temperature is not the storage temperature indicated in the specifications

• Places where the temperature varies greatly

• In direct sunlight or near a heater

• Places where the humidity levels are not the operating humidity levels indicated in the

specifications and where the camera may be exposed to liquid

• Places where the humidity levels are not the storage humidity levels indicated in the

specifications and where the camera may be exposed to liquid

• Close to a strong source of magnetism or ratio waves

• Places where there are vibrations

• Places where the camera may come into contact with corrosive gases (such as chlorine or

fluorine)

Place the camera with water connectors on the side.

Do not place the camera with the vent opening, water c onnections or re ar panel on

the bottom. (Do not block ventilation openings.)

Do not allow the ventilation ports to become blocked.

To prevent the camera from overheating, do not wrap the camera in cloth or any

blocked. If the camera is being operated in an

clearance of at least 10 cm from both the intake and exhaust vents when setting

Weight of the camera

Be careful not to drop the camera when moving it as it is approx. 2.2 kg.

8

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

CCoonntteennttss

1. SAFETY PRECAUTIONS ................................................................................... 3

1-1 SYMBOLS ........................................................................................................................... 3

1-2 CLASSIFICATION OF WARNINGS ................................................................................... 3

2. CHECK THE CONTENTS OF PACKAGE .......................................................... 7

3. INSTALLATION .................................................................................................. 8

4. OVERVIEW ....................................................................................................... 11

5. FEATURES ....................................................................................................... 12

6. NAME AND FUNCTION O F PARTS ................................................................ 15

7. CONNECTION .................................................................................................. 18

8. WATER COOLING ........................................................................................... 20

8-1 CAUTIONS ........................................................................................................................ 20

8-2 CONNECTION OF WATER COOLING HOSES ............................................................... 22

8-3 DISCONNECTION OF WATER COOLING HOSES ......................................................... 23

9. OPERATIONS .................................................................................................. 24

9-1 OPERATING PRECAUTIONS .......................................................................................... 24

9-2 PREPARATING FOR IMAGING ....................................................................................... 25

9-3 IMAGING ........................................................................................................................... 25

9-4 END OF IMAGING ............................................................................................................ 25

9-5 STARTUP DCAM CONFIGURATOR ............................................................................... 26

10. DESCRIPTION OF CMOS IMAGE SENSOR ................................................... 28

10-1 THEORY OF CMOS IMAGE SENSOR ............................................................................. 28

10-2 READOUT METHOD OF CMOS IMAGE SENSOR ......................................................... 29

10-3 PRECAUTION WHEN USING CMOS IMAGE SENSOR ................................................. 29

11. DESCRIP T ION OF VARIOUS FUNCTIONS .................................................... 30

11-1 NORMAL AREA MODE .................................................................................................... 30

11-2 LIGHTSHEET READOUT MODE ..................................................................................... 49

11-3 W-VIEW MODE ................................................................................................................. 56

11-4 DUAL LIGHTSHEET READOUT MODE .......................................................................... 68

11-5 REAL-TIME DEFECT PIXEL CORRECTION ................................................................... 74

11-6 DATA REDUCTION FUNCTIONS .................................................................................... 75

11-7 MASTER PULSE............................................................................................................... 77

12. MAINTENANCE ................................................................................................ 79

12-1 CARE ................................................................................................................................. 79

12-2 INFORMATION ON COOLING WATER FOR THE CIRCULATING WATER COOLER . 80

13. TROUBLESHOOTING ...................................................................................... 81

13-1 IMAGE IS NOT TRANSFERRED ...................................................................................... 81

13-2 ALTHOUGH IMAGES ARE TRANSFFERED .................................................................. 81

9

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

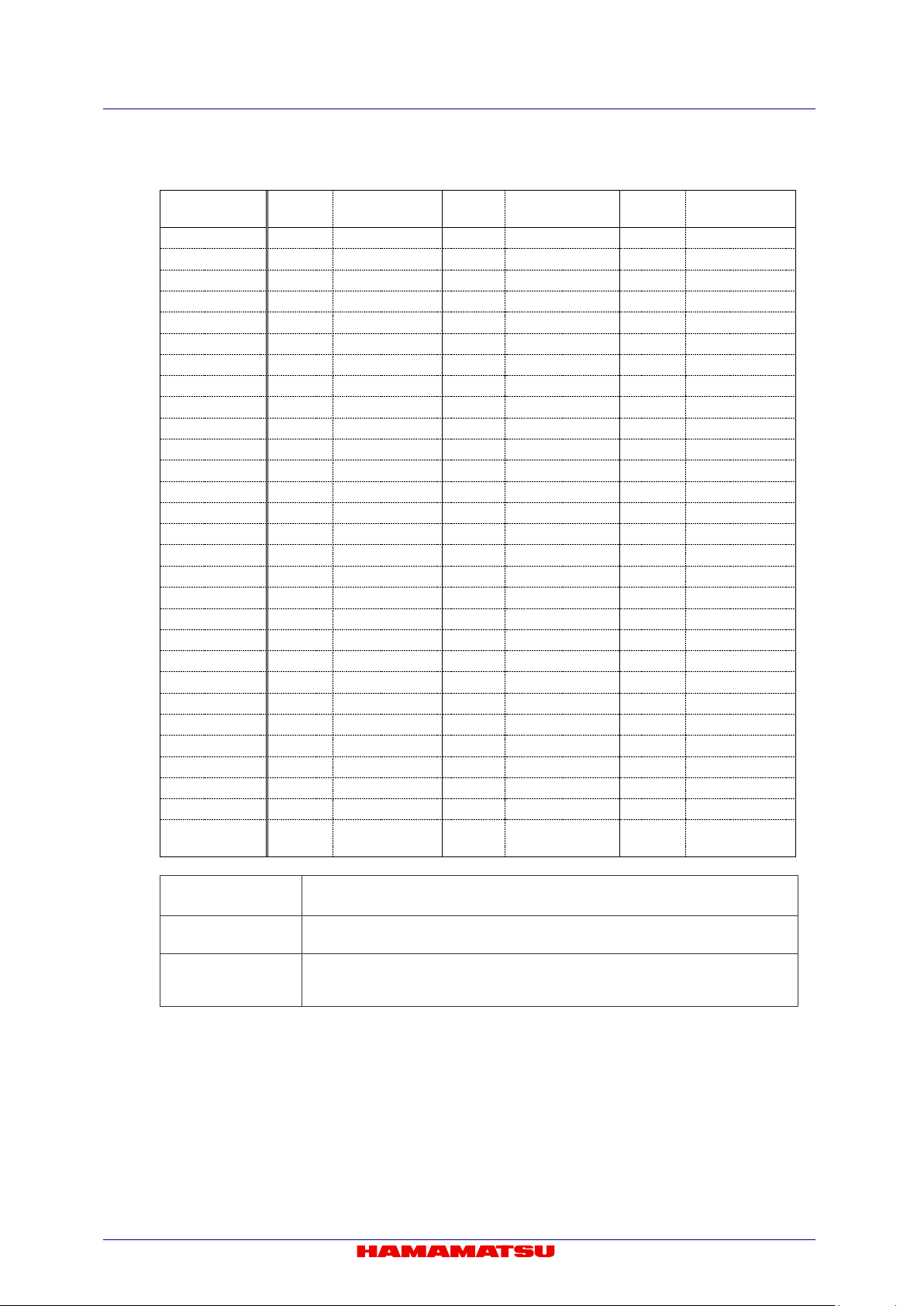

14. SPECIFICATIONS ............................................................................................ 82

14-1 CAMERA SPECIFICATIONS ............................................................................................ 82

14-2 CONDENSATION.............................................................................................................. 85

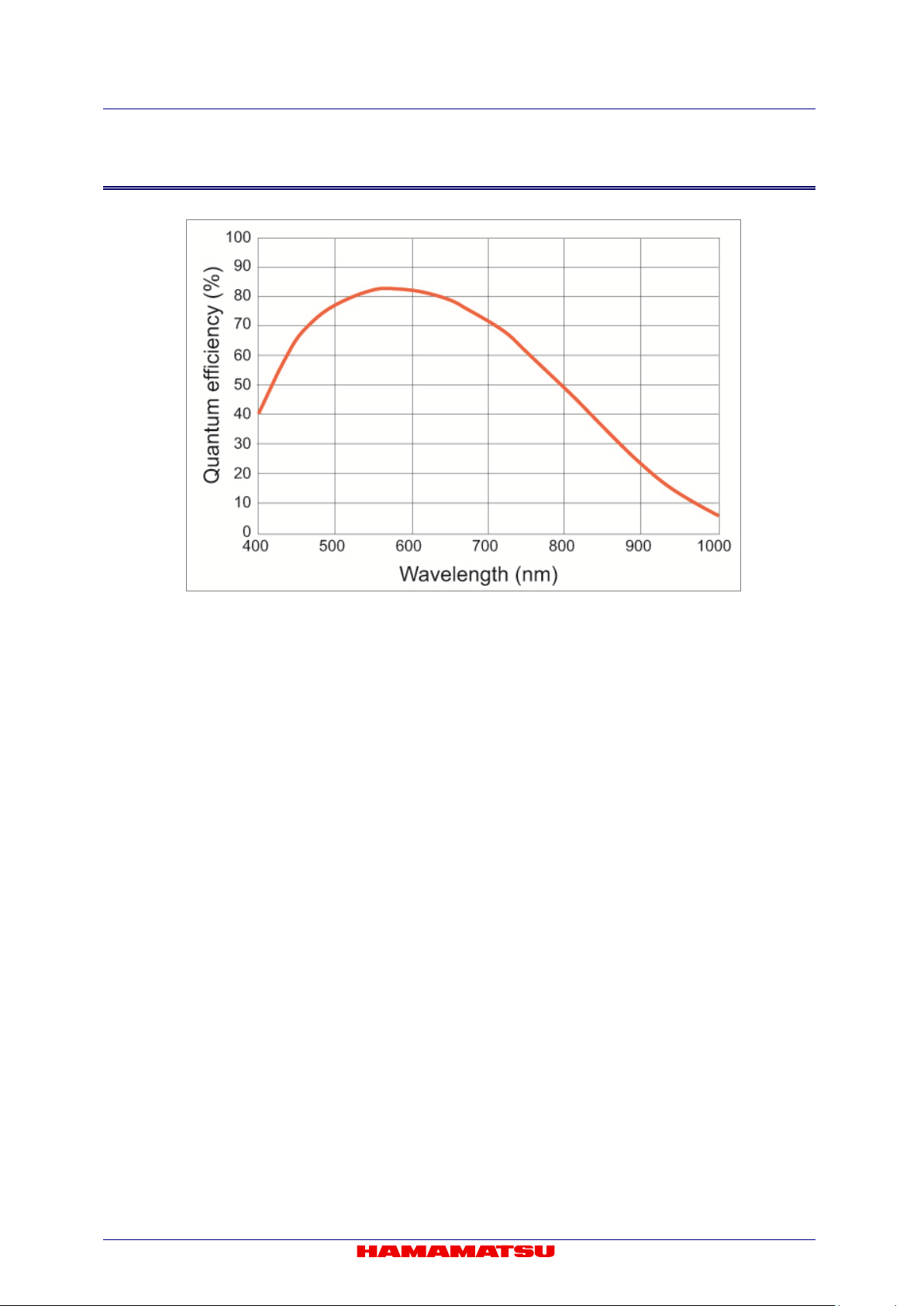

14-3 SPECTRAL RESPONSE CHARACTERISTICS (TYP.) ................................................... 86

14-4 INTERFACE SPECIFIC ATIONS ....................................................................................... 87

14-5 OUTPUT TIMING SPECIFICATIONS ............................................................................... 89

15. DIMENSIONAL OUTLINES .............................................................................. 93

15-1 C13440-20CU .................................................................................................................... 93

15-2 C13440-20CU01 ................................................................................................................ 94

16. WARRANTY ..................................................................................................... 95

16-1 BASIC WARRANTY ......................................................................................................... 95

16-2 REPAIRS ........................................................................................................................... 95

17. CONTACT INFORMATION .............................................................................. 96

10

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

4. OVERVIEW

C13440-20CU / C13440-20CU01 is equipped with the new scientific image sensor, an advanced

CMOS device that realizes the multiple benefits of high resolution, high readout speed, and low

noise all at once.

The camera provides 4.0 megapixels resolution at 100 fps (frames/s) (and up to 25 655 fps by

sub-array readout) while achieving 1.0 electrons (median) 1.6 electrons (r.m.s) readout noise

performance. Moreover, the camera delivers high sensitivity through its on-chip micro lens, 37

000:1 high dynamic ra nge that m akes the c a mera s uitab le for alm ost any sc ient ific app licat ion fro m

bright field imaging to low-light fluorescence imaging across a wide spectral range. Various

external trigger functions and timing output functions ensure proper timing control with peripheral

equipment to cover a wide range of applications.

The camera is the new scientific digital camera for life science microscopy, semiconductor

inspection, x-ray scintill at or readout or industrial imaging.

11

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

5. FEATURES

(1) Readout noise

In the camera, the pixel amplifier is optimized: it has high gain from optimizing the semiconductor

process, and the d ifference among pix el amplifiers are greatly minim ized. In addition, there is

on-chip CDS (correlated doubl e sam pling) circuit, which pla ys an import ant role in achieving low

noise. Moreover, the sensor featur es a split r eadout sc hem e in which t he top and bottom halves

of the sensor are readou t in depe nde ntly, a nd t he d ata of eac h hor izo nta l l ine is r e ad by 2 lines of

column amplifier and A/D in the top an d the bott om in para llel and s imultaneo usly. As a result, it

achieves very fast readout speed whi le keep ing very good low-noise performance.

The camera has lower readout noise (1.0 electrons (median), 1.6 electrons (r.m.s)) than the

conventional cooled CCD camera. Moreover, high-speed readout (100 fps with 2048 pixels ×

2048 pixels) with very low readout noise, wh ich was im pos sibl e, can now be achi e ved.

In addition, the camera can achieve further lower readout noise (0.8 electrons (median), 1.4

electrons (r.m.s) with slow scan mode (30 fps with 2048 pixels × 2048 pixels).

(2) Cooling structure

In the camera, the CMOS image sensor is cooled down by a peltier element to suppress the dark

current. If the CMOS image sens or is ex posed to the atmos phere, condens ation of the m oisture

from the air might occur. However the camera has a special hermetic chamber structure to isolate

the sensor from the atmosphere, and the chamber is filled with nitrogen gas.

(3) Pixel number and pixel size

CMOS image sensor has 6.5 µm x 6.5 µm pixel sizes that is equivalent to conventi onal CCD

image sensor (2/3 inch, 1.3 megapixels). Also, the camera can observe a wider field of view

because the pixel num ber is about 3 tim es t hat of the conventional CCD image s ensor ( 2/3 inch,

1.3 megapixels)

(4) Readout methods

The camera has a var iety of readout modes. In add ition to full resolution reado ut mode (1×1),

sub-array readout and binning readout (2×2, 4×4) are supported.

(5) Frame rate

CMOS image se nsor which this camera adopts realizes both lo w noise (1.0 elec trons (median)

1.6 electrons (r.m.s)) and high speed readout (100 fps with 2048 pixels x 2048 pixels)

simultaneously, by a split readout scheme in which t he top and the bott om halves of the s ensor

are readout independently, and the data of each horizontal line is read by 2 lines of column

amplifier and A/D in the top and the bottom in parallel and simultaneously.

(6) Real-time correction functions

There are a few pixe ls in CMOS image s ensor that have br ighter or darker int ensity, and a few

pixels that have slightly higher readout noise performance, when compared to surrounding pixels.

The camera has a r eal-time vari ant (defective) p ixel correct ion feature to f urther improve im age

quality. The correction can be performed in real-time without sacrificing any of the readout speed.

(7) Data reduction functions

The camera provides a maximum 4.0 megapixel resolution at a rate of 100 fps and with 16 bit

intensity levels per pixel. With these conditions, the camera outputs 800 MB of data per second,

making it necessary to store a large amount of data. With data reduction functions now

available in the camera, it is possible to select reduced areas of the image and/or reduced

intensity levels to transfer and store only the data of interest.

12

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Lightsheet

ReadoutMode

DualLightsheet

(8) Interface

This camera has both Camera Link and USB 3.0 interface.

Camera Link Interface:

The camera Link interface is able to transfer large volumes of data. It can transfer a 4 megapixels

image with 100 fps.

In order to realize such a large volume data transfer, the camera uses Camera Link "Full

Configuration Deca Mode " which is an expanded version of Cam era Link "Full Configurati on". It

enables a transfer maximum 85 MHz x 10 Taps (8 bit) image data to computer as fast as 100 fps.

In order to use this interf ace, a Camera Link inter face board which su pports "Full Configur ation

Deca Mode" is required.

USB 3.0 Interface:

USB 3.0 interfac e is able to transfer a 4 megapixels im age with 40 fps. It is versatile interface

which is suitable to use when fast data transfer is not required.

This interface does not require a Camer a Link interf ace board. It transfers image with m oderate

transfer speed.

• When a connection interface is changed from Camera Link to USB 3.0, and vice versa, the

application software must be closed and the camera must be turned off.

• Do not connect Camera Link and USB 3.0 interface simultaneously.

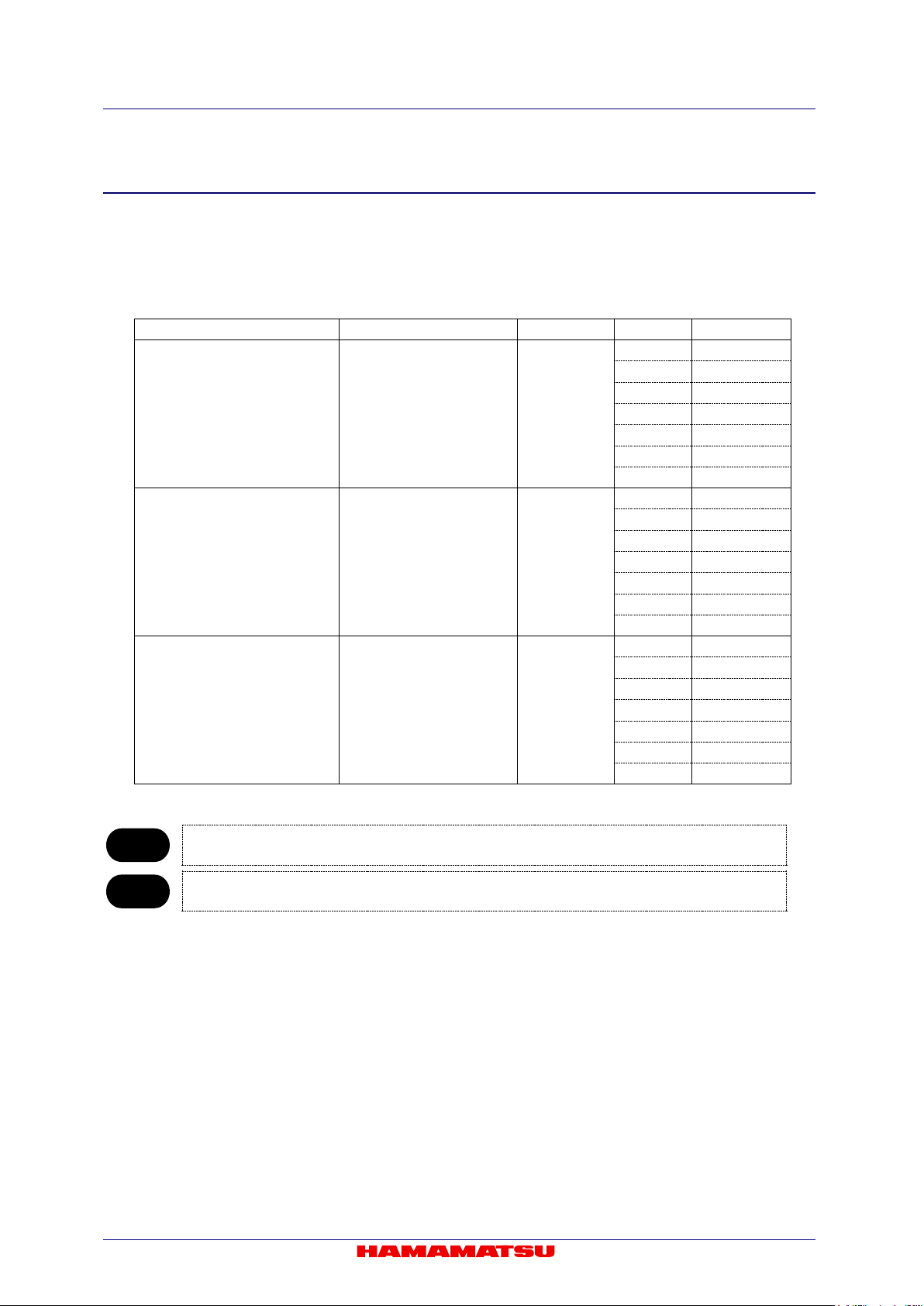

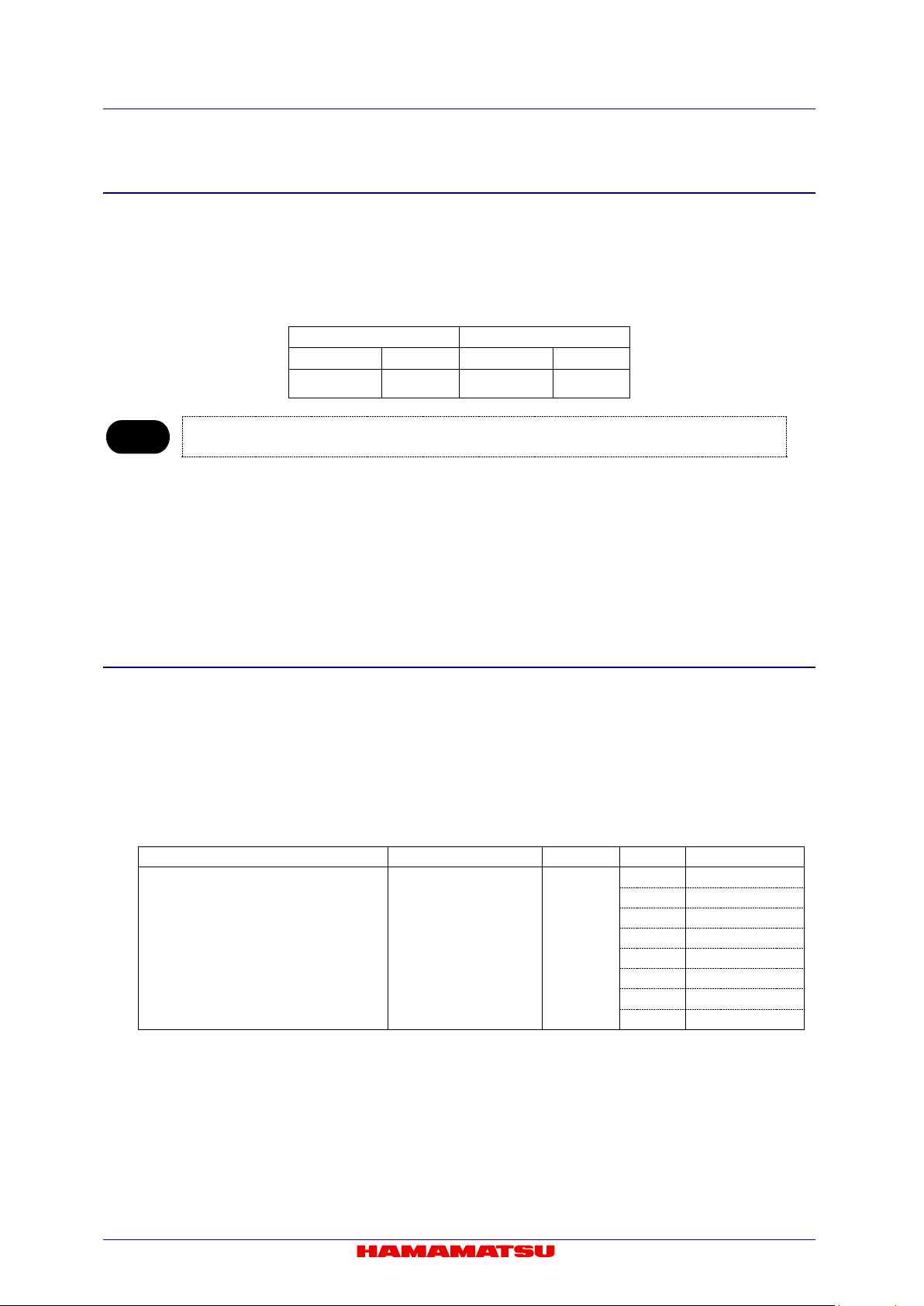

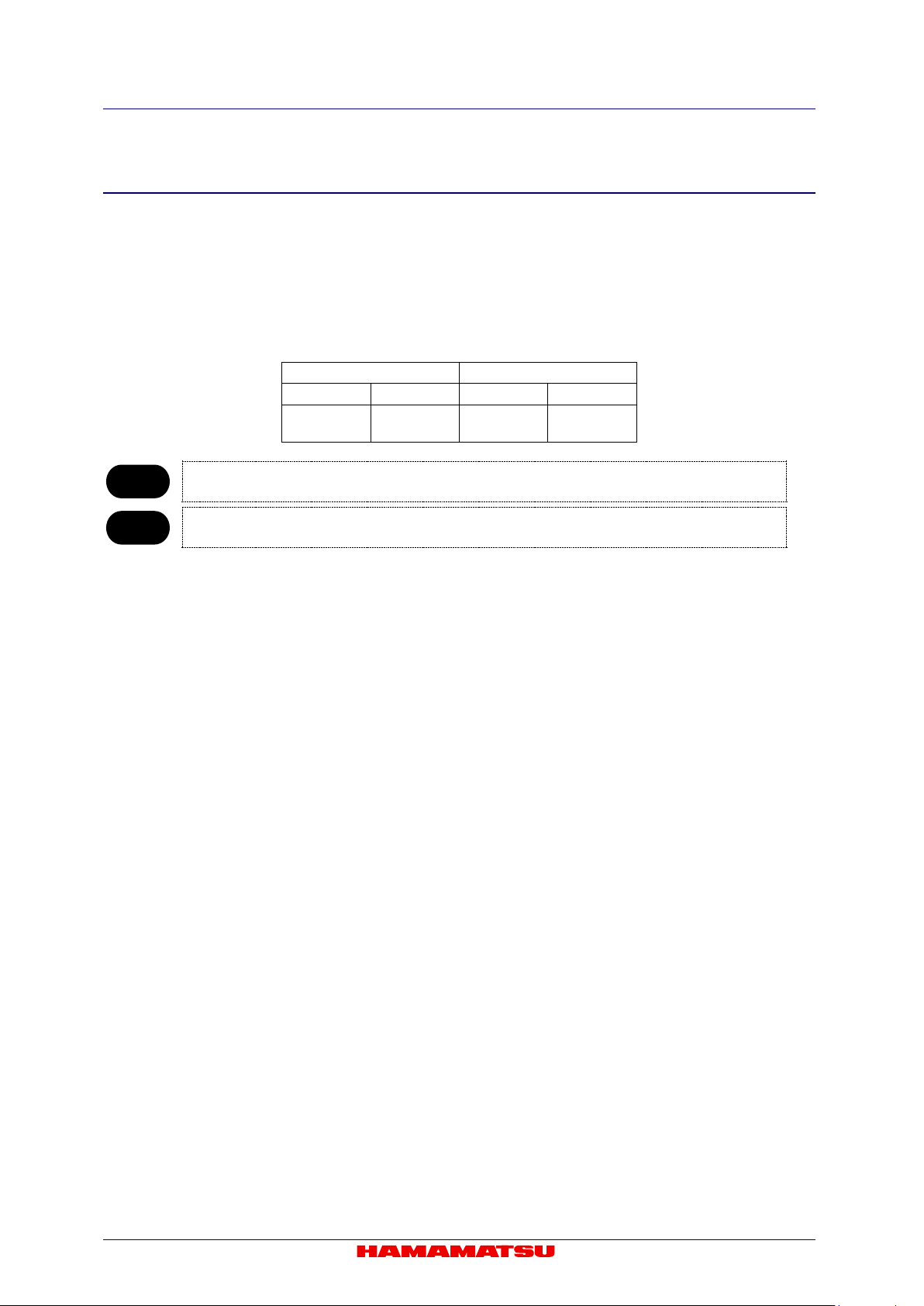

(9) Camera readout modes

The camera has four kinds of readout mode, Normal Area Mode, Lightsheet Readout Mode,

W-VIEW Mode and Dual Lightsheet Readout Mode. T he camera also has two scan speed in

Normal Area Mode and W -VIEW Mode, and two read out direction in Li ghtsheet Readout M ode,

W-VIEW Mode and Dual Lightsheet Readout Mode.

(Camerareadoutmodes) (Scanspeed) (Readoutdirection)

NormalAreaMode

W-VIEWMode

Standardscan

Slowscan

Standardscan

Standardscan

ToptoBottom

BottomtoTop

ToptoBottom

BottomtoTop

Slowscan

Standardscan

ReadoutMode

ToptoBottom

BottomtoTop

ToptoBottom

BottomtoTop

13

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Globalreset

Globalreset

Synchronousreadout

triggermode

LightsheetReadout

Globalreset

Globalreset

Synchronousreadout

triggermode

DualLightsheet

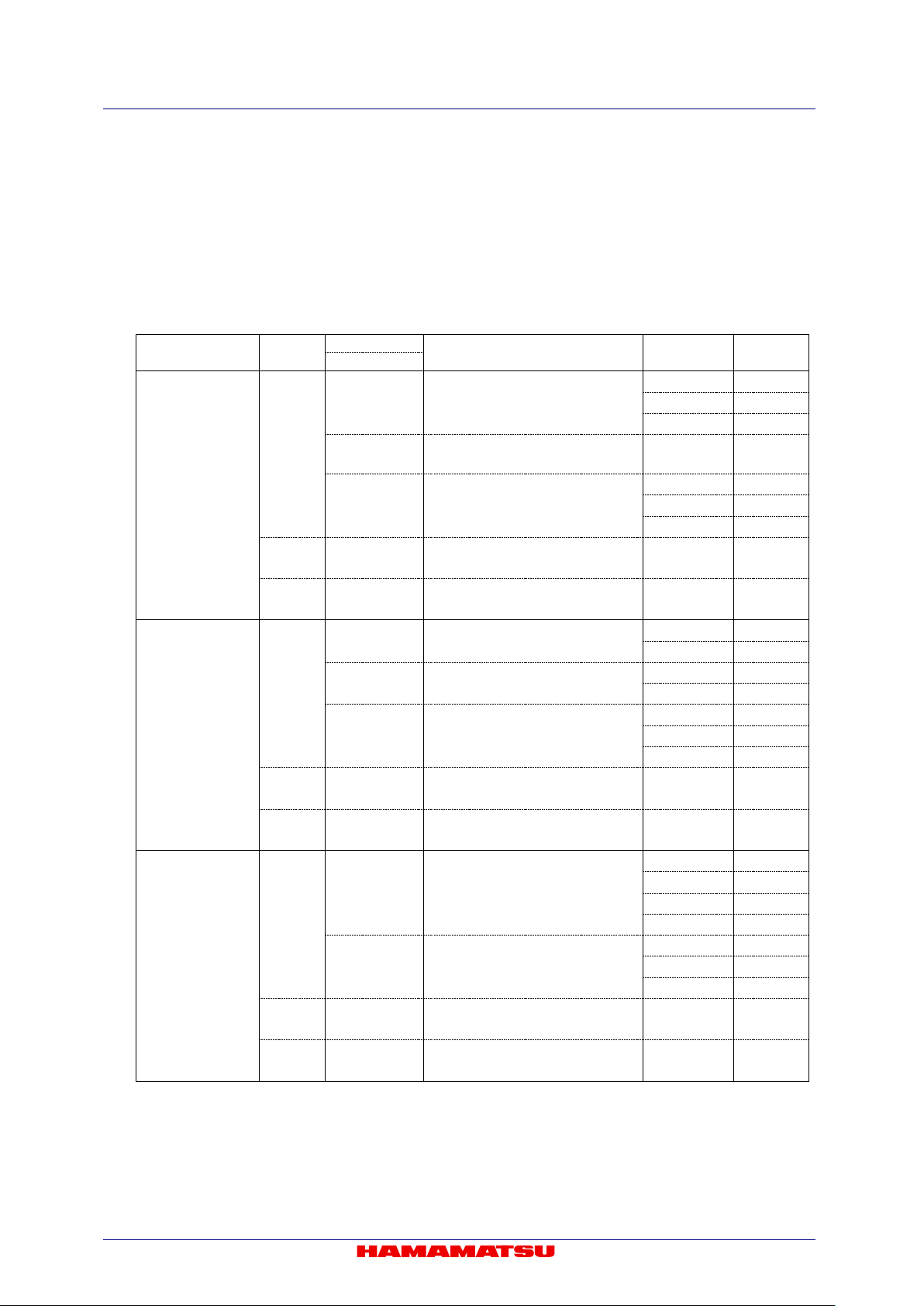

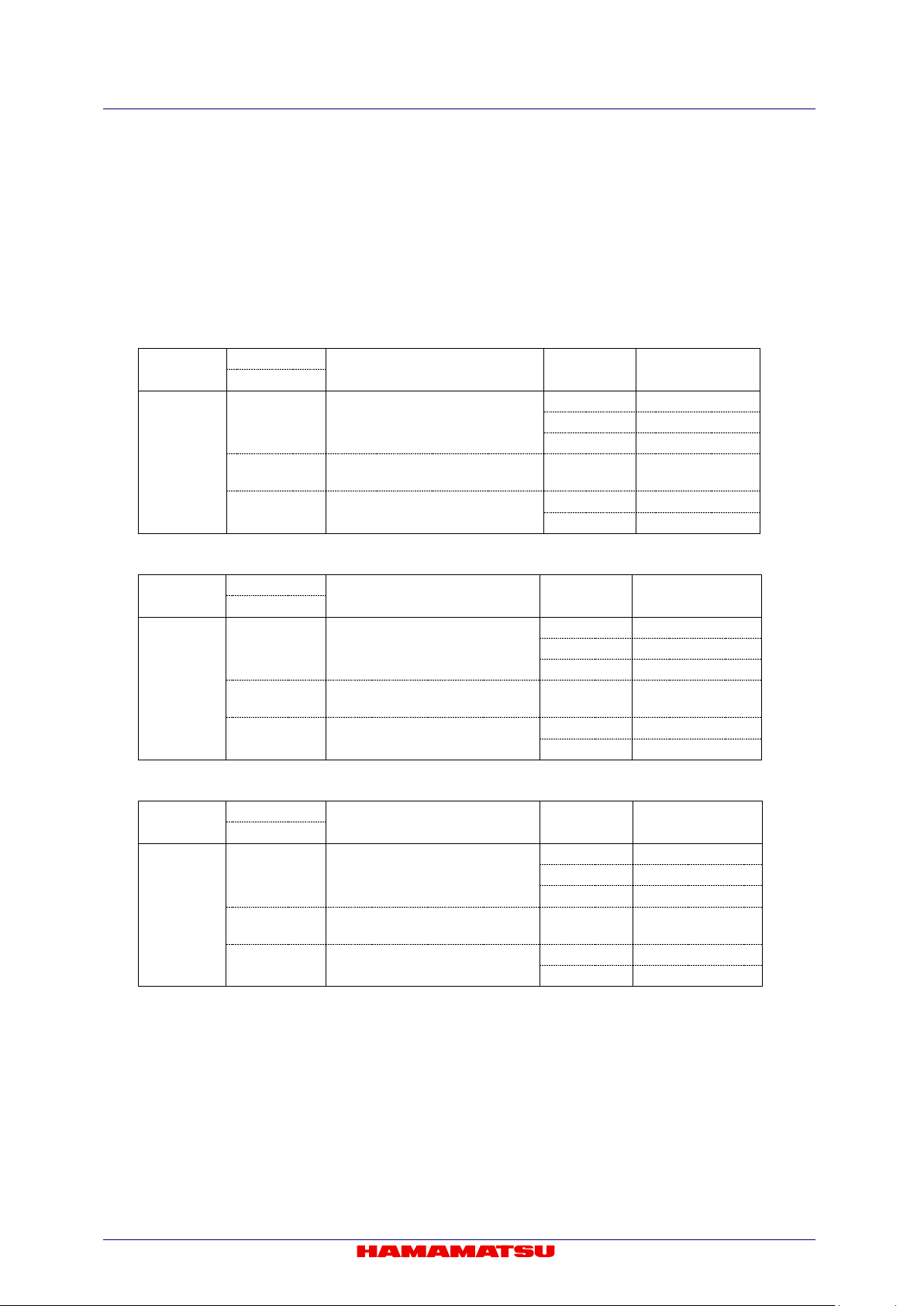

(10) Camera operation modes

The camera has three operation modes: 1) Free running mode, in which the exposure and

readout timing are controlled b y the internal m icroprocessor, and 2) External trigger mode, in

which the exposure and readout timing are decided by an external trigger. 3) Start trigger mode is

used to start operating the camera by a trigger input for a continuous imaging.

(Camerar eadoutmodes) (Cameraoperat ionmodes) (Externaltriggermodes)

NormalAreaMode

Freerunningmode

Externaltriggermode

Starttriggermode

Mode

Freerunningmode

Externaltriggermode

Starttriggermode

W-VIEWMode

Freerunningmode

Edgetriggermode

Edgetriggermode

Leveltriggermode

Leveltriggermode

Edgetriggermode

14

Externaltriggermode

Starttriggermode

ReadoutMode

Freerunningmode

Externaltriggermode

Starttriggermode

Edgetriggermode

Edgetriggermode

Leveltriggermode

Leveltriggermode

Edgetriggermode

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

6. NAME AND FUNCTION O F PARTS

(1) C13440-20CU (C-mount type)

b a d c e

k f

g h i j

l

Figure 6-1

(2) C13440-20CU01 (F-mount type)

b a d c e

k f

g h i j

l

Figure 6-2

15

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Place the camera the water connectors to be lateral side. Do not place the rear

block ventilation openings.).

Note

Note

Lighting color

Status of power distribution

Turn off (no color)

Power off

Orange (Blinking)

Initialization

Green (lighting)

Power on

Orange (lighting)

Data transfer

Red (lighting)

Heat up

AC adapter immediately.

•

panel of the camera, which connectors are located, to be at the bottom (Do not

a. Lens mount

C13440-20CU can be attached to C-mount lens or an optics system.

C13440-20CU01 can be attached to F-mount lens or an optics system.

• The depth of the C-mount is 7 mm. Screwing in the C-mount too deeply might

scratch the glass surface.

b. WATER connector [WATER] (when using Water-cooling)

It connects the camera and the circulating water cooler with the c ooling water hoses. The connector

position of WATER IN/OUT is not specified.

• See 8 “WATER COOLING” for instruction of water-cooling.

c. Camera Link interface connector 1 [DIGITAL OUT 1]

d. Camera Link interface connector 2 [DIGITAL OUT 2]

The connector 1 is connected to the Camera Link interface connector 1 on the computer.

The connector 2 is connected to the Camera Link interface connector 2 on the computer.

• When a connection interface is changed from Camera Link to USB 3.0, and vice

versa, the application software must be closed and the camera must be turned off.

• Do not connect Camera Link and USB 3.0 interface simultaneously.

e. Trigger input connector [EXT.TRIG]

This is used when the camera is being operated using external synchronization.

Input is 3.3 V LVCMOS level, and input impedance is 10 kΩ.

When an external trigger is input, the trigger is activated at the falling or rising edge of the signal. (You

can choose external trigger polarity between Negative and Positive.)

f. Timing out connector 1,2,3 [TIMING 1,2,3]

This is used when periph eral device(s) require synchronizat io n w ith the camera.

Output is 3.3 V LVCMOS level, and it is output though BUS TRANSCEIVER IC SN74LVC541. Output

impedance is 33 Ω.

• Determine termination according to cable length and so on.

g. STATUS lamp [STATUS]

The LED indicates status of camera.

• When the camera heats up, stop operation and unplug the

16

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Note

h. Power switch [POWER]

The power is turned on/off.

- When the power switch is set to "ON", the camera turns on and starts initialization and the lamp

blinks in green.

- When the initialization is completed, the lamp color stays in green.

- When the camera transfers data, and the lamp color turns orange.

- When the power switch is set to "OFF", the camera returns to the power off state and the lamp turns

off.

i. DC power input connector [DC IN]

This is the power supply terminal. Use the accessory AC adapter.

j. USB 3.0 interface connector [USB 3.0 ]

This is connected to the USB 3.0 interface connector on the computer.

• When a connecti on interface is changed from Camera Link to USB 3.0, and vice

versa, the application software must be closed and the camera must be turned off.

• Do not connect Camera Link and USB 3.0 interface simultaneously.

k. Air inlet

This is the inlet for the heat ventilation.

• If the camera is being operated in an enclosed environment, ensure to keep

clearance at least 10 cm from both intake and exhaust vents when setting up.

• To prevent overheating inside the camera, do not wrap the camera in cloth or other

material, or block the camera’s ventilation.

l. Base plate

This base plate is for attaching to a lab jack or a tripod.

When you use an adjustable pole (A11185-01) or a fixing bracket (A13261-01), pl ease detach the base

plate, and then attach the options.

• Please refer to the installation manual of options about the detaching method of

base plate and the attaching method of the option.

17

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Place the camera the water connectors to be lateral side. Do not place the rear

block ventilation openings.).

Note

7. CONNECTION

Refer to the figure when connecting the various cables.

(1) Camera Link interface

Camera (Rear)

b

b

a Computer Circuit

water cooler

d to connector 2

c to connector 1

Camera Link interface board

Figure 7-1

(2) USB 3.0 interface

Camera (Rear)

b

b

a Computer Circuit

water cooler

e

USB 3.0 port

Figure 7-2

•

panel of the camera, which connectors are located, to be at the bottom (Do not

• When you connect cables, turn off the power supply of the camera and the peripheral devices.

• If you use the above options, see each installation manual.

18

Note

• Hamamatsu recommends A14038-04 optional Camera Link interface cable for this

fulfill the EMC directive requirements.

Note

• Hamamatsu recommends A12467-03 optional USB 3.0 interface cable for this

fulfill the EMC directi ve requirem ents.

a. AC adapter

This is the cord to supply a power supply. Use the accessory AC adapter.

b. Cooling water hose (at Water-cooling: Option)

It connects the camera and circulating water cooler. The insert position of WATER IN/OUT on the

camera WATER connector is not specified.

• See 8 “WATER COOLING” for instruction of water-cooling.

c. Camera Link interface cable 1 (Option)

This is the cable to connect the Camera Link interface connector 1 of the camera and the Camera Link

interface connector 1 on the computer.

d. Camera Link interface cable 2 (Option)

This is the cable to connect the Camera Link interface connector 2 of the camera and the Camera Link

interface connector 2 on the computer.

• When a connection interface is changed from Camera Link to USB 3.0, and vice

versa, the application software must be closed and the camera must be turned off.

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

• Do not connect Camera Link and USB 3.0 interface simultaneously.

camera. The camera complies with EMC direction with using A14038-04 Camera

Link interface cable. Be careful that the camera with other interface cable may not

e. USB 3.0 interface cable (Option)

This is the cable to connect the USB 3.0 interface connector of the camera and the USB 3.0 interface

connector on the computer.

• When a connection interface is changed from Camera Link to USB 3.0, and vice

versa, the application software must be closed and the camera must be turned off.

• Do not connect Camera Link and USB 3.0 interface simultaneously.

camera. The camera complies with EMC direction with using A12467-03 Camera

Link interface cable. Be careful that the camera with other interface cable may not

19

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

personal injury to the user or damage to property.

8. WATER COOLING

• Improper handling of the camera without observing these cautions could lead to

8-1 CAUTIONS

(1) Change the cooling method

The default setting of cooling m ethod is Air-coo ling. Cooling m ode can be chan ged by sof tware

which is called, “DCAM Configurator”. (refer to 9-5 “STARTUP DCAM CONFIGURATOR”).

(2) Cooling water

It is recommended to use soft water (except pure water) for cooling water.

If you plan on using water other than soft water as recomm ended for example antifreeze etc,

please refer to descript ion of c ooling water w hich is written in 12. “MAINTENANCE” or contact a

Hamamatsu subsidiary or your local distributor.

(3) Recommendation temperature

Hamamatsu recommends 20 °C for Circulating water temperature.

For the appropriate temperature range of the cooling water , confirm with the instruction manual of

your circulating water cooler.

(4) Condensation

Use the camera under the environment where condensatio n will not take place referring to the

following graph.

20

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Follow the instruction in S ection 8-2 “CONNECTION OF WATER COOLING

HOSES” to connect / disconnect the hose.

Blue hose

Gray hose

Joint

Button

(5) Handling of the circulating water cooler

Handle the circulati ng water cooler an d the cooling water according to an i nstruction manua l of

the circulating water cooler.

Proper performance may not be achievable if a non-recommended circulating water cooler is

used.

(6) Start water cooling and water cooling in operation

- Confirm the water is flowing before starting the camera cooling and that the camera does cool.

- Keep 0.45 L/min flow rate for water circulation.

- Do not stop the circulating water cooler while the camera is working.

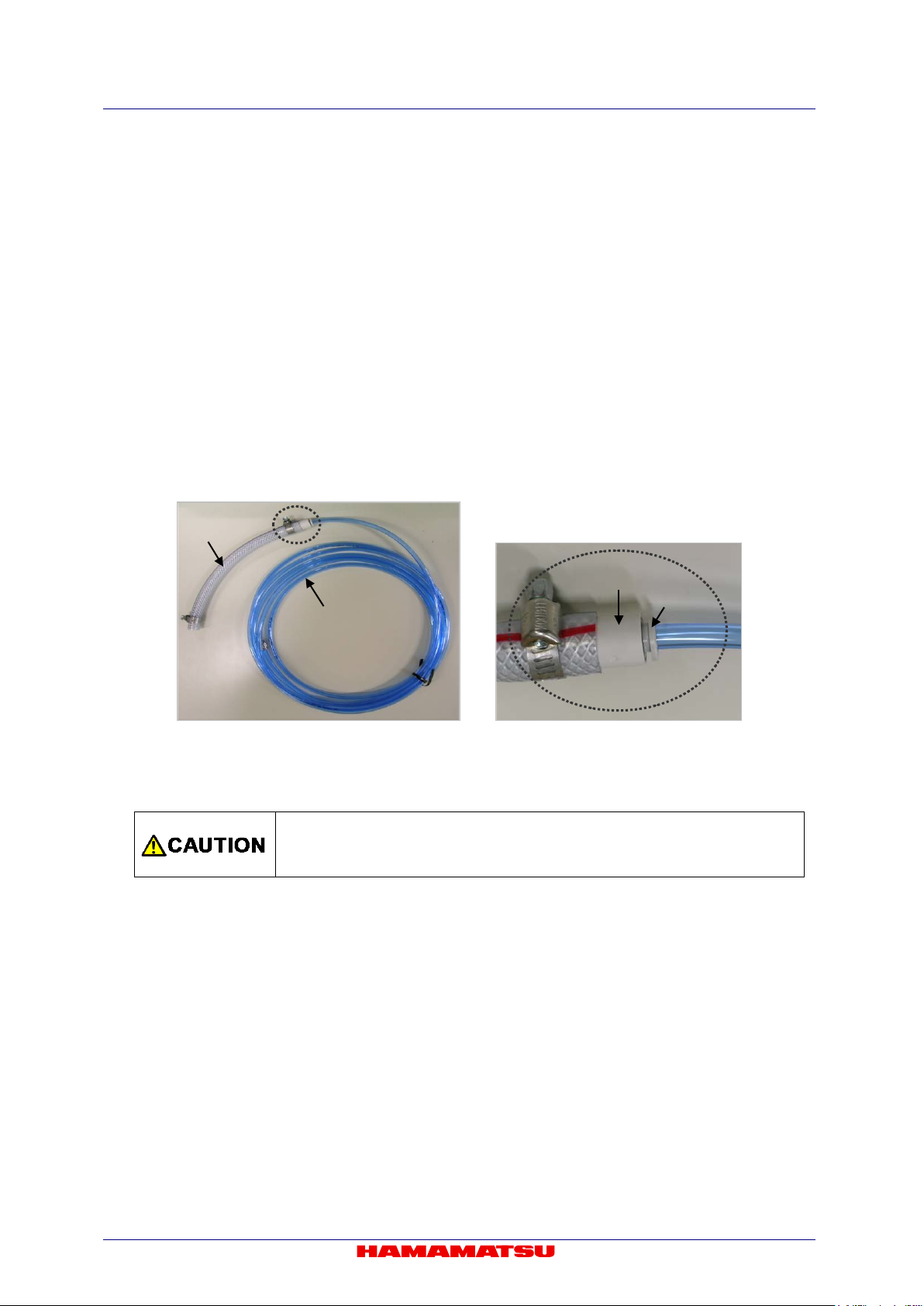

(7) Cooling water hose

The hose has a blue hose (Interna l diameter : 4 mm / Externa l diam eter: 6 mm ) and a gray hos e

(Internal diameter: 8 mm / External diameter: 13.5 mm). (Figure 8-1)

If the hose size on circulati ng water c ooler is the same as blue hos e, rem ove gra y hose from the

joint part. The gray hose can be removed when blue hose is pulled with pushing the button of the

joint on gray hose. (Figure 8-2)

Figure 8-1 Figure 8-2

(8) Connection of the cooling water hose

•

HOSES” and Section 8-3 “DISCONNECTION OF WATER COOLING

- Stop water circulation whe n connecting / disc onnecting the hose, and turn off the power of the

camera and the circulating water cooler.

- Confirm that cooling water stops.

- Prepare water absorp tion sheet (s uch as Waste, Towel or so) and catch pan in o rder to avoi d

water drop or water splash.

(9) Deterioration of the cooling water hose

Replace the water hos e with a new on e whenever it c annot keep 0.45 L/min flow r ate for water

circulation due to the hose deteriorat ion.

21

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Stop the circulating water cooler when the water flow is abnormal or water

drop or splash is found.

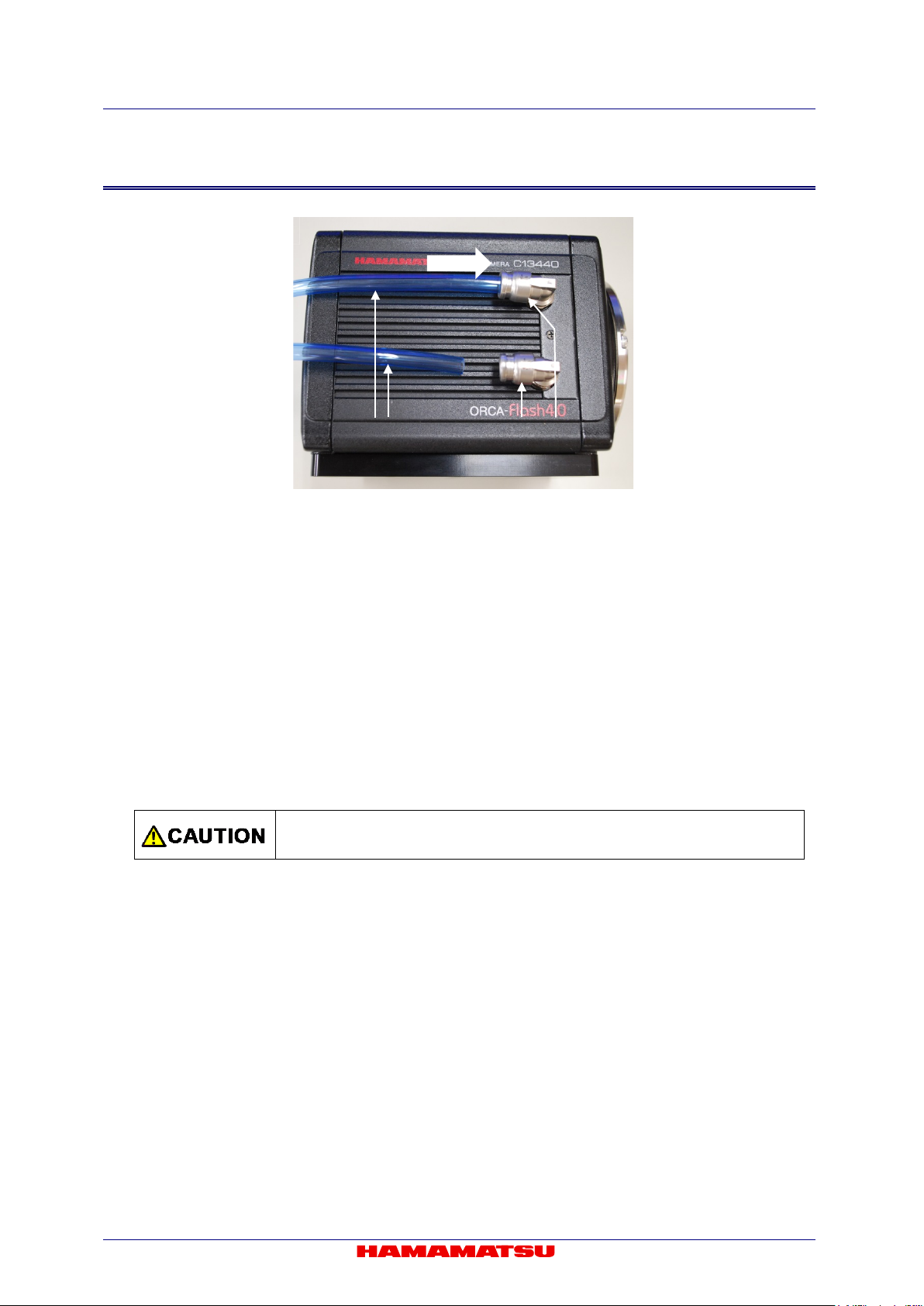

Water cooling hose

WATER connector

8-2 CONNECTION OF WATER COOLING HOSES

Figure 8-3

1. Place the camera on the stable table.

2. Connect water cooling hose into the WATER connector on the camera.

- Insert the hose fully into the WATER connector on the camera. (as shown in Figure 8-3)

- Confirm the hose stops at it.

3. Set the camera onto a microscope (If the camera is used on the microscope).

If it is easy to connect the hose onto the camera after the camera is set onto the microscope then it is

OK to connect the hose after the camera is set on the microscope.

4. Connect the hose onto the circulating water cooler.

Follow the instruction on the circulating water cooler when you connect the hose onto the circulating

water cooler.

5. Turn on the circulating water cooler and confirm the cooling water is flowing normally.

•

22

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

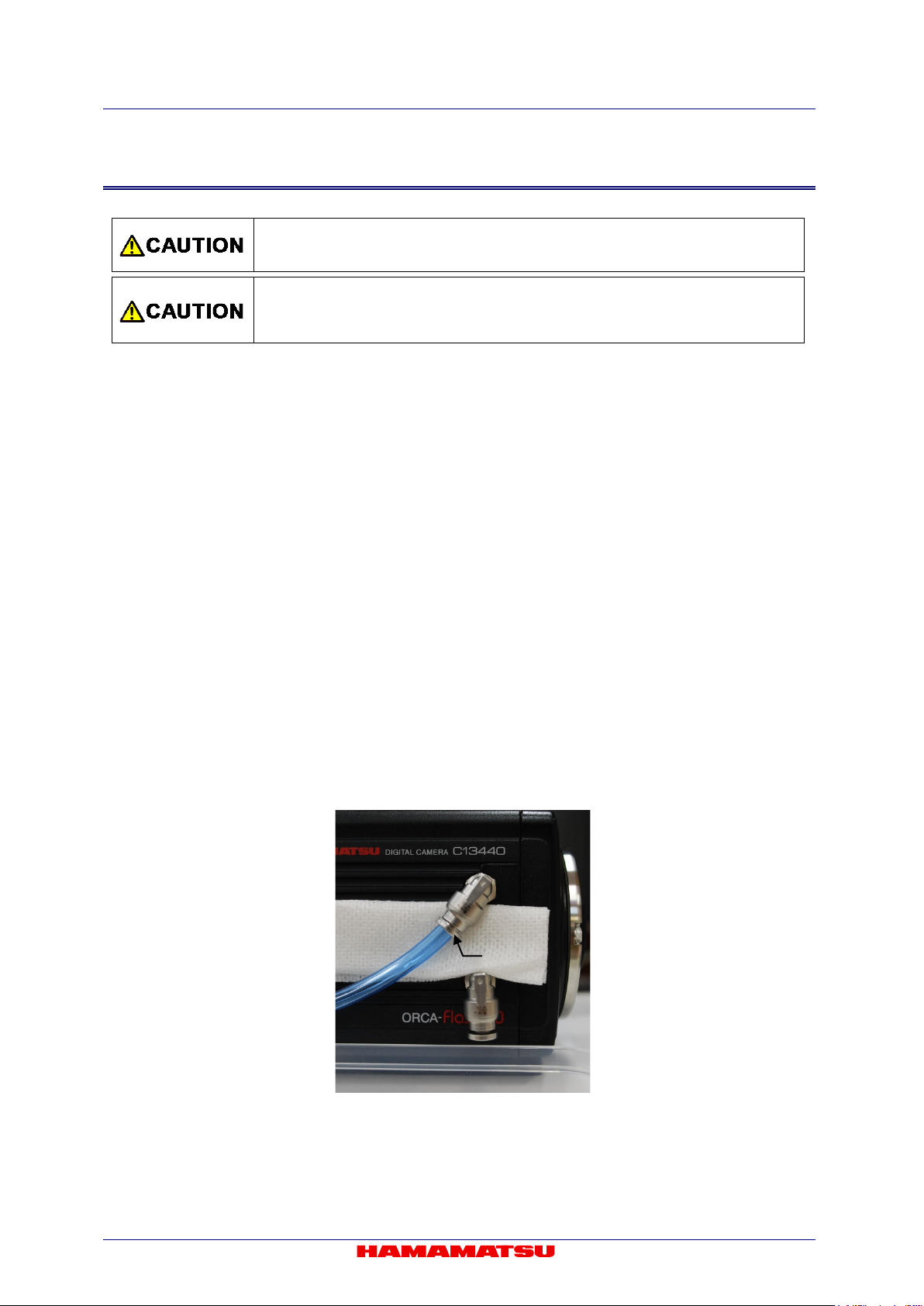

Cooling water may be left inside the camera even after hoses are removed. In such

water onto the camera.

Button

8-3 DISCONNECTION OF WATER COOLING HOSES

• Remove the water cooling hoses only when it is necessary to remove.

•

case, remove water inside by blowing air from connectors. Be careful not to splash

1. Turn off the camera power and all peripheral devices including circulating water cooler.

2. Remove the hose on circulating water cooler side.

Follow the instructio n o n th e c i r cula ting water cooler when you di sco nne ct t he hos e f ro m t he circulating

water cooler.

3. Remove water or water drop inside the hose and the camera by air.

- Blow air from one side of hose. Prepare water absorption sheet (such as Waste, Towel or so) and

catch pan on another side of hose in order to avoid water drop or water splash.

- Blow Air until no water drop come out.

4. Remove the camera from the microscope (if the camera is used on the microscope).

It is not necessary to remove the camera from th e microscope if it is p os sibl e t o remove the hoses fr om

the camera as it is.

5. Place the camera on the stable table.

Put the lens cap on to protect the sensor.

6. Change the WATER connector direction to be downward.

Prepare water absorption sheet (such as Waste, Towel or so) and catch pan.

7. Remove hoses one by one, and wipe water.

Disconnect hoses with pushing button while being careful not to splash water.

Figure 8-4

23

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Cooling method

Detail

Air-cooling method

(Default)

The heated side of a peltier element is cooled by a fan inside the camera. When

Circulating water cooler (Optional) is used for cooling the heated side of a peltier

element. Cooling does not start just turning on the camera. Cooling water

A fan inside the camera does not rotate.

9. OPERATIONS

9-1 OPERATING PRECAUTIONS

Be careful of the following w hen you operate the camera.

(1) Cooling method

Cooling of this equipment is done using a Peltier element.

With a Peltier e lement, when curr ent is s upplie d, one surfac e is cooled, and th e other surfac e is

heated. CMOS image sensor is positioned on the cooled side, and cooling is done by discharging

the heat from the heated surface.

The camera has two cooling methods, Air-cooling method and Water-cooling method.

The default of cooling m ethod is Air-c ooling. C ooling m ode c an be ch anged b y softw are wh ich is

called, “DCAM Configurator”. (refer to 9-5 “STARTUP DCAM CONFIGURATOR”).

(Forced air-cooled)

Water-cooling method

• Do not switch to water-cooling method when water-cooling is unnecessary.

the camera is turned on, the fan starts rotating and cooling is started.

circulation must be started before start operating the camera in water-cooling.

• See 8 “WATER COOLING” for instruction of water-cooling.

(2) Ambient temperature

The recommended ambient temperature for camera operation is 20 °C.

Both water-cooling or air-c ooling are available as cooling method, CMO S image sensor cooling

temperature is more stable under water cooling operation.

(3) Protection circuit

This camera’s thermoelectric cooling device is protected by a thermal protection circuit.

If the internal temperature of the camera becomes abnormally hot, the protection circuit operates

to inform the user b y a buzzer alarm (beep tone) an d lighting the camera red LED li ght while

simultaneously cutting the current supply to the Peltier element. As soon as this protection is

implemented, turn off t he power switch, unplug the AC supply. Then remove t he cause of the

overheating.

24

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Note

• After cooling mode was changed, the camera memorizes the last sett ing as the def ault setting for

Configurator”. (refer to 9-5 “STARTUP DCA M CONFI GURAT OR ”)

Note

9-2 PREPARATING FO R IMAGING

Use the following procedu r e when start operating the camera.

• When you connect cables, turn off the power supply of the camera and the peripheral devices.

cooling. The present cooling mode set-up of this camera can be checked using “DCAM

9-2-1 WHEN USING AIR-COOLING

1. Connect the equipment as shown in Figure 7-1 before operating of the camera.

2. Turn on the camera.

3. Check cooling fan is operating properly and air is circulating.

• When cooling method of the camera is set by water-cooling method, the fan does not start rotating.

9-2-2 WHEN USING WATER-COOLING

1. Connect the equipment as shown in Figure 7-1 before operating of the camera.

2. Turn on the circulating water cooler.

3. Check cooling water is circulating properly.

4. Turn on the camera.

5. Turn on the cooling switch of the camera from application software.

• Please refer to the manual of application software for ON/OFF of the cooling switch of a camera.

9-3 IMAGING

Operate the camera from application software.

9-4 END OF IMAGING

Follow the procedure belo w when imaging is finished.

1. End the imaging or transmission of image data with the application software.

2. Turn off the camera and peripheral devices.

3. Turn off the circulating water cooler. (at water-cooling)

25

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

9-5 STARTUP DCAM CONFIGURATOR

The following is a procedure to startup “DCAM Configurator”.

1. Open “Setup.exe” in the DCAM-API software’s folder.

If the DCAM-API software is not installed on your computer, insert the media of DCAM-API software in

the slot of your computer .

When it is inserted, “DCAM-API Setup” window is displ ay ed auto mati cal ly.

2. Click on “Tools”.

3. Click on “DCAM Configurator”.

26

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

4. “DCAM Configurator” window is displayed. The startup is completed with this.

- Even if the camera's power supply is turned off, the state of setting is kept.

- The state of setting can confirm according to “Hardware” icon on DCAM Configurator window.

- After the startup, operate DCAM Configurator according to "DCAM Configurator Instruction manual".

The manual is displayed when the following buttons on DCAM Setup window are clicked.

27

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

10. DESCRIPTION OF CMOS IMAGE SENSOR

10-1 THEORY OF CMOS IMAGE SENSOR

The pixel of a CMOS image sensor is composed of the photodiode and the amplifier that converts

the charge into voltage. Entered light is converted to charge and converted to voltage in the pixel.

The voltage of each pixel is output by switching the switch one by one. ( Fig ur e 10-1)

The scientific CMOS image sensor used in this camera has an on-chip CDS (correlated double

sampling ) circ uit, which plays an important role in achieving low noise. In addition, CMOS image

sensor realizes both low noise and high speed readout simultaneously, by a split readout scheme

in which the top and the bottom halves of the sensor are readout independently, and the data of

each horizontal line is read by 2 lines of column amplifier and A/D in the top and the bottom in

parallel and simultaneou sl y.

Figure 10-1 Structure of CMOS image sensor

28

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

10-2 READOUT METHOD OF CMOS IMAGE SENSOR

The exposure and the readout method of CMOS image sensor which this camera adopts is

rolling shutter. In the rolling shutter, the exposure and readout are done line by line. Therefore, the

exposure timing is different on one screen. (Figure 10-2) But even if the object moves during the

exposure, the affect of roll ing sh utter is very small.

Figure 10-2 Readout timing of Roll ing sh utter

10-3 PRECAUTION WHEN USING CMOS IMAGE SENSOR

This camera uses scientific CMOS image sensor. Careful attention must be paid to the following

points when using CMOS i mag e sensor.

(1) White spot

Subjecting CMOS im age sensor to extended ex posures may cause failure in part of the silicon

wafer, resulting in white spots. Currentl y this phenomenon is not preventable. If CMOS im age

sensor is at a fixed tem perature, recurrence of the white spot increases proport ionally with the

exposure time, so this c an be rectified with dark subtraction*. Cosm ic ray may generate white

spot.

Dark subtraction: A fter a cquiri ng an im age using a certain exposure time is loaded, CMOS image sensor is exposed to darkness for

*

(2) Folding distortion

A rough-edged flicker may be visible when im aging striped patterns, lines, and s imilar subject

matter.

(3) Over light

the same amount of time, and another image is obtained. After this, the difference between the images is

determined, and the data for the dark portion of the original image is nullified.

• Be careful not to input too strong light such as high-energy laser into CMOS

image sensor because CMOS image sensor may be damaged by over light.

29

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Size

Position

Horizontal

Vertical

Horizontal

Vertical

Note

Note

11. DESCRIPTION OF VARIOUS FUNCTIONS

11-1 NORMAL AREA MODE

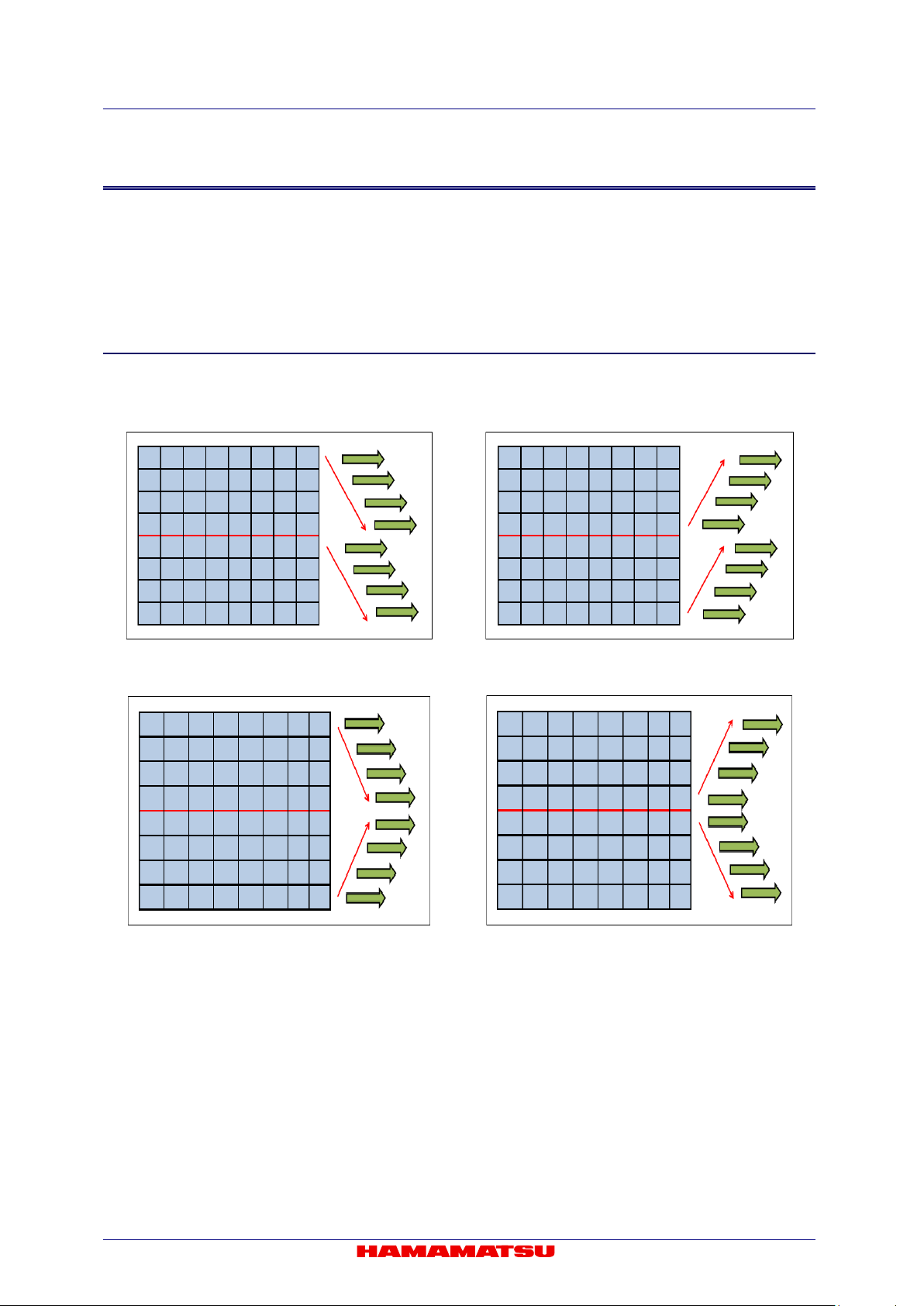

11-1-1 CAMERA READOUT MODES (READOUT DIRECTION)

The camera reads out the im age sensor f rom the ce nter line to the top an d from the center l ine to the

bottom simultaneously (center line is depicted in red line in the diagram).

Figure 11-1 Normal area mode readout direction

11-1-2 READOUT METHODS

(1) Normal readout (Full resolution readout mode; 1×1 readout)

Perform charge readout from camera individually for all pixels.

(2) Binning readout (2×2 / 4×4 readout)

With this camera, 2×2 binning readout and 4×4 binning are available by adding the signal of

adjacent pixels in t he di git a l d omain. Binning readout is a method for achieving high sensitivity in

exchange for losing resolution.

(3) Sub-array readout

Sub-array readout is a procedure onl y a region of interest is s canned. It is possibl e to increase

the frame rate by r educin g the num ber of vertica l lines s canned. W hen a targ et ar ea is pl aced in

the center of the screen, sub-array readout can perform the fastest readout. In sub-array readout,

binning configuration is enabled.

Size and a position of the readout area can be configured according to the table below.

128 pixels 4 lines 4 pixels 4 lines

• Minimum settable step of the size and position on the table is in only the case that the camera is used

30

with DCAM.

• Please refer to 11-1-4 “FRAME RATE CALCULATION” about the frame rate of each readout mode.

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Frame rate for full resolution

Camera Link

USB 3.0

16 bit

40 fps

12 bit

53 fps

8 bit

80 fps

16 bit

12 bit

8 bit

Note

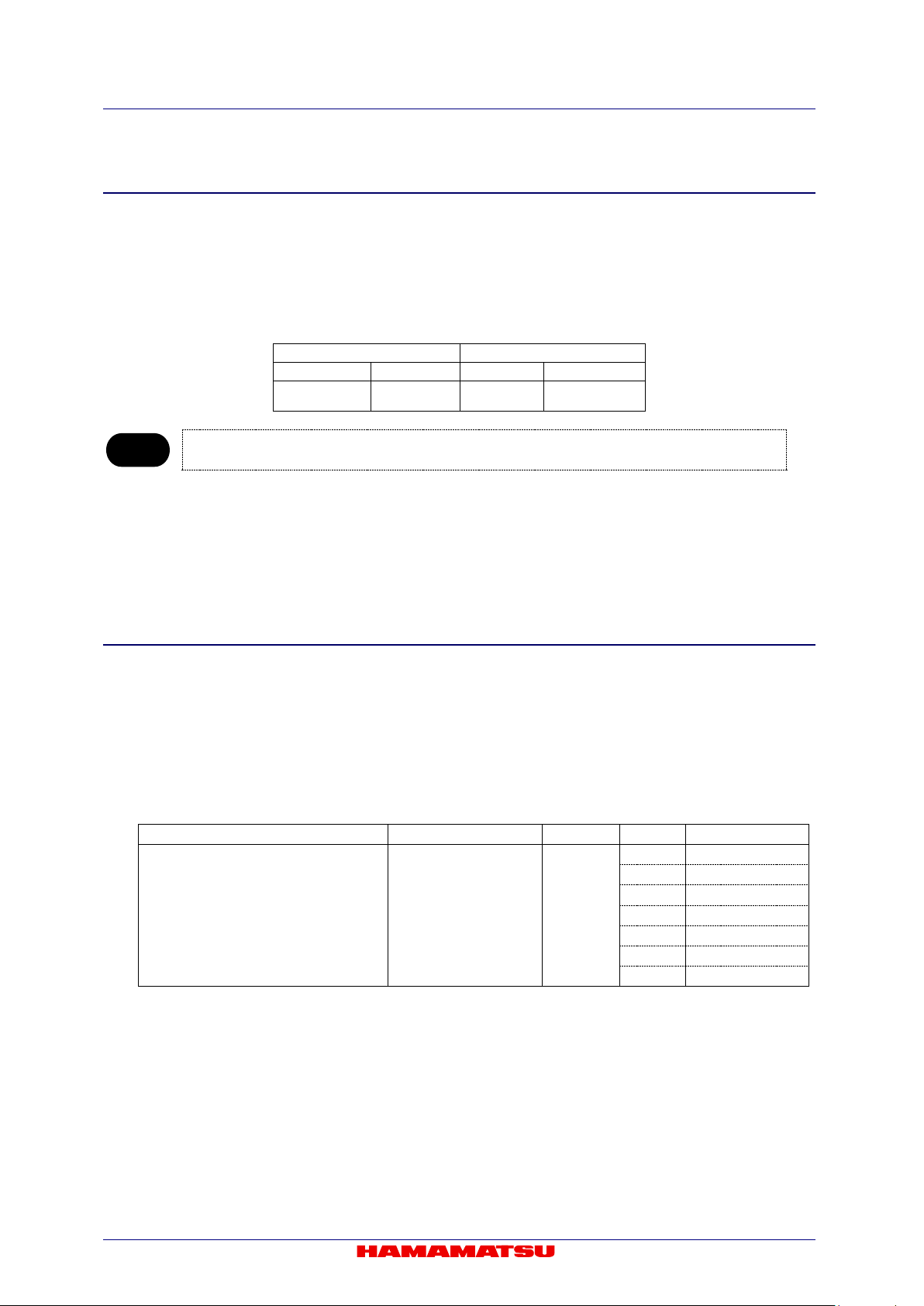

11-1-3 READOUT SPEED (SCAN SPEED)

The standard scan rea dout speed c an achi eve a fram e rate of 100 fps f or full resolut ion with l ow noise

(1.0 electrons (m edian), 1.6 electrons (r.m.s.)), and the slow scan readout speed can achieve even

lower noise (0.8 electrons (median), 1.4 electrons (r.m.s.)) with a frame rate of 30 fps for full resolution.

Camera Link interf ace is necessary to transfer the image d ata with 100 fps of fast frame r ate for full

resolution.

When you use USB 3.0 interface, the frame rate is up to 40 fps (16 bit of digital output) for full resolution.

The frame rate with USB 3.0 interface will be faster when you use 12 bit or 8 bit of digital output.

Scan speed Digital output

Standard scan

Slow scan

100 fps

30 fps 30 fps

• Please refer to 11-1-4 “FRAME RATE CALCULATION” about the frame rate of each readout mode.

31

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

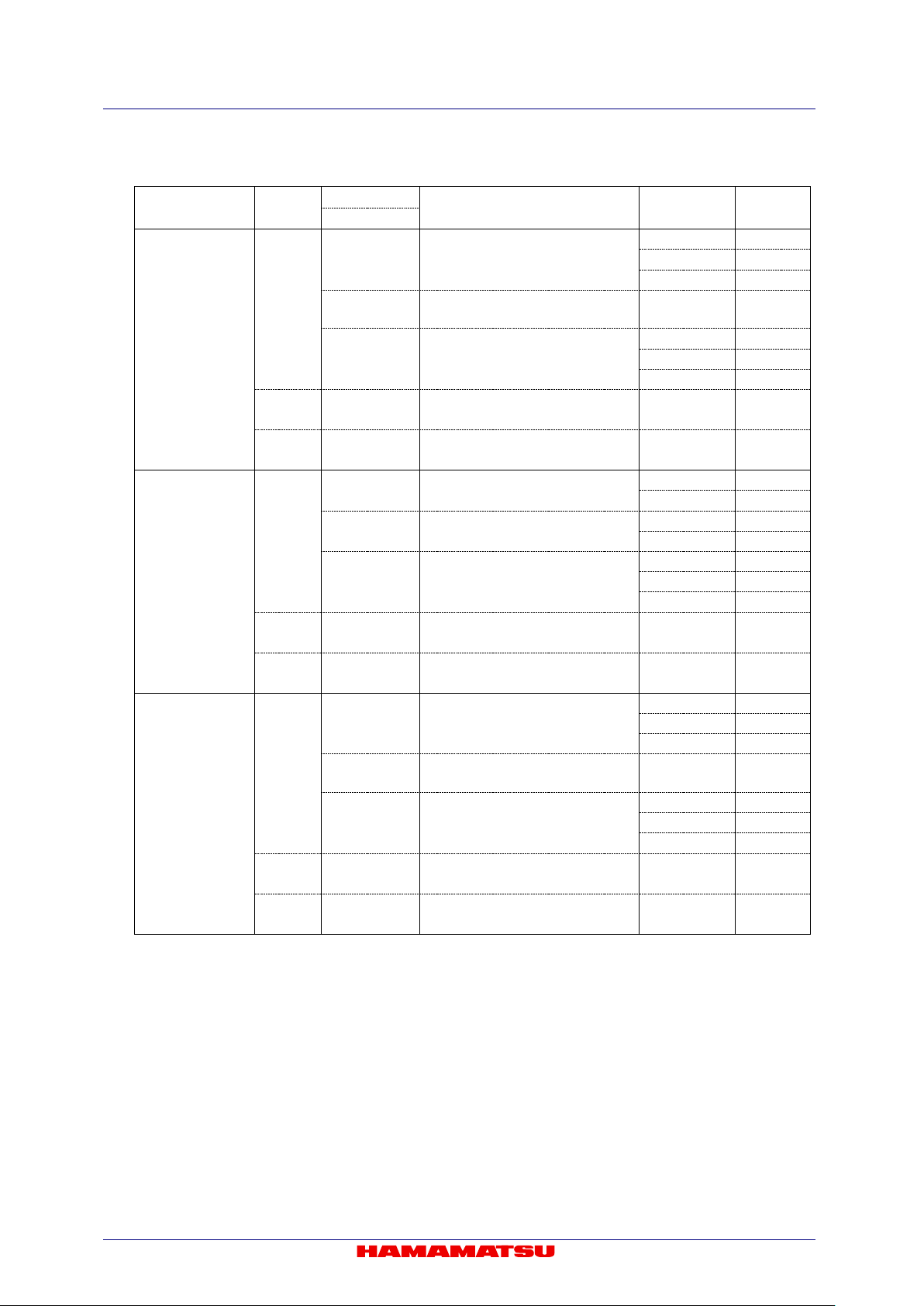

Operation modes

Calculation formula

Horizontal

Vertical

Frame rate

Free running mode

1/(Vn/2×1H)

2048

2048

100

1024

200

512

400

256

801

128

1603

64

3206

8

25 655

External trigger mode

1/(Vn/2×1H+Exp1+10×1H)

2048

2048

90

1024

164

512

278

256

425

128

579

64

707 8 877

External trigger mode

1/(Vn/2×1H+5×1H)

2048

2048

99

1024

198

512

393

256

771

128

1487

64

2773

8

11 402

Note

Note

11-1-4 FRAME RATE CALCULATION

(1) Standard scan: Camera Link

Vn = Number of vertical line (at the center area of the image sensor)

Exp1 = 1.004 ms to 10 s (input in units of seconds)

1H = 9.744 36 µs

(Edge trigger / Level trigger)

(Synchronous readout trigger)

• The calculation formula and the frame rate value of Start trigger mode (External trigger m ode) are

same as Free running mode. About this mode, refer to 11-1-6-3 “Start trigger mode”.

• The calculation formula and the frame rate value do not depend on the bit depth of digital output.

32

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Horizontal

Frame

rate (fps)

Vertical

Free running

2048 × 2048

40

2048 × 512

160

2048 × 64

1282

Hn>512

Vn≤8

512 × 2048

100

512 × 512

400

512 × 8

25 655

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

External trigger

2048 ×2048

40

2048 × 512

160

Vn≤144

2048 × 64

707

2048 × 8

877

512 × 2048

90

512 × 512

278

512 × 8

877

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

External trigger

2048 × 2048

40

2048 × 512

160

2048 × 64

1282

2048 × 8

10 262

512 × 2048

99

512 × 512

393

512 × 8

11 402

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

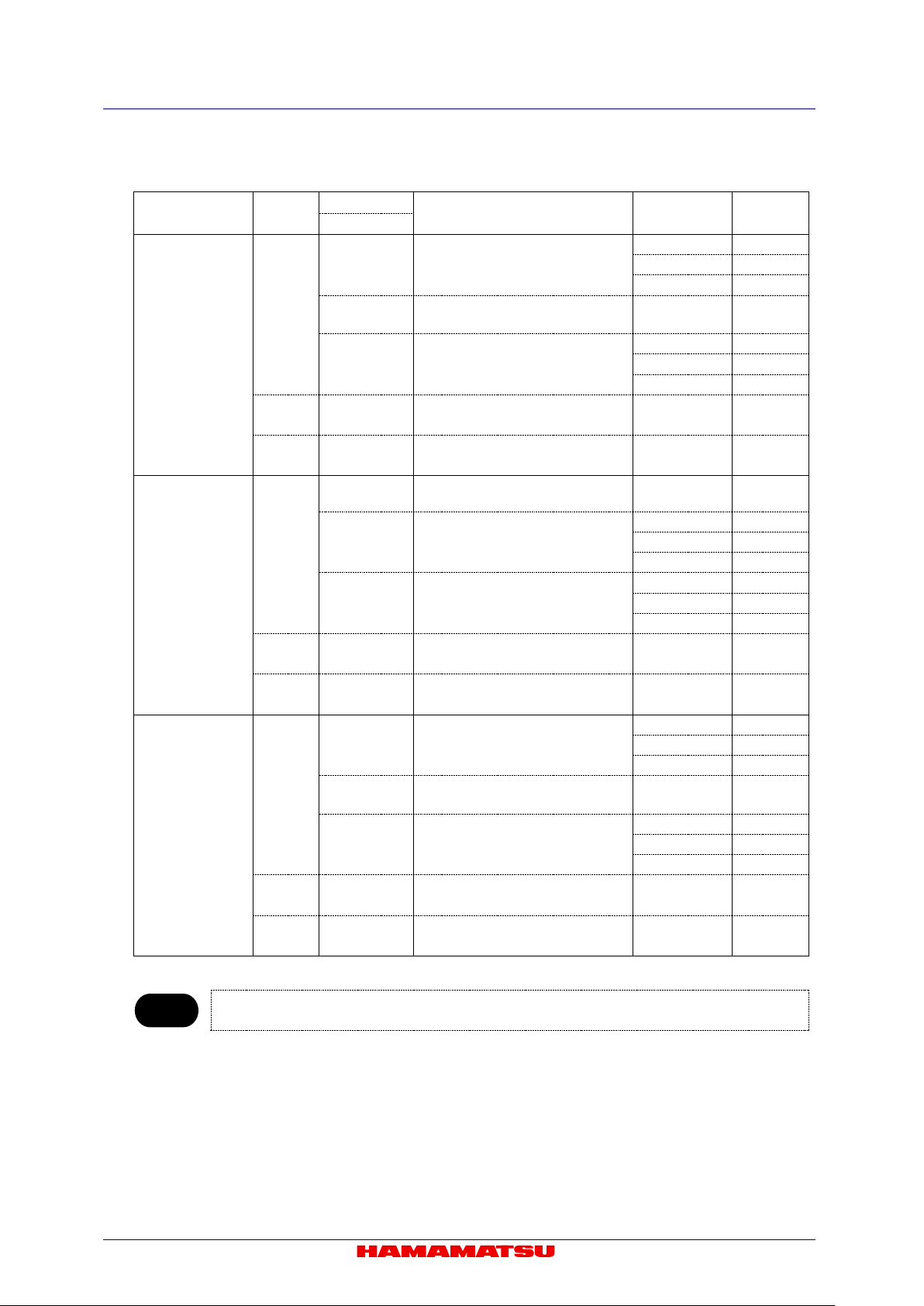

(2) Standard scan: USB 3.0

Hn = Number of horizontal pixel

Vn = Number of vertical line (at the center area of the image sensor)

Exp1 = 1.004 ms to 10 s (input in units of seconds)

1H = 9.744 36 µs

round () = Round down to integer

roundup() = Round up to integer

1. 16 bit Digital output

Operation modes Binning

mode

1×1

2×2

4×4

mode

(Edge trigger /

Level trigger)

1×1

2×2

Hn>512

V≥16

Hn≤512

8≤Vn≤2048

Hn>512

V≥152

Hn>512

Hn≤512

8≤Vn≤2048

Calculation formula Hn × Vn

1/(round(Vn/2048/40/1H) ×1H)

1/(roundup(Vn/2048/40/1H) ×1H) 2048 × 8 9329

1/(Vn/2×1H)

1/(Vn×1H) 1024 × 1024 100

1/(Vn×2×1H) 512 × 512 100

1/(round(Vn/2048/40/1H) ×1H)

1/(Vn/2×1H+Exp1+10×1H)

1/(Vn/2×1H+Exp1+10×1H)

1/(Vn×1H+Exp1+10×1H) 1024 × 1024 90

mode

(Synchronous

readout trigger)

4×4

Hn>512

8≤Vn≤2048

1/(Vn×2×1H+Exp1+10×1H) 512 × 512 90

1/(round(Vn/2048/40/1H) ×1H)

1×1

Hn≤512

8≤Vn≤2048

2×2

4×4

1/(Vn/2×1H+5×1H)

1/(Vn×1H+5×1H) 1024 × 1024 99

1/(Vn×2×1H+5×1H) 512 × 512 99

33

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Horizontal

Vertical

Free running

2048 × 2048

53

2048 × 512

212

2048 × 64

1710

Hn>512

Vn≤8

512 × 2048

100

512 × 512

400

512 × 8

25 655

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

External trigger

Hn>512

Vn≥256

2048 × 2048

53

2048 × 512

212

Hn>512

Vn≤248

2048 × 64

707

2048 × 8

877

512 × 2048

90

512 × 512

278

512 × 8

877

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

External trigger

2048 × 2048

53

2048 × 512

212

2048 × 64

1710

Hn>512

Vn≤8

512 × 2048

99

512 × 512

393

512 × 8

11 402

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

2. 12 bit Digital output

Operation modes Binning

mode

1×1

2×2

4×4

mode

(Edge trigger /

Level trigger)

1×1

2×2

Hn>512

Vn≥16

Hn≤512

8≤Vn≤2048

Hn≤512

8≤Vn≤2048

Calculation formula Hn × Vn

1/(round(Vn/2048/53/1H) ×1H)

1/(roundup(Vn/2048/53/1H) ×1H) 2048 × 8 12 827

1/(Vn/2×1H)

1/(Vn×1H) 1024 × 1024 100

1/(Vn×2×1H) 512 × 512 100

1/(round(Vn/2048/53/1H) ×1H)

1/(Vn/2×1H+Exp1+10×1H)

1/(Vn/2×1H+Exp1+10×1H)

1/(Vn×1H+Exp1+10×1H) 1024 × 1024 90

Frame

rate (fps)

mode

(Synchronous

readout trigger)

4×4

Hn>512

Vn≥16

1×1

Hn≤512

8≤Vn≤2048

2×2

4×4

1/(Vn×2×1H+Exp1+10×1H) 512 × 512 90

1/(round(Vn/2048/53/1H) ×1H)

1/(Vn/2×1H+5×1H) 2048 × 8 11 402

1/(Vn/2×1H+5×1H)

1/(Vn×1H+5×1H) 1024 × 1024 99

1/(Vn×2×1H+5×1H) 512 × 512 99

34

Horizontal

(fps)

Vertical

Free running

2048 × 2048

80

2048 × 512

320

2048 × 64

2565

Hn>512

Vn≤8

512 × 2048

100

512 × 512

400

512 × 8

25 655

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

External trigger

Hn>512

Vn≥912

2048 × 512

278

2048 × 64

707

2048 × 8

877

512 × 2048

90

512 × 512

278

512 × 8

877

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

External trigger

2048 × 2048

80

2048 × 512

320

2048 × 64

2565

Hn>512

Vn≤40

512 × 2048

99

512 × 512

393

512 × 8

11 402

64≤Hn≤1024

4≤Vn≤1024

32≤Hn≤512

2≤Vn≤512

Note

3. 8 bit Digital output

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Operation modes Binning

mode

1×1

2×2

4×4

mode

(Edge trigger /

Level trigger)

1×1

2×2

Hn>512

Vn≥16

Hn≤512

8≤Vn≤2048

Hn>512

Vn≤904

Hn≤512

8≤Vn≤2048

Calculation formula Hn × Vn

1/(round(Vn/2048/80/1H) ×1H)

1/(roundup(Vn/2048/80/1H) ×1H) 2048 × 8 17 103

1/(Vn/2×1H)

1/(Vn×1H) 1024 × 1024 100

1/(Vn×2×1H) 512 × 512 100

1/(round(Vn/2048/80/1H) ×1H) 2048 × 2048 80

1/(Vn/2×1H+Exp1+10×1H)

1/(Vn/2×1H+Exp1+10×1H)

1/(Vn×1H+Exp1+10×1H) 1024 × 1024 90

Frame rate

mode

(Synchronous

readout trigger)

4×4

Hn>512

Vn≥48

1×1

Hn≤512

8≤Vn≤2048

2×2

4×4

• The calculation formula and the frame rate value of Start trigger mode (External trigger mode) are

same as Free running mode. About this mode, refer to 11-1-6-3 “Start trigger mode”.

1/(Vn×2×1H+Exp1+10×1H) 512 × 512 90

1/(round(Vn/2048/80/1H) ×1H)

1/(Vn/2×1H+5×1H) 2048 × 8 11 402

1/(Vn/2×1H+5×1H)

1/(Vn×1H+5×1H) 1024 × 1024 99

1/(Vn×2×1H+5×1H) 512 × 512 99

35

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

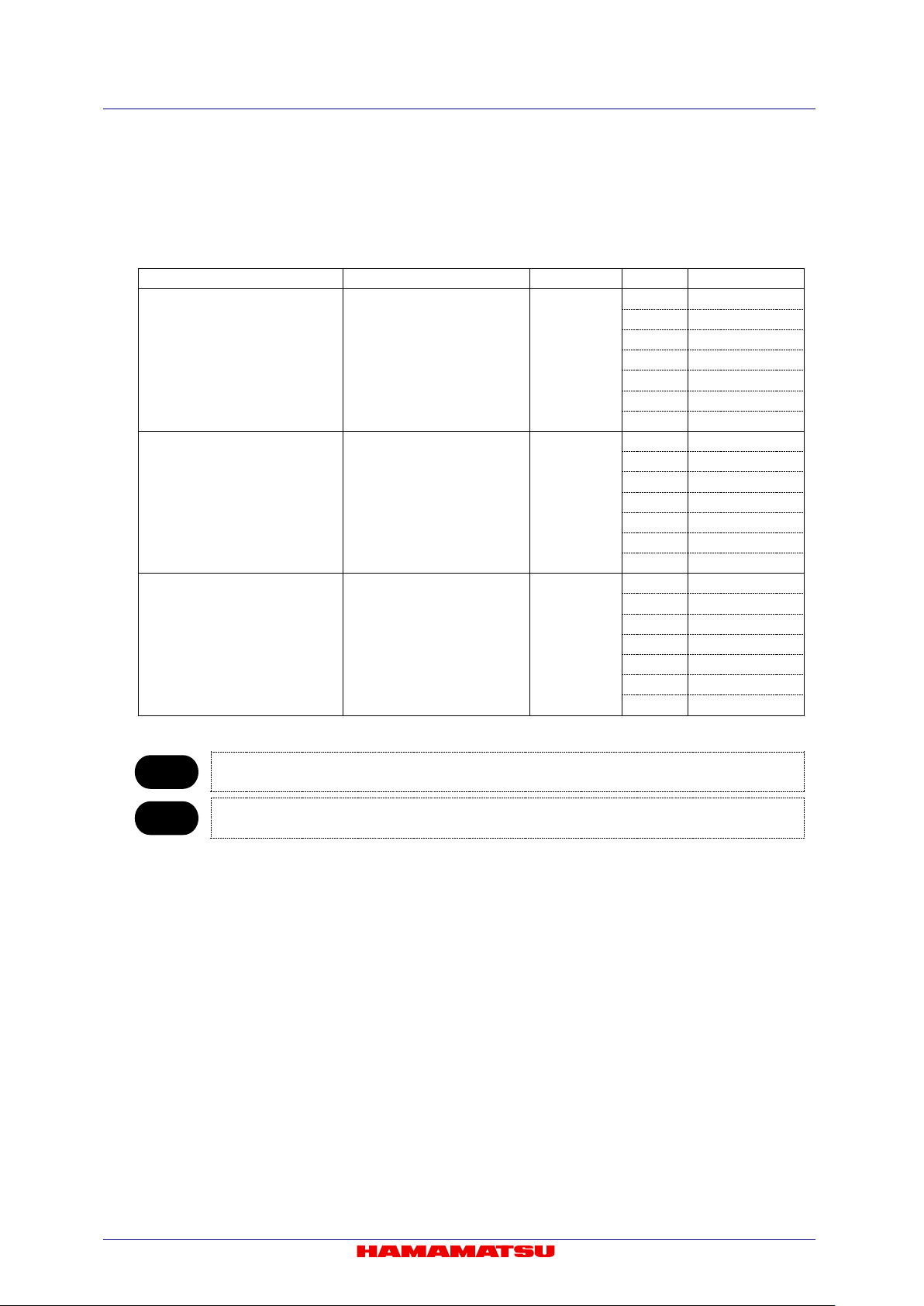

Operation modes

Calculation formula

Horizontal

Vertical

Frame rate (fps)

Free running mode

1/(Vn/2×1H)

2048

2048

30

1024

60

512

120

256

240

128

481

64

962

8

7696

External trigger mode

1/(Vn/2×1H+Exp1+10×1H)

2048

2048

27

1024

50

512

85

256

133

128

184

64

228 8 287

External trigger mode

1/(Vn/2×1H+5×1H)

2048

2048

29

1024

59

512

117

256

231

128

446

64

832

8

3420

Note

Note

(3) Slow scan: Camera Link, USB 3.0 (Common to the two interfaces)

Vn = Number of vertical line (at the center area of the image sensor)

Exp1 = 3.021 ms to 10 s (input in units of seconds)

1H = 32.4812 µs

(Edge trigger / Level trigger)

(Synchronous readout trigger)

• The calculation formula and the frame rate value of Start trigger mode (External trigger m ode) are

• The calculation formula and the frame rate value do not depend on the bit depth of digital output.

same as Free running mode. About this mode, refer to 11-1-6-3 “Start trigger mode”.

36

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

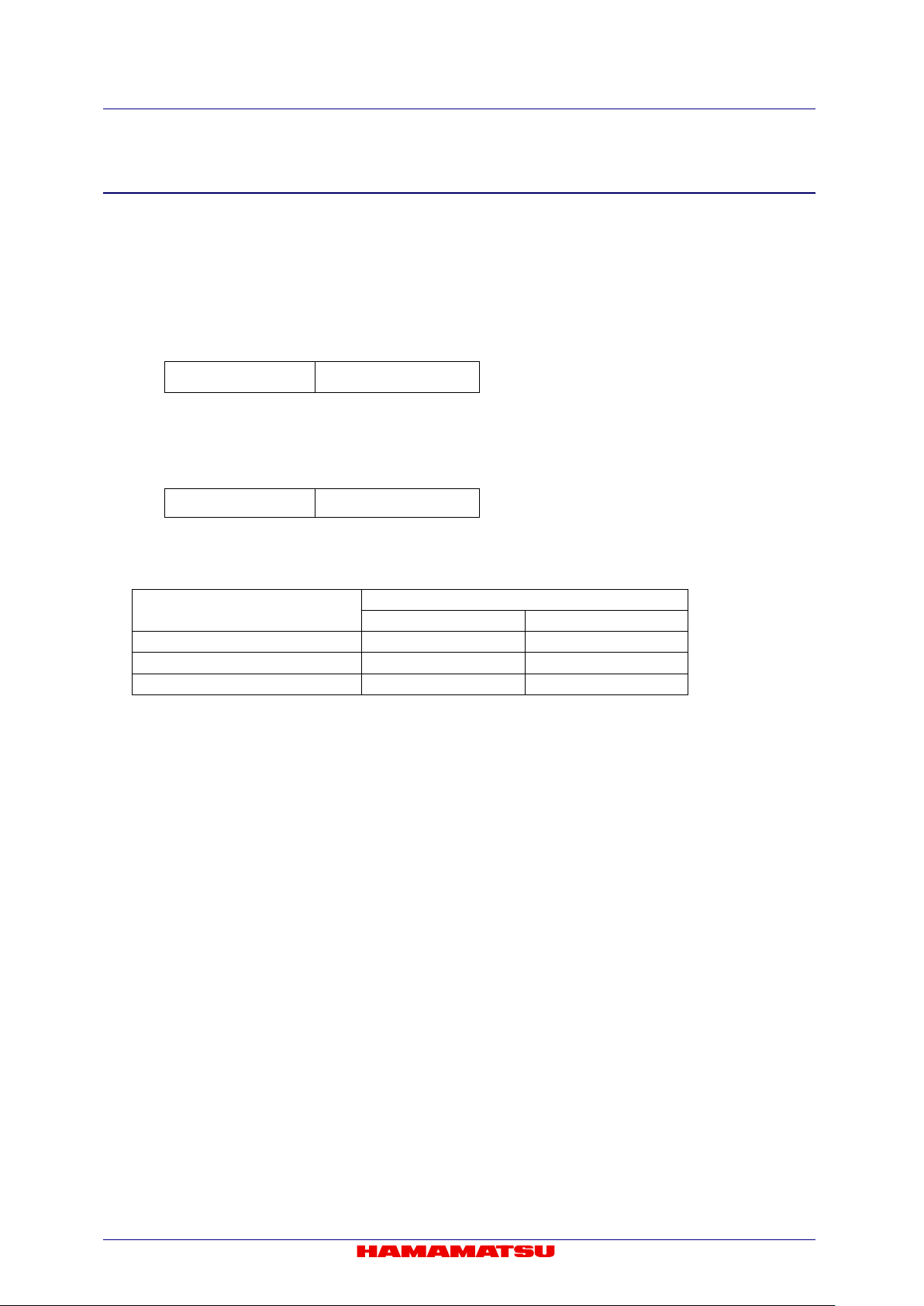

Setting range

Standard scan

Slow scan

Free running mode

1 ms to 10 s

3 ms to 10 s

Free running mode (at Sub-array)

38.96 µs* to 10 s

129.99 µs* to 10 s

External trigger mode

1 ms to 10 s

3 ms to 10 s

11-1-5 CONFIGURING EXPOSURE TIME

The exposure time setting can be done by the units of seconds.

The actual exposure time setting is defined by the following formula, and the camera automatically

calculates a longer and closest value from the specified exposure time setting.

(1) Standard scan

Exp1 = 1 ms to 10 s (38.96 µs to 10 s with sub-array sett ing) ( input in units of seco nds)

Exp2 = Exp1 ÷ 9.744 36 µs (round up to integer)

Calculation formula 9.744 36 µs × Exp2

(2) Slow scan

Exp1 = 3 ms to 10 s (129.99 µs to 10 s with sub-array setting) (input in units of seconds)

Exp2 = Exp1 ÷ 32.4812 µs (round up to integer)

Calculation formula 32.4812 µs × Exp2

Available setting range of the exposure time is the following.

Operation modes

38.96 µs (Standard scan) and 129.99 µs (Slow scan) is the minimum exposure time when sub-array is set to 8 lines vertically symmetric

*

(4 lines in top half and 4 lines i n botto m half ) with respect to t he hori zontall y center axis. Th e mi nimum e xposur e tim e vary depend on

vertical line number of sub-array setting.

37

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Note

11-1-6 CAMERA OPERATION MODES

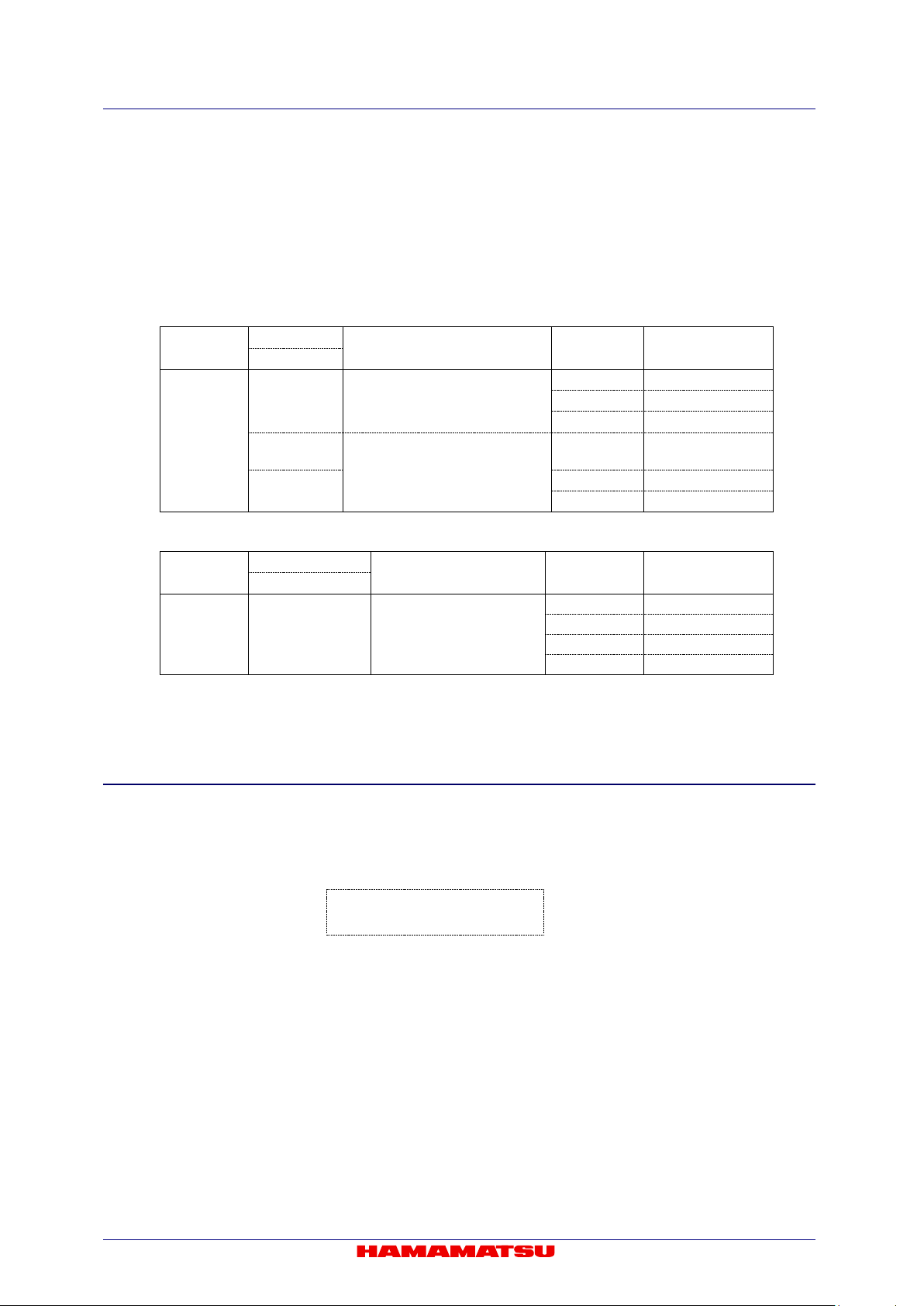

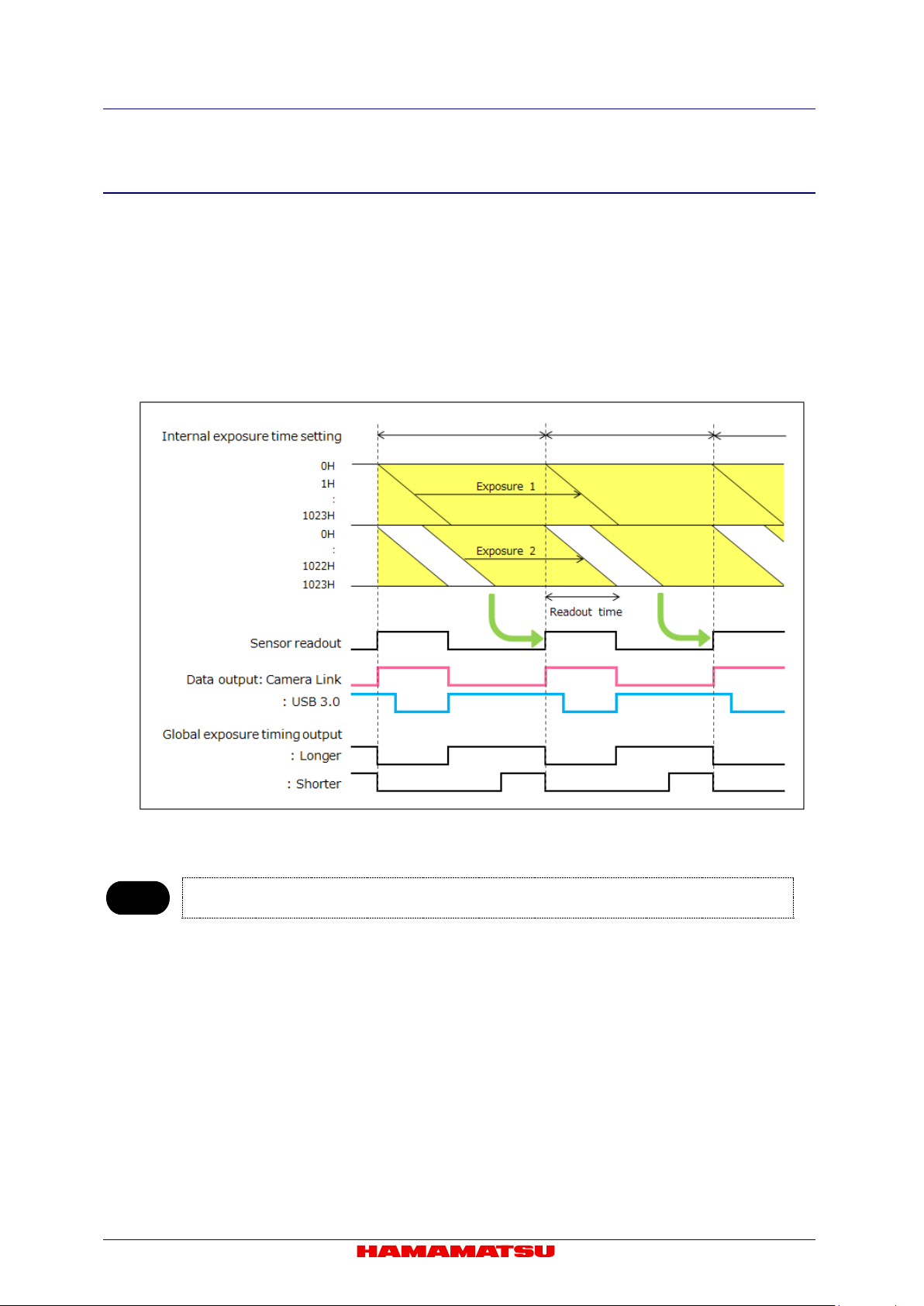

11-1-6-1 Free running mode

The camera has Free r unning m ode which the expos ure and read out tim ing can be set and co ntrolled

by an internal micr oprocessor. Free running mode has normal readout m ode (in which the expos ure

time is longer than the 1 frame readout time) and electrical shutter mode (in which the exposure time is

shorter than the 1 frame readout time). These readout modes are automatically switched depending on

the exposure time setting.

• Please cont act a Hamam atsu subsidiary or your local distributor for the detail of the timing information.

(1) Normal readout

The normal readout mode is suitable for observation, monitoring, field of view and focus

adjustment, and anim ation because it can operate with f ull resolution, which is faster than the

video rate*. (* 100 fps with standar d scan with Camer a Link, 40 fps with USB 3.0 (16 bit digital

output) and 30 fps with slow scan)

In addition, t he exposur e time can be extended t o collect m ore signals an d increase the signal to

noise ratio if the object is dark. In the normal readout mode, the exposure time is the same or longer

than the 1 fr ame read out tim e. In this mode, the fram e rate de pends o n the exp osure tim e, and i t

becomes frame rate = 1/exposure time. The maximum exposure time is 10 s.

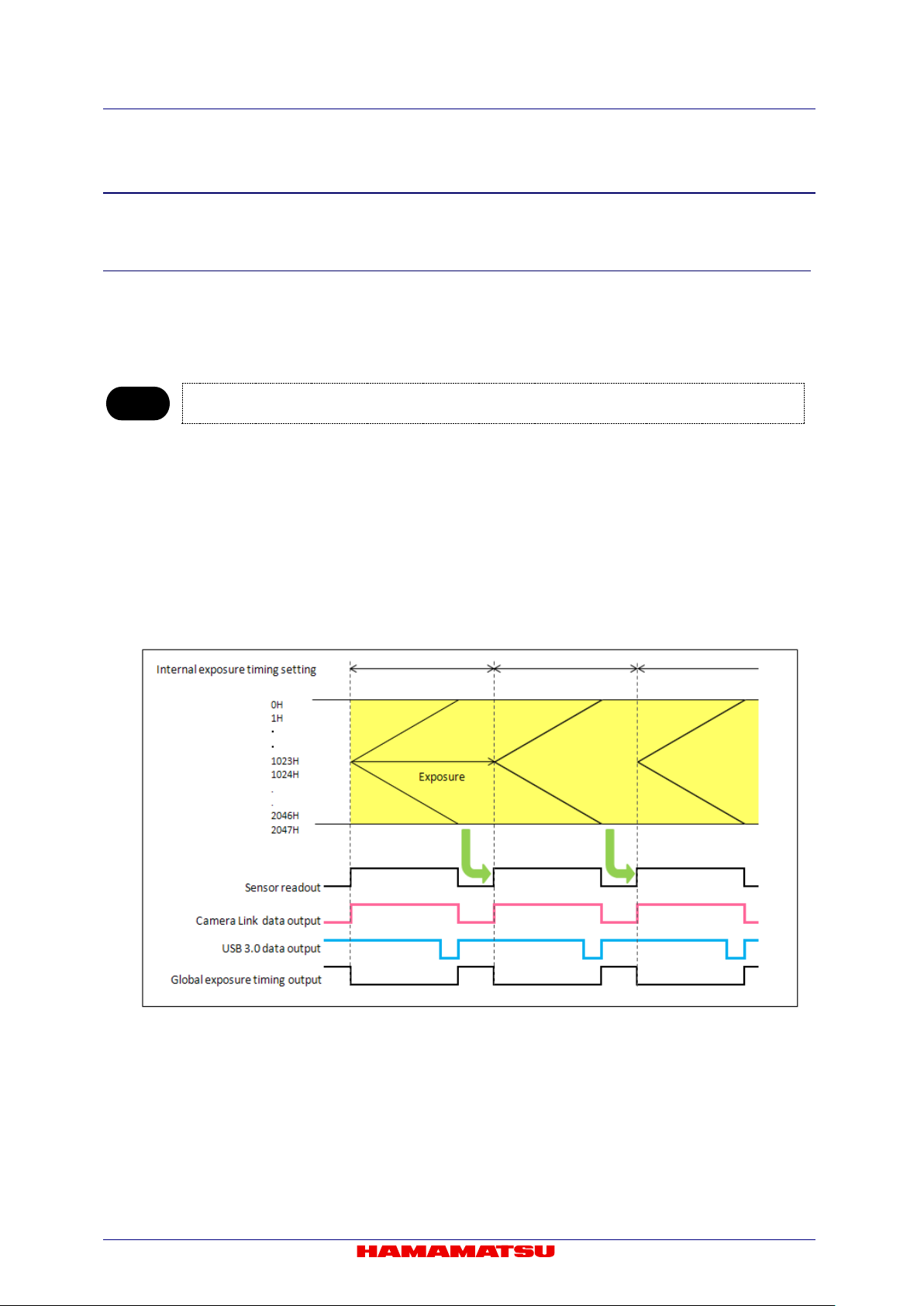

Figure 11-2

38

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

(2) Electrical shutter

The electrical shutter mode is used to get a proper signal level when signal overflow happens due

to too much input photons in normal readout mode. In this mode, the fastest frame rate is 100 fps

(standard scan via Cam era Link), 40 fps (standard scan via USB 3.0) or 30 fps (slow scan) at full

resolution even when the exposure time is short.

Camera Link:

Figure 11-3

USB 3.0:

Figure 11-4

39

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Note

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

Sens or readout

Camera Link data output

USB 3.0 da ta output

Globa l exposure timing output

Exposure

Trigger ready output

(Camera Link)

Triggerready output

(USB

3.0)

*

External trigger

* Delay: 87.7 μs Jitter: 9.74 μs (S tanda rd sc an)

* Delay: 292.33 μs Jitter: 32.48 μs (Slow scan)

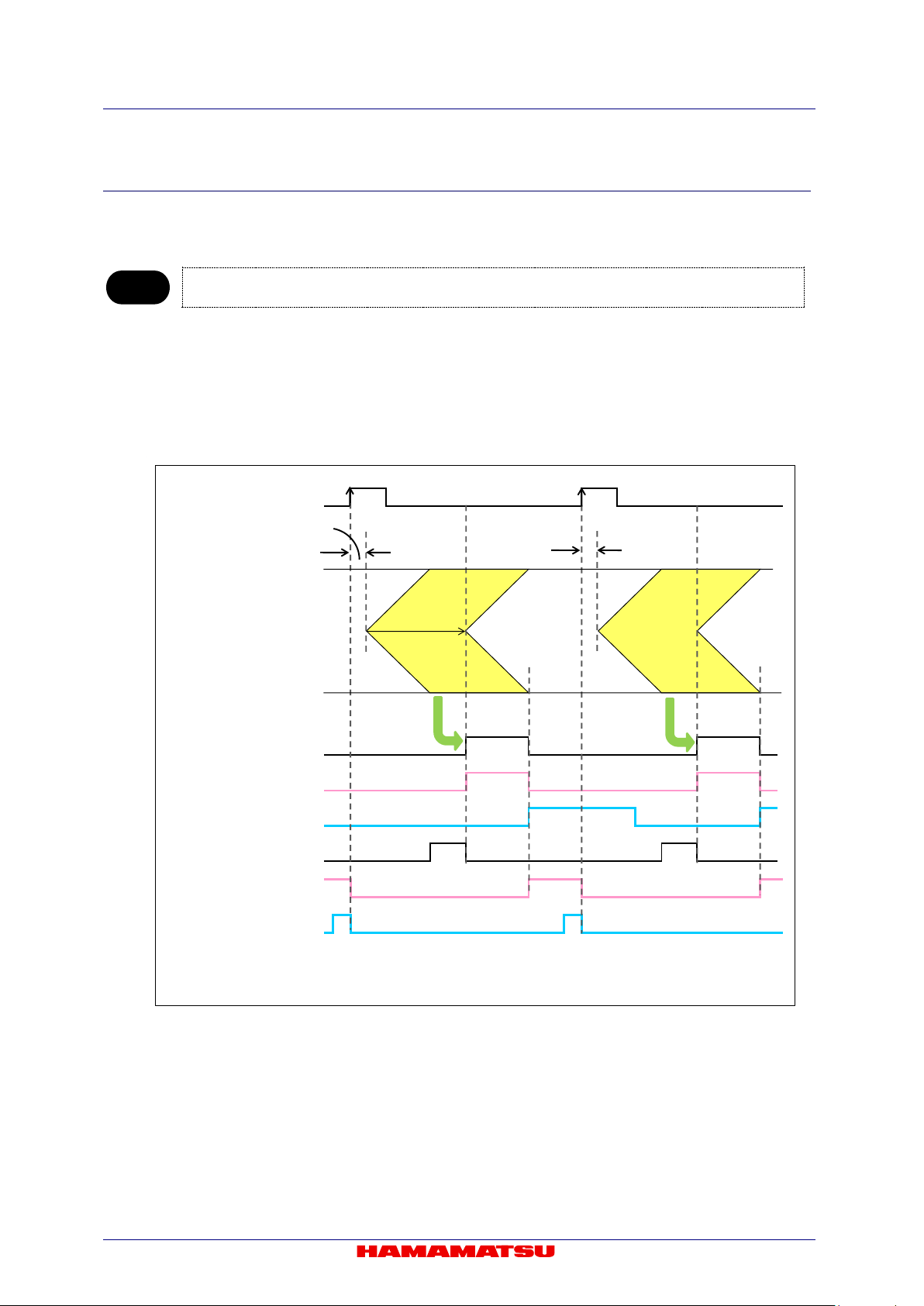

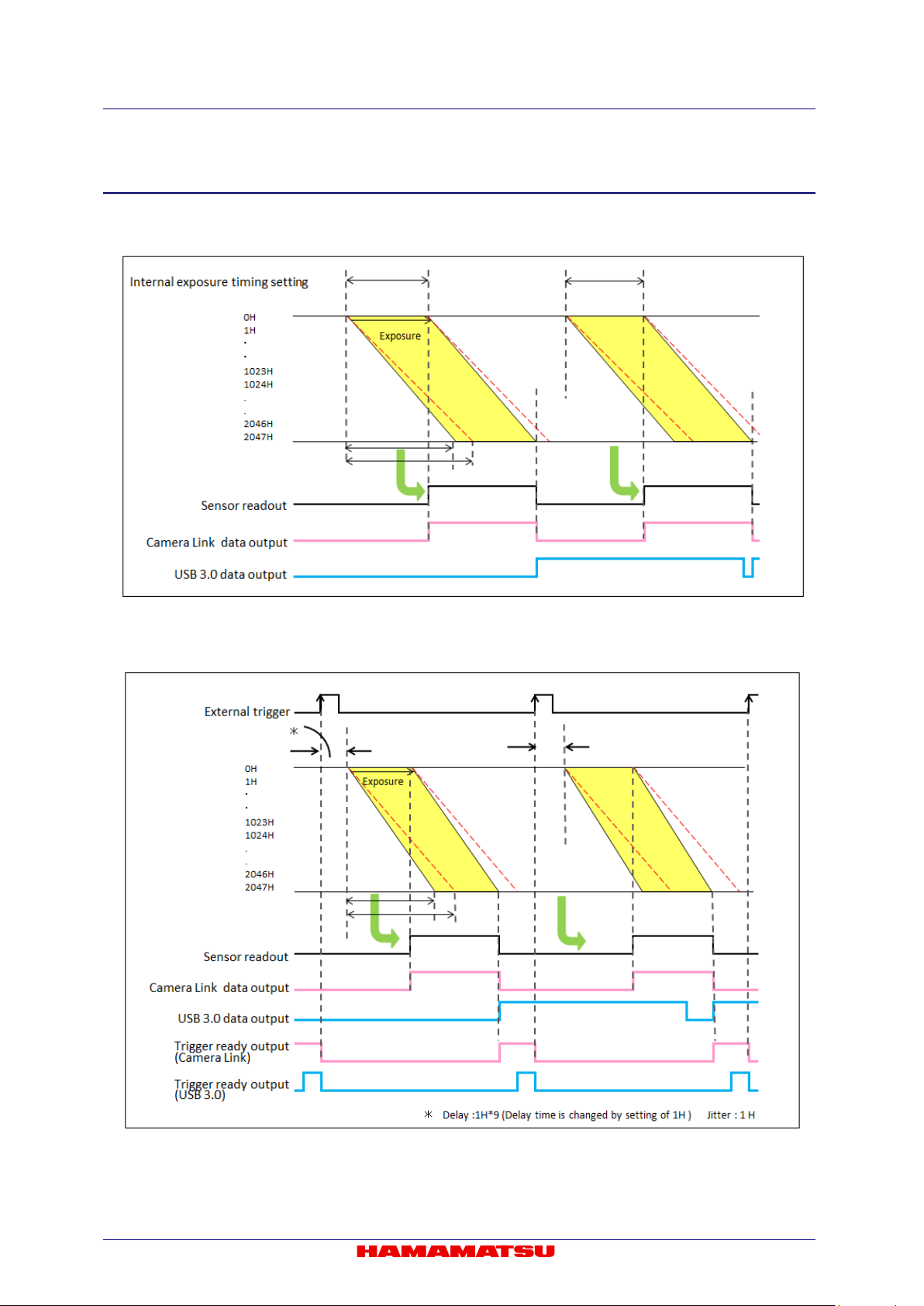

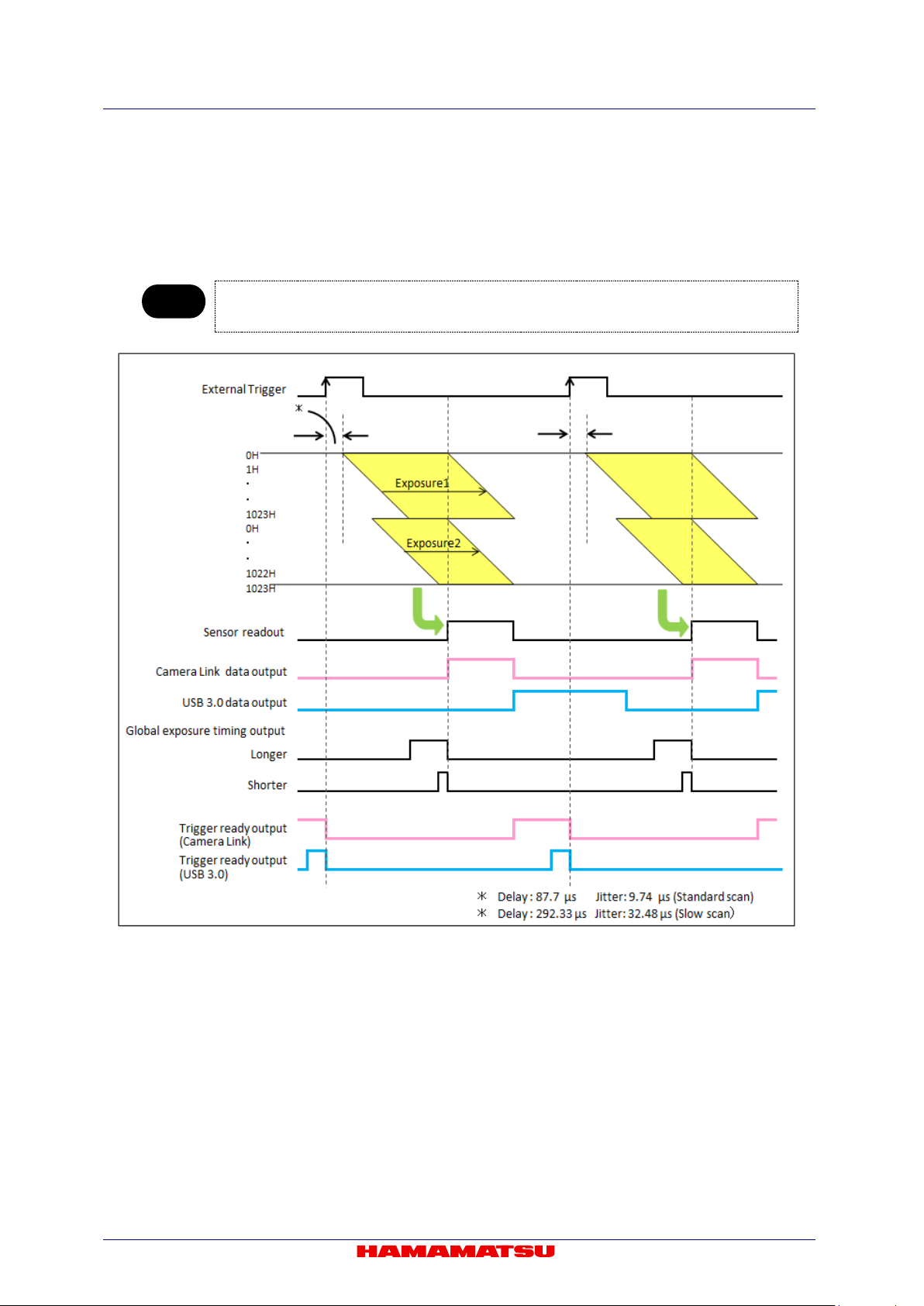

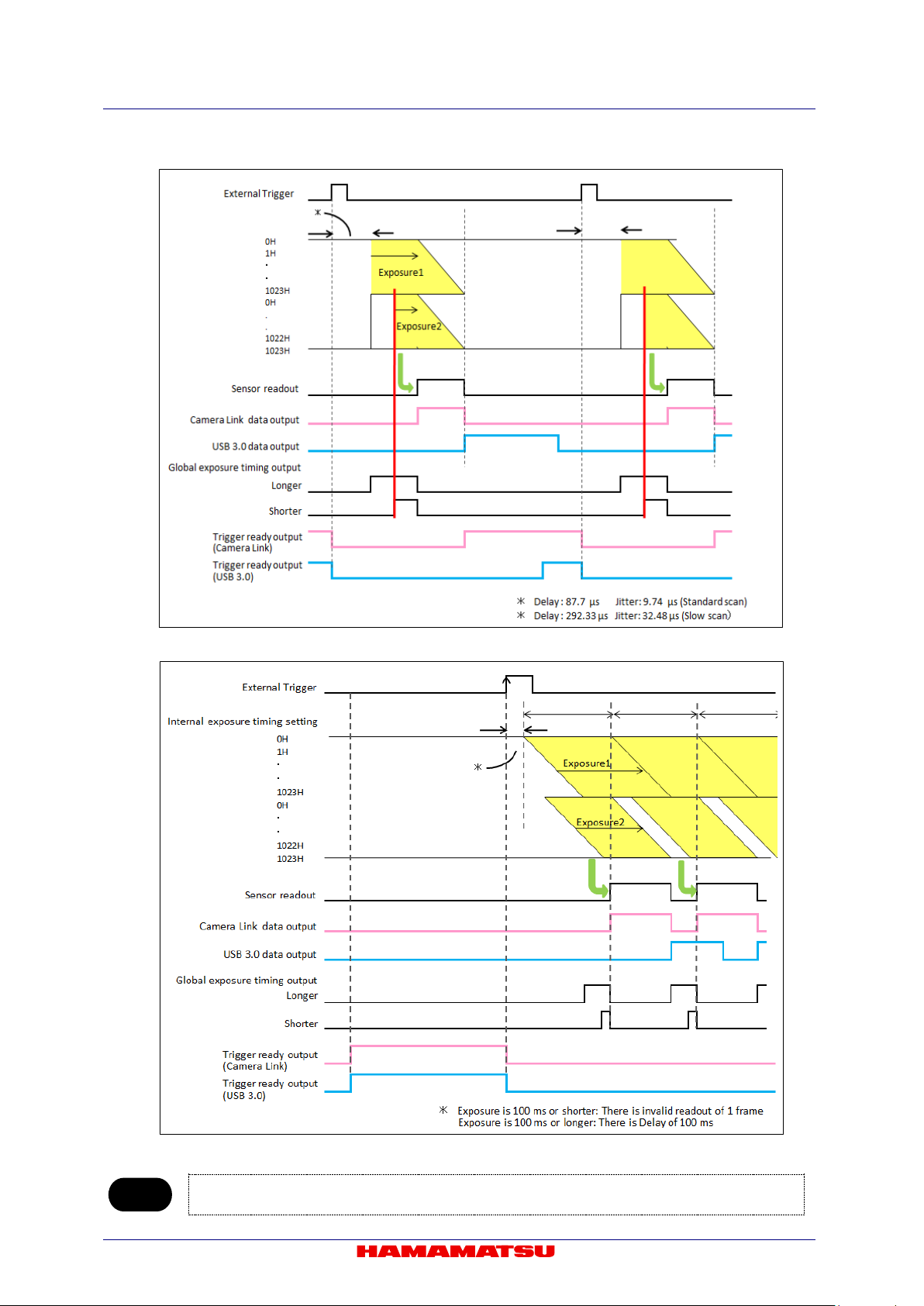

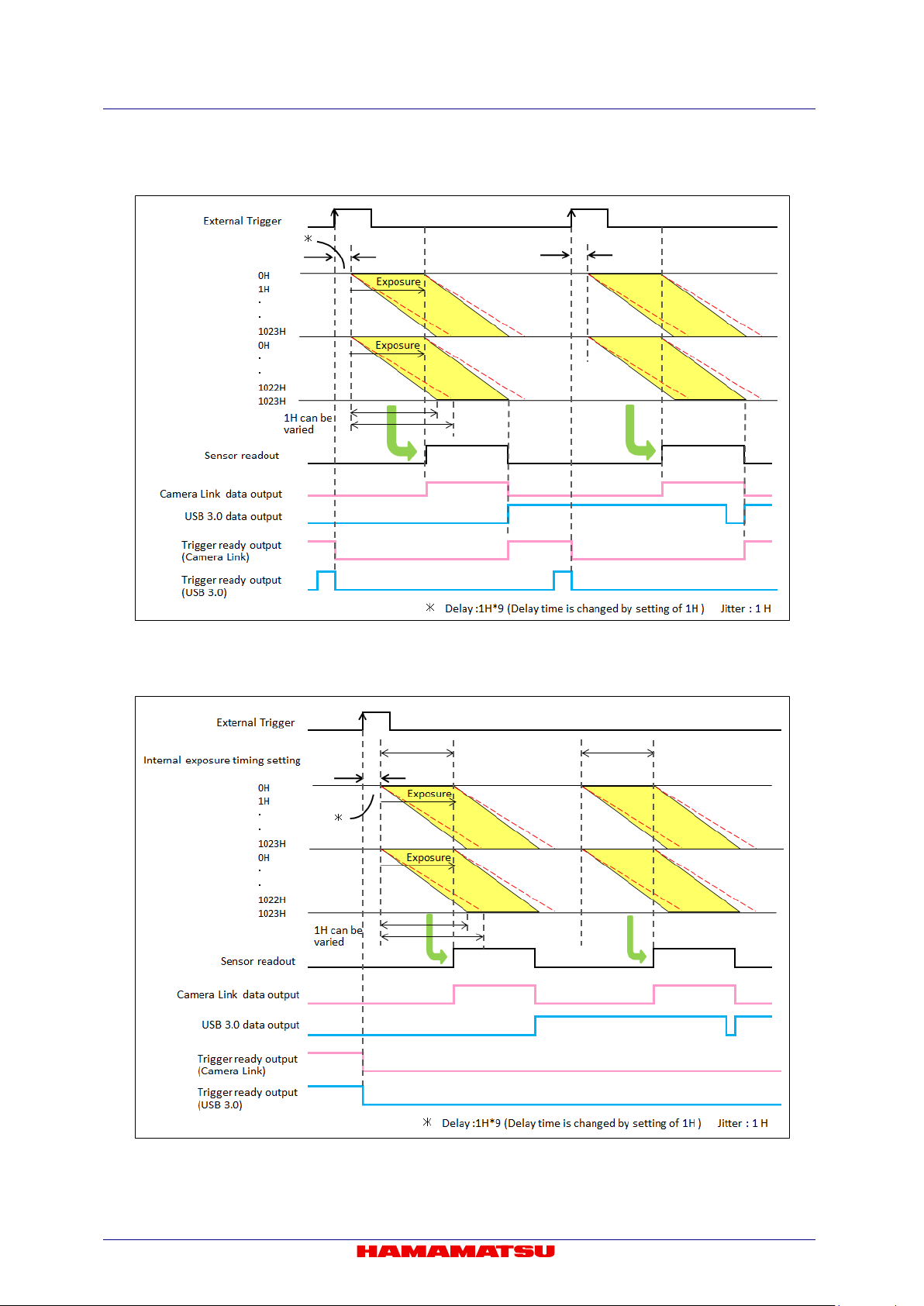

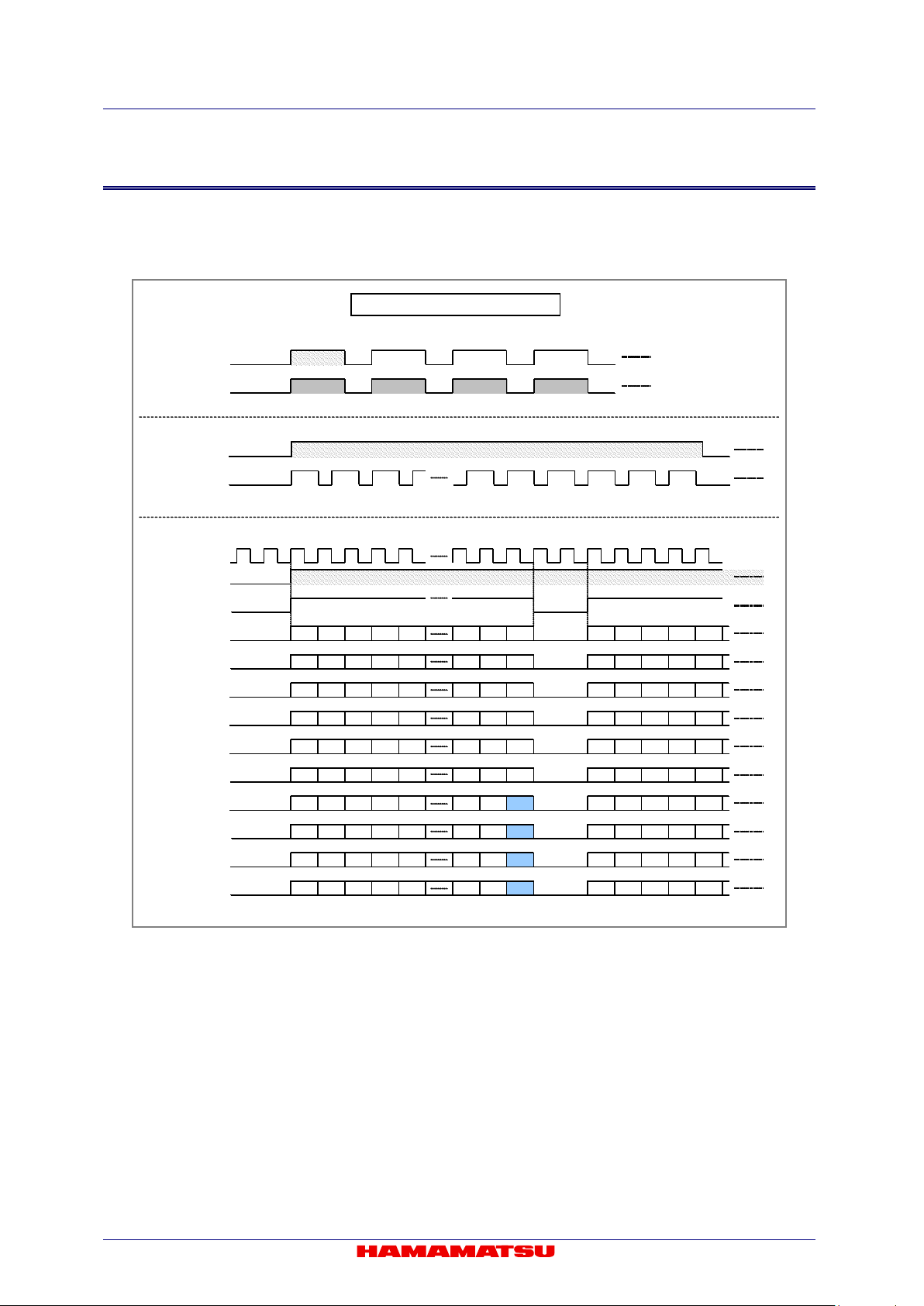

11-1-6-2 External trigger mode

The camera has various external trigger functions to synchronize the camera with the external

equipment. In External trigger mode, the external equipment becomes a master and the camera

becomes a slave.

• Please contact a Hamamatsu subsidiary or your local distributor for the detail of the timing information.

(1) Edge trigger mode

The Edge trigger mode is used so that the exposure starts according to an external signal.

Exposure time is set. In this mode, the exposure of the first line begins on the edge (rising /

falling) timing of the input trigger signal into the camera. (1023H and 1024H in the following

figure) The exposure of the second line is begun after the readout time of one line passes (1022H

and 1025H in the following figure), and the exposure is begun one by one for each line.

Figure 11-5 (Ex. rising edge)

40

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

Sensor readout

Camera Link data output

USB 3.0 data output

Global e xposure ti mi ng output

Exposure

External trigger

Triggerready output

(Camera Link)

Triggerready output

(USB 3.0)

*

*Delay:87.7 μs jitter: 9.74 μs (Standard scan)

*Delay: 292.33 μs Jitter: 32.48 μs (Slow scan)

(2) Global reset Edge trigger mode

Global reset function e nables to reset t he electric c harge of all pixe ls at the sam e time. Then all

pixels can start exposure at the same time.

With this Global r eset Edge tr igger m ode, the exposu re of all pix els begins on the e dge (rising /

falling) timing of the input trigger signal into the camera.

41

Figure 11-6 (Ex. rising edge)

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

Sens or readout

Camera Link

data output

USB 3.0 da ta output

Globa l exposure timing output

Exposure

Trigger ready output

(Camera Link)

Triggerready output

(USB 3.0)

*

External trigger

* Delay: 87.7 μs

Jitter: 9.74 μs

(Standa rd s ca n)

* Delay: 292.33 μs Jitter: 32.48 μs (Slow scan)

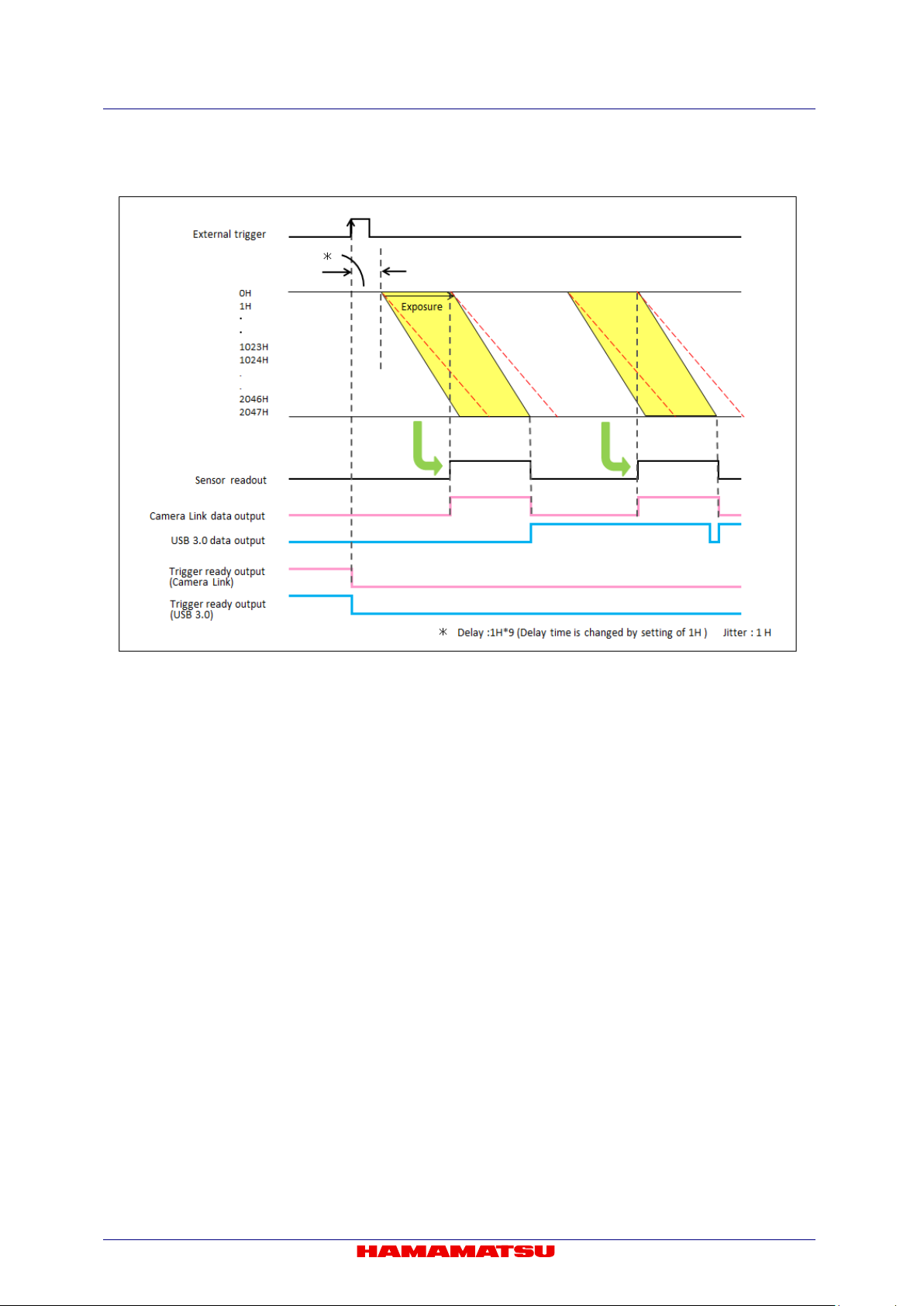

(3) Level trigger mode

The Level trigger mode is used to control both exposure start timing and exposure time length by

inputting external tri gger pulses. In this mode, the camer a starts exposure at the star t of high or

low period of the i nput trigger pulse and stops expos ure at the end of high or low period of the

input trigger pulse. T he exam ple below is f or the trigge r level High. T he expos ure of the first line

begins when the tri gger signal becom es High, and the exposure of the second lin e begins after

the readout time of line one passes. Each exposure begins one by one for each line. The

exposure of the first line is finished when the trigger signal becom es low, and signal readout is

begun. The exposure tim e of each line is defined by the tim e that the input trigger is hig h. The

minimum trigger pulse width is 1.05 ms (standard scan) or 3.18 ms (slow scan).

Figure 11-7 (Ex. level High)

42

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

Sensor readout

Camera Link data output

USB 3.0 data output

Global exposure timing output

露光

Exposure

External Trigger

Triggerready output

(Camera Link)

Triggerready output

(USB 3.0)

*

*Delay:87.7 μs jitter: 9.74μs (Standard s can)

*Delay: 292.33 μs Jitter: 32.48 μs (Slow scan)

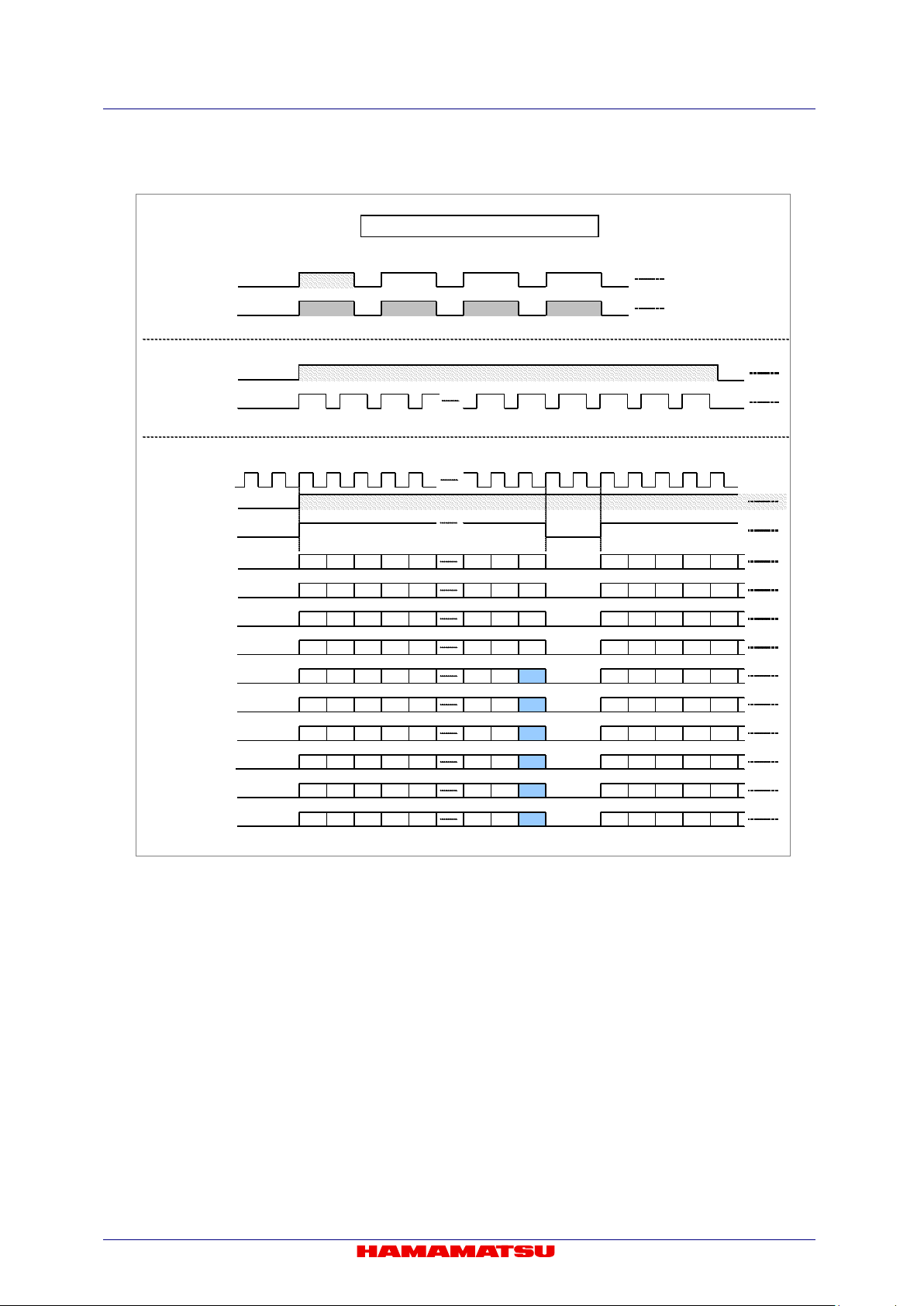

(4) Global reset Level trigger mode

Global reset function e nables to reset t he electric c harge of all pixe ls at the sam e time. Then all

pixels can start exposure at the same time.

The example below is for the trigger level High. With this Global r eset Level trigger mode, the

exposure of all pixels begins when the trigger signal becomes High.

Figure 11-8 (Ex. level High)

43

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Sens or readout

Camera Link data output

USB 3.0 da ta output

Globa l exposure timing output

Exposure

Triggerready output

(Camera Link)

Triggerready output

(USB 3.0)

*

External trigger

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

* Delay:38.96μs Jitter :9.74 μs (Standa rd sc an)

* Delay:129.92μs Jitter :32.48 μs (Slow scan)

(5) Synchronous readout trigger mode

The Synchronous rea dout trigger mode is used for continuous imaging when it is necessary to

control the exposure start t iming of each fr ame from an external source. It is useful for conf ocal

microscopy. For example, when the camera is used with a spinning disk confocal microscope and

the camera exposur e time i s synchronized to the s pinning dis k's rotatio n speed, i t is possi ble to

eliminate uneven illumination (called banding noise) caused by variation of the spinning disk

rotation speed. Also, i t is usef ul for securing as long expos ure time as poss ible while c ontrolling

the exposure start timings by external trigger signals.

Normal operation (when the Trigger Time is set as 1.);

The Synchronous rea dout trigger mode is used for continuous imaging when it is necessary to

control the exposure start timing of each frame from an outside source and also when it is

necessary to secure as long exposure time as possible. In the Synchronous readout trigger mode,

the camera ends each exp osure, starts the readout and also, at the sam e time, starts the next

exposure at the edge of the input trigger signal (rising / falling edge). That is, the interval between

the same edges of the input trigger becomes the exposure time.

44

Figure 11-9 (Ex. rising edge)

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Sens or readout

Camera Link data output

USB 3.0 da ta output

Globa l exposure timing output

Exposure

Trigger ready output

(Camera Link)

Triggerready output

(USB 3.0)

*

External trigger

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

* Delay:38.96μs Jitter :9.74 μs (Standa rd sc an)

* Delay:129.92μs Jitter :32.48 μs (Slow scan)

Trigger Times;

Also in the Synchronous readout trigger mode, synchronous readout can be controlled by

specifying, the number of timing pulses to determine the exposure time. The following figure

shows the exposure timing when the Trigger Times is set as 3.

Figure 11-10 (Trigger Times)

45

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

0H

1H

・

・

1023H

1024H

.

.

2046H

2047H

Sens or readout

Camera Link data output

USB 3.0 da ta output

Globa l exposure timing output

Exposure

Trigger ready output

(Camera Link)

Trigger ready output

(USB 3.0)

External trigger

* Exposur e is 100 ms or sho rter: There is invalid readout of 1 frame

Exposure is 100 ms or longer:There is Delayof 100 ms

*

Internal e x posure time

setting

11-1-6-3 Start trigger mode

Start trigger mode is to s tart operating the camera by a trigger input for a c ontinuous imaging. It is

useful to secure the frame rate as fast as possible when continuous image acquisition and not to

sacrifice the exposure time. For example, when it is necessary to measure the phenomenon after

stimulation, it is possible to start continuous image acquisition at the stimulation timing.

Start trigger mode is to start operating the camera by a trigg er input for continuous imaging, and i t

works at the high est frame rate because it is operated in internal trigger mode. In Start trigger m ode,

the camera starts ex posure and switches to internal trigger m ode by the edge of an external trigger

signal (rising / falling edge).

11-1-6-4 External trigger delay function

In most cases when a del ay between the laser pulse em ission and the exposure start is needed, a

delay unit is set between the laser and camera to control trigger timing. In each external trigger mode of

the camera, the delay can be set to the trigger signal input to the camera by command. With this setting,

a range of trigger can be arranged witho ut a de lay uni t. The ra nge f or dela y time is 0 µs t o 10 s (1 µs

steps).

46

Figure 11-11 (Ex. rising edge)

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Note

Reference signal

Output signal

Camera outputs a pulse after certain delay, from the end of sensor readout.

Also the pulse width can be set.

Camera outputs a pulse after certain delay, from the beginning of readout.

Also the pulse width can be set.

Camera outputs a pulse after certain delay, from the input trigger signal.

Also the pulse width can be set.

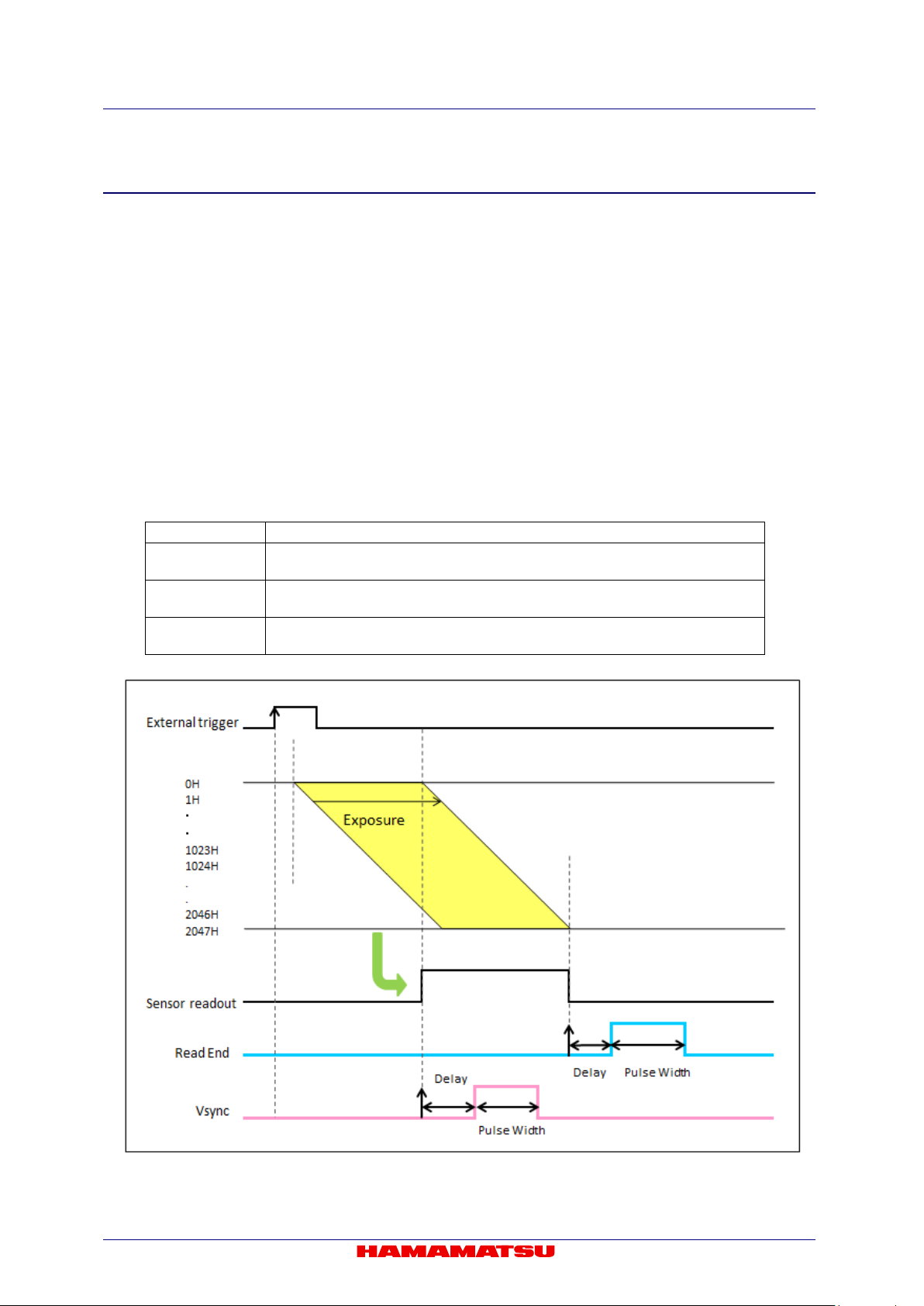

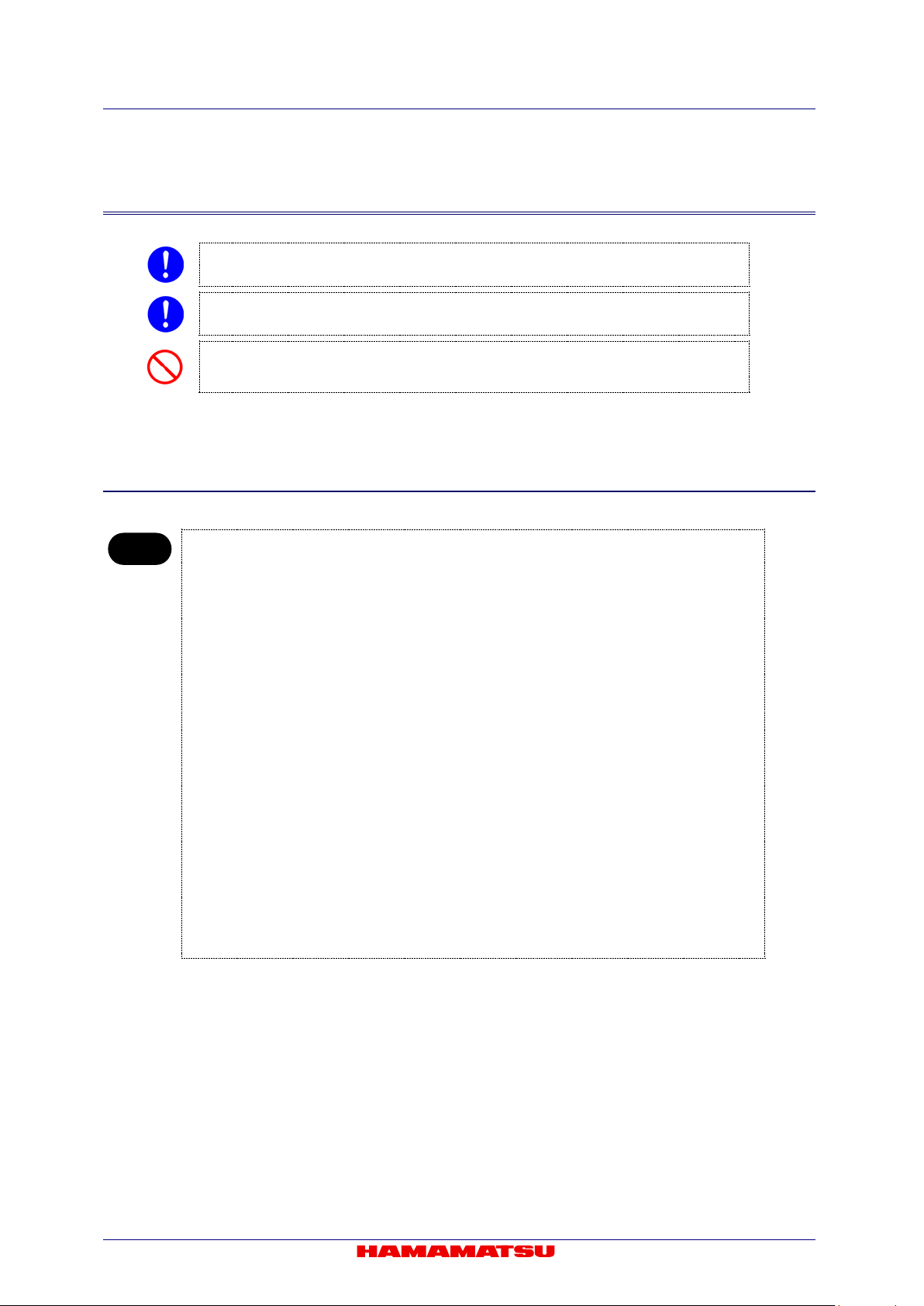

11-1-7 TRIGGER OUTPUT

The camera provides a ran ge of trigger output signals to s ynchronize with an exter nal instrument and

the camera becomes the master and the external instrument becomes the slave.

There are three different trigger output functions as follows.

- Global exposure timing output

- Programmable timing output

- Trigger ready output

Also, it can output con tinuous High output (High output f ixed) or continuous Low output (Lo w output

fixed). They are output from Timing out connector.

(1) Global exposure timing output

It shows the global exposure timing where all lines expose at the same time. There is a case that

one event is divided into two f rames becaus e the tim ing of the exposur e in each li ne is different

for the rolling shutter. However, by using the Global exposure tim ing output the global ex posure

becomes possible for the phenomenon that happens for this period. Global exposure timing

output shows the period where all lines expose at the same time.

• There is no output signal when the exposure time is less than the frame rate.

(2) Programmable timing output

By using the programmable timing output, synchronizing external devices is simple. A system that

needs simple timing signal does not require a delay unit or pulse generator. It is possible to

program and output a puls e that has an optiona l pulse width an d an optiona l dela y time to Read

End (the end of readout timing), Vsync or Input trigger signal. The setting range for delay time is 0

µs to 10 s, and the setting range for pulse width is 1 µs to 10 s.

The relation between the parameter which can be set with e ach referenc e signal, and an outp ut

signal becomes below.

Read End

Vsync

Input trigger signal

47

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Figure 11-12 Programmable timing output

(3) Trigger ready output

The trigger ready output is useful to make the frame intervals as short as possible in external

trigger mode. For example, when the camera is working in the Edge trigger mode, the next frame

can start after the previous frame exposure is done. Thus, the camera cannot accept a trigger for

the next frame during the exposure period. To reduce useless time to be as short as possible, it is

necessary to know the period when the camera can accept a tr igger for the next frame. The

trigger ready output shows the trigger ready period when the camera can accept an external

trigger in External trigger mode.

48

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

11-2 LIGHTSHEET READOUT MODE

Lightsheet Readout Mode is a unique feature of CMOS image sensor which provides improved

control over the rolling shut t er mec hanism.

By finely synchronizing the camera readout with the illumination scan, scattered light is rejected

allowing images of higher sign al t o noise ratios to be acquired.

The detail information of Light sheet Readout Mode is published on our website.

Website http://www.hamamatsu.com/jp/en/technology/innovation/lightsheetreadout/index.html

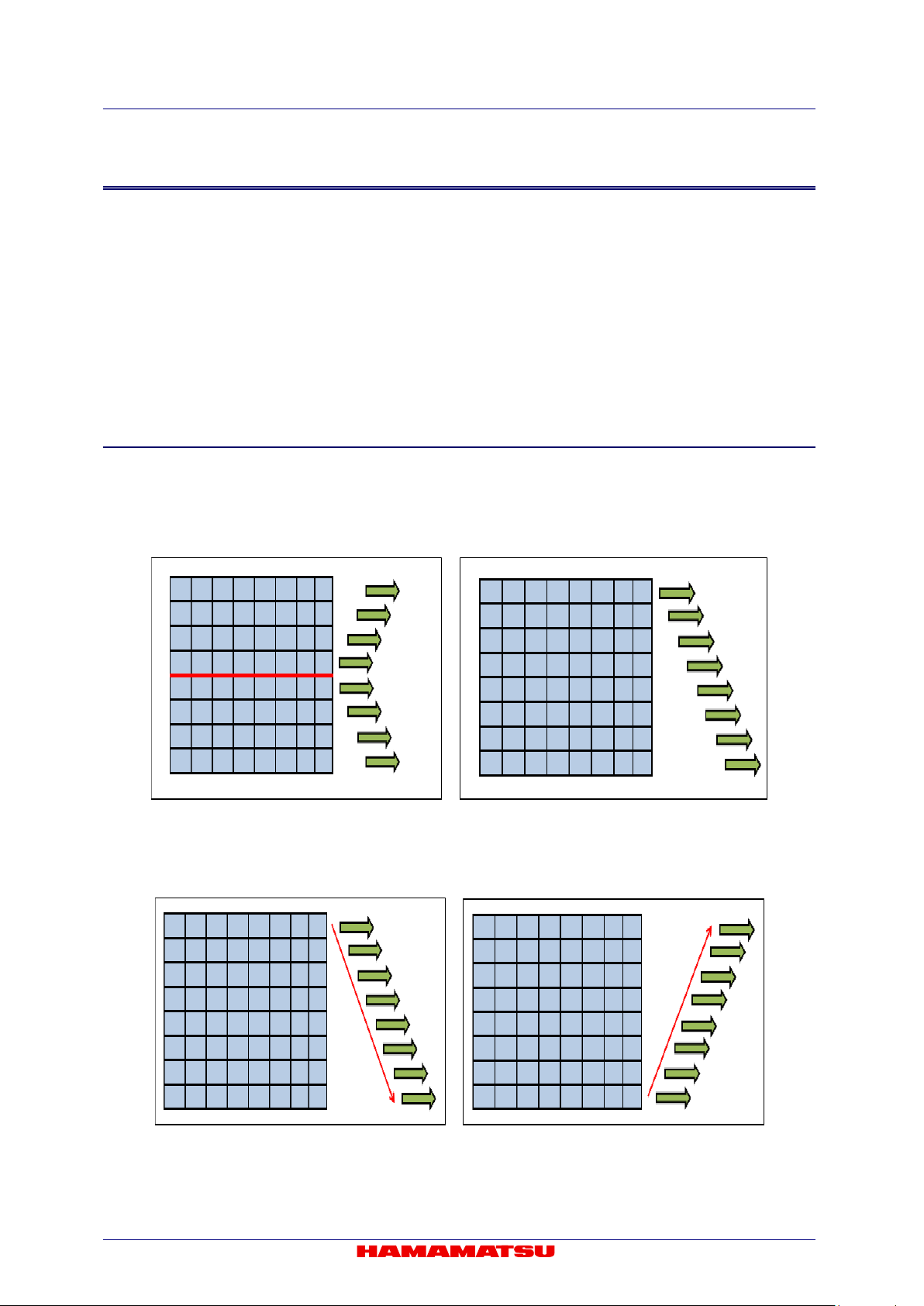

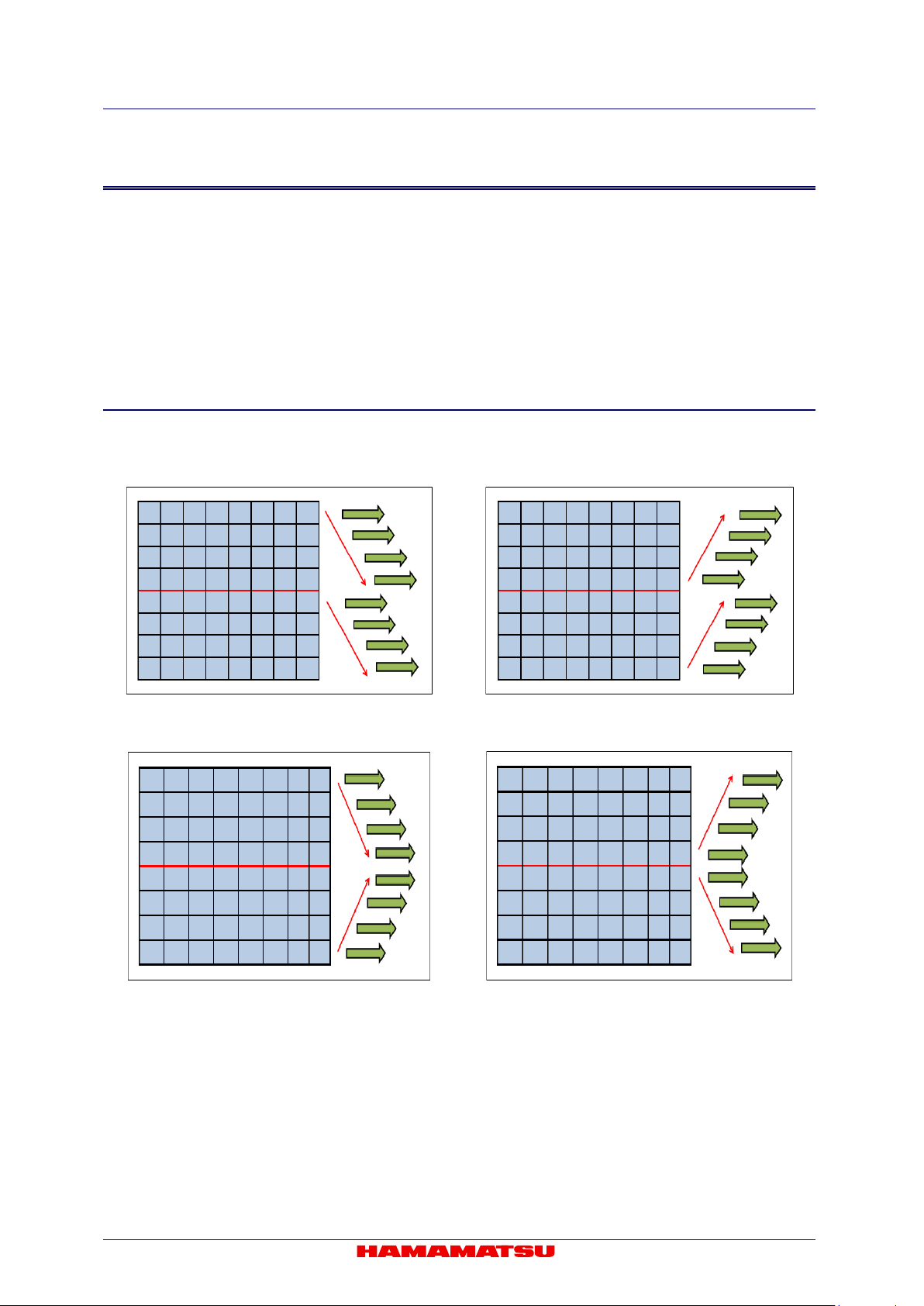

11-2-1 READOUT DIRECTION

The camera reads out from the center line to the top line and to the bottom line simultaneously in normal

area mode. (Figure 11-13)

The camera reads out f rom the top to the bottom line or from the bottom to the top line in Lightsheet

Readout Mode. (Figure 11-14)

Figure 11-13 Normal area mode Figure 11-14 Lightsheet Readout Mode

- Top to bottom readout (Figure 11-15): The data is readout from the top to the bottom line.

- Bottom to top readout (Figure 11-16): The data is readout from the bottom to the top line.

Figure 11-15 Top to bottom readout Figure 11-16 Bottom to top readout

49

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Size

Position

Horizontal

Vertical

Horizontal

Vertical

Note

Operation modes

Calculation formula

Horizontal

Vertical

Frame rate (fps)

Common to all modes

1/(Exp1+(Vn+10)×1H)

2048

2048

49

1024

99

512

196

256

384

128

738

64

1368

8

5401

4

6841

11-2-2 ABOUT READOUT AT LIGHTSHEET READOUT MODE

(1) Readout methods

This mode can set Normal readout and Sub-array readout.

Binning readout mode is not supported at Lightsheet Readout Mode.

The size and the position of the sub-array readout can be configured according to the table

below.

128 pixels 4 lines 4 pixels 4 lines

• Minimum settable step of the size and position on the table is in only the case that the camera is used

with DCAM.

(2) Camera operation modes

This mode can use; Free r unning mode, Edge trigger mode (Exter nal trigger mode), and Start

trigger mode.

11-2-3 FRAME RATE CALCULATION

The frame rate calculation and the value of frame rate are common to all camera operation modes (Free

running mode / External trigger mode (Edge trigger) / Start trigger mode).

(1) Camera Link

Vn = Number of vertical line

Exp1 = 9.744 36 µs to 10 s (input in units of seconds to the calculation formula)

1H = 9.744 36 µs to 100 ms

(Free running mode /

External trigger mode (Edge trigger) /

Start trigger mode)

50

C13440-20CU / C13440-20CU01 Instruction manual_Ver.1.3

Horizontal

Vertical

2048 × 2048

40

2048 × 512

160

2048 × 64

1282

Hn>512

Vn≤44

4≤Vn≤2048

512 × 2048

49

512 × 512

196

Horizontal

Vertical

2048 × 2048

49

2048 × 512

196

2048 × 64

1368

2048 × 8

6841

(2) USB 3.0

Hn = Number of horizontal pixel

Vn = Number of vertical line

Exp1 = 9.744 36 µs to 10 s (input in units of seconds to the calculation formula)

1H = 9.744 36 µs to 100 ms

round () = Round down to integer

roundup() = Round up to integer

1. 16 bit Digital output

Readout

Hn>512

Vn≥48

1×1

Hn≤512

Calculation formula Hn × Vn Frame rate (fps)

1/(round(Vn/2048/40/1H) ×1H)

1/(Exp1+(Vn+10)×1H)

2. 12 bit / 8 bit Digital output

Readout

1×1

128≤Hn ≤2048

4≤Vn≤2048

Calculation formula Hn × Vn Frame rate (fps)

1/(Exp1+(Vn+10)×1H)

11-2-4 READOUT TIME OF THE HORIZONTAL LINE

2048 × 8 6841

Readout time and exposur e time can be varied with Lightsheet Readout Mod e for synchronizing the

camera readout with the illumination scan.

Vn = Number of vertical line

1H = 9.744 36 µs to 100 ms

Readout time = Vn × 1H