Digital Camera

C11440-42U / C11440-42U01

Instruction manual

CAUT ION

Thank you for your purchase

• Follow the safety precautions in Chapter 1 in order to avoid personal

injury and damage to property when using this camera. Be sure to read

this Instruction manual beforehand in order to use the digital camera

correctly. The manual describes the correct method of handing the

camera and provides cautions in order to avoid accidents.

• After reading, keep the manual where it can be referred to at any time.

Ver. 1.1

February 2014

HAMAMATSU PHOTONICS K.K.

97710301-01

~ Blank page ~

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

1. SAFETY PRECAUTIONS

1-1 INDICATION OF THE SYMBOLS

The following symbols can be found on this camera:

Direct current

Alternating current

1-2 CLASSIFICATION OF WARNING

We have classified the warnings symbols that appear in this instruction manual and on the

camera as follows for your convenience. Make sure that you fully understand them and obey the

instructions they contain.

WARNING

CAUT ION

This symbol indicates a note to help you get the best performance from the

Note

camera. Read the contents of the note carefully to ensure correct and safe

use. Failure to observe one of these notes might impair the performance of

the camera.

This symbol indicates a cautionary item that should be obeyed when

handling the camera. Read the contents carefully to ensure correct and

safe use.

Improper handling of the camera without observing these

warnings could lead to serious injury to the user and even death.

Improper handling of the camera without observing these cautions

could lead to personal injury to the user or damage to property.

This symbol indicates an action that is forbidden. Read the contents

carefully and be sure to obey them.

This symbol indicates a compulsory action or instruction. Read the

contents carefully and be sure to obey them.

1

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

WARNING

Power supply

Use the camera with the voltage indicated on the rating sticker. Using a

different voltage can damage the camera and lead to fire or electric shock.

Cables

Be careful not to place heavy objects on cables or bend it excessively.

Doing so can damage the cable and lead to fire or electric shock.

Power supply cord

Use the accessory of the AC adaptor when this camera is used.

Do not touch the plug with wet hand. Doing so can lead to electric shock.

Do not attempt to dismantle or modify the camera

Doing so can also lead to damage and even injury, as some internal

components become very hot. Only touch parts as indicated in this

manual.

Do not insert a foreign substance into the camera

Do not allow foreign objects such as combustible substances, metal

objects or water to get inside the camera. They can damage the camera

and lead to fire or electric shock.

If an abnormality occurs

Such as the image suddenly disappearing or a strange noise, smell or see

smoke coming from the camera, stop the power supply immediately and

contact Hamamatsu subsidiary or local distributor. Never attempt to repair

the camera yourself.

2

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

CAUT ION

AC adaptor

When unplugging the AC adaptor, always pull by the plug, not the cord.

Doing so can lead to fire or electric shock.

Remove the AC adaptor from the outlet when not using the camera for long

periods of time. Doing so can damage the cable and lead to fire or electric

shock.

Connecting and disconnecting cables

Always turn off the power supply of the peripheral device before

connecting and disconnecting cables.

Fixed the camera

When fitting the camera to a tripod or other fixture, use the optional base

plate. Be careful that the fitting screw does not enter more than 8 mm from

the surface of the base plate. Screwing it in excessively can impair normal

operation.

Lenses (C11440-42U)

Be careful not to screw the lens more than 7 mm onto the C-mount of the

camera. Doing so can scratch the protective glass. (Some wide-angle

lenses in particular can have a thread of 7 mm or more.)

Shipping precautions

When transporting the camera by truck, ship, airplane, etc., wrap it

securely in packaging material or something similar.

Strong impact

Do not subject the camera to strong shocks by dropping it, for example.

Doing so can damage the camera.

Operating environment

This system is designed and tested for use in an industrial environment. If

this system is used in residential areas, EMI (electro-magnetic

interference) may occur. This system must not be used in residential

areas.

Disposal

When disposing of the camera, take appropriate measures in compliance

with applicable regulations regarding waste disposal and correctly

dispose of it yourself, or entrust disposal to a licensed industrial waste

disposal company. In any case, be sure to comply with the regulations in

your country, state, region or province to ensure the camera is disposed of

legally and correctly.

3

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

2. CHECK THE CONTENTS OF PACKAGE

When you open the package, check that the following items are included before use. If the

contents are incorrect, insufficient or damaged in any way, contact your local dealer without

attempting to operate the camera.

Camera (C11440-42U or C11440-42U01) 1

AC adaptor 1

Power supply cord for AC adaptor 1

Lens mount cap (attached to the camera) 1

C11440-42U/C11440-42U01 Before Use (Booklet) 1

C11440-42U/C11440-42U01 Instruction manual (CD-ROM) 1

[Option]

SMA-BNC cable A12106-05

Note

Note

SMA-SMA cable A12107-05

USB 3.0 A to Micro B cable A12046-03

USB 3.0 interface board M9982-22

Adjuster pole A11185-01

Base plate A11186-01

• The cable listed in option is highly recommended for use with the camera. The camera

system may not confirm to CE marking regulation if other type of cable is used with.

• If you use the adjuster pole and the base plate, see each installation manual.

4

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

3. INSTALLATION

Avoid using or storing this camera in the following places

• When the ambient temperature for using this system might fall below 0 °C or rise

above + 40 °C

• When the ambient temperature for storing this system might fall below - 10 °C or

rise above + 50 °C

• Where the temperature varies extremely

• In direct sunlight or near a heater

• Where the humidity is 70 % or more or where there is dripping water

• Close to a strong source of magnetism or ratio waves

• Where there is vibration

• Where it might come into contact with corrosive gases (such as chlorine or

fluorine)

• Where there is a lot of dust

How to place the camera (when the camera is placed on a table)

Do not place the camera the rear panel of the camera, which connectors

are located, to be at the bottom. (Do not block ventilation openings.)

Do not block ventilation openings

To prevent overheating in the camera’s interior, do not wrap the camera

in cloth or other material, or in any way allow the camera’s ventilation

ports to become blocked. If the camera is being operated in an enclosed

environment, ensure clearance of at least 2 cm from both the intake and

exhaust vents when setting up.

5

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

CCoonntteennttss

1. SAFETY PRECAUTIONS............................................................................ 1

1-1 INDICATION OF THE SYMBOLS ....................................................................... 1

1-2 CLASSIFICATION OF WARNING ...................................................................... 1

2. CHECK THE CONTENTS OF PACKAGE................................................... 4

3. INSTALLATION........................................................................................... 5

4. OVERVIEW.................................................................................................. 8

5. FEATURES.................................................................................................. 8

6. NAME AND FUNCTION OF THE PARTS ................................................. 10

7. CONNECTION........................................................................................... 13

7-1 CONNECTING OF CABLES ............................................................................. 13

8. OPERATION.............................................................................................. 14

8-1 PRECAUTIONS................................................................................................. 14

8-2 PREPARATION FOR IMAGING........................................................................ 14

8-3 IMAGING ........................................................................................................... 14

8-4 END OF IMAGING............................................................................................. 14

9. DESCRIPTION OF VARIOUS FUNCTIONS ............................................. 15

9-1 THEORY OF CMOS IMAGE SENSOR .............................................................15

9-2 READOUT METHOD (SCAN MODE) ............................................................... 17

9-3 CAMERA OPERATION MODES....................................................................... 18

9-4 FRAME RATE CALCULATION......................................................................... 19

9-5 CONFIGURING EXPOSURE TIME................................................................... 22

9-6 TIMING CHART OF CAMERA OPERATION MODES...................................... 23

9-6-1 FREE RUNNING MODE......................................................................................... 23

9-6-2 EXTERNAL TRIGGER MODE................................................................................ 25

9-6-3 TRIGGER OUTPUT................................................................................................ 30

9-6-4 GLOBAL RESET..................................................................................................... 33

9-7 REAL-TIME CORRECTION FUNCTIONS ........................................................ 34

10. PRECAUTION WHEN USING FL-400....................................................... 35

11. MAINTENANCE ........................................................................................ 36

11-1 CARE................................................................................................................. 36

12. TROUBLESHOOTING CHECKLIST ......................................................... 37

12-1 IMAGE IS NOT TRANSFERRED ...................................................................... 37

12-2 ALTHOUGH IMAGES ARE TRANSFFERED ................................................... 37

13. SPECIFICATIONS..................................................................................... 38

13-1 CAMERA SPECIFICATIONS ............................................................................ 38

13-2 SPECTRAL RESPONSE CHARACTERISTICS ............................................... 40

14. DIMENSIONAL OUTLINES....................................................................... 41

14-1 C11440-42U for C-mount ................................................................................. 41

6

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

14-2 C11440-42U01 for F-mount ............................................................................. 42

15. WARRANTY .............................................................................................. 43

REPAIRS ............................................................................................................................. 43

16. CONTACT INFORMATION ....................................................................... 44

7

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

4. OVERVIEW

C11440-42U/C11440-42U01 is equipped with the new scientific image sensor “FL-400”, an

advanced CMOS device that realizes the multiple benefits of high resolution, high readout speed,

and low noise all at once.

The camera provides 4.0 megapixels resolution at 30 frame/s (and up to 25 000 frame/s by

sub-array readout) while achieving 0.9 electrons (median) 1.5 electrons (r.m.s) readout noise

performance. Moreover, the camera delivers high sensitivity through its on-chip micro lens, 33

000:1 high dynamic range that make the camera suitable for almost any scientific application

from bright field imaging to low-light fluorescence imaging across a wide spectral range. Various

external trigger functions and timing output functions ensure proper timing control with peripheral

equipment to cover a wide range of applications.

The camera is the new scientific digital camera for life science microscopy, semiconductor

inspection, x-ray scintillator readout or industrial imaging.

5. FEATURES

(1) Readout noise

In the camera, the pixel amplifier is optimized: it has high gain from optimizing the

semiconductor process, and the difference among pixel amplifiers are greatly

minimized. In addition, there is on-chip CDS (correlated double sampling) circuit, which

plays an important role in achieving low noise. Moreover, the sensor features a split

readout scheme in which the top and bottom halves of the sensor are readout

independently, and the data of each horizontal line is read by 2 lines of column

amplifier and A/D in the top and the bottom in parallel and simultaneously. As a result, it

achieves very fast readout speed while keeping very good low-noise performance.

The camera has lower readout noise (0.9 electrons (median), 1.5 electrons (r.m.s))

than the conventional cooled CCD camera. Moreover, high-speed readout (30 frame/s

with 2048 pixels × 2048 pixels) with very low readout noise, which was impossible, can

now be achieved.

(2) Cooling structure

In the camera, the FL-400 is cooled down by the peltier element to suppress the dark

current. The camera has a special chamber structure to avoid the condensation.

(3) Pixel number and pixel size

The FL-400 sensor has 6.5 µm x 6.5 µm pixel sizes that is equivalent to conventional

CCD image sensor (2/3 inch, 1.3 megapixels). Also, the camera can observe a wider

field of view because the pixel number is about 3 times that of the conventional CCD

image sensor (2/3 inch, 1.3 megapixels)

(4) Readout method

The camera has a variety of readout modes. In addition to full resolution readout mode,

sub-array readout and binning readout are supported.

8

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

(5) Frame rate

The FL-400 realizes both low noise (0.9 electrons (median) 1.5 electrons (r.m.s)) and

high speed readout (30 frame/s with 2048 pixels x 2048 pixels) simultaneously, by a

split readout scheme in which the top and the bottom halves of the sensor are readout

independently, and the data of each horizontal line is read by 2 lines of column

amplifier and A/D in the top and the bottom in parallel and simultaneously.

(6) Real-time correction functions

When using the camera, there is a case that shading caused by uneven illumination or

optics is not negligible in the image. Also, there are a few pixels in FL-400 that have

slightly higher readout noise performance compared to surrounding pixels. For those

cases, the camera has real-time offset level, shading and defective pixel correction

features to further improve image quality. The correction is performed in real-time

without sacrificing the readout speed at all.

(7) Interface

This camera has USB 3.0 interface.

USB 3.0 interface is able to transfer 4 megapixels image with 30 frame/s. It is versatile

interface. It transfers image with moderate transfer speed.

(8) Camera operation modes

The camera has three operation modes: 1) the free running mode, in which the

exposure and readout timing are controlled by the internal microprocessor, and 2) the

external trigger mode, in which the exposure and readout timing are decided by an

external trigger. 3) the start trigger mode is used to start operating the camera by a

trigger input for a continuous imaging.

9

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

6. NAME AND FUNCTION OF THE PARTS

(1) C11440-42U for C-mount

① ② ③ ④

⑧ ⑨

⑤ ⑥ ⑦

(2) C11440-42U01 for F-mount

① ② ③ ④

⑧ ⑨

⑤ ⑥ ⑦

10

CAUT ION

• Do not place the rear panel of the camera, which connectors are

located, to be at the bottom (Do not block ventilation openings.).

① Lens mount

C11440-42U can be attached to C-mount lens or an optics system.

C11440-42U01 can be attached to F-mount lens or an optics system.

Note

• The depth of the C-mount is 7 mm. Screwing in the mount too far

can scratch the glass surface.

② USB 3.0 interface connector [USB 3.0]

This is connected to the USB 3.0 interface connector on the computer.

③ Trigger input connector [EXT.TRIG]

This is used when the camera is being operated using external synchronization.

Input is 3.3 V LVCMOS level, and input impedance is 10 kΩ.

When an external trigger is input, the trigger is activated at the falling or rising edge of the

signal. (You can choose external trigger polarity between Negative and Positive.)

④ Timing out connector 1,2,3 [TIMING 1,2,3]

This is used when peripheral device(s) require synchronization with the camera.

Output is 3.3 V LVCMOS level, and it is output though

Output impedance is 33 Ω.

Note

• Determine termination according to cable length and so on.

⑤ DC power input connector [DC IN]

This is the power supply terminal. Use the accessory AC adaptor.

⑥ Power switch [POWER]

The power is turned on/off.

When the power switch is set to "ON", the camera turns on and starts initialization and the lamp

blinks in green.

When the initialization is completed , the lamp color stays in green.

When the camera transfers data and the lamp color is orange.

When the power switch is set to "OFF", the camera returns to the power off state and the lamp

turns off.

⑦ STATUS lamp [STATUS]

The LED indicates status of camera.

Lighting color Status of power distribution

Turn off (no color) Power off

Green (Blinking) Initialization

Green (lighting) Power on

Orange (lighting) Data transfer

Red (lighting) Heat up

CAUT ION

• When the camera heats up, stop operation and unplug the AC

adaptor immediately.

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

BUS TRANSCEIVER IC SN74AVC8T245.

11

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

⑧ Air outlet

This is the outlet for the heat ventilation.

• To prevent overheating inside the camera, do not wrap the camera in cloth or

other material, or block the camera’s ventilation.

• If the camera is being operated in an enclosed environment, ensure to keep

clearance at least 2 cm from both intake and exhaust vents when setting up.

⑨ Installation holes for Base plate

These are the holes to install the base plate.

• If you use the adjuster pole and the base plate, see each installation manual.

12

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

7. CONNECTION

7-1 CONNECTING OF CABLES

Refer to the figure when connecting the various cables.

Camera (Rear)

USB 3.0 Interface board

Computer

① AC adaptor

② USB 3.0 Interface cable

• When you connect cables, turn off the power supply of the camera and the peripheral devices.

• If you use the adjuster pole and the base plate, see each installation manual.

CAUT ION

• Do not place the rear panel of the camera, which connectors are located,

to be at the bottom (Do not block ventilation openings.).

① AC adaptor

This is the cord to supply a power supply. Use the accessory AC adaptor.

② USB 3.0 interface cable (Option)

This is the cable to connect the USB 3.0 interface connector of the camera and the USB 3.0

interface connector on the computer.

Note

• Hamamatsu recommends A12046-03 optional USB 3.0 interface cable for this

camera. The camera complies with EMC direction with using A12467-03 Camera

Link interface cable. Be careful that the camera with other interface cable may not

fulfill the EMC directive requirements.

Figure 7-1

13

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

8. OPERATION

8-1 PRECAUTIONS

Be careful of the following when you operate the camera.

(1) Cooling method

Cooling of this equipment is done using a Peltier element. With a Peltier element, when

current is supplied, one surface is cooled, and the other surface is heated. The FL-400

is positioned on the cooling side, and cooling is done by discharging the heat from the

heated surface. This cooling method is passive air-cooling.

(2) Ambient temperature

The recommended ambient temperature for camera operation is between 20 ºC and

25 °C. Thus, the maximum temperatures to which the FL-400 can be cooled, and the

stability of the cooled temperature, are affected by the ambient temperature. The

ambient temperature should be maintained at a constant temperature in order for

cooling to be effective.

(3) Protection circuit

A double protection circuit protects this camera’s thermoelectric cooling device. If the

heat dissipater becomes abnormally hot, the protection circuit sets off a buzzer alarm

and stopping current supply to Peltier element simultaneously.

When the protection circuit is activated immediately turn off the power switch. Then

investigate cause and remove the cause of the overheating and restart the camera.

8-2 PREPARATION FOR IMAGING

Use the following procedure when starting operating of the camera.

(1) Connect devices as shown in Figure 7-1 before you start operation.

(2) Turn on the computer's power switch.

The cooling temperature becomes stable about 5 minutes after cooling begins.

• When the cables are connected, confirm the power switch of peripheral device is in the OFF position.

8-3 IMAGING

Start the control and imaging with the application software.

Note

• Please refer to the instruction manual attached to the software for the way of using it and the details.

8-4 END OF IMAGING

Carry out the procedure below when imaging is finished.

(1) End the imaging or transmission of image data with the application software.

(2) Turn off the power to the peripheral device.

14

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9. DESCRIPTION OF VARIOUS FUNCTIONS

9-1 THEORY OF CMOS IMAGE SENSOR

The pixel of a CMOS image sensor is composed of the photodiode and the amplifier that

converts the charge into voltage. Entered light is converted to charge and converted to voltage in

the pixel. The voltage of each pixel is output by switching the switch one by one. (Figure 9-1)

The FL-4

double sampling) circuit, which plays an important role in achieving low noise. In addition, the

FL-400 realizes both low noise and high speed readout simultaneously, by a split readout

scheme in which the top and the bottom halves of the sensor are readout independently, and the

data of each horizontal line is read by 2 lines of column amplifier and A/D in the top and the

bottom in parallel and simultaneously.

00 scientific CMOS image sensor used in this camera has an on-chip CDS (correlated

Figure 9-1 Structure of the FL-400

15

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

The exposure and the readout method of FL-400 is rolling shutter.

In the rolling shutter, the exposure and readout are done line by line. Therefore, the exposure

timing is different on one screen. (Figure 9-2)

But even if th

e object moves during the exposure, the affect of rolling shutter is very small.

Figure 9-2 Readout timing of Rolling shutter

16

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-2 READOUT METHOD (SCAN MODE)

The camera has the following scan modes.

(1) Normal readout

Perform charge readout from camera individually for all pixels.

(2) Binning readout

With this camera, 2×2 binning readout and 4×4 binning are available by adding the

signal of adjacent pixels in the digital domain, Binning readout is a method for

achieving high sensitivity in exchange for losing resolution.

(3) Sub-array readout

Sub-array readout is a procedure only a region of interest is scanned. It is possible to

increase the frame rate by reducing the number of vertical lines scanned. When a

target area is placed in the center of the screen, sub-array readout can perform the

fastest readout. In sub-array readout, binning configuration is enabled.

Size and a position of the readout area can be configured according to the table below.

Settings

Binning Size Position Size Position

1×1 (Normal readout) 512 pixels 32 pixels 8 lines 4 lines

Horizontal Vertical

2×2 binning readout 256 pixels 16 pixels 4 lines 2 lines

4×4 binning readout 128 pixels 8 pixels 2 lines 1 lines

(4) Rapid Rolling Mode

This readout mode is preferred to be used when acquiring images of fast moving

samples in order to minimize distortion come from rolling shutter.

Note

• Please refer to 9-4 [FRAME RATE CALCULATION] about the frame rate of each readout

mode. However, Rapid Rolling mode is different from other modes.

17

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-3 CAMERA OPERATION MODES

The camera has the following operation modes.

(1) Free running mode

The camera has the free running mode which the exposure and readout timing can be

set by software command and controlled by an internal microprocessor. The free

running mode has normal readout mode (in which the exposure time is longer than the

1 frame readout time) and electrical shutter mode (in which the exposure time is

shorter than the 1 frame readout time). These readout modes are automatically

switched depending on the exposure time setting.

(2) External trigger mode

The camera has various external trigger functions to synchronize the camera with the

external equipment. In the external trigger mode, the external equipment becomes a

master and the camera becomes a slave.

① Edge trigger mode

The edge trigger mode is used so that the exposure starts according to an external signal.

② Level trigger mode

The level trigger mode is used to control both exposure start timing and exposure time length

by inputting external trigger pulses.

③ Synchronous readout trigger mode

The synchronous readout trigger mode is used for continuous imaging when it is necessary to

control the exposure start timing of each frame from an external source. It is useful for confocal

microscopy.

(3) Start trigger mode

The start trigger mode is to start operating the camera by a trigger input for a

continuous imaging.

Note

• Please refer to 9-6 [TIMING CHART OF CAMERA OPERATION MODES] about the detail of

timing chart of these modes.

18

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-4 FRAME RATE CALCULATION

The calculation formula of frame rate and the value of frame rate are as below.

■ Calculation formula

Vn = Number of vertical line

(The center of the set area is the middle of the sensor.)

Exp1 = 3 ms to 10 s

1H = 32.4812 × 10

Free running mode 1/(Vn/2×1H)

External trigger mode (Edge/Level) 1/(Vn/2×1H+Exp1+1H×9)

External trigger mode (Synchronous readout) 1/(Vn/2×1H+1H×17)

• The Exp1 value has to be input to the calculation formula below in units of seconds.

■ Value of frame rate

Horizontal width

× Vertical width

2048

The calculation formula of frame rate and the value of frame rate for Rapid Rolling Mode are

shown in next page.

2048

1024

512

256

128

64

8

-6

Free running mode

30 27

60 50

120 85

240 133

481 185

962 229

7696 290

External trigger mode

(Edge/Level)

(frame/s)

External trigger mode

(Synchronous readout)

29

58

112

212

380

628

1466

19

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

■ Calculation formula (Rapid Rolling Mode)

Vn = Number of vertical line

(The center of the set area is the middle of the sensor.)

Exp1 = 1 ms to 10 s

Exp2 = 1.05 ms to 10 s

1H = 10 × 10

-6

int () = The decimal point is rounded down.

• The Exp1 and Exp2 values must be input to the calculation formula below in units of

seconds.

Binning

Free running mode

External trigger mode

(Edge trigger)

External trigger mode

(Level trigger)

External trigger mode

(Synchronous readout)

1×1

1×1 512 -

2×2

4×4

1×1 112≦Vn≦2048 1/(Vn/2×1H+Exp1+1H×9)

1×1

1×1 512 -

2×2

4×4

1×1

1×1

1×1 512 -

2×2

4×4

1×1

1×1

1×1 512 -

2×2

4×4

Horizontal

width

1024

1536

2048

- -

1024

1536

2048

- -

1024

1536

2048

1024

1536

2048

- -

1024

1536

2048

64

1024

1536

2048

- -

Vertical

width

- 1/(int(Vn/2048/30/1H)×1H)

8≦Vn≦104

112≦Vn≦2048 1/(int(Vn/2048/30/1H)×1H)

8≦Vn≦104

32 ≦Vn≦2048 1/(int(Vn/2048/30/1H)×1H)

8 ≦Vn≦24

Calculation formula

1/(Vn/2×1H)

1/(Vn/2×1H+1H×9+Exp1)

1/(Vn/2×1H+1H×4+Exp2)

1/(Vn/2×1H+1H×17)

20

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

■ Value of frame rate (Rapid Rolling Mode)

1×1 (Normal readout)

Vertical width

width

Free running mode

External trigger mode

(Edge trigger)

External trigger mode

(Level trigger)

External trigger mode

(Synchronous readout)

Horizontal

2048 30 97 97

1024 60 195 195

512 120 390 390

256 240 781 781

128 480 1562 1562

64 961 3125 3125

8 7692 25 000 25 000

2048 30 88 88

1024 60 160 160

512 120 271 271

256 240 416 416

128 480 568 568

64 694 694 694

8 862 862 862

2048 30 87 87

1024 60 159 159

512 120 270 270

256 240 413 413

128 480 561 561

64 684 684 684

8 847 847 847

2048 30 96 96

1024 60 189 189

512 120 366 366

256 240 689 689

128 480 1234 1234

64 961 2040 2040

8 4761 4761 4761

Note

• The calculation formula and the frame rate value of Start trigger mode (External trigger

mode) are same as the free running mode. About this mode, refer to 9-6-2-4 [Start

trigger mode].

1024 / 1536

/ 2048

(frame/s)

Binning:

2×2 / 4×4

512 ―

21

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-5 CONFIGURING EXPOSURE TIME

The exposure time setting can be done by absolute value. The actual exposure time setting is

defined by the following formula, and the camera automatically calculates a larger and closest

value from the specified exposure time setting.

Exp1 = 3 ms to 10 s (at sub-array 129.99 µs to 10 s)

Exp2 = Exp1 × 10

The actual exposure time setting for Rapid Rolling Mode is defined by the following formula.

• The Exp1 values must be input to the calculation formula below in units of seconds.

32.4812 µs × Exp2

6

÷ 32.4812 µs (round up at decimal point)

10 µs × Exp2

Exp1 = 1 ms to 10 s (at sub-array 40 µs to 10 s)

Exp2 = Exp1 × 10

6

÷ 10 µs (round up at decimal point)

Available setting range of the exposure time is the following.

Free running mode

Free running mode (at Sub-array)

External trigger mode

1 ms to 10 s (Rapid Rolling Mode)

129.99 µs* to 10 s

40 µs* to 10 s (Rapid Rolling Mode)

1 ms to 10 s (Rapid Rolling Mode)

Note

* 129.99 µs and 40 µs (Rapid Rolling Mode) for the Free running mode (at Sub-array) is

the minimum exposure time when sub-array is set to 8 lines vertically symmetric (4 lines

in top half and 4 lines in bottom half) with respect to the horizontally center axis. The

minimum exposure time vary depend on vertical line number of sub-array setting.

3 ms to 10 s

3 ms to 10 s

22

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6 TIMING CHART OF CAMERA OPERATION MODES

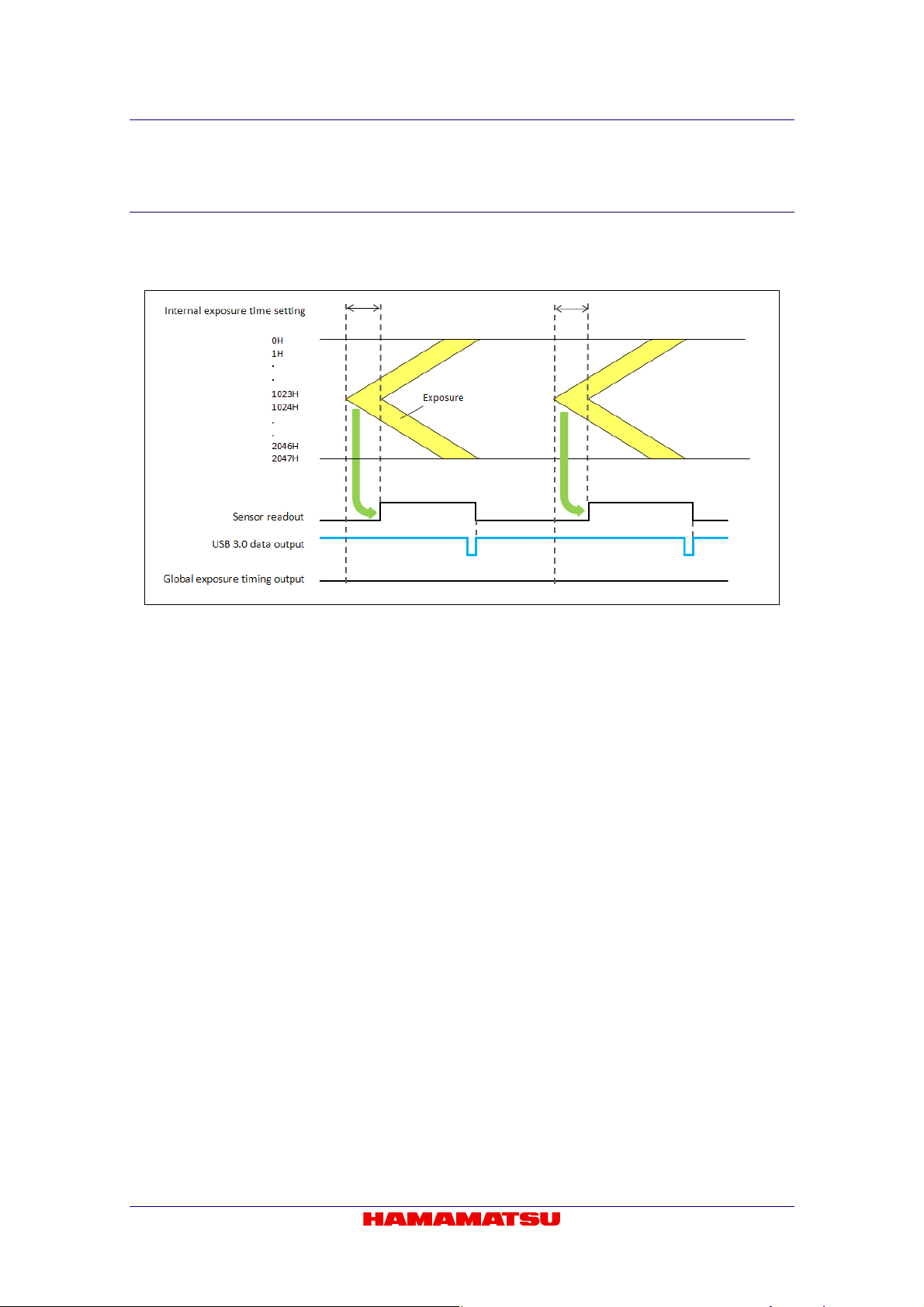

9-6-1 FREE RUNNING MODE

The camera has the free running mode which the exposure and readout timing can be set by

software command and controlled by an internal microprocessor. The free running mode has

normal readout mode (in which the exposure time is longer than the 1 frame readout time) and

electrical shutter mode (in which the exposure time is shorter than the 1 frame readout time).

These readout modes are automatically switched depending on the exposure time setting.

Note

9-6-1-1 Normal readout mode

The normal readout mode is suitable for observation, monitoring, field of view and focus

adjustment, and animation because it can operate with full resolution, which is faster than the

video rate (30 frame/s).

In addition, the exposure time can be extended to collect more signals and increase the

signal-to-noise ratio if the object is dark. In the normal readout mode, the exposure time is the

same or longer than the 1 frame readout time. In this mode, the frame rate depends on the

exposure time, and it becomes frame rate = 1/exposure time. The maximum exposure time is 10

s.

• Please contact to Hamamatsu subsidiary or local distributor for the detail of the timing

information.

Figure 9-3

23

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-1-2 Electrical shutter mode

The electrical shutter mode is used to get a proper signal level when signal overflow happens

due to too much input photons in normal readout mode. In this mode, the fastest frame rate is 30

Hz at full resolution even when the exposure time is short.

Figure 9-4

24

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

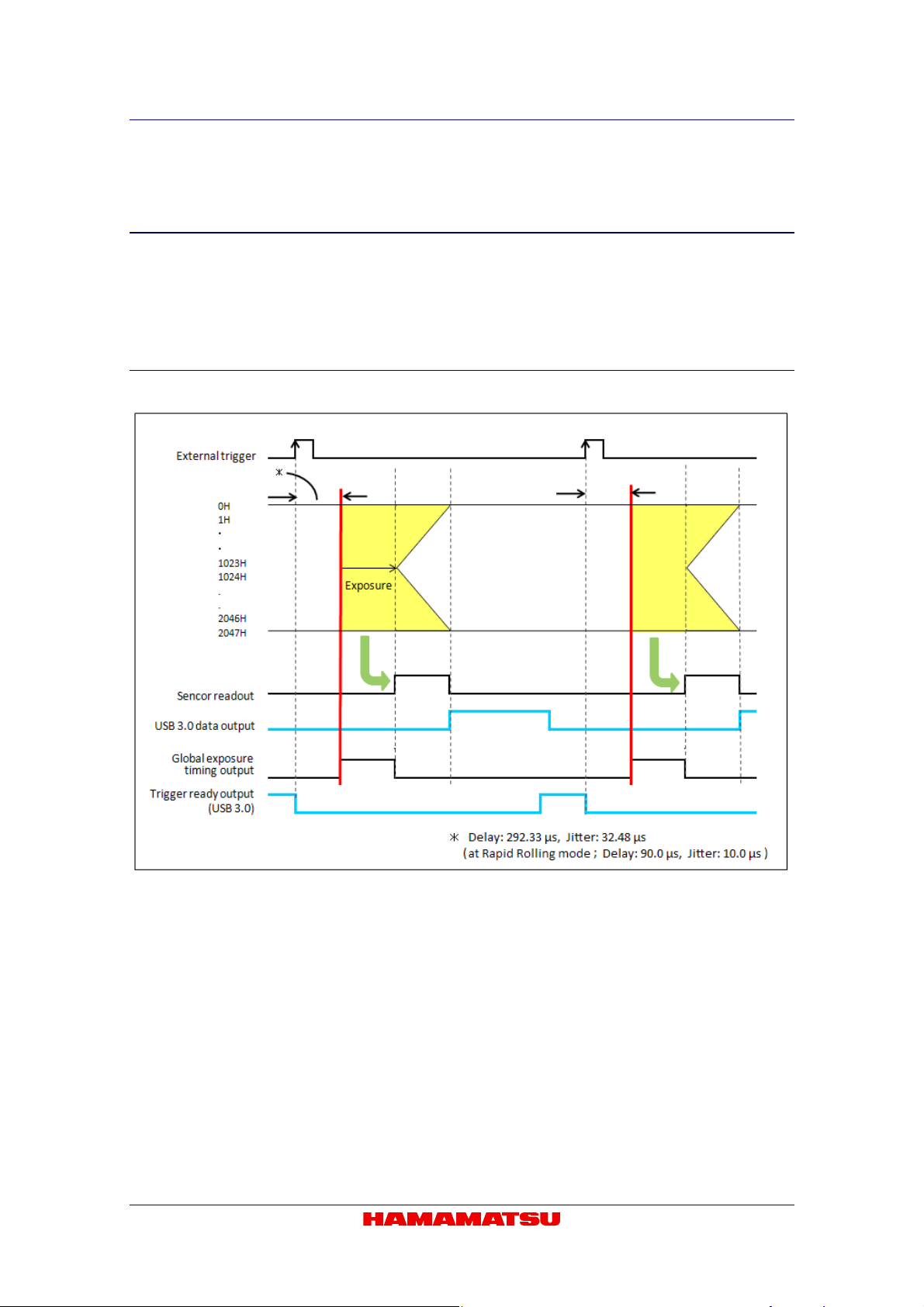

9-6-2 EXTERNAL TRIGGER MODE

The camera has various external trigger functions to synchronize the camera with the external

equipment. In the external trigger mode, the external equipment becomes a master and the

camera becomes a slave.

Not e

9-6-2-1 Edge trigger mode

The edge trigger mode is used so that the exposure starts according to an external signal.

Exposure time is set by software command. In this mode, the exposure of the first line begins on

the edge (rising/falling) timing of the input trigger signal into the camera. (1023H and 1024H in

the following figure) The exposure of the second line is begun after the readout time of one line

passes (1022H and 1025H in the following figure), and the exposure is begun one by one for

each line.

• Please contact to Hamamatsu subsidiary or local distributor for the detail of the timing

information.

Figure 9-5 (Ex. rising edge)

25

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-2-2 Level trigger mode

The level trigger mode is used to control both exposure start timing and exposure time length by

inputting external trigger pulses. In the mode, the camera starts exposure at the start of high or

low period of the input trigger pulse and stops exposure at the end of high or low period of the

input trigger pulse. The example below is for the trigger level High. The exposure of the first line

begins when the trigger signal becomes High, and the exposure of the second line begins after

the readout time of line one passes. Each exposure begins one by one for each line. The

exposure of the first line is finished when the trigger signal becomes low, and signal readout is

begun. The exposure time of each line is defined by the time that the input trigger is high. The

minimum trigger pulse width is 1 ms + 50 µs.

Figure 9-6 (Ex. rising edge)

26

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-2-3 Synchronous readout trigger mode

The synchronous readout trigger mode is used for continuous imaging when it is necessary to

control the exposure start timing of each frame from an external source. It is useful for confocal

microscopy. For example, when the camera is used with a spinning disk confocal microscope

and the camera exposure time is synchronized to the spinning disk's rotation speed, it is possible

to eliminate uneven illumination (called banding noise) caused by variation of the spinning disk

rotation speed. Also, it is useful for securing as long exposure time as possible while controlling

the exposure start timings by external trigger signals.

(1) Normal operation (when the pulse count is set as 1.)

The synchronous readout trigger mode is used for continuous imaging when it is

necessary to control the exposure start timing of each frame from an outside source

and also when it is necessary to secure as long exposure time as possible. In the

synchronous readout trigger mode, the camera ends each exposure, starts the readout

and also, at the same time, starts the next exposure at the edge of the input trigger

signal (rising / falling edge). That is, the interval between the same edges of the input

trigger becomes the exposure time.

Figure 9-7 (Ex. rising edge)

27

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

(2) Pulse count

Also in the synchronous readout trigger mode, synchronous readout can be controlled

by specifying, set by command, the number of timing pulses to determine the exposure

time. The following figure shows the exposure timing when the pulse count is set as 3.

Figure 9-8 (Pulse count)

28

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-2-4 Start trigger mode

The start trigger mode is to start operating the camera by a trigger input for a continuous imaging.

It is useful to secure the frame rate as fast as possible when continuous image acquisition and

not to sacrifice the exposure time. For example, when it is necessary to measure the

phenomenon after stimulation, it is possible to start continuous image acquisition at the

stimulation timing.

The start trigger mode is to start operating the camera by a trigger input for continuous imaging,

and it works at the highest frame rate because it is operated in internal trigger mode. In the start

trigger mode, the camera starts exposure and switches to internal trigger mode by the edge of an

external trigger signal (rising / falling edge).

Figure 9-9 (Ex. rising edge)

9-6-2-5 External trigger delay function

In most cases when a delay is needed between the laser pulse emission and the exposure start

is needed, a delay unit is set between the laser and camera to control trigger timing. In each

external trigger mode of the camera, the delay can be set to the trigger signal input to the camera

by command. With this setting, a range of trigger can be arranged without a delay unit. The

range for delay time is 0 µs to 10 s (10 µs steps).

29

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-3 TRIGGER OUTPUT

The camera provides a range of trigger output signals to synchronize with an external instrument

and the camera becomes the master and the external instrument becomes the slave. There are

three different trigger output functions as follows. Also, it can output continuous High output

(High output fixed) or continuous Low output (Low output fixed).

These three different trigger output functions can be selected by software command, and

they are output from Timing out connector.

Note

9-6-3-1 Global exposure timing output

It shows the global exposure timing where all lines expose at the same time. There is a case that

one event is divided into two frames because the timing of the exposure in each line is different

for the rolling shutter. However, by using the Global exposure timing output the global exposure

becomes possible for the phenomenon that happens for this period. Global exposure timing

output shows the period where all lines expose at the same time.

Note

• Please refer to Figure 9-3 to Figure 9-9 about details of each trigger output functions.

• There is no output signal when the exposure time is less than the frame rate.

30

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-3-2 Programmable timing output

By using the programmable timing output, synchronizing external devices is simple. A system

that needs simple timing signal does not require a delay unit or pulse generator. It is possible to

program and output a pulse that has an optional pulse width and an optional delay time to the

end of readout timing or Vsync. The setting range for delay time is 0 µs to 10 s, and the setting

range for pulse width is 10 µs to 10 s.

The relation between the parameter which can be set with each reference signal, and an output

signal becomes below.

Reference signal Output signal

Read End

Vsync

Camera outputs a pulse after certain delay, from the end of sensor readout.

Also the pulse width can be set.

Camera outputs a pulse after certain delay, from the beginning of readout. Also

the pulse width can be set.

Figure 9-10

9-6-3-3 Trigger ready output

The trigger ready output is useful to make the frame intervals as short as possible in external

trigger mode. For example, when the camera is working in the edge trigger mode, the next frame

can start after the previous frame exposure is done. Thus, the camera cannot accept a trigger for

the next frame during the exposure period. To reduce useless time to be as short as possible, it

is necessary to know the period when the camera can accept a trigger for the next frame. The

trigger ready output shows the trigger ready period when the camera can accept an external

trigger in the external trigger mode.

31

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-3-4 Multi-channel sync

The camera provides 3 programmable timing outputs from Timing out connector 1, 2 and 3 in a

sequence. For example, these programmable timing outputs are useful to control a light source

and get a color image.

Figure 9-11

32

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-4 GLOBAL RESET

Global reset function enables to reset the electric charge of all pixels at the same time. Then all

pixels can start exposure at the same time.

Global reset can work with Edge trigger mode and Level trigger mode.

9-6-4-1 Edge trigger mode

Figure 9-12

33

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

9-6-4-2 Level trigger mode

Figure 9-13

9-7 REAL-TIME CORRECTION FUNCTIONS

There are a few pixels in FL-400 that have slightly higher readout noise performance compared

to surrounding pixels. The camera has real-time variant pixel correction features to improve

image quality. The correction is performed in real-time without sacrificing the readout speed at all.

This function can be turned ON and OFF. (Default is ON)

34

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

10. PRECAUTION WHEN USING FL-400

This camera uses FL-400 (scientific CMOS image sensor). Careful attention must be paid to the

following points when using FL-400:

(1) White spot

Subjecting FL-400 to extended exposures may cause failure in part of the silicon wafer,

resulting in white spots. Currently this phenomenon is not currently preventable. If

FL-400 is at a fixed temperature, recurrence of the white spot increases proportionally

with the exposure time, so this can be rectified with dark subtraction*. Cosmic ray may

generate white spot.

* After acquiring an image using a certain exposure time is loaded, the FL-400 is exposed to darkness for the same

amount of time, and another image is obtained. After this, the difference between the images is determined, and the

data for the dark portion of the original image is nullified.

(2) Folding distortion

A rough-edged flicker may be visible when imaging striped patterns, lines, and similar

subject matter.

(3) Over light

CAUT ION

• Be careful not to input too strong light such as high-energy laser

into FL-400 because FL-400 may be damaged by over light.

35

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

11. MAINTENANCE

11-1 CARE

Perform cleaning of the camera with the dry soft cloth.

Then, the glass window on the image sensor should be cleaned according to the following.

(1) Blow the dust from the glass window with an air duster.

(2) Moisten a lens cleaning paper with a little ethanol, and wipe over center area of the

window, gently.

(3) Confirm whether dust is not left.

Attach the camera to an optics, and check if there is dust or not under the uniform light

condition. If there is dust on the image, please clean the glass window again.

• Do not wipe with a damp cloth or unclean cloth.

• Use Lens Cleaning Paper for cleaning of glass window in front of the image sensor.

• Please use a plastic tweezers and take extra care not to scratch the glass window with the

tweezers. Even with plastic tweezers, there is possibility to make scratch on the glass

window in case tweezers touch it.

• Please avoid touching the surrounding parts of image area when wiping the glass window.

36

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

12. TROUBLESHOOTING CHECKLIST

If an abnormality occurs, look up the possible causes in the following tables and, if necessary,

report the details to Hamamatsu subsidiary or local distributor.

12-1 IMAGE IS NOT TRANSFERRED

Cause Measures Chapter

AC adaptor or other cable is loose Reconnect the cable 7

AC adaptor or other cable is broken Replace the cable 7

The correct command has not been sent

to the camera

12-2 ALTHOUGH IMAGES ARE TRANSFFERED

(1) Scratches or discoloration visible on the screen

Cause Measures Chapter

Lens is dirty Wipe the lens 11

Recheck command

(2) Image is blurred

Cause Measures Chapter

Lens is not focused Contact Hamamatsu subsidiary or local distributor 16

Condensation appear Confirm the operating environmental conditions 13

(3) Only shadowed images are output

Cause Measures Chapter

Lens mount cap has been left on Remove the cap

Amount of light is too much or too low Reduce amount of light

(4) All screens overflow

Cause Measures Chapter

Too much amount of light Reduce amount of light

Contrast enhancement is too high Reduce gain

(5) Noise appears on the screen

Cause Measures Chapter

Exogenous noise Find and remove cause

Poor connection of internal connector

Defective circuit system

Contact Hamamatsu subsidiary or

local distributor

16

37

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

13. SPECIFICATIONS

13-1 CAMERA SPECIFICATIONS

(1) Electric specifications

Imaging device Scientific CMOS image sensor FL-400

Effective number of pixels 2048 (H) × 2048 (V)

Cell size 6.5 µm (H) × 6.5 µm (V)

Effective area 13.312 mm (H) × 13.312 mm (V)

Full well capacity (typ.) 30 000 electrons

Readout speed

Readout noise (r.m.s)

Dynamic range *1 33 000 : 1

Cooling method Peltier device + Forced air-cooled

Cooling temperature + 10 °C (Ambient temperature: + 10 °C to + 30 ºC)

Frame rate

Readout mode

Dark current 0.6 electron/pixel/s (at Cooling temperature: + 10 °C)

Exposure time

A/D bit 16 bit

Linearity Less than 3 %

Conversion factor 0.46 electrons/count (typ.)

Dark offset 100 counts (at Normal readout)

External trigger Function

External signal input External input (SMA connector)

External trigger input level 3.3 V LVCMOS level

External trigger output level 3.3 V LVCMOS level

33 ms

10 ms (Rapid Rolling Mode)

1.5 electrons (typ.)

1.9 electrons (typ.) (Rapid Rolling Mode)

at Full resolution 30 frame/s

at 1024 lines

at center position

at 8 lines

at center position

at Horizontal 512 pixels at

8 lines at center position

Normal readout mode 1×1

Binning readout mode 2×2,4×4 (Digital binning) *2

Sub-array readout mode

Free running mode

Free running mode

/ Sub-array mode

External trigger mode

Edge trigger / Global reset edge trigger

Level trigger / Global reset level trigger

Synchronous readout trigger

Start trigger

60 frame/s

7696 frame/s

25 000 frame/s

(Rapid Rolling Mode)

Configurable for each vertical 8

pixels and horizontal 512 pixels.

3 ms to 10 s

1 ms to 10 s (Rapid Rolling Mode)

129.99 µs to 10 s

40 µs to 10 s (Rapid Rolling Mode)

3 ms to 10 s

1 ms to 10 s (Rapid Rolling Mode)

38

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

External trigger delay

function

External signal output

Image processing function

Interface USB 3.0 Super Speed

Lens mount

* 1 Calculated from the ratio of the full well capacity and the readout noise.

* 2 Digital binning processing in the camera.

0 µs to 10 s (10 µs steps)

Global exposure timing output

Trigger ready output

Programmable timing output 1

Programmable timing output 2

Programmable timing output 3

(Continuous High or Low output)

Multi-channel Sync

Real-time offset correction

Real-time gain correction

Real-time defect pixel correction (Default)

C11440-42U: C-mount

C11440-42U01: F-mount

(2) Power supply specifications

Camera

AC adaptor

Note

Input power supply DC12 V

Power consumption 26 W

Input power supply AC100 V to AC240 V 50 Hz/60 Hz

Typical output DC12 V

Power consumption 75 VA

• Fluctuations of input power supply voltages are not to exceed ± 10 % of the nominal

voltage.

(3) Operating environment

Ambient operating temperature 0 ºC to + 40 ºC

Ambient storage temperature -10 ºC to + 50 ºC

Ambient operating humidity Less than 70 %, no condensation

Ambient storage humidity Less than 90 %, no condensation

Operating space Indoor, altitude up to 2000 m

(4) Dimensional outline and weight

Dimensional outline 85 mm (W) × 85.5 mm (H) × 120.5 mm (D)

Weight

Note

• Please see Chapter 14 [DIMENSIONAL OUTLINES] for detail of dimensions.

Camera Approx. 1.1 kg

AC adaptor + power supply cord Approx. 1.0 kg

(5) Applicable standards

EMC EN61326-1: 2006 Class A

39

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

13-2 SPECTRAL RESPONSE CHARACTERISTICS

80.0

70.0

60.0

50.0

40.0

Q.E. [%]

30.0

20.0

10.0

0.0

400 500 600 700 800 900 1000

Wavelength [nm]

Figure 13-1

40

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

14. DIMENSIONAL OUTLINES

14-1 C11440-42U for C-mount

(Unit: mm)

41

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

14-2 C11440-42U01 for F-mount

(Unit: mm)

42

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

15. WARRANTY

Hamamatsu Photonics have fully inspected this system and checked that its performance

conforms to specifications. In the unlikely event of breakdown or other malfunction, contact

Hamamatsu subsidiary or local distributor.

(1) Unless otherwise stated by Hamamatsu subsidiary or local distributor, this system is

under warranty for 24 months from the delivery date.

- Degradation with cosmic rays, the radiation (X-rays, gamma rays, UV light, etc.) of FL-400 is

excepted.

(2) The warranty only covers defects in the materials and manufacturing of the system.

You may be liable for repairs during the warranty period in the event of a natural disaster

or if you handle the system contrary to the instructions in this manual, use it without due

caution, or try to modify it.

(3) We will repair the system or replace it, subject to availability, free of charge within the

terms of the warranty.

REPAIRS

(1) If you notice anything wrong with the camera, confirm whether or not it is malfunctioning by

referring to the troubleshooting checklist in this instruction manual. You must first clarify

the symptoms in order to avoid any misunderstanding or error.

(2) If you have any trouble or are unclear about anything, contact Hamamatsu subsidiary or

local distributor giving the product name, serial number and details of the problem. If

Hamamatsu Photonics consider the problem to be a malfunction, we will decide whether

dispatch an engineer or have the camera returned to us for repairs.

43

C11440-42U/C11440-42U01 Instruction manual_Ver.1.1

16. CONTACT INFORMATION

HAMAMATSU PHOTONICS K. K., Systems Division

812 Joko-cho, Higashi-ku, Hamamatsu City, 431-3196, Japan

Telephone (81) 53-431-0124, Fax: (81) 53-435-1574

E-mail: export@sys.hpk.co.jp

U.S.A. and Canada

Hamamatsu Corporation

360 Foothill Road, Bridgewater, N.J. 08807-0910, U.S.A.

Telephone: (1) 908-231-0960, Fax: (1) 908-231-0852

E-mail: usa@hamamatsu.com

Germany

Hamamatsu Photonics Deutschland GmbH

Arzbergerstr. 10, D-82211 Herrsching am Ammersee, Germany

Telephone: (49) 8152-375-0, Fax: (49) 8152-265-8

E-mail: info@hamamatsu.de

France

Hamamatsu Photonics France S.A.R.L.

19, Rue du Saule Trapu, Parc du Moulin de Massy, 91882 Massy Cedex, France

Telephone: (33) 1 69 53 71 00, Fax: (33) 1 69 53 71 10

E-mal: infos@hamamatsu.fr

United Kingdom

Hamamatsu Photonics UK Limited

2 Howard Court, 10 Tewin Road, Welwyn Garden City Hertfordshire AL7 1BW, United Kingdom

Telephone: (44) 1707-294888, Fax: (44) 1707-325777

E-mail: info@hamamatsu.co.uk

North Europe

Hamamatsu Photonics Norden AB

Smidesvagän 12, SE-171 41 Solna, Sweden

Telephone: (46) 8-509-031-00, Fax: (46)8-509-031-01

E-mail: info@hamamatsu.se

Italy

Hamamatsu Photonics Italia S.R.L.

Strada della Moia, 1/E 20020 Arese (Milano), Italy

Telephone: (39) 02-935 81 733, Fax: (39) 02-935 81 741

E-mail: info@hamamatsu.it

China

Hamamatsu Photonics (China) Co., Ltd.

1201 Tower B, Jiaming Center, 27 Dongsanhuan Beilu, Chaoyang District, Beijing 100020, China

Telephone: (86)10-6586-6006, Fax: (86)10-6586-2866

E-mail: hpc@hamamatsu.com.cn

The contents of this manual are subject to change without notice.

The unauthorized reproduction or distribution of parts or all of this manual is prohibited.

If one of the following problems occurs, please contact Hamamatsu Photonics.

(See the CONTACT INFORMATION.) We will deal with the problem immediately.

Some contents of the manual are dubious, incorrect or missing.

Some pages of the manual are missing or in the wrong order.

The manual is missing or dirty.

44

Loading...

Loading...