Page 1

S3 and S4 Hall Effect Sensor

Installation and Setup Procedure

Page 2

E.2.3 Hall Effect Sensors

The Haltech hall effect sensor is a two channel device that can be used to trigger the

Haltech range of ECU’s in a wide range of applications.

The most common application is in a direct fire configuration where a synchronisation

event is required. As the Haltech hall effect sensor is dual channel, it can provide this

synchronisation pulse as well as the trigger signal.

The principle behind its operation is quite simple. As a magnet passes the sensor the

output state changes fro m high to low. The orientation of the magnets determines the

output signals from the sensor.

There are two types of hall effect sensors available from Haltech

The S3 Hall Effect Sensor

The S3 sensor which is identified by a black cable gland, operates i n the following

way:

As a south pole passes the sensor face the signal in both the primary (PIN C) and

secondary (PIN D) channels are switched to a low state. As a north pole passes the

sensor a low state will only occur on the primary channel.

Note: magnets should always be mounted in a non ferrous material

such as aluminium, stainless steel or titanium.

Many installers have successfully mounted the rare earth magnets in non -ferrous

surrounds such as modified aluminium and stainless steel bolts, and ins talled the bolts

into ferrous material.

With these characteristics a direct fire can be set up in the following way:

Using the sensor on the crank

After a suitable mounting location for the sensor has been found the engine should be

positioned at approx imately 75° BTDC on cylinder no.1 compression. The magnet

should now be placed in the aluminium disk with the south pole facing towards the

sensor, making sure the magnet is in line with the sensor when the engine is in this

position. This is now the refer ence point for all the other magnets. The number of

cylinders will determine the number of magnets required and the angle of installation.

The remainder of the magnets to be fitted will all have a north pole facing the sensor.

The adjustment of the air ga p will be determined by the strength of the magnets used.

This should be tested once the wheel assembly has been installed. Checking the

Engine Data page for steady RPM is usually a good indication that the airgap is

acceptable.

Page 3

Identifying the magnets poles

If you need to identify the magnet poles this can be done easily with the use of a

multimeter. By powering up the sensor, using 12 volts (PIN B) and ground (PIN A)

the secondary trigger channel (PIN D) can be checked to identify a south pole.

Connecting the multimeter between PIN D and ground, 12 volts should be present.

When a South pole is placed in front of the sensor this value will go to 0 volts.

Fitting the magnets

We insist that only Haltech rare earth magnets (part number REM1) be used for the

purpose of triggering the sensor. Rare earth magnets purchased from your local

electronics store may be less expensive but they are not good enough! Haltech rare

earth magnets are strong with good stability to reasonably high temperatures and

which have a long service life. Some rare earth magnets are stronger but break down

under excessive temperature, or are too brittle for the purpose, or do not have a long

service life. Ordinary magnets ie not rare earth types, may not have the strength

required for satisfactory triggering at high speeds.

Haltech REM1 rare earth magnets are normally 5mm dia x 2mm depth, although other

sizes are available upon special order.

The magnets should be fitted in non -ferrous surrounds such as aluminium, stainless

steel or titanium. The trigger wheel is normally made of the chosen material but

various users have reported good results when the magnets are set in a suitable non ferrous surround and the surround is set into a ferrous material.

The magnets should be set flush w ith or slightly back from the surface of the trigger

wheel or surround. If set too far back the magnetic signal may be too weak. The

magnets should be set in place with a strong and durable fixing compound such as

high strength epoxy, Loctite stud locking compound eg 603, or JBweld. Some users

rely only on the fixing compound but to ensure that the magnets remain in place but

many prefer that they be retained by mechanical means such as peening, and this

gives an added safety factor.

WARNING:

RARE EARTH MAGNETS ARE EASILY DAM AGED AND THE

PEENING PROCESS (OR LOCATION BY GRUB SCR EWS

ETC) SHOULD BE VERY CAREFULLY CARRIED OUT SO AS

NOT TO DAMAGE THE MA

WILL NOT HAVE SUFFIC IENT MAGNETIC STRENG

MAY FAIL MAGNETICALL Y OR PHYSICALLY AFTER A

PERIOD OF TIME.

If installed correctly the magnets will have a long life.

GNETS. IF DAMAGED THEY

TH OR

Page 4

Note: In the following examples, for ease of reference, the magnets are

shown mounted on the circumference of a wheel with the Haltech Hall

effect sensor oriented to one side. If so mounted the magnets need to

be mounted with sufficient strength to resist centrifugal force. In

practice the magnets are often mounted within the circumference of the

wheel and the sensor is mounted so that its base is pointed towards the

magnets in the face of the wheel.

Typical set -ups - S3

4 cylinder / 2 rotor engine

For a four cylinder 2 magnets are required in total, positioned exactly 180° apart.

Figure 1: Typical 4 cylinder/ 2 rotor application

6 Cylinder / 3 Rotor Engine

For a six cylinder 3 magnets are required in total, positioned exactly 120° apart.

Figure 2: Typical 6 cylinder/ 3 rotor application

Page 5

8 Cylinder

For an eight cylinder 4 magnets are required in total, positioned exactly 90° apart.

Figure 3: Typical 8 cylinder application

The ignition set-up for the S3 needs to be configured in the following way:

Trigger Edge: Rising

Trigger type: Standard

Home Edge: Falling

Page 6

The S4 Hall Effect Sensor

The S4 sensor which is identified by a grey cable gland operates in the following

way:

As a south pole passes the sensor face the signal in the secondary (PIN D) channel is

switched to a low state. As a north pole passes the sensor a low state will only occur

on the primary channel (PIN C).

The set-up for this sensor is similar to the S3 except that one extra magnet is required

as well as the orientation being changed. The north pole of the magnet is used to

generate the main trigger while a south pole is used to generate the home or

synchronisation pulse.

Typical set -ups - S4

4 cylinder / 2 rotor engine

For a four cylinder 3 magnets are required in total. Two north poles positioned exactly

180° apart while a south pole needs to trigger the sensor before the trigger for

cylinder No 1. Th e positioning of the magnet for cylinder one is done the same way

as the for the S3 making sure the north pole is triggering the sensor at approximately

75° BTDC.

FIGURE 4: TYPICAL 4 CYLINDER/ 2 ROTOR APPLICATION

Page 7

6 CYLINDER / 3 ROTOR ENGINE

For a six cylinder 4 magnets are required in total. The three north poles are positioned

exactly 120° apart while a south pole need to trigger the sensor before the trigger for

cylinder No 1.

Figure 5: Typical 6 cylinder/ 3 rotor application

8 Cylinder

For an eight cylinder 5 magnets are required in total positioned exactly 90 ° apart. A

south pole needs to trigger the sensor before the trigger for cylinder No 1.

Figure 6: Typical 8 cylinder application

The ignition set-up for the S4 needs to be configured in the following way:

Trigger Edge: Falling

Trigger type: Standard

Home Edge: Falling or Rising

Page 8

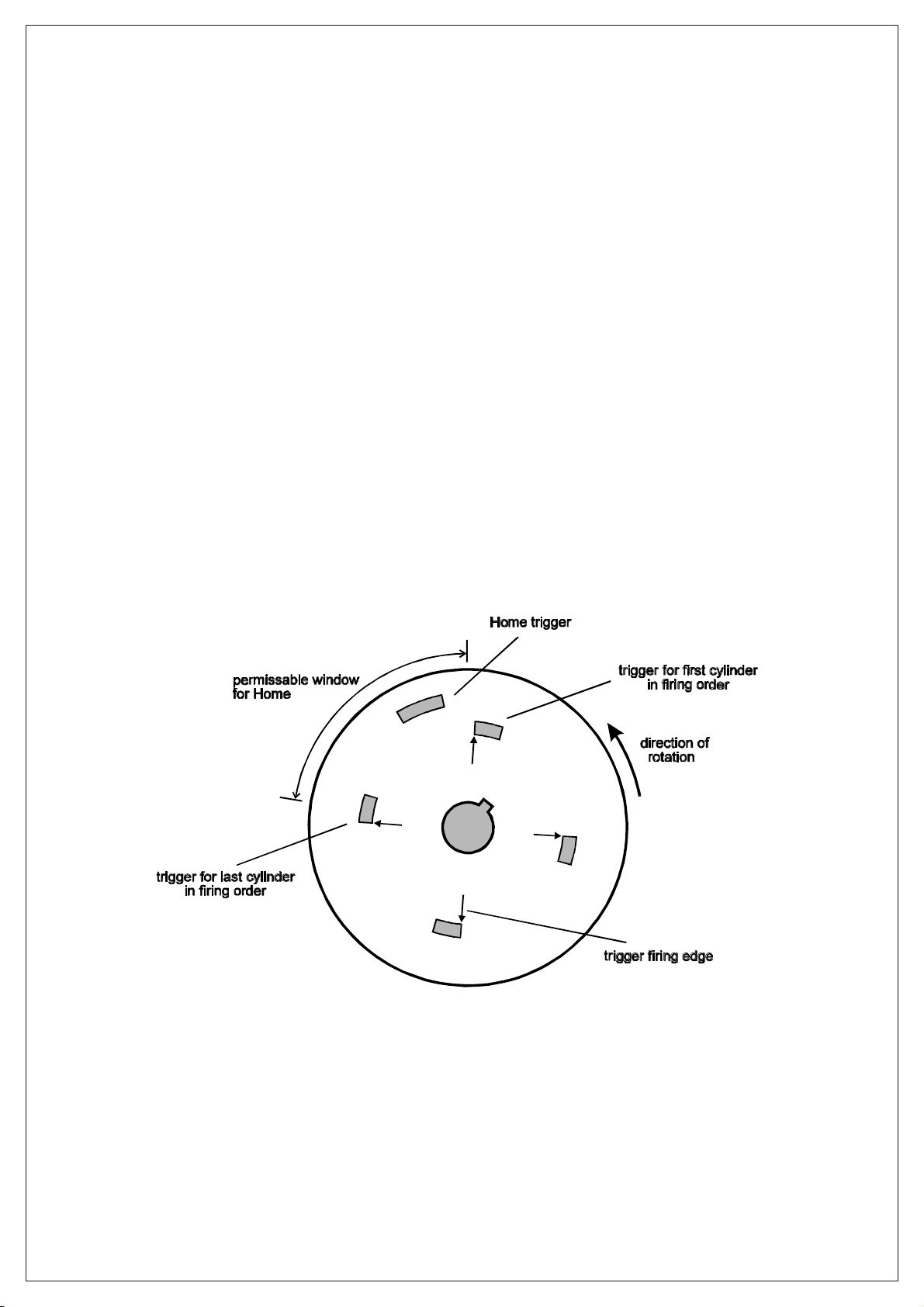

E.3 Synchronisation Events

Synchronisation Events (Sync Events) are required for sequential and direct fire

systems. The Sync Event gives the ECU in indication of the engines position. The

most common form of Sync Event is a Home Trigger. Other Sync Events a re the

missing teeth on multitooth triggers. A Home Trigger is usually a separate trigger

from the main trigger, but some special trigger sensors, such as the Haltech Hall

Effect Sensor, can generate both signals from the one sensor.

For a direct fire sys tem the home trigger tells the ECU that the next trigger is for coil

one (which is usually connected to cylinder one). The ECU then cycles through its

ignition outputs until it expects a Home trigger again. If it receives a Home it will

cycle again. If it does not receive a Home before the next trigger, it will not output a

spark until the Home is received.

Home triggers for the E6K do not need to be accurately timed. All it does is tell the

ECU that the next main trigger is significant. Usually, but not n ecessarily, the

significance is that the next main trigger is for cylinder one. Therefore, the Home

trigger must occur before the main trigger for cylinder one and after the main trigger

preceding the cylinder one trigger. (See Figure 6). The Home trigger should not occur

at the same time as any other trigger. Check that the trigger and Home Edges are set

correctly.

Figure 6. Home Trigger position on a cam angle sensor for 4 cylinder with a home trigger

occurring every cam revolution.

Page 9

PIN

+13.8VDC SWITCHED

1

HOME

2

TRIGGER

3

GROUND

4

CONNECT TO

HALTECH S3 / S4 HALL EFFECT SENSOR

HALTECH S3 / S4 HALL EFFECT SENSOR

4 PIN CONNECTOR

4 PIN CONNECTOR

Looking into connector

1 2 3 4

FEED WIRE THROUGH BOOT,

CRIMP PIN TO WIRE AND THEN INSERT INTO BACK OF PLUG, PUSH UP LOCKING TAB

CRIMP PIN TO WIRE AND THEN INSERT INTO BACK OF PLUG, PUSH UP LOCKING TAB

FEED WIRE THROUGH BOOT,

TRIGGER INPUT:

TRIGGER EDGE:

HALL EFFECT

RISING

HOME INPUT:

HOME EDGE:

HALL EFFECT

FALLING

S3 SENSOR S4 SENSOR

BLACK GLAND

22331144

Looking Into Connector Looking Into Connector

22331144

HALTECH S3 / S4 HALL EFFECT SENSORHALTECH S3 / S4 HALL EFFECT SENSOR

TRIGGER INPUT:

TRIGGER EDGE:

GREY GLAND

HALL EFFECT

RISING / FALLING

S3 / S4 HALL SENSOR TERMINATIONS

HALTECH, SYDNEY AUSTRALIA

DATE: 16TH MARCH 2009

SHEET 1 OF 1REV C

TRIGGER INPUT:

TRIGGER EDGE:

DEF

A B C

LOOKING IN PIN

SIDE OF PLUG

COLOUR

PIN

A

BLUE

B

YELLOW

C

D

E

GREEN

F

RED

HALL EFFECT

RISING

S3 SENSOR S4 SENSOR

BLACK GLAND

CONNECT TO

GROUND

TRIGGER

N/C

N/C

HOME

+13.8VDC INJ

HOME INPUT:

HOME EDGE:

HALL EFFECT

FALLING

D

AFBEC

Looking into Front Of Connector

FEED SEALING RING ONTO WIRE,

CRIMP PIN AND SEAL TO WIRE AND THEN INSERT INTO BACK OF PLUG

CRIMP PIN AND SEAL TO WIRE AND THEN INSERT INTO BACK OF PLUG

FEED SEALING RING ONTO WIRE,

TRIGGER INPUT:

TRIGGER EDGE:

DEF

C

A B

LOOKING IN PIN

SIDE OF PLUG

HALL EFFECT

RISING / FALLING

GREY GLAND

S3 / S4 HALL SENSOR TERMINATIONS

HALTECH, SYDNEY AUSTRALIA

DATE: 31ST OCTOBER 2008

SHEET 1 OF 1REV A

Loading...

Loading...