Universal Streak Camera C5680 Series

Measurements Ranging From X-Ray to Near Infrared With a Temporal Resolution of 2 ps

The streak camera is an ultra high-speed

detector which captures light emission

phenomena occurring in extremely short

time periods. Not only can the streak camera

measure intensity variations with superb

temporal resolution, but it can also be used

for simultaneous measurement of the spatial

(or spectral) distribution.

The C5680 Streak Camera Series is a

universal streak camera which incorporates

all of the specialized technology and

expertise HAMAMATSU has acquired in over

20 years of research. The streak tubes are

manufactured on a regular production

schedule at Hamamatsu to provide

consistency and reliability. Special requests

and custom designs are also available.

APPLICATIONS

•

Measurement of electron bunch for

synchrotron and LINAC applications

•

Research involving X-ray lasers, free

electron lasers, and various other types

of pulsed lasers

•

Plasma light emission, radiation, laser

ablasion, combustion and explosions

•

Fluorescence lifetime measurement,

transient absorption measurement,

time-resolved raman spectroscopy

•

Optical soliton communications, response

measurement with quantum devices

•

Lidar Thomson scattering, laser distance

measurement

FEATURES

•

Temporal resolution of within 2 ps

A temporal resolution of 2 ps is achieved for both synchroscan

and single shot.

Several plug-in module, operating mode.

•

Accommodates a diverse range of experimental setups

•

from single light emitting phenomena to high-speed

repeated phenomena in the GHz.

•

Can be used in X-ray to near infrared fields

By selecting the appropriate streak tube (light sensor), the

C5680 can be used in a wide range of measurement applications, from X-rays to near infrared light.

Simultaneous measurement of light intensity on

•

temporal and spatial (wavelength) axes

Spectrograph can be placed in front of the streak camera, to

convert the spatial axis to a wavelength axis. This enables

changes in the light intensity to be measured over various

wavelength (time-resolved spectroscopy).

•

Ultra-high sensitivity (detection of single photons)

The streak tube converts light into electrons which are then

multiplied by an electron multiplier. This enables detection of

extremely faint light (at the single-photon level).

(See photon counting integration principle)

IEEE-488 (GP-IB) control

•

Computer control enables remote control and advanced

measurements to be performed out using very simple operation.

•

Diverse selection of peripheral equipment

A full lineup of peripheral devices is available, including

spectroscopes, optical trigger heads, and expansion units.

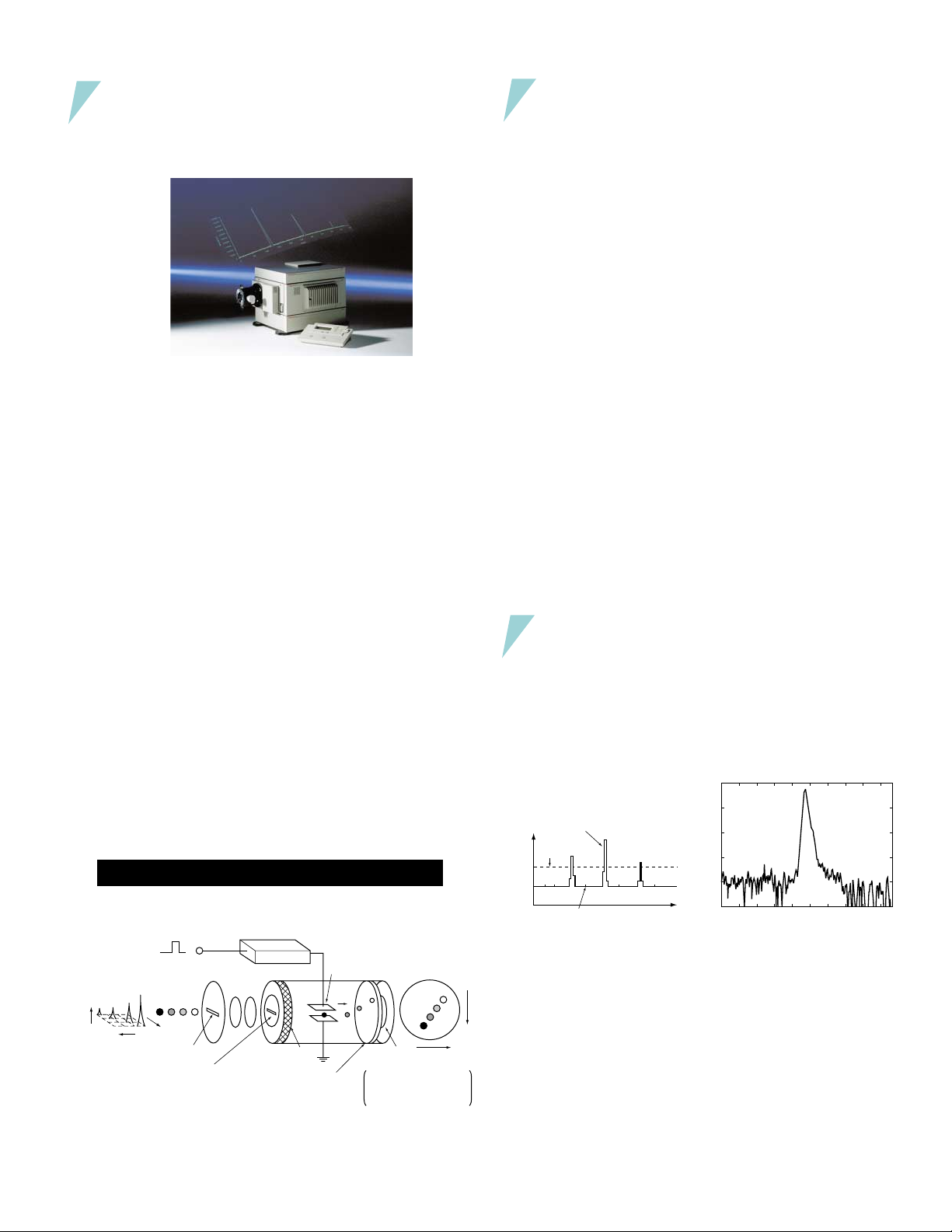

The operating principle of the streak camera

Sweep electrode

(where electrons

are swept in the

direction from top

to bottom)

MCP

(which multiplies

electrons)

Phosphor screen

(electrons → light)

The intensity of the incident light

can be read from the brightness

of the phosphor screen, and the

time and space from the position

of the phosphor screen.

Optical

intensity

Time

Incident light

Trigger signal

Space

Slit

Photocathode

(light → electrons)

Sweep circuit

Lens

Accelerating electrode

(where electrons

are accelerated)

Streak image

on phosphor screen

Time

Space

OPERATING PRINCIPLE

The light pulse to be measured is projected onto the slit and is

focused by the lens into an optical image on the photocathode

of the streak tube. Changing the temporal and spatial offset

slightly each time, four light pulses, each with a different light

itensity, are introduced through the slit and conducted to the

photocathode.

Here, the photons are converted into a number of electrons

proportional to the intensity of the incident light. The four light

pulses are converted sequentially to electrons which are then

accelerated and conducted towards the photocathode.

As the group of electrons created from the four light pulses

passes between a pair of sweep electrodes, a high voltage is

applied (see above), resulting in a high-speed sweep (the electrons are swept in the direction from top to bottom). The electrons are deflected at different times, and at slightly different

angles in the perpendicular direction, and are then conducted

to the MCP (micro-channel plate).

As the electrons pass the MCP, they are multiplied several

thousands of times and are then bombarded against the phosphorscreen, where they are converted back into light.

The fluorescence image corresponding to the first incident

light pulse is positioned at the top of the phosphor screen, followedby the others, with images proceeding in descending order; inother words, the axis in the perpendicular direction on

the phosphor screen serves as the temporal axis. The brightnesses ofthe various fluorescence images are proportional to

theintensities of the corresponding incident light pulses. The

positions in the horizontal direction on the phosphor screen

correspond to the positions of the incident light in the horizontal direction.

THE PRINCIPLE OF PHOTON COUNTING INTEGRATION

Photoelectrons given off from the photocathode of the streak

tube are multiplied at a high integration rate by the MCP, and

one photoelectron is counted as one intensity point on the

phosphor screen. A threshold value is then used with this photoelectron image to clearly separate out noise.

Separation of Photoelectron

Image and Noise

A/D

conversion

Photoelectron image

value

Threshold

value

Signal output from CCD camera

Noise

Time

(wavelength)

Positions in the photoelectron image which are above the

threshold value are detected and are integrated in the memory,

enabling noise to be eliminated completely. This makes it possible to achieve data measurements with a high dynamic range

and high S/N.

Photon Counting Integration

0ps

200ps400ps 600ps800ps 1ns 1.2ns 1.4ns 1.6ns 1.8ns

Light source: PLP (λ = 800 nm)

Integration time: 1 min.

2

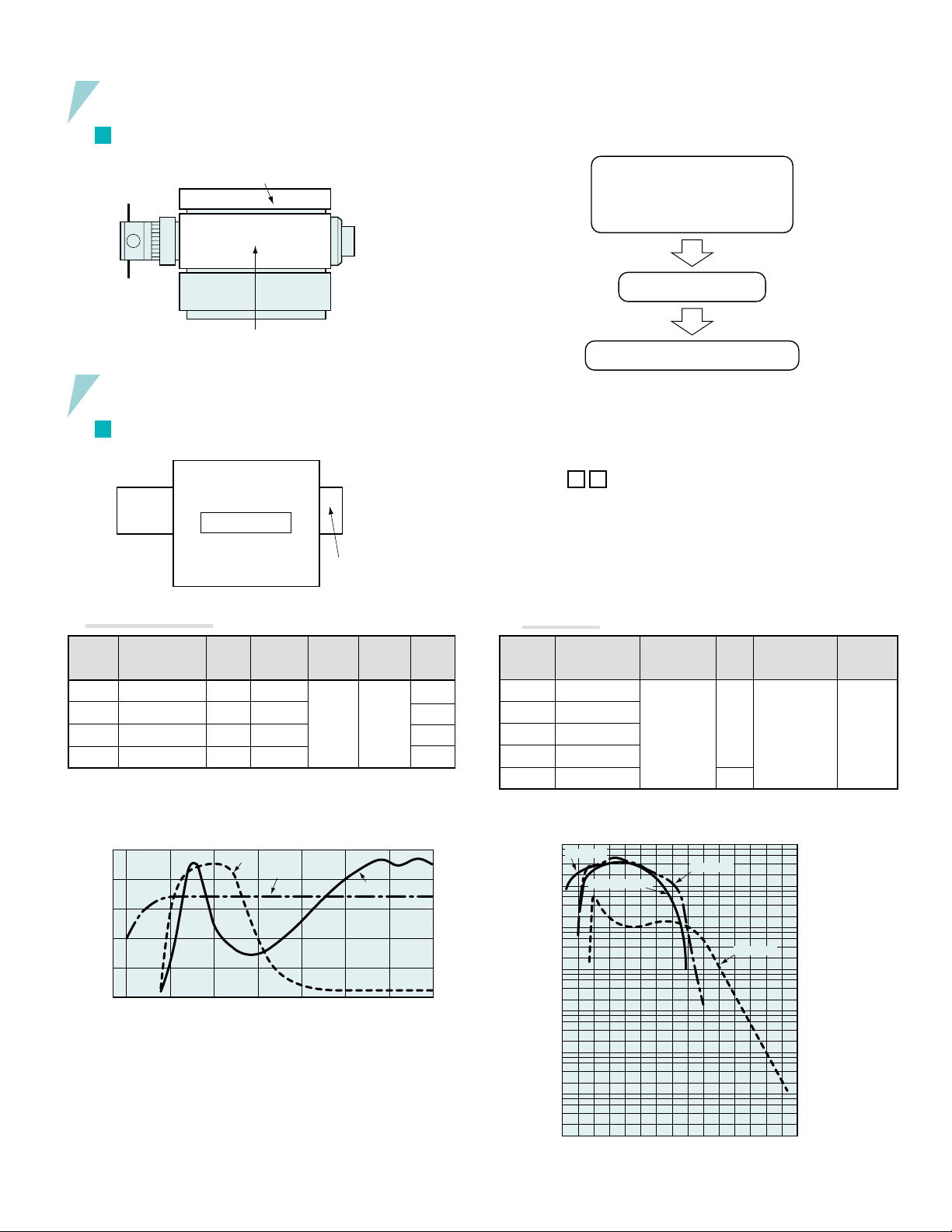

FUNCTION CONFIGURATION

1

C5680 Main Unit (with power supply and camera controller)

Function expansion unit

£

SPECIFICATIONS

1

C5680 Main Unit

1

Input

optics

system

1 Input Optics System

™Sweep unit

2

Streak tube

3

Output

format

Selection of C5680 main unit

Selection of input optics system

Selection of streak tube

Selection of output format

Selection of sweep unit

Selection of function expansion unit

[Suffix (Model No.)]

One of the following suffixes is appended to the model number of

the C5680, depending on the type of streak tube and output format

used.

C5680–

..........

1 Accommodates 200 nm to 850 nm, 1 MCP

2 Accommodates 300 nm to 1600 nm, 1 MCP

. . . .

2 Lens output type

3 Video output type

3 Accommodates 115 nm to 850 nm, 1 MCP

4 Accommodates 200 nm to 900 nm, 1 MCP

5 Accommodates 200 nm to 850 nm, 2 MCPs

2 Streak Tube

Model

Name

A1976-01

A1974

A1974-01

A1976-04

Spectral

Transmission

200 nm to 1600 nm

400 nm to 900 nm

400 nm to 1600 nm

200 nm to 1600 nm

Effective

F Value

Image

Multiplica-

tion Ratio

5.0 1 : 1

1.2 1 : 1

1.2 1 : 1

3.5 1 : 1

The A1974 and A1974-01 are optional units.

100

80

60

40

Transmittance (%)

20

0

Spectral transmittance of input optics system

A1974

A1976-01

200 400 600

800

Wavelength (nm)

1000 1200 1400 1600

Slit

Width

0 to 5 mm

A1974-01

Slit Width

Reading

Precision

5 µ

m

Overall

Length

98.2 mm

159 mm

159 mm

98.2 mm

Model

Name

N5716

N5716-02

N5716-01

N5716-03

N5864

Spectral

Response

Characteristic

200 nm to 850 nm

300 nm to 1600 nm

115 nm to 850 nm

200 nm to 900 nm

200 nm to 850 nm

Effective

Photocathode

Size

• 0.15 × 5.3 mm

Lens output

type

• 0.15 × 4.8 mm

Video output

type

MCP

Gain

3 × 10

6 × 10

3

5

Phosphor

Screen

• Photocathode

characteristic

P-43

• Fiber-optic output

• Effective photo-

cathode size

•

18 mm

Spatial

Resolution

25 lp/mm

or more

centered

on

photocathode

X-ray streak cameras designed for use with 10 eV to 10 keV can

also be selected.

Spectral response of the streak tube

5

10

10

10

10

10

Radiant sensitivity (µA/W)

10

10

N5716-01

4

3

2

1

0

-1

N5716, N5864

N5716-03

N5716-02

-2

10

200 400 600

800 1000 1200 1400 1600

Wavelength (nm)

3

Loading...

Loading...