Page 1

PLATINUM SERIES

Haltech I/O Expander 12

HT059900

QUICK START GUIDE

Page 2

LIMITED WARRANTY

Lockin Pty Ltd trading as Haltech warrants the HaltechTM Programmable Fuel Injection System to be

free from defects in material or workmanship for a period of 12 months from the date of purchase.

Proof of purchase, in the form of a bill of sale or receipted invoice, which indicates that the product is

within the warranty period, must be presented to obtain warranty service. Lockin Pty Ltd trading as

Haltech suggests that the purchaser retain the dealer’s dated bill of sale as evidence of the date of

retail purchase.

If the HaltechTM Programmable Fuel Injection System is found to be defective as mentioned above, it

will be replaced or repaired if returned prepaid along with proof of purchase. This shall constitute the

sole liability of Lockin Pty Ltd trading as Haltech.

To the extent permitted by law, the foregoing is exclusive and in lieu of all other warranties or

representations, either expressed or implied, including any implied warranty of merchantability or

fitness. In no event shall Lockin Pty Ltd trading as Haltech, be liable for special or consequential

damages.

DISCLAIMER

Haltech will not be held responsible for any damage caused by the incorrect installation or tuning of this

product. It is the installers responsibility to ensure the wiring connections and pinouts match that of the

vehicle the unit is being installed into.

Haltech has taken all care to make sure the connections match the specified vehicles listed, but variations

in wiring and connections on vehicles can occur and therefore this should be checked BEFORE the unit

is installed.

Haltech highly recommends installation and tuning of this product is to be carried out by a professional,

with an understanding on installing and tuning engine management systems.

Misuse of this product can destroy your engine.

WARNING

This ECU is designed and sold for Racing use only. Using this product for street / road use may be

prohibited by law. Please check with your local vehicle authority before using this product.

GENERAL INSTALLATION WARNING

Avoid open sparks, flames or operation of electrical devices near flammable substances.

Always disconnect the battery cables when doing electrical work on your vehicle.

Do not charge the battery with a 24 Volt truck charger or reverse the polarity of the battery

or any charging unit. Do not charge the battery with the engine running as this could

expose the ECU to an unregulated power supply that could destroy the ECU and other

electrical equipment.

All fuel system components and wiring should be mounted away from heat sources,

shielded if necessary and well ventilated. Disconnect the Haltech ECU from the electrical

system whenever doing any arc welding on the vehicle by unplugging the wiring harness

connector from the ECU.

After completing the installation, make sure that there are no fuel leaks, and no wiring

left un-insulated in case a spark or short-circuit occurs and causes a fire. Also make sure

that you follow all proper workshop safety procedures. If you're working underneath

a jacked-up car, always use safety stands!

Page 3

Haltech I/O Expander 12

Quick Start Guide

Congratulations on purchasing a Haltech I/O Expander 12

This Plug and Play product allows the user the ability to increase the functionality

of their Haltech ECU by using the Haltech CAN system which is fitted to all

Platinum Series ECU's.

The Haltech I/O Expander 12 instantly makes available 12 additional user configurable

inputs and outputs. Simply plug in the CAN cable and start using your extra I/O.

This quick start guide will walk you through installation of the Haltech I/O Expander 12

into a vehicle. This guide is accompanied by the full service manual located

on the software CD provided with the ECU that you or your tuner will need to refer to

before completing your installation and configuration. The Manual can also be

downloaded from the Haltech website www.haltech.com.

Included in Haltech I/O Expander 12 Kit

• Haltech I/O Expander 12

• Haltech CAN direct connection cable Black 600mm

• Quick start guide

• Haltech Sticker

Optional Accessories ( Sold Separately )

• I/O Expander 12 – Flying Lead Harness ( HT049902 )

• I/O Expander 12 – Plug and Pin Set ( HT030007 )

• CAN Cable Hub Connection White available in various sizes 75mm up to 3600mm

( Please contact Haltech for sizes and prices )

• CAN Cable Direct Connection Black available in various sizes 75mm up to 3600mm

( Please contact Haltech for sizes and prices )

Page 4

Installation

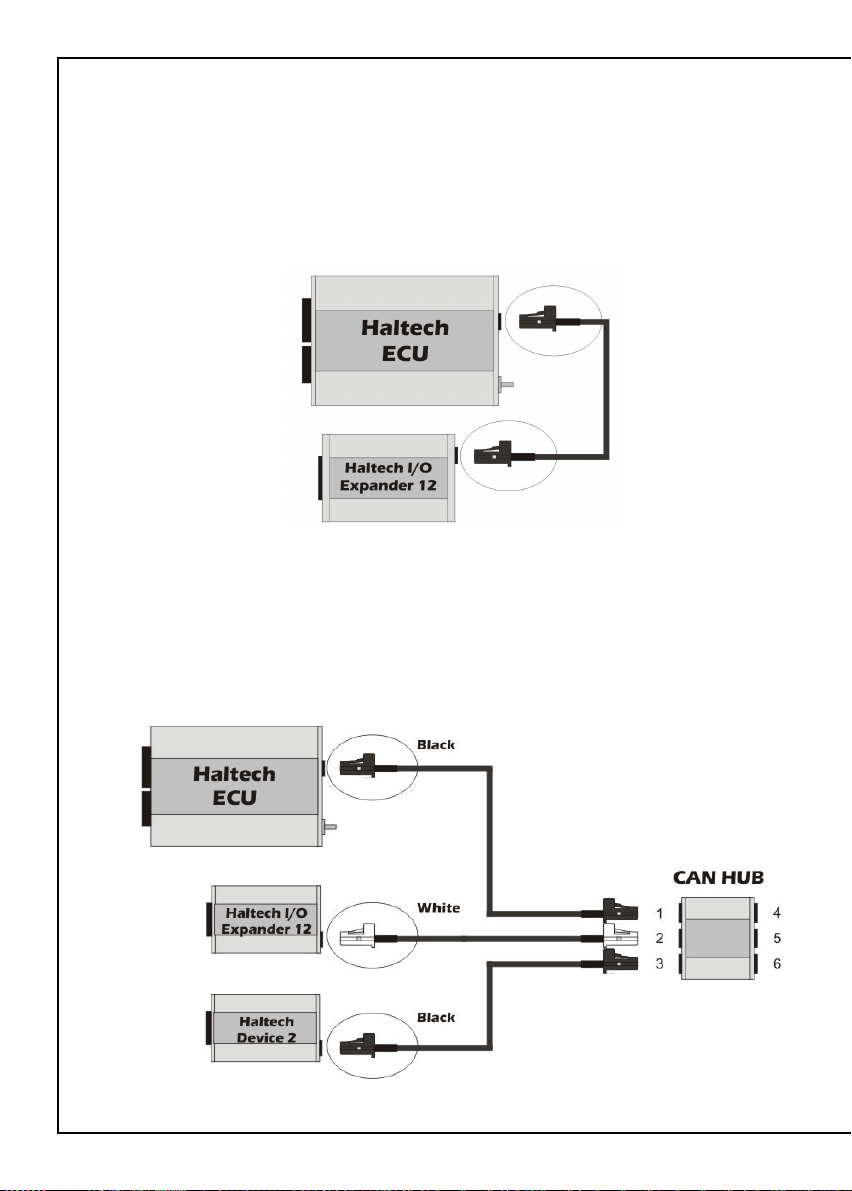

Installing the Haltech I/O Expander 12 is quick and simple there are 2 possible

methods for connection to your Haltech ECU, they are outlined below:

Method 1: Direct Connection to Haltech Platinum Series ECU

• Connect the Haltech I/O Expander 12 directly to a Haltech Platinum series ECU via

the CAN direct connection cable included with the kit

Figure 1 – Direct connection to Haltech ECU

Method 2 : Connection Via Haltech CAN Hub ( HT059990)

• Connect the Haltech I/O Expander 12 directly to the CAN Hub attached to a Haltech

Platinum Series ECU ( a Haltech CAN Hub Connection Cable may need to be

purchased depending on your setup. Please refer to the Haltech CAN Hub quick start

guide for details on connecting multiple devices to your Platinum Series ECU.)

Figure 2 – CAN Hub connection to Haltech ECU with 2 Devices

Page 5

Wiring Harness (optional)

The Haltech I/O Expander 12 can be supplied with a 24 pin wiring harness,

Connections are outlined in detail below:

WARNING!

Please make sure you configure your I/O Expander 12 with your ECU using

ECU Manager Software before you plug in the wiring harness, as outputs may

turn on undesirably when power is applied if not configured.

Main Inputs

There are four main inputs to the Haltech I/O Expander 12

+12V DC Switched (Pink)

Connect this wire to a +12V DC Switched ignition source

+12V DC Battery (Red)

Connect this wire to a constant +12V DC battery supply

Signal Ground (Black / White)

Connect this wire to the signal ground on the ECU

Ground (Black)

Connect this wire to a chassis ground point on the vehicle

Figure 1- Main inputs

Page 6

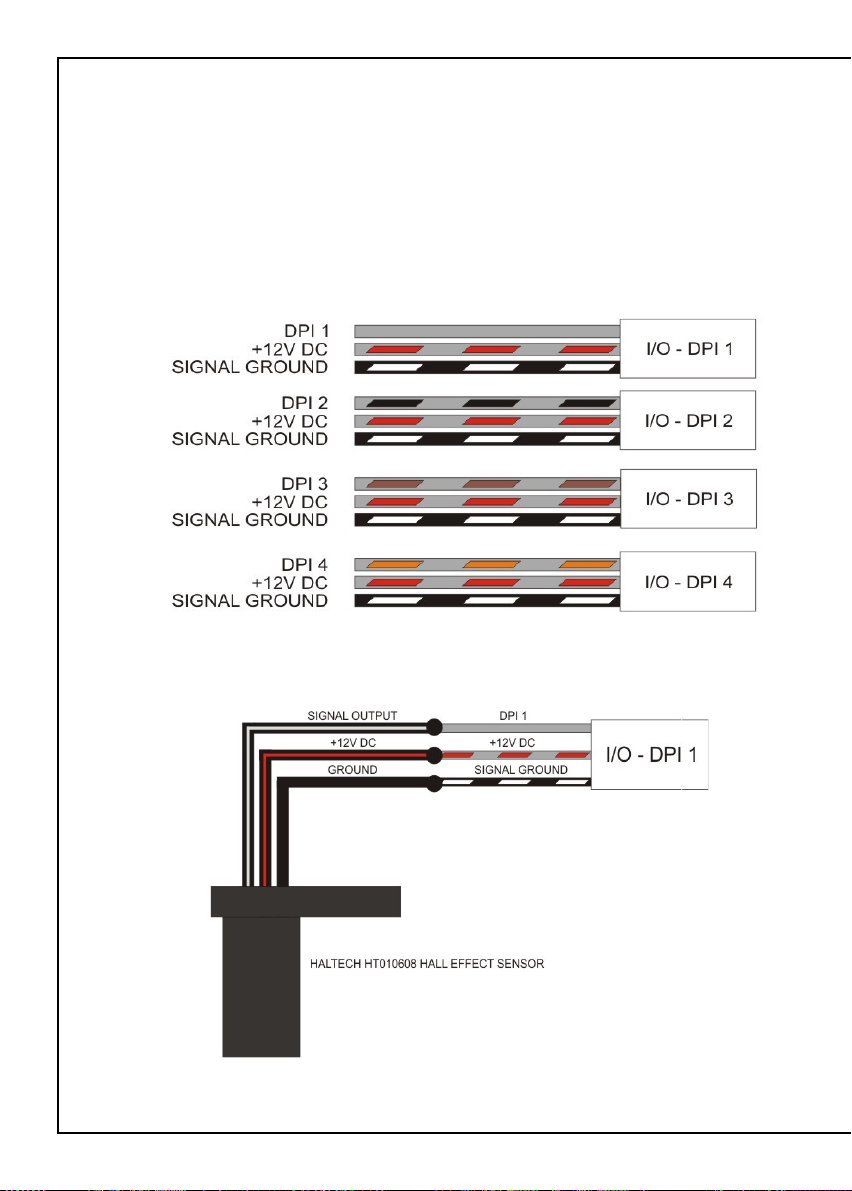

Digital Pulsed Inputs ( DPI )

The Haltech I/O Expander 12 features 4 Digital Pulsed Inputs. Each input has been

grouped with a +12V DC Source and a signal ground within the harness, this allows

the user to fit an external pull-up to 12V or pull- down to ground resistor if required

and or to supply power to a 12V rated sensor.

Digital Pulsed Inputs are capable of accepting pulsed input information such as

for a road speed sensor. These inputs measure the time periods between the pulses

and can process this information to provide quantities such as road speed.

Figure 2 - Digital Pulsed Inputs

Figure 3 - Haltech HT1010608 wiring to DPI 1

Page 7

Analogue Voltage Inputs ( AVI )

The Haltech I/O Expander 12 features 4 Analogue Voltage Inputs. Each input has

been grouped with a +5V DC Source and a signal ground within the harness, this

allows the user to fit an external pull-up to 5V or pull-down to ground resistor

if required and or to supply power to a 5V rated sensor.

Analog Voltage Inputs accept variable voltage inputs from 0V to 5V.

AVI inputs can also accept switch inputs that change between two different voltage

levels. The On Voltage and Off Voltage define the thresholds between the On and Off

states. The input voltage can be viewed as a channel in the software to determine the

thresholds for a switched input.

Figure 4 - Analogue Voltage Inputs

Figure 5 - Haltech HT010302 Coolant Temperature Sensor wiring to AVI 1

Page 8

Digital Pulsed Outputs ( DPO )

The Haltech I/O Expander 12 features 4 Digital Pulsed Outputs. Each output has

been grouped with a +12V DC Source within the harness, this allows the user to fit

an external relay to control high current devices.

Digital Pulsed outputs are capable of outputting pulsed waveforms with varying duty

and frequency. DPO's can be used to control various devices such as thermo fans,

shift lights, bypass air control valves, boost control solenoids etc.

When a Digital Pulsed output is activated by the ECU the output will switch to ground.

Solenoid valves and shift lights etc can be run directly from the output. However

high current devices such as thermo fans and additional fuel pumps must be

activated through a relay. This way the DPO is only switching a relay and not a high

current draw device.

Digital Pulsed Outputs are limited to 1A Max current draw.

Figure 6 - Digital Pulsed Outputs

Figure 7 - Digital Pulsed Output Relay Wiring

Page 9

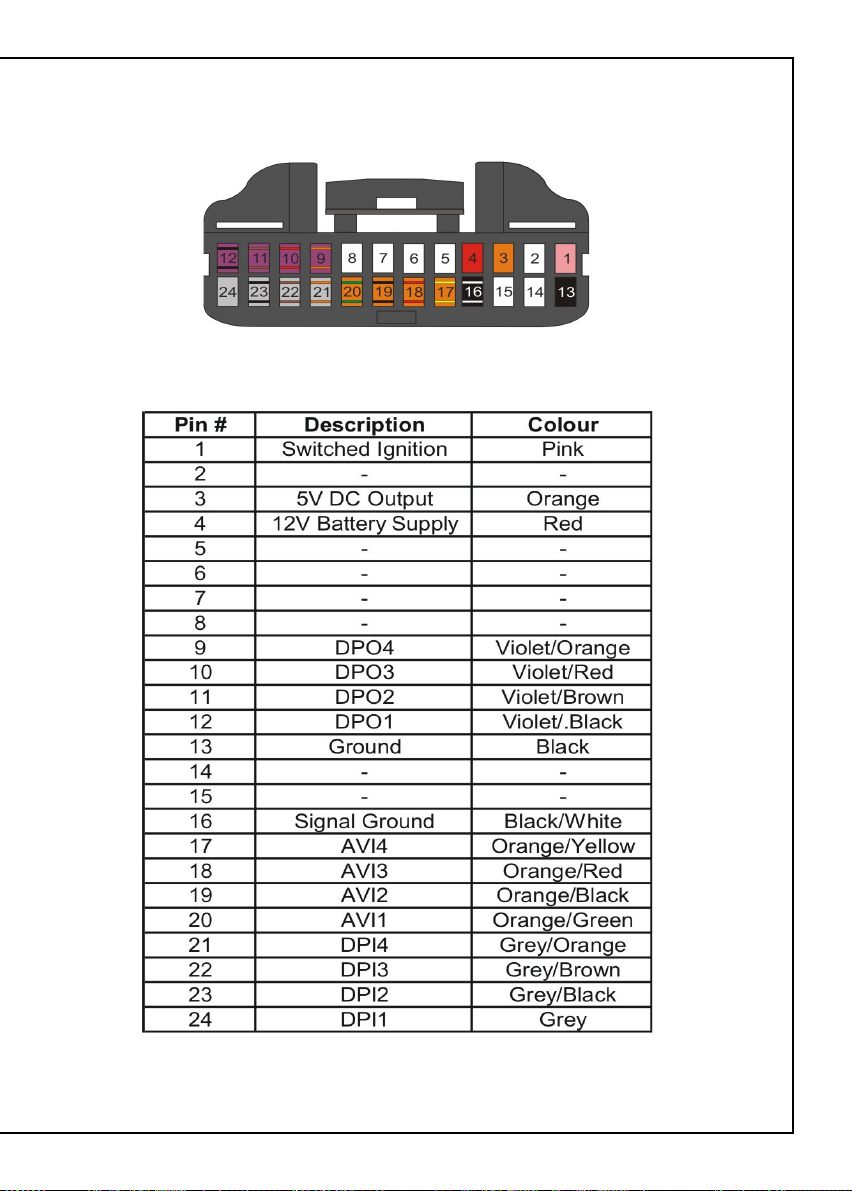

Appendix

Looking into the wire side of the connector

Figure 8 - Wiring Harness pinout information

Page 10

Notes

Page 11

Page 12

HALTECH HEAD OFFICE: PH: +612 9729 0999

FAX: +612 9729 0900

EMAIL: sales@haltech.com

HALTECH US OFFICE: EMAIL: usa@haltech.com

See the Haltech Website for your local authorized dealer.

www.haltech.com

Version 1

Loading...

Loading...